Page 1

Translation of the Original

Operating Manual

Version 03/2013

Piston Pumps

Flow Rate 15 cm3 - 30 cm

3

II 2G IIB c T3 X

B_04119

Page 2

Page 3

VERSION 03/2013 ORDER NUMBER DOC 2310799

OPERATING MANUAL

Contents

1 ABOUT THIS OPERATING MANUAL 5

1.1 Preface 5

1.2 Warnings, Notices, and Symbols in this Operating Manual 5

1.3 Languages 6

1.4 Abbreviations in the Text 6

2 CORRECT USE 7

2.1 Device Types 7

2.2 Type of Use 7

2.3 Use in an Explosion Hazard Area 7

2.4 Safety Parameters 7

2.5 Processible Materials 8

2.6 Reasonably Foreseeable Misuse 8

2.7 Residual Risks 9

3 IDENTIFICATION 10

3.1 Explosion Protection Identi cation 10

3.2 Identi cation X 10

4 GENERAL SAFETY INSTRUCTIONS 11

4.1 Safety Instructions for the Operator 11

4.1.1 Electrical Equipment 11

4.1.2 Sta Quali cations 11

4.1.3 Safe Work Environment 11

4.2 Safety Instructions for Sta 12

4.2.1 Safe Handling of WAGNER Spray Devices 12

4.2.2 Grounding the Device 13

4.2.3 Material Hoses 13

4.2.4 Cleaning 14

4.2.5 Handling Hazardous Liquids, Varnishes, and Paints 14

4.2.6 Touching Hot Surfaces 14

4.3 Use in Areas Subject to Explosion Hazards 15

4.3.1 Safety Regulations 15

4.3.2 Operation without Fluid 15

5 DESCRIPTION 16

5.1 Field of Application 16

5.1.1 Correct Use 16

5.1.2 Processible Materials 16

5.2 Scope of Delivery 17

5.3 Data 17

5.3.1 Materials of Paint-wetted Parts 17

5.3.2 Technical Data 18

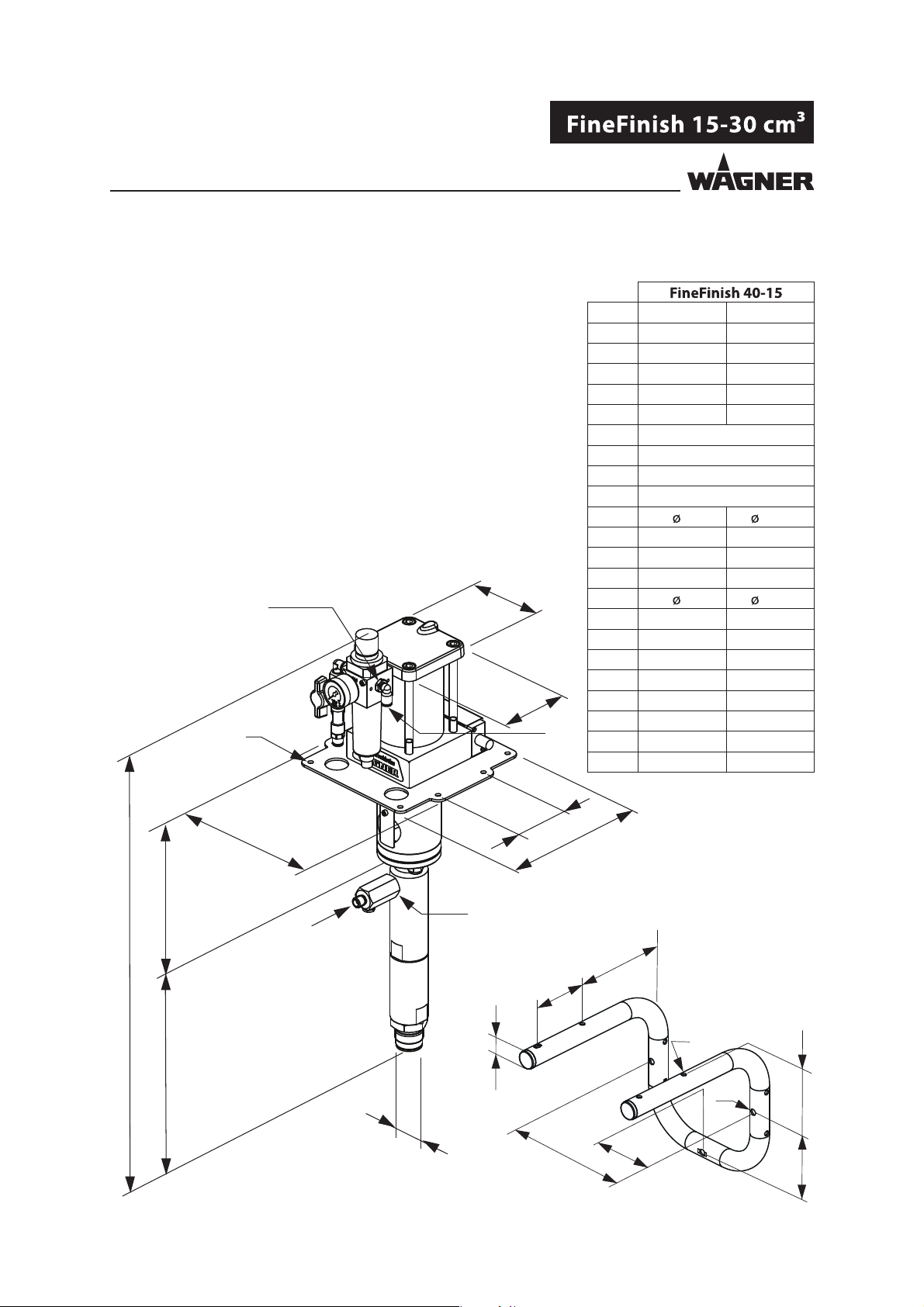

5.3.3 Measurements and Connections for FineFinish 40-15 20

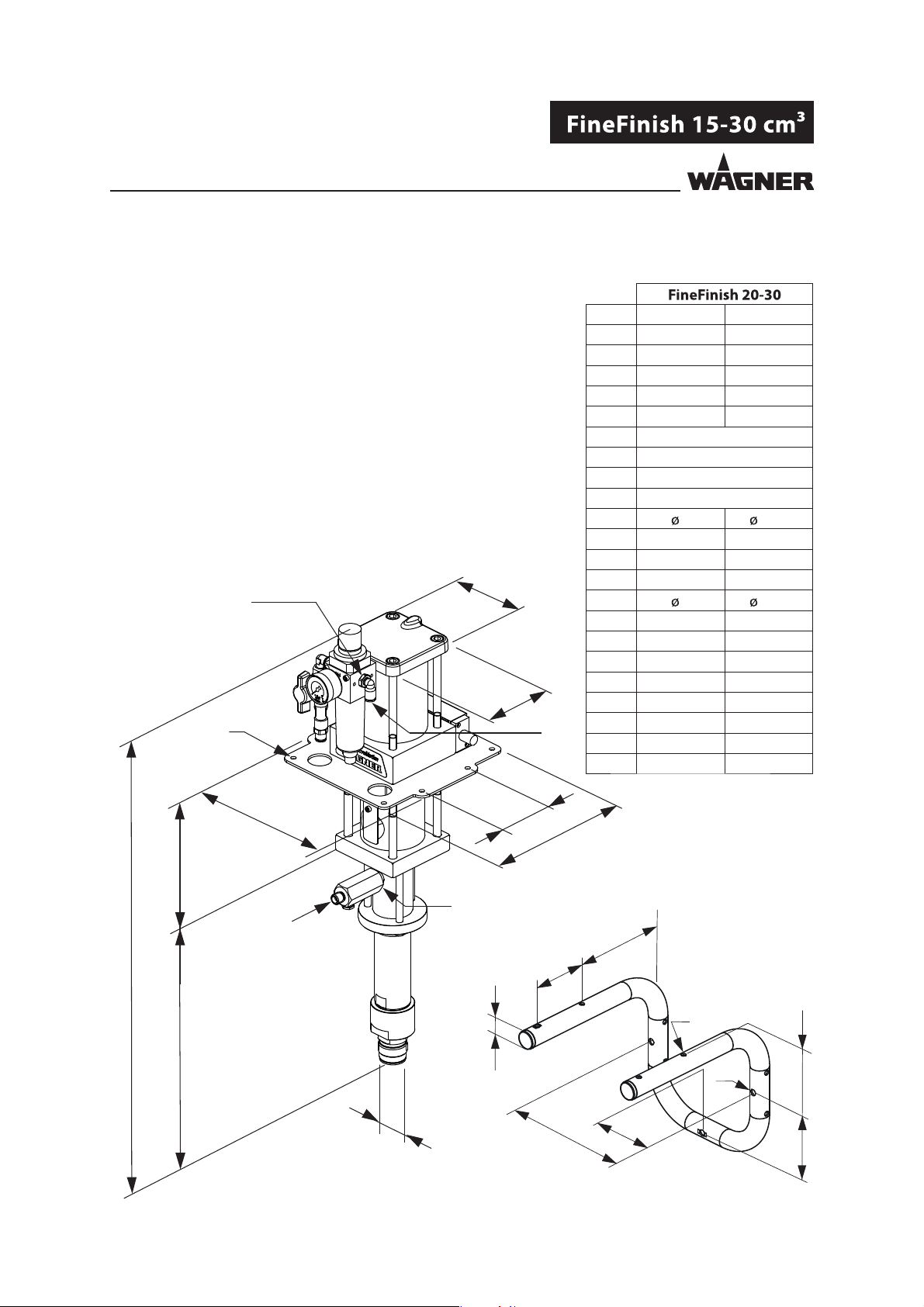

5.3.4 Measurements and Connections for FineFinish 20-30 21

5.3.5 Performance Diagrams 22

5.4 Function 25

5.4.1 Pump 25

5.4.2 Pressure Regulator Unit 26

5.4.3 Safety and Motor Pressure Relief Valve 27

5.4.4 Return Valve 27

3

Page 4

VERSION 03/2013 ORDER NUMBER DOC 2310799

OPERATING MANUAL

Contents

6 ASSEMBLY AND COMMISSIONING 28

6.1 Transportation 28

6.2 Storage 28

6.3 Assembling the Pump 29

6.4 Grounding 30

6.5 Commissioning 32

6.5.1 Safety Instructions 32

6.5.2 Filling with Separating Agent 34

6.5.3 Basic Flushing 35

7 OPERATION 36

7.1 Filling with Working Material 36

7.2 Work 37

7.2.1 Spraying 37

7.2.2 Pressure Relief/Work Interruption 38

7.2.3 Decommissioning and Cleaning 39

7.3 Long-term Storage 40

8 TROUBLESHOOTING AND RECTIFICATION 41

9 MAINTENANCE 42

9.1 High-pressure Hoses 43

9.2 Decommissioning 43

10 ACCESSORIES 44

11 SPARE PARTS 47

11.1 How Can Spare Parts Be Ordered? 47

11.2 Overview of the Components 48

11.2.1 Components for FineFinish 40-15 48

11.2.2 Components for FineFinish 20-30 49

11.3 Air Motor 50

11.3.1 Reversing Valve 53

11.4 Fluid sections 54

11.4.1 Fluid Section 15 54

11.4.2 Fluid Section 30 56

11.5 Air Regulator Set 58

11.6 Air Regulator Set for AirCoat Air 59

11.7 Trolley, 4" 60

11.8 4-Wheel Trolley 61

12 3+2 YEARS GUARANTEE FOR PROFESSIONAL FINISHING 62

12.1 Scope of Guarantee 62

12.2 Guarantee Period and Registration 62

12.3 Handling 62

12.4 Exclusion of Guarantee 63

12.5 Additional Regulations 63

12.6 CE Declaration of Conformity 65

12.7 Reference to German Regulations and Guidelines 65

4

Page 5

VERSION 03/2013 ORDER NUMBER DOC 2310799

OPERATING MANUAL

1 ABOUT THIS OPERATING MANUAL

1.1 PREFACE

The operating manual contains information about safely operating, maintaining, cleaning

and repairing the device.

