Page 1

www.wackerneuson.com

Operator’s Manual

Wheel Loader WL 30

Page 2

December 10 Edition

Page 3

You have opted for a Wacker Neuson loader – thank you very much for putting your trust in us.

Your Wacker Neuson loader is a powerful product with robust technology and a wide range of applications to aid you in

your day-to-day work. In order to familiarize yourself with your loader in a quick, comprehensive manner, please read

this Operator’s Manual attentively.

In addition to the information regarding operation, this Operator’s Manual also contains important maintenance and operating instructions for conserving the value of your loader. Furthermore, we will show you how to operate your loader in

an environmentally sound manner.

Should you have any questions or problems relating to your loader, please contact your Wacker Neuson partner or importer. They will be happy to respond to your questions, suggestions or criticisms at any time.

We are condent that you will be very satised with your new Wacker Neuson loader.

Wacker Neuson SE

Page 4

CO NTE NT S

2

TABLE OF CONTENTS

PREFACE ............................................................................................................................................................... 7

1 BASIC INFORMATION .....................................................................................................................................8

1.1 Notes about this Operator’s Manual ....................................................................................................... 9

1.2 Explanation of the symbols used in this Operator’s Manual ................................................................. 10

1.3 Warranty and liability............................................................................................................................. 12

1.4 Intended use ......................................................................................................................................... 13

2 BASIC SAFETY INSTRUCTIONS .................................................................................................................. 16

2.1 Organizational measures ...................................................................................................................... 17

2.2 Selection and qualication of personnel / basic duties ......................................................................... 19

2.3 Safety instructions for certain operating phases .................................................................................. 20

2.3.1 Safety instructions for normal operation ............................................................................................... 20

2.3.2 Safety instructions for other operating modes ...................................................................................... 22

2.4 Safety instructions for particular hazards ............................................................................................. 25

2.4.1 Forklift attachment ................................................................................................................................ 25

2.4.2 Working near overhead power lines ..................................................................................................... 26

2.4.3 Electrical power..................................................................................................................................... 27

2.4.4 Flying sparks / re danger ..................................................................................................................... 27

2.4.5 Gas, dust, steam, smoke ......................................................................................................................28

2.4.6 Hydraulics, pneumatics ......................................................................................................................... 28

2.4.7 Tip-overs ............................................................................................................................................... 29

2.4.8 Noise ..................................................................................................................................................... 29

2.4.9 Oils, grease and other chemical substances ........................................................................................ 29

2.5 Transporting and towing / restarting ..................................................................................................... 30

Page 5

CO NTE NT S

3

W L 3 0

2.6 Final decommissioning / dismantling .................................................................................................... 30

2.7 Safety labels used ................................................................................................................................. 31

2.8 Safety devices ....................................................................................................................................... 36

2.8.1 Fire extinguisher ................................................................................................................................... 36

2.8.2 Rotating beacon .................................................................................................................................... 36

2.8.3 Seat belt ................................................................................................................................................ 37

2.8.4 Backup alarm for reverse drive ............................................................................................................. 37

2.8.5 Emergency exit ..................................................................................................................................... 38

2.8.6 Battery disconnect switch ..................................................................................................................... 39

2.8.7 Loader lift arm locking system .............................................................................................................. 40

3 TECHNICAL DATA .......................................................................................................................................... 41

3.1 Technical description ............................................................................................................................ 41

3.2 Loader data ........................................................................................................................................... 43

3.3 Product identication number plates ..................................................................................................... 45

3.4 Dimensions ...........................................................................................................................................46

4 DESCRIPTION OF THE INDICATOR, WARNING AND CONTROL ELEMENTS ......................................... 48

4.1 Operating elements and instruments .................................................................................................... 48

4.2 Control and warning indicator lights ...................................................................................................... 50

4.3 Switches / rocker switches .................................................................................................................... 54

4.4 Indicator devices ................................................................................................................................... 58

5 OPERATING AND OPERATION .................................................................................................................... 60

5.1 Before starting up .................................................................................................................................60

Page 6

CO NTE NT S

4

5.1.1 Fueling .................................................................................................................................................. 60

5.1.2 Operation ..............................................................................................................................................62

5.1.3 Doors and windows............................................................................................................................... 64

5.1.4 Adjusting the steering column ............................................................................................................... 65

5.1.5 Adjusting the operator’s seat ................................................................................................................ 66

5.1.6 Seat belt ................................................................................................................................................ 67

5.2 Starting up ............................................................................................................................................ 70

5.2.1 Lighting system and forward warning device ........................................................................................ 70

5.2.2 Wipers and windshield washer system ................................................................................................. 72

5.2.3 Headlights and rotating beacon ............................................................................................................ 74

5.2.4 Ventilation and heating of the cab ......................................................................................................... 76

5.2.5 Before starting the engine ..................................................................................................................... 77

5.2.6 Starting the engine ................................................................................................................................ 78

5.3 Propulsion operation ............................................................................................................................. 80

5.3.1 Preparation for travel in public trafc .................................................................................................... 80

5.3.2 Travel speed .......................................................................................................................................... 81

5.3.3 Stopping and parking ............................................................................................................................ 85

5.4 Work operation ...................................................................................................................................... 86

5.4.1 Operating lever for Loader lift arms ...................................................................................................... 88

5.4.2 Activating the optional hydraulics .......................................................................................................... 90

5.4.3 Loader lift arms locking system ............................................................................................................94

5.4.4 Differential lock ..................................................................................................................................... 95

5.4.5 Changing attachments .......................................................................................................................... 96

5.4.6 Bucket ................................................................................................................................................. 101

5.4.7 Tip-overs ............................................................................................................................................. 107

5.4.8 Precaution measures for various temperature conditions .................................................................. 108

Page 7

CO NTE NT S

5

W L 3 0

5.5 Optional equipment ..............................................................................................................................110

6 TOWING AND TRANSPORTING ..................................................................................................................114

6.1 Towing ..................................................................................................................................................114

6.2 Transporting .........................................................................................................................................118

7 LOWERING LOADER ARMS........................................................................................................................ 125

8 RELIEVING RESIDUAL PRESSURE IN THE HYDRAULIC SYSTEM ........................................................ 126

9 SECURING THE LOADER ........................................................................................................................... 129

10 SERVICING AND INSPECTION ................................................................................................................... 130

10.1 Basic safety instructions for servicing and inspection ........................................................................ 130

10.2 Servicing and inspection intervals ...................................................................................................... 138

10.3 Lubrication schedule ........................................................................................................................... 150

10.4 Cleaning the loader ............................................................................................................................. 152

10.5 General safety check .......................................................................................................................... 154

10.6 Specications and lling quantities ..................................................................................................... 155

10.7 Maintenance and inspection work ...................................................................................................... 156

10.7.1 Preparation for maintenance and inspection work.............................................................................. 156

10.7.2 Servicing the engine ........................................................................................................................... 162

10.7.3 Servicing the fuel system .................................................................................................................... 168

10.7.4 Servicing the air lter system .............................................................................................................. 173

10.7.5 Servicing the cooling system .............................................................................................................. 176

10.7.6 Servicing the hydraulic system ........................................................................................................... 182

Page 8

CO NTE NT S

6

10.7.7 Servicing the axles.............................................................................................................................. 191

10.7.8 Servicing the cab vent lter ................................................................................................................. 195

10.7.9 Servicing the brakes ........................................................................................................................... 196

10.7.10 Servicing the tires and wheels ............................................................................................................ 198

10.7.11 Servicing the electrical system ........................................................................................................... 202

10.8 Jump-starting / emergency starting .................................................................................................... 210

10.9 Loader storage .................................................................................................................................... 213

11 TROUBLESHOOTING AND EMERGENCY MAINTENANCE ...................................................................... 216

12 SAFETY INSTRUCTIONS FOR REPAIRS ................................................................................................... 220

12.1 General safety regulations for repairs ................................................................................................. 220

12.2 Engine ................................................................................................................................................. 223

12.3 Welding work ...................................................................................................................................... 223

12.4 Hydraulic system ................................................................................................................................. 225

12.5 Brakes ................................................................................................................................................. 225

13 FINAL SHUTDOWN OF THE LOADER / DECOMMISSIONING .................................................................226

14 APPENDIX .................................................................................................................................................... 228

14.1 Ordering replacement parts ................................................................................................................ 228

14.2 Inspection verication .........................................................................................................................230

Index ............................................................................................................................................................ 234

List of gures ...................................................................................................................................................... 238

Page 9

PR E FA C E

7

W L 3 0

PREFACE

This Operator’s Manual describes how to operate and

service the loader. It provides operating and maintenance

personnel with the necessary knowledge of the loader‘s

functional characteristics in order to allow them to operate,

diagnose, maintain and repair the loader safely.

