Vulcan Hart VSX42GT, VSX42ET, VSX42RT Operation Manual

FOOD STEAMERS

MODEL

INSTALLATION,

OPERATION, SERVICE &

PARTS MANUAL

VSX24G ML-52163

VSX36G ML-52360

VSX42GT ML-52832

VSX24E ML-52164

VSX36E ML-52829

VSX42ET ML-52833

VSX24D ML-52827

VSX36D ML-52830

VSX42DT ML-52834

VSX36R ML-52831

VSX42RT ML-52835

MODEL VSX24

VULCAN-HART COMPANY, P.O. BOX 696, LOUISVILLE, KY 40201-0696, TEL. (502) 778-2791

FORM 30798 (Rev. A, 10-95)

2

IMPORTANT FOR YOUR SAFETY

THIS MANUAL HAS BEEN PREPARED FOR PERSONNEL QUALIFIED TO INSTALL GAS

EQUIPMENT, WHO SHOULD PERFORM THE INITIAL FIELD START-UP AND

ADJUSTMENTS OF THE EQUIPMENT COVERED BY THIS MANUAL.

POST IN A PROMINENT LOCATION THE INSTRUCTIONS TO BE FOLLOWED IN THE

EVENT THE SMELL OF GAS IS DETECTED. THIS INFORMATION CAN BE OBTAINED

FROM THE LOCAL GAS SUPPLIER.

IMPORTANT

IN THE EVENT A GAS ODOR IS DETECTED, SHUT

DOWN UNITS AT MAIN SHUTOFF VALVE AND

CONTACT THE LOCAL GAS COMPANY OR GAS

SUPPLIER FOR SERVICE.

FOR YOUR SAFETY

DO NOT STORE OR USE GASOLINE OR OTHER

FLAMMABLE VAPORS OR LIQUIDS IN THE

VICINITY OF THIS OR ANY OTHER APPLIANCE.

WARNING

IMPROPER INSTALLATION, ADJUSTMENT,

ALTERATION, SERVICE OR MAINTENANCE CAN

CAUSE PROPERTY DAMAGE, INJURY OR DEATH.

READ THE INSTALLATION, OPERATING AND

MAINTENANCE INSTRUCTIONS THOROUGHLY

BEFORE INSTALLING OR SERVICING THIS

EQUIPMENT.

IN THE EVENT OF A POWER FAILURE, DO NOT

ATTEMPT TO OPERATE THIS DEVICE.

3

INSTALLATION, OPERATION, SERVICE & PARTS MANUAL

CONVECTION FOOD STEAMERS

GAS, ELECTRIC, REGENERATIVE OR DIRECT STEAM

MODELS VSX24, VSX36 & VSX42 INDEX

PLEASE KEEP THIS MANUAL FOR FUTURE REFERENCE

Your Vulcan Steam Cooker is produced with quality

workmanship and material. Proper installation, usage

and maintenance of your steam cooker will result in

many years of satisfactory performance.

The manufacturer suggests that you thoroughly read

this entire manual and carefully follow all of the instructions provided.

DESCRIPTION PAGE

INDEX 4, 5

INSTALLATION 6

UNPACKING 6

LOCATION 6

INSTALLATION CODES AND STANDARDS 6, 7

LEVELING AND ANCHORING 7

SERVICE CONNECTIONS 7-19

Steam Connections 7

Gas Connections 7

Electrical Connections 8

Drain Connections 8

Plumbing Connections 8

VENT HOOD 8

SERVICE CONNECTION DIAGRAMS 9-19

START-UP TEST RUN 20, 21

BLOW DOWN BOILER 21

OPERATION 22

CONTROLS - CABINET BASE GENERATOR 22, 23

CONTROLS - COMPARTMENT 24

LIGHTING STANDING PILOT (GAS BASE GENERATORS ONLY) 24

4

DESCRIPTION PAGE

OPERATION (CONT’D.)

OPERATING STEAMERS WITH INTERMITTENT PILOTS (GAS BASE GENERATORS ONLY) 24, 25

DAILY STARTING PROCEDURE 25

CLEANING 25, 26

MAINTENANCE 26

COOKING CHART 27-29

TROUBLESHOOTING 30-32

SERVICE 33

COOKING COMPARTMENT 33

CABINET BASE GENERATOR 33-38

All Generators 33-37

Gas Generators 37, 38

Electric Generators 38

Regenerating (Steam Coil) Generators 38

REPLACEMENT PARTS LIST 39-70

5

INSTALLATION

UNPACKING

This steam cooker was inspected before leaving the

factory. The transportation company assumes full

responsibility for safe delivery upon acceptance of the

shipment. Immediately after unpacking, check for

possible shipping damage. If the cooker is found to be

damaged after unpacking, save the packaging material

and contact the carrier within 15 days of delivery.

Before installing, verify that the gas (natural or propane)

and/or electrical supplies agree with the specifications

on the rating plate which is located on the inside base

cabinet door. If the supply and equipment requirements

do not agree, do not proceed with the installation.

Contact your dealer or Vulcan-Hart immediately.

LOCATION

Position the steamer in its final location. Check that

there are sufficient clearances to service the controls,

for door swings, etc., so there will be no problem in

making the required supply and drain connections.

Recommended clearances are 18" on the sides and

back and 36" in the front.

The steamer must be installed so that the flow of

combustion and ventilation air will not be obstructed.

Adequate clearance for air openings into the combustion

chamber of the gas cabinet base generator must be

provided. The floor area beneath the burners must be

kept free and clear. Make sure there is an adequate

supply of air in the room to allow for combustion of the

gas at the burners.

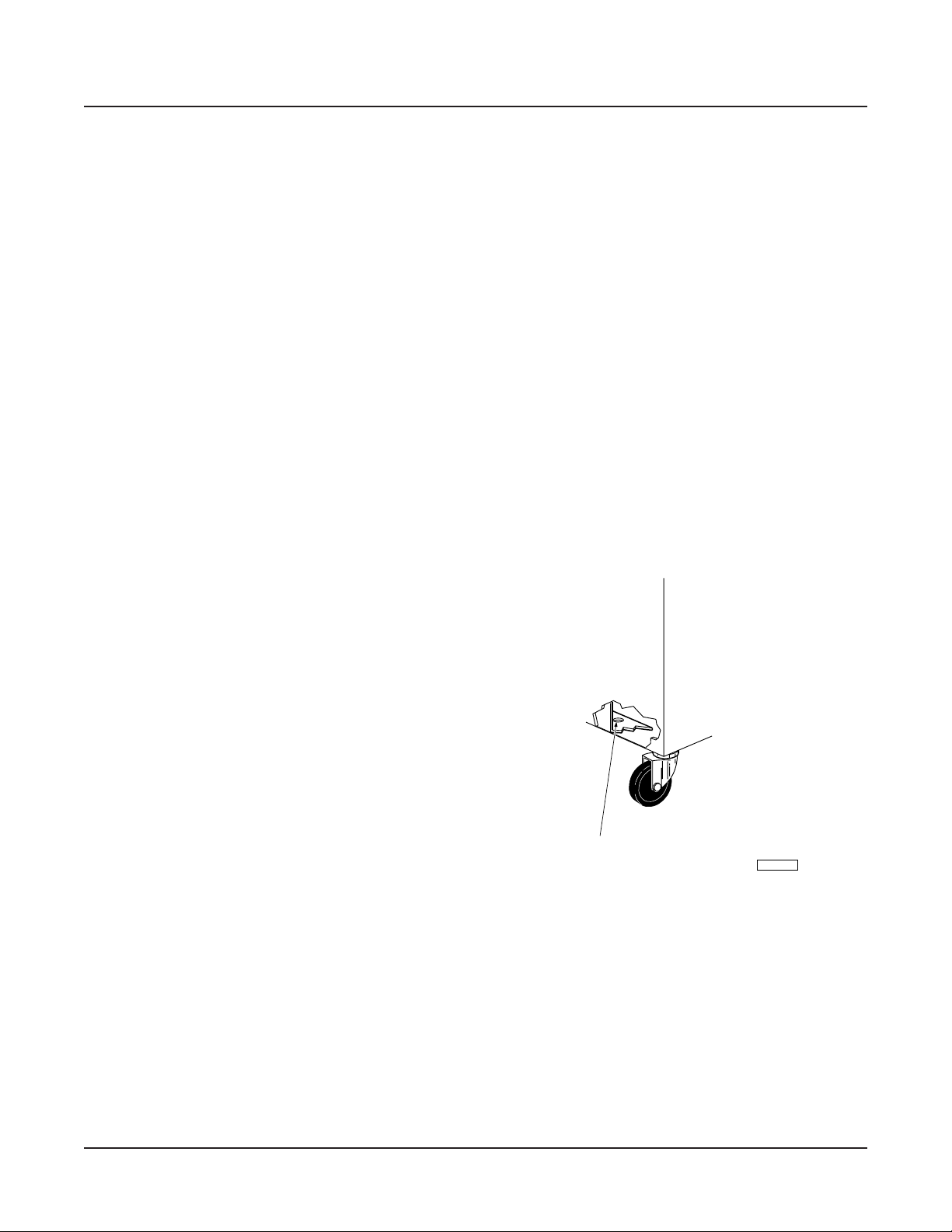

When steamers are mounted on casters, you must use

a connector that complies with the Standard for

Connectors of Movable Gas Appliances, ANSI-Z21.69

(latest edition), and a quick-disconnect device that

complies with the Standard for Quick-Disconnect

Devices for Use With Gas Fuel, ANSI-Z21.41 (latest

edition).

Provide a gas line strain relief to limit movement of the

steamer without depending on the connector and/or any

quick-disconnect device or its associated piping to limit

movement of the steamer. Attach the gas line strain

relief to the rear of the steamer (Fig. 1).

Allow enough space between any other piece of

equipment or a wall for access. All service on the

compartment controls begins by removing the panel on

the right side of the compartments. Service on the

cabinet base may require the removal of the panel on

either or both the left or right sides.

A floor drain (open gap) is required immediately below

the steamer drain.

An exhaust system should be located directly above

the steamer to exhaust steam and heat generated by

the steamer.

For Gas Powered Steam Generators Only

The equipment area must be kept free and clear of

combustible substances.

The steamer, when installed, must have a minimum

clearance from combustible and noncombustible

construction of 6" at the sides and 6" at the back. It

must be installed on a noncombustible floor. The

installation location must allow adequate clearances

for servicing and proper operation.

1/2 IN. DIA. HOLE

PROVIDED FOR

STRAIN RELIEF

Should it be necessary to disconnect the restraint, turn

off the gas supply before disconnection. Reconnect the

restraint before turning the gas supply on and returning

the steamer to its installation position.

