Page 1

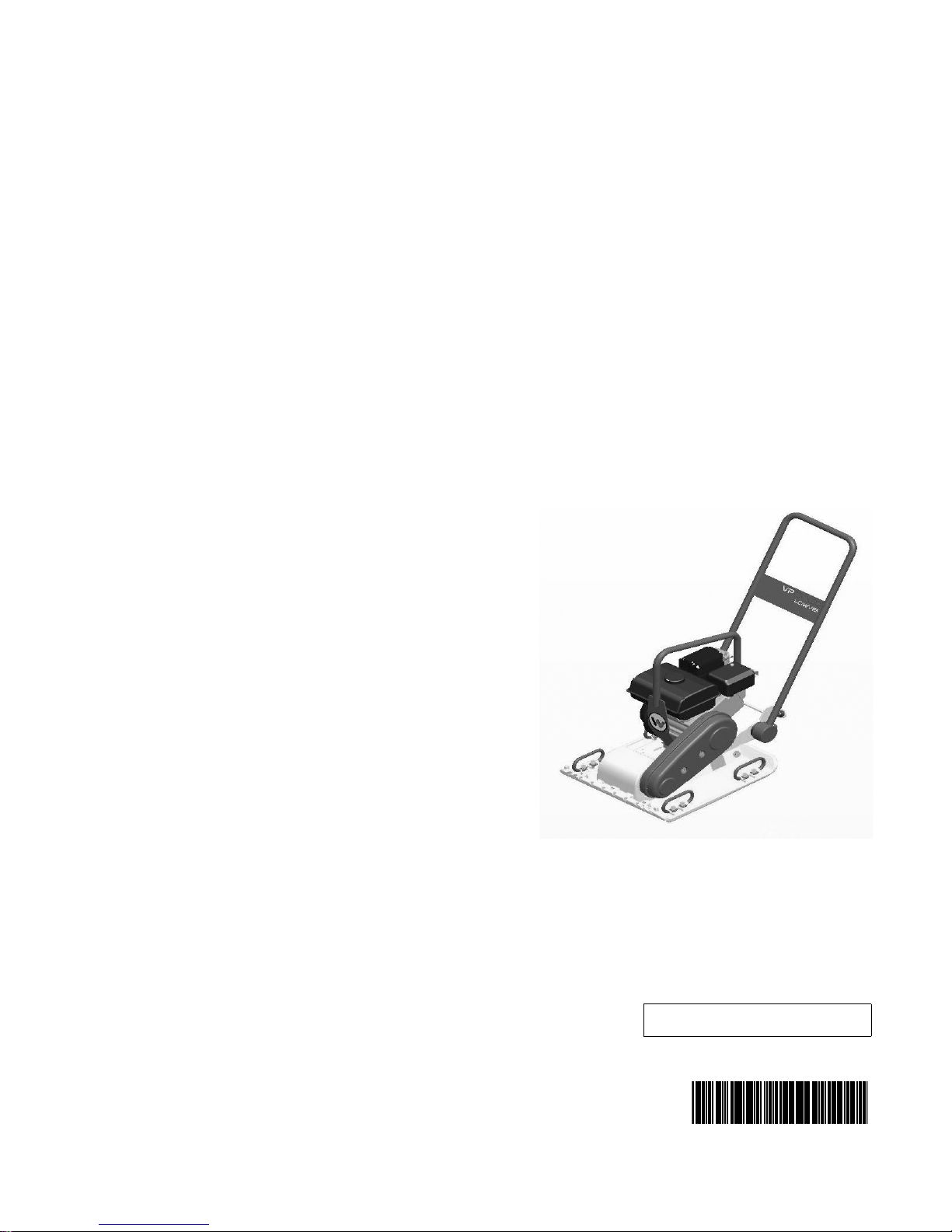

Operator’s Manual

Vibroplate

VP 2050

VP 2050W

500191658

5000191658

005 0110

Page 2

Copyright

notice

© Copyright 2010 by Wacker Neuson Corporation.

All rights, including copying and distribution rights, are reserved.

This publication may be photocopied by the original purchaser of the machine. Any

other type of reproduction is prohibited without express written permission from

Wacker Neuson Corporation.

Any type of reproduction or distribution not authorized by W acker Neuson Corp oration

represents an infringement of valid copyrights. Violators will be prosecuted.

T ra d emarks

Manufacturer

Tra n slated

instructions

All trademarks referenced in this manual are the property of their respective owners.

Wacker Neuson Manila Incorporated

Lot 2,Blk 1 Phase 3, PEZA Drive, First Cavite Industrial Estate, Brgy. Langkaan

Dasmariñas, Cavite, Philippines

Tel: +63-(0)2-580-7136 Fax: +63-(0)2-580-712

www.wackerneuson.com

This Operator’s Manual presents a translation of the original instructions. The original

language of this Operator’s Manual is American English.

Page 3

VP 2050/W Table of Contents

Foreword 3

1. Safety Information 4

1.1 Laws Pertaining to Spark Arresters ...................................................... 4

1.2 Operating Safety .................................................................................. 5

1.3 Operator Safety while using Internal Combustion Engines .................. 6

1.4 Service Safety ...................................................................................... 7

1.5 Label Locations .................................................................................... 8

1.6 Warning and Informational Labels ........................................................ 9

2. Technical Data 12

2.1 Engine Data ........................................................................................ 12

2.2 Machine Data ..................................................................................... 13

2.3 Sound and Vibration Measurements .................................................. 13

2.4 Dimensions ......................................................................................... 14

3. Operation 15

3.1 Recommended Fuel ........................................................................... 15

3.2 Application .......................................................................................... 15

3.3 Before Starting ................................................................................... 15

3.4 To Start ............................................................................................... 16

3.5 To Stop ............................................................................................... 16

3.6 Operation ............................................................................................ 17

wpm_bo0400324005enTOC.fm 1

Page 4

Table of Contents VP 2050/W

4. Maintenance 18

4.1 Periodic Maintenance Schedule ..........................................................18

4.2 Spark Plug ...........................................................................................20

4.3 Air Cleaner ..........................................................................................21

4.4 Engine Oil ............................................................................................22

4.5 Adjusting the Engine Speed ................................................................22

4.6 Cleaning Fuel Strainer .........................................................................23

4.7 Drive Belt .............................................................................................24

4.8 Exciter Lubrication ...............................................................................25

4.9 Cleaning the Plate ...............................................................................25

4.10 Lifting Machine ....................................................................................26

4.11 Transporting Machine ..........................................................................27

4.12 Storage ................................................................................................27

4.13 Troubleshooting ...................................................................................28

wpm_bo0400324005enTOC.fm 2

Page 5

Foreword

WARNING

CALIFORNIA

Proposition 65 Warning:

Engine exhaust, some of its constituents, and certain vehicle

components, contain or emit chemicals known to the State of

California to cause cancer and birth defects or other reproductive

harm.