Observing the specications in this Operator’s Manual assures:

• proper, safe, professional operation of the loader

• professional service, cleaning and care of the loader

Observe the applicable OSHA 1910 and 1926 safety regulations when they apply to the user.

If required, the user/operator should supplement the Operator’s Manual with instructions and regulations regarding

environmental protection and national regulations relating

to accident prevention.

All persons involved in work on or with the loader must

read and apply this Operator’s Manual, for example with

regard to:

• operation, including setup, maintenance during operation, care, disposal of auxiliary materials and operating

materials as well as disposal of the entire loader.

• maintenance (inspection, servicing, care).

• transport.

Should you have questions about this Operator’s Manual, please contact your dealer or visit us at www.wackerneuson.com.

The Operator’s Manual must always be located in

the loader or at the place where it is being used.

This Operator’s Manual is not designed for purposes of extensive maintenance work. Such work

must be performed by approved professionals.

Page 10

B A S I C I N F O R MAT I O N

8

Each new user must be instructed before using the loader

for the rst time.

Instructions for using the Operator’s Manual:

•

Read the Operator’s Manual carefully before starting

up the loader

• Observe all the safety instructions

• Follow the regulations and laws applicable at the place

of use

• Keep the Operator’s Manual in the protected compart-

ment provided in the operator station/cab.

1 BASIC INFORMATION

If it is not possible to rule out hazards to persons or material

during work according to the loader‘s intended use, these

hazards will be indicated by means of safety labels.

Instructions relate to the direction of travel of the loader;

this means that, when directional information is given, it

can be assumed that this refers to the direction of travel

of the loader.

Page 11

B A S I C I N F O R MAT I O N

9

W L 3 0

1.1 Notes about this Operator’s Manual

The specications, illustrations, weight information and

technical data are not binding and correspond to the state

of the art at the time of printing. We must reserve the right

to make changes without prior notice in the area of design,

conguration, appearance and technology on account of

the ongoing further development of the products.

Contact your dealer for clarication of use and/or instructions concerning intended use and attachments identied

in this Operator’s Manual.

Always strictly observe the safety instructions in this Operator’s Manual and the legal and trade association regulations

at the usage location.

This Manual provides information and procedures to safely

operate and maintain this Wheel Loader. For your own safety

and to reduce the risk of injury, carefully read, understand,

and observe all instructions described in this Manual.

Wacker Neuson Corporation expressly reserves the right

to make technical modications, even without notice, which

improve the performance or safety standards of its machines. The information contained in this manual is based

on machines manufactured up until the time of publication.

Wacker Neuson Corporation reserves the right to change

any portion of this information without notice.

Page 12

B A S I C I N F O R MAT I O N

10

1.2 Explanation of the symbols used in this Operator’s Manual

To ensure safe operation and maintenance of the wheel

loader, it is necessary that you follow all the instructions in

this Operator’s Manual.

The following symbols and the signal words DANGER,

WARNING, CAUTION, NOTICE, and NOTE, and the adjacent text, indicate hazards and instructions.

This is the safety alert symbol. It is used to alert

you to potential personal hazards.

► Obey all safety messages that follow this sym-

bol.

DANGER

DANGER indicates a hazardous situation which,

if not avoided, will result in death or serious injury.

►

Obey all safety messages that follow this symbol

to avoid injury or death.

WARNING

WARNING indicates a hazardous situation which, if

not avoided, could result in death or serious injury.

►

Obey all safety messages that follow this symbol

to avoid possible injury or death.

Page 13

B A S I C I N F O R MAT I O N

11

W L 3 0

CAUTION

CAUTION indicates a hazardous situation which,

if not avoided, could result in minor or moderate

injury.

►

Obey all safety messages that follow this symbol

to avoid possible minor or moderate injury.

NOTICE: Used without the safety alert symbol,

NOTICE indicates a situation which, if not avoided,

could result in property damage.

Important general instructions

ENVIRONMENTAL NOTE

Important general instructions for environmental

protection

Note: Contains additional information important to

a procedure.

Page 14

B A S I C I N F O R MAT I O N

12

1.3 Warranty and liability

Observe the following points:

• Do not make any changes to the wheel loader.

•

Use only Wacker Neuson-approved attachments for

your loader.

• The loader many only be started up, operated and serviced as described in the Operator’s Manual.

• Use the loader only if all the safety and protection devices are intact.

• Observe the monitoring systems during operation.

• Repairs may only be perform by trained professionals.

• Follow the Operator’s Manual exactly.

The manufacturer/supplier is not liable for damage

resulting from unintended use. The operator/user

is the sole bearer of this risk.

The Operator’s Manual must always be located in

the loader or at the place where it is being used.

Place the Operator’s Manual in the document pocket at the rear of the operator‘s platform.

Fig. 1

Document pocket

Page 15

B A S I C I N F O R MAT I O N

13

W L 3 0

Read and understand the operating instructions in this Manual before operating this wheel loader. Before performing

production work, the operator should nd a remote site to

become familiar with the controls and machine response.

The machine shall be in serviceable condition before attempting to use it as described in the operating instructions.

If the wheel loader is determined not to be in serviceable

condition, notify the site or machine supervisor to have it

repaired before use.

The loader is used to dislodge and load material by moving

the loader forward, taking into account the safety instructions

/ regulations and time periods listed by Wacker Neuson in

the Operator’s Manual. One work cycle consists of picking

up, lifting, transporting and unloading the material.

1.4 Intended use

The loader has been built according to applicable standards

and regulations. Operation by inexperienced persons, or in

an unintended manner, can result in hazards that can lead

to personal risk and subsequent harm to the operator and

persons in the operating area of the wheel loader. Improper

use can damage the wheel loader as well as property in the

vicinity of operation.

Unintended use can endanger the lives of operating

personnel or other persons and cause injuries or

extensive material damage.

Page 16

B A S I C I N F O R MAT I O N

14

Similar uses of the loader with alternative attachments which

do not change the safety requirements for the loader but

modify the way in which it is used are only acceptable when

attachments that have been expressly approved by Wacker

Neuson are employed. Special conditions apply if you use

optional Wacker Neuson attachments.

The intended operation is described in this Operator’s

Manual. The instructions describe how to operate, maintain, inspect and adjust the wheel loader safely. The repair

manual provides additional instruction for safely diagnosing

malfunctions and repairing the wheel loader to maintain

service and performance levels.

The wheel loader shall not be employed for any of the following work activities:

• lifting or transporting people

• using it as a working platform

• using it to lift or transport loads without providing work

equipment for it

• pulling trailer loads

•

operating after the machine has received unauthorized

repairs

• operating with unauthorized modications

Page 17

B A S I C I N F O R MAT I O N

15

W L 3 0

Page 18

B A S I C S A F E T Y I N S T R U C T I O N S

16

2 BASIC SAFETY INSTRUCTIONS

•

Use the loader and attachments only as intended and

in serviceable condition.

•

Observe the operating instructions described in this

Operator’s Manual and all applicable work site safety

regulations.

• Observe the permissible payloads.

• Wheel Loaders may only be used on suitable terrain.

This Wheel Loader is equipped with a Starter Lock

/ Drive Lock which must be kept operational.