INSTALLATION CODES AND STANDARDS

Your Vulcan steamer must be installed in accordance

with:

PL-51218

6

In the United States:

STEAM CONNECTIONS

1. State and local codes.

2. National Fuel Gas Code, ANSI-Z233.1 (latest

edition). Copies may be obtained from The

American Gas Assoc., Inc., 1515 Wilson Blvd.,

Arlington, VA 22209.

3. National Electrical Code, ANSI/NFPA No. 70 (latest

edition). Copies may be obtained from The

National Fire Protection Assoc., Batterymarch Park,

Quincy, MA 02269.

In Canada:

1. Local codes.

2. CAN/CGA-B149.1 Installation for Natural Gas

Burning Appliances and Equipment (latest edition).

3. CAN/CGA-B149.2 Installation for Propane Burning

Appliances and Equipment (latest edition). Copies

may be obtained from The Canadian Gas Assoc.,

55 Scarsdale Road, Don Mills, Ontario, Canada

M3B 2R3.

Provide dry steam to the inlets. If the steam is heavy

with condensate, install a ball float trap before the

pressure regulator valve. To ensure rapid heat-up of

heavy cold loads, the steam supply line must be sized

to maintain pressure and flow as follows:

Direct Connected Steamers (Fig’s. 2-4)

Supply steam at a pressure of 10-12 psi and at a

minimum flow rate of 50 lb. per hour per compartment.

A pressure reducing valve is furnished and set at 10 psig.

Additional steam kettles and kettle modules can

be interconnected to the steamer. Consult Vulcan-Hart

for recommendations.

Regenerating (Steam Coil) Generators (Fig’s. 5 & 6)

The steam supply to the steam coils must be 15 psi at

a minimum flow rate of 125 lb. per hour to the coil.

GAS CONNECTIONS (Fig’s. 7, 8 & 9)

All gas supply connections and any pipe joint

compound used must be resistant to the action of

propane gases.

4. The Canadian Electrical Code, Part 1, C22.1 (latest

edition). Copies may be obtained from the

Canadian Standards Assoc., 178 Rexdale Blvd.,

Rexdale, Ontario, Canada M9W 1R3.

LEVELING AND ANCHORING

Using a spirit level, adjust the feet to level the steamer

left-to-right and front-to-back. Steamers should be

elevated in the front just enough (about 1/16" to 1/8") to

give proper drainage. To do this, rotate rear leg

adjusting nut by 1 to 11⁄2 turns clockwise after leveling.

(Check by pouring a little water in the compartment; all

the water should drain.)

The rear feet have holes in the flanges for anchor bolts.

DIRECT STEAM COOKERS (STEAMERS WITHOUT

GENERATORS) MUST BE ANCHORED TO THE

FLOOR.

SERVICE CONNECTIONS (See Fig’s. 2-12)

Connect gas supply to the gas cabinet base generator

using 3⁄4” pipe. Make sure the pipes are clean and free

of obstructions.

Codes require that a gas shutoff valve be installed in

the gas line ahead of the steam generator.

This gas cabinet base generator is equipped with fixed

orifices for use with natural or propane gas and no

adjustment is necessary.

The gas line must be capable of delivering gas to the

generator without excessive pressure drop at the rate

specified on the rating plate. The generator is equipped

with a factory preset pressure regulator. Natural gas

pressure regulators are preset for 3.5" W.C. (Water

Column) for natural gas. Propane gas pressure

regulators are preset for 10" W.C. No further adjustment

should be required.

WARNING: PRIOR TO LIGHTING, CHECK ALL

JOINTS IN THE GAS SUPPLY LINE FOR LEAKS.

USE SOAP AND WATER SOLUTION. DO NOT USE

AN OPEN FLAME.

After piping has been checked for leaks, all piping

receiving gas should be fully purged to remove air.

7

Testing The Gas Supply System

DRAIN CONNECTIONS (Fig’s. 2-12)

When test pressures exceed 1⁄2 psig (3.45 kPa), the

generator and its individual shutoff valve must be

disconnected from the gas supply piping system.

When test pressures are 1⁄2 psig (3.45 kPa) or less, the

generator must be isolated from the gas supply system

by closing its individual manual shutoff valve.

ELECTRICAL CONNECTIONS (Fig’s. 2-12)

WARNING: ELECTRICAL AND GROUNDING

CONNECTIONS MUST COMPLY WITH THE

APPLICABLE PORTIONS OF THE NATIONAL

ELECTRICAL CODE ANSI/NFPA-70 (LATEST

EDITION) AND/OR OTHER LOCAL ELECTRICAL

CODES.

WARNING: DISCONNECT ELECTRICAL POWER

SUPPLY AND PLACE A TAG AT THE DISCONNECT

SWITCH TO INDICATE THAT YOU ARE WORKING

ON THE CIRCUIT.

Do not connect the steamer to electrical supply until

after gas connections (if applicable) have been made.

All Models

Drain connections must be the open air gap type.

Provide a suitable drain under the drain pipes. For

proper drainage, a floor sink with minimum of 12" depth

is recommended.

CAUTION: In order to avoid any back pressure in

the steamer, do not connect solidly to any drain

connection.

PLUMBING CONNECTIONS (Fig’s. 2-12)

WARNING: PLUMBING CONNECTIONS MUST

COMPLY WITH APPLICABLE SANITARY, SAFETY

AND PLUMBING CODES.

Before connecting the steamer to water, the water

supply should be analyzed to make sure hardness is

less than 2.0 grains per gallon and pH of 7.5. The water

supply should be clear with no sediment or suspended

material present. If the water supply fails to meet these

standards, it will be necessary to install a water

conditioner on the boiler water feed. APPLIANCE

FAILURE CAUSED BY INADEQUATE WATER

QUALITY IS NOT COVERED UNDER WARRANTY.

The use of strainers or filters will not remove minerals

from the water.

Unless otherwise specified, field wire electrical

connection is to be 120 volts, 60 Hertz, single phase,

with grounding wire. Connect electrical supply to the

pigtail leads in the supply junction box located next to

the boiler control box for electric generators in a 24"

wide base, and under the boiler control box for all other

generator bases. The supply junction box is located on

the underside of the cabinet top on direct steam

models. Use copper wire suitable for at least 75°C

temperature. A grounding wire must be connected to

the ground lug in the junction box.

When optional step down transformer is used on

electrically heated generators, the 120 volt connection

is not required.

Electrically Heated Generators

Make the electrical supply connection in the junction

box on the contactor box. The supply wiring and circuit

protection must be adequate for the kilowatt load drawn

by the cooker. A grounding wire must be connected to

the ground lug in the junction box. Use copper wire of

the size and temperature rating marked on the supply

label.

Cold Water

Used as boiler fill water and cold water condenser on

boiler blowdown line. Connect a cold water line to the

1

⁄4” N.P.T. cold water condensor line. Twenty (20) psig

minimum water pressure is required at the connections.

VENT HOOD

Information on the construction and installation of

ventilating hoods may be obtained from the standard

for “Vapor Removal from Cooking Equipment,” NFPA

No. 96 (latest edition).

