Page 1

5200015081

Operator’s Manual

Mobile Generator

G 25 (T4i)

G 25 (T4f)

EN

5200015081

04 0215

Page 2

Copyright

notice

© Copyright 2015 by Wacker Neuson Production Americas LLC

All rights, including copying and distribution rights, are reserved.

This publication may be photocopied by the original purchaser of the machine. Any

other type of reproduction is prohibited without express written permission from

Wacker Neuson Production Americas LLC.

Any type of reproduction or distribution not authorized by Wacker Neuson Production

Americas LLC represents an infringement of valid copyrights. Violators will be

prosecuted.

T ra d emarks

Manufacturer

All trademarks referenced in this manual are the property of their respective owners.

Wacker Neuson Production Americas LLC

N92W15000 Anthony Avenue

Menomonee Falls, WI 53051 U.S.A.

Tel: (262) 255-0500 · Fax: (262) 255-0550 · Tel: (800) 770-0957

www.wackerneuson.com

Original

instructions

This Operator’s Manual presents the original instructions. The original language of this

Operator’s Manual is American English.

Page 3

Machine Identification

wc_gr010874

SAVE THESE INSTRUCTIONS—This manual contains important instructions for

the machine models below. These instructions have been written expressly by

Wacker Neuson Production Americas LLC and must be followed during inst allation,

operation, and maintenance of the machines.

Machine Item Number

G 25 0620640, 0620641, 062042, 0620709, 0620931,

5200001316, 5200003991, 52000055 57, 5200009370,

5200009371, 5200009372, 52000093 73, 5200009374,

5200009375, 5200009376, 52000093 77, 5200014460,

5200014461, 5200014462, 5100014166, 5100014167

Machine

identification

Serial number

(S/N)

A nameplate listing the model number, item number, revision number, and serial

number is attached to this machine. The location of the nameplate is shown above.

For future reference, record the serial number in the space provided below . You will

need the serial number when requesting parts or service for this machine.

Serial Number:

wc_tx003541gb_FM10.fm

3

Page 4

Foreword

Foreword

Machine

documentation

Expectations

for

information in

this manual

From this point forward in this documentation, Wacker Neuson Production

Americas LLC will be referred to as Wacker Neuson.

Keep a copy of the Operator’s Manual with the machine at all times.

Use the separate Parts Book supplied with the machine to order replacement

parts.

If you are missing any of these documents, please contact Wacker Neuson to

order a replacement or visit www.wackerneuson.com.

When ordering parts or requesting service information, be prepared to provide

the machine model number, item number, revision number, and serial number.

This manual provides information and procedures to safely operate and

maintain the above Wacker Neuson model(s). For your own safety and to

reduce the risk of injury , carefully read, underst and, and observe all instructions

described in this manual.

Wacker Neuson expressly reserves the right to make technical modifications,

even without notice, which improve the performance or safety standards of its

machines.

The information contained in this manual is based on machines manufactured

up until the time of publication. Wacker Neuson reserves the right to change

any portion of this information without notice.

The illustrations, parts, and procedures in this manual refer to Wacker Neuson

factory-installed components. Your machine may vary depending on the

requirements of your specific region.

CALIFORNIA

Proposition

65 Warning

Laws

pertaining to

spark

arresters

Combustion exhaust, some of its constituents, and certain vehicle components

contain or emit chemicals known to the State of California to cause cancer and

birth defects or other reproductive harm.

NOTICE: State Health Safety Codes and Public Resources Codes specify that in

certain locations spark arresters be used on internal combustion engines that use

hydrocarbon fuels. A spark arrester is a device designed to prevent accidental

discharge of sparks or flames from the engine exhaust. Spark arresters are

qualified and rated by the United States Forest Service for this purpose. In order to

comply with local laws regarding spark arresters, consult the engine distributor or

the local Health and Safety Administrator.

4 wc_tx003565gb_FM10.fm

Page 5

Foreword

Manufacturer’s

approval

This manual contains references to approved parts, attachments, and

modifications. The following definitions apply:

Approved parts or attachments are those either manufactured or provided by

Wacker Neuson.

Approved modifications are those performed by an authorized Wacker

Neuson service center according to written instructions published by Wacker

Neuson.

Unapproved parts, attachments, and modifications are those that do not

meet the approved criteria.

Unapproved parts, attachments, or modifications may have the following

consequences:

Serious injury hazards to the operator and persons in the work area

Permanent damage to the machine which will not be covered under warranty

Contact your Wacker Neuson dealer immediately if you have questions about

approved or unapproved parts, attachments, or modifications.

wc_tx003565gb_FM10.fm 5

Page 6

Foreword

Notes

6 wc_tx003565gb_FM10.fm

Page 7

G 25

Table of Contents

Foreword 4

1 Safety Information 13

1.1 Signal Words Used in this Manual ..................................................... 13

1.2 Machine Description and Intended Use ............................................. 14

1.3 Safety Guidelines for Operating the Machine ..................................... 15

1.4 Service Safety .................................................................................... 17

1.5 Operator Safety while Using Internal Combustion Engines ............... 19

1.6 Safety Guidelines for Mobile Generators ........................................... 20

1.7 Safety Guidelines for Towing the Machine ......................................... 22

1.8 Safety Guidelines for Lifting the Machine ........................................... 23

1.9 Reporting Safety Defects ................................................................... 23

2 Label Locations 24

3 Label Meanings 26

4 Lifting and Transporting 36

4.1 Lifting the Machine ............................................................................. 36

4.2 Before Towing Checklist ..................................................................... 37

4.3 Towing the Machine ........................................................................... 38

4.4 Preparing the Machine for Transport on a Truck or Trailer ................ 39

4.5 Hazardous Materials Placards ........................................................... 40

4.6 Testing the Breakaway System (Hydraulic Surge Brakes) ................. 41

4.7 Testing the Breakaway System (Electric Brakes) .............................. 43

5 Machine Setup 45

5.1 Preparing the Machine for First Use ................................................... 45

5.2 Positioning the Machine ..................................................................... 46

5.3 Grounding the Generator ................................................................... 48

5.4 Recommended Fuel ........................................................................... 49

5.5 Refueling the Machine (Basler Controller) ......................................... 50

5.6 Refueling the Machine (Deep Sea Controller) .................................... 51

6 Operation, Control, and Component Locations 52

6.1 Control / Component Locations .......................................................... 52

6.2 Control Panel Components ................................................................ 53

wc_bo5200015081_03_FM10TOC.fm

7

Page 8

Table of Contents

G 25

7 Operation (Basler Controller) 54

7.1 Main Circuit Breaker ...........................................................................54

7.2 Engine Start Switch ............................................................................55

7.3 Genset Pre-Alarms and Alarms (Shut-Down Conditions) ...................56

7.4 Overcurrent Condition .........................................................................57

7.5 Using the Lugs and the Convenience Receptacles ............................58

7.6 Selecting the Voltage ..........................................................................59

7.7 Before Starting the Machine ...............................................................61

7.8 Starting and Running the Machine .....................................................62

7.9 Stopping the Machine .........................................................................64

7.10 Emergency Stop Switch ......................................................................64

7.11 LCD Panel: Monitoring Machine Operation ........................................65

8 Working with Basler Controller 67

8.1 How to Use the Genset Controller LCD and Keypad .......................... 67

8.2 Menu Diagram of the Genset Controller .............................................68

8.3 Menu Diagram Components ...............................................................69

8.4 Using the Metering and Settings Menus .............................................70

8.5 Logging in to the Genset Controller by Entering the Password .......... 71

8.6 Adjusting the LCD Screen Contrast ....................................................74

8.7 Changing the Time/Date Settings .......................................................75

8.8 Changing the Sender Fail Time Delays ..............................................76

8.9 Changing the Units of Measure ..........................................................78

8.10 Changing the Low Fuel Pre-Alarm Setting .........................................80

8.11 Changing or Disabling the Low Fuel Alarm Setting ............................82

8.12 Changing the Cooldown Time Setting ................................................84

8.13 Changing the Pre-Crank Time Delay (Glow Plug Timer) ....................86

8.14 Changing the Maintenance Interval ....................................................88

8.15 Resetting the Maintenance Interval Pre-Alarm ...................................90

8.16 Resetting a Loss of Voltage Pre-Alarm ...............................................92

8.17 Accessing and Using the Event Log ...................................................93

9 Operation (Deep Sea Controller) 95

9.1 Main Circuit Breaker ...........................................................................95

9.2 Genset Controller Power Switch .........................................................96

9.3 Selecting the Voltage ..........................................................................97

9.4 Deep Sea Controller Buttons/Functions .............................................99

9.5 Genset Controller Alarms and Shut-Down Conditions ......................101

wc_bo5200015081_03_FM10TOC.fm

8

Page 9

G 25

9.6 Before Starting the Machine ............................................................. 103

9.7 Starting and Running the Generator ................................................ 104

9.8 Stopping the Generator .................................................................... 106

9.9 Emergency Stop Switch ................................................................... 107

9.10 Engine and Generator Monitoring .................................................... 108

Table of Contents

10 Working with Deep Sea Controller: DSE 7310 109

10.1 Introduction ....................................................................................... 109

10.2 Navigating the Menus ....................................................................... 110

10.3 Adjusting Screen Contrast ................................................................ 112

10.4 How to Reset the Maintenance Timer .............................................. 113

11 How to Connect Loads (480V) 114

11.1 Lug Terminal Connection Diagrams ................................................. 114

11.2 Best Practices for Balancing Loads .................................................. 115

11.3 Connecting 480V, 3-Phase and Single-Phase Loads ...................... 118

11.4 Connecting a 240V 3Ø Load and a 240V 1Ø Load .......................... 119

11.5 Connecting 240V and 120V Single-Phase Loads ............................ 120

11.6 Connecting a 208V 3Ø Load and Multiple 120V 1Ø Loads .............. 121

11.7 Connecting a 220–240V 3Ø Load and Multiple 127–133V 1Ø Loads 122

12 How to Connect Loads (600V) 123

12.1 Lug Terminal Connection Diagrams ................................................. 123

12.2 Best Practices for Balancing Loads .................................................. 124

12.3 Connecting a 240V 3Ø Load and a 240V 1Ø Load .......................... 127

12.4 Connecting 240V and 120V Single-Phase Loads ............................ 128

12.5 Connecting a 208V 3Ø Load and Multiple 120V 1Ø Loads .............. 129

12.6 Connecting a 220–240V 3Ø Load and Multiple 127–133V 1Ø Loads 130

12.7 Connecting 480V, 3-Phase Loads .................................................... 131

12.8 Connecting 600V, 3-Phase Loads .................................................... 132

13 Using Remote Start Capabilities 133

13.1 Remote Run Terminal Block ............................................................ 133

13.2 Remote Transfer Switch ................................................................... 134

13.3 Preparing for Automatic/Remote Start-Up (Basler) .......................... 135

13.4 Preparing for Automatic/Remote Start-Up (Deep Sea) .................... 136

wc_bo5200015081_03_FM10TOC.fm

9

Page 10

Table of Contents

G 25

14 Diagnostic Trouble Codes (DTC) 138

14.1 Accessing DTCs with the Basler Controller ......................................138

14.2 Accessing Engine DTCs using the Deep Sea Controller ..................139

14.3 List of Engine Diagnostic Trouble Codes (DTCs) .............................140

15 Factory-Installed Options 143

15.1 Battery Charger ................................................................................143

15.2 Lockable Battery Disconnect ............................................................144

15.3 Camlocks ..........................................................................................145

15.4 Containment System ........................................................................146

15.5 Extended Run Tank (ERT) ...............................................................146

15.6 Engine Block Heater .........................................................................147

15.7 Automatic LCD Heat .........................................................................147

15.8 Low Coolant Shutdown .....................................................................148

15.9 Temperature-Activated Shutters .......................................................149

15.10 Positive Air Shutoff Valve .................................................................150

15.11 Quick-Disconnect Fuel Fittings .........................................................151

15.12 Lube Level Maintainer ......................................................................152

16 General Maintenance 153

16.1 Periodic Maintenance Schedule .......................................................153

16.2 Maintaining the Emission Control System ........................................153

16.3 Preparing for Maintenance ...............................................................154

16.4 Cleaning the Machine .......................................................................154

16.5 Inspecting the Machine .....................................................................155

16.6 Maintaining the Trailer ......................................................................156

16.7 Checking and Draining the Containment System .............................157

16.8 Checking the Exhaust System ..........................................................158

16.9 Maintaining the Battery .....................................................................159

16.10 Cleaning the Diesel Particulate Filter (DPF) (if equipped) ................ 160

16.11 Storage .............................................................................................161

16.12 Machine Disposal / Decommissioning ..............................................162

wc_bo5200015081_03_FM10TOC.fm

10

Page 11

G 25

Table of Contents

17 Maintenance Tier 4i Engines: Isuzu 163

18 Maintenance Tier 4f Engines: Isuzu 166

19 Troubleshooting 172

20 Technical Data 173

20.1 Engine .............................................................................................. 173

20.2 Generator ......................................................................................... 175

20.3 Trailer and Skid ................................................................................ 176

20.4 Dimensions ....................................................................................... 177

Tire Safety Information 178

21 User’s Information for Transport Canada Fuel Tank 190

22 Emission Control Systems Information and Warranty 193

22.1 Emission Control System Background Information .......................... 193

22.2 Limited Defect Warranty for Exhaust Emission Control System ....... 194

22.3 Limited Defect Warranty for Wacker Neuson Emission Control

Systems ............................................................................................ 194

23 General Machine Schematics 197

23.1 Fuses .............................................................................................. 197

23.2 Trailer Wiring .................................................................................... 198

23.3 Trailer Wiring Components ............................................................... 199

24 Schematics, Machines with Basler Controller 200

24.1 AC Schematic: ................................................................................. 200

24.2 AC Schematic Components: ........................................................... 201

24.3 DC Schematic: G 25, T4i Isuzu, Basler ............................................ 202

24.4 DC Schematic Components: G 25, T4i Isuzu, Basler ...................... 203

24.5 DC Schematic: G 25, T4f Isuzu, Basler ............................................ 204

24.6 DC Schematic Components: G 25, T4f Isuzu, Basler ...................... 205

24.7 AC Schematic: G25, Isuzu, 600V, Basler ......................................... 206

24.8 AC Schematic Components: G 25, Isuzu, 600V, Basler .................. 207

wc_bo5200015081_03_FM10TOC.fm

11

Page 12

Table of Contents

25 Schematics, Machines with Deep Sea Controller 208

25.1 AC Schematic: ..................................................................................208

25.2 AC Schematic Components: ............................................................209

25.3 DC Schematic: G 25, T4i Isuzu, Deep Sea .......................................210

25.4 DC Schematic Components: G 25, T4i Isuzu, Deep Sea ..................211

G 25

wc_bo5200015081_03_FM10TOC.fm

12

Page 13

Mobile Generator

1 Safety Information

1.1 Signal Words Used in this Manual

This manual contains DANGER, WARNING, CAUTION, NOTICE, and NOTE

signal words which must be followed to reduce the possibility of personal injury,

damage to the equipment, or improper service.