Page 19

B A S I C S A F E T Y I N S T R U C T I O N S

17

W L 3 0

2.1 Organizational measures

The following safety instructions are directed at the operator

/ user of the loader.

•

Always keep the Operator’s Manual in the compartment

provided for it.

• As a supplement to the Operator’s Manual, universally

valid legal and other binding regulations relating to road

trafc, compulsory coverage, accident prevention and

environmental protection must be observed, and users

must be instructed to observe them. This applies in particular to the maximum speed, depending on the model

and the permissible total weight of the loader.

•

If required, instruct that personal protective equipment be

worn. This applies particularly to the handling of harmful

substances at the location of use.

•

Supplement the Operator’s Manual with instructions,

including supervisory and reporting requirements, taking

into account differences between various companies,

e.g. with regard to the organization of work, work processes or personnel used.

•

Personnel who have been assigned to operate the loader

must have read the Operator’s Manual before operating

the wheel loader especially the chapter Basic Safety

Instructions.

• Observe all safety messages on the loader and in the

Operator’s Manual.

•

Make sure that all safety messages on the machine

are legible.

•

If the loader becomes unserviceable, stop operating and

inform the supervisor that the wheel loader is not functioning normally. Alternately, contact a trained technician

to diagnose and correct the condition before resuming

operation.

•

No modications shall be made to the wheel loader.

Contact your Wacker Neuson dealer for specic advice

regarding the use of the wheel loader and approved

attachments.

Page 20

B A S I C S A F E T Y I N S T R U C T I O N S

18

• If worn or damaged parts need replacement, use only

Wacker Neuson replacement parts to ensure optimum

performance and safety.

• Inspect hydraulic hoses and ttings prior to the start of

each work shift. Correct any observed leaks or abrasion

issues before operating the machine. Extended environmental exposure can cause undetectable damage.

Replace hose assemblies periodically as advised in the

maintenance schedule.

•

Thoroughly inspect the wheel loader before each operating shift.

•

The Wheel Loader Repair Manual describes the special

tools, diagnosis techniques, repair sequence procedures, lifting and supporting devices needed to repair this

machine. To avoid unnecessary hazards and possible

damage to the Wheel Loader, do not attempt to repair

this machine without complying with the instructions in

the Repair Manual.

•

Make the location and means of operation of the re

extinguishers known, and consider the options for re

detection and ghting.

•

A Falling Object Protection System (FOPS) is available

for the Wheel Loader Operator Protection System. OSHA

and MSHA require this protection when operating with

overhead hazards. Contact your Wacker Neuson dealer

for advice and availability of a certied FOPS.

Page 21

B A S I C S A F E T Y I N S T R U C T I O N S

19

W L 3 0

2.2 Selection and qualication of personnel / basic duties

•

Personnel being trained, educated, instructed or participating in a general training program may only work on

or with the machine under constant supervision of an

experienced, authorized supervisor.

•

Work on the machine‘s electrical equipment may only

be perform by an electrician or by trained persons under

the direction and supervision of an electrician.

• Work on the chassis, brakes and steering system may

only be performed by trained, specialized personnel.

•

Only trained, specialized personnel with specic knowl-

edge of and experience in hydraulics may work on hydraulic units.

•

The operator of the wheel loader must be qualied to

operate the machine through demonstration of comprehension of the operating instructions. No one shall

operate the wheel loader if impaired due to intoxication

or drug reaction.

•

Diagnosis and repair of the wheel loader shall be performed by trained competent technicians unimpaired by

intoxication or drug reaction.

•

Prohibit unauthorized and untrained people from access

to the starting key and operation of the wheel loader.

•

The wheel loader operator is responsible for visually

monitoring the work area of the wheel loader and preventing anyone from entering the area without permission. If a person enters the area while the wheel loader

is in operation, the operator shall stop the wheel loader

and instruct the person to leave the work area until the

wheel loader has been stopped in a safe mode. The

person may then approach the machine in full view of

the operator.

Page 22

B A S I C S A F E T Y I N S T R U C T I O N S

20

2.3 Safety instructions for certain operating phases

•

If the wheel loader does not respond as expected to the

operator command or exhibits a malfunction, stop the

machine, contact the supervisor and restore the machine

to serviceable condition before resuming operation.

•

Start and operate the loader only from the operator’s

seat.

•

When switching on and off, observe the indicator displays in accordance with the Operator’s Manual.

•

Make sure no one is located in the operating area of the

loader before starting the engine.

•

After starting the engine and conrming that the indi-

cators are responding correctly, activate the steering,

brakes, lights, signals and loader/accessory functions

to conrm that these devices are responding correctly

to the control command.

•

To avoid damage to the wheel loader, position the loader

bucket or accessories before moving the machine. Re-

conrm that there are no people in the work or travel

area before moving the machine.

The safety instructions are directed at all persons involved

in work on or with the loader.

2.3.1 Safety instructions for normal operation

•

Refrain from any measures that could put safety into

question.

•

Before starting work, familiarize yourself with the working

environment in which you will be using the loader. The

working environment includes, for example, obstacles in

the working and trafc area, the bearing capacity of the

ground and the necessary safeguarding of the location

to allow it to be used as a public trafc area.

• Take precautions to ensure that the loader is operated

only in a safe, serviceable state.

•

Only operate the loader if all the protection devices and

safety devices, e.g. detachable protection devices, sound

absorbers and exhaust equipment, are serviceable and

operational.

•

Check the loader at least once a day for visible defects.

Page 23

B A S I C S A F E T Y I N S T R U C T I O N S

21

W L 3 0

•

When driving on public roads, lanes and squares, ob-

serve the valid road trafc regulations and put the loader

into a condition permissible for the road beforehand.

•

As a matter of principle, turn on the lights when traveling

on public roads to increase awareness for road trafc..

•

When driving through underpasses, gates, bridges, tunnels, overhead lines, etc., always make sure that you

have enough clearance above and on both sides and a

sufcient safety margin.

•

Always keep sufcient distance away from excavations,

embankments and the edges of piled up material.

•

Refrain from any method of operation that could adversely affect the loader‘s stability. This also includes

the duty to pass on information regarding the approved

carrying capacity (=payload) for the relevant loader at-

tachments. (carrying capacity / approved payload are

specied in the Operator’s Manual)

• Do not drive transversely on slopes; always keep work

equipment and load near the ground, especially when

driving down slopes.

•

When driving down a slope, always adjust your driving speed to take account of the respective conditions.

Always reduce your speed before reaching a downhill

slope, and not after you have reached it.

•

The load must be located on the uphill side during driving on downhill or uphill slopes.

• As a matter of principle, always secure the loader from

accidentally rolling away and against unauthorized use.

Turn off the engine, put on the parking brake, lower the

work equipment, remove the starting key and, if necessary, employ a wheel chock.

Page 24

B A S I C S A F E T Y I N S T R U C T I O N S

22

2.3.2 Safety instructions for other operating modes

These safety instructions refer to special tasks relating to the

use of the loader and servicing tasks - as well as emergency

maintenance during operation or work concerning disposal

of the auxiliary and operating materials.

•

The Operator’s Manual provides adjustment, maintenance and inspection information and schedules in

subsequent sections. This information is essential to

ensuring peak performance satisfaction and safety over

the life of the wheel loader.

•

This Operator’s Manual provides routine adjustment

and maintenance procedures in addition to operating

instructions. Diagnosis and repair of the wheel loader

requires special skill, training and tools. Your Wacker

Neuson dealer has the trained technicians to perform

such work safely and effectively.

•

Maintenance and repair work shall be performed by

operators and technicians trained and knowledgeable

of the wheel loader function and attachments.

•

Do not attempt to perform maintenance or repair on the

wheel loader until the machine and engine is stopped

and all attachments are in a stable position. Do not attempt to perform maintenance or repair work on hot

surfaces or components of the machine. Read and understand the procedure for maintenance and repair in

the Operator’s and Repair Manuals for this wheel loader.

•

Secure the maintenance area, allowing as large a space

as required.

