Page 1

Operator’s Manual

Roller

RD 27-100

RD 27-120

0171754en 003 1109

0171754EN

Page 2

Copyright

notice

© Copyright 2009 by Wacker Neuson Corporation.

All rights, including copying and distribution rights, are reserved.

This publication may be photocopied by the original purchaser of the machine. Any

other type of reproduction is prohibited without express written permission from

Wacker Neuson Corporation.

Any type of reproduction or distribution not authorized by Wacker Neuson Corporation

represents an infringement of valid copyrights. Violators will be prosecuted.

Trademarks

Manufacturer

Translated

instructions

All trademarks referenced in this manual are the property of their respective owners.

Wacker Neuson Corporation

N92W15000 Anthony Avenue

Menomonee Falls, WI 53051 U.S.A.

Tel: (262) 255-0500 · Fax: (262) 255-0550 · Tel: (800) 770-0957

www.wackerneuson.com

This Operator’s Manual presents a translation of the original instructions. The original

language of this Operator’s Manual is American English.

Page 3

RD 27 Foreword

Foreword

Machines

covered in

this manual

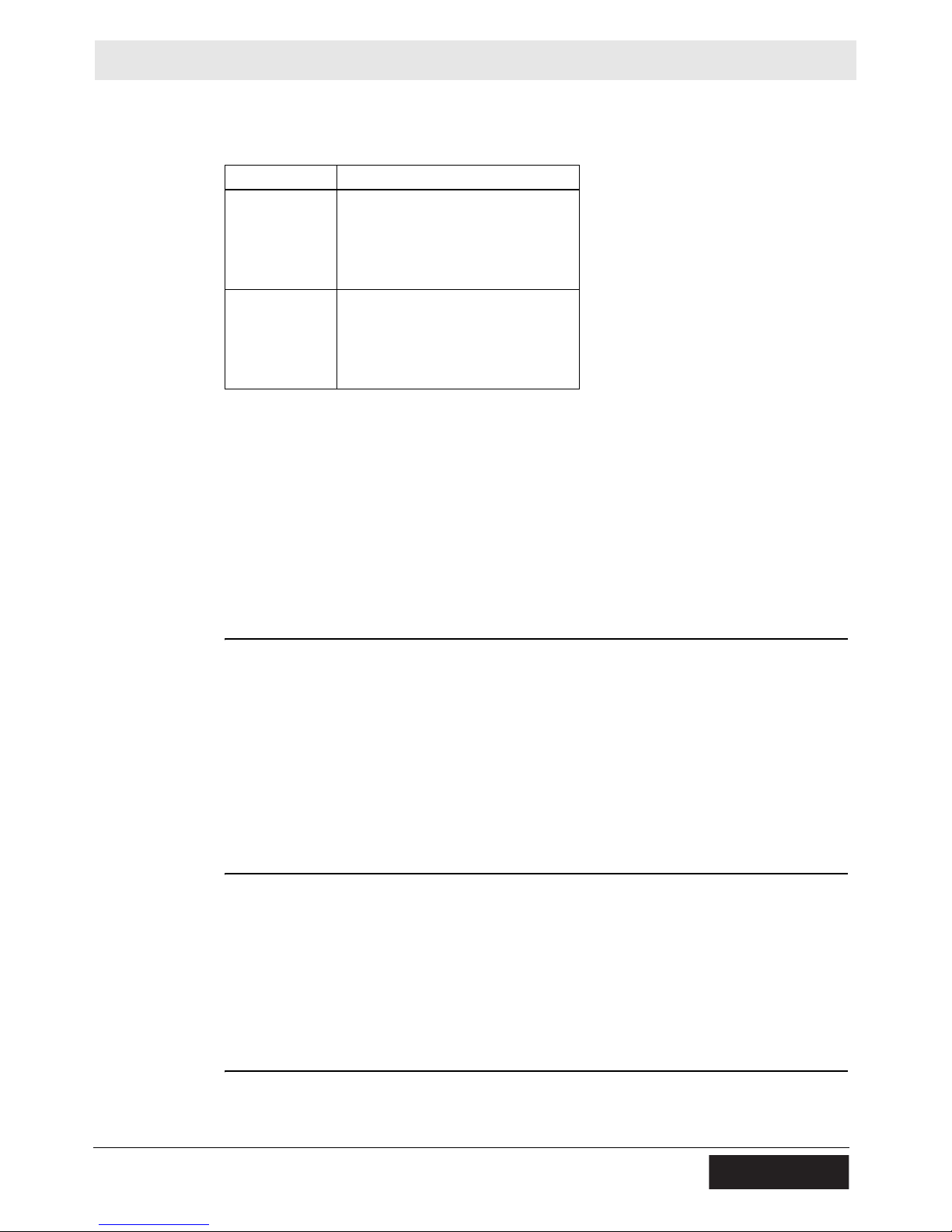

Machine Item Number

RD 27-100 0620393

0620395

0620508

0620510

0620512

RD 27-120 0620396

0620394

0620509

0620511

0620513

Machine

documentation

Expectations

for

information in

this manual

Keep a copy of the Operator’s Manual with the machine at all times.

Use the separate Parts Book supplied with the machine to order replacement

parts.

Refer to the separate Repair Manual for detailed instructions on servicing and

repairing the machine.

If you are missing any of these documents, please contact Wacker Neuson

Corporation to order a replacement or visit www.wackerneuson.com.

When ordering parts or requesting service information, be prepared to provide

the machine model number, item number, revision number, and serial number.

This manual provides information and procedures to safely operate and main-

tain the above Wacker Neuson model(s). For your own safety and to reduce the

risk of injury, carefully read, understand, and observe all instructions described

in this manual.

Wacker Neuson Corporation expressly reserves the right to make technical

modifications, even without notice, which improve the performance or safety

standards of its machines.

The information contained in this manual is based on machines manufactured

up until the time of publication. Wacker Neuson Corporation reserves the right

to change any portion of this information without notice.

Copyright

notice

All rights, especially copying and distribution rights, are reserved.

Copyright 2009 by Wacker Neuson Corporation.

This publication may be reproduced through photocopying by the original pur-

chaser of the machine. Any other type of reproduction is prohibited without

express written permission from Wacker Neuson Corporation.

Any type of reproduction or distribution not authorized by Wacker Neuson Cor-

poration represents an infringement of valid copyrights, and violators will be

prosecuted.

wc_tx000836gb.fm 3

Page 4

Foreword RD 27

CALIFORNIA

Proposition

65 Warning:

Laws

pertaining to

spark

arresters

Trademarks

Engine exhaust, some of its constituents, and certain vehicle components, contain

or emit chemicals known to the State of California to cause cancer and birth

defects or other reproductive harm.

NOTICE: State Health Safety Codes and Public Resources Codes specify that in

certain locations spark arresters be used on internal combustion engines that use

hydrocarbon fuels. A spark arrester is a device designed to prevent accidental discharge of sparks or flames from the engine exhaust. Spark arresters are qualified

and rated by the United States Forest Service for this purpose. In order to comply

with local laws regarding spark arresters, consult the engine distributor or the local

Health and Safety Administrator.

All trademarks referenced in this manual are the property of their respective owners.