8

SERVICE CONNECTIONS

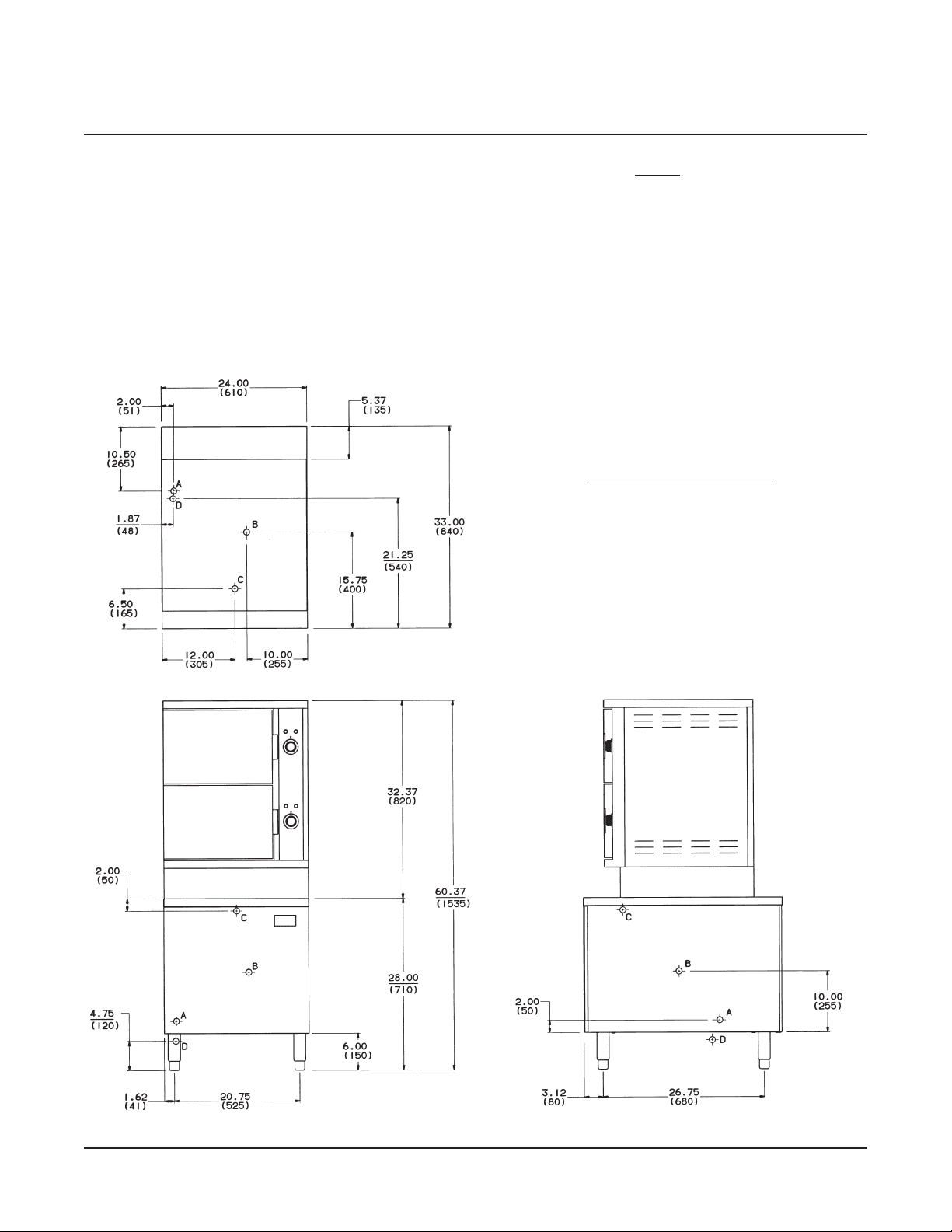

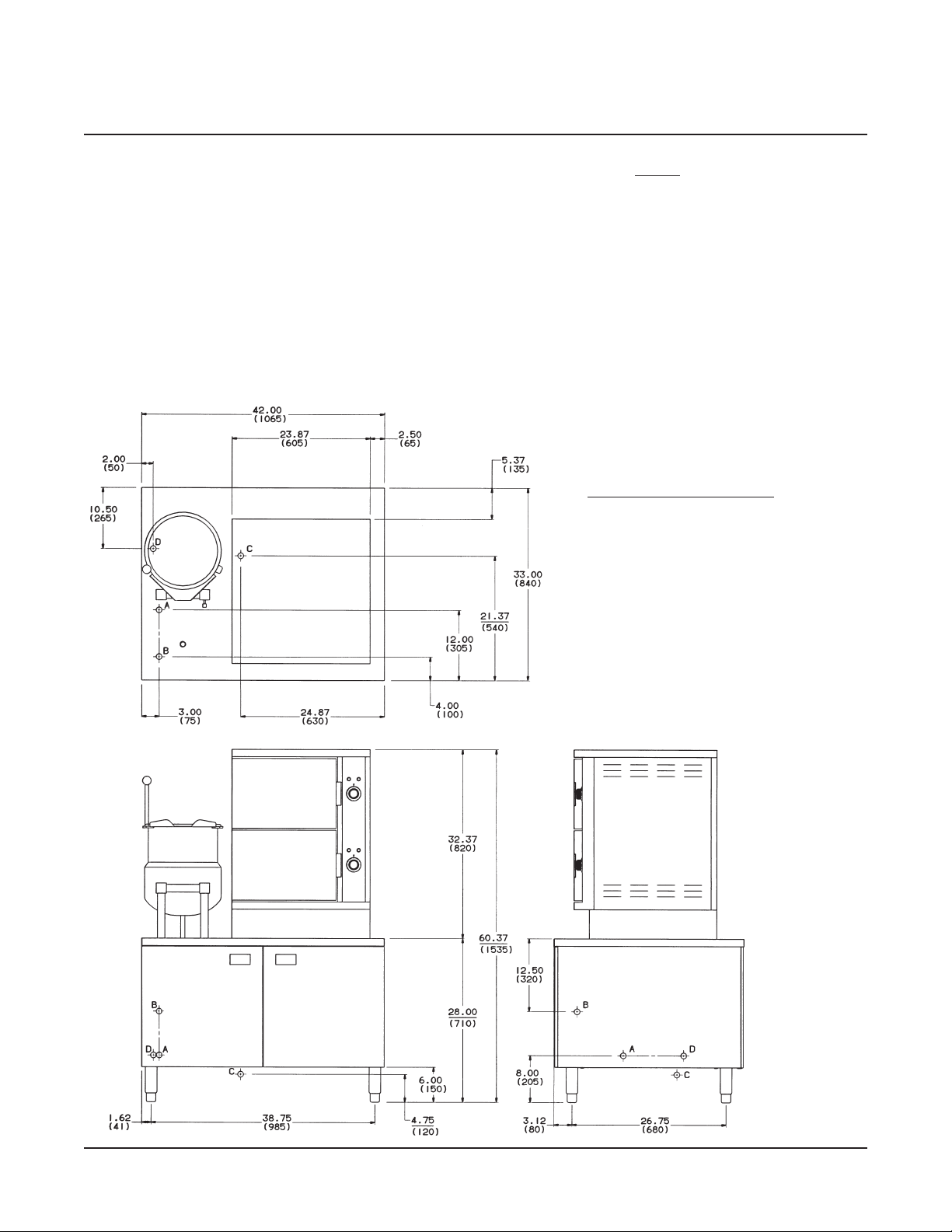

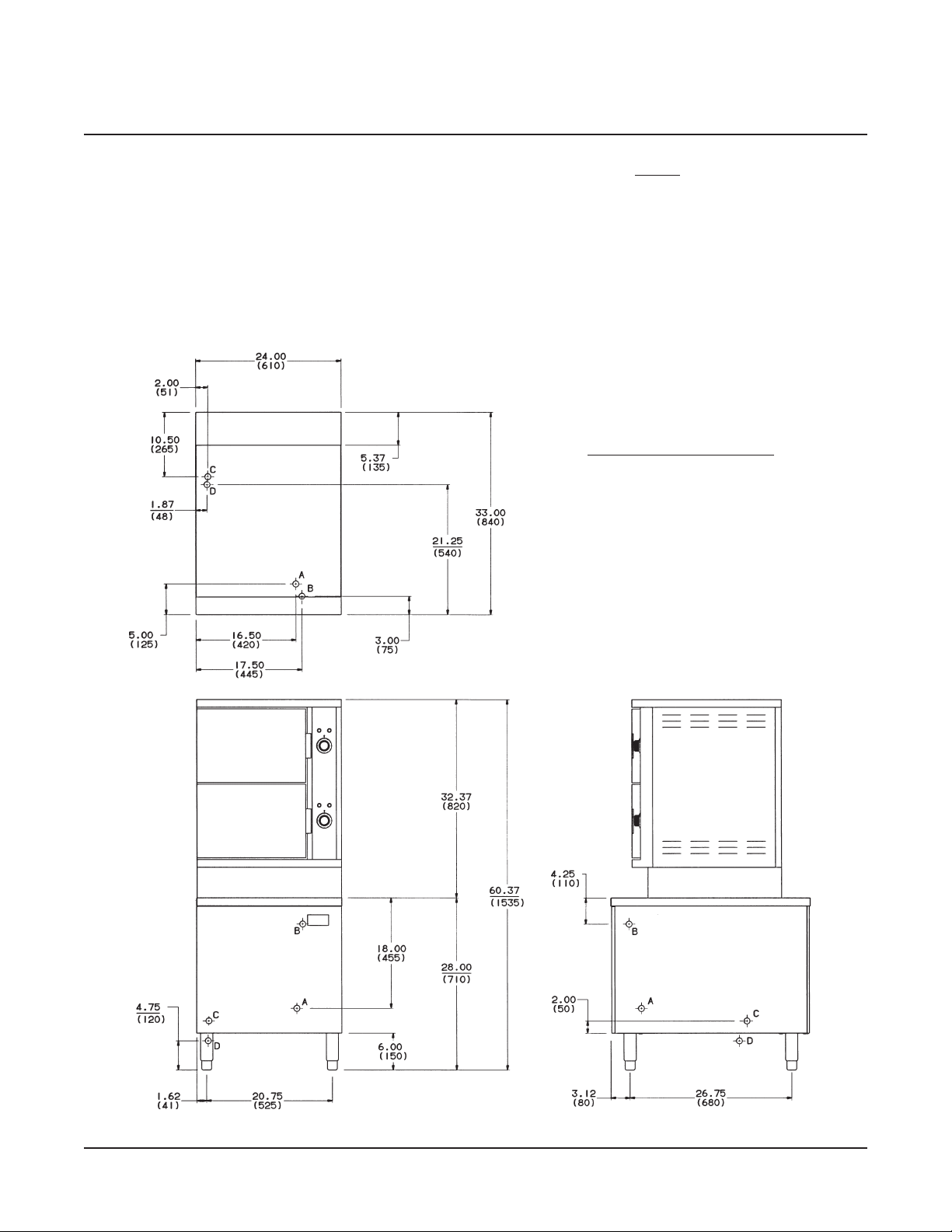

DIRECT STEAM, VSX24D FIG. 2

LEGEND

A. COLD SUPPLY WATER CONNECTION:

CONDENSER SUPPLY, AND BOILER FEED.

B. STEAM SUPPLY CONNECTION:

PRESSURE REDUCING VALVE IS MOUNTED AS STANDARD AND SET FOR 10

PSI MAXIMUM INPUT TO UNIT).

C. ELECTRICAL CONNECTION FOR CONTROLS: 120V/60HZ/1PH/300 WATT

MAXIMUM, POWER SUPPLY WITH GROUNDING WIRE REQUIRED. (FOR

OTHER THAN 120 VOLT SUPPLY CONSULT FACTORY FOR LOCATION OF

THIS CONNECTION.)

D. DRAIN: COPPER TUBE COMPARTMENT & EXHAUST GROUP APPROXIMATELY

2" IN DIAMETER. (PROVIDE AN OPEN AIR GAP TYPE DRAIN DIRECTLY

UNDER THE UNIT FRAME. DO NOT CONNECT SOLIDLY TO ANY DRAIN

CONNECTION.)

NOTE: DIMENSIONS WHICH LOCATE THE ABOVE CONNECTIONS HAVE A

TOLERANCE OF ± 3 IN. (± 75 MM). NORMAL DIMENSIONS ARE IN INCHES.

DIMENSIONS IN ( ) ARE IN MILLIMETERS.

EQUIPMENT CLEARANCES

TO COMBUSTIBLE CONSTRUCTION

REAR: 2 IN. MIN. (50 MM.)

