Page 1

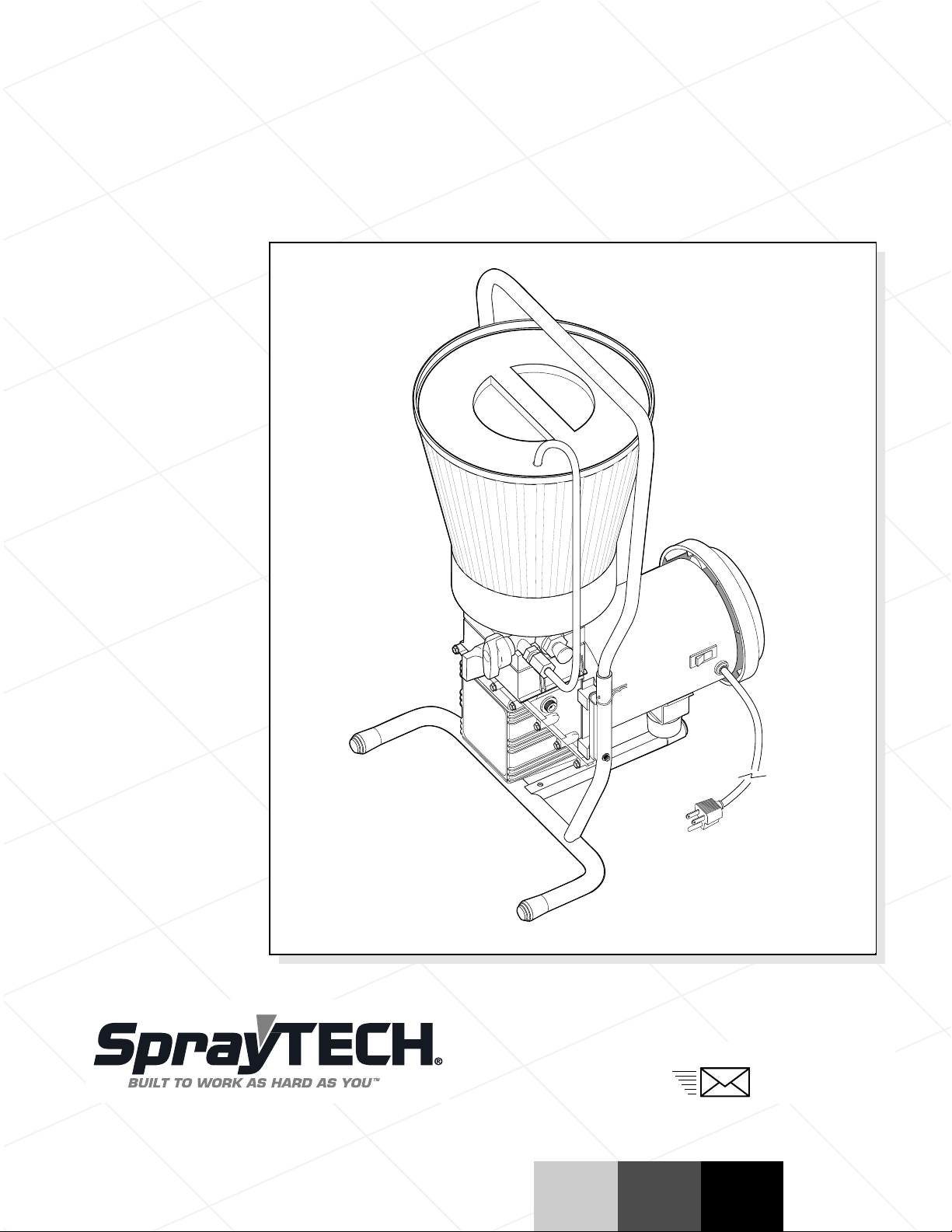

ED655 Airless Pump

Owner’s Manual • Notice d’utilisation • Manual del Propietario

PRIME

SPRAY

PRIME

Model Number 0508028

SprayTECH

1770 Fernbrook Lane

Minneapolis, MN 55447

Printed in the U. S. A.

0999 © 1999 SprayTECH Corporation. All rights reserved. Form No. 0279573B

EnglishFrançaisEspañol

Page 2

Table of Contents

Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

General Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Safety Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Grounding Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Attaching the Handle . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Attaching the Paint Hose . . . . . . . . . . . . . . . . . . . . . . . . 5

Attaching the Tip . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Pressure Relief Procedure . . . . . . . . . . . . . . . . . . . . . . . . . 6

Priming. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-7

Preparing to Prime. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Mounting the Paint Hopper. . . . . . . . . . . . . . . . . . . . . . . 7

Attaching the Return Tube . . . . . . . . . . . . . . . . . . . . . . . 7

Priming the Pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Spraying . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Spraying Technique . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Practice . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Cleanup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-10

Overnight Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Long-Term Storage . . . . . . . . . . . . . . . . . . . . . . . . . . 9-10

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-12

Removing and Cleaning theInlet Valves . . . . . . . . . . . . 11

Removing and Cleaning the Outlet Valve . . . . . . . . . . . 11

Cleaning the Spray Tip. . . . . . . . . . . . . . . . . . . . . . . . . 12

Cleaning the Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Replacing the Valve Spring Unit . . . . . . . . . . . . . . . . . . 12

Choosing the Correct Spray Gun Filter . . . . . . . . . . . . . 12

Cleaning the Hopper Screen . . . . . . . . . . . . . . . . . . . . 12

Tightening the PRIME/SPRAY knob . . . . . . . . . . . . . . . 12

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Parts Listings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38-41

Final Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Hopper Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Paint Pump Assembly . . . . . . . . . . . . . . . . . . . . . . . . . 40

G-10 Spray Gun. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Français. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Español . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

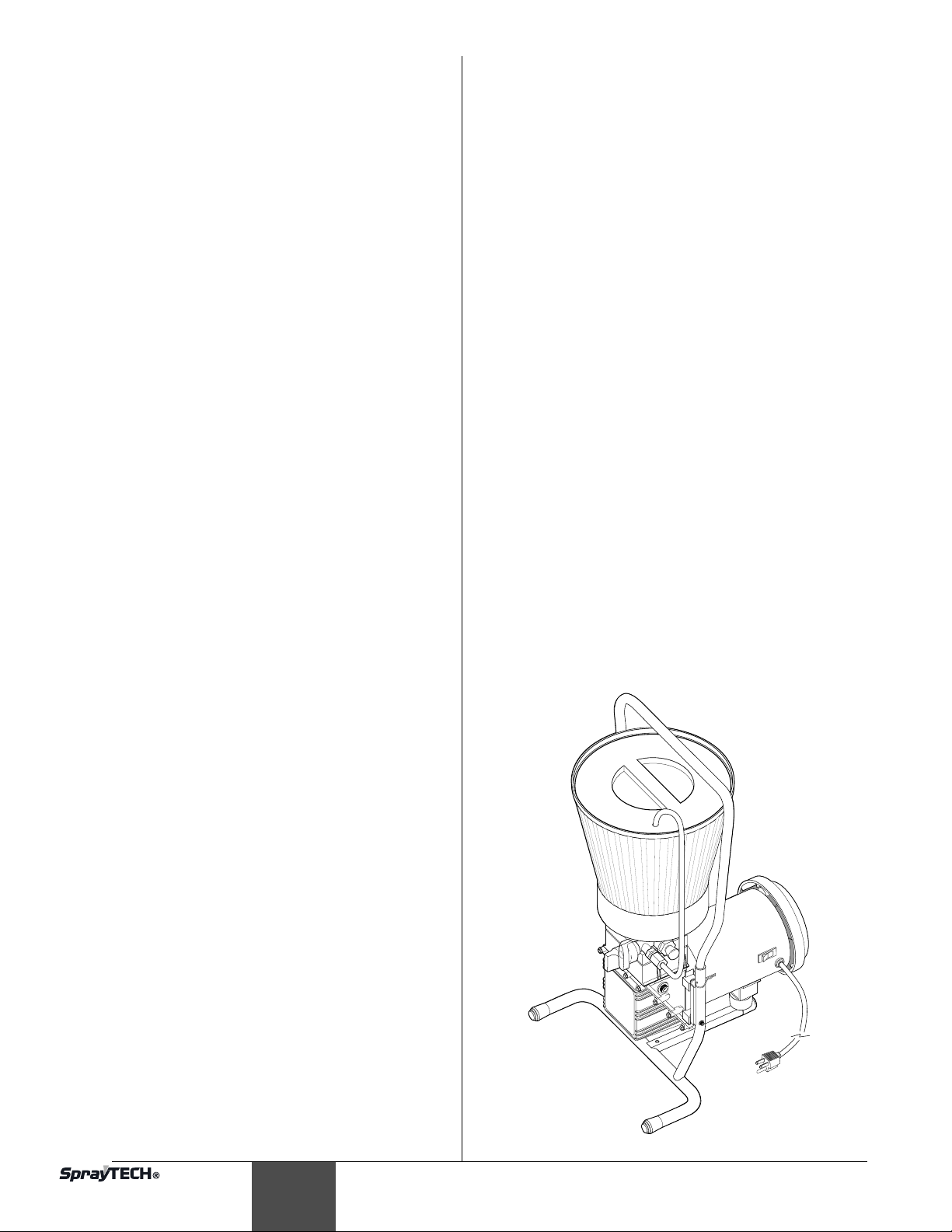

General Description

This high performance airless sprayer is a precision power tool

used for spraying many types of materials. Read and follow

this instruction manual carefully for proper operating

instructions, maintenance and safety information.

Specifications

Weight ..............................27 lbs.

Capacity ...........................Up to .35 gallon (1.25 liters) per

minute.

Power source ...................Electric motor, totally enclosed, fan

cooled.

Power requirement...........15 amp minimum circuit on 115

VAC, 60 Hz current.

Generator .........................15 amp A/C.

Spraying pressure ............Up to 2600 psi.

Safety features .................Spray gun trigger lock and pressure

diffuser; built-in tip safety guard;

priming knob for safe pressure

release.

Portability..........................Compact design, light weight for

easy movement.

Capability..........................Sprays a variety of paints, oil base

latex, primers, stains, preservatives

and other nonabrasive materials,

including pesticides and liquid

fertilizers.

Components

The shipping carton for your painting system contains the

following:

• Stand, motor, and pump attached

• Handle and two handle pins

• Paint hopper and return tube

• Spray gun and filter

• Spray tip and gasket

• Pressure hose

The following are located in the literature set with this owner’s

manual:

• Registration card

English

PRIME

SPRAY

PRIME

2 © SprayTECH Corporation. All rights reserved.

Page 3

Safety Precautions

WARNING

CAUTION

CAUTION

WARNING

This manual contains information which must be read and

understood before using the equipment. When you come to an

area which has one of the following symbols, pay particular

attention and make certain to heed the safeguard.

This symbol indicates a potential hazard which may cause

serious injury or loss of life. Important safety information will

follow.

This symbol indicates a potential hazard to you or to the

equipment. Important information that tells how to prevent

damage to the equipment or how to avoid causes of minor

injuries will follow.

NOTE: Notes give important information which

should be given special attention.

This unit is provided witha a thermally protected

automatic reset. If an overload occurs the thermally

protected automatic reset disconnects the motor from the

power supply.

• The motor will restart without warning when the protector

automatically resets.

• Always disconnect the motor from the power supply

before working on the equipment.

• When the thermally protected automatic reset disconnects

the motor from the power supply, relieve pressure by

turning the priming valve to PRIME.

• Turn the ON/OFF switch to OFF.

NOTE: The cause of the overload should be corrected

before restarting. See TROUBLESHOOTING.

HAZARD: Injection injury - A high pressure stream of

paint produced by this equipment can pierce

the skin and underlying tissues, leading to

serious injury and possible amputation.

DO NOT TREAT AN INJECTION INJURY AS A SIMPLE CUT!

Injection can lead to amputation. See a physician

immediately.

The maximum operating range of the gun is 2800 PSI fluid

pressure.

PREVENTION:

• NEVER aim the gun at any part of the body.

• NEVER allow any part of the body to come in contact

with the fluid stream. DO NOT come in contact with a fluid

stream created by a leak in the fluid hose.

• NEVER put your hand in front of the gun. Gloves will not

provide protection against an injection injury.

• ALWAYS lock the gun trigger, shut the fluid pump off and

release all pressure before servicing, cleaning the tip

guard, changing tips, or leaving unattended. Pressure will

not be released by turning off the engine. The

PRIME/SPRAY knob must be turned to PRIME to relieve

the pressure. Refer to the PRESSURE RELIEF

PROCEDURE described in this manual.

• ALWAYS have the tip guard in place while spraying. The

tip guard provides some protection against injection

injuries but is mainly a warning device.

• ALWAYS remove the spray tip before flushing or cleaning

the system.

• Inspect the paint hose before each use. The paint hose

can develop leaks from wear, kinking and abuse. A leak is

capable of injecting material into the skin.

• NEVER use a spray gun which does not have a trigger

lock or trigger guard in place and in working order.

• All accessories must be rated at or above 2800 PSI. This

includes spray tips, guns, extensions, and hose.

NOTE TO PHYSICIAN:

Injection into the skin is a traumatic injury. It is important

to treat the injury surgically as soon as possible. DO NOT

delay treatment to research toxicity. Toxicity is a concern

with some coatings injected directly into the blood

stream. Consultation with a plastic surgeon or

reconstructive hand surgeon may be advisable.

HAZARD: EXPLOSION OR FIRE - Solvent and paint fumes

can explode or ignite, causing property damage

and/or severe injury.