This manual provides information and procedures to safely operate

and maintain this Wacker Neuson model. For your own safety and

protection from injury, carefully read, understand and observe the

safety instructions described in this manual.

Keep this manual or a copy of it with the machine. If you lose this

manual or need an additional copy, please contact Wacker Neuson

Corporation. This machine is built with user safety in mind; however,

it can present hazards if improperly operated and serviced. Follow

operating instructions carefully! If you have questions about operating

or servicing this equipment, please contact Wacker Neuson

Corporation.

The information contained in this manual was based on machines in

production at the time of publication. Wacker Neuson Corporation

reserves the right to change any portion of this information without

notice.

All rights, especially copying and distribution rights, are reserved.

Copyright 2010 by Wacker Neuson Corporation.

No part of this publication may be reproduced in any form or by any

means, electronic or mechanical, including photocopying, without

express written permission from Wacker Neuson Corporation.

Any type of reproduction or distribution not authorized by Wacker

Neuson Corporation represents an infringement of valid copyrights

and will be prosecuted. We expressly reserve the right to make

technical modifications, even without due notice, which aim at

improving our machines or their safety standards.

wc_tx000001gb.fm 3

Page 6

Safety Information VP 2050/W

1. Safety Information

This manual contains DANGER, WARNING, CAUTION, NOTICE, and

NOTE signal words which must be followed to reduce the possibility

of personal injury, damage to the equipment, or improper service.

This is the safety alert symbol. It is used to alert you to potential

personal injury hazards. Obey all safety messages that follow this

symbol to avoid possible injury or death.

DANGER indicates a hazardous situation which, if not avoided, will

result in death or serious injury.

DANGER

WARNING indicates a hazardous situation which, if not avoided, could

result in death or serious injury.

WARNING

CAUTION indicates a hazardous situation which, if not avoided, could

result in minor or moderate injury.

CAUTION

NOTICE: Used without the safety alert symbol, NOTICE indicates a

situation which, if not avoided, could result in property damage.

Note: Contains additional information important to a procedure.

1.1 Laws Pertaining to Spark Arresters

Notice: State Health Safety Codes and Public Resources Codes

specify that in certain locations spark arresters be used on internal

combustion engines that use hydrocarbon fuels. A spark arrester is a

device designed to prevent accidental discharge of sparks or flames

from the engine exhaust. Spark arresters are qualified and rated by

the United States Forest Service for this purpose.

In order to comply with local laws regarding spark arresters, consult

the engine distributor or the local Health and Safety Administrator.

wpm_si000312gb.fm 4

Page 7

VP 2050/W Safety Information

1.2 Operating Safety

Familiarity and proper training are required for the safe operation of the

machine. Machines operated improperly or by untrained personnel

can be hazardous. Read the operating instructions contained in this

WARNING

1.2.1 Do not allow anyone to operate this equipment without proper training.

1.2.2 Do not touch the engine or muffler while the engine is on or

1.2.3 Do not use accessories or attachments that are not recommended by

manual and the engine manual, and familiarize yourself with the

location and proper use of all controls. Inexperienced operators should

receive instruction from someone familiar with the machine before

being allowed to operate it.

People operating this equipment must be familiar with the risks and

hazards associated with it.

immediately after it has been turned off. These areas get hot and may

cause burns.

Wacker Neuson. Damage to equipment and injury to the user may

result.

1.2.4 NEVER operate the machine with the beltguard missing. Exposed

drive belt and pulleys create potentially dangerous hazards that can

cause serious injuries.

1.2.5 Never leave the machine running unattended.

1.2.6 Be sure operator is familiar with proper safety precautions and

operation techniques before using machine.

1.2.7 Always wear protective clothing appropriate to the job site when

operating the machine.

1.2.8 Wear hearing protection when operating equipment.

1.2.9 Close fuel valve on engines equipped with one when machine is not

being operated.

1.2.10 Store the machine properly when it is not being used. The machine

should be stored in a clean, dry location out of the reach of children.

1.2.11 Always operate machine with all safety devices and guards in place

and in working order. Do not modify or defeat safety devices. Do not

operate machine if any safety devices or guards are missing or

inoperative.

1.2.12 Read, understand, and follow procedures in the Operator’s Manual

before attempting to operate the machine.

wpm_si000312gb.fm 5

Page 8

Safety Information VP 2050/W

1.3 Operator Safety while using Internal Combustion Engines

Internal combustion engines present special hazards during operation

and fueling. Read and follow the warning instructions in the engine

owner’s manual and the safety guidelines below. Failure to follow the

WARNING

1.3.1 DO NOT run the machine indoors or in an enclosed area such as a

1.3.2 Do not smoke while operating the machine.

1.3.3 Do not smoke when refueling the engine.

1.3.4 Do not refuel a hot or running engine.

1.3.5 Do not refuel the engine near an open flame.

1.3.6 Do not spill fuel when refueling the engine.

1.3.7 Do not run the engine near open flames.

warnings and safety standards could result in severe injury or death.

deep trench unless adequate ventilation, through such items as

exhaust fans or hoses, is provided. Exhaust gas from the engine

contains poisonous carbon monoxide gas; exposure to carbon

monoxide can cause loss of consciousness and may lead to death.

1.3.8 Refill the fuel tank in a well-ventilated area.

1.3.9 Replace the fuel tank cap after refueling.

1.3.10 ALWAYS check the fuel lines and the fuel tank for leaks and cracks

before starting the engine. Do not run the machine if fuel leaks are

present or the fuel lines are loose.

wpm_si000312gb.fm 6

Page 9

VP 2050/W Safety Information

1.4 Service Safety

A poorly maintained machine can become a safety hazard! In order

for the machine to operate safely and properly over a long period of

time, periodic maintenance and occasional repairs are necessary.

WARNING

1.4.1 Do not attempt to clean or service the machine while it is running.

Rotating parts can cause severe injury.

1.4.2 Do not crank a flooded engine with the spark plug removed on

gasoline-powered engines. Fuel trapped in the cylinder will squirt out

the spark plug opening.