4 wc_tx000836gb.fm

Page 5

RD 27 Table of Contents

Foreword 3

1 Safety Information 9

1.1 Signal Words Found in this Manual ...................................................... 9

1.2 Machine Description and Intended Use ............................................. 10

1.3 Safety Guidelines for Operating the Machine ..................................... 11

1.4 Safety Guidelines while Using Internal Combustion Engines ............. 13

1.5 Guidelines for Service Safety ............................................................. 14

2 Labels 16

2.1 Label Locations .................................................................................. 16

2.2 Safety and Warning Labels ................................................................ 17

2.3 Informational Labels ........................................................................... 20

3 Lifting and Transporting 23

3.1 Lifting the Machine ............................................................................. 23

3.2 Tying Down/Transporting the Machine ............................................... 24

4 Operation 25

4.1 Preparing the Machine for First Use ................................................... 25

4.2 Position of the Operator ..................................................................... 25

4.3 Operation & Maintenance Locations .................................................. 26

4.4 Unlocking/Locking the Articulated Joint .............................................. 28

4.5 Using the Roll Over Protection Structure (ROPS) .............................. 29

4.6 Installing the Rotating Beacon ............................................................ 30

4.7 Using the Seat Belt ............................................................................. 31

4.8 Adjusting the Seat .............................................................................. 32

4.9 Adjusting the Steering Column ........................................................... 33

4.10 Positioning the Scraper Bars .............................................................. 33

4.11 Using the Anti-Vandalism Protection Devices .................................... 34

4.12 Using the Water Spray System .......................................................... 35

4.13 Using the Forward/Reverse Lever ...................................................... 36

4.14 Backup Alarm ..................................................................................... 37

4.15 Using the Flow Divider (if equipped) .................................................. 38

4.16 Using the Vibration System ................................................................ 39

4.17 Using the Parking Brakes ................................................................... 40

4.18 Warning Lights ................................................................................... 41

4.19 Using the Lights and Horn .................................................................. 42

4.20 Machine Stability ................................................................................ 43

4.21 Operating on Slopes ........................................................................... 44

wc_bo0171754en_003TOC.fm 5

Page 6

Table of Contents RD 27

4.22 Preliminary Checks .............................................................................45

4.23 Mounting and Dismounting the Machine .............................................45

4.24 Starting the Engine ..............................................................................46

4.25 Stopping the Engine ............................................................................47

4.26 Understanding the Operator Present System .....................................48

4.27 Emergency Shutdown Procedure ........................................................48

5 Maintenance 50

5.1 Periodic Maintenance Schedule ..........................................................50

5.2 Major Component Locations ...............................................................52

5.3 Major Components ..............................................................................53

5.4 Safety-Related Spare Parts .................................................................54

5.5 Maintaining the Seat and Seat Belt .....................................................59

5.6 Checking the Air Filter Indicator ..........................................................60

5.7 Cleaning the Air Cleaner and Primary Air Filter Element ....................61

5.8 Changing the Air Filter Elements .........................................................62

5.9 Testing the Backup Alarm ...................................................................63

5.10 Checking the Engine Coolant Level ....................................................64

5.11 Checking the Engine Oil ......................................................................65

5.12 Checking Hydraulic Oil Level ..............................................................66

5.13 Checking the Neutral Switch ...............................................................67

5.14 Adjusting the Scraper Bars ..................................................................68

5.15 Inspecting the Seat Belt ......................................................................69

5.16 Cleaning the Water Spray Nozzles .....................................................70

5.17 Cleaning the Water Spray System Filter .............................................71

5.18 Cleaning and Changing the Fuel Filter/Water Separator ....................72

5.19 Priming the Fuel System .....................................................................73

5.20 Draining Water and Sediment from the Fuel Tank ..............................74

5.21 Cleaning the Water Tank Strainer .......................................................75

5.22 Adjusting Alternator Belt Tension ........................................................76

5.23 Lubricating the Articulated Steering Joint ............................................77

5.24 Lubricating the Steering Cylinder ........................................................78

5.25 Testing the Brake System ...................................................................79

5.26 Changing the Engine Oil and Filter .....................................................80

5.27 Cleaning the Fuel Tank Cap and Fuel Strainer ...................................81

5.28 Changing the Hydraulic Oil Filter .........................................................82

5.29 Cleaning the Hydraulic Oil Cooler .......................................................83

5.30 Disconnecting/Connecting the Battery ................................................84

5.31 Adjusting the Forward/Reverse Lever .................................................85

5.32 Changing the Hydraulic Oil ..................................................................86

5.33 Checking and Cleaning the Hydraulic Tank Breather .........................87

6 wc_bo0171754en_003TOC.fm

Page 7

RD 27 Table of Contents

5.34 Cleaning the Hydraulic Oil Strainer .................................................... 88

5.35 Cleaning the Radiator Filler Cap ........................................................ 89

5.36 Checking the Engine Water Pump ..................................................... 90

5.37 Changing the Cooling System Coolant .............................................. 91

5.38 Replacing the Water Temperature Regulator ..................................... 93

5.39 Draining the Water Spray System ...................................................... 94

5.40 Towing the Machine ........................................................................... 95

5.41 Manually Releasing the Parking Brakes ............................................. 97

5.42 Troubleshooting .................................................................................. 98

6 Schematics 100

6.1 Electrical Schematic ......................................................................... 100

6.2 Hydraulic Schematic ......................................................................... 106

7 Technical Data 110

7.1 Engine .............................................................................................. 110

7.2 Roller ................................................................................................ 111

7.3 Lubrication ........................................................................................ 111

7.4 Sound Measurements ...................................................................... 112

7.5 Measurements of Operator Exposure to Vibration ........................... 112

7.6 Dimensions ....................................................................................... 113

wc_bo0171754en_003TOC.fm 7

Page 8

Table of Contents RD 27

8 wc_bo0171754en_003TOC.fm

Page 9

RD 27 Safety Information

1 Safety Information

1.1 Signal Words Found in this Manual

This manual contains DANGER, WARNING, CAUTION, NOTICE, and NOTE

callouts which must be followed to reduce the possibility of personal injury, damage

to the equipment, or improper service.

This is the safety alert symbol. It is used to alert you to potential personal hazards.

f Obey all safety messages that follow this symbol.

DANGER

DANGER indicates a hazardous situation which, if not avoided, will result in death

or serious injury.

f To avoid death or serious injury from this type of hazard, obey all safety mes-

sages that follow this signal word.

WARNING

WARNING indicates a hazardous situation which, if not avoided, could result in

death or serious injury.

f To avoid possible death or serious injury from this type of hazard, obey all safety

messages that follow this signal word.

CAUTION

CAUTION indicates a hazardous situation which, if not avoided, could result in

minor or moderate injury.

f To avoid possible minor or moderate injury from this type of hazard, obey all

safety messages that follow this signal word.

NOTICE: Used without the safety alert symbol, NOTICE indicates a situation

which, if not avoided, could result in property damage.

Note: A Note contains additional information important to a procedure.

wc_si000247gb.fm 9

Page 10

Safety Information RD 27

1.2 Machine Description and Intended Use

This machine is a dual drum, ride-on roller. The Wacker Neuson Ride-On Roller

consists of an articulated frame onto which is mounted a gasoline or diesel engine,

a fuel tank, a hydraulic tank, a water tank, a hydrostatic drive system, two steel

drums containing internal eccentric weights, and an operator’s platform with a

ROPS (Roll Over Protective Structure). The engine powers the hydraulic systems

that provide machine movement and drum vibration. The vibrating drums smooth

and compact the work surface as the machine moves. Machine speed, direction,

and vibration are controlled by the operator from the operator’s seat on the platform.

The machine is designed as a lightweight roller to be used in the compaction of

sublayers and finish layers of asphalt on roads, driveways, parking lots, and other

types of asphalt-covered surfaces.

This machine has been designed and built strictly for the intended use described

above. Using the machine for any other purpose could permanently damage the

machine or seriously injure the operator or other persons in the area. Machine

damage caused by misuse is not covered under warranty.

The following are some examples of misuse:

Using the machine as a ladder, support, or work surface

Using the machine to carry or transport passengers or equipment

Using the machine to tow other machines

Using the machine to spray liquids other than water (i.e., diesel fuel on asphalt)

Operating the machine outside of factory specifications.

Operating the machine in a manner inconsistent with all warnings found on the

machine and in the Operator’s Manual.

This machine has been designed and built in accordance with the latest global

safety standards. It has been carefully engineered to eliminate hazards as far as

practicable and to increase operator safety through protective guards and labeling.

However, some risks may remain even after protective measures have been taken.

They are called residual risks. On this machine, they may include exposure to:

Heat, noise, exhaust, and carbon monoxide from the engine

Burns from hot hydraulic fluid

Fire hazards from improper refueling techniques

Fuel and its fumes

Personal injury from improper lifting techniques

Crushing hazards from improper operation (feet, legs, or arms extending

outside of the operator work station) and for other persons in the work zone

Line of sight blockage by the ROPS

To protect yourself and others, make sure you thoroughly read and understand the

safety information presented in this manual before operating the machine.

10 wc_si000247gb.fm

Page 11

RD 27 Safety Information

1.3 Safety Guidelines for Operating the Machine

Operator

qualifications

Personal

Protective

Equipment

(PPE)

Operator

training

Only trained personnel are permitted to start, operate, and shut down the machine.

They also must meet the following qualifications:

have received instruction on how to properly use the machine

are familiar with required safety devices

The machine must not be accessed or operated by:

children

people impaired by alcohol or drugs

Wear the following Personal Protective Equipment (PPE) while operating this

machine:

Close-fitting work clothes that do not hinder movement

Safety glasses with side shields

Hearing protection

Safety-toed footwear

Before operating the machine:

Read and understand the operating instructions contained in all manuals

delivered with the machine.

Familiarize yourself with the location and proper use of all controls and safety

devices.

Contact Wacker Neuson Corporation for additional training if necessary.

Machine’s

safety devices

When operating this machine:

Do not allow improperly trained people to operate the machine. People

operating the machine must be familiar with the potential risks and hazards

associated with it.

Disengage and stow the locking bar for the articulated steering joint before

operating the machine. The machine cannot be steered when the locking bar is

engaged.

Check that all controls are functioning properly immediately after start-up!

To ensure safe operation of the machine:

Do not operate the machine if any safety devices or guards are missing or

inoperative.

Do not operate the machine unless all controls operate correctly.

Do not modify or defeat safety devices.

Do not use accessories or attachments that are not recommended by Wacker

Neuson. Damage to equipment and injury to the user or others may result.

wc_si000247gb.fm 11

Page 12

Safety Information RD 27

Safe

operating

practices

When operating this machine:

Always remain seated and wear the seat belt at all times while operating the

machine.

Remain aware of changing positions and the movement of other equipment and

personnel on the job site.

Be sure that all other persons are at a safe distance from the machine. Stop the

machine if people step into the working area of the machine.

Remain aware of changing surface conditions, for example, uneven ground,

hills, trench edges, soft or coarse material. Be sure that the surface is stable

enough to support the weight of the machine and that there is no chance of the

machine sliding, falling, or tipping.

Remain aware of the machine’s moving parts. Keep hands, feet, and loose

clothing away from the machine’s moving parts.

Wear protective clothing appropriate to the job site when operating the machine.

Wear safety glasses when operating this machine.

Store the machine properly when it is not being used. The machine should be

stored in a clean, dry location out of the reach of children.

When operating this machine:

Do not drive off curbs or other uneven surfaces that will result in jarring impacts

to the machine and operator.

Do not touch the engine or muffler while the engine is on or immediately after it

has been turned off. These areas get hot and may cause burns.

Do not allow anyone to ride on any part of the machine. Passengers can be

seriously injured or killed from falls, tip-overs, or roll-over incidents.

Do not leave the machine running unattended.

Do not operate a machine in need of repair.

Do not attempt to start the machine while standing alongside it. Only start the

engine when seated in the driver’s seat and with the forward/reverse control in

the neutral position.

Do not operate a machine when its fuel cap is loose or missing.

Do not use a cellphone or send text messages while operating this machine.

Do not operate the machine with unapproved accessories or attachments.

Do not transport the machine while it is running.

12 wc_si000247gb.fm

Page 13

RD 27 Safety Information

1.4 Safety Guidelines while Using Internal Combustion Engines

WARNING

Internal combustion engines present special hazards during operation and fueling.

Failure to follow the warnings and safety standards could result in severe injury or death.

f Read and follow the warning instructions in the engine owner’s manual and the

safety guidelines below.

DANGER

Exhaust gas from the engine contains carbon monoxide, a deadly poison.

Exposure to carbon monoxide can kill you in minutes.

f NEVER operate the machine inside an enclosed area, such as a tunnel, unless

adequate ventilation is provided through such items as exhaust fans or hoses.

Operating

safety

Refueling

safety

When running the engine:

Keep the area around exhaust pipe free of flammable materials.

Check the fuel lines and the fuel tank for leaks and cracks before starting the engine.

Do not run the machine if fuel leaks are present or the fuel lines are loose.

When running the engine:

Do not smoke while operating the machine.

Do not run the engine near sparks or open flames.

Do not touch the engine or muffler while the engine is running or immediately after it

has been turned off.

Do not operate a machine when its fuel cap is loose or missing.

Do not start the engine if fuel has spilled or a fuel odor is present. Move the machine

away from the spill and wipe the machine dry before starting.

Do not remove the radiator cap when the engine is running or hot. The radiator

fluid is hot and under pressure and may cause severe burns!

When refueling the engine:

Clean up any spilled fuel immediately.

Refill the fuel tank in a well-ventilated area.

Replace the fuel tank cap after refueling.

Do not smoke.

Do not refuel a hot or running engine.

Do not refuel the engine near sparks or open flames.

Do not refuel if the machine is positioned in a truck fitted with a plastic bed liner.

Static electricity can ignite the fuel or fuel vapors.

wc_si000247gb.fm 13

Page 14

Safety Information RD 27

1.5 Guidelines for Service Safety

WARNING

A poorly maintained ained machine can become a safety hazard! In order for the

machine to operate safely and properly over a long period of time, periodic

maintenance and occasional repairs are necessary.

f ALWAYS do periodic maintenance as recommended in the Operator’s Manual.

Personal

Protective

Equipment

(PPE)

Precautions

Wear the following Personal Protective Equipment (PPE) while servicing or

maintaining this machine:

Close-fitting work clothes that do not hinder movement

Safety glasses with side shields

Hearing protection

Safety-toed footwear

In addition, before servicing or maintaining the machine:

Tie back long hair.

Remove all jewelry (including rings).

To reduce the risk of personal injury, read and understand the service

procedures before performing any service to the machine.

Some service procedures require that the machine’s battery be disconnected.

All adjustments and repairs MUST be completed before operation. NEVER

operate the machine with a known problem or deficiency! All repairs and

adjustments should be completed by a qualified technician.

Stop the engine before servicing the machine. If the engine has electric start,

disconnect the negative terminal on the battery.

Secure the articulated steering joint using the locking bar before lifting, jacking,

and servicing the machine. Machine halves could swing together unexpectedly

and cause a serious injury.

Accessories,

safety

devices, and

modifications

Replacing

parts and

labels

Do not modify, weld, or drill safety frames (ROPS) fitted as original equipment.

Do not loosen or remove bolts.

Do not weld, drill, or modify a broken safety frame.

Do not modify the machine without the express written approval of the manufacturer.

Replace worn or damaged components.

When replacement parts are required for this machine, use only Wacker

Neuson replacement parts or those parts equivalent to the original in all types of

specifications, such as physical dimensions, type, strength, and material.

