Page 1

ED655 Plus Airless Pump

SprayTECH

1770 Fernbrook Lane

Minneapolis, MN 55447

Technical Assistance: 1-800-292-4637

Order Entry: 1-800-443-4500

Fax: 1-800-525-9501

www.spraytechinc.com

Owner’s Manual

Printed in the U. S. A.

Model Number 0508090

0505 © 2005 SprayTECH. All rights reserved. Form No. 0508278A

Page 2

Table of Contents

CAUTION

CAUTION

WARNING

WARNING

Safety Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Grounding Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

General Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Preparing to Paint . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Attaching the Tip to the Gun. . . . . . . . . . . . . . . . . . . . . . . 4

hecking the Outlet Valve (optional) . . . . . . . . . . . . . . . . 4

C

ttaching the Paint Hose . . . . . . . . . . . . . . . . . . . . . . . . . 5

A

ressure Relief Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . 5

P

Priming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Preparing to Prime . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Mounting the Paint Hopper. . . . . . . . . . . . . . . . . . . . . . . . 6

Attaching the Return Tube . . . . . . . . . . . . . . . . . . . . . . . . 6

Priming the Pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Spraying . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Spraying Technique . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Practice . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Cleanup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Overnight Storage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Long-Term Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Removing and Cleaning the Inlet Valves . . . . . . . . . . . . 10

Removing and Cleaning the Outlet Valve. . . . . . . . . . . . 10

Cleaning the Hopper Screen . . . . . . . . . . . . . . . . . . . . . 10

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Parts Listings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Main Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Diaphragm Pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Pump Head Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Hopper Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Limited Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Safety Precautions

This manual contains information which must be read and

understood before using the equipment. When you come to an

area which has one of the following symbols, pay particular

attention and make certain to heed the safeguard.

This symbol indicates a potential hazard which may cause

serious injury or loss of life. Important safety information

will follow.

This symbol indicates a potential hazard to you or to the

equipment. Important information that tells how to prevent

damage to the equipment or how to avoid causes of minor

injuries will follow.

NOTE: Notes give important information which

should be given special attention.

This unit is provided with a thermally protected automatic

reset. If an overload occurs the thermally protected

automatic reset disconnects the motor from the power

supply.

• The motor will restart without warning when the protector

automatically resets.

• Always disconnect the motor from the power supply

before working on the equipment.

• When the thermally protected automatic reset disconnects

the motor from the power supply

turning the priming valve to PRIME.

• Turn the ON/OFF switch to OFF.

, relieve pressure by

NOTE: The cause of the overload should be corrected

A. SAVE THESE INSTRUCTIONS – To reduce the risks of

. WARNING – To reduce the risk of fire or explosion:

B

2 © SprayTECH. All rights reserved.

before restarting. See TROUBLESHOOTING.

IMPORTANT SAFETY INSTRUCTIONS

fire or explosion, electrical shock, and the injury to

persons, read and understand all instructions

included in this manual. Be familiar with the controls

and the proper usage of the equipment.

1. Do not spray flammable or combustible materials near

an open flame, pilot lights or sources of ignition such as

hot objects, cigarettes, motors, electrical equipment and

electrical appliances. Avoid creating sparks from

connecting and disconnecting power cords.

2. For units intended for use with only water-based

materials — Do not spray or clean with flammable

liquids. For use with water-based liquids only.

3. For units intended for use with only water-based or

mineral spirit-type materials with a minimum flash point

of 21ºC (69.8ºF) — Do not spray or clean with liquids

having a flash point of less than 21ºC (69.8ºF). Flash

point is the temperature at which a fluid can produce

enough vapor to ignite.

4. Paint or solvent flowing through the equipment is able

to result in static electricity. Static electricity creates a

risk of fire or explosion in the presence of paint or

solvent fumes. All parts of the spray system, including

the pump, hose assembly, spray gun and objects in and

around the spray area shall be properly grounded to

protect against static discharge and sparks. Use only

conductive or grounded high-pressure airless paint

sprayer hoses specified by the manufacturer.

5. Verify that all containers and collection systems are

grounded to prevent static discharge.

6. Connect to a grounded outlet and use grounded

extension cords. Do not use a 3 to 2 adapter.

7. Do not use a paint or solvent containing halogenated

hydrocarbons. Such as chlorine, bleach mildewcide,

methylene chloride and trichloroethane. They are not

compatible with aluminum. Contact the coating

supplier about compatibility of material with aluminum.

8. Keep spray area well ventilated. Keep a good supply of

fresh air moving through the area to keep the air within

the spray area free from accumulation of flammable

vapors. Keep pump assembly in well ventilated area.

Do not spray pump assembly

9. Do not smoke in the spray area.

10. Do not operate light switches, engines, or similar spark

producing products in the spray area.

11. Keep area clean and free of paint or solvent

containers, rags, and other flammable materials.

12. Know the contents of the paint and solvents being

sprayed. Read all Material Safety Data Sheets (MSDS)

and container labels provided with the paints and

solvents. Follow the paint and solvent manufacture’s

safety instructions.

13. Place pump at least 25 feet (7.62 meters) from the

spray object in a well ventilated area (add more hose if

necessary). Flammable vapors are often heavier than

air. Floor area must be extremely well ventilated. The

pump contains arcing parts that emit sparks and can

ignite vapors.

14. Plastic can cause static sparks. Never hang plastic to

enclose spray area. Do not use plastic drop cloths

when spraying flammable material.

15. Fire extinguisher equipment shall be present and

working.

.

Page 3

C. WARNING – To reduce the risk of skin injection:

WARNING

WARNING

CAUTION

Grounded Outlet

Grounding Pin

Cover for grounded outlet box

AZARD:

H

Injection injury – A high pressure fluid stream produced

by this equipment can pierce the skin and underlying

tissues, leading to a serious injury and possible

amputation. See a physician immediately. DO NOT

TREAT AN INJECTION AS A SIMPLE CUT.

. Do not aim the gun at, or spray any person or animal.

1

2. Keep hands and other body parts away from the

discharge. For example, do not try to stop leaks with

any part of the body.

3. Always use the nozzle tip guard. Do not spray without

the nozzle tip guard in place.

4. Only use a nozzle tip specified by the manufacturer.

5. Use caution when cleaning and changing nozzle tips.

In the case where the nozzle tip clogs while spraying,

ALWAYS lock gun trigger, shut pump off, and release all

pressure before servicing, cleaning tip or guard, or

changing tip. Pressure will not be released by turning

off the motor. The PRIME/SPRAY valve handle must

be turned to PRIME to relieve the pressure. Refer to

PRESSURE RELIEF PROCEDURE described in the

pump manual.

6. Do not leave the unit energized or under pressure while

unattended. When the unit is not in use, turn off the unit

and relieve the pressure in accordance with the

manufacturer’s instructions.

7. High-pressure spray is able to inject toxins into the

body and cause serious bodily injury. In the event that

injection occurs, seek medical attention immediately.

8. Check hoses and parts for signs of damage, a leak can

inject material into the skin. Inspect hose before each

use. Replace any damaged hoses or parts.

9. This system is capable of producing 2800 PSI / 19.3

MPa. Only use replacement parts or accessories that

are specified by the manufacturer and that are rated a

minimum of 3100 PSI. This includes spray tips, nozzle

guards, guns, extensions, fittings, and hose.

10. Always engage the trigger lock when not spraying.

Verify the trigger lock is functioning properly.

11. Verify that all connections are secure before operating

the unit.

Know how to stop the unit and bleed pressure quickly.

12.

Be thoroughly familiar with the controls. Pressure will

not be released by turning off the motor

PRIME/SPRAY

to relieve the pressure. Refer to PRESSURE RELIEF

PROCEDURE described in the pump manual.

13. Always remove the spray tip before flushing or cleaning

the system.

valve handle must be turned to PRIME

The

.

6. Do not kink or over-bend the hose. Airless hose can

develop leaks from wear, kinking and abuse. A leak

can inject material into the skin.

. Do not expose the hose to temperatures or pressures in

7

xcess of those specified by manufacturer.

e

8. Do not use the hose as a strength member to pull or lift

the equipment.

9. Use lowest possible pressure to flush equipment.

10. Follow all appropriate local, state and national codes

governing ventilation, fire prevention and operation.

11. The United States Government Safety Standards have

been adopted under the Occupational Safety and

Health Act (OSHA). These standards, particularly part

1910 of the General Standards and part 1926 of the

Construction Standards should be consulted.

12. Before each use, check all hoses for cuts, leaks,

abrasion or bulging of cover. Check for damage or

movement of couplings. Immediately replace hose if

any of those conditions exist. Never repair a paint hose.

Replace with a conductive high-pressure hose.

13. Do not spray outdoors on windy days.

14. Always unplug cord from outlet before working on

equipment.

