Wacker Neuson WM 80 Repair Manual

Repair Manual

Engine

WM 80

0162695en 003 0610

0162695EN

Copyright

notice

© Copyright 2010 by Wacker Neuson Corporation.

All rights, including copying and distribution rights, are reserved.

This publication may be photocopied by the original purchaser of the machine. Any

other type of reproduction is prohibited without express written permission from

Wacker Neuson Corporation.

Any type of reproduction or distribution not authorized by W acker Neuson Corp oration

represents an infringement of valid copyrights. Violators will be prosecuted.

T ra d emarks

Manufacturer

All trademarks referenced in this manual are the property of their respective owners.

Wacker Neuson Corporation

N92W15000 Anthony Avenue

Menomonee Falls, WI 53051 U.S.A.

Tel: (262) 255-0500 · Fax: (262) 255-0550 · Tel: (800) 770-0957

www.wackerneuson.com

Foreword

Foreword

Machine

documentation

Expectations

for

information in

this manual

CALIFORNIA

Proposition

65 Warning

Keep a copy of the Operator’s Manual with the machine at all times.

Use the separate Parts Book supplied with the machine to order replacement

parts.

If you are missing any of these documents, please contact Wacker Neuson

Corporation to order a replacement or visit www.wackerneuson.com.

When ordering parts or requesting service information, be prepared to provide

the machine model number, item number, revision number, and serial number.

This manual provides information and procedures to repair the above Wacker

Neuson model(s). For your own safety and to reduce the risk of injury , ca refully

read, understand, and observe all instructions described in this manual.

Wacker Neuson Corporation expressly reserves the right to make technical

modifications, even without notice, which improve the performance or safety

standards of its machines.

The information contained in this manual is based on machines manufactured

up until the time of publication. Wacker Neuson Corporation reserves the right

to change any portion of this information without notice.

Engine exhaust, some of its constituents, and certain vehicle components, contain

or emit chemicals known to the State of California to cause cancer and birth

defects or other reproductive harm.

Laws

pertaining to

spark

arresters

Manufacturer’s

approval

NOTICE: State Health Safety Codes and Public Resources Codes specify that in

certain locations spark arresters be used on internal combustion engines that use

hydrocarbon fuels. A spark arrester is a device designed to prevent accidental discharge of sparks or flames from the engine exhaust. Spark arresters are qualified

and rated by the United States Forest Service for this purpose. In order to comply

with local laws regarding spark arresters, consult the engine distributor or the local

Health and Safety Administrator.

This manual contains references to approved parts, attachments, and modifications. The following definitions apply:

Approved parts or attachments are those either manufactured or provided by

Wacker Neuson.

Approved modifications are those performed by an authorized Wacker Neu-

son service center according to written instructions published by Wacker Neuson.

Unapproved parts, attachments, and modifications are those that do not

meet the approved criteria.

Unapproved parts, attachments, or modifications may have the following consequences:

Serious injury hazards to the operator and persons in the work area

Permanent damage to the machine which will not be covered under warranty

Contact your Wacker Neuson dealer immediately if you have questions about

approved or unapproved parts, attachments, or modifications.

wc_tx001528gb.fm 3

Foreword

4 wc_tx001528gb.fm

WM 80 Table of Contents

Foreword 3

1 Safety Information 9

1.1 Signal Words Used in this Manual ....................................................... 9

1.2 Safety Guidelines for Operating the Machine ..................................... 10

1.3 Operator Safety while Using Internal Combustion Engines ............... 12

1.4 Service Safety .................................................................................... 13

2 Technical Data 14

2.1 Engine Specifications ......................................................................... 14

2.2 Tune-up Specifications ....................................................................... 15

2.3 Carburetor Specifications for Bing, and Tillotson (Standard**) .......... 16

2.4 Operating and Idle Speeds ................................................................. 19

3 Maintenance 20

3.1 Periodic Maintenance Schedule ......................................................... 20

3.2 Storage ............................................................................................... 21

3.3 General Air Filter Maintenance ........................................................... 21

3.4 Cartridge-Type Air Filter ..................................................................... 22

3.5 Disc-Type Air Filter ............................................................................. 23

3.6 Low-Maintenance Air Filter ................................................................. 24

3.7 Dual-Element Air Cleaner ................................................................... 25

3.8 Three-Stage Air Cleaners ................................................................... 26

3.9 Engine Cleaning ................................................................................. 28

3.10 Spark Plug .......................................................................................... 28

3.11 Muffler ................................................................................................ 28

3.12 Fuel Filter ........................................................................................... 30

3.13 Fuel Hoses ......................................................................................... 30

4 Starting and Ignition 31

4.1 Starter Assembly Exploded View ....................................................... 31

4.2 Disassembling the Starter .................................................................. 32

wc_br0162695en_003TOC.fm 5

Table of Contents WM 80

4.3 Inspecting the Starter ..........................................................................32

4.4 Assembling the Starter ........................................................................33

4.5 Replacing the Starter Rope .................................................................34

4.6 Ignition System Diagram ...................................................................36

4.7 Ignition System Operation ...................................................................37

4.8 Checking Spark ...................................................................................38

4.9 Using Ignition Tester ...........................................................................39

4.10 Setting Air Gap ....................................................................................40

4.11 Replacing the Ignition Module .............................................................42

5 Carburetor Basics 46

5.1 Brands Used ........................................................................................46

5.2 Walbro Carburetor Operation ..............................................................47

5.3 Versions of Tillotson Carburetor ..........................................................54

5.4 Tillotson Carburetor Operation ............................................................55

5.5 Bing Carburetor Operation ..................................................................61

5.6 Carburetor Adapters ............................................................................64

6 Carburetor Replacement 66

6.1 Replacing the Walbro Carburetor (auto-release choke models) .........66

6.2 Removing Walbro Carburetor (standard choke models) .....................70

6.3 Removal, Tillotson with composite adapter .........................................72

6.4 Tillotson with Straight-Through Adapters ............................................74

6.5 Tillotson with Elbow Adapters .............................................................74

6.6 Bing .....................................................................................................75

7 Carburetor Overhaul 76

7.1 Walbro Carburetor Exploded View (auto-release choke models) .......76

7.2 Walbro Carburetor Components (auto-release choke models) ...........77

7.3 Rebuilding the Walbro Carburetor (auto-release choke models) ........78

7.4 Walbro Carburetor Exploded View (standard choke models) .............84

7.5 Walbro Carburetor Components (standard choke models) .................85

7.6 Rebuilding the Walbro Carburetor (standard choke models) ..............86

7.7 Tillotson Carburetor Exploded View ..................................................92

7.8 Tillotson Components ..........................................................................93

6 wc_br0162695en_003TOC.fm

WM 80 Table of Contents

7.9 Bing Carburetor Exploded View ......................................................... 94

7.10 Bing Carburetor Components ............................................................. 95

8 Carburetor Inspection and Adjustment 96

8.1 Inspection ........................................................................................... 96

8.2 Adjusting the Inlet Control Lever ........................................................ 97

8.3 Carburetor Adjustments ..................................................................... 98

9 Carburetor Troubleshooting 101

9.1 Troubleshooting Walbro Carburetors ............................................... 101

9.2 Troubleshooting Tillotson and Bing Carburetors .............................. 102

10 Disassembly and Assembly 104

10.1 Tools ................................................................................................. 104

10.2 Special Tools .................................................................................... 104

10.3 Ordering Parts ................ .................................................................. 105

10.4 Reference Numbers ( ) ..................................................................... 105

10.5 Threadlocking Compounds .............................................................. 105

10.6 Removing the WM 80 Engine from BS Rammers (auto-release

choke models) .................................................................................. 106

10.7 Removing Engine From BS Model Rammers

(standard choke models) .................................................................. 108

10.8 Removing Engine From BH 23 Breakers ......................................... 110

10.9 Removing Clutch .............................................................................. 112

10.10 WM 80 Exploded View .................................................................... 114

10.11 WM 80 Components ......................................................................... 115

10.12 WM 80 Cross Section ..................................................................... 116

10.13 WM 80 Cross Section Components ................................................. 117

10.14 Vacuum Testing Cylinder ................................................................. 118

10.15 Cylinder and Piston Removal ........................................................... 120

10.16 Cylinder and Piston Inspection ......................................................... 122

10.17 Cylinder and Piston Installation ........................................................ 124

10.18 Inspecting Connecting Rod and Crankshaft ..................................... 126

10.19 Disassembling Crankcase ................................................................ 128

10.20 Assembling Crankcase ..................................................................... 130

wc_br0162695en_003TOC.fm 7

Table of Contents WM 80

10.21 Crankshaft Bearings ..........................................................................132

10.22 Bearing Installation ............................................................................134

8 wc_br0162695en_003TOC.fm

WM 80 Safety Information

1 Safety Information

1.1 Signal Words Used in this Manual

This manual contains DANGER, WARNING, CAUTION, NOTICE, and

NOTE signal words which must be followed to reduce the possibility

of personal injury, damage to the equipment, or improper service.

This is the safety alert symbol. It is used to alert you to potential personal hazards.

f Obey all safety messages that follow this symbol.

