Page 1

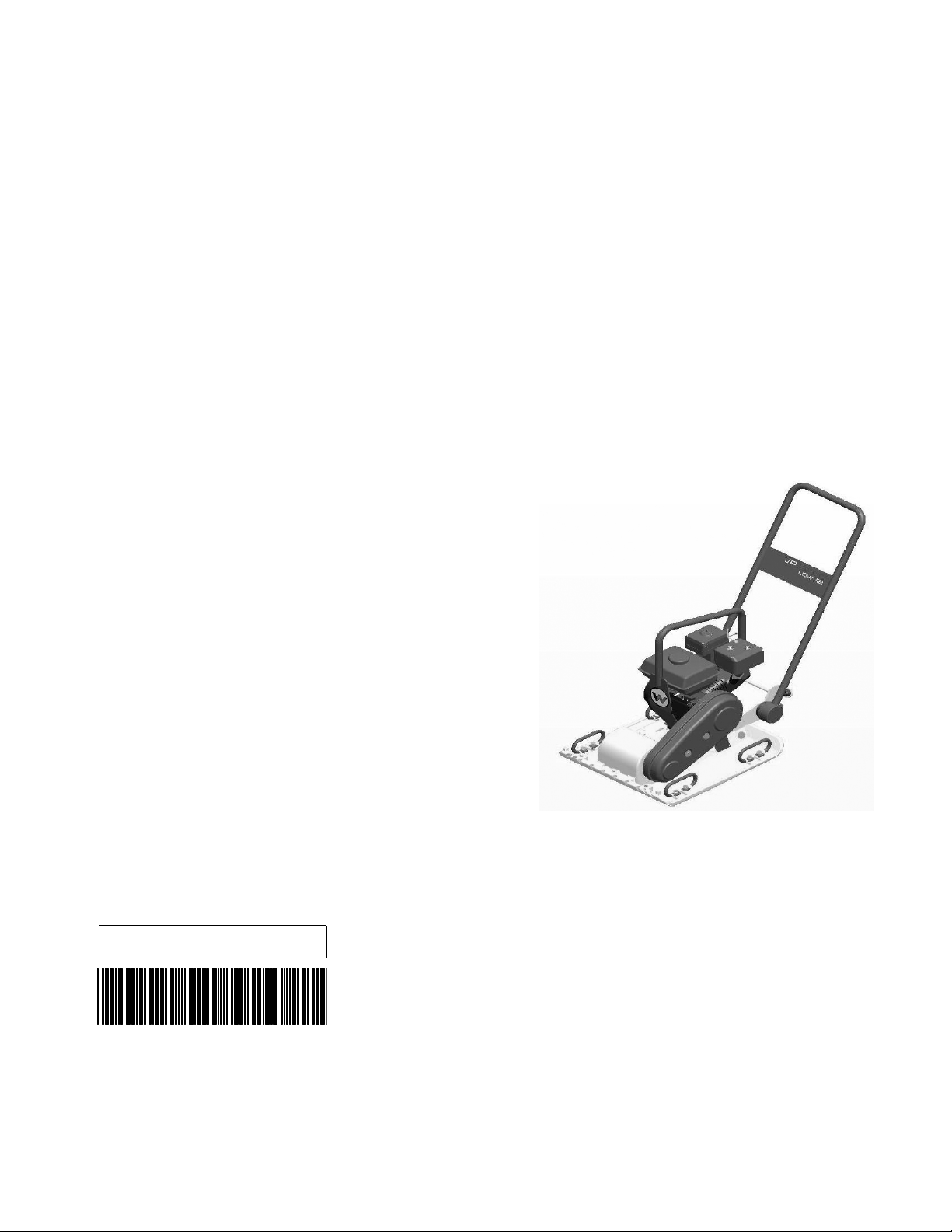

Operator’s Manual

Vibroplate

VP 2050A

VP 2050AW

0154570en 010 0110

0154570EN

Page 2

Copyright

notice

© Copyright 2010 by Wacker Neuson Corporation.

All rights, including copying and distribution rights, are reserved.

This publication may be photocopied by the original purchaser of the machine. Any

other type of reproduction is prohibited without express written permission from

Wacker Neuson Corporation.

Any type of reproduction or distribution not authorized by W acker Neuson Corp oration

represents an infringement of valid copyrights. Violators will be prosecuted.

T ra d emarks

Manufacturer

Tra n slated

instructions

All trademarks referenced in this manual are the property of their respective owners.

Wacker Neuson Manila Incorporated

Lot 2,Blk 1 Phase 3, PEZA Drive, First Cavite Industrial Estate, Brgy. Langkaan

Dasmariñas, Cavite, Philippines

Tel: +63-(0)2-580-7136 Fax: +63-(0)2-580-712

www.wackerneuson.com

This Operator’s Manual presents a translation of the original instructions. The original

language of this Operator’s Manual is American English.

Page 3

VP 2050A/AW Table of Contents

Foreword 3

1. Safety Information 4

1.1 Laws Pertaining to Spark Arresters ...................................................... 5

1.2 Operating Safety .................................................................................. 6

1.3 Operator Safety while using Internal Combustion Engines .................. 7

1.4 Service Safety ...................................................................................... 8

1.5 Label Locations .................................................................................... 9

1.6 Warning and Informational Labels ...................................................... 10

2. Technical Data 13

2.1 Engine Data ........................................................................................ 13

2.2 Machine Data ..................................................................................... 14

2.3 Sound and Vibration Measurements .................................................. 14

2.4 Dimensions ......................................................................................... 15

3. Operation 16

3.1 Recommended Fuel ........................................................................... 16

3.2 Application .......................................................................................... 16

3.3 Before Starting ................................................................................... 16

3.4 To Start ............................................................................................... 17

3.5 To Stop ............................................................................................... 17

3.6 Operation ............................................................................................ 18

wpm_bo0154570010enTOC.fm 1

Page 4

Table of Contents VP 2050A/AW

4. Maintenance 19

4.1 Periodic Maintenance Schedule ..........................................................19

4.2 Spark Plug ...........................................................................................21

4.3 Air Cleaner ..........................................................................................22

4.4 Engine Oil ............................................................................................23

4.5 Adjusting Engine Speed ......................................................................23

4.6 Carburetor Adjustment ........................................................................24

4.7 Cleaning Sediment Cup ......................................................................24

4.8 Drive Belt .............................................................................................25

4.9 Exciter Lubrication ...............................................................................26

4.10 Cleaning the Plate ...............................................................................26

4.11 Lifting Machine ....................................................................................27

4.12 Transporting Machine ..........................................................................28

4.13 Storage ................................................................................................28

4.14 Troubleshooting ...................................................................................29

wpm_bo0154570010enTOC.fm 2

Page 5

Foreword

WARNING

CALIFORNIA

Proposition 65 Warning:

Engine exhaust, some of its constituents, and certain vehicle

components, contain or emit chemicals known to the State of

California to cause cancer and birth defects or other reproductive

harm.

This manual provides information and procedures to safely operate

and maintain this Wacker Neuson model. For your own safety and

protection from injury, carefully read, understand and observe the

safety instructions described in this manual.

Keep this manual or a copy of it with the machine. If you lose this

manual or need an additional copy, please contact Wacker Neuson

Corporation. This machine is built with user safety in mind; however,

it can present hazards if improperly operated and serviced. Follow

operating instructions carefully! If you have questions about operating

or servicing this equipment, please contact Wacker Neuson

Corporation.

The information contained in this manual was based on machines in

production at the time of publication. Wacker Neuson Corporation

reserves the right to change any portion of this information without

notice.

All rights, especially copying and distribution rights, are reserved.

Copyright 2010 by Wacker Neuson Corporation.

No part of this publication may be reproduced in any form or by any

means, electronic or mechanical, including photocopying, without

express written permission from Wacker Neuson Corporation.

Any type of reproduction or distribution not authorized by Wacker

Neuson Corporation represents an infringement of valid copyrights

and will be prosecuted. We expressly reserve the right to make

technical modifications, even without due notice, which aim at

improving our machines or their safety standards.

wc_tx000001gb.fm 3

Page 6

Safety Information VP 2050A/AW

1. Safety Information

This manual contains DANGER, WARNING, CAUTION, NOTICE, and

NOTE callouts which must be followed to reduce the possibility of

personal injury, damage to the equipment, or improper service.

This is the safety alert symbol. It is used to alert you to potential

personal injury hazards. Obey all safety messages that follow this

symbol to avoid possible injury or death.

DANGER indicates a hazardous situation which, if not avoided, will

result in death or serious injury.

DANGER

WARNING indicates a hazardous situation which, if not avoided, could

result in death or serious injury.

WARNING

CAUTION

CAUTION indicates a hazardous situation which, if not avoided, could

result in minor or moderate injury.

NOTICE: Used without the safety alert symbol, NOTICE indicates a

situation which, if not avoided, could result in property damage.

Note: Contains additional information important to a procedure.

wpm_si000310gb.fm 4

Page 7

VP 2050A/AW Safety Information

1.1 Laws Pertaining to Spark Arresters

Notice: State Health Safety Codes and Public Resources Codes

specify that in certain locations spark arresters be used on internal

combustion engines that use hydrocarbon fuels. A spark arrester is a

device designed to prevent accidental discharge of sparks or flames

from the engine exhaust. Spark arresters are qualified and rated by

the United States Forest Service for this purpose.

In order to comply with local laws regarding spark arresters, consult

the engine distributor or the local Health and Safety Administrator.

wpm_si000310gb.fm 5

Page 8

Safety Information VP 2050A/AW

1.2 Operating Safety

Familiarity and proper training are required for the safe operation of the

machine. Machines operated improperly or by untrained personnel

can be hazardous. Read the operating instructions contained in this

WARNING

1.2.1 Do not allow anyone to operate this equipment without proper training.

1.2.2 Do not touch the engine or muffler while the engine is on or

1.2.3 Do not use accessories or attachments that are not recommended by

manual and the engine manual, and familiarize yourself with the

location and proper use of all controls. Inexperienced operators should

receive instruction from someone familiar with the machine before

being allowed to operate it.

People operating this equipment must be familiar with the risks and

hazards associated with it.

immediately after it has been turned off. These areas get hot and may

cause burns.

Wacker Neuson. Damage to equipment and injury to the user may

result.

1.2.4 NEVER operate the machine with the beltguard missing. Exposed

drive belt and pulleys create potentially dangerous hazards that can

cause serious injuries.

1.2.5 Never leave the machine running unattended.

1.2.6 Be sure operator is familiar with proper safety precautions and

operation techniques before using machine.

1.2.7 Always wear protective clothing appropriate to the job site when

operating the machine.

1.2.8 Wear hearing protection when operating equipment.

1.2.9 Close fuel valve on engines equipped with one when machine is not

being operated.

1.2.10 Store the machine properly when it is not being used. The machine

should be stored in a clean, dry location out of the reach of children.

1.2.11 Always operate machine with all safety devices and guards in place

and in working order. Do not modify or defeat safety devices. Do not

operate machine if any safety devices or guards are missing or

inoperative.

1.2.12 Read, understand, and follow procedures in the Operator’s Manual

before attempting to operate the machine.

wpm_si000310gb.fm 6

Page 9

VP 2050A/AW Safety Information

1.3 Operator Safety while using Internal Combustion Engines

Internal combustion engines present special hazards during operation

and fueling. Read and follow the warning instructions in the engine

owner’s manual and the safety guidelines below. Failure to follow the

WARNING

1.3.1 DO NOT run the machine indoors or in an enclosed area such as a

1.3.2 Do not smoke while operating the machine.

1.3.3 Do not smoke when refueling the engine.

1.3.4 Do not refuel a hot or running engine.

1.3.5 Do not refuel the engine near an open flame.

1.3.6 Do not spill fuel when refueling the engine.

1.3.7 Do not run the engine near open flames.

warnings and safety standards could result in severe injury or death.

deep trench unless adequate ventilation, through such items as

exhaust fans or hoses, is provided. Exhaust gas from the engine

contains poisonous carbon monoxide gas; exposure to carbon

monoxide can cause loss of consciousness and may lead to death.

