Page 1

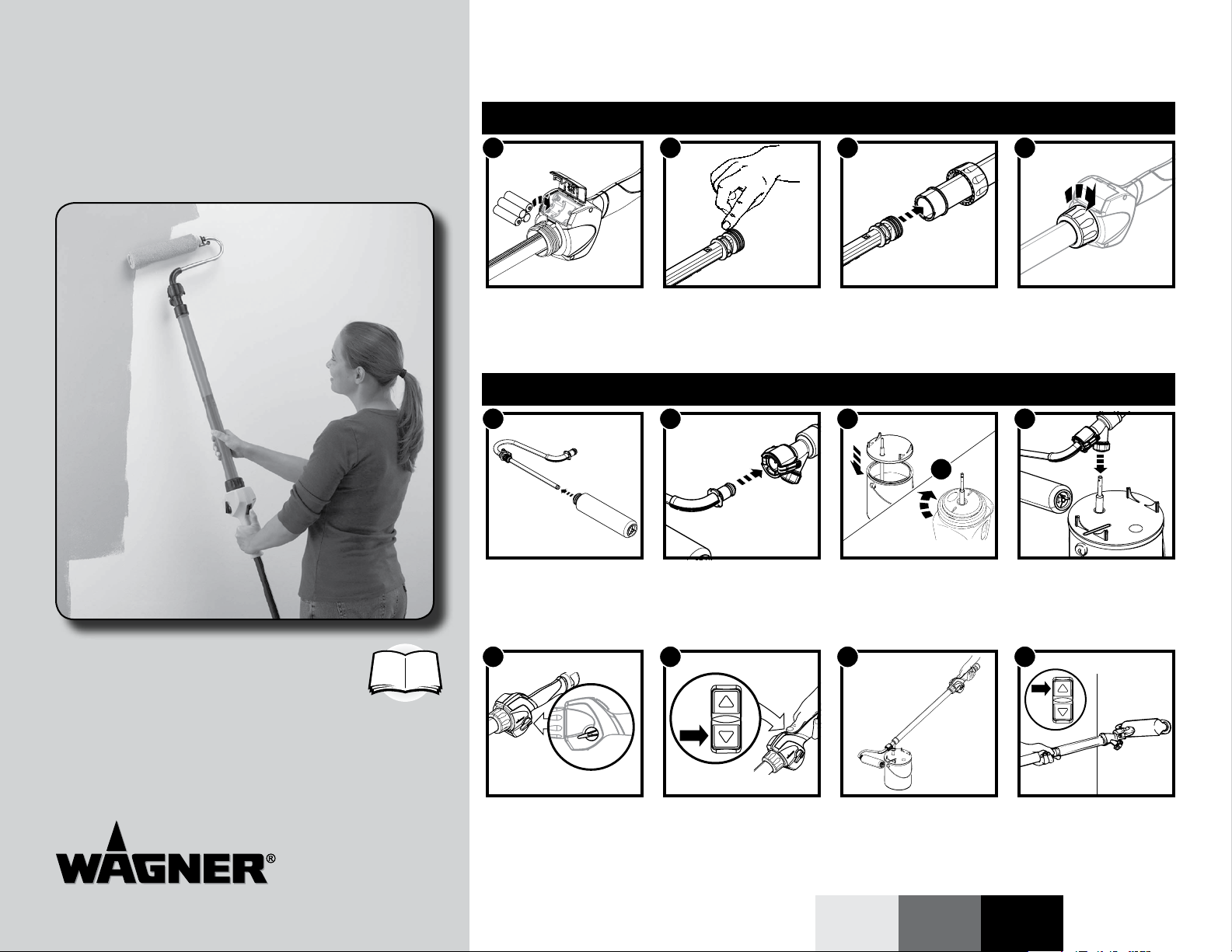

Quick Start Guide • Guide de démarrage rapide • Guía Rápida para comenzar

TURBOROLL

pOweRed painT ROLLeR

Owner’s Manual (page 2)

