Wacker neuson WP1540, WP1550 User Manual

Operator's manual

Vibratory plate

WP, VP

Model |

WP, VP |

Document |

5100027605 |

Issue |

10.2015 |

Version |

01 |

Language |

en |

Manufacturer

Wacker Neuson Produktion GmbH & Co. KG Preussenstrasse 41

80809 Munich www.wackerneuson.com

Tel.: +49-(0)89-354 02-0

Fax: +49-(0)89-354 02-390

Original operator's manual

100_0000_0001.fm |

2 |

|

|

|

Table ofcontents |

|

|

|

|

1 |

Preface .................................................................................................................................... |

5 |

|

2 |

Introduction ............................................................................................................................ |

6 |

|

|

2.1 |

Using the manual............................................................................................................ |

............. 6 |

|

2.2 |

Storage location of the manual.............................................................................................. |

...... 6 |

|

2.3 |

Accident prevention regulations............................................................................................. |

...... 6 |

|

2.4 |

More information............................................................................................................ |

.............. 6 |

|

2.5 |

Target group ................................................................................................................ |

................ 6 |

|

2.6 |

Explanation of symbols...................................................................................................... |

.......... 6 |

|

2.7 |

Wacker Neuson Contact partner ............................................................................................... |

.. 7 |

|

2.8 |

Disclaimer.................................................................................................................. |

.................. 7 |

|

2.9 |

Product identification of the machine....................................................................................... |

.... 7 |

3 |

Safety ...................................................................................................................................... |

8 |

|

|

3.1 |

Policy ........................................................................................................................................... |

8 |

|

3.2 |

Areas of responsibility of the operator ..................................................................................... |

.... 9 |

|

3.3 |

Operator responsibilities................................................................................................... |

........... 9 |

|

3.4 |

Personnel qualification................................................................................................................. |

9 |

|

3.5 |

General sources of danger ................................................................................................... |

....... 9 |

|

3.6 |

General safety instructions ................................................................................................. |

......... 9 |

|

3.7 |

Specific safety instructions – Vibratory plates ........................................................................... |

10 |

|

3.8 |

General safety instructions - Combustion engines .................................................................... |

11 |

|

3.9 |

General safety instructions – fuel, lubricants and coolants........................................................ |

11 |

|

3.10 |

Maintenance ................................................................................................................ |

.............. 12 |

|

3.11 |

Personal Protective Equipment .............................................................................................. |

... 12 |

|

3.12 |

Safety devices ............................................................................................................. |

.............. 13 |

|

3.13 |

Behavior in dangerous situations........................................................................................... |

.... 13 |

4 |

Safety and information labels ............................................................................................ |

14 |

|

5 |

Setup and function .............................................................................................................. |

16 |

|

|

5.1 |

Standard package ............................................................................................................ |

......... 16 |

|

5.2 |

Application areas ........................................................................................................... |

............ 16 |

|

5.3 |

Short description........................................................................................................... |

............. 16 |

|

5.4 |

Versions.................................................................................................................... |

................. 16 |

6 |

Components and operator's controls ................................................................................ |

17 |

|

|

6.1 |

Components .................................................................................................................. |

............ 17 |

|

6.2 |

Operator's controls ......................................................................................................... |

........... 17 |

7 |

Transport .............................................................................................................................. |

18 |

|

|

7.1 |

Loading and transport....................................................................................................... |

......... 18 |

8 |

Operation and use ............................................................................................................... |

20 |

|

|

8.1 |

Initial operation ........................................................................................................... |

............... 20 |

|

8.2 |

Before commissioning ........................................................................................................ |

....... 20 |

|

8.3 |

Notes about operation ....................................................................................................... |

........ 20 |

|

8.4 |

Commissioning ............................................................................................................... |

........... 21 |

|

8.5 |

Operation................................................................................................................... |

................ 22 |

|

8.6 |

Decommissioning ............................................................................................................. |

......... 22 |

9 |

Maintenance ......................................................................................................................... |

23 |

|

|

9.1 |

Maintenance table ........................................................................................................... |

.......... 24 |

|

9.2 |

Maintenance jobs............................................................................................................ |

........... 24 |

10 |

Troubleshooting .................................................................................................................. |

31 |

|

|

10.1 |

Fault table................................................................................................................ |

.................. 31 |

5100021600IVZ.fm |

3 |

Table of contents

11 |

Accessories ......................................................................................................................... |

32 |

|

12 |

Technical data ..................................................................................................................... |

33 |

|

|

12.1 |

WP1540 ..................................................................................................................................... |

33 |

|

12.2 |

WP1550 ..................................................................................................................................... |

34 |

|

12.3 |

Combustion engine.................................................................................................................... |

35 |

|

EC declaration of conformity ..................................................................................... |

36 |

|

4 |

5100021600IVZ.fm |

1 Preface

1 Preface

This operator's manual contains information and procedures for the safe operation and safe maintenance of your Wacker Neuson machine. For your own safety and to protect against injuries, you must read the safety instructions carefully, familiarize yourself with them and observe them at all times.