PREVENTION:

• Exhaust and fresh air introduction must be provided to keep

the air within the spray area free from accumulation of

flammable vapors.

• Avoid all ignition sources such as static electricity sparks,

open flames, pilot lights, hot objects, cigarettes, and sparks

from connecting and disconnecting power cords or working

light switches.

• Fire extinguishing equipment must be present and in good

working order.

• Keep the pump away from the spray area to avoid solvent

and paint fumes.

• High velocity flow of material through equipment may

develop static electricity. The equipment being used, as well

as objects in and around the spray area must be properly

grounded to prevent static discharge and sparks.

• Use only conductive or grounded high pressure fluid hoses

for airless applications. Be sure that the gun is grounded

properly through hose connections.

• Follow the material and solvent manufacturer's safety

precautions and warnings.

• When flushing equipment use the lowest possible pressure.

HAZARD: EXPLOSION HAZARD DUE TO INCOMPATIBLE

MATERIALS - May cause property damage or

severe injury.

PREVENTION:

• Do not use bleach.

• Do not use Halogenated hydrocarbon solvents such as

methylene chloride and 1,1,1 - trichloroethane. They are

not compatible with aluminum and may cause an

explosion. If you are unsure of a material’s compatibility

with aluminum, contact your coating's supplier.

© SprayTECH Corporation. All rights reserved.. 3

English

Page 4

HAZARD: HAZARDOUS VAPORS - Paints, solvents,

CAUTION

WARNING

Grounded Outlet

Grounding Pin

Tab for

Grounding Screw

Adapter

Metal Screw

Cover for grounded outlet box

WARNING

insecticides, and other materials may be

harmful if inhaled, causing severe nausea,

fainting, or poisoning.

PREVENTION:

• Use a respirator or mask whenever there is a chance that

vapors may be inhaled. Read all instructions with the

mask to ensure that it will provide the necessary

protection against the inhalation of harmful vapors.

HAZARD: GENERAL - May cause property damage or

severe injury.

PREVENTION:

• Read all instructions and safety precautions before

operating any equipment.

• Comply with all appropriate local, state, and national

codes governing ventilation, fire prevention, and

operation.

• The United States Government Safety Standards have

been adopted under the Occupational Safety and Health

Act (OSHA). These standards, particularly part 1910 of

the General Standards and part 1926 of the Construction

Standards should be consulted.

• This high pressure airless pump is designed to be used

with manufacturer authorized parts only. When using this

pump with parts that do not comply with the minimum

specifications and safety devices of the pump

manufacturer, the user assumes all risks and liabilities.

• Before each use, check all hoses for cuts, leaks, abrasion

or bulging of cover, as well as damage or movement of

couplings. If any of these conditions exist, replace the

hose immediately. Never repair a paint hose. Replace it

with another grounded hose.

• All hoses, swivels, guns, and accessories used with this

unit must be pressure rated at or above 2800 PSI.

• Do not spray on windy days.

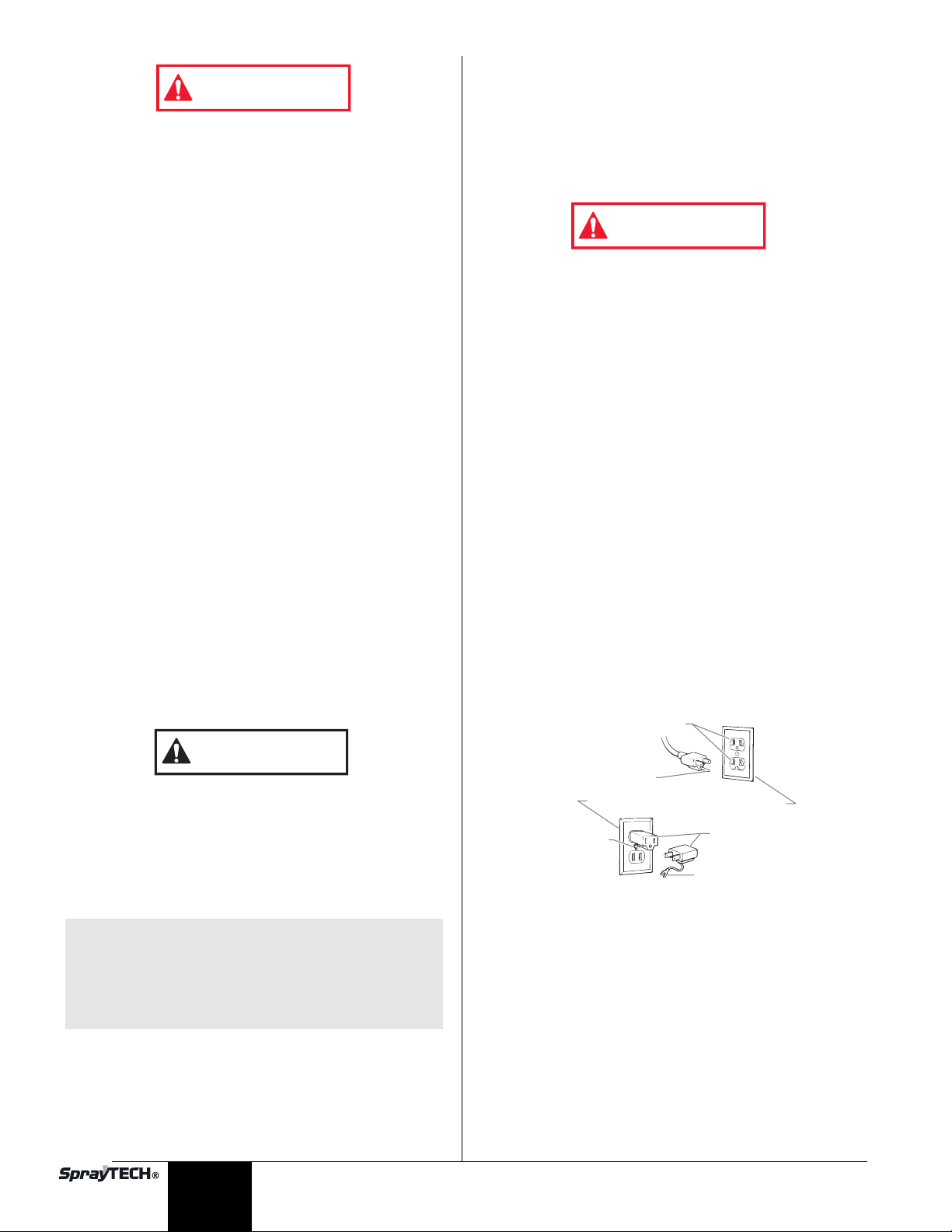

Grounding Instructions

This product must be grounded. In the event of an electrical

short circuit, grounding reduces the risk of electric shock by

providing an escape wire for the electric current. This product

is equipped with a cord having a grounding wire with an

appropriate grounding plug. The plug must be plugged into an

outlet that is properly installed and grounded in accordance

with all local codes and ordinances.

Improper installation of the grounding plug can result in a

risk of electric shock.

If repair or replacement of the cord or plug is necessary, do not

connect the green grounding wire to either flat blade terminal.

The wire with insulation having a green outer surface with or

without yellow stripes is the grounding wire and must be

connected to the grounding pin.

Check with a qualified electrician or serviceman if the

grounding instructions are not completely understood, or if you

are in doubt as to whether the product is properly grounded.

Do not modify the plug provided. If the plug will not fit the

outlet, have the proper outlet installed by a qualified

electrician.

This product is for use on a nominal 120 volt circuit and has a

grounding plug that looks like the plug illustrated below. A

temporary adapter which looks like the adapter illustrated in

the figure below may be used to connect this plug to a 2 pole

receptacle as shown if a properly grounded outlet is not

available.

The temporary adapter should be used only until a properly

grounded outlet as shown below can be installed by a qualified

electrician. The green colored rigid ear lug or the grounding

wire extending from the adapter must be connected to a

permanent ground such as a properly grounded outlet box

cover. Whenever the adapter is used, it must be held in place

by a metal screw.

Use only a 3-wire extension cord that has a 3-blade grounding

plug and a 3-slot receptacle that will accept the plug on the

product. Make sure your extension cord is in good condition.

When using an extension cord, be sure to use one heavy

enough to carry the current your product will draw. An

undersized cord will cause a drop in line voltage resulting in loss

of power and overheating. A 14 or 12 gauge cord is

recommended.

NOTE: Do not use more than 100 feet of extension

cord. If you need to paint further than 100

feet from your power source, use more paint

hose, not more extension cord. Shorter

extension cords will ensure maximum

electrical power for proper operation.

English

4 © SprayTECH Corporation. All rights reserved.

Page 5

Setup

High Pressure Hose

Begin

tightening

the tip at

this angle

to achieve

the desired

spray angle

when tight.

Gun locked OFF

(gun will not spray)

Spray Guard

Tip

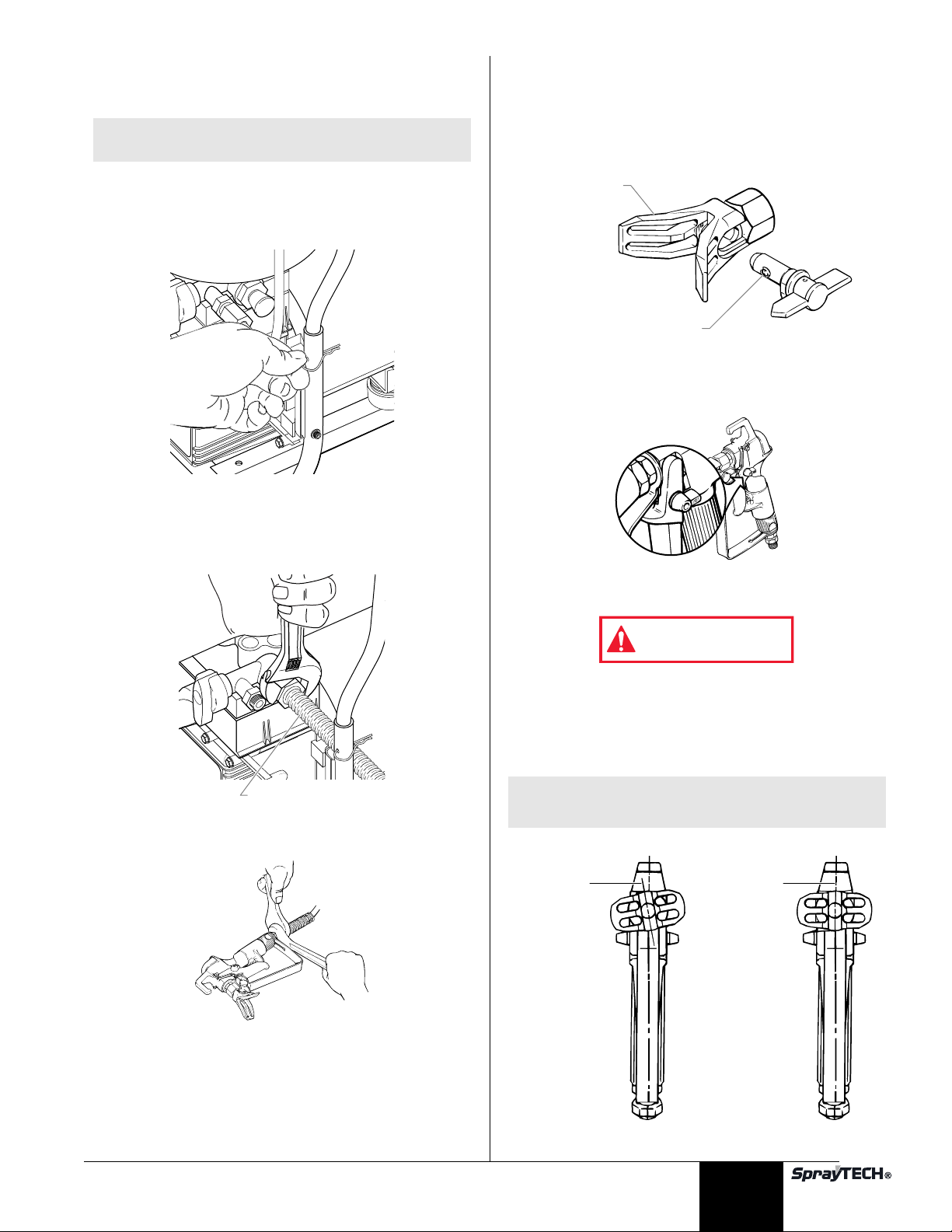

Attaching the Handle

NOTE: The sprayer should remain unplugged during

assembly.

1. Slide the handle into the stand until the holes on the

handle line up with the holes in the stand.

2. Slide the handle pins through the holes in the stand and

the handle to secure the handle in position.

SPRAY

Attaching the Paint Hose

1. Attach the high pressure hose to the paint hose port. Use

a wrench to tighten the paint hose securely.

Attaching the Tip

Assembling the Tip

If the spray tip is disassembled:

1. Insert the tip into the spray guard and turn the tip to the

spray position so that the arrow is facing toward the front

of the spray gun.

Attaching the Tip to the Gun

1. Lock the gun by turning the gun trigger lock so that it is

parallel to the gun body.

SPRAY

PRIME

2. Attach the gun to the other end of the high pressure hose.

Tighten securely with two wrenches.