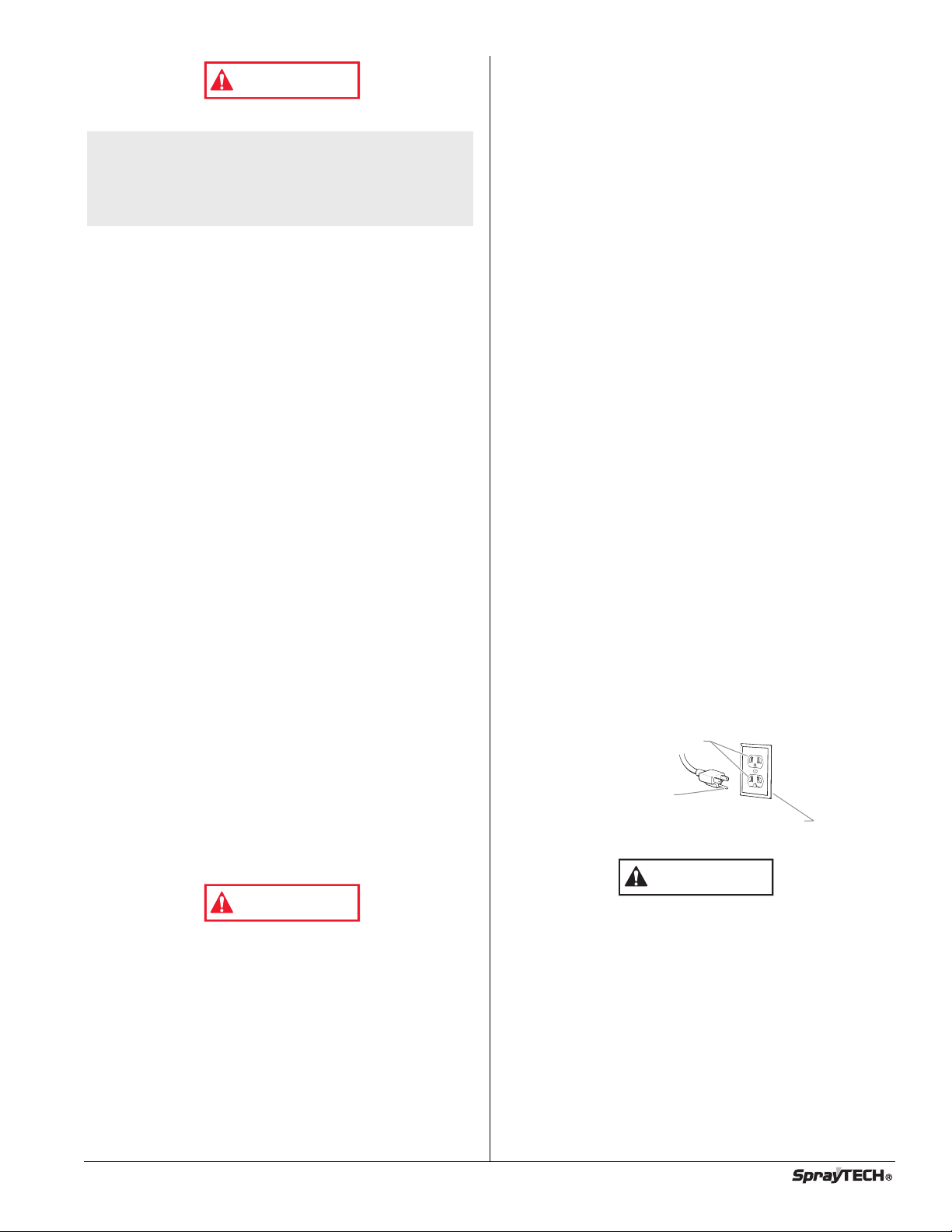

Grounding Instructions

This product must be grounded. In the event of an electrical

short circuit, grounding reduces the risk of electric shock by

providing an escape wire for the electric current. This product

is equipped with a cord having a grounding wire with an

appropriate grounding plug. The plug must be plugged into an

outlet that is properly installed and grounded in accordance

with all local codes and ordinances.

DANGER — Improper installation of the grounding plug can

result in a risk of electric shock. If repair or replacement of the

cord or plug is necessary, do not connect the green grounding

wire to either flat blade terminal. The wire with insulation

having a green outer surface with or without yellow stripes is

the grounding wire and must be connected to the grounding

pin.

Check with a qualified electrician or serviceman if the

grounding instructions are not completely understood, or if you

are in doubt as to whether the product is properly grounded.

Do not modify the plug provided. If the plug will not fit the

outlet, have the proper outlet installed by a qualified

electrician.

D. WARNING – To reduce the risk of injury:

1. Always wear appropriate gloves, eye protection,

clothing and a respirator or mask when painting.

Hazardous vapors – Paints, solvents, insecticides, and

other materials can be harmful if inhaled or come in

contact with body

fainting or poisoning.

Do not operate or spray near children. Keep children

2.

away from equipment at all times.

3. Do not overreach or stand on an unstable support.

Keep effective footing and balance at all times.

Stay alert and watch what you are doing.

4.

Do not operate the unit when fatigued or under the

5.

influence of drugs or alcohol.

© SprayTECH. All rights reserved.. 3

apors can cause severe nausea,

. V

Use only a 3-wire extension cord that has a 3-blade

grounding plug and a 3-slot receptacle that will accept the

plug on the product. Make sure your extension cord is in

good condition. When using an extension cord, be sure

to use one heavy enough to carry the current your

product will draw. An undersized cord will cause a drop

in line voltage resulting in loss of power and overheating.

A 12 gauge cord is recommended. If an extension cord is

to be used outdoors, it must be marked with the suffix WA after the cord type designation. For example, a

designation of SJTW-A would indicate that the cord would

be appropriate for outdoor use.

Page 4

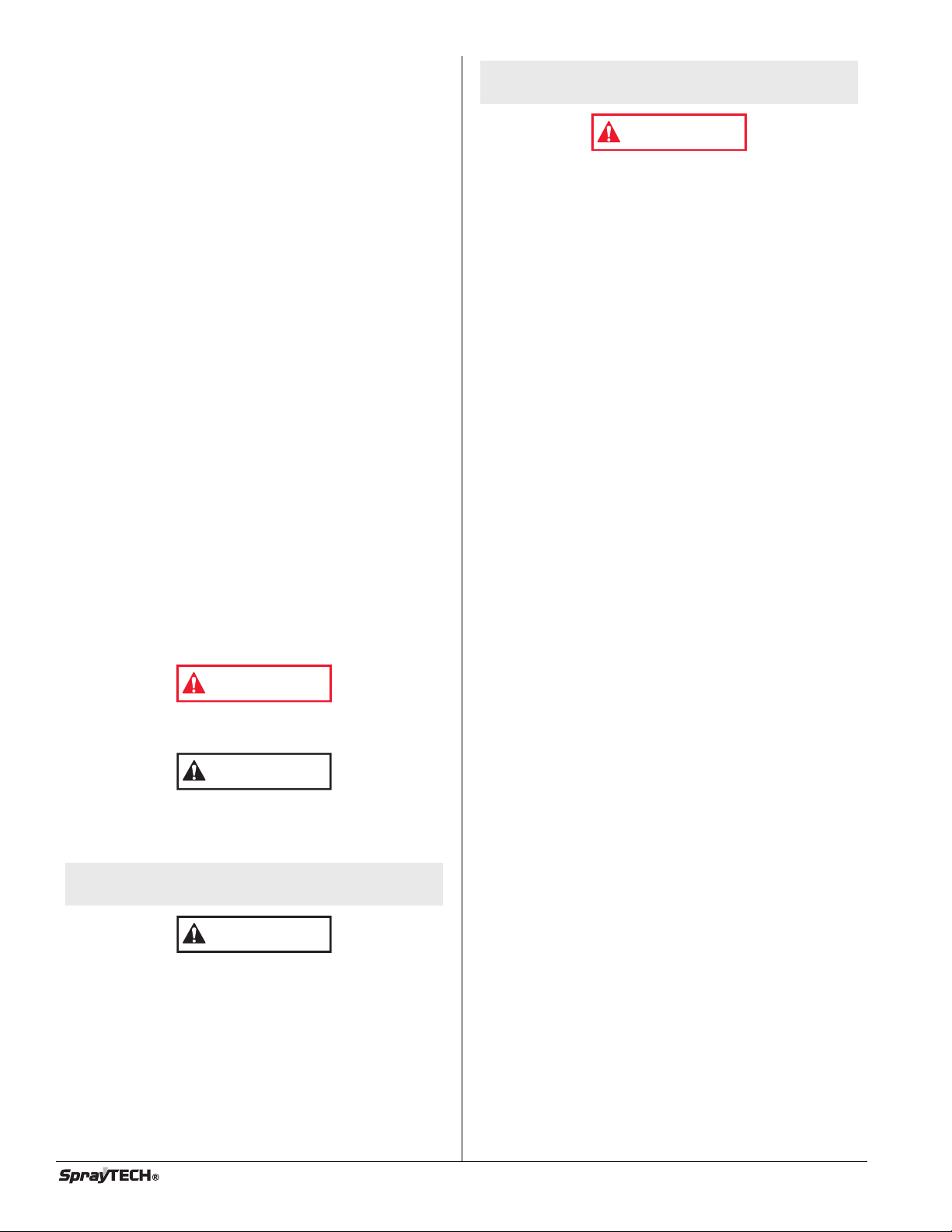

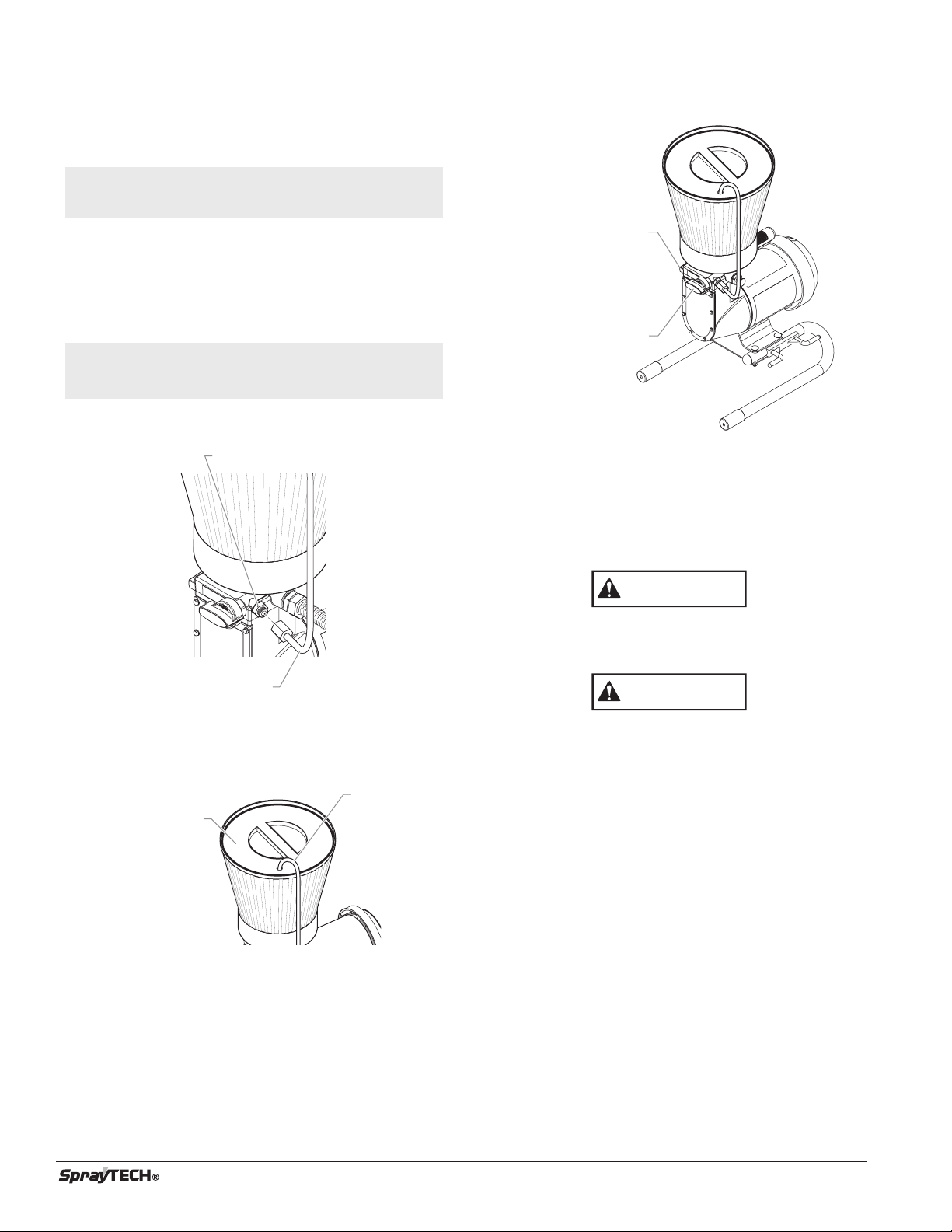

General Description

Pressure Control

Knob

PRIME/SPRAY

Knob

Paint Hopper Return Tube

Outlet Valve

Power Cord

Pusher Valve Button

(optional)

Begin

tightening

the tip guard

at this angle

to achieve

the desired

spray angle

when tight.

