Page 1

FOOD STEAMERS

MODEL

INSTALLATION,

OPERATION, SERVICE &

PARTS MANUAL

VSX24G ML-52163

VSX36G ML-52360

VSX42GT ML-52832

VSX24E ML-52164

VSX36E ML-52829

VSX42ET ML-52833

VSX24D ML-52827

VSX36D ML-52830

VSX42DT ML-52834

VSX36R ML-52831

VSX42RT ML-52835

MODEL VSX24

VULCAN-HART COMPANY, P.O. BOX 696, LOUISVILLE, KY 40201-0696, TEL. (502) 778-2791

FORM 30798 (Rev. A, 10-95)

Page 2

2

Page 3

IMPORTANT FOR YOUR SAFETY

THIS MANUAL HAS BEEN PREPARED FOR PERSONNEL QUALIFIED TO INSTALL GAS

EQUIPMENT, WHO SHOULD PERFORM THE INITIAL FIELD START-UP AND

ADJUSTMENTS OF THE EQUIPMENT COVERED BY THIS MANUAL.

POST IN A PROMINENT LOCATION THE INSTRUCTIONS TO BE FOLLOWED IN THE

EVENT THE SMELL OF GAS IS DETECTED. THIS INFORMATION CAN BE OBTAINED

FROM THE LOCAL GAS SUPPLIER.

IMPORTANT

IN THE EVENT A GAS ODOR IS DETECTED, SHUT

DOWN UNITS AT MAIN SHUTOFF VALVE AND

CONTACT THE LOCAL GAS COMPANY OR GAS

SUPPLIER FOR SERVICE.

FOR YOUR SAFETY

DO NOT STORE OR USE GASOLINE OR OTHER

FLAMMABLE VAPORS OR LIQUIDS IN THE

VICINITY OF THIS OR ANY OTHER APPLIANCE.

WARNING

IMPROPER INSTALLATION, ADJUSTMENT,

ALTERATION, SERVICE OR MAINTENANCE CAN

CAUSE PROPERTY DAMAGE, INJURY OR DEATH.

READ THE INSTALLATION, OPERATING AND

MAINTENANCE INSTRUCTIONS THOROUGHLY

BEFORE INSTALLING OR SERVICING THIS

EQUIPMENT.

IN THE EVENT OF A POWER FAILURE, DO NOT

ATTEMPT TO OPERATE THIS DEVICE.

3

Page 4

INSTALLATION, OPERATION, SERVICE & PARTS MANUAL

CONVECTION FOOD STEAMERS

GAS, ELECTRIC, REGENERATIVE OR DIRECT STEAM

MODELS VSX24, VSX36 & VSX42 INDEX

PLEASE KEEP THIS MANUAL FOR FUTURE REFERENCE

Your Vulcan Steam Cooker is produced with quality

workmanship and material. Proper installation, usage

and maintenance of your steam cooker will result in

many years of satisfactory performance.

The manufacturer suggests that you thoroughly read

this entire manual and carefully follow all of the instructions provided.

DESCRIPTION PAGE

INDEX 4, 5

INSTALLATION 6

UNPACKING 6

LOCATION 6

INSTALLATION CODES AND STANDARDS 6, 7

LEVELING AND ANCHORING 7

SERVICE CONNECTIONS 7-19

Steam Connections 7

Gas Connections 7

Electrical Connections 8

Drain Connections 8

Plumbing Connections 8

VENT HOOD 8

SERVICE CONNECTION DIAGRAMS 9-19

START-UP TEST RUN 20, 21

BLOW DOWN BOILER 21

OPERATION 22

CONTROLS - CABINET BASE GENERATOR 22, 23

CONTROLS - COMPARTMENT 24

LIGHTING STANDING PILOT (GAS BASE GENERATORS ONLY) 24

4

Page 5

DESCRIPTION PAGE

OPERATION (CONT’D.)

OPERATING STEAMERS WITH INTERMITTENT PILOTS (GAS BASE GENERATORS ONLY) 24, 25

DAILY STARTING PROCEDURE 25

CLEANING 25, 26

MAINTENANCE 26

COOKING CHART 27-29

TROUBLESHOOTING 30-32

SERVICE 33

COOKING COMPARTMENT 33

CABINET BASE GENERATOR 33-38

All Generators 33-37

Gas Generators 37, 38

Electric Generators 38

Regenerating (Steam Coil) Generators 38

REPLACEMENT PARTS LIST 39-70

5

Page 6

INSTALLATION

UNPACKING

This steam cooker was inspected before leaving the

factory. The transportation company assumes full

responsibility for safe delivery upon acceptance of the

shipment. Immediately after unpacking, check for

possible shipping damage. If the cooker is found to be

damaged after unpacking, save the packaging material

and contact the carrier within 15 days of delivery.

Before installing, verify that the gas (natural or propane)

and/or electrical supplies agree with the specifications

on the rating plate which is located on the inside base

cabinet door. If the supply and equipment requirements

do not agree, do not proceed with the installation.

Contact your dealer or Vulcan-Hart immediately.

LOCATION

Position the steamer in its final location. Check that

there are sufficient clearances to service the controls,

for door swings, etc., so there will be no problem in

making the required supply and drain connections.

Recommended clearances are 18" on the sides and

back and 36" in the front.

The steamer must be installed so that the flow of

combustion and ventilation air will not be obstructed.

Adequate clearance for air openings into the combustion

chamber of the gas cabinet base generator must be

provided. The floor area beneath the burners must be

kept free and clear. Make sure there is an adequate

supply of air in the room to allow for combustion of the

gas at the burners.

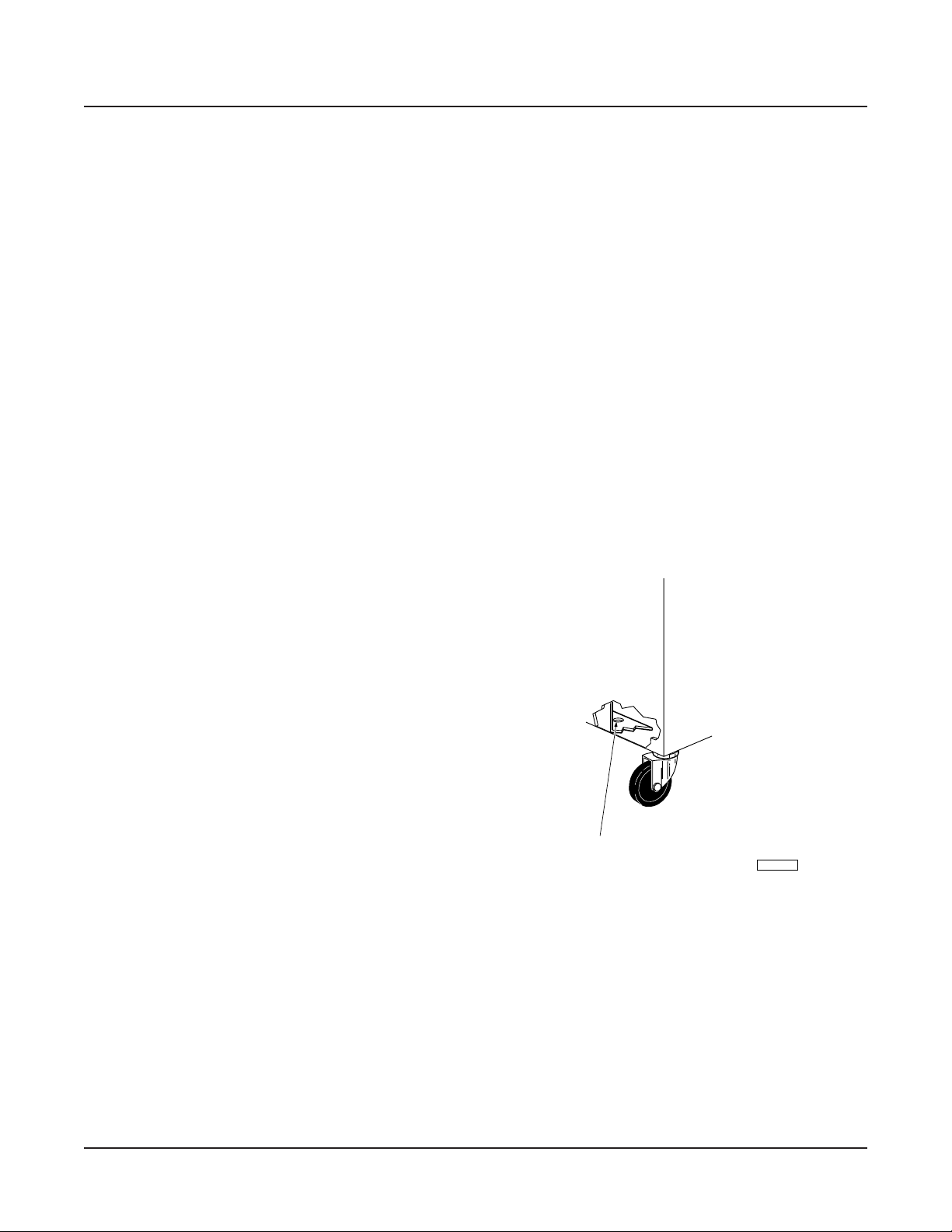

When steamers are mounted on casters, you must use

a connector that complies with the Standard for

Connectors of Movable Gas Appliances, ANSI-Z21.69

(latest edition), and a quick-disconnect device that

complies with the Standard for Quick-Disconnect

Devices for Use With Gas Fuel, ANSI-Z21.41 (latest

edition).

Provide a gas line strain relief to limit movement of the

steamer without depending on the connector and/or any

quick-disconnect device or its associated piping to limit

movement of the steamer. Attach the gas line strain

relief to the rear of the steamer (Fig. 1).

Allow enough space between any other piece of

equipment or a wall for access. All service on the

compartment controls begins by removing the panel on

the right side of the compartments. Service on the

cabinet base may require the removal of the panel on

either or both the left or right sides.

A floor drain (open gap) is required immediately below

the steamer drain.

An exhaust system should be located directly above

the steamer to exhaust steam and heat generated by

the steamer.

For Gas Powered Steam Generators Only

The equipment area must be kept free and clear of

combustible substances.

The steamer, when installed, must have a minimum

clearance from combustible and noncombustible

construction of 6" at the sides and 6" at the back. It

must be installed on a noncombustible floor. The

installation location must allow adequate clearances

for servicing and proper operation.

1/2 IN. DIA. HOLE

PROVIDED FOR

STRAIN RELIEF

Should it be necessary to disconnect the restraint, turn

off the gas supply before disconnection. Reconnect the

restraint before turning the gas supply on and returning

the steamer to its installation position.

INSTALLATION CODES AND STANDARDS

Your Vulcan steamer must be installed in accordance

with:

PL-51218

6

Page 7

In the United States:

STEAM CONNECTIONS

1. State and local codes.

2. National Fuel Gas Code, ANSI-Z233.1 (latest

edition). Copies may be obtained from The

American Gas Assoc., Inc., 1515 Wilson Blvd.,

Arlington, VA 22209.

3. National Electrical Code, ANSI/NFPA No. 70 (latest

edition). Copies may be obtained from The

National Fire Protection Assoc., Batterymarch Park,

Quincy, MA 02269.

In Canada:

1. Local codes.

2. CAN/CGA-B149.1 Installation for Natural Gas

Burning Appliances and Equipment (latest edition).

3. CAN/CGA-B149.2 Installation for Propane Burning

Appliances and Equipment (latest edition). Copies

may be obtained from The Canadian Gas Assoc.,

55 Scarsdale Road, Don Mills, Ontario, Canada

M3B 2R3.

Provide dry steam to the inlets. If the steam is heavy

with condensate, install a ball float trap before the

pressure regulator valve. To ensure rapid heat-up of

heavy cold loads, the steam supply line must be sized

to maintain pressure and flow as follows:

Direct Connected Steamers (Fig’s. 2-4)

Supply steam at a pressure of 10-12 psi and at a

minimum flow rate of 50 lb. per hour per compartment.

A pressure reducing valve is furnished and set at 10 psig.

Additional steam kettles and kettle modules can

be interconnected to the steamer. Consult Vulcan-Hart

for recommendations.

Regenerating (Steam Coil) Generators (Fig’s. 5 & 6)

The steam supply to the steam coils must be 15 psi at

a minimum flow rate of 125 lb. per hour to the coil.

GAS CONNECTIONS (Fig’s. 7, 8 & 9)

All gas supply connections and any pipe joint

compound used must be resistant to the action of

propane gases.

4. The Canadian Electrical Code, Part 1, C22.1 (latest

edition). Copies may be obtained from the

Canadian Standards Assoc., 178 Rexdale Blvd.,

Rexdale, Ontario, Canada M9W 1R3.

LEVELING AND ANCHORING

Using a spirit level, adjust the feet to level the steamer

left-to-right and front-to-back. Steamers should be

elevated in the front just enough (about 1/16" to 1/8") to

give proper drainage. To do this, rotate rear leg

adjusting nut by 1 to 11⁄2 turns clockwise after leveling.

(Check by pouring a little water in the compartment; all

the water should drain.)

The rear feet have holes in the flanges for anchor bolts.

DIRECT STEAM COOKERS (STEAMERS WITHOUT

GENERATORS) MUST BE ANCHORED TO THE

FLOOR.

SERVICE CONNECTIONS (See Fig’s. 2-12)

Connect gas supply to the gas cabinet base generator

using 3⁄4” pipe. Make sure the pipes are clean and free

of obstructions.

