Page 1

EP2005 Piston Pump

S

P

R

A

Y

P

R

IM

E

Owner’s Manual • Notice d’utilisation • Manual del Propietario

Printed in the U. S. A.

Model Number 0295000

SprayTECH

1770 Fernbrook Lane

Minneapolis, MN 55447

Technical Assistance: 1-800-292-4637

Order Entry: 1-800-443-4500

Fax: 1-800-525-9501

www.spraytechinc.com

1299 © 1999 SprayTECH Corporation. All rights reserved. Form No. 0295627A

EnglishFrançaisEspañol

Page 2

Table of Contents

WARNING

CAUTION

General Description ................................................................2

Safety Precautions..................................................................2

Grounding Instructions ..........................................................3

Extension Cord Selection ......................................................4

Operation .................................................................................4

Purging and Priming..............................................................4

Operating the Spray Gun ......................................................5

Spraying...................................................................................6

Spraying Technique...............................................................6

Practice..................................................................................6

Cleanup ....................................................................................6

Flushing the Unit ...................................................................7

Maintenance ............................................................................7

Daily Maintenance.................................................................7

Maintaining the Fluid Section ................................................7

Cleaning the Spray Tip..........................................................9

Cleaning the Filter .................................................................9

Choosing the Correct Spray Gun Filter.................................9

Accessories .............................................................................9

Troubleshooting....................................................................10

Limited Warranty...................................................................11

Français .................................................................................12

Español ..................................................................................22

Parts Listings ........................................................................32

Main Assembly ....................................................................32

Filter Assembly (Optional) ...................................................33

Drive Assembly....................................................................34

Pressure Control Assembly.................................................36

Fluid Section Assembly ......................................................37

Spray Gun ...........................................................................38

Suction Set Assembly..........................................................38

Prime/Spray Valve Assembly...............................................39

Transducer Assembly..........................................................40

Relay ...................................................................................40

Pressure Control Assembly Wiring Diagram.......................40

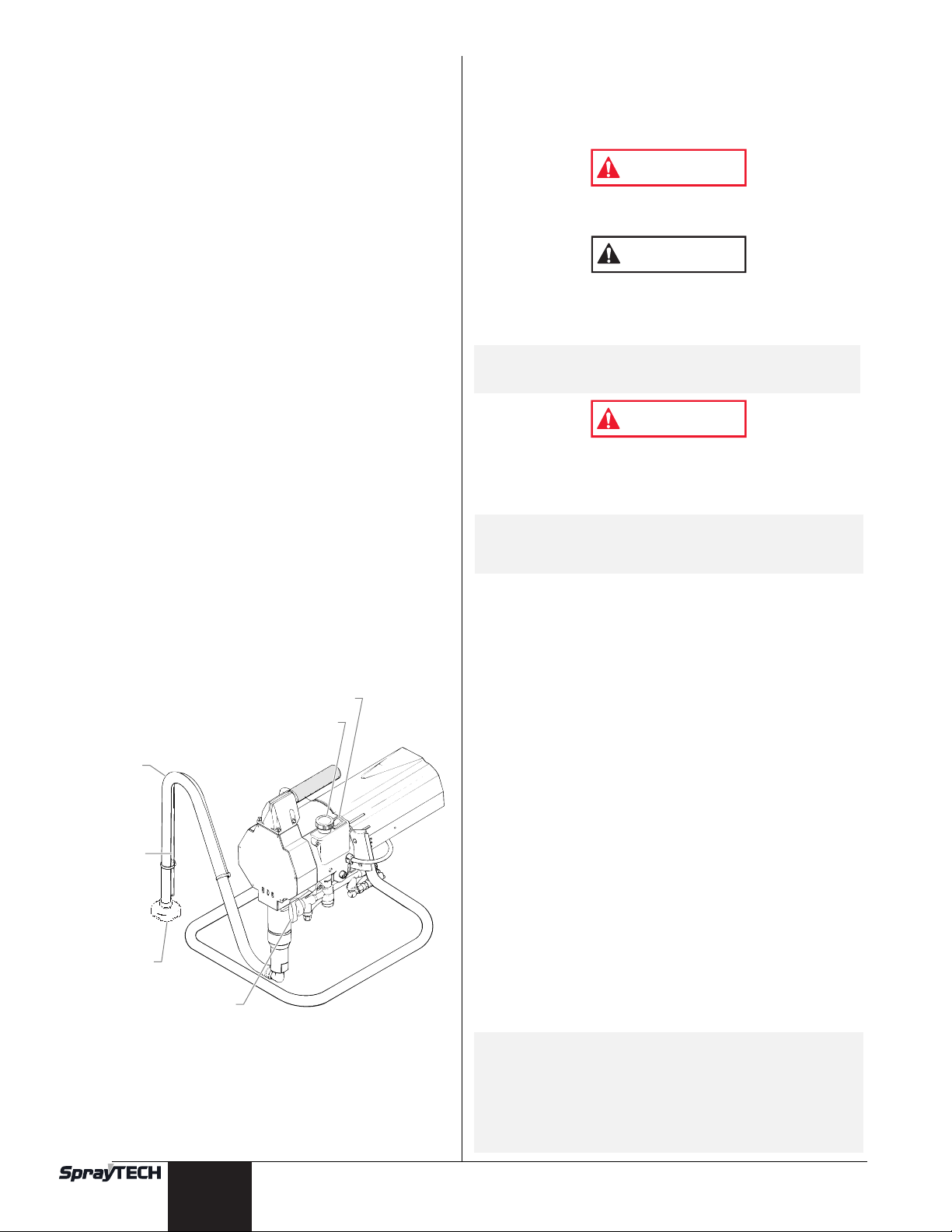

General Description

This high performance piston pump is a precision power tool

used for spraying many types of materials. Read and follow

this instruction manual carefully for proper operating

instructions, maintenance and safety information.

ON / OFF Switch

Pressure Control Knob

Suction Set

Return Tube

E

IM

SP

PR

RA

Y

Intake Screen

PRIME / SPRAY Knob

Safety Precautions

This manual contains information which must be read and

understood before using the equipment. When you come to an

area which has one of the following symbols, pay particular

attention and make certain to heed the safeguard.

WARNING

This symbol indicates a potential hazard which may cause

serious injury or loss of life. Important safety information will

follow.

This symbol indicates a potential hazard to you or to the

equipment. Important information that tells how to prevent

damage to the equipment or how to avoid causes of minor

injuries will follow.

NOTE: Notes give important information which should

be given special attention.

HAZARD: INJECTION INJURY - A high pressure stream

of paint produced by this equipment can pierce

the skin and underlying tissues, leading to

serious injury and possible amputation.

DO NOT TREAT AN INJECTION INJURY AS A

SIMPLE CUT! Injection can lead to

amputation. See a physician immediately.

PREVENTION:

• The maximum operating range of the unit is 3000 PSI fluid

pressure.

• NEVER aim the gun at any part of the body.

• NEVER allow any part of the body to come in contact with

the fluid stream. DO NOT come in contact with a fluid

stream created by a leak in the fluid hose.

• NEVER put your hand in front of the gun. Gloves will not

provide protection against an injection injury.

• ALWAYS lock the gun trigger, shut the fluid pump off and

release all pressure before servicing, cleaning the tip

guard, changing tips, or leaving unattended. Pressure will

not be released by turning off the engine. The

PRIME/SPRAY knob must be turned to PRIME to relieve

the pressure. Refer to the PRESSURE RELIEF

PROCEDURE described in this manual.

• The tip guard must always be in place while spraying. The

tip guard provides some protection against injection

injuries but is mainly a warning device.

• ALWAYS remove the spray tip before flushing or cleaning

the system.

• The paint hose can develop leaks from wear, kinking and

abuse. A leak is capable of injecting material into the skin.

Inspect the paint hose before each use.

• NEVER use a spray gun which does not have a trigger

lock or trigger guard in place and in working order.

• All accessories must be rated at or above 3000 PSI. This

includes spray tips, guns, extensions, and hose.

• In case of skin injection see physician immediately.

NOTE TO PHYSICIAN:

Injection into the skin is a traumatic injury. It is

important to treat the injury surgically as soon as

possible. DO NOT delay treatment to research toxicity.

Toxicity is a concern with some coatings injected

directly into the blood stream. Consultation with a

plastic surgeon or reconstructive hand surgeon may be

advisable.

English

2 © SprayTECH Corporation. All rights reserved.

Page 3

HAZARD: EXPLOSION OR FIRE - Solvent and paint fumes

can explode or ignite, causing property damage

and/or severe injury.

PREVENTION:

• Exhaust and fresh air introduction must be provided to

keep the air within the spray area free from accumulation

of flammable vapors.

• Avoid all ignition sources such as static electricity sparks,

open flames, pilot lights, hot objects, cigarettes, and

sparks from connecting and disconnecting power cords or

working light switches.

• Fire extinguishing equipment must be present and in good

working order.

• Keep the unit in a well ventilated location away from the

spray area to avoid solvent and paint fumes. The pump

contains arcing parts which emit sparks.

• High velocity flow of material through equipment may

develop static electricity. The equipment being used, as

well as objects in and around the spray area, must be

properly grounded to prevent static discharge and sparks.

• Use only conductive or grounded high pressure fluid

hoses for airless applications. Be sure that the gun is

grounded properly through hose connections.

• The unit must be connected to a grounded object. Use

the green grounding wire to connect the pump to a water

pipe, steel beam, or other electrically grounded surface.

• Use extreme caution when using materials with a

flashpoint below 70° F (21°C). A fluid’s flashpoint is the

temperature at which vapors from the fluid could ignite if

exposed to a flame or spark.

• Follow the material and solvent manufacturer's safety

precautions and warnings.

• When flushing equipment use the lowest possible

pressure.

HAZARD: EXPLOSION HAZARD DUE TO INCOMPATIBLE

MATERIALS- May cause property damage or

severe injury.

PREVENTION:

• Do not use bleach.

• Do not use halogenated hydrocarbon solvents such as

methylene chloride and 1,1,1 - trichloroethane. They are

not compatible with aluminum and may cause an

explosion. If you are unsure of a material’s compatibility

with aluminum, contact your coating's supplier.

HAZARD: HAZARDOUS VAPORS - Paints, solvents,

insecticides, and other materials may be

harmful if inhaled, causing severe nausea,

fainting, or poisoning.

PREVENTION:

• Use a respirator or mask whenever there is a chance that

vapors may be inhaled. Read all instructions with the

mask to ensure that it will provide the necessary

protection against the inhalation of harmful vapors.

HAZARD: GENERAL - May cause property damage or

severe injury.

PREVENTION:

• Read all instructions and safety precautions before

operating any equipment.

• Comply with all appropriate local, state, and national

codes governing ventilation, fire prevention, and

operation.

• The United States Government Safety Standards have

been adopted under the Occupational Safety and Health

Act (OSHA). These standards, particularly part 1910 of

the General Standards and part 1926 of the Construction

Standards should be consulted.

• This high pressure airless pump is designed to be used

with manufacturer authorized parts only. When using this

pump with parts that do not comply with the minimum

specifications and safety devices of the pump

manufacturer, the user assumes all risks and liabilities.

• Before each use, check all hoses for cuts, leaks, abrasion

or bulging of cover, as well as damage or movement of

couplings. If any of these conditions exist, replace the

hose immediately. Never repair a paint hose. Replace it

with another grounded hose.

• All hoses, swivels, guns, and accessories used with this

unit must be pressure rated at or above 3000 PSI.

• Do not spray on windy days.

• Wear protective eyewear.