This operator's manual is not a manual for extensive maintenance or repair work. Such work should be carried out by Wacker Neuson service or by technically trained personnel.

When building this machine, great value was placed on the safety of its operator. However, an improper operation or improper maintenance can pose dangers. Please operate and maintain your

Wacker Neuson machine in a ccordance with the information in this operator's ma nual. Your attention will be rewarded with trouble-free service and a high level of availability.

Defective machine parts must be exchanged immediately!

Please contact your Wacker Neuson contact partner for questions regarding the operation or maintenance.

All rights are reserved, in particular the right of duplication and distribution.

Copyright 2015 Wacker Neuson Produktion GmbH & Co. KG

This operator's manual — even in part — may only be reproduced, used, copied or distributed with the express, prior written consent from Wacker Neuson .

Any type of reproduction, distribution or storage on data carriers in any form or type that is not approved by Wacker Neuson represents a violation of the valid copyright and you will be prosecuted.

We reserve the express right to technical modifications that are used to improve our machines or to raise the safety standard, even without special notice.

100_0000_0002.fm |

5 |

2 Introduction

2 Introduction

2.1Using the manual

This manual is to be considered part of the machine and should be carefully stored during the entire service life of the machine. This manual shall be transferred to subsequent owners or users of the machine.

2.2Storage location of the manual

This manual is part of the machine and must be kept in the immediate vicinity of the machine and made accessible to staff at all times.

If this manual is lost, or if a second copy is required, there are two options to obtain a replacement:

Download from the Internet www.wackerneuson.com

Contact your Wacker Neuson contact partner.

2.3Accident prevention regulations

In addition to the notes and safety instructions in this manual, the local accident prevention regulations as well as the national health and safety regulations apply.

2.4More information

This manual applies to various machine types from one product series. For this reason, some figures may vary slightly in appearance from the machine purchased. Depending on the model, there may be descriptions of components that are not included in the standard package.

The information contained in this manual is based on machines manufactured up to the time of printing. Wacker Neuson reserves the right to change this information.

The manufacturer shall immediately include any modifications or additions in this manual.

2.5Target group

Individuals working with this machine must be regu larly trained on the dangers of handling the machine. This operator's manual is intended for the following persons:

Operating personnel:

These individuals have been trained on the machine and informed about the possible dangers in the event of improper conduct.

Technically trained personnel:

These people have professional training as well as additional knowledge and experience. They are able to assess the tasks assigned to them and recognize possible dangers.

2.6Explanation of symbols

This manual contains specially emphasized safety instructions in the following categories: DANGER, WARNING, CAUTION and NOTE.

Before performing any work on or with this machine, the notes and safety instructions must be read and understood. All notes and safety instructions in this manual must be passed on to the maintenance, repair, and transport personnel.

DANGER

This combination of symbol and signal word indicates a hazardous situatio n that will lead to death or serious injury if it is not avoided.

WARNING

This combination of symbol and signal word in dicates a hazardous situation that can lead to death or serious injury if it is not avoided.

CAUTION

This combination of symbol and signal word in dicates a hazardous situation that can lead to minor injury or damage to the machine if it is not avoided.

100_0000_0013.fm |

6 |

2 Introduction

NOTE

Supplementary information.

2.7Wacker Neuson Contact partner

Depending on the country, the Wacker Neuson contact partner is a Wacker Neuson service, a Wacker Neuson affiliate, or a Wacker Neuson dealer.

On the Internet at www.wackerneuson.com

The manufacturer's address can be found at the beginning of this manual.

2.8Disclaimer

For the following violations, Wacker Neuson dismisses any liability for personal injury or material damage:

Failure to follow this manual.

Unintended use.

Deployment of untrained personnel.

Using non-approved spare parts and accessories.

Improper handling.

Structural modifications of any kind.

Failure to observe the "General Terms and Conditions" (GT&Cs).