The operating manual is part of the device and must be available to operating and service

sta .

Operating and service sta should be instructed according to the safety instructions.

The device may only be operated in compliance with this operating manual.

This equipment can be dangerous if it is not operated according to the instructions in this

operating manual.

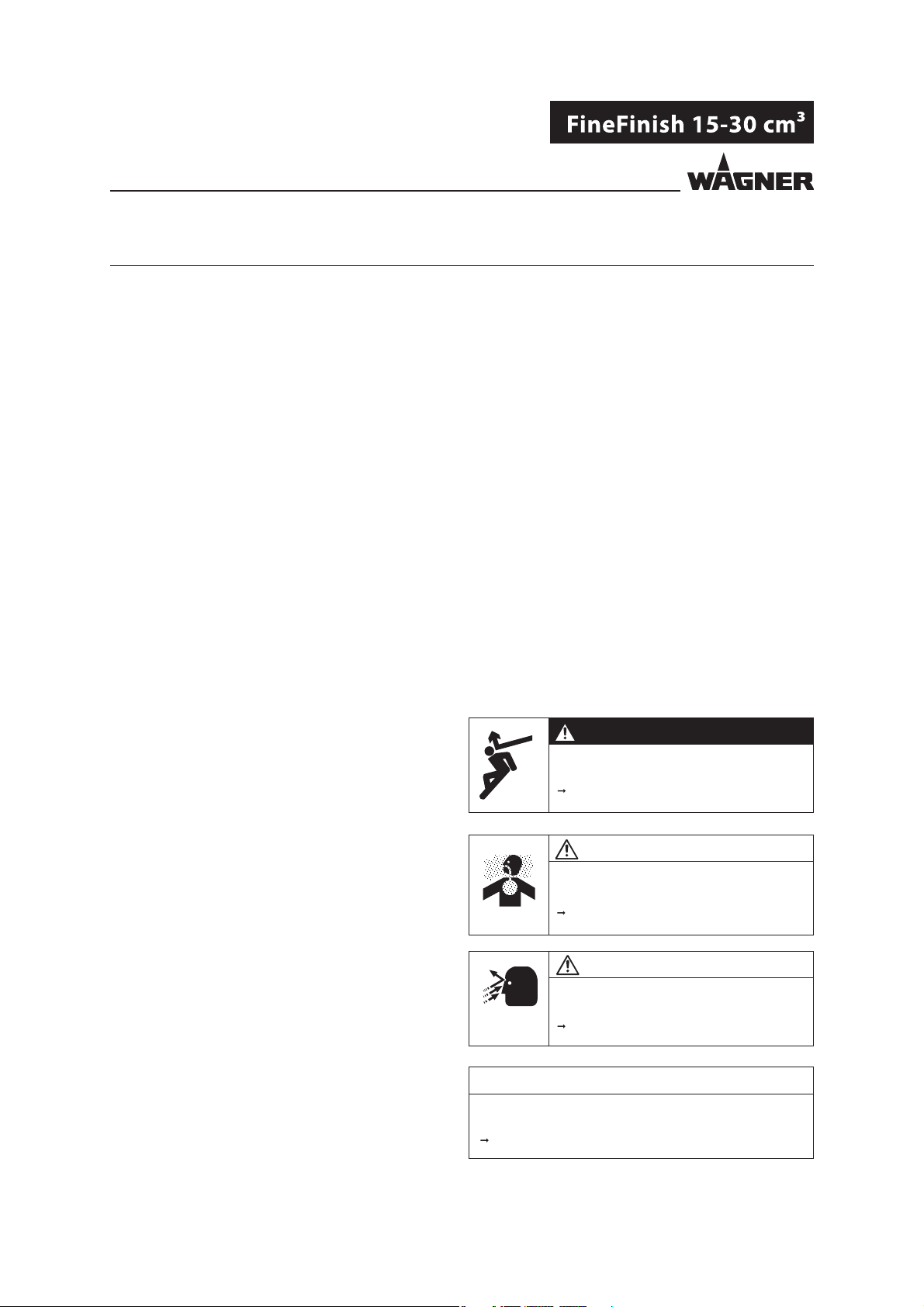

1.2 WARNINGS, NOTICES, AND SYMBOLS IN THIS OPERATING MANUAL

Warning instructions in this operating manual highlight particular dangers to users and

to the device and state measures for avoiding the hazard. These warning instructions fall

into the following categories:

DANGER

Danger - immediate risk of danger.

Non-observance will result in death or serious injury.

Warning - possible imminent danger.

Non-observance may result in death or serious injury.

Caution - a possibly hazardous situation.

Non-observance may result in minor injury.

This notice warns you of a hazard!

Possible consequences of not observing the warning instructions.

The signal word indicates the hazard level.

The following are measures which can be taken to prevent

the hazard and its consequences.

WARNING

This notice warns you of a hazard!

Possible consequences of not observing the warning instructions.

The signal word indicates the hazard level.

The following are measures which can be taken to prevent

the hazard and its consequences.

CAUTION

This notice warns you of a hazard!

Possible consequences of not observing the warning instructions.

The signal word indicates the hazard level.

The following are measures which can be taken to prevent

the hazard and its consequences.

Notice - a possibly hazardous situation.

Non-observance may result in material damage.

This notice warns you of a hazard!

Possible consequences of not observing the warning instructions. The signal word

indicates the hazard level.

The following are measures which can be taken to prevent the hazard and its

consequences.

NOTICE

Note - provides information about particular characteristics and how to proceed.

5

Page 6

VERSION 03/2013 ORDER NUMBER DOC 2310799

OPERATING MANUAL

1.3 LANGUAGES

The operating manual is available in the following languages:

Language Order No. Language Order No.

German 2310798 English 2310799

French 2310800 Spanish 2310803

Italian 2310802 Dutch 2310801

Portuguese 2310804 Swedish 2310806

Danish 2310805

1.4 ABBREVIATIONS IN THE TEXT

Number of pieces

Position

Marking in the spare parts lists

Order No. Order No.

No. Number

Double stroke

Stainless steel

Two components

6

Page 7

VERSION 03/2013 ORDER NUMBER DOC 2310799

OPERATING MANUAL

2 CORRECT USE

2.1 DEVICE TYPES

Pneumatic pump with spraypack:

2.2 TYPE OF USE

The device is suitable for processing liquid materials such as paints and varnishes in

accordance with their classi cation into explosion classes IIA or IIB.

2.3 USE IN AN EXPLOSION HAZARD AREA

The pneumatic pump can be employed in explosion hazard zones (Zone 1).

2.4 SAFETY PARAMETERS

WAGNER accepts no liability for any damage arising from incorrect use.

Use the device only to work with the materials recommended by WAGNER.

Only operate the device as a whole.

Do not deactivate safety xtures.

Use only WAGNER original spare parts and accessories.

The pneumatic pump may only be operated under the following conditions:

The operating sta must be trained on the basis of this operating manual.

The safety regulations listed in this operating manual must be observed.

The operating, maintenance, and repair information in this operating manual must

be observed.

The statutory requirements and accident prevention regulation standards in the

country of use must be observed.

7

Page 8

VERSION 03/2013 ORDER NUMBER DOC 2310799

OPERATING MANUAL

2.5 PROCESSIBLE MATERIALS

Fluid materials such as paints and varnishes.

NOTICE

Abrasive materials and pigments!

Greater wear of parts carrying the material.

Use the application-oriented model ( ow rate/cycle, material, valves, etc.) as

indicated in Chapter 5.3.2.

Check if the uids and solvents used are compatible with the pump construction

materials as indicated in Chapter 5.3.1.

2.6 REASONABLY FORESEEABLE MISUSE

The following is prohibited:

coating work pieces which are not grounded,

unauthorized conversions and modi cations to the pneumatic pump,

processing powder or similar coating materials, and

using defective components, spare parts, or accessories other than those described

in Chapter 10 of this operating manual.

The forms of misuse listed below may result in health issues and/or material damage:

use of powder as coating material and

incorrectly set values for processing.

Wagner pneumatic pumps are not designed for pumping food.

8

Page 9

VERSION 03/2013 ORDER NUMBER DOC 2310799

OPERATING MANUAL

2.7 RESIDUAL RISKS

Residual risks are risks which cannot be excluded even in the event of correct use.

If necessary, warning and prohibition signs at the relevant points of risk indicate residual

risks.

Residual risk Source Consequences Speci c measures Lifecycle phase

Skin contact with

paints and cleaning

agents

Paint in air outside

the de ned working

area

Handling of paints

and cleaning agents

Painting outside the

de ned working

area

Skin irritations, Wear protective

clothing,

allergies Observe safety data

sheets

Inhalation of

substances which are

hazardous to health

Observe working

and operating

instructions

Operation,

maintenance,

disassembly

Operation,

maintenance

9

Page 10

VERSION 03/2013 ORDER NUMBER DOC 2310799

OPERATING MANUAL

3 IDENTIFICATION

3.1 EXPLOSION PROTECTION IDENTIFICATION

As de ned in Directive 94/9/EC (ATEX 95), the device is suitable for use in areas where there

is an explosion hazard.

European Communities

Symbol for explosion protection

Device class II

Category 2 (Zone 1)

Ex-atmosphere gas

Explosion group

Constructional safety

Temperature class: maximum surface temperature < 200 °C; 392 °F

Special Notes (see Chapter 3.2)

3.2 IDENTIFICATION X

Maximum surface temperature

The maximum surface temperature of the piston pump can be reached if it runs dry.

Ensure that the piston pump is lled with su cient working or ushing agent.

Ensure that the separating agent container is lled with su cient separating agent.

Ignition temperature of the coating material

Ensure that the ignition temperature of the coating material is above the maximum

surface temperature.

Ambient temperature

The permissible ambient temperature is: +5 °C to +60 °C; +41 °C to 140 °F.

Medium supporting atomizing

To atomize the material, use only weakly oxidizing gases, e.g. air.

10

Page 11

VERSION 03/2013 ORDER NUMBER DOC 2310799

OPERATING MANUAL

4 GENERAL SAFETY INSTRUCTIONS

4.1 SAFETY INSTRUCTIONS FOR THE OPERATOR

Keep this operating manual at hand near the unit at all times.