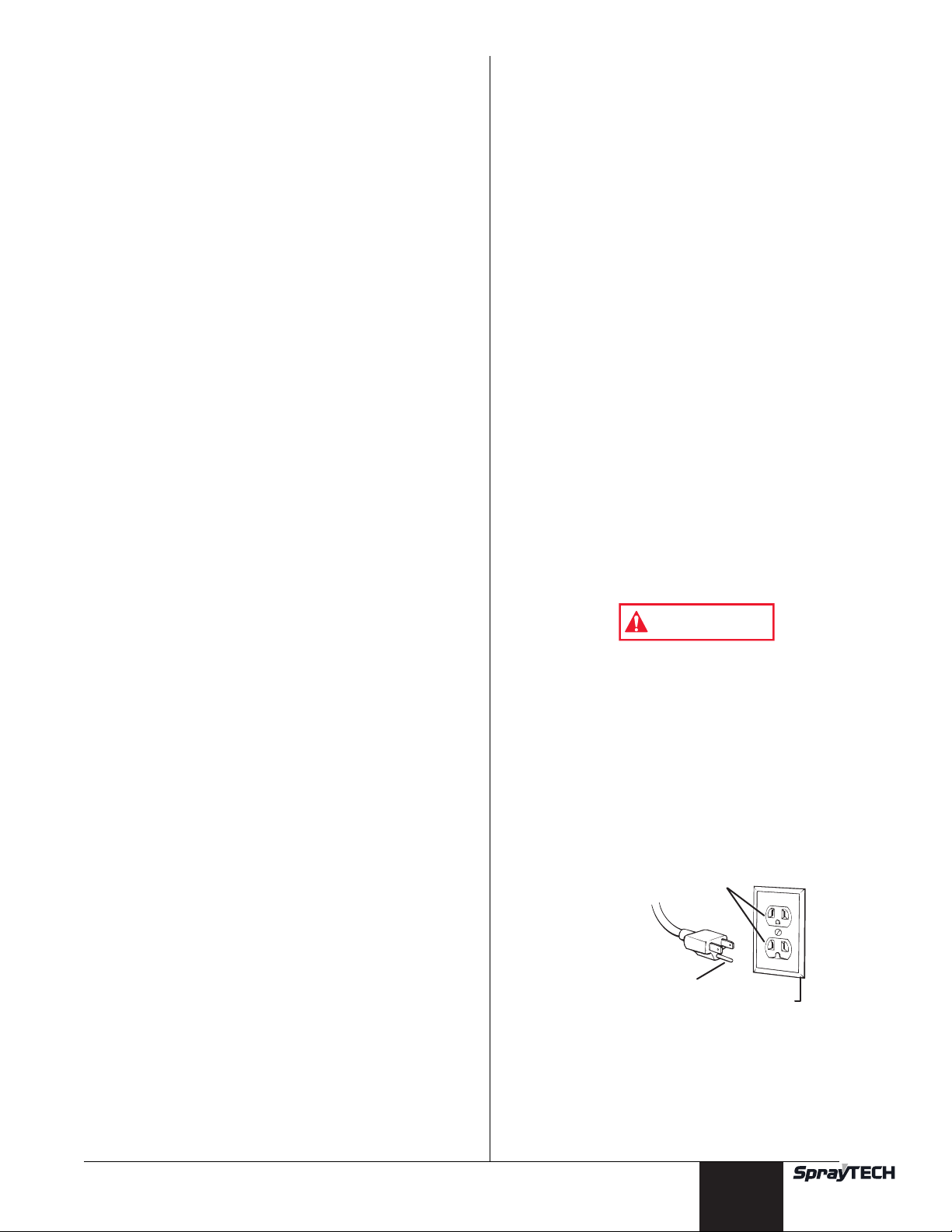

Grounding Instructions

This product must be grounded. In the event of an electrical

short circuit, grounding reduces the risk of electric shock by

providing an escape wire for the electric current. This product

is equipped with a cord having a grounding wire with an

appropriate grounding plug. The plug must be plugged into an

outlet that is properly installed and grounded in accordance

with all local codes and ordinances.

WARNING

Improper installation of the grounding plug can result in a

risk of electric shock.

If repair or replacement of the cord or plug is necessary, do not

connect the green grounding wire to either flat blade terminal.

The wire with insulation having a green outer surface with or

without yellow stripes is the grounding wire and must be

connected to the grounding pin.

Check with a qualified electrician or serviceman if the

grounding instructions are not completely understood, or if you

are in doubt as to whether the product is properly grounded.

Do not modify the plug provided. If the plug will not fit the

outlet, have the proper outlet installed by a qualified

electrician.

This product is for use on a nominal 120 volt circuit and has a

grounding plug that looks like the plug illustrated below.

Grounded Outlet

© SprayTECH Corporation. All rights reserved. 3

Grounding Pin

Cover for grounded outlet box

English

Page 4

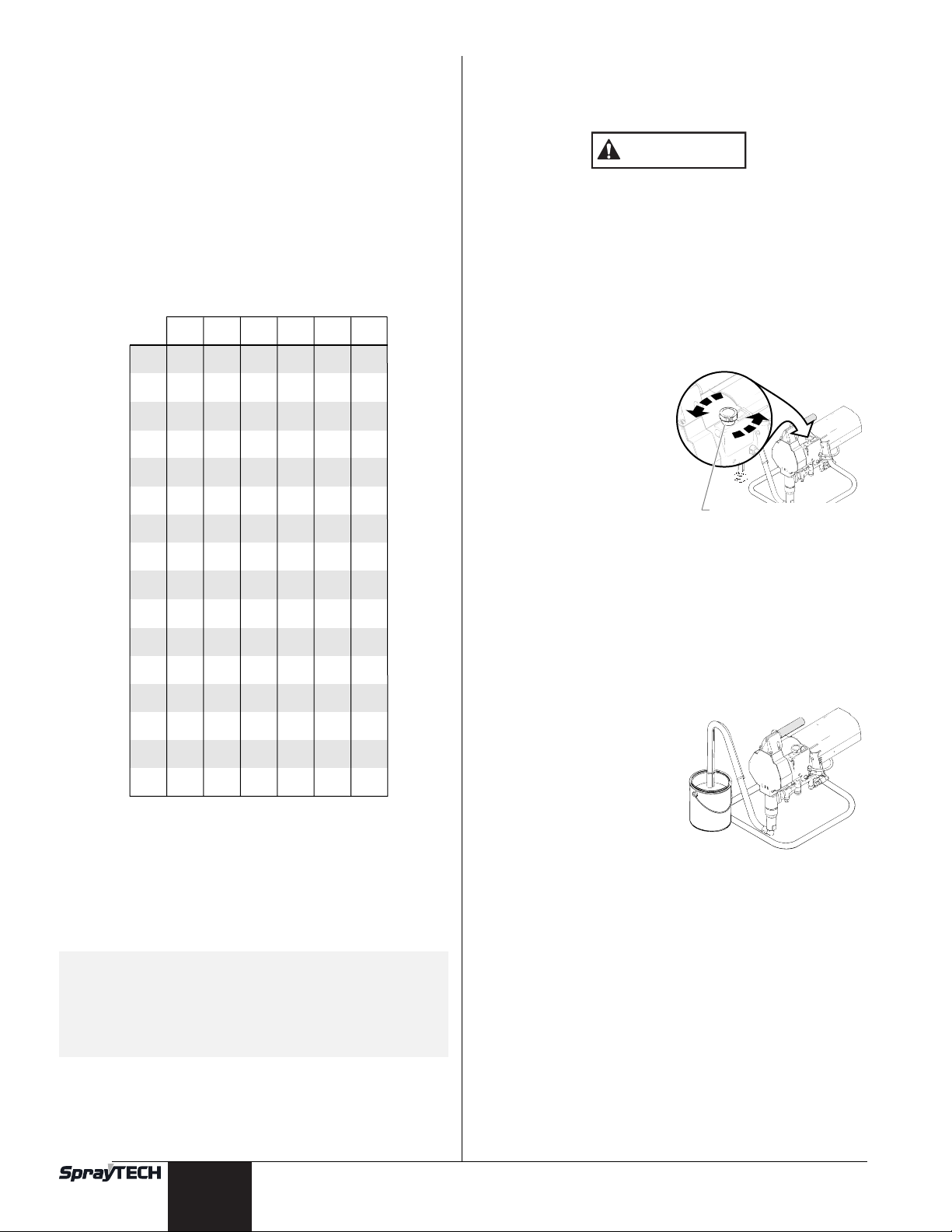

Extension Cord Selection

Extension Cord Length

Nameplate Ampere Rating

25 ft.

0 to 5 18 18 18 18 18 18

18 18 18 18 18 16

18 18 18 18 16 16

18 18 18 16 16 16

18 18 18 16 16 14

18 18 18 16 14 14

16 16 16 16 14 14

16 16 16 16 14 14

16 16 16 14 14 14

14 14 14 14 14 12

14 14 14 14 14 12

14 14 14 14 12 12

14 14 14 14 12 12

14 14 14 14 12 12

12 12 12 12 12 12

12 12 12 12 12 12

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

50 ft. 75 ft. 100 ft.125 ft.150 ft.

S

P

R

A

Y

P

R

I

M

E

SP

R

A

Y

PRI

ME

Pressure Control Knob

If an extension cord is used, make sure that it is of the 3conductor type with NEMA connectors so a continuous

grounding circuit is provided from the tool to the power circuit

receptacle. Also, be sure that the conductor size is large

enough to prevent excessive voltage drop which will cause

loss of power and possible motor damage to the unit. A table

of recommended extension cord sizes is shown below.

For nameplate ampere ratings which are between those given,

use the extension cord recommended for the next higher

ampere rating.

If an extension cord is to be used outdoors, it must be marked

with the suffix W-A following the cord type designation. For

example, SJTW-A to indicate that it is acceptable for outdoor

use.

Use only a 3-wire extension cord that has a 3-blade grounding

plug and a 3-slot receptacle that will accept the plug on the

product. Make sure your extension cord is in good condition.

When using an extension cord, be sure to use one heavy

enough to carry the current your product will draw. An

undersized cord will cause a drop in line voltage resulting in

loss of power and overheating. A 14 or 12 gauge cord is

recommended.

NOTE: Do not use more than 100 feet of extension

cord. If you need to paint further than 100 feet

from your power source, use more paint hose,

not more extension cord. Shorter extension

cords will ensure maximum electrical power for

proper operation.

Operation

Purging and Priming

CAUTION

Always keep the spray gun locked in the off position while

purging the system.

If this unit is new, it is shipped with test fluid in the fluid section

to prevent corrosion during shipment and storage. If you are

going to spray with latex paint, this fluid must be thoroughly

cleaned out of the system. For spraying with solvent-based

paint, thorough cleaning of this material is not necessary.

If it is already in service, you will need to purge the water or

solvent used in cleanup.

Purging and Priming the Pump for Latex Paint

1. Secure the return hose into a waste container.

2. Place a bucket of soapy water under the suction tube.

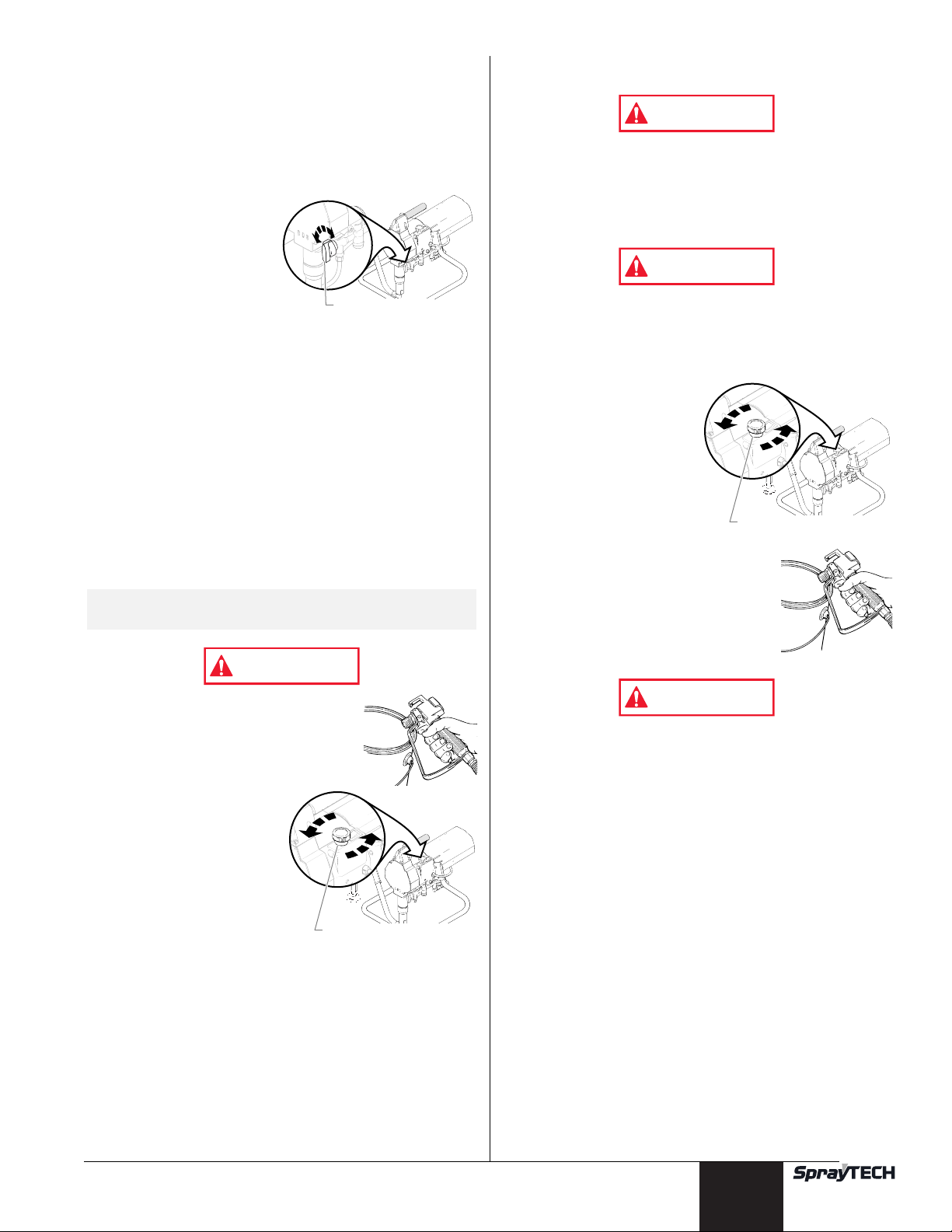

3. Turn the pressure control

knob fully counterclockwise

to reduce the pressure to

its lowest setting.