•

If the loader is being completely shut off during servicing

and maintenance work, please observe the following

(see the chapter »Securing the Loader«):

- Secure the loader from being accidentally turned back

on by removing the starting key.

- Attach a warning note to indicate that the loader is be-

ing worked on.

-

Only perform servicing and maintenance work if the

loader is parked on an even, hard surface and secured

from rolling away and articulating at the steering swivel

point..

-

Before performing work with the loader arms raised,

install the support provided to prevent the loader arms

from lowering suddenly and inadvertently.

- This device shall conform to ISO 10533.

Page 25

B A S I C S A F E T Y I N S T R U C T I O N S

23

W L 3 0

•

Use lifting devices to raise and support parts and assemblies exceeding 10 kg (22 lbs) weight during repair

and replacement activity. Use only OSHA approved

devices to perform the lifting operation and verify that

the lifting devices are in serviceable condition.

• The use of a crane to lift heavy assemblies or compo-

nents requires that the operator is certied by OSHA.

The person attaching the load and signaling the operator

must be trained in proper techniques as well as voice

and hand signals to instruct the crane operator.

•

For assembly above head height, use only climbing aids

and working platforms which are intended for this purpose, or which are safe for use in this situation. Do not

use machine parts as climbing aids. Keep all handles,

steps, pedestals, platforms and ladders free of dirt, snow

and ice.

•

Clean the entire loader, especially the connections

and threaded connections, with oil, fuel or care products when beginning maintenance and servicing work.

Use lint-free cleaning rags and no aggressive cleaning

agents.

•

Before cleaning the loader with water or by steam jet

(high-pressure cleaner) or with other cleaning agents,

cover up / seal off all the openings into which water,

steam and cleaning agents are not permitted to enter.

Electrical components, inlets and outlets for the engine‘s

combustion air and reservoir openings are particularly

at risk. Completely remove the covers / seals after you

have nished cleaning.

•

Before restarting, retighten any threaded connections

loosened during servicing and repairs, in particular for oil

or fuel lines. When performing maintenance and servicing work, check all the lines and threaded connections

for leaks and tight t.

Page 26

B A S I C S A F E T Y I N S T R U C T I O N S

24

•

Should it be necessary to remove safety devices during

setup, servicing or repairs, reinstall and check the safety

devices immediately after nishing the work and verify

that the devices perform correctly.

•

Replace the ROPS (Roll Over Protective Structure) or

FOPS structure if it is permanently deected, a member

is deformed, it has become corroded, and/or it has been

modied. If the mounting structure, base, or mounting

hardware is damaged, consult your Wacker Neuson

dealer for assistance. Do not attempt to repair, straighten

or reuse a damaged ROPS or FOPS.

•

Responsibly dispose of the unwanted materials and

uids resulting from the repair. Hazardous material shall

be disposed in a hazardous material container(s). Parts

and assemblies can be recycled.

WARNING

Never use the machine without the ROPS/FOPS

properly installed.

►

Do not drill, weld, straighten, or bend the ROPS

/ FOPS protective structures.

►

Allow only trained authorized personnel to install

new ROPS / FOPS structures.

ROPS / FOPS - protective structures

Page 27

B A S I C S A F E T Y I N S T R U C T I O N S

25

W L 3 0

2.4 Safety instructions for particular hazards

2.4.1 Forklift attachment

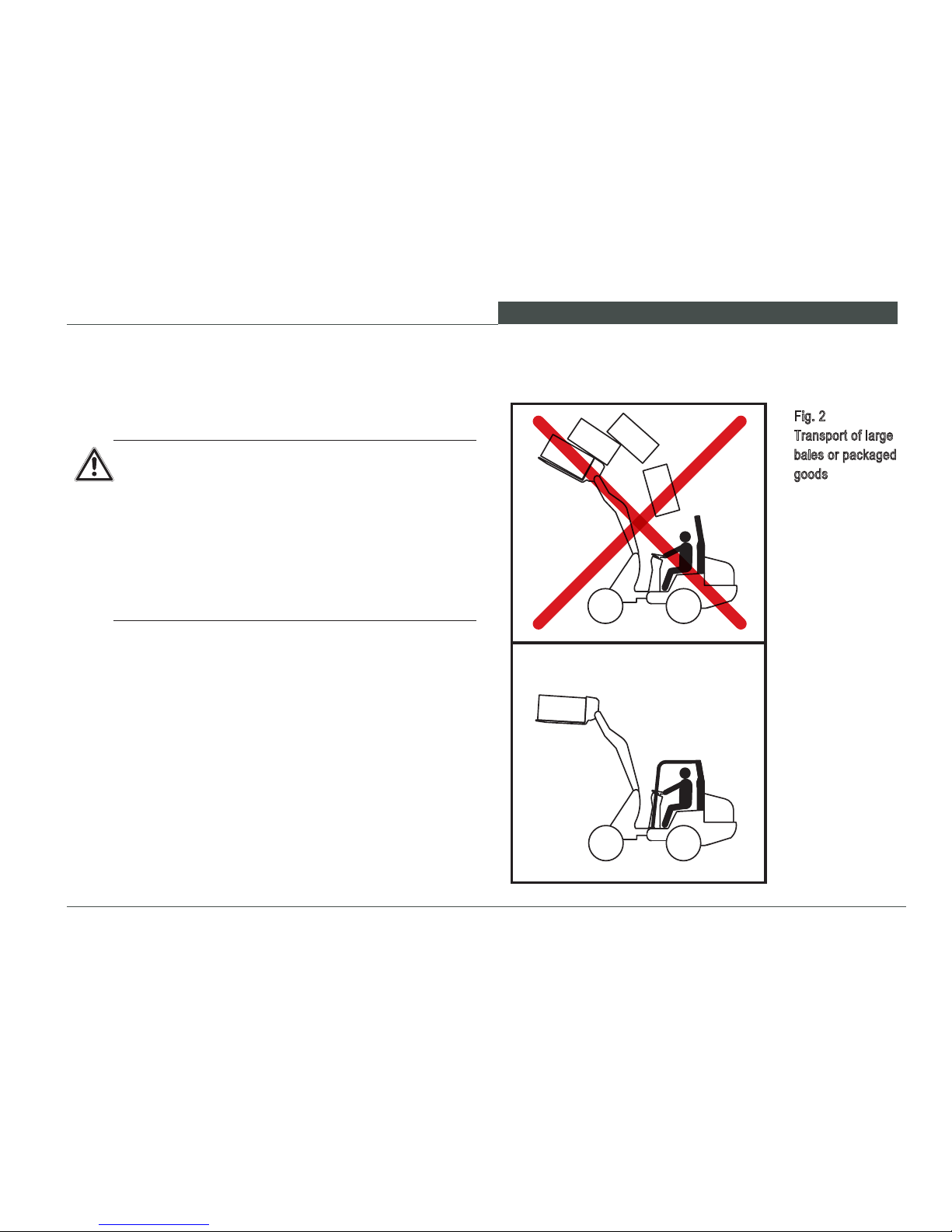

WARNING

Personal injury hazard.

Falling objects can strike the operator.

►

Do not transport large bales or packaged goods

without a FOPS (operator canopy or cabin).

►

Ensure that large loads are properly secured

and supported. See ANSI B56.1, OSHA1910 and

OSHA1926 for regulations on carrying material.

► Do not stack load higher than fork restraint.