Always follow local regulations concerning occupational safety and accident

prevention.

4.1.1 ELECTRICAL EQUIPMENT

Electrical devices and equipment

To be provided in accordance with the local safety requirements with regard to the

operating mode and ambient in uences.

May only be maintained by skilled electricians or under their supervision.

Must be operated in accordance with the safety regulations and electrotechnical

regulations.

Must be repaired immediately in the event of problems.

Must be decommissioned if they pose a hazard.

Must be de-energized before work is commenced on active parts. Inform sta about

planned work. Observe electrical safety regulations.

4.1.2 STAFF QUALIFICATIONS

Ensure that the device is operated and repaired only by trained persons.

4.1.3 SAFE WORK ENVIRONMENT

Ensure that the oor in the working area is electrically conductive in accordance with

EN61340-4-1 (resistance must not exceed 100 Mohm).

Ensure that all persons within the working area wear electrostatically conductive shoes.

Footwear must comply with EN 20344. The measured insulation resistance must not

exceed 100 Mohm.

Ensure that during spraying, persons wear electrically conductive gloves. The grounding

takes place via the spray gun handle.

If protective clothing is worn, including gloves, it has to comply with EN1149-5. The

measured insulation resistance must not exceed 100 Mohm.

Paint mist extraction systems must be tted on site according to local regulations.

Ensure that the following components of a safe working environment are available:

– Material/air hoses adapted to the working pressure.

– Personal safety equipment (breathing and skin protection).

Ensure that there are no ignition sources such as naked ames, sparks, glowing wires,

or hot surfaces in the vicinity. Do not smoke.

11

Page 12

VERSION 03/2013 ORDER NUMBER DOC 2310799

OPERATING MANUAL

4.2 SAFETY INSTRUCTIONS FOR STAFF

Always follow the information in these instructions, particularly the general safety

instructions and the warning instructions.

Always follow local regulations concerning occupational safety and accident

prevention.

4.2.1 SAFE HANDLING OF WAGNER SPRAY DEVICES

The spray jet is under pressure and can cause dangerous injuries.

Avoid injection of paint or cleaning agents:

Never point the spray gun at people.

Never reach into the spray jet.

Before all work on the device, in the event of work interruptions and functional faults:

– Switch o the energy/compressed air supply.

– Relieve the pressure from the spray gun and device.

– Secure the spray gun against actuation.

– In the event of functional faults: remedy the fault as described in the " Troubleshooting"

chapter.

The liquid emitters are to be checked for safe working conditions by an expert

(e.g. Wagner Service Technician) as often as necessary or at least every 12 months,

in accordance with the guidelines for liquid emitters (ZH1/406 and BGR500 Part 2

Chapter2.36).

– For shut down devices, the examination can be suspended until the next commissioning.

Carry out the work steps as described in the "Pressure Relief/Work Interruptions"

chapter:

– if pressure relief is required.

– if the spraying work is interrupted or stopped.

– before the device is cleaned on the outside, checked, or serviced.

– before the spray nozzle is installed or cleaned.

In the event of skin injuries caused by paint or cleaning agents:

Note down the paint or cleaning agent that you have been using.

Consult a doctor immediately.

Avoid danger of injury through recoil forces:

Ensure that you have firm footing when operating the spray gun.

Only hold the spray gun brie y in a position.

12

Page 13

VERSION 03/2013 ORDER NUMBER DOC 2310799

OPERATING MANUAL

4.2.2 GROUNDING THE DEVICE

In order to avoid electrostatic charging of the device, the device must be grounded.

Friction, owing liquids, and air or electrostatic coating processes create charges. Flames

or sparks can form during discharge.

Ensure that the device is grounded for every spraying operation.

Ground the work pieces to be coated.

Ensure that all persons inside the working area are grounded, e.g. that they are wearing

electrostatically conductive shoes.

Wear electrostatically conductive gloves when spraying. The grounding takes place via

the spray gun handle.

4.2.3 MATERIAL HOSES

Ensure that the hose material is chemically resistant to the sprayed materials.

Ensure that the material hose is suitable for the pressure generated in the device.

Ensure that the following information can be seen on the high-pressure hose:

– Manufacturer

– Permissible operating overpressure

– Date of manufacture

Make sure that the hoses are laid only in suitable places. In no case, should hoses be laid

in the following places:

– in high-traffic areas,

– on sharp edges,

– on moving parts, or

– on hot surfaces

Make sure that the hoses are never used to pull or move the equipment.

The electrical resistance of the complete high-pressure hose must be less than 1 Mohm.

Several liquids have a high expansion coe cient. In some cases their volume can rise with

consequent damage to pipes, ttings, etc. and cause uid leakage.

When the pump sucks liquid from a closed container, ensure that air or suitable gas can

enter the container to avoid a vacuum being generated in the container itself. Thus a

negative pressure is avoided. The vacuum could implode the container (squeeze) and can

cause it to break. The container would leak and the liquid would ow out.

The pressure created by the pump is a multiplication of the inlet air pressure.

13

Page 14

VERSION 03/2013 ORDER NUMBER DOC 2310799

OPERATING MANUAL

4.2.4 CLEANING

De-energize the device electrically.

Disconnect the pneumatic supply line.

Relieve the pressure from the device.

Ensure that the flash point of the cleaning agent is at least 5 K above the ambient

temperature.

To clean, use cloths and brushes moistened with solvent. Never use hard objects or

spray on cleaning agents with a gun.

Preferably, non-combustible cleaning agents should be used.

An explosive gas/air mixture forms in closed containers.

When cleaning devices with solvents, never spray into a closed container.

Only use electrically conductive containers for cleaning liquids.

The containers must be grounded.

4.2.5 HANDLING HAZARDOUS LIQUIDS, VARNISHES, AND PAINTS

When preparing or working with paint and when cleaning the device, follow the

working instructions of the manufacturer of the paints, solvents, and cleaning agents

being used.

Take the speci ed protective measures. In particular, wear safety goggles, protective

clothing, and gloves, as well as hand protection cream if necessary.

Use a mask or a breathing apparatus if necessary.

For su cient health and environmental safety: operate the device in a spray booth or

on a spraying wall with the ventilation (extraction) switched on.

Wear suitable protective clothing when working with hot materials.

4.2.6 TOUCHING HOT SURFACES

Only touch hot surfaces if you are wearing protective gloves.

When operating the device with a coating material with a temperature of >43°C;109°F:

- Identify the device with a warning label "Warning - hot surface".

Order No.

9998910 Instruction label

9998911 Protection sticker

Note: Order the two stickers together.

14

Page 15

VERSION 03/2013 ORDER NUMBER DOC 2310799

OPERATING MANUAL

4.3 USE IN AREAS SUBJECT TO EXPLOSION HAZARDS

The pneumatic pump may be used in areas subject to explosion hazards. The following

safety regulations must be observed and followed.

4.3.1 SAFETY REGULATIONS

Safe handling of WAGNER spray devices

Mechanical sparks can form if the device comes into contact with metal.

In an explosive atmosphere:

Do not knock or push the unit against steel or rusty iron.

Do not drop the device.

Only use tools that are made of a permitted material.

Ignition temperature of the pumped material

Check that the ignition temperature of the pumped material is higher than the max.

allowable surface temperature.

Medium supporting atomizing

To atomize the material, use only weakly oxidizing gases, e.g. air.

Surface spraying, electrostatics

Do not spray device parts using electrostatic equipment.

Cleaning

If there are deposits on the surfaces, the device may form electrostatic charges. Flames or

sparks can form during discharge.

Remove deposits from the surfaces to maintain conductivity.

Only use a damp cloth to clean the device.

4.3.2 OPERATION WITHOUT FLUID

Avoid running the pump so that it sucks in air (without uid inside). The air, combined with

the vapor of ammable uids, can generate internal areas with an explosion hazard.

Periodically check that the pump is working smoothly, paying special attention to the

presence of air in the pumped uid, which may be caused by damaged packings.

Avoid operating the pump with damaged packings.

Ensure that the separating agent container is lled with su cient separating agent.

15

Page 16

VERSION 03/2013 ORDER NUMBER DOC 2310799

OPERATING MANUAL

5 DESCRIPTION

5.1 FIELD OF APPLICATION

5.1.1 CORRECT USE

The pneumatic piston pump is suitable for conveying and processing (AirCoat technique)

liquid materials in accordance with Chapter 5.1.2.

5.1.2 PROCESSIBLE MATERIALS

Application

Water-based materials

Solvent-based materials

Low viscosity (<40 sec. DIN No. 4)

Medium viscosity (40 to 60 sec. DIN No. 4)

High viscosity ( >60 sec. DIN No. 4)

UV - sensitive materials

Shear sensitive materials

Humidity sensitive materials

Legend

recommended limited suitability less suitable

NOTICE

Abrasive materials and pigments!

Greater wear of parts carrying the material.

Use suitable combinations of devices (packings, valves, etc.)

16

Page 17

VERSION 03/2013 ORDER NUMBER DOC 2310799

OPERATING MANUAL

5.2 SCOPE OF DELIVERY

Pneumatic piston pump consisting of:

- Fluid section

- Air motor

- Connection elements

Separating agent 250 ml Order No.: 9992504

Conformity certi cate GM2000W see Chapter 12

Operating manual, German Order No.: 2310798

Operating manual in the local language see Chapter 1

The delivery note shows the exact scope of delivery.

Accessories: see Chapter 10.