3. Plug the sprayer into a properly grounded outlet or heavy

duty grounded extension cord. Do not use more than 100

feet of cord. If you must spray a long distance from a

power source, use more paint hose, not more extension

cords. Use a minimum size of 16 gauge for power

extension cords up to 50 feet in length, or 12 to 14 gauge

for power extension cords between 50 and 100 feet in

length.

WARNING

POSSIBLE INJECTION HAZARD. Do not spray without the

tip guard in place. Never trigger the gun unless the tip is in

either the spray or the unclog position. Always engage the

gun trigger lock before removing, replacing, or cleaning tip.

2. Thread the spray tip onto the gun. Tighten the nut by

hand first, then tighten more firmly with a wrench.

NOTE: When attaching the tip to the gun, align the

tip guard as shown in the figure below, then

tighten with a wrench.

© SprayTECH Corporation. All rights reserved. 5

English

Page 6

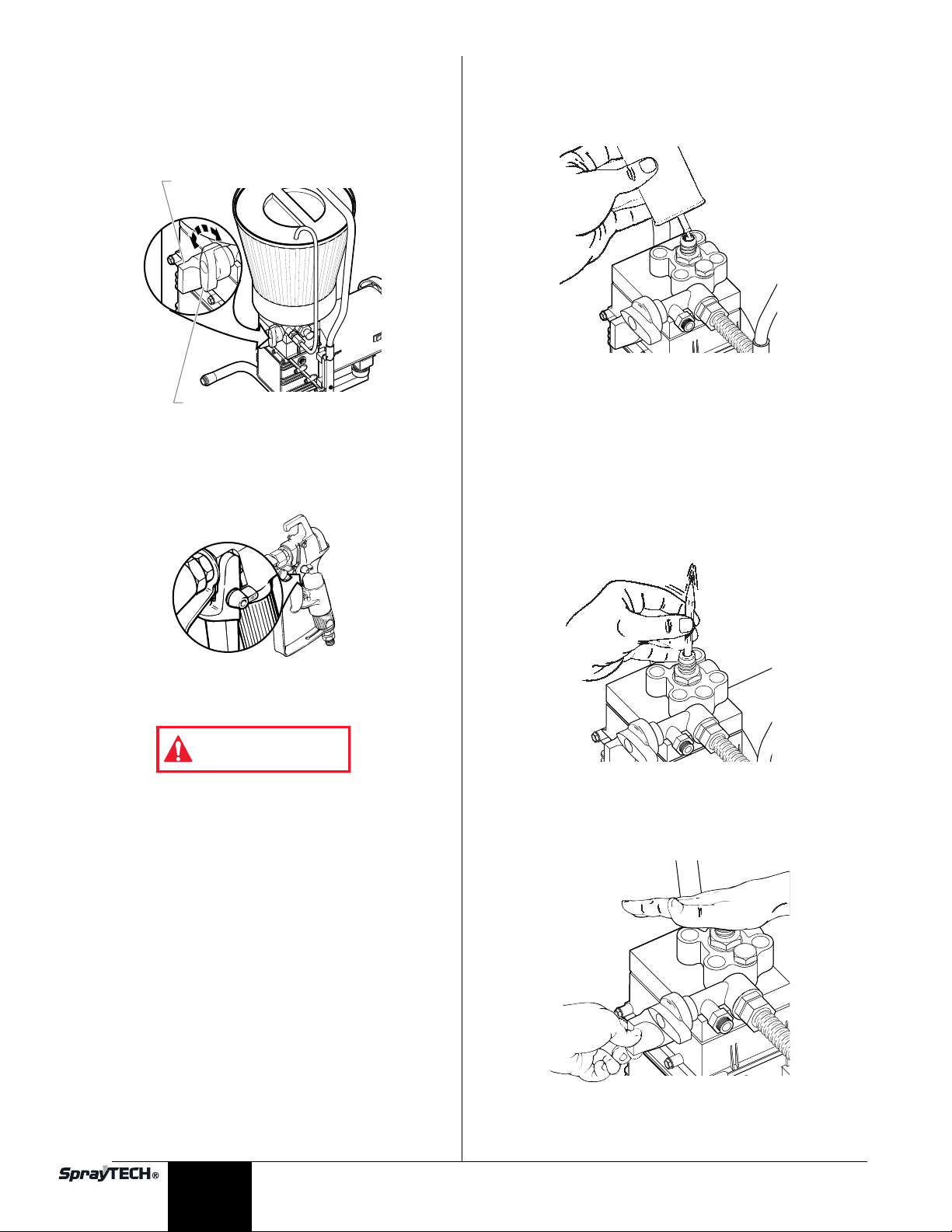

Pressure Relief Procedure

WARNING

SPRAY

PRIME

PRIME

PRIME/SPRAY Knob

Pressure Control Knob

Follow this procedure after the unit is assembled and before

any operation which involves the spray gun such as cleaning

and maintenance or changing tips or accessories.

1. Turn the pressure control knob counterclockwise to its

lowest setting.

Priming

Preparing to Prime

1. Fill the inlet valve with water or with a light household oil.

PRIME

SPRAY

PRIME

2. Turn the PRIME/SPRAY knob to PRIME.

3. Trigger the gun to remove any pressure which may still be

in the hose.

4. Lock the gun by turning the gun trigger lock so that it is

parallel to the gun body.

Gun locked OFF

(gun will not spray)

SPRAY

PRIME

2. Make certain that the PRIME/SPRAY knob is set to

PRIME and that the pressure control knob is turned

counterclockwise to the lowest pressure setting.

3. Turn the motor switch to ON.

4. Increase the pressure by turning the pressure control

knob clockwise 1/2 turn.

5. Force the inlet valve to open and close by pushing on it

with a screwdriver or the eraser end of a pencil. It should

move up and down about 1/16 of an inch. Continue until

water or oil is sucked into the sprayer. This will wet the

moving parts and break loose any old paint residue.

SPRAY

PRIME

Injection hazard. Do not spray without the tip guard in place.

NEVER trigger the gun unless the tip is completely turned to

either the spray or the unclog position. ALWAYS engage the gun

trigger lock before removing, replacing or cleaning tip.

English

6. Put the palm of your hand over the inlet. Turn the

pressure control knob clockwise to its maximum setting.

You should feel suction coming from the inlet valve. If you

do not, see the section on cleaning and servicing the outlet

valve.

SPRAY

PRIME

7. Turn the pressure control knob counterclockwise to the

minimum pressure setting.

8. Turn the motor switch to OFF.

6 © SprayTECH Corporation. All rights reserved.

Page 7

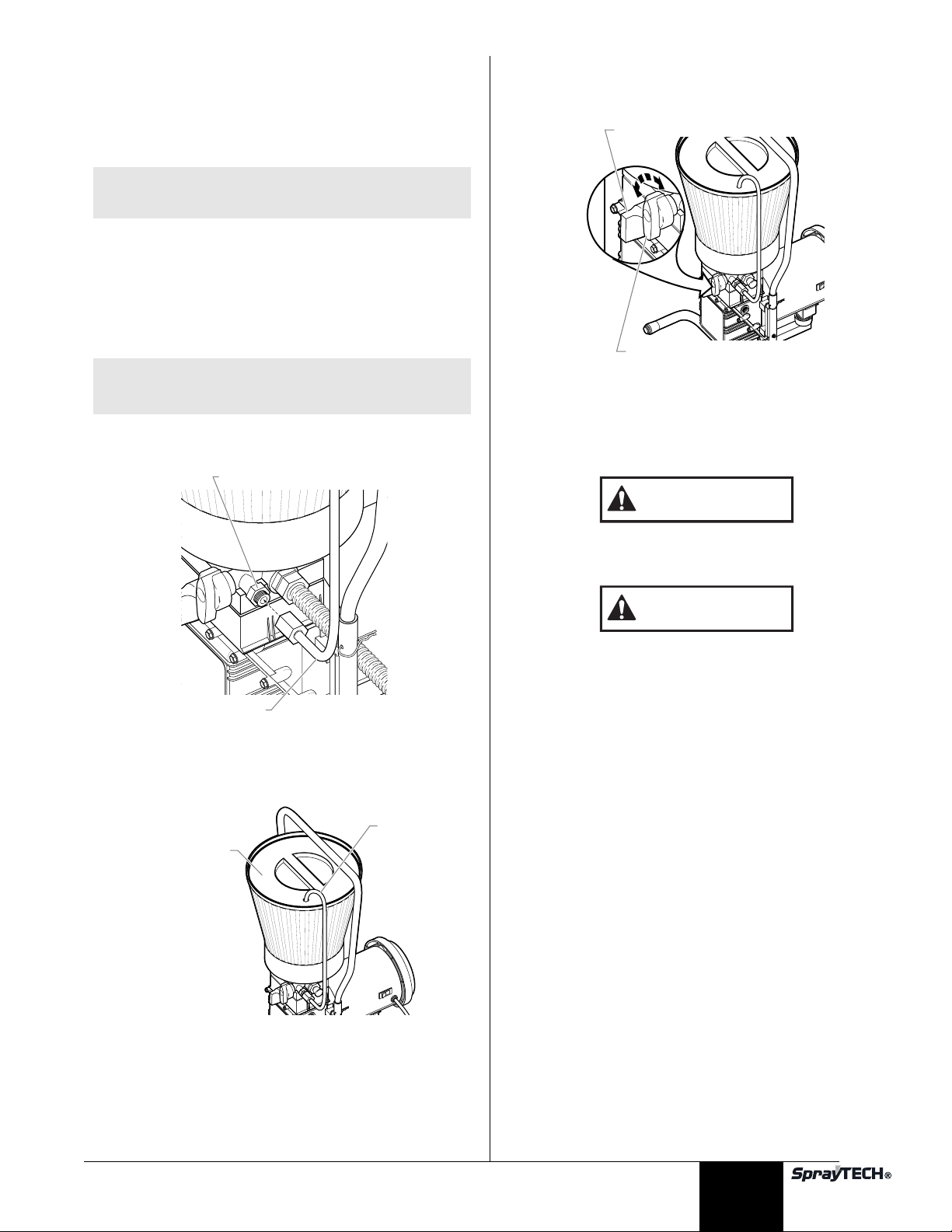

Mounting the Paint Hopper

SPRAY

PRIME

PRIME

Return Tube

Paint Hopper Cover

Return Tube Fitting

Return Tube

SPRAY

PRIME

CAUTION

SPRAY

PRIME

PRIME

PRIME/SPRAY Knob

Pressure Control Knob

1. Align the bottom of the paint hopper with the threaded

inlet valve on the paint pump block.

2. Turn the paint hopper clockwise to thread it onto the inlet

valve. Continue to turn the paint hopper until it is secure

on the inlet valve.

NOTE: Make sure the threads are straight and the

hopper turns freely on the inlet valve. Do not

cross-thread.

3. Place the filter screen into the bottom of the paint hopper

and snap it in position.

Attaching the Return Tube

1. Make sure that the motor switch is turned to OFF.

2. Screw the return tube fitting found in the literature set into the

return tube port on the side of the pump and tighten firmly by

hand.

Priming the Pump

1. Turn the pressure control knob counterclockwise to its

lowest pressure setting.

PRIME

SPRAY

PRIME

NOTE: Do not over-tighten. Hand-tighten only. Some

threads will be visible even when fully

tightened.

3. Place the straight end of the return tube into the return

tube fitting.

4. Thread the nut on the return tube onto the return tube

fitting and tighten until the return tube is secure.

5. Place the hook end of the return tube into the hole in the

paint hopper cover.

2. Turn the PRIME/SPRAY knob to PRIME.

3. Turn the motor switch to ON.

4. Turn the pressure control knob clockwise to between half

and full pressure. You should see the paint move through

the suction tube to the pump. Let the unit prime 1 to 2

minutes after paint begins to flow through the return tube.

CAUTION

Always reduce the pressure to zero before changing the

position of the priming knob. Failure to do so may cause

damage to the paint pump diaphragm.

If the pressure control knob is reduced to zero and the

PRIME/SPRAY knob is still on SPRAY while the sprayer is

operating, there will be high pressure in the hose and

spray gun until the priming knob is turned to PRIME or

until the spray gun is triggered to relieve the pressure.