This is the safety alert symbol. It is used to alert you to potential personal hazards.

► Obey all safety messages that follow this symbol.

DANGER

DANGER indicates a hazardous situation which, if not avoided, will result in death

or serious injury.

► To avoid death or serious injury from this type of hazard, obey all safety mes-

sages that follow this signal word.

Safety Information

WARNING

WARNING indicates a hazardous situation which, if not avoided, could result in

death or serious injury.

► To avoid possible death or serious injury from this type of hazard, obey all safety

messages that follow this signal word.

CAUTION

CAUTION indicates a hazardous situation which, if not avoided, could result in

minor or moderate injury.

► To avoid possible minor or moderate injury from this type of hazard,

safety messages that follow this signal word.

NOTICE: Used without the safety alert symbol, NOTICE indicates a situation

which, if not avoided, could result in property damage.

Note: A Note contains additional information important to a procedure.

obey all

wc_tx003567gb_FM10.fm

13

Page 14

Safety Information

1.2 Machine Description and Intended Use

This machine is a mobile electric power source. The Wacker Neuson Mobile

Generator consists of a trailer-mounted cabinet containing an electric alternator, a

fuel tank, and a diesel engine. A control panel, receptacles, and connection lugs

are provided on the side of the cabinet. As the engine runs, the generator converts

mechanical energy into electric power. The operator connects loads to the electric

power receptacles and connection lugs.

This machine is intended for the purpose of supplying electrical power to

connected loads. Refer to the product specifications for the output voltage and

frequency of this generator, and for the maximum output power limit of this

generator.

This machine has been designed and built strictly for the intended use described

above. Using the machine for any other purpose could permanently damage the

machine or seriously injure the operator or other persons in the area. Machine

damage caused by misuse is not covered under warranty.

The following are some examples of misuse:

■ Connecting a load that has voltage and frequency requirements that are

incompatible with the generator output

■ Overloading the generator with a load that draws excessive power during either

continuous running or start-up

■ Operating the generator in a manner that is inconsistent with all federal, state

and local codes and regulations

■ Using the machine as a ladder, support, or work surface

■ Using the machine to carry or transport passengers or equipment

■ Using the machine to tow other machines

■ Operating the machine outside of factory specifications

■ Operating the machine in a manner inconsistent with all warnings found on the

machine and in the Operator’s Manual

Mobile Generator

This machine has been designed and built in accordance with the latest global

safety standards. It has been carefully engineered to eliminate hazards as far as

practicable and to increase operator safety through protective guards and labeling.

However, some risks may rema in even after protective measures have been t aken.

They are called residual risks. On this machine, they may include exposure to:

■ Heat, noise, exhaust, and carbon monoxide from the engine

■ Fire hazards from improper refueling techniques

■ Fuel and its fumes

■ Electric shock and arc flash

■ Personal injury from improper lifting the trailer tongue

■ Typical hazards related to towing a trailer on roads and highways

To protect yourself and others, make sure you thoroughly read and understand the

safety information presented in this manual before operating the machine.

14

wc_tx003567gb_FM10.fm

Page 15

Mobile Generator

1.3 Safety Guidelines for Operating the Machine

Safety Information

Operator

training

Operator

qualifications

Before operating the machine:

■ Read and understand the operating instructions contained in all manuals

delivered with the machine.

■ Familiarize yourself with the location and proper use of all controls and safety

devices.

■ Contact Wacker Neuson for additional training if necessary.

When operating this machine:

■ Do not allow improperly trained people to operate the machine. People

operating the machine must be familiar with the potential risks and hazards

associated with it.

Only trained personnel are permitted to start, operate, and shut down the machine.

They also must meet the following qualifications:

■ have received instruction on how to properly use the machine

■ are familiar with required safety devices

The machine must not be accessed or operated by:

■ children

■ people impaired by alcohol or drugs

Application

area

Safety

devices,

controls, and

attachments

Be aware of the application area.

■ Keep unauthorized personnel, children, and pets away from the machine.

■ Remain aware of changing positions and the movement of other equipment and

personnel in the application area/job site.

■ Identify whether special hazards exist in the application area, such as toxic

gases, or unstable ground conditions, and take appropriate action to eliminate

the special hazards before using the machine.

Be aware of the application area.

■ Do not operate the machine in areas that contain flammable objects, fuels, or

products that produce flammable vapors.

Only operate the machine when:

■ All safety devices and guards are in place and in working order.

■ All controls operate correctly.

■ The machine is set up correctly according to the instructions in the Operator’s

Manual.

■ The machine is clean.

■ The machine’s labels are legible.

To ensure safe operation of the machine:

■ Do not operate the machine if any safety devices or guards are missing or

inoperative.

■ Do not modify or defeat the safety devices.

■ Only use accessories or attachments that are approved by Wacker Neuson.

wc_tx003567gb_FM10.fm

15

Page 16

Safety Information

Mobile Generator

Safe

operating

practices

Personal

Protective

Equipment

(PPE)

After use

When operating this machine:

■ Remain aware of the machine’s moving parts. Keep hands, feet, and loose

clothing away from the machine’s moving parts.

When operating this machine:

■ Do not operate a machine in need of repair.

■ Do not consume the operating fluids used in this machine. Depending on your

machine model, these operating fluids may include water, wetting agents, fuel

(gasoline, diesel, kerosene, propane, or natural gas), o il, coolant, hydraulic fluid,

heat transfer fluid (propylene glycol with additives), battery acid, or grease.

Wear the following Personal Protective Equipment (PPE) while operating this

machine:

■ Close-fitting work clothes that do not hinder movement

■ Safety glasses with side shields

■ Hearing protection

■ Safety-toed footwear

■ Stop the engine when the machine is not being operated.

■ Close the fuel valve on engines equipped with one when the machine is not

being operated.

■ Ensure that the machine will not tip over, roll, slide, or fall when not being

operated.

■ Store the machine properly when it is not being used. The machine should be

stored in a clean, dry location out of the reach of children.

16

wc_tx003567gb_FM10.fm

Page 17

Mobile Generator

1.4 Service Safety

Safety Information

Service

training

Precautions

Before servicing or maintaining the machine:

■ Read and understand the instructions contained in all manuals delivered with

the machine.

■ Familiarize yourself with the location and proper use of all controls and safety

devices.

■ Only trained personnel shall troubleshoot or repair problems occurring with the

machine.

■ Contact Wacker Neuson for additional training if necessary.

When servicing or maintaining this machine:

■ Do not allow improperly trained people to service or maintain the machine.

Personnel servicing or maintaining the machine must be familiar with the

associated potential risks and hazards.

Follow the precautions below when servicing or maintaining the machine.

■ Read and understand the service procedures before performing any service to

the machine.

■ All adjustments and repairs must be completed before operating the machine.

Do not operate the machine with a known problem or deficiency.

■ All repairs and adjustments shall be completed by a qualified technician.

■ Turn off the machine before performing maintenance or making repairs.

■ Remain aware of the machine’s moving parts. Keep hands, feet, and loose

clothing away from the machine’s moving parts.

■ Re-install the safety devices and guards after repair and maintenance

procedures are complete.

Machine

modifications

Replacing

parts and

labels

Cleaning

wc_tx003567gb_FM10.fm

When servicing or maintaining the machine:

■ Use only accessories/attachments that are approved by Wacker Neuson.

When servicing or maintaining the machine:

■ Do not defeat safety devices.

■ Do not modify the machine without the express written approval of Wacker

■ Replace worn or damaged components.

■ Replace all missing and hard-to-read labels.

■ When replacing electrical components, use components that are identical in

■ When replacement parts are required for this machine, use only Wacker

When cleaning and servicing the machine:

■ Keep the machine clean and free of debris such as leaves, paper, cartons, etc.

■ Keep the labels legible.

Neuson.

rating and performance to the original components.

Neuson replacement parts or those p arts equivalent to the original in a ll types of

specifications, such as physical dimensions, type, strength, and material.

17

Page 18

Safety Information

When cleaning the machine:

■ Do not clean the machine while it is running.

■ Never use gasoline or other types of fuels or flammable solvents to clean the

machine. Fumes from fuels and solvents can become explosive.

Mobile Generator

Personal

Protective

Equipment

(PPE)

Electrical

service safety

Cooling

system safety

Wear the following Personal Protective Equipment (PPE) while servicing or

maintaining this machine:

■ Close-fitting work clothes that do not hinder movement

■ Safety glasses with side shields

■ Hearing protection

■ Safety-toed footwear

In addition, before servicing or maintaining the machine:

■ Tie back long hair.

■ Remove all jewelry (including rings).

■ Make sure clothing and shoes are dry , st and on a dry wooden plat form or rubber

insulating mat, and use tools with insulated handles when servicing the

machine.

■ Do not allow water to accumulate around the base of the machine. If water is

present, move the machine and allow the machine to dry before servicing.

■ Do not pressure wash the control panel, generator end, or any other electrical

components when cleaning the machine.

■ Do not attempt to open the radiator cap while the unit is running or before the

engine has cooled down. Severe burns may result!

■ Engine coolant is toxic to humans and animals. Clean up spills and dispose of

waste engine coolant in accordance with local environmental regulations.

18

wc_tx003567gb_FM10.fm

Page 19

Mobile Generator

Safety Information

1.5 Operator Safety while Using Internal Combustion Engines

WARNING

Internal combustion engines present special hazards during operation and fueling.

Failure to follow the warnings and safety standards could result in severe injury or

death.

► Read and follow the warning instructions in the engine owner’s manual and the

safety guidelines below.

DANGER

Exhaust gas from the engine contains carbon monoxide, a deadly poison.

Exposure to carbon monoxide can kill you in minutes.

► NEVER operate the machine inside an enclosed area, such as a tunnel, unless

adequate ventilation is provided through such items as exhaust fans or hoses.

Operating

safety

Refueling

safety

When running the engine:

■ Keep the area around exhaust pipe free of flammable materials.

■ Check the fuel lines and the fuel tank for leaks and cracks before starting the

engine. Do not run the machine if fuel leaks are present or the fuel lines are

loose.

When running the engine:

■ Do not smoke while operating the machine.

■ Do not run the engine near sparks or open flames.

■ Do not touch the engine or muffler while the engine is running or immediately

after it has been turned off.

■ Do not operate a machine when its fuel cap is loose or missing.

■ Do not start the engine if fuel has spilled or a fuel odor is present. Move the

machine away from the spill and wipe the machine dry before starting.

When refueling the engine:

■ Clean up any spilled fuel immediately.

■ Refill the fuel tank in a well-ventilated area.

■ Re-install the fuel tank cap after refueling.

■ Use suitable tools for refueling (for example, a fuel hose or funnel).

When refueling the engine:

■ Do not smoke.

■ Do not refuel a hot or running engine.

■ Do not refuel the engine near sparks or open flames.

wc_tx003567gb_FM10.fm

19

Page 20

Safety Information

1.6 Safety Guidelines for Mobile Generators

DANGER

Carbon monoxide. Using a generator indoors CAN KILL YOU IN MINUTES.

Generator exhaust contains carbon monoxide (CO). This is a poison you cannot

see or smell. If you can smell the generator exhaust, you are breathing CO. But

even if you cannot smell the exhaust, you could be breathing CO.

► NEVER use a generator inside homes, garages, crawlspaces, or other partly

enclosed areas. Deadly levels of carbon monoxide can build up in these areas.

Using a fan or opening windows and doors does NOT supply enough fresh air.

► ONLY use a generator outside and far away from windows, doors, and vents.

These openings can pull in generator exhaust.

► Even when you use a generator correctly , CO may leak into the home. ALWA YS

use a battery-powered or battery-backup CO alarm in the home.

► If you start to feel sick, dizzy, or weak after the generator has been running,

move to fresh air RIGHT AW AY. See a doctor. You could have carbon monoxide

poison.

Mobile Generator

Installing as

backup power

WARNING

Electrocution hazard. Machines that generate electric power present special

hazards while the engine is running. These include the risk of electrocution or

severe electrical shock.

► Read and follow the instructions in this Operator’s Manual.

