Page 1

1000184973 US

www.wackerneuson.com

1000184973

0909

Wheel loaders

WL 750

WL 850

2.1

OPERATOR'S MANUAL

Page 2

Introduction

1 Introduction

1.1 Important information on this Operator's Manual

This Operator's Manual contains important information on how to work safely, correctly

and economically with the machine. Therefore, it aims not only at new operators, but it also

serves as a reference for experienced ones. It helps to avoid dangerous situations and

reduce repair costs and downtimes. Furthermore, the reliability and the service life of the

machine will be increased by following the instructions in the Operator's Manual. This is

why the Operator's Manual and the service booklet must always be kept at hand in

the machine.

Your own safety, as well as the safety of others, depends to a great extent on how the

machine is moved and operated. Therefore, carefully read and understand this Operator's

Manual before operating the machine for the first time. The Operator's Manual will help to

familiarize yourself more easily with the machine, thereby enabling you to use it more

safely and efficiently.

Before operating the machine, carefully read chapter “Safety Instructions” as well, in

order to be prepared for possibly hazardous situations. As a rule, keep the following in

mind:

Careful and prudent working is the best way to avoid accidents!

Operational safety and readiness of the machine do not only depend on your skill, but also

on maintenance and servicing of the machine. This is why regular maintenance and service work is absolutely necessary (see service booklet). Always have a technician with

appropriate training or an authorized service center perform the maintenance and repair

work which are not included in this Operator's Manual. Insist on using original spare parts

when performing maintenance and repair work. This ensures operational safety and readiness of your machine, and maintains its value.

Your Wacker Neuson dealer will be pleased to answer any further questions regarding the

machine or the Operator's Manual.

Introduction

Abbreviations/symbols

☞This symbol requires you to perform the activity described

☞Subdivision within lists or an activity. Follow the steps in the recommended sequence

• This symbol stands for a list

• Subdivision within lists or an activity. Follow the steps in the recommended sequence

➥Description of the effects or results of an activity

“Option” = optional equipment

Stated whenever controls or other components of the machine are installed as an option.

Traveling direction in drawings or figures.