1.4.3 Do not test for spark on gasoline-powered engines if the engine is

flooded or the smell of gasoline is present. A stray spark could ignite

the fumes.

1.4.4 Do not use gasoline or other types of fuels or flammable solvents to

clean parts, especially in enclosed areas. Fumes from fuels and

solvents can become explosive.

1.4.5 Keep the area around the muffler free of debris such as leaves, paper,

cartons, etc. A hot muffler could ignite the debris and start a fire.

1.4.6 Replace worn or damaged components with spare parts designed and

recommended by Wacker Neuson Corporation.

1.4.7 Disconnect the spark plug on machines equipped with gasoline

engines, before servicing, to avoid accidental start-up.

1.4.8 Keep the machine clean and labels legible. Replace all missing and

hard-to-read labels. Labels provide important operating instructions

and warn of dangers and hazards.

wpm_si000312gb.fm 7

Page 10

Safety Information VP 2050/W

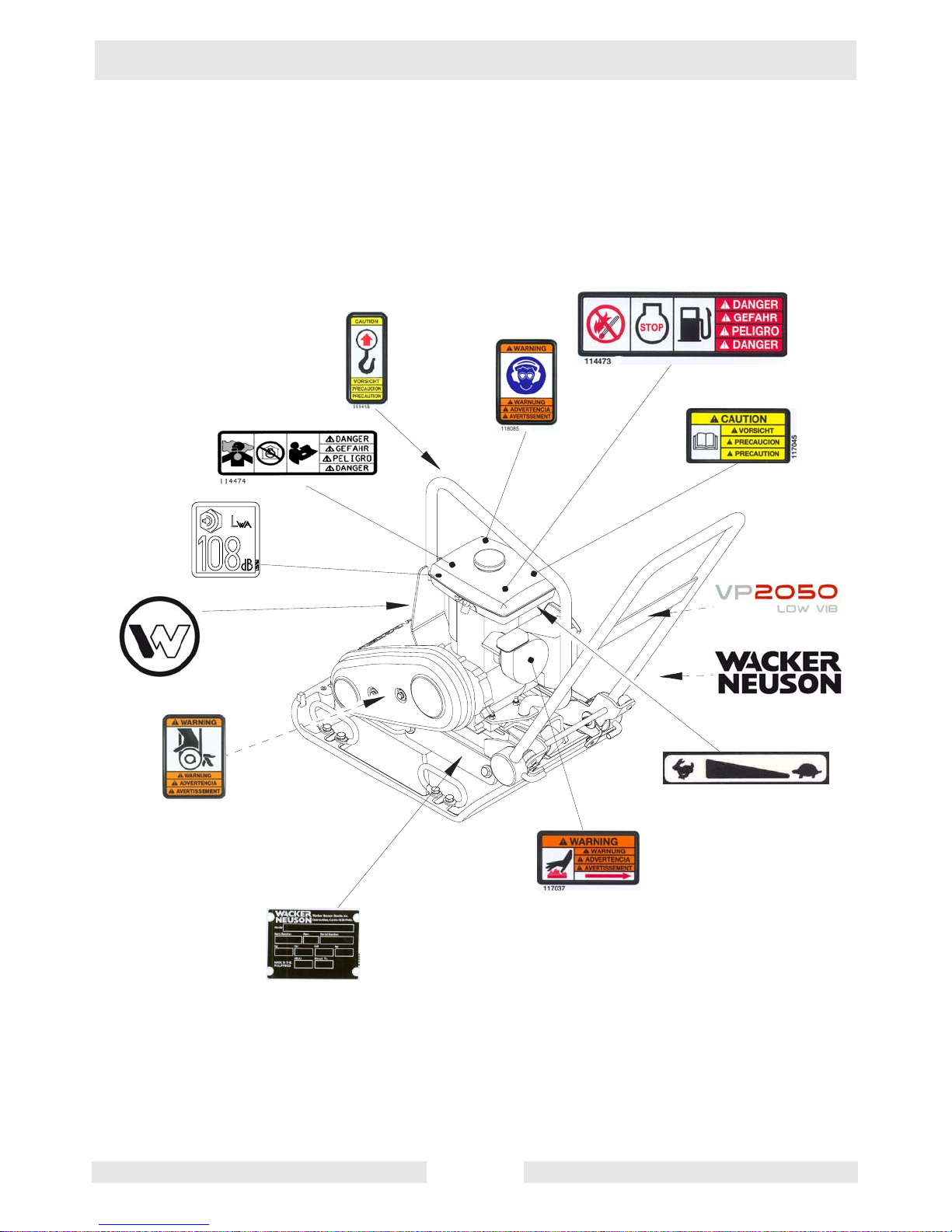

1.5 Label Locations

wpm_si000312gb.fm 8

wpmgr005945

Page 11

VP 2050/W Safety Information

1.6 Warning and Informational Labels

Wacker Neuson machines use international pictorial labels where

needed. These labels are described below:

Label Meaning

WARNING!

Hot surface!

Guaranteed sound power level in dB(A).

WARNING!

Hand injury if caught in moving belt.

Always replace beltguard.

CAUTION!

Read and understand the supplied Operator’s

Manual before operating this machine. Failure

to do so increases the risk of injury to yourself

and others.

CAUTION

Lifting point.

WARNING!

Always wear hearing and eye protection when

operating this machine.

wpm_si000312gb.fm 9

Page 12

Safety Information VP 2050/W

Label Meaning

Throttle control lever:

Rabbit = Full or Fast

Turtle = Idle or Slow

DANGER!

Engines emit carbon monoxide; operate only

in well-ventilated area.

Read the Operator’s Manual for machine information.

DANGER!

Before fueling, stop the engine. No sparks,

flames, or burning objects near the machine.

Use only fresh, clean fuel.

Label-machine model

Company logo

Company label

wpm_si000312gb.fm 10

Page 13

VP 2050/W Safety Information

Label Meaning

A nameplate listing the model number, item

number, revision number, and serial number is

attached to each unit. Please record the information found on this plate so it will be available should the nameplate become lost or

damaged. When ordering parts or requesting

service information, you will always be asked

to specify the model number, item number,

revision number , and serial number of the unit.

This machine may be covered by one or more

patents.

wpm_si000312gb.fm 11

Page 14

Technical Data VP 2050/W

2. Technical Data

2.1 Engine Data

Engine Power Rating

Net power rating per SAE J1349. Actual power output may vary due to

conditions of specific use.