5.3 DATA

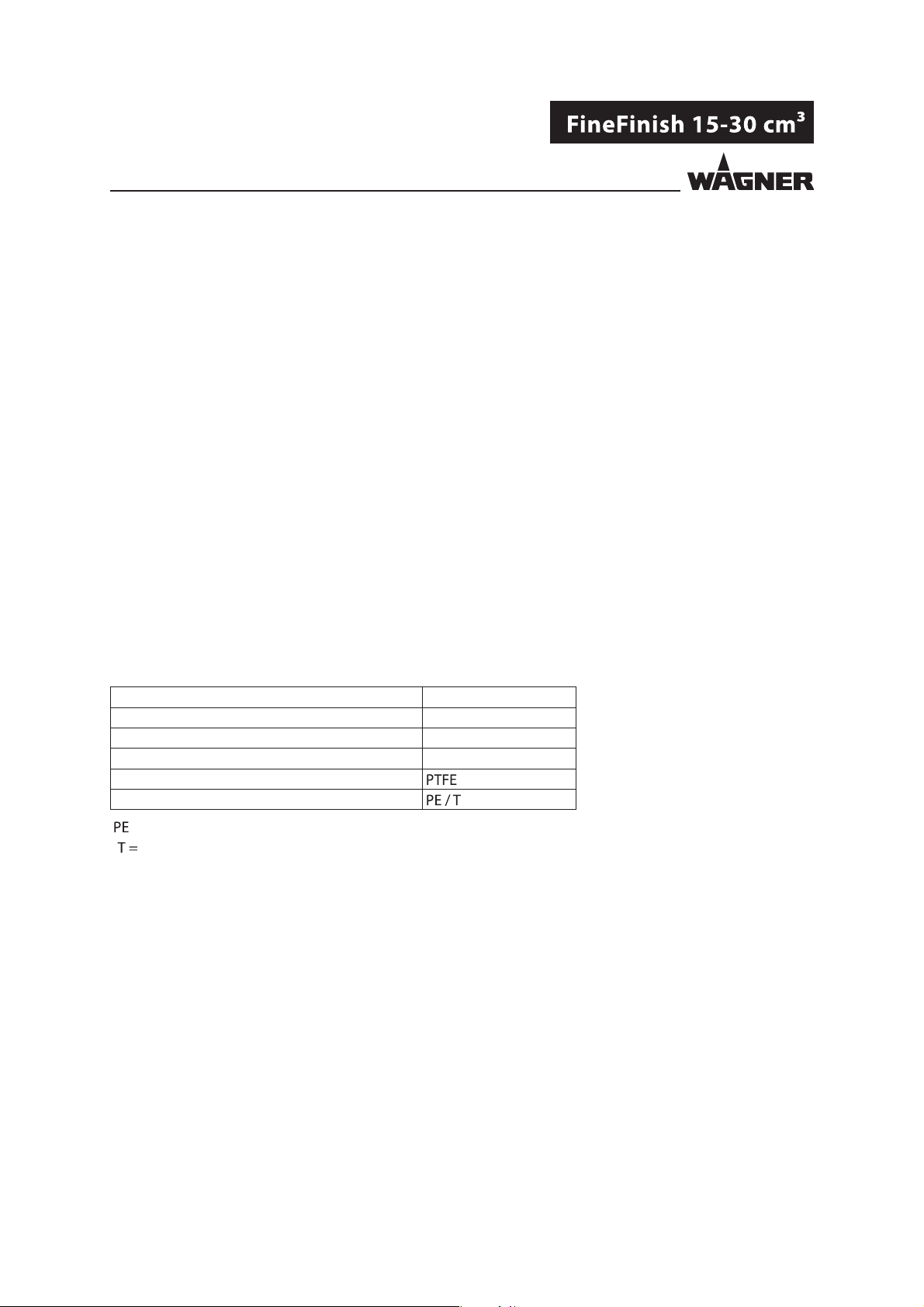

5.3.1 MATERIALS OF PAINTWETTED PARTS

Pump housing Stainless steel

Piston Stainless steel

Valve balls Stainless steel

Valve seats Stainless steel

Static seals

Packings

Ultra high molecular weight polyethylene

=

PTFE

17

Page 18

VERSION 03/2013 ORDER NUMBER DOC 2310799

OPERATING MANUAL

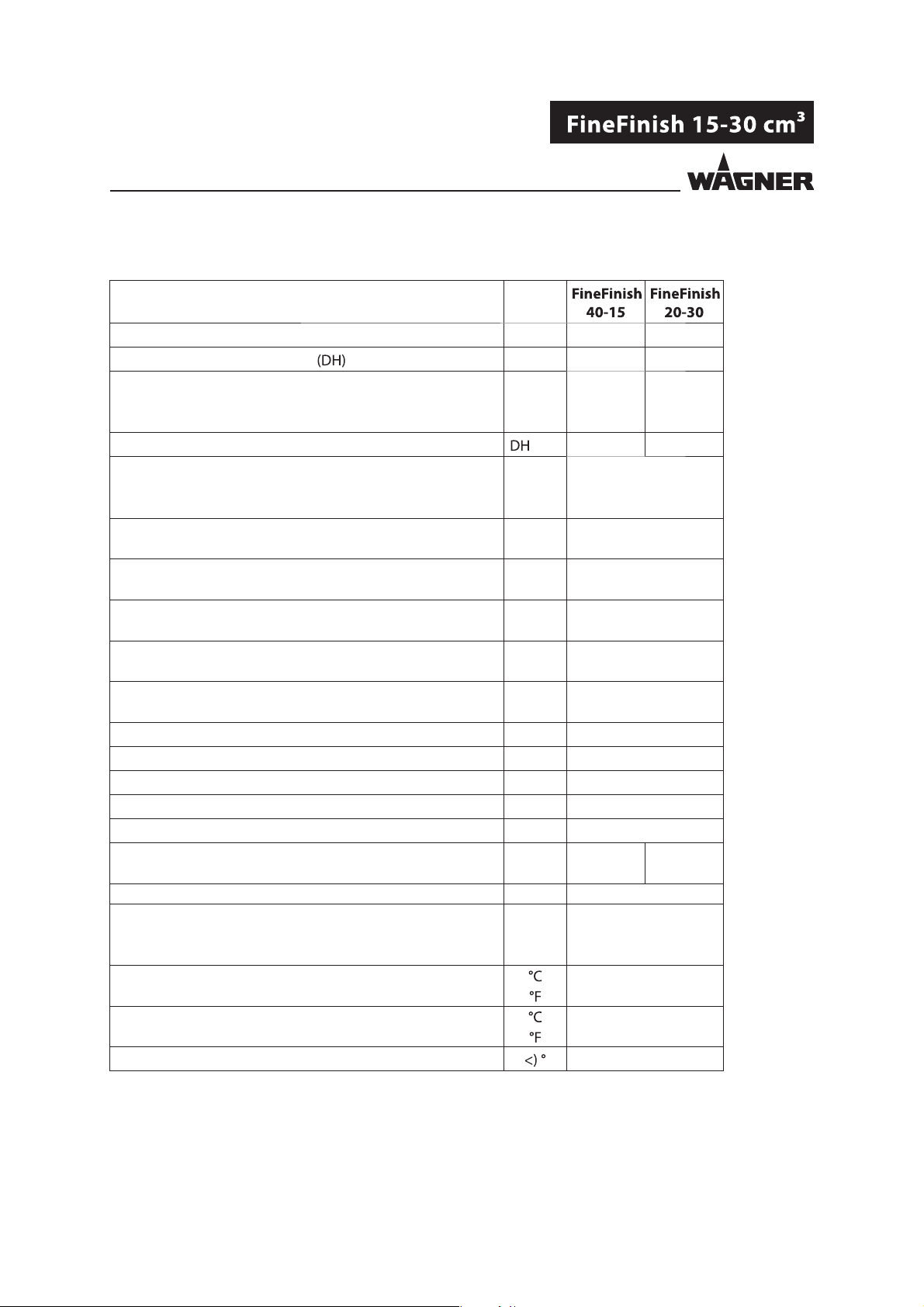

5.3.2 TECHNICAL DATA

Description Units

Pump ratio 40:1

Volume ow per double stroke cm; cc 15 30

Maximum operating overpressure MPa 25.0 16.0

bar 250 160

psi 3626 2320

Maximum possible strokes in operation /min 60 60

Minimum/maximum air inlet pressure MPa 0.2-0.8

bar 2-8

psi 28-116

Ø air inlet connection (inside thread) mm 8.0

inch 0.31

Minimum Ø of the compressed air supply line mm 9.0

inch 0.35

Air consumption at 0.6 MPa; 6 bar; 87 psi per double stroke nl 3.9

scf 0.14

Air motor piston diameter mm 80

inch 3.15

Air motor piston stroke mm 60

inch 2.4

Sound pressure level at maximum permissible air pressure* dB(A) 72

Sound pressure level at 0.6 MPa; 6 bar; 87 psi air pressure* dB(A) 69

Sound pressure level at 0.4 MPa; 4 bar; 58 psi air pressure* dB(A) 65

Material inlet (outside thread) mm M36x2

Material outlet (outside thread) inch NPS 1/4"

Weight kg 9 11

lb 19.8 24.7

Material pH value pH 3.5 ÷ 9

Maximum material pressure at pump inlet MPa 2

bar 20

psi 90

Material temperature

Ambient temperature +5 ÷ +60

Allowable inclination for operation ± 10

20:1

+5 ÷ +80

+41 ÷ +176

+41 ÷ +140

* A-rated sound pressure level measured at 1 m distance, LpA1m, in accordance with DIN EN 14462: 2005.

18

Page 19

VERSION 03/2013 ORDER NUMBER DOC 2310799

OPERATING MANUAL

WARNING

Outgoing air containing oil!

Risk of poisoning if inhaled.

Air motor switching problems.

Provide compressed air free from oil and water

(Quality Standard 5.5.4 in accordance with ISO 8573.1)

5.5.4 = 40 m / +7 / 5 mg/m³.

19

Page 20

VERSION 03/2013 ORDER NUMBER DOC 2310799

OPERATING MANUAL

5.3.3 MEASUREMENTS AND CONNECTIONS FOR FINEFINISH 4015

A

H1

B

L

H2

mm inch

A 104 4.09

B 108.5 4.27

C 621 24.45

D 276.5 10.89

E 134 5.28

F1 G 1/4"

F2 NPS 1/4"

G M36x2

H1 G 1/4"

H2 8 0.31

I 210 8.27

J 207 8.15

K 86 3.39

L 7 0.28

M 182 7.17

N 80 3.15

O 106 4.17

P 96.5 3.8

Q ø 9 ø 0.35

R ø 7 ø 0.28

S 149 5.87

T ø 25 ø 1

K

J

I

E

F1

F2

S

Wall mount

N

C

T

R

D

Q

O

G

B_04120

M

M/2

P

20

Page 21

VERSION 03/2013 ORDER NUMBER DOC 2310799

OPERATING MANUAL

5.3.4 MEASUREMENTS AND CONNECTIONS FOR FINEFINISH 2030

A

H1

B

L

H2

mm inch

A 104 4.09

B 108.5 4.27

C 643 25.3

D 201 7.91

E 134.5 5.3

F1 G 3/8"

F2 NPS 1/4"

G M36x2

H1 G 1/4"

H2 8 0.31

I 210 8.27

J 207 8.15

K 80 3.15

L 7 0.28

M 182 7.17

N 80 3.15

O 106 4.17

P 96.5 3.8

Q ø 9 ø 0.35

R ø 7 ø 0.28

S 149 5.87

T ø 25 ø 0.98

J

K

I

E

F1

F2

S

Wall mount

N

T

C

D

B_04100

G

M

M/2

R

Q

O

P

21

Page 22

VERSION 03/2013 ORDER NUMBER DOC 2310799

OPERATING MANUAL

5.3.5 PERFORMANCE DIAGRAMS

Example

Stroke frequency

BAR

BAR

BAR

Material pressure bar (MPa) psi

"?