Read this manual for complete instructions

Plunger tube assembly • Assemblage pour le piston • Ensamblaje para el émbolo

™

1

2

3

4

™

Install batteries

Installer les piles

Instale las baterías

Setup • Montage • Disposición

1

Attach roller cover assembly

Fixer l’ensemble du manchon

du rouleau

Acople el conjunto de cubierta

del rodillo

5

Lubricate plunger O-rings

Lubrier les joints toriques du

piston

Lubrique las juntas tóricas del

émbolo

2

Attach roller arm

Fixer le bras du rouleau

Acople el brazo del rodillo

6

Insert plunger into main tube

Insérer le piston dans le manche

réservoir

Inserte el émbolo en el tubo

principal

3

or

Mount ll tube / lid

Installer le tube de remplissage

et le couvercle

Monte el tubo y la tapa de

llenado

7

Tighten locking collar securely

Serrer solidement la bague de

blocage

Ajuste rmemente el collar de

sujeción

4

Press ll valve onto tube

Insérer la valve de remplissage

dans le tube

Presione la válvula de llenado

en el tubo

8

Manuel de l’utilisateur (page 8)

Lire ce manuel pour obtenir des directives complètes

Manual del usario (página 14)

Lea este manual para obtener las instrucciones completas

0911 • Form No. 0271823C

Patent pending

Turn lever to POWER

Mettre la manette à POWER

Gire la palanca a POWER

Press switch

Appuyer sur le commutateur

Presione el interruptor

Hold switch until tube is full

Maintenir le commutateur

enfoncé jusqu’à ce que le

manche réservoir soit plein

Mantenga el interruptor presion-

ado hasta que el tubo esté lleno

Press switch and begin rolling

Appuyer sur le commutateur et

commencer à peindre

Presione el interruptor y

comience a hacerlo rodar

Español Français English

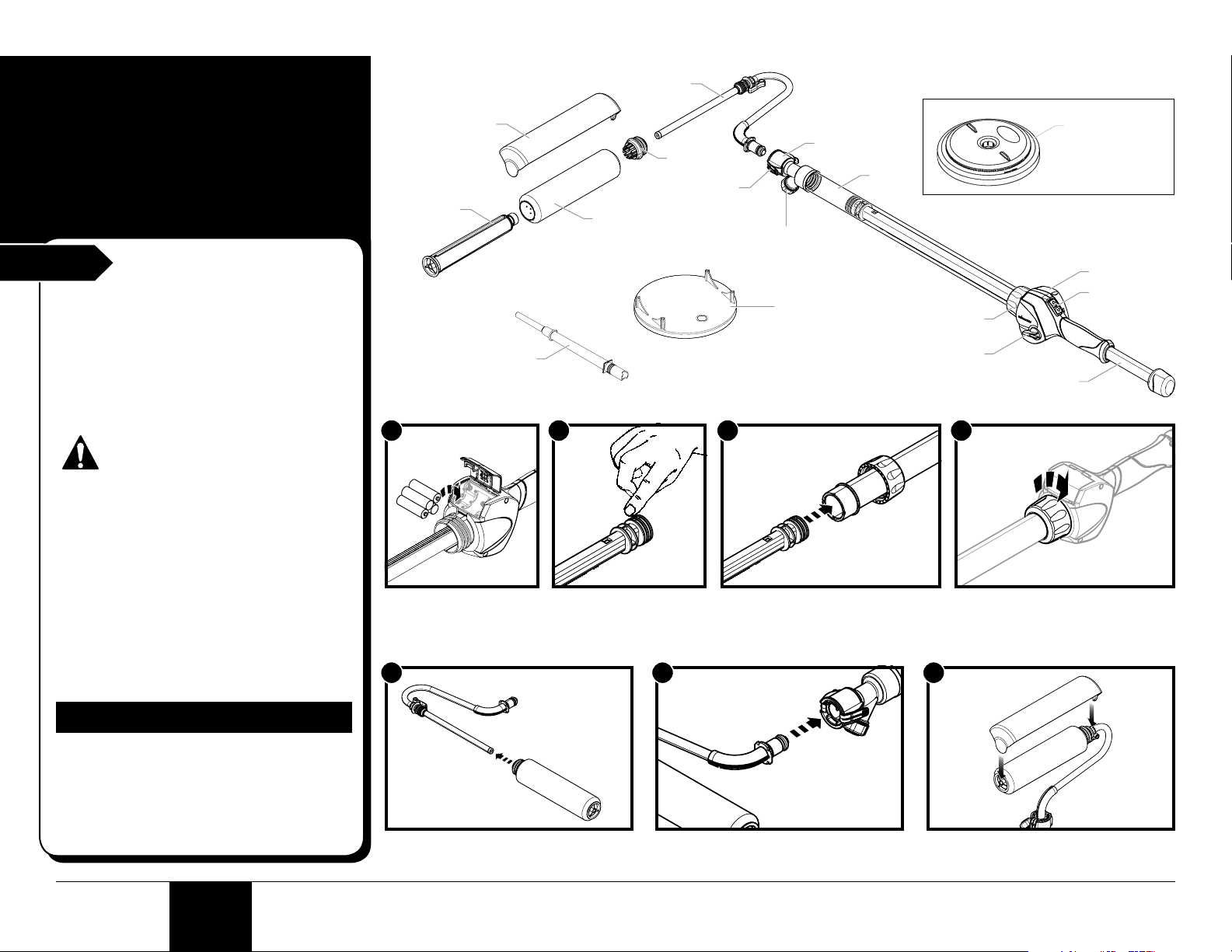

Page 2

Getting

Quick-release

tabs

Roller arm

assembly

Spatter

guard

Roller

core

Fill valve