3

⁄4” NPT FOR STEAM COOKING (A STEAM

1

⁄4” TUBING FOR COLD WATER

9

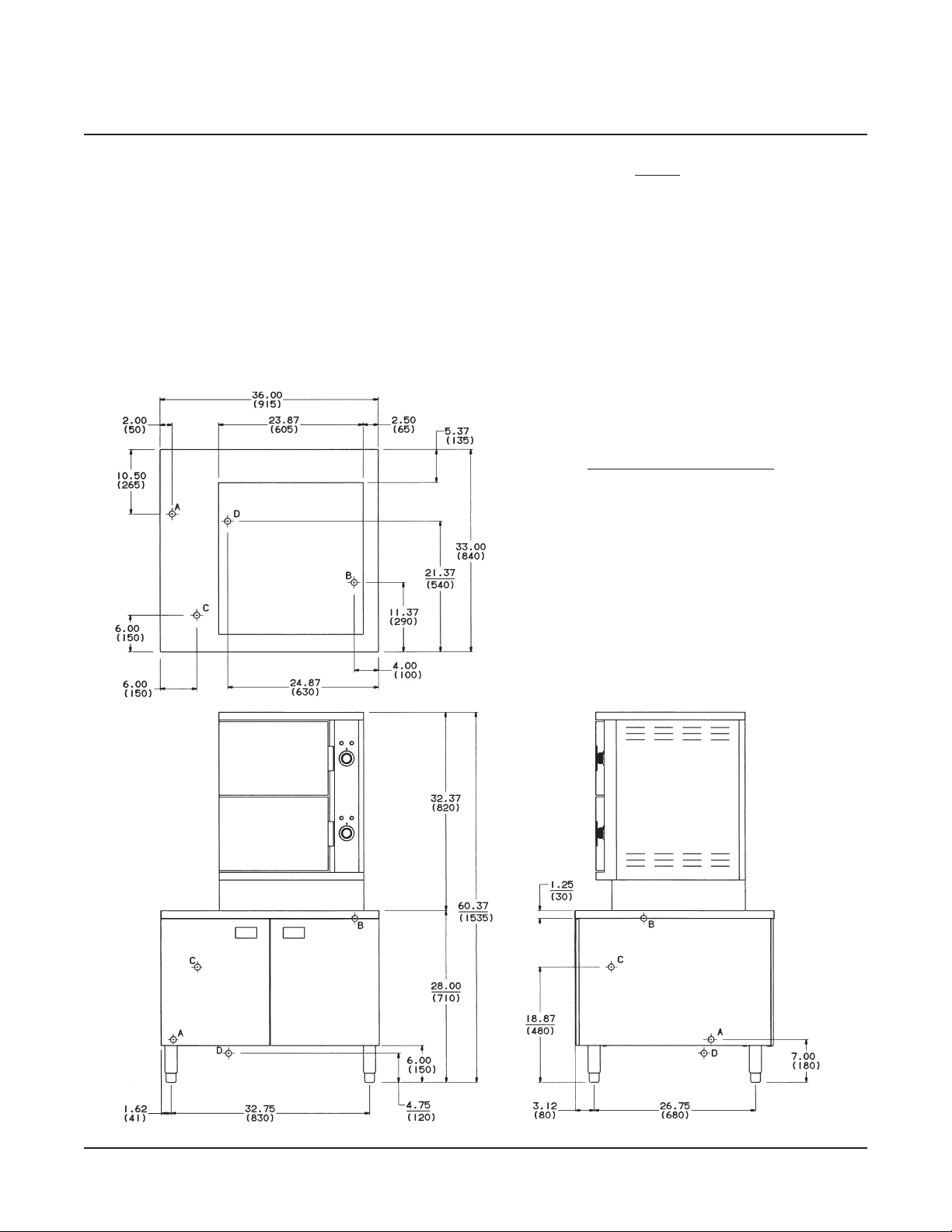

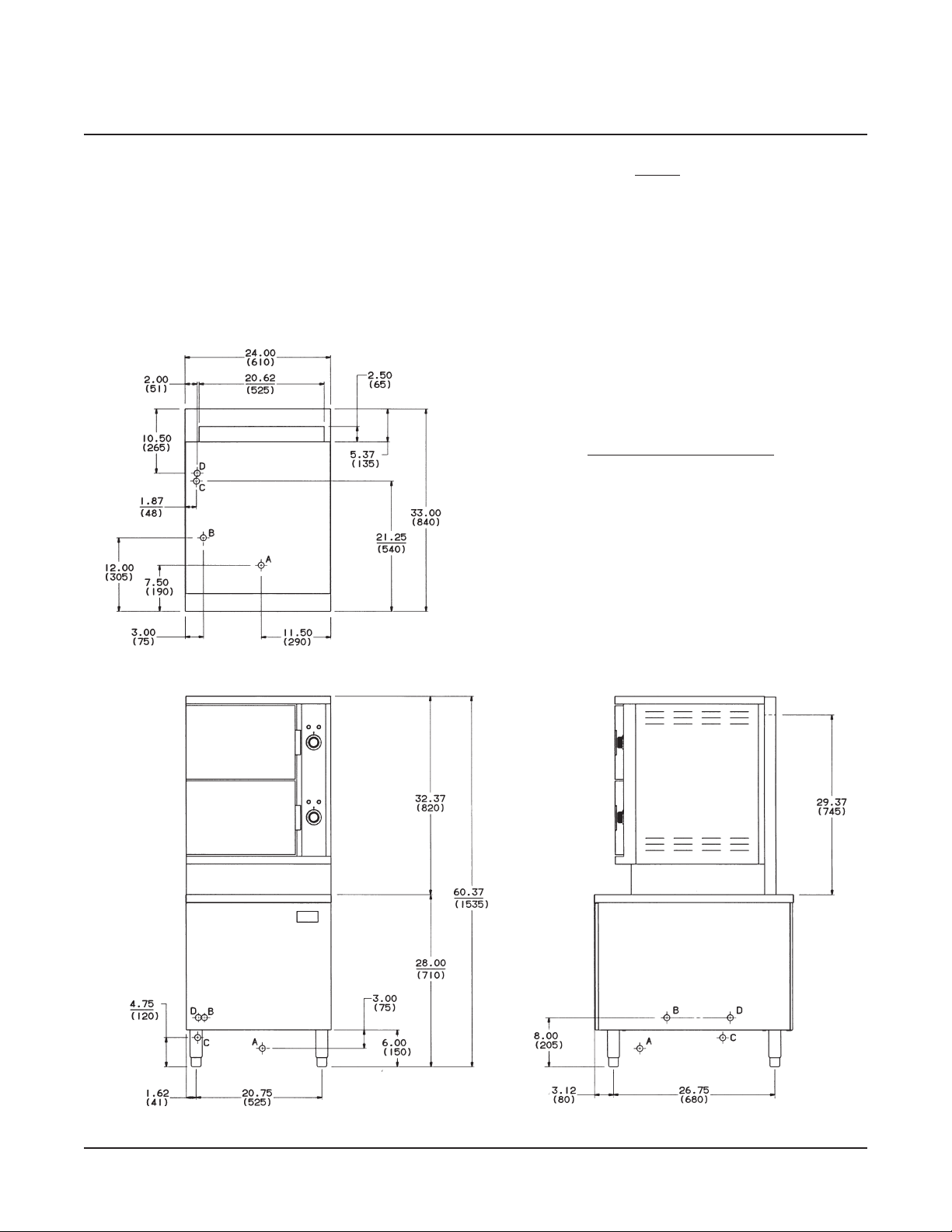

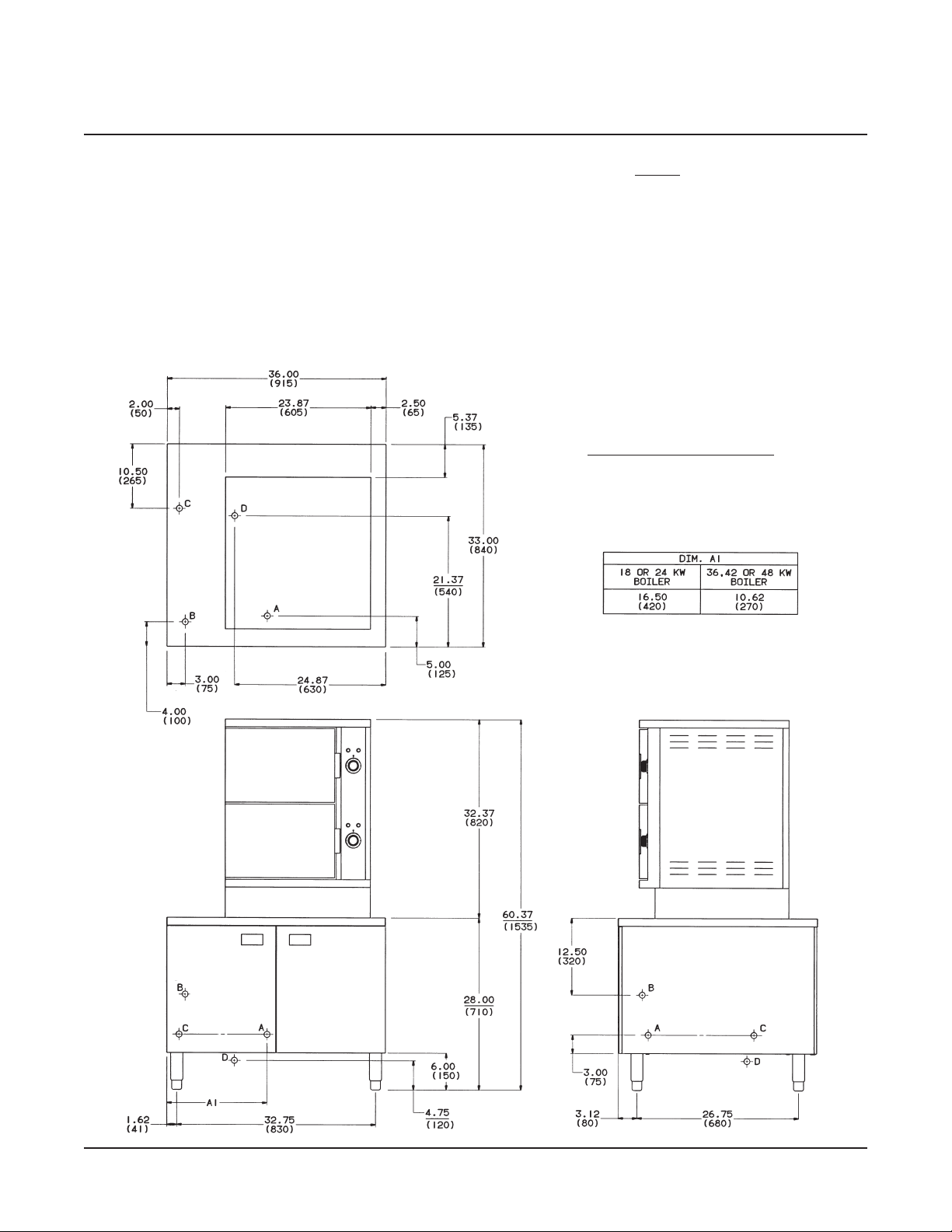

SERVICE CONNECTIONS

DIRECT STEAM, VSX36D FIG. 3

LEGEND

A. COLD SUPPLY WATER CONNECTION:

CONDENSER, AND BOILER FEED.

B. STEAM SUPPLY CONNECTION:

PRESSURE REDUCING VALVE IS MOUNTED AS STANDARD AND SET FOR

10 PSI MAXIMUM INPUT TO UNIT.)

C. ELECTRICAL CONNECTION FOR CONTROLS: 120V/60HZ/1PH/300 WATT

MAXIMUM, POWER SUPPLY WITH GROUNDING WIRE REQUIRED. (FOR

OTHER THAN 120 VOLT SUPPLY CONSULT FACTORY FOR LOCATION OF

THIS CONNECTION.)

D. DRAIN: COPPER TUBE COMPARTMENT & EXHAUST GROUP APPROXIMATELY

2" DIAMETER. (PROVIDE AN OPEN AIR GAP TYPE DRAIN DIRECTLY UNDER

UNIT FRAME. DO NOT CONNECT SOLIDLY TO ANY DRAIN CONNECTION.)

NOTE: DIMENSIONS WHICH LOCATE THE ABOVE CONNECTIONS HAVE A

TOLERANCE OF ± 3 IN. (± 75 MM). NORMAL DIMENSIONS ARE IN INCHES.

DIMENSIONS IN ( ) ARE IN MILLIMETERS.

EQUIPMENT CLEARANCES

TO COMBUSTIBLE CONSTRUCTION

REAR: 2 IN. MIN. (50 MM.)