WARNING

Trigger locked

(gun will not spray)

Trigger unlocked

(gun will spray)

This high performance airless sprayer is a precision power tool

used for spraying many types of materials. Read and follow

this instruction manual carefully for proper operating

instructions, maintenance and safety information.

Preparing to Paint

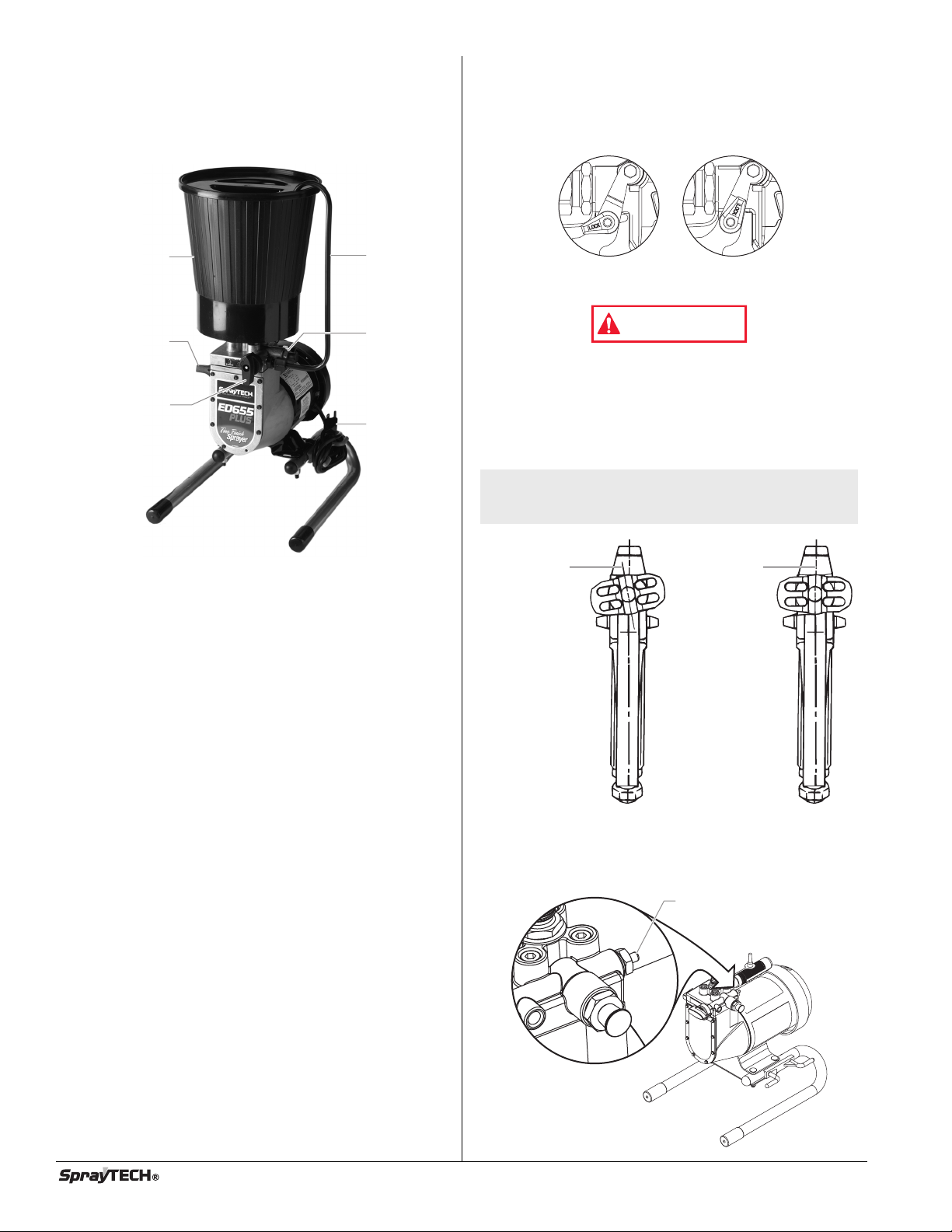

Attaching the Tip to the Gun

1. Lock the trigger by rotating the trigger lock forward until it

stops.

POSSIBLE INJECTION HAZARD. Do not spray without the

tip guard in place. Never trigger the gun unless the tip is

in either the spray or the unclog position. Always engage

the gun trigger lock before removing, replacing or

cleaning tip.

2. Thread the tip guard onto the gun. Tighten the nut first by

hand, then tighten more firmly with a wrench.

NOTE: When attaching the tip guard to the gun, align

the tip guard as shown in the figure below,

then tighten with a wrench.

Specifications

Weight ..............................27 lbs

Capacity ...........................Up to .35 gallon (1.25 liters) per

Power source ...................Electric motor, totally enclosed, fan

Power requirement...........15 amp minimum circuit on 115

Generator .........................15 amp A/C.

Spraying pressure ............Up to 2750 PSI

Capabilities

.......................Sprays a variety of oil-based and

minute

cooled

VAC, 60 Hz current.

latex paints, primers, and stains

Checking the Outlet Valve (optional)

Firmly press the optional pusher valve button on the side

1.

of the pump housing to make sure the outlet ball valve

moves freely.

4 © SprayTECH. All rights reserved.

Page 5

Attaching the Paint Hose

WARNING

Trigger locked

(gun will not spray)

Pressure Control Knob

PRIME/SPRAY Knob

. Attach the high pressure hose to the paint sprayer. Use a

1

rench to tighten the paint hose securely.

w

2. Attach the spray gun to the other end of the high pressure

hose. Tighten the hose securely to the gun using two

wrenches.

3. Plug the sprayer into a properly grounded outlet or heavy

duty grounded extension cord. Do not use more than 100

feet of cord. If you must spray a long distance from a

power source, use more paint hose, not more extension

cords. Use a minimum size of 16 gauge extension cord

for up to 50 feet in length, or 12 to 14 gauge for extension

cords between 50 and 100 feet in length.

Priming

Preparing to Prime

1. Fill the inlet valve with water or with a light household oil.

2. Make sure the PRIME/SPRAY knob is set to PRIME and

that the pressure control knob is turned counterclockwise

to the lowest pressure setting.

3. Turn the motor switch to ON.

4. Increase the pressure by turning the pressure control

knob clockwise 1/2 turn.

5. Force the inlet valve to open and close by pushing on it

with a screwdriver or the eraser end of a pencil. It should

move up and down about 1/16 of an inch. Continue until

water or oil is sucked into the sprayer. This will wet the

moving parts and break loose any old paint residue.

Pressure Relief Procedure

Follow this procedure after the unit is assembled and before

any operation which involves the spray gun such as cleaning

and maintenance or changing tips or accessories.

1. Turn the pressure control knob counterclockwise to its

lowest setting.

2. Turn the PRIME/SPRAY knob to PRIME.

3. Trigger the gun to remove any pressure which may still be

in the hose.

4. Lock the trigger by rotating the trigger

lock forward until it stops.

Injection hazard. Do not spray without

the tip guard in place. NEVER trigger

the gun unless the tip is completely

turned to either the spray or the unclog

position. ALWAYS engage the gun trigger lock before

removing, replacing or cleaning tip.

6. Put the palm of your hand over the inlet. Turn the

pressure control knob clockwise to its maximum setting.

ou should feel suction coming from the inlet valve. If you

Y

do not, see the section on cleaning and servicing the outlet

valve.

7. Turn the pressure control knob counterclockwise to the

minimum pressure setting.

urn the motor switch to OFF

T

8.

.