Fill tube

Locking

collar

Manual

override

lever

Plunger

Motor switch

Motor housing

Head

Main

tube

Standard

container lid

Non-standard

container lid (not

included with

all models)

Roller

cover

Roller cap

Started

Parts and Components

Start

• The TurboRoll™ requires four (4) high-

• Make sure the type of paint you use can

• It is a good idea to have drop cloths

different battery type, inserted backwards or

disassembled. Replace all batteries at the

same time with new batteries. Do not carry

batteries loose in your pocket or purse. Do

not remove battery label.

IMPORTANT: Some oil-based paints require

a stronger cleaning solution than mineral

spirits and should not be used with the

TurboRoll™. Using a cleaning solution

stronger than mineral spirits may cause

damage to the TurboRoll™. Check with

your paint supplier to be sure the oil-based

paint you have can be cleaned with mineral

spirits.

Questions?

Call Wagner Technical Service at:

1-800-760-3844

Register your product online at:

www.wagnerspraytech.com

2

Before you begin:

quality, alkaline, AA size batteries.

be cleaned with either mineral spirits (for

oil-based paints) or a warm water and soap

solution (for latex paints).

protecting your oors and furnishings in

case of accidental spatters.

Batteries may explode or leak and

cause skin burns if recharged,

disposed of in fire, mixed with a

English

Assembly

1 2

1. Install batteries.

Remove plastic bag

from plunger.

5 6 7

5. Attach the roller cover assembly to

the roller arm.

2. Lubricate the

plunger O-rings with

petroleum jelly.

6. Press the quick-release tabs on the

unit and attach the roller arm.

3 4

3. Insert the plunger into the main

tube. Make sure O-rings do

not twist or cut.

4. Tighten the locking collar.

7. If painting a ceiling, attach the

spatter guard.