1.3.8 Refill the fuel tank in a well-ventilated area.

1.3.9 Replace the fuel tank cap after refueling.

1.3.10 ALWAYS check the fuel lines and the fuel tank for leaks and cracks

before starting the engine. Do not run the machine if fuel leaks are

present or the fuel lines are loose.

wpm_si000310gb.fm 7

Page 10

Safety Information VP 2050A/AW

1.4 Service Safety

A poorly maintained machine can become a safety hazard! In order

for the machine to operate safely and properly over a long period of

time, periodic maintenance and occasional repairs are necessary.

WARNING

1.4.1 Do not attempt to clean or service the machine while it is running.

Rotating parts can cause severe injury.

1.4.2 Do not crank a flooded engine with the spark plug removed on

gasoline-powered engines. Fuel trapped in the cylinder will squirt out

the spark plug opening.

1.4.3 Do not test for spark on gasoline-powered engines if the engine is

flooded or the smell of gasoline is present. A stray spark could ignite

the fumes.

1.4.4 Do not use gasoline or other types of fuels or flammable solvents to

clean parts, especially in enclosed areas. Fumes from fuels and

solvents can become explosive.

1.4.5 Keep the area around the muffler free of debris such as leaves, paper,

cartons, etc. A hot muffler could ignite the debris and start a fire.

1.4.6 Replace worn or damaged components with spare parts designed and

recommended by Wacker Neuson Corporation.

1.4.7 Disconnect the spark plug on machines equipped with gasoline

engines, before servicing, to avoid accidental start-up.

1.4.8 Keep the machine clean and labels legible. Replace all missing and

hard-to-read labels. Labels provide important operating instructions

and warn of dangers and hazards.

wpm_si000310gb.fm 8

Page 11

VP 2050A/AW Safety Information

1.5 Label Locations

wpm_si000310gb.fm 9

wpmgr005944

Page 12

Safety Information VP 2050A/AW

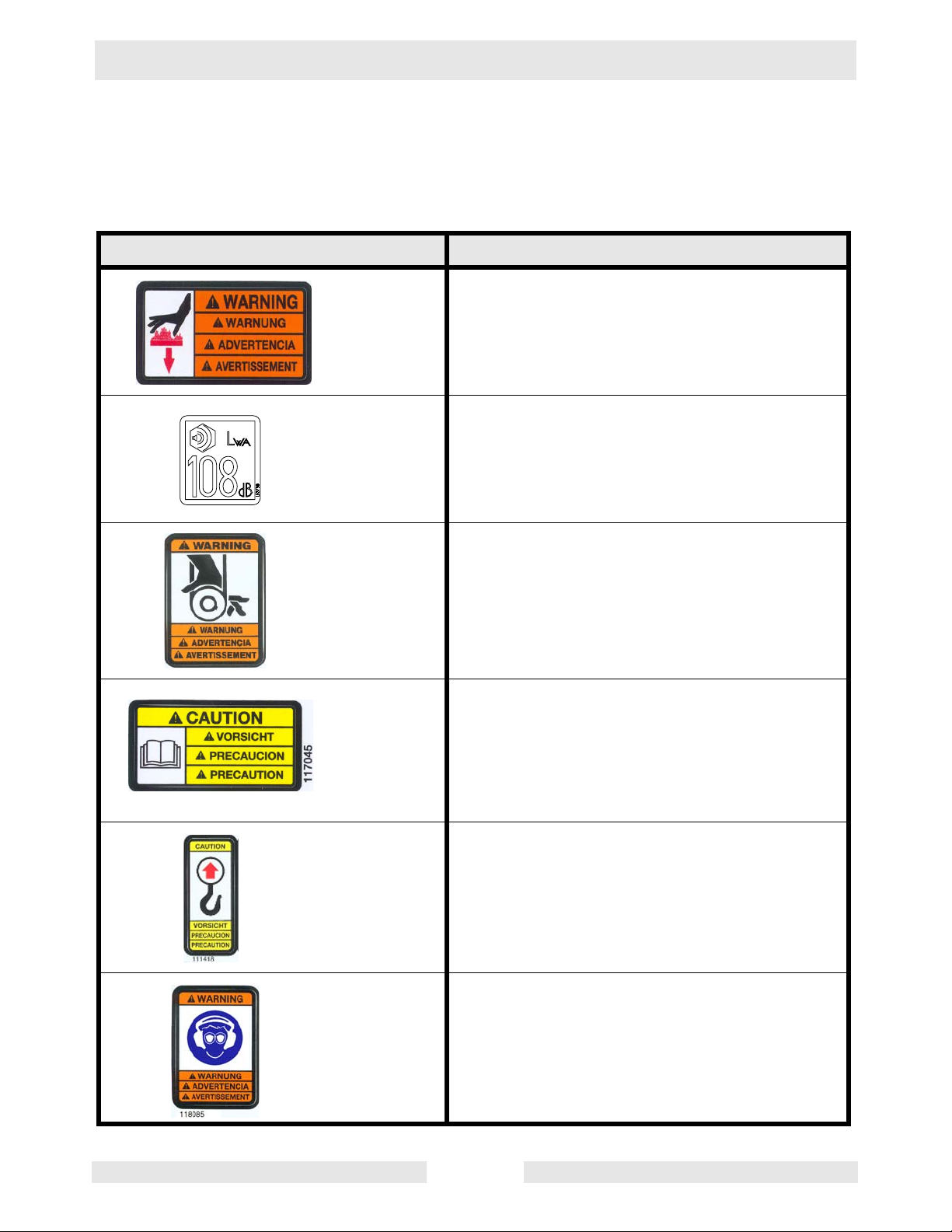

1.6 Warning and Informational Labels

Wacker Neuson machines use international pictorial labels where

needed. These labels are described below:

Label Meaning

WARNING!

Hot surface!

Guaranteed sound power level in dB(A).

WARNING!

Hand injury if caught in moving belt.

Always replace beltguard.

CAUTION!

Read and understand the supplied Operator’s

Manual before operating this machine. Failure

to do so increases the risk of injury to yourself

or others.

CAUTION

Lifting point.

WARNING!

Always wear hearing and eye protection when

operating this machine.

wpm_si000310gb.fm 10

Page 13

VP 2050A/AW Safety Information

Label Meaning

Throttle control lever:

Rabbit = Full or Fast

Turtle = Idle or Slow

DANGER!

Engines emit carbon monoxide; operate only

in well-ventilated area. Read the Operator’s

Manual.

No sparks, flames, or burning objects near the

machine. Shut off the engine before refueling.

Label-machine model

Company logo

Company label

A nameplate listing the model number, item

number, revision number, and serial number is

attached to each unit. Please record the information found on this plate so it will be available should the nameplate become lost or

damaged. When ordering parts or requesting

service information, you will always be asked

to specify the model number, item number,

revision number , and serial number of the unit.

wpm_si000310gb.fm 11

Page 14

Safety Information VP 2050A/AW

Label Meaning

This machine may be covered by one or more

patents.

wpm_si000310gb.fm 12

Page 15

VP 2050A/AW Technical Data

2. Technical Data

2.1 Engine Data

Engine Power Rating

Net power rating per SAE J1349. Actual power output may vary due to

conditions of specific use.

VP 2050A

0009087

VP 2050AW

0009510

Engine

Engine Make Honda

Engine Model GX 160 UT1 SWX2

Max. rated power @ rated

kW (Hp)

3.6 (4.8) @ 3600 rpm

speed

Spark Plug NGK BPR 6ES

Electrode Gap

Operating speed

Air Cleaner

Engine Lubrication

mm (in.)

rpm

type

oil grade

0.7-0.8 (0.028–0.031)

3600

Dual element

SAE 10W30

SG or SF

Engine Oil Capacity

Fuel

ml (oz.)

type

600 (20)

Regular unleaded gasoline

Fuel Tank Capacity

l (qts.)

Valve Clearance (cold)

Inlet:

mm (in.)

Outlet:

wpm_td000319gb.fm 13

3.6 (3.7)

0.15 (0.006)

0.20 (0.008)

Page 16

Technical Data VP 2050A/AW

2.2 Machine Data

VP 2050A

0009087

Plate

Weight

Water Tank Capacity

Exciter Speed

Exciter Lubrication

kg (lbs.)

l (qts.)

rpm

ml (oz.)

Dextron III/Mercon or equivalent

Dimensions

mm (in.)

2.3 Sound and Vibration Measurements

The required sound specification, Paragraph 1.7.4.f of 89/392/EEC

Machinery Directive, is:

• The guaranteed sound power level (LWA) = 108 dB(A).

VP 2050AW

0009510

103 (230)

7.6 (8)

5800 ± 100

296 (10)

Automatic transmission fluid

588 (23) x 500 (20) x 919 (36)

• The sound pressure level at operator’s location (LpA) = 97 dB(A).

These sound values were determined according to ISO 3744 for the

sound power level (LWA) and ISO 6081 for the sound pressure level

(LpA) at the operator’s location.

The weighted effective acceleration value, determined according to

EN ISO 5349, is approximately 4.5 m/s2.

The sound and vibration measurements were obtained with the

machine operating on crushed gravel at nominal engine speed.

wpm_td000319gb.fm 14

Page 17

VP 2050A/AW Technical Data

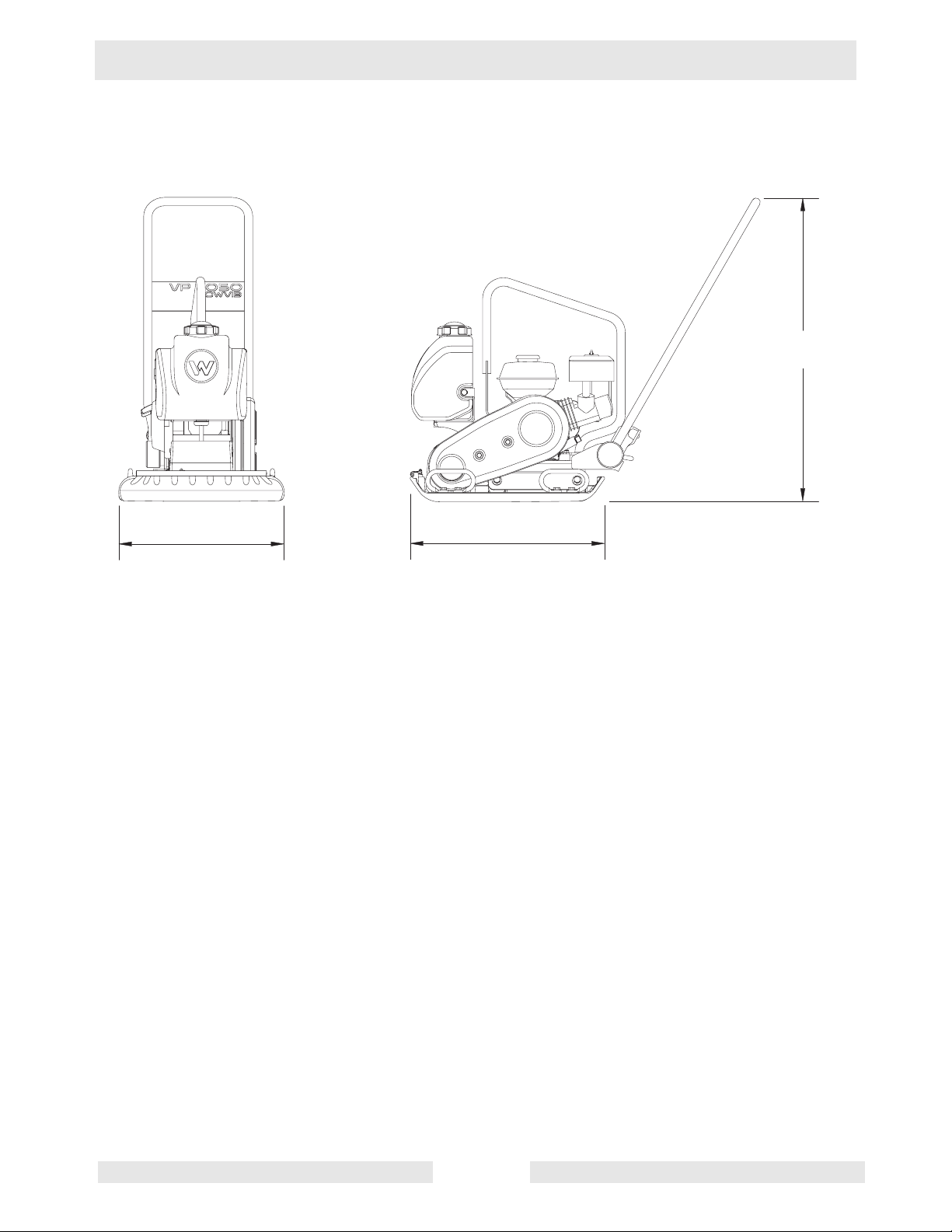

2.4 Dimensions

mm (in.)