Fig. 2

Transport of large

bales or packaged

goods

Page 28

B A S I C S A F E T Y I N S T R U C T I O N S

26

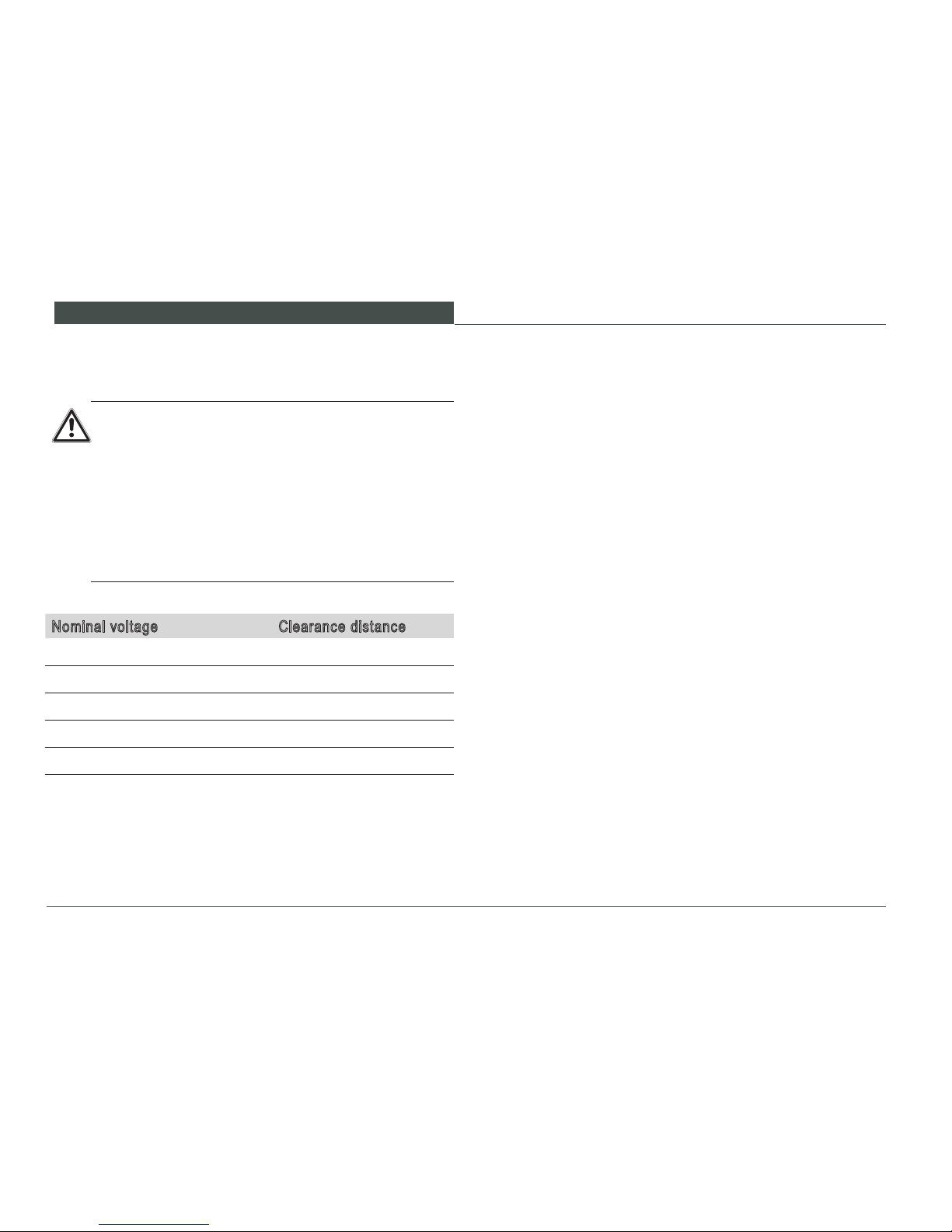

WARNING

Electric shock hazard.

The operator of the Wheel Loader can be killed if

the Wheel Loader comes in contact with electrical

wires.

► Keep the loader and attachment tools at a suf-

cient distance from overhead power lines and

other electrical lines of more than 50 V (see

table below).

If inadvertent contact with a live electric source occurs:

•

Do not leave the loader until the electricity has been

disconnected and a qualied technician directs the operator to leave the machine..

• If feasible, drive the loader away from the danger area!

•

Warn any people around the loader not to get any nearer

and not to touch the machine.

• Arrange to have the power turned off.

2.4.2 Working near overhead power lines

Nominal voltage Clearance distance

up to 1000 V 1 m 3.3 ft

over 1 kV up to 110 kV 3 m 9.8 ft

over 110 kV up to 220 kV 4 m 13 ft

over 220 kV up to 380 kV 5 m 16.4 ft

Unknown nominal voltage 5 m 16.4 ft

Page 29

B A S I C S A F E T Y I N S T R U C T I O N S

27

W L 3 0

2.4.3 Electrical power

• Regularly check the loader‘s electrical equipment. Defects, such as loose plug connections or cables with

burnt insulation, shall be replaced before resuming operation.

•

If an electrical malfunction is discovered, stop the wheel

loader in a safe location, lower the loader arms and attachment to the ground and stop the engine. Contact

the supervisor for diagnosis and repair by a qualied

technician before resuming operation.

•

Replacement fuses shall be of the same type and capac-

ity as specied by the manufacturer in the Operator’s

and Repair Manuals. Do not attempt to bypass a fused

system to resume operation.

2.4.4 Flying sparks / re danger

WARNING

Fire hazard.

Sparks from the exhaust, or electrical equipment, or

hot machine parts can ignite explosions and res.

►

Do not work in enclosed spaces where am-

mable materials, explosive vapors, or combustible dust are found.

► Stay clear of ammable materials such as hay

and straw.

►

Park the Wheel Loader only in areas free of

ammable materials.

Page 30

B A S I C S A F E T Y I N S T R U C T I O N S

28

2.4.5 Gas, dust, steam, smoke

•

Diesel engine exhaust emissions are toxic in concentrated amounts. Do not operate the wheel loader in enclosed spaces or inadequately ventilated spaces.

•

Determine and follow regulations regarding safe opera-

tion at the specic work site.

- Do not operate the wheel loader near open ames.

-

Do not perform welding repairs in explosive atmospheres.

-

Do not weld fuel reservoirs or fuel system components.

- Do not perform any welding operation unless qualied

to do so.

•

Wear appropriate personal protective equipment (breath-

ing lter, protective suit) for protection against specic

dangers, e.g. poisonous gases, corrosive steam, poisonous (i.e. containing toxins) surroundings, etc.

2.4.6 Hydraulics, pneumatics

• When detected, oil leaks shall be repaired to avoid:

- environmental hazards

- re hazards

- slip hazards

- explosion hazards

- personal injury hazards.

•

Do not attempt to repair a hydraulic system or component

until the hydraulic pressure has been relieved. Relieve

the pressure by activating controls as advised in this

Operator’s Manual or the Repair Manual.

• Replace hydraulic lines and ttings with original equipment parts from your Wacker Neuson dealer to assure

original performance and safety. The reinstalled hydraulic line routing and attachment shall conform to the

original routing. Conrm that the replacement routing

is not interfering with other parts, chang across sharp

surfaces or resting on or near hot surfaces.

Page 31

B A S I C S A F E T Y I N S T R U C T I O N S

29

W L 3 0

NOTICE

Use the appropriate fuel for climate temperature

ranges to avoid engine stoppage from fuel gelling.

2.4.8 Noise

•

All the loader‘s sound-proong devices must be in their

protection position during operation.

• If necessary, the operator must wear personal hearing

protection.

2.4.9 Oils, grease and other chemical substances

• Observe the valid safety regulations for the respective

product when handling oil, grease and other chemical

substances.

• Do not service the wheel loader immediately after op-

eration. Wait until hot surfaces have cooled and can be

touched comfortably.

•

Smoking and open ames are prohibited during fueling.

Danger of re or explosion!

2.4.7 Tip-overs

WARNING

Personal injury hazard.

Falling Loader can strike or crush the operator.

►

Do not operate the wheel loader without fastening the seat belt.

►

Keep the loader lift arms and attachment as low

as practical when traveling.

If the machine tips over, or in the event of an extreme slope condition, take the following steps to

avoid engine damage:

►

Stop the engine as quickly as practical to avoid

damage from lubrication starvation.

► Do not operate the engine or machine after an

incident until a technician has inspected and corrected any damage resulting from the incident.

Page 32

B A S I C S A F E T Y I N S T R U C T I O N S

30

2.5 Transporting and towing / restarting

• Instructions are provided in this Operator’s Manual for

towing, loading and transporting the wheel loader safely

without machine damage.