BA 34603_04 US – Edition 2.1 * 34603_04b110.fm 1-1

Page 3

Introduction

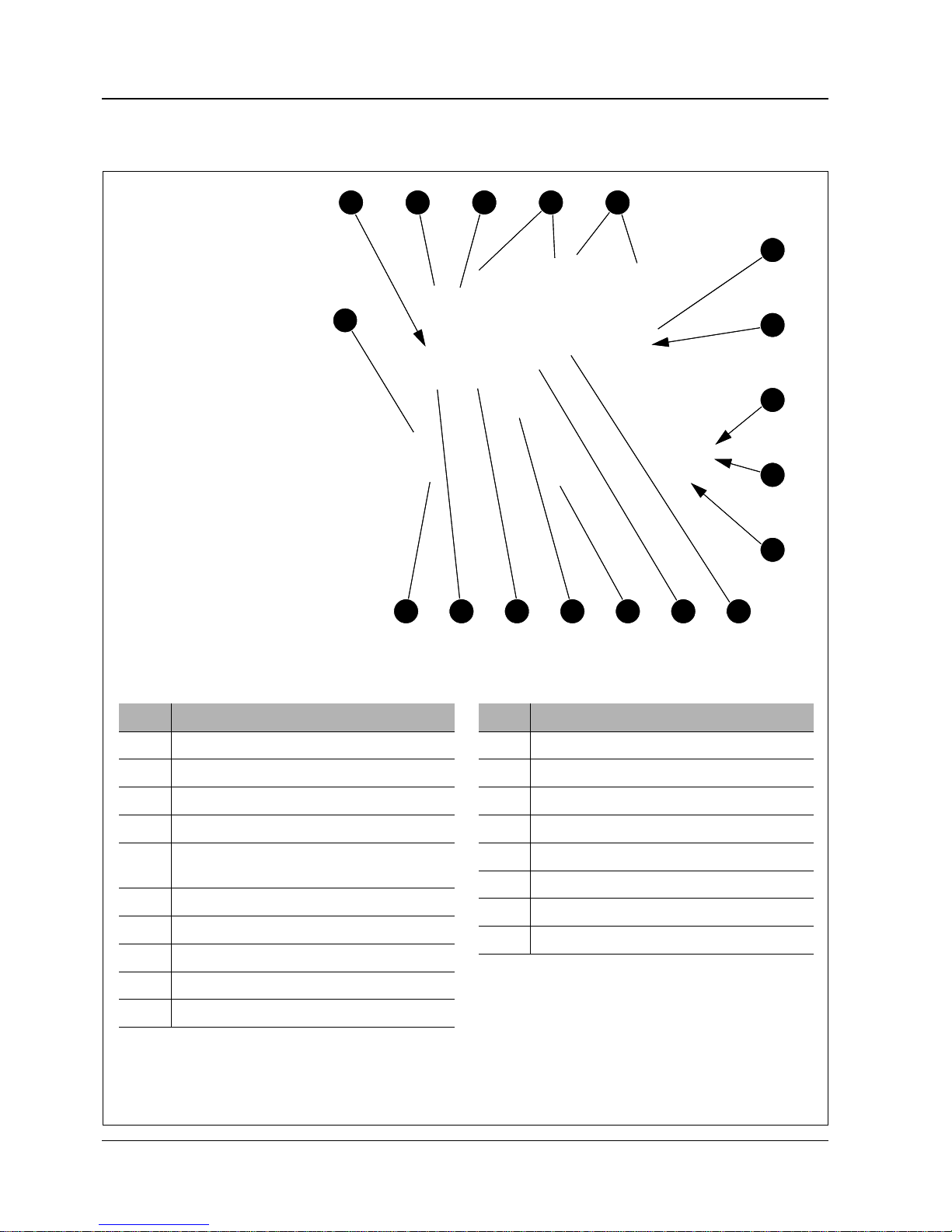

Fig. 1: Machine outside views

Pos.

Description

1

Service flap (fuses, relays, recirculated air filter)

2

Rearview mirror

3

Handle

4

Working lights

5

Eye hook for removing the cab only

(may not be used for crane-lifting the machine.)

6

Brake, rear and turn indicator lights

7

Door arrester

8

Towing facility

9

Reflectors

10

Rear eye hook for loading/tying down the machine

11

Door handle

12

Headlight with turn indicator

13

Access

14

Wheel chock

15

Loader unit

16

Tilt cylinder

17

Front eye hook for loading/tying down the machine

18

Lift cylinder

Pos.

Description

521 3 4

9

10

8

151617 111213

7

6

18

14

1.2 Machine overview

1-2 BA 34603_04 US – Edition 2.1 * 34603_04b110.fm

Page 4

1.3 Models and trade names: overview

Wheel loader model Trade name

346-03 WL 750

346-04 WL 850

1.4 Brief description of the wheel loader

The wheel loader is a self-propelled work machine according to German traffic regulations.

Get informed on and follow the legal regulations of your country.

This machine is a versatile and powerful tool for moving earth, gravel and debris on construction sites and elsewhere.

The wide range of attachments accounts for the numerous applications of the machine: as

a fork lift, a snow plow, a spreader for grit, salt etc., a sweeper or a tree replanter.

See chapter Attachments with certified material densities on page 1-5 for further applications. Retrofit the machine with appropriate safety features when using it in lifting gear

operation (see section “Applications with lifting gear” in chapter Safety Instructions).

The main components of the machine are:

• ROPS/FOPS tested closed cab

Check number: ROPS 04139-CE (cab without protective screen)

Check number: FOPS 04140-CE (cab with optional protective screen)

• Water-cooled Deutz four-cylinder in-line engine

• Exhaust emissions according to EC standard 2004/26 EC

• Rubber-mounted engine

• Sturdy steel sheet frame

• Automotive drive, infinitely variable hydrostatic axial-piston gearbox;

maximum speed 20 kph / 12.5 mph (30 kph / 18.8 mph option)

• Hydraulic four-wheel power steering with emergency steering features

• Front and rear planetary steering axles, rear axle with oscillation

• Service brake (mechanical and hydrostatic), mechanical disc-type parking brake

Introduction

BA 34603_04 US – Edition 2.1 * 34603_04b110.fm 1-3

Page 5

Introduction

Hydrostatic drive

The diesel engine permanently drives a hydraulic pump (variable displacement pump),

whose oil flow is sent to a hydraulic motor flanged on the gearbox. The force of the hydraulic motor is transmitted to the rear axle via the transfer gearbox. At the same time, the front

axle is driven by the cardan shaft, ensuring permanent 4 wheel drive.