© SprayTECH. All rights reserved. 5

Page 6

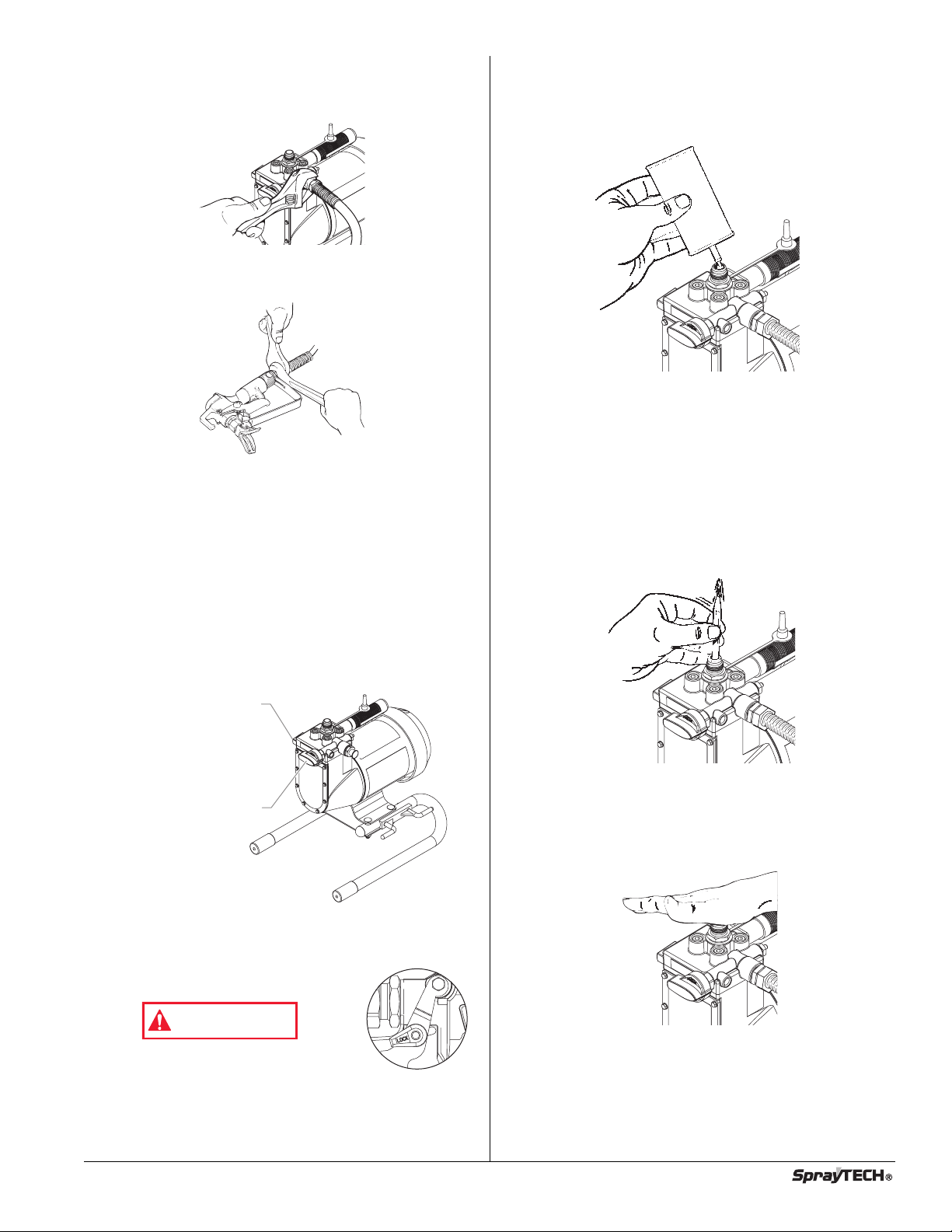

Mounting the Paint Hopper

Return Tube

Paint Hopper Cover

Return Tube Fitting

Return Tube

CAUTION

CAUTION

Pressure Control Knob

PRIME/SPRAY Knob

1. Align the bottom of the paint hopper with the threaded

inlet valve on the paint pump block.

. Turn the paint hopper clockwise to thread it onto the inlet

2

valve. Continue to turn the paint hopper until it is secure

on the inlet valve.

NOTE: Make sure the threads are straight and the

3. Place the filter screen into the bottom of the paint hopper

hopper turns freely on the inlet valve. Do not

cross-thread.

and snap it in position.

Attaching the Return Tube

1. Make sure that the motor switch is turned to OFF.

2. Screw the return tube fitting found in the literature set into

the return tube port on the side of the pump.

NOTE: Do not over-tighten. Hand-tighten only. Some

threads will be visible even when fully

tightened.

3. Place the straight end of the return tube into the return

tube fitting.

Priming the Pump

. Turn the pressure control knob counterclockwise to its

1

owest pressure setting.

l

2. Remove the paint hopper cover and fill the paint hopper

with material.

3. Turn the PRIME/SPRAY knob to PRIME.

4. Turn the motor switch to ON.

5. Turn the pressure control knob clockwise to between half

and full pressure. Let the unit prime 1 to 2 minutes after

material begins to flow through the return tube.

4. Thread the nut on the return tube onto the return tube

fitting and tighten until the return tube is secure.

5. Place the hook end of the return tube into the hole in the

paint hopper cover

Always reduce the pressure to zero before changing the

position of the PRIME/SPRAY knob. Failure to do so may

cause damage to the paint pump diaphragm.

If the pressure control knob is reduced to zero and the

PRIME/SPRAY knob is still on SPRAY while the sprayer is

.

operating, there will be high pressure in the hose and

spray gun until the PRIME/SPRA

or until the spray gun is triggered to relieve the pressure.

knob is turned to PRIME

Y

6 © SprayTECH. All rights reserved.

Page 7

Spraying

Approximately

10 to 12 inches

Right way

Wrong way

Keep stroke smooth and at an even speed.

Even coat throughout

Approximately

10 to 12 inches

Heavy Coat

Do not flex wrist while spraying.

Light Coat Light Coat

Good spray pattern

Paint tailing pattern

Pressure Control Knob

PRIME/SPRAY Knob

P

roper way to trigger the spray gun

Aproximately

1

0 to 12 inches

Keep stroke

e

ven

Start stroke End strokePull trigger Release triggerKeep steady

Spraying Technique

The key to a good paint job is an even coating over the entire

surface. This is done by using even strokes. Keep your arm

moving at a constant speed and keep the spray gun at a

constant distance from the surface. The best spraying

distance is 10 to 12 inches between the spray tip and the

surface.

Keep the spray gun at right angles to the surface. This means

moving your entire arm back and forth rather than just flexing

your wrist.

Overlap each stroke by about 30%. This will ensure an even coating.

hen you stop painting, lock the gun trigger lock, turn the

W

pressure control knob counterclockwise to its lowest setting

and set the PRIME/SPRAY knob to PRIME. Turn the motor

switch to OFF and unplug the sprayer.

If you expect to be gone more than 1 hour, follow the short

term clean up procedure described in the CLEANUP section of

this manual.

Practice

1. Be sure that the paint hose is free of kinks and clear of

objects with sharp cutting edges.

2. Turn the pressure control knob counterclockwise to its to

its lowest setting.

Keep the spray gun perpendicular to the surface, otherwise

one end of the pattern will be thicker than the other.

The spray gun should be triggered by turning it on and off with

each stroke.

end of the stroke. Do not trigger the gun during the middle of a

This will save paint and avoid paint buildup at the

stroke. This will result in an uneven spray and splotchy

coverage.

© SprayTECH. All rights reserved. 7

3. Turn the PRIME/SPRAY knob to SPRAY.

4. Turn the pressure control knob clockwise to its highest

setting. The paint hose should stiffen as paint begins to

flow through it.

5. Unlock the gun trigger

lock by turning the

switch so that it is

parallel to the handle.

6. Trigger the spray gun to

bleed air out of the

hose.

7. When paint reaches the

spray tip, spray a test

area to check the spray

pattern.

Use the lowest pressure setting necessary to get a good

8.

spray pattern. If the pressure is set too high, the spray

pattern will be too light. If the pressure is set too low,

tailing will appear or the paint will spatter out in gobs

rather than in a fine spray.

Page 8

Cleanup

Trigger locked

(gun will not spray)

Trigger locked

(gun will not spray)

CAUTION

WARNING

Overnight Storage

Long-Term Storage

Shutdown

. Turn the pressure control knob counterclockwise to the

1

inimum setting.

m

. Turn the PRIME/SPRAY knob to PRIME to release system

2

ressure.

p

3. Trigger the gun to remove any pressure that may still be in

he hose.

t

4. Lock the trigger by rotating the trigger

lock forward until it stops.

5. Turn the motor switch to OFF and

unplug the sprayer.

6. For latex materials only, pour 1/2 cup

water slowly on the top of the paint to

prevent the paint from drying. For

other materials, seal the paint hopper

with the hopper cover keeping the

return tube in the paint.

7. Wrap the spray gun assembly in a damp cloth and place it

in a plastic bag. Seal the bag shut.

8. Place the sprayer in a safe place out of the sun for short-

term storage.

Startup

1. Remove the gun from the plastic bag.

2. Stir the water into the paint for latex materials. Remove

the hopper cover from the paint hopper and stir the paint

for all other materials.

Do not allow paint to build up on the motor or the motor

will overheat. Do not allow flammable solvents to come in

ontact with the motor or they could ignite.

c

NOTE: You will need a bucket, cleaning solution, a

NOTE: If spraying with latex paint, use warm soapy

Do not use mineral spirits or paint thinner on latex paint,

or the mixture will turn into a jelly-like substance which is

difficult to remove.

oothbrush, a wrench and cleaning rags.

t

ater for cleaning. If using oil or alkyd-based

w

aints, use mineral spirits or paint thinner.

p

Clearing the Paint Hopper

1. Lock the gun trigger by rotating the

trigger lock forward until it stops.

2. Turn the pressure control knob

counterclockwise to the minimum

setting.

3. Turn the PRIME/SPRAY knob to

PRIME.

4. Turn the motor switch to OFF.

5. Direct the return tube into the original

paint bucket.

6. Turn the motor switch to ON.

7. Turn the pressure control knob to 1/2 maximum pressure.

This will draw the remaining paint in the paint hopper through

the pump, up the return tube, and into the paint bucket.

8. Turn the pressure control knob counterclockwise to the

minimum pressure setting.

9. Trigger the gun to relieve pressure and lock the gun.

10. Remove the spray tip and guard and place them into a

container of water or appropriate solvent for the type of

material with which you are painting.

Fill the paint hopper with water or an appropriate solvent

1.

1

for the type of material with which you are painting.

12. Direct the return tube into a waste bucket.

13. Increase the pressure to 1/2 the maximum pressure. Let

the water or solvent circulate for 2-3 minutes to flush paint

out of the pump, the paint hopper

, and the return tube.

Clearing the Paint Hose

1. To save paint left in the hose, release the gun trigger lock

and carefully trigger the gun with the spray tip removed

against the inside of the paint container

.

Check to be sure that the PRIME/SPRA

3.

PRIME and that the pressure is completely reduced.

Plug sprayer in and turn the motor switch to ON.

4.

5. After the sprayer is primed, turn the PRIME/SPRAY knob

to SPRAY and gradually turn the pressure control knob

clockwise to increase the pressure.

6. Test the sprayer on a practice piece and begin spraying.

Y knob is set to

2. Turn the pressure control knob counterclockwise to the

minimum pressure setting.

3. Turn the PRIME/SPRAY knob to SPRAY.

8 © SprayTECH. All rights reserved.