919 (36)

500 (20)

588 (23)

wpmgr005971

wpm_td000319gb.fm 15

Page 18

Operation VP 2050A/AW

3. Operation

3.1 Recommended Fuel

The engine requires regular grade unleaded gasoline. Use only fresh,

clean gasoline. Gasoline containing water or dirt will damage fuel

system. Consult engine owner’s manual for complete fuel

specifications.

3.2 Application

This plate is designed for compacting loose granular soils, gravel, and

paving stones. It is intended to be used in confined areas and areas

next to structures such as walls, curbs, and foundations.

This plate is not recommended for compacting cohesive soils with a

heavy clay content.

3.3 Before Starting

3.3.1 Read and understand the safety and operating instructions at the

beginning of this manual.

3.3.2 Check:

• Oil level in the engine

• Fuel level

• Condition of the air cleaner

• Tightness of the external fasteners

• Condition of the fuel lines

wpm_tx001097gb.fm 16

Page 19

VP 2050A/AW Operation

3.4 To Start

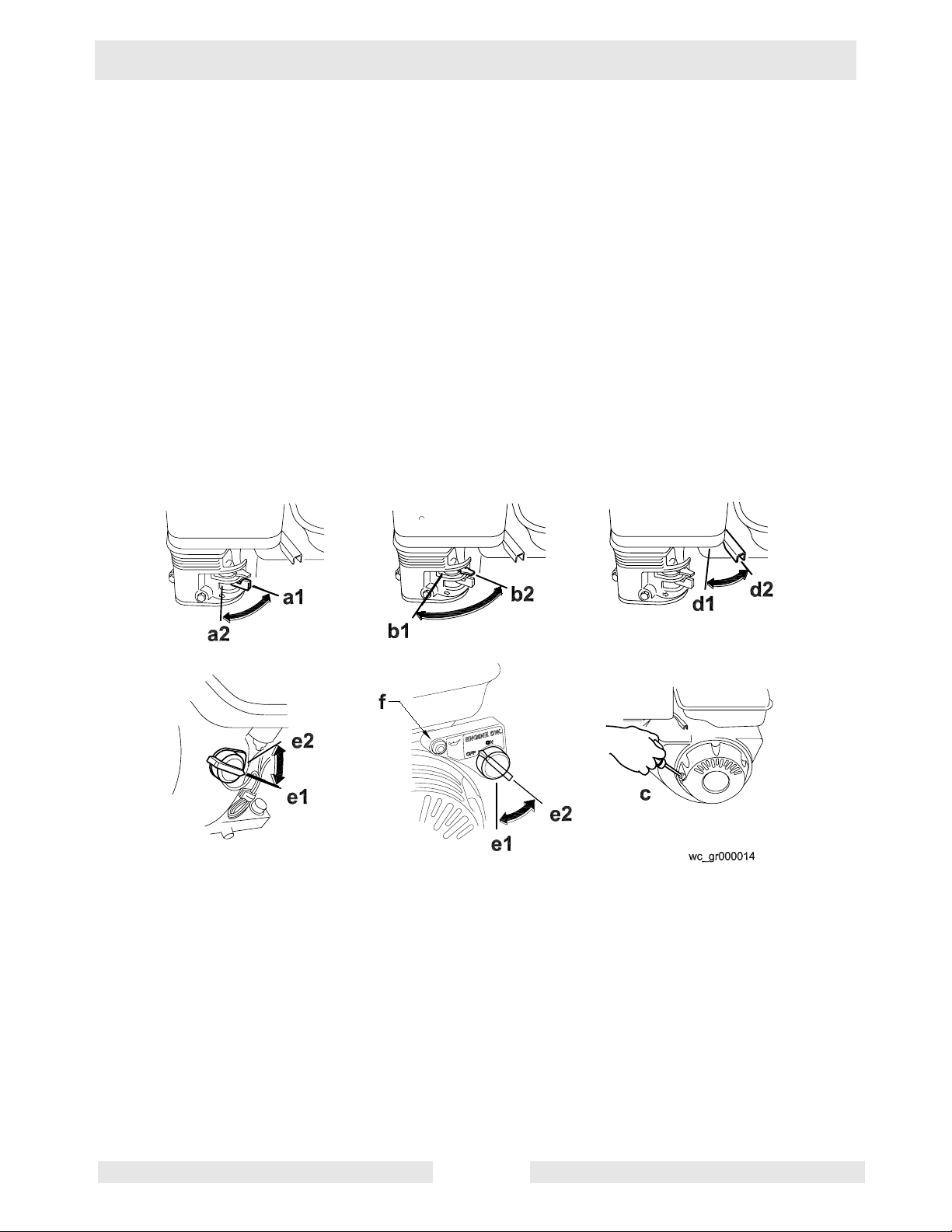

See Graphic: wc_gr000014

3.4.1 Open fuel valve by moving lever to the right (a1).

Note: If engine is cold, move choke lever to close position (b1). If

engine is hot, set choke to open position (b2).

3.4.2 Turn engine switch to “ON” (e1).

3.4.3 Open throttle by moving it slightly to left (d1).

3.4.4 Pull starter rope (c).

Note: If the oil level in the engine is low, the engine will not start. If this

happens, add oil to engine. Some engines are equipped with an oil

alert light (f) that will come on while pulling the starter rope.

3.4.5 Open choke as engine warms (b2).

3.4.6 Open throttle fully to operate.

3.5 To Stop

See Graphic: wc_gr000014

3.5.1 Reduce engine RPM to idle by moving throttle completely to right (d2).

3.5.2 Turn engine switch to “OFF” (e2).

3.5.3 Close fuel valve by moving lever to the left (a2).

wpm_tx001097gb.fm 17

Page 20

Operation VP 2050A/AW

3.6 Operation

Run the engine at full throttle and allow the plate to pull itself along at

its normal speed. When operating on an incline it may be necessary to

assist the plate by pushing it forward slightly. When operating downhill

hold the plate back slightly, if it begins to pick up speed. Depending on

the material being compacted, three or four passes are recommended

to achieve the best compaction.

While a certain amount of moisture in the soil is necessary, excessive

moisture may cause soil particles to stick together and prevent good

compaction. If soil is extremely wet, allow it to dry somewhat before

compacting.

If soil is so dry as to create dust clouds while operating plate, some

moisture should be added to the ground material to improve

compaction. This will also reduce service to the air filter.

For compacting asphalt, use a water tank to wet the asphalt and the

underside of plate. This will prevent asphalt material from sticking.

Two passes are usually sufficent to ensure good compaction.

When using the plate on paving stones, attach a pad to the bottom of

the plate to prevent chipping or grinding surface of stones. A special

polyurethane pad designed for this purpose is available as an optional

accessory.

NOTICE: DO NOT operate the plate on concrete or on extremely hard,

dry, compacted surfaces. The plate will jump rather than vibrate and

could damage both the plate and the engine.

wpm_tx001097gb.fm 18

Page 21

VP 2050A/AW Maintenance

4. Maintenance

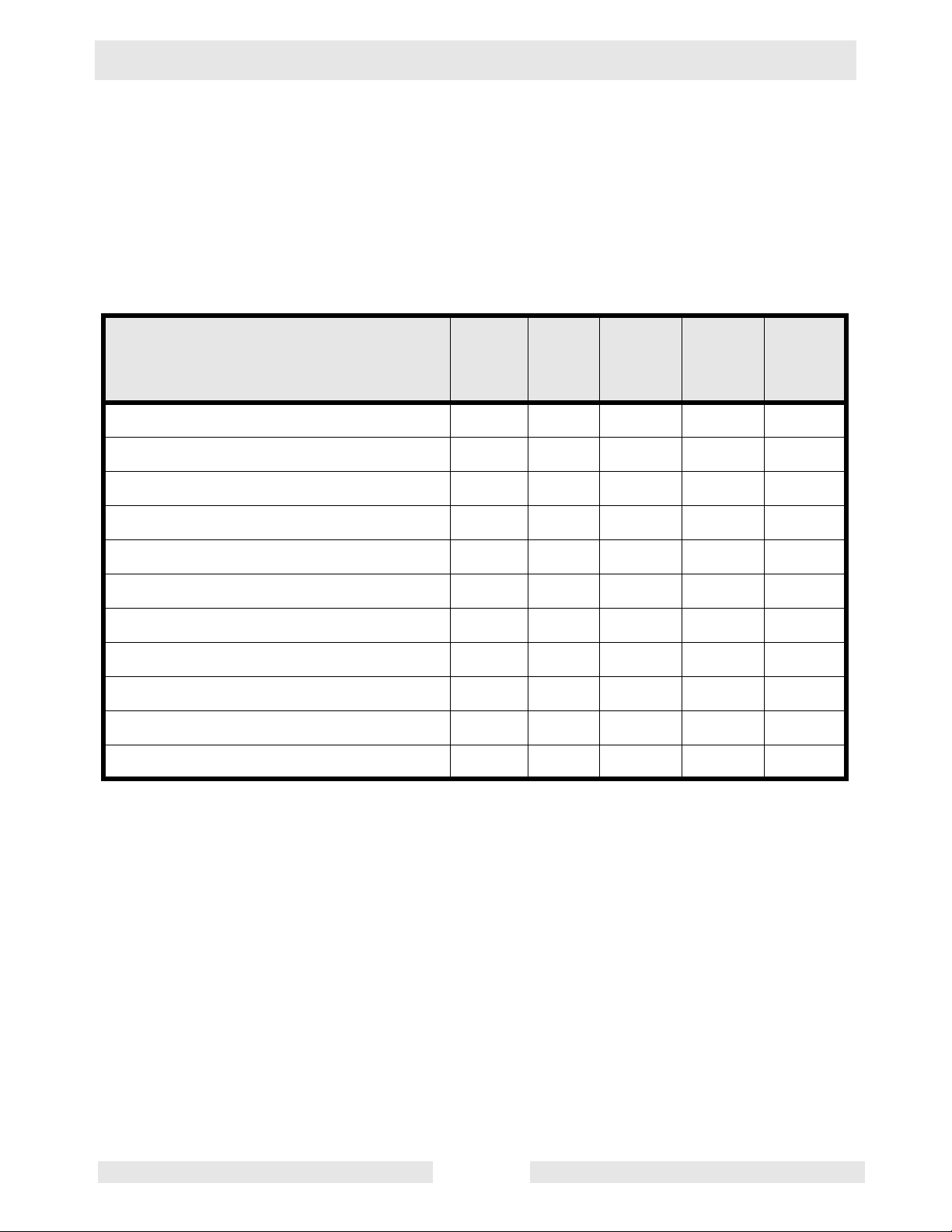

4.1 Periodic Maintenance Schedule

4.1.1 Engine Maintenance

The chart below lists basic engine maintenance. Refer to the engine

manufacturer’s Operation Manual for additional information.