© SprayTECH Corporation. All rights reserved. 7

English

Page 8

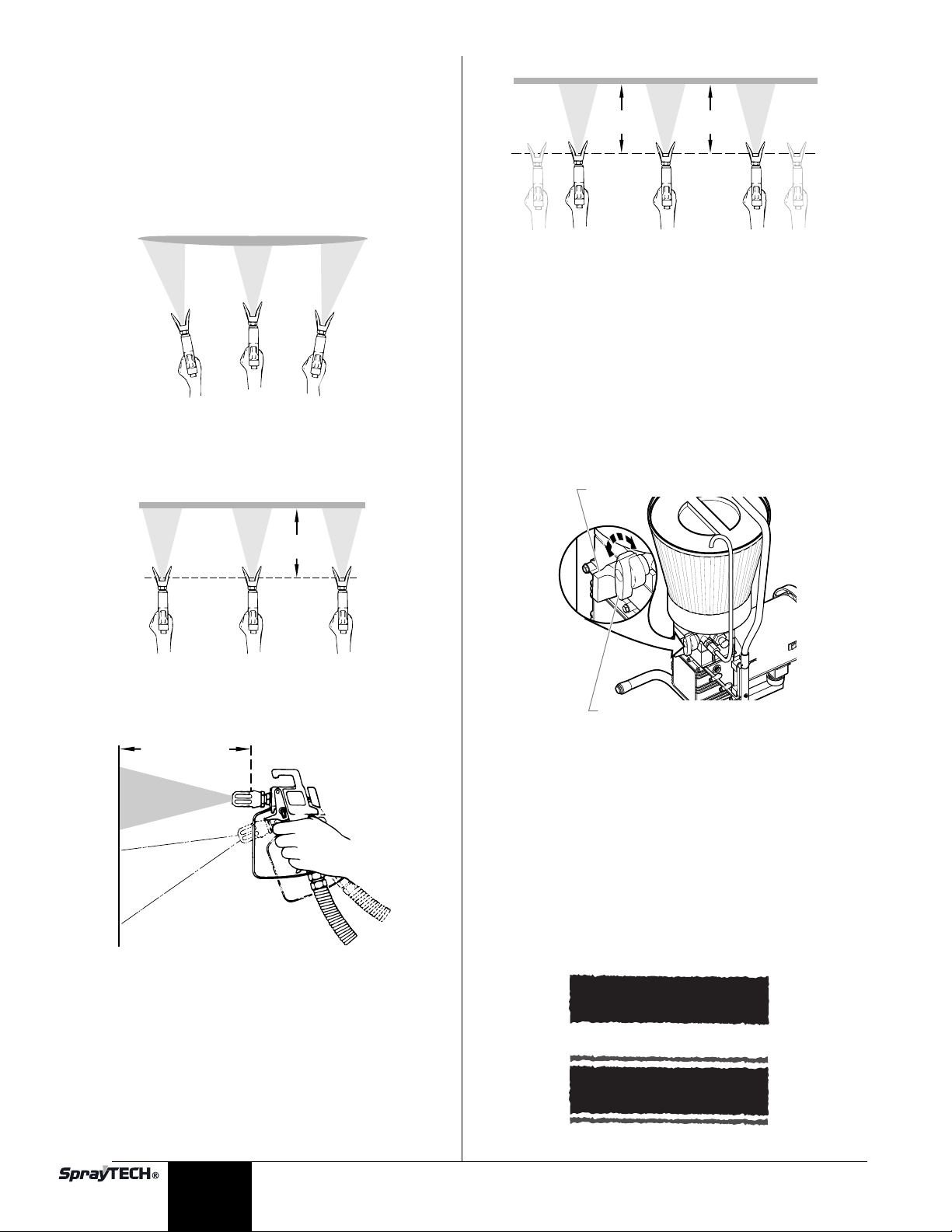

Spraying

Keep stroke smooth and at an even speed.

Even coat throughout

Approximately

10 to 12 inches

Heavy Coat

Do not flex wrist while spraying.

Light Coat Light Coat

Good spray pattern

Paint tailing pattern

SPRAY

PRIME

PRIME

Proper way to trigger the spray gun

Aproximately

10 to 12 inches

Keep stroke

even

Start stroke End strokePull trigger Release triggerKeep steady

Spraying Technique

The key to a good paint job is an even coating over the entire

surface. This is done by using even strokes. Keep your arm

moving at a constant speed and keep the spray gun at a

constant distance from the surface. The best spraying

distance is 10 to 12 inches between the spray tip and the

surface.

Keep the spray gun at right angles to the surface. This means

moving your entire arm back and forth rather than just flexing

your wrist.

Overlap each stroke by about 30%. This will ensure an even coating.

When you stop painting, lock the gun trigger lock, turn the

pressure control knob counterclockwise to its lowest setting

and set the priming knob to PRIME. Turn the motor switch to

OFF and unplug the sprayer.

If you expect to be gone more than 1 hour, follow the short

term clean up procedure described in the CLEANUP section of

this manual.

Practice

1. Be sure that the paint hose is free of kinks and clear of

objects with sharp cutting edges.

2. Turn the pressure control knob counterclockwise to its to

its lowest setting.

Pressure Control Knob

Keep the spray gun perpendicular to the surface, otherwise

one end of the pattern will be thicker than the other.

Approximately

10 to 12 inches

Right way

Wrong way

The spray gun should be triggered by turning it on and off with

each stroke. This will save paint and avoid paint buildup at the

end of the stroke. Do not trigger the gun during the middle of a

stroke. This will result in an uneven spray and splotchy

coverage.

PRIME

SPRAY

PRIME

PRIME/SPRAY Knob

3. Turn the PRIME/SPRAY knob to SPRAY.

4. Turn the pressure control knob clockwise to its highest

setting. The paint hose should stiffen as paint begins to

flow through it.

5. Unlock the gun trigger lock by turning the switch so that it

is parallel to the handle.

6. Trigger the spray gun to bleed air out of the hose.

7. When paint reaches the spray tip, spray a test area to

check the spray pattern.

8. Use the lowest pressure setting necessary to get a good

spray pattern. If the pressure is set too high, the spray

pattern will be too light. If the pressure is set too low,

tailing will appear or the paint will spatter out in gobs

rather than in a fine spray.

English

8 © SprayTECH Corporation. All rights reserved.

Page 9

Cleanup

CAUTION

Long-Term Storage

Overnight Storage

Shutdown

1. Lock the gun by turning the gun trigger lock parallel with

the gun body.

2. Turn the pressure control knob counterclockwise to the

minimum setting.

3. Turn the PRIME/SPRAY knob to PRIME.

4. Turn the motor switch to OFF and unplug the sprayer.

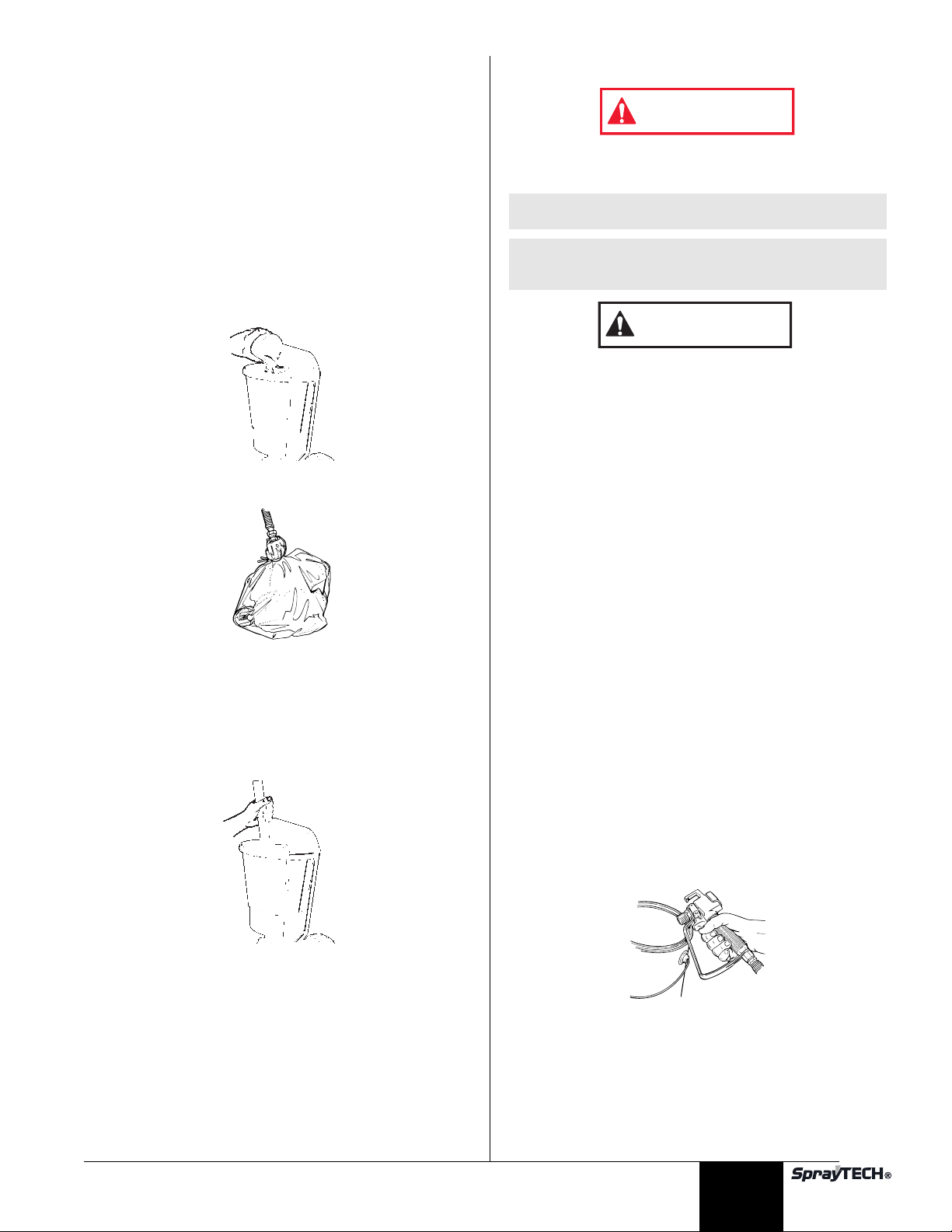

5. For latex materials only, pour 1/2 cup water slowly on the

top of the paint to prevent the paint from drying. For other

materials, seal the paint hopper with the hopper cover

keeping the return tube in the paint.

6. Wrap the spray gun assembly in a damp cloth and place it

in a plastic bag. Seal the bag shut.

7. Place the sprayer in a safe place out of the sun for shortterm storage.

Startup

1. Remove the gun from the plastic bag.

2. Stir the water into the paint for latex materials. Remove

the hopper cover from the paint hopper and stir the paint

for all other materials.

WARNING

Do not allow paint to build up on the motor or the motor

will overheat. Do not allow flammable solvents to come in

contact with the motor or they could ignite.

NOTE: You will need a bucket, cleaning solution, a

toothbrush, a wrench and cleaning rags.

NOTE: If spraying with latex paint, use warm soapy

water for cleaning. If using oil or alkyd-based

paints, use mineral spirits or paint thinner.

Do not use mineral spirits or paint thinner on latex paint,

or the mixture will turn into a jelly-like substance which is

difficult to remove.

Clearing the Paint Hopper

1. Lock the gun by turning the gun trigger lock parallel with

the gun body.

2. Turn the pressure control knob counterclockwise to the

minimum setting.

3. Turn the PRIME/SPRAY knob to PRIME.

4. Turn the motor switch to OFF and unplug the sprayer.

5. Direct the return tube into the original paint bucket.

6. Plug the sprayer in and turn the motor switch to ON.

7. Turn the pressure control knob to 1/2 maximum pressure.

This will draw the remaining paint in the paint hopper through

the pump, up the return tube, and into the paint bucket.

8. Turn the pressure control knob counterclockwise to the

minimum pressure setting.

9. Trigger the gun to relieve pressure and lock the gun.

10. Remove the spray tip and guard and place them into a

container of water or appropriate solvent for the type of

material with which you are painting.

11. Fill the paint hopper with water or an appropriate solvent

for the type of material with which you are painting.

12. Increase the pressure to 1/2 the maximum pressure. Let

the water or solvent circulate for 2-3 minutes to flush paint

out of the pump, the paint hopper, and the return tube.

Clearing the Paint Hose

1. To save paint left in the hose, release the gun trigger lock

and carefully trigger the gun with the spray tip removed

against the inside of the paint container.

3. Check to be sure that the PRIME/SPRAY knob is set to

PRIME and that the pressure is completely reduced.

4. Plug sprayer in and turn the motor switch to ON.

5. Turn the PRIME/SPRAY knob to SPRAY and gradually

turn the pressure control knob clockwise to increase the

pressure.

6. Test the sprayer on a practice piece and begin spraying.

© SprayTECH Corporation. All rights reserved. 9

2. Turn the pressure control knob counterclockwise to the

minimum pressure setting.

3. Turn the PRIME/SPRAY knob to SPRAY.

4. Turn the pressure control knob slowly until paint starts to

flow into the bucket. As soon as the water or solvent

starts to come into the bucket, release the trigger.

5. Change to clean water or solvent and continue circulating

for another 5 minutes to thoroughly clean the hose, pump

and spray gun.

English

Page 10

6. Turn the pressure control knob counterclockwise to its

lowest setting.

7. Turn the PRIME/SPRAY knob to PRIME.

8. Trigger the gun to remove any pressure which may still be

in the hose.

9. Lock the gun by turning the gun trigger lock so that it is

parallel to the gun body.