Water delivery rate l/min <gpm>

/min

BAR

BAR

BAR

Air consumption nl/min <scfm>

22

Page 23

VERSION 03/2013 ORDER NUMBER DOC 2310799

OPERATING MANUAL

Diagram of FineFinish 40-15

bar (MPa)

<psi>

300 (30)

<4350>

240 (24)

<3480>

180 (18)

<2610>

120 (12)

<1740>

60 (6)

<870>

Material pressure

C_00054

Stroke frequency /min

10 20 30 40 50 60

0

A

B

C

0

0.60

0.45

0.30

0.15

0

<0.04>

<0.08>

<0.12>

<0.16>

Material ow - water

A = 8 bar; 0.8 MPa; 116 psi air pressure

B = 6 bar; 0.6 MPa; 87 psi air pressure

C = 4 bar; 0.4 MPa; 58 psi air pressure

0.75

<0.20>

A

B

C

0.90

<0.24>

nl/min

<scfm>

300

<11>

240

<8>

180

<6>

120

<4>

60

<2>

0

l/min

<gpm>

Air consumption

Diagram of FineFinish 20-30

bar (MPa)

Material pressure

<psi>

150 (15)

<2176>

120 (12)

<1740>

90 (9)

<1305>

60 (6)

<870>

30 (3)

<435>

0

0

0

C_00142

Stroke frequency /min

10 20 30 40 50 60

A

A

B

B

C

C

1.80

1.50

1.20

0.90

0.60

0.30

<0.08>

<0.16>

<0.23>

<0.31>

<0.39>

<0.47>

Material ow - water

A = 8 bar; 0.8 MPa; 116 psi air pressure

B = 6 bar; 0.6 MPa; 87 psi air pressure

C = 4 bar; 0.4 MPa; 58 psi air pressure

nl/min

<scfm>

350

<12.5>

280

<10>

210

<7.5>

140

<5>

70

<2.5>

0

l/min

<gpm>

Air consumption

23

Page 24

VERSION 03/2013 ORDER NUMBER DOC 2310799

OPERATING MANUAL

24

Page 25

VERSION 03/2013 ORDER NUMBER DOC 2310799

OPERATING MANUAL

5.4 FUNCTION

5.4.1 PUMP

1 Air motor

2 Air inlet

3 Mounting ange

4 Separating uid

container

5 Material outlet

6 Fluid section

7 Material inlet

8 Grounding connection

9 Reversing valve

10 Safety valve

(air motor ventilation)

11 Air pressure regulator

12 Ball valve

13 Air outlet to the

reversing valve

14 Air inlet into the

reversing valve

Function principle

The piston pump is driven with compressed air (11). This compressed air moves the air piston up and down in

the air motor (1) and it also moves the associated pump piston up and down in the uid section (6). At the end

of each stroke, the compressed air is redirected by a reversing valve (9).

The working material is sucked up during the upwards stroke and is continuously conveyed towards the

material outlet (5) in both stroke directions.

1

8

4

10

6

B_04121

7

11

2

3

9

8

13

12

5

14

7

Air motor

The air motor (1) with its pneumatic reverse (9) does not require pneumatic oil.

The compressed air is fed to the motor via an air regulator (11) and the ball valve (12).

The air motor is to be equipped with a safety valve (10) in accordance with Chapter 5.4.3. The safety valve (10)

has been set and sealed at the factory. In case of pressures over and above the permissible operating pressure,

the valve, which is held with a spring, automatically opens and releases the excess pressure.

WARNING

Overpressure!

Risk of injury from bursting components.

Never change the safety valve setting.

Fluid section (6)

The uid section has been designed as a piston pump with exchangeable ball valves. The

pump piston runs in two xed packings which are self-adjusting by means of a pressure

spring, thus resulting in a long service life.

Between the air motor and the uid section there is a separating agent cup (4) for holding

the separating agent.

25

Page 26

VERSION 03/2013 ORDER NUMBER DOC 2310799

OPERATING MANUAL

5.4.2 PRESSURE REGULATOR UNIT

1 Pressure regulator

2 Ball valve

3 Pressure gage (air inlet pressure)

4 Pressure gage for AirCoat air (option)

5 Compressed air inlet

6 Pressure regulator AirCoat (option)

7 Safety and motor pressure relief valve

2

1

3

7

Ball valve positions:

4

6

2

7

1

3

5

5

B_04122

1 Open: working position

2 Closed: the air motor may still be

under pressure.

open

1

2

closed

B_04123

26

Page 27

VERSION 03/2013 ORDER NUMBER DOC 2310799

OPERATING MANUAL

5.4.3 SAFETY AND MOTOR PRESSURE RELIEF VALVE

Safety valve

The safety valve (10) has been factory adjusted so as to ensure that if pressure exceeds the

permitted operating pressure, the valve, which is held with a spring, automatically opens

and releases the excess pressure.

As well as handling pressure limits, the valve is also used as a pressure relief valve for the

air motor.

10

Pressure relief of the air motor:

1 Close ball valve (2).

2 Pull back the ring on the safety

valve (10) and hold it there until

the pressure in the air motor has

been equalized.

WARNING

Overpressure!

Risk of injury from bursting components.

Never change the safety valve setting.

5.4.4 RETURN VALVE

10

2

B_04124

So that the complete pressure relief of the pump can be

performed (see Chapter 7.2.2), the installation of a return

valve is mandatory.

The suitable return valves (ball valves), return pipes and hoses

for the device can be found in the accessories list.

1 Material outlet

2 Return valve

3 Material return line

2

1

B_04075

3

27

Page 28

VERSION 03/2013 ORDER NUMBER DOC 2310799

OPERATING MANUAL

6 ASSEMBLY AND COMMISSIONING

6.1 TRANSPORTATION

The pump can be moved on a trolley or manually without lifting equipment.

6.2 STORAGE

Store the pump in a closed and dry environment.

Thoroughly clean the pump, if a long-term decommissioning is planned.

When resuming pump operation, proceed as described in the following sections.

WARNING

Discharge of electrostatically charged components in atmospheres

containing solvents!

Explosion hazard from electrostatic sparks.

Only use a damp cloth to clean the pump.

28

Page 29

VERSION 03/2013 ORDER NUMBER DOC 2310799

OPERATING MANUAL

6.3 ASSEMBLING THE PUMP

Notice

This pump can be used as part of a spraying system for Airless

or AirCoat applications. Individual supplement components

for this pump can be found in the Wagner Accessories

Catalogue, or can be put together with the Spraypack

Con gurator. The nozzles must be selected according to the

gun instructions. In the case of spraypack orders, the pumps

(1) are already pre-mounted on a trolley (6) or on a stand at

the factory.

Procedure:

1 Mount pump (1) on stand, trolley (6), or wall mount.

2 Mount an AirCoat system with the pressure regulator

(7) and secure the thread at the air inlet to the pump

(1) with Loctite 270.

3 Mount suction system (5).

4 Mount the return valve (8) for pressure relief or

material circulation.

5 Mount return tube (4) or return hose.

6 Connect the high pressure hose (2) and gun (3) in

accordance with the gun operating manual.

Example:

Airless system

3

2

5

Example:

AirCoat system

6

1

8

4

B_04076

7

WARNING

Inclined ground!

Risk of accidents if the device rolls away/falls.

3

1

2

8

4

5

6

B_04077

29

Page 30

VERSION 03/2013 ORDER NUMBER DOC 2310799

OPERATING MANUAL

6.4 GROUNDING

WARNING

Discharge of electrostatically charged components in atmospheres

containing solvents!

Explosion hazard from electrostatic sparks.

Only use a damp cloth to clean the piston pump.

WARNING

Heavy paint mist if grounding is insu cient!

Danger of poisoning.

Insu cient paint application quality.

Ground all device components.

Ground the work pieces to be coated.

Grounding scheme (example)

Note for the sprayer

Safety shoes and gloves, if

used, must be electrostatically

conductive.

Paint container

Work piece

Conveyor

Spraying stand

R max < 1 M Ω

B_00304

Floor, electrostatically conductive

30

Page 31

VERSION 03/2013 ORDER NUMBER DOC 2310799

OPERATING MANUAL

Cable cross sections

Pump 4 mm;

Paint container 6 mm;

Conveyor 16 mm;

Spray booth 16 mm;

Spraying stand 16 mm;

Procedure:

1 Screw on grounding cable with eye.

2 Clamp the grounding cable clip to a grounding connection on site.

3 Ground the material (paint) container to an on-site grounding connection.

4 Ground the other parts of the system to an on-site grounding connection.

Grounding cable

B_04127

31

Page 32

VERSION 03/2013 ORDER NUMBER DOC 2310799

OPERATING MANUAL

6.5 COMMISSIONING

6.5.1 SAFETY INSTRUCTIONS

Before carrying out any work, the following points must be observed in accordance with

the operating manual:

- Observe all safety regulations in accordance with Chapter 4.

- Carry out commissioning properly.

WARNING

High-pressure spray jet!

Danger to life from injecting paint or solvent.

Never reach into the spray jet.

Never point the spray gun at people.

Consult a doctor immediately in the event of skin injuries caused

by paint or solvent. Inform the doctor about the paint or solvent

used.

Never seal defective high-pressure parts; instead relieve the

pressure from them and replace them.

WARNING

Toxic and/or ammable vapor mixtures!

Risk of poisoning and burns.

Operate the device in a spray booth approved for the working

materials.

-or Operate the device on an appropriate spraying wall with the

ventilation (extraction) switched on.

Observe national and local regulations for the outgoing air

speed.

WARNING

Gas mixtures can explode if there is an incompletely filled pump!

Danger to life from ying parts.

Ensure that the pump and suction system are always completely

lled with ushing agent or working medium.

Do not spray the device empty after cleaning.

32

Page 33

VERSION 03/2013 ORDER NUMBER DOC 2310799

OPERATING MANUAL

Before every start-up, the following points should be observed as laid down in the

operating manual:

- Check the permissible pressures.

- Check all connecting parts for leaks.

- Check hoses for damage.

It should be ensured that the device is in the following state before carrying out any work

on it:

- Interrupt the air supply (2).

- Depressurize the air motor (pull the ring on the safety valve (10)).

- Relieve the pressure from the uid section.

10

closed

10

2

open

EMERGENCY STOP

In the case of unforeseen occurrences

the ball valve (2) should be closed

immediately.

Open the safety valve (10) and relieve the

material-conveying parts completely of

pressure via the return valve (3).

B_04124

2

C_00157

3

B_04078

33

Page 34

VERSION 03/2013 ORDER NUMBER DOC 2310799

OPERATING MANUAL

6.5.2 FILLING WITH SEPARATING AGENT

NOTICE

Piston pump runs dry!

High wear/damage to the packings.

Paint or solvent can escape if the seals are dry.

Ensure that the separating agent container is lled with su cient separating agent.

Filling level 2 cm; 0.8 inch under the cup edge.

Pour the supplied separating agent into the intended opening.

Filling level: 2 cm; 0.8 inch under the cup edge

Separating agent: See accessories.

Notice

Maximum permissible inclination of pump for moving, transportation

etc. after lling it with separating agent ± 30°.

The pump must be vertical during operation.

B_04130

34

Page 35

VERSION 03/2013 ORDER NUMBER DOC 2310799

OPERATING MANUAL

6.5.3 BASIC FLUSHING

Before each basic ushing, the nozzle must be removed from the pistol. The data in the

gun's operating manual are to be observed.

With AirCoat systems, carry out the basic ushing of the system without atomizing air (8)

1 Place empty container (5) under return tube (4).

2 Place suction hose (7) in the container with ushing agent (6).

3 Open return valve (3).

4 Slowly open the ball valve (2).

5 Adjust the air pressure on the pressure regulator (1) so that the pump runs smoothly.

6 Flush the system until clean ushing agent ows into the container (5).

7 Close ball valve (2).

8 Close return valve (3).

9 Point the gun (9), without nozzle, into container (5) and open it.

10 Slowly open the ball valve (2).

11 Rinse until clean ushing agent ows from the gun.

12 Close ball valve (2).

13 Relieve the system pressure, either by opening the return valve (3) or via the trigger

on the gun (9).