Check fuel level.

Check engine oil level.

Inspect fuel lines.

Inspect air filter. Replace as needed.

Clean air cleaner elements.

Change engine oil.

Clean engine cooling fins.

Clean sediment cup / fuel filter.

Check and clean spark plug.

Check and adjust valve clearance.

Change exciter oil.

Daily

before

starting

After

first

20 hrs.

Every

2 weeks

or

50 hrs.

Every

month

or

100 hrs.

Every

year

or

300 hrs.

wpm_tx001098gb.fm 19

Page 22

Maintenance VP 2050A/AW

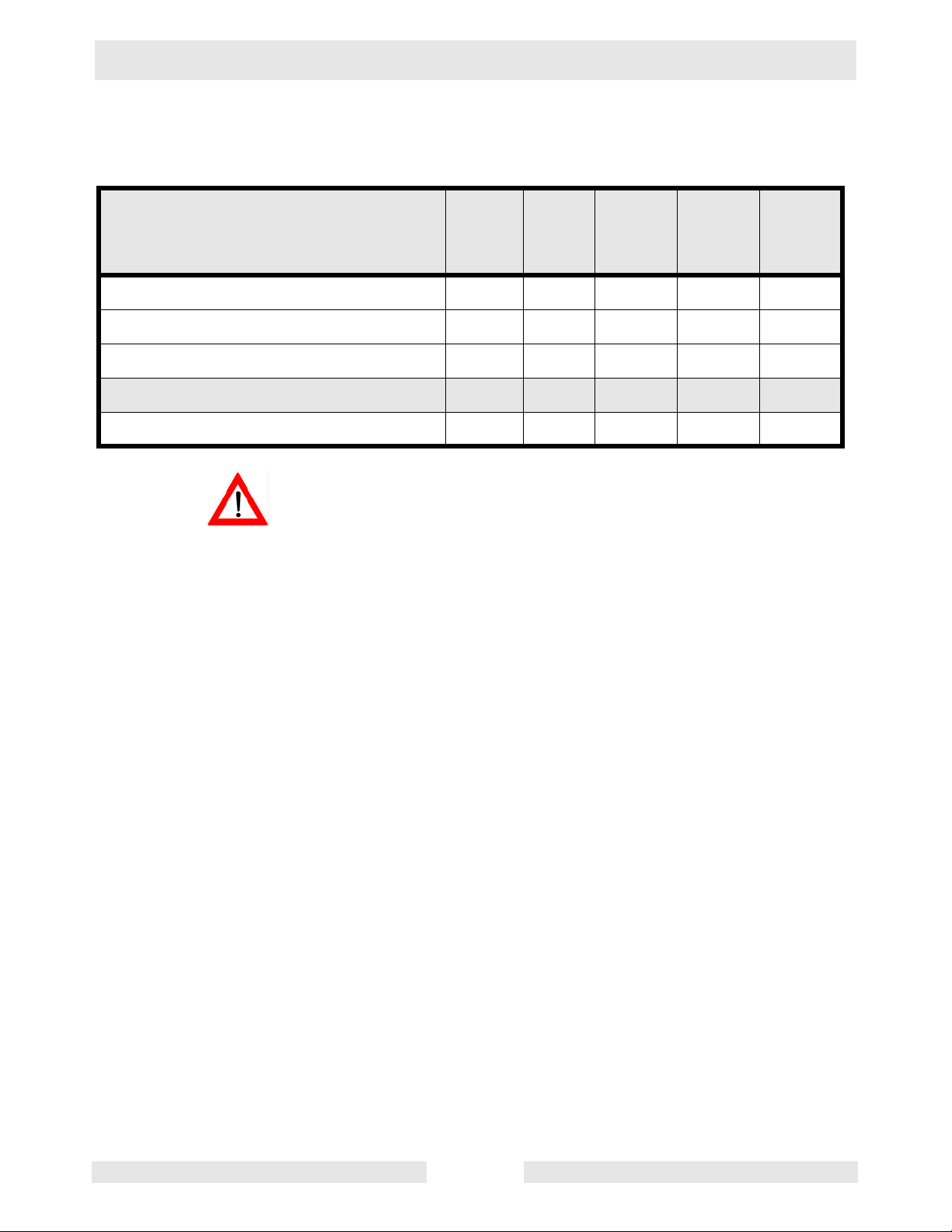

4.1.2 Machine Maintenance

The chart below lists basic machine maintenance.

Check external hardware.

Check and adjust drive belt.

Inspect shockmounts for damage.

Replace shockmounts as needed.

Change exciter oil.

Note: When machine is being used in asphalt, it is highly

recommended that shockmounts are replaced every year or

after 300 hours of usage.

Daily

before

starting

After

first

20 hrs.

Every

2 weeks

or

50 hrs.

Every

month

or

100 hrs.

Every

year

or

300 hrs.

wpm_tx001098gb.fm 20

Page 23

VP 2050A/AW Maintenance

4.2 Spark Plug

See Graphic: wc_gr000028

Clean or replace the spark plug as needed to ensure proper operation.

Refer to your engine operator’s manual.

The muffler becomes very hot during operation and remains hot for a

while after stopping the engine. Do not touch the muffler while it is hot.

WARNING

Note: Refer to section “Technical Data” for the recommended spark

plug type and the electrode gap setting.

4.2.1 Remove the spark plug and inspect it.

4.2.2 Replace the spark plug if the insulator is cracked or chipped.

4.2.3 Clean the spark plug electrodes with a wire brush.

4.2.4 Set the electrode gap (a).

4.2.5 Tighten the spark plug securely.

NOTICE: A loose spark plug can become very hot and may cause

engine damage.

wpm_tx001098gb.fm 21

Page 24

Maintenance VP 2050A/AW

4.3 Air Cleaner

See Graphic: wc_gr000025

The engine is equipped with a dual element air cleaner. Service air

cleaner frequently to prevent carburetor malfunction.

NOTICE: NEVER run engine without air cleaner. Severe engine

damage will occur.

NEVER use gasoline or other types of low flash point solvents for

cleaning the air cleaner. A fire or explosion could result.

WARNING

To service:

4.3.1 Remove air cleaner cover (a). Remove both elements and inspect them for holes or tears. Replace damaged elements.

4.3.2 Wash foam element (b) in solution of mild detergent and warm water. Rinse thoroughly in clean water. Allow element to dry thoroughly. Soak element in clean engine oil and squeeze out excess oil.

4.3.3 Tap paper element (c) lightly to remove excess dirt. Replace paper element if it appears heavily soiled.

wpm_tx001098gb.fm 22

Page 25

VP 2050A/AW Maintenance

4.4 Engine Oil

See Graphic: wc_gr000022

4.4.1 Drain the oil while the engine is still warm.

4.4.2 Remove the oil filler plug (a) and the drain plug (b) to drain the oil.

Note: In the interests of environmental protection, place a plastic sheet

and a container under the machine to collect any liquid that drains off.

Dispose of this liquid in accordance with environmental protection

legislation.

4.4.3 Install the drain plug.

4.4.4 Fill the engine crankcase with the recommended oil up to the level of

the plug opening (c). See section Technical Data for oil quantity and

type.

4.4.5 Install the oil filler plug.

wc_gr000022

4.5 Adjusting Engine Speed

See Graphic: wc_gr000280

Adjust engine to the full load speed. See Technical Data.

To adjust idle speed:

4.5.1 Place machine on a rubber test mat to prevent it from moving.

4.5.2 Start the engine and allow it to warm up to normal operating temperature.

4.5.3 Turn the throttle stop screw (a) in to increase speed, out to decrease speed. Make sure the throttle lever is touching the stop screw before measuring rpm.

NOTICE: Running the plate at a speed higher than that listed in

Technical Data can damage both the plate and the engine.

a

wc_gr000280

wpm_tx001098gb.fm 23

Page 26

Maintenance VP 2050A/AW

4.6 Carburetor Adjustment

See Graphic: wc_gr000032

4.6.1 Start the engine and allow it to warm up to operating temperature.

4.6.2 Set the pilot screw (a) two turns out. See Note.

4.6.3 With the engine idling, turn the pilot screw (a) in or out to the setting that produces the highest rpm.

4.6.4 After the pilot screw is adjusted, turn the throttle stop screw (b) to obtain the standard idle speed. See Technical Data.

Note: On some engines the pilot screw is fitted with a limiter cap (c)

to prevent excessive enrichment of the air-fuel mixture in order to

comply with emission regulations. The mixture is set at the factory and

no adjustment should be necessary. Do not attempt to remove the

limiter cap. The limiter cap cannot be removed without breaking the

pilot screw.

wc_gr000032

4.7 Cleaning Sediment Cup

See Graphic: wc_gr000029

4.7.1 Turn the fuel valve off.

4.7.2 Remove the sediment cup (a) and the O-ring (b).

4.7.3 Wash both thoroughly in a nonflammable solvent. Dry and reinstall them.

4.7.4 Turn the fuel valve on and check for leaks.

wpm_tx001098gb.fm 24

Page 27

VP 2050A/AW Maintenance

4.8 Drive Belt

See Graphic: wpmgr005996

On new machines or after installing a new belt, check the belt tension

after first 20 hours of operation. Check and adjust the belt every 50

hours thereafter.

To adjust the belt:

4.8.1 Loosen the two screws (a) on the beltguard, then remove the beltguard, keeping the screw assemblies captured on the beltguard.

4.8.2 Loosen the four nuts (b) which hold the engine to the console, and the screw (c) which holds the beltguard back to the console.

4.8.3 Slide the engine backward (towards the handle) to tighten the belt, forward to loosen the belt.

4.8.4 Adjust the belt so that it deflects 10-13 mm (3/8in–1/2in) (d) when

pressed midway between the belt pulleys.

4.8.5 Make sure that the clutch pulley (f) and the exciter pulley (e) are in alignment. Place a straight edge against the exciter pulley (e) and move the engine so that the two pulleys are parallel.

4.8.6 Torque all nuts and screws to 20.5 Nm (15 ft.lbs.) as you reassemble the machine.

a

b

c

d

wpmgr005996

wpm_tx001098gb.fm 25

Page 28

Maintenance VP 2050A/AW

4.9 Exciter Lubrication

See Graphic: wpmgr006020

The bearings in the exciter assembly are splash lubricated and rotate

at very high speed. It is important to maintain the exciter oil at the

correct level and change it regularly.

Check oil level in exciter every 50 hours of operation.

To check oil level, place plate on a flat, level surface. Remove the drain

plug (a) with seal ring (b). Oil level should be at drain plug threads. Add

oil as required.

Change exciter oil every 300 hours of operation.

To drain oil: Remove plug (a) from end of exciter and tilt plate up.

Note: In the interests of environmental protection, place a plastic sheet

and a container under the machine to collect any liquid which drains

off. Dispose of this liquid in accordance with environmental protection

legislation.

Place plate on a level surface and add approximately 296 ml of oil

through plug opening until oil reaches the drain plug threads.

NOTICE: DO NOT overfill. Too much oil in exciter can reduce

performance and damage drive belt.