Codes require that a gas shutoff valve be installed in

the gas line ahead of the steam generator.

This gas cabinet base generator is equipped with fixed

orifices for use with natural or propane gas and no

adjustment is necessary.

The gas line must be capable of delivering gas to the

generator without excessive pressure drop at the rate

specified on the rating plate. The generator is equipped

with a factory preset pressure regulator. Natural gas

pressure regulators are preset for 3.5" W.C. (Water

Column) for natural gas. Propane gas pressure

regulators are preset for 10" W.C. No further adjustment

should be required.

WARNING: PRIOR TO LIGHTING, CHECK ALL

JOINTS IN THE GAS SUPPLY LINE FOR LEAKS.

USE SOAP AND WATER SOLUTION. DO NOT USE

AN OPEN FLAME.

After piping has been checked for leaks, all piping

receiving gas should be fully purged to remove air.

7

Page 8

Testing The Gas Supply System

1

When test pressures exceed

⁄2 psig (3.45 kPa), the

generator and its individual shutoff valve must be

disconnected from the gas supply piping system.

When test pressures are 1⁄2 psig (3.45 kPa) or less, the

generator must be isolated from the gas supply system

by closing its individual manual shutoff valve.

DRAIN CONNECTIONS (Fig’s. 2-12)

Drain connections must be the open air gap type.

Provide a suitable drain under the drain pipes. For

proper drainage, a floor sink with minimum of 12" depth

is recommended.

CAUTION: In order to avoid any back pressure in

the steamer, do not connect solidly to any drain

connection.

ELECTRICAL CONNECTIONS (Fig’s. 2-12)

WARNING: ELECTRICAL AND GROUNDING

CONNECTIONS MUST COMPLY WITH THE

APPLICABLE PORTIONS OF THE NATIONAL

ELECTRICAL CODE ANSI/NFPA-70 (LATEST

EDITION) AND/OR OTHER LOCAL ELECTRICAL

CODES.

WARNING: DISCONNECT ELECTRICAL POWER

SUPPLY AND PLACE A TAG AT THE DISCONNECT

SWITCH TO INDICATE THAT YOU ARE WORKING

ON THE CIRCUIT.

Do not connect the steamer to electrical supply until

after gas connections (if applicable) have been made.

All Models

Unless otherwise specified, field wire electrical

connection is to be 120 volts, 60 Hertz, single phase,

with grounding wire. Connect electrical supply to the

pigtail leads in the supply junction box located next to

the boiler control box for electric generators in a 24"

wide base, and under the boiler control box for all other

generator bases. The supply junction box is located on

the underside of the cabinet top on direct steam

models. Use copper wire suitable for at least 75°C

temperature. A grounding wire must be connected to

the ground lug in the junction box.

When optional step down transformer is used on

electrically heated generators, the 120 volt connection

is not required.

PLUMBING CONNECTIONS (Fig’s. 2-12)

WARNING: PLUMBING CONNECTIONS MUST

COMPLY WITH APPLICABLE SANITARY, SAFETY

AND PLUMBING CODES.

Before connecting the steamer to water, the water

supply should be analyzed to make sure hardness is

less than 2.0 grains per gallon and pH of 7.5. The water

supply should be clear with no sediment or suspended

material present. If the water supply fails to meet these

standards, it will be necessary to install a water

conditioner on the boiler water feed. APPLIANCE

FAILURE CAUSED BY INADEQUATE WATER

QUALITY IS NOT COVERED UNDER WARRANTY.

The use of strainers or filters will not remove minerals

from the water.

Cold Water

Used as boiler fill water and cold water condenser on

boiler blowdown line. Connect a

1

⁄4” N.P.T. cold water condensor line. Twenty (20) psig

cold water line to the

minimum water pressure is required at the connections.

VENT HOOD

Information on the construction and installation of

ventilating hoods may be obtained from the standard

for “Vapor Removal from Cooking Equipment,” NFPA

No. 96 (latest edition).

Electrically Heated Generators

Make the electrical supply connection in the junction

box on the contactor box. The supply wiring and circuit

protection must be adequate for the kilowatt load drawn

by the cooker. A grounding wire must be connected to

the ground lug in the junction box. Use copper wire of

the size and temperature rating marked on the supply

label.

8

Page 9

SERVICE CONNECTIONS

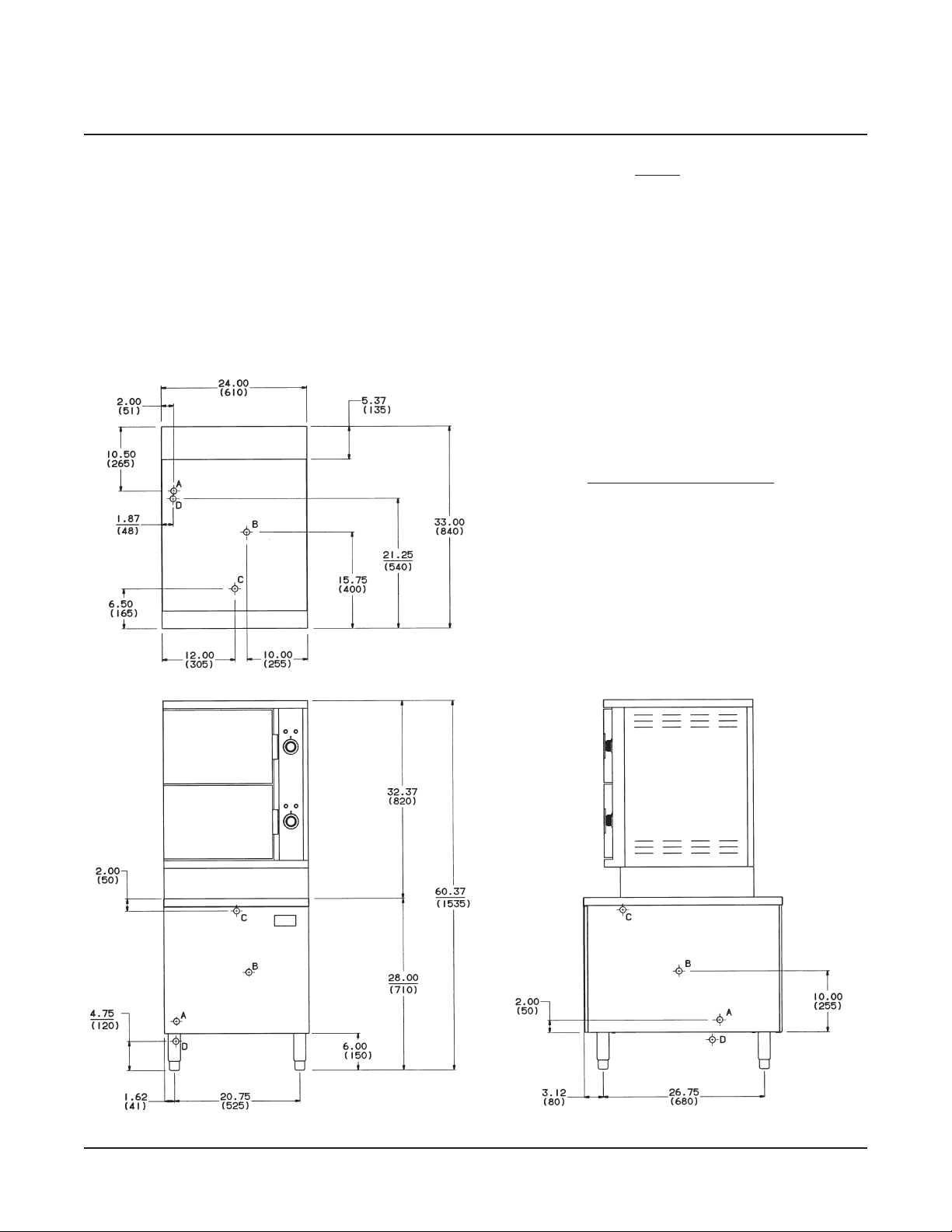

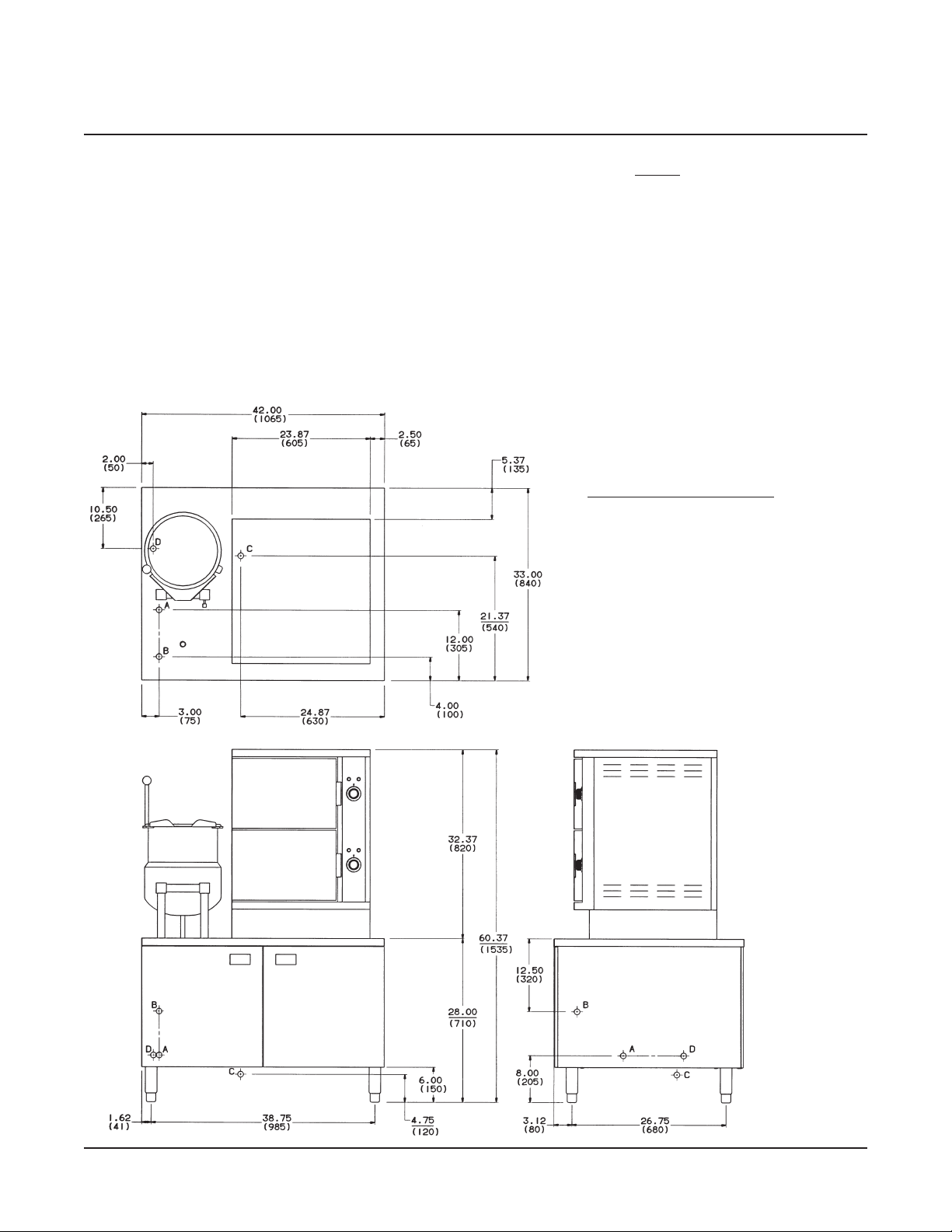

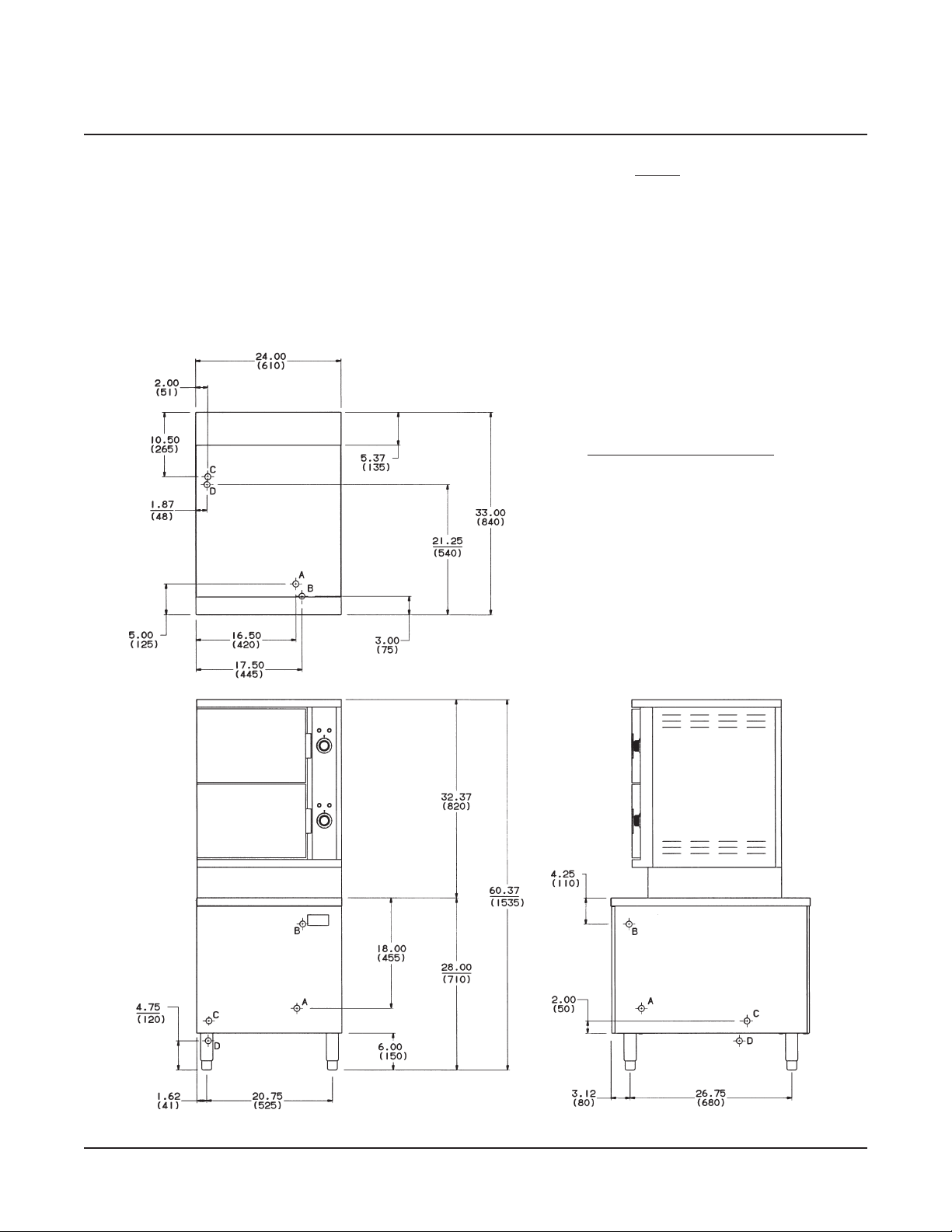

DIRECT STEAM, VSX24D FIG. 2

LEGEND

A. COLD SUPPLY WATER CONNECTION:

CONDENSER SUPPLY, AND BOILER FEED.