Page 3

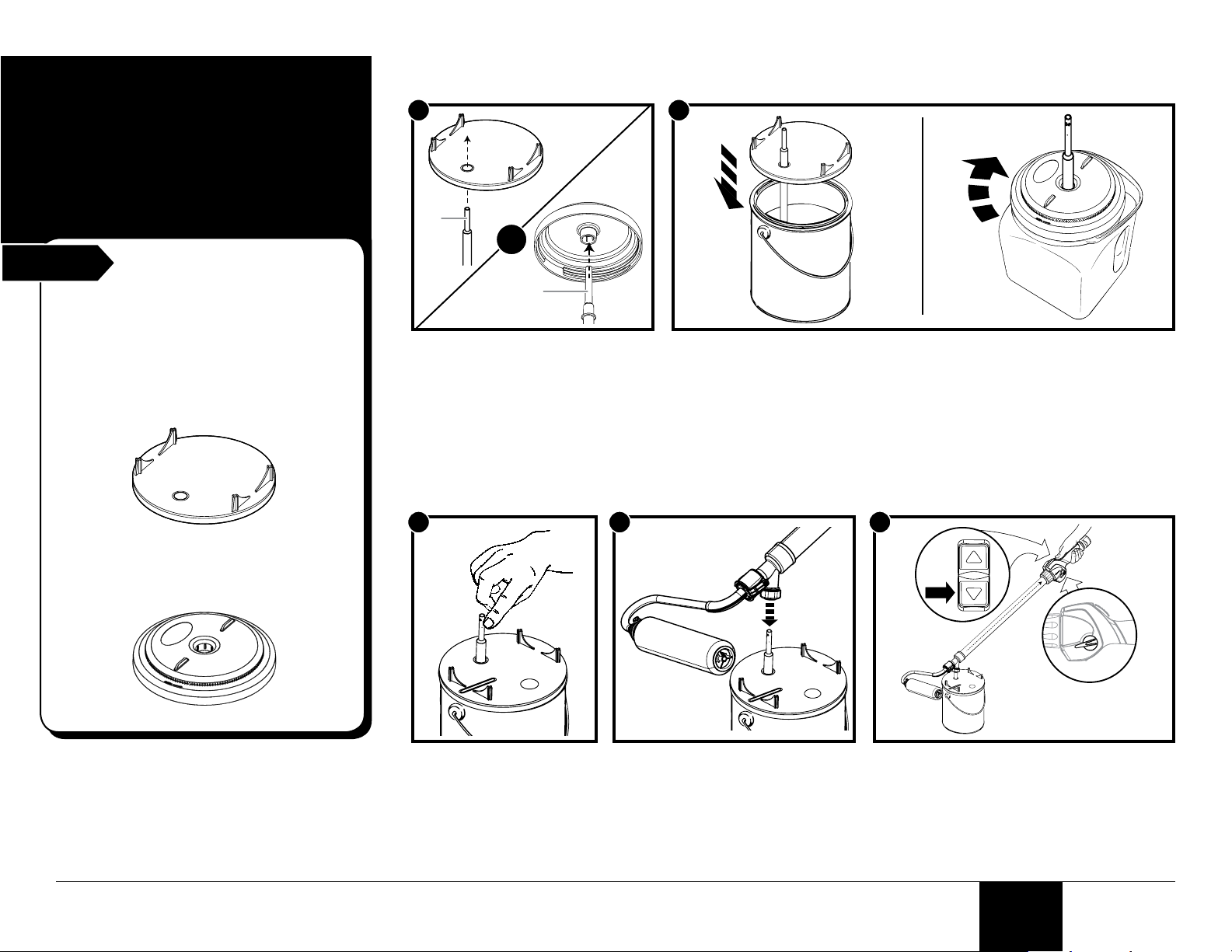

Attaching the container lid / fill tube

(a)

(a)

(b)

(c)

1. Filling the

main tube

Start

Your TurboRoll™ can be used with two types

of container lids that are used to allow you to

pull material from the material container into the

TurboRoll™.

The lid below is desiged for use with standard,

one-gallon, round material containers. This lid

comes standard with your TurboRoll™.

Use the lid shown below if you are using

something other than a standard, one-gallon,

round material container. *Not included with

all models.

Before filling:

1

OR

1. Slide the small end of the ll tube

(a) through the hole in the container

lid you plan to use.

Filling the main tube

1

2 3

2

2a. Standard containers - Attach the

container lid with ll tube securely

to the material container.

2b. All other containers - Thread the

container lid with ll tube onto the

material container.

1. Apply a thin layer of

3

petroleum jelly to the ll

tube. This will help the ll

valve slide easily off the ll

tube.

2. Press down and rmly hold the ll

valve onto the ll tube.

3. Make sure lever is switched to POWER (b).

Push the lower part of the switch (c) to draw

the plunger out and ll the tube. When the

tube is full, you are ready to begin rolling.

English

Page 4

2. Usage

General Rolling Tips:

Preparing the room

Remove all pictures, mirrors, and decorations

from the walls and draperies from the

windows. Remove all nails, hardware and

switch and receptacle covers. Cover furniture

and oor with drop cloths.

Surface Preparation

• Always remove wallpaper before painting.