Never use or attempt to repair a damaged safety belt or ROPS. Replace these

components before operating the machine.

Replace all missing and hard-to-read labels. Labels provide important operating

instructions and warn of dangers and hazards.

Check all external fasteners at regular intervals.

14 wc_si000247gb.fm

Page 15

RD 27 Safety Information

Lifting and

transporting

Cleaning and

servicing the

machine

When lifting the machine:

Make sure slings, chains, hooks, ramps, jacks and other types of lifting devices

are attached securely and have enough weight-bearing capacity to lift or hold

the machine safely.

Remain aware of the location of other people when lifting the machine.

To reduce the possibility of injury:

Do not stand under the machine while it is being hoisted or moved.

Do not get onto the machine while it is being hoisted or moved.

While cleaning or servicing the machine:

Keep the area around the muffler free of debris such as leaves, paper, cartons,

etc. A hot muffler could ignite the debris and start a fire.

Keep the machine clean and labels legible.

Keep hands, feet, and loose clothing away from moving parts.

While cleaning or servicing the machine:

Do not remove air cleaner cover, paper element, or precleaner while engine is

running.

Do not attempt to open the radiator cap while the machine is running or before

the engine has cooled down. Severe burns may result!

Do not attempt to clean or service the machine while it is running. Rotating parts

can cause severe injury.

Do not use gasoline or other types of fuels or flammable solvents to clean parts,

especially in enclosed areas. Fumes from fuels and solvents can become

explosive.

Do not tip the machine for cleaning or for any other reason.

WARNING

Possibility of injury. Hydraulic fluid under pressure can penetrate the skin, cause

burns, blind, or create other potentially dangerous hazards.

f Set all controls to neutral, turn the engine off, and allow fluids to cool before

loosening hydraulic fittings or attaching test gauges.

f Do not open hydraulic lines or loosen hydraulic connections when the engine is

running.

f Before dismantling hydraulic connectors or hoses, ensure that all pressure has

been bled from the circuit.

f Fluid leaks from small holes are often practically invisible. DO NOT use your

bare hands to check for leaks. Check for leaks using a piece of cardboard or

wood.

f Always make sure hose connections have been reconnected back to the cor-

rect fitting. Failure to do so may result in damage to the machine and/or injury to

person on or near the machine.

Always replace safety devices and guards after completing repairs and

maintenance.

Before you start the machine, ensure that all tools have been removed from the

machine and that replacement parts and adjusters are firmly tightened.

wc_si000247gb.fm 15

Page 16

Labels RD 27

2 Labels

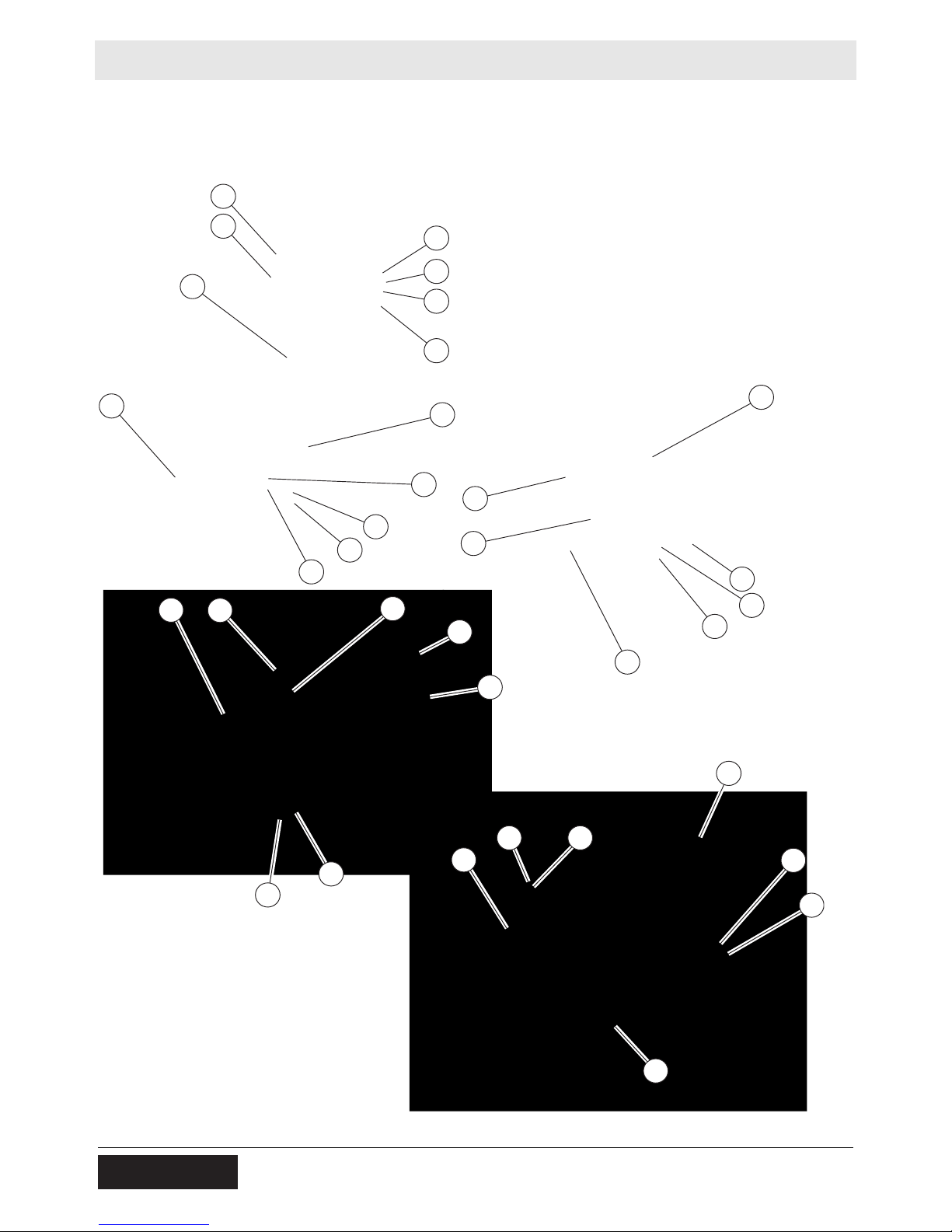

2.1 Label Locations

v

n

q

g

o

i

g

k

b

x

v

n

s

p

w

d

u

a

k

f

d

c

g

g

h

r

m

j

f

t

l

d

g

f

wc_gr005053

16 wc_si000393gb.fm

Page 17

RD 27 Labels

STOP

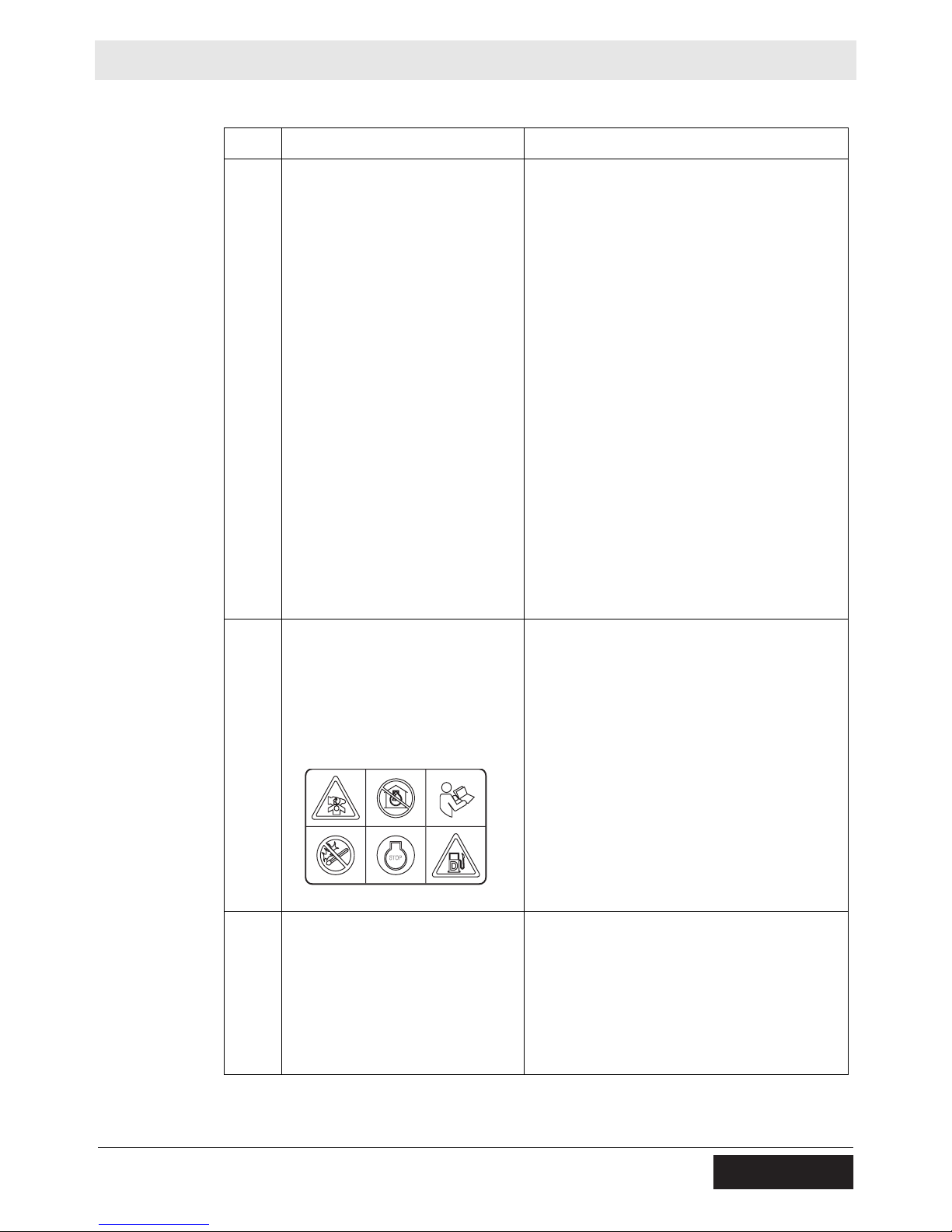

2.2 Safety and Warning Labels

Ref. Label Definition

b DANGER!

Read and understand the supplied

Operator's Manuals before operating this

machine. Failure to do so increases the risk

of injury to yourself and others.

Do not run the machine indoors or in an

enclosed area without adequate ventilation.

Engine exhaust contains carbon monoxide.

This is a poison you cannot see or smell.

Exposure to carbon monoxide can cause

loss of consciousness and CAN KILL YOU IN

MINUTES.

To reduce the risk of hearing loss, wear hearing protection when operating this machine.

Always wear seat belt when operating the

machine.

Never operate the machine sideways on

slopes.

c DANGER!

Asphyxiation hazard. Do not run the machine

indoors or in an enclosed area without adequate ventilation. Read the Operator’s Manual for instructions. No sparks, flames, or

burning objects near machine. Stop the

engine before adding fuel. Use only diesel

fuel.

0178715

dCAUTION

Lifting point.

wc_si000393gb.fm 17

Page 18

Labels RD 27

Ref. Label Definition

f WARNING!

Avoid crushing area.

h WARNING!

Disconnect battery before servicing.

Read Repair Manual.

Explosion hazard. Batteries can emit explosive hydrogen gas. Keep all sparks and

flames away from the battery.

lWARNING!

Pinching hazard. Rotating machinery.

m WARNING!