Special hazards exist when installing this machine as a backup power supply.

Improper connection of generator to a building’s electrical system can allow

electrical current from the generator to backfeed into utility lines. This may result in

electrocution of utility workers, fire, or explosion.

WARNING

Backfeed from the generator into the public power distribution system can cause

serious injury or death to utility workers!

► Connections to a building’s electrical system must be made by a qualified elec-

trician and comply with all applicable laws and electrical codes.

If connected to a building’s electrical system, the generator must meet the power,

voltage, and frequency requirements of the equipment in the building. Differences

in power, voltage, and frequency requirements may exist and improper connectio n

may lead to equipment damage, fire, and personal injury or death.

20

wc_tx003567gb_FM10.fm

Page 21

Mobile Generator

Safety Information

General safety

Ground

connection

■ Do not use evaporative starting fluids to start the engine. They are highly

explosive.

■ Do not store items such as excess oil, rags, or tools on top of or inside the

machine. These items are a fire hazard and can restrict cooling air.

■ Ensure that electrical cords attached to the machine are in serviceable condition

without cuts, cracks, or exposed wires.

■ Do not route electrical cords over vibrating or hot parts of the machine.

■ Do not stand on the machine.

■ Do not enclose or cover the machine when it is use, or when it is hot.

The generator must be connected to a good earthen ground for proper operating

safety.

A central “equipment ground” is provided at the customer connection lugs. This

point is connected directly to the generator set base. All other system grounds are

connected to this central point. Ground the generator in accordance with the

standards defined in national, state, and local regulations.

wc_tx003567gb_FM10.fm

21

Page 22

Safety Information

1.7 Safety Guidelines for Towing the Machine

WARNING

Risk of severe injury or death. Improper trailer condition and towing technique can

lead to an accident.

► Obey the trailer manufacturer’s instructions and the instructions below to reduce

the risk of an accident.

When towing the machine:

■ Do not tow the machine if the towing vehicle’s hitch or the trailer’s coupler are

damaged.

■ Do not tow the machine if any of the trailer’s lug nuts are missing.

■ Do not tow the machine if the trailer’s tires have less than 1.5 mm (1/16 inch) of

tread.

■ Do not tow the machine unless the trailer’s brakes are functioning properly.

■ Do not exceed the trailer manufacturer’s speed limitations.

When towing the machine:

■ Only tow the machine when the trailer’s lug nuts are properly torqued.

■ Only tow the machine when the trailer’s tires are properly inflated.

■ Only tow the machine when all trailer lights are functioning correctly.

■ Only tow the machine when the trailer’s safety chains are connected to the

towing vehicle in a crisscross pattern.

■ Maintain extra distance between the towing vehicle and other vehicles.

■ Avoid soft shoulders, curbs, and sudden lane changes.

■ Abide by all licensing requirements for your area.

Mobile Generator

If you have not driven a towing vehicle with trailer before, practice turning,

stopping, and backing up the towing vehicle with trailer in an area away from traffic.

Only drive the towing vehicle with trailer when you are confident in your ability to do

so.

wc_tx003567gb_FM10.fm

22

Page 23

Mobile Generator

1.8 Safety Guidelines for Lifting the Machine

When lifting the machine:

■ Make sure slings, chains, hooks, ramps, jacks, forklifts, cranes, hoists, and any

other type of lifting device used is attached securely and has enough weightbearing capacity to lift or hold the machine safely. See section Technical Data

for machine weight.

■ Remain aware of the location of other people when lifting the machine.

■ Only use the lifting points and tie downs described in the Operator’s Manual.

■ Make sure the transporting vehicle has sufficient load cap acity and platform size

to safely transport the machine.

To reduce the possibility of injury:

■ Do not stand under the machine while it is being lifted or moved.

■ Do not get onto the machine while it is being lifted or moved.

1.9 Reporting Safety Defects

Safety Information

If you believe your trailer has a defect which could cause a crash or could cause

injury or death, you should immediately inform the National Highway Traffic Safety

Administration (NHTSA) in addition to notifying Wacker Neuson.

If NHTSA receives similar complaints, it may open an investigation; and if it finds

that a safety defect exists in a group of trailers, it may order a recall and remedy

campaign. However, NHTSA cannot become involved in individual problems

between you, your dealer, or Wacker Neuson.

To contact NHTSA, you may either contact the Vehicle Safety Hotline toll-free at

1-888-327-4236 (TTY: 1-800-424-9153); go to http://www.safercar.gov; or write to:

Administrator

NHTSA

1200 New Jersey Avenue S.E.

Washington, DC 20590

You can also obtain other information about your motor vehicle safety from

http://www.safercar.gov

wc_tx003567gb_FM10.fm

23

Page 24

Label Locations G 25

GG

GG

JJ

C

H

F

VV

EE

K

E

W

D

X

wc_gr011688

2 Label Locations

24

wc_si000835gb_FM10.fm

Page 25

wc_gr011684

A

Ø

HZ

V

R

Basler

DIAGNOSTICS

DIAGNOSEN

DIAGNOSTICOS

DIAGNOSTICS

AUSAUS

APAGADOAPAGADO

ARRETARRET

OFFOFF

REMOTE STARTREMOTE START

FERNSTARTFERNSTART

ARRANQUE REMOTOARRANQUE REMOTO

DEMARRAGE A DEMARRAGE A

DISTANCEDISTANCE

START / LAUFENSTART / LAUFEN

ARRANQUE / MARCHAARRANQUE / MARCHA

DEMARRER / MARCHEDEMARRER / MARCHE

START / RUNSTART / RUN

T4i

T4f

J J

B

D

I

G

C

P

M

M

JT J

SS TT

RR

DD

JJ

AAMM

FF

G

NO

KK

L

CC

Y

Z S V R N

Q1

BB

QQ

Q2

I

X

G 25 Label Locations

wc_si000835gb_FM10.fm

25

Page 26

Label Meanings G 25

INSTRUCCIONES DE REMOLQUEINSTRUCCIONES DE REMOLQUE

1.LEA EL MANUAL DEL OPERARIO.1.LEA EL MANUAL DEL OPERARIO.

2.UTILICE UN ACOPLE CORRECTAMENTE 2.UTILICE UN ACOPLE CORRECTAMENTE

CLASIFICADO PARA LA "CLASE DE PESO CLASIFICADO PARA LA "CLASE DE PESO

BRUTO" DEL VEHICULO DEL REMOLQUE. BRUTO" DEL VEHICULO DEL REMOLQUE.

3.ASEGURESE DE AMARRAR CORRECTAMENTE EL 3.ASEGURESE DE AMARRAR CORRECTAMENTE EL

REMOLQUE AL VEHICULO DE REMOLQUE. REMOLQUE AL VEHICULO DE REMOLQUE.

4.FIJE EN CRUZ LAS CADENAS DE SEGURIDAD.4.FIJE EN CRUZ LAS CADENAS DE SEGURIDAD.

5.FIJE EN EL VEHICULO DE REMOLQUE 5.FIJE EN EL VEHICULO DE REMOLQUE

LA CADENA DE DESPRENDIMIENTO. LA CADENA DE DESPRENDIMIENTO.

6.CONTROLE LAS LUCES DEL REMOLQUE.6.CONTROLE LAS LUCES DEL REMOLQUE.

1.READ OPERATOR'S MANUAL. 1.READ OPERATOR'S MANUAL.

2.USE HITCH RATED FOR TRAILER'S 2.USE HITCH RATED FOR TRAILER'S

"GROSS VEHICLE WEIGHT RATING". "GROSS VEHICLE WEIGHT RATING".

3.SECURELY ATTACH TRAILER TO TOW VEHICLE.3.SECURELY ATTACH TRAILER TO TOW VEHICLE.

4.ATTACH SAFETY CHAINS USING CROSS 4.ATTACH SAFETY CHAINS USING CROSS

PATTERN. PATTERN.

5.ATTACH BREAKDOWN CHAIN TO VEHICLE.5.ATTACH BREAKDOWN CHAIN TO VEHICLE.

6.CHECK TRAILER LIGHTS.6.CHECK TRAILER LIGHTS.

TOWING INSTRUCTIONSTOWING INSTRUCTIONS ABSCHLEPPINSTRUKTIONENABSCHLEPPINSTRUKTIONEN

1.BETRIEBSVORSCHRIFT LESEN.1.BETRIEBSVORSCHRIFT LESEN.

2.ANHANGEVORRICHTUNG VERWENDEN, 2.ANHANGEVORRICHTUNG VERWENDEN,

DIE DER GESAMTBETRIEBSGEWICHTSKLASSE DIE DER GESAMTBETRIEBSGEWICHTSKLASSE

ENTSPRICHT. ENTSPRICHT.

3.ANHANGER SICHER AM ZUGFAHRZEUG 3.ANHANGER SICHER AM ZUGFAHRZEUG

BEFESTIGEN. BEFESTIGEN.

4.SICHERHEITSKETTEN KREUZWEISE ANBRINGEN.4.SICHERHEITSKETTEN KREUZWEISE ANBRINGEN.

5.ABREISSKETTE AM FAHRZEUG ANBRINGEN.5.ABREISSKETTE AM FAHRZEUG ANBRINGEN.

6.ANHANGERLEUCHTEN PRUFEN.6.ANHANGERLEUCHTEN PRUFEN.

....

....

....

....

INSTRUCTIONS DE REMORQUAGEINSTRUCTIONS DE REMORQUAGE

1.LIRE LA NOTICE D'EMPLOI.1.LIRE LA NOTICE D'EMPLOI.

2.UTILISER UN CROCHET D'ATTELAGE CONFORME2.UTILISER UN CROCHET D'ATTELAGE CONFORME

AU DEBIT NOMINAL DU POIDS BRUT DE AU DEBIT NOMINAL DU POIDS BRUT DE

VEHICULE DU VEHICULE TRACTEUR. VEHICULE DU VEHICULE TRACTEUR.

3.ATTACHER LA REMORQUE FERMEMENT AU 3.ATTACHER LA REMORQUE FERMEMENT AU

VEHICULE TRACTEUR. VEHICULE TRACTEUR.

4.ATTACHER LES CHAINES DE SURETE EN 4.ATTACHER LES CHAINES DE SURETE EN

UTILISANT UNE METHODE CROISEE. UTILISANT UNE METHODE CROISEE.

5.ATTACHER LA CHAINE DE REMORQUAGE AU VEHICULE.5.ATTACHER LA CHAINE DE REMORQUAGE AU VEHICULE.

6.VERIFIER LES LAMPES DE LA REMORQUE.6.VERIFIER LES LAMPES DE LA REMORQUE.