4. Set the PRIME/SPRAY

valve to PRIME.

5. Turn the ON/OFF switch to

ON.

6. Slowly turn the pressure

control knob clockwise to

increase the pressure until fluid starts to come out of the

return hose. Use only enough pressure to keep the fluid

coming out.

7. Turn the pressure control knob fully counterclockwise to

its lowest setting when the test fluid is purged and soapy

water is coming out of the return hose.

8. Remove the bucket of soapy water from the suction tube

and replace it with a bucket of clear water.

9. Increase the pressure to the minimum necessary to keep

fluid flowing until clear water is coming out of the return hose.

10. Turn the pressure control knob fully counterclockwise to

its lowest setting.

11. Remove the bucket of water

from under the suction tube

and replace it with a

container of latex paint.

12. Increase the pressure slowly

until paint is coming through

the return hose.

13. Remove the return hose

from the waste container and

place it in its operating

position above the container of latex paint.

14. Keep circulating the paint through the system until the

paint coming out of the return hose is free of air bubbles.

15. Turn the pressure control knob fully counterclockwise to

its lowest setting.

The pump is now purged. Skip to Purging and Priming the

Spray Hose.

English

4 © SprayTECH Corporation. All rights reserved.

Page 5

Purging and Priming for Solvent-Based Paint

SPRAY

PRIME

Pressure Control Knob

WARNING

S

P

R

A

Y

P

R

I

M

E

SP

R

A

Y

P

R

IM

E

PRIME/SPRAY Knob

S

P

RA

Y

P

R

IM

E

Pressure Control Knob

WARNING

Thorough cleaning is not necessary when using solvent-based

paint. All you need to do is purge the test fluid from the

system.

1. Secure the return hose into a waste container.

2. Place a full container of paint under the suction tube.

3. Turn the pressure control knob fully counterclockwise to

reduce the pressure to its lowest setting.

4. Set the PRIME/SPRAY

valve to PRIME.

5. Turn the ON/OFF switch

to ON.

6. Slowly turn the pressure

control knob clockwise to

increase the pressure

until fluid starts to come

out of the return hose.

Use only enough pressure to keep the fluid coming out.

7. Turn the pressure control knob fully counterclockwise to

its lowest setting when the test fluid is purged and paint is

coming out of the return hose.

8. Remove the return hose from the waste container and

place it in its operating position above the container of

solvent-based paint.

9. Keep circulating the paint through the system until the

paint coming out of the return hose is free of air bubbles.

10. Turn the pressure control knob fully counterclockwise to

its lowest setting.

The pump is now purged. Skip to Purging and Priming the

Spray Hose.

Purging and Priming the Spray Hose

After the pump is purged and primed, you must do the same

for the spray hose.

NOTE: Make certain that the spray gun has no tip

installed.

Operating the Spray Gun

WARNING

POSSIBLE INJECTION HAZARD. Do not spray without the

tip guard in place. Never trigger the gun unless the tip is

in either the spray or the unclog position. Always engage

the gun trigger lock before removing, replacing or

cleaning tip.

Pressure Relief Procedure

Be sure to follow the pressure relief procedure when

shutting the unit down for any purpose, including

servicing or adjusting any part of the spray system,

changing or cleaning spray tips, or preparing for cleanup.

1. Lock the gun by turning the gun trigger lock to the locked

position.

2. Turn the motor off.

3. Turn the pressure control

knob counterclockwise to

its lowest setting.

4. Turn the PRIME/SPRAY

knob to PRIME.

5. Unlock the gun by turning

the gun trigger lock to the

unlocked position.

6. Hold the metal part of the gun firmly to

the side of a metal container to ground

the gun and avoid a build up of static

electricity.

7. Trigger the gun to remove any pressure

that may still be in the hose.

8. Lock the gun by turning the gun trigger

lock to the locked position.

If a metal container is used, ground the

gun by holding it against the edge of the

container while flushing. Failure to do

so may lead to a static electric discharge

which may cause a fire.

1. Turn the pressure control

knob fully counterclockwise

to its lowest setting.

2. Set the PRIME/SPRAY

knob to SPRAY.

3. Unlock the spray gun.

4. Turn the pressure control

knob slowly clockwise to

increase pressure.

5. Trigger the gun into a

waste container until all air, water or solvent is purged

from the spray hose and paint is flowing freely.

6. Turn the pressure control knob fully counterclockwise to

its lowest setting.

7. Set the PRIME/SPRAY knob to PRIME and trigger the gun

into the waste container to be sure that no pressure is left

in the hose.

8. Lock the spray gun off.

© SprayTECH Corporation. All rights reserved. 5

WARNING

POSSIBLE INJECTION HAZARD. Do not spray without the

tip guard in place. Never trigger the gun unless the tip is

in either the spray or the unclog position. Always engage

the gun trigger lock before removing, replacing or

cleaning tip.

English

Page 6

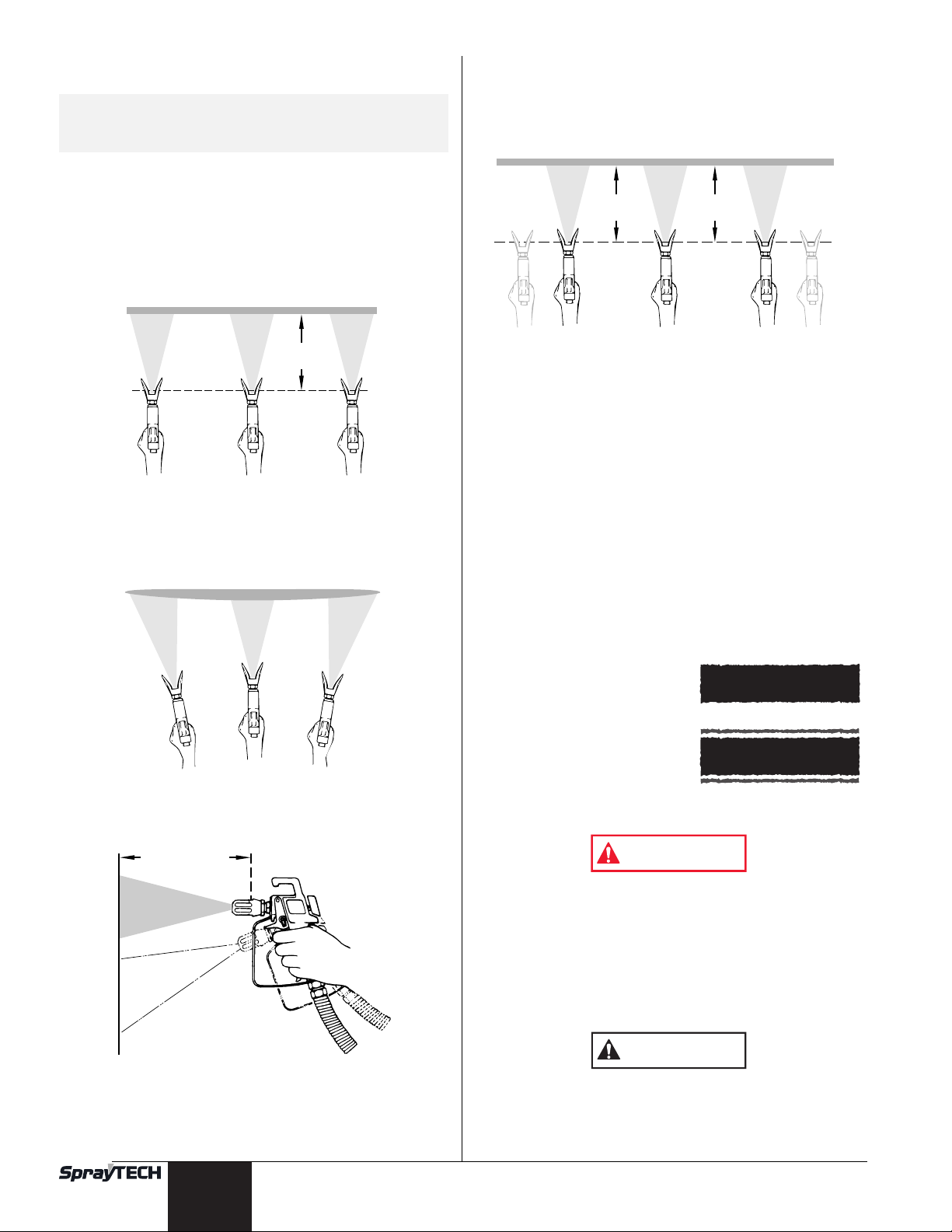

Spraying

Approximately

10 to 12 inches

Right way

Wrong way

Heavy Coat

Do not flex wrist while spraying.

Light Coat Light Coat

Keep stroke smooth and at an even speed.

Even coat throughout

Approximately

10 to 12 inches

CAUTION

Proper way to trigger the spray gun

Approximately

10 to 12 inches

Keep stroke

even

Start stroke End strokePull trigger Release triggerKeep steady

NOTE: When spraying block filler, mastics or high

solid coating, leave out the gun filter and high

pressure filter screens.

Spraying Technique

The key to a good paint job is an even coating over the entire

surface. This is done by using even strokes. Keep your arm

moving at a constant speed and keep the spray gun at a

constant distance from the surface. The best spraying

distance is 10 to 12 inches between the spray tip and the

surface.

Keep the spray gun at right angles to the surface. This means

moving your entire arm back and forth rather than just flexing

your wrist.

Keep the spray gun perpendicular to the surface, otherwise

one end of the pattern will be thicker than the other.

The spray gun should be triggered by turning it on and off with

each stroke. This will save paint and avoid paint buildup at the

end of the stroke. Do not trigger the gun during the middle of

a stroke. This will result in an uneven spray and splotchy

coverage.

Overlap each stroke by about 30%. This will ensure an even

coating.

When you stop painting, lock the gun trigger lock, turn the

pressure control knob counterclockwise to its lowest setting

and set the PRIME/SPRAY valve to PRIME. Turn the motor

switch to OFF and unplug the sprayer.

Practice

1. Be sure that the paint hose is free of kinks and clear of

objects with sharp cutting edges.

2. Turn the pressure control knob counterclockwise to its to

its lowest setting.

3. Turn the PRIME/SPRAY valve to SPRAY.

4. Turn the pressure control knob clockwise to its highest

setting. The paint hose should stiffen as paint begins to

flow through it.

5. Unlock the gun trigger lock.

6. Trigger the spray gun to bleed air out of the hose.

7. When paint reaches the spray tip, spray a test area to

check the spray pattern.

8. Use the lowest pressure

setting necessary to get a

good spray pattern. If the

pressure is set too high, the

spray pattern will be too light.

If the pressure is set too low,

tailing will appear or the paint

will spatter out in gobs rather

than in a fine spray.

Good spray pattern

Paint tailing pattern

Cleanup

English

WARNING

Special cleanup instructions for use with flammable

solvents:

• Always flush spray gun at least one hose length from

spray pump.

• If collecting flushed solvents in a one gallon metal

container, place it into an empty five gallon container, then

flush solvents.

• Area must be free of flammable vapors.

• Follow all cleanup instructions.

The pump, hose, and gun should be cleaned thoroughly

after daily use. Failure to do so permits material to cake,

seriously affecting the performance of the unit.

6 © SprayTECH Corporation. All rights reserved.