Wash off old adhesive and rinse with

water. Allow the walls to dry before

painting.

• Wash and rinse dirt, grease and oil build-

up off the walls with soap and water.

• Fill all nail holes, joints and cracks with

patching paste. Let dry and sand the

surface until smooth. Clean sanded area

with a damp cloth.

• Spot prime all patched areas and any

marker and/or pen marks before applying

rst coat.

TIP: Write the important information from

your paint can (color, formula, brand and

paint type) on the back of a switch plate for

future reference.

Painting the Room

TIP: If you need more than one gallon of

paint to do the room’s walls, mix them

together to ensure color uniformity.

• Always make sure to open a window or

door to ensure proper ventilation. If you are

painting both the ceiling and walls in your

room, start with the ceiling rst and then

move to the walls.

Ceilings:

• To minimize spills and spatters, use the

spatter guard and paint across the short

width of the ceiling.

Walls:

• Tape off around base and window and

door trim.

• Paint one wall at a time.

• Pick an area to start where you can

saturate the roller cover and evenly

distribute the paint. Working in threefoot sections, begin by cutting-in around

windows, doors, cabinets, base and other

breaks in the wall surface with a pad or

brush.

• Press the switch until paint appears

through the roller cover.

• Start painting at one end of a wall and roll

out the letter “W”. Fill it in with crosswise

strokes, working your way across the wall

in 3’ x 3’ sections. Finish the sections by

painting one solid swipe from ceiling to

oor. This will give you a nice even paint

nish.

• Press the switch as needed for more paint.

Be careful not to over-saturate the roller

cover as it may drip, slide on the wall or

spatter.

• Make sure to run the roller cover over

the areas you cut-in around the trim and

baseboards to even out the texture.

• If you need to stop and take a break; nish

painting the entire wall, or stop at a break

in the wall such as a doorway or corner to

prevent lap marks.

Loading the roller

1

1. Push upper part of the switch to push the plunger forward and bring

material to the roller. When you start to see material come out of the roller,

you are ready to begin rolling.

2. Push the switch as necessary to bring additional material to the roller.

3. Rell as needed (see Filling the Main Tube, page 3).

PINCH CAUTION - Keep your hand away

from the area between the rear of the

handle and the plunger cap. The geardriven plunger can pinch.

TIP: During extended break periods, place a plastic bag around the

roller cover and ll valve to keep it from drying out.

TIP: For best results, maintain a steady ow of material to the roller.

cover and avoid rolling it dry.

TIP: Do not reverse plunger direction during rolling. This will cause air

build-up in the main tube and cause spatters.

TIP: If batteries run out during rolling, ip the lever to MANUAL.

Material can be brought to the roller by pushing the plunger forward.

4

English

Page 5

Returning excess material to material container

x5

x5

x5

3. Cleanup

Start

When cleaning the TurboRoll™, make sure to

use the appropriate cleaning solution for the

type of material used.

• If you used latex-based materials, use

• If you used oil-based materials, use mineral

IMPORTANT: DO NOT submerge the motor

housing and avoid dripping any cleaning

solution on it!

You will need:

• A large bucket or other container that will

Before you begin cleaning:

warm, soapy water to clean the TurboRoll™.

spirits.

hold cleaning solution.

1

1. Push the lower part of

the switch to draw any

remaining material from

the roller arm back into

the main tube.

Cleaning the TurboRoll™

1

2 3 4

2. Press the ll valve onto

the ll tube. Push upper

part of the switch to push

excess material back into

the container.

2

3. Remove the spatter

guard. Press locking tab

and remove roller cover

assembly from the roller

arm.

3

4. Remove the roller cap.

Push the roller core out

the other end. Place

spatter guard, cap, core

and cover in a bucket of

the appropriate cleaning

solution.

TIP: A large laundry tub lled with warm,

soapy water is ideal for cleanup if you used

latex-based materials.

5

1. Remove ll tube from the container

lid. Install end of the ll tube into the

valve housing.

4

4. Remove the ll tube. Submerge the

ll valve and roller arm and pull the

plunger in and out a minimum of 5

times.

2. Flip lever toward MANUAL. This

will allow you to manually slide the

plunger back and forth.