117960117960

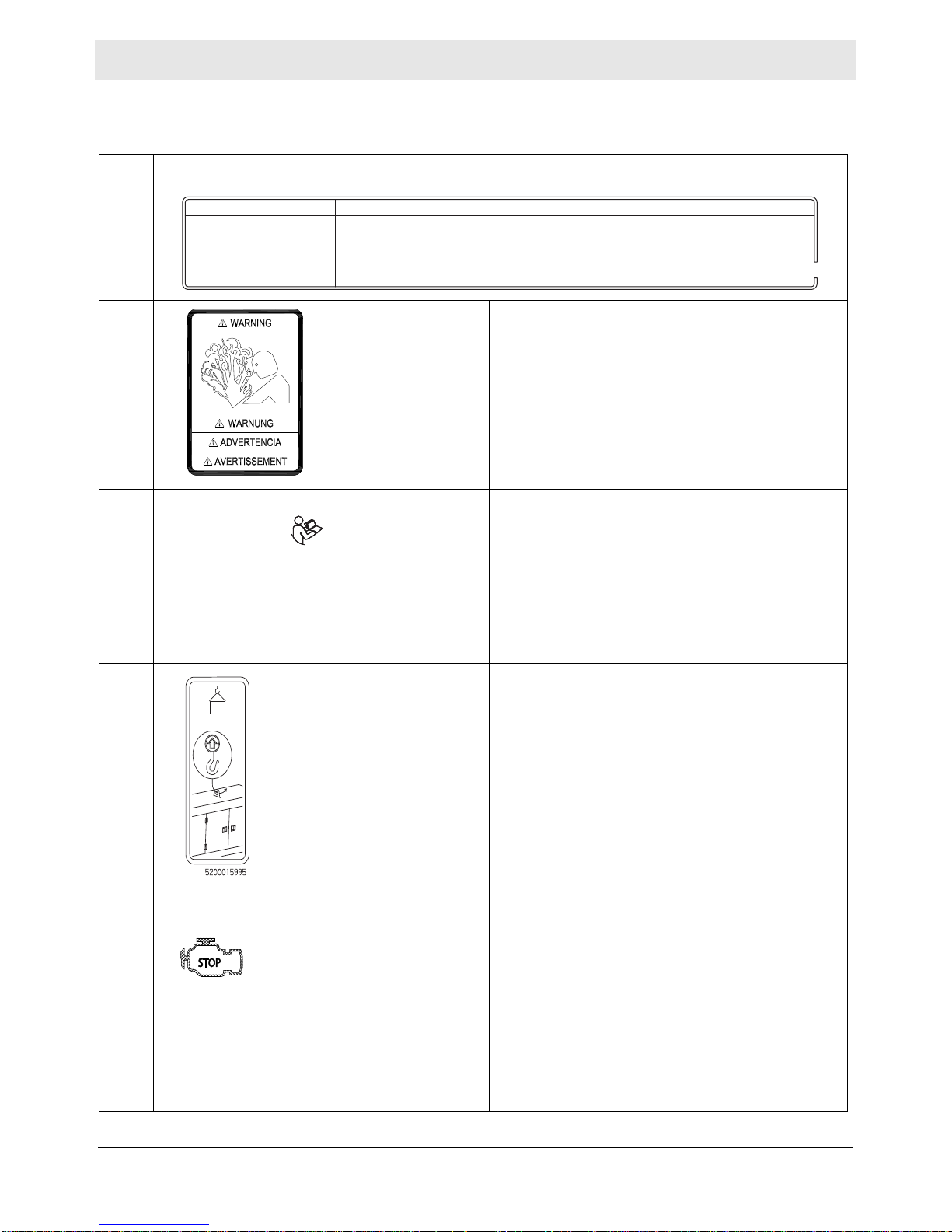

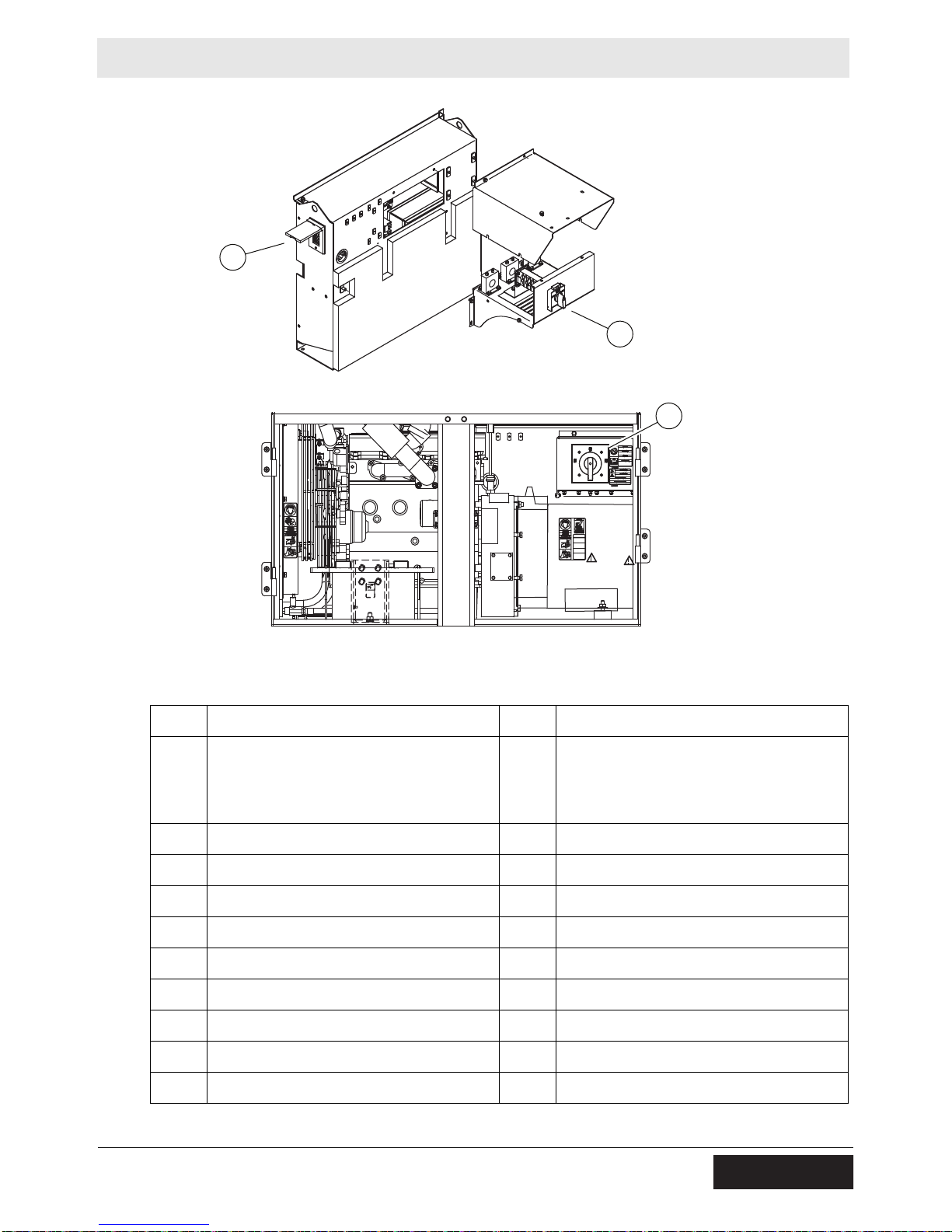

3 Label Meanings

A

(on trailer , if equipped)

B WARNING

Pressurized contents. Do not open when hot!

C WARNING

Lock doors. Access can cause electric shock or

injury.

D NOTICE

Lifting point

E NOTICE

Never change switch position with engine

running. Results in damage to machine.

26

wc_tx003634gb_FM10.fm

Page 27

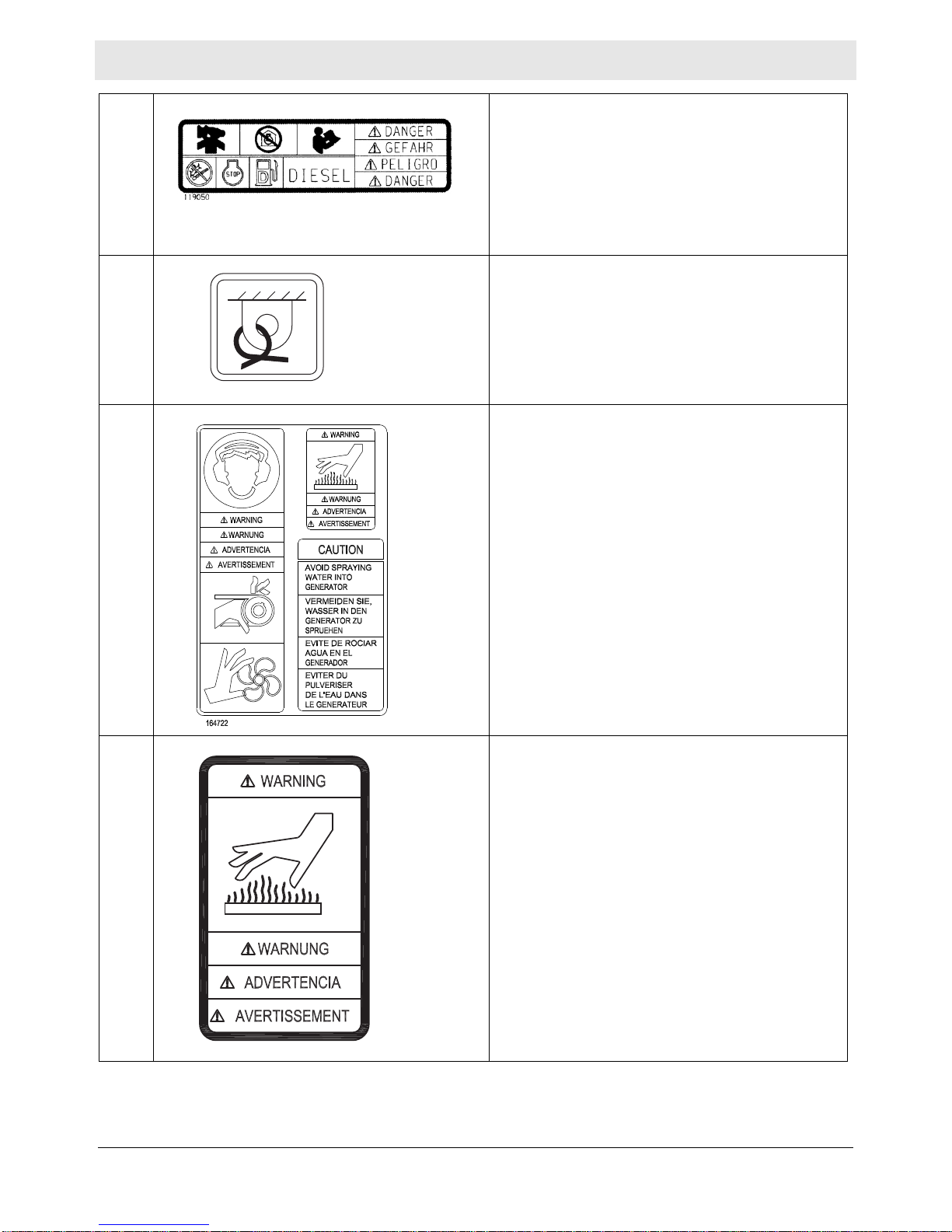

G 25 Label Meanings

113726

F DANGER

Asphyxiation hazard. Do not run the machine

indoors or in an enclosed area without adequate

ventilation. Read the Operator’s Manual for

instructions. No sparks, flames, or burning

objects near machine. Stop the engine before

adding fuel. Use only diesel fuel.

G Tie-down point

113726

H WARNING

To prevent hearing loss, wear hearing protection.

Hand injury if entangled in moving belt.

Rotating machinery! Do not reach inside with

engine running.

WARNING

Hot surface

CAUTION

Avoid spraying water into generator.

I WARNING

Hot surface

wc_tx003634gb_FM10.fm

27

Page 28

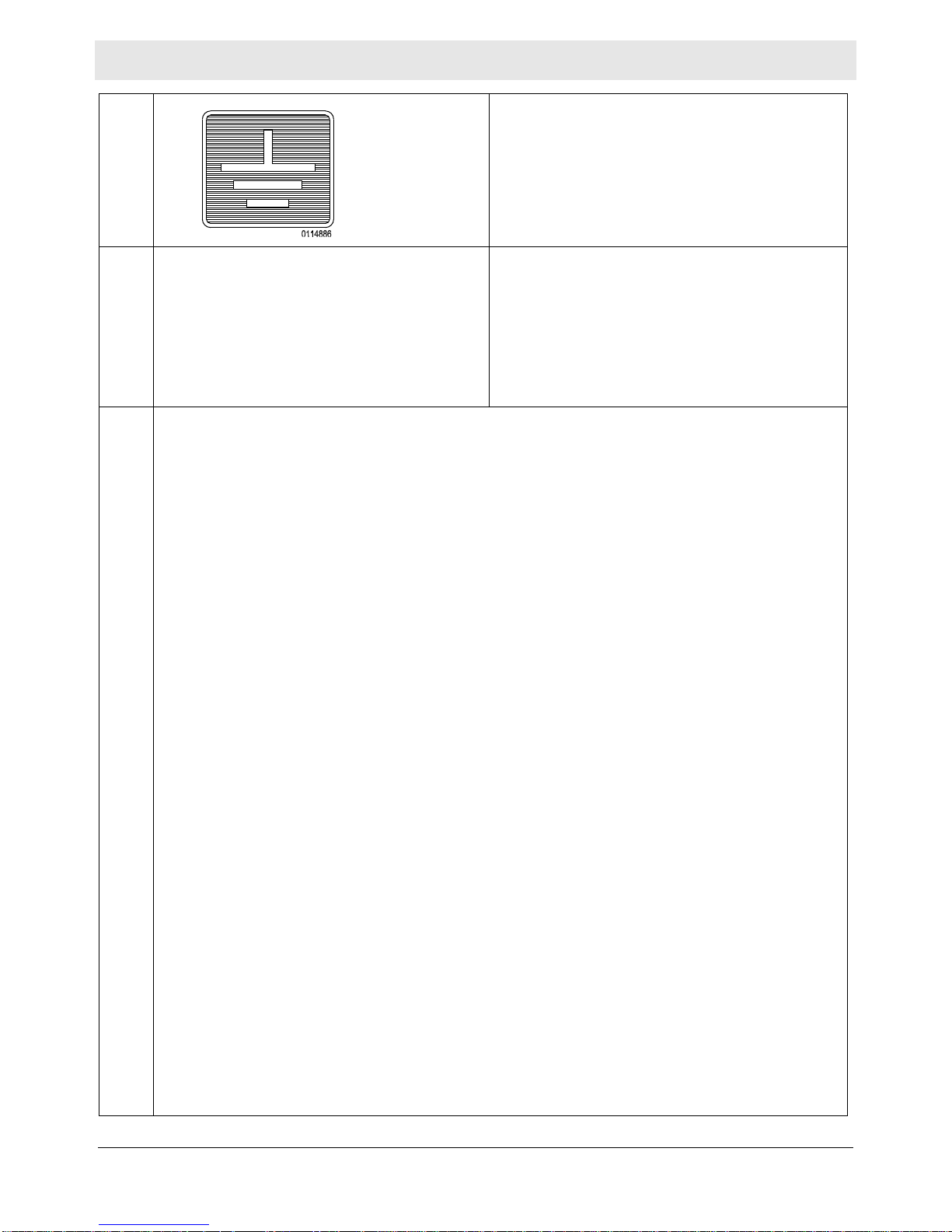

Label Meanings G 25

J Electrical ground

K WARNING

Electric shock and arc flash can cause serious

injury or death.

