Vulcan-Hart VSX 9000 User Manual

VULCAN-HART COMPANY, P.O. BOX 696, LOUISVILLE, KY 40201- 0696, TEL. (502) 778-2791

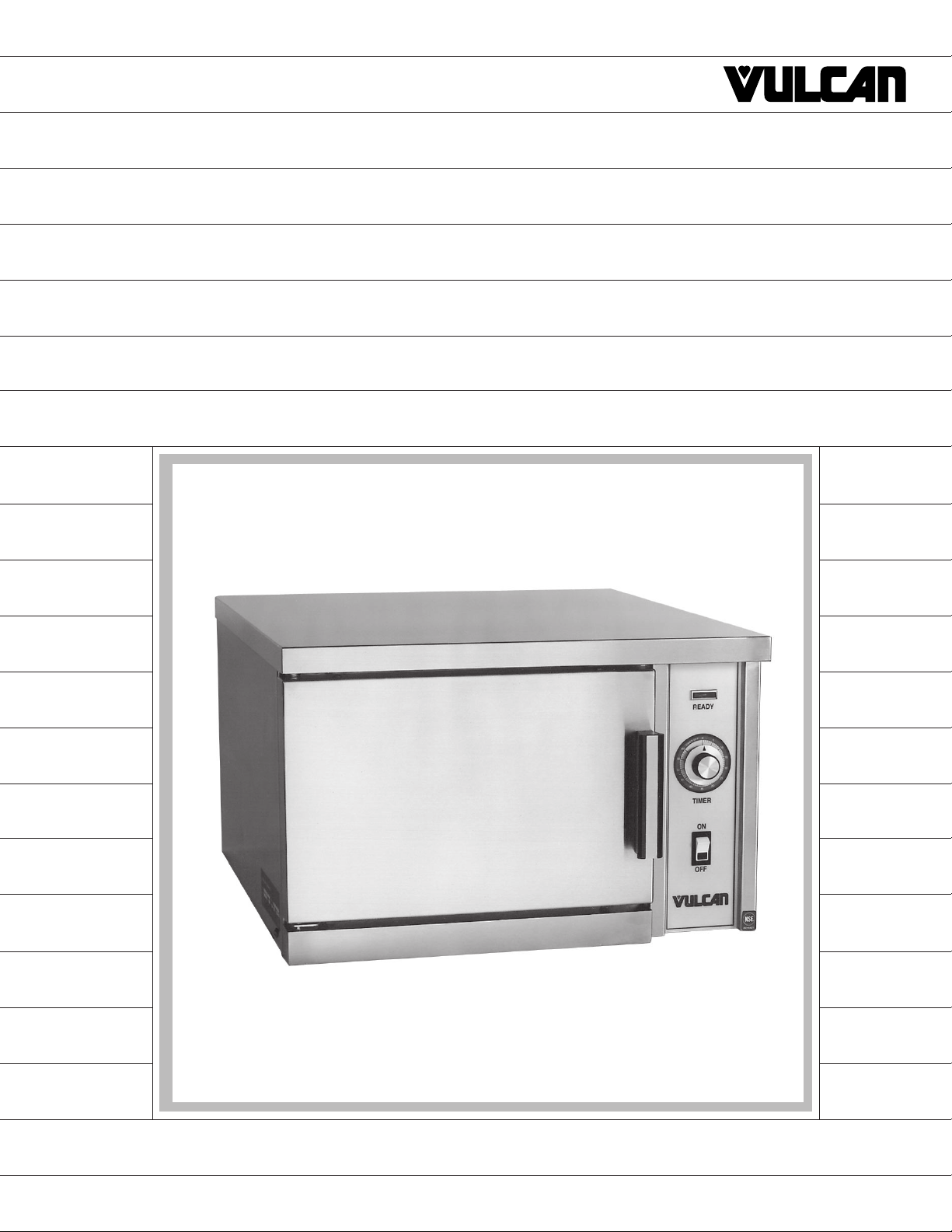

SERVICE & PARTS MANUAL FOR

ELECTRIC COUNTERTOP

CONVECTION STEAMER

MODEL VSX9000

FORM 30847 (1-94)

THIS

PAGE

INTENTIONALLY

LEFT

BLANK

- 3 -

TABLE OF CONTENTS

GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

WATER QUALITY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

SERVICE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

ADJUSTMENT FOR HIGH ALTITUDE LOCATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

TEST PROCEDURES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

WATER FLOWS INTO DRAIN DURING SHUTDOWN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

WATER OVERFLOWS INTO COOKING COMPARTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

HEATER ELEMENTS DO NOT COME ON . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

COOKING CYCLE DOES NOT OPERATE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

REPLACEMENT PARTS LIST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

WIRING DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

- 4 -

Service and Parts Manual

MODEL VSX9000 ELECTRIC COUNTERTOP

CONVECTION STEAMER

PLEASE KEEP THIS MANUAL

GENERAL

Your Vulcan Steamer is a one-compartment pressureless steam cooker that has been factory assembled and

tested to provide for easy installation. It has been factory set when on to maintain water temperature during the

ready phase at approximately 205°F (just below water boiling point).

Vulcan steamers are produced with quality workmanship and material. Proper installation, usage and

maintenance of your steamer will result in many years of satisfactory performance.

The manufacturer suggests that you thoroughly read this entire manual and carefully follow all of the instructions

provided.

WATER QUALITY

The fact that a water supply is potable is no guarantee that it is suitable for steam generation. Your water supply

must be within these general guidelines:

TOTAL DISSOLVED SOLIDS . . . . . . . . . Less than 60 PPM

TOTAL ALKALINITY . . . . . . . . . . . . . . . . . Less than 20 PPM

SILICA . . . . . . . . . . . . . . . . . . . . . . . . . . . . Less than 13 PPM

CHLORIDE . . . . . . . . . . . . . . . . . . . . . . . . Less than 30 PPM

pH FACTOR . . . . . . . . . . . . . . . . . . . . . . . 7-8

Other factors affecting steam generation are iron content, amount of chloridation and dissolved gases. Water

supplies vary from state to state and from locations within a state. Therefore, it is necessary that the local water

treatment specialist be consulted before the installation of any steam generating equipment.

Untreated water contains scale producing minerals which can precipitate onto the surfaces in the boiler. Due

to the temperatures in the boiler, the minerals can bake onto the surfaces and components. This can result in

early component failure and reduced product life.

Mineral scale on components causes several problems:

1. The surfaces of the heating devices become coated with scale, reducing the heat transfer efficiency. This

can produce hot spots on the heating elements and result in premature failure.

2. The water level probes become coated with scale. Scale will bridge across the probe insulator from the metal

extension which senses the water level in the boiler shell. Once this scale becomes wet, the water level

control is unable to maintain the proper water level in the boiler. This situation may cause an electric heating

element to fail as a result of the element not being adequately covered by water.

Strainers and filters will NOT remove minerals from the water.

Loading...

Loading...