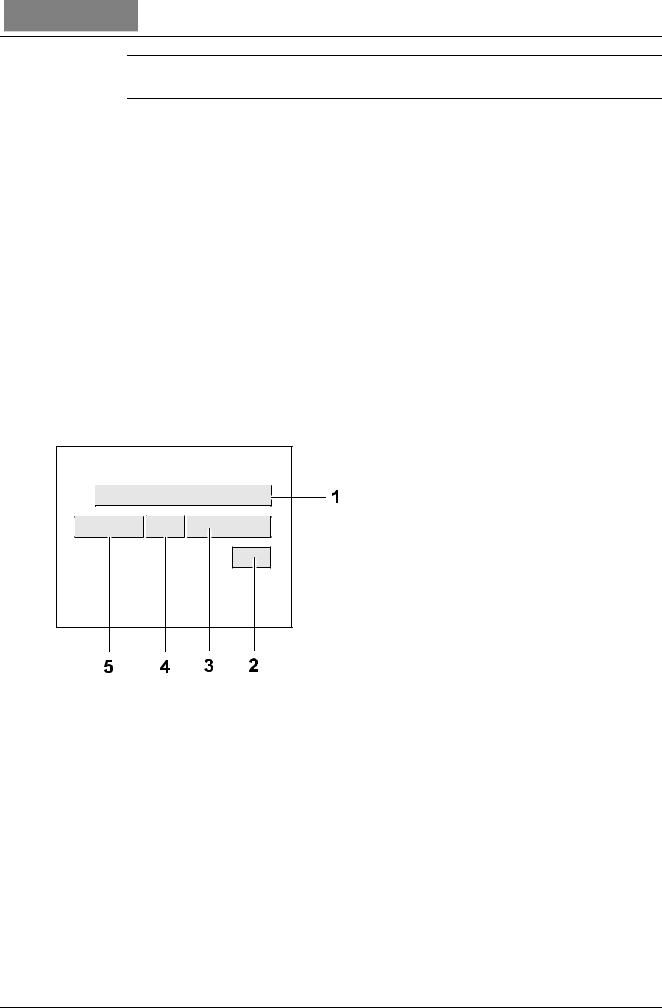

2.9Product identification of the machine

Data of the nameplate

The nameplate contains information t hat uniquely identifies this machin e. This information is required for ordering spare parts and when inquiring about technical issues.

Enter information about the machine in the following table:

Item |

Designation |

Your information |

1 |

Group and model |

|

2 |

Year of manufacture |

|

3 |

Serial number |

|

4 |

Version no. |

|

5 |

Item number |

|

100_0000_0013.fm |

7 |

3 Safety

3 Safety

NOTE

Read and comply with all notes and safety instructions in this manual. Failure to comply with these instructions can cause electric shock, fire and/or serious injuries as well as damage to the machine and/or damage to other objects. Keep safety instructions and notes for the future.

3.1Policy

In keeping with the latest technological developments

The machine has been built in keeping with the latest technological developments and the recognized technical safety rules. Nevertheless, improper use can result in hazards to life and limb of the user or third parties as well as damage to the equipment and other material assets.

Proper use

The machine may only be used for the following purposes:

Soil compaction.

Asphalt compaction.

Vibration of sett paving (paving stones).

The machine may not be used for the following purposes:

Compaction of very cohesive soils.

Compaction of frozen soils.

Compaction of hard, non-compressible soils.

Compaction of non-load-bearing soils.

Use in accordance with the intended purpose also includes the observation of all safety instructions in this manual as well as complying with the prescribed care and maintenance instructions.

Any other use or extended use is considered not in accordance with the intended purpose. The manufacturer's liability and warranty are canceled for any damage resu lting from improper use. The risk lies entirely with the operator.

Structural changes

Structural modifications may not be undertaken without the written permission of the manufacturer. Unapproved structural changes may result in risks to the operator and/or third parties as well as damage to the machine.

In the case of unauthorized structural changes, the liability and warranty of the manufacturer are no longer applicable.

The following cases are considered structural changes:

Opening the machine and the permanent removal of components.

Installing spare parts that do not originate from Wacker Neuson or are not comparable in the design system and quality of the original parts.

Attaching any accessories that do not originate from Wacker Neuson.

Spare parts or accessories that originate from Wacker Neuson can be safely mounted. They can be found on the Internet under www.wackerneuson.com.

100_0202_si_0010.fm |

8 |

3 Safety

3.2Areas of responsibility of the operator

The operator is the individual who personally operates this machine for industrial or commercial purposes or who entrusts a third party with the use. The operator bears legal responsibility for his/her protection as well as that of third parties.

The user must make the operator's manual available to the operator and ensure that this has been read and understood.

The manual must be kept next to the machine or place of use.

The operator must hand over the manual to subsequent operators or owners of the machine.