L

28

wc_tx003634gb_FM10.fm

Page 29

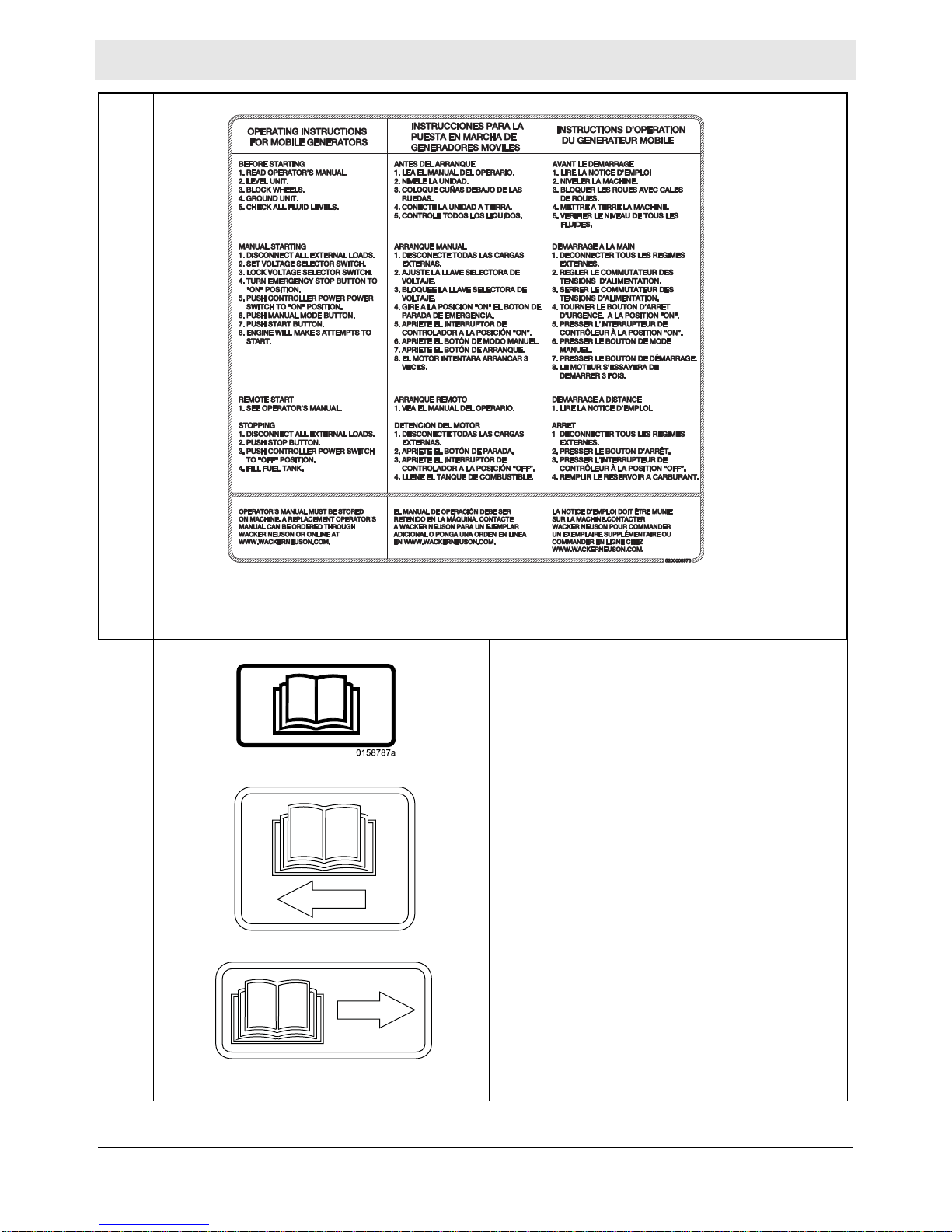

G 25 Label Meanings

L

M Operator’s Manual must be stored on machine.

Replacement Operator’s Manual can be ordered

through your local Wacker Neuson distr ibutor.

wc_sy0158787

wc_sy0160602

wc_tx003634gb_FM10.fm

29

Page 30

Label Meanings G 25

AND

N WARNING!

Operation of this equipment may create sparks

Operation of This Equipment May Create Sparks That Can Start Fires Around Dry

Vegetation. A Spark Arrestor May be Required. The Operator Should Contact Local

Fire Agencies For Laws or Regulations Relating to Fire Prevention Requirements.

WARNING

Per CAL. PRC. CODE

P Read and understand the supplied Operator’s

Q1 WARNING

that can start fires around dry vegetation. A sp ark

arrestor may be required. The operator should

contact local fire agencies for laws or regulations

relating to fire prevention requirements.

Manual before operating the machine. Failure to

do so increases the risk of injury to yourself and

others.

To reduce the risk of electrical shock and arc

flash, read the Operator’s Manual. Improper

connection of the generator to a building’s

electrical system can allow electrical current from

the generator to backfeed into utility lines. This

may result in electrocution of utility workers, fire,

or explosion. Connections to a building’s

electrical system must be made by a qualified

electrician and comply with all applicable laws

and electrical codes.

Q2 Voltage selector label

R Remote start operation. Read Operator’s Manual

for instructions.

S CAUTION

Receptacles not to be used when:

Selector switch set to 208/120V and voltage

greater than 228V.

Selector switch set to 480/277V and voltage

greater than 457V.

30

wc_tx003634gb_FM10.fm

Page 31

G 25 Label Meanings

T WARNING

Disconnect battery before servicing.

Read the Operator’s Manual.

U

(on trailer, if equipped)

W Drain containment system.

X WARNING

To prevent hearing loss, wear hearing protection

when operating the machine.

WARNING

Pressurized contents. Do not open when hot!

WARNING

Hand injury if entangled in moving belt.

WARNING

Rotating machinery! Do not reach inside

machine with engine running.

wc_tx003634gb_FM10.fm

31

Page 32

Label Meanings G 25

Y Operating the main circuit breaker supplies or

interrupts power to the customer connection lugs.

Z Neutral bonded to frame

AA Fuses

Read the Operator’s Manual for machine

information.

BB WARNING

CC Generator and receptacle wiring

Electric shock at cooling fins.

wc_tx003634gb_FM10.fm

32

Page 33

G 25 Label Meanings

DD Engine wiring

EE WARNING

Hot surface

FF (if equipped)

Battery disconnect must be in “ON” position to

start engine.

NOTICE

Do not use the battery disconnect switch while

engine is running. Damage to the electrical

components may occur.

GG Low sulfur fuel or ultra low sulfur fuel only.

JJ Protecting Our Environment

Fluid containment system

wc_tx003634gb_FM10.fm

33

Page 34

Label Meanings G 25

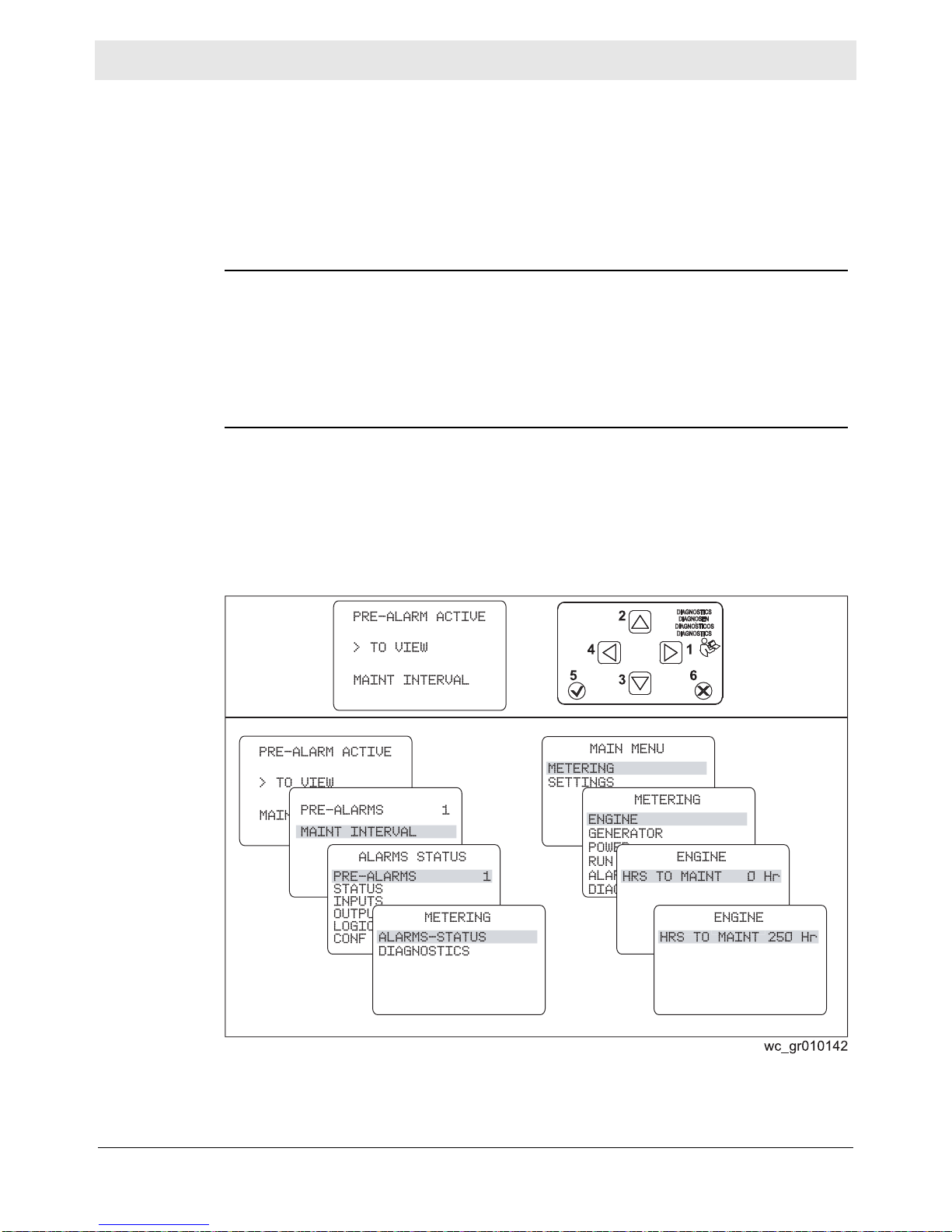

KK Diagnostic menu navigation

MM This machine may be covered by one or more

patents.

NN

QQ (Camlock models only)

RR (Camlock models only)

(on trailer , if equipped)

(On trailer, if equipped)

Certification Label (VIN Number)

Also attached to each unit is a Certification Label.

This label specifies that the trailer conforms with

all Federal Motor Vehicle Standards in effect at

the time of manufacture. The label includes the

Vehicle Identification Number (VIN) for the trailer.

Lug door must be closed for lugs and recept acles

to energize.

WARNING

Electric shock can cause serious injury or death.

34

wc_tx003634gb_FM10.fm

Page 35

G 25 Label Meanings

0183199

SS (Camlock models only)

NOTICE

Separate overcurrent protection must be

provided. Do not exceed 400 amps per

receptacle.

TT (Camlock models only)

WARNING

Electric shock and arc flash can cause serious

injury or death.

UU WARNING

Explosion hazard. Do not use evaporative

starting fluids such as ether on this engine. The

engine is equipped with a cold starting aid. Using

evaporative starting fluids can cause an

explosion which can cause engine damage,

personal injury, or death. Read and follow the

engine starting instructions in this Operator's

Manual.

V V WARNING

Keep all sparks and open flames away from

the battery.

Wear eye protection.

Keep away from children.

0183199

Battery acid is poisonous and corrosive.

Read the Operator’s Manual.

Explosion hazard.

Dispose of waste batteries in accordance with

local environmental regulations. Battery contains

mercury (Hg), cadmium (Cd), or lead (Pb).

WW WARNING

Operation of this equipment may create sparks

that can start fires around dry vegetation. A spark

arrester may be required. The operator should

contact local fire agencies for laws or regulations

relating to fire prevention requirements.

wc_tx003634gb_FM10.fm

35

Page 36

Lifting and Transporting

4 Lifting and Transporting

4.1 Lifting the Machine

Mobile Generator

Requirements

Lifting the

machine

■ Lifting equipment (crane, hoist, or fork truck) capable of supporting the

machine’s weight

■ Lifting devices (hooks, chains, and shackles) capable of supporting the

machine’s weight

■ Engine stopped

A lifting eye is used for lifting the machine.

wc_gr011429

Perform the procedure below to lift the machine.

1. Attach the lifting devices and equipment to the lifting eye. Do not attach lifting

devices to any other part of the machine.

2. Lift the machine a small distance.

WARNING

Crushing hazard. An unstable machine may cause the lifting devices and

equipment to fail. You may be crushed if the lifting devices and equipment fail.

► Check for stability before continuing.

3. Check for stability . If necessary, lower the machine, reposition the lifting devices,

and lift the machine a small distance again.

4. Continue lifting the machine only when it is stable.

36

wc_tx003570gb_FM10.fm

Page 37

Mobile Generator

4.2 Before Towing Checklist

Before towing the machine, check the licensing requirements for trailers in your

area. Also check the following items:

Towing vehicle

Check that the towing vehicle is rated to tow the load.

Check that the towing vehicle is in serviceable condition.

Do any necessary service/maintenance on the towing vehicle.

Hitch and coupler

Check that the towing vehicle and hitch have a rating equal to or greater than

the GVWR of the machine. See Technical Data.

Check that the hitch of the towing vehicle and coupler of the trailer are compatible.

Check the condition of both the coupler and the hitch.

Check that all fasteners on the coupler are tight.

Check that the coupler has fresh grease applied to it.

Wheels

Check that wheel chocks are available at the work site.

Check that all lug nuts are in place and are properly torqued.

Check the tread wear of the tires.

Check that the tires are inflated to the proper pressure.

Lifting and Transporting

Trailer preparation

Check that all doors and access panels are closed and latched.

Check that outriggers (if applicable) are retracted.

Check local regulations regarding hazardous materials placards. If applicable,

install the appropriate placards.

Trailer operation

Check that the trailer jacks are in the traveling (horizontal) position.

Check that the directional and running lights on the trailer function correctly.

Check that the safety chains of the trailer are connected to the towing vehicle

using a crisscross pattern.