Page 9

4. Turn the pressure control knob slowly until paint starts to

flow into the bucket. As soon as the water or solvent

starts to come into the bucket, release the trigger.

5. Change to clean water or solvent, point the gun to the

side of the waste bucket, and continue circulating for

another 5 minutes to thoroughly clean the hose, pump and

spray gun.

6. Turn the pressure control knob counterclockwise to its

lowest setting.

7. Turn the PRIME/SPRAY knob to PRIME.

8. Trigger the gun to remove any pressure which may still be

in the hose.

9. Lock the gun trigger by rotating the trigger lock forward

until it stops.

0. Turn the motor switch to OFF.

1

Clearing the Gun

1. Remove the spray gun from the paint hose using two

adjustable wrenches.

2. Remove the filter housing from the gun. Place the gun

and the filter assembly into a container of water or solvent

to soak.

3. Cover the paint container and set it aside.

4. Clean the spray tip and gun filter with a soft brush.

5. Reassemble the gun and filter. Assemble the spray tip in

the cleaning position with the arrow pointing to the back of

the gun.

13. Trigger the gun to remove any pressure which may still be

in the hose.

14. Lock the gun trigger by rotating the trigger lock forward

until it stops.

5. Turn the motor switch to OFF.

1

Final Cleanup

1. Remove the tip assembly.

2. Turn the motor to ON.

3. Turn the PRIME/SPRAY knob to SPRAY.

4. Turn the pressure control knob clockwise to 1/2 power.

. Trigger the gun into the cleaning bucket until the hopper is

5

empty.

. Refill the hopper and continue flushing the system until

6

he solution coming out of the gun appears clean.

t

7. Lock the gun and turn the pressure control knob

counterclockwise to its lowest setting.

8. Turn the PRIME/SPRAY knob to PRIME.

9. Remove the hopper from the inlet valve.

10. Clean the threads of the inlet valve with a damp cloth.

11. Fill the inlet valve with a light household oil.

6. Attach the paint hose to the gun and tighten using two

wrenches.

7. Turn the motor switch to ON.

8. Unlock gun trigger by turning the gun trigger lock so that it

is parallel to the gun handle.

9. Turn the PRIME/SPRAY knob to SPRAY and point the gun

to the side of the waste bucket.

10 Trigger the gun and gradually turn the pressure control

knob clockwise to 1/2 pressure. Continue to trigger the

gun for approximately 30 seconds.

11. Turn the pressure control knob counterclockwise to its

lowest setting.

12. Turn the PRIME/SPRAY knob to PRIME.

12. Turn the PRIME/SPRAY knob to SPRAY to distribute the

oil.

NOTE: Proper cleaning and oiling of the pump after

13. Turn the pressure control knob counterclockwise to its

14. Turn the PRIME/SPRAY knob to PRIME.

15. T

16.

17.

18. Remove the hopper filter and clean in clean water or the

19. Return the hopper filter to its position in the hopper and

20. Wipe the entire unit, hose and gun with a damp cloth to

use are the most important steps you can take

to insure proper operation after storage.

lowest setting.

rigger the gun to remove any pressure that may still be

in the hose.

Lock the gun trigger by rotating the trigger lock forward

until it stops..

urn the motor switch to OFF

T

appropriate solvent. Use a soft brush.

replace the hopper on the inlet valve.

remove accumulated paint.

.

© SprayTECH. All rights reserved. 9

Page 10

Maintenance

Valve Body

O-ring

Seal

Seat

Ball

Spring

Ball Stop

Follow these procedures when encountering problems

indicated in the troubleshooting section.

Removing and Cleaning the Inlet Valves

1. Be certain that the sprayer is off.

2. Remove the inlet valve assembly using a 27 millimeter

socket or box end wrench.

3. Test movement of the valve by pushing on it from the

open end of the valve housing with a screwdriver or the

eraser end of a pencil. It should move about 1/16 of an

inch. If it does not move, it should be cleaned or

replaced.

OTE: This spring is manufactured to a very specific

N

3. Remove the seat and ball assembly.

4. Clean all parts thoroughly. If the ball or seat show any

5. Cover all parts with a thin coat of light oil before

NOTE: You will need to align the ridge on the seat with

6. Drop in the valve ball.

7. Insert the ball stop and spring and replace the valve body.

8. Tighten the valve body securely with an adjustable

tension. Do not put in an unauthorized

substitute. See the paint pump assembly parts

diagram for the proper replacement part

number.

sign of wear or damage, replace them with new parts.

This carbide ball must seal tightly against its seat for the

valve to function properly.

reassembling.

the groove in the pump housing when

reassembling.

Be sure that the o-ring is positioned properly and that the

tongue on the cap fits inside the spring.

wrench. Do not over-tighten.

NOTE: The inlet valve must be oiled after every job.

4. Thoroughly clean the valve assembly with water or the

5. If you have properly cleaned the valve and water drips out

6. Install a new or cleaned valve in the pump block and then

This will reduce or eliminate priming problems

the next time the sprayer is used.

appropriate solvent. Use a small brush.

of the bottom, the valve is worn and needs to be replaced.

properly seated valve filled with water and held vertically

A

will not drip.

fill the valve with light oil or solvent.

Removing and Cleaning the Outlet Valve

It may be necessary to remove and clean the outlet valve or to

replace parts inside the valve worn out through normal use.

1. Remove the outlet valve body with a wrench.

Remove and clean the ball stop and small spring inside

2.

the valve using a wire hook or tweezers. Replace the

spring if it is broken or worn.

Cleaning the Hopper Screen

The screen at the bottom of the paint hopper may need

cleaning periodically. Check it every time you add paint.

Remove the screen by pulling it out of the hopper with a pliers.

Clean the screen with water or solvent and a soft-bristle brush,

if necessary.

10 © SprayTECH. All rights reserved.

Page 11

P

roblem

The sprayer does not start up.

Troubleshooting

C

ause

1. The sprayer is not plugged in.

. The ON/OFF switch is set to OFF.

2

3. Low or no voltage is coming from the

wall plug.

4. The sprayer was turned off while still under

pressure.

5. The extension cord is damaged or has too

low a capacity.

6. The thermal overload on the sprayer is

tripped.

7. There is a problem with the motor.

S

olution

1. Plug the sprayer in.

. Turn the ON/OFF switch to ON.

2

3. Properly test the power supply voltage.

4. Turn the PRIME/SPRAY knob to PRIME.

5. Replace the extension cord.

6. Allow the motor to cool and move the sprayer to a

cooler spot.

7. Take the sprayer to a SprayTECH Authorized Service

Center.

The sprayer starts up but does not

draw in paint when the

PRIME/SPRAY knob is set to

PRIME.

The sprayer draws up paint but

the pressure drops when the gun

is triggered.

The sprayer will not shut off.

The spray gun leaks.

The tip assembly leaks.

1. The unit will not prime properly or has lost prime.

2. The paint hopper is empty

3. The hopper filter is clogged.

4. The inlet valve is stuck.

5. The outlet valve is stuck.

6. The PRIME/SPRAY valve is plugged.

7.

The inlet valve is worn or damage.

. There is a problem with the diaphragm.

8

9. The hydraulic oil level is low or empty.

1. The spray tip is worn.

2. The hopper filter is clogged.

3. The gun or spray tip filter is plugged.

4. The paint is too heavy or coarse.

5. The outlet valve assembly is dirty or worn.

6. The inlet valve assembly is damaged or worn.

1. The inlet or outlet valve ball or ball seat is

worn.

2. Foreign matter or paint has built up between

the ball and the seat.

1. Internal parts of the gun are worn

or dirty.

1. The tip was assembled incorrectly.

2. A seal is worn.

1. Try to prime the unit again.

2. Fill the paint hopper with paint.

3. Clean the hopper filter.

4. Clean the inlet valve.

5. Clean the outlet valve and replace any

worn parts.

6. Take the sprayer to a SprayTECH Authorized Service

Center.

7.

Replace the inlet valve.

. Take the sprayer to a SprayTECH Authorized Service

8

Center.

9. Take the sprayer to a SprayTECH Authorized Service

Center.

1. Replace the spray tip with a new tip.

2. Clean the hopper filter.

3. Clean or replace the proper filter. Always keep

extra filters on hand.

4. Thin or strain the paint.

5. Clean or replace the outlet valve assembly.

6. Replace the inlet valve.

1. Take the sprayer to a SprayTECH Authorized

Service Center.

2. Take the sprayer to a SprayTECH Authorized

Service Center.

1. Take the sprayer to a SprayTECH Authorized

Service Center.

1. Check the tip assembly and assemble properly.

2. Replace the seal.

The spray gun will not spray.

The paint pattern is tailing.

The thermal overload tripped and

shut off the sprayer.

NOTE:

When the PRIME/SPRA

1. The spray tip, the gun filter or the tip filter is

plugged.

2. The spray tip is in the CLEAN position.

1. The pressure is set too low.

The gun, the tip, or the hopper filter

2.

is plugged.

3. The tip is worn.

4. The paint is too thick.

1. The motor overheated.

2. The extension cord is too long or is too

small a gauge.

3. Paint has built up on the motor.

4. The motor was started while the sprayer

was under pressure.

5. The sprayer was sitting in the hot sun.

valve is on SPRAY and there is flow through the return tube, remove the

Y

PRIME/SPRAY valve and clean or replace it.

NOTE:

The electric motor should always be kept clean and dry

motor will cause the motor to overheat.

© SprayTECH. All rights reserved. 11

1. Clean the spray tip, gun filter or tip filter.

2. Put the tip in the SPRAY position.

1. Increase the pressure.

2. Clean the filters.

3. Replace the spray tip.

4. Thin the paint.

Allow to cool for 30 minutes.

1.

2. Allow to cool for 30 minutes and replace the

extension cord with a shorter extension or a thicker

gauge cord.

3. Clean the paint from the motor.

4. Restart the sprayer in the PRIME mode.

5. Move the sprayer out of the sun.

. Paint acts as an insulator

. Too much paint on the

Page 12

Consignes de sécurité

AVERTISSEMENT

ATTENTION

AVERTISSEMENT

CET ENSEMBLE EST DOTÉ D'UN DISPOSITIF DE REMISE

EN MARCHE AUTOMATIQUE AVEC PROTECTION

THERMIQUE. EN CAS DE SURCHARGE, CE DISPOSITIF

DÉBRANCHE LE MOTEUR DU BLOC D'ALIMENTATION.