10. Turn the motor switch to OFF.

Clearing the Gun

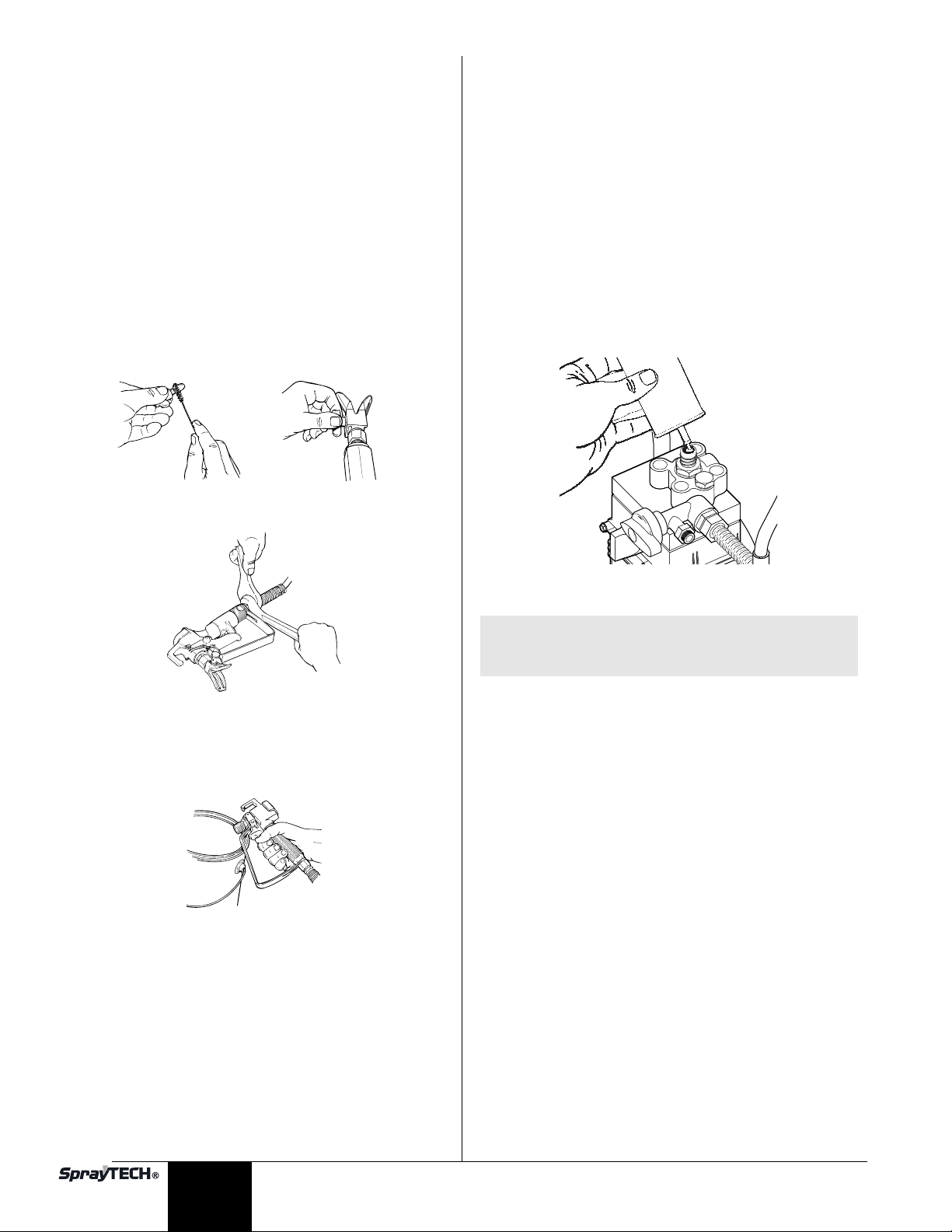

1. Remove the spray gun from the paint hose using two

adjustable wrenches.

2. Remove the filter housing from the gun. Place the gun

and the filter assembly into a container of water or solvent

to soak.

3. Cover the paint container and set it aside.

4. Clean the spray tip and gun filter with a soft brush.

Assemble the spray tip in the cleaning position with the

arrow pointing to the back of the gun.

5. Attach the paint hose to the gun and tighten using two

wrenches.

Final Cleanup

1. Remove the tip assembly.

2. Turn the motor to ON.

3. Turn the PRIME/SPRAY knob to SPRAY.

4. Turn the pressure control knob clockwise to 1/2 power.

5. Trigger the gun into the cleaning bucket until the hopper is

empty.

6. Refill the hopper and continue flushing the system until

the solution coming out of the gun appears clean.

7. Lock the gun and turn the pressure control knob

counterclockwise to its lowest setting.

8. Turn the PRIME/SPRAY knob to PRIME.

9. Remove the hopper from the inlet valve.

10. Clean the threads of the inlet valve with a damp cloth.

11. Fill the inlet valve with a light household oil. Slowly

increase the pressure to distribute the oil through the pump.

SPRAY

PRIME

6. Turn the motor switch to ON.

7. Unlock gun trigger by turning the gun trigger lock so that it

is parallel to the gun handle.

8. Turn the PRIME/SPRAY knob to SPRAY and point the gun

to the side of the cleaning bucket.

9. Trigger the gun and gradually turn the pressure control

knob clockwise to 1/2 pressure. Continue to trigger the

gun for approximately 30 seconds.

10. Turn the pressure control knob counterclockwise to its

lowest setting.

11. Turn the PRIME/SPRAY knob to PRIME.

12. Trigger the gun to remove any pressure which may still be

in the hose.

13. Lock the gun by turning the gun trigger lock so that it is

parallel to the gun body.

14. Turn the motor switch to OFF.

12. Turn the PRIME/SPRAY knob to SPRAY to distribute the

oil.

NOTE: Proper cleaning and oiling of the pump after

use are the most important steps you can take

to insure proper operation after storage.

13. Turn the pressure control knob counterclockwise to its

lowest setting.

14. Turn the PRIME/SPRAY knob to PRIME.

15. Trigger the gun to remove any pressure which may still be

in the hose.

16. Lock the gun by turning the gun trigger lock so that it is

parallel to the gun body.

17. Turn the motor switch to OFF.

18. Remove and clean the hopper filter in clean water or the

appropriate solvent. Use a soft brush.

19. Return the hopper filter to its postion in the hopper and

replace the hopper on the inlet valve.

20. Wipe the entire unit, hose and gun with a damp cloth to

remove accumulated paint.

English

10 © SprayTECH Corporation. All rights reserved.

Page 11

Maintenance

SPRAY

PRIME

Follow these procedures when encountering problems

indicated in the troubleshooting section.

Removing and Cleaning the Inlet Valves

1. Be certain that the sprayer is off.

2. Remove the inlet valve assembly using a 27 millimeter

socket or box end wrench.

3. Test movement of the valve by pushing on it from the

open end of the valve housing with a screwdriver or the

eraser end of a pencil. It should move about 1/16 of an

inch. If it does not move, it should be cleaned or

replaced.

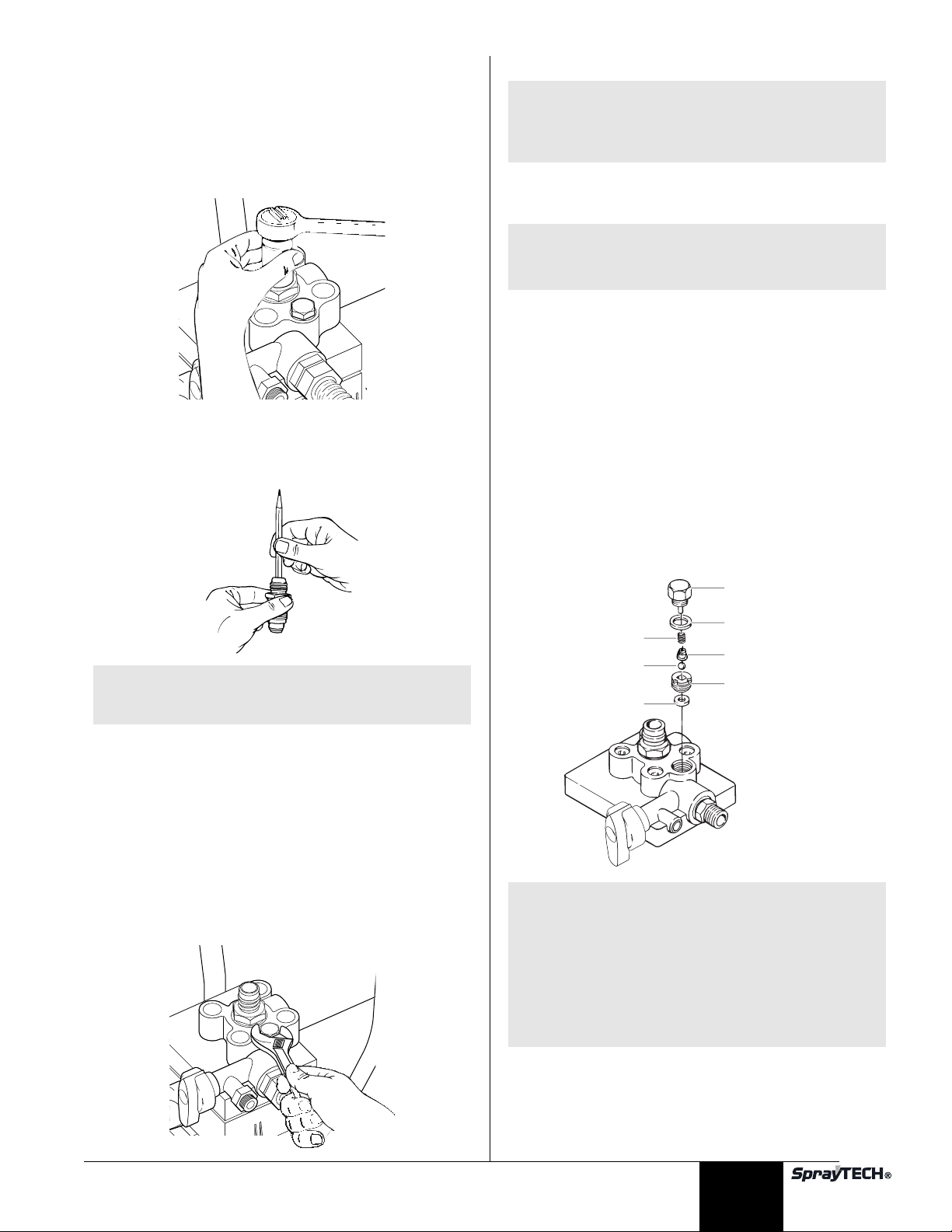

2. Leave the copper washer under the cap in place.

NOTE: If the copper washer falls out, be sure to

replace it with the same side up. The top will

show the imprint of the end cap, while the

bottom should be perfectly flat to match the

seat in the pump casting.

3. Remove and clean the small spring inside the valve using

a wire hook or tweezers. Replace the spring if it is broken

or worn.

NOTE: This spring is manufactured to a very specific

tension. Do not put in an unauthorized

substitute. See the paint pump assembly parts

diagram for the proper replacement part number.

4. Remove the seat and ball assembly using a 3/8 inch allen

wrench.

5. Clean all parts thoroughly. If the ball or seat show any

sign of wear or damage, replace them with new parts.

This carbide ball must seal tightly against its seat for the

valve to function properly.

6. Cover all parts with a thin coat of light oil before

reassembling.

7. Tighten the valve seat securely with the 3/8 inch allen

wrench.

8. Drop in the valve ball.

9. Insert the protector and spring and replace the cap. Be

sure that the copper washer is positioned properly and

that the tongue on the cap fits inside the spring.

10. Tighten the cap securely with an adjustable wrench. Do

not overtighten.

NOTE: The inlet valve must be oiled after every job.

This will reduce or eliminate priming problems

the next time the sprayer is used.

4. Thoroughly clean the valve assembly with water or the

appropriate solvent. Use a small brush.

5. If you have properly cleaned the valve and water drips out

of the bottom, the valve is worn and needs to be replaced.

A properly seated valve filled with water and held vertically

will not drip.

6. Install a new or cleaned valve in the pump block and then

fill the valve with light oil or solvent.

Removing and Cleaning the Outlet Valve

It may be necessary to remove and clean the outlet valve or to

replace parts inside the valve worn out through normal use.

1. Remove the outlet cap with a wrench.

Cap

Copper Washer

Spring

Ball

Protector

Seat

Seal

E

IM

R

S

P

P

R

A

Y

NOTE: Wear on the ball is almost impossible to

detect visually. To test for a worn outlet valve

assembly, turn the pressure control knob

clockwise to its highest setting and run water

only through the sprayer for 10 to 15 minutes

without triggering the gun.

If the valve is defective, the end cap will get

very hot to the touch. If it is functioning

properly, it will stay approximately the same

temperature as the water running through it.