•

The towing machine shall be capable of towing the wheel

loader.

•

The loading and transport equipment shall be appropriate to safely complete the sequence of operation. If the

wheel loader is to be lifted by a crane device, consult

the machine specications to select the correct crane

capacity and OSHA lifting devices to safely complete

the lifting operation.

•

Only restart the loader according to the Operator’s

Manual.

•

See Chapter 6 for complete transporting and towing

instructions.

2.6 Final decommissioning / dismantling

•

Drain and dispose of all uids in suitable containers and

dispose of the uids in an environmentally responsible

manner. Do not dispose in sewers, streams, lakes or

on the ground.

• Remove the battery and dispose of it at an authorized

recycling center. Remove the starting motor to disable

the engine.

•

Dismantle and recycle the components according to the

material instructions on the individual parts. Tires and

rubber based parts can be recycled separately.

Page 33

B A S I C S A F E T Y I N S T R U C T I O N S

31

W L 3 0

1

5

311

15

6

8 9

10

2

14

7

12

13

Fig. 3

Location of the

Safety labels

2.7 Safety labels used

Maintain all safety message labels on the machine

in a legible manner. If a safety label becomes damaged or illegible, replace it with a new label available from your Wacker Neuson dealer or at www.

wackerneuson.com.

Page 34

B A S I C S A F E T Y I N S T R U C T I O N S

32

Safety label 3

Warning

Personal injury hazard from falling

equipment.

Never stand in the unsecured danger

area.

Use the safety supports.

Safety label 1

Warning

Do not stand near the loader during

operation.

Do not go under the loader lift arms

when raised.

Safety label 2

Shearing hazard

Shearing hazard from rotating fan. Stop

the engine before entering the area.

Safety label 4

Warning

Personal injury hazard. The rollover bar

should always be locked in protection

position, insofar as this is possible given

the working conditions.

Page 35

B A S I C S A F E T Y I N S T R U C T I O N S

33

W L 3 0

Safety label 5

Important

Remove the starting key and read the

Repair Manual before proceeding with

any work activity on the wheel loader.

Safety label 6

Important

Lubricate the center joint daily before

beginning work. Refer to your Operator’s Manual for more information.

Safety label 7

Warning

Hot surfaces can cause burns.

Do not touch hot surfaces.

Safety label 8

Warning

Never lift or transport people with the

lifting attachment.

Page 36

B A S I C S A F E T Y I N S T R U C T I O N S

34

Safety label 12

Warning

Personal injury hazard. The Wheel

Loader can injure people on the work

site who are in the danger zone.

Keep personnel away from the Wheel

Loader during operation!

Safety label 11

Warning

Pinching/crushing hazard. Avoid the articulation area while the Wheel Loader

is in operation. Before working in the

articulation area and before transporting, secure the articulation pivot. Refer

to Operator’s Manual.

Safety label 10

Warning

Personal injury hazard.

Never transport passengers on the

Wheel Loader.

Safety label 9

Warning

Personal injury hazard. Always wear

the seat belt while operating the wheel

loader.

Page 37

B A S I C S A F E T Y I N S T R U C T I O N S

35

W L 3 0

Safety label 14

Warning

Safety label 13

Warning

15 PSI

1 BAR

If the ROPS / FOPS protective structures are damaged,

they can not serve their protective function.

Never drill or weld the ROPS / FOPS protective structures.

Refer to Operator’s Manual.

Hot liquids or steam escaping

under pressure can cause burns.

Do not open radiator when it is hot. Re-

fer to Operator’s Manual.

Label 15

Possibility of equipment

damage

Close both doors before tilting the cab.

Page 38

B A S I C S A F E T Y I N S T R U C T I O N S

36

2.8 Safety devices

2.8.1 Fire extinguisher Fig. 4

Fire extinguisher

Fig. 5

Attaching the rotating beacon

The receptacle for the rotating beacon can be attached to

the operator cab roof in the back (Fig. 5).

To switch the rotating beacon on and off, see the chapter

»Switches / rocker switches«.

Use the yellow rotating beacon according to local

regulations.

Contact your Wacker Neuson dealer if you want

to install a re extinguisher or a rotating beacon.

Your Wacker Neuson dealer has the trained technicians to perform such work safely and effectively.

A re extinguisher can be installed to operator cab rail to

the right of the operator ‘s seat. (Fig. 4).

2.8.2 Rotating beacon (Optional equipment)

Page 39

B A S I C S A F E T Y I N S T R U C T I O N S

37

W L 3 0

2.8.3 Seat belt

Before starting the engine:

•

adjust the seat to provide comfortable access

to all control ranges.

•

examine the seat belt webbing for any mechanical or chemical damage and replace if necessary.

•

inspect all seat belt hardware for functionality and serviceability, repairing or replacing if

necessary.

•

fasten the seat belt and adjust to contact the

lower torso rmly.

When not in use:

• store the seat belt by placing it across the seat

pad.

•

ensure that the seat belt retractors work freely.

2.8.4 Backup alarm for reverse drive

(Optional equipment)

A backup alarm sounds when reverse gear is engaged.

The sound is to warn persons who are in the vicinity of the

loader that the loader is going into reverse.

Fig. 6

Seat belt

Page 40

B A S I C S A F E T Y I N S T R U C T I O N S

38

2.8.5 Emergency exit

Fig. 7

Emergency exitThe cab door on the left side of the machine fac-

ing the forward direction of travel is the primary

access system to the operator station. The right

hand access is a secondary opening intended for

emergency use only.

Page 41

B A S I C S A F E T Y I N S T R U C T I O N S

39

W L 3 0

2.8.6 Battery disconnect switch

Disconnect the battery from the electrical system by rotating

the key counter-clockwise. In an emergency, the disconnect switch can be used to disconnect the battery from

the electrical system. Disconnecting the battery from the

electrical system will reduce the possibility of discharge

before the next use. Also, disconnecting the battery from

the electrical system and removing the key is a means of

resisting machine theft.

• Turn the switch lever counter-clockwise:

– The battery is disconnected from the electrical system

• Turn the switch lever clockwise:

– The battery is connected to the electrical system.

After removing the disconnect switch key, place the

attached cover over the key opening to prevent dirt

and water from entering the switch.

To connect the battery to the electrical system,

remove the cover, insert the key and rotate the key

clockwise. To avoid inadvertent control behavior,

do not disconnect the battery from the electrical

system with the engine running or any electrical

systems activated.

Fig. 8

Battery disconnect

switch

Page 42

B A S I C S A F E T Y I N S T R U C T I O N S

40

2.8.7 Loader lift arm locking system

Apply the locking system for the loader lift arm by shifting

the lever located to the right of the operator’s seat Item 1

(Fig. 9).

•

Push the switching control rearward toward the seat

frame:

– the locking system is now on.

•

Pull the switching control forward away from the seat

frame:

– the locking system is now off.

CAUTION

Possibility of inadvertent loader lift arm activation.

Inadvertent activation can result in the loader arms

dropping causing the bucket or attachment to engage the road surface. This can result in loss of

machine control with possible injury to the operator

and other work site persons.

►

Always lock the loader lift arm control to prevent

inadvertent activation during travel.

► The operator shall not leave the operator seat

until the loader arms and attachment have been

lowered to and are resting on the ground.

The loader lift arm can be secured against unintentional operation by means of a locking mechanism.

If you have switched on the locking mechanism, the

loader lift arms will not move if the loader controls

are moved. The fact that the loader lift arm is locked

is not shown via indicator lights, but instead can be

seen from the position of the switching lever (Fig. 9).

Fig. 9

Lever for the locking

mechanism of the

Loader lift arm

1

Page 43

TE CH N IC A L D ATA

41

W L 3 0

3 TECHNICAL DATA

3.1 Technical description

The loader consists of the vehicle frame, the drive and the

axles. The vehicle frame contains all the drive and control

units for the standard conguration. The vehicle frame consists of the front carriage with the loader lift arms, and the

rear carriage, in which the drive unit is situated. They are

connected by an articulated swivel joint.