DANGER

DANGER indicates a hazardous situation which, if not avoided, will result in death

or serious injury.

f

To avoid death or serious injury from this type of hazard, obey all safety messages that

follow this signal word.

WARNING

WARNING indicates a hazardous situation which, if not avoided, could result in

death or serious injury.

To avoid possible death or serious injury from this type of hazard, obey all safety mes-

f

sages that follow this signal word.

CAUTION!

CAUTION indicates a hazardous situation which, if not avoided, could result in

minor or moderate injury.

f

To avoid possible minor or moderate injury from this type of hazard, obey all safety messages that follow this signal word.

NOTICE: Used without the safety alert symbol, NOTICE indicates a

situation which, if not avoided, could result in property damage.

Note: A Note contains additional information important to a procedure.

wc_si000509gb.fm 9

Safety Information WM 80

1.2 Safety Guidelines for Operating the Machine

Operator qualifications

Only trained personnel are permitted to start, operate, and shut down

the machine. They also must meet the following qualifications:

• have received instruction on how to properly use the machine

• are familiar with required safety devices

The machine must not be accessed or operated by:

• children

• people impaired by alcohol or drugs

Operator training

Before operating the machine:

• Read and understand the operating instructions contained in all

manuals delivered with the machine.

• Familiarize yourself with the location and proper use of all

controls and safety devices.

• Contact Wacker Neuson Corpor ation for additional training if

necessary.

When operating this machine:

• Do not allow improperly trained people to operate the machine.

People operating the machine must be familiar with the potential

risks and hazards associated with it.

Personal Protective Equipment (PPE)

Wear the following Personal Protective Equipment (PPE) while

operating this machine:

• Close-fitting work clothes that do not hinder movement

• Safety glasses with side shields

• Hearing protection

• Safety-toed footwear

1.2.1 Never operate this machine in applications for which it is not intended.

1.2.2 Do not allow anyone to operate this equipment without proper training.

People operating this equipment must be familiar with the risks and

hazards associated with it.

1.2.3 Do not touch the engine or muffler while the engine is on or

immediately after it has been turned off. These areas get hot and may

cause burns.

1.2.4 Do not operate the machine with unapproved accessories or

attachments.

1.2.5 Never leave the machine running unattended.

10 wc_si000509gb.fm

WM 80 Safety Information

1.2.6 Never tamper with or disable the function of operating controls.

1.2.7 Never use the choke to stop the engine.

1.2.8 Never operate the machine in areas where explosions may occur.

1.2.9 Read, understand, and follow procedures in the Operator’s Manual

before attempting to operate the machine.

1.2.10 Make sure that all other persons are at a safe distance from the

machine. Stop the machine if people step into the working area of the

machine.

1.2.11 Be sure operator is familiar with proper safety precautions and

operation techniques before using machine.

1.2.12 Always keep hands, feet, and loose clothing away from moving parts

of the machine.

1.2.13 Always use common sense and caution when operating the machine.

1.2.14 Always be sure the rammer will not tip over, roll, slide, or fall when not

being operated.

1.2.15 Always turn the engine OFF when the rammer is not being operated.

1.2.16 Always guide the rammer in such a way that the operator is not

squeezed between the rammer and solid objects. Special care is

required when working on uneven ground or when compacting coarse

material. Make sure to stand firmly when operating the machine under

such conditions.

1.2.17 When working near the edges of breaks, pits, slopes, trenches and

platforms, always operate the rammer in such a way that there is no

danger of it tipping over or falling in.

1.2.18 Store the machine properly when it is not being used. The machine

should be stored in a clean, dry location out of the reach of children.

1.2.19 Close fuel valve on engines equipped with one when machine is not

being operated.

1.2.20 Always operate machine with all safety devices and guards in place

and in working order. Do not modify or defeat safety devices. Do not

operate machine if any safety devices or guards are missing or

inoperative.

1.2.21 Do not transport the machine while it is running.

1.2.22 Do not tip the machine for cleaning or for any other reason.

wc_si000509gb.fm 11

Safety Information WM 80

1.3 Operator Safety while Using Internal Combustion Engines

WARNING

Internal combustion engines present special hazards during operation and fueling. Failure to

follow the warnings and safety standards could result in severe injury or death.

f Read and follow the warning instructions in the engine owner’s manual and the

safety guidelines below.

DANGER

Exhaust gas from the engine contains carbon monoxide, a deadly poison. Exposure to carbon monoxide can kill you in minutes.

f NEVER operate the machine inside an enclosed area, such as a tunnel, unless

adequate ventilation is provided through such items as exhaust fans or hoses.

Operating safety

When running the engine:

• Keep the area around exhaust pipe free of flammable materials.

• Check the fuel lines and the fuel tank for leaks and cracks before

starting the engine. Do not run the machine if fuel leaks are present

or the fuel lines are loose.

When running the engine:

• Do not smoke while operating the machine.

• Do not run the engine near sparks or open flames.

• Do not touch the engine or muffler while the engine is running or

immediately after it has been turned off.

• Do not operate a machine when its fuel cap is loose or missing.

• Do not start the engine if fuel has spilled or a fuel odor is present.

Move the machine away from the spill and wipe the machine dry

before starting.

Refueling safety

When refueling the engine:

• Clean up any spilled fuel immediately.

• Refill the fuel tank in a well-ventilated area.

• Replace the fuel tank cap after refueling.

• Do not smoke.

• Do not refuel a hot or running engine.

• Do not refuel the engine near sparks or open flames.

12 wc_si000509gb.fm

WM 80 Safety Information

• Do not refuel if the machine is positioned in a truck fitted with a

plastic bed liner. Static electricity can ignite the fuel or fuel vapors.

1.4 Service Safety

A poorly maintained machine can become a safety hazard! In order

for the machine to operate safely and properly over a long period of

time, periodic maintenance and occasional repairs are necessary.

WARNING

1.4.1 Do not attempt to clean or service the machine while it is running.

Rotating parts can cause severe injury.

1.4.2 DO NOT operate the machine without an air cleaner.

1.4.3 DO NOT remove air cleaner cover, paper element, or precleaner while

engine is running.

1.4.4 DO NOT alter engine speeds. Run the engine only at speeds specified

in the Technical Data Section.

1.4.5 Do not crank a flooded engine with the spark plug removed on

gasoline-powered engines. Fuel trapped in the cylinder will squirt out

the spark plug opening.

1.4.6 Do not test for spark on gasoline-powered engines if the engine is

flooded or the smell of gasoline is present. A stray spark could ignite

the fumes.

1.4.7 Do not use gasoline or other types of fuels or flammable solvents to

clean parts, especially in enclosed areas. Fumes from fuels and

solvents can become explosive.

1.4.8 ALWAYS replace the safety devices and guards after repairs and

maintenance.

1.4.9 Keep the area around the muffler free of debris such as leaves, paper,

cartons, etc. A hot muffler could ignite the debris and start a fire.

1.4.10 ALWAYS do periodic maintenance as recommended in the Operator’s

Manual.

1.4.11 ALWAYS clean debris from engine cooling fins.

1.4.12 Replace worn or damaged components with spare parts designed and

recommended by Wacker Neuson Corporation.

1.4.13 Disconnect the spark plug on machines equipped with gasoline

engines, before servicing, to avoid accidental start-up.

1.4.14 Keep the machine clean and labels legible. Replace all missing and

hard-to-read labels. Labels provide important operating instructions

and warn of dangers and hazards.