SPRAY

PRIME

© SprayTECH Corporation. All rights reserved. 11

English

Page 12

Cleaning the Spray Tip

Gun Housing

Valve Spring

Unit

Sliding Pin

Nut

Retainer Block

Diffuser

Gun Housing

Filter

Handle

WARNING

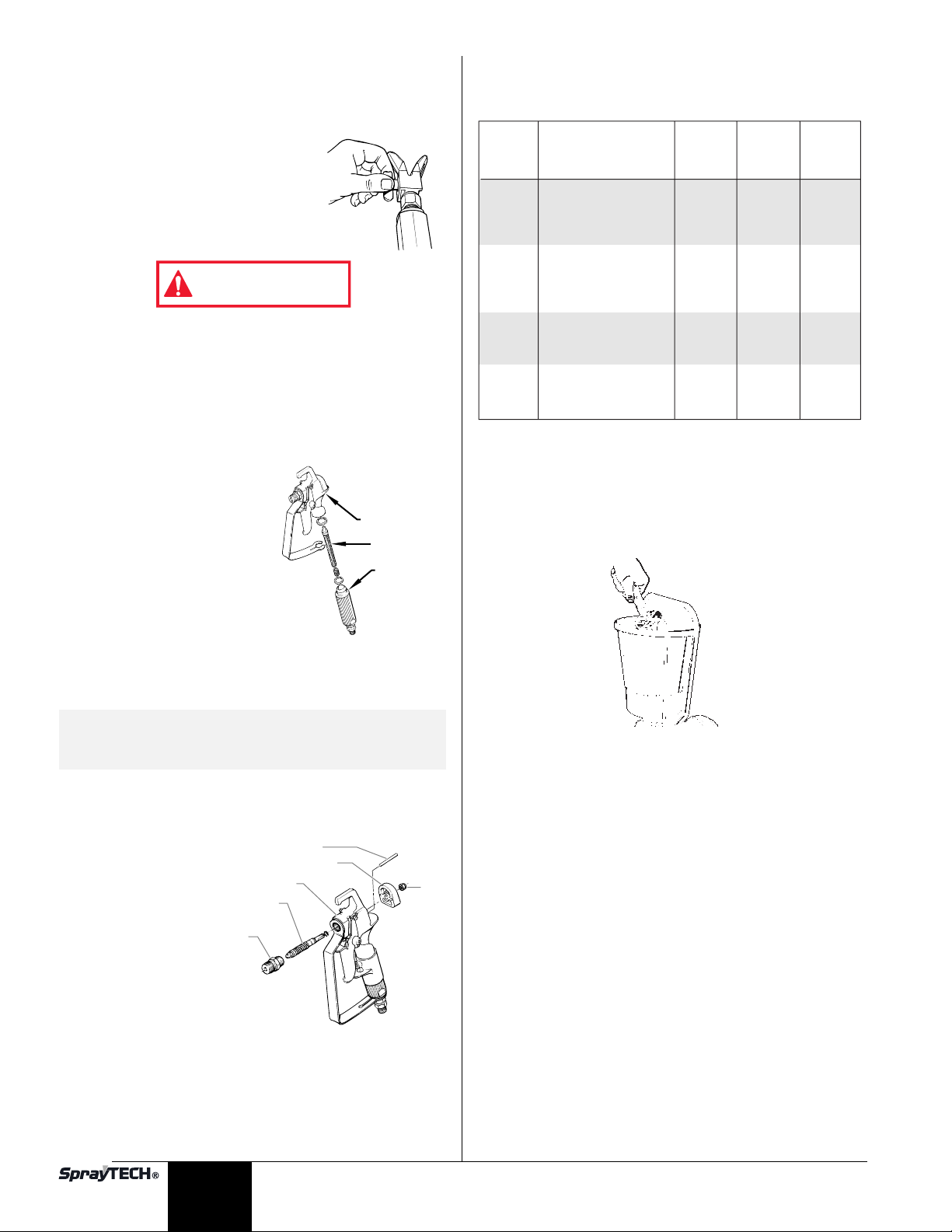

Part no. Application Filter

type

Mesh

number

Color of

Filter

body

0089960 Synthetic resin,

enamels, clean

varnishes, stains

azures

Extrafine 0.084 mm red

0089959 Base coat enamels,

primer enamels,

fillers, marking paints,

textured enamels

Fine 0.140 mm yellow

0089958 Emulsions,

latex paints,

acrylic paints

Medium 0.315 mm white

0089957 Filler paints,

large area surfaces

Coarse 0.560 mm green

1. Flush the gun with solvent immediately after the work is

completed.

2. Oil the sliding pins to prevent them from seizing up.

Should the spray tip become clogged,

reverse the spray tip with the lever and

pull the trigger. Once the obstruction

comes out of the spray tip, release the

trigger, reverse the spray tip back to the

spray pattern setting, and resume

spraying.

Do not attempt to clean the tip with your finger.

Do not use a needle or other sharp pointed instrument to

clean the tip. The hard tungsten carbide is brittle and can

be chipped.

Cleaning the Filter

Clean the filter with a brush dipped in solvent. Never poke the

filter with a sharp instrument.

Changing the Filter

1. Pull the trigger guard forward

so that it comes loose from

the handle.

2. Unscrew the handle from the

housing and remove the old

filter.

3. Slide the new filter, taper end

first, into the gun housing.

4. Replace the handle, washer

and spring. Screw the handle

into the housing until hand-tight. Replace the trigger

guard.

Replacing the Valve Spring Unit

Choosing the Correct Spray Gun Filter

Use the proper gun filter based on the type of material being

applied as shown below.

Cleaning the Hopper Screen

The screen at the bottom of the paint hopper may need

cleaning periodically. Check it every time you add paint.

Remove the screen by pulling it out of the hopper with a pliers.

Clean the screen with water or solvent and a soft-bristle brush,

if necessary.

NOTE: Replace the packing if the spray gun is

1. Unscrew the spray tip.

2. Lock the gun in the ON position and remove the diffuser

3. Unlock the gun.

4. Unscrew the nut

5. Remove the

6. Drive the valve

disassembled. Replace the sliding pins if they

are worn.

with a wrench

with a wrench

and remove the

retainer block.

sliding pins with

care and store

them in a safe

place so they will

not be lost.

spring unit forward from the back of the retainer block.

Use the handle of a wooden hammer or similar soft tool to

avoid damaging the valve spring unit.

English

Tightening the PRIME/SPRAY Knob

Sometimes the two allen screws holding the PRIME/SPRAY

knob outer cover will vibrate loose. This allows the cover to

turn without changing the valve setting. If this happens,

loosen the screw with a 1/16 allen wrench, turn the knob to

SPRAY and tighten the screw.

12 © SprayTECH Corporation. All rights reserved.

Page 13

Problem

The sprayer does not start up.

Troubleshooting

Cause

1. The sprayer is not plugged in.

2. The ON/OFF switch is set to OFF.

3. Low or no voltage is coming from the

wall plug.

4. The sprayer was turned off while still under

pressure.

5. The extension cord is damaged or has too

low a capacity.

6. The thermal overload on the sprayer is

tripped.

7. There is a problem with the motor.

Solution

1. Plug the sprayer in.

2. Turn the ON/OFF switch to ON.

3. Properly test the power supply voltage.

4. Turn the PRIME/SPRAY knob to PRIME.

5. Replace the extension cord.

6. Allow the motor to cool and move the sprayer to a

cooler spot.

7. Take the sprayer to a SprayTECH Authorized Service

Center.

The sprayer starts up but does not

draw in paint when the

PRIME/SPRAY knob is set to

PRIME.

The sprayer draws up paint but

the pressure drops when the gun

is triggered.

The sprayer will not shut off.

The spray gun leaks.

The tip assembly leaks.

1. The unit will not prime properly or has lost prime.

2. The paint hopper is empty

3. The hopper filter is clogged.

4. The inlet valve is stuck.

5. The outlet valve is stuck.

6. The PRIME/SPRAY valve is plugged.

7. The inlet valve is worn or damage.

8. There is a problem with the diaphragm.

9. The hydraulic oil level is low or empty.

1. The spray tip is worn.

2. The hopper filter is clogged.

3. The gun or spray tip filter is plugged.

4. The paint is too heavy or coarse.

5. The outlet valve assembly is dirty or worn.

6. The inlet valve assembly is damaged or worn.

1. The inlet or outlet valve ball or ball seat is

worn.

2. Foreign matter or paint has built up between

the ball and the seat.

1. Internal parts of the gun are worn

or dirty.

1. The tip was assembled incorrectly.

2. A seal is worn.

1. Try to prime the unit again.

2. Fill the paint hopper with paint.

3. Clean the hopper filter.

4. Clean the inlet valve.

5. Clean the outlet valve and replace any

worn parts.

6. Take the sprayer to a SprayTECH Authorized Service

Center.

7. Replace the inlet valve.

8. Take the sprayer to a SprayTECH Authorized Service

Center.

9. Take the sprayer to a SprayTECH Authorized Service

Center.

1. Replace the spray tip with a new tip.

2. Clean the hopper filter.

3. Clean or replace the proper filter. Always keep

extra filters on hand.

4. Thin or strain the paint.

5. Clean or replace the outlet valve assembly.

6. Replace the inlet valve.

1. Take the sprayer to a SprayTECH Authorized

Service Center.

2. Take the sprayer to a SprayTECH Authorized

Service Center.

1. Take the sprayer to a SprayTECH Authorized

Service Center.

1. Check the tip assembly and assemble properly.

2. Replace the seal.

The spray gun will not spray.

The paint pattern is tailing.

The thermal overload tripped and

shut off the sprayer.

1. The spray tip, the gun filter or the tip filter is

plugged.

2. The spray tip is in the CLEAN position.

1. The pressure is set too low.

2. The gun, the tip, or the hopper filter

is plugged.

3. The tip is worn.

4. The paint is too thick.

1. The motor overheated.

2. The extension cord is too long or is too

small a gauge.

3. Paint has built up on the motor.

4. The motor was started while the sprayer

was under pressure.

5. The sprayer was sitting in the hot sun.

1. Clean the spray tip, gun filter or tip filter.

2. Put the tip in the SPRAY position.

1. Increase the pressure.

2. Clean the filters.

3. Replace the spray tip.

4. Thin the paint.

1. Allow to cool for 30 minutes.

2. Allow to cool for 30 minutes and replace the

extension cord with a shorter extension or a thicker

gauge cord.

3. Clean the paint from the motor.

4. Restart the sprayer in the PRIME mode.

5. Move the sprayer out of the sun.

NOTE: When the PRIME/SPRAY valve is on SPRAY and there is flow through the return tube, remove the

PRIME/SPRAY valve and clean or replace it.

NOTE: The electric motor should always be kept clean and dry. Paint acts as an insulator. Too much paint on the

motor will cause the motor to overheat.

© SprayTECH Corporation. All rights reserved. 13

English

Page 14

Table des matières

Composants . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Description générale. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Spécification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Consignes de sécurité. . . . . . . . . . . . . . . . . . . . . . . . . 15-16

Directives sur la mise à la terre . . . . . . . . . . . . . . . . . . 16

Montage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Assemblage de la poignée . . . . . . . . . . . . . . . . . . . . . . 17

Comment attacher le tuyau à peinture . . . . . . . . . . . . . 17

Comment attacher la tête de pulvérisation . . . . . . . . . . 17

Limitation de la pression procédure . . . . . . . . . . . . . . . . 18

Amorçage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18-19

Préparation à l'amorçage . . . . . . . . . . . . . . . . . . . . . . . 18

Montage de la trémie à peinture . . . . . . . . . . . . . . . . . . 19

Assemblage du tube de retour . . . . . . . . . . . . . . . . . . . 19

Amorçage de la pompe . . . . . . . . . . . . . . . . . . . . . . . . 19

Pulvérisation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Technique de pulvérisation . . . . . . . . . . . . . . . . . . . . . . 20

Pratique . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Nettoyage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21-22

Rangement du jour au lendemain. . . . . . . . . . . . . . . . . 21

Rangement à long terme. . . . . . . . . . . . . . . . . . . . . 21-22

Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23-24

Comment enlever et nettoyer la soupapes d'admission . . 23

Comment enlever et nettoyer la soupape de sortie . . . . 23

Nettoyage de la tête de pulvérisation . . . . . . . . . . . . . . 24

Nettoyage du fitre. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Remplacement du ressort de valve . . . . . . . . . . . . . . . 24

Choix du filtre approprié pour le pistolet de pulvérisation . 24

Nettoyage du tamis de la trémie. . . . . . . . . . . . . . . . . . 24

Comment serrer le bouton AMORCER/PULVÉRISER . . 24

En cas de problème . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Schémas des pièces . . . . . . . . . . . . . . . . . . . . . . . . . . 38-41

Montage Final . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Ensemble trémie . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Ensemble de la pompe à peinture . . . . . . . . . . . . . . . . 40

Pistolet G-10 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Garantie. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Composants

Le carton d'expédition pour votre système de peinture contient

les composants suivants :

• Support, moteur et pompe attachés

• Poignée avec ses deux broches

• Trémie à peinture et tube de retour

• Pistolet et filtre.

• Tête de pulvérisation et joint d'étanchéité.

• Tuyau à pression.

Les composants suivants se trouvent dans le jeu de

documentation qui accompagne le présent manuel :

• Carte d'enregistrement.

Description Générale

Ce pistolet de pulvérisation sans air à haut rendement est un

outil mécanique de grande précision dont on peut se servir

pour pulvériser une grande diversité de matériaux. Il faut lire et

suivre ce manuel d'instructions avec soin, afin de profiter de

bonnes consignes en matière d'exploitation, de maintenance

et de sécurité.

Spécification

Poids.........................................12 kg (27 lb)

Débit .........................................Jusqu'à 1,25 litre (0,35 gallon)

par minute.

Alimentation ..............................Moteur électrique, entièrement

protégé, refroidi par ventilateur.

Besoin en énergie.....................Circuit d'au moins 15 ampères,

courant de 60 Hz et de 115

volts CA.

Génératrice ...............................15 ampères CA.

Pression de pulvérisation .........Jusqu'à 2600 psi.

Caractéristiques de sûreté........Cran de sûreté au pistolet,

diffuseur de pression, protecteur

de tête intégré, bouton

d'amorçage pour la décharge de

la pression sans danger.

Caractère portatif......................Le pistolet, compact et léger,

est facile à transporter.

Polyvalence ..............................Le pistolet sert à pulvériser une

grande variété de peintures à

huile ou au latex, d'apprêts, de

teintures, d'agents de

conservation et d'autres

produits non abrasifs, y

compris les pesticides et les

engrais liquide

Français

PRIME

SPRAY

PRIME

14 © SprayTECH Corporation. Tous droits réservés.

Page 15

Consignes de sécurité

AVERTISSEMENT

ATTENTION

ATTENTION

TLe présent manuel comprend des renseignements devant

être lus attentivement avant toute utilisation de l'appareil.

Lorsque l'un des symboles suivants apparaît, il est

recommandé d'être particulièrement attentif et de tenir compte

des mesures de sécurité indiquées.

AVERTISSEMENT

Ce symbole indique un danger potentiel pouvant causer des

blessures graves ou même mortelles. Des renseignements

importants sur la sécurité sont également indiqués

Ce symbole indique un danger potentiel pouvant causer des

blessures corporelles ou des dommages à l'équipement. Des

renseignements importants sur la façon de prévenir tout

dommage à l'équipement ou toute blessure corporelle mineure

sont également indiqués.