B. STEAM SUPPLY CONNECTION:

PRESSURE REDUCING VALVE IS MOUNTED AS STANDARD AND SET FOR 10

PSI MAXIMUM INPUT TO UNIT).

C. ELECTRICAL CONNECTION FOR CONTROLS: 120V/60HZ/1PH/300 WATT

MAXIMUM, POWER SUPPLY WITH GROUNDING WIRE REQUIRED. (FOR

OTHER THAN 120 VOLT SUPPLY CONSULT FACTORY FOR LOCATION OF

THIS CONNECTION.)

D. DRAIN: COPPER TUBE COMPARTMENT & EXHAUST GROUP APPROXIMATELY

2" IN DIAMETER. (PROVIDE AN OPEN AIR GAP TYPE DRAIN DIRECTLY

UNDER THE UNIT FRAME. DO NOT CONNECT SOLIDLY TO ANY DRAIN

CONNECTION.)

NOTE: DIMENSIONS WHICH LOCATE THE ABOVE CONNECTIONS HAVE A

TOLERANCE OF ± 3 IN. (± 75 MM). NORMAL DIMENSIONS ARE IN INCHES.

DIMENSIONS IN ( ) ARE IN MILLIMETERS.

EQUIPMENT CLEARANCES

TO COMBUSTIBLE CONSTRUCTION

REAR: 2 IN. MIN. (50 MM.)

3

⁄4” NPT FOR STEAM COOKING (A STEAM

1

⁄4” TUBING FOR COLD WATER

9

Page 10

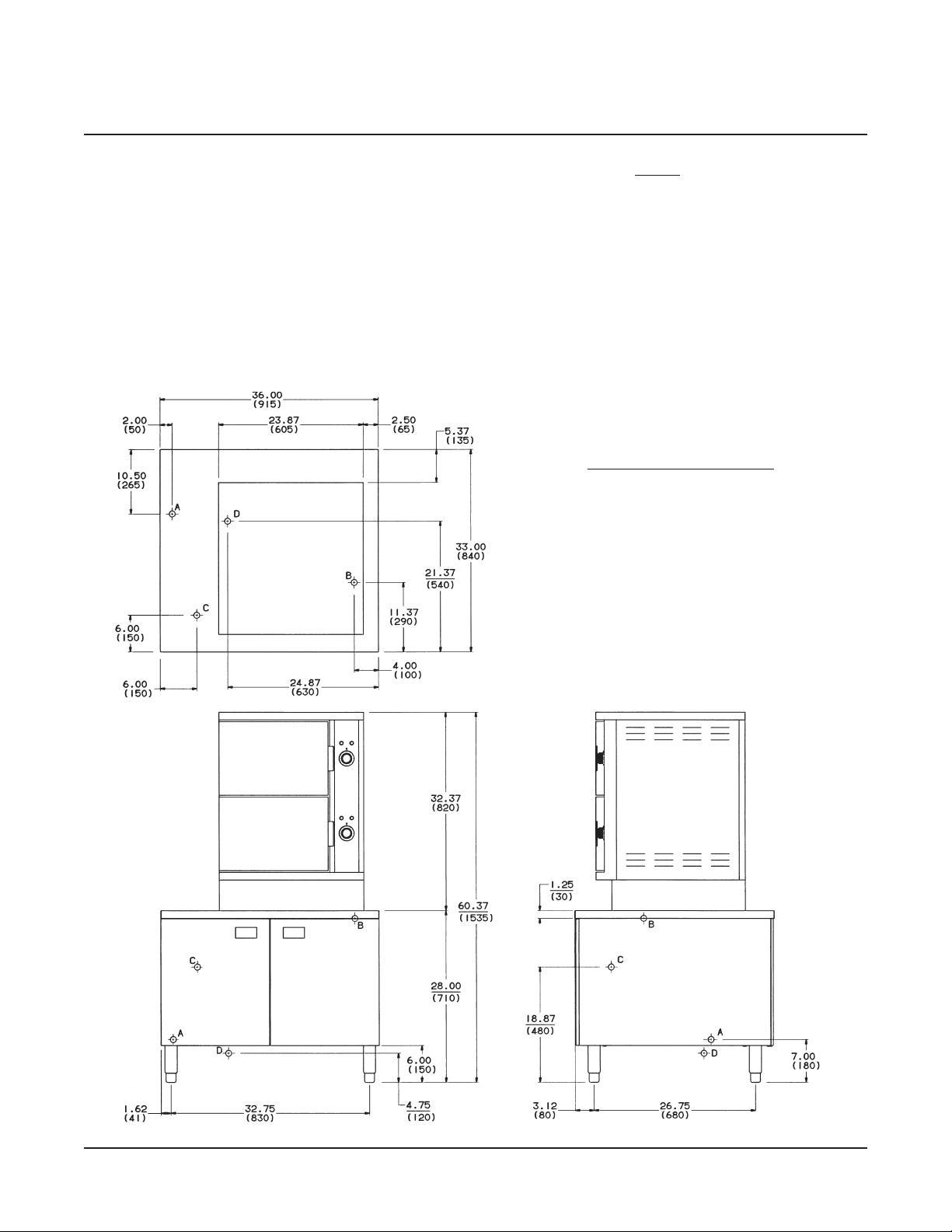

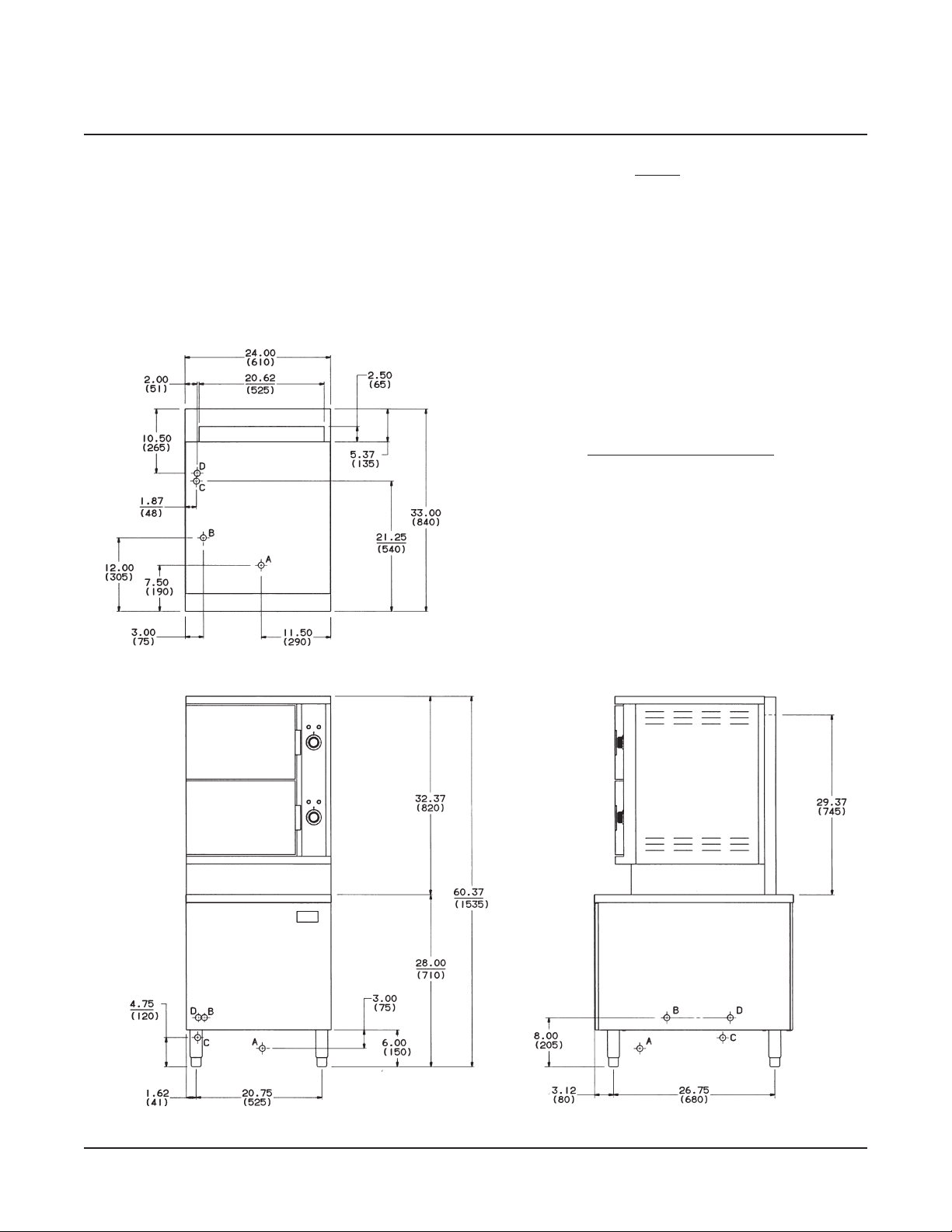

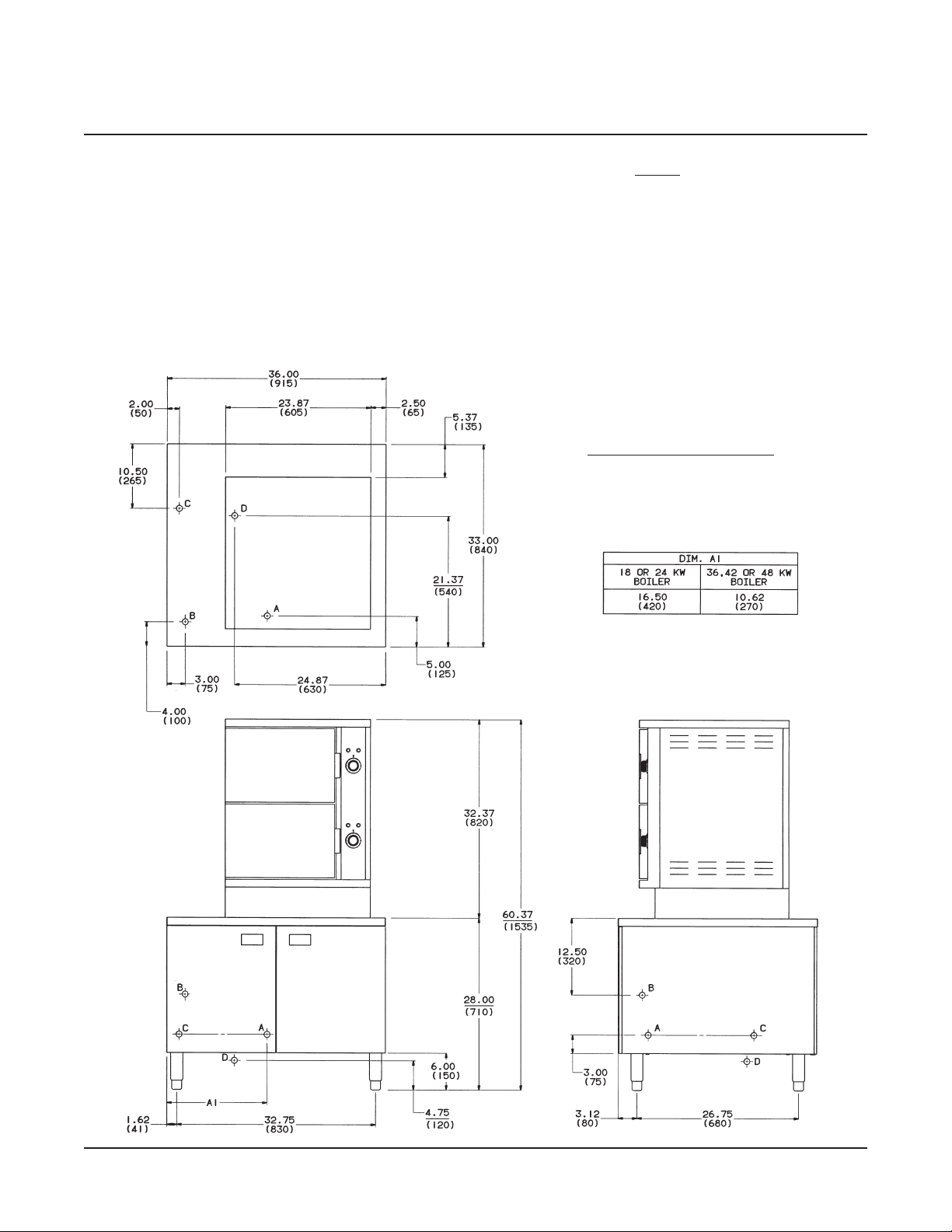

SERVICE CONNECTIONS

DIRECT STEAM, VSX36D FIG. 3

LEGEND

A. COLD SUPPLY WATER CONNECTION:

CONDENSER, AND BOILER FEED.