Drive

The loader is driven by a diesel engine, which powers the

steering and working hydraulics and the driving hydraulics.

The propulsion hydraulics provide power to the transfer

gear box by a directly attached hydraulic motor. The rear

axle is integral with the transfer gear box. The front axle is

powered by a driveshaft connecting the transfer gear box

to the front axle.

The axles are designed as rigid axles.

Brakes

Service braking is provided by the propulsion hydraulic

system through the transfer gearbox and driveshaft to both

axles. The braking-inching pedal provides a secondary service brake by contacting a hub-mounted differential in the

transfer gear box. A separate parking brake with separate

control is provided that engages the differential hub in the

transfer gear box.

Steering

The fully hydraulic articulated swivel steering system operates via a dual action cylinder.

Page 44

TE CH N IC A L D ATA

42

Hydraulics

The loader has two hydraulic systems supplied by a hy-

draulic uid reservoir:

- hydrostatic drive

- steering and working hydraulics

The hydrostatic drive consists of an axial piston variable

displacement pump, which drives an axial piston motor. The

axial piston variable displacement pump is rigid coupled

directly to the diesel engine, while the axial piston motor is

directly coupled to the transfer case.

Displacement is automatic and continuous, but depends on

speed and load. The travel speed depends on the engine

speed and the machine load. Operating speed is set by

the accelerator pedal position, engine speed and torque

demand of the loading operation. Depending on load, the

variable displacement pump automatically adjusts pump

displacement to balance torque and speed requirements

within the power capability of the diesel engine. Since the

input power is limited to the diesel engine output, increased

demands from traversing a grade or loading the bucket will

result in speed reduction which increases the torque to meet

the performance demand. This adjustment control allows

the entire range of performance to be utilized optimally.

Actuating the inching pedal is an override control that can

reduce wheel loader speed as operation demands. Depressing the pedal to the full range will stop the travel motion

of the wheel loader. The inching pedal permits an innite

number of control positions. The inching pedal provides the

service brake function by destroking the pump until no uid

is transmitted between the pump and motor.

A gear hydraulic pump supplies the steering and working

hydraulics with oil. The gear pump is rigid coupled to the

drive‘s variable displacement pump. Pump ow output is

directly proportional to the diesel engine speed.

The hydraulic system is equipped with relief valves, lters

and oil coolers.

Page 45

TE CH N IC A L D ATA

43

W L 3 0

Electrical system

The electrical system operates at 12 volts and the electrical

circuits are protected by fuses to prevent overload damage

to the system and its components.

Equipment

The loading equipment consists of the loader lift arms with

an integrated mechanical or hydraulic quick-change receptacle, lifting and tipping cylinders and the appropriate

attachments.

The loader is equipped with a rollover protective structure

(ROPS).

3.2 Loader data

Engine

4-cylinder Perkins diesel engine

Output

35.7 kW / 49 hp at 2600 rpm

SAE rating according to ISO9249

Type 404 D – 22 water-cooled

Capacity 2216 cm³ (135 inch³)

Dr ive (driving speed)

1. gear

0 – 7 km/h

0 – 4.35 mph

2. gear

0 – 20 km/h

0 – 12.43 mph

Steer ing

Fully hydraulic center-pivot steering

Rotating angle 12°

Turn angle 45°

Elect rical system

Working voltage 12 volts

Battery 77 Ah

Page 46

TE CH N IC A L D ATA

44

Weight spec ifications

Operating weight 3120 kg 6878 lb

Permissible total weight 3400 kg 7496 lb

Permissible axle load per axle 2500 kg 5512 lb

Permissible payload with shovel 828 kg 1825 lb

Permissible payload with pallet fork 798 kg 1759 lb

Hydraulics

Driving hydraulics

Flow rate 78 l/min 20.61 gallons/min

Working pressure 450 bar 6527 psi

Working hydraulics

Flow rate 49 l/min 12.94 gallons/min

Working pressure 210 bar 3046 psi

Steering hydraulics

Flow rate 49 l/min 12.94 gallons/min

Working pressure 190 bar 2756 psi

Noise values

Average LwA measured at the operator‘s ear 98.4 dB(A)

Guaranteed LwA measured at the operator‘s

ear

100 dB(A)

Specied LpA measured at the operator‘s ear 80 dB(A)

Vibrations (weighted effective value)

Upper extremities no more than 2.50 m/s² 8.19 ft/s²

Feet or seat surface no more than 0.80 m/s² 2.64 ft /s²

Page 47

TE CH N IC A L D ATA

45

W L 3 0

1

3.3 Product identication number plates

A product identication number plate is attached to the

loader on the right side of the front carriage (Fig. 10).

It lists the following information:

• Manufacturer

• Vehicle ID

• Type

• Engine power

• Axle loads

• Operating weight

• Permissible total weight

In addition, the vehicle ID is engraved on the right side of

the rear end near the entry area (Fig. 10/1).

Furthermore, the following loader components each have

their own rating plate:

• The diesel engine

•

The axial piston variable displacement pump (hydraulic

transmission pump)

• The oil engines (hydraulic traction motor)

• The axles.

Fig. 10

Vehicle ID

Wacker Neuso n SE

Preußenstraße 41

80809 M unich/Ge rmany

Fahrzeug-Ident-Nr.

Betriebsgewicht kg zul. Achslast hinten kg

zul. Ges Gew. kg

Hom.-Nr

zul. Anhängelast kg

Art.-Nr.

Motorleistung kW

zul. Achslast vorn kg

Radlader

Made by Weidemann / Flechtorf Germany

Typ

Page 48

TE CH N IC A L D ATA

46

3.4 Dimensions

Fig. 11 Dimensions

Page 49

TE CH N IC A L D ATA

47

W L 3 0

*In the event of deviating tires or reversed wheel rims the dimensions will change

Dimensions with 31x15,5-15EM tires

Item Designation Value

A Overall length with standard

shovel

4554 mm 179.29 inch

A‘ Overall length without shovel 3748 mm 147.56 inch

B Axle center to shovel pivot-

point

722 mm 28.43 inch

C Wheelbase 1732 mm 68.19 inch

D Rear overhang 1179 mm 46.42 inch

E Overhead loading height* 2990 mm 117.72 inch

F Max. height of shovel pivot

point*

3209 mm 126.33 inch

G Height of seat* 1254 mm 49.37 inch

H Max. dumping height* 2416 mm 95.12 inch

I Scraping depth* 26 mm 1.02 inch

K Reach at H* 334 mm 13.15 inch

L Height to top of cab* 2251 mm 88.62 inch

Item Designation Value

M Total working height* 4070 mm 160.24 inch

N Max. dumping angle at max.

lift height

43°

O Reverse roll angle on ground 43°

P Reverse roll angle at max. lift 50°

Q Inside turning radius* 1413 mm 55.63 inch

R Overall width* 1345 mm 52.95 inch

S Radius at outer edge* 2793 mm 109.96 inch

T Ground clearance* 261 mm 10.28 inch

U Turn angle 45°

V Width across cab 870 mm 34.25 inch

W Track width* 941 mm 37.05 inch

Z Maximum turning radius

(depends on shovel width)

3186 mm 125.43 inch

Page 50

DE SCR I PT ION O F T HE I NDI CATO R , WA R NI NG A ND CO N TR OL EL E ME NTS

48

4 DESCRIPTION OF THE INDICATOR, WARNING AND CONTROL ELEMENTS

4.1 Operating elements and instruments

Fig. 12

Operating elements

1

2

3

4

5

6

7

8

9

10

11

Page 51

DE SCR I PT ION O F T HE I NDI CATO R , WA R NI NG A ND CO N TR OL EL E ME NTS

49

W L 3 0

Item Designation

1

Steering wheel turning knob

2

Instrument panel

3

Steering wheel

4 Accelerator

5

Operating lever for load arm / drive

6

Operating lever for optional hydraulics

7

Operating lever for parking brake

8

Operator’s seat

9

Braking-inching pedal

10

Operating lever for adjusting the steering column

11

Operating lever for lighting, turn signals and signal horn

Page 52

DE SCR I PT ION O F T HE I NDI CATO R , WA R NI NG A ND CO N TR OL EL E ME NTS

50

4.2 Control and warning indicator lights

• If the indicator lights do not illuminate properly

at the starting sequence, repair the malfunction

before operating the machine.