wc_si000509gb.fm 13

Technical Data WM 80 Repair

2 Technical Data

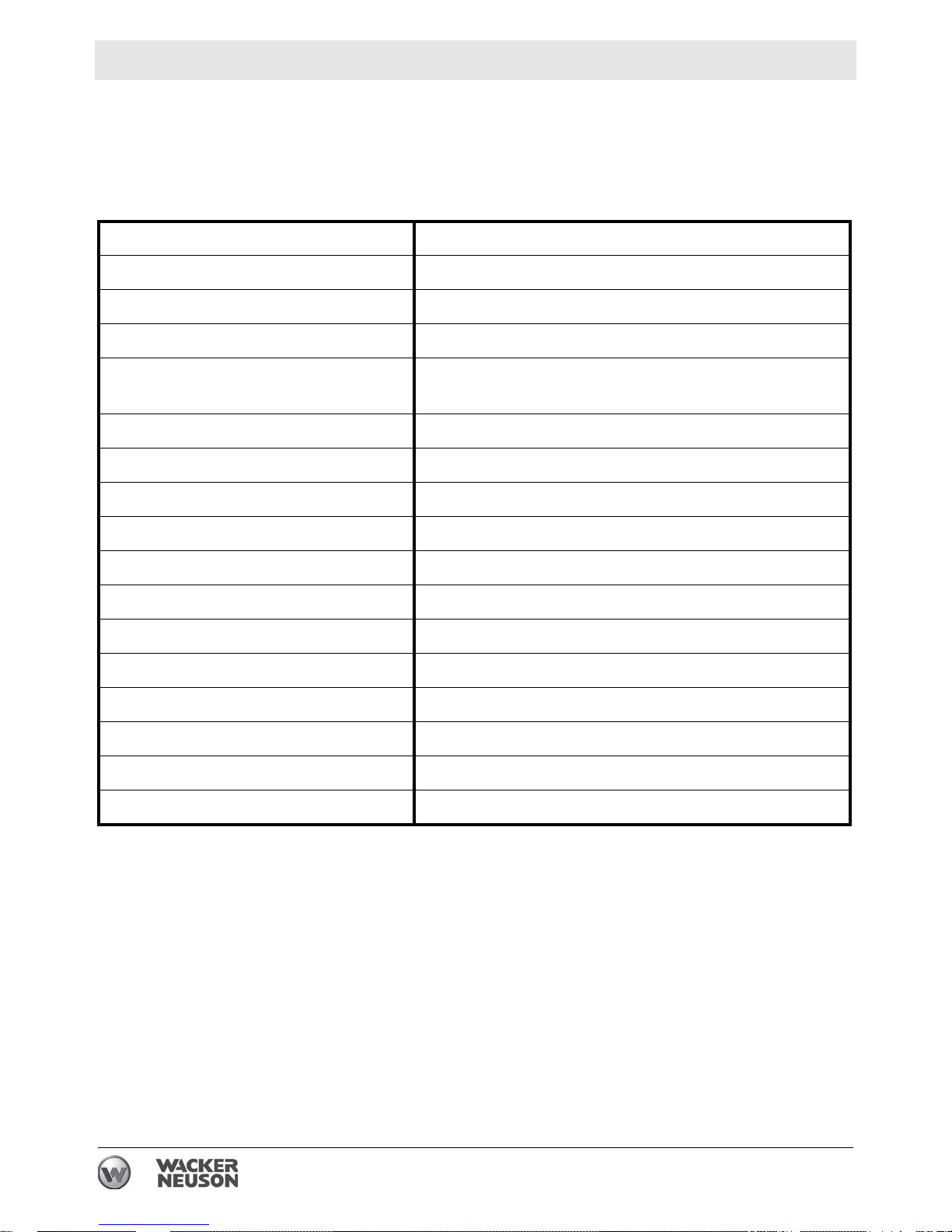

2.1 Engine Specifications

Engine Model WM 80

Type 2-cycle

Maximum rated power (kW) hp 3.0 (4.0)

Number of cylinders 1

Piston displacement cc

80 (4.9)

(cu.in.)

Cylinder bore mm (in.) (45) 1.77

Stroke mm (in.) 50 (1.96)

Compression ratio 9:1

Operating speed range rpm 3,000–5,000

Starter Pull-type, recoil starter

Ignition Transistor-controlled electronic (TCI)

Carburetor Diaphragm

Fuel Gas/oil mixture

Fuel:oil ratio between 120–50:1 (first tank 25:1)

Cooling Forced air

Weight kg (lbs.) 7.8 (17)

Direction of rotation Counterclockwise when viewed from drive end

14 wc_td000166gb.fm

WM 80 Repair Technical Data

2.2 Tune-up Specifications

Engine Model

Ring gap:

New

Maximum

mm (in.)

mm (in.)

Cylinder wear:

Maximum bore taper

mm (in.) 0.2 (0.008)

Cylinder head

compression

Ignition module air gap*

kg/cc (psi) 8.0–9.7 (120–140)

mm (in.) 0.4 (0.016)

Spark plug gap:

Champion RL86C

Champion UJ11G

Champion RL95YC**

* On models with adjustable air gap

** Must be used on models with oil injection

mm (in.)

mm (in.)

mm (in.)

WM 80

0.2–0.4 (0.008–0.016)

1.0–1.2 (0.039–0.047)

0.5 (0.020)

1.0–1.1 (0.040–0.045)

0.5 (0.020)

wc_td000166gb.fm 15

Technical Data WM 80 Repair

2.3 Carburetor Specifications for Bing, and Tillotson (Standard**)

Machine Carburetor

Make

Low-speed jet

size (x 0.01)

High-speed jet

size (x 0.01)

Carburetor

adapter bore

diameter

mm (in.)

BS 45Y •Bing

•Tillotson

#35

Adjustable

#62

#71*

8 (0.315)

8 (0.315)

•Tillotson w/

idle bypass

#36

#70

8 (0.315)

BS 50 Bing #40 #64 12 (0.472)

BS 52Y •Bing

•Tillotson

#35

Adjustable

#62

#71*

9 (0.354)

9 (0.354)

•Tillotson w/

idle bypass

BS 60Y •Bing

•Tillotson

#36

#35

Adjustable

#70

#62

#71*

9 (0.354)

12 (0.472)

11 (0.433)

•Tillotson w/

idle bypass

BS 62Y •Bing

•Tillotson

#36

#35

Adjustable

#70

#62

#71*

11 (0.433)

12 (0.472)

14 (0.551)

•Tillotson w/

idle bypass

#36

#70

14 (0.551)

BS 65Y

#35 #62 16 (0.630)

BS 100Y #40 #64 16 (0.630)

BPS 1330 #40 #58 10 (0.394)

Bing

BPS 1350 #40 #58 10 (0.394)

BVNPN #40 #64 12 (0.472)

BHF 30S #40 #58 16 (0.630)

BH 23 Tillotson w/ idle

#42 #74 10 (0.394)

bypass

BS 500 7550

Rev. 100–102

BS 500 7550

Tillotson w/ idle

bypass

#36 #78 13 (0.512)

#36 #66 13 (0.512)

Rev. 103–110

16 wc_td000166gb.fm

WM 80 Repair Technical Data

BS 500 7550

Rev. 111–121

BS 500 7550

Rev. >121

BS 500 8048

Rev. 100–102

BS 500 8048

Rev. 103–110

BS 500 8048

Rev. 111–118

BS 500 8048

Rev. >118

BS 500 8049

Rev. 100–102

BS 500 8049

Rev. 103–110

BS 500 8049

Rev. 111–119

Tillotson w/ idle

bypass

#36 #70 13 (0.512)

#36 #70 11 (0.433)

#36 #78 13 (0.512)

#36 #66 13 (0.512)

#36 #70 13 (0.512)

#36 #70 11 (0.433)

#36 #78 13 (0.512)

#36 #66 13 (0.512)

#36 #70 13 (0.512)

BS 500 8049

#36 #70 11 (0.433)

Rev. >120

BS 500 9074

#36 #70 16 (0.630)

High Altitude

Rev. 116

BS 500oi 9166 #36 #72 11 (0.433)

BS 600 7551

#36 #78 14 (0.551)

Rev. 100–103

BS 600 7551

#36 #66 13 (0.512)

Rev. 105–120

BS 600 7551

#36 #72 13 (0.512)

Rev. >121

BS 600 8207

#36 #78 16 (0.630)

High Altitude

Rev. <104

wc_td000166gb.fm 17

Technical Data WM 80 Repair

BS 600 8207

#36 #74 18 (0.709)

High Altitude

Rev. > 104

BS 600oi 9166 #36 #72 18 (0.709)

BS 600oi 9262

#36 #74 18 (0.709)

High Altitude

BS 700 7552

#36 #78 16 (0.630)

Rev. <104

BS 700 7552

#36 #74 18 (0.709)

Rev. 104–118

BS 700 7552

#36 #74 18 (0.709)

Rev. >118

BS 700 8051

#36 #78 16 (0.630)

Rev. 100–120

BS 700 8051

Rev. >120

BS 700 8052

Tillotson w/ idle

bypass

#36 #74 16 (0.630)

#36 #78 16 (0.630)

Rev. 100–102

BS 700 8052

#36 #74 18 (0.709)

Rev. 103–118

BS 700 8052

#36 #74 18 (0.709)

Rev. >118

BS 700oi 9167 #36 #74 18 (0.709)

BS 50-2 9384 #36 #72 19 (0.748)

BS 50-2i 9338 #36 #72 19 (0.748)

BS 50-2i 9383 #36 #72 19 (0.748)

BS 60-2i 9339 #36 #72 19 (0.748)

BS 60-2i 9393 #36 #72 19 (0.748)

BS 70-2i 9341 #36 #72 19 (0.748)

BS 70-2i 9401 #36 #72 19 (0.748)

* Single-needle Tillotson carburetors only. Dual-needle Tillotson carburetors use an adjustable needle

for high-speed adjustment.

** Standard sizes listed. Operation at altitudes above 3000 m (5000 feet) may require different jet and

carburetor adapter sizes. Contact Wacker Neuson Neuson Service for the modifications required.