Pressurized contents. Do not open when hot!

18 wc_si000393gb.fm

Page 19

RD 27 Labels

Ref. Label Definition

n WARNING!

Avoid crushing area.

s WARNING!

Do not drill or weld the ROPS.

Read the Operator’s Manual.

t WARNING!

Avoid crushing area.

Articulated steering joint locking location.

Lock the articulated steering joint before servicing the machine.

Read Repair Manual.

wc_si000393gb.fm 19

Page 20

Labels RD 27

2.3 Informational Labels

Ref. Label Definition

a Operator’s Manual must be stored on

O P E R A T O R ' S M A N U A L M U S T B E

S T O R E D O N M A C H I N E .

R E P L A C E M E N T O P E R A T O R ' S

M A N U A L C A N B E O R D E R E D

L O C A L W A C K E R

T H R O U G H Y O U R

D I S T R I B U T O R .

D I E B E T R I E B S V O R S C H R I F T M U S S

A N D E R M A S C H I N E A U F B E W A H R T

W E R D E N . Z U R B E S T E L L U

E R S A T Z B Ü C H E R N W E N D E N S I E

S I C H B I T T E A N I H R E N

Ö R T L I C H E N W A C K E R H Ä N D L E R .

N G V O N

E L M A N U A L D E O P E R A C I O N D E B E

S E R R E T E N I D O E N L A M A Q U I N A .

C O N T A C T E A S U D I S T R I B U I D O R

W A C K E R M A S C E R C A N O P

P E D I R U N E J E M P L A R

A D I C I O N A L .

L A N O T I C E D ' E M P L O I D O I T

E T R E M U N I E S U R L A M A C H I N E .

C O N T A C T E R L E D I S T R I

W A C K E R L E P L U S P R O C H E

P O U R C O M M A N D E R U N

E X E M P L A I R E S U P P L E M E N T A I R E .

B U T E U R

A R A

machine. Replacement Operator’s Manual

can be ordered through your local Wacker

Neuson distributor.

1 1 5 0 9 6

e A nameplate listing the model number, item

number, revision number, and serial number

is attached to each unit. Please record the

information found on this plate so it will be

available should the nameplate become lost

or damaged. When ordering parts or

requesting service information, you will

always be asked to specify the model number, item number, revision number, and serial

number of the unit.

g Tie-down point.

i Hydraulic oil drain.

HYDRAULIC OIL

HYDRAULIKÖL

ACEITE HIDRÁULICO

HUILE HYDRAULIQUE

j Hydraulic oil reservoir fill.

20 wc_si000393gb.fm

Page 21

RD 27 Labels

Ref. Label Definition

k Water tank fill.

o Engine oil drain.

ENGINE OIL

MOTOROEL

ACEITE DE MOTOR

HUILE À MOTEURS

p Key switch positions.

STOP

Power to glowplugs.

Engine stopped (OFF).

Engine ON.

Power to starter motor.

q Throttle lever positions.

High speed.

Low speed.

wc_si000393gb.fm 21

Page 22

Labels RD 27

Ref. Label Definition

r Vibration activation and deactivation switch.

Forward/reverse lever positions.

u Fuse identifications.

v Tighten screw to reduce vibration.

1

2

Read Operator’s Manual.

wc_gr002757

w Guaranteed sound power level in dB(A).

x ROPS certification label

y Biodegradable hydraulic oil reservoir fill

(if equipped)

22 wc_si000393gb.fm

Page 23

RD 27 Lifting and Transporting

3 Lifting and Transporting

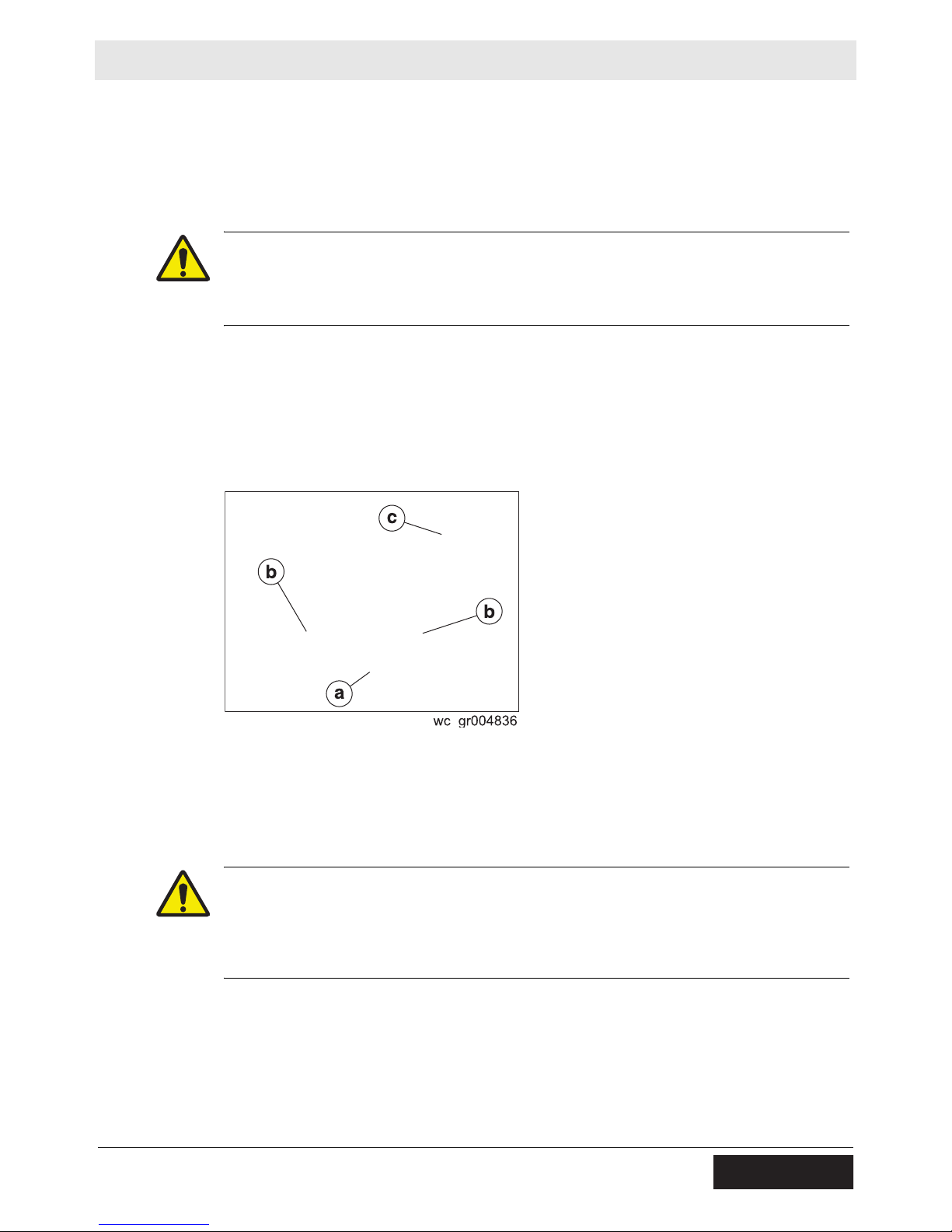

3.1 Lifting the Machine

Prerequisites

Procedure

Lifting equipment (crane or hoist) capable of supporting 2722 kgs. (6000 lbs.)

Four lifting hooks and chains capable of supporting 2722 kgs. (6000 lbs.)

WARNING

Crushing hazard. You may be crushed if the lifting devices fail.

f Never stand under, or get onto, the machine while it is being lifted or moved.

f Use only the designated lifting points to lift the machine.

Follow the procedure below to lift the machine.

1. Stop the engine.

2. Engage the parking brake.

3. Lock the articulated steering joint (a).

4. Attach one lifting chain to each of the four lifting eyes (b) on the machine (two

per side) using hooks or shackles.

5. Attach the other end of the chains to the lifting equipment.

6. Lift the machine as necessary.

CAUTION

Crushing / machine damage hazards. The Roll Over Protection Structure (ROPS)

(c) is intended strictly to protect the operator during a rollover or tip-over incident.

The ROPS must not be used to lift the machine.

f Use only the designated lifting eyes to lift the machine.

wc_tx001351gb.fm 23

Page 24

Lifting and Transporting RD 27

3.2 Tying Down/Transporting the Machine

Prerequisites

Procedure

Engine shut down

Parking brake ON

Follow the procedure below to tie down the machine.

1. Make sure that the transport vehicle is capable of handling the weight and size

of the machine. See Technical Data for dimensions and operating weight.

2. Lock the articulated steering joint (a).

c

wc_gr004992

3. Attach steel ropes or chains to each of the four tie down eyes (b) on the

machine (two per side) and the two tie down bars (c) on the front and rear of the

machine.

c

4. Attach the other end of the chains to an appropriate vehicle capable of handling

the weight of the machine.

Note: The transmission is normally braked when the diesel engine is off, or when

the hydraulic system is not functioning, unless there is a fault and/or the parking

brakes have been manually disabled.

NOTICE: Do not position ropes or chains across the machine frame or the articulated joint when tying down the machine. Damage to the machine may occur.

NOTICE: Do not completely compress the shock mounts when tying down the

machine. Damage to the shock mounts may occur.

NOTICE: Do not leave the machine tied down for extended periods of time (except

when transporting). Damage to the shock mounts may occur.

24 wc_tx001351gb.fm

Page 25

RD 27 Operation

4 Operation

4.1 Preparing the Machine for First Use

Preparing for

first use

To prepare your machine for first use:

1. Make sure all loose packaging materials have been removed from the machine.

2. Check the machine and its components for damage. If there is visible damage,

do not operate the machine! Contact your Wacker Neuson dealer immediately

for assistance.

3. Take inventory of all items included with the machine and verify that all loose

components and fasteners are accounted for.

4. Attach component parts not already attached.

5. Add fluids as needed, including fuel, engine oil, and battery acid.

6. Move the machine to its operating location.

4.2 Position of the Operator

Safe and efficient use of this machine is the operator’s responsibility. Full control of

the machine is not possible unless the operator maintains the proper working

position at all times.