B. STEAM SUPPLY CONNECTION:

PRESSURE REDUCING VALVE IS MOUNTED AS STANDARD AND SET FOR

10 PSI MAXIMUM INPUT TO UNIT.)

C. ELECTRICAL CONNECTION FOR CONTROLS: 120V/60HZ/1PH/300 WATT

MAXIMUM, POWER SUPPLY WITH GROUNDING WIRE REQUIRED. (FOR

OTHER THAN 120 VOLT SUPPLY CONSULT FACTORY FOR LOCATION OF

THIS CONNECTION.)

D. DRAIN: COPPER TUBE COMPARTMENT & EXHAUST GROUP APPROXIMATELY

2" DIAMETER. (PROVIDE AN OPEN AIR GAP TYPE DRAIN DIRECTLY UNDER

UNIT FRAME. DO NOT CONNECT SOLIDLY TO ANY DRAIN CONNECTION.)

NOTE: DIMENSIONS WHICH LOCATE THE ABOVE CONNECTIONS HAVE A

TOLERANCE OF ± 3 IN. (± 75 MM). NORMAL DIMENSIONS ARE IN INCHES.

DIMENSIONS IN ( ) ARE IN MILLIMETERS.

EQUIPMENT CLEARANCES

TO COMBUSTIBLE CONSTRUCTION

REAR: 2 IN. MIN. (50 MM.)

3

⁄4” NPT FOR STEAM COOKING. (A STEAM

1

⁄4” TUBING FOR COLD WATER

10

Page 11

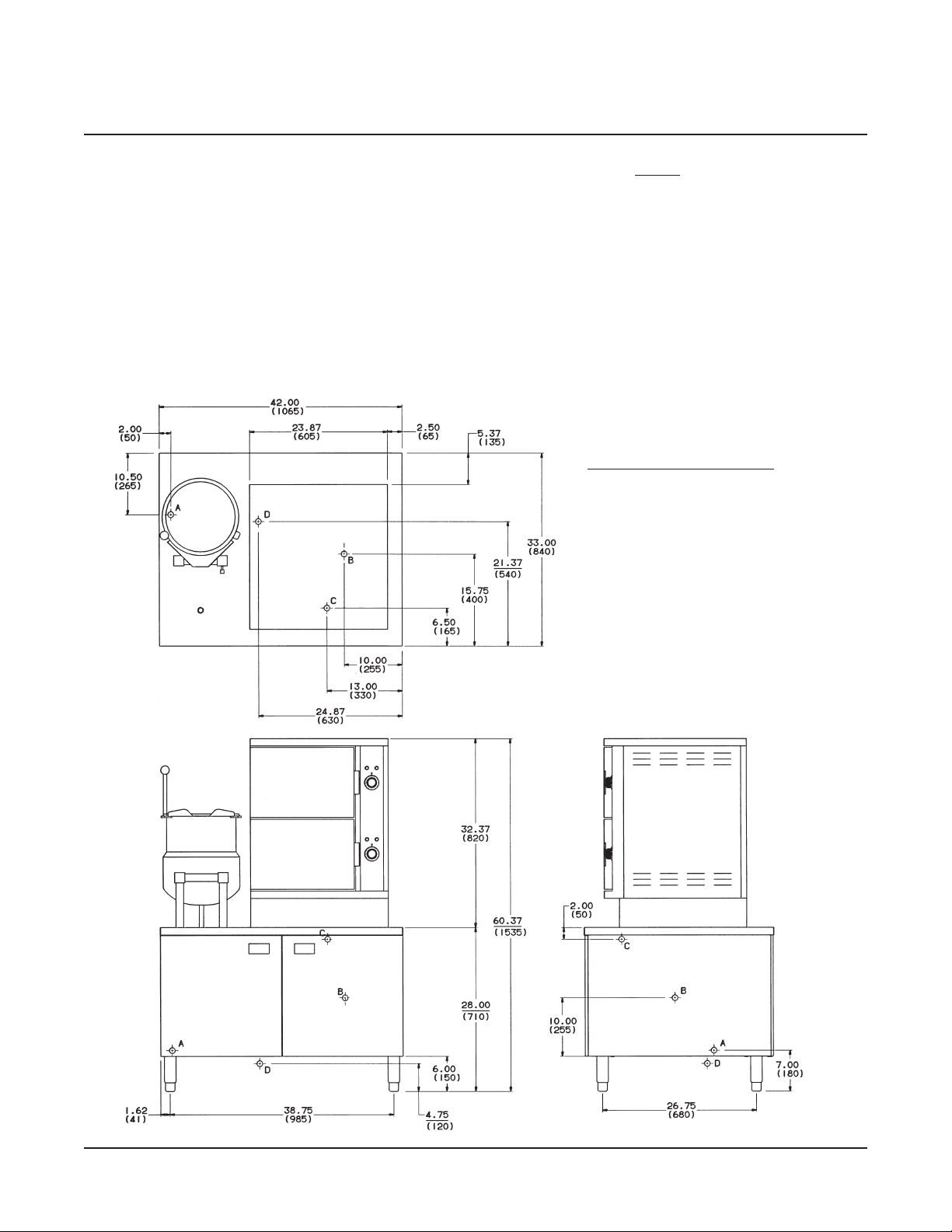

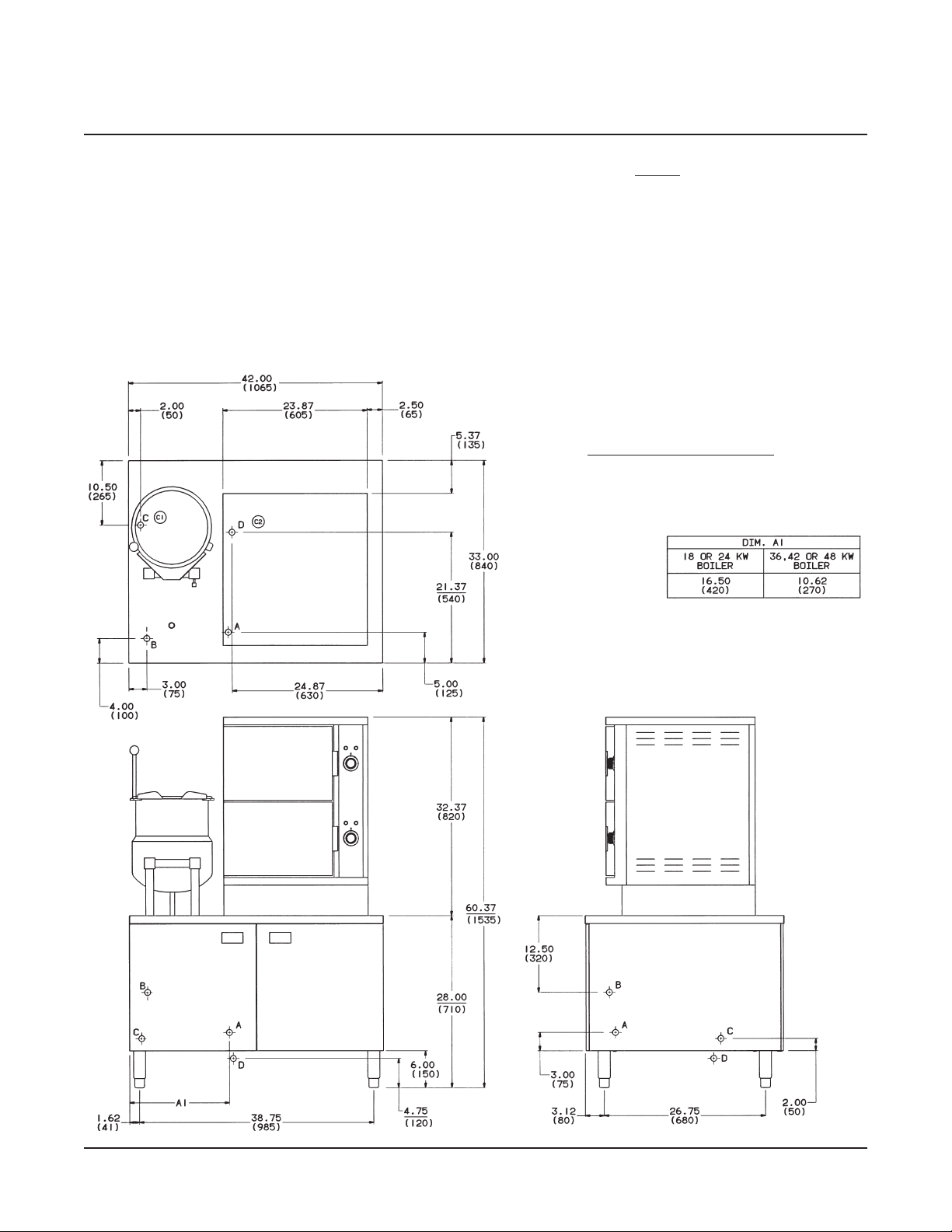

SERVICE CONNECTIONS

DIRECT STEAM, VSX42DT FIG. 4

LEGEND

A. COLD SUPPLY WATER CONNECTION:

CONDENSER, AND BOILER FEED.

B. STEAM SUPPLY CONNECTION:

PRESSURE REDUCING VALVE IS MOUNTED AS STANDARD AND SET FOR

10 PSI MAXIMUM INPUT TO UNIT.)

C. ELECTRICAL CONNECTION FOR CONTROLS: 120V/60HZ/1PH/300 WATT

MAXIMUM, POWER SUPPLY WITH GROUNDING WIRE REQUIRED. (FOR

OTHER THAN 120 VOLT SUPPLY CONSULT FACTORY FOR LOCATION OF

THIS CONNECTION.)

D. DRAIN: COPPER TUBE COMPARTMENT & EXHAUST GROUP APPROXIMATELY

2" DIAMETER. (PROVIDE AN OPEN AIR GAP TYPE DRAIN DIRECTLY UNDER

UNIT FRAME. DO NOT CONNECT SOLIDLY TO ANY DRAIN CONNECTION.)

NOTE: DIMENSIONS WHICH LOCATE THE ABOVE CONNECTIONS HAVE A

TOLERANCE OF ± 3 IN. (± 75 MM). NORMAL DIMENSIONS ARE IN INCHES.

DIMENSIONS IN ( ) ARE IN MILLIMETERS.

EQUIPMENT CLEARANCES

TO COMBUSTIBLE CONSTRUCTION

REAR: 2 IN. MIN. (50 MM.)