VP 2050

0009530

Engine

Engine Make Wacker

Engine Model WM170

Maximum rated power

@ rated speed

Operating speed

Clutch Engagement

kW (Hp)

rpm

rpm

4.2 (5.7)

@ 4000 rpm

3600

2100

Spark Plug NGK BR6HS

Champion RL86C

Electrode Gap

Air Cleaner

Engine Lubrication

mm (in.)

type

oil grade

0.6-0.7 (0.024–0.028)

Dual element

SAE 10W30

SE or higher

VP 2050W

0009537

Engine Oil Capacity

Fuel

Fuel Tank Capacity

Valve Clearance (cold)

Inlet:

Outlet:

wpm_td000321gb.fm 12

ml (oz.)

type

l (qts.)

mm (in.)

600 (20)

Regular unleaded gasoline

3.6 (3.8)

0.07-0.13 (0.003-0.005)

0.17-0.23 (0.007-0.009)

Page 15

VP 2050/W Technical Data

2.2 Machine Data

VP 2050

0009530

Plate

Weight

Water Tank Capacity

Exciter Speed

Exciter Lubrication

kg (lbs.)

l (qts.)

rpm

ml (oz.)

Dextron III/Mercon or equivalent

Dimensions

mm (in.)

2.3 Sound and Vibration Measurements

The required sound specification, Paragraph 1.7.4.f of 89/392/EEC

Machinery Directive, is:

• the guaranteed sound power level (LWA) = 108 dB(A).

VP 2050W

0009537

103 (228)

7.6 (8)

5800 ± 100

240 (8)

Automatic transmission fluid

588 (23) x 500 (20) x 919 (36)

• the sound pressure level at operator’s location (LpA):

VP 2050 = 91 dB(A).

These sound values were determined according to ISO 3744 for the

sound power level (LWA) and ISO 6081 for the sound pressure level

(LpA) at the operator’s location.

The weighted effective acceleration value, determined according to

2

EN ISO 5349, is approximately = 4.5 m/s

.

The sound and vibration measurements were obtained with the

machine operating on crushed gravel at nominal engine speed.

wpm_td000321gb.fm 13

Page 16

Technical Data VP 2050/W

2.4 Dimensions

mm (in.)

919 (36)

500 (20)

588 (23)

wpmgr005973

wpm_td000321gb.fm 14

Page 17

VP 2050/W Operation

3. Operation

3.1 Recommended Fuel

The engine requires regular grade unleaded gasoline. Use only fresh,

clean gasoline. Gasoline containing water or dirt will damage fuel

system. Consult engine owner’s manual for complete fuel

specifications.

3.2 Application

This plate is designed for compacting loose, granular soils, gravel, and

paving stones. It is intended to be used in confined areas and areas

next to structures such as walls, curbs, and foundations. Plates

equipped with water tanks can be used for compacting asphalt.

This plate is not recommended for compacting cohesive soils with a

heavy clay content. For cohesive soil, use a vibratory rammer or

sheepsfoot roller.

3.3 Before Starting

3.3.1 Read and understand the safety and operating instructions at the

beginning of this manual.

3.3.2 Check:

• Oil level in the engine

• Fuel level

• Condition of the air cleaner

• Tightness of the external fasteners

• Condition of the fuel lines

wpm_tx001101gb.fm 15

Page 18

Operation VP 2050/W

3.4 To Start

See Graphic: wc_gr000655

3.4.1 Open fuel valve by moving lever down (a1).

Note: If engine is cold, move choke lever to close position (d2). If

engine is hot, set choke to open position (d1).

3.4.2 Turn engine switch to “ON” (b2).

3.4.3 Open throttle by moving it slightly to left (c2).

3.4.4 Pull starter rope (e).

Note: If the oil level in the engine is low, the engine will not start. If this

happens, add oil to engine.

3.4.5 Open choke as engine warms (d1).

3.4.6 Open throttle fully to operate (c1).

a2

a1

d2

3.5 To Stop

See Graphic: wc_gr000655

3.5.1 Reduce engine RPM to idle by moving throttle completely to right (c3).

d1

b2

b1

c3

c2

c1

e

wc_gr000655

3.5.2 Turn engine switch to “OFF” (b1).

3.5.3 Close fuel valve (a2).

wpm_tx001101gb.fm 16

Page 19

VP 2050/W Operation

3.6 Operation

Run the engine at full throttle and allow the plate to pull itself along at

its normal speed. When operating on an incline it may be necessary to

assist the plate by pushing it forward slightly. When operating downhill

hold the plate back slightly, if it begins to pick up speed. Depending on

the material being compacted, three or four passes are recommended

to achieve the best compaction.

While a certain amount of moisture in the soil is necessary, excessive

moisture may cause soil particles to stick together and prevent good

compaction. If soil is extremely wet, allow it to dry somewhat before

compacting.

If soil is so dry as to create dust clouds while operating plate, some

moisture should be added to the ground material to improve

compaction. This will also reduce service to the air filter.

For compacting asphalt, use a water tank to wet the asphalt and the

underside of plate. This will prevent asphalt material from sticking.

Two passes are usually sufficent to ensure good compaction.

When using the plate on paving stones, attach a pad to the bottom of

the plate to prevent chipping or grinding surface of stones. A special

polyurethane pad designed for this purpose is available as an optional

accessory.

NOTICE: DO NOT operate the plate on concrete or on extremely hard,

dry, compacted surfaces. The plate will jump rather than vibrate and

could damage both the plate and the engine.

wpm_tx001101gb.fm 17

Page 20

Maintenance VP 2050/W

4. Maintenance

4.1 Periodic Maintenance Schedule

4.1.1 Engine Maintenance

The chart below lists basic engine maintenance. Refer to the engine

manufacturer’s Operation Manual for additional information.

Check fuel level.

Check engine oil level.

Inspect fuel lines.

Inspect air filter. Replace as needed.

Clean air cleaner elements.

Change engine oil.

Clean engine cooling fins.

Clean sediment cup / fuel filter.

Check and clean spark plug.

Check and adjust valve clearance.

Change exciter oil.

Daily

before

starting

After

first

20 hrs.

Every

2 weeks

or

50 hrs.

Every

month

or

100 hrs.

Every

year

or

300 hrs.

wpm_tx001102gb.fm 18

Page 21

VP 2050/W Maintenance

4.1.2 Machine Maintenance

The chart below lists basic machine maintenance.

Check external hardware.

Check and adjust drive belt.

Inspect shockmounts for damage.

Replace shockmounts as needed.

Change exciter oil.

Note: When machine is being used in asphalt, it is highly

recommended that shockmounts are replaced every year or

after 300 hours of usage.