Page 7

Always spray at minimum pressure with the gun nozzle tip

Housing

Intake Screen

S

P

R

A

Y

P

R

I

M

E

S

P

R

A

Y

P

R

IM

E

PRIME/SPRAY Knob

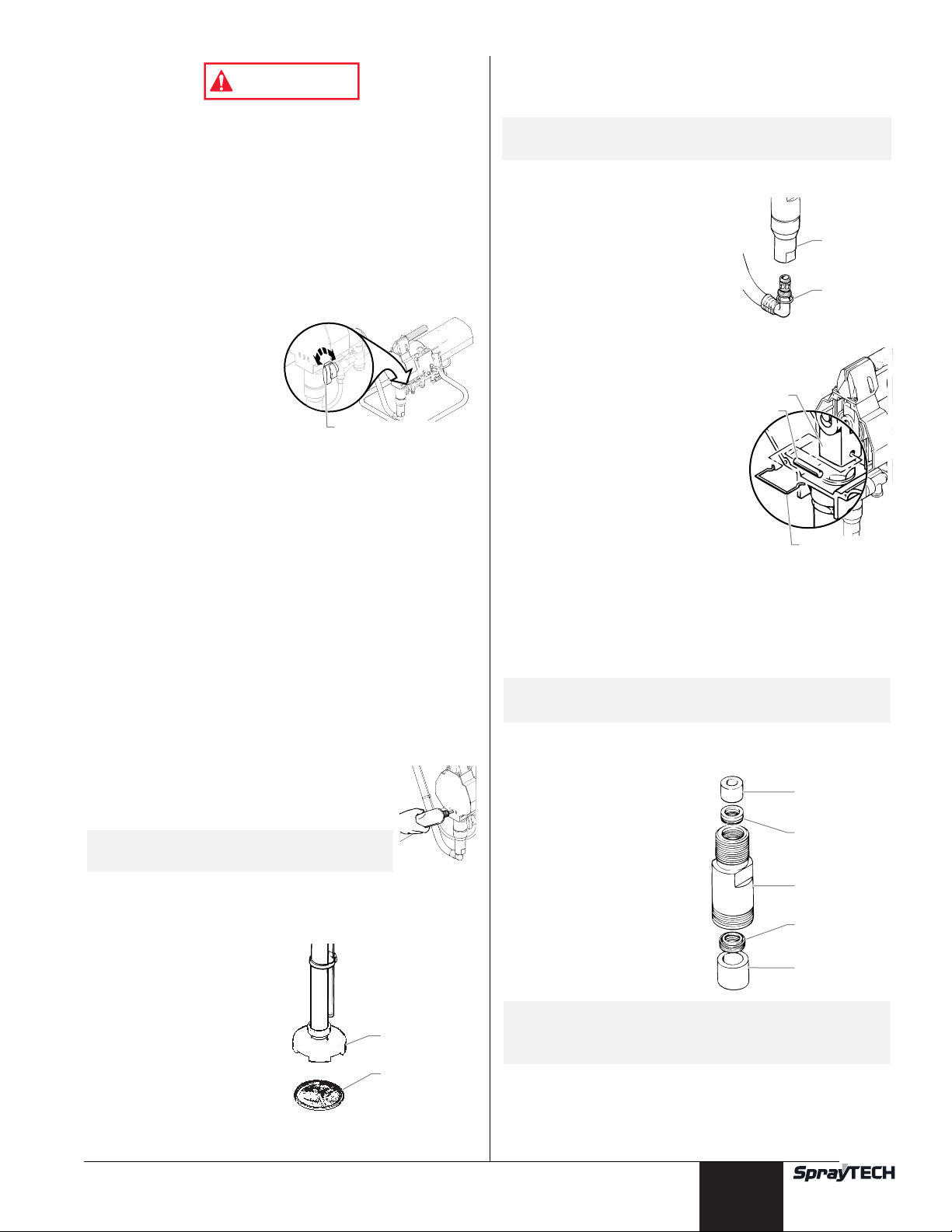

WARNING

Retaining

Ring

Inlet Valve

Housing

removed when using mineral spirits or any other solvent

to clean the pump, hose, or gun. Static electricity buildup

may result in a fire or explosion in the presence of

flammable vapors.

Flushing the Unit

Flush the unit with the solvent appropriate to the material

being used after daily use (use solvents at room temperature).

The unit should then be flushed again with mineral spirits.

For long term storage, flush the unit with an appropriate oil

before storing.

1. Follow the pressure relief procedure found earlier in this

manual.

2. Turn the PRIME/SPRAY

valve to SPRAY to bleed

off any pressure

remaining in the pump.

3. Remove the gun tip and

clean with a solution

appropriate to the type of

material being sprayed.

4. Remove the material

container and replace it with a container of solvent

appropriate to the type of material being sprayed.

5. Check to be sure the pressure control knob is turned fully

counterclockwise to its lowest setting.

6. Turn the power switch to ON.

7. Trigger the spray gun into a waste container until solvent

comes out and the pump, hose, and gun are clean.

8. Follow the pressure relief procedure found earlier in this

manual.

9. Make certain that the power switch is turned to OFF.

10. Turn the PRIME/SPRAY valve to SPRAY to bleed off any

remaining solvent.

11. Unplug the unit and store in a clean, dry area.

Maintenance

Daily Maintenance

Perform the following procedures daily.

Filling the Packing Nut Reservoirs With Oil

Before you start to spray each day, squirt a

lubricant such as hydraulic oil into the slots in the

upper pump housing. Household oil and cooking

oil also work when hydraulic oil is not available.

NOTE: Do not apply so much that it

overflows and drips into the paint.

This lubricant keeps the piston seals pliant, minimizing paint

bypass and piston wear. If the unit is operated several hours a

day, lubricate approximately every 4 hours.

Cleaning the Intake Screen

1. Remove the intake screen

and clean with a solvent

appropriate to the type of

material being used.

Maintaining the Fluid Section

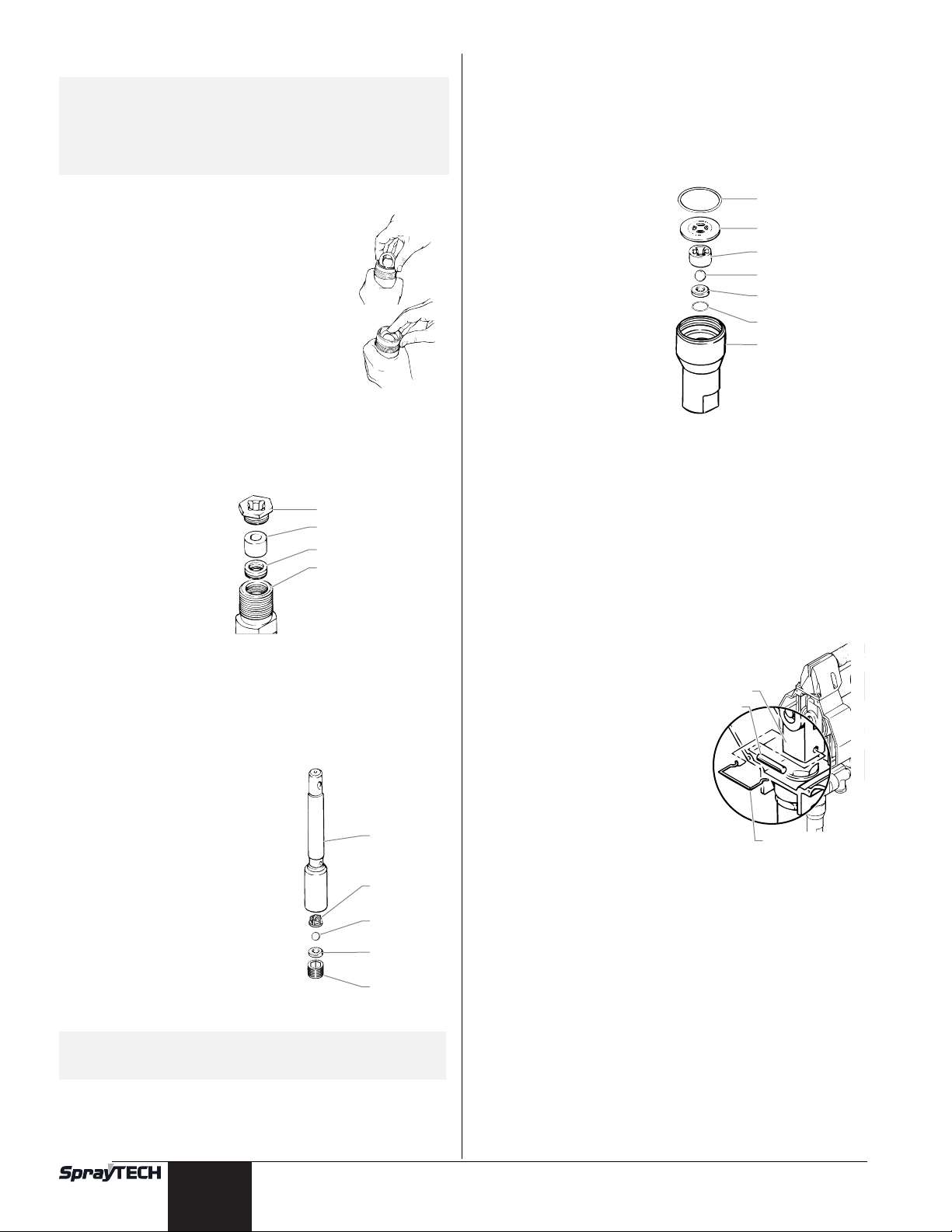

Servicing the fluid section includes replacing the T-lip

packings, the piston, and valve parts that show signs of wear.

NOTE: If any parts are difficult to disassemble, soak them

Removing the Fluid Section

1. Using a flat blade screwdriver, pry

2. Unscrew the fluid hose from the

3. Loosen and turn the return line

4. Unscrew the 6 screws holding the

5. Pull the retaining clip from the

6. Push the pin out of the piston and

7. Loosen the locknut at the top of

8. Unscrew the fluid section

Maintaining the T-lip Packings

Removing the T-lip Packings

1. Place the wrench flats of the inlet valve housing into a

2. Unscrew the packing nut from the fluid section.

NOTE: When removing the piston, keep the piston

3. Push the piston out through the lower end of the fluid

4. Remove the upper and

E

IM

R

S

P

P

R

A

Y

5. Push the T-lip packings out

NOTE: When removing the T-lip packings, be careful

in an appropriate solvent until the paint softens.

the retaining ring out of the

bottom of the inlet valve housing

and remove the suction set

assembly.

fluid section assembly.

fitting away from the fluid section

assembly.

cover to the front of the pump

housing and remove the cover.

yoke and pin.

Yoke

Pin

yoke. Use the short end of a hex

wrench if necessary.

the fluid section assembly.

assembly from the pump.

Retaining Clip

vise and unscrew the fluid section from the inlet valve

housing.

from falling or the piston may be damaged.

section. Tap the top of the piston with a rubber mallet if

necessary.

lower spacers from the fluid

Upper Spacer

section.

of the fluid section with a

screwdriver. To push out

Upper T-lip

Packing

the upper seal, insert the

screwdriver through the

lower end of the fluid

Fluid Section

Cylinder

section. To push out the

lower seal, insert the

screwdriver through the

Lower T-lip

Packing

upper end of the fluid

section.

Lower Spacer

not to scrape or gouge the inside surface of the

fluid section with the screwdriver.

© SprayTECH Corporation. All rights reserved. 7

English

Page 8

Replacing the T-lip Packings

Piston

Outlet Ball

Guide

Outlet Ball

Outlet Ball

Seat

Piston Seat

Retainer

Fluid Section

Cylidner

Upper T-lip Packing

Upper Spacer

Packing Nut

Yoke

Pin

Retaining Clip

NOTE: For maximum lower T-lip packing life, use a

1. Apply a light coat of household oil to the new lower T-lip

2. Turn the T-lip packing inside the fluid

3. Push the lower T-lip packing as far into

4. Insert the lower spacer into the fluid

5. Apply a light coat of household oil to the

6. Thread the packing nut into the fluid section to push the

7. Insert the upper

8. Push the upper spacer

9. Screw the packing nut

packing guide tool (see fluid section parts list

for part number) to insert the lower T-lip

packing into the cylinder. If you do not have a

packing guide tool, follow steps 1 – 2 of the

procedure below.

packing and insert it edge-first into the lower end of the

fluid section.

section cylinder so that the springs of the

T-lip packing face into the cylinder. To do

this, hold the lower edge of the T-lip

packing in place while pressing the upper

edge further into the cylinder.

the fluid section as it will go.

section.

new upper T-lip packing and place it into the upper end of

the fluid section. Position the T-lip packing so that it is

level and the springs of the T-lip packing face into the

cylinder.

upper T-lip packing farther into the cylinder, then remove

the packing nut.

spacer into the fluid

section.

as far into the fluid

section as it will go.

into the fluid section.

Torque to 25-30 ft./lbs.

Maintaining the Valves

Replacing the Piston and Worn Parts of the Outlet Valve

1. Turn the piston upside down and use a hex wrench to

remove the piston seat retainer from the lower end of the

piston.

2. Cover the open end of the piston and turn the piston rightside up again to remove the outlet ball seat and outlet ball.

3. Insert a new outlet ball guide into

the new piston. The open end of

the ball guide should face the

open end of the piston. Use the

head of a long nail or screw to

seat the ball guide past the

threads inside the piston if

necessary.

4. Insert a new outlet ball into the

outlet ball guide.