The country-specific regulations, standards, and guidelines on accident prevention and environmental protection must be observed. The operator's manual must be supplemented with additional instructions that take regulatory, national or generally applicable safety standards into consideration.

3.3Operator responsibilities

Know and implement the applicable industrial safety regulations.

Use a risk assessment to identify the dangers that result from the working conditions at the site of application.

Create operating instructions for the operation of this machine.

Periodically check whether the user instructions correspond to the current state of regulations.

Clearly regulate and specify responsibilities for operation, troubleshooting, maintenance, and cleaning.

Regularly train employees and inform them about potential hazards.

Provide employees with the necessary equipment.

3.4Personnel qualification

This machine may only be installed and operated by trained personnel.

Faulty operation, misuse or operation by untrained personnel can endanger health of the operator or third parties and lead to damage to or total loss of the machine.

In addition, the operator should be:

Physically and mentally fit.

Not under the influence of drugs, alcohol or medication that can impair responsiveness.

Familiar with the safety instructions in this manual.

Familiar with the intended use of this machine.

Have reached the minimum age of 18 to operate this machine.

Be instructed in the independent operation of the machine.

Be authorized to operate machines and systems inde pendently according to the standards of safety engineering.

3.5General sources of danger

Residual dangers in particular are hazards when dealing with machines that, despite a safe design, cannot be eliminated.

These residual dangers are not obvious and may be the source of a possible injury or health hazard.

If unforeseeable residual dangers occur, the operat ion of the machine is to be stopped immediately and the competent supervisor is to be informed. This supervisor shall make the following decisions and initiate everything required to eliminate the occurring risk.

If necessary, the machine manufacturer is to be informed.

3.6General safety instructions

The safety instructions in this chapter include the "General Safety Instructions", which should be reported in the manual in accordance with the applicable standards. There may be information that is not relevant to this machine.

9 |

100_0202_si_0010.fm |

3 Safety

3.6.1Working area

Before beginning work, familiarize yourself with the working environment, e.g. the load-bearing capacity of the floor or obstacles in the vicinity.

Make working area safe for the public transport sector.

Necessary fuse protection of walls and ceilings, e.g. in trench applications.

Keep the working area tidy. Cluttered or dark working areas can lead to accidents.

Using this machine in an explosive atmosphere is prohibited.

When using this machine, children and unauthorized individuals must be kept away. Distraction can lead to loss of control of the machine.

Always protect the machine against tilting, rolling, sliding, and crashing. Risk of injury!

3.6.2Service

The machine should only be maintained/repaired by technically trained personnel.

Use only original spare parts and accessories. This ensures the operational safety of the machine.

3.6.3Personal safety

Working under the influence of drugs, alcohol, or drugs can lead to serious injuries.

Protective equipment should be worn for all work. Appropriate personal protective equipment considerably reduces the risk of injury.

Remove any tools before the machine is put into operation. Tools that are located on a rotating machine part can be ejected and cause serious injury.

Always ensure good footing.

|

In the case of extensive work with this machine, long-term vibration-induced damage cannot be ruled |

|

out. For exact values of vibration measurement, refer to the Technical Data chapter. |

|

Wear suitable clothing. Keep loose clothing, gloves, jewelry, and long hair away from moving/rotating |

|

machine parts. Danger of being pulled! |

Ensure that no other individuals are in the danger zone!

3.6.4Handling and use

Handle machines with care. Do not operate machines with defective components or operator's controls. Immediately replace defective components or operator's controls. Machines with defective components or operator's controls carry a high risk of injury!

The operator's controls of the machine shall not be improperly locked, manipulated, or changed.

The machine, accessories, and tools should be used in accordance with these instructions.

Store unused machines out of reach of children. The machine may only be operated by authorized personnel.

After operation, store the cooled-down machine in a locked, clean, frost-protected, and dry location that is inaccessible to children and other unauthorized individuals.

3.7Specific safety instructions – Vibratory plates

3.7.1External influences

In the case of the following external influences, the vibratory plate may not be operated:

In heavy rain on sloped surfaces. Risk of slipping!

Oil field environments – methane leaks from bottom. Explosion hazard!

In dry, flammable vegetation. Fire hazard!

In potentially explosive areas. Explosion hazard!

100_0202_si_0010.fm |

10 |

3 Safety

3.7.2Operational safety

When operating the machine, make sure that no gas, water, or electric lines are damaged.

The machine must not be operated in tunnels or enclosed spaces.

Pay maximum attention near drops or slopes. Risk of crashing!

The operator must not leave the machine while it is in operation.