Daily

before

starting

After

first

20 hrs.

Every

2 weeks

or

50 hrs.

Every

month

or

100 hrs.

Every

year

or

300 hrs.

wpm_tx001102gb.fm 19

Page 22

Maintenance VP 2050/W

4.2 Spark Plug

See Graphic: wc_gr000028

Clean or replace the spark plug as needed to ensure proper operation.

Refer to your engine operator’s manual.

The muffler becomes very hot during operation and remains hot for a

while after stopping the engine. Do not touch the muffler while it is hot.

WARNING

Note: Refer to section “Technical Data” for the recommended spark

plug type and the electrode gap setting.

4.2.1 Remove the spark plug and inspect it.

4.2.2 Replace the spark plug if the insulator is cracked or chipped.

4.2.3 Clean the spark plug electrodes with a wire brush.

4.2.4 Set the electrode gap (a).

4.2.5 Tighten the spark plug securely.

NOTICE: A loose spark plug can become very hot and may cause

engine damage.

wpm_tx001102gb.fm 20

Page 23

VP 2050/W Maintenance

4.3 Air Cleaner

See Graphic: wc_gr000656

NEVER use gasoline or other types of low-flash point solvents for

cleaning the air cleaner. A fire or explosion could result.

WARNING

NOTICE: NEVER run the engine without the air cleaner. Severe

engine damage will occur.

The engine is equipped with a dual-element air cleaner. Under normal

operating conditions, the elements should be cleaned once every

week. Under severe, dry and dusty conditions, the elements should be

maintained daily. Replace an element when it is saturated with dirt that

cannot be removed.

4.3.1 Remove the air cleaner cover (a). Remove the filter assembly by

pulling it straight up. Inspect both elements for holes or tears. Replace

damaged elements.

4.3.2 Wash the foam element (b) in a solution of mild detergent and warm

water. Rinse it thoroughly in clean water. Allow the element to dry

thoroughly.

4.3.3 Tap the paper element (c) lightly to remove excess dirt or blow

compressed air through the filter from the inside out. Replace the

paper element if it appears heavily soiled.

a

b

c

wc_gr000656

wpm_tx001102gb.fm 21

Page 24

Maintenance VP 2050/W

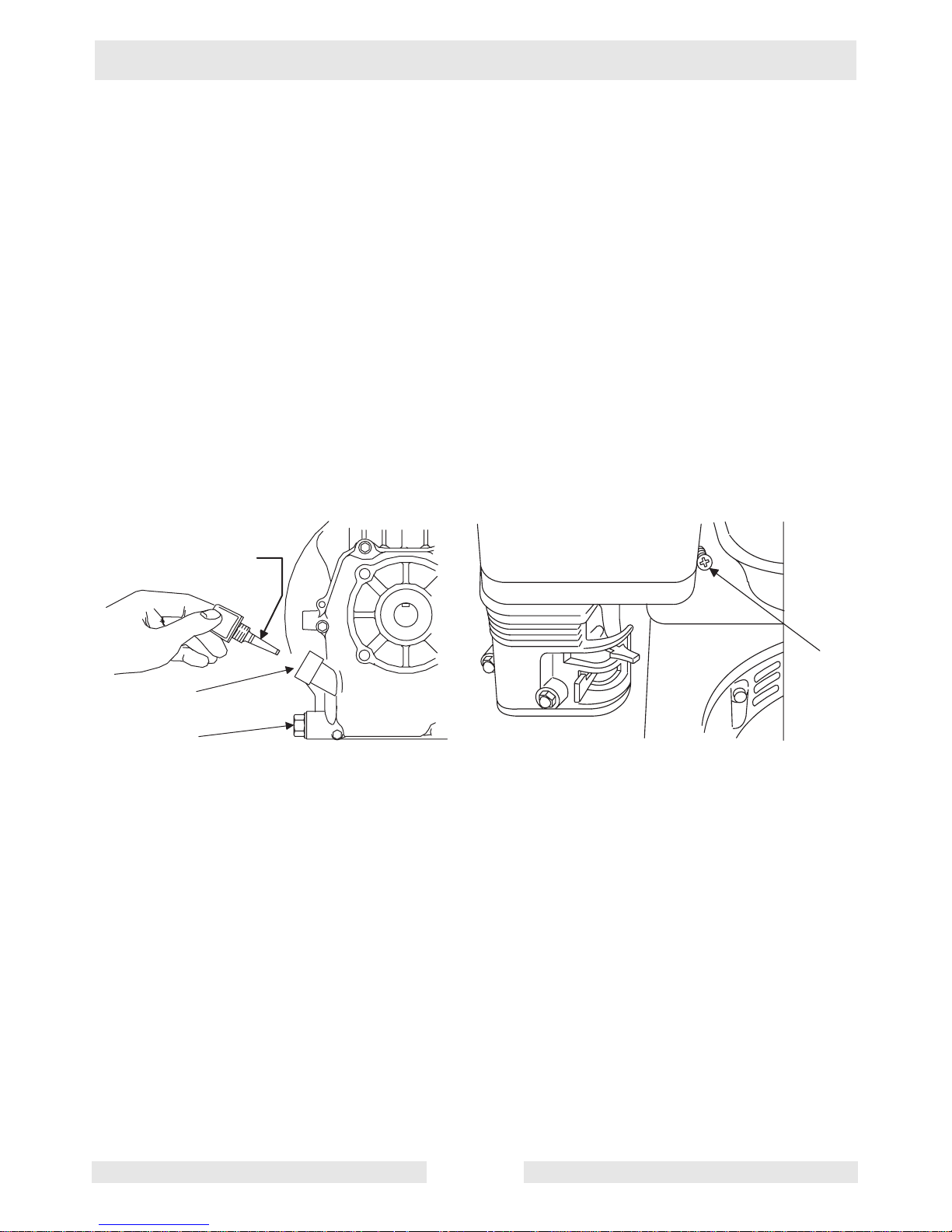

4.4 Engine Oil

See Graphic: wc_gr000087

4.4.1 Drain oil while engine is still warm.

Note: In the interests of environmental protection, place a plastic sheet

and a container under the machine to collect any liquid which drains

off. Dispose of this liquid in accordance with environmental protection

legislation.

4.4.2 Remove the oil drain plug (a).

4.4.3 Allow the oil to drain.

4.4.4 Install the drain plug.

4.4.5 Fill the engine crankcase through the oil filler opening (b), to the upper

mark on the dipstick (c). Do not thread in the dipstick to check the level.