5. Check the outlet ball seat for

wear. If worn, insert a new ball

seat into the piston on top of the

ball.

6. Apply an appropriate threadlocking compound to the threads

of the piston seat retainer.

NOTE: Do not put the new piston into a vise. Putting

the piston into a vise may damage the piston.

English

7. Screw the piston seat retainer into the lower end of the

piston. Torque the retainer to 12 ft./lbs.

8. Apply a light coat of household oil to the piston and insert

it, shaft first, into the lower end of the fluid section until it

seats. Tap the bottom of the piston gently with a rubber

mallet if necessary.

Replacing Worn Parts of the Inlet Valve

1. Remove the O-ring from the inlet valve housing.

2. Cover the top of the inlet

valve housing and turn it

upside down to remove

the inlet ball stop disk,

inlet ball guide, inlet ball,

inlet ball seat, and inlet

ball seal.

3. Insert a new inlet ball seal

into the inlet valve

housing.

4. Check the inlet ball seat

for wear. If worn, insert a

new ball seat into the

housing.

5. Place a new inlet ball on

the inlet ball seat in the

housing.

6. Place the inlet ball guide over the inlet ball.

7. Place the inlet ball stop plate over the ball guide.

8. Insert a new O-ring into the inlet valve housing.

9. Place the wrench flats of the inlet valve housing into a

vise and screw the fluid section into the inlet valve

housing. Torque the inlet valve housing to 85-95 ft./lbs.

O-Ring

Ball Stop Plate

Inlet Ball Guide

Inlet Ball

Inlet Ball Seat

Inlet Ball Seal

Inlet Valve

Housing

Attaching the Fluid Section

1. Turn the locknut on the fluid section until it reaches the

bottom of the threads.

2. Thread the fluid section into the pump housing.

3. Rotate the fluid section to align the hole in the piston shaft

with the holes in the yoke.

4. Insert the pin through the yoke

and piston.

5. Snap the retaining clip around

the pin and yoke.

6. Screw the fluid section into the

pump housing as far as it will

go, then unscrew it slightly so

that the fluid hose fitting will

align with the fluid hose.

7. Firmly tighten the locknut at the

top of the fluid section assembly

against the pump housing using

an adjustable wrench.

8. Tighten the return line fitting

back to its original position.

9. Fill the reservoirs in the packing nut with hydraulic oil.

10. Replace the pump housing cover and screw in the 6

screws that hold it in place.

11. Tighten the fluid hose onto the fluid hose fitting on the fluid

section.

12. Insert the elbow on the suction set asssembly into the

bottom of the inlet valve housing.

13. Push the retaining ring up into the groove inside the inlet

valve housing to secure the suction set assembly in

position.

8 © SprayTECH Corporation. All rights reserved.

Page 9

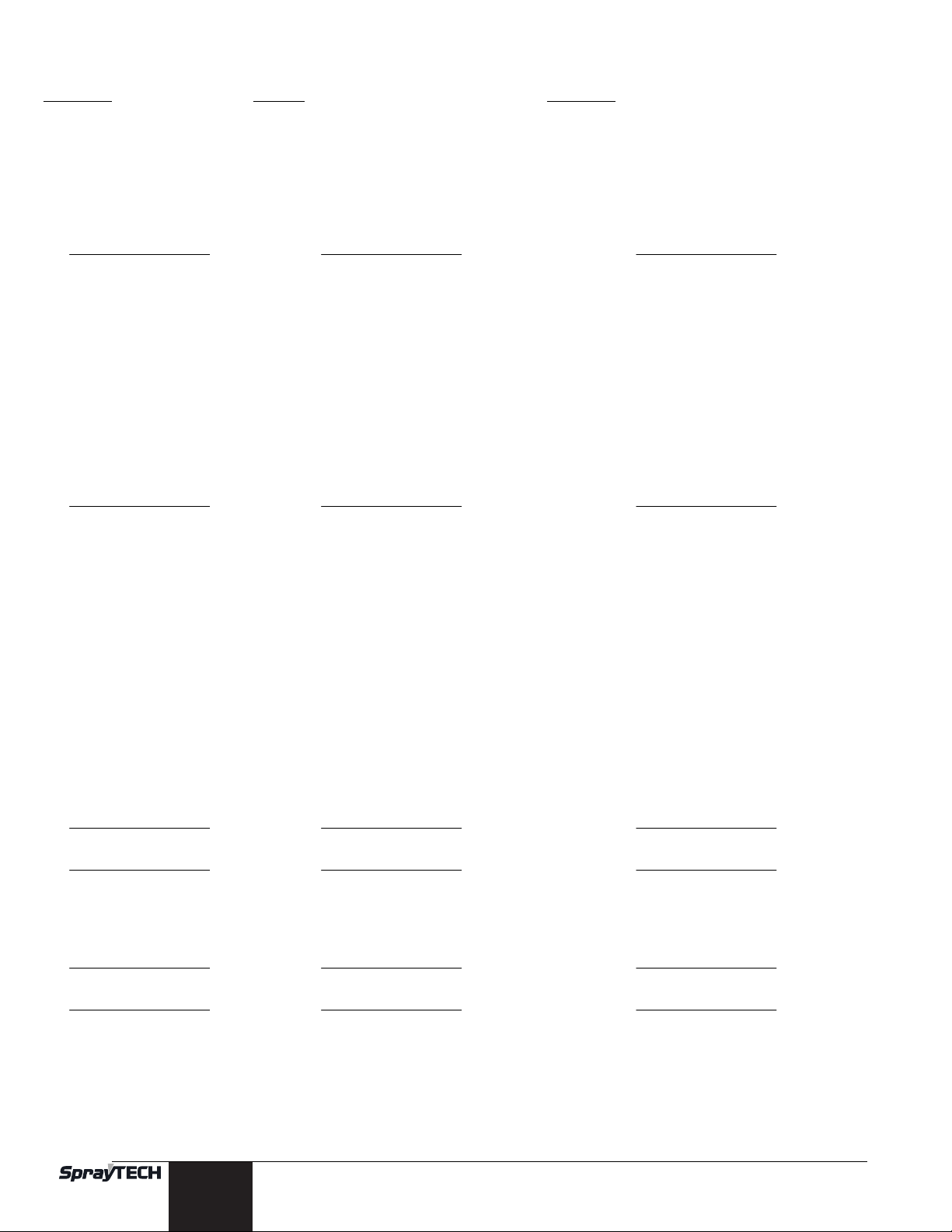

Cleaning the Spray Tip

Gun Housing

Valve Spring

Unit

Sliding Pin

Nut

Retainer Block

Diffuser

Gun Housing

Filter

Handle

WARNING

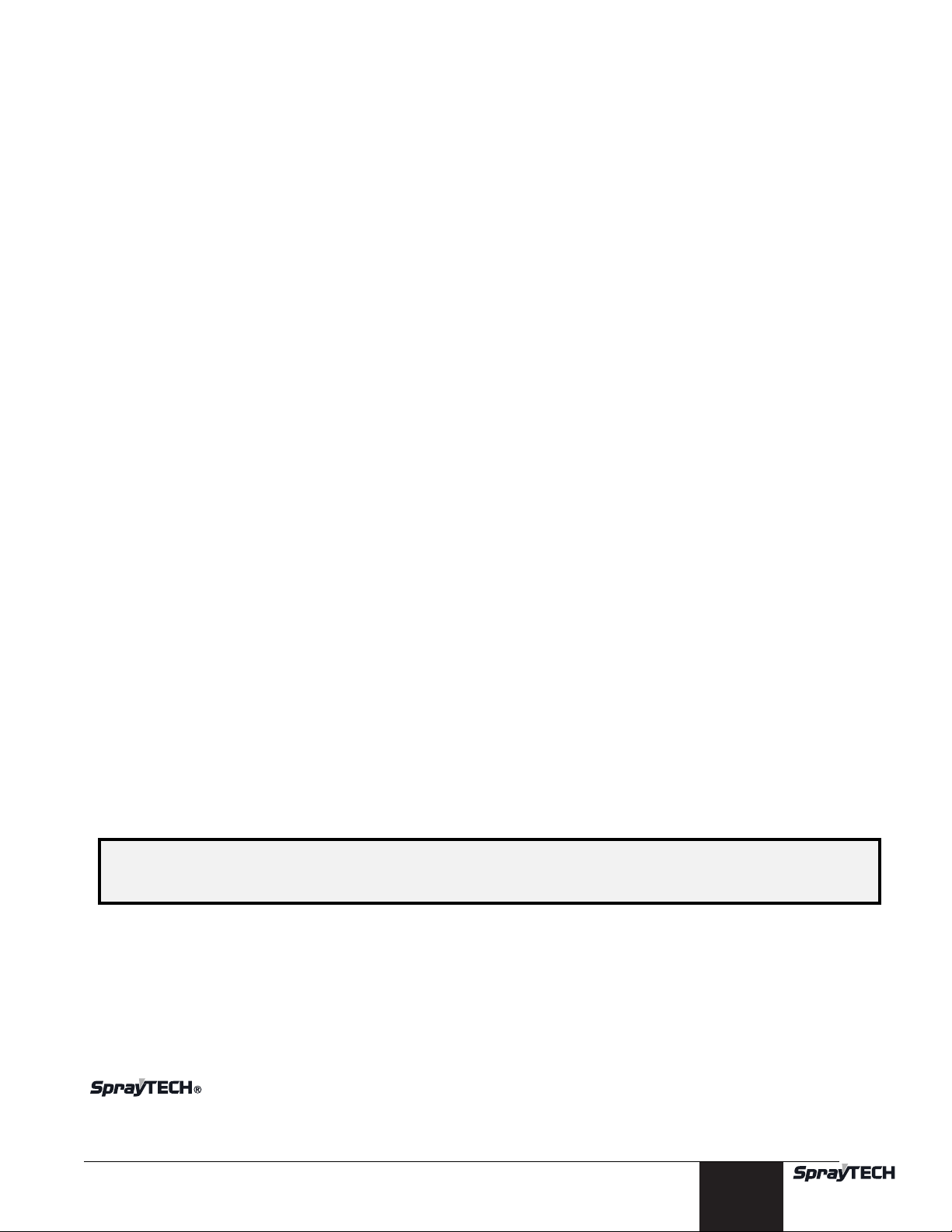

Part no. Application Filter

type

Mesh

number

Color of

Filter

body

0089960 Synthetic resin,

enamels, clean

varnishes, stains

azures

Extrafine 0.084 mm red

0089959 Base coat enamels,

primer enamels,

fillers, marking paints,

textured enamels

Fine 0.140 mm yellow

0089958 Emulsions,

latex paints,

acrylic paints

Medium 0.315 mm white

0089957 Filler paints,

large area surfaces

Coarse 0.560 mm green

1. Flush the gun with solvent immediately after the work is

completed.

2. Oil the sliding pins to prevent them from seizing up.

Should the spray tip become clogged,

reverse the spray tip with the lever and

pull the trigger. Once the obstruction

comes out of the spray tip, release the

trigger, reverse the spray tip back to the

spray pattern setting, and resume

spraying.

Do not attempt to clean the tip with your finger.

Do not use a needle or other sharp pointed instrument to

clean the tip. The hard tungsten carbide is brittle and can

be chipped.

Cleaning the Filter

Clean the filter with a brush dipped in solvent. Never poke the

filter with a sharp instrument.

Changing the Filter

1. Pull the trigger guard forward

so that it comes loose from

the handle.

2. Unscrew the handle from the

housing and remove the old

filter.

3. Slide the new filter, taper end

first, into the gun housing.

4. Replace the handle, washer

and spring. Screw the handle

into the housing until handtight. Replace the trigger

guard.

Replacing the Valve Spring Unit

NOTE: Replace the packing if the spray gun is

1. Unscrew the spray tip.

2. Lock the gun in the ON position and remove the diffuser

3. Unlock the gun.

4. Unscrew the nut

5. Remove the

6. Drive the valve

© SprayTECH Corporation. All rights reserved. 9

disassembled. Replace the sliding pins if they

are worn.

with a wrench

with a wrench

and remove the

retainer block.

sliding pins with

care and store

them in a safe

place so they will

not be lost.

spring unit

forward from the back of the retainer block. Use the

handle of a wooden hammer or similar soft tool to avoid

damaging the valve spring unit.

Choosing the Correct Spray Gun Filter

Use the proper gun filter based on the type of material being

applied as shown below.

Accessories

Part No.