Work hydraulics and 4 wheel steering

The diesel engine also drives the joint gear pump for work hydraulics and hydrostatic 4

wheel steering. The oil flow of this pump depends on the diesel engine speed only.

When the machine is in operation, the entire diesel engine output can be transmitted to the

gear pump for work hydraulics and steering. This is made possible by an inching valve

which responds as soon as the service brake is used, reducing or cutting off power input of

the drive. Therefore, engine output is fully available for the loader unit by pressing the

accelerator pedal and the brake pedal at the same time.

Cooling system

A combined oil/water radiator (for the diesel engine and the hydraulic oil) is located at the

rear of the machine.

The indicators on the instrument panel of the machine ensure constant monitoring of the

coolant temperature and level, and of the hydraulic oil temperature.

1-4 BA 34603_04 US – Edition 2.1 * 34603_04b110.fm

Page 6

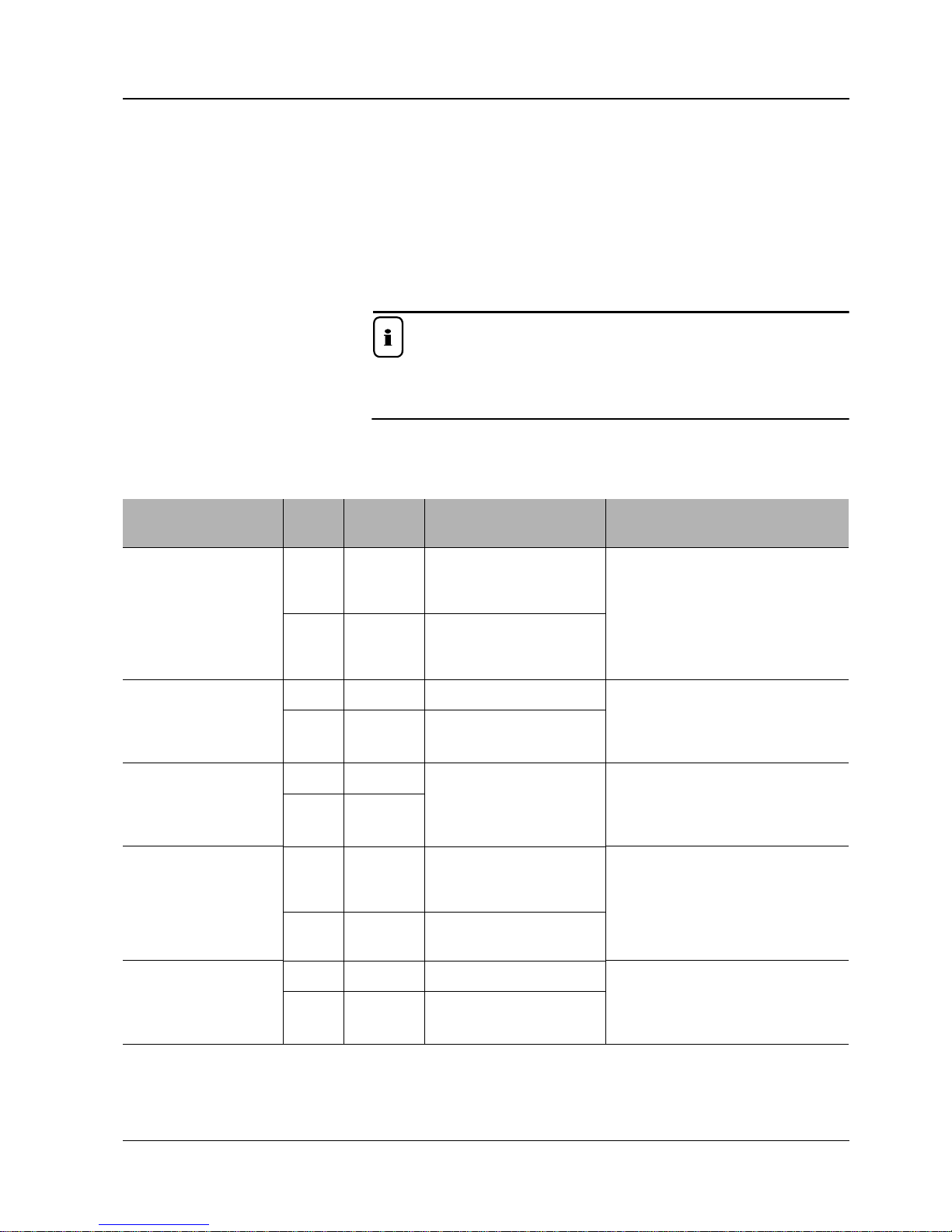

1.5 Fields of application and using the wheel loader with an attachment

Important

The attachments installed determine the intended use of this machine.