Check the operation of the trailer brakes by brakin g the towing vehicle at a slow

speed. Both the vehicle and the trailer must brake smoothly. If the trailer pushes,

check the fluid level in the surge brakes or the operation of the electric brakes.

Check tha t the trailer’s breakaway cable (if applicable) is attached to the towin g

vehicle.

Test the function of the breakaway system (if applicable).

wc_tx003570gb_FM10.fm

37

Page 38

Lifting and Transporting

wc_gr011430

b

a

c

4.3 Towing the Machine

Mobile Generator

Background

Brakes

Licensing

requirements

The generator’s trailer is equipped with brakes (surge or electric), safety chains (a),

lights, and a coupler (pintle or ball-type) (b).

Only use the brakes as designed.

■ The breakaway cable (c) is not a parking brake and should not be used as one.

■ In most states, large trailers must be registered and licensed by the State

Department of Transportation. Before towing, be sure to check licensing

requirements.

■ Drivers towing trailers may be required to carry a commercial driver’s license

(CDL). Check your local and state licensing regulations before towing the

generator.

Coupler

maintenance

Towing safety

■ A film of grease on the coupler will extend coupler life and eliminate squeaking.

Wipe the coupler clean and apply fresh grease each time the trailer is towed.

■ When towing, maintain extra space between vehicles and avoid soft shoulders,

curbs and sudden lane changes. If you have not pulled a trailer before, practice

turning, stopping, and backing up in an area away from heavy traffic.

■ Do not exceed 55 mph when towing a trailer.

38

wc_tx003570gb_FM10.fm

Page 39

Mobile Generator

Lifting and Transporting

4.4 Preparing the Machine for Transport on a Truck or Trailer

Requirements

Checklist

■ Machine stopped

■ Flatbed truck or trailer capable of supporting the machine’s weight

■ Chains, hooks, or straps capable of supporting the machine’s weight

WARNING

Crushing hazard. Improperly securing the machine can lead to a crushing hazard.

► Use only the designated tie-down points to secure the machine to a truck or

trailer.

Before transporting the machine, check the following items:

Machine

Check that all accessories are securely stored within the machine.

Check that all doors and access panels of the machine are closed.

Check that all electrical supplies are disconnected from the machine.

For machines with external fuel supplies, check that all fuel supplies are

disconnected from the machine.

For machines with generators, check that the generator is shut down.

Loading and transporting equipment

Check t hat the transport vehicle or trailer can sup port the weight of the machine.

Check that the transport vehicle or trailer is wide enough to support the

machine.

Check that the wheels of the transport vehicle or trailer are chocked during the

loading process.

Check that the transport vehicle or trailer is clean and free of grease, oil, ice,

and other loose material.

If the machine is mounted to a trailer, check that the jackstand or other transport

block (piece of wood or other similar material) is available to support the trailer

tongue during transporting. Do not use the machine’s trailer jack to support the

trailer tongue during transporting.

Check that any ramps used in the loading process:

■ Can support the weight of the machine.

■ Are clean and free of grease, oil, ice, and other loose material.

■ Are securely connected to the transport vehicle or trailer.

■ Are of sufficient length to keep the loading angle 15° or less.

In addition:

Check that the loading area is flat and the ground is stable.

Check the overall height of the machine once it is loaded on the truck or trailer.

Plan your travel route so there will be adequate clearance for overpasses, road

signs, buildings, etc.

Check local regulations regarding transporting and obey these regulations.

wc_tx003570gb_FM10.fm

39

Page 40

Lifting and Transporting

4.5 Hazardous Materials Placards

Mobile Generator

Overview

Requirements

Hazardous materials placards may have been provided with your machine.

Transport Canada, and the Canadian Transportation of Dangerous Goods Act,

require that these hazardous materials placards be permanently applied to certain

machines if they are to be transported or towed on Canadian roads.

Contact Transport Canada if you have questions about driver’s licensing

requirements for transporting machines that bear hazardous materials placard, or

questions about other restrictions for use of this machine

Note: The owner/operator of this machine is responsible for applying the placards.

Use the procedure described below.

wc_gr009231

■ Placard mounting surfaces and surrounding ambient temperature should be

at least 10°C (50°F). In colder conditions, see application step 2 below.

■ Mild soap or detergent

■ Fresh, clean, warm water supply

■ Isopropyl (rubbing) alcohol, lacquer thinner, or mineral spirits

■ Soft, clean, dry cloths

■ Plastic squeegee or stiff cardboard

Apply the

Placards

Four placards have been provided with this machine—one for each side, one for

the front, and one for the back.

To apply the placards, do the following.

1. Clean the placard mounting surfaces with mild soap and water. Dry thoroughly.

2. Use isopropyl (rubbing) alcohol to clean the placard mounting surfaces if:

■ they, and the surrounding ambient temperature, are below 10°C (50°F)

■ the placard mounting surfaces are covered with grease and oil.

3. Peel about 2 cm (1 in.) of backing paper from the top of the placard. Fold the

backing paper away from the placard.

4. Apply the top of the placard to the mounting surface. Gradually remove the

backing paper and apply the remainder of the placard. Firmly press and smooth

the placard into place with a plastic squeegee, stiff cardboard, or a soft cloth.

Puncture any air bubbles that may form.

40

wc_tx003570gb_FM10.fm

Page 41

Mobile Generator

wc_gr008509

a

Lifting and Transporting

4.6 Testing the Breakaway System (Hydraulic Surge Brakes)

Requirements

When

Procedure

■ Hydraulic reservoir filled

■ Machine parked on a flat surface

Test the breakaway system:

■ Before towing

■ After filling the hydraulic reservoir

Perform the following procedure to test the breakaway system.

1. Position the machine/trailer on a flat surface.

2. Connect the breakaway cable (a) to the tow vehicle. Do not connect the

machine/trailer to the tow vehicle via the hitch.

b

wc_gr008508

3. Slowly move the tow vehicle so that it pulls on the breakaway cord until the

emergency lever reaches its second notch (b) and locks into the ON position.

4. Connect the machine/trailer to the tow vehicle via the hitch.

5. Attempt to tow the machine/trailer at a very slow speed (less than 5 mph). When

activated, a properly working breakaway system will cause substantial drag on

the trailer wheels and may even cause the trailer wheels to lock.

WARNING

Personal injury hazard. A faulty breakaway system may lead to an accident and

personal injury if the machine/trailer breaks away.

► Do not tow the machine/trailer if the breakaway system is faulty.

6. If the brakes did not function, repair any faults before towing.

This procedure continues on the next page.

wc_tx003570gb_FM10.fm

41

Page 42

Lifting and Transporting

wc_gr008510

c

Continued from the previous page.

7. Stop the tow vehicle.

8. Release the brake by simultaneously pulling on the breakaway cord and prying

the locking spring with a screwdriver (c) or pry bar.

Mobile Generator

Result

The procedure to test the breakaway system is now complete.

42

wc_tx003570gb_FM10.fm

Page 43

Mobile Generator

wc_gr008513

a

Lifting and Transporting

4.7 Testing the Breakaway System (Electric Brakes)

Requirements

When

Procedure

■ Voltmeter

■ Battery charger or backup battery (charged)

Test the breakaway system:

■ Before towing

■ Monthly if the machine is not in service

Perform the following procedure to test the breakaway system.

NOTICE: Disconnect the trailer wiring plug from the tow vehicle before testing.

Failure to do so will result in severe damage to the electronic brake control.

1. Connect the machine/trailer to the tow vehicle.

2. Disconnect the trailer wiring plug (a) from the tow vehicle.

c

b

wc_gr008514

3. Pull the breakaway pin (b) out of the brake switch (c) (to activate the brakes)

and attempt to tow the machine/trailer at a very slow speed (less than 5 mph).

When activated, a properly working breakaway system will cause substantial

drag on the trailer wheels and may even cause the trailer wheels to lock.

4. Stop the tow vehicle.

WARNING

Personal injury hazard. A faulty breakaway system may lead to an accident and

personal injury if the machine/trailer breaks away.

► Do not tow the machine/trailer if the breakaway system is faulty.

This procedure continues on the next page.

wc_tx003570gb_FM10.fm

43

Page 44

Lifting and Transporting

wc_gr008515

d

VDC

1000

200

20

2

200m

F

V

A

V- COM

Continued from the previous page.

5. If the brakes did not function, check the voltage of the breakaway battery.

To do so:

a.Remove the cover of the battery box.

b.Remove the wires connected to the breakaway battery (d).

c.Measure the voltage. If 12–14 VDC is not measured, replace or recharge the

breakaway battery.

Mobile Generator

Result

6. If 12–14 VDC was measured but the brakes did not function, there is a wiring or

mechanical fault with the brakes. Repair any faults before towing.

7. If the brakes function properly:

a.Reconnect the wires to the breakaway battery.

b.Re-install the cover to the battery box.

c.Re-install the breakaway pin (b) into the brake switch.

d.Connect the trailer wiring plug to the tow vehicle.

The procedure to test the breakaway system is now complete.

44

wc_tx003570gb_FM10.fm

Page 45

Mobile Generator

5Machine Setup

5.1 Preparing the Machine for First Use

1. Make sure all loose packaging materials have been removed from the machine.

2. Check the machine and its components for damage. If there is visible damage,

do not operate the machine! Contact your Wacker Neuson dealer immediately

for assistance.

3. Take inventory of all items included with the machine and verify that all loose

components and fasteners are accounted for.

4. Attach component parts not already attached.

5. Add fluids as needed and applicable, including fuel, engine oil, and battery acid.

6. Move the machine to its operating location.

Machine Setup

Safety

information

CO Alarms

■ Do not exceed the power output of the generator . Damage to tools or generator

will occur. Refer to Technical Data.

■ When using the generator as a standby or substitute power supply, make sure

the voltage and phase rotation of the line connections match those of the utility

lines. Failure to match phase rotation and voltage may cause equipment

connected to the generator to operate incorrectly! This could create unsafe

operating conditions.

■ Do not exceed the rated current limit of any receptacle.

■ The bonding bar between the ground connections must remain in place at all

times unless a qualified electrician determines otherwise.

Because this machine produces carbon monoxide (CO), Wacker Neuson

recommends that CO alarms be installed in all structures in close proximity to the

machine. CO alarms provide an extra measure of protection against this poison

that you cannot see or smell.

Install battery-operated CO alarms or plug-in CO alarms with battery backup,

according to the manufacturer’s instructions. CO alarms should be certified to the

requirements of the latest safety standards (UL 2034, IAS 6-96, or CSA 6.19.01).

Test the CO alarm batteries monthly.

wc_tx003572gb_FM10.fm

45

Page 46

Machine Setup

5.2 Positioning the Machine

WARNING

Fire hazard. Do not move the machine while it is running.

► Shut down the machine before moving or repositioning it.

WARNING

Fire hazard. Machines positioned on a hill or an incline may slide, break away or

roll over.

► Do not position the machine on a hill or an incline.

WARNING

Explosion and fire hazard. Risk of severe injury or death.

► Do not operate the machine near flammable vapors, fuels, or combustibles.

Mobile Generator

CO Alarms

Requirements

Because this machine produces carbon monoxide (CO), Wacker Neuson

recommends that CO alarms be installed in all structures in close proximity to the

machine. CO alarms provide an extra measure of protection against this poison

that you cannot see or smell.

Install battery-operated CO alarms or plug-in CO alarms with battery backup,

according to the manufacturer’s instructions. CO alarms should be certified to the

requirements of the latest safety standards (UL 2034, IAS 6-96, or CSA 6.19.01).

Test the CO alarm batteries monthly.

Position the machine:

■ so that engine exhaust will not enter nearby structures.

■ so that the machine does not block traffic.

■ so that the machine is not close to any combustible material or flammable vapor .

■ so that all of the machine’s access doors/panels may be accessed.

■ so that the area overhead is clear of debris that could fall onto or into the

machine or exhaust compartment.

■ so that the machine is on a firm, level surface and will not tip, roll, slide, or fall

while operating.

This procedure continues on the next page.

46

wc_tx003572gb_FM10.fm

Page 47

Mobile Generator

Continued from the previous page.

Machine Setup

Procedure

Result

Perform the following procedure to position the machine.

1. Place the machine on solid, stable, and level ground.

a

wc_gr009186

2. For machines with trailers, install chocks (a) under the wheels.

The machine is now properly positioned.

wc_tx003572gb_FM10.fm

47

Page 48

Machine Setup

wc_gr011524

5.3 Grounding the Generator

Mobile Generator

Location

Function

A ground connection is located at the customer connection terminal lugs.

This ground connection is used for electrically grounding the generator when

necessary to comply with the National Electrical Code and other federal, state, and

local regulations. For grounding requirements in your area, consult with a qualified

electrician, electrical inspector, or local agency having jurisdiction over electrical

compliance.

■ If the generator is used at a construction site, there may be additional

regulations which must be observed.

■ In some areas, generators are required to be registered with local utility

companies.

48

wc_tx003572gb_FM10.fm

Page 49

Mobile Generator

5.4 Recommended Fuel

Low temperatures cause diesel fuel to gel. Always use the proper fuel for the

conditions. Follow the guidelines in the table below.

Machine Setup

Lowest expected ambient

temperature

Above freezing

< 0°C (32°F)

Below freezing

> 0°C (32°F)

1

Your engine may require ultra low sulfur fuel. Consult the engine owner’s manual.

Recommended fuel

#2 diesel plus additives

Winter-blend diesel

1

NOTICE: Consult the engine owner’s manual regarding the use of biodiesel fuel in

this machine. Some biodiesel blends may clog the fuel system or gel at cold

ambient temperatures sooner than petroleum-based diesel.