5

5. Remove the roller arm. Submerge

the head of the TurboRoll™ and the

ll valve and pull the plunger in and

out a minimum of 5 times.

3. Submerge the ll tube into the

appropriate cleaning solution

and pull the plunger in and out a

minimum of 5 times.

6

6. Clean the remaining parts (cap,

core, cover and spatter guard) by

hand using the appropriate cleaning

solution.

English

Page 6

Lubricating the components

(a)

(b)

(c)

4. Storage

Start

Proper cleaning and lubrication of certain

components of the TurboRoll™ are critical to

prolonging the life of the components.

If after extended use the plunger has a

tendency to stick, apply a generous amount

of petroleum jelly located on the end of the

plunger (see Lubricating the components,

step 2).

IMPORTANT: When storing the

TurboRoll™, make sure the ll valve is

pointing downward, and never store the

TurboRoll™ with the ll tube inserted into

the ll valve.

IMPORTANT: Remove the batteries when

storing the TurboRoll™ for a prolonged

period of time.

Storage notes:

1

1. Turn the locking collar as shown until

the main tube slides easily off of the

plunger.

4

4. Lubricate the inside of the ll valve

housing on the main tube with

petroleum jelly.

2

2. Lubricate around and in between the

plunger O-rings with petroleum jelly.

5

5. Clean and lubricate with petroleum

jelly the indicated areas on the roller

arm.

Connecting areas

Seal

O-ring

3

3. Re-insert the plunger back inside the

main tube. Make sure the O-rings

do not twist or cut. Tighten the

locking collar.

6

6. Reassemble roller cover. Place

back onto roller arm.

Cleaning the fill valve

1. Unscrew the locking cap (a) on the valve housing.

Cleaning the fill valve note:

The inner parts of the ll valve should be

cleaned ONLY if you are experiencing leakage

problems, or if you are unable to draw material

into the main tube.

6

English

2. Remove the retainer disk (b) and the duckbill (c) from the

valve housing.

3. Clean these parts using the appropriate cleaning solution.

4. Replace the duckbill (c) and the retainer disk (b).

5. Screw the locking cap (a) back onto the valve housing.

Page 7

Troubleshooting

Problem A: There is leakage on the roller arm assembly.

Cause Solution

1. The roller arm seal is backwards. Turn the seal around.

2. The roller arm seal was not properly cleaned. Clean and properly lubricate.

3. The O-ring and the connecting areas on the roller arm were not cleaned properly. Clean and properly lubricate (see Cleaning the TurboRoll™ and Lubricating

4. Residue on the connecting area inside of the head. Clean out any remaining residue inside the head of the TurboRoll™.

5. The O-ring on the roller arm is damaged or missing. Clean or replace*.

6. The roller cover is worn or damaged. Replace the roller cover*.

7. The roller core or cap is worn or damaged. Replace the roller core or cap*.

Problem B: Plunger does not move.

Cause Solution

1. The lever is set to MANUAL. Flip lever to POWER.

2. The batteries are weak. Replace with new batteries.

3. The batteries are improperly installed. Reinstall. Follow the graphic on the inside of the battery door.

4. The plunger O-rings are not lubricated. Lubricate the plunger O-rings (see Lubricating the components, page 6)

the TurboRoll™, pages 5-6).

Problem C: The main tube will not fill, or there is leakage from the fill valve.

Cause Solution

1. Residue on the ll valve components. a) Insert the ll tube into the ll valve and twist the ll tube several times to break

Have you tried the recommendations above and

are still having problems? In the United States, to

speak to a customer service representative, call

our Technical Service at 1-800-760-3844 Monday

through Friday between 8:00 AM and 4:30 PM

Central time.

Product Registration

Register your product online at www.wagnerspraytech.com.

Proper registration will serve as proof of purchase in the

event your original receipt becomes misplaced or lost.

7

up the residue.

b) If the problem persists, refer to Cleaning the ll valve, page 6.

Wagner one year limited warranty - Keep on le

This product, manufactured by Wagner Spray Tech Corporation (Wagner) is warranted against defects in material

and workmanship for one year following date of purchase if operated in accordance with Wagner’s printed

recommendations and instructions. This warranty does not cover damage resulting from improper use, accidents,

user’s negligence or normal wear. This warranty does not cover any defects or damages caused by service or

repair performed by anyone other than a Wagner Authorized Service Center.