4.10 Cleaning the Plate

wpmgr006020

Clean plate after use to remove dirt, stones, and mud caught under the

engine console. If plate is being used in a dusty area, check engine

cylinder cooling fins for heavy dirt accumulation. Keep engine cylinder

fins clean to prevent engine from overheating.

wpm_tx001098gb.fm 26

Page 29

VP 2050A/AW Maintenance

4.11 Lifting Machine

See Graphic: wpmgr006168

See Technical Data for weight of machine.

To lift machine manually:

4.11.1 Stop the engine.

4.11.2 Obtain help from a partner and plan the lift. To avoid burns or fire hazards, let the engine cool before transporting

the machine or storing it indoors. Turn the fuel valve to the off position

and keep the engine level to prevent fuel from spilling.

WARNING

4.11.3 Grasp machine by the lifting handles (a).

4.11.4 Lift machine as shown. To reduce risk of back injury while lifting, keep feet flat on ground and

shoulder width apart. Keep head up and back straight.

WARNING

To lift machine mechanically:

NOTICE: Before attempting to lift, be sure that lifting devices can

safely handle weight of machine. See Technical Data for weight of

machine.

4.11.5 Attach hook, harness, or cable to machine as shown, and lift as desired.

NOTICE: DO NOT lift the vibroplate by its guide handle. The vibroplate

can shift, causing it to fall.

c

CAUTION

VORSICHT

PRECAUTION

PRECAUCION

a

b

wpm_tx001098gb.fm 27

wpmgr006168

Page 30

Maintenance VP 2050A/AW

4.12 Transporting Machine

See Graphic: wpmgr006042

To avoid burns or fire hazards, let engine cool before transporting

machine or storing indoors.

WARNING

4.12.1 Turn fuel valve to the off position and keep the engine level to prevent fuel from spilling.

4.12.2 Tie down machine on vehicle to prevent machine from sliding or tipping over. Tie machine to vehicle at points shown on graphic.

4.13 Storage

If plate is being stored for more than 30 days:

4.13.1 Remove loose stones and dirt from plate.

4.13.2 Clean engine cylinder cooling fins.

4.13.3 Clean or replace air filter.

4.13.4 Change exciter oil.

4.13.5 Change engine oil and follow procedures described in engine manual for engine storage.

4.13.6 Cover plate and engine and store in a clean, dry area.

wpm_tx001098gb.fm 28

wpmgr006042

Page 31

VP 2050A/AW Maintenance

4.14 Troubleshooting

Problem / Symptom Reason / Remedy

Plate does not develop full

speed. Poor compaction.

Engine running, no vibration • Engine throttle not open.

• Engine throttle control not completely open.

• Throttle control not adjusted correctly.

• Ground too wet, plate sticking. Allow soil to dry

before compacting.

• Drive belt loose or worn, slipping on pulleys. Adjust

or replace belt. Check that engine mounting bolts

are tight.

• Exciter bearings binding. Check condition and level

of oil in exciter. Add or change oil.

• Air filter clogged with dust, reducing engine

performance. Clean or replace air filter.

• Engine speed too low. Check engine speed with

tachometer. Adjust or repair engine to run at correct

speed. Refer to engine manual.

• Drive belt loose or broken. Adjust or replace.

• Clutch damaged. Inspect and replace clutch.

Plate jumps or compacts

unevenly.

• Engine speed too low. Check engine speed.

• Too much oil in exciter. Adjust oil to correct level.

• Ground surface too hard.

• Shockmounts loose or damaged.

wpm_tx001098gb.fm 29

Page 32

Page 33

EC DECLARATION OF CONFORMITY

WACKER NEUSON MANILA, INC., DASMARIÑAS, CAVITE, PHILIPPINES

AUTHORIZED REPRESENTATIVE IN THE EUROPEAN UNION Axel Häret

WACKER NEUSON SE

Preußenstraße 41

80809 München

hereby certifies that the construction equipment specified hereunder:

1. Category

Vibratory Plates

2. Machine function:

This plate is designed for compacting loose granular soils, gravel, and paving stones. It is intended to be

used in confined areas and areas next to structures such as walls, curbs, and foundations.

3. Type / Model

VP 2050A, VP 2050AW

4. Item number of equipment:

0009087, 0009510

5. Net installed power:

VP 2050A, VP 2050AW 3,6kW

Has been sound tested per Directive 2000/14/EC:

Conformity Assessment

Procedure

Annex VI VDE-Prüf- und

6. This machinery fulfills the relevant provisions of Machinery Directive 2006/42/EC and is also produced in accordance with these

standards:

Name and address of notified body Measured sound power level Guaranteed sound power level

Zertifizierungsinstitut

Zertifizierungsstelle

Merianstraße 28

63069 Offenbach/Main

VP 2050A 101 dB(A)

VP 2050AW 101 dB(A)

VP 2050A 108 dB(A)

VP2050AW 108 dB(A)

2000/14/EC

2004/108/EC

EN 500-1

EN 500-4

He inz Gengnagel

President & CEO

23.12.09

Date

The original language of this EC Declaration of Conformity is American English.

VP 2050A-en_2010_WN.fm

WACKER NEUSON CORPORATION

Page 34

Page 35

CE-KONFORMITÄTSERKLÄRUNG

WACKER NEUSON MANILA, INC., DASMARIÑAS, CAVITE, PHILIPPINES

BEVOLLMÄCHTIGTER VER TRETER FÜR DIE EUROPÄISCHE

GEMEINSCHAFT

bescheinigt, daß das Baugerät:

1. Art:

Axel Häret

WACKER NEUSON SE

Preußenstraße 41

80809 München

Rüttelplatten

2. Maschinenfunktion:

Diese Platte eignet sich zum Verdichten von losen und körnigen Böden, Kies und Verbundsteinen, ebenso in

engen Bereichen an Gebäuden, Randsteinen und Fundamenten.

3. Typ / Modell:

VP 2050A, VP 2050AW

4. Artikelnummer:

0009087, 0009510

5. Absolute installierte Leistung:

VP 2050A, VP 2050AW 3,6kW

In Übereinstimmung mit Richtlinie 2000/14/EG bewertet worden ist:

Konformitätsbewertungsverfahren

ANHANG VI VDE-Prüf- und

6. Diese Maschine erfüllt die relevanten Bestimmungen der Richtlinie für Maschinen 2006/42/EG und wurde auch gemäß deren Normen hergestellt:

Bei folgender einbezogener

Prüfstelle

Zertifizierungsinstitut

Zertifizierungsstelle

Merianstraße 28

63069 Offenbach/Main

Gemessener Schallleistungspegel Garantierter Schallleistungspegel

VP 2050A 101 dB(A)

VP 2050AW 101 dB(A)

VP 2050A 108 dB(A)

VP2050AW 108 dB(A)

2000/14/EC

2004/108/EC

EN 500-1

EN 500-4

He inz Gengnagel

President & CEO

23.12.09

Datum

WACKER NEUSON CORPORATION

Diese EG-Konformitätserklärung ist eine Übersetzung des Originalzertifikats.

VP 2050A-de_2010_WN.fm

Page 36

Page 37

DECLARACIÓN DE CONFORMIDAD DE LA CE

WACKER NEUSON MANILA, INC., DASMARIÑAS, CAVITE, PHILIPPINES

REPRESENTANTE AUTORIZADO EN LA UNIÓN EUROPEA Axel Häret

WACKER NEUSON SE

Preußenstraße 41

80809 München

certifica que la máquina de construcción:

1. Categoría:

Planchas Vibratorias

2. Función de la máquina:

Esta placa está diseñada para compactar suelos granulares sueltos, grava y adoquines de hormigón. Se

entiende que será usada en areas confinadas y areas cercanas a estructuras tales como muros, curvas y

fundaciones.

3. Tipo / Modelo:

VP 2050A, VP 2050AW

4. Número de referencia de la máquina:

0009087, 0009510

5. Potencia instalada neta:

VP 2050A, VP 2050AW 3,6kW

Ha sido ensayado en conformidad con la norma 2000/14/CE:

Procedimiento para ensayar

conformidad

ANEXO VI VDE-Prüf- und

6. Esta maquinaria cumple con las cláusulas pertinentes de la Directiva 2006/42/CE sobre maquina ria y también se fabrica en conformidad con estas pautas:

Oficina matriculadora Nivel de potencia acústica

determinado

VP 2050A 101 dB(A)

Zertifizierungsinstitut

Zertifizierungsstelle

Merianstraße 28

63069 Offenbach/Main

VP 2050AW 101 dB(A)

Nivel de potencia acústica

garantizado

VP 2050A 108 dB(A)

VP2050AW 108 dB(A)

2000/14/EC

2004/108/EC

EN 500-1

EN 500-4

VP 2050A-es_2010_WN.fm

23.12.09

Fecha

Esta Declaración de conformidad CE presenta una traducción del certificado original.

He inz Gengnagel

President & CEO

WACKER NEUSON CORPORATION

Page 38

Page 39

DÉCLARATION DE CONFORMITÉ C.E.

WACKER NEUSON MANILA, INC., DASMARIÑAS, CAVITE, PHILIPPINES

REPRÉSENTANT AGRÉÉ AUPRÈS DE L’UNION

EUROPÉENNE

atteste que le matériel:

1. Catégorie:

Plaques Vibrantes

2. Fonction de la machine :

Axel Häret

WACKER NEUSON SE

Preußenstraße 41

80809 München

Cette plaque est conçue pour le compactage de la terre lâche et granuleuse, du gravier et des pavés. Elle est

destinée à être utilisée dans les endroits fermés et à côté de structures telles que murs, bordures et

fondations.

3. Tipo / Modelo:

VP 2050A, VP 2050AW

4. Numéro de référence du matériel:

0009087, 0009510

5. Puissance installée nette :

VP 2050A, VP 2050AW 3,6kW

A été mis à l’épreuve conforme aux dispositions de la directive 2000/14/CEE:

Procédé pour l’épreuve de

conformité

ANNEXE VI VDE-Prüf- und

6. Cette machine est conforme aux dispositions pertinentes de la Directive sur les machines 2006/42/CE et également produite conformément à ces normes :

Organisme agrée Niveau de puissance

acoustique fixé

VP 2050A 101 dB(A)

Zertifizierungsinstitut

Zertifizierungsstelle

Merianstraße 28

63069 Offenbach/Main

VP 2050AW 101 dB(A)

Niveau de puissance acoustique

garanti

VP 2050A 108 dB(A)

VP2050AW 108 dB(A)

2000/14/EC

2004/108/EC

EN 500-1

EN 500-4

He inz Gengnagel

President & CEO

23.12.09

Date

WACKER NEUSON CORPORATION

Cette déclaration de conformité CE est une traduction du certificat d’origine.

VP 2050A-fr_2010_WN.fm

Page 40

Wacker Construction Equipment AG · Preußenstraße 41 · D-80809 München · Tel.: +49-(0)89-3 54 02 - 0 · Fax: +49 - (0)89-3 54 02-3 90

Neuson Corporation · P.O. Box 9007 · Menomonee Falls, WI 53052-9007 · Tel. : (262) 255-0500 · Fax: (262) 255-0550 · Tel. : (800) 770-0957

Wacker

Wacker Asia Pacific Operations · Skyline Tower, Suite 2303, 23/F · 39 Wang Kwong Road, Kowloon Bay, Hong Kong · Tel. +852 2406 60 32 · Fax: +852 2406 60 21

Page 41

Notice d’emploi

Patin Vibrant

VP 2050A

VP 2050AW

0154570fr 010 0110

0154570FR

Page 42

Copyright

© Copyright 2010 – Wacker Neuson Corporation.

Tous les droits, y compris les droits de copie et de distribution, sont réservés.

Cette publication pourra être photocopiée par l’acheteur initial de la machine.

Tout autre type de reproduction est interdit sans l’autorisation écrite expresse de

Wacker Neuson Corporation.