CAUTION

Fire hazard.

► Do not use gasoline, crankcase oil, or any oil containing gasoline.

wc_tx003572gb_FM10.fm

49

Page 50

Machine Setup

A

Ø

HZ

V

R

Basler

DIAGNOSTICS

DIAGNOSEN

DIAGNOSTICOS

DIAGNOSTICS

wc_gr008413

a

5.5 Refueling the Machine (Basler Controller)

Mobile Generator

Requirements

Procedure

■ Machine shut down

■ Engine cool

■ Machine/fuel tank level with the ground

■ Remote switch disconnected from the remote run terminal

■ Fresh, clean fuel supply

Perform the procedure below to refuel the machine.

WARNING

Fire hazard. Fuel and its vapors are extremely flammable. Burning fuel can cause

severe burns.

► Keep all sources of ignition away from the machine while refueling.

► Refuel only when the machine is outdoors.

► Clean up spilled fuel immediately.

1. Remove the fuel cap.

2. Place the engine start switch (a) in the REMOTE START position.

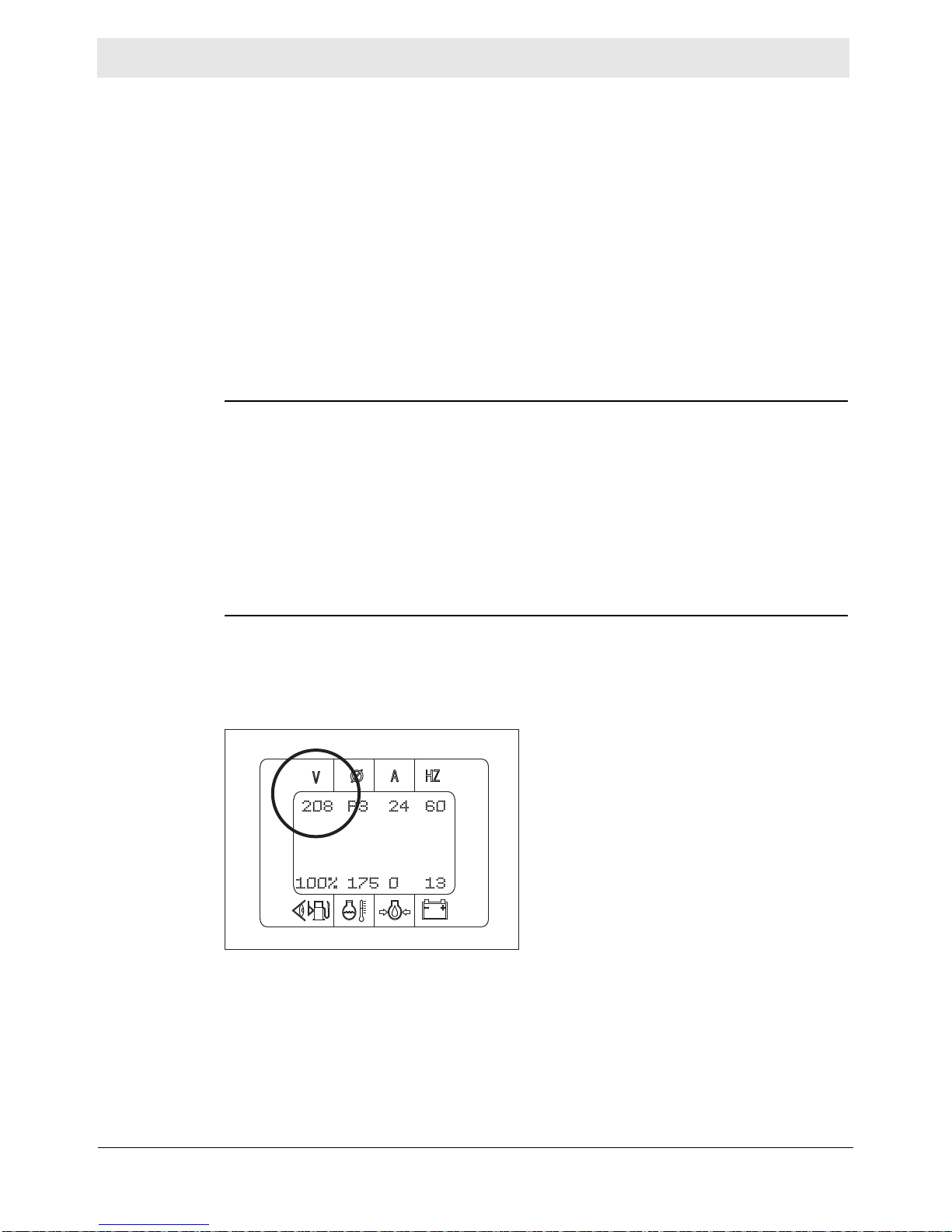

3. The fuel level (in percentage of the fuel tank capacity) will be displayed in the

lower left corner of the LCD screen.

4. Fill the fuel tank until the fuel level reaches 100%.

CAUTION

Fire and health hazard. Fuel expands when heated. Expanding fuel in an ove r-filled

tank can lead to spills and leaks.

► Do not overfill the fuel tank.

5. Re-install the fuel cap.

6. Place the engine start switch in the OFF position.

Result

The procedure to refuel the machine is now complete.

wc_tx003572gb_FM10.fm

50

Page 51

Mobile Generator

wc_gr011443

oo

AUTOAUTO

DEEP SEA ELECTRONICSDEEP SEA ELECTRONICS

DSE 7310DSE 7310

DSEDSE

OpenOpen

CloseClose

Gen-SetGen-Set

OpenOpen

CloseClose

LoadLoad

AlarmAlarm

WarningWarning

Main Breaker OpenMain Breaker Open

Low Speed ActiveLow Speed Active

StartStartLamp TestLamp Test

Horn ResetHorn Reset

AutoAuto

ModeMode

ManualManual

ModeMode

Stop/ResetStop/Reset

Generator Availabl eGenerator Available

L-NL-N

L-LL-L

0 kW0 kW

0 V0 V 0.0 Hz0.0 Hz

--- pf--- pf

0 V0 V 0 A0 A

DSE

DEEP SEA ELECTRONICS

DSE 7310

Alarm

Warning

Main Breaker Open

Low Speed Active

5.6 Refueling the Machine (Deep Sea Controller)

Machine Setup

Requirements

Procedure

■ Engine stopped

■ Machine/fuel tank level with the ground

■ Remote switch disconnected from the remote run terminal

■ Fresh, clean fuel supply

Perform the procedure below to refuel the machine.

WARNING

Fire hazard. Fuel and its vapors are extremely flammable. Burning fuel can cause

severe burns.

► Keep all sources of ignition away from the machine while refueling.

► Refuel only when the machine is outdoors.

► Clean up spilled fuel immediately.

1. Remove the fuel cap.

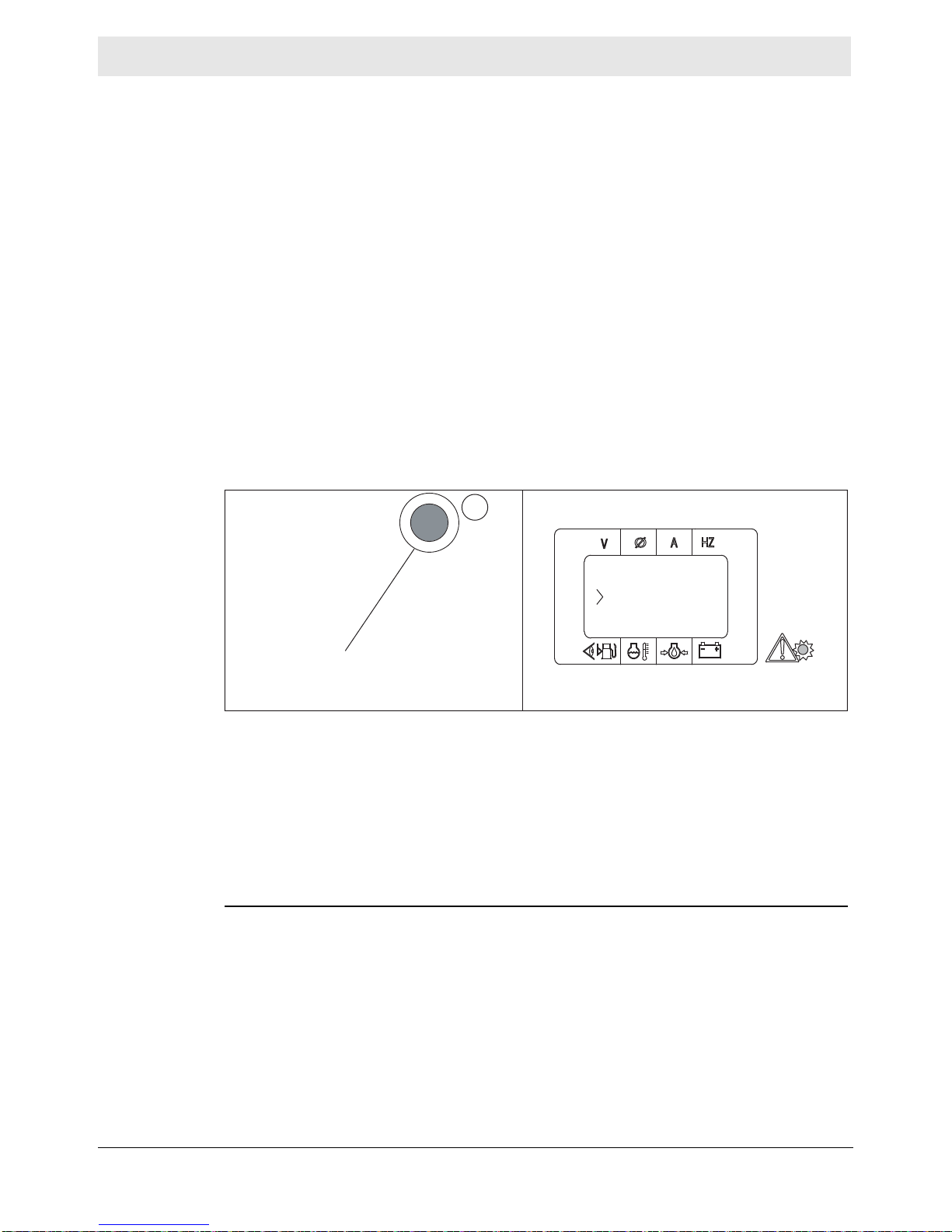

2. Place the genset controller power switch in the ON position and wait for the

Deep Sea controller to boot up.

3. Press the right arrow key to navigate to the “Engine” screen.

4. Use the up or down arrow key to navigate to the “Engine Fuel Level” screen.

The fuel level (in percentage of the fuel tank capacity) will be displayed.

Note: The “Engine Fuel Level” screen will revert back to status screen after three

minutes of inactivity.

5. Fill the fuel tank until the fuel level reaches 100%.

CAUTION

Fire and health hazard. Fuel expands when heated. Expanding fuel in an over-filled

tank can lead to spills and leaks.

► Do not overfill the fuel tank.