18 wc_td000166gb.fm

WM 80 Repair Technical Data

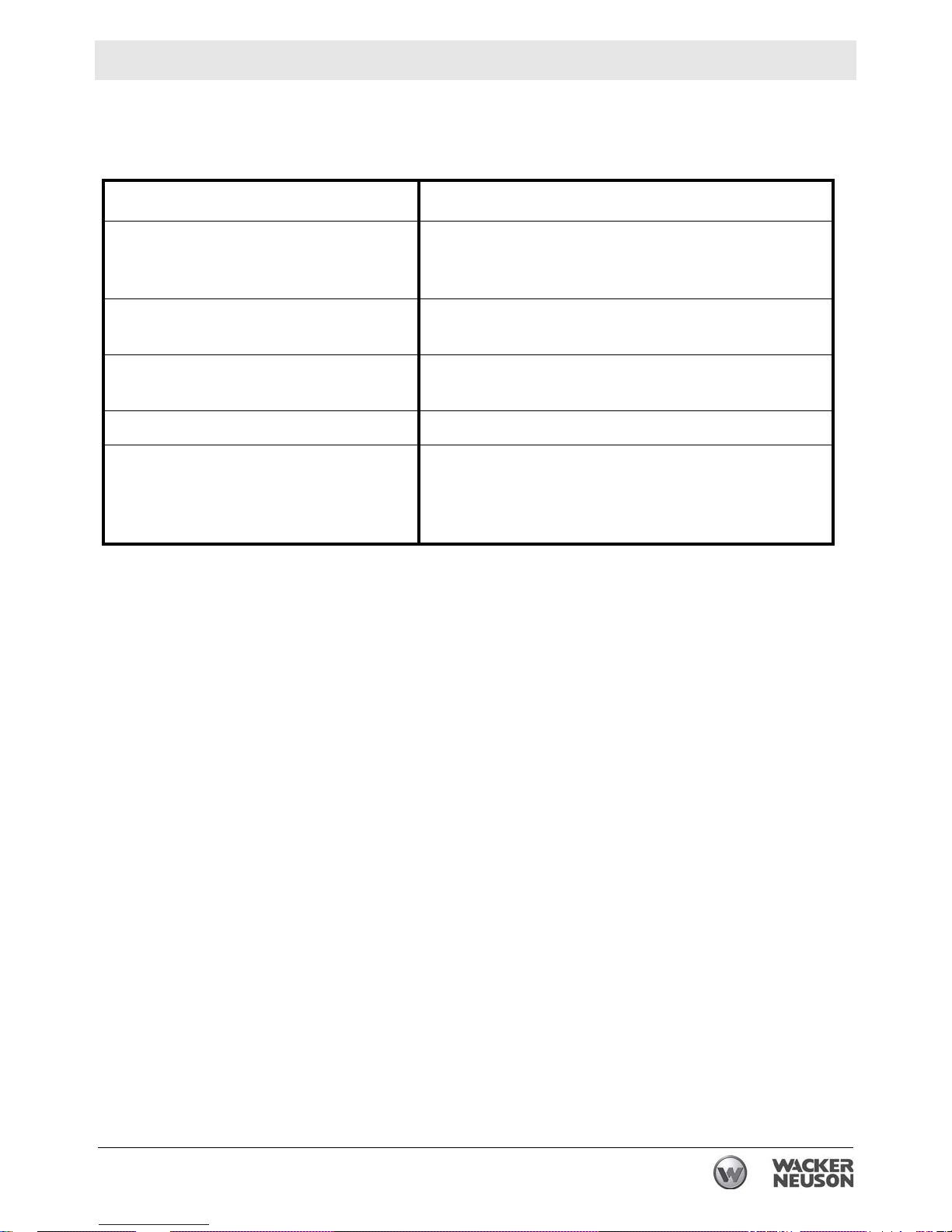

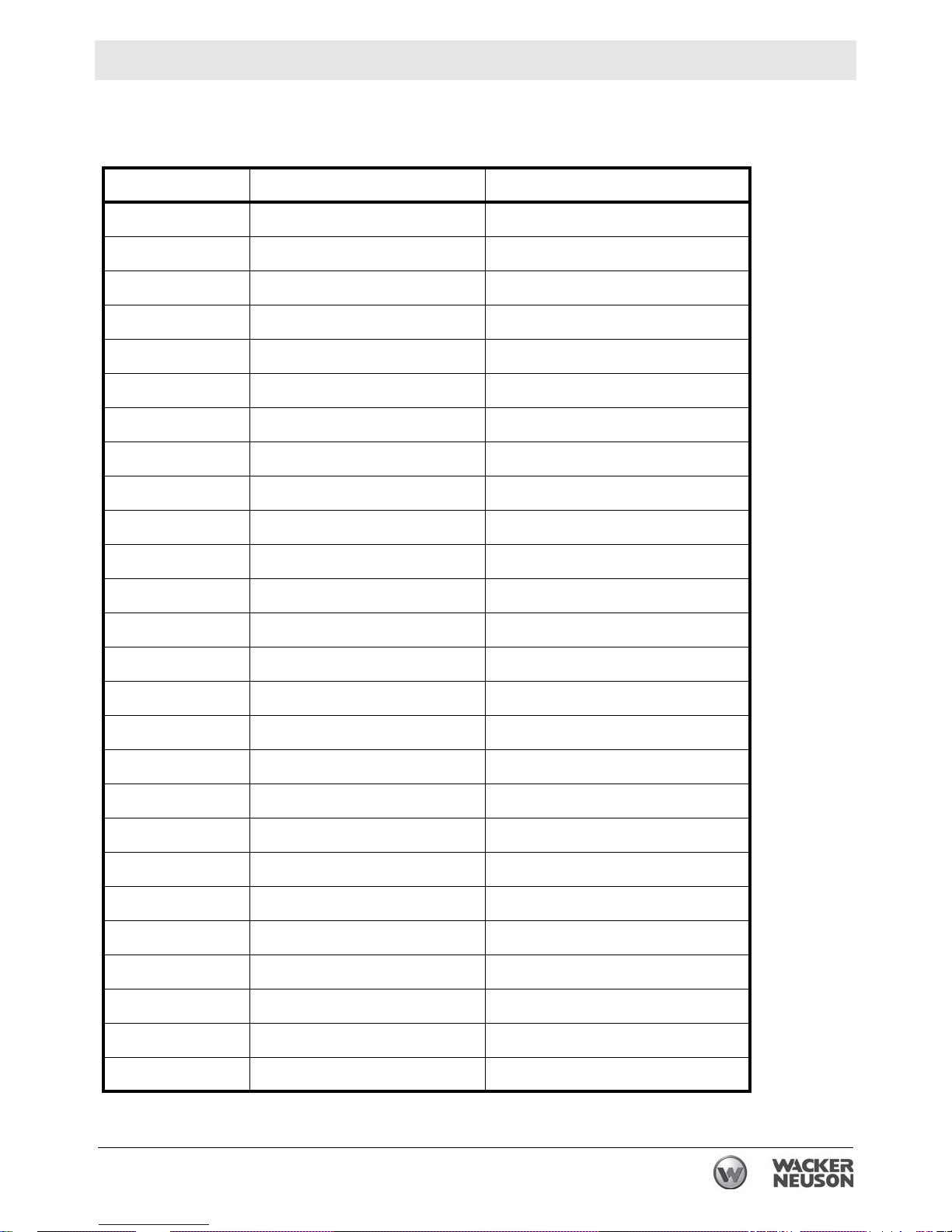

2.4 Operating and Idle Speeds

Machine Idle speed ±100 rpm Full speed ±100 rpm

BS 45Y 1800 4300

BS 52Y 1800 4300

BS 60Y 1800 4600

BS 62Y 1800 4500

BS 65Y 1500 4400

BS 100Y 1500 4300

BS 105Y/92Y 1500 4400

BPS 1330 1500 4800

BPS 1350 1500 4800

BVNPN 1700 4500

BHF 30S 1500 4300

BH 23 1500 4250

BS 500 1800 4400

BS 500-oi 1800 4400

BS 50-2 1800 4400

BS 50-2i 1800 4400

BS 600 1800 4350

BS 600-oi 1800 4350

BS 60-2 1800 4350

BS 60-2i 1800 4350

BS 650 1800 4350

BS 65V 1800 4350

BS 700 1800 4350

BS 700-oi 1800 4350

BS 70-2 1800 4350

BS 70-2i 1800 4350

wc_td000166gb.fm 19

Maintenance WM 80

3 Maintenance

3.1 Periodic Maintenance Schedule

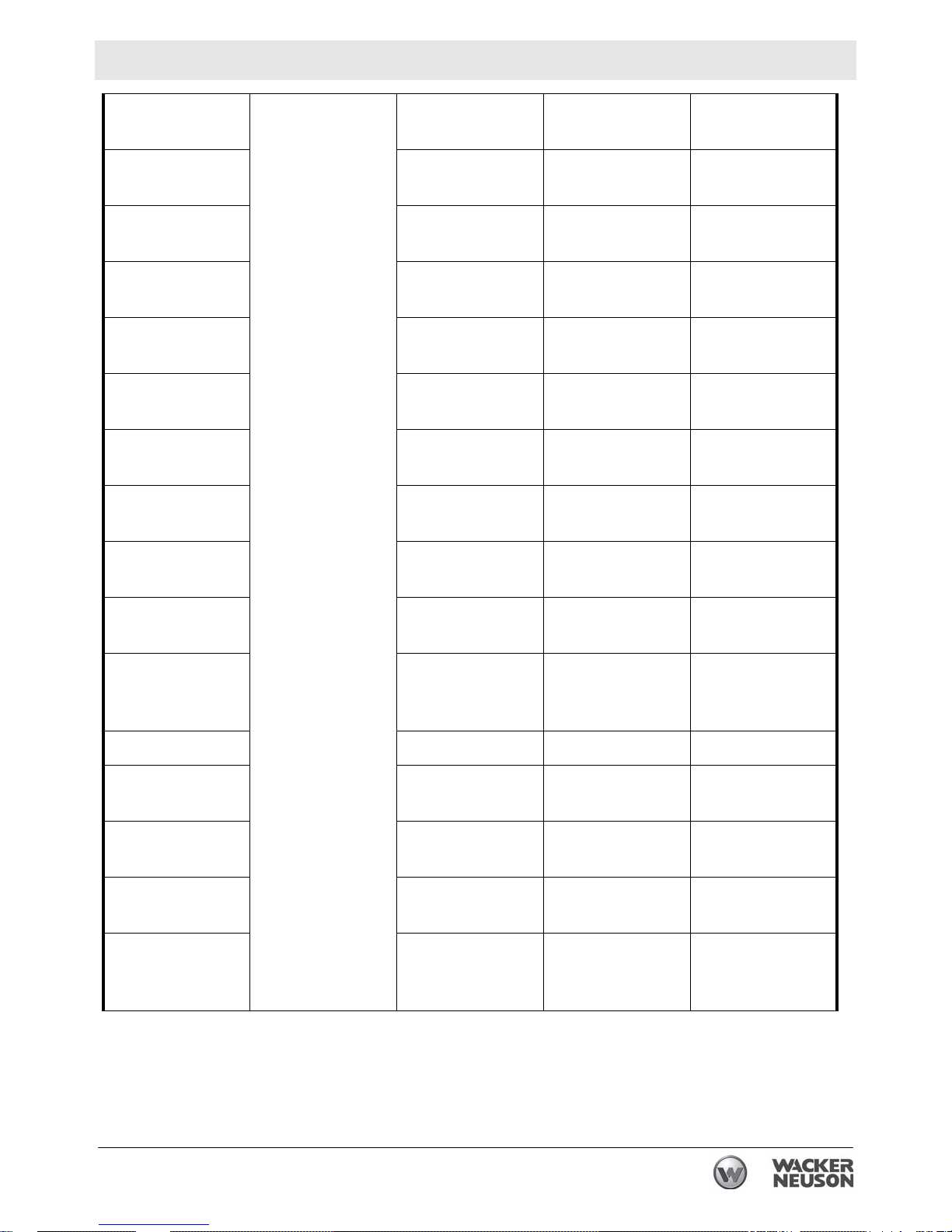

Daily After first

5 hours

Check fuel level. •

Clean and/or inspect air filter (cartridge type). •

Clean and oil foam precleaner where equipped. •

Check condition of fuel lines. •

Check & tighten engine cylinder screws. ••

Check & tighten external fasteners. ••

Clean and check spark plug gap. ••

Clean engine cooling fins. •

Replace cartridge style air filter element. •

Replace spark plug. •

Clean recoil starter. •

Remove carbon deposits from muffler & cylinder

exhaust port.

Every

week or

25 Hours

Every

month or

100 Hours

Every 3

months or

300 hours

•

Replace in-line fuel filter. •

Inspect in-tank fuel filter. •

20 wc_tx000520gb.fm

WM 80 Maintenance

3.2 Storage

If storing the unit for a long period of time (more than 30 days) carry

out the following:

3.2.1 Drain fuel from the tank.

3.2.2 Start the engine and run it until all the fuel in the carburetor is used.