Note that not all attachments listed in the table comply with local traffic regulations.

The attachments complying with local traffic regulations and the applicable provisions are

listed in the machine documentation!

The legislation of your country may require specific permits, certifications, registrations etc.

for the use of attachments that are not certified or not listed in the machine documentation!

Get informed on and follow the legal regulations of your country.

To minimize the risk of equipment damage and unsafe operating characteristics, the attachments listed below are the only attachments approved for use

with this wheel loader.

Attachments with certified material densities

Possible equipment and authorized material densities.

Introduction

Description of

attachment

Standard bucket –

normal material

Standard bucket – lightweight material

Standard bucket – superlightweight material

Multipurpose bucket

2

2

3

Wheel

loader

WL 750

WL 850

Part no.

(model)

1000102344

1000102345

1000160648

1000096388

1000096389

1000137538

Dimensions Use

1750 mm (68.89”) with teeth

1750 mm (68.89”) without teeth

1

1750 mm (68.89”) without teeth

1850 mm (72.83”) with teeth

1850 mm (72.83”) without teeth

1850 mm (72.83”) without teeth

Loosening, picking up, transporting and

loading loose or solid material

(material density ≤ p = 1.8 t/m³)

(material density ≤ p = 112 lbs./cu. ft.)

WL 750 1000096389 1850 mm (72.83”) without teeth Picking up, transporting and loading very

lightweight material

WL 850 1000096393 2050 mm (80.70”) without teeth

WL 750 1000096394

2150 mm (84.64”) without teeth

WL 850 1000096397

WL 750

WL 850

1000113244

1000113492

1000168415

1000050770

1000096400

1750 mm (68.89”) with teeth

1750 mm (68.89”) without teeth

1750 mm (68.89”) without teeth

1850 mm (72.83”) with teeth

1850 mm (72.83”) without teeth

(material density ≤ p = 1.3 t/m³)

(material density ≤ p= 81 lbs./cu. ft.)

Picking up, transporting and loading lightweight material

(material density ≤ p = 0.9 t/m³)

(material density ≤ p = 56 lbs./cu. ft.)

Grading, removing and scraping vegetation,

for example; picking up and evenly spreading material; grabbing bulky material; loading

trucks (material density ≤ p = 1.8 t/m³)

(material density ≤ p = 112 lbs./cu. ft.)

WL 750 1000175757 1744 mm (68.66”) without teeth As standard bucket, however with benefits

Side swing bucket

2, 3

WL 850 1000176121 1844 mm (72.60”) without teeth

BA 34603_04 US – Edition 2.1 * 34603_04b110.fm 1-5

for filling and backfilling material

(material density ≤ p = 1.8 t/m³)

(material density ≤ p = 112 lbs./cu. ft.)

Page 7

Introduction

Description of

attachment

High-tilt bucket

Heavy duty bucket with

hydraulic clamp

3, 4, 5

3, 4,5

Heavy duty forks with

hydraulic clamp

(silage bucket)

Pallet forks

Pallet forks with foldable fork

3, 6, 7

arms

Material pusher

3, 4

3, 4, 6

3, 4

Wheel

loader

WL 750

WL 850

Part no.

(model)

1000156433

1000108803

1000156433

1000154475

Dimensions Use

1850 mm (72.83”) without teeth

1850 mm (72.83”) without teeth

As standard bucket, with a 80 – 100 cm

higher dump height

(material density ≤ p = 1.8 t/m³)

1850 mm (72.83”) without teeth

(material density ≤ p = 112 lbs./cu. ft.)

WL 750 1000111090 1850 mm (72.83”) Picking up and transporting e.g. bulky recy-

cling material

WL 850 1000111053 2050 mm (80.70”)

(material density ≤ p = 1.3 t/m³)

(material density ≤ p= 81 lbs./cu. ft.)

Picking up and transporting e.g. bulky and

WL 750

WL 850

1000128262 1800 mm (70.86”)

fibrous recycling material (e.g. grass,

manure, brushwood;

material density ≤ p = 1.3 t/m³)

(material density ≤ p= 81 lbs./cu. ft.)