0297xxx RC Tip Assembly

0502xxx Replacement Core, RC Tip

0297078 Tip Guard, RC Tip (11/16”)

0297070 Tip Guard, RC Tip (7/8”)

0291004 Hose, Whip End, 3' x 3/16"

0291003 Hose, Whip End, 5’ x 3/16”

0291002 Hose, Wireless, 25’ x 1/4"

0291000 Hose, Wireless, 50’ x 1/4"

0093896 Hose Connector, 1/4” x 1/4”M

0088154 Pressure Gauge

0152001 Power Roller Gun Attachment

0152308 9" Roller Cover, 3/8” Nap

0152307 9" Roller Cover, 1/2” Nap

0152309 9" Roller Cover, 3/4” Nap

0152310 9" Roller Cover, 1-1/4” Nap

0152235 12" Roller Cover, 1/2" Nap

0152236 12" Roller Cover, 3/8" Nap

0152237 12" Roller Cover, 3/4" Nap

0152238 12" Roller Cover, 1-1/4" Nap

0152700 Adapter, Power Roller Extension

0270145 G-10 Four Finger Airless Spray Gun (no tip)

0093930 Anti-Seize Compound

0152909 R-10 Telescoping Roller, 9", 3/8" Nap

0152900 R-10 Telescoping 12" Roller, 3/8" Nap

0502007 G-10 Four Finger Airless Spray Gun with 517

0502011 G-10 Two Finger Airless Spray Gun (no tip)

0502009 G-10 Two Finger Airless Spray Gun with 517

0270214 G-10 Four Finger Spray Pack with 50’ x 1/4”

0502012 G-10 Two Finger Spray Pack with 50” x 1/4”

Description

Reversible Tip

Reversible TIp

airless hose

Airless Hose

English

Page 10

Problem

The unit will not run.

Troubleshooting

Cause

1. Blown panel fuse or tripped breaker.

2. The unit is not plugged in.

3. The pressure control knob is set too

low.

4. Faulty or loose wiring.

5. Worn motor brushes.

6. Faulty on/off switch fuse.

Solution

1. Check and replace or reset.

2. Plug the unit in.

3. Turn the knob clockwise to increase the

pressure.

4. Inspect and take to a SprayTECH authorized

service center.

5. Take to a SprayTECH authorized service

center.

6. Take to a SprayTECH authorized service

center.

The unit will not prime.

The unit will not build or

maintain pressure.

1. The piston packings are dried out.

2. The pump inlet screen is plugged.

3. There is air in the pump or hose.

4. The packings are worn.

5. The fluid is too viscous.

6. The suction tube is clogged.

7. The suction tube has an air leak.

1. The pressure adjusting knob is not

properly set.

2. The pump intake screen is dirty.

3. The PRIME/SPRAY valve balls or seals

are worn or dirty.

4. There is air in the pump or hose.

5. The packings are worn.

6. The spray tip is worn.

7. There is internal leakage.

8. There is a fluid leak.

9. The fluid is too viscous.

10. The spray tip is too large.

1. Remove the suction tube and feel the lower

ball check to be sure it is free to move off its

seat. Place a full cup of paint thinner over the

end of the fluid section and turn the pump on.

2. Remove the screen and clean.

3. Trigger the gun and run the unit for about 10

seconds until air is purged.

4. Replace the packings.

5. Prime the pump with a solvent appropriate to

the material being used. Carefully remove the

pump from the solvent container and immerse

the suction tube in heavy material to be

sprayed. With the nozzle tip removed, trigger

the gun until the heavy material appears at the

gun. Replace the nozzle tip.

6. Remove the suction tube and clean.

7. Check the connection and seal.

1. Turn the pressure control knob clockwise to

increase the pressure.

2. Remove and clean the intake screen.

3. Replace or clean.

4. Trigger the gun and run the unit for about 10

seconds until the air is purged.

5. Replace the packings.

6. Replace the spray tip following the instructions

that came with your gun.

7. With the gun trigger closed, allow the unit to

pump up to pressure and shut off. If the pump

momentarily starts, internal leakage is

indicated and fluid section repacking or valve

replacement is necessary.

8. Check for external leaks including hydraulic

fittings attached to the pressure control

housing.

9. Consult the manufacturer's recommendations

on the material container.

10. Replace the spray tip following the instructions

that came with your gun.

Fluid leakage at the upper end

of the fluid section.

Poor spray pattern.

The unit lacks power.

Blown fuses at the pump.

English

1. The upper packings are worn.

2. The piston rod is worn.

1. The spray tip is too large for the

material being used.

2. The pressure adjustment is wrong.

3. Insufficient fluid delivery.

4. The fluid is too viscous.

1. The pressure adjustment is too low.

2. Improper voltage supply.

1. There is excessive pressure.

2. A circuit breaker has tripped.

3. The gear box, linkage, or motor has

failed.

10 © SprayTECH Corporation. All rights reserved.

1. Relieve the pressure or replace the packings.

2. Replace the piston rod.

1. Change to a smaller tip.

2. Adjust the pressure control knob.

3. Clean all screens and filters.

4. Add solvent according to the manufacturer's

recommendations.

1. Increase the pressure.

2. Reconnect the input voltage for 120V AC.

1. Take to a SprayTECH authorized service

center.

2. Take to a SprayTECH authorized service

center.

3. Repair or replace the malfunctioning parts.

Page 11

Limited Warranty

Commercial Airless Spray Equipment

Two Year Warranty

Spray Tech, a division of Wagner Spray Tech Corporation ("Spray Tech"), warrants this product against defects in material and

workmanship for a period of two years following the date of purchase by the original purchaser. During that period, Spray Tech

will repair or replace any defective or worn-out component or, at Spray Tech’s option, refund to the original purchaser the full

purchase price for the product in exchange for the return of that product. However, Spray Tech will not replace or repair any fluid

pump component on account of wear more than twice during the two year warranty period. This warranty does not cover

consumable products such as filters and tips.

Lifetime Warranty on Gear Trains, Electric Motors, and Gas Engines

Spray Tech warrants any gear train, electric motor (excluding brushes) and gas engine (excluding the clutch) in this product

against defects in material and workmanship for the lifetime of the original purchaser. If Spray Tech determines that the foregoing

warranty has been breached, Spray Tech will repair or replace the defective components without charge or, at Spray Tech’s

option, refund to the original purchaser the full purchase price for the product in exchange for the return of that product.

Warranty Claims

Any request for repair or replacement pursuant to the warranties above must be accompanied by the return of the applicable

parts, with transportation charges prepaid, to a service center authorized by Spray Tech or to Wagner Spray Tech Corporation,

1770 Fernbrook Lane, Minneapolis, MN 55447.

Limitation of Remedies

THE REMEDIES SET FORTH ABOVE ARE THE EXCLUSIVE REMEDIES AVAILABLE FOR BREACH OF EXPRESS AND

IMPLIED WARRANTIES. These remedies shall not be deemed to have failed of their essential purpose so long as Spray Tech is

willing to repair or replace parts, or to refund the purchase price, as set forth above.

What Is Not Covered By This Warranty

This warranty does not cover defects or damages caused by:

• the use or installation of repair or replacement parts or accessories not manufactured by Spray Tech;

• repair performed by anyone other than a Spray Tech Authorized Service Center; or

• abuse, misuse, negligence, accident, faulty installation or tampering in a manner which impairs normal operation.

This warranty also does not cover equipment and accessories supplied to Spray Tech from an original equipment manufacturer,

including but not limited to hoses, tips, and accessories. Spray Tech will provide the purchaser with copies of the original

equipment manufacturer’s express warranties provided to Spray Tech along with the name and address of the appropriate

manufacturer.

Limitation of Remedies

IN NO CASE SHALL SPRAY TECH BE LIABLE FOR ANY INCIDENTAL, SPECIAL OR CONSEQUENTIAL DAMAGES OR

LOSS, INCLUDING TRANSPORTATION COSTS, WHETHER SUCH DAMAGES ARE BASED UPON A BREACH OF EXPRESS

OR IMPLIED WARRANTIES, BREACH OF CONTRACT, NEGLIGENCE, STRICT TORT, OR ANY OTHER LEGAL THEORY.

Disclaimer of Implied Warranties

THE FOREGOING WARRANTIES ARE IN LIEU OF ALL OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT

NOT LIMITED TO THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE.

No Ability To Transfer

This warranty is extended to the original purchaser only and is not transferable.

SprayTECH 30-Day Satisfaction Guarantee

If, within a 30-day period from the date of purchase, you are not totally satisfied with a SprayTECH/CAPSpray unit, you

may return it for full credit toward another SprayTECH or CAPSpray product of equal or greater value.

Patents

These products are covered by one or more of the following U.S. patents:

5,234,592 D344,832 5,318,314 5,252,210 5,228,842 5,192,425 5,099,183

5,346,037 5,494,199 5,472,318 5,435,697 5,211,611 5,671,656 D384,676

5,282,722 4,992,633 5,725,364 5,769,321 5,848,566 D376,637 D387,414

D382,938 3,963,180 4,025,045 D405,159 D412,965 5,505,381 5,765,753

5,887,793 5,893,522

1770 Fernbrook Lane

Minneapolis, Minnesota 55447

Telephone 1-800-292-4637

© SprayTECH Corporation. All rights reserved. 11

English

Page 12

Table des matières

Introduction ...........................................................................12

Sécurité ..................................................................................12

Instructions de mise à la terre.............................................13

Choix d'une rallonge............................................................14

Mode d'emploi .......................................................................14

Vidange et amorçage ..........................................................14

Mode d'emploi du pistolet de pulvérisation .........................15

Pulvérisation..........................................................................16

Technique de pulvérisation..................................................16

Utilisation .............................................................................16

Nettoyage...............................................................................16

Purge de l'appareil...............................................................17

Entretien.................................................................................17

Entretien quotidien...............................................................17

Entretien du compartiment à liquide....................................17

Nettoyage de la tête de pulvérisation..................................19

Nettoyage du filtre ...............................................................19

Choix du filtre approprié pour le pistolet

de pulvérisation................................................................19

Accessoires ...........................................................................19

En cas de problème..............................................................20

Garantie limitée .....................................................................21

English .....................................................................................2

Español ..................................................................................22

Liste des pièces ....................................................................32

Dispositif de principale ........................................................32

Filtre (facultatif)....................................................................33

Dispositif de entraînement...................................................34

Dispostif de réglage de la pression.....................................36

Compartiment liquide...........................................................37

Pistolet.................................................................................38

Dispositif de succion............................................................38

Valve amorçage/pulvérisation..............................................39

Transducteur........................................................................40

Relais...................................................................................40

Dispostif de réglage de la pression

connectant le diagramme ................................................40

Introduction

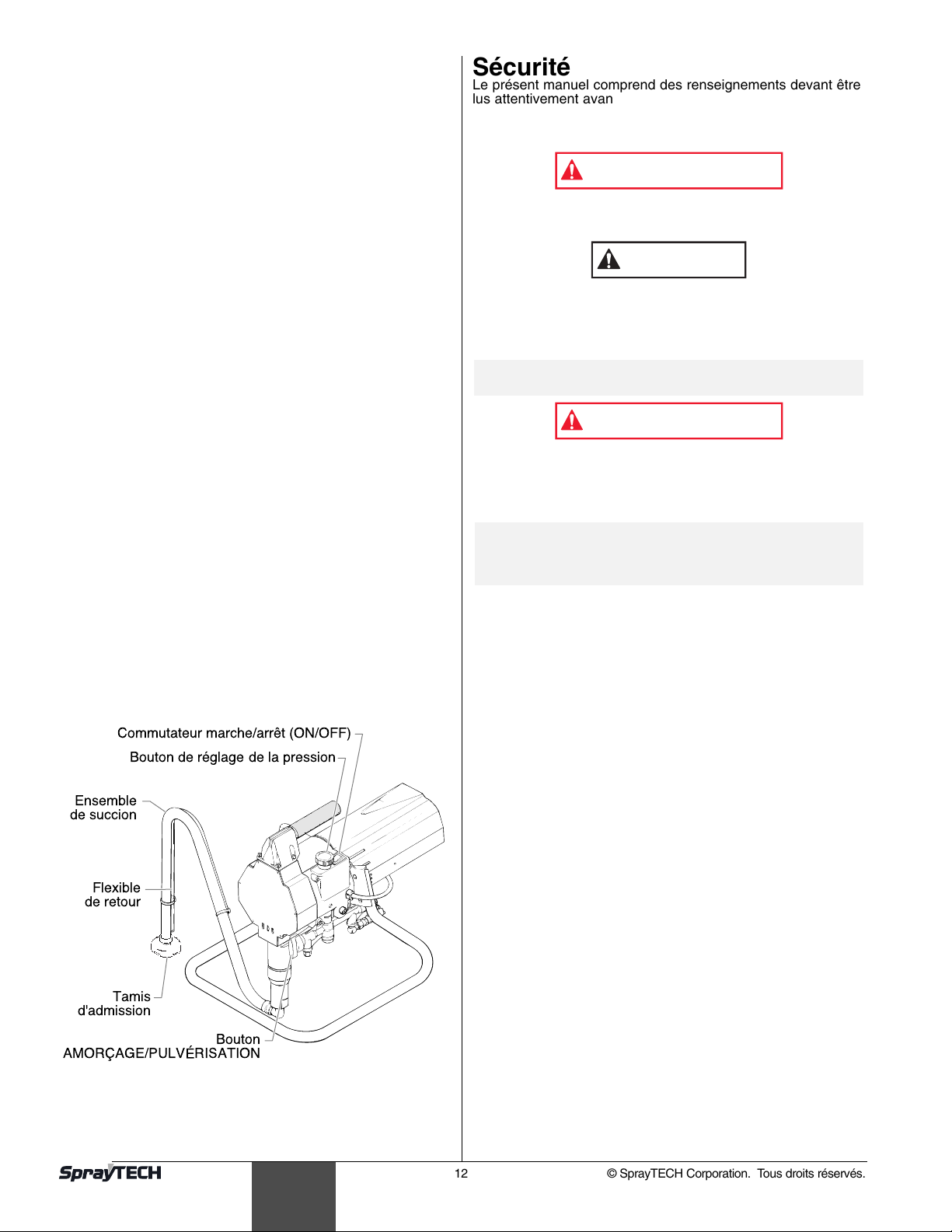

Cette pompe à piston de haute performance est un appareil

électrique de précision qui peut être utilisé pour la pulvérisation

d'un grand nombre de produits. Lisez attentivement ce manuel

et suivez scrupuleusement les consignes qui y sont données

quant au mode de fonctionnement, à l'entretien et l'utilisation

sécuritaire de l'appareil.