3

⁄4” NPT FOR STEAM COOKING. (A STEAM

1

⁄4” TUBING FOR COLD WATER

10

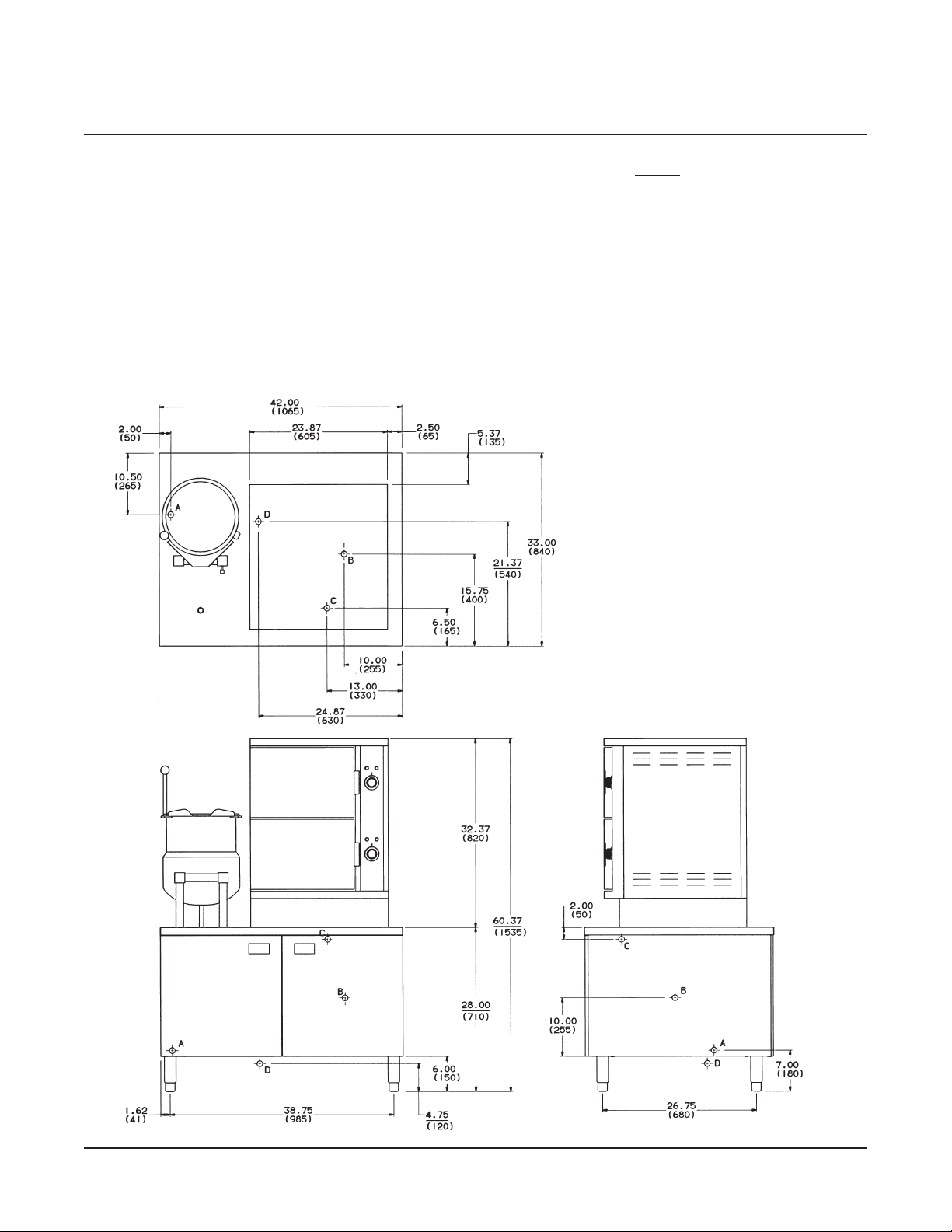

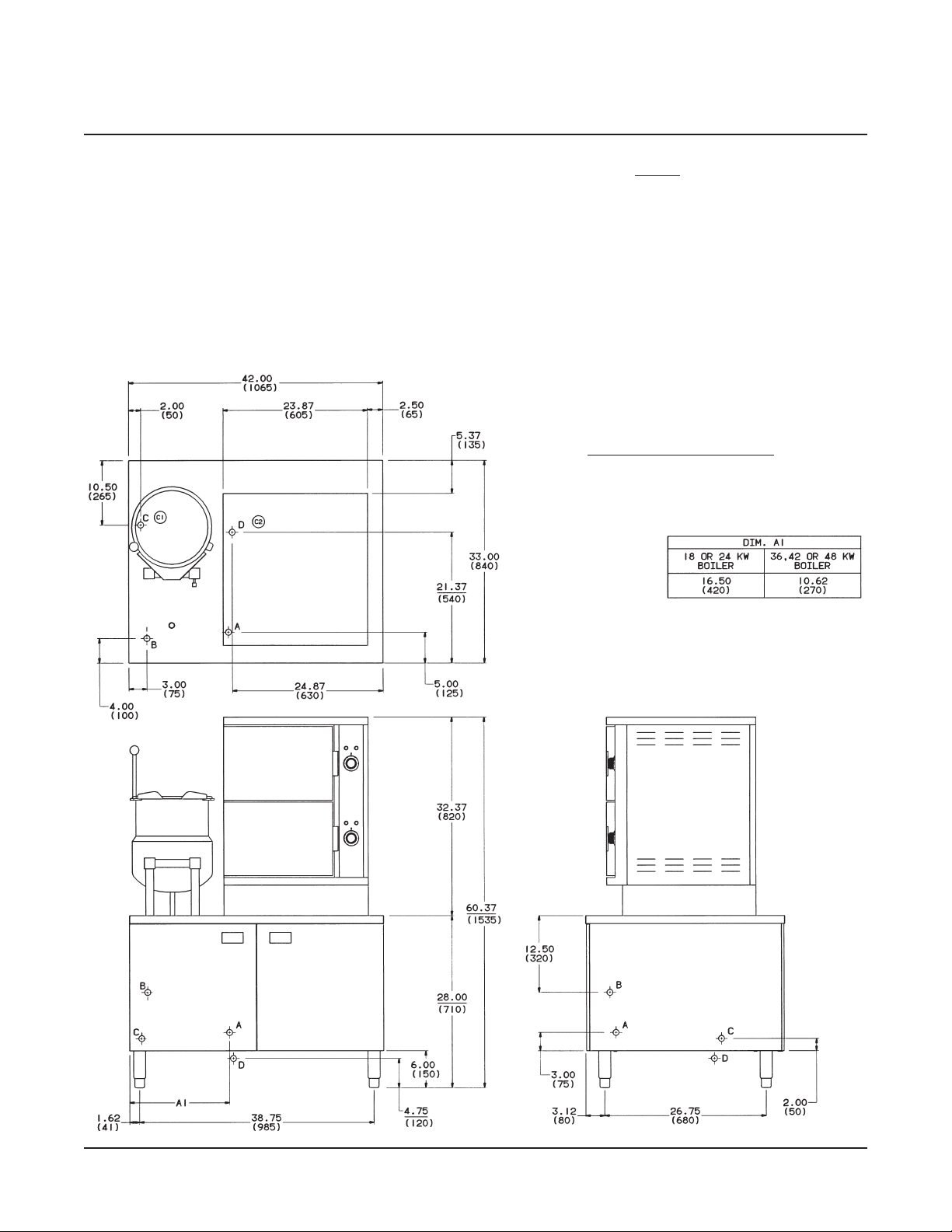

SERVICE CONNECTIONS

DIRECT STEAM, VSX42DT FIG. 4

LEGEND

A. COLD SUPPLY WATER CONNECTION:

CONDENSER, AND BOILER FEED.

B. STEAM SUPPLY CONNECTION:

PRESSURE REDUCING VALVE IS MOUNTED AS STANDARD AND SET FOR

10 PSI MAXIMUM INPUT TO UNIT.)

C. ELECTRICAL CONNECTION FOR CONTROLS: 120V/60HZ/1PH/300 WATT

MAXIMUM, POWER SUPPLY WITH GROUNDING WIRE REQUIRED. (FOR

OTHER THAN 120 VOLT SUPPLY CONSULT FACTORY FOR LOCATION OF

THIS CONNECTION.)

D. DRAIN: COPPER TUBE COMPARTMENT & EXHAUST GROUP APPROXIMATELY

2" DIAMETER. (PROVIDE AN OPEN AIR GAP TYPE DRAIN DIRECTLY UNDER

UNIT FRAME. DO NOT CONNECT SOLIDLY TO ANY DRAIN CONNECTION.)

NOTE: DIMENSIONS WHICH LOCATE THE ABOVE CONNECTIONS HAVE A

TOLERANCE OF ± 3 IN. (± 75 MM). NORMAL DIMENSIONS ARE IN INCHES.

DIMENSIONS IN ( ) ARE IN MILLIMETERS.

EQUIPMENT CLEARANCES

TO COMBUSTIBLE CONSTRUCTION

REAR: 2 IN. MIN. (50 MM.)