See Technical Data for oil quantity and type.

4.4.6 When the crankcase is full, reinstall the dipstick.

c

b

a

wc_gr000087

4.5 Adjusting the Engine Speed

See Graphic: wc_gr000280

Adjust to a full load speed of 3600 ± 100 rpm.

To adjust engine speed:

4.5.1 Place machine on a rubber test mat to prevent it from moving.

4.5.2 Start engine and allow it to warm up for a minute.

4.5.3 Turn throttle stop screw (a) in to increase speed, out to decrease

speed. Make sure throttle lever is touching stop screw before

measuring RPM.

a

wc_gr000280

NOTICE: Running plate at a speed higher than that listed in Technical

Data can damage both the plate and the engine.

wpm_tx001102gb.fm 22

Page 25

VP 2050/W Maintenance

4.6 Cleaning Fuel Strainer

See Graphic: wc_gr001093

4.6.1 To remove water and dirt, close the fuel lever and remove the fuel

strainer.

4.6.2 Inspect the fuel strainer (a) for water and dirt.

4.6.3 After removing any dirt and water, wash the fuel cup with a

nonflammable solvent.

4.6.4 Reinstall securely to prevent leakage.

wpm_tx001102gb.fm 23

Page 26

Maintenance VP 2050/W

4.7 Drive Belt

See Graphic: wpmgr005997

On new machines or after installing a new belt, check the belt tension

after first 20 hours of operation. Check and adjust the belt every 50

hours thereafter.

To adjust the belt:

4.7.1 Loosen the two screws (a) on the beltguard, then remove the

beltguard, keeping the screw assemblies captured on the beltguard.

4.7.2 Loosen the four nuts (b) which hold the engine to the console, and the

screw (c) which holds the beltguard back to the console.

4.7.3 Slide the engine backward (towards the handle) to tighten the belt,

forward to loosen the belt.

4.7.4 Adjust the belt so that it deflects 10-13 mm (3/8in–1/2in) (d) when

pressed midway between the belt pulleys.

4.7.5 Make sure that the clutch pulley (f) and the exciter pulley (e) are in

alignment. Place a straight edge against the exciter pulley (e) and

move the engine so that the two pulleys are parallel.

4.7.6 Torque all nuts and screws to 20.5 Nm (15 ft.lbs.) as you reassemble

the machine.

a

b

c

d

wpmgr005997

wpm_tx001102gb.fm 24

Page 27

VP 2050/W Maintenance

4.8 Exciter Lubrication

See Graphic: wpmgr006020

The bearings in the exciter assembly are splash lubricated and rotate

at very high speed. It is important to maintain the exciter oil at the

correct level and change it regularly.

Check oil level in exciter every 50 hours of operation.

To check oil level, place plate on a flat, level surface. Remove the drain

plug (a) with seal ring (b). Oil level should be at drain plug threads. Add

oil as required.

Change exciter oil every 300 hours of operation.

To drain oil: Remove plug (a) from end of exciter and tilt plate up.

Note: In the interests of environmental protection, place a plastic sheet

and a container under the machine to collect any liquid which drains

off. Dispose of this liquid in accordance with environmental protection

legislation.

Place plate on a level surface and add approximately 296 ml of oil

through plug opening until oil reaches the drain plug threads.

NOTICE: DO NOT overfill. Too much oil in exciter can reduce

performance and damage drive belt.

4.9 Cleaning the Plate

wpmgr006020

Clean plate after use to remove dirt, stones, and mud caught under the

engine console. If plate is being used in a dusty area, check engine

cylinder cooling fins for heavy dirt accumulation. Keep engine cylinder

fins clean to prevent engine from overheating.

wpm_tx001102gb.fm 25

Page 28

Maintenance VP 2050/W

4.10 Lifting Machine

See Graphic: wpmgr006169

See Technical Data for weight of machine.

To lift machine manually:

4.10.1 Stop the engine.

4.10.2 Obtain help from a partner and plan the lift.

To avoid burns or fire hazards, let the engine cool before transporting

the machine or storing it indoors. Turn the fuel valve to the off position

and keep the engine level to prevent fuel from spilling.

WARNING

4.10.3 Grasp machine by the lifting handles (a).

4.10.4 Lift machine as shown.

To reduce risk of back injury while lifting, keep feet flat on ground and

shoulder width apart. Keep head up and back straight.

WARNING

To lift machine mechanically:

NOTICE: Before attempting to lift, be sure that lifting devices can

safely handle weight of machine. See Technical Data for weight of

machine.

4.10.5 Attach hook, harness, or cable to machine as shown, and lift as

desired.

NOTICE: DO NOT lift the vibroplate by its guide handle. The vibroplate

can shift, causing it to fall.

c

CAUTION

VORSICHT

PRECAUTION

PRECAUCION

a

b

wpm_tx001102gb.fm 26

wpmgr006169

Page 29

VP 2050/W Maintenance

4.11 Transporting Machine

See Graphic: wpmgr006043

To avoid burns or fire hazards, let engine cool before transporting

machine or storing indoors.

WARNING

4.11.1 Turn fuel valve to the off position and keep the engine level to prevent

fuel from spilling.

4.11.2 Tie down machine on vehicle to prevent machine from sliding or tipping

over. Tie machine to vehicle at points shown on graphic.

4.12 Storage

If plate is being stored for more than 30 days:

4.12.1 Remove loose stones and dirt from plate.

4.12.2 Clean engine cylinder cooling fins.

4.12.3 Clean or replace air filter.

4.12.4 Change exciter oil.

4.12.5 Change engine oil and follow procedures described in engine manual

for engine storage.

4.12.6 Cover plate and engine and store in a clean, dry area.

wpm_tx001102gb.fm 27

wpmgr006043

Page 30

Maintenance VP 2050/W

4.13 Troubleshooting

Problem / Symptom Reason / Remedy

Plate does not develop full

speed. Poor compaction.

• Engine throttle control not completely open.

• Throttle control not adjusted correctly.

• Ground too wet, plate sticking. Allow soil to dry

before compacting.

• Drive belt loose or worn, slipping on pulleys. Adjust

or replace belt. Check that engine mounting bolts

are tight.

• Exciter bearings binding. Check condition and level

of oil in exciter. Add or change oil.

• Air filter clogged with dust, reducing engine performance. Clean or replace air filter.

• Engine speed too low. Check engine speed with

tachometer. Adjust or repair engine to run at correct

speed. Refer to engine manual.

Engine running, no vibration • Engine throttle not open.