•

If an indicator light illuminates during operation,

move the machine to a safe place, lower the

loader arms and stop the engine.

•

Do not operate the wheel loader until the reason

for the illuminated indicator is determined and

corrective action has been completed.

Immediately turn off the engine if a light marked with

this * symbol is illuminated in the adjacent table.

Fig. 13 Control and warning lights

123467895

Page 53

DE SCR I PT ION O F T HE I NDI CATO R , WA R NI NG A ND CO N TR OL EL E ME NTS

51

W L 3 0

Item Designation Function Symbol

1 Not used No function

2 Heater indicator light Illuminates during preheating

3 Not used No function

4 * Warning light for engine oil pressure Illuminates when engine oil pressure is too low

5 * Warning light for generator Illuminates if the battery is not charged

6 * Warning light for engine temperature Illuminates when engine temperature

7 Indicator light for for ward drive Illuminates when gear is set to forward drive

8 Indicator light for reverse drive Illuminates when gear is set to reverse drive

9 Indicator light for crawler gear Illuminates when crawler gear is engaged

Page 54

DE SCR I PT ION O F T HE I NDI CATO R , WA R NI NG A ND CO N TR OL EL E ME NTS

52

• If the indicator lights do not illuminate properly

at the starting sequence, repair the malfunction

before operating the machine.

•

If an indicator light illuminates during operation,

move the machine to a safe place, lower the

loader arms and stop the engine.

•

Do not operate the wheel loader until the reason

for the illuminated indicator is determined and

corrective action has been completed.

Immediately turn off the engine if a light marked with

this * symbol is illuminated in the adjacent table.

Control and warning indicator lights

Fig. 13 Control and warning lights

101112131516171814

Page 55

DE SCR I PT ION O F T HE I NDI CATO R , WA R NI NG A ND CO N TR OL EL E ME NTS

53

W L 3 0

Item Designation Function Symbol

10 Indicator light for parking brake Illuminates when the parking brake is on

11 Not used No function

12

Indicator light for main beam Illuminates when the main beam is switched on

13 Not used No function

14

Air lter indicator light Illuminates when the air lter is contaminated

15 Turn signal indicator light Illuminates when a turn signal is on

16 Warning light for return lter Illuminates if the pressure at the return lter is too high

17 * Warning light for hydraulic oil temperature Illuminates when hydraulic oil temperature is too high

18 Indicator light for overdrive Illuminates when overdrive is engaged

Page 56

DE SCR I PT ION O F T HE I NDI CATO R , WA R NI NG A ND CO N TR OL EL E ME NTS

54

4.3 Switches / rocker switches

Fig. 14 Switches / rocker switches (1)

1 2 3 4 5 6 7 8

Page 57

DE SCR I PT ION O F T HE I NDI CATO R , WA R NI NG A ND CO N TR OL EL E ME NTS

55

W L 3 0

Item Designation Function Symbol

1 Combination switch Switches lighting and signal horn on/off

2

No function

Available for optional equipment

Switches the optional hydraulics in order to release the

hydraulic locking device for attachments

3 Rocker switch for hazard warning lights Switches hazard warning lights on/off

4 No function

Available for optional equipment

Switches electrical connector on the lift arms on/off

5 No function Available for optional equipment

6

No function Available for optional equipment

7

No function Available for optional equipment

8 Engine starting switch For switching the engine on/off

Page 58

DE SCR I PT ION O F T HE I NDI CATO R , WA R NI NG A ND CO N TR OL EL E ME NTS

56

9 10 11 12 13 14

Switches / rocker switches

Fig. 15

Switches / rocker

switches (2)

Page 59

DE SCR I PT ION O F T HE I NDI CATO R , WA R NI NG A ND CO N TR OL EL E ME NTS

57

W L 3 0

Item Designation Function Symbol

9 Rocker switch for front windshield wipers Switches front windshield wipers on/off

10 Rocker switch for rear windshield wipers Switches rear windshield wipers on/off

11 Rocker switch for front headlights Switches front headlights on/off

12 Rocker switch for rear headlights Switches rear headlights on/off

13 Rocker switch for rotating beacon Switches rotating beacon on/off

14 No function Available for optional equipment

Page 60

DE SCR I PT ION O F T HE I NDI CATO R , WA R NI NG A ND CO N TR OL EL E ME NTS

58

4.4 Indicator devices

Fig. 16 Indicator devices

2 431

Item Designation Function Symbol

1 Fuel gauge Shows the fuel quantity

2 Tachometer Shows the diesel engine‘s rpm

3 Hour meter

Adds up the loader‘s operating

time. Plan your service work

and inspection work according

to the meter reading

4

Engine temperature

Shows the diesel engine‘s

temperature

Page 61

DE SCR I PT ION O F T HE I NDI CATO R , WA R NI NG A ND CO N TR OL EL E ME NTS

59

W L 3 0

Page 62

O P E R A T I N G A ND O PE R A T I O N

60

5 OPERATING AND OPERATION

5.1 Before starting up 5.1.1 Fueling

Read the Operator’s Manual before starting up the

loader.

•

Only operate the loader from the operator’s seat.

• Observe OSHA safety regulations.

•

Arrange for training with an experienced operator. Practice operating the wheel loader in a

remote at area to become familiar with control

response.

•

Using this Manual as a reference, conduct an

inspection before operating the wheel loader.

•

After prolonged storage or inactivity, refer to the

procedure for preparing to operate the loader.

•

Lower the loader lift arms and attachment to the

ground and stop the engine to fuel the loader.

•

Fire hazard – diesel fuel is ammable! Do not

smoke and avoid re and open ames when

fueling.

•

Do not use gasoline. Use only diesel fuel. Do

not add gasoline to diesel fuel.

•

Diesel fuel is hazardous to your health. Wear

appropriate gloves.

•

If an inadvertent incident occurs during fueling, take immediate appropriate measures to

avoid hazards. Inform the supervisor or person

responsible for the fueling operation.

Page 63

O P E R A T I N G A ND O PE R A T I O N

61

W L 3 0

The diesel reservoir is located in the front frame of the

loader. The reservoir‘s ller neck is located on the right side

of the front frame (Fig. 17).

• Unscrew the cap from the ller neck.

• Fuel the loader‘s reservoir through the ller neck.

•

Carefully replace the fuel cap on the ller neck after

fuelling.

NOTICE

Use only clean, conventional high-grade diesel fuel

to operate the loader.

If at all possible, use a ne lter in the lling line.

ENVIRONMENTAL NOTE

Diesel fuel is hazardous to the environment.

Do not allow it to be released uncontrollably into

the environment.

Immediately soak up with binding material any fuel

that has leaked, overowed or been spilled, and

dispose of it in an ecologically sound manner.

Immediately inform the persons responsible if fuel

has been released into the environment.

Fig. 17

Fuel filler neck

L O W SU L F UR F UE L

O R U LT RA

L O W

S U L FU R

F U EL O N LY

3 9 0 1 9 9 3 9 0

Page 64

O P E R A T I N G A ND O PE R A T I O N

62

Before entering the cab

• Check that the loader is clean and undamaged.

•

Check that the handles and steps are in good condition

and clean.

• Check that the cab windows are in good condition and

clean.

• Check that all safety components are present and fully

functional.

• Check that the rods, cylinders, hinge pins and coolers

are clean.

•

Check that all the fasteners, joints and hinge pins t

tightly.

•

Check that all the safety messages and instructional

labels are present and in good condition.

• Check the loader for oil, fuel and coolant leaks.

5.1.2 Operation

WARNING

Personal injury hazard.

► Do not operate the loader if it is not in service-

able condition or responding correctly to control

commands.

►

Park the machine in a safe place, lower the