3

⁄4” NPT FOR STEAM COOKING. (A STEAM

1

⁄4” TUBING FOR COLD WATER

11

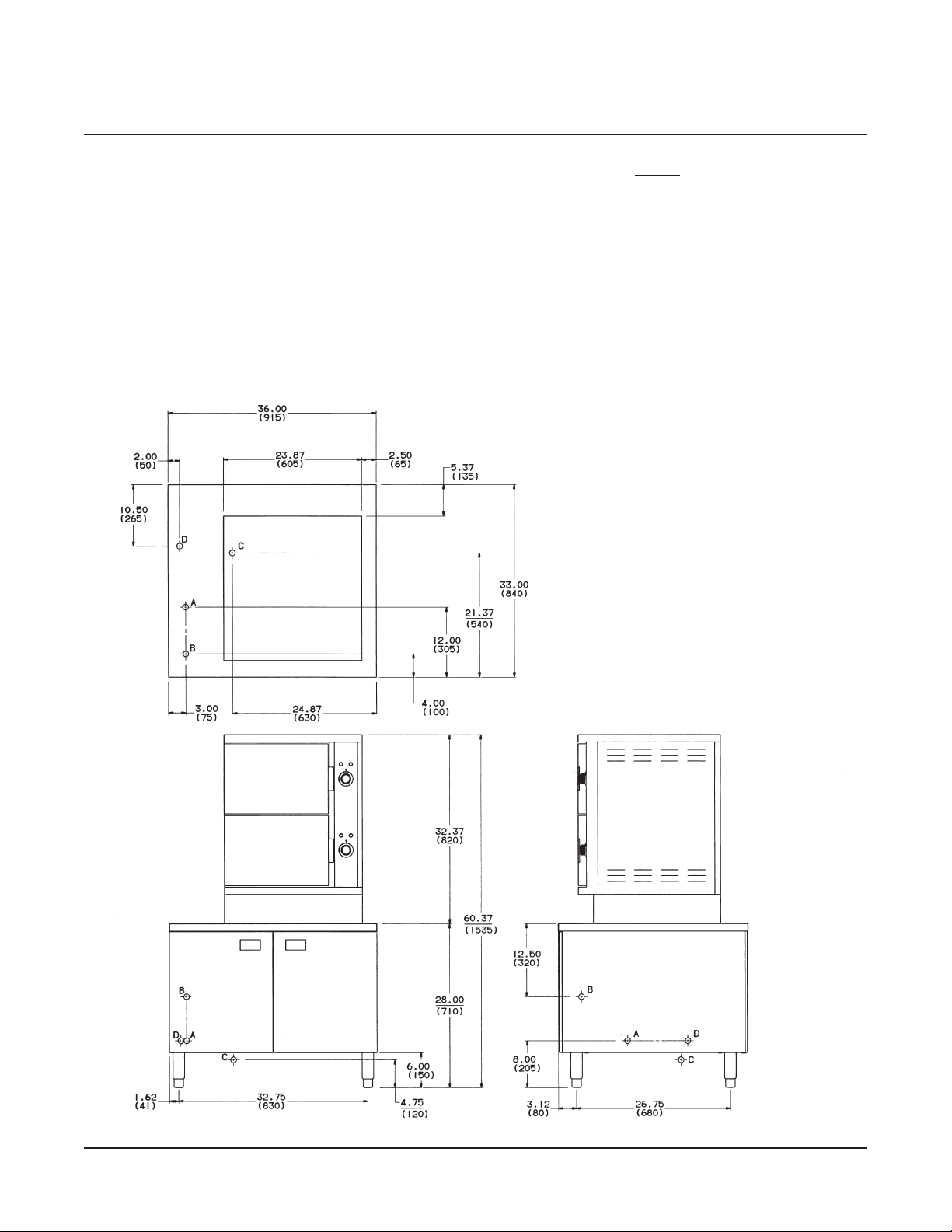

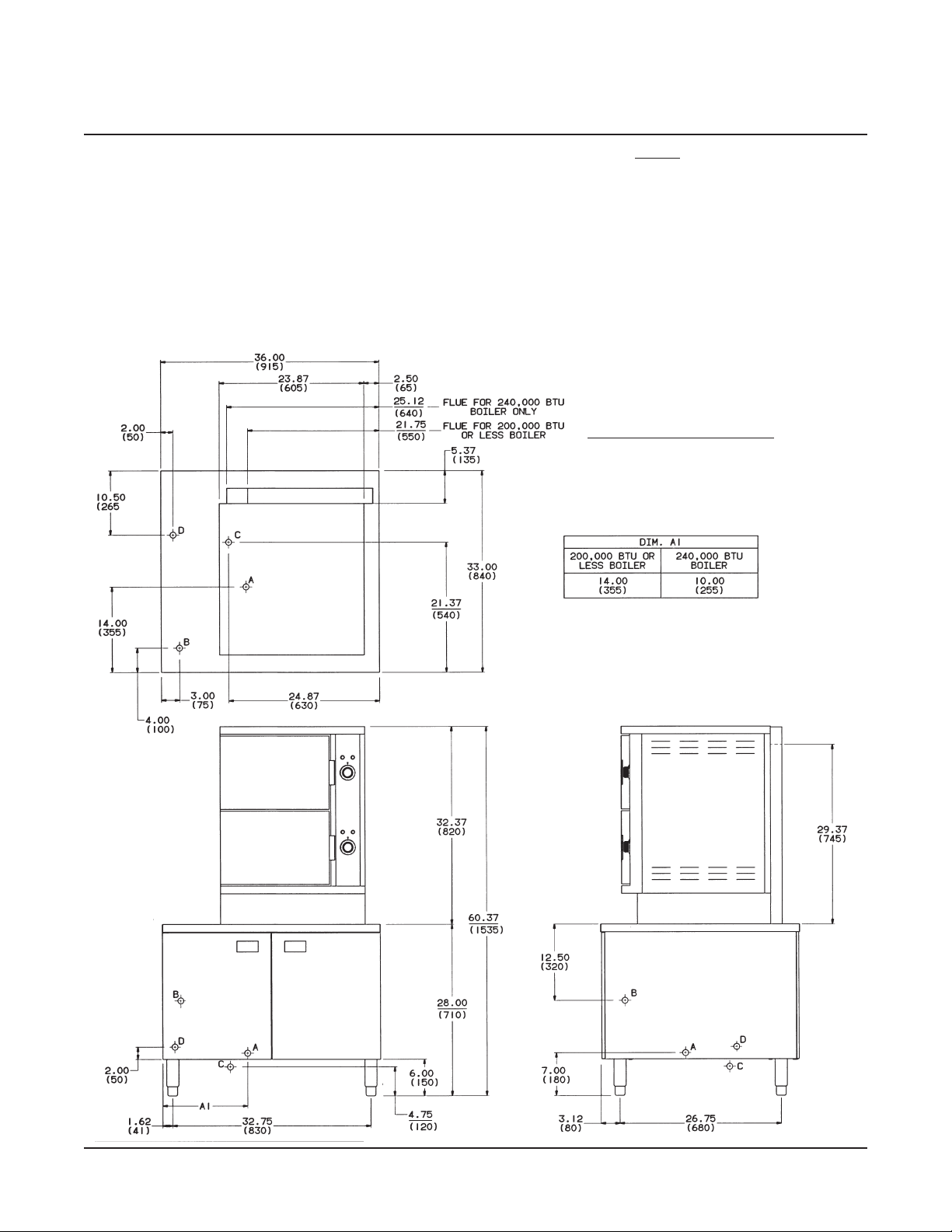

SERVICE CONNECTIONS

REGENERATING STEAM, VSX36R FIG. 5

LEGEND

A. STEAM SUPPLY CONNECTION:

STEAM PRESSURE REDUCING VALVE IS SHIPPED WITH THE UNIT AND

MUST BE FIELD INSTALLED AND ADJUSTED FOR 15 PSI MAXIMUM TO THE

UNIT.)

B. ELECTRICAL CONNECTION FOR CONTROLS: 120V/60HZ/1PH/300 WATT

MAXIMUM, POWER SUPPLY WITH GROUNDING WIRE REQUIRED. (FOR

OTHER THAN 120 VOLT SUPPLY CONSULT FACTORY FOR LOCATION OF

THIS CONNECTION.)

C. DRAIN: COMPARTMENT, BOILER AND EXHAUST GROUP APPROXIMATELY

2" IN DIAMETER. (PROVIDE AN OPEN AIR GAP TYPE DRAIN DIRECTLY

UNDER UNIT FRAME. DO NOT CONNECT SOLIDLY TO ANY DRAIN

CONNECTION.)

D. COLD SUPPLY WATER CONNECTION:

COMPARTMENT DRAIN COLD WATER CONDENSERS, AND BOILER FEED.

NOTE: DIMENSIONS WHICH LOCATE THE ABOVE CONNECTIONS HAVE A

TOLERANCE OF ± 3" (±75MM). NORMAL DIMENSIONS ARE IN INCHES. DIMENSIONS

IN ( ) ARE IN MILLIMETERS.

EQUIPMENT CLEARANCES

TO COMBUSTIBLE CONSTRUCTION

REAR: 2 IN. MIN. (50 MM.)

3

⁄4” NPT FOR STEAM INLET TO BOILER. (A

1

⁄4” NPT FOR BOILER DRAIN &

12

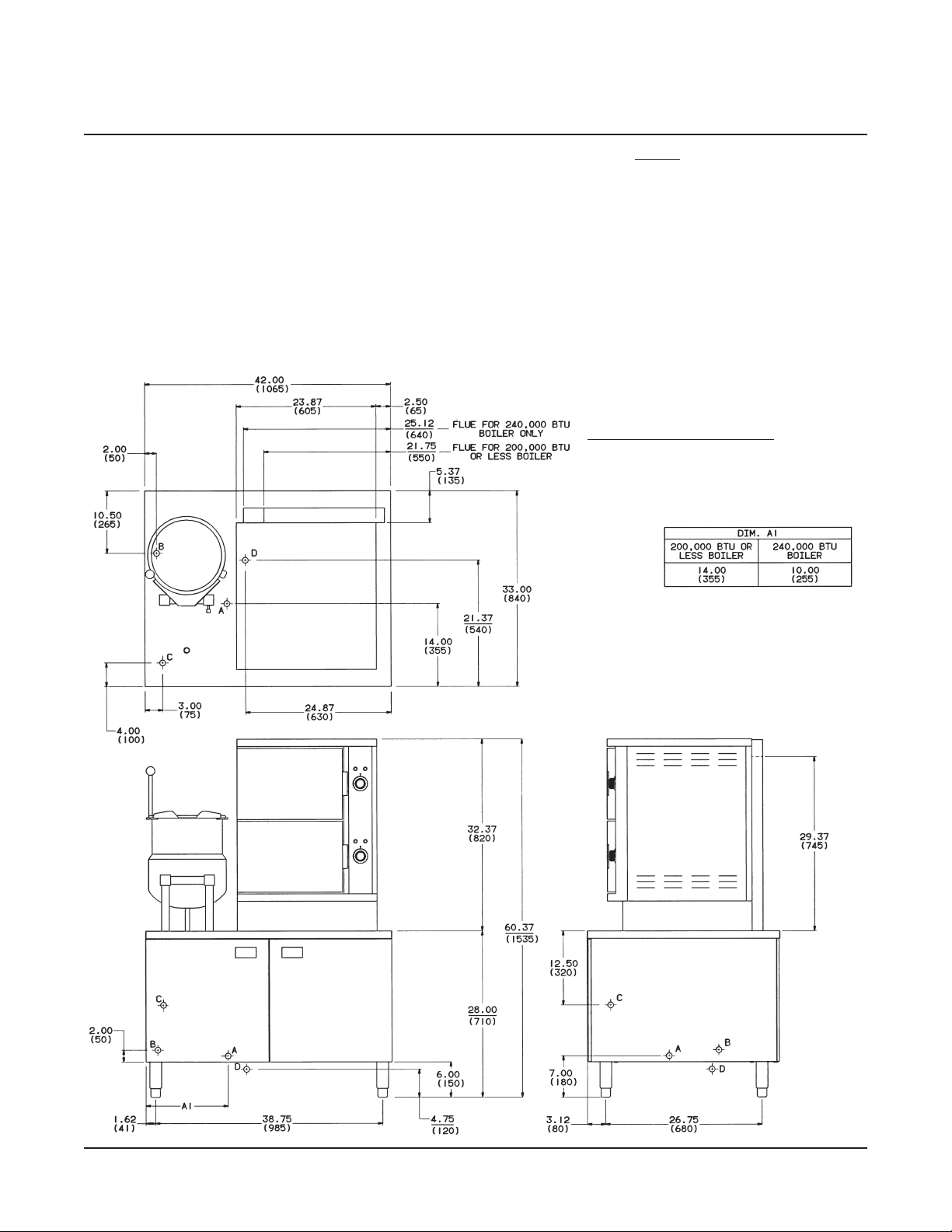

SERVICE CONNECTIONS

REGENERATING STEAM, VSX42RT FIG. 6

LEGEND

A. STEAM SUPPLY CONNECTION:

STEAM PRESSURE REDUCING VALVE IS SHIPPED WITH THE UNIT AND

MUST BE FIELD INSTALLED AND ADJUSTED FOR 15 PSI MAXIMUM TO THE

UNIT.)