• Le moteur se remet en marche sans avertissement

lorsque le protecteur est réarmé automatiquement.

Il faut toujours débrancher le moteur du bloc

•

'alimentation avant de travailler sur le matériel.

d

• Lorsque le dispositif de remise en marche automatique

débranche le moteur du bloc d'alimentation, réduire la pression

en tournant la soupape d'amorçage à AMORCER.

• Mettre l'interrupteur MARCHE/ARRÊT à ARRÊT.

NOTA : Il faut remédier à la cause de la surcharge

DANGER: Blessures résultant d'une injection cutanée - Le

NE PAS TRAITER CE TYPE DE BLESSURE COMME S'IL

S'AGISSAIT D'UNE SIMPLE COUPURE ! Une amputation

peut en résulter. Consulter un médecin immédiatement.

Le plus haut niveau de fonctionnement du pistolet est une

pression du fluide de 2800 PSI.

PRÉVENTION:

• NE JAMAIS diriger le pulvérisateur vers toute partie du corps.

• NE JAMAIS placer toute partie du corps devant le jet.

• NE JAMAIS placer les mains devant le pulvérisateur. Les

• TOUJOURS bloquer la détente du pistolet, fermer la pompe à

• Toujours débrancher le pistolet avant d'effectuer toute

•

• TOUJOURS enlever la tête de pulvérisation avant

•

• NE JAMAIS utiliser un pistolet qui ne soit pas muni d'un

•

avant de relancer l'appareil. À ce sujet, voir la

rubrique DÉPANNAGE.

jet de peinture haute pression produit par cet

appareil peut transpercer la peau et les tissus

sous-jacents, causant des blessures graves

pouvant aller jusqu'à l'amputation.

ÉVITER d'entrer en contact avec un jet de fluide sortant

d'une fuite dans le tuyau à fluide.

gants ne sont pas une protection suffisante contre les

risques d'injection cutanée.

fluide et décharger toute la pression avant de faire de l'entretien,

de nettoyer le protecteur de la tête, de changer de tête ou de

laisser l'appareil sans surveillance. Le bouton

AMORCER/PULVÉRISER doit être tourné à AMORCER, afin

d'éliminer la pression. Consulter la PROCÉDURE DE

ATION DE LAPRESSION décrite dans le présent manuel.

LIMIT

opération d'entretien ou de nettoyage du protecteur de

tête ou de remplacement des embouts, ou lorsque le

pistolet n'est pas utilisé.

OUJOURS garder le protecteur de tête en place durant

T

l'opération de pulvérisation. Ce dispositif fournit une

certaine protection contre toute blessure résultant d'une

injection cutanée; on l'utilise principalement à titre

d'avertissement.

d'effectuer un lavage ou un nettoyage du système.

Des fuites peuvent être provoquées dans le tuyau à

peinture par l'usure, par des faux plis ou par la mauvaise

utilisation. Une fuite peut injecter des substances dans la

peau, et il est donc indispensable d'examiner le tuyau à

peinture avant chaque utilisation.

cran de sûreté ou de pontet en place et en bon état de

fonctionnement.

ous les accessoires doivent avoir une valeur nominale

T

d'au moins 2800 PSI. Cette exigence s'applique aux têtes

de pulvérisation, aux pistolets, aux rallonges et aux tuyaux.

REMARQUE DESTINÉE AU MÉDECIN:

Une injection cutanée est une blessure du type

traumatique. Il est essentiel de traiter ce genre de

blessure à l'aide d'une intervention chirurgicale et ce,

dans les plus brefs délais. NE PAS retarder le traitement

dans le but d'effectuer des recherches sur le degré de

toxicité du produit. La toxicité d'un produit ne doit être

considérée que pour certaines substances ayant été

directement injectées dans les vaisseaux sanguins. Il

pourrait s'avérer nécessaire de consulter un spécialiste

en chirurgie plastique, ou encore, un spécialiste en

chirurgie reconstructive de la main.

DANGER: EXPLOSION OU INCENDIE - Les émanations

RÉVENTION:

P

• Un approvisionnement d'air frais et une évacuation des

• Éviter toute source d'ignition, telle que des étincelles

• Des appareils d'extinction d'incendie doivent être en place

• Garder la pompe à l'écart de la zone de pulvérisation, afin

• L'écoulement à haute vitesse d'un liquide à travers le

• Pour le travail sans air, utiliser uniquement les tuyaux à

• Respecter les mesures de sécurité et les avertissements

•

DANGER: EXPLOSION CAUSÉE P

PRÉVENTION:

•

•

provenant des solvants et des peintures peuvent

exploser ou s'enflammer, entraînant des

dommages matériels ou des blessures graves.

gaz doivent être assurés, afin que l'air entourant la zone

de pulvérisation soit libre de toute accumulation de

vapeurs inflammables.

d'électricité statique, des flammes nues, des veilleuses,

des objets chauds, des cigarettes, ou des étincelles

produites lors du branchement ou du débranchement des

cordons d'alimentation ou du déclenchement des

interrupteurs d'éclairage.

et en bon état de fonctionnement.

d'éviter les vapeurs de solvants et de peintures.

matériel peut générer l'électricité statique. Il faut donc

assurer une bonne mise à la terre du matériel dont on se

sert ainsi que des objets dans la zone de pulvérisation et

aux alentours, pour éviter la décharge de l'électricité

statique et les étincelles.

fluide à haute pression qui soient mis à la terre ou qui

soient bons conducteurs de l'électricité. S'assurer que le

pistolet est mis à la terre correctement à travers les

raccords des tuyaux.

du fabricant des solutions et des produits.

Lors du lavage du matériel, utiliser la plus basse pression

possible.

TIBILITÉ

DES MATÉRIAUX - Peut causer des dommages

AR L'INCOMP

matériels ou des blessures graves.

Ne pas utiliser de l'eau de Javel.

Ne pas utiliser de solutions halocarbonées, tels que le

chlorure de méthylène et le 1-1-1 trichloro-éthane. Ces

produits ne sont pas compatibles avec l'aluminium et

peuvent provoquer une explosion. En cas de doute,

communiquer avec le fournisseur du produit en question.

A

Français

12 © SprayTECH. Tous droits réservés.

Page 13

DANGER: VAPEURS DANGEREUSES - Les peintures, les

ATTENTION

ATTENTION

Prise de terre

Goupille de mise à la terre

Couvercle du boîtier de prise de terre

PRÉVENTION:

• Utiliser un respirateur ou un masque dans toute situation où il

• Utiliser des lunettes de protection pour empêcher les

ANGER :GÉNÉRALITÉS - Peut causer des dommages

D

PRÉVENTION:

• Lire toutes les directives et toutes les mesures de sécurité

• Se conformer aux règlements locaux, provinciaux et

• Les normes de sécurité du gouvernement des États-Unis

• Cette pompe, qui fonctionne à haute pression sans air, est

• Avant chaque utilisation, vérifier tous les tuyaux pour

• Tous les tuyaux, pivots, pistolets et accessoires utilisés avec ce

• Ne pas pulvériser par des temps de grand vent.

solutions, les insecticides et autres produits

peuvent être dangereux en cas d'inhalation,

provoquant des nausées graves, des

évanouissements ou un empoisonnement.

y a risque d'inhalation de vapeurs. Lire toute la

documentation accompagnant le produit de pulvérisation et le

masque, afin de s'assurer qu'une protection adéquate est

offerte contre l'inhalation de vapeurs dangereuses.

vapeurs dangereuses de pénétrer dans les yeux.

atériels ou des blessures graves

m

portant sur l'équipement et sur le produit de pulvérisation

avant l'emploi de tout équipement.

nationaux appropriés régissant la ventilation, laprévention

des incendies et l'exécution des opérations.

ont été adoptées en application de la Occupational Safety

and Health Act (OSHA) (Loi sur la santé et la sécurité au

travail). Il convient de prendre connaissance de ces

normes, et surtout de l'article 1910 des Normes générales

et de l'article 1926 des Normes de construction.

conçue pour être utilisée exclusivement avec des pièces

autorisées par le fabricant. L'utilisateur qui emploie cette

pompe avec des pièces qui ne se conforment pas à la

spécification minimum et aux mesures de sûreté prévues

par le fabricant de la pompe assume tous les risques et

toutes les responsabilités découlant d'un tel usage.

repérer éventuellement des coupures, des fuites, des

zones d'abrasion et le renflement du revêtement ainsi que

des dommages aux raccords ou leur déplacement. Si un

de ces problèmes est constaté, il faut remplacer le tuyau

immédiatement. Ne jamais réparer un tuyau à peinture; il

faut le remplacer avec un autre tuyau mis à la terre.

matériel doivent avoir une valeur nominale d'au moins 2800 PSI.

Instructions de mise à la terre

Cet appareil doit être mis à la terre. La mise à la terre réduit

es risques d'électrocution lors d'un court-circuit en permettant

l

au courant de s'écouler par le fil de mise à la terre. Cet

ppareil est muni d'un cordon électrique avec fil de mise à la

a

terre ainsi que d'une fiche de terre. La fiche doit être branchée

sur une prise installée correctement et mise à la terre

conformément à la réglementation et aux codes en vigueur.

DANGER — Une prise de terre mal branchée peut être à

l'origine d'électrocutions. S'il s'avère nécessaire de réparer ou

de remplacer le cordon électrique ou la fiche, ne pas brancher le

fil vert de mise à la terre sur l'une ou l'autre des bornes à broche

plate. Le fil recouvert d'un isolant vert avec ou sans rayures

jaunes est le fil de mise à la terre et doit être branché sur la

broche de mise à la terre.

Si vous ne comprenez pas les instructions de mise à la terre

ou si vous n'êtes pas sûr que l'appareil est correctement mis à

la terre, contactez un électricien agréé. Ne pas modifier la

fiche d'origine. Si la prise ne convient pas à la fiche, faites

installer la prise adéquate par un électricien agréé.

Utiliser uniquement une rallonge à trois fils munie d'une

fiche de terre dans une prise secteur mise à la terre

correspondant au type de fiche de l'appareil. S'assurer que

votre rallonge est en bon état. Lorsque vous utilisez une

rallonge, assurez-vous qu'elle soit d'un calibre suffisant

pour supporter l'intensité du courant requise par l'appareil.