• Drive belt loose or broken. Adjust or replace.

• Clutch damaged. Inspect and replace clutch.

Plate jumps or compacts

unevenly.

• Engine speed too low. Check engine speed.

• Too much oil in exciter. Adjust oil to correct level.

• Ground surface too hard.

• Shockmounts loose or damaged.

wpm_tx001102gb.fm 28

Page 31

EC DECLARATION OF CONFORMITY

WACKER NEUSON MANILA, INC., DASMARIÑAS, CAVITE, PHILIPPINES

AUTHORIZED REPRESENTATIVE IN THE EUROPEAN UNION Axel Häret

WACKER NEUSON SE

Preußenstraße 41

80809 München

hereby certifies that the construction equipment specified hereunder:

1. Category

Vibratory Plates

2. Machine function:

This plate is designed for compacting loose, granular soils, gravel, and paving stones. It is intended to be

used in confined areas and areas next to structures such as walls, curbs, and foundations. Plates equipped

with water tanks can be used for compacting asphalt.

3. Type / Model

VP 2050, VP 2050W

4. Item number of equipment:

0009530, 0009537

5. Net installed power:

VP 2050, VP 2050W 4,2kW

Has been sound tested per Directive 2000/14/EC:

Conformity Assessment

Procedure

Annex VI VDE-Prüf- und

6. This machinery fulfills the relevant provisions of Machinery Directive 2006/42/EC and is also produced in accordance with these

standards:

Name and address of notified body Measured sound power level Guaranteed sound power level

Zertifizierungsinstitut

Zertifizierungsstelle

Merianstraße 28

63069 Offenbach/Main

VP 2050 91 dB(A)

VP 2050W 91 dB(A)

VP 2050 108 dB(A)

VP 2050W 108 dB(A)

2000/14/EC

2004/108/EC

EN 500-1

EN 500-4

He inz Gengnagel

President & CEO

23.12.09

Date

WACKER NEUSON CORPORATION

The original language of this EC Declaration of Conformity is American English.

VP 2050-en_2010_WN.fm

Page 32

Page 33

CE-KONFORMITÄTSERKLÄRUNG

WACKER NEUSON MANILA, INC., DASMARIÑAS, CAVITE, PHILIPPINES

BEVOLLMÄCHTIGTER VER TRETER FÜR DIE EUROPÄISCHE

GEMEINSCHAFT

bescheinigt, daß das Baugerät:

1. Art:

Axel Häret

WACKER NEUSON SE

Preußenstraße 41

80809 München

Rüttelplatten

2. Maschinenfunktion:

Diese Platte eignet sich zum Verdichten von losen und körnigen Böden, Kies und Verbundsteinen, ebenso

in engen Bereichen an Gebäuden, Randsteinen und Fundamenten. Platten mit Wasserberieselungsanlage

können zur Verdichtung von Asphalt angewendet werden.

3. Typ / Modell:

VP 2050, VP 2050W

4. Artikelnummer:

0009530, 0009537

5. Absolute installierte Leistung:

VP 2050, VP 2050W 4,2kW

In Übereinstimmung mit Richtlinie 2000/14/EG bewertet worden ist:

Konformitätsbewertungsverfahren

ANHANG VI VDE-Prüf- und

6. Diese Maschine erfüllt die relevanten Bestimmungen der Richtlinie für Maschinen 2006/42/EG und wurde auch gemäß deren Normen hergestellt:

Bei folgender einbezogener

Prüfstelle

Zertifizierungsinstitut

Zertifizierungsstelle

Merianstraße 28

63069 Offenbach/Main

Gemessener Schallleistungspegel Garantierter Schallleistungspegel

VP 2050 91 dB(A)

VP 2050W 91 dB(A)

VP 2050 108 dB(A)

VP 2050W 108 dB(A)

2000/14/EC

2004/108/EC

EN 500-1

EN 500-4

He inz Gengnagel

President & CEO

23.12.09

Datum

Diese EG-Konformitätserklärung ist eine Übersetzung des Originalzertifikats.

WACKER NEUSON CORPORATION

VP 2050-de_2010_WN.fm

Page 34

Page 35

DECLARACIÓN DE CONFORMIDAD DE LA CE

WACKER NEUSON MANILA, INC., DASMARIÑAS, CAVITE, PHILIPPINES

REPRESENTANTE AUTORIZADO EN LA UNIÓN EUROPEA Axel Häret

WACKER NEUSON SE

Preußenstraße 41

80809 München

certifica que la máquina de construcción:

1. Categoría:

Planchas Vibratorias

2. Función de la máquina:

Esta placa está diseñada para compactar suelos granulares sueltos, grava y adoquines de hormigón. Se

entiende que será usada en areas confinadas y areas cercanas a estructuras tales como muros, curvas y

fundaciones. Planchas equipadas con tanque de agua pueden ser usadas en la compactación de asfalto.

3. Tipo / Modelo:

VP 2050, VP 2050W

4. Número de referencia de la máquina:

0009530, 0009537

5. Potencia instalada neta:

VP 2050, VP 2050W 4,2kW

Ha sido ensayado en conformidad con la norma 2000/14/CE:

Procedimiento para ensayar

conformidad

ANEXO VI VDE-Prüf- und

6. Esta maquinaria cumple con las cláusulas pertinentes de la Directiva 2006/42/CE sobre maquina ria y también se fabrica en conformidad con estas pautas:

Oficina matriculadora Nivel de potencia acústica

determinado

VP 2050 91 dB(A)

Zertifizierungsinstitut

Zertifizierungsstelle

Merianstraße 28

63069 Offenbach/Main

VP 2050W 91 dB(A)

Nivel de potencia acústica

garantizado

VP 2050 108 dB(A)

VP 2050W 108 dB(A)

2000/14/EC

2004/108/EC

EN 500-1

EN 500-4

23.12.09

Fecha

Esta Declaración de conformidad CE presenta una traducción del certificado original.

VP 2050-es_2010_WN.fm

He inz Gengnagel

President & CEO

WACKER NEUSON CORPORATION

Page 36

Page 37

DÉCLARATION DE CONFORMITÉ C.E.

WACKER NEUSON MANILA, INC., DASMARIÑAS, CAVITE, PHILIPPINES

REPRÉSENTANT AGRÉÉ AUPRÈS DE L’UNION

EUROPÉENNE

atteste que le matériel:

1. Catégorie:

Axel Häret

WACKER NEUSON SE

Preußenstraße 41

80809 München

Plaques Vibrantes

2. Fonction de la machine :

Cette plaque est conçue pour le compactage de la terre lâche et granuleuse, du gravier et des pavés. Elle est

destinée à être utilisée dans les endroits fermés et à côté de structures telles que murs, bordures et

fondations. Les plaques pourvues de réservoirs d’eau peuvent être utilisées pour le compactage de

l’asphalte.