WL 750

WL 850

WL 850 1000147393 1200 mm (47.24”)

WL 750

WL 850

1000101820

1000101822

1000 mm (39.37”)

1200 mm (47.24”)

Picking up and transporting

pallets

Picking up and transporting

pallets

1000050660 3000 mm (118.11”) For moving loose bulk material

Manure forks with grab

Hydraulic round bale clamp

Tree replanter

Front scarifier

Work platform

3, 4

3, 4

8

Rotary broom

Snow plow

1. Bucket with screwed-on exchangeable blade

2. Only in connection with additional lights order no. 1000105002 and mounting kit order no. 1000137629 when traveling on public roads

3. See the Operator's Manual of the attachment for putting the attachment into service and using it

4. Not certified for traveling on public roads (individual certification may be possible depending on your country's legislation)

5. Only in connection with restrictor unit order no. 1000114139

6. Only in connection with load diagrams for model WL 750 (order no. 1000138363) and for model WL 850 (order no. 1000143064)

7. Get informed on the legal regulations of your country which may require specific permits, certifications, registrations etc. for use on public roads!

8. Model WL 750: only in connection with assembly 1000169659

9. Only in connection with rotating beacon order no. 1000133985

See “Merkblatt für Anbaugeräte“ (leaflet with specific instructions for attachments) § 30 clauses 10/11/12 of the StVZO German road traffic regulations for further information on mounting attachments.

2, 3, 4, 9

Model WL 850: only in connection with assembly 1000169660

WL 750

WL 850

WL 750

WL 850

WL 750

346-02

WL 750

WL 850

WL 750

WL 850

WL 750

WL 850

WL 750

WL 850

1000178474 1800 mm (70.86”)

1000177701

800 – 1800 mm

(31.49 – 70.86”)

1000100840 – Digging and transporting nursery trees

1000100841 – Scarifying dense soil, loosening humus soil

1000109953 –

1000139717 – Cleaning roads or facilities

1000142915 – Winter service

Picking up and transporting e.g. grass,

manure, brushwood and straw

Picking up and transporting round bales

For repair, assembly, disassembly, maintenance and inspection work above ground

1-6 BA 34603_04 US – Edition 2.1 * 34603_04b110.fm

Page 8

1.6 EC declaration of conformity, model 346-03 (WL 750)

EC Declaration of Conformity

Manufacturer

Kramer-Werke GmbH

Wacker-Neuson-Str. 1

D-88630 Pfullendorf

Product

Conformity assessment procedure

According to 2000/14/EC, appendix VIII, by the following inspection body:

Fachausschuss Tiefbau, Prüf- und Zertifizierungsstelle

Landsberger Str. 309

D-80687 München

Directives and standards

We hereby declare that this product corresponds to the relevant regulations and

requirements of the following EC Directives and standards:

98/37/EC, 89/336/EEC, DIN EN ISO 12100-1, DIN EN ISO 12100-2, D INEN474-1,

DIN EN 474-3, ISO 3471, ISO 13510, EN ISO 3744, EN ISO 3746, ISO 3449

Pfullendorf, (date)

i. A.

Dipl.-Ing. Manfred Mack

Head of Research & Development

KRAMER-WERKE GmbH

Product Wheel Loader

Model 346

Version 346-03

Serial number 346 03 _ _ _ _ _

Output kW 45

Measured sound power level dB(A) 99.8

Guaranteed sound power level dB(A) 101

Introduction

BA 34603_04 US – Edition 2.1 * 34603_04b110.fm 1-7

Page 9

Introduction

EC Declaration of Conformity

Manufacturer

Kramer-Werke GmbH

Wacker-Neuson-Str. 1

D-88630 Pfullendorf

Product

Conformity assessment procedure

According to 2000/14/EC, appendix VIII, by the following inspection body:

Fachausschuss Tiefbau, Prüf- und Zertifizierungsstelle

Landsberger Str. 309

D-80687 München

Directives and standards

We hereby declare that this product corresponds to the relevant regulations and

requirements of the following EC Directives and standards:

98/37/EC, 89/336/EEC, DIN EN ISO 12100-1, DIN EN ISO 12100-2, D INEN474-1,

DIN EN 474-3, ISO 3471, ISO 13510, EN ISO 3744, EN ISO 3746, ISO 3449

Pfullendorf, (date)

i. A.