3

⁄4” NPT FOR STEAM COOKING. (A STEAM

1

⁄4” TUBING FOR COLD WATER

11

Page 12

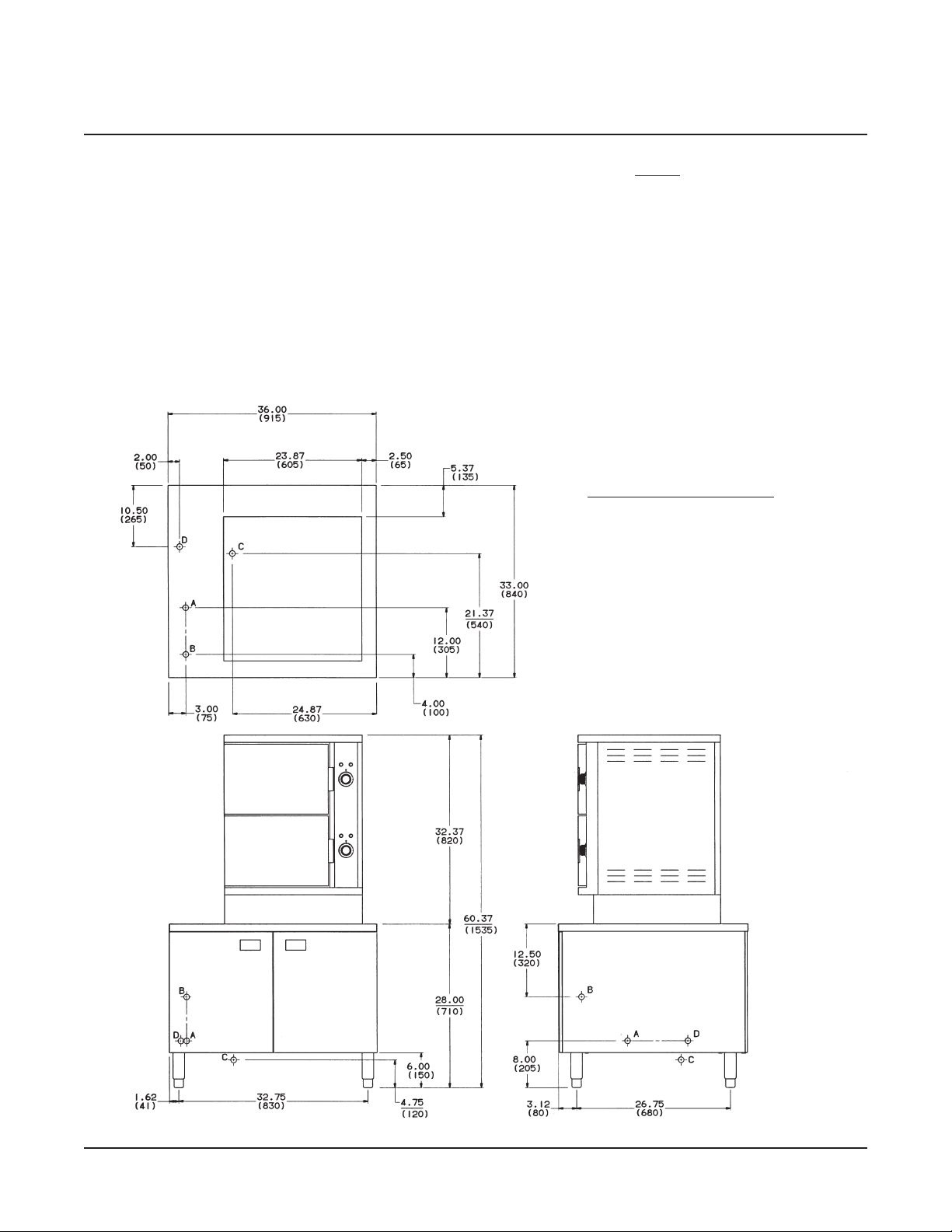

SERVICE CONNECTIONS

REGENERATING STEAM, VSX36R FIG. 5

LEGEND

A. STEAM SUPPLY CONNECTION:

STEAM PRESSURE REDUCING VALVE IS SHIPPED WITH THE UNIT AND

MUST BE FIELD INSTALLED AND ADJUSTED FOR 15 PSI MAXIMUM TO THE

UNIT.)

B. ELECTRICAL CONNECTION FOR CONTROLS: 120V/60HZ/1PH/300 WATT

MAXIMUM, POWER SUPPLY WITH GROUNDING WIRE REQUIRED. (FOR

OTHER THAN 120 VOLT SUPPLY CONSULT FACTORY FOR LOCATION OF

THIS CONNECTION.)

C. DRAIN: COMPARTMENT, BOILER AND EXHAUST GROUP APPROXIMATELY

2" IN DIAMETER. (PROVIDE AN OPEN AIR GAP TYPE DRAIN DIRECTLY

UNDER UNIT FRAME. DO NOT CONNECT SOLIDLY TO ANY DRAIN

CONNECTION.)

D. COLD SUPPLY WATER CONNECTION:

COMPARTMENT DRAIN COLD WATER CONDENSERS, AND BOILER FEED.

NOTE: DIMENSIONS WHICH LOCATE THE ABOVE CONNECTIONS HAVE A

TOLERANCE OF ± 3" (±75MM). NORMAL DIMENSIONS ARE IN INCHES. DIMENSIONS

IN ( ) ARE IN MILLIMETERS.

EQUIPMENT CLEARANCES

TO COMBUSTIBLE CONSTRUCTION

REAR: 2 IN. MIN. (50 MM.)

3

⁄4” NPT FOR STEAM INLET TO BOILER. (A

1

⁄4” NPT FOR BOILER DRAIN &

12

Page 13

SERVICE CONNECTIONS

REGENERATING STEAM, VSX42RT FIG. 6

LEGEND

A. STEAM SUPPLY CONNECTION:

STEAM PRESSURE REDUCING VALVE IS SHIPPED WITH THE UNIT AND

MUST BE FIELD INSTALLED AND ADJUSTED FOR 15 PSI MAXIMUM TO THE

UNIT.)

B. ELECTRICAL CONNECTION FOR CONTROLS: 120V/60HZ/1PH/300 WATT

MAXIMUM, POWER SUPPLY WITH GROUNDING WIRE REQUIRED. (FOR

OTHER THAN 120 VOLT SUPPLY CONSULT FACTORY FOR LOCATION OF

THIS CONNECTION.)

C. DRAIN: COMPARTMENT, BOILER AND EXHAUST GROUP APPROXIMATELY

2" IN DIAMETER. (PROVIDE AN OPEN AIR GAP TYPE DRAIN DIRECTLY

UNDER UNIT FRAME. DO NOT CONNECT SOLIDLY TO ANY DRAIN

CONNECTION.)

D. COLD SUPPLY WATER CONNECTION:

COMPARTMENT DRAIN COLD WATER CONDENSERS, AND BOILER FEED.

NOTE: DIMENSIONS WHICH LOCATE THE ABOVE CONNECTIONS HAVE A

TOLERANCE OF ± 3" (± 75MM). NORMAL DIMENSIONS ARE IN INCHES. DIMENSIONS

IN ( ) ARE IN MILLIMETERS.

EQUIPMENT CLEARANCES

TO COMBUSTIBLE CONSTRUCTION

REAR: 2 IN. MIN. (50 MM.)

3

⁄4” NPT FOR STEAM INLET TO BOILER. (A

1

⁄4” NPT FOR BOILER DRAIN &

13

Page 14

SERVICE CONNECTIONS

GAS HEAT, VSX24G FIG. 7

LEGEND

A. GAS CONNECTION:

B. ELECTRICAL CONNECTION FOR CONTROLS: 120V/60HZ/1PH/300 WATT

MAXIMUM, POWER SUPPLY WITH GROUNDING WIRE REQUIRED. (FOR

OTHER THAN 120 VOLT SUPPLY CONSULT FACTORY FOR LOCATION OF

THIS CONNECTION.)

C. DRAIN: COMPARTMENT, BOILER AND EXHAUST GROUP APPROXIMATELY

1

3

⁄2” IN DIAMETER. (PROVIDE AN OPEN AIR GAP TYPE DRAIN DIRECTLY

UNDER UNIT FRAME. DO NOT CONNECT SOLIDLY TO ANY DRAIN

CONNECTION.)

D. COLD SUPPLY WATER CONNECTION:

COMPARTMENT DRAIN COLD WATER CONDENSERS, AND BOILER FEED.

NOTE: DIMENSIONS WHICH LOCATE THE ABOVE CONNECTIONS HAVE A

TOLERANCE OF ± 3 IN. (± 75 MM). NORMAL DIMENSIONS ARE IN INCHES.

DIMENSIONS IN ( ) ARE IN MILLIMETERS.

3

⁄4” NPT.

1

⁄4” NPT FOR BOILER DRAIN &

EQUIPMENT CLEARANCES

TO COMBUSTIBLE CONSTRUCTION

REAR: 6 IN. MIN. (150 MM.)

LEFT SIDE: 6 IN. MIN. (150 MM.)

RIGHT SIDE: 6 IN. MIN. (150 MM.)

14

Page 15

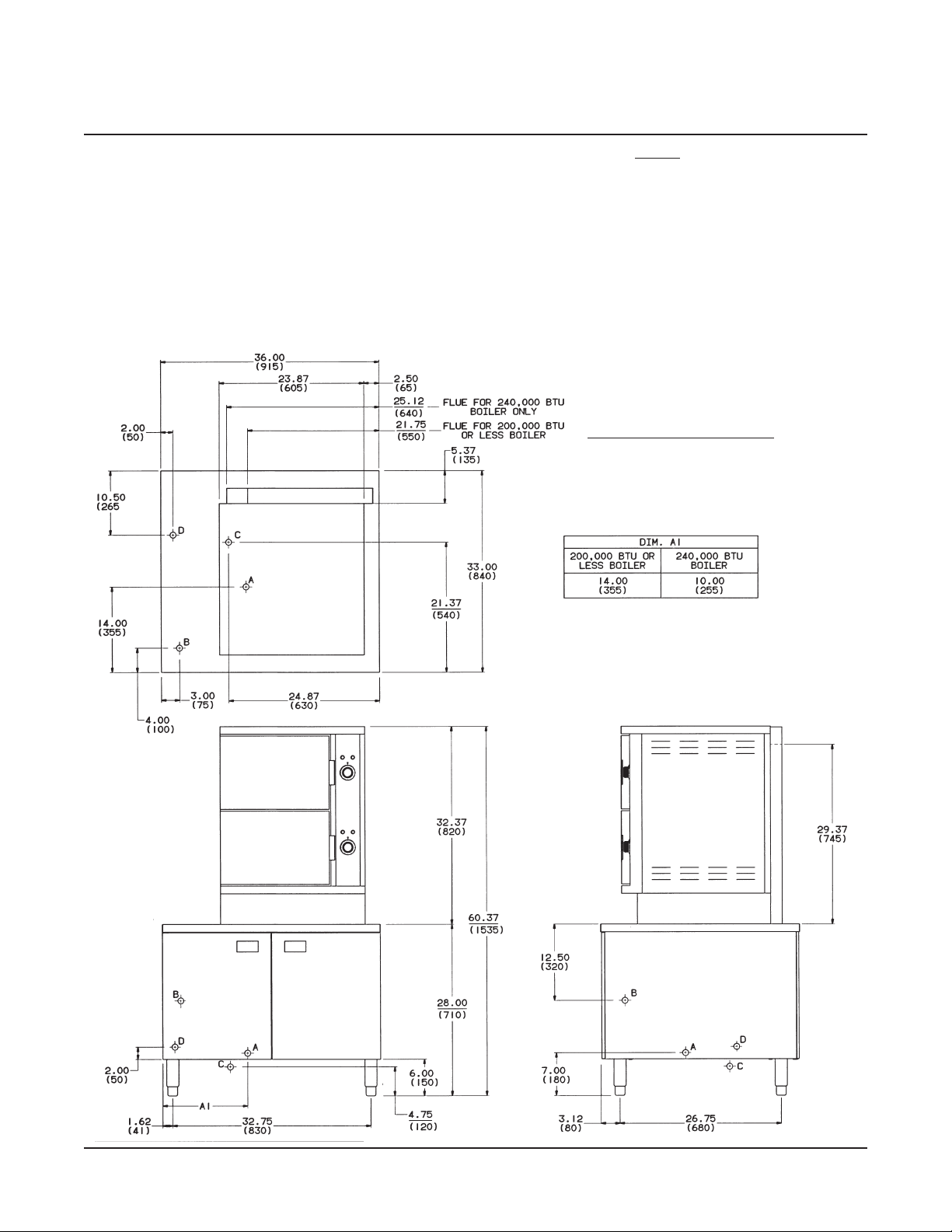

SERVICE CONNECTIONS

GAS HEAT, VSX36G FIG. 8

LEGEND

A. GAS CONNECTION:

B. ELECTRICAL CONNECTION FOR CONTROLS: 120V/60HZ/1PH/300 WATT

MAXIMUM, POWER SUPPLY WITH GROUNDING WIRE REQUIRED. (FOR

OTHER THAN 120 VOLT SUPPLY CONSULT FACTORY FOR LOCATION OF

THIS CONNECTION.)

C. DRAIN: COMPARTMENT, BOILER AND EXHAUST GROUP APPROXIMATELY

1

3

⁄2” IN DIAMETER. (PROVIDE AN OPEN AIR GAP TYPE DRAIN DIRECTLY

UNDER UNIT FRAME. DO NOT CONNECT SOLIDLY TO ANY DRAIN

CONNECTION.)

D. COLD SUPPLY WATER CONNECTION:

COMPARTMENT DRAIN COLD WATER CONDENSERS, AND BOILER FEED.

NOTE: DIMENSIONS WHICH LOCATE THE ABOVE CONNECTIONS HAVE A

TOLERANCE OF ± 3 IN. (± 75 MM). NORMAL DIMENSIONS ARE IN INCHES.

DIMENSIONS IN ( ) ARE IN MILLIMETERS.

3

⁄4” NPT.

1

⁄4” NPT FOR BOILER DRAIN &

EQUIPMENT CLEARANCES

TO COMBUSTIBLE CONSTRUCTION

REAR: 6 IN. MIN. (150 MM.)

LEFT SIDE: 6 IN. MIN. (150 MM.)

RIGHT SIDE: 6 IN. MIN. (150 MM.)