14 When there is no pressure remaining in the system, close the gun (9) or the return

valve (3).

15 Secure the gun.

16 Dispose of the contents of the container (5) according to the local regulations.

.

closed

open

1

8

2

7

3

4

6

5

9

B_04079

35

Page 36

VERSION 03/2013 ORDER NUMBER DOC 2310799

OPERATING MANUAL

7 OPERATION

7.1 FILLING WITH WORKING MATERIAL

Note:

Before each lling, the nozzle must be removed from the pistol. The data in the gun's

operating manual are to be observed.

In case of AirCoat systems, carry out the lling of the system without atomizing air (8).

1 Place empty container (5) under return tube (4).

2 Place suction hose (7) in the container with working material (6).

3 Open return valve (3).

4 Slowly open the ball valve (2).

5 Adjust the air pressure on the pressure regulator (1) so that the pump runs smoothly.

6 Spray until clean working material ows into the container (5).

7 Close ball valve (2).

8 Close return valve (3).

9 Point the gun (9), without nozzle, into container (5) and open it.

10 Slowly open the ball valve (2).

11 Spray until clean working material ows from the gun (9).

12 Close ball valve (2).

13 Relieve the system pressure, either by opening the return valve (3) or via the trigger

on the gun (9).

14 When there is no pressure remaining in the system, close the gun (9) or the return

valve (3).

15 Secure the gun.

16 Dispose of the contents of the container (5) according to the local regulations.

36

Page 37

VERSION 03/2013 ORDER NUMBER DOC 2310799

OPERATING MANUAL

7.2 WORK

7.2.1 SPRAYING

System example for

the AirCoat procedure

closed

open

7

6

1 Secure the gun and insert the nozzle into the gun.

2 Close return valve (3).

3 Slowly open the ball valve (2).

4 Set required working pressure on the pressure regulator (1).

5 Optimize the spraying results according to the data in the gun operating manual.

6 Start work process.

2

8

1

9

3

4

5

B_04080

37

Page 38

VERSION 03/2013 ORDER NUMBER DOC 2310799

OPERATING MANUAL

7.2.2 PRESSURE RELIEF/WORK INTERRUPTION

Pressure relief of the material

1 Close the spray gun.

2 Close ball valve (2).

3 Relieve the system pressure, either by opening the gun or by opening the return

valve (3).

4 Close and secure gun.

5 Open and close the return valve (3) to completely depressurize the system.

Pressure relief of the air (in case of longer work interruptions)

1 Carry out pressure relief of the material (as mentioned above).

2 Ensure that the ball valve (2) is closed.

3 Pull back the ring on the safety valve (10) and hold it there until the pressure in the

air motor has been equalized.

10

10

B_04124

If the system has been used with 2-component materials:

2

NOTICE

Hardened working material in the spraying system when two-component material

is processed!

Destruction of pump and injection system.

Follow the manufacturer‘s processing rules, particularly regarding the pot life.

Flush thoroughly before the end of the pot life.

The pot life is decreased by warmth.

38

Page 39

VERSION 03/2013 ORDER NUMBER DOC 2310799

OPERATING MANUAL

7.2.3 DECOMMISSIONING AND CLEANING

Notice

The device should be cleaned for maintenance purposes. Ensure that no remaining

material dries and sticks.

Procedure:

1 Carry out pressure relief of the material and air -> Chapter 7.2.2.

2 Basic cleaning -> carry out the steps in Chapter 6.5.3.

3 Maintain the gun according to the operating manual.

4 Clean and check the suction system and the suction lter.

5 Clean the outside of the system.

WARNING

Brittle lter pressure regulator!

The container on the lter pressure regulator becomes brittle

through contact with solvents and can burst.

Flying parts can cause injury.

Do not clean the container on the lter pressure regulator with

solvent.

6 Put the whole system back together.

7 Check the level of the separating agent -> Chapter 6.5.2.

8 Fill the system with ushing agent as laid down in Chapter 7.1 "Filling with Working

Material".

WARNING

Gas mixtures can explode if there is an incompletely filled

pump!

Danger to life from ying parts.

Ensure that the pump and suction system are always completely

lled with ushing agent or working medium.

Do not spray the device empty after cleaning.

39

Page 40

VERSION 03/2013 ORDER NUMBER DOC 2310799

OPERATING MANUAL

7.3 LONGTERM STORAGE

When storing the device for longer periods of time, it is necessary to thoroughly clean it

and protect it from corrosion. For the last rinse, replace the water or solvent in the material

pump with a suitable preservative. Fill separating agent cup with separating agent. Store

pump vertically.

Procedure:

1 Chapter 7.2.3 "Decommissioning and Cleaning", perform points 1 to 7.

2 Flush with preservative according to Chapter 6.5.3 and paint supplier's instructions.

3 If the discharge duct is to be removed, seal material outlet with plug.

4 If the suction system is to be removed, seal material inlet with plug.

40

Page 41

VERSION 03/2013 ORDER NUMBER DOC 2310799

OPERATING MANUAL

8 TROUBLESHOOTING AND RECTIFICATION

Problem Cause Remedy

Pump does not work. Air motor does not work or stops. Open and close ball valve on the pressure

regulator unit or brie y disconnect

compressed air supply.

No pressure indication on the

pressure gage

(air pressure regulator defective).

Spray nozzle is clogged. Clean the nozzle according to the instructions.

Insu cient compressed air supply. Check compressed air supply.

Filter insert in spray gun is clogged. Clean the parts and use a suitable working

Fluid section or high pressure hose

are blocked (e.g., two-component

material hardened).

Sometimes, the pump stops at a

switching point.

Poor spray pattern See gun instructions.

Irregular pump

operation: spray jet

collapses (pulsation).

The pump runs evenly,

does not however,

suck up material.

Pump runs when the

gun is closed.

Air motor is iced up. There is a lot of condensation water

Viscosity is too high. Thin spraying material.

Spraying pressure is too low. Increase air inlet pressure.

Valves are clogged. Clean pump, if necessary leave it to soak in

Foreign body in suction valve. Dismount suction valve housing, clean, and

Diameter of compressed air line too

small.

Valves, packings, or pistons are worn

out.

Pressure regulator lter is clogged. Check lter and clean it if necessary.

The suction system's union nut is

loose; the pump is taking in air.

Suction lter is clogged. Clean lter.

Ball in suction or piston valve is stuck. Clean balls and valve seats.

Packings, valves, or pistons are worn

out.

in the air supply.

Disconnect compressed air supply brie y or

repair or change pressure regulator.

material.

Dismount and clean uid section, replace

high-pressure hose.

Press the starter on the reversing valve and

restart the pump.

Clean the slide on the reverse valve carefully

and if necessary lubricate it with a light

layer of oil.

Use a smaller nozzle.

solvent.

check valve seat.

Assemble a larger incoming line

-> Technical Data, Chapter 5.3.2.

Replace the parts.

Tighten union nut.

Replace the parts.

Install a water separator.

If none of the causes of malfunction mentioned are present, the defect can be remedied by a WAGNER Service

Center.

41

Page 42

VERSION 03/2013 ORDER NUMBER DOC 2310799

OPERATING MANUAL

9 MAINTENANCE

WARNING

Incorrect maintenance/repair!

Danger to life and equipment damage.

Only a WAGNER service center or a suitably trained person may

carry out repairs and replace parts.

Only repair and replace parts that are listed in the "Spare Parts"

chapter and that are assigned to the device.

Before all work on the device and in the event of work

interruptions:

- Disconnect the control unit from the mains.

- Relieve the pressure from the spray gun and device.

- Secure the spray gun against actuation.

Observe the operating manual and service instructions at all

times when carrying out work.

1 Check the level of separating agent in the separating agent cup every day, and top

up if necessary.

2 Check and clean the high pressure lter every day or as required (if available).

3 Every decommissioning should be carried out as laid down in Chapter 7.2.3!

4 Check hoses, pipes, and couplings every day and replace if necessary.

In accordance with the guideline for liquid emitters (ZH1/406 and BGR500 Part2

Chapter 2.36):

- The liquid emitters should be checked by an expert (e.g. Wagner ser vice technician)

for their safe working conditions as required and at least every 12 months.

- If devices have been decommissioned, the examination can be suspended until

the next start-up.

42

Page 43

VERSION 03/2013 ORDER NUMBER DOC 2310799

OPERATING MANUAL

9.1 HIGHPRESSURE HOSES

The service life of the uid hoses is reduced due to environmental in uences even when

handled correctly.

Check hoses, pipes, and couplings every day and replace if necessary.

As a precaution, uid hoses should be replaced after a period speci ed by the

operator.

DANGER

Bursting hose, bursting threaded joints!

Danger to life from injection of material.

Ensure that the hose material is chemically resistant to the

sprayed materials.

Ensure that the spray gun, threaded joints, and material hose

between the device and the spray gun are suitable for the

pressure generated in the device.

Ensure that the following information can be seen on the high-

pressure hose:

- Manufacturer

- Permissible operating pressure

- Date of manufacture

9.2 DECOMMISSIONING

When the equipment must be scrapped, please di erentiate the disposal of the waste

materials.

The following materials have been used:

Steel

Aluminum

Elastomers

Plastics

Carbide

The consumable materials (paints, adhesives, sealers, solvents) must be disposed of

according to the valid speci c standards.

43

Page 44

VERSION 03/2013 ORDER NUMBER DOC 2310799

OPERATING MANUAL

10 ACCESSORIES

Accessories

Designation Order No. Order No.

1 Pump PE/T 2329450 2329452

2

3 Grounding cable, complete 3 m; 9.8 ft 236219

4 Separating agent 250 ml 9992504

5 Separating agent 500 ml 9992505

Material outlet accessories

11 Ball valve R1/4"-G1/4"-PN350-SSt 2334488

12 Ball valve R1/4"-G1/4"-PN350-CS 2334472

13 Return tube DN6-G1/4"-100mm-PA 2331752

14 Return hose DN6-PN310-G1/4"-PA 2329046

Material inlet accessories

15 Suction pipe DN16-SSt, complete 2324158

16 Suction hose DN16-SSt, complete 2324110

17 Suction elbow for top reservoir SSt 2323225

18 Top reservoir set, 5 l for piston pump 2332169

19 Suction lter DN16-18mesh-SSt 2323396

Wearing part

AirCoat regulator set T6145.00A

Designation Order No.

Designation Order No.

44

Page 45

VERSION 03/2013 ORDER NUMBER DOC 2310799

OPERATING MANUAL

3

14

11

x

1

12

13

x

4/5

2

15

18

16

17

19

B_04081

45

Page 46

VERSION 03/2013 ORDER NUMBER DOC 2310799

OPERATING MANUAL

Trolley, rack and wall bracket accessories

Designation Order No.

21 Wall mount 4", complete 2332143

22 4-leg stand 2332374

23 Trolley, 4 wheels T6196.00

24 Trolley 4", complete 2325901

21

22

23

24

B_04113

46

Page 47

VERSION 03/2013 ORDER NUMBER DOC 2310799

OPERATING MANUAL

11 SPARE PARTS

11.1 HOW CAN SPARE PARTS BE ORDERED?

Always supply the following information to ensure delivery of the right spare part:

Order number, designation, and quantity

The quantity need not be the same as the number given in the quantity column " " on

the lists. This number merely indicates how many of the respective parts are used in each

component.