Une rallonge trop mince entraîne une chute de tension, une

diminution de l'intensité et une surchauffe. Une rallonge de

calibre 12 est recommandée. Si vous devez utiliser une

rallonge à l’extérieur, celle-ci doit comprendre la marque WA après la désignation indiquant le type de cordon. Par

exemple, la désignation SJTW-A indique que le cordon est

conçu pour être utilisé à l’extérieur.

Utiliser uniquement une rallonge à trois fils dotée d'une fiche

de mise à la terre à trois broches et d'une prise à trois fentes

pouvant accepter la fiche sur le produit. S'assurer que la

rallonge est en bon état. S'assurer également que cette

dernière convient au courant consommé par l'appareil. Pour

une longueur inférieure à 15,2 m (50 pieds), utiliser une

rallonge no 18 AWG. Pour une longueur supérieure à 15,2 m

(50 pieds), utiliser une rallonge no 14 ou no 16 AWG. Une

rallonge de section inférieure produira une perte de tension,

entraînant une perte de puissance et la surchauffe.On

recommande l'utilisation d'un cordon de calibre 14 ou 12.

NOTA : Ne pas utiliser plus de 100 pieds de cordon

© SprayTECH. Tous droits réservés. 13

de rallonge. Au cas où il serait nécessaire de

faire de la peinture à une distance de plus de

100 pieds du bloc d'alimentation, utiliser

d'autres tuyaux à peinture et non pas d'autres

rallonges. Par ailleurs, les rallonges plus

courtes assureront une alimentation

maximale et un bon fonctionnement.

Français

Page 14

Advertencias de seguridad

ADVERTENCIA

PRECAUCION

ADVERTENCIA

LA UNIDAD CUENTA CON UN MECANISMO DE

ESTABLECIMIENTO AUTOMÁTICO TÉRMICAMENTE

R

PROTEGIDO. EL MECANISMO DE RESTABLECIMIENTO

UTOMÁTICO TÉRMICAMENTE PROTEGIDO HACE QUE

A

EL MOTOR SE DESCONECTE DEL SUMINISTRO DE

ENERGÍA SI SE PRESENTA UNA SOBRECARGA.

• El motor arrancará de nuevo sin ninguna advertencia

uando el protector se restablezca automáticamente.

c

• Desconecte siempre el motor del suministro de energía

antes de empezar a trabajar con el equipo.

• Cuando el mecanismo de restablecimiento automático

térmicamente protegido haga que el motor se desconecte del

suministro de energía, gire la válvula de cebadura hasta la

posición PRIME (cebar) para liberar la presión.

• Gire el interruptor ON/OFF (encendido/apagado) hasta la

posición OFF (apagado).

NOTA: La causa de la sobrecarga debe corregirse

antes de arrancar de nuevo. Vea la sección

DETECCIÓN DE PROBLEMAS.

PELIGRO: LESIÓN DE PERFORACIÓN – Este equipo

¡NO SE TRATE COMO UNA SIMPLE CORTADURA! la

perforación de la piel puede llevar a la amputación. Véase

inmediatamente a un médico.

El valor máximo de operación de la pistola corresponde a

una presión de fluido de 2800 lb/pulg2.

PREVENCIÓN:

• JAMAS apunte la pistola hacia cualquier parte de su cuerpo.

• JAMAS permita que alguna parte de su cuerpo entre en

• JAMAS ponga su mano delante de la pistola. Los guantes

• Bloquee SIEMPRE el gatillo de la pistola, apague la

• SIEMPRE desenchufe la pistola de pulverización antes de

• Quite SIEMPRE la boquilla del atomizador antes de

•

• No use NUNCA una pistola de atomización que no tenga

produce un chorro de pintura a alta presión

que puede perforar la piel y los tejidos que se

encuentran abajo, ocasionando lesiones graves

y la posible amputación.

contacto con el chorro. EVITE TENER CONTACTO con el

fluido que salga de fugas que haya en la manguera de fluido.

no proporcionan protección adecuada contra lesiones de

perforación.

bomba de fluido y libere toda la presión antes de dar

mantenimiento, limpiar el protector de la boquilla, cambiar

las boquillas o dejar desatendido el sistema. La presión no

se liberará al apagar el motor. Para liberar la presión debe

girarse la perilla PRIME/SPRAY hasta la posición PRIME .

Consulte el PROCEDIMIENTO DE LIBERACIÓN DE

PRESIÓN que se describe en este manual.

dar servicio, limpiar el protector de la punta, cambiar las

boquillas o dejar la pistola sin supervisión.

enjuagar o limpiar el sistema.

Pueden desarrollarse fugas en la manguera de pintura

por causa del desgaste, retorcimientos o el abuso. Una

fuga es capaz de inyectar el material en la piel.

Inspeccione antes la manguera de pintura cada vez que

la use.

un bloqueador o un protector de gatillo puesto y que

funcione.

• Todos los accesorios deben tener una capacidad de 2800

b/pulg2 o mayor. Esto incluye las boquillas de

l

atomización, las pistolas, las extensiones y la manguera.

OTA PARA EL MÉDICO:

N

Il a perforación de la piel constituye un serio

traumatismo. Es importante tratar quirúrgicamente la

herida lo más pronto posible. NO RETRASE el

ratamiento para poder estudiar la toxicidad. La

t

toxicidad es importante cuando determinadas resinas

xóticas penetran directamente en el torrente

e

sanguíneo. Se recomienda consultar con un cirujano

plástico o un cirujano especializado en la

reconstrucción de las manos.

PELIGRO: EXPLOSION O FUEGO - Los vapores emitidos

PREVENCIÓN:

• Suministre aire fresco y de escape para evitar la

• Evite cualquier fuente de encendido como las chispas de

• Mantenga equipo de extinción cerca y en buenas

• Mantenga la bomba lejos del área de atomización para

• Un flujo de material con una velocidad elevada que

• Use solamente mangueras para fluidos de alta presión

• Observe las precauciones y advertencias de seguridad del

• Cuando enjuague el equipo utilice la presión más baja posible.

PELIGRO: EXPLOSIONES OCASIONADAS POR

PREVENCIÓN:

• No use blanqueadores.

• No use solventes que contengan hidrocarburos halogenados,

PELIGRO: VAPORES PELIGROSOS - Las pinturas, los

PREVENCIÓN:

• Use un respirador o una mascarilla cuando exista la

por solventes y pinturas pueden explotar o

incendiarse, causando daños a la propiedad

y/o severas lesiones personales.

acumulación de vapores inflamables en el ambiente que

rodea al pulverizador.

electricidad estática, llamas, luces piloto, objetos

calientes, cigarrillos y chispas producidas por la conexión

o desconexión de cables de alimentación eléctrica o

conmutadores de luces.

condiciones.

evitar los vapores de solvente y pintura.

atraviese el equipo puede generar electricidad estática. El

equipo que se utilice, así como los objetos que estén

dentro y alrededor del área de atomización, deben

conectarse a tierra de manera apropiada para prevenir las

descargas eléctricas y las chispas.

conductoras o conectadas a tierra para las aplicaciones sin

aire. Asegúrese de que la pistola esté conectada a tierra de

manera apropiada mediante conexiones de manguera.

fabricante con respecto al uso de substancias y solventes.

SUBSTANCIAS INCOMPATIBLES - Pueden

causar daños a la propiedad o lesiones graves.

como el cloruro de metileno y el 1,1,1-tricloroetano. Estas

substancias no son compatibles con el aluminio y podrían

ocasionar una explosión. Si tiene dudas acerca de la

compatibilidad de una substancia con el aluminio, póngase en

contacto con su proveedor de recubrimientos.

solventes, los insecticidas y otras substancias

pueden ser dañinos al inhalarse y causar

severas náuseas, desmayos o envenenamiento.

posibilidad de inhalación de vapores. Léanse todas las

instrucciones incluidas con las substancias que se vayan

a rociar y con la mascarilla para asegurar la protección

necesaria contra la inhalación de vapores dañinos.

Español

14 © SprayTECH. Todos los derechos reservados.

Page 15

PELIGRO: GENERAL - Puede causar daños a la propiedad

PRECAUCION

PRECAUCION

Tomacorriente aterrado

Terminal de tierra

Tapa de la caja del tomacorriente aterrado

o severas lesiones.

PREVENCIÓN:

• Antes de operar cualquier equipo, lea todas las

instrucciones y los avisos de seguridad del equipo y de

las substancias que se vayan a rociar.

• Observe todas las normas locales, estatales y nacionales

relativas a la ventilación, prevención y operación.

• Los Estándares de Seguridad del Gobierno de los

Estados Unidos se han adoptado bajo el Acta de

Seguridad y Salud Ocupacionales (OSHA por sus siglas

en inglés). Deben consultarse estos estándares,

particularmente la parte 1910 de los Estándares

Generales y la parte 1926 de los Estándares de la

Construcción.

• La bomba de alta presión sin aire está diseñada para

usarse solamente con piezas autorizadas por el fabricante.

Cuando se use esta bomba con piezas que no cumplan

con las especificaciones mínimas ni con los dispositivos de

seguridad del fabricante de la bomba, el usuario asumirá

todos los riesgos y responsabilidades legales.

• Antes de usarlo cada vez, revise todas las mangueras para

ver que no tengan cortadas, fugas, una cubierta desgastada

por abrasión o con abolladuras, así como uniones dañadas o

que se hayan movido. Si existiera cualquiera de estas

condiciones, reemplace la manguera inmediatamente. No

repare nunca una manguera de pintura. Reemplácela con

otra manguera conectada a tierra.

• Todas las mangueras, soportes giratorios, pistolas y

accesorios que se usen con esta unidad deben tener una

capacidad de presión de 2800 lb/pulg2 o mayor.

• No atomice en días con viento.

Instrucciones para conectar a tierra

Este producto se debe conectar a tierra. En caso de que

ocurra un corto circuito, la conexión a tierra reduce el riesgo

de choque eléctrico al proporcionar un alambre de escape

para la corriente eléctrica. Este producto está equipado con

un cable que tiene un alambre de conexión a tierra con un

enchufe de conexión a tierra apropiado. El enchufe se debe

enchufar en una toma de corriente que se haya instalado y

conectado a tierra debidamente, de acuerdo con todos los

códigos y estatutos locales.