B. ELECTRICAL CONNECTION FOR CONTROLS: 120V/60HZ/1PH/300 WATT

MAXIMUM, POWER SUPPLY WITH GROUNDING WIRE REQUIRED. (FOR

OTHER THAN 120 VOLT SUPPLY CONSULT FACTORY FOR LOCATION OF

THIS CONNECTION.)

C. DRAIN: COMPARTMENT, BOILER AND EXHAUST GROUP APPROXIMATELY

2" IN DIAMETER. (PROVIDE AN OPEN AIR GAP TYPE DRAIN DIRECTLY

UNDER UNIT FRAME. DO NOT CONNECT SOLIDLY TO ANY DRAIN

CONNECTION.)

D. COLD SUPPLY WATER CONNECTION:

COMPARTMENT DRAIN COLD WATER CONDENSERS, AND BOILER FEED.

NOTE: DIMENSIONS WHICH LOCATE THE ABOVE CONNECTIONS HAVE A

TOLERANCE OF ± 3" (± 75MM). NORMAL DIMENSIONS ARE IN INCHES. DIMENSIONS

IN ( ) ARE IN MILLIMETERS.

EQUIPMENT CLEARANCES

TO COMBUSTIBLE CONSTRUCTION

REAR: 2 IN. MIN. (50 MM.)

3

⁄4” NPT FOR STEAM INLET TO BOILER. (A

1

⁄4” NPT FOR BOILER DRAIN &

13

SERVICE CONNECTIONS

GAS HEAT, VSX24G FIG. 7

LEGEND

A. GAS CONNECTION:

B. ELECTRICAL CONNECTION FOR CONTROLS: 120V/60HZ/1PH/300 WATT

MAXIMUM, POWER SUPPLY WITH GROUNDING WIRE REQUIRED. (FOR

OTHER THAN 120 VOLT SUPPLY CONSULT FACTORY FOR LOCATION OF

THIS CONNECTION.)

C. DRAIN: COMPARTMENT, BOILER AND EXHAUST GROUP APPROXIMATELY

1

3

⁄2” IN DIAMETER. (PROVIDE AN OPEN AIR GAP TYPE DRAIN DIRECTLY

UNDER UNIT FRAME. DO NOT CONNECT SOLIDLY TO ANY DRAIN

CONNECTION.)

D. COLD SUPPLY WATER CONNECTION:

COMPARTMENT DRAIN COLD WATER CONDENSERS, AND BOILER FEED.

NOTE: DIMENSIONS WHICH LOCATE THE ABOVE CONNECTIONS HAVE A

TOLERANCE OF ± 3 IN. (± 75 MM). NORMAL DIMENSIONS ARE IN INCHES.

DIMENSIONS IN ( ) ARE IN MILLIMETERS.

3

⁄4” NPT.

1

⁄4” NPT FOR BOILER DRAIN &

EQUIPMENT CLEARANCES

TO COMBUSTIBLE CONSTRUCTION

REAR: 6 IN. MIN. (150 MM.)

LEFT SIDE: 6 IN. MIN. (150 MM.)

RIGHT SIDE: 6 IN. MIN. (150 MM.)

14

SERVICE CONNECTIONS

GAS HEAT, VSX36G FIG. 8

LEGEND

A. GAS CONNECTION: 3⁄4” NPT.

B. ELECTRICAL CONNECTION FOR CONTROLS: 120V/60HZ/1PH/300 WATT

MAXIMUM, POWER SUPPLY WITH GROUNDING WIRE REQUIRED. (FOR

OTHER THAN 120 VOLT SUPPLY CONSULT FACTORY FOR LOCATION OF

THIS CONNECTION.)

C. DRAIN: COMPARTMENT, BOILER AND EXHAUST GROUP APPROXIMATELY

1

3

⁄2” IN DIAMETER. (PROVIDE AN OPEN AIR GAP TYPE DRAIN DIRECTLY

UNDER UNIT FRAME. DO NOT CONNECT SOLIDLY TO ANY DRAIN

CONNECTION.)

D. COLD SUPPLY WATER CONNECTION:

COMPARTMENT DRAIN COLD WATER CONDENSERS, AND BOILER FEED.

NOTE: DIMENSIONS WHICH LOCATE THE ABOVE CONNECTIONS HAVE A

TOLERANCE OF ± 3 IN. (± 75 MM). NORMAL DIMENSIONS ARE IN INCHES.

DIMENSIONS IN ( ) ARE IN MILLIMETERS.

EQUIPMENT CLEARANCES

TO COMBUSTIBLE CONSTRUCTION

REAR: 6 IN. MIN. (150 MM.)

LEFT SIDE: 6 IN. MIN. (150 MM.)

RIGHT SIDE: 6 IN. MIN. (150 MM.)

1

⁄4” NPT FOR BOILER DRAIN &

15

SERVICE CONNECTIONS

GAS HEAT, VSX42GT FIG. 9

LEGEND

A. GAS CONNECTION:

B. ELECTRICAL CONNECTION FOR CONTROLS: 120V/60HZ/1PH/300 WATT

MAXIMUM, POWER SUPPLY WITH GROUNDING WIRE REQUIRED. (FOR

OTHER THAN 120 VOLT SUPPLY CONSULT FACTORY FOR LOCATION OF

THIS CONNECTION.)

C. DRAIN: COMPARTMENT, BOILER AND EXHAUST GROUP APPROXIMATELY

1

3

⁄2” IN DIAMETER. (PROVIDE AN OPEN AIR GAP TYPE DRAIN DIRECTLY

UNDER UNIT FRAME. DO NOT CONNECT SOLIDLY TO ANY DRAIN

CONNECTION.)

D. COLD SUPPLY WATER CONNECTION:

COMPARTMENT DRAIN COLD WATER CONDENSERS, AND BOILER FEED.

NOTE: DIMENSIONS WHICH LOCATE THE ABOVE CONNECTIONS HAVE A

TOLERANCE OF ± 3 IN. (± 75 MM). NORMAL DIMENSIONS ARE IN INCHES.

DIMENSIONS IN ( ) ARE IN MILLIMETERS.

3

⁄4” NPT.

1

⁄4” NPT FOR BOILER DRAIN &

EQUIPMENT CLEARANCES

TO COMBUSTIBLE CONSTRUCTION

REAR: 6 IN. MIN. (150 MM.)

LEFT SIDE: 6 IN. MIN. (150 MM.)

RIGHT SIDE: 6 IN. MIN. (150 MM.)

16

SERVICE CONNECTIONS

ELECTRIC HEAT, VSX24E FIG. 10

LEGEND

A. JUNCTION BOX: J.I.C. 6X6X4 FOR ELECTRICAL SUPPLY CONNECTION FOR

HEAT.

B. ELECTRICAL CONNECTION FOR CONTROLS: 120V/60HZ/1PH/300 WATT

MAXIMUM, POWER SUPPLY WITH GROUNDING WIRE REQUIRED. (NOT

PROVIDED IF A STEP DOWN TRANSFORMER IS FURNISHED.)

C. COLD SUPPLY WATER CONNECTION:

COMPARTMENT DRAIN COLD WATER CONDENSERS.

D. DRAIN: COMPARTMENT, BOILER AND EXHAUST GROUP APPROXIMATELY

1

3

⁄2” IN DIAMETER. (PROVIDE AN OPEN AIR GAP TYPE DRAIN DIRECTLY

UNDER UNIT FRAME. DO NOT CONNECT SOLIDLY TO ANY DRAIN

CONNECTION.)

NOTE: DIMENSIONS WHICH LOCATE THE ABOVE CONNECTIONS HAVE A

TOLERANCE OF ± 3 IN. (± 75 MM). NORMAL DIMENSIONS ARE IN INCHES.

DIMENSIONS IN ( ) ARE IN MILLIMETERS.

EQUIPMENT CLEARANCES

TO COMBUSTIBLE CONSTRUCTION

REAR: 2 IN. MIN. (50 MM.)

1

⁄4” NPT FOR BOILER DRAIN AND

17

SERVICE CONNECTIONS

ELECTRIC HEAT, VSX36E FIG. 11

LEGEND

A. JUNCTION BOX: J.I.C. 6X6X4 FOR ELECTRICAL SUPPLY CONNECTION FOR

HEAT.

B. ELECTRICAL CONNECTION FOR CONTROLS: 120V/60HZ/1PH/300 WATT

MAXIMUM, POWER SUPPLY WITH GROUNDING WIRE REQUIRED. (NOT

PROVIDED IF A STEP DOWN TRANSFORMER IS FURNISHED.)

C. COLD SUPPLY WATER CONNECTION:

COMPARTMENT DRAIN COLD WATER CONDENSERS.

D. DRAIN: COMPARTMENT, BOILER AND EXHAUST GROUP APPROXIMATELY

1

3

⁄2” IN DIAMETER. (PROVIDE AN OPEN AIR GAP TYPE DRAIN DIRECTLY

UNDER UNIT FRAME. DO NOT CONNECT SOLIDLY TO ANY DRAIN

CONNECTION.)

NOTE: DIMENSIONS WHICH LOCATE THE ABOVE CONNECTIONS HAVE A

TOLERANCE OF ± 3 IN. (± 75 MM). NORMAL DIMENSIONS ARE IN INCHES.

DIMENSIONS IN ( ) ARE IN MILLIMETERS.

EQUIPMENT CLEARANCES

TO COMBUSTIBLE CONSTRUCTION

REAR: 2 IN. MIN. (50 MM.)

1

⁄4” NPT FOR BOILER DRAIN AND

18

SERVICE CONNECTIONS

ELECTRIC HEAT, VSX42ET FIG. 12

LEGEND

A. JUNCTION BOX: J.I.C. 6X6X4 FOR ELECTRICAL SUPPLY CONNECTION FOR

HEAT.

B. ELECTRICAL CONNECTION FOR CONTROLS: 120V/60HZ/1PH/300 WATT

MAXIMUM, POWER SUPPLY WITH GROUNDING WIRE REQUIRED. (NOT

PROVIDED IF A STEP DOWN TRANSFORMER IS FURNISHED.)