Dipl.-Ing. Manfred Mack

Head of Research & Development

KRAMER-WERKE GmbH

Product Wheel Loader

Model 346

Version 346-04

Serial number 346 04 _ _ _ _ _

Output kW 45

Measured sound power level dB(A) 99.8

Guaranteed sound power level dB(A) 101

1.7 EC declaration of conformity, model 346-04 (WL 850)

1-8 BA 34603_04 US – Edition 2.1 * 34603_04b110.fm

Page 10

1.8 Type labels and component numbers

Fig. 2: Serial number location

A

B

Fig. 3: Cab certification number

Fig. 4: Diesel engine serial number

Serial number

The serial number is stamped on the machine frame A (next to the cab attachment, on the

right in traveling direction). It is also located on the type label B (fig. 2).

The type label B is located on the machine frame, at the front right in traveling direction (on

one side of the loader unit bulkhead, fig. 2).

Type label information

Example:

Machine model: 346

Version: 346 03

Serial no.: 346 03 55

Model year: 2008

Front gross axle weight rating: 3600 kg (7920 lbs.)

Rear gross axle weight rating: 4000 kg (8800 lbs.)

Gross weight rating: 5500 kg (12,100 lbs.)

Output: 45 kW (60.3 SAE hp)

Other information – see chapter 6 “Specifications” on page 6-1

Introduction

Cab certification number

The cab certification number (arrow, fig. 3) is located in the cab, at the top right in traveling

direction.

Engine serial number

The serial number (arrow, fig. 4) is located on the cylinder-head cover (engine).

Example: Deutz D2011 L04 W

BA 34603_04 US – Edition 2.1 * 34603_04b110.fm 1-9

Page 11

Introduction

Fig. 5: Hydraulic pump serial number

Fig. 6: Hydraulic motor serial number

Fig. 7: Rear axle and gearbox serial number

Fig. 8: Front axle serial number

Hydraulic pump serial number

Hydraulic motor serial number

The type label (arrow) is located on the hydraulic pump housing (next to where the pump is

installed on the diesel engine)

The type label (arrow) is located on the hydraulic motor, on the right in traveling direction.

Rear axle serial number

Front axle serial number

The serial number (arrow, fig. 7) is located on the upper side of the differential housing, at

the rear.

The serial number (arrow, fig. 8) is located on the upper side of the differential housing, at

the front.

1-10 BA 34603_04 US – Edition 2.1 * 34603_04b110.fm

Page 12

1.9 Labels overview

XX

N = 1900kgN = 1400kg

1000149082

346-01

Introduction

BA 34603_04 US – Edition 2.1 * 34603_04b110.fm 1-11

Page 13

Introduction

Fig. 9: Eye hook label

Fig. 10: Label for points used for tying down the machine

XX

Fig. 11: Noise level label

Fig. 12: Safety alert symbol

Fig. 13: Keep distance

Fig. 14: CE mark

ce.ai

1.10 Signs and symbols

Labels on the outside of the machine

Label: cab eye hooks

The eye hooks on the cab are for removing the cab only and may not be used for crane

handling the machine – see chapter 3 “Crane handling the machine” on page3-50 for further details.

Location

Cab roof (4x)

Description

Tie-down points for tying down the machine.

Tie-down points are for tying down the machine during loading and transport

– see chapter 3 “Loading and tying down the machine” on page 3-52 for further details.

Location

On the left and right of the machine frame above the front axle attachment, and at the rear

underneath the engine

Description

Noise levels produced by the machine.

L

WA

Other information – see chapter 6 “Noise levels” on page 6-9

Location

Rear window

= sound power level

Description

Safety alert symbol

This label alerts persons to possible safety hazards in the area where the symbol is

located.

Location

At rear of machine.

Description

Crushing hazard label. This label alerts persons standing or working near the machine to

an existing safety hazard within the area around the machine. Keep clear of machine!

Location

On the loader unit on the left and right, and at the rear on the engine cover.

Description

The CE mark means that the machine meets the requirements of the Machine Directive

and that the conformity procedure has been performed. The machine meets all the health

and safety requirements of the Machine Directive.

Location

On the rear window.

1-12 BA 34603_04 US – Edition 2.1 * 34603_04b110.fm

Page 14

Labels inside the cab

Important

Fig. 15: Load diagram

Fig. 16: Label: control lever operation (overview)

A

D

B C

E

F

E

A B C

Introduction

Description (example)

... when using pallet forks with fork arms:

The framed numbers indicate the maximum authorized load on the fork arms for industrial

and off-road applications respectively. The maximum load varies according to the distance

from the load center.