PELIGRO — Una instalación inapropiada del enchufe de

conexión a tierra puede dar como resultado el que exista un

riesgo de choque eléctrico. Si es necesario reparar o

reemplazar el cable o el enchufe, no conecte el alambre de

conexión a tierra a ninguno de los terminales de hoja planos.

El alambre con aislamiento que tiene la superficie exterior de

color verde con franjas amarillas o sin ellas es el alambre de

conexión a tierra que debe conectarse al conector de conexión

a tierra.

Verifique con un electricista o técnico de servicio calificado si

las instrucciones para conectar a tierra no le han quedado

completamente claras, o si duda que el producto haya

quedado conectado a tierra de manera apropiada. No

modifique el enchufe que se proporciona. Si el enchufe no

entra en la toma de corriente, pídale a un electricista calificado

que instale la toma apropiada.

Use sólo un cable de extensión de tres hilos que tenga un

enchufe con tres contactos y un tomacorriente con conexión

de tierra que sea compatible con el enchufe del producto.

Asegúrese que su cable de extensión esté en buenas

condiciones. Cuando use un cable de extensión, asegúrese de

usar uno que pueda soportar la corriente que consuma su

producto. Para distancias inferiores a 50 pies, use un cable de

extensión AWG No. 18. Para distancias mayores de 50 pies

use un cable de extensión AWG No. 14 ó 16. Un cable de

menor capacidad causará una caída del voltaje de la línea,

ocasionando pérdida de potencia y recalentamiento. Se

recomienda un alambre de calibre 14 ó 12.

NOTA: No use una extensión de más de 100 pies. Si

necesita pintar a una distancia que esté más

allá de 100 pies de su fuente de energía,

alargue la manguera de pintura, no la

extensión. Las extensiones más cortas

asegurarán que se tenga la máxima energía

eléctrica para una operación apropiada.

Use solamente extensiones trifilares que tengan un enchufe

de conexión a tierra de 3 hojas y un receptáculo de triple

ranura que acepte el enchufe del producto. Asegúrese de

que su extensión esté en buenas condiciones. Cuando use

una extensión, asegúrese de usar una que sea lo

suficientemente resistente como para soportar la corriente

que descargue su producto. Un cable de un tamaño menor

causará una caída de voltage en la línea que dará como

resultado una pérdida de energía y un sobrecalenta|ôento.

Se recomienda usar un cable de calibre 12. Si se utiliza un

cable de extensión en el exterior, tiene que estar marcado

con el sufijo W-A después de la designación del tipo de

cable. Por ejemplo, SJTW-A para indicar que el cable es

apropiado para uso en exteriores.

© SprayTECH. Todos los derechos reservados. 15

Español

Page 16

Parts Listing

1

2

3

4

10

11

12

13

14

15

16

8

9

5

6

7

Main Assembly

Item Part # Description Quantity

1

2

3 ---------- Pump head assembly ...........................1

4 0555124 Diaphragm pump ..................................1

5 0508271 Left leg..................................................1

6 0551525 Plug.......................................................2

7 0555513 Tube cap...............................................2

8 0508259 Handle assembly ..................................1

0288144

9801533 Carriage bolt .........................................4

Hopper assembly

..................................

Item Part # Description Quantity

1

9

10

11 9820206 Washer..................................................2

12 0508660 Screw....................................................2

13 0508270 Right leg................................................1

14 0508377 Cord wrap .............................................1

15 0508267 Mounting plate ......................................1

16 9811122 Lock nut ................................................4

0288478

0508276 Screw....................................................2

Handle grip

...........................................

1

16 © SprayTECH. All rights reserved.

Page 17

Diaphragm Pump (P/N 0555124)

17

18

19

18

4

5

6

7

8

9

10

11

12

13

14

15

16

1

2

3

20

21

22

23

25

24

26

Item Part # Description Quantity

1 0555123 Pump head .................................................1

2 0270494 Diaphragm ring...........................................1

0278240

3

0288775

4

5 9801109 Set screw....................................................2

6 0270529 Valve stem ..................................................1

7 0047373 Pressure regulating spring..........................1

8 0089518 O-ring..........................................................1

9 0089475 Pressure valve needle................................1

10 0278339 Hydraulic piston ..........................................1

11 0005311 Piston spring...............................................1

0270548

12

0089456 Retainer ......................................................1

13

14 0278359 Gasket ........................................................1

0278341

15

Diaphragm

Pressure control knob.................................1

Piston washer

Hydraulic cover

..................................................1

.............................................

...........................................

Item Part # Description Quantity

16 9800049 Screw..........................................................9

17 0047393 Retaining ring..............................................1

0090031

18

0089829

19

20 9900355 Socket screw ..............................................4

21 9921601 Lock washer................................................4

22 0270546 Motor (includes items 27 and 28)...............1

23 0089930 Seal.............................................................1

24 0270477 Seal.............................................................1

25 0089929 Ball bearing.................................................1

26 0278237 Hydraulic housing assembly

1

0270462 Fan (not shown)..........................................1

27

28 0270612 Fan cover (not shown)................................1

1

Eccentric sleeve and bearing assembly

Shaft key.....................................................1

(includes items 23 – 25)

...........................

.....1

1

© SprayTECH. All rights reserved. 17

Page 18

Pump Head Assembly

2

1

3

5

6

7

8

9

10

11

4

1

2

13

14

1

5

16

1

2

3

4

6

5

7

Item Part # Description Quantity

1 0278242 Inlet valve assembly (includes item 2)........1

2 0089482 Sealing washer, nylon.................................1

3 0278334 Paint pump..................................................1

4 0555850 PRIME/SPRAY valve assembly..................1

5 0278362 Outlet seal...................................................1

6 0278241 Ball seat......................................................1

7 0093635 Ball..............................................................1

8 0047485 Outlet spring ...............................................1

9 0278361 Ball guide....................................................1

10 9871114 O-ring..........................................................1

11 0278335 Outlet fitting.................................................1

12 0278337 Pusher body................................................1

13 0278250

14 0278368 Pusher spring..............................................1

0156646

15

16 0278340 Pusher washer............................................1

Pusher stem assembly ...............................1

Seal.............................................................1

HopperAssembly

Item Part # Description Quantity

1 0279591 Cover, hopper .......................................1

2 0089917 Filter screen, fine (shown) ....................1

0088871 Filter screen, coarse

3 0090283 Hopper..................................................1

4 0093865 Return tube...........................................1

5 0090617 Fitting....................................................1

6 0090560 Return tube assembly...........................1

(includes items 4 and 5)

7 0279971 Hopper complete .................................1

(includes items 1 – 6)

18 © SprayTECH. All rights reserved.

Page 19

Notes/Nota

© SprayTECH. All rights reserved. 19

Page 20

Limited Warranty

SprayTECH

1770 Fernbrook Lane

Minneapolis, MN 55447

Technical Assistance: 1-800-292-4637

Order Entry: 1-800-443-4500

Fax: 1-800-525-9501

www.spraytechinc.com

SprayTECH, a division of Wagner Spray Tech Corporation ("SprayTECH"), warrants that at the time of delivery to the original

purchaser for use (“End User”), the equipment covered by this warranty is free from defects in material and workmanship. With

the exception of any special, limited, or extended warranty published by SprayTECH, SprayTECH ’s obligation under this

warranty is limited to replacing or repairing without charge those parts which, to SprayTECH ’s reasonable satisfaction, are

shown to be defective within twelve (12) months after sale to the End User. This warranty applies only when the unit is installed

nd operated in accordance with the recommendations and instructions of SprayTECH.

a

This warranty does not apply in the case of damage or wear caused by abrasion, corrosion or misuse, negligence, accident,

faulty installation, substitution of non- SprayTECH component parts, or tampering with the unit in a manner to impair normal

operation.

Defective parts are to be returned to an authorized SprayTECH sales/service outlet. All transportation charges, including return

to the factory, if necessary, are to be borne and prepaid by the End User. Repaired or replaced equipment will be returned to the

nd User transportation prepaid.

E

THERE IS NO OTHER EXPRESS WARRANTY. SPRAYTECH HEREBY DISCLAIMS ANY AND ALL IMPLIED WARRANTIES

INCLUDING, BUT NOT LIMITED TO, THOSE OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE, TO

HE EXTENT PERMITTED BY LAW. THE DURATION OF ANY IMPLIED WARRANTIES WHICH CANNOT BE DISCLAIMED IS

T

LIMITED TO THE TIME PERIOD SPECIFIED IN THE EXPRESS WARRANTY. IN NO CASE SHALL SPRAYTECH LIABILITY

EXCEED THE AMOUNT OF THE PURCHASE PRICE. LIABILITY FOR CONSEQUENTIAL, INCIDENTAL OR SPECIAL

DAMAGES UNDER ANY AND ALL WARRANTIES IS EXCLUDED TO THE EXTENT PERMITTED BY LAW.

SPRAYTECH MAKES NO WARRANTY AND DISCLAIMS ALL IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS

FOR A PARTICULAR PURPOSE WITH RESPECT TO ACCESSORIES, EQUIPMENT, MATERIALS OR COMPONENTS SOLD

BUT NOT MANUFACTURED BY SPRAYTECH. THOSE ITEMS SOLD, BUT NOT MANUFACTURED BY SPRAYTECH (SUCH

AS GAS ENGINES, SWITCHES, HOSES, ETC.)

SPRAYTECH WILL PROVIDE THE PURCHASER WITH REASONABLE ASSISTANCE IN MAKING ANY CLAIM FOR BREACH

OF THESE WARRANTIES.

These products are covered by one or more of the following U.S. patents:

5,286,045 D349,711 5,263,789 5,252,210 D345,841 5,059,099 5,084,964

5,217,238 4,720,801 4,785,719 4,828,464 5,145,331 4,390,324 4,403,924

4,928,722 4,416,588 4,003,504 RE29,055 4,624,602 4,834,287 5,073,092

D376,637 D387,414 D382,938 3,963,180 4,025,045 D405,159 D412,965

5,505,381 5,765,753 5,887,793 5,893,522

ARE SUBJECT TO THE WARRANTY, IF ANY, OF THEIR MANUFACTURER.

Patents

Material Safety Data Sheets (MSDS) are available on SprayTECH’s website or by calling Technical Service.

20 © SprayTECH. All rights reserved.

Loading...

Loading...