3. Type / modèle :

VP 2050, VP 2050W

4. Numéro de référence du matériel:

0009530, 0009537

5. Puissance installée nette :

VP 2050, VP 2050W 4,2kW

A été mis à l’épreuve conforme aux dispositions de la directive 2000/14/CEE:

Procédé pour l’épreuve de

conformité

ANNEXE VI VDE-Prüf- und

6. Cette machine est conforme aux dispositions pertinentes de la Directive sur les machines 2006/42/CE et également produite conformément à ces normes :

Organisme agrée Niveau de puissance

acoustique fixé

VP 2050 91 dB(A)

Zertifizierungsinstitut

Zertifizierungsstelle

Merianstraße 28

63069 Offenbach/Main

VP 2050W 91 dB(A)

Niveau de puissance acoustique

garanti

VP 2050 108 dB(A)

VP 2050W 108 dB(A)

2000/14/EC

2004/108/EC

EN 500-1

EN 500-4

He inz Gengnagel

President & CEO

23.12.09

Date

WACKER NEUSON CORPORATION

Cette déclaration de conformité CE est une traduction du certificat d’origine.

VP 2050-fr_2010_WN.fm

Page 38

Important: For spare parts information, please see your Wacker Neuson Dealer, or visit the

Wacker Neuson website at http://www.wackerneuson.com/.

Wichtig! Informationen über Ersatzteile erhalten Sie von Ihrem Wacker Neuson Händler oder

besuchen Sie die Wacker Neuson Website unter http://www.wackerneuson.com/.

Important : Pour des informations sur les pièces détachées, merci de consulter votre

distributeur Wacker Neuson, ou de visiter le site Internet de Wacker Neuson sur

http://www.wackerneuson.com/.

Importante : Para saber más sobre las piezas de repuesto, póngase en contacto con su

distribuidor de Wacker Neuson o acceda al sitio web de Wacker Neuson en

http://www.wackerneuson.com/.

Importante : Per informazioni sui pezzi di ricambio, contattare il rivenditore Wacker Neuson o

visitare il sito di Wacker Neuson all’indirizzo www.wackerneuson.com.

Viktigt : För information om reservdelar, kontakta din Wacker Neuson-leverantör eller besök

Wacker Neusons webbplats på http://www.wackerneuson.com/.

Tärkeää : Pyydä varaosatietoja Wacker Neusonin jälleenmyyjältä tai vieraile Wacker Neusonin

web-sivustolla osoitteessa http://www.wackerneuson.com/

Viktig : For informasjon om reservedeler, vennligst kontakt din Wacker Neuson-forhandler, eller

besøk Wacker Neusons nettside på http://www.wackerneuson.com/.

Vigtigt : Hvis du ønsker oplysninger om reservedele, bedes du kontakte din Wacker Neuson

forhandler eller besøg Wacker Neuson websiden på http://www.wackerneuson.com/.

Belangrijk! Neem contact op met uw Wacker Neuson dealer of bezoek de website van Wacker

Neuson op http://www.wackerneuson.com/ voor meer informatie over reserveonderdelen.

Importante : Para obter informações sobre as peças sobresselentes, consulte o seu

fornecedor da Wacker Neuson ou aceda ao site Web da Wacker Neuson em

http://www.wackerneuson.com

Ważne : W celu uzyskania informacji na temat części zamiennych skontaktuj się z

przedstawicielem firmy Wacker Neuson lub skorzystaj z witryny internetowej

http://wackerneuson.com/.

Důležité upozornění! Pro informace o náhradních dílech, prosím, kontaktujte svého Wacker

Neuson dealera, nebo navštivte webové stránky http://www.wackerneuson.com/.

FONTOS: A pótalkatrészekre vonatkozó információkért kérjük, forduljon Wacker Neuson

kereskedőjéhez vagy látogasson el a Wacker Neuson weboldalára a következő címen:

http://www.wackerneuson.com/.

Важно! Для ознакомления с информацией о запасных частях, пожалуйста, обратитесь к

местному торговому представителю компании Wacker Neuson или посетите веб-сайт

http://www.wackerneuson.com/.

Σημαντικό : Γι

α πληροφορίες σχετικά με τα ανταλλακτικά, μιλήστε με τον αντιπρόσωπό σας της

Wacker Neuson, ή επισκεφθείτε τον ιστότοπο http://www.wackerneuson.com/.

Važno : Za rezervne dijelove obratite se svom Wacker Neuson prodavaču ili posjetite mrežne

stranice tvrtke Wacker Neuson: http://www.wackerneuson.com/.

Önemli : Yedek parça bilgileri için Wacker Neuson Bayinize bakın veya Wacker Neuson web

sitesini ziyaret edin. http://www.wackerneuson.com/

重要 交換部品の情報については、ワッカーノイソンディーラーにお問い合わせ頂くか、ワッ

カーノイソンウェブサイト http://www.wackerneuson.com/ をご覧ください。

重要 有关备件信息,请咨询您的威克诺森经销商或访问威克诺森网站:

http://www.wackerneuson.com/。

Important : Pentru informaţii referitoare la piesele de schimb, vă rugăm să vă adresaţi

distribuitorului Wacker Neuson sau să vizitaţi site-ul web Wacker Neuson la adresa

http://www.wackerneuson.com/.

Важно : За информация относно резервни части, моля, обърнете се към местния дилър

на W

acker Neuson или посетете уебсайта на Wacker Neuson на адрес

http://www.wackerneuson.com/.

Wacker Neuson Produktion GmbH & Co. KG, Preußenstraße 41, D-80809 München,

Wacker Neuson Production Americas LLC, N92W15000 Anthony Ave., Menomonee Falls, WI. 53051

Wacker Neuson Limited - Room 1701–03 & 1717–20, 17/F. Tower 1, Grand Century Place, 193 Prince Edward

Road West, Mongkok, Kowloon, Hongkong. Tel: (852) 3605 5360, Fax: (852) 2758 0032

Tel.: +49-(0)89-3 54 02-0 Fax: +49 - (0)89-3 54 02-390

Tel.: (262) 255-0500 Fax: (262) 255-0550 Tel.: (800) 770-0957

Loading...

Loading...