3.2.3 Remove the spark plug and pour 30 ml (1 oz.) of clean SAE 30W

engine oil into the cylinder through the spark plug opening.

3.2.4 Pull the starter rope slowly to distribute oil in the engine.

3.2.5 Reinstall the spark plug.

3.3 General Air Filter Maintenance

Inspect the air filter daily. Severe damage to the engine components

can occur if the engine is operated with a damaged element. This is

especially important when operating in extremely dusty conditions; dirt

and sand, if allowed to enter the engine, can quickly destroy the

cylinder wall and piston.

NOTICE: Never operate the engine without an air filter. Damage to the

engine will occur.

wc_tx000520gb.fm 21

Maintenance WM 80

3.4 Cartridge-Type Air Filter

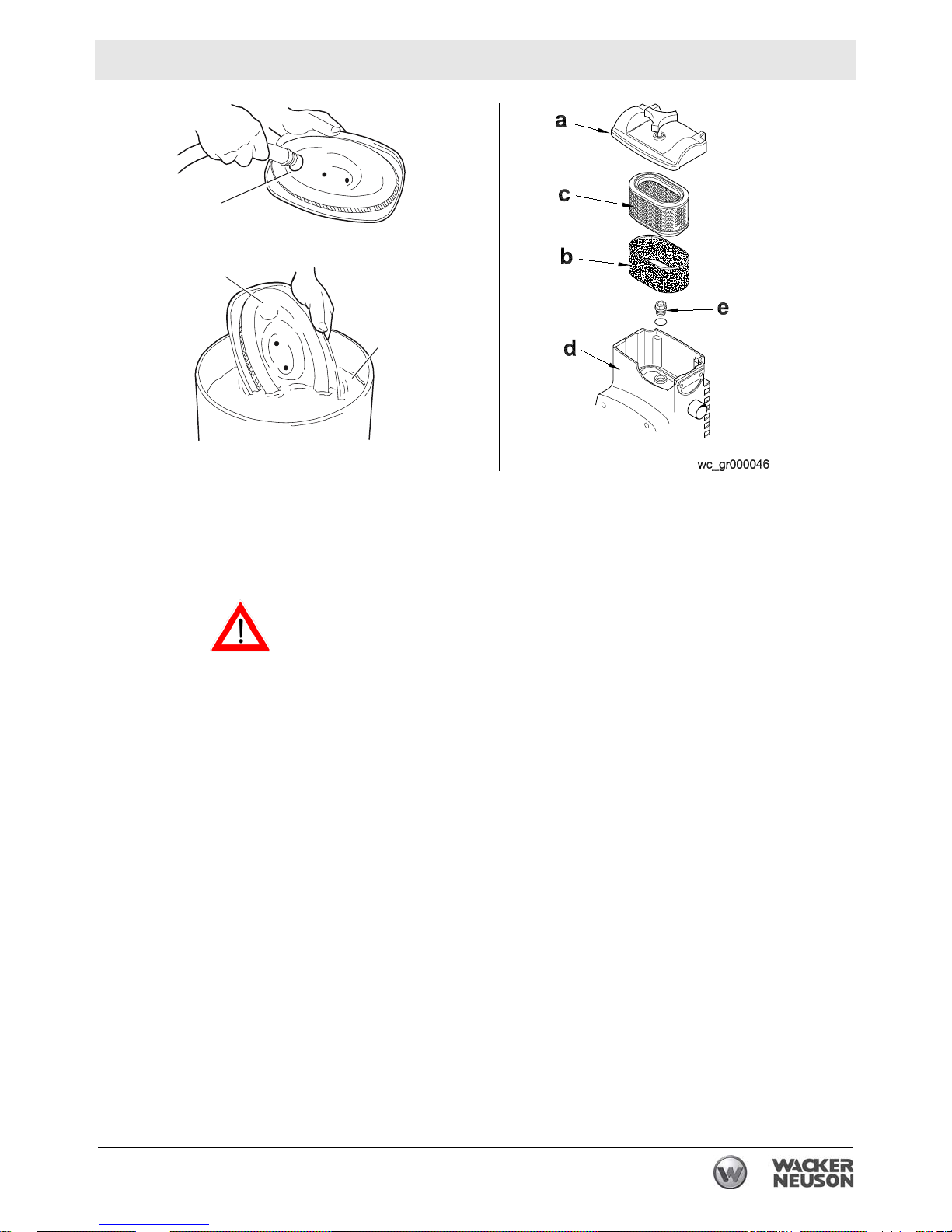

See Graphic: wc_gr002875

3.4.1 This type of air filter is found on rammers with Bing carburetors and on

early rammers with Tillotson carburetors. To service:

3.4.2 Unsnap the spring clips (1) on the protective cover (2) and remove the

filter element (3).

3.4.3 Inspect the paper filter element and replace it if it appears wet, heavily

soiled, or torn.

3.4.4 Inspect the condition of the rubber seals (4) on each end of the

element. Replace the element if the seals are damaged or deformed.

3.4.5 The element can be cleaned by tapping it against a firm surface. Take

care not to damage the seals or puncture the filter paper when

cleaning the filter. Do not use cleaning agents or solvents to clean the

filter.

3.4.6 Clean and inspect the seating surfaces on the mounting base (5) and

inside of the protective cover. Replace any damaged parts. Lightly oil

filter the seals and install the element.