While operating this machine, the operator must:

be seated in the operator’s seat facing forward

wear the seat belt, properly adjusted and latched

have both feet on the control deck

have one hand on the steering wheel at all times

have the other hand free to operate the controls as needed

wc_tx000814gb.fm 25

Page 26

Operation RD 27

4.3 Operation & Maintenance Locations

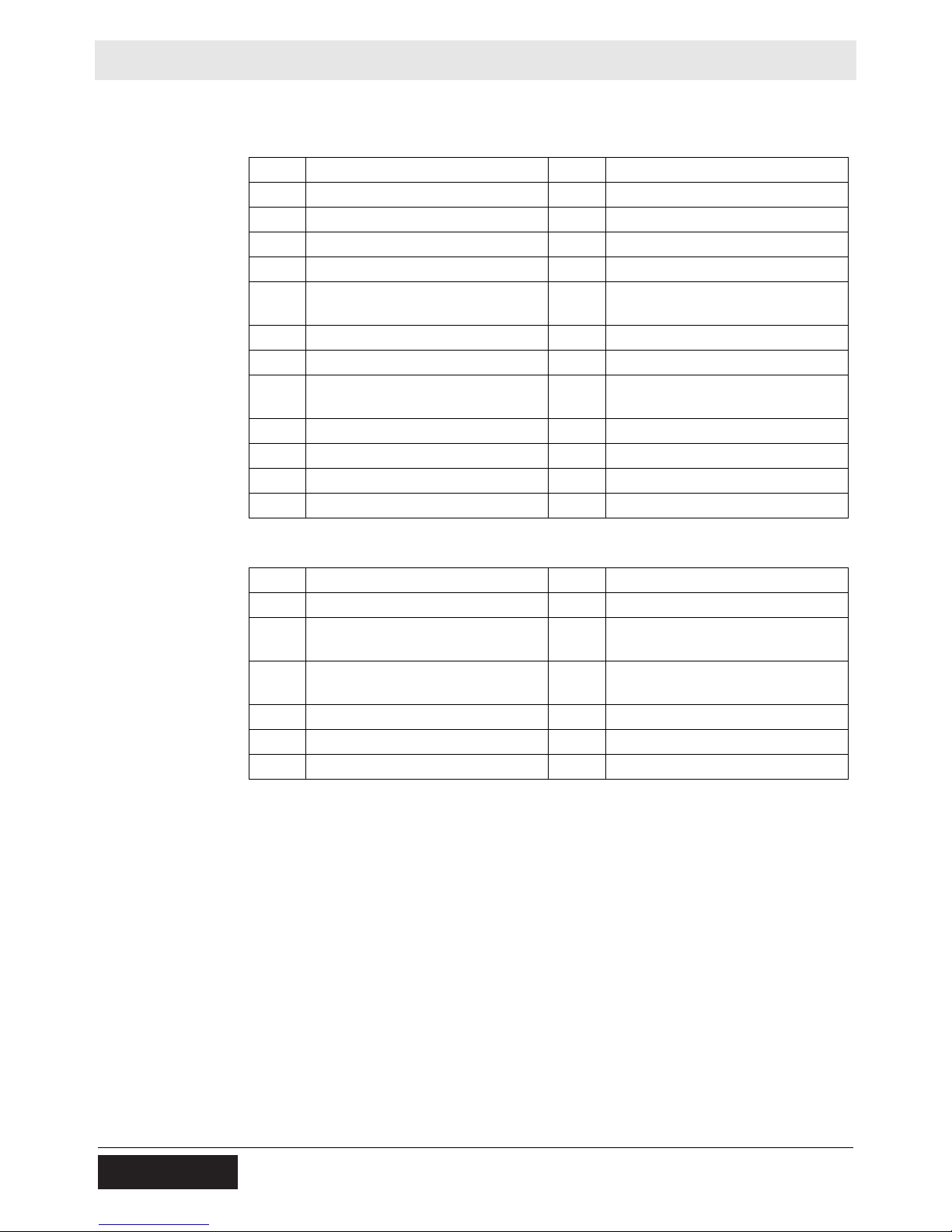

Ref. Description Ref. Description

a Throttle lever l Vibration mode switch

b Ignition key block m Vibration ON/OFF switch

c Alternator warning light n Water pump switch

d Engine oil pressure warning light o Engine temperature warning light

e Hydraulic oil temperature warn-

ing light

f Forward-reverse lever q Turn signal switch

g Horn r Flashers ON warning light

h Parking brake warning light and

control

i Vibration-on warning light t Flow divider switch (if equipped)

j Light switch u Turn signal indicator

k Fuse box v Lights ON indicator

-- -- w Light switch

p Hour meter

s Flasher activation switch

Ref. Description Ref. Description

1 Diesel engine 7 Front exciter hydraulic motor

2 Hydraulic transmission pump 8 Rear hydraulic transmission

motor

3 Front hydraulic transmission

motor

4 Rear exciter hydraulic motor 10 Brake

5 Exciter hydraulic pump 11 Oil cooler

6 Steering hydraulic pump 12 Electric water pump

9 Servo steering

26 wc_tx000814gb.fm

Page 27

RD 27 Operation

v

rwq iu s c hode

p

n l g j

b

a

9

t

1

11

7

10

3 10

2

k

m

12

6

5

10

f

4

10

8

wc_gr005016

wc_tx000814gb.fm 27

Page 28

Operation RD 27

4.4 Unlocking/Locking the Articulated Joint

Locking

Unlocking

Install the articulated steering joint pin in the LOCKED position (a) before you lift

the machine, transport the machine, or perform maintenance near the center of the

machine.

Install the articulated steering joint pin in the UNLOCKED position (b) before you

operate the machine.

NOTICE: Attempting to steer the machine with the articulated steering joint pin in

the locked position may destroy the steering cylinder and locking mechanism.

28 wc_tx000814gb.fm

Page 29

RD 27 Operation

4.5 Using the Roll Over Protection Structure (ROPS)

Background

Positioning

The machine is equipped with a Roll Over Protection Structure (ROPS). The ROPS

is designed to protect the operator in a rollover accident.

WARNING

Crushing hazard. You may be crushed if the machine rolls over.

f Never use the machine without the ROPS in place.

Follow the procedure below to position the ROPS in the upright position.

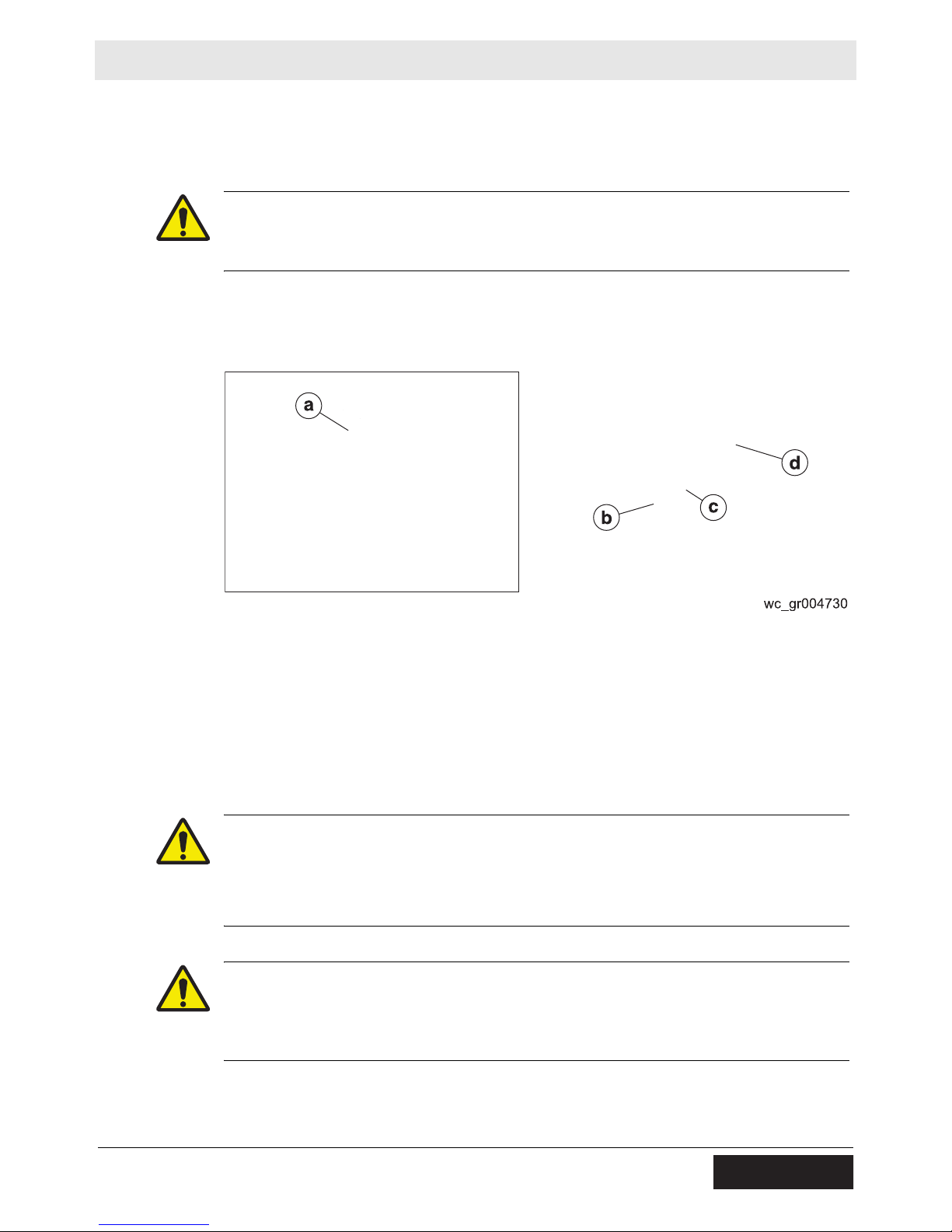

1. Support the ROPS (a) using a crane and suitable rigging capable of supporting

70 kg (155 lbs.).

2. Remove the safety pin (b) and pull out the locking pin (c).

3. Lift the ROPS into the upright position.

4. Insert the locking pin and secure it with the safety pin.

5. Tighten the adjusting screw (d) as needed to reduce vibration.

Keep the ROPS in the extended (upright) position when using the roller.

WARNING

Crushing / machine damage hazards. The ROPS is intended strictly to protect the

operator during a rollover or tip-over incident and must not be used to lift the

machine.

f Use only the designated lifting eyes to lift the machine. See Lifting the Machine.

WARNING

Personal injury hazard. The ROPS is not a handhold for passengers. Passengers

can be seriously injured or killed from falls, tip-overs, or roll-over incidents.

f Do not allow anyone to ride on any part of the machine.

wc_tx000814gb.fm 29

Page 30

Operation RD 27

Checking

Rules for reinstalling

Each month, check:

the torque on all of the screws holding the ROPS in place

the ROPS frame for rust, cracks, and any other damage

When reinstalling the ROPS:

Use the original nuts and bolts.

Use oil to lubricate the bolts before installing the ROPS.

Tighten the bolts to the specified torques.

NOTICE: Do not weld or drill into the ROPS. Drilling or welding on the ROPS will

nullify the ROPS certification.