Tout type de reproduction ou de distribution non autorisé par Wacker Neuson

Corporation représente une violation des copyrights en vigueur. Les contrevenants

feront l’objet de poursuites.

Marques

commerciales

Fabricant

Version

traduite des

instructions

Toutes les marques commerciales qui apparaissent dans ce manuel sont la propriété

de leur détenteur respectif.

Wacker Neuson Manila Incorporated

Lot 2,Blk 1 Phase , PEZA Drive, First Cavite Industrial Estate, Brgy. Langkaan

Dasmariñas, Cavite, Philippines

Tйl. :

+63-(0)2-580-7136

www.wackerneuson.com

Cette notice d’emploi est une version traduite des instructions originales. La version

originale est en anglais américain.

Tйlйcopieur :

+63-(0)2-580-7122

Page 43

VP 2050A/AW Table des matières

Avant-Propos 3

1. Informations sur la sécurité 4

1.1 Lois relatives aux étouffeurs d’étincelles .............................................. 4

1.2 Sécurité de fonctionnement .................................................................. 5

1.3 Sécurité lors de l’entretien .................................................................... 7

1.4 Situation des Etiquettes ........................................................................ 8

1.5 Étiquettes de sécurité et d’information ................................................. 9

2. Specifications techniques 13

2.1 Données de la Moteur ........................................................................ 13

2.2 Données de la Machine ...................................................................... 14

2.3 Mesures du Bruit et de la Vibration .................................................... 14

2.4 Dimensions ......................................................................................... 15

3. Fonctionnement 16

3.1 Carburant recommandé ..................................................................... 16

3.2 Application .......................................................................................... 16

3.3 Avant la mise en service .................................................................... 16

3.4 Démarrage ......................................................................................... 17

3.5 Arrêt .................................................................................................... 17

3.6 Fonctionnement .................................................................................. 18

wpm_bo0154570010frTOC.fm 1

Page 44

Table des matières VP 2050A/AW

4. Entretien 19

4.1 Calendrier d’entretien périodique ........................................................19

4.2 Épurateur d’air .....................................................................................21

4.3 Changer l’huile ....................................................................................22

4.4 Réglage de la vitesse du moteur .........................................................22

4.5 Réglage du carburateur .......................................................................23

4.6 Nettoyage du séparateur .....................................................................23

4.7 Courroie d’entraînement ......................................................................24

4.8 Graissage de l’allumeur .......................................................................25

4.9 Nettoyage de la plaque .......................................................................25

4.10 Levage de la machine .........................................................................26

4.11 Transport .............................................................................................27

4.12 Entreposage ........................................................................................27

4.13 Guide de dépannage ...........................................................................28

wpm_bo0154570010frTOC.fm 2

Page 45

Avant-Propos

Ce manuel fournit des informations et renseigne sur les procédures

d’utilisation et de maintenance sans risque de ce modèle Wacker

Neuson. En gage de sécurité et de protection contre les risques de

blessure, lire attentivement, bien assimiler et observer les consignes

de sécurité fournies dans ce manuel.

Conserver le manuel ou une copie avec la machine. En cas de perte

du manuel ou pour se procurer un exemplaire supplémentaire, prière

de contacter Wacker Neuson Corporation. Cette machine a été

conçue avec comme objectif primordial la sécurité de l’utilisateur ;

toutefois, elle peut présenter des dangers si elle n’est pas utilisée ou

entretenue conformément aux indications. Suivre attentivement les

instructions d’utilisation ! Pour toute question sur l’utilisation ou la

maintenance de ce matériel, prière de contacter Wacker Neuson

Corporation.

Les informations contenues dans ce manuel portent sur des machines

en production au moment de la mise sous presse. Wacker Neuson

Corporation se réserve le droit de modifier toute information sans

préavis.

Tous les droits, en particulier les droits de copie et de distribution, sont

réservés.

Copyright 2010 - Wacker Neuson Corporation.

Il est interdit de reproduire tout ou partie de cette publication, sous

quelque forme ou par quelque moyen que ce soit, électronique ou

mécanique, y compris par photocopie, sans l’autorisation écrite

préalable expresse de Wacker Neuson Corporation.

Tout type de reproduction ou de distribution non autorisé par Wacker

Neuson Corporation représente une violation des copyrights en

vigueur et fera l’objet de poursuites. Wacker Neuson Corporation se

réserve expressément le droit d’apporter des modifications

techniques, même sans préavis, visant à améliorer ses machines ou

leurs normes de sécurité.

wc_tx000001fr.fm 3

Page 46

Informations sur la sécurité VP 2050A/AW

1. Informations sur la sécurité

Ce manuel contient des instructions identifiées par DANGER,

AVERTISSEMENT, PRÉCAUTION, ATTENTION et REMARQUE qui

doivent être respectées pour réduire toute possibilité de lésion

corporelle, de dommage à l’équipement ou d’utilisation non conforme.

Ce symbole signale un point de sécurité. Il est utilisé pour vous avertir

qu’il existe un risque potentiel de lésion corporelle. Respecter toutes

les consignes de sécurité qui suivent ce symbole pour éviter une

éventuelle lésion corporelle.

DANGER indique une situation dangereuse qui, si elle n’est pas

évitée, risque d’entraîner des lésions corporelles graves voire la mort.

DANGER

AVERTISSEMENT indique une situation dangereuse qui, si elle n’est

pas évitée, risque d’entraîner des lésions corporelles graves voire la

AVERTISSEMENT

mort.

PRÉCAUTION indique une situation dangereuse qui, si elle n’est pas

évitée, risque d’entraîner des lésions corporelles mineures ou

PRECAUTION

modérées.

ATTENTION : utilisé sans le symbole d’alerte de sécurité,

ATTENTION indique une situation qui, si elle n’est pas évitée, risque

d’entraîner des dommages matériels.

Remarque : contient des informations complémentaires importantes

pour une procédure.

1.1 Lois relatives aux étouffeurs d’étincelles

Attention : Les codes de l’inspection du travail et les codes des

ressources publiques stipulent que dans certaines localités, les pareétincelles doivent être utilisés sur des moteurs à combustion interne

qui utilisent des hydrocarbures. Un pare-étincelles est un appareil mis

au point pour éviter une émission inopinée d’étincelles ou de flammes

émanant de l’échappement du moteur. A cet égard, les pare-étincelles

sont définis et évalués par le Service Forestier des Etats-Unis.

Afin d’être conforme aux lois locales en matière de pare-étincelles,

consulter le distributeur du moteur ou l’inspecteur du travail de votre

localité.

wpm_si000310fr.fm 4

Page 47

VP 2050A/AW Informations sur la sécurité

1.2 Sécurité de fonctionnement

Pour une utilisation sécurisée du matériel, il faut en avoir une

connaissance solide et avoir reçu une formation appropriée. Une

utilisation du matériel non conforme aux indications ou une utilisation

AVERTISSEMENT

1.2.1 Ne JAMAIS autoriser quelqu’un qui n’a pas reçu de formation

1.2.2 Ne JAMAIS toucher le moteur ou le pot d’échappement lorsque le

1.2.3 Ne JAMAIS utiliser d’accessoires ou de raccords qui ne sont pas

par un personnel non formé peut être dangereuse. Lire les instructions

d’utilisation fournies à la fois dans ce manuel et dans le manuel du

moteur et prendre connaissance de l’emplacement et de l’utilisation

appropriée des commandes. Les opérateurs inéxpérimentés devraient

recevoir des instructions de la part d’une personne ayant l’habitude

d’utiliser le matériel avant d’être autorisés à utiliser la machine.

appropriée à utiliser le matériel. Les personnes utilisant ce matériel

doivent connaître les risques et les dangers qui y sont rattachés.

moteur est en marche ou immédiatement aprés son arrêt. Ces zones

deviennent chaudes et peuvent provoquer des brûlures.

recommandés par Wacker Neuson. L’équipement peut être

endommagé et l’utilisateur peut se blesser.

1.2.4 Ne JAMAIS utiliser la machine sans la protection de courroie.

L’exposition de la courroie d’entraînement et des poulies entraîne des

dangers potentiels qui peuvent causer des blessures graves.

1.2.5 Ne JAMAIS laisser la machine en marche sans surveillance.

1.2.6 SIEMPRE asegúrese de que el operario esté familiarizado con las

precauciones de seguridad y las técnicas de operación adecuadas,

antes de utilizar la máquina.

1.2.7 TOUJOURS porter des vêtements de protection adaptés au lieu de

travail lors de l'utilisation du matériel.

1.2.8 Porter un dispositif de protection des oreilles en utilisant la machine.

1.2.9 TOUJOURS fermer le robinet de carburant sur les moteurs qui en sont

équipés lorsque la machine n'est pas utilisée.

1.2.10 TOUJOURS ranger convenablement le matériel lorsqu’il n’est pas

utilisé. Le matériel doit être rangé dans un endroit propre, sec et hors

de portée des enfants.

1.2.11 TOUJOURS utiliser la machine lorsque les appareils et les protections

de sécurité sont en place et en bon état de marche. NE PAS modifier

ou bloquer les appareils de sécurité. NE PAS utiliser la machine si les

appareils et les protections de sécurité sont manquants ou non

opérationnels.

1.2.12 TOUJOURS lire, assimiler et suivre les procédures indiquées dans le

Manuel de l’utilisateur avant d’essayer d’utiliser le matériel.

1.2.13 Sécurité pour l’opérateur en utilisant le moteur

wpm_si000310fr.fm 5

Page 48

Informations sur la sécurité VP 2050A/AW

LLes moteurs à combustion interne présentent des dangers

spécifiques pendant l’utilisation et l’alimentation. Lire et suivre les

mises en garde exposées dans le manuel du propriétaire du moteur

DANGER

1.2.14 NE PAS utiliser la machine à l’intérieur ou dans un endroit clos tel

1.2.15 Ne pas fumer en utilisant la machine.

1.2.16 Ne pas fumer en réalimentant le moteur.

1.2.17 NE PAS réalimenter un moteur chaud ou en marche.

1.2.18 NE PAS réalimenter le moteur près d’un feu.

1.2.19 NE PAS renverser de carburant lors de la réalimentation du moteur.

ainsi que les consignes de sécurités énumérées au-dessous. Le non

respect des mises en garde et des consignes de sécurité peut

entraîner des blessures graves ou mortelles.

qu’une fosse profonde, à moins qu’une ventilation appropriée ne soit

garantie par le biais de ventilateurs ou de tuyaux d’échappement. Les

gaz d’échappement émanant du moteur contiennent du monoxyde de

carbone toxique et l’exposition au monoxyde de carbone peut

provoquer une perte de connaîssance et peut entraîner la mort.

1.2.20 NE PAS faire fonctionner le moteur près de feux.

1.2.21 TOUJOURS remplir le réservoir de carburant dans un endroit bien

ventilé.

1.2.22 TOUJOURS remettre le chapeau de réservoir après réalimentation.

1.2.23 TOUJOURS contrôler les tuyaux d’essence et le réservoir, et les

remplacer si elles présentent des fissures ou des fuites. Ne pas mettre

en route la machine si de l’essence a été repandue.

wpm_si000310fr.fm 6

Page 49

VP 2050A/AW Informations sur la sécurité

1.3 Sécurité lors de l’entretien

Un matériel mal entretenu peut devenir un danger pour la sécurité !