wc_tx003572gb_FM10.fm

6. Re-install the fuel cap.

7. Place the genset controller power switch in the OFF position.

51

Page 52

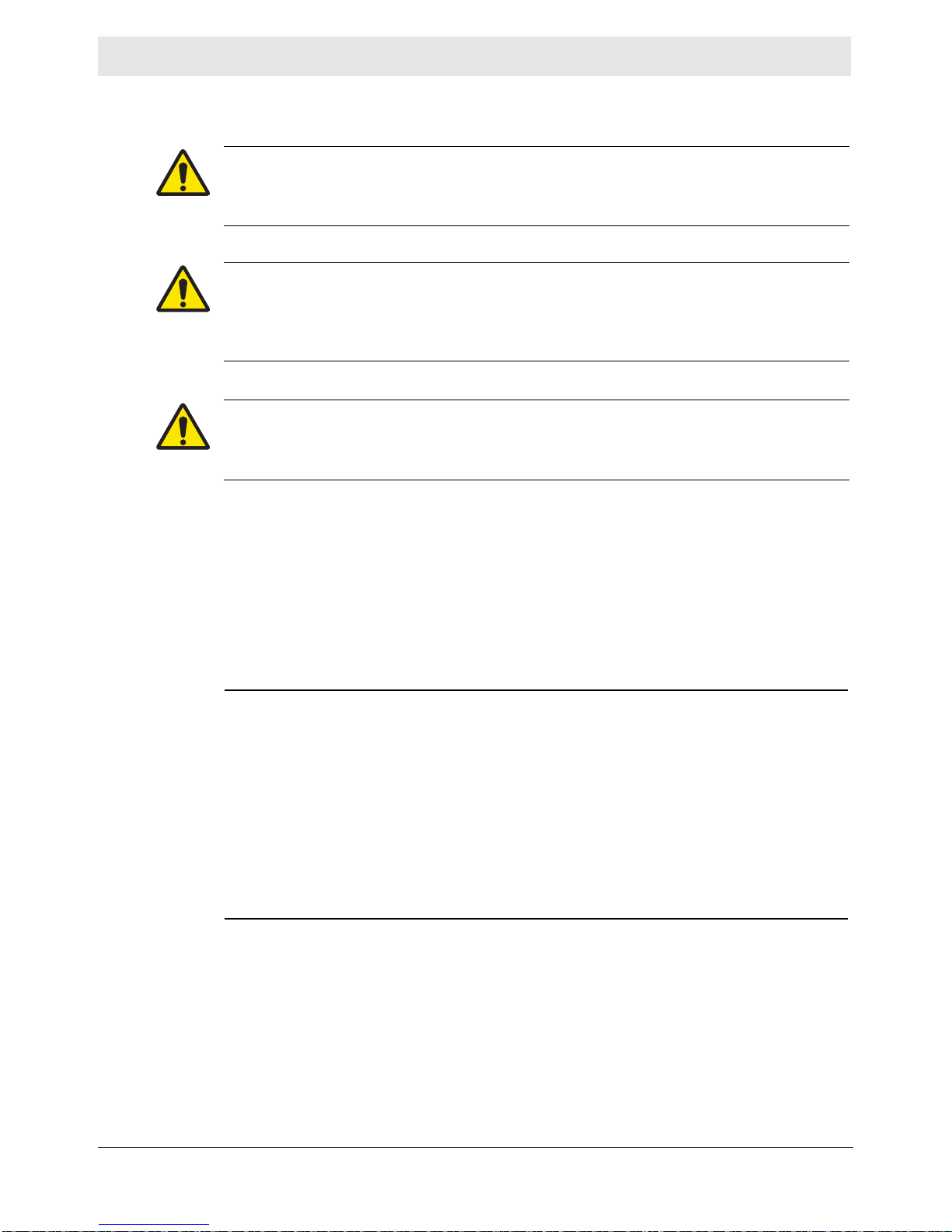

Operation, Control, and Component Locations

L2L2

L1L1

L3L3

WARNINGWARNING

20A20A

50A50A

0 0 5 6 3 2

wc_gr011689

m op

q

r

e

n

l

a

b f

g

h

j

k

AUSAUS

APAGADOAPAGADO

ARRETARRET

OFFOFF

REMOTE STARTREMOTE START

FERNSTARTFERNSTART

ARRANQUE REMOTOARRANQUE REMOTO

DEMARRAGE A DEMARRAGE A

DISTANCEDISTANCE

START / LAUFENSTART / LAUFEN

ARRANQUE / MARCHAARRANQUE / MARCHA

DEMARRER / MARCHEDEMARRER / MARCHE

START / RUNSTART / RUN

d

A

Ø

HZ

V

DIAGNOSTICS

DIAGNOSEN

DIAGNOSTICOS

DIAGNOSTICS

c

STOP

6 Operation, Control, and Component Locations

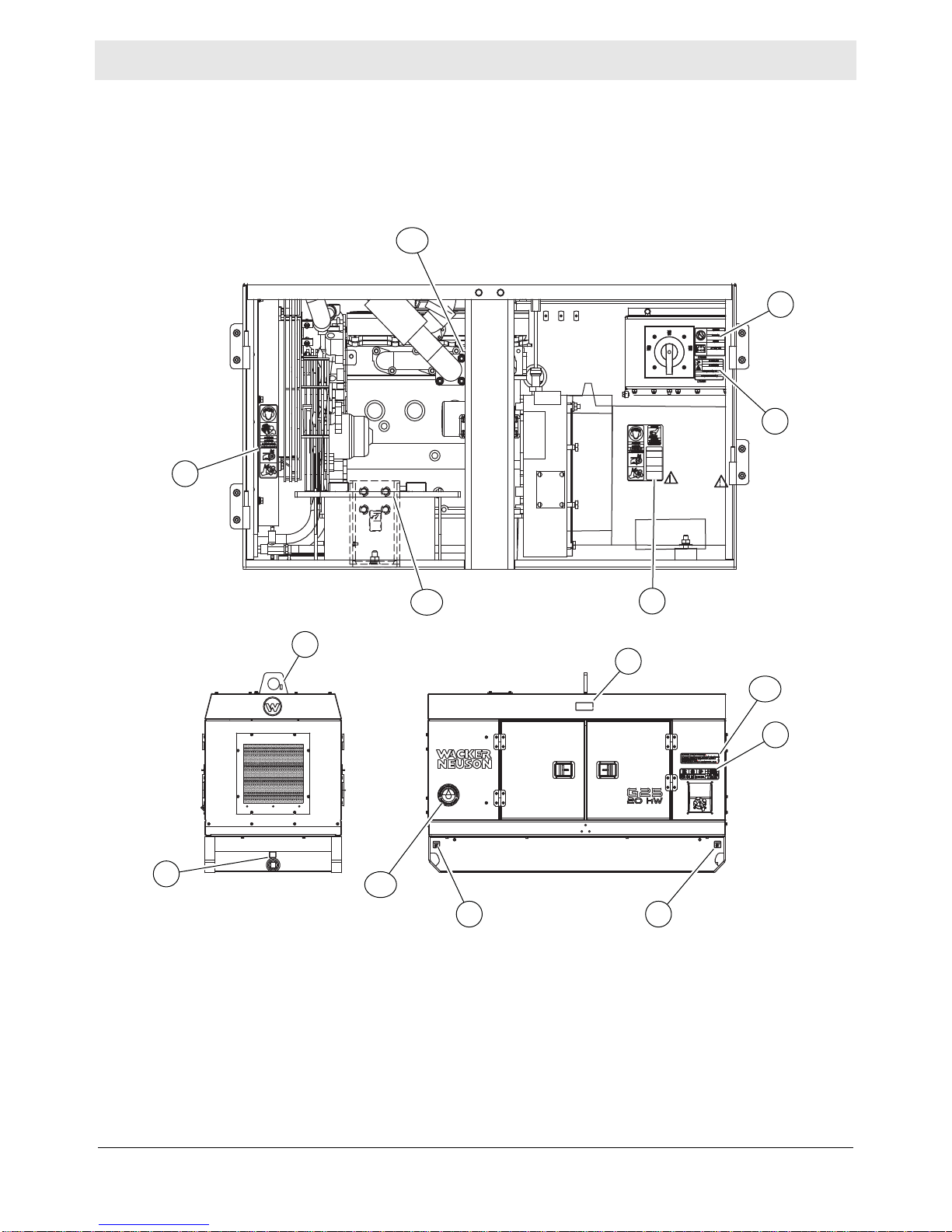

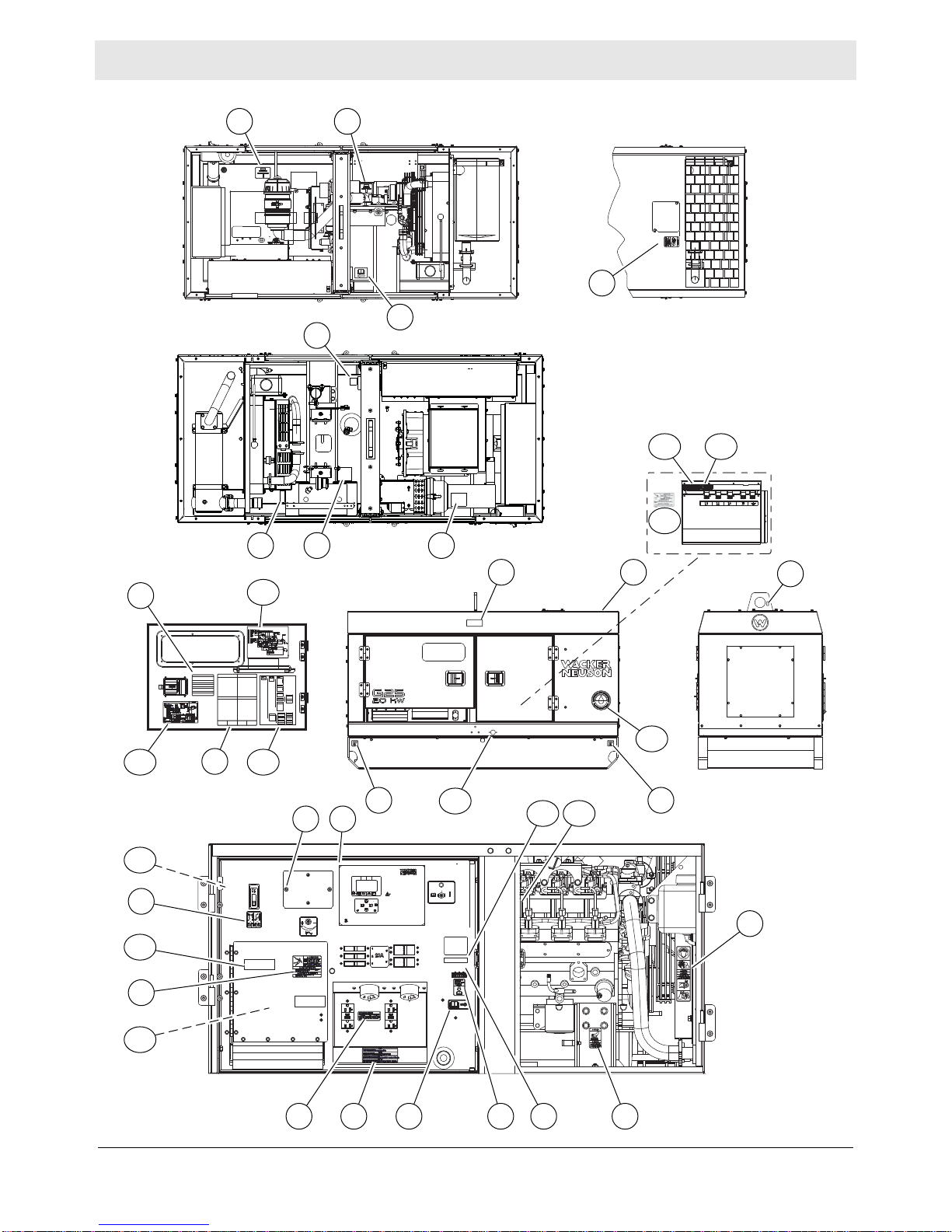

6.1 Control / Component Locations

52

wc_tx003635gb_FM10.fm

Page 53

Operation, Control, and Component Locations

s

s

t

wc_gr011690

6.2 Control Panel Components

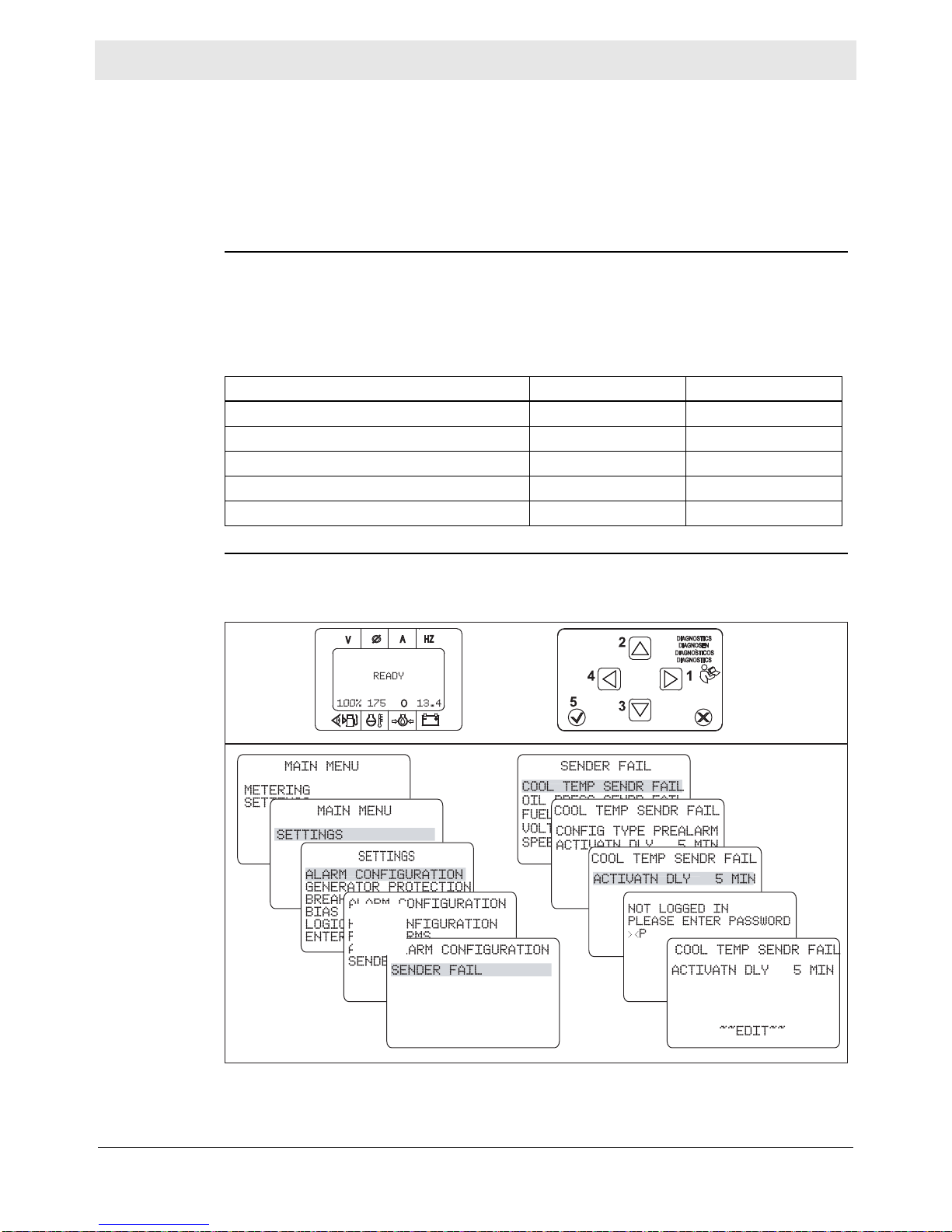

Ref. Description Ref. Description

Main circuit breaker

a