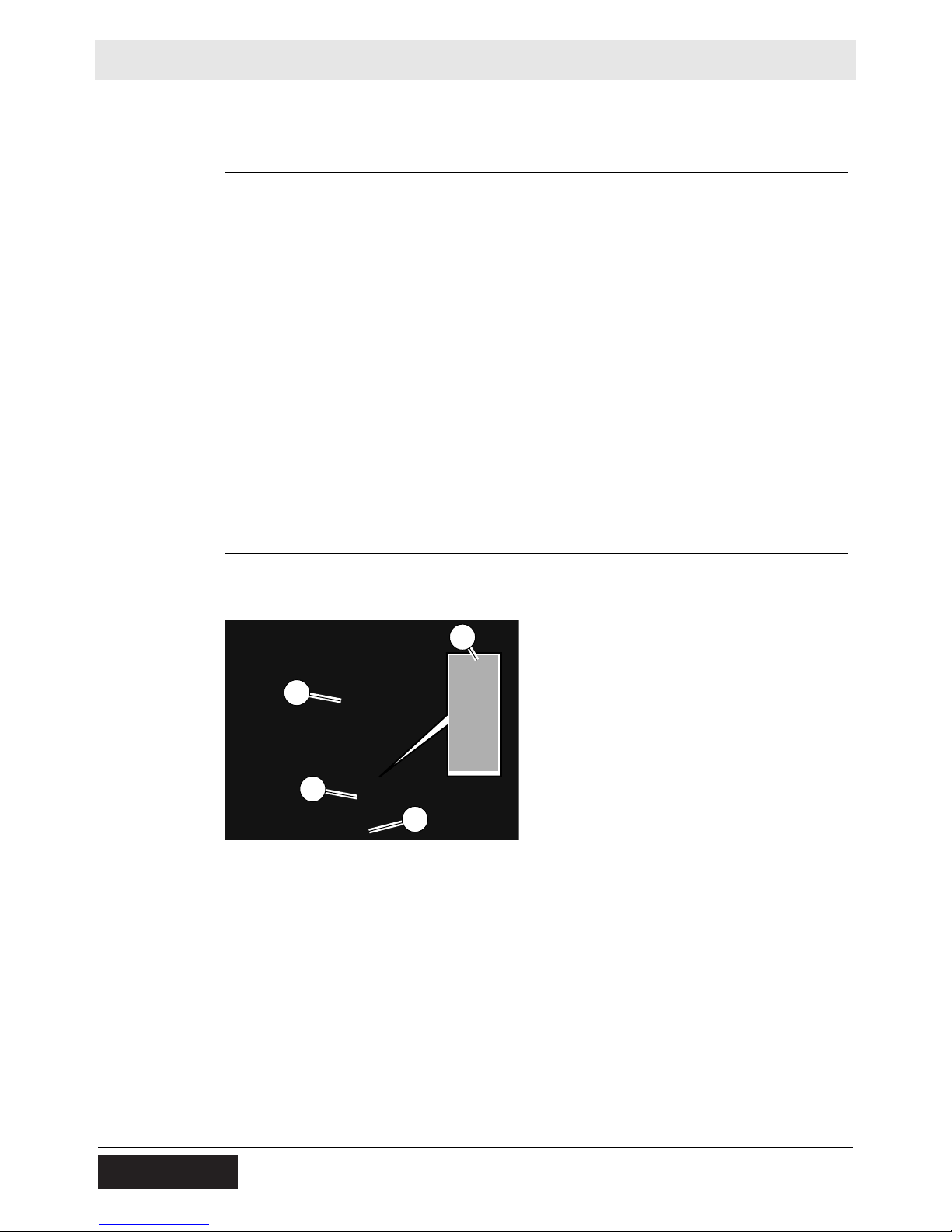

4.6 Installing the Rotating Beacon

Background

The rotating beacon illuminates and rotates when the key switch is in the ON

position.

Procedure

Follow the procedure below to install the beacon.

1. Thread the power wire (c) through the light staff and fix it to the upper connector.

a

d

b

c

wc_gr004731

2. Insert the connector into the light staff.

3. Insert the light staff assembly (a) into the left side of the machine ROPS and

tighten the set screw (b).

4. Slide the rotating beacon (d) onto the light staff.

30 wc_tx000814gb.fm

Page 31

RD 27 Operation

4.7 Using the Seat Belt

Precaution

To use

Always use the seat belt when operating the machine.

To use the seat belt:

1. Pull seat belt (c) out of the retractor in a continuous motion.

c

d

b

a

wc_gr002238

2. Fasten seat belt catch (b) into buckle (a).

3. Position the seat belt low across the lap of the operator. The retractor will adjust

the belt length and the retractor will lock in place.

4. Push the release button (d) on the buckle in order to release the seat belt. The

seat belt will automatically retract into the retractor.

wc_tx000814gb.fm 31

Page 32

Operation RD 27

4.8 Adjusting the Seat

Background

To adjust

Adjust the seat position and tension (firmness) according to working conditions and

operator’s weight.

The seat can be adjusted in three ways:

Tension Use knob (a) for adjusting seat tension. Turn from a minimum of

60 kg to a maximum of 120 kg (132 lb–264 lb).

Front to back Use lever

controls.

Side to side (optional) Use pin

ment holes (if so equipped).

(b) to adjust the front-to-back distance from the driving

(c) to set one of the three side-to-side position place-

32 wc_tx000814gb.fm

Page 33

RD 27 Operation

4.9 Adjusting the Steering Column

Background

To adjust

Adjust the angle of the steering column according to working conditions and the

operator’s height and personal preference.

The angle of the steering column can be adjusted as follows:

1. Loosen the four mounting bolts (a) at the base of the steering column.

2. Pivot the steering column forward or backward as desired.

3. Once the desired angle has been reached, re-tighten the mounting bolts.

4.10 Positioning the Scraper Bars

Prerequisites

Positions

Machine shut down

Parking brake engaged

Each drum has two scrapers (a, b). They may be set in the travel position (1) or the

scraping position (2).

wc_tx000814gb.fm 33

Page 34

Operation RD 27

4.11 Using the Anti-Vandalism Protection Devices

Background

Procedure

Parts of the machine may be subject to theft or vandalism when the machine is

unattended. These parts can be locked to prevent unauthorized access or use.

Lockable parts include:

Engine cover

Control console cover

Operator’s Manual holder

Follow the procedure below to lock the machine.

1. Close the engine cover and attach a padlock to the fastener (a).

wc_gr004735

2. Slide the control console cover over the console and attach a padlock to the

fastener (b).

3. Close the Operator’s Manual holder lid and attach a padlock to the fastener (c).

Note: Padlocks are supplied with the machine as standard.

34 wc_tx000814gb.fm

Page 35

RD 27 Operation

4.12 Using the Water Spray System

Switch

positions

Guidelines

when using

Water from the tank is fed to the spray nozzles by an electric pump. The switch

controls the water pump motor. The switch has three positions:

Position 1: activates the

intermittent water spray

Mid position (0): turns

off the water spray

0

system

Position 2: activates the

continuous water spray

When using the water spray system:

Check that the tank is full of water.

Use only clean water. Dirty water, even when filtered, can clog the system.

Keep the water system clean and well maintained. See Maintenance Section.

If spray does not begin immediately when the system is turned on, it may be

necessary to bleed air from the water lines. Opening the diaphragm valve (a)

while the system is running will force air out of the lines. Close the diaphragm

valve when water begins to spray through the nozzles.

Adjusting

To adjust the angle of spray:

Insert a screwdriver into the nozzle (b) and adjust the angle as desired.

Note: Ensure that water spray covers entire length of drum.

Draining

During winter, or when temperatures drop below 0°C (32°F), drain the water spray

system. See section Draining the Water Spray System.

wc_tx000814gb.fm 35

Page 36

Operation RD 27

4.13 Using the Forward/Reverse Lever

Background

Travel

direction

Both roller drums are driven. An infinitely variable displacement pump and

hydrostatic transmission drive the hydraulic motors fitted to each drum. The

machine moves forward or reverse by using the forward/reverse lever located to

the side of the driver’s seat.

Move the forward/reverse lever into FORWARD (f) or REVERSE (r) according to

the direction of travel desired.

To change direction of travel from FORWARD to REVERSE or vice versa:

Travel speed

Braking

Operator

present

system

1. Move the forward/reverse lever to the “N” NEUTRAL position (n).

2. Allow the machine to come to a complete stop.

3. Move the forward/reverse lever in the direction desired.

Note: In order to comply with safety standards, the machine has a device which

only enables starting of the engine when the forward/reverse lever is in the neutral

position.

Travel speed varies from “ZERO” to a permitted maximum of 10 kph (6.2 mph).

The farther forward or reverse the forward/reverse lever is positioned, the faster

the roller will travel.

Travel speed is the same in both FORWARD and REVERSE.

Note: When negotiating slopes, keep the forward/reverse lever at minimum travel

speed.

The forward/reverse lever can be used as an engine brake. Shifting the forward/

reverse lever to the neutral position stops the machine.

The machine is equipped with an operator present system. The system prevents

the machine from moving forward or reverse unless the operator is seated. The

operator should remain seated at all times.

36 wc_tx000814gb.fm

Page 37

RD 27 Operation

4.14 Backup Alarm

Location

Operation

The backup alarm (e) is located on the rear of the machine.

Start the engine and move the forward-reverse lever to the reverse position. The

backup alarm should sound immediately. The backup alarm will continue to sound

until the forward-reverse lever is moved to the neutral position or to the forward

position.

If the backup alarm does not sound, make the necessary repairs before using the

roller.

e

wc_gr005034

wc_tx000814gb.fm 37

Page 38

Operation RD 27

4.15 Using the Flow Divider (if equipped)

Background

Flow divider

switch

This machine may be equipped with an optional flow divider. Non-uniform soil

conditions, such as a combination of loose sandy material and large particles, may

cause the drums to rotate at unequal speeds. This may impede machine

movement. When activated, the flow divider equalizes the flow of hydraulic oil

traveling to each drive motor so that movement can be re-established.

The activation switch for the flow divider is foot-operated. Follow the procedure

below to activate the flow divider.

1. Locate the activation switch (a) on the operator’s platform to the right of the

steering column.

a

wc_gr005009

2. Press the activation switch once to turn the flow divider system on.

3. Press the activation switch again to turn the flow divider off.

NOTICE: The flow divider is designed for intermittent use only. Continuous use of

the flow divider will cause the hydraulic oil to become overheated, possibly

damaging the hydraulic system. Only use the flow divider if necessary to reestablish machine movement.

38 wc_tx000814gb.fm

Page 39

RD 27 Operation

4.16 Using the Vibration System

Background

Vibration

mode switch

Vibration

ON-OFF

switch

The machine has an exciter on each drum. The exciters are driven by gear-type

hydraulic motors. The exciter motors are fed by a fixed-displacement, gear-type

hydraulic pump.

Position 1: vibration of front drum

only.

Position 2: vibration of both drums.

When the switch is activated in

Position 1 or Position 2, the light (i)

on the control panel illuminates.

To start vibration, press button (m).

To stop vibration, press button (m)

again.

Frequency

NOTICE: Do not leave the vibration

running when the vehicle is to remain

stationary for some time. Leaving the

exciter on for a prolonged period

when the machine is stationary may

damage the exciter.

Note: Vibration will not run when the

forward/reverse control is in NEUTRAL.

Position 1: Use when starting or

shutting down the engine.

Position 2: Use for approximately 55

Hz of vibration.

Position 3: Use for approximately 66

Hz of vibration.

Note: Always use Position 2 or Position 3 when operating the machine.

wc_tx000814gb.fm 39

Page 40

Operation RD 27

4.17 Using the Parking Brakes

Background

To aid in holding the machine in a stopped position (parked), there is a mechanical

parking brake on each drum drive motor. The mechanical parking brakes are

spring-activated and hydraulically released (SAHR) type brakes.

The parking brakes are applied when any of the following conditions exist:

The parking brake push button (h) is pressed.

The engine is switched off.

The operator leaves the seat.

There is a fault in the hydraulic system.

h

wc_gr005010

Engaging and

releasing

Emergency

use

Pushing the button engages the parking brakes.

The “Brakes On” warning light illuminates when the button is pressed.

Pulling the button up allows the release of the parking brakes.

Note: All of the following conditions must be met for the parking brakes to release:

The engine must be running.

The forward/reverse lever must be in the neutral position.

The operator must be seated.

NOTICE: Do not use the parking brakes to stop the machine during normal

operating conditions. Using the parking brake while the machine is moving may

damage the drive motors.

Only use the parking brakes to stop the machine during an emergency condition.

For example:

During failure of the main hydraulic braking system (no braking action when the

forward/reverse lever is moved to the neutral position)

During a runaway condition traveling down a slope

40 wc_tx000814gb.fm

Page 41

RD 27 Operation

4.18 Warning Lights

Warning light Description Action Required

Engine oil pressure This light (d) illuminates

when the key switch is in

the ON position; it goes out

once the engine has

started, if engine oil pressure is OK.