Pour que le matériel fonctionne en toute sécurité et de façon

AVERTISSEMENT

1.3.1 NE PAS tenter de nettoyer ou d’entretenir la machine pendant qu’elle

1.3.2 NE PAS essayer de nettoyer ou d’entretenir la machine lorsqu'elle est

1.3.3 NE PAS chercher l’origine des étincelles sur les moteurs à essence si

1.3.4 NE PAS utiliser d’essence, d’autres types de carburant ou des

convenable sur une longue période, il est nécessaire de procéder à un

entretien périodique et à des réparations occasionnelles.

tourne. Les parties rotatives pourraient occasionner des blessures

graves.

en marche. Les pièces pivotantes peuvent entraîner des blessures

graves.

le moteur est submergé ou si il y a une odeur d’essence. Une étincelle

isolée peut causer l’inflammation des gaz d’échappement.

solvants inflammables pour nettoyer des pièces détachées,

particulièrement dans des endroits clos. Les gaz d’échappement

émanant des carburants et des solvants peuvent devenir explosifs.

1.3.5 TOUJOURS veiller à ce que la zone autour du pot d’échappement ne

soit pas encombrée de débris tels que des feuilles, du papier, du

carton etc. Un pot d’échappement chaud peut provoquer

l’inflammation des débris et ainsi déclencher un feu.

1.3.6 TOUJOURS remplacer les parties constituantes usées ou

endommagées par des pièces de rechange recommandées et mises

au point par Wacker Neuson Corporation.

1.3.7 TOUJOURS débrancher la bougie d’allumage sur les machines

équipées de moteurs essence avant l’entretien afin d’éviter un

démarrage inopiné.

1.3.8 TOUJOURS veiller à ce que la machine soit propre et les autocollants

lisibles. Remplacer tous les autocollants manquants ou difficiles à lire.

Les autocollants fournissent des instructions d’utilisation importantes

qui servent à prévenir des dangers.

wpm_si000310fr.fm 7

Page 50

Informations sur la sécurité VP 2050A/AW

1.4 Situation des Etiquettes

wpm_si000310fr.fm 8

wpmgr005944

Page 51

VP 2050A/AW Informations sur la sécurité

1.5 Étiquettes de sécurité et d’information

Des autocollants internationaux illustrés figurent sur les machines

Wacker Neuson lorsque cela est nécessaire. Ces autocollants sont

décrits ci-dessous :

Etiquette Signification

AVERTISSEMENT !

Surface chaude !

Niveau de puissance acoustique garanti en

dB(A).

AVERTISSEMENT !

Si la main est prise dans la courroie en mouvement, il y a risque de blessure.

Toujours remettre la protection de courroie.

PRÉCAUTION !

Avant de mettre cette machine en marche, lire

attentivement et comprendre le Manuel de

l’utilisateur. Dans le cas contraire, vous augmentez le risque de vous blesser et de blesser

les autres.

PRECAUTIÓN

Point de levage

wpm_si000310fr.fm 9

Page 52

Informations sur la sécurité VP 2050A/AW

Etiquette Signification

AVERTISSEMENT !

Toujours porter une protection pour les oreilles

et pour les yeux en utilisant la machine.

Levier des gaz :

Lapin = Rapide ou pleine

Tortue = Petite vitesse ou Marche à vide

DANGER !

Les moteurs émettant du monoxyde de carbone, la machine doit fonctionner dans un

endroit bien ventilé. Lire attentivement le Manuel de l’utilisateur.

Pas d’étincelles, de flammes ou d’objets en

feu à proximité de la machine. Eteindre le

moteur avant réalimentation.

Autocollant-modèle de machine

Company logo

Company label

wpm_si000310fr.fm 10

Page 53

VP 2050A/AW Informations sur la sécurité

Etiquette Signification

Une plaque signalétique mentionnant le

numéro de modèle, le numéro de référence, le

niveau de révision et le numéro de série est

apposée sur chaque machine. Veuillez noter

les informations relevées sur cette plaque de

façon à ce qu’elles soient toujours disponibles

si la plaque signalétique venait à être perdue

ou endommagée. Lorsque vous commandez

des pièces détachées ou sollicitez des informations après-vente, on vous demandera toujours de préciser le numéro de modèle, le

numéro de référence, le niveau de révision et

le numéro de série de la machine.

Cette machine peut être protégée sous des

brevets d’invention.

wpm_si000310fr.fm 11

Page 54

Specifications techniques VP 2050A/AW

2. Specifications techniques

2.1 Données de la Moteur

Puissance nominale des moteur

Puissance nominale nette conformément à SAE J1349. La puissance

réelle peut varier selon les conditions spécifiques d'utilisation.

VP 2050A

0009087

VP 2050AW

0009510

Moteur

Constructeur Honda

Modèle GX 160 UT1 SWX2

Puissance max. nominale à

kW

3,6 @ 3600 rpm

vitesse nominale

Bougie NGK BPR 6ES

Ecartement de l’électrode

Régime d’exploitation

Filtre à air

Lubrification du moteur

Capacité du carter d’huile

Carburant

mm

tours/min.

type

huile

class.

ml

type

0,7-0,8

3600

Élément double

SAE 10W30

SG or SF

600

Essence régulière sans plomb

Capacité du réservoir

Réglage des soupapes

liter

mm

(froid)

admission:

échapp:

wpm_td000319fr.fm 12

3,6

0,15

0,20

Page 55

VP 2050A/AW Specifications techniques

2.2 Données de la Machine

Plaque

Poids

Contenance - réservoir à

kg

liter

eau

Vitesse de l’excitateur

Lubrification de l’excitateur

Dimensions

tours/min.

ml

mm

2.3 Mesures du Bruit et de la Vibration

Les spécifications acoustiques demandées suivant Paragraphe 1.7.4.f

de la réglementation 89/392/CEE pour machines sont:

VP 2050A

0009087

VP 2050AW

0009510

103

7,6

5800 ± 100

296

Liquide pour boîte automatique

Dextron III / Mercon ou l’équivalent.

588 x 500 x 919

• Niveau de puissance acoustique garanti (LWA) = 108 dB(A).

• Niveau de pression acoustique á l’oreille de l’opérateur (LpA) = 97

dB(A).

Ces valeurs acoustiques étaient fixées suivant ISO 3744 pour le

niveau de puissance acoustique (LWA) et ISO 6081 pour le niveau de

pression acoustique (LpA) à l’oreille de l’opérateur.

La valeur pondérée effective de l’accélération, fixée suivant EN ISO

2

5349, est 4,5 m/s

.

Les mesures du bruit et de la vibration étaient fixées lors de l’utilisation

sur du béton trop mouillé à vitesse de régime nominale du moteur.

wpm_td000319fr.fm 13

Page 56

Specifications techniques VP 2050A/AW

2.4 Dimensions

mm (po.)

919 (36)

500 (20)

588 (23)

wpmgr005971

wpm_td000319fr.fm 14

Page 57

VP 2050A/AW Fonctionnement

3. Fonctionnement

3.1 Carburant recommandé

Le moteur fonctionne avec de l'essence ordinaire sans plomb. Utiliser

exclusivement de l'essence propre. Une essence contenant de l’eau

ou des impuretés endommagera le circuit de carburant. Consulter les

instructions pour l’utilisation et l’entretien du fabricant du moteur pour

les specifications complètes du carburant.

3.2 Application

Cette plaque est conçue pour le compactage de la terre lâche et

granuleuse, du gravier et des pavés. Elle est destinée à être utilisée

dans les endroits fermés et à côté de structures telles que murs,

bordures et fondations.

Cette plaque n’est pas recommandée pour le compactage de sols

cohérents à forte teneur en argile. Pour sols cohérents utiliser une

pilonneuse ou un rouleau à pieds de mouton.

3.3 Avant la mise en service

3.3.1 Lire et comprendre les consignes de sécurité et de fonctionnement de

cette notice d’emploi.

3.3.2 Vérifier :

• le niveau d’huile moteur.

• le niveau de carburant.

• l’état du filtre à air.

• que toutes les attaches externes sont serrées.

• l’état des tuyaux de carburant.

wpm_tx001097fr.fm 15

Page 58

Fonctionnement VP 2050A/AW

3.4 Démarrage

Voir Dessin : wc_gr000014

3.4.1 Ouvrir le robinet d’essence en basculant le levier (a1) vers la droite.

Remarque : Lorsque le moteur est froid, placer l’étrangleur en position

fermée (b1). Lorsque le moteur est chaud, placer le starter en position

ouverte (b2).

3.4.2 Placer l’interrupteur sur la position “ON” (e1).

3.4.3 Ouvrir la manette des gaz en la basculant légèrement vers la gauche

(d1).

3.4.4 Tirer sur la corde de démarrage (c).

Remarque : Si le niveau de l’huile est bas, le moteur ne démarre pas.

Le cas échéant, ajouter de l’huile au moteur. Certains modèles sont

équipés avec une lampe d’alerte d’huile (f) qui s’allume pendant le

tirage de la corde de démarrage.

3.4.5 Ouvrir l’étrangleur au fur et à mesure que le moteur chauffe (b2).

3.4.6 Ouvrir complètement la manette des gaz pour que fonctionne.

3.5 Arrêt

Voir Dessin : wc_gr000014

3.5.1 Réduire le régime du moteur en basculant la manette des gaz à fond

vers la droite (d2).

3.5.2 Placer l’interrupteur sur “OFF” (e2).

3.5.3 Fermer le robinet d’essence en basculant le levier vers la gauche (a2).

wpm_tx001097fr.fm 16

Page 59

VP 2050A/AW Fonctionnement

3.6 Fonctionnement

Faire tourner le moteur à plein régime et laisser la plaque avancer à sa

vitesse normale. En montée, il peut s’avérer nécessaire d’aider la

plaque en la poussant légèrement vers l’avant. En descente, retenir

légèrement la plaque si elle commence à prendre de la vitesse.

Suivant le matériau compacté, trois ou quatre passes sont

recommandées pour obtenir le meilleur compactage.

Lorsqu’une certaine quantité d’humidité dans le sol est nécessaire,

l’humidité excessive peut causer l’adhérence des particules du sol et

empêcher un bon compactage. Si le sol est extrêmement humide, le

laisser sécher quelque peu avant de compacter.

Si le sol est tellement sec qu’il crée des nuages de poussière durant le

fonctionnement de la plaque, on doit humidifier le sol afin d’améliorer

le compactage. Ceci réduira également l’entretien du filtre à air.

Pour compacter l’asphalte, ouvrir le robinet du réservoir d’eau pour

mouiller l’asphalte et le dessous de la plaque. Ceci empêchera

l’asphalte d’adhérer. Deux passes suffisent habituellement à assurer

un bon compactage.

Lorsque la plaque est utilisée sur des pavés, fixer un tapis sur le fond

de la plaque pour empêcher celle-ci de faire éclater ou de broyer la

surface des pavés. Un tapis spécial en polyuréthane conçu à cette fin

est proposé comme accessoire.

ATTENTION : NE PAS utiliser la plaque sur le béton ou sur des

surfaces compactées extrêmement dures et sèches. La plaque

sautera, plutôt que de vibrer, ce qui peut abîmer la plaque aussi bien

que le moteur.

wpm_tx001097fr.fm 17

Page 60

Entretien VP 2050A/AW

4. Entretien

4.1 Calendrier d’entretien périodique

Le tableau ci-dessous donne le calendrier des entretiens de base de

la machine et du moteur. Se référer à la Notice d’Emploi du

constructeur du moteur pour de plus amples informations sur

l’entretien de celui-ci.

Vérifier le niveau de carburant.

Vérifier le niveau de l'huile moteur.

Contrôler les tuyaux de carburant.

Vérifier le filtre à air; remplacer si

nécessaire.

Vérifier la visserie extérieure.

Vérifier et régler la courroie de

transmission.

Nettoyer l’élément du filtre à air.

Contrôler les silentblocs.

Vérifier le liquide pour boîte

automatique.

Tous les

jours

avant le

démar-

rage

Après les

20

premières

heures

Toutes

les 2

semaines

ou toutes

les 50

heures

Tous les

mois ou

toutes

les 100

heures

Tous les

ans ou

toutes

les 300

heures

Changer l’huile moteur.