15

Page 16

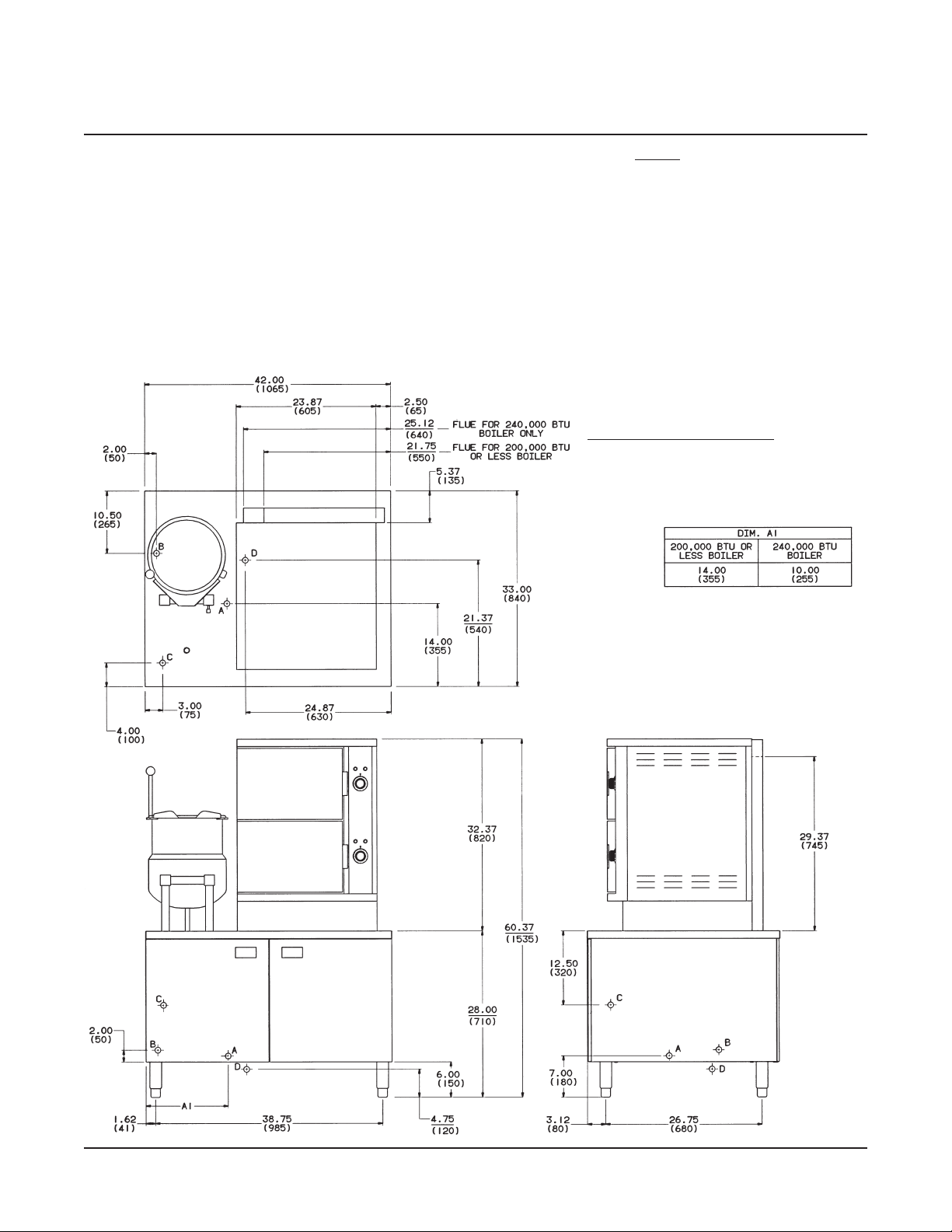

SERVICE CONNECTIONS

GAS HEAT, VSX42GT FIG. 9

LEGEND

A. GAS CONNECTION:

B. ELECTRICAL CONNECTION FOR CONTROLS: 120V/60HZ/1PH/300 WATT

MAXIMUM, POWER SUPPLY WITH GROUNDING WIRE REQUIRED. (FOR

OTHER THAN 120 VOLT SUPPLY CONSULT FACTORY FOR LOCATION OF

THIS CONNECTION.)

C. DRAIN: COMPARTMENT, BOILER AND EXHAUST GROUP APPROXIMATELY

1

3

⁄2” IN DIAMETER. (PROVIDE AN OPEN AIR GAP TYPE DRAIN DIRECTLY

UNDER UNIT FRAME. DO NOT CONNECT SOLIDLY TO ANY DRAIN

CONNECTION.)

D. COLD SUPPLY WATER CONNECTION:

COMPARTMENT DRAIN COLD WATER CONDENSERS, AND BOILER FEED.

NOTE: DIMENSIONS WHICH LOCATE THE ABOVE CONNECTIONS HAVE A

TOLERANCE OF ± 3 IN. (± 75 MM). NORMAL DIMENSIONS ARE IN INCHES.

DIMENSIONS IN ( ) ARE IN MILLIMETERS.

3

⁄4” NPT.

1

⁄4” NPT FOR BOILER DRAIN &

EQUIPMENT CLEARANCES

TO COMBUSTIBLE CONSTRUCTION

REAR: 6 IN. MIN. (150 MM.)

LEFT SIDE: 6 IN. MIN. (150 MM.)

RIGHT SIDE: 6 IN. MIN. (150 MM.)

16

Page 17

SERVICE CONNECTIONS

ELECTRIC HEAT, VSX24E FIG. 10

LEGEND

A. JUNCTION BOX: J.I.C. 6X6X4 FOR ELECTRICAL SUPPLY CONNECTION FOR

HEAT.

B. ELECTRICAL CONNECTION FOR CONTROLS: 120V/60HZ/1PH/300 WATT

MAXIMUM, POWER SUPPLY WITH GROUNDING WIRE REQUIRED. (NOT

PROVIDED IF A STEP DOWN TRANSFORMER IS FURNISHED.)

C. COLD SUPPLY WATER CONNECTION:

COMPARTMENT DRAIN COLD WATER CONDENSERS.

D. DRAIN: COMPARTMENT, BOILER AND EXHAUST GROUP APPROXIMATELY

1

3

⁄2” IN DIAMETER. (PROVIDE AN OPEN AIR GAP TYPE DRAIN DIRECTLY

UNDER UNIT FRAME. DO NOT CONNECT SOLIDLY TO ANY DRAIN

CONNECTION.)

NOTE: DIMENSIONS WHICH LOCATE THE ABOVE CONNECTIONS HAVE A

TOLERANCE OF ± 3 IN. (± 75 MM). NORMAL DIMENSIONS ARE IN INCHES.

DIMENSIONS IN ( ) ARE IN MILLIMETERS.

EQUIPMENT CLEARANCES

TO COMBUSTIBLE CONSTRUCTION

REAR: 2 IN. MIN. (50 MM.)

1

⁄4” NPT FOR BOILER DRAIN AND

17

Page 18

SERVICE CONNECTIONS

ELECTRIC HEAT, VSX36E FIG. 11

LEGEND

A. JUNCTION BOX: J.I.C. 6X6X4 FOR ELECTRICAL SUPPLY CONNECTION FOR

HEAT.

B. ELECTRICAL CONNECTION FOR CONTROLS: 120V/60HZ/1PH/300 WATT

MAXIMUM, POWER SUPPLY WITH GROUNDING WIRE REQUIRED. (NOT

PROVIDED IF A STEP DOWN TRANSFORMER IS FURNISHED.)

C. COLD SUPPLY WATER CONNECTION:

COMPARTMENT DRAIN COLD WATER CONDENSERS.

D. DRAIN: COMPARTMENT, BOILER AND EXHAUST GROUP APPROXIMATELY

1

3

⁄2” IN DIAMETER. (PROVIDE AN OPEN AIR GAP TYPE DRAIN DIRECTLY

UNDER UNIT FRAME. DO NOT CONNECT SOLIDLY TO ANY DRAIN

CONNECTION.)

NOTE: DIMENSIONS WHICH LOCATE THE ABOVE CONNECTIONS HAVE A

TOLERANCE OF ± 3 IN. (± 75 MM). NORMAL DIMENSIONS ARE IN INCHES.

DIMENSIONS IN ( ) ARE IN MILLIMETERS.

EQUIPMENT CLEARANCES

TO COMBUSTIBLE CONSTRUCTION

REAR: 2 IN. MIN. (50 MM.)

1

⁄4” NPT FOR BOILER DRAIN AND

18

Page 19

SERVICE CONNECTIONS

ELECTRIC HEAT, VSX42ET FIG. 12

LEGEND

A. JUNCTION BOX: J.I.C. 6X6X4 FOR ELECTRICAL SUPPLY CONNECTION FOR

HEAT.

B. ELECTRICAL CONNECTION FOR CONTROLS: 120V/60HZ/1PH/300 WATT

MAXIMUM, POWER SUPPLY WITH GROUNDING WIRE REQUIRED. (NOT

PROVIDED IF A STEP DOWN TRANSFORMER IS FURNISHED.)

C. COLD SUPPLY WATER CONNECTION:

COMPARTMENT DRAIN COLD WATER CONDENSERS.

D. DRAIN: COMPARTMENT, BOILER AND EXHAUST GROUP APPROXIMATELY

1

3

⁄2” IN DIAMETER. (PROVIDE AN OPEN AIR GAP TYPE DRAIN DIRECTLY

UNDER UNIT FRAME. DO NOT CONNECT SOLIDLY TO ANY DRAIN

CONNECTION.)

NOTE: DIMENSIONS WHICH LOCATE THE ABOVE CONNECTIONS HAVE A

TOLERANCE OF ± 3 IN. (± 75 MM). NORMAL DIMENSIONS ARE IN INCHES.

DIMENSIONS IN ( ) ARE IN MILLIMETERS.

EQUIPMENT CLEARANCES

TO COMBUSTIBLE CONSTRUCTION

REAR: 2 IN. MIN. (50 MM.)

1

⁄4” NPT FOR BOILER DRAIN AND

19

Page 20

START-UP TEST RUN

After the appliance is installed and proper service

connections have been made, thoroughly test the

steam cooker before operation.

8. When timer knobs are on “0”, each buzzer will

sound, steam generation will cease, COOKING

lights will go off and READY lights will come on.

To silence buzzers, turn timer knobs to OFF

position.

Gas Powered Steam Generator

1. Open manual gas shutoff valve, and if the

appliance has a manual blowdown valve, close it.

Open left cabinet door and turn water fill and power

switch ON. The red light will come on and water

will fill boiler to the required level in about 15

minutes. Observe water level gauge glass to

verify. Both valves on gauge glass assembly must

be open.

2. The dial on the gas combination control valve has

three positions (On-Pilot-Off) for manual gas control

of main burners and pilot. Turn dial on gas

combination valve to PILOT. Depress dial and light

pilot burner; maintain dial in depressed position for

about 30 seconds and release. Observe that pilot

burner flame stays on. If the flame should go out,

wait 5 minutes before relighting.

3. Turn gas combination control valve dial to ON and

burners will ignite. Steam generation will begin and

be completed in about 15 minutes. Observe that

the boiler pressure gauge indicates steam pressure

in the range of 9-12 psi (9-13 psi if a kettle is

connected to the steamer).

9. During simulation of cooking cycle, burners will

cycle on and off to maintain steam pressure in

boiler.

10. Turn power switch OFF. Amber light will go out.

11. Blow down boiler (see BLOW DOWN BOILER in

this manual).

Electrically Powered Steam Generator

1. If steamer has a manual blowdown valve, close it.

Open left cabinet door and turn power switch ON.

Water will fill boiler to the required level in about 15

minutes. Observe water level gauge glass to

verify. Both valves on gauge glass assembly must

be open. Steam generation will begin and be

completed in about 15 minutes.

2. Set both timer knobs to “0”. Open both

compartment doors and observe that no steam has

entered the cooking compartments. Close doors.

3. Set both timer knobs to 2 minutes. READY lights

will go off, COOKING lights will come on, and

steam will be heard entering the compartments.

4. Set both timer knobs to “0”. Open both

compartment doors and observe that no steam has

entered the cooking compartments. Close doors.

5. Set both timer knobs to 2 minutes. The READY

lights will go off, the COOKING lights will come on,

and steam will be heard entering the

compartments.

After one minute, open each door and observe that

steam has ceased to enter each compartment, but

COOKING lights and cooking times at “01” are

maintained.

WARNING: THE COOKING COMPARTMENTS

CONTAIN LIVE STEAM. STAY CLEAR WHILE

OPENING EACH DOOR.

7. Close doors. Steam generation and cook times will

resume. Observe appliance drain that live steam

from compartments is being cooled by cold water

from the cold water solenoid valve.

After one minute, open each door and observe that

steam has ceased to enter each compartment, but

COOKING lights and cooking times at “01” are

maintained.

WARNING: THE COOKING COMPARTMENTS

CONTAIN LIVE STEAM. STAY CLEAR WHILE

OPENING EACH DOOR.

4. Close doors. Steam generation and cook times will

resume. Observe appliance drain that live steam

from compartments is being cooled by cold water

from the cold water solenoid valve.

5. When timer knobs are on “0”, each buzzer will

sound, steam generation will cease, COOKING

lights will go off and READY lights will come on.

To silence buzzers, turn timer knobs to OFF

position.

6. During simulation of cooking cycle, the heating

elements will cycle on and off to maintain steam

pressure in the boiler.

20

Page 21

7. Turn power switch OFF. Amber light will go out.

8. Blow down boiler (see BLOW DOWN BOILER in

this manual).

Direct Steam Powered Cooker

1. Set both timer knobs to “0”. Open both

compartment doors and observe that no steam has

entered cooking compartments. Close doors.

2. Set both timer knobs to 2 minutes. READY lights

will go off, COOKING lights will come on, and

steam will be heard entering the compartments.

After one minute, open each door and observe that

steam has ceased to enter each compartment, but

COOKING lights and cooking times at “01” are

maintained.

WARNING: THE COOKING COMPARTMENTS

CONTAIN LIVE STEAM. STAY CLEAR WHILE

OPENING EACH DOOR.

3. Close doors. Steam generation and cook times will

resume. Observe appliance drain that live steam

from compartments is being cooled by cold water

from the cold water solenoid valve.