Example:

• Off-road operation

➥Load distance = 500 mm (19.68”)

• The maximum load amounts to e.g. 465 kg (1025.15 lb)!

Tire pressure table

List of authorized types of tires with prescribed tire inflation pressures.

Other information – see chapter 6 “Tires” on page6-8

Location

Inside the cab, on left side of front window

The load diagram is valid only for applications with certified pallet forks.

• – see Attachments on page 1-5

• Observe the specific load diagrams of other attachments used, e.g. rotary

➝ S = 1.67 (safety factor)

crane jib!

Description

Control lever elements (joystick)

• A = traveling direction: (F) forward/(R) reverse and (N) neutral position

• B = control lever (joystick) unlocked/locked for road travel

• C = control lever (3rd control circuit for attachments) unlocked/locked

• D = loader unit operation: raise, lower, curl and dump

• E = 3rd control circuit operation. Pick up/set down attachment

• F = loader unit operation: raise, lower with float position, curl and dump

Location

On the lower right on the side window

BA 34603_04 US – Edition 2.1 * 34603_04b110.fm 1-13

Page 15

Introduction

Fig. 17: Brake fluid label

Fig. 18: Label: Read the Operator's Manual

Fig. 19: Seat; fastening the seat belt

Fig. 20: Read the Operator‘s Manual

Description

Brake fluid label. Use only LHM brake fluids.

➥– see chapter 5 “Maintenance of the brake system” on page 5-21

➥– see chapter 5 “Fluids and lubricants” on page 5-37

Location

On the brake-fluid reservoir

Description

Caution!

Read and understand the Operator's Manual before starting, operating, adjusting, maintaining, or repairing the machine.

Location

Inside the cab on the right on the pillar

Description

• Risk of being thrown from the machine. Operate the machine only from the operator's

seat.

• Fasten seat belt when operating the machine.

• Operate within stability limits of machine to avoid tipping over.

• Read the Operator's Manual – see chapter 3 “Seat belt (lap belt)” on page 3-45

Location

Inside the cab on the right on the pillar

Description

Caution! Remove the starter key before working on the machine.

Read the Service Manual.

Location

Inside the cab on the right-hand side pillar.

1-14 BA 34603_04 US – Edition 2.1 * 34603_04b110.fm

Page 16

Description

Fig. 21: Prohibiting sign: transport of persons

Fig. 22: Safety alert: safety distance to persons

Fig. 23: Load diagram for load hook

N = 1900kgN = 1400kg

1000149082

346-01

AB

Fig. 24: Shearing hazard

Fig. 25: Label: hot fluid (coolant)

Warning! Do not raise or transport persons in the bucket or on the pallet forks.

Location:

In the cab on the cover plate between the steering wheel and the front window.

. Description

Collision hazard! Bystanders must stay clear of the machine when it is being operated.

Location:

In the cab at the rear above the rear window.

Description

Load diagram for load hook (option)

Example: Maximum load for model WL 750

• A Extended loader unit and curled quickhitch

➥Max N => 1900 kg (4188.71 lb)

• B Extended loader unit and quickhitch

➥Max N => 1400 kg (3086.42 lb)

Location

➥Inside the cab, on left side of front window

Introduction

Engine compartment labels

Description

Shearing hazard! Do not touch any moving or turning parts!

Location

In the engine compartment on the right on the sheet-metal separation of the radiator.

Description

Burn hazard!

The reservoir is hot and under pressure.

Do not open the reservoir when it is hot.

Carefully and slowly open the cover only after the cooling fluid has cooled down, to allow

the pressure to escape.

Location:

In the engine compartment on the right, next to the expansion reservoir (coolant).

BA 34603_04 US – Edition 2.1 * 34603_04b110.fm 1-15

Page 17

Introduction

Fig. 26: Label: hot surface

Fig. 27: Label: filler opening for hydraulic oil

Fig. 28: Label: filler opening for fuel

Description

Burn hazard! Do not touch.

Location:

In the engine compartment on the right on the sheet-metal separation of the radiator, next

to the muffler.

Description

Filler opening for hydraulic oil.

Location:

In the engine compartment on the left next to the engine cover attachment

Description

Filler opening for diesel fuel.

Location:

On left-hand side of cab, above the filler opening of the fuel reservoir.

1-16 BA 34603_04 US – Edition 2.1 * 34603_04b110.fm

Loading...

Loading...