NOTA : Les remarques donnent des renseignements

importants requérant une attention particulière.

CET ENSEMBLE EST DOTÉ D'UN DISPOSITIF DE REMISE

EN MARCHE AUTOMATIQUE AVEC PROTECTION

THERMIQUE. EN CAS DE SURCHARGE, CE DISPOSITIF

DÉBRANCHE LE MOTEUR DU BLOC D'ALIMENTATION.

• Le moteur se remet en marche sans avertissement

lorsque le protecteur est réarmé automatiquement.

• Il faut toujours débrancher le moteur du bloc

d'alimentation avant de travailler sur le matériel.

• Lorsque le dispositif de remise en marche automatique

débranche le moteur du bloc d'alimentation, réduire la pression

en tournant la soupape d'amorçage à AMORCER.

• Mettre l'interrupteur MARCHE/ARRÊT à ARRÊT.

NOTA : Il faut remédier à la cause de la surcharge

avant de relancer l'appareil. À ce sujet, voir la

rubrique DÉPANNAGE.

DANGER: Blessures résultant d'une injection cutanée - Le

jet de peinture haute pression produit par cet

appareil peut transpercer la peau et les tissus

sous-jacents, causant des blessures graves

pouvant aller jusqu'à l'amputation.

NE PAS TRAITER CE TYPE DE BLESSURE COMME S'IL

S'AGISSAIT D'UNE SIMPLE COUPURE ! Une amputation

peut en résulter. Consulter un médecin immédiatement.

Le plus haut niveau de fonctionnement du pistolet est une

pression du fluide de 2800 PSI.

PRÉVENTION:

• NE JAMAIS diriger le pulvérisateur vers toute partie du corps.

• NE JAMAIS placer toute partie du corps devant le jet.

ÉVITER d'entrer en contact avec un jet de fluide sortant

d'une fuite dans le tuyau à fluide.

• NE JAMAIS placer les mains devant le pulvérisateur. Les

gants ne sont pas une protection suffisante contre les

risques d'injection cutanée.

• TOUJOURS bloquer la détente du pistolet, fermer la pompe à

fluide et décharger toute la pression avant de faire de l'entretien,

de nettoyer le protecteur de la tête, de changer de tête ou de

laisser l'appareil sans surveillance. Le bouton

AMORCER/PULVÉRISER doit être tourné à AMORCER, afin

d'éliminer la pression. Consulter la PROCÉDURE DE

LIMITATION DE LA PRESSION décrite dans le présent manuel.

• Toujours débrancher le pistolet avant d'effectuer toute

opération d'entretien ou de nettoyage du protecteur de

tête ou de remplacement des embouts, ou lorsque le

pistolet n'est pas utilisé.

• TOUJOURS garder le protecteur de tête en place durant

l'opération de pulvérisation. Ce dispositif fournit une

certaine protection contre toute blessure résultant d'une

injection cutanée; on l'utilise principalement à titre

d'avertissement.

• TOUJOURS enlever la tête de pulvérisation avant

d'effectuer un lavage ou un nettoyage du système.

• Des fuites peuvent être provoquées dans le tuyau à

peinture par l'usure, par des faux plis ou par la mauvaise

utilisation. Une fuite peut injecter des substances dans la

peau, et il est donc indispensable d'examiner le tuyau à

peinture avant chaque utilisation.

• NE JAMAIS utiliser un pistolet qui ne soit pas muni d'un

cran de sûreté ou de pontet en place et en bon état de

fonctionnement.

• Tous les accessoires doivent avoir une valeur nominale

d'au moins 2800 PSI. Cette exigence s'applique aux têtes

de pulvérisation, aux pistolets, aux rallonges et aux tuyaux.

REMARQUE DESTINÉE AU MÉDECIN:

Une injection cutanée est une blessure du type

traumatique. Il est essentiel de traiter ce genre de

blessure à l'aide d'une intervention chirurgicale et ce,

dans les plus brefs délais. NE PAS retarder le traitement

dans le but d'effectuer des recherches sur le degré de

toxicité du produit. La toxicité d'un produit ne doit être

considérée que pour certaines substances ayant été

directement injectées dans les vaisseaux sanguins. Il

pourrait s'avérer nécessaire de consulter un spécialiste

en chirurgie plastique, ou encore, un spécialiste en

chirurgie reconstructive de la main.

DANGER: EXPLOSION OU INCENDIE - Les émanations

provenant des solvants et des peintures peuvent

exploser ou s'enflammer, entraînant des

dommages matériels ou des blessures graves.

PRÉVENTION:

• Un approvisionnement d'air frais et une évacuation des

gaz doivent être assurés, afin que l'air entourant la zone

de pulvérisation soit libre de toute accumulation de

vapeurs inflammables.

•Éviter toute source d'ignition, telle que des étincelles

d'électricité statique, des flammes nues, des veilleuses,

des objets chauds, des cigarettes, ou des étincelles

produites lors du branchement ou du débranchement des

cordons d'alimentation ou du déclenchement des

interrupteurs d'éclairage.

• Des appareils d'extinction d'incendie doivent être en place

et en bon état de fonctionnement.

• Garder la pompe à l'écart de la zone de pulvérisation, afin

d'éviter les vapeurs de solvants et de peintures.

• L'écoulement à haute vitesse d'un liquide à travers le

matériel peut générer l'électricité statique. Il faut donc

assurer une bonne mise à la terre du matériel dont on se

sert ainsi que des objets dans la zone de pulvérisation et

aux alentours, pour éviter la décharge de l'électricité

statique et les étincelles.

• Pour le travail sans air, utiliser uniquement les tuyaux à

fluide à haute pression qui soient mis à la terre ou qui

soient bons conducteurs de l'électricité. S'assurer que le

pistolet est mis à la terre correctement à travers les

raccords des tuyaux.

• Respecter les mesures de sécurité et les avertissements

du fabricant des solutions et des produits.

• Lors du lavage du matériel, utiliser la plus basse pression

possible.

© SprayTECH Corporation. Tous droits réservés. 15

Français

Page 16

DANGER: EXPLOSION CAUSÉE PAR L'INCOMPATIBILITÉ

AVERTISSEMENT

AVERTISSEMENT

DES MATÉRIAUX - Peut causer des dommages

matériels ou des blessures graves.

PRÉVENTION:

• Ne pas utiliser de l'eau de Javel.

• Ne pas utiliser de solutions halocarbonées, tels que le

chlorure de méthylène et le 1-1-1 trichloro-éthane. Ces

produits ne sont pas compatibles avec l'aluminium et

peuvent provoquer une explosion. En cas de doute,

communiquer avec le fournisseur du produit en question.

DANGER: VAPEURS DANGEREUSES - Les peintures, les

solutions, les insecticides et autres produits

peuvent être dangereux en cas d'inhalation,

provoquant des nausées graves, des

évanouissements ou un empoisonnement.

PRÉVENTION:

• Utiliser un respirateur ou un masque dans toute situation où il

y a risque d'inhalation de vapeurs. Lire toute la

documentation accompagnant le produit de pulvérisation et le

masque, afin de s'assurer qu'une protection adéquate est

offerte contre l'inhalation de vapeurs dangereuses.

• Utiliser des lunettes de protection pour empêcher les

vapeurs dangereuses de pénétrer dans les yeux.

DANGER :GÉNÉRALITÉS - Peut causer des dommages

matériels ou des blessures graves

PRÉVENTION:

• Lire toutes les directives et toutes les mesures de sécurité

portant sur l'équipement et sur le produit de pulvérisation

avant l'emploi de tout équipement.

• Se conformer aux règlements locaux, provinciaux et

nationaux appropriés régissant la ventilation, laprévention

des incendies et l'exécution des opérations.

• Les normes de sécurité du gouvernement des États-Unis

ont été adoptées en application de la Occupational Safety

and Health Act (OSHA) (Loi sur la santé et la sécurité au

travail). Il convient de prendre connaissance de ces

normes, et surtout de l'article 1910 des Normes générales

et de l'article 1926 des Normes de construction.

• Cette pompe, qui fonctionne à haute pression sans air, est

conçue pour être utilisée exclusivement avec des pièces

autorisées par le fabricant. L'utilisateur qui emploie cette

pompe avec des pièces qui ne se conforment pas à la

spécification minimum et aux mesures de sûreté prévues

par le fabricant de la pompe assume tous les risques et

toutes les responsabilités découlant d'un tel usage.

• Avant chaque utilisation, vérifier tous les tuyaux pour

repérer éventuellement des coupures, des fuites, des

zones d'abrasion et le renflement du revêtement ainsi que

des dommages aux raccords ou leur déplacement. Si un

de ces problèmes est constaté, il faut remplacer le tuyau

immédiatement. Ne jamais réparer un tuyau à peinture; il

faut le remplacer avec un autre tuyau mis à la terre.

• Tous les tuyaux, pivots, pistolets et accessoires utilisés avec ce

matériel doivent avoir une valeur nominale d'au moins 2800 PSI.

• Ne pas pulvériser par des temps de grand vent.

NOTA : Ne pas utiliser plus de 100 pieds de cordon

de rallonge. Au cas où il serait nécessaire de

faire de la peinture à une distance de plus de

100 pieds du bloc d'alimentation, utiliser

d'autres tuyaux à peinture et non pas d'autres

rallonges. Par ailleurs, les rallonges plus

courtes assureront une alimentation

maximale et un bon fonctionnement.

Directives sur la mise à la terre

Ce dispositif doit être mis à la terre. En cas de court-circuit, ce

procédé permet de réduire le risque d'un choc électrique en

fournissant un fil d'évacuation pour le courant. Ce produit est

équipé d'un cordon comportant un fil de mise à la terre muni

d'une fiche appropriée. Cette fiche doit être connectée sur

une prise adéquatement installée et mise à la terre selon les

codes et règlements locaux en vigueur.

Danger! Une installation inadéquate de la fiche de mise à

la terre risque de provoquer un choc électrique.

S'il est nécessaire de réparer ou de remplacer le cordon ou la

fiche, ne pas connecter le fil de mise à la terre vert à aucune

des bornes à broches plates. Le fil comportant un isolant de

couleur verte, avec ou sans lignes jaunes, est le fil de mise à

la terre devant être connecté à la broche de mise à la terre.

Il est recommandé de consulter un électricien qualifié ou un

technicien si les directives sur la mise à la terre ne sont pas

entièrement comprises, ou si l'on n'est pas sûr que le produit

soit correctement mis à la terre. Ne pas modifier la fiche. Si

la fiche ne peut être insérée dans la prise, demander à un

électricien qualifié d'installer la prise appropriée.

Ce produit doit être utilisé sur un circuit d'une tension nominale de

120 volts et comporte une fiche de mise à la terre semblable à celle

illustrée ci-dessous. Un adapteur temporaire ressemblant à celui

présenté à la figure ci-dessous peut être utilisé pour connecter cette

fiche à une prise à deux pôles, comme il est illustré, en l'absence

d'une prise mise à la terre de façon appropriée.

L'adapteur temporaire ne doit être utilisé qu'en attendant l'installation

d'une prise appropriée (voir la figure ci-dessous) par un électricien

qualifié. La languette rigide verte ou le fil de mise à la terre

provenant de l'adapteur doit être connecté de façon permanente à

une mise à la terre comme, par exemple, le couvercle de la boîte de

sortie mis à la terre correctement. L'adapteur, le cas échéant, doit

être maintenu en place au moyen d'une visse métallique.

Prise de terre

Goupille de mise à la terre

Couvercle du boîtier de prise de terre

Vis métallique

Adapteur

ATTENTION

Utiliser uniquement une rallonge à trois fils dotée d'une fiche

de mise à la terre à trois broches et d'une prise à trois fentes

pouvant accepter la fiche sur le produit. S'assurer que la

rallonge est en bon état. S'assurer également que cette

dernière convient au courant consommé par l'appareil. Pour

une longueur inférieure à 15,2 m (50 pieds), utiliser une

rallonge no 18 AWG. Pour une longueur supérieure à 15,2 m

(50 pieds), utiliser une rallonge no 14 ou no 16 AWG. Une

rallonge de section inférieure produira une perte de tension,

entraînant une perte de puissance et la surchauffe.On

recommande l'utilisation d'un cordon de calibre 14 ou 12.

Français

Patte pour

vis de mise

à la terre

16 © SprayTECH Corporation. Tous droits réservés.

Page 17

Montage

SPRAY

PRIME

Tuyau à haute pression

Commencer

à serrer

l'embout

à l'angle

indiqué

pour pulvériser

dans la

direction

voulue une

fois l'embout

serré.

AVERTISSEMENT

Pistolet bloqué

(le pistolet ne peut pas pulvériser)

Protecteur d'embout

Embout

Assemblage de la poignée

NOTA : Le pistolet doit être débranché pendant le

montage.

1. Faire glisser la poignée dans le support jusqu'à ce que les

trous sur la poignée soient alignés avec les trous dans le

support.

2. Faire glisser les broches de poignée dans les trous du

support et de la poignée pour que la poignée soit bien

maintenue.

SPRAY

Comment Attacher la Tête de

Pulvérisation

Montage de la Tête

Si la tête de pulvérisation n'est pas assemblée :

1. Insérer la tête dans le protecteur et la tourner à la position

de pulvérisation, pour que la flèche se trouve face au

devant du pistolet.