Commutateur marche/arrt (ON/OFF)

Bouton de rglage de la pression

Ensemble

de succion

Flexible

de retour

E

S

PRIM

PR

A

Y

Tamis

d'admission

AMORAGE/PULVRISATION

Bouton

Français

Sécurité

Le présent manuel comprend des renseignements devant être

lus attentivement avant toute utilisation de l'appareil. Lorsque

l'un des symboles suivants apparaît, il est recommandé d'être

particulièrement attentif et de tenir compte des mesures de

sécurité indiquées.

AVERTISSEMENT

Ce symbole indique un danger potentiel pouvant causer des

blessures graves ou même mortelles. Des renseignements

importants sur la sécurité sont également indiqués.

ATTENTION

Ce symbole indique un danger potentiel pouvant causer des

blessures corporelles ou des dommages à l'équipement. Des

renseignements importants sur la façon de prévenir tout

dommage à l'équipement ou toute blessure corporelle mineure

sont également indiqués.

NOTA : Les remarques donnent des renseignements

importants requérant une attention particulière.

AVERTISSEMENT

DANGER: BLESSURES PAR PERFORATION - Le jet de

peinture à haute pression produit par cet

appareil peut perforer la peau et les tissus

sous-jacents et entraîner de sévères blessures

pouvant nécessiter une amputation.

NE PAS TRAITER UNE BLESSURE PAR PERFORATION

COMME UNE SIMPLE COUPURE! Une perforation peut

entraîner des risques d'amputation. Consultez

immédiatement un médecin.

MESURES PRéVENTIVES:

• Pression de service maximale du fluide dans l’appareil :

3000 lb/po2.

• NE JAMAIS diriger le pistolet vers une quelconque partie

du corps.

• NE JAMAIS mettre une quelconque partie du corps en

contact avec le jet de liquide. NE JAMAIS se mettre au

contact d'un jet de liquide provenant d'une fuite du flexible

d'alimentation en liquide.

• NE JAMAIS placer votre main devant le pistolet. Des

gants ne vous protégeront pas contre les risques de

blessures par perforation.

• TOUJOURS verrouiller la gâchette du pistolet, fermer la

pompe à liquide et décompresser l'appareil lorsque vous

travaillez sur celui-ci, nettoyez le protecteur de tête,

remplacez la tête de pulvérisation ou vous éloignez de

l'appareil. Couper le moteur ne décompresse pas l'appareil.

Vous devez, pour le décompresser, placer le bouton

AMORÇAGE/PULVÉRISATION en position AMORÇAGE.

Reportez-vous, pour cela, à la PROCÉDURE DE

DÉCOMPRESSION décrite dans de ce manuel.

• TOUJOURS s'assurer que le protecteur de tête est en

place lorsque vous pulvérisez. Le protecteur de tête offre

une certaine protection contre les blessures par perforation

mais sa principale fonction est d'ordre préventif.

• TOUJOURS ôter la tête de pulvérisation avant de purger

ou nettoyer l'appareil.

• Le flexible d'alimentation en peinture peut fuir à la suite

d'une usure, de chocs ou de mauvais traitements. Une

fuite peut entraîner une perforation de la peau. Inspecter

le flexible avant chaque utilisation.

• NE JAMAIS utiliser un pistolet dont la gâchette n'est pas

munie d'un loquet ou un cran de sécurité qui soit en état

de fonctionner.

• Tous les accessoires doivent être homologués pour une

pression égale ou supérieure à 3 000 lb/po2. Cela

s'applique, entre autres, aux têtes de pulvérisation, aux

accessoires du pistolet et aux flexibles.

• Une perforation peut entraîner des risques d'amputation.

Consulter immédiatement un médecin.

12 © SprayTECH Corporation. Tous droits réservés.

Page 13

AVERTISSEMENT AUX MÉDECINS : Une perforation

sous-cutanée constitue un traumatisme. Il est important

de traiter la blessure de façon chirurgicale aussitôt que

possible. NE RETARDEZ PAS ce traitement pour des

recherches de toxicité. La toxicité n'est un risque que

dans les cas où certains produits de revêtement

pénètrent dans le flux sanguin. Il peut être nécessaire de

faire appel à des soins de chirurgie plastique ou de

reconstruction de la main.

DANGER: RISQUES D'EXPLOSION OU D'INCENDIE - Les

vapeurs dégagées par le solvant ou la peinture

sont explosives et inflammables et peuvent

causer des dommages matériels ou corporels

sérieux.

MESURES PRéVENTIVES:

• Veiller à éviter toute accumulation de vapeurs

inflammables en vous assurant que la zone où la

pulvérisation a lieu est suffisamment ventilée.

• Veiller à éviter la présence de toute source incandescente

telle qu'étincelle électrostatique, flamme nue, flammepilote, objet brûlant, cigarette et étincelle provenant du

branchement ou du débranchement d'un cordon

d'alimentation électrique ou d'un commutateur.

• Toujours avoir un extincteur en état de fonctionner à

portée de la main.

• Garder l’appareil dans un endroit bien aéré, à l’écart de la

zone de pulvérisation, afin d’éloigner les vapeurs de

solvant et de peinture. La pompe contient des pièces

produisant des arcs et émettant des étincelles.

• La vitesse élevée du produit dans l'appareil peut causer

l'accumulation d'électricité statique. Le matériel utilisé,

ainsi que les objets se trouvant à proximité de la zone de

pulvérisation, doivent être convenablement reliés à la terre

afin d'éviter toute étincelle ou toute décharge

électrostatique.

• N'utiliser que des flexibles d'alimentation en liquide à

haute pression conducteurs ou reliés à la terre dans les

cas d'utilisation sans air comprimé. S'assurer que le

pistolet est convenablement relié à la terre par

l'intermédiaire du flexible.

• Le cordon d’alimentation doit être raccordé à un circuit

mis à la terre.

• S’entourer de toutes les précautions possibles lorsqu’on

utilise des produits ayant un point d’éclair inférieur à 21

°C (70 °F). Le point d’éclair d’un fluide est la température

à laquelle les vapeurs émanant du fluide peuvent

s’enflammer au contact d’une flamme ou d’une étincelle.

• Se conformer aux consignes et recommandations de

sécurité du fabricant du solvant ou du produit.

• Lorsque vous purgez l'appareil, veillez à utiliser à la

pression minimale.

DANGER: RISQUES D'EXPLOSION PAR INCOMPATIBILITÉ

DES MATÉRIAUX - Peuvent être à l'origine de

dommages matériels ou corporels sérieux.

MESURES PRéVENTIVES:

• Ne pas utiliser d'eau de Javel.

• Ne pas se servir de solvants aux hydrocarbures

halogénés comme le chlorure de méthylène et le

trichloroéthane-1,1,1. Ces produits ne sont pas

compatibles avec l’aluminium et peuvent causer une

explosion. En cas de doute sur la compatibilité d’un

produit avec l’aluminium, communiquer avec son

fournisseur de revêtement.

DANGER: VAPEURS TOXIQUES - La peinture, les

solvants, les insecticides et d'autres produits

peuvent être toxiques s'ils sont inhalés et

provoquer des nausées graves, des

évanouissement ou des empoisonnements.

MESURES PRéVENTIVES:

• Utiliser un respirateur ou un masque chaque fois qu'il y a

des risques d'inhalation de vapeurs. Lire attentivement

toutes les instructions se rapportant au masque pour

vérifier que celui-ci vous assure une protection suffisante

contre les vapeurs toxiques.

DANGER: GÉNÉRALITÉS - Peut causer des dommages

matériels ou corporels sérieux.

MESURES PRéVENTIVES:

• Avant d'utiliser tout équipement, lire attentivement toutes

les instructions et les consignes de sécurité

• Se conformer à la législation locale, provinciale ou

fédérale pour tout ce qui concerne la ventilation, la

prévention des incendies et les conditions générales

d'utilisation.

• Les normes de sécurité du Gouvernement américain sont

régies par le Occupational Safety and Health Act (OSHA).

Il est important de consulter ces normes, en particulier la

section 1910 sur le normes générales et la section 1926

sur les des normes de la construction.

• Cette pompe à haute pression sans air comprimé est

conçue pour être utilisée uniquement avec des pièces

agrées par le fabricant. Toute utilisation de l'appareil avec

des pièces non conformes aux exigences techniques de

base et de sécurité du fabricant est aux risques et périls

de l'utilisateur.

• Vérifier, avant toute utilisation, que les flexibles ne

présentent pas d'entaille ou de fuite, que le couvercle ne

soit pas gonflé et que les raccords ne soient pas

endommagés. Si le flexible a subi l'un des dommages

précités, remplacez-le immédiatement. Ne jamais réparer

un flexible d'alimentation en peinture. Le remplacer par un

autre flexible mis à la terre.

• Tout flexible, raccord orientable, pistolet et accessoire

utilisé avec cet appareil doit pouvoir fonctionner à une

pression égale ou supérieure à 3 000 lb/po2.

• Ne jamais pulvériser lorsqu'il vente.

• Porter des lunettes de protection.

Instructions de mise à la terre

Cet appareil doit être mis à la terre. La mise à la terre réduit

les risques d'électrocution lors d'un court-circuit en permettant

au courant de s'écouler par le fil de mise à la terre. Cet

appareil est muni d'un cordon électrique avec fil de mise à la

terre ainsi que d'une fiche de terre. La fiche doit être branchée

sur une prise installée correctement et mise à la terre

conformément à la réglementation et aux codes en vigueur.

AVERTISSEMENT

Une prise de terre mal branchée peut être à l'origine

d'électrocutions.

S'il s'avère nécessaire de réparer ou de remplacer le cordon

électrique ou la fiche, ne pas brancher le fil vert de mise à la terre

sur l'une ou l'autre des bornes à broche plate. Le fil recouvert d'un

isolant vert avec ou sans rayures jaunes est le fil de mise à la

terre et doit être branché sur la broche de mise à la terre.

Si vous ne comprenez pas les instructions de mise à la terre

ou si vous n'êtes pas sûr que l'appareil est correctement mis à

la terre, contactez un électricien agréé. Ne pas modifier la

fiche d'origine. Si la prise ne convient pas à la fiche, faites

installer la prise adéquate par un électricien agréé.

Cet appareil est conçu pour un tension normale de 120 V et

est muni d'une fiche de mise à la terre semblable à celle de

l'illustration ci-dessous.

Prise de terre

Broche de mise à la terre

Couvercle du boîtier de prise de terre

© SprayTECH Corporation. Tous droits réservés. 13

Français

Page 14

Choix d'une rallonge

S

P

R

A

Y

P

R

I

M

E

SP

RAY

P

RI

M

E

Bouton de rglage

de la pression

S'il est nécessaire d'utiliser une rallonge, vérifiez qu'elle soit

munie de 3 broches et de connecteurs NEMA afin qu'un circuit

de mise à la terre continu soit établi entre l'appareil et la prise

du circuit d'alimentation. Il faut également que le conducteur

soit d'un calibre suffisant pour éviter toute baisse de tension

importante risquant d'entraîner des pertes d'intensité et

d'endommager le moteur de l'appareil. Vous trouverez cidessous un tableau des rallonges recommandées.

Si l'ampérage nominal affiché sur la plaque d'identification se

trouve entre deux valeurs données, utilisez une rallonge

recommandée pour la valeur supérieure.