4. When timer knobs are on “0”, each buzzer will sound,

steam generation will cease, COOKING

lights will go off and READY lights will come on.

To silence buzzers, turn timer knobs to OFF

position.

Regenerative Steam Powered Generator

1. If the steamer has a manual blowdown valve, close

it. Turn power switch ON. Water will fill the boiler

to the required level in about 15 minutes. Observe

water level gauge glass to verify. Both valves on

gauge glass assembly must be open. Steam

generation will begin and be completed in about 15

minutes.

2. Set both timer knobs to “0”. Open both

compartment doors and observe that no steam has

entered the cooking compartments. Close doors.

3. Set both timer knobs to 2 minutes. READY lights

will go off, COOKING lights will come on, and

steam will be heard entering the compartments.

After one minute, open each door and observe that

steam has ceased to enter each compartment, but

COOKING lights and cooking times at “01” are

maintained.

WARNING: THE COOKING COMPARTMENTS

CONTAIN LIVE STEAM. STAY CLEAR WHILE

OPENING EACH DOOR.

4. Close doors. Steam generation and cook times will

resume. Observe appliance drain that live steam

from compartments is being cooled by cold water

from the cold water solenoid valve.

5. When timer knobs are on “0”, each buzzer will

sound, steam generation will cease, COOKING

lights will go off and READY lights will come on.

To silence buzzers, turn timer knobs to OFF position.

6. During simulation of cooking cycle, steam coils will

cycle on and off to maintain steam pressure in the

boiler.

7. Turn power switch OFF. Amber light will go out.

8. Blow down boiler (see BLOW DOWN BOILER in

this manual).

BLOW DOWN BOILER

Always blow down boiler when boiler is under maximum

pressure and no steam is being used.

Automatic Blowdown

Turn power switch OFF. Depress blowdown button.

Blowdown timer will operate for 4 minutes. At end of

blowdown, turn fill switch to ON and allow boiler to fill.

Manual Blowdown

Turn power switch OFF. Open blowdown valve. After

boiler has drained completely, close blowdown valve

and turn fill switch to ON and allow boiler to fill.

21

Page 22

OPERATION

WARNING: THE STEAMER AND ITS PARTS ARE

HOT. USE CARE WHEN OPERATING, CLEANING

OR SERVICING THE STEAMER. THE COOKING

COMPARTMENTS CONTAIN LIVE STEAM. STAY

CLEAR WHILE OPENING EACH DOOR.

CONTROLS — CABINET BASE GENERATOR (Fig. 13)

Handhole Cover Assembly — when unbolted and

removed, allows internal examination and cleaning of

boiler if required.

Water Level Gauge Assembly — permits visual

confirmation that water level is being maintained in the

boiler during operation. The correct water level is a

point one-half of the height of the glass. The manual

valves at the top and bottom of this assembly must be

fully open, and only closed if the glass tube should be

damaged.

Observe that the water is clean and clear in the

glass tube. The appearance of extreme murkiness

in the water indicates inadequate water quality and

will cause failure of controls and the steamer.

Warranty does not cover malfunction due to poor

water conditions. Blow down and/or clean the

generator.

Pilot Burner (Gas Base Generator Only) — should

remain lit at all times unless the steamer will not be in

use for an extended period of time. If at any time the

flame goes out, wait 5 minutes before relighting.

Drain Solenoid Valve — a quick acting drain valve

provided for daily blowdown of the generator.

Strainers — a strainer is used in the water inlet line to

prevent foreign matter from becoming lodged in the

inlet solenoid valve. A “Y” strainer is inserted upstream

of the drain solenoid valve to allow the valve to operate

smoothly. A strainer is used in the pressure regulating

valve on models using direct steam supply.

Boiler Fill Solenoid Valve — admits water to the

boiler when demanded by the automatic fill controls in

order to maintain the correct water level in the steam

generator.

Blowdown Drain CWC Solenoid Valve — allows cold

water to flow to boiler blowdown drain and helps cool

the boiler water prior to its discharge into the drain.

Cycling Pressure Switch — controls boiler pressure

between prescribed limits by turning the heat source on

and off. A back-up switch of identical design is provided

and has a higher high setting and a lower low setting

than the primary control.

Power Switch — when turned ON will automatically

begin the steam generating process in the boiler. The

power switch is fastened to the front face of the

generator control box.

Pressure Regulating Valve — used to control

manifold steam pressure at 10-12 psi on models using

direct steam supply.

Main Burners (Gas Base Generator Only) — cycle

on and off to maintain steam pressure in the boiler.

Gas Combination Control Valve (Gas Base

Generator Only) — regulates flow of gas to burners.

Low Water Cutoff/Automatic Fill Control — Level

Sensing Probes — these controls allow the feed water

to enter the generator when the water level is low.

They will also shut off the heat source to the boiler if

the water level drops too low. The level sensing probes

may be easily removed to inspect for lime build-up. As

a rule, the condition of these devices will indicate the

overall water condition of the boiler. Clean the probes

if needed. Controls may not function and serious

clogging will occur if a daily blowdown procedure

is not followed.

22

Water Inlet Ball Valve — water service valve which

can be used to stop water flow to the steamer when the

steamer is being serviced.

High Limit Thermostat — a protective device which

shuts off the gas or electric power if the boiler

overheats.

Descaler — hangs submerged in water inside the

generator and helps control scaling.

Drain — drains steam condensate and water from

cooking compartments and boiler.

Page 23

Boiler Blowdown Valve — plumbed to the drain pipe

of the boiler, and when specified as automatic, will be

a solenoid (electrically operated) valve which will close

to assist in maintaining proper water level in the boiler

and open whenever the steamer is turned off to blow

down sediment and scalant that may be lodged in the

chamber of the boiler.

Pressure Gauge — indicates boiler steam pressure.

Normal operating pressure range is 9-12 psi for the

steamer, or 9-13 psi if a kettle is connected to the

steamer.

Fig. 13

23

Page 24

CONTROLS — COMPARTMENT (Fig. 14)

The upper section of the steamer consists of two

cooking compartments. Each compartment functions

independently with its own controls, and is a separated,

sealed steam chamber during the cooking operation.

Gasket Plate Screw (Not Shown) — a stainless steel

screw on the gasket plate immediately adjacent to each

corner of the gasket allows adjustment of the gasket if

necessary.

Door Gasket (Not Shown) — provided on each

compartment door and ensures proper sealing of the

cooking compartment. CAUTION: Damage to the

gasket sealing surface, such as nicks or cuts, will

cause steam leakage.

Door Striker (Not Shown) — provides positive

latching of door.

LIGHTING THE STANDING PILOT (GAS BASE

GENERATORS ONLY) (On Steamers So Equipped)

1. Before lighting the pilot, both the burner and the

pilot must have been off for at least 5 minutes.

2. Turn power switch (upper left of generator cabinet)

to OFF. Be sure gas to the steamer is turned ON.

3. Turn knob of combination control valve to PILOT.

With a lit taper, ignite pilot while depressing knob of

combination control valve. Keep knob depressed

for about 1 minute after pilot is lit.

4. Release knob. Pilot should continue burning. If

not, repeat Steps 1 through 3.

5. Turn knob counterclockwise to ON.

Shutdown

Ready Light (Green) — when lit, indicates appliance

is ready for the cooking cycle.

Cooking Light (Red) — when lit, indicates appliance

is in the cooking phase.

Timer — use to set desired cooking cycle time. Timer

range is 0-60 minutes.

Ready

Light

Timer

Ready

Light

Timer

READY

READY

COOKING

TIMER

COOKING

TIMER

Cooking

Light

Cooking

Light

1. Turn gas service valve and power switch OFF.

2. Close water inlet valve.

OPERATING STEAMERS WITH INTERMITTENT

PILOTS (GAS BASE GENERATORS ONLY)

1. Before lighting the pilot, both the burner and the

pilot must have been off for at least 5 minutes. Do

not attempt to manually light the pilot.

2. Turn knob of gas combination control valve

counterclockwise until it stops at the ON position.

3. Turn boiler power switch to ON position (light on).

4. The electrode will begin sparking and pilot will light.

5. Ensure pilot light has lit by observing pilot flame.

6. The pilot light will remain lit as long as the boiler

power switch is in the ON position.

7. The cycling pressure switch will open and close the

gas combination control valve, which will in turn

cycle the main burner.

24

PL-50860

Fig. 14

Page 25

Shutdown

1. Turn the boiler power switch to the OFF position

to extinguish the pilot light.

2. To make the pilot light and main burners

inoperable, turn the gas combination control valve

clockwise until it stops (OFF position).

CLEANING

Never use steel wool on stainless steel surfaces.

Never apply food oils or petroleum lubricants directly

to the door gasket.

Daily

3. To completely shut off pilot light and main burners,

close the main gas valve.

DAILY STARTING PROCEDURE

1. If boiler has manual blowdown drain valve, close

it.

2. On gas powered generators, ensure that pilot

burner flame is ON. If flame is out, a 5-minute

period of complete shutoff of gas supply is required

before relighting.

3. Turn power switch ON.

4. Wait 20 minutes before starting cooking operation.

5. This step is required only when the cooking

chamber is cold or when cooker is first used for

the day. When READY light is on, preheat cooking

compartment(s) for 1 minute. Turn timer knob to

“1”. READY light will go off and COOKING light

will come on. Make sure door is closed. When

buzzer sounds, open and close door to silence

buzzer.

6. With compartment(s) preheated and READY light

on, place pans of food into cooking compartment

and shut door. Refer to COOKING CHART in this

manual and set desired cooking time.

7. Turn timer knob to desired cooking time. Cooking

cycle will begin.

Cooking cycle may be interrupted at any time by

opening door and resumed again by closing door.

8. The buzzer will sound when the cooking cycle ends

and no more steam is entering the cooking

compartment(s). The buzzer must be silenced by

opening the door. Remove cooked food. The

COOKING light will go off and the READY light will

come on indicating the cooker is now ready for the

next cooking cycle.

At the end of each day, or more often if necessary,

turn steamer OFF and allow compartments to cool.

Remove pans and side racks from compartments and

clean in a sink.

Remove food sediment from compartment bottoms.

Wipe all solids away from the drain opening, especially

any large particles, to prevent possible clogging of the

drain.

Clean the drain screen at least daily, or more often if

required. Remove drain screen by pulling straight

out. Clean drain screen in a sink.

Wash compartment interiors with mild detergent.

Rinse thoroughly and wipe dry with a soft clean cloth.

Replace racks.

After cooking grease-producing foods, pour one-half

gallon of soapy water down the drain and rinse with

one-half gallon of hot clear water.

For maximum gasket life, wash gasket sealing surface

of compartment doors with mild detergent to remove

harmful food acids. Follow with a warm water rinse to

remove all traces of detergent. Then wipe with a soft,

dry cloth. Leave the door slightly open when not in

use.

Use a clean damp cloth to wipe down the exterior.

Polish with a soft dry cloth. Remove discolorations

with a non-abrasive cleaner.

If the water in the sight glass becomes extremely

murky, the generator should be blown down and/or

cleaned.

As Required

After a period of time, all gas burners accumulate

carbon in their ports and this restricts performance.

To clean burners, boil them in a strong solution of lye

water for 1⁄2 hour. Then clean gas ports with a sharp

pointed metal instrument to ensure open ports. Clean

as needed (usually about once a year will be often

enough).

25

Page 26

Remove the “Y” strainer upstream of the drain solenoid

valve by unscrewing the cap on the section protruding

down towards the floor. Remove the screen and any

foreign particles. Rinse the screen thoroughly and

replace. Replace cap.

MAINTENANCE

The pressure regulating valve strainer will become

clogged if dirty steam lines are connected to direct

steam models. Remove the hex nut on the bottom of

the pressure regulating valve to clean the strainer and

valve seat.

WARNING: THE STEAMER AND ITS PARTS ARE

HOT. USE CARE WHEN OPERATING, CLEANING

OR SERVICING THE STEAMER. THE COOKING

COMPARTMENTS CONTAIN LIVE STEAM. STAY

CLEAR WHILE OPENING EACH DOOR.

DOOR GASKET

If door gasket is nicked or cut or at the end of its useful

life, it must be replaced. Damage to the gasket

sealing surface will cause steam leakage.

However, if a leak occurs in one corner only and

gasket appears serviceable, turn the stainless steel

screw on the gasket plate immediately adjacent to the

leaking corner one-half turn counterclockwise. Do

not attempt excessive turning of screws since

misalignment of door is likely.

BOILER BLOWDOWN VALVE

Turn the steamer off at least once daily and blow

down the boiler in order to remove sediments, scalants

and lime build-up in the boiler. If the steamer is

supplied with a manual valve, open it daily when the

steamer is shut down. The manual blowdown valve is

located on the bottom front of the cabinet base.

DESCALER

Inspect the descaler every three months. Replace it

when it has shrunk to one-half its original size. Local

water conditions generally determine the life of the

descaler.

LEVEL SENSING PROBES

Inspect level sensing probes for lime build-up once a

month. Clean probes if needed.

WATER LEVEL GAUGE ASSEMBLY

Check sight glass assembly daily. Extreme murkiness

indicates the generator should be blown down and/or

cleaned, and is an indication of bad water conditions.

The correct water level is a point one-half of the height

of the glass.

FLUE (GAS BASE GENERATOR ONLY)

Annually check the flue when cool to be sure it is free

of obstructions.