C. COLD SUPPLY WATER CONNECTION:

COMPARTMENT DRAIN COLD WATER CONDENSERS.

D. DRAIN: COMPARTMENT, BOILER AND EXHAUST GROUP APPROXIMATELY

1

3

⁄2” IN DIAMETER. (PROVIDE AN OPEN AIR GAP TYPE DRAIN DIRECTLY

UNDER UNIT FRAME. DO NOT CONNECT SOLIDLY TO ANY DRAIN

CONNECTION.)

NOTE: DIMENSIONS WHICH LOCATE THE ABOVE CONNECTIONS HAVE A

TOLERANCE OF ± 3 IN. (± 75 MM). NORMAL DIMENSIONS ARE IN INCHES.

DIMENSIONS IN ( ) ARE IN MILLIMETERS.

EQUIPMENT CLEARANCES

TO COMBUSTIBLE CONSTRUCTION

REAR: 2 IN. MIN. (50 MM.)

1

⁄4” NPT FOR BOILER DRAIN AND

19

START-UP TEST RUN

After the appliance is installed and proper service

connections have been made, thoroughly test the

steam cooker before operation.

8. When timer knobs are on “0”, each buzzer will

sound, steam generation will cease, COOKING

lights will go off and READY lights will come on.

To silence buzzers, turn timer knobs to OFF

position.

Gas Powered Steam Generator

1. Open manual gas shutoff valve, and if the

appliance has a manual blowdown valve, close it.

Open left cabinet door and turn water fill and power

switch ON. The red light will come on and water

will fill boiler to the required level in about 15

minutes. Observe water level gauge glass to

verify. Both valves on gauge glass assembly must

be open.

2. The dial on the gas combination control valve has

three positions (On-Pilot-Off) for manual gas control

of main burners and pilot. Turn dial on gas

combination valve to PILOT. Depress dial and light

pilot burner; maintain dial in depressed position for

about 30 seconds and release. Observe that pilot

burner flame stays on. If the flame should go out,

wait 5 minutes before relighting.

3. Turn gas combination control valve dial to ON and

burners will ignite. Steam generation will begin and

be completed in about 15 minutes. Observe that

the boiler pressure gauge indicates steam pressure

in the range of 9-12 psi (9-13 psi if a kettle is

connected to the steamer).

9. During simulation of cooking cycle, burners will

cycle on and off to maintain steam pressure in

boiler.

10. Turn power switch OFF. Amber light will go out.

11. Blow down boiler (see BLOW DOWN BOILER in

this manual).

Electrically Powered Steam Generator

1. If steamer has a manual blowdown valve, close it.

Open left cabinet door and turn power switch ON.

Water will fill boiler to the required level in about 15

minutes. Observe water level gauge glass to

verify. Both valves on gauge glass assembly must

be open. Steam generation will begin and be

completed in about 15 minutes.

2. Set both timer knobs to “0”. Open both

compartment doors and observe that no steam has

entered the cooking compartments. Close doors.

3. Set both timer knobs to 2 minutes. READY lights

will go off, COOKING lights will come on, and

steam will be heard entering the compartments.

4. Set both timer knobs to “0”. Open both

compartment doors and observe that no steam has

entered the cooking compartments. Close doors.

5. Set both timer knobs to 2 minutes. The READY

lights will go off, the COOKING lights will come on,

and steam will be heard entering the

compartments.

After one minute, open each door and observe that

steam has ceased to enter each compartment, but

COOKING lights and cooking times at “01” are

maintained.

WARNING: THE COOKING COMPARTMENTS

CONTAIN LIVE STEAM. STAY CLEAR WHILE

OPENING EACH DOOR.

7. Close doors. Steam generation and cook times will

resume. Observe appliance drain that live steam

from compartments is being cooled by cold water

from the cold water solenoid valve.

After one minute, open each door and observe that

steam has ceased to enter each compartment, but

COOKING lights and cooking times at “01” are

maintained.

WARNING: THE COOKING COMPARTMENTS

CONTAIN LIVE STEAM. STAY CLEAR WHILE

OPENING EACH DOOR.

4. Close doors. Steam generation and cook times will

resume. Observe appliance drain that live steam

from compartments is being cooled by cold water

from the cold water solenoid valve.

5. When timer knobs are on “0”, each buzzer will

sound, steam generation will cease, COOKING

lights will go off and READY lights will come on.

To silence buzzers, turn timer knobs to OFF

position.

6. During simulation of cooking cycle, the heating

elements will cycle on and off to maintain steam

pressure in the boiler.

20

7. Turn power switch OFF. Amber light will go out.

8. Blow down boiler (see BLOW DOWN BOILER in

this manual).

Direct Steam Powered Cooker

1. Set both timer knobs to “0”. Open both

compartment doors and observe that no steam has

entered cooking compartments. Close doors.

2. Set both timer knobs to 2 minutes. READY lights

will go off, COOKING lights will come on, and

steam will be heard entering the compartments.

After one minute, open each door and observe that

steam has ceased to enter each compartment, but

COOKING lights and cooking times at “01” are

maintained.

WARNING: THE COOKING COMPARTMENTS

CONTAIN LIVE STEAM. STAY CLEAR WHILE

OPENING EACH DOOR.

3. Close doors. Steam generation and cook times will

resume. Observe appliance drain that live steam

from compartments is being cooled by cold water

from the cold water solenoid valve.

4. When timer knobs are on “0”, each buzzer will sound,

steam generation will cease, COOKING

lights will go off and READY lights will come on.

To silence buzzers, turn timer knobs to OFF

position.

Regenerative Steam Powered Generator

1. If the steamer has a manual blowdown valve, close

it. Turn power switch ON. Water will fill the boiler

to the required level in about 15 minutes. Observe

water level gauge glass to verify. Both valves on

gauge glass assembly must be open. Steam

generation will begin and be completed in about 15

minutes.

2. Set both timer knobs to “0”. Open both

compartment doors and observe that no steam has

entered the cooking compartments. Close doors.

3. Set both timer knobs to 2 minutes. READY lights

will go off, COOKING lights will come on, and

steam will be heard entering the compartments.

After one minute, open each door and observe that

steam has ceased to enter each compartment, but

COOKING lights and cooking times at “01” are

maintained.

WARNING: THE COOKING COMPARTMENTS

CONTAIN LIVE STEAM. STAY CLEAR WHILE

OPENING EACH DOOR.

4. Close doors. Steam generation and cook times will

resume. Observe appliance drain that live steam

from compartments is being cooled by cold water

from the cold water solenoid valve.

5. When timer knobs are on “0”, each buzzer will

sound, steam generation will cease, COOKING

lights will go off and READY lights will come on.

To silence buzzers, turn timer knobs to OFF position.

6. During simulation of cooking cycle, steam coils will

cycle on and off to maintain steam pressure in the

boiler.

7. Turn power switch OFF. Amber light will go out.

8. Blow down boiler (see BLOW DOWN BOILER in

this manual).

BLOW DOWN BOILER

Always blow down boiler when boiler is under maximum

pressure and no steam is being used.

Automatic Blowdown

Turn power switch OFF. Depress blowdown button.

Blowdown timer will operate for 4 minutes. At end of

blowdown, turn fill switch to ON and allow boiler to fill.

Manual Blowdown

Turn power switch OFF. Open blowdown valve. After

boiler has drained completely, close blowdown valve

and turn fill switch to ON and allow boiler to fill.

21

OPERATION

WARNING: THE STEAMER AND ITS PARTS ARE

HOT. USE CARE WHEN OPERATING, CLEANING

OR SERVICING THE STEAMER. THE COOKING

COMPARTMENTS CONTAIN LIVE STEAM. STAY

CLEAR WHILE OPENING EACH DOOR.

CONTROLS — CABINET BASE GENERATOR (Fig. 13)

Handhole Cover Assembly — when unbolted and

removed, allows internal examination and cleaning of

boiler if required.

Water Level Gauge Assembly — permits visual

confirmation that water level is being maintained in the

boiler during operation. The correct water level is a

point one-half of the height of the glass. The manual

valves at the top and bottom of this assembly must be

fully open, and only closed if the glass tube should be

damaged.

Observe that the water is clean and clear in the

glass tube. The appearance of extreme murkiness

in the water indicates inadequate water quality and

will cause failure of controls and the steamer.

Warranty does not cover malfunction due to poor

water conditions. Blow down and/or clean the

generator.

Pilot Burner (Gas Base Generator Only) — should

remain lit at all times unless the steamer will not be in

use for an extended period of time. If at any time the

flame goes out, wait 5 minutes before relighting.

Drain Solenoid Valve — a quick acting drain valve

provided for daily blowdown of the generator.

Strainers — a strainer is used in the water inlet line to

prevent foreign matter from becoming lodged in the

inlet solenoid valve. A “Y” strainer is inserted upstream

of the drain solenoid valve to allow the valve to operate

smoothly. A strainer is used in the pressure regulating

valve on models using direct steam supply.

Boiler Fill Solenoid Valve — admits water to the

boiler when demanded by the automatic fill controls in

order to maintain the correct water level in the steam

generator.

Blowdown Drain CWC Solenoid Valve — allows cold

water to flow to boiler blowdown drain and helps cool

the boiler water prior to its discharge into the drain.

Cycling Pressure Switch — controls boiler pressure

between prescribed limits by turning the heat source on

and off. A back-up switch of identical design is provided

and has a higher high setting and a lower low setting

than the primary control.

Power Switch — when turned ON will automatically

begin the steam generating process in the boiler. The

power switch is fastened to the front face of the

generator control box.

Pressure Regulating Valve — used to control

manifold steam pressure at 10-12 psi on models using

direct steam supply.

Main Burners (Gas Base Generator Only) — cycle

on and off to maintain steam pressure in the boiler.

Gas Combination Control Valve (Gas Base

Generator Only) — regulates flow of gas to burners.

Low Water Cutoff/Automatic Fill Control — Level

Sensing Probes — these controls allow the feed water

to enter the generator when the water level is low.

They will also shut off the heat source to the boiler if

the water level drops too low. The level sensing probes

may be easily removed to inspect for lime build-up. As

a rule, the condition of these devices will indicate the

overall water condition of the boiler. Clean the probes

if needed. Controls may not function and serious

clogging will occur if a daily blowdown procedure

is not followed.

22

Water Inlet Ball Valve — water service valve which

can be used to stop water flow to the steamer when the

steamer is being serviced.

High Limit Thermostat — a protective device which

shuts off the gas or electric power if the boiler

overheats.

Descaler — hangs submerged in water inside the

generator and helps control scaling.

Drain — drains steam condensate and water from

cooking compartments and boiler.

Loading...

Loading...