Nettoyer le système de refroidisse-

ment.

Vérifier et nettoyer la bougie.

Nettoyer le séparateur.

Vérifier et régler l’ouverture de la

soupape.

Remplacer le liquide pour boîte

automatique.

Bougie d’allumage

wpm_tx001098fr.fm 18

Page 61

VP 2050A/AW Entretien

Voir Dessin : wc_gr000028

Nettoyer ou remplacer la bougie d’allumage lorsque c’est nécessaire

pour garantir un fonctionnement correct. Se reporter au manuel

utilisateur du moteur.

Le pot d’échappement devient très chaud pendant le fonctionnement

et reste chaud pendant longtemps après avoir arrêté le moteur. Ne

AVERTISSEMENT

4.1.1 Retirer la bougie d’allumage et inspecter-la.

4.1.2 Remplacer la bougie d’allumage si l’isolant est fissuré ou éclaté.

4.1.3 Nettoyer les électrodes de la bougie d’allumage avec une brosse

4.1.4 Régler l’écartement des électrodes (a).

4.1.5 Serrer fermement la bougie d’allumage.

toucher pas le pot d’échappement lorsqu’il est chaud.

Remarque : Voir la Données Techniques pour la bougie d’allumage

recommandée et l’ecartement des électrodes.

métallique.

ATTENTION : Une bougie d’allumage mal serrée peut devenir très

chaude et risque d’endommager le moteur.

wpm_tx001098fr.fm 19

Page 62

Entretien VP 2050A/AW

A

4.2 Épurateur d’air

Voir Dessin : wc_gr000025

Le moteur est équipé d’un filtre à air à deux éléments. Entretenir

fréquemment le filtre à air afin d’éviter un mauvais fonctionnement du

carburateur.

ATTENTION : NE JAMAIS faire fonctionner le moteur sans filtre à air.

Le moteur serait sérieusement endommagé.

NE JAMAIS utiliser d’essence ou d’autres types de solvant à point

d’inflammation bas pour nettoyer le filtre à air. Cela pourrait provoquer

VERTISSEMENT

4.2.1 Démonter le couvercle du filtre à air (a). Retirer les deux éléments et

4.2.2 Laver l’élément en mousse (b) dans une solution de détergent doux et

un incendie ou une explosion.

Pour l’entretien

vérifier s’ils ne sont pas percés ou effilochés. Remplacer les éléments

endommagés.

d’eau chaude. Rincer soigneusement à l’eau claire et laisser l’élément

sécher complètement. Tremper l’élément dans de l’huile moteur

propre et essorer l’huile excessive.

4.2.3 Frapper légèrement l’élément en papier (c) pour éliminer l’excès de

poussière ou souffler de l’air comprimé au travers du filtre de l’intérieur

vers l’extérieur. Remplacer l’élément en papier s’il semble fortement

encrassé.

wpm_tx001098fr.fm 20

Page 63

VP 2050A/AW Entretien

4.3 Changer l’huile

Voir Dessin : wc_gr000022

4.3.1 Vidanger l’huile pendant que le moteur est encore chaud.

4.3.2 Retirer le bouchon de remplissage (a) et le bouchon de vidange (b)

pour vidanger l’huile.

Remarque : Pour assurer la protection de l’environnement, placer

sous la machine un récipient pour recueillir le liquide qui s’écoule et

une toile imperméable pour protéger le sol. L’élimination des liquides

recueillis doit se faire conformément aux normes en vigueur

4.3.3 Remettre le bouchon de vidange en place.

4.3.4 Remplir le carter du moteur avec de l’huile recommandée jusqu’au

niveau de l’ouverture du bouchon (c). Voir la Données Techniques

pour la quantité et la qualitité de l’huile.

4.3.5 Remettre le bouchon de remplissage en place.

wc_gr000022

4.4 Réglage de la vitesse du moteur

Voir Dessin : wc_gr000280

Régler la vitesse au régime pleine puissance. Voir les Données

Techniques.

Pour régler le ralenti :

4.4.1 Placer la machine sur un tapis de caoutchouc pour l'empêcher de se

déplacer.

4.4.2 Démarrer le moteur et le laisser chauffer jusqu'à sa température de

fonctionnement normal.

4.4.3 Tourner la vis de butée de papillon (a) vers l'intérieur pour augmenter

la vitesse, vers l'extérieur pour la réduire. S'assurer que le levier de

papillon est en contact avec la vis de butée avant de mesurer la

vitesse.

a

wc_gr000280

ATTENTION : le fait de faire tourner la plaque à une vitesse plus

élevée que celle qui est indiquée dans les Données Techniques peut

endommager la plaque et le moteur.

wpm_tx001098fr.fm 21

Page 64

Entretien VP 2050A/AW

4.5 Réglage du carburateur

Voir Dessin : wc_gr000032

4.5.1 Démarrer et laisser chauffer le moteur jusqu’à ce qu’il atteigne sa

température de fonctionnement normale.

4.5.2 Dévisser la vis à téton (a) de 2 tours. Voir Remarque.

4.5.3 Pendant que le moteur tourne au ralenti, tourner la vis à téton (a)

jusqu’à obtenir le régime le plus élevé possible.

4.5.4 Après avoir ajusté la vis à téton, tourner la vis de réglage (b) jusqu’à

obtenir le régime de ralenti standard. Voir la Données Techniques.

Remarque : Sur certains moteurs, pour se conformer aux règlements

d’émission, la vis de ralenti est équipée avec un couvercle limite (c)

pour prévenir un enrichissement excessif du mélange air/combustible.

Le mélange est réglé en usine. Aucun ajustement ne serait

nécessaire. Ne pas essayer d’enlever le couvercle limite ou bien la vis

de ralenti se rompra aussi.

wc_gr000032

4.6 Nettoyage du séparateur

Voir Dessin : wc_gr000029

4.6.1 Fermer le robinet de carburant.

4.6.2 Retirer le séparateur (a) et le joint torique (b).

4.6.3 Nettoyer-les soigneusement dans un solvant ininflammable. Sécherles et remonter-les.

4.6.4 Ouvrir le robinet de carburant et vérifier s’il n’y a pas de fuite.

wpm_tx001098fr.fm 22

Page 65

VP 2050A/AW Entretien

4.7 Courroie d’entraînement

Voir Dessin : wpmgr005996

Vérifier la tension de la courroie sur les machines neuves, ou après

avoir installé une nouvelle courroie, au bout des cinq premières heures

de fonctionnement. Vérifier et régler la courroie toutes les 50 heures

par la suite.

Pour régler la courroie :

4.7.1 Desserrez les deux vis (a) du protège-courroie, puis retirez ce dernier,

en laissant les vis fixées sur le protège-courroie.

4.7.2 Desserrez les quatre l’écrou (b) qui retiennent le moteur sur sa

console et boulons (c) qui retient la partie arrière du protège-courroie

sur la console.

4.7.3 Faites glisser le moteur en arrière (vers le guidon) pour resserrer la

courroie, vers l’avant pour la desserrer.

4.7.4 Régler la courroie jusqu’à ce qu’elle s’infléchisse de 10 à 13 mm (d)

en exerçant une pression au centre de la courroie entre les poulies.

4.7.5 Vérifier que la poulie d’embrayage (f) et la poulie d’excitateur (e) sont

alignées. Placer une règle de vérification contre la poulie d’excitateur

(e) et déplacer le moteur afin que les deux poulies soient parallèles.

4.7.6 Serrez l’écrou et tous les boulons et vis au couple à 20,5 Nm en

remontant la machine.

a

b

c

d

wpmgr005996

wpm_tx001098fr.fm 23

Page 66

Entretien VP 2050A/AW

4.8 Graissage de l’allumeur

Voir Dessin : wpmgr006020

Les roulements à billes de l’ensemble allumage sont graissés par

barbotage et tournent à vitesse élevée. Il est important de maintenir

l’huile à son niveau correct et de la changer régulièrement.

Vérifiez le niveau d’huile dans l’allumeur toutes les 50 heures de

fonctionnement. Pour vérifier le niveau d’huile, placez la plaque sur

une surface plane, unie. Retirez le bouchon de vidange (a) et la bague

d’étanchéité (b). L’huile doit être au niveau du filetage du bouchon de

vidange. Ajoutez la quantité d’huile nécessaire.

Changez l’huile de l’allumeur toutes les 300 heures de

fonctionnement.

Pour vidanger l’huile : Retirez le bouchon (a) de l’extrémité de

l’allumeur et relevez l’avant de la plaque.

Remarque : Pour contribuer à protéger l’environnement, placez une

feuille de plastique et un récipient sous la machine afin de recueillir le

liquide que s’en échappe. Débarrassez-vous de ce liquide selon la

réglementation sur la protection de l’environnement.

Placez la plaque sur une surface plane et ajoutez environ 296 ml

d’huile par l’ouverture du bouchon jusqu’à ce que l’huile atteigne le

niveau du filetage du bouchon de vidange.

ATTENTION : NE remplissez PAS trop. L’excès d’huile dans

l’allumeur peut en diminuer les performances et abîmer la courroie

d’entraînement.

4.9 Nettoyage de la plaque

wpmgr006020

Nettoyer la plaque après usage pour enlever la saleté, les pierres et la

boue qui se sont logées sous la console du moteur. Si la plaque est

utilisée dans un endroit poussiéreux, vérifier les ailettes de

refroidissement de cylindre du moteur pour y relever une importante

accumulation de saleté. Garder ces ailettes en bon état de propreté

pour empêcher le moteur de surchauffer.

wpm_tx001098fr.fm 24

Page 67

VP 2050A/AW Entretien

4.10 Levage de la machine

Voir Dessin : wpmgr006168

Voir Caractéristiques techniques pour le poids de la machine.

Pour lever manuellement la machine :

4.10.1 Arrêtez le moteur.

4.10.2 Demandez de l’aide et synchronisez le levage.

Pour éviter de brûlures ou des dangers d'incendie, laisser le moteur

refroidir avant de transporter la machine ou de la ranger en intérieur.

Fermer le robinet de carburant et maintenir le moteur horizontal pour

AVERTISSEMENT

4.10.3 Saisissez la machine par les poignées de levage (a).

4.10.4 Levez la machine comme illustré.

AVERTISSEMENT

empêcher le carburant de se répandre.

Pour éviter tout risque de lésion au dos pendant le levage, maintenez

vos pieds bien à plat sur le sol et les épaules bien écartées. Gardez la

tête relevée et le dos droit.

Pour lever la machine par un moyen mécanique :

ATTENTION : Avant de procéder au levage, assurez-vous que les

dispositifs de levage peuvent supporter en toute sécurité le poids de la

machine. Voir Caractéristiques techniques pour le poids de la

machine.

4.10.5 Accrochez un crochet, un harnais ou un câble à la machine comme

illustré et soulevez-la suivant le besoin.

ATTENTION : NE PAS lever la machine par la poignée pour assurer

que la machine ne risque pas de se déplacer et tomber à terre.

c

CAUTION

VORSICHT

PRECAUTION

PRECAUCION

wpm_tx001098fr.fm 25

a

b

wpmgr006168

Page 68

Entretien VP 2050A/AW

A

4.11 Transport

Voir Dessin : wpmgr006042

Pour éviter les brûlures ou les risques d'incendie, laissez le moteur

refroidir avant de transporter la machine ou de l'entreposer à l'intérieur.

VERTISSEMENT

4.11.1 Tournez le robinet de carburant sur la position de coupure (OFF), et

maintenez le moteur de niveau pour prévenir tout déversement de

carburant.

4.11.2 Arrimez la machine sur le véhicule de transport, afin de l'empêcher de