Engine high temperature This light (o) illuminates

when the engine is overheating.

Alternator This light (c) illuminates

when the key switch is in

the ON position; it goes out

once the engine has

started, if the charging system is OK.

Hydraulic oil temperature This light (e) illuminates

when the hydraulic oil is too

hot.

Turn off the engine immediately if this light illuminates

when the engine is running.

Check:

Engine oil level

Engine oil viscosity

Turn off the engine immediately if this light illuminates.

Check:

Engine coolant level

Turn off the engine immediately if this light illuminates

while the engine is running.

Check:

Alternator belt

Turn off the engine immediately if this light illuminates.

Check:

Hydraulic oil level

Hydraulic oil viscosity

wc_tx000814gb.fm 41

d

o

c

e

wc_gr005012

Page 42

Operation RD 27

4.19 Using the Lights and Horn

Background

Identifying the

lights

Operating the

lights and

horn

The rotary switch on the control panel controls power to the machine’s lights.

Headlights (a)

Working light (b)

Front turn signal lights / roading lights (c)

Rear turn signal lights / roading lights (d)

dc a c d b

wc_gr005035

Position 0: all lights off

Position 1: headlights and roading lights ON

Position 2: headlights, roading lights, and work lights ON

Press the center of the switch to sound the horn.

0

1

2

wc_gr005032

WARNING

Collision hazard. Failure to use all available lights when working in the dark or in

bad visibility may increase the possibility of colliding with nearby people, vehicles,

or stationary objects.

f Use all available lights when working in the dark or in bad visibility.

f Replace broken lamps immediately.

42 wc_tx000814gb.fm

Page 43

RD 27 Operation

2

4.20 Machine Stability

WARNING

Crushing hazards. Certain job site conditions or operating practices may adversely

affect machine stability.

f

Follow the instructions below to reduce the risk of tipping or falling incidents.

Surface

conditions

Steering angle

Pay attention to changing surface conditions while operating the machine. Adjust

speed and travel direction as necessary to maintain safe operation.

Machine stability and traction may be severely reduced when operating on

uneven or rough terrain, rocky soils, or wet or loosely packed surface material.

The machine may suddenly tip, sink, or fall when moved onto surfaces that have

been newly filled with earth.

An articulated roller is more likely to tip when moving off an elevated surface if the

machine is turned away from the edge.

As shown in the illustration on the right, always turn the machine toward the

edge when moving off an elevated surface.

Travel speed

A fast moving machine is more likely to tip or fall over while making turns or

changing direction.

Reduce travel speed before turning the machine.

Drum

overhang

The machine can tip suddenly if more than half of the drum width extends beyond

the edge of the elevated surface.

Reduce travel speed and watch the drum position carefully when operating

along the edge of an elevated surface.

Keep as much of the drum on the elevated surface as possible.

Vibrating on a

compacted

surface

Activating the vibratory system on a fully compacted surface may cause the drums

to rebound and momentarily lose contact with the ground. If this occurs while the

machine is on an incline, the machine may slide.

If the drums rebound on the compacted surface, reduce vibration speed or stop

vibration entirely.

wc_tx000814gb.fm 43

wc_gr00704

Page 44

Operation RD 27

4.21 Operating on Slopes

Background

Procedure

When operating on slopes or hills, special care must be taken to reduce the risk of

personal injury or damage to the machine.

Always operate the machine up and down slopes rather than from side to side. For

safe operation and for protection of the engine, continuous duty use should be

restricted to slopes of 19° (35% grade) or less.

WARNING

Crushing hazard. Never operate the machine sideways on slopes. The machine

may tip or roll over even on stable ground.

f Operate the machine straight up and down slopes.

Surface

conditions

Pay attention to changing surface conditions while operating the machine. Adjust speed

and travel direction as necessary to maintain safe operation.

Machine stability and traction may be severely reduced when operating on uneven

or rough terrain, rocky soils, or wet or loosely packed surface material.

The machine may suddenly tip, sink, or fall when moved onto surfaces that have

been newly filled with earth.

44 wc_tx000814gb.fm

Page 45

RD 27 Operation

4.22 Preliminary Checks

Prerequisites

Before

starting

Before

operating

Machine on a flat, level surface

Before starting the machine, check the following items:

Engine coolant level

Engine oil level

Engine air filter indicator

Hydraulic oil level

Diesel fuel level

Condition of oil cooler and radiator cooling fins

Water level in tank

NOTICE: Top off the lubricating and hydraulic oil levels using products with the

grades and specifications shown in the “Lubricants” table found in the Technical

Data chapter of this Operator’s Manual. When doing so, use clean containers, funnels, etc., to avoid contamination.

Before operating the machine:

Unlock the articulated joint.

Adjust drum scraper position.

Check the machine for fluid leaks. Repair them before operating.

Check the work area for obstructions. Remove all obstructions.

Check that all handles, steps, and platforms are free of dirt, snow, grease, fuel,

or anything else which might endanger operator safety.

Allow the engine to warm up according to the following schedule:

Ambient Temperature Time (min.)

Above 0°C (32°F) 15

Below 0°C (32°F) 30*

* More time may be required if hydraulic controls are sluggish.

4.23 Mounting and Dismounting the Machine

When climbing on and off the machine, maintain a three-point contact with the

steps and the handholds.

Three-point contact can be:

two feet and one hand

one foot and two hands

wc_tx000814gb.fm 45

Page 46

Operation RD 27

4.24 Starting the Engine

DANGER

Asphyxiation hazard. Engine exhaust contains carbon monoxide which CAN KILL

YOU IN MINUTES. This is a poison that you cannot see or smell.

f Do not start the engine in enclosed spaces.

Procedure

Follow the procedure below to start the engine.

1. Sit down in the operator’s seat and fasten the seat belt.

2. Move the forward/reverse (f) lever to the NEUTRAL position.

3. Push the parking brake push button (h) to engage the parking brake.

4. Move the throttle to the LOW position (1).

5. Turn the starting key to POSITION 1. Check for power to the control panel. The

oil pressure and alternator lights should illuminate.

6. Turn the starting key to POSITION 2 and hold it there for approximately 15

seconds to supply power to the glow plugs. In warmer weather the time period

may be reduced.

7. Immediately after powering the glow plugs, turn the key to POSITION 3 to crank

the engine. When the engine fires, release the starting key to avoid straining the

starter motor.

NOTICE: Do not crank the engine for periods longer than 30 seconds. Turn the

key back to OFF and wait 15 seconds before cranking the engine again.

46 wc_tx000814gb.fm

Page 47

RD 27 Operation

4.25 Stopping the Engine

Prerequisites

Procedure

Flat surface with a suitable load-bearing capacity

Follow the procedure below to stop the engine.

1. Stop the machine on a flat surface with a suitable load bearing capacity.

2. Move the forward/reverse (f) lever to the NEUTRAL position.

3. Move the throttle lever to the LOW position (1).

NOTICE: Do not stop the engine suddenly after a lengthy period of running under

heavy loading. Allow the engine to run at low idling speed for a few minutes before

stopping it. This avoids a sudden drop in engine temperature when the engine is

stopped.

4. Push the parking brake push button (h).

5. Turn the key switch to POSITION 0 (OFF).

6. Remove the starting key before you leave the operator’s seat.

7. Chock the drums if the machine must be parked on a slope.

CAUTION

Obstruction hazard.

f Mark the machine with signs, lights, and other identification if the machine

poses an obstacle to traffic when parked.

wc_tx000814gb.fm 47

Page 48

Operation RD 27

4.26 Understanding the Operator Present System

Background

Operation

The machine is equipped with an operator present system. This system prevents

machine movement if the operator is not seated in the operator’s seat. The system

includes the seat switch and the neutral switch.

If the machine stops during operation, take the following steps to resume operation:

1. Sit in the operator’s seat.

2. Return the forward/reverse lever to the NEUTRAL position.

3. Operate the machine as normal.

Note: The seat switch is activated by operator weight when seated. Adjust the seat

tension so that the operator’s weight activates the seat switch. See section “Adjusting the Seat.”

4.27 Emergency Shutdown Procedure

If a breakdown/accident occurs while the machine is operating, follow the

procedure below.

1. Stop the engine.

2. Allow the engine and exhaust system to cool.

3. Using appropriate equipment, return the machine to an upright position if tipped

over.

4. Contact rental yard or machine owner.

48 wc_tx000814gb.fm

Page 49

RD 27 Operation

Notes:

wc_tx000814gb.fm 49

Page 50

Maintenance RD 27

5 Maintenance

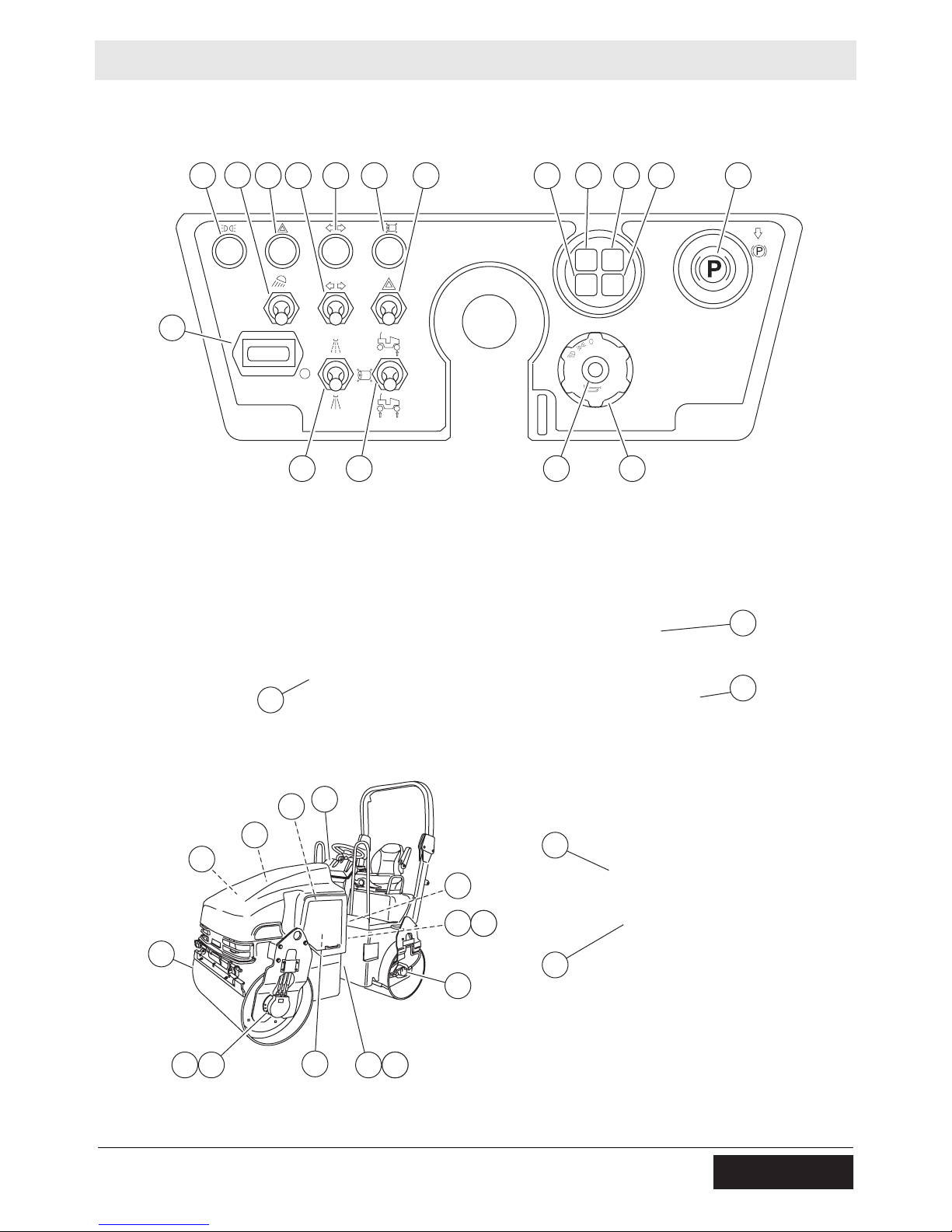

5.1 Periodic Maintenance Schedule

Tasks designated with check marks may be performed by the operator. Tasks

designated with square bullet points require special training and equipment.