The following information is also required to ensure smooth processing of your order:

- Billing address

- Delivery address

- Name of the person to be contacted in the event of any queries

- Type of delivery (normal mail, express delivery, air freight, courier, etc.)

Identi cation in spare parts lists

Explanation of column " " (labeling) in the following spare parts lists:

Wearing parts

Note: No liability is assumed for wearing parts.

Not part of the standard equipment but available as a special accessory.

WARNING

Incorrect maintenance/repair!

Risk of injury and equipment damage.

Have repairs and part replacements carried out only by specially

trained sta or a WAGNER service center.

Before all work on the device and in the event of work

interruptions:

- Switch o the energy/compressed air supply.

- Relieve the pressure from the spray gun and device.

- Secure the spray gun against actuation.

Observe the operating manual and service instructions at all

times when carrying out work.

47

Page 48

VERSION 03/2013 ORDER NUMBER DOC 2310799

OPERATING MANUAL

11.2 OVERVIEW OF THE COMPONENTS

11.2.1 COMPONENTS FOR FINEFINISH 4015

Designation Order No.

1 1 2329450

2 Fluid section 15 PE/T EM 1 2329635

3 Air motor M80 EM 1 U3B08018060

4 D 25 X 160 Spacer 1 A359.71A

5 Safety xture spacer 1 E516.71A

6 Hexagon socket head cap screw 2 9900353

7 Holder plate 1 2332394

8 Washer 4 9920106

9 Hexagon socket head cap screw 4 9900330

10 Hexagon nut with clamp 3 3055157

11 Tie rod 3 H115.62

12 Pump air regulator set 1 T6140.00A

13 Screwing in angle 1 9998253

13

12

20 Nm; 14.7 lbft

1

6

5

2

30 Nm; 22.1 lbft

3

7

8

9

4

11

10

B_04135

48

Page 49

VERSION 03/2013 ORDER NUMBER DOC 2310799

OPERATING MANUAL

11.2.2 COMPONENTS FOR FINEFINISH 2030

Designation Order No.

1 1 2329452

2 Fluid section 30 PE/T EM 1 2329639

3 Air motor M80 EM 1 U3B08018060

4 D 25 X 160 Spacer 1 A359.71A

5 Safety xture spacer 1 E516.71A

6 Hexagon socket head cap screw 2 9900353

7 Holder plate 1 2332394

8 Threaded bolt 4 9901115

9 Washer 4 9920106

10 Hexagon extension nut 4 2332990

11 Hexagon socket head cap screw 4 9906024

12 Pump air regulator set 1 T6140.00

13 Screwing in angle 1 9998253

14 Loctite 222 50ml; 50cc 1 9992590

13

3

12

7

8

9

1

30 Nm; 22.1 lbft

6

5

77

2

10

4

14

B_04115

30 Nm; 22.1 lbft

11

49

Page 50

VERSION 03/2013 ORDER NUMBER DOC 2310799

OPERATING MANUAL

11.3 AIR MOTOR

WARNING

Incorrect maintenance/repair!

Risk of injury and equipment damage.

Have repairs and part replacements carried out only by specially

trained sta or a WAGNER service center.

Before all work on the device and in the event of work

interruptions:

- Switch o the energy/compressed air supply.

- Relieve the pressure from the spray gun and device.

- Secure the spray gun against actuation.

Observe the operating manual and service instructions at all

times when carrying out work.

Air motor spare parts list EM M80

Designation Order No.

1 Air motor EM M80 1 U3B08018060

2 Motor ange, upper, M50 EM 1 F132.91C

3 O-ring 2 L108.06

4 Cylinder motor 1 D608.81

5 Hexagon nut with clamp 1 3055157

6 Washer 1 9920106

7

8 Gasket DE 80 1 L413.06

9 Motor piston 1 A164.01

10 Sliding ring 1 L802.08

11 O-ring 1 L110.06

12 Piston rod, M80 EM 1 D404.12

13

14 Air tube, M80 EM 1 A408.12

15 Motor ange, complete M80 EM, at bottom 1 T616.00C

16 Type plate 1 -17 Grounding, complete 1 367258

18

19 Sensor below, M80 1 T703.00

20 Lock washer for shaft 2 K606.02

21 Washer 1 A160.01A

22

23 Threaded elbow tting 1 9992757

24 Silencer 2 H505.07

25 Reducing nipple 1 M432.00

= Wearing part

= Included in service set

= Not part of the standard equipment but available as an accessory.

Steamer 2 G903.06

O-ring 2 L109.06

Rod seal 1 L403.06

Pilot valve 1 369290

50

Page 51

VERSION 03/2013 ORDER NUMBER DOC 2310799

OPERATING MANUAL

30 Nm; 22 lbft

28

2

3

29

16

5

6

7

4

35 Nm; 25.8 lbft

30

29

8

9

29

13

30

7

29

1

11

10

14

13

3

29

17

4.5 Nm; 3.3 lbft

29

36

35

B_04347

27

20 Nm; 14.7 lbft

29

18

15

22

12

20

21

20

23

32

33

34

24

19

27

25

Installation instructions:

Mount piston rod (12) always

from bottom to top by the

assigned rod seal (18).

31

51

Page 52

VERSION 03/2013 ORDER NUMBER DOC 2310799

OPERATING MANUAL

Air motor spare parts list EM M80

Designation Order No.

27 Loctite 542 1 9992831

28 Hexagon socket head cap screw 4 9907241

29 Mobilux EP 2 grease 1 9998808

30 Loctite 480 1 9998157

31 Reversing valve ISO N/1

(consisting of items 32 to 36)

32 Reversing valve

(spare parts list, see Chapter 11.3.1)

33 Valve plate 1 A818.71B

34 Valve sealing 1 G735.06AB

35 Washer, A4.3 4 9920104

36 Hexagon socket head cap screw 4 9900386

Service set EM Air motor M80 1 T910.00

= Wearing part

= Included in service set

= Not part of the standard equipment but available as an accessory.

1 P498.00KNE

1 P498.00

WARNING

Incorrect maintenance/repair!

Risk of injury and equipment damage.

Have repairs and part replacements carried out only by specially

trained sta or a WAGNER service center.

Before all work on the device and in the event of work

interruptions:

- Switch o the energy/compressed air supply.

- Relieve the pressure from the spray gun and device.

- Secure the spray gun against actuation.

Observe the operating manual and service instructions at all

times when carrying out work.

52

Page 53

VERSION 03/2013 ORDER NUMBER DOC 2310799

OPERATING MANUAL

11.3.1 REVERSING VALVE

1

4

2

3

B_03139

Spare parts list for the reversing valve

Designation Order No.

1 Reversing valve 1 P498.00

2 O-ring 6 9971123

3 Reversing valve gasket 1 P521.00

4 Steamer 2 P520.00

= Wearing part

53

Page 54

VERSION 03/2013 ORDER NUMBER DOC 2310799

OPERATING MANUAL

11.4 FLUID SECTIONS

11.4.1 FLUID SECTION 15

24

29

2

3

4

30

1

6

30 Nm; 22.1 lbft

36

2.5 Nm; 1.84 lbft

30

20

27

28

27

28

27

28

27

28

27

28

27

21

8

22

25

30

30

5

25

23

10

11

26

26

12

9

31

33

34

B_03445

35

35

30

13

14

19

15

10

17

16

31

18

32

7

54

Page 55

VERSION 03/2013 ORDER NUMBER DOC 2310799

OPERATING MANUAL

Spare parts list for uid section 15

Designation Order No.

1 Fluid section 15 SS PE/T EM 1 2329635

2 Connecting ange 15 1 A661.12

3 Snap ring 1 K617.03

4 Snap ring ange 15 1 A662.12

5

6 Spring, upper 1 H204.03

7 Tube 15 1 A658.03

8 Spring 1 H203.03

9

10 O-ring 2 L107.06

11 Cylinder 15 1 B534.03

12 Piston 15 SS 1 T6157.00I

13 Support spring 1 A170.03

14 Ball 1 K801.03

15 Valve screw 15 1 A169.03

16 Ball 1 K803.03

17 Securing ring 1 K601.03

18 Inlet housing 15 1 2323838

19 Loctite 542 1 9992831

20 Support ring, outside 1 A171.03

21 Support ring, inside 1 A172.03

22 Support ring, inside 1 A411.03

23 Support ring, outside 1 A410.03

24 Connector 1 T6158.00

25

26

27

28

29 Hexagon screw without shaft 1 9900136

30 Mobilux EP 2 grease 1 9998808

31

32 Sealing sleeve 1 2329898

33 Fitting-DF-MM-R1/4"-1/4"NPS-PN350 1 B0461.03A

34 Hexagon plug 1 2323718

35 Loctite 270 1 9992528

36 Loctite 222 1 9992590

Packing PE/T 13/25 1 T9037.00E

Packing PE/T 18/29 1 T9038.00E

Sealing collar T 18/29 2 G101.05

Sealing collar PE 18/29 2 G101.08E

Sealing collar T 13/25 6 G104.05

Sealing collar PE 13/25 5 G104.08E

Anti-seize paste 1 9992609

Service set EM 15 PE/T 1 T9039.00E

= Wearing part

= Included in service set

= Not part of the standard equipment but available as an accessory.

55

Page 56

VERSION 03/2013 ORDER NUMBER DOC 2310799

OPERATING MANUAL

11.4.2 FLUID SECTION 30

30 Nm; 22.1 lbft

2

41

3

21

4

22

42

5

6

7

8

42

7

8

8

8

10

7

7

9

42

11

1

45

12

14

42

25

27

27

23

24

26

29

26

28

30

15

16

43

B_04116

18

45

19

20

17

42

13

31

44

32

33

34

35

36

37

56

Page 57

VERSION 03/2013 ORDER NUMBER DOC 2310799

OPERATING MANUAL

Spare parts list for uid section 30

Designation Order No.

1 Fluid section 30 PE/T, complete 1 2329639

2 Connector 1 T6158.00

3 Hexagon screw without shaft 1 9900136

4 Connecting ange 30 1 B0388.62

5

6 Support ring, outside 1 G119.08

7 Sealing collar PE 18/29 4 G101.08E

8 Sealing collar T 18/29 4 G101.05

9 Support ring, inside 1 G120.08

10 Packing PE/T, complete 18/29 1 T920.00D

11 Support ring plate 1 A114.03

12

13 O-ring 2 L170.06

14 Tube 30 1 B0391.03

15 Fitting-DF-MM-R3/8"-1/4"NPS-PN350 1 B0461.03

16 Hexagon plug 1 2323718

17 Piston 30 1 T6181.00

18 Support spring 1 A156.03

19 Ball 1 K802.03

20 Valve screw 30 1 A155.03

21 Lower pump ange 1 B0387.62

22 Hexagon socket head cap screw 3 9907087

23

24 Ring 1 B0099.03

25

26 Sealing collar T 25/36 2 G152.05

27

28 Support ring, outside 1 G184.05

29 Packing PE/T, complete 25/36 1 T941.00G

30 Round wire snap ring for waves 1 K640.02

31 Cylinder 30 1 B0392.03

32 Ball stopper 1 A961.03B

33 Ball 1 K803.03

34 O-ring 2 L170.06

35 Inlet tting 1 2323833

36 Sealing sleeve 1 2329898

37 Valve screw 30 1 B0389.03

41 Loctite 222 1 9992590

42 Mobilux EP 1 grease 1 9998008

43 Loctite 542 1 9992831

44 Anti-seize paste 1 9992609

45 Loctite 270 1 9992528

O-ring 1 L112.06

Spring 1 H203.03

Pressure spring 1 H222.03

Support ring, inside 1 G185.05

Sealing collar PE 25/36 2 G152.08E

Service set EM 20 PE/T 1 T940.00G

= Wearing part

= Included in service set

= Not part of the standard equipment but available as an accessory.