ANY IMPLIED WARRANTY OF MERCHANTABlLITY OR FITNESS FOR A PARTICULAR PURPOSE IS LIMITED

TO ONE YEAR FOLLOWING DATE OF PURCHASE. THIS PRODUCT IS DESIGNED FOR HOME USAGE ONLY.

IF USED FOR COMMERCIAL OR RENTAL PURPOSES, THIS WARRANTY APPLIES ONLY FOR 30 DAYS

FROM DATE OF PURCHASE. WAGNER SHALL NOT IN ANY EVENT BE LIABLE FOR ANY INCIDENTAL OR

CONSEQUENTIAL DAMAGES OF ANY KIND, WHETHER FOR BREACH OF THIS WARRANTY OR ANY OTHER

REASON. THIS WARRANTY DOES NOT APPLY TO ACCESSORIES.

If any product is defective in material and/or workmanship during the applicable warranty period, return it with proof

of purchase, transportation prepaid, to any Wagner Authorized Service Center. Call the Wagner Technical Service

at 1-800-760-3844 Monday through Friday between 8:00 AM and 4:30 PM Central time.

English

Page 8

Parts List • Liste de pièces • Lista de piezas

1

2

4

5

12

6

3

11

10

7

8

9

Optional Accessories • Accessoires Optional • Accesorios Opciónal

Part No.

Nº de piéce

Pieza No.

0155206C 3/8” nap roller

0155208C 3/4” nap roller

0284001G GlassMask™ GlassMask™ GlassMask™

0513030 Trim It™ Trim It™ Trim It™

0284112B Roller Cleanup

0284051A 5 gallon paint

0284419 Non-standard

English

Description

cover

cover

Kit™

adapter

container lid

Français

Description

Manchon de rouleau à

grain de 3/8 ” (1 cm)

Manchon de rouleau à

grain de 3/4 ” (1,9 cm)

Roller Cleanup Kit™ Roller Cleanup Kit™

Adaptateur pour

contenant à peinture

de 5 gallons (19 l)

Couvercle de

contenant spécial

Español

Descripción

Cubierta del rodillo con

lanilla de 3/8”

Cubierta del rodillo con

lanilla de 3/4”

Adaptador para pintura

de 5 gallones

Tapa de recipiente no

estándar

Item

Article

Articulo

1 0514118 Roller core and cap* Corps du rouleau et capuchon* Centro y tapa del rodillo* 1

2 0155206C 3/8” nap roller cover Manchon de rouleau à grain de 3/8 ” (1 cm) Cubierta del rodillo con lanilla de 3/8” 1

3 0514230 Spatter guard Garde-éclaboussures Protección contra salpicaduras 1

4 0514150 Roller arm assembly (includes item 5) Ensemble de bras de rouleau (inclut l’article 5) Conjunto del brazo del rodillo (incluye el artículo 5) 1

5 0514112 Seal and O-ring* Joint d’étanchéité et joint torique* Sello y junta tórica* 1

6 0284136 Plunger O-rings Joints toriques du piston Juntas tóricas del émbolo 2

7 0284398 Locking cap Capuchon de blocage Tapa de sujeción 1

8 0284395 Retainer disk Disque de retenue Disco retenedor 1

9 0271434 Duckbill valve Valve bec de canard Válvula pico de pato 1

10 0284443 Standard container lid Couvercle de contenant normal Tapa de recipiente estándar 1

11 0284432 Fill tube Tube de remplissage Tubo de llenado 1

12 0284419 Non-standard container lid** Couvercle de contenant spécial** Tapa de recipiente no estándar** 1

20

Part No.

Nº de piéce

Pieza No.

English

Description

* Can only be purchased together and not separately.

** Not included with all models

English Français Español

Français

Description

* Forment un ensemble et ne peuvent pas être

** Non inclus avec tous les modèles.

achetés séparément.

Español

Descripción

* Sólo se puede comprar junto, no por separado.

** No se incluye con todos los modelos.

Quantity

Quantite

Cantidad

Loading...

Loading...