Interval* (hours of service)

(10) (100) (250) (500) (1000) (3000) (12,000)

Item Task

Air cleaner Clean

Backup alarm Test

Engine coolant level Check

Engine oil level Check

Fuel level Check

Hydraulic oil level Check

Neutral switch Test

Scrapers Check

Seat belt Inspect

Spray nozzles Clean

Spray system filter Clean

External hardware Check

Daily 2

weeks3 months

3

3

3

3

3

3

3

3

3

3

3

3

Yearly Yearly 3

years

6

years

Fuel system water separator

Fuel tank Drain

Throttle control Lubricate

Water tank strainer Clean

Alternator belt Check

Articulated steering joint Lubricate

Steering cylinder Lubricate

Braking system Test

Engine oil and filter Change

Clean/

Drain

water/

sediment

3

3

3

3

3

3

3

3

3

50 wc_tx000815gb.fm

Page 51

RD 27 Maintenance

Interval* (hours of service)

(10) (100) (250) (500) (1000) (3000) (12,000)

Item Task

Exciter shaft bearings Re-pack

Fuel system water separator element

Fuel tank cap and strainer Clean

Hydraulic oil filter Change

Radiator/hydraulic oil

cooler

Shock mounts Check

Battery Check

Control lever tension Adjust

Engine: mounting bolts,

valve lash, cylinder head

bolts, exhaust system

Hydraulic oil Change

Hydraulic tank breather Replace

Replace

Clean

Inspect

Daily 2

weeks3 months

Yearly Yearly 3

years

3

3

3

3

3

3

3

3

3

3

6

years

Hydraulic tank strainer Clean

Radiator filler cap Clean

ROPS and mounting hardware

Engine water pump Check

Fuel injector Test

Cooling system coolant Change

Temperature

regulator

* Use whichever comes first, calendar time or service hours.

Inspect/

torque

Replace

3

3

3

3

3

wc_tx000815gb.fm 51

Page 52

Maintenance RD 27

5.2 Major Component Locations

1

5678

2

3

4

12

13

11

8

14

10 9

15

16

17

4

wc_gr005054

52 wc_tx000815gb.fm

Page 53

RD 27 Maintenance

5.3 Major Components

Ref. Description Ref. Description

1 Forward/reverse lever 10 Seat switch solenoid

2 Hydraulic tank 11 Hydraulic oil filter

3 Oil cooler 12 Suction strainer

4 Front vibration motor 13 Suction strainer

5 Steering cylinder 14 Drive pump

6 Steering pump 15 Flow divider

7 Vibration pump 16 Flow divider solenoid

8 Hydraulic motor 17 Vibration manifold

9 Steering valve - ---

wc_tx000815gb.fm 53

Page 54

Maintenance RD 27

3

5.4 Safety-Related Spare Parts

Overview

ROPS

diagram

This machine is equipped with several features to enhance operator safety. These

include the ROPS, the seat belt, and the Operator Presence switch. For your

convenience, we have provided the following diagrams and lists of replacement

parts for these safety-related features.

For a complete list of spare parts for this machine, contact your Wacker Neuson

dealer or visit www.wackerneuson.com.

wc_gr00704

54 wc_tx000815gb.fm

Page 55

RD 27 Maintenance

ROPS parts

list

Ref. Part No. Qty. Description Measurement

1 0161542 4 Screw

2 0161617 2 Shim

4 0162243 2 Control lever

5 0174257 1 ROPS frame

7 0161769 1 Label—warning

8 0162357 2 Label

9 0162007 2 Nut M16 x 2

10 0162011 2 Bolt M16 x 2

11 0162017 4 Bolt M16 x 2 x 50

12 0162059 8 Washer

13 0161850 2 Cable

14 0161940 4 Pin

15 0162247 4 Clevis pin

wc_tx000815gb.fm 55

Page 56

Maintenance RD 27

Seat

assembly

diagram

wc_gr007044

56 wc_tx000815gb.fm

Page 57

RD 27 Maintenance

Seat

assembly

parts list

Ref. Part No. Qty. Description Measurement

1 0161620 1 Skirt replacement kit

2 0161621 1 Seat slide kit

3 0161622 1 Indicator kit

4 0161744 1 Adjustable seat kit

5 0161853 1 Seat switch kit

6 0161855 1 Seat

7 0161854 1 Arm rest kit

8 0161856 1 Seat belt kit

wc_tx000815gb.fm 57

Page 58

Maintenance RD 27

Seat switch

diagram

wc_gr007045

58 wc_tx000815gb.fm

Page 59

RD 27 Maintenance

Seat switch

parts list

Ref. Part No. Qty. Description Measurement

1 0162359 1 Wiring harness, seat

2 0161998 1 Seat assembly

3 0174165 2 Spacer

4 0174181 2 Bolt 7/16-20

5 0161879 4 Strap—mounting

6 0174353 1 Clip

7 0161903 2 Washer

8 0161925 1 Cable clip

9 0174405 1 Grommet

10 0174406 2 Lock nut 7/16-20

11 0162006 1 Washer

12 0162023 2 Washer

5.5 Maintaining the Seat and Seat Belt

Background

Maintaining

the seat and

seat belt

In order for the seat and seat belt to operate safely and properly over a long period

of time, periodic maintenance and occasional repairs are necessary. Poorly

maintained equipment can become a safety hazard!

Keep the seat clean. Dirt, dust, or harsh chemicals can damage the upholstery.

Repair holes or tears immediately.

If necessary, clean the seat belt with a mild soap solution. Do not use chemical

cleaners, as they will damage the fabric.

Periodically test the operation of the seat tension knob and the front-to-back

lever. Repair or replace worn or malfunctioning components.

If the seat does not move smoothly during adjustment, apply a small amount of

standard bearing grease (such as Shell Alvania

®

RL2 or equivalent) to the rails.

wc_tx000815gb.fm 59

Page 60

Maintenance RD 27

5.6 Checking the Air Filter Indicator

Prerequisites

When

Procedure

Engine running

Parking brake on

Every 10 hours of service or daily

l

Follow the procedure below to check the air filter indicator.

1. Open the engine compartment.

2. Start the engine.

3. Place the throttle lever in the HIGH idle position.

4. Locate the air filter indicator (a).

If the yellow piston in the air filter indicator enters the red zone, clean the air

cleaner/air filters.

5. Turn off the engine.

60 wc_tx000815gb.fm

Page 61

RD 27 Maintenance

5.7 Cleaning the Air Cleaner and Primary Air Filter Element

Prerequisites

Background

Procedure

Machine shut down

Source of clean, dry, and low-pressure (less than 207 kpA (30 psi)) compressed

air

The air intake system is equipped with a filter indicator (a), which indicates when a

filter change is required. The primary air filter element can be cleaned and reused

up to six times; after that it must be replaced.

Follow the procedure below to clean the primary air filter element.

WARNING

Fire hazard.

f Never use gasoline or low flash-point solvents for cleaning the air filter.

1. Remove the cover (b) from the air filter housing.

2. Remove the primary air filter element (c) from the air filter housing.

3. Clean inside of the air filter housing.

4. Clean the primary air filter element with low-pressure (207 kpA (30 psi))

compressed air. Blow the air through the primary air filter element from the

inside to the outside.

5. Hold the primary air filter element up to the light or pass a lamp through the

middle to check the condition of the element.

NOTICE:

Do not re-use a damaged primary air filter element. Replace it even if damage is

very slight.

Do not tap or strike the primary air filter element to clean it.

Do not wash the primary air filter element.

6. Re-install the primary air filter element (c).

7. Reassemble the cover (b), positioning the breather (d) so that it is not

obstructed.

8. Push the black rubber button (several times if need be) on top of the filter

indicator to reset it.

wc_tx000815gb.fm 61

Page 62

Maintenance RD 27

5.8 Changing the Air Filter Elements

Prerequisites

Primary filter

element

Machine shut down

New primary air filter element

New secondary air filter element if required

NOTICE: Do not use the air filters as a starting aid (e.g., ether) intake.

Follow the procedure below to change the primary air filter element.

1. Remove the cover (b) from the air filter housing.

Secondary

filter element

2. Remove the primary air filter element (c).

3. Clean the inside of the air filter housing.

4. Install the new primary air filter element.

5. Replace the cover. Position it so that the breather (d) is not obstructed.

6. Reset the filter indicator (a).

Follow the procedure below to change the secondary air filter element.

Note: Change the secondary air filter element (e) every third time the primary air

filter element is changed.

1. Remove the cover (b) from the air filter housing.

2. Remove the primary air filter element (c).

3. Remove the secondary air filter element.

4. Cover the intake port and clean inside of the air filter housing.

NOTICE: Do not allow dirt to get into the engine intake port. Damage to the engine

will result.

5. Remove the cover from the intake port and install the new secondary air filter

element.

NOTICE: The secondary filter element has two rubber seals—one wider than the

other. Make sure to insert the end with the narrow seal. Damage to the engine will

result if the filter element is inserted incorrectly.

This procedure continues on the next page.

62 wc_tx000815gb.fm

Page 63

RD 27 Maintenance

Continued from the previous page.

6. Install the new primary air filter element.

7. Replace the cover (b). Position it so that the breather (d) is not obstructed.

8. Reset the filter indicator (a).

5.9 Testing the Backup Alarm

Background

When

Testing

Procedure

The backup alarm is located on the rear of the machine.

Every 10 hours of service or daily

Follow the procedure below to test the backup alarm.

1. Turn the starting key to POSITION 1.

2. Move the forward/reverse lever to the reverse position.

The backup alarm should sound immediately. The backup alarm will continue to

sound until the forward/reverse lever is moved to the NEUTRAL position or to the

FORWARD position.

NOTICE: If the backup alarm does not sound, make the necessary repairs before

using the machine.

wc_tx000815gb.fm 63

Page 64

Maintenance RD 27

5.10 Checking the Engine Coolant Level

Prerequisites

When

Procedure

Machine shut down

Engine cool

Every 10 hours of service or daily

l

Follow the procedure below to check the engine coolant level.

WARNING

Burn hazard. Engine coolant is hot and under pressure at operating temperature. It

can cause severe personal injury.

f Check the coolant level only after the engine has been shut down and is cool.

1. Open the engine compartment.

2. Open the radiator filler cap (a) slowly in order to relieve the pressure. Remove

the filler cap after the pressure has been released.

CAUTION

Burn hazard. Coolant can contain alkali.