57

Page 58

VERSION 03/2013 ORDER NUMBER DOC 2310799

OPERATING MANUAL

11.5 AIR REGULATOR SET

14

14

14

14

8

9

5

1

2

14

10

11

B_04117

Spare parts list for air regulator set

12

4

13

3

Designation Order No. Order No.

1 Pump air regulator set 1 T6140.00A T6140.00

2 Hexagon socket head cap screw 2 9906026

3

4 Reducer 1 9985682

5 Screw-in connection's elbow 1 9998039

8

9 Safety valve 1/4" 1 P484.00C1 P484.00C0

10 T-connection 1 M297.00

11 Straight threaded tting 1 9992743

12 Hose, black AD8 x 1.25 (0.32m;1.05 ft long) 0.32 m 9982078

13

14 Loctite 542 1 9992831

= Wearing part

Pressure gage 0-1 MPa; 0-10 bar; 0-145psi(d40) 1 9998677

Ball valve, FM 1 M101.00

Filter regulator, CZ 1/4 1 P124.00M

58

Page 59

VERSION 03/2013 ORDER NUMBER DOC 2310799

OPERATING MANUAL

11.6 AIR REGULATOR SET FOR AIRCOAT AIR

7

4

5

1

7

B_03436

Spare parts list for air regulator set for AirCoat Air

Designation Order No.

1 AirCoat regulator set 1 T6145.00A

2

3 Elbow with taper 1 9992129

4 Detachable double nipple 1 9998719

5 T-piece 1 9985694

6

7 Loctite 270 1 9992528

= Wearing part

Pressure gage 0-1 MPa; 0-10 bar; 0-145 psi (d40) 1 9998677

Air pressure regulator, 1/4" 1 P123.00

2

6

7

3

59

Page 60

VERSION 03/2013 ORDER NUMBER DOC 2310799

OPERATING MANUAL

11.7 TROLLEY, 4"

15

5

10

13

2

Distance

Spare parts list for trolley, 4"

Designation Order No.

1 Trolley, complete 1 2325901

2 Stand left 4" (welded) 1 -3 Stand right 4" (welded) 1 -4 Hexagon screw DIN931 M6x75 4 9907140

5 Self-locking hexagon nut, M6 6 9910204

6

7 Washer 4 340372

8 Cotter pin 4 9995302

9 Wheel axle 4" 1 --

10 Connecting part 4" 2 367943

11 Tube plug, ribbed 2 -12 Saddle feet for round tubes 2 -13 Plug 2 -14 Hexagon screw 4 9900218

15 Wall mount 1 2332143

16 Hexagon screw without shaft M6x55 2 3061695

17 Handle 2 9998747

= Wearing parts

Wheel, D250 2 2304440

14

9

5

A

11

12

17

4

16

B_04074

6

1

3

7

8

60

Page 61

VERSION 03/2013 ORDER NUMBER DOC 2310799

OPERATING MANUAL

11.8 4WHEEL TROLLEY

4

12

2

13

1

10

6

8

5

3

9

11

7

B_03439

Designation Order No.

1 Trolley, 4 wheels 1 T6196.00

2 Hexagon nut with clamp 5 9910204

3 Stand, right 1 E3107.92B

4 Stand, left 1 E3107.92C

5 Spray gun hook 1 H009.62

6 Stand pin 1 H1156.62

7 Plug 4 R204.07

8 Contact washer, M08 4 3155404

9 Washer 4 9920106

10

11 Hexagon socket head cap screw 4 9900311

12 Hexagon socket head cap screw 4 9900389

13 Hexagon socket head cap screw 2 9900309

14 Hexagon nut with clamp 4 3055157

= Wearing part

Wheel 4 R120.00F

14

61

Page 62

VERSION 03/2013 ORDER NUMBER DOC 2310799

OPERATING MANUAL

12 3+2 YEARS GUARANTEE FOR PROFESSIONAL FINISHING

12.1 SCOPE OF GUARANTEE

All Wagner professional colour application devices (hereafter referred to as products)

are carefully inspected, tested, and subject to strict checks under Wagner quality

assurance. Wagner exclusively issues extended guarantees to commercial or professional

users (hereafter referred to as "customer") who have purchased the product in an

authorized specialist shop, and which relate to the products listed on the Internet at

.

The buyer’s claim for liability for defects from the purchase agreement with the seller and

statutory rights are not impaired by this guarantee.

We provide a guarantee in that we decide whether to replace or repair the product or

individual parts, or take the device back and reimburse the purchase price. The costs for

materials and working hours are our responsibility. Replaced products or parts become

our property.

12.2 GUARANTEE PERIOD AND REGISTRATION

The guarantee period amounts to 36 months. For industrial use or equal wear, such as shift

operations in particular, or in the event of rentals, it amounts to 12 months.

Systems driven by petrol or air are also guaranteed for a 12 month period.

The guarantee period begins with the day of delivery by the authorized specialist shop.

The date on the original purchase document is authoritative.

For all products bought in authorized specialist shops from 2009-02-01 the guarantee

period is extended to 24 months providing the buyer of these devices registers in

accordance with the following conditions within 4 weeks of the day of delivery by the

authorized specialist shop.

Registration can be completed on the Internet at

The guarantee certi cate is valid as con rmation, as is the original purchase document

that carries the date of the purchase. Registration is only possible if the buyer agrees to the

data that is entered during registration being stored.

When services are carried out under guarantee the guarantee period for the product is

neither extended nor renewed.

Once the guarantee period has expired, claims made against the guarantee or from the

guarantee can no longer be enforced.

12.3 HANDLING

If defects can be seen in the materials, processing, or performance of the device during the

guarantee period, guarantee claims must be made immediately, or at the latest within a

period of 2weeks.

The authorized specialist shop that delivered the device is entitled to accept guarantee

claims. Guarantee claims may also be made to the service centers named in the operating

manual. The product has to be sent without charge or presented together with the

original purchase document that includes details of the purchase date and the name of

the product. In order to claim for an extension to the guarantee, the guarantee certi cate

must be included.

The costs as well as the risk of loss or damage to the product in transit or by the center that

accepts the guarantee claims or who delivers the repaired product, are the responsibility

of the customer.

62

Page 63

VERSION 03/2013 ORDER NUMBER DOC 2310799

OPERATING MANUAL

12.4 EXCLUSION OF GUARANTEE

Guarantee claims cannot be considered

- for parts that are subject to wear and tear due to use or other natural wear and tear, as

well as defects in the product that are a result of natural wear and tear, or wear and tear

due to use. This includes in particular cables, valves, packings, nozzles, cylinders, pistons,

means-carrying housing components, lters, pipes, seals, rotors, stators, etc. Damage

due to wear and tear that is caused in particular by sanded coating materials, such as

dispersions, plasters, putties, adhesives, glazes, quartz foundation.

- in the event of errors in devices that are due to non-compliance with the operating

instructions, unsuitable or unprofessional use, incorrect assembly and/or commissioning

by the buyer or by a third party, utilization other than is intended, abnormal ambient

conditions, unsuitable coating materials, the in uence of chemical, electrochemical, or

electrical agents, unsuitable operating conditions, operation with the incorrect mains

voltage supply/frequency, overload, or defective servicing or care and/or cleaning.

- for errors in the device that have been caused by using accessory parts, additional

components, or spare parts that are not original Wagner parts.

- for products to which modi cations or additions have been carried out.

- for products where the serial number has been removed or is illegible.

- for products to which attempts at repairs have been carried out by unauthorized persons.

- for products with slight deviations from the target properties, which are negligible with

regard to the value and usability of the device.

- for products that have been partially or fully taken apart.

12.5 ADDITIONAL REGULATIONS

The above guarantees apply exclusively to products that have been bought from authorized

specialist shops in the EU, CIS, Australia and are used within the reference country.

If an inspection nds damage not covered by the present guarantee, repairs are carried out

at the expense of the buyer.

The above regulations manage the legal relationship to us concludingly. Additional claims,

in particular for damages and losses of any type, which occur as a result of the product

or its use, are excluded from the product liability act except with regard to the area of

application.

Claims for liability for defects to the specialist trader remain una ected.

German law applies to this guarantee. The contractual language is German. In the event

that the meaning of the German and a foreign text of this guarantee deviate from one

another, the meaning of the German text has priority.

Germany

Wagner professional guarantee

(As of 2009-02-01)

63

Page 64

VERSION 03/2013 ORDER NUMBER DOC 2310799

OPERATING MANUAL

64

Page 65

VERSION 03/2013 ORDER NUMBER DOC 2310799

OPERATING MANUAL

12.6 CE DECLARATION OF CONFORMITY

Herewith we declare that the supplied version of pneumatic pumps and their spraypacks

FineFinish

comply with the following guidelines:

2006/42/EC 94/9/EC

Applied standards, in particular:

Applied national technical standards and speci cations, in particular:

Part 2 Chapter 2.29 and Chapter 2.36

Identi cation:

II 2G IIB c T3 X

EC Certi cate of Conformity

The CE certi cate of conformity is enclosed with this product. If needed, further copies

can be ordered through your WAGNER dealer by specifying the product name and serial

number.

Order number: 2312813

12.7 REFERENCE TO GERMAN REGULATIONS AND GUIDELINES

Part 2, Chapter 2.36 Working with Liquid Ejection Devices

Part 2, Chapter 2.29 Working with Coating Materials

Explosion protection rules

Avoiding ignition risks

Equipment for cleaning work pieces with solvents

Guidelines for liquid ejection devices

Painting rooms and equipment

Plant Safety Ordinance

Note: All titles can be ordered from Heymanns Publishing House in Cologne, or they can

be found on the Internet.

65

Page 66

VERSION 03/2013 ORDER NUMBER DOC 2310799

OPERATING MANUAL

66

Page 67

Page 68

C

E

R

T

I

F

I

E

D

A

Tel.

Fax

DK

Tel.

Fax

GB

Fax

B

Tel.

Fax

CH

Tel.

Fax

D

Tel. +49 / 75 44 / 505 -1664

Fax

E

F

CZ

Tel.

Fax

Tel.

Fax

Tel.

Fax

I

Tel.

Fax

NL

Tel.

Fax

S

Tel.

Fax

Subject to changes and errors.

Loading...

Loading...