2

3

4

5

1

wc_gr002875

22 wc_tx000520gb.fm

WM 80 Maintenance

3.5 Disc-Type Air Filter

See Graphic: wc_gr002876

The disc-type air filter with oil-wetted foam precleaner is used on BPS

1330, BPS 1350, BVPN 50, and the BHF 30S. To service the filter:

3.5.1 Close the carburetor choke. Loosen the clamp (1) around the

carburetor and remove the precleaner housing (2).

3.5.2 Remove the metal screen (3) from the carburetor and inspect it.

Replace the screen if it is heavily soiled or damaged. The screen can

be cleaned by tapping it against a firm surface or by using lowpressure (30 psi) compressed air.

3.5.3 Remove the retainer (4) and the foam precleaner (5) from the housing

and inspect. Replace the precleaner if it appears heavily soiled or

damaged. The precleaner can be cleaned by using a mild detergent

and warm water. Rinse it thoroughly and dry it with a lint-free cloth.

3.5.4 After cleaning, soak the precleaner in clean engine oil (SAE 30W),

squeeze out excess oil, and reinstall the filter.

3

2

1

5

4

wc_gr002876

wc_tx000520gb.fm 23

Maintenance WM 80

3.6 Low-Maintenance Air Filter

See Graphic: wc_gr002877

This type of air filter is found on rammers. The air filter is self-cleaning

and uses the movement of the machine to shake dust and dirt loose

from the air filter element while the rammer is operating. Under normal

operating conditions this element will not require cleaning and should

not be removed from the machine. If the element does become

plugged with dirt, the engine will begin to lose power. In this case, the

air filter element can be removed and cleaned as described below.

Replace the element if it becomes so plugged with dirt it can no longer

be cleaned.

3.6.1 Remove the two locknuts from the top of the air filter and lift the air filter

off.

3.6.2 Use compressed air directed from the inside of the air filter, through the

grommet hole (1), to blow dirt and dust from the element.

NOTICE: Air pressure must not exceed 100 psi.

3.6.3 Run fresh water through the grommet hole (1) until water runs clear

NOTICE: DO NOT use solvents, fuel oil, or gasoline to wash the filter.

3.6.4 Plug or cover the hole in the air filter (2) using a cork or tape to prevent

dirty water from entering inside the element. Soak the air filter in a

solution (3) of warm water and a low-suds detergent for at least 15

minutes. Longer periods of time (up to several hours) of soaking may

be required, depending on how dirty the element is.

3.6.5 Remove the air filter from the water and repeat rinsing the filter as

described in Step 3. Allow the element to air dry in a dust-free area.

DO NOT use heat to speed drying.

3.6.6 Inspect the grommet before assembly and replace it if it is worn or

damaged. Install the grommet on the element carefully to avoid cutting

it.

3.6.7 Install the air filter on the machine and secure it with washers and

locknuts. DO NOT overtighten. Overtightening can deform washers

and indent the top of the air filter.

Note: Apply grease or liquid soap to inside of grommet so it slides

easily on machine.

24 wc_tx000520gb.fm

WM 80 Maintenance

1

2

3

wc_gr002877

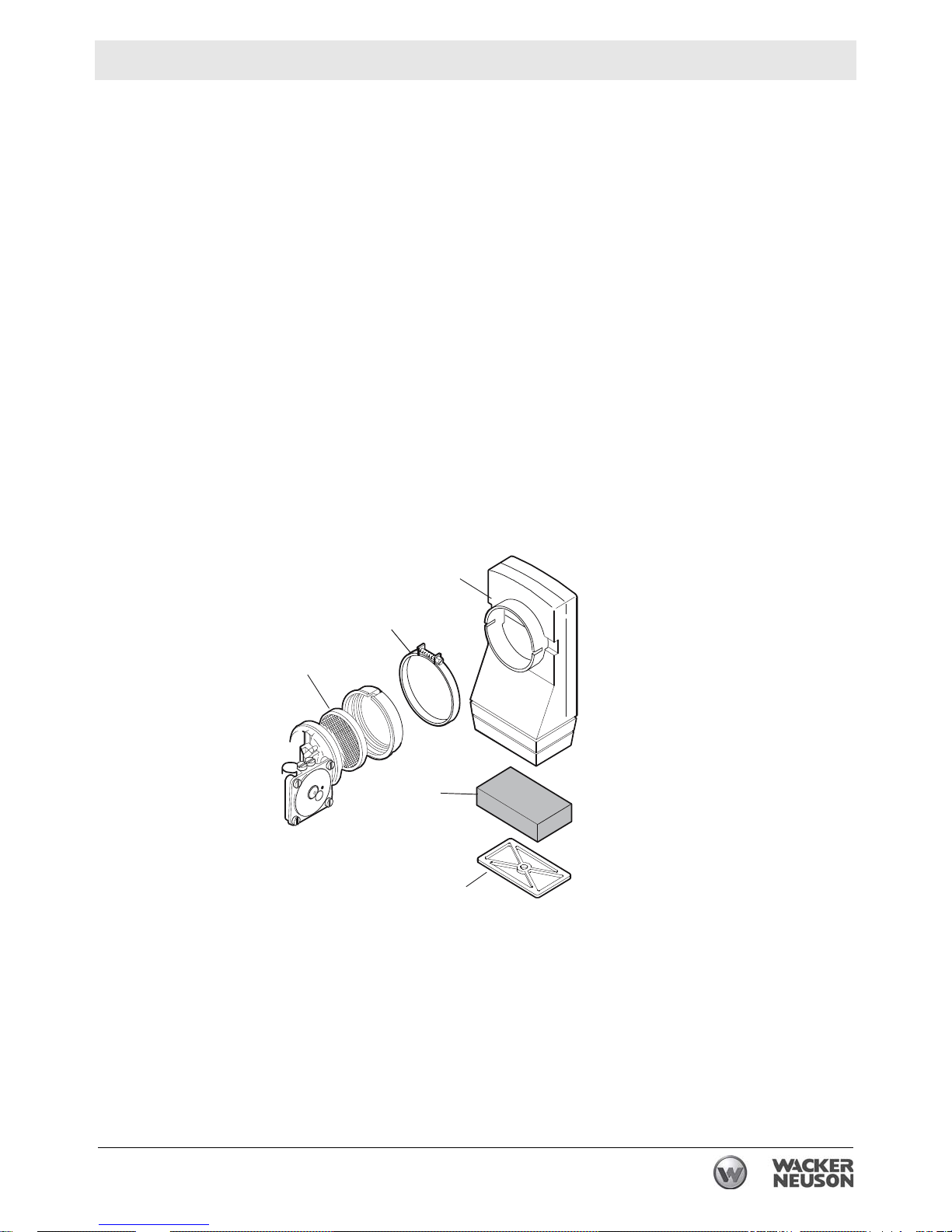

3.7 Dual-Element Air Cleaner

See Graphic: wc_gr000046

NEVER use gasoline or other types of low flash-point solvents for

cleaning the air cleaner. A fire or explosion could result.

WARNING

NOTICE: NEVER run engine without air cleaner. Severe engine

damage will occur.

The rammer is equipped with a dual-element air cleaner. Under normal

operating conditions, elements should be cleaned once every week.

Under severe, dry and dusty conditions, the elements should be

maintained daily. Replace an element when saturated with dirt that

cannot be removed. Clean elements using the following procedure:

3.7.1 Remove air cleaner cover (a). Remove precleaner and paper element

and inspect them for holes or tears. Replace if damaged.

3.7.2 Precleaner (b): Clean with low-pressure compressed air. When very

soiled, wash in solution of mild detergent and warm water. Rinse

thoroughly in clean water. Allow to dry thoroughly before re-installing.

Note: Do not oil precleaner.

3.7.3 Paper element (c): Tap element lightly to remove excess dirt. Replace

paper element if it appears heavily soiled.

3.7.4 Wipe out filter housing (d) with a clean cloth.

NOTICE: Do not allow dirt to get into the engine intake port while

cleaning—damage to the engine will result.