Do not leave the machine unattended. Risk of injury!

Delimit spacious workspace and restrict access to unauthorized individuals. Risk of injury!

Machine operators must ensure that people in the wo rkingarea keep a minimu m distance of 2 meters from the running machine.

Do not use any starting aid sprays . These can cause misfires as well as engine damage. Fire hazard!

Always approach gradients from below when operating the machine on sloped surfaces. The machine could slip or tip over.

Do not exceed max. allowable slanting position of the machine – possible failure of the engine lubrication, see chapter Technical Data.

3.7.3Minimum safety distances

Compaction work near buildings can cause damage to buildings. Therefore, all potential effects and vibrations on surrounding buildings must be checked in advance.

The relevant rules and regulations for measuring, evaluating and reducing vibration emissions - especially the DIN 4150-3 - must be considered.

Wacker Neuson assumes no liability for any damage to buildings.

3.8General safety instructions - Combustion engines

The following notes must be observed:

Before starting work, check the engine to ensure th ere are no leaks and cracks in the fuel lines, tank and fuel cap.

Do not operate a defective engine. Replace damaged parts immediately.

The pre-set engine speed may not be adjusted. This could lead to engine damage.

Make sure that the exhaust system of the engine is free of debris. Fire hazard!

Switch off the engine and allow to cool before refueling.

Use the correct fuel type. The fuel may not be mixed with other liquids.

Use clean filling aids for refueling. Do not spill fuel. Immediately wipe up any spilled fuel.

The engine may not be started near spilled fuel. Explosion hazard!

For operation in partially closed spaces, sufficient ventilation and aeration must be ensured. Do not inhale exhaust fumes. Risk of poisoning!

The engine surface and exhaust system can quickly become extremely hot. Risk of burns!

NOTE

This machine is outfitted with an EPA-certified engine.

Changing the revolutions per minute (RPM) impacts the EPA-certification and the emissions. Settings for this engine may only be changed by a professional.

For more information, contact the manufacturer or your Wacker Neuson contact partner.

3.9General safety instructions – fuel, lubricants and coolants

The following notes must be observed:

Always wear safety glasses and protective gloves when handling fuel, lubricants, and coolants. If hydraulic oil, fuel, oil, or coolant gets into your eyes, see a doctor immediately.

Avoid direct skin contact with fuel, lubricants and coolants. Immediately rinse skin with soap and water.

Do not eat or drink while working with fuel, lubricants and coolants.

Contaminated hydraulic oil or fuel from dirt or water can lead to premature wear or failure of the machine.

Dispose of spilled fuel, lubricants and coolants according to the applicable provisions for environmental protection.

If fuel, lubricants and coolants escape from the machine, do not operate the machine any longer and have it repaired immediately by the Wacker Neuson contact partner.

11 |

100_0202_si_0010.fm |

3 Safety

3.10Maintenance

The following notes must be observed:

This machine may not be maintained, repaired, adjusted or cleaned while switched on.

Adhere to maintenance intervals.

After each maintenance or repair, the safety devices on this machine must be reattached.

Observe the maintenance schedule. Non-listed work must be taken over by the service department of the Wacker Neuson contact partner.

Immediately replace worn or damaged machine parts. Only use spare parts from Wacker Neuson.

Keep the machine clean.

Missing, damaged, or illegible safety warning labels should be replaced immediately. Safety stickers contain important information for the protection of the operator.

Maintenance jobs must be performed in a clean and dry vicinity (e.g. workshop).

3.11Personal Protective Equipment

NOTE

To prevent personal injury when handling this machine, personal protective equipment must be worn when working on or around this machine.

Pictogram |

Significance |

Description |

|

|

|

|

Wear safety shoes! |

Safety shoes provide protection from bruises, falling |

|

|

|

|

objects, and slipping. |

|

|

|

|

|

|

|

|

Wear protective gloves! |

Protective gloves provide protection from abrasion, |

|

|

|

|

cuts, punctures, and hot surfaces. |

|

|

|

|

|

|

|

|

Wear ear protection! |

Ear protection provides protection from permanent |

|

|

|

|

hearing impairment. |

|

|

|

|

|

|

|

|

|

|

|

NOTE

With this machine, the permissible, country-specific noise limit (persona l rating level) may be exceeded. Therefore, ear protection must be worn. For exact values of noise emissions, refer to the Technical Data section.

Work particularly cautiously an d pay attention when wearing ear protection, as your ability to hear noises, such as screams or signal tones, is restricted.

Wacker Neuson recommends always wearing ear protection.

100_0202_si_0010.fm |

12 |

Loading...

Loading...