Si vous devez utiliser une rallonge en extérieur, la mention WA doit suivre la désignation du type de rallonge. Par exemple,

SJTW-A représente une rallonge appropriée pour une

utilisation en extérieur.

Longueur de rallonge

7,6 m

15,2 m

22,9 m

30,5

38,10 m

(25 pi).

(50 pi)

(75 pi)

(100 pi)

0 to 5 18 18 18 18 18 18

6

18 18 18 18 18 16

7

18 18 18 18 16 16

18 18 18 16 16 16

8

9

18 18 18 16 16 14

10

18 18 18 16 14 14

16 16 16 16 14 14

11

12

16 16 16 16 14 14

13

16 16 16 14 14 14

14

14 14 14 14 14 12

15

14 14 14 14 14 12

16

Intensité nominale - plaque signalétique

14 14 14 14 12 12

17

14 14 14 14 12 12

18

14 14 14 14 12 12

19

12 12 12 12 12 12

20

12 12 12 12 12 12

Utiliser uniquement une rallonge à trois fils munie d'une fiche

de terre dans une prise secteur mise à la terre correspondant

au type de fiche de l'appareil. S'assurer que votre rallonge est

en bon état. Lorsque vous utilisez une rallonge, assurez-vous

qu'elle soit d'un calibre suffisant pour supporter l'intensité du

courant requise par l'appareil. Une rallonge trop mince

entraîne une chute de tension, une diminution de l'intensité et

une surchauffe. Une rallonge de calibre 14 ou 12 est

recommandée.

NOTA : Ne pas utiliser de rallonge de plus de 33 m

(100 pi). Si vous devez peindre à plus de 33 m

de la prise d'alimentation, utilisez un tuyau de

peinture plus long et non une rallonge plus

longue. Les rallonges plus courtes assurent

une alimentation optimale en électricité et un

meilleur fonctionnement.

(125 pi)

45,7 m

(150 pi)

Mode d'emploi

Vidange et amorçage

ATTENTION

Toujours garder le pistolet en position FERMÉE (OFF) lors

de la vidange de l'appareil.

Un appareil neuf est rempli d'un liquide d'essai afin

d'empêcher toute corrosion pendant le transport et

l'entreposage. Si vous utilisez ce pistolet avec de la peinture

au latex, il est important de complètement drainer ce fluide du

système. Si vous devez utiliser une peinture à base de

solvant, un nettoyage complet n'est pas nécessaire.

Si cet appareil a déjà été utilisé, vous devez vidanger l'eau ou

le solvant utilisé pour le nettoyage.

Vidange et amorçage de la pompe pour utilisation avec de la peinture au latex

1. Placez l'extrémité du flexible de retour dans un récipient

de récupération.

2. Plongez le flexible de succion dans un seau d'eau

savonneuse.

3. Tournez le bouton de

réglage de la pression à

fond dans le sens contraire

des aiguilles d'une montre

afin de réduire la pression

au minimum.

4. Placez le bouton

AMORÇAGE/

PULVÉRISATION dans la

position AMORÇAGE.

5. Placez le commutateur MARCHE/ARRÊT sur MARCHE .

6. Tournez doucement le bouton de réglage de la pression

dans le sens des aiguilles d'une montre afin d'augmenter

la pression jusqu'à ce que le liquide commence à sortir

par le flexible de retour. N'utilisez que la pression

minimale nécessaire à ce que le liquide s'écoule.

7. Lorsque le liquide d'essai a été vidangé et que l'eau

savonneuse s'écoule par le flexible de retour, tournez le

bouton de commande de la pression dans le sens

contraire des aiguilles d'une montre jusqu'à la position

minimale.

8. Retirez le flexible de succion du seau d'eau savonneuse

et plongez-le dans un seau d'eau claire.

9. Augmentez la pression jusqu'à ce que de l'eau claire

commence à sortir du flexible de retour.

10. Tournez le bouton de réglage de la pression à fond dans

le sens contraire des aiguilles d'une montre jusqu'à la

position minimale.

11. Retirez le flexible de succion

du seau d'eau claire et

plongez-le dans le pot de

peinture au latex.

12. Augmentez progressivement

la pression jusqu'à ce que la

peinture sorte par le flexible

de retour.

13. Retirez le flexible de retour

du récipient de récupération et placez-le dans sa position

de fonctionnement au-dessus du pot de peinture au latex.

14. Continuez de faire circuler la peinture dans l'appareil

jusqu'à ce que la peinture sortant du flexible de retour ne

contienne plus de bulles.

15. Tournez le bouton de réglage de la pression à fond dans

le sens contraire des aiguilles d'une montre jusqu'à la

position minimale.

La pompe est maintenant vidangée. Passez maintenant à la

section Vidange et amorçage du flexible de pulvérisation.

Français

14 © SprayTECH Corporation. Tous droits réservés.

Page 15

Vidange et amorçage pour peinture à base de

SPRAY

PRIME

Bouton de rglage

de la pression

S

P

R

A

Y

P

R

IM

E

S

P

R

A

Y

P

R

IM

E

Bouton AMORAGE/

PULVRISATION

AVERTISSEMENT

S

P

RAY

P

RIM

E

Bouton de rglage

de la pression

AVERTISSEMENT

solvant

Un nettoyage complet n'est pas nécessaire pour l'utilisation de

peinture à base de solvant. Seule la purge du fluide d'essai de

l'appareil est nécessaire.

1. Placez l'extrémité du flexible de retour dans un récipient

récupération.

2. Placez le flexible de succion dans un pot de peinture.

3. Tournez le bouton de réglage de la pression à fond dans

le sens contraire des aiguilles d'une montre afin de

réduire la pression au minimum.

4. Placez le bouton

AMORÇAGE/

PULVÉRISATION sur

AMORÇAGE.

5. Placez le commutateur

MARCHE/ARRÊT sur

MARCHE.

6. Tournez doucement le

bouton de réglage de la

pression dans le sens des aiguilles d'une montre afin

d'augmenter la pression jusqu'à ce que le liquide

commence à sortir par le flexible de retour. N'utilisez que

la pression minimale nécessaire à ce que le liquide

s'écoule.

7. Lorsque le liquide d'essai a été vidangé et que la peinture

s'écoule par le flexible de retour, tournez le bouton de

commande de la pression à fond dans le sens contraire

des aiguilles d'une montre jusqu'à la position minimale.

8. Retirez le flexible de retour du récipient de récupération et

placez-le dans sa position de fonctionnement au-dessus

du pot de peinture à base de solvant.

9. Continuez de faire circuler la peinture dans l'appareil

jusqu'à ce que la peinture sortant par le flexible de retour

ne contienne plus de bulles.

10. Tournez le bouton de réglage de la pression à fond dans

le sens contraire des aiguilles d'une montre jusqu'à la

position minimale.

La pompe est maintenant vidangée. Passez maintenant à la

section Vidange et amorçage du flexible de pulvérisation.

Vidange et amorçage du flexible de pulvérisation

Une fois la pompe vidangée et amorcée, il faut effectuer la

même procédure pour le flexible de pulvérisation.

NOTA : S'assurer qu'aucune tête de pulvérisation n'est

installée sur le pistolet.

AVERTISSEMENT

Si vous utilisez un récipient métallique,

maintenez le pistolet contre la paroi du

récipient pour créer une mise à la terre

durant la purge. Si vous ne faites pas cela,

vous risquez que se produisent des

décharges d'électricité statique qui

pourraient entraîner un incendie.

1. Tournez le bouton de

réglage de la pression à

fond dans le sens

contraire des aiguilles

d'une montre jusqu'à la

position minimale.

2. Placez le bouton

AMORÇAGE/

PULVÉRISATION sur

PULVÉRISATION.

3. Déverrouillez le pistolet.

4. Tournez doucement le bouton de réglage de la pression

dans le sens des aiguilles d'une montre afin d'augmenter

la pression.

© SprayTECH Corporation. Tous droits réservés. 15

5. Appuyer sur la gâchette du pistolet, celui-ci étant dirigé

sur un récipient de récupération, jusqu'à ce l'air, l'eau ou

le solvant soit purgé du flexible de pulvérisation et que la

peinture s'écoule librement.

6. Tournez le bouton de réglage de la pression à fond dans

le sens contraire des aiguilles d'une montre jusqu'à la

position minimale.

7. Placez le bouton AMORÇAGE/PULVÉRISATION sur

AMORÇAGE, dirigez le pistolet sur le récipient de

récupération et appuyez sur la gâchette du pistolet afin de

vous assurer que le flexible n'est plus sous pression.

8. Verrouillez le pistolet.

Mode d'emploi du pistolet de pulvéri-

sation

RISQUES DE PERFORATION. Ne jamais utiliser le pistolet

sans protecteur de tête. Ne jamais utiliser le pistolet sans

tête de pulvérisation que ce soit en position pulvérisation

ou débouchage. Toujours mettre le cran de sûreté du

pistolet avant d'enlever, de remplacer ou de nettoyer la tête.

AVERTISSEMENT

Toujours verrouiller le pistolet lorsqu’il ne sert pas.

Procédure de décompression

AVERTISSEMENT

Assurez-vous de bien suivre la procédure de

décompression lorsque vous fermez l'appareil pour

quelque raison que ce soit : entretien, réglage d'une pièce

du système de pulvérisation, remplacement ou nettoyage

des têtes de pulvérisation, préparation de l'appareil pour

son nettoyage ou autre.

1. Verrouillez le pistolet en plaçant le loquet dans la position

de verrouillage.

2. Coupez le moteur.

3. Tournez le bouton de

réglage de la pression à

fond dans le sens

contraire des aiguilles

d'une montre jusqu'à la

position minimale.

4. Placez le bouton

AMORÇAGE/

PULVÉRISATION en

position AMORÇAGE.

5. Déverrouillez le pistolet en plaçant le loquet dans la

position de déverrouillage.

6. Appuyez fermement la partie métallique

du pistolet contre la paroi d'un récipient

métallique afin de mettre le pistolet à la

terre et d'éviter l'accumulation

d'électricité statique.

7. Appuyez sur la gâchette afin de libérer

toute pression qui pourrait rester dans

le flexible.

8. Verrouillez le pistolet en plaçant le loquet dans la position

de verrouillage.

RISQUES DE PERFORATION. Ne jamais utiliser le pistolet

sans protecteur de tête. Ne jamais utiliser le pistolet sans

tête de pulvérisation que ce soit en position pulvérisation

ou débouchage. Toujours mettre le cran de sûreté du

pistolet avant d'enlever, de remplacer ou de nettoyer la tête.

Français

Page 16

Pulvérisation

Environ 25 à 30 cm

(10 à 12 pi)

Bonne

technique

Mauvaise

technique

Revêtement épais

Ne pas fléchir le poignet durant la pulvérisation.

Revêtement fin Revêtement fin

Déplacez votre bras d'un mouvement régulier

et à vitesse constante.

Revêtement également réparti

Environ 25 à 30 cm

(10 à 12 pi)

Comment bien utiliser la gâchette du pistolet

Environ 25 à 30 cm

(10 à 12 pi)

Déplacez votre bras

d'un mouvement

régulier

Début

du passage

Fin

du passage

Appuyez sur

la gâchette

Relâchez

la gâchette

Gardez une

vitesse constante

NOTA : Lorsque vous pulvérisez du hourdis, du mastic

ou une peinture à haut extrait sec, n'utilisez pas le

filtre du pistolet ou le filtre tamis de haute

pression.

Technique de pulvérisation

Pour obtenir une peinture d'un fini impeccable il est essentiel

que le produit soit également réparti sur toute la surface. Il

faut pour cela que vous appliquiez la peinture de façon

régulière en déplaçant votre bras à vitesse constante et en

gardant le pistolet de pulvérisation à une distante constante

de la surface. La meilleure distance de pulvérisation est de 25

à 30 cm (10 à 12 po) entre le pistolet et la surface traitée.

Gardez le pistolet perpendiculaire à la surface traitée. Il vous

faut pour cela déplacer tout votre bras de haut en bas et non

pas seulement fléchir votre poignet.

Veillez à garder le pistolet perpendiculaire à la surface traitée

afin d'éviter qu'une extrémité de chaque passage soit plus

épaisse que l'autre.

Chevauchez chaque passage d'environ 30% afin d'obtenir un fini

régulier.

Lorsque vous vous arrêtez, verrouillez le loquet de sécurité du

pistolet, tournez le bouton de commande de la pression à fond

dans le sens contraire des aiguilles d'une montre jusqu'à la position

minimale et placez le bouton AMORÇAGE/PULVÉRISATION en

position AMORÇAGE. Placez le commutateur du moteur en

position ARRÊT (OFF) et débranchez le pulvérisateur.

Utilisation

1. Vérifiez que le flexible d'alimentation en peinture ne soit