wc_tx000520gb.fm 25

Maintenance WM 80

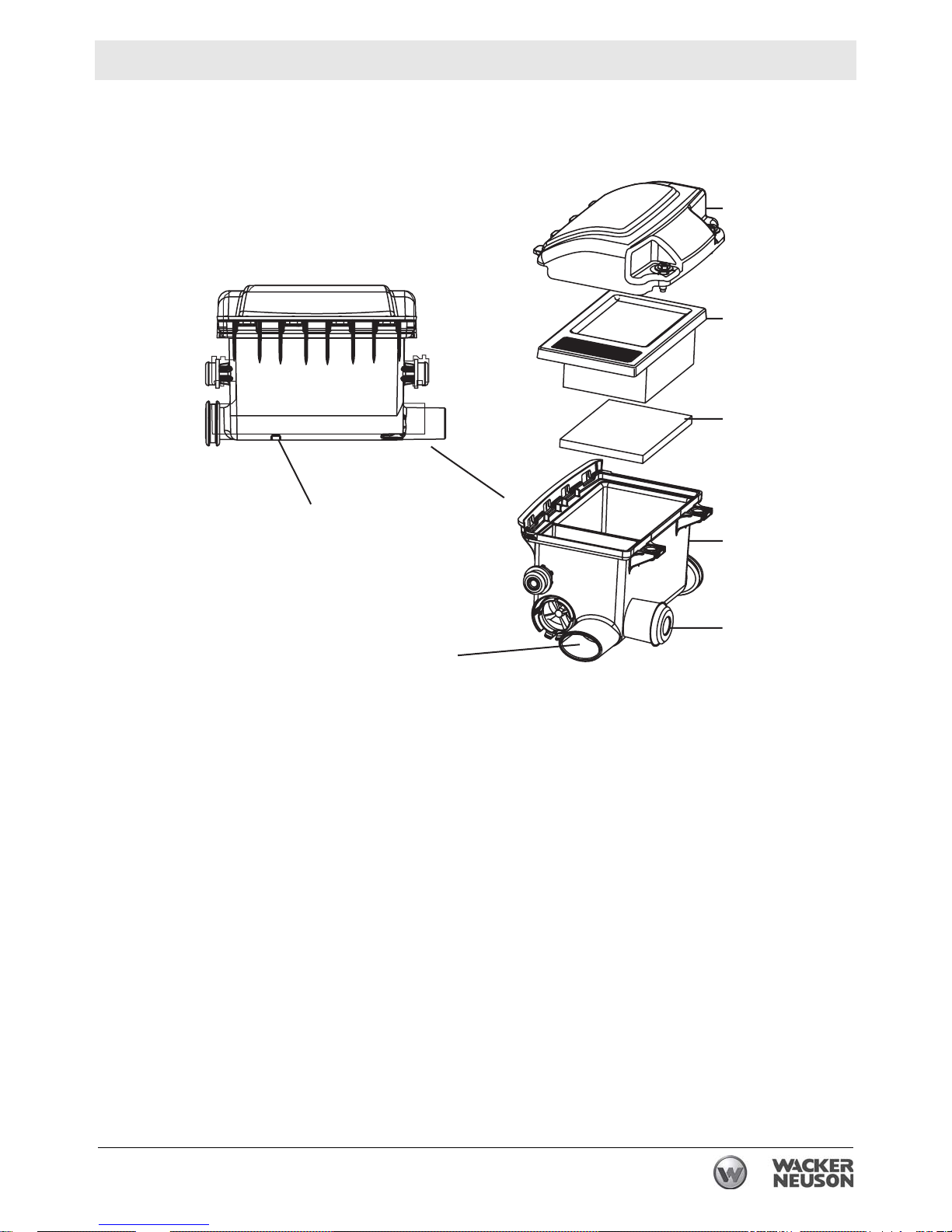

3.8 Three-Stage Air Cleaners

See Graphic: wc_gr001168

NEVER use gasoline or other types of low flash point solvents for

cleaning the air filter. A fire or explosion could result.

WARNING

NOTICE: NEVER run engine without main paper filter element (b).

Severe engine damage will occur.

Filter Indicator

The air intake system is equipped with a filter indicator (h), which

indicates when a filter change is required. Replace the main paper filter

element (b) when the yellow plunger of the indicator appears in or near

the red line. Push and hold in the yellow plunger on top of the indicator

to reset it after replacing the main paper filter element.

Clean elements using the following procedure:

3.8.1 Remove the air cleaner cover (a). Remove the main paper filter

element (b) and the secondary prefilter (c) and inspect them for holes

or tears. Replace the elements if they are damaged.

3.8.2 Main paper filter element (b): Replace the main paper filter element if

it appears heavily soiled and/or when the yellow plunger of indicator

appears in or near the red line.

3.8.3 Prefilter (c): Clean it with low-pressure compressed air. When the

prefilter is very soiled, wash it in a solution of mild detergent and warm

water. Rinse it thoroughly in clean water. Allow the prefilter to dry

thoroughly before reinstalling it.

Note: Do not oil the prefilter.

3.8.4 Wipe out the filter housing (d) with a clean cloth. Do not use

compressed air.

NOTICE: Do not allow dirt to get into the engine intake port (k) while

cleaning. Damage to engine will result.

3.8.5 Check that the precleaner debris ejector slot (i) is clear.

26 wc_tx000520gb.fm

WM 80 Maintenance

a

b

c

i

k

d

h

wc_gr001168

wc_tx000520gb.fm 27

Maintenance WM 80

3.9 Engine Cleaning

The WACKER WM 80 engine is air cooled and depends on the

cylinder cooling fins to dissipate heat. Dirt and debris caught in the

cooling fins can prevent them from dissipating heat causing the engine

to overheat. For this reason, it is important to inspect and clean the fins

as often as job conditions dictate. Clean debris from between the fins

using a screwdriver or similar implement.

3.10 Spark Plug

A well-maintained spark plug is essential to good combustion. Keep

the spark plug’s electrode clean and gapped to the correct setting. See

section Tune-up Specifications. Before removing the spark plug from

the engine, clean the immediate area around the spark plug to prevent

any dirt from falling into the cylinder when the spark plug is removed.

3.11 Muffler

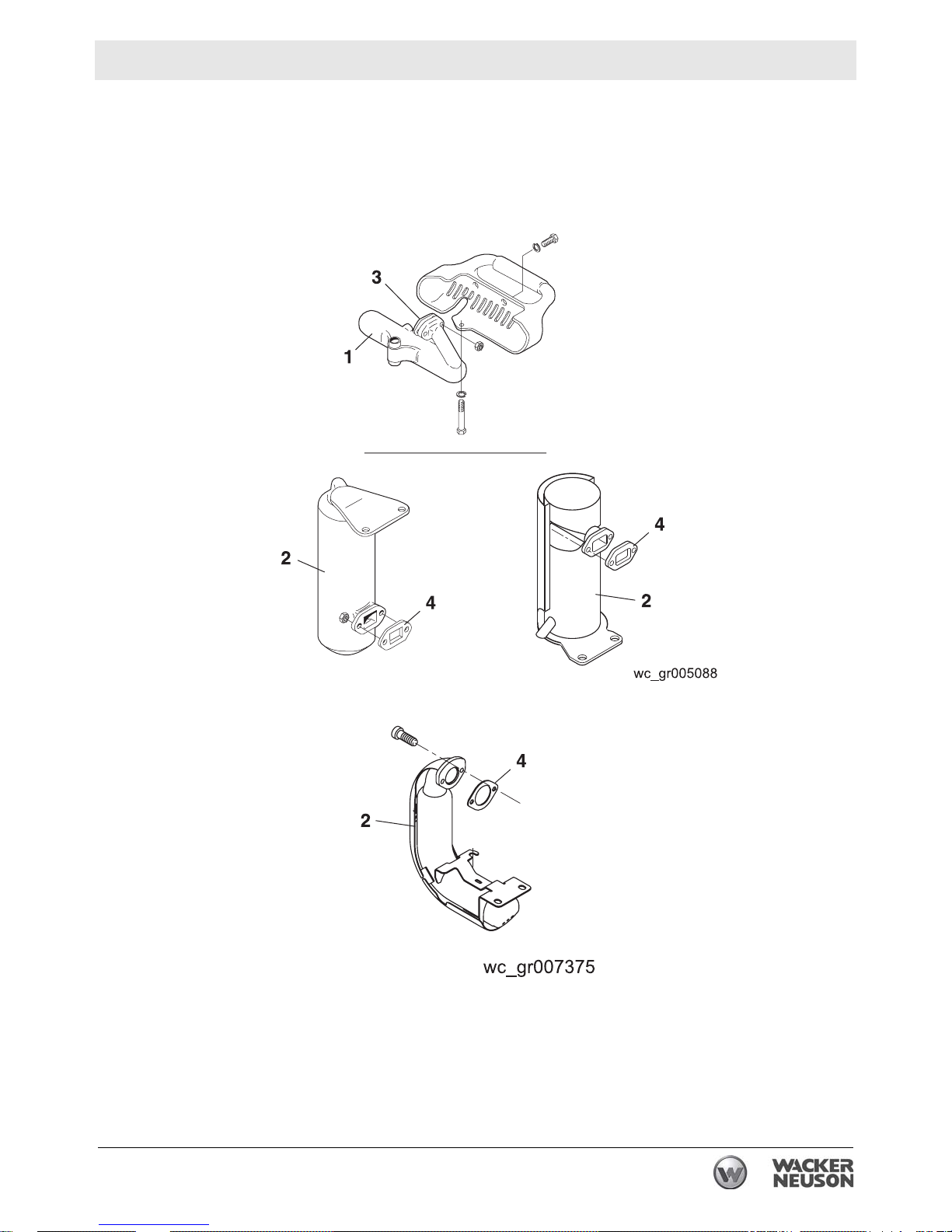

See Graphic: wc_gr005088, wc_gr007375

NOTICE: Do not remove the spark plug while the engine is hot. The

aluminum threads of the cylinder may strip.

Carbon deposits normally form over a period of time at the engine

exhaust and the muffler. If allowed to accumulate, these deposits may

eventually restrict the exhaust passages, resulting in poor

performance and hard starting. Factors contributing to excessive

carbon buildup include:

• Too much oil in the fuel mixture

• Dirty air filter

• Excessive idling

• Dirty carburetor

• Too rich fuel/air mixture

• Incorrect fuel jets

To service the muffler:

3.11.1 Remove the muffler (1, 2) from the engine.

3.11.2 Crank the engine until the piston is at the top of its stroke and covering

the exhaust port.