Comment Attacher la Tête au Pistolet

1. Bloquer le pistolet en tournant le cran de sûreté pour qu'il

soit parallèle au corps du pistolet.

Comment Attacher le Tuyau à Peinture

1. Attacher le tuyau à haute pression au port du tuyau à

peinture. Utiliser une clé à molette pour bloquer le tuyau à

peinture solidement en place.

2. Attacher le pistolet à l'autre extrémité du tuyau à haute

pression. Bloquer le pistolet solidement à l'aide de deux clés.

DANGER D'INJECTION ÉVENTUEL. Ne pas faire de la

pulvérisation sans que le protecteur de la tête de

pulvérisation ne soit en place. Ne jamais déclencher le

pistolet si la tête de pulvérisation n'est pas en position de

pulvérisation ou de décolmatage. Toujours mettre le cran de

sûreté avant d'enlever, de remplacer ou de nettoyer la tête.

2. Visser la tête de pulvérisation sur le pistolet. Serrer l'écrou

d'abord à la main, puis plus solidement à l'aide d'une clé.

NOTA: En attachant la tête de pulvérisation au

pistolet, aligner le protecteur de la tête

comme l'indique la figure ci-dessous, puis

serrer le protecteur à l'aide d'une clé.

3. Brancher l'appareil de pulvérisation à une prise de courant

correctement mise à la terre ou à une rallonge pour

service intensif mis à la terre. Ne pas utiliser plus de 100

pieds de cordon. Au cas où il serait nécessaire de faire de

la peinture à une distance de plus de 100 pieds du bloc

d'alimentation, utiliser d'autres tuyaux à peinture et non

pas d'autres rallonges. Les cordons de rallonge ayant une

longueur allant jusqu'à 50 pieds doivent avoir un calibre

d'au moins 16, et les cordons ayant une longueur entre 50

et 100 pieds doivent avoir un calibre de 12 à 14.

© SprayTECH Corporation. Tous droits réservés. 17

Français

Page 18

Limitation de la pression

AVERTISSEMENT

Pistolet bloqué

(le pistolet ne peut pas pulvériser)

SPRAY

PRIME

PRIME

Bouton AMORCER/PULVÉRISER

Bouton de réglage de la pression

procédure

Suivre la présente procédure après le montage de l'appareil et avant

toute intervention portant sur le pistolet, telle que le nettoyage ou la

maintenance des têtes de pulvérisation et des accessoires.

1. Tourner le bouton de réglage de la pression dans le sens

inverse des aiguilles d'une montre, jusqu'à ce qu'il se

trouve à sa valeur minimum.

Amorçage

Préparation à L'amorçage

1. Remplir la soupape d'entrée avec de l'eau ou de l'huile

légère (huile de machine à coudre).

SPRAY

PRIME

PRIME

SPRAY

PRIME

2. Tourner le bouton AMORCER/PULVÉRISER à la position

AMORCER.

3. Déclencher le pistolet afin d'éliminer toute pression qui

puisse toujours exister dans le tuyau.

4. Bloquer le pistolet en tournant le cran de sûreté pour qu'il

soit parallèle au corps du pistolet.

Danger d'injection. Ne pas faire de la pulvérisation sans

que le protecteur de la tête de pulvérisation ne soit ne

place. NE JAMAIS déclencher le pistolet si la tête de

pulvérisation n'est pas en position de pulvérisation ou de

décolmatage. TOUJOURS mettre le cran de sûreté avant

d'enlever, de remplacer ou de nettoyer la tête.

2. S'assurer que le bouton AMORCER/PULVÉRISER est

tourné à la position AMORCER et que le bouton de

réglage de la pression est tourné dans le sens inverse

des aiguilles d'une montre, jusqu'à ce qu'il se trouve à sa

valeur minimum.

3. Mettre le commutateur du moteur à la position MARCHE.

4. Augmenter la pression en imprimant un demi-tour, dans le

sens inverse des aiguilles d'une montre, au bouton de

réglage de la pression.

5. Obliger la soupape d'admission à s'ouvrir et à se fermer

en appuyant sur elle avec un tournevis ou avec la gomme

au bout d'un crayon. La soupape devrait se déplacer de

1/16 po sur l'axe vertical. Poursuivre cette action jusqu'à

ce que l'eau ou l'huile est aspirée dans l'appareil de

pulvérisation, ce qui mouillera les pièces mobiles et

détachera tout ancien reste de peinture.

SPRAY

PRIME

6. Mettre la paume sur le port d'admission. Tourner le bouton de

réglage de la pression dans le sens des aiguilles d'une

montre. Il faut sentir l'aspiration qui provient de la soupape

d'admission; sinon, consulter la section du présent manuel qui

porte sur le nettoyage et l'entretien de la soupape de sortie.

Français

SPRAY

PRIME

7. Tourner le bouton de réglage de la pression dans le sens

inverse des aiguilles d'une montre, jusqu'à ce que la

valeur de pression minimum soit atteinte.

8. Tourner le commutateur du moteur à la position ARRÊT.

18 © SprayTECH Corporation. Tous droits réservés.

Page 19

Montage de la trémie à peinture

SPRAY

PRIME

PRIME

Tube de retour

Couvercle de la trémie

à peinture

Raccord du tube de retour

Tube de retour

SPRAY

PRIME

SPRAY

PRIME

PRIME

Bouton AMORCER/PULVÉRISER

Bouton de réglage de la pression

1. Présenter le fond de la trémie à peinture dans

l'alignement de la soupape d'entrée filetée sur le bloc de

la pompe à peinture.

2. Tourner la trémie à peinture dans le sens des aiguilles

d'une montre pour la visser sur la soupape d'entrée.

Continuer à tourner la trémie à peinture jusqu'à ce qu'elle

soit bien fixée sur la soupape d'entrée.

NOTA: S'assurer que les filets sont bien appariés et

que la trémie tourne sans contrainte sur la

soupape d'entrée. Ne pas fausser les filets.

3. Placer le tamis filtrant dans le fond de la trémie à peinture

et l'emboîter dans son emplacement.

Assemblage du tube de retour

1. Vérifier que le commutateur du moteur est mis à la

position ARRÊT.

2. Visser le raccord du tube de retour, que l'on trouvera dans

le jeu de documents, dans l'orifice du tube de retour sur le

côté de la pompe et serrer fermement à la main.

NOTA: Ne serre trop beaucoup. Serrer par la main

seulement.

3. Placer l'extrémité droite du tube de retour dans le raccord

du tube de retour.

Amorçage de la pompe

1. Tourner le bouton de réglage de la pression dans le sens

inverse des aiguilles d'une montre, jusqu'à ce que la

valeur minimum de pression soit atteinte.

PRIME

SPRAY

PRIME

2. Tourner le bouton AMORCER/PULVÉRISER à la position

AMORCER.

3. Tourner le commutateur du moteur à la position MARCHE.

4. Tourner le bouton de réglage de la pression dans le sens

des aiguilles d'une montre, pour atteindre une valeur entre

la demi-pression et la pression maximale. On devrait voir

le déplacement de la peinture à travers le tube

d'aspiration et jusqu'à la pompe. Permettre à l'appareil

d'amorcer pendant une minute ou deux après que la

peinture commence à s'écouler à travers le tube de retour.

4. Visser l'écrou du tube de retour sur le raccord du tube de

retour et serrer jusqu'à ce que le tube de retour soit bien

maintenu.

5. Placer l'extrémité en crochet du tube de retour dans le

trou du couvercle de la trémie à peinture.

ATTENTION

Toujours réduire la pression à zéro avant de changer la

position du bouton d'amorçage. Si on ne le fait pas, la

membrane de la pompe à peinture risque d'être endommagée.

ATTENTION

Si le bouton de réglage de la pression est tourné à zéro et

le bouton AMORCER/PULVÉRISER est toujours à la

position PULVÉRISER pendant que l'appareil de

pulvérisation fonctionne, il y aura une haute pression au

tuyau et au pistolet de pulvérisation jusqu'à ce que le

bouton d'amorçage soit tourné à la position AMORCER ou

le pistolet soit déclenché pour réduire la pression.

© SprayTECH Corporation. Tous droits réservés. 19

Français

Page 20

Pulvèrisation

Déplacez votre bras d'un mouvement régulier

et à vitesse constante.

Revêtement également réparti

Environ 25 à 30 cm

(10 à 12 pi)

SPRAY

PRIME

PRIME

Bouton AMORCER/PULVÉRISER

Bouton de réglage de la pression

Comment bien utiliser la gâchette du pistolet

Environ 25 à 30 cm

(10 à 12 pi)

Déplacez votre bras

d'un mouvement

régulier

Début

du passage

Fin

du passage

Appuyez sur

la gâchette

Relâchez

la gâchette

Gardez une

vitesse constante

Technique de pulvérisation

Pour obtenir une peinture d'un fini impeccable il est essentiel

que le produit soit également réparti sur toute la surface. Il

faut pour cela que vous appliquiez la peinture de façon

régulière en déplaçant votre bras à vitesse constante et en

gardant le pistolet de pulvérisation à une distante constante

de la surface. La meilleure distance de pulvérisation est de 25

à 30 cm (10 à 12 po) entre le pistolet et la surface traitée.

Revêtement Revêtement fin

Ne pas fléchir le poignet durant la pulvérisation.

Gardez le pistolet perpendiculaire à la surface traitée. Il vous

faut pour cela déplacer tout votre bras de haut en bas et non

pas seulement fléchir votre poignet.

Revêtement épais

Chevauchez chaque passage d'environ 30% afin d'obtenir un fini régulier.

Lorsqu'on arrête la peinture, il faut bloquer le cran de sûreté, tourner le

bouton de réglage de la pression dans le sens inverse des aiguilles

d'une montre jusqu'à ce qu'il atteigne sa valeur minimum, puis régler le

bouton d'amorçage à la position AMORCER. Tourner le commutateur

du moteur à ARRÊT et débrancher le pulvérisateur.

Si l'on s'attend à être absent pendant plus d'une heure, il faut

suivre la courte procédure de nettoyage qui est décrite dans la

section NETTOYAGE du présent manuel.

Pratique

1. Vérifier que le tuyau à peinture n'a pas de faux plis et ne

touche pas à des objets ayant des rebords tranchants.

2. Tourner le bouton de réglage de la pression dans le sens

inverse des aiguilles d'une montre, jusqu'à ce qu'il

atteigne sa valeur minimum.

Veillez à garder le pistolet perpendiculaire à la surface traitée

afin d'éviter qu'une extrémité de chaque passage soit plus

épaisse que l'autre.

Environ 25 à 30 cm

(10 à 12 pi)

Bonne

technique

Mauvaise

technique

Appuyez sur la gâchette au début et à la fin de chaque

passage. Vous éviterez ainsi de gaspiller de la peinture ou

d'avoir une accumulation de peinture à l'extrémité du passage.

Ne jouez pas avec la gâchette durant le passage afin d'éviter

un fini irrégulier ou des éclaboussures.

PRIME

SPRAY

PRIME

3. Tourner le bouton AMORCER/PULVÉRISER à la position

PULVÉRISER.

4. Tourner le bouton de réglage de la pression à sa valeur la

le plus élevée. Le tuyau à peinture devrait devenir raide à

mesure que la peinture commencera à s'y écouler.

5. Défaire le cran de sûreté en le tournant jusqu'à ce qu'il se

trouve parallèle à la poignée.

6. Déclencher le pistolet pour purger l'air du tuyau.

7. Lorsque la peinture arrive à la tête de pulvérisation, il faut

peindre une zone d'essai au pistolet, puis vérifier la forme

du jet de pulvérisation.

8. Utiliser le réglage de la pression le plus bas qui soit nécessaire

pour obtenir une bonne forme du jet de pulvérisation. Si la

pression est réglée à une valeur trop élevée, la forme du jet sera

trop légère. Par contre, si la pression est réglée à une valeur trop

basse, le filage apparaîtra, ou la peinture sera giclée sous forme

de crachats plutôt que dans une pulvérisation fine.

Bonne répartition de la pulvérisation

Traînées de peinture

Français

20 © SprayTECH Corporation. Tous droits réservés.

Page 21

Nettoyage

ATTENTION

AVERTISSEMENT

Rangement du Jour au Lendemain

Préparation Pour le Rangement

1. Bloquer le pistolet en tournant le cran de sûreté pour qu'il

soit parallèle au corps du pistolet.

2. Tourner le bouton de réglage de la pression dans le sens

inverse des aiguilles d'une montre, pour atteindre la valeur

minimum.

3. Tourner le bouton AMORCER/PULVÉRISER à la position

AMORCER.

4. Mettre le commutateur du moteur à la position ARRÊT,

puis débrancher le pulvérisateur.

5. Pour des matériaux au latex seulement, verser une demitasse d'eau doucement sur la surface de la peinture, pour

l'empêcher de sécher. Pour les autres matériaux, fermer

la trémie à peinture avec le couvercle de trémie en

gardant le tube de retour dans la peinture.

6. Enrouler l'ensemble du pistolet dans un chiffon humide et

le mettre dans un sac en plastique. Sceller le sac.

7. Pour le rangement à court terme, mettre le pulvérisateur

dans un endroit sûr, à l'abri des rayons du soleil.

Préparer Pour la Réutilisation

1. Enlever le pistolet du sac en plastique.

2. Dans le cas de matériaux au latex, agiter la peinture pour

incorporer l'eau sur la surface. Enlever le couvercle de

trémie de la trémie à peinture et agiter la peinture pour