28 wc_tx000520gb.fm

WM 80 Maintenance

3.11.3 Clean the exhaust port using a blunt scraper. Inspect the gasket (3, 4)

and replace it if torn or cracked.

3.11.4 Soak the muffler in carburetor cleaner until the carbon deposits break

up. Drain the muffler and blow dry it dry with compressed air.

wc_tx000520gb.fm 29

Maintenance WM 80

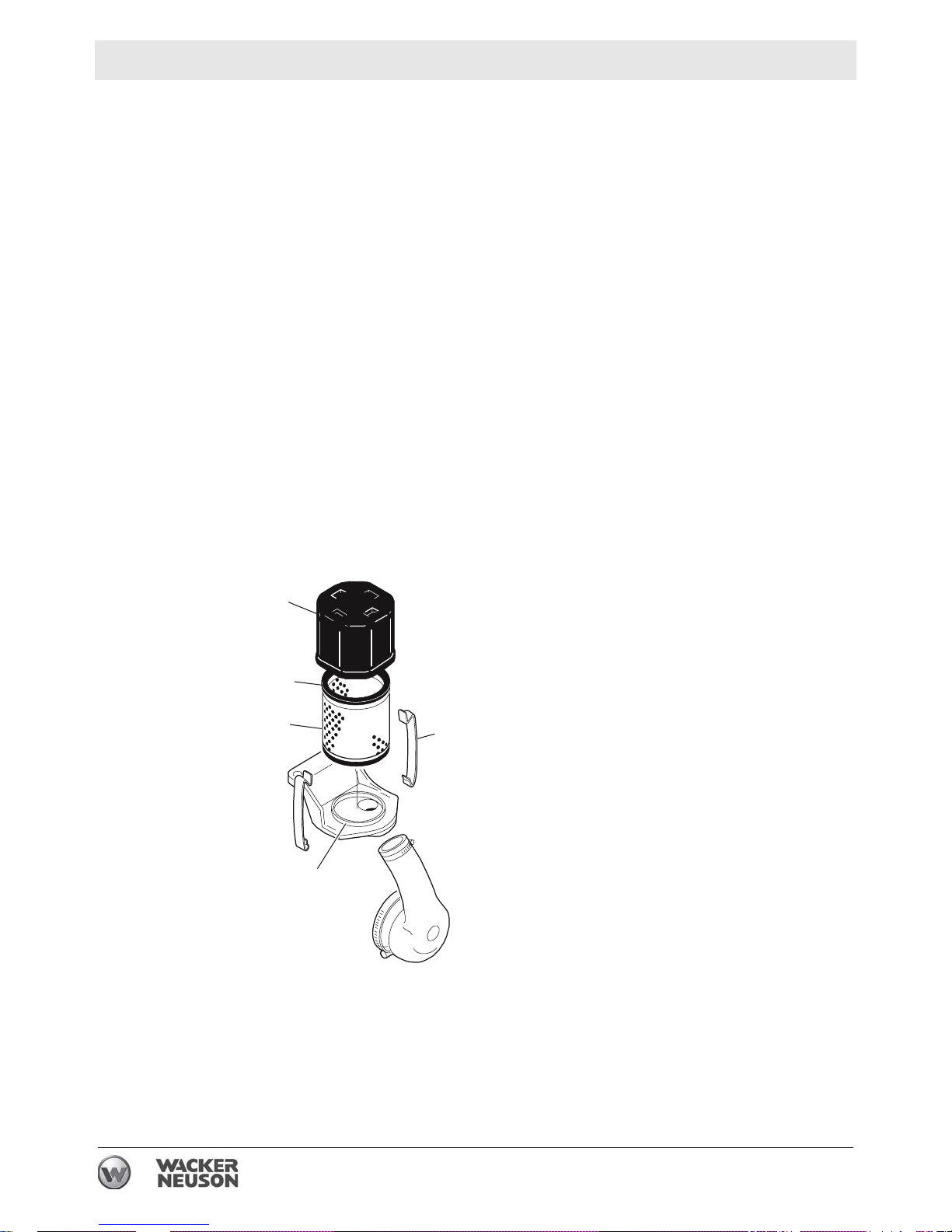

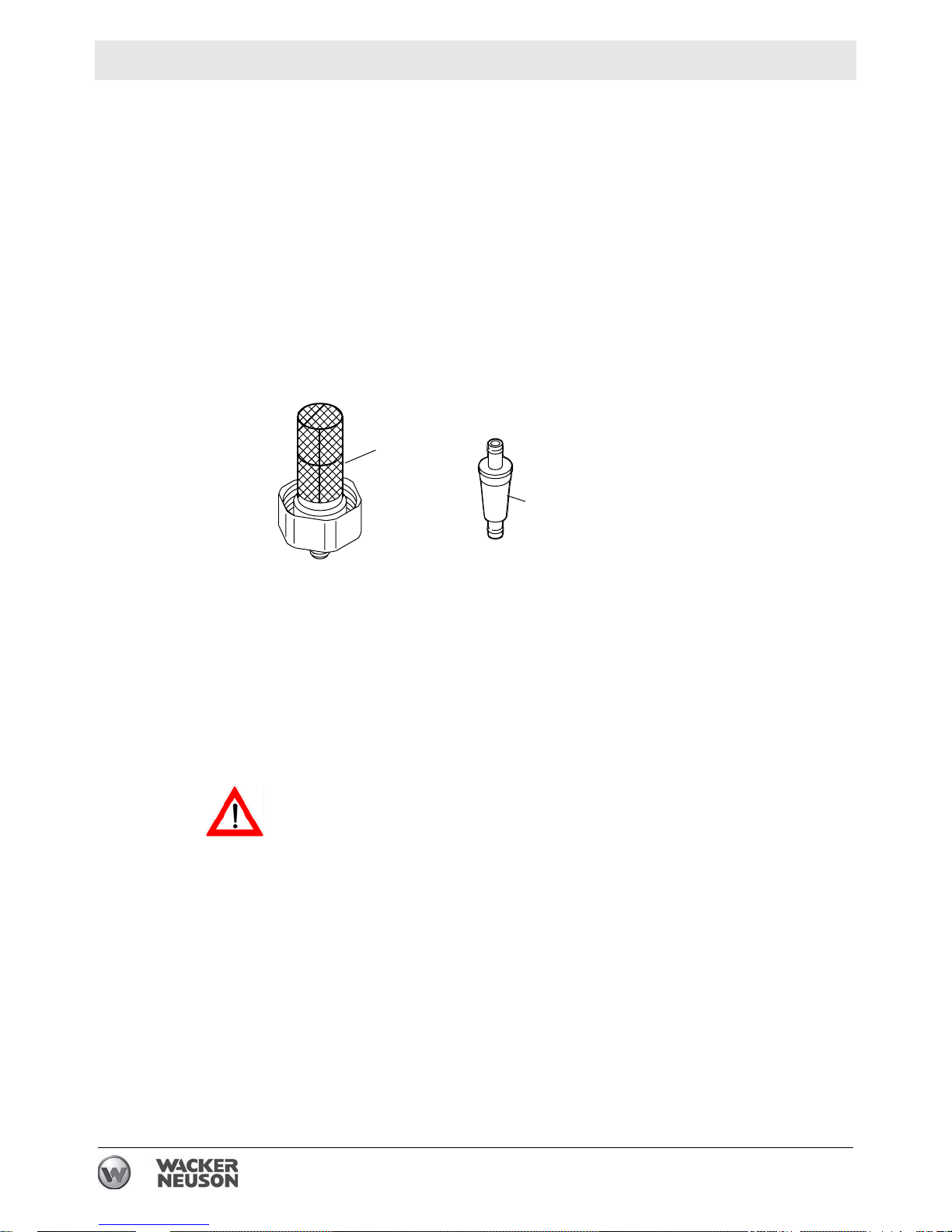

3.12 Fuel Filter

See Graphic: wc_gr002879

Dirt is the primary cause of carburetor problems. Unfiltered fuel can

quickly plug the passages in the carburetor and cause poor

performance. Two different styles of fuel filters are used with the WM

80 engine. One is an in-tank, self-cleaning style (h), the other is an inline replaceable filter (i). No matter the style, it is imperative the fuel

filter be clean. Check in-line fuel filters often and replace at regular

intervals. Check in-tank fuel filters yearly. Clean the filter by back

flushing with solvent. Replace the fuel filter if necessary. See section

Periodic Maintenance Schedule.

h

i

3.13 Fuel Hoses

Check the condition of the fuel hoses frequently and make sure they

are adequately clamped at the tanks and the filters.

Use extreme caution when working on the fuel system. Do not spill fuel

on yourself or others. Clean up any spilled fuel. See section Engine

WARNING

Safety.

wc_gr002879

30 wc_tx000520gb.fm

Loading...

Loading...