Contact your Vulcan-Hart service representative for

any other maintenance required.

26

Page 27

COOKING CHART

The following table lists suggested cooking times and weights. These times, which will vary depending on initial

product temperature, size, shape, etc., are approximate and should be adjusted to suit your operation.

PRODUCTS TO BE COOKED IN SOLID PANS

TIMER SETTING WEIGHT

PRODUCT IN MINUTES PER PAN

Eggs, Scrambled 10-12 8 Dozen

Rice, Long Grain (Cover with 4 cups water/lb.) 25 2 Lb.

Pasta (Place perforated pan inside solid pan, cover pasta

with cold water)

Spaghetti - Regular/Vermicelli 12-15

Macaroni - Shells/Elbows 15-18

Noodles - 1⁄2" Wide 12-15

Lasagna Noodles 15-18

Frozen Casseroles, Lasagna 35 Full Pan

Meat Loaf, 3-5 Lb. Each 40 15 Lb.

Beef

Ground Chuck 20-25 10 Lb.

Sliced as Purchased 35-40 10 Lb.

Shrimp, Frozen, 10 Shrimp per Lb. 5 4 Lb.

Beans

Baked 9 10 Lb. Can

Refried 9 10 Lb. Can

Canned Vegetables 6 10 Lb. Can

Prunes, Dried 12-15

PRODUCTS TO BE COOKED IN PERFORATED PANS

TIMER SETTING WEIGHT

PRODUCT IN MINUTES PER PAN

Clams

Frozen 10-12 3 Dozen

Fresh, Cherrystone 5-6 3 Dozen

King Crab, Frozen

Claws 4 21⁄2 Lb.

Legs 4-6 41⁄2 Lb.

Lobster Tail, Frozen 6 10 Lb.

Lobster, Live, 10"-12" 5 4 Per Pan

27

Page 28

PRODUCTS TO BE COOKED IN PERFORATED PANS (Cont’d.)

TIMER SETTING WEIGHT

PRODUCT IN MINUTES PER PAN

Salmon Fillets, Frozen, 8 Oz. Ea. 5 71⁄2 Lb.

Scallops, Fresh 4 3 Lb.

Scrod Fillets, Fresh 3-5 4 Lb.

Eggs

Hard Cooked 15 4 Dozen

Soft Cooked 9-10 4 Dozen

Soft Yoke for Caesar Salad 6-8 4 Dozen

Chicken, Breasts, Legs, Thighs 20 15 Lb.

Turkey, Frozen

Breasts (2) 90 6-7 Lb. Ea.

Cut Lengthwise 55 20-25 Lb.

Corned Beef 40-75 6-8 Lb.

Hot Dogs or Wieners 3 80-100 Count

Asparagus Spears

Frozen 10-12 3 Dozen

Fresh 5 5 Lb.

Beans

Green, 2" Cut, Frozen/Fresh 6 5 Lb.

Lima, Frozen 8 5 Lb.

Baby Lima, Frozen 5 5 Lb.

Broccoli

Spears, Frozen 8 4 Lb.

Spears, Fresh 6 5 Lb.

Flowerettes, Frozen 6 5 Lb.

Brussel Sprouts, Frozen 6 5 Lb.

Cabbage, Fresh, 1/6 Cut 8 5 Lb.

Carrots

Baby Whole, Frozen 8 7 Lb.

Crinkle Cut, Frozen 7-8 4 Lb.

Sliced, Fresh 11 9 Lb.

Cauliflower, Flowerettes

Frozen 6 4 Lb.

Fresh 7-8 5 Lb.

Celery, 1" Diagonal Cut 7 5 Lb.

28

Page 29

PRODUCTS TO BE COOKED IN PERFORATED PANS (Cont’d.)

TIMER SETTING WEIGHT

PRODUCT IN MINUTES PER PAN

Corn

Yellow Whole Kernel, Frozen 5 5 Lb.

Cobbettes, Frozen 8 27 Ears

16-18 80 Ears

Corn-On-Cob, Fresh 10-12 18 Ears

16-18 54 Ears

Peas, Green 6 5 Lb.

Potatoes, Whole Russet 55 10 Lb.

Spinach

Chopped, Frozen 17 6 Lb.

Defrosted 5 6 Lb.

Fresh Cut 3 2 Lb.

Squash, Acorn, Halves 25 10 Halves

Zucchini, Slices 8 10 Lb.

Frozen Mixed Vegetables 6-7 5 Lb.

Fruit, Blanch for Peeling

Grapefruit 3

Oranges

Pineapple, Whole for Cutting 4

COOKING HINTS

Where possible, spread food out evenly in pans. Do

not allow food to protrude above pans, since this will

interfere with steam circulation between pans in the

compartment.

Always preheat compartments for satisfactory results.

When time does not allow for defrosting of frozen

vegetables, such as loose-pack peas, corn, diced

carrots, etc., they may be cooked at once provided

just half of the suggested portions in the cooking chart

are used.

29

Page 30

TROUBLESHOOTING

PROBLEM CAUSE CORRECTIVE MEASURES

Steamer Will Not Heat or Build

Pressure

1. Problem with low water cut-off. Replace low water cut-off control.

2. Problem with pressure switch. Replace pressure switch.

3. Loose wiring. Check against diagram and tighten

connections.

4. Problem with combination control Replace valve.

valve on gas base generator.

5. Problem with pressure reducing Clean strainer on pressure reducing

valve on steam generator. valve and adjust to spec or replace.

6. Problem with pressure gauge. Replace gauge.

7. Problem with contactor on Replace contactor.

electric generator.

8. Problem with auto blow-down Replace auto blow-down control.

control on steamers so equipped.

9. Problem with heat switch. Replace heat switch.

10. Problem with heating elements. Replace heating elements.

11. Pressure control set too high and Adjust to specification. Some high

operating on back-up. input units may need to be set below

spec to compensate for overshoot.

12. Pilot not lit on gas generators. Light pilot. See lighting instructions in

this manual.

13. Generator not filling. Check fill valve and water level

controls.

14. Power/steam/gas off to steamer. Check that power, steam or gas

supply is on.

Pilot Won’t Light 1. Problem with combination control Replace combination control valve.

valve.

2. Gas leak in pilot tubing. Tighten.

3. Obstruction in gas line or Locate and remove obstruction.

combination control valve.

4. Pilot flame adjusted too small. Adjust pilot flame.

5. Thermocouple not completely Push thermocouple completely into

inserted into holder. holder.

Generator Leaks Water 1. Problem with boiler hand hole Tighten or replace gasket.

gasket.

2. Problem with fitting on water or Tighten or replace fitting.

steam lines.

3. Leak at gauge glass. Replace gauge glass and seals.

30

Page 31

PROBLEM CAUSE CORRECTIVE MEASURES

Compartment Won’t Heat 1. Loose or misadjusted door switch Adjust and tighten bracket on door.

striker.

2. Boiler not building pressure. Adjust pressure switch.

3. Problem with steam solenoid Replace steam solenoid valve.

valve.

Generator Off, Won’t Heat 1. No electric power to controls. Check connections.

2. No fuel supply to steamer (steam Examine physical plant for flow

to steam heated generator, gas problems.

to gas heated generators, power

to heating elements).

3. Problem with pressure switch. Check pressure switch.

4. Water level too low. Turn water supply on, or check for

stuck water feeder.

5. Problem with low water cut-off. Check low water cut-off for operation.

6. On gas heated generator only, Check around unit for drafts, or vapor

burner ignition pilot out (due to from drain causing pilot outage.

drafts, problem with combination

control valve or interruption of

gas supply).

7. Open circuit or short in control Check wiring.

circuit.

Generator Water Level Too High 1. Water feeder solenoid valve not Clean or replace water feeder

closing properly. solenoid valve.

Generator Steam Pressure Too 1. Problem with pressure switch. Properly set Hi-Lo limits on pressure

High (Pressure Relief Valve switch.

Leaking), or Too Low (Below 10

psi When Controls Cut Heat Off)

Steam Output Low as 1. For cause and cure, see Check for blockage in fuel or steam

Compared to Usual Generator CABINET BASE GENERATOR in line.

Performance the Service section of this

manual.

Door Won’t Stay Closed 1. Door liner spring adjusted too Lift liner out of door and bend springs

tightly. to loosen.

2. Latch out of adjustment or loose. Adjust latch and tighten.

3. Latch worn. Dress retaining surface of latch or

replace.

4. Striker plate out of adjustment. Adjust plate to obtain good latching.

31

Page 32

PROBLEM CAUSE CORRECTIVE MEASURES

Steam Leak Around Door 1. Worn gasket. Replace gasket.

2. Drain line obstructed or not to an Clean or open drain line.

open gap drain.

3. Cold water condenser not Check solenoid valve and spray

spraying properly. nozzle for proper operation. Replace

as required.

4. Door liner needs adjustment. Lift off door liner and adjust pressure

springs to obtain uniform seal.

Heat Coming On Without Water 1. Dirty low water cut-off probes. Remove probes and clean insulator

(Dry Firing) with soft clean cloth.

2. Retention of water in probe Remove housing or housing cover

housing. and mechanically clean interior.

3. Sticking low water cut-off Replace contactor.

contactor.

Pressure Gauge Not Working 1. Problem with pressure gauge. Replace pressure gauge.

2. Tubing crimped, plugged or Repair or replace tubing.

broken.

Steam Leaking Inside Unit 1. Problem with fitting or valve. Tighten or replace fitting or valve.

2. Steam pressure too high. Adjust pressure switches.

32

Page 33

SERVICE

These service procedures should only be performed

by a qualified servicer.

WARNING: THE STEAMER AND ITS PARTS ARE

HOT. USE CARE WHEN OPERATING, CLEANING

OR SERVICING THE STEAMER. THE COOKING

COMPARTMENTS CONTAIN LIVE STEAM. STAY

CLEAR WHILE OPENING EACH DOOR.

WARNING: BEFORE SERVICING, DISCONNECT

ELECTRICAL POWER SUPPLY AND PLACE A TAG

AT THE DISCONNECT SWITCH TO INDICATE THAT

YOU ARE WORKING ON THE CIRCUIT. TURN

WATER SUPPLY OFF, RELIEVE LINES OF

PRESSURE AND ALLOW HOT PARTS TO COOL.

COOKING COMPARTMENT

CONTROLS

For access to compartment controls, remove two

screws holding compartment control panel and remove

control panel.

Check for failure of the control circuit in the following

order:

1. Check that electric power is reaching control

circuit through compartment switch when it is

turned ON.

7. Check that all connections and terminals are

securely fastened (no open circuits).

8. Check that all connections are made according to

compartment control wiring diagram.

WATER ACCUMULATION ON BOTTOM OF

COMPARTMENT

Water accumulation on the bottom of the cooking

compartment(s) is primarily condensed steam. Failure

to drain out quickly and completely may be due to

clogged debris on the compartment drain screen.

Pull screen straight out and thoroughly clean, then

replace.

Failure to drain completely may also be due to

improperly levelled steamer.

COOKING CYCLE CANNOT BE ACTIVATED

Inspect all wire terminations to ensure they are positive

and secure before assuming any other problem.

When power switch on base generator is ON, set the

timer knob to 2 minutes. Both READY lights should

go off, COOKING lights should come on and steam

should be entering both compartments.

2. On electric heat models with a transformer, check

step down transformer for proper operation.

3. Check limit switch, operated by a tab on the

compartment door, for proper function.

4. Check that timer switches are functioning as

shown on the wiring diagram.

5. Check that timer motor operates when connected

to power.

If problem is found in timer, replace it; do not take

timer apart.

6. Check wiring for damaged insulation (no short

circuit).

CABINET BASE GENERATOR

ALL GENERATORS

Removal of Scalants From Boiler

It is recommended that the boiler be thoroughly

inspected on at least three-month intervals, and more

frequently in hard water areas and/or for units heavily

used. This inspection consists of an internal

examination and cleaning of the generator shell, an

examination and possible replacement of the descaler,

a check of lime build-up on the level sensing probes,

and a check of all generator controls, including the

pressure switches.

33

Page 34

Local water conditions may cause excessive boiler

scale build-up and cause the generator and

compartment controls not to work. Proper periodic

service must be performed as outlined in the operating

and service instructions. It may also be necessary to

install a water conditioner on the generator water

feed. Contact your local water conditioner dealer.

Inspect and Clean Inside of Generator Shell

Flush (blow down) steam generator. Drain water from

the shell with the electric power OFF (no heat on).

Hold the pressure relief valve open to allow air to

enter for better drainage.

Remove generator hand hole cover (top front of shell)

by removing the nut and clamp, then tapping the

cover lightly to free it while holding the cover stud (this

prevents cover from dropping into generator). When

replacing cover, clean gasket seating surfaces.

Always use a new cover gasket.

Use wire brushes to free the scale. Loose material

must be either scooped from the steam generator or

flushed through the drain.

A suitable agent for removing lime may be used to

remove scale build-up, but use caution to avoid

damage to brass and copper parts of generator

controls, etc.

If a solvent is used, it is recommended that the

generator be removed (see REMOVING

GENERATOR ASSEMBLY), the descaler, sensing

probes and heating elements or steam coils, if

furnished, be removed, and that the shell be stood on

its end and filled with the solvent. One solvent

commonly used for removing lime is muriatic

(hydrochloric) acid (two parts of commercial muriatic

acid to 14 parts of cold water should be strong

enough). A heavily scaled shell may require a soaking

period of several hours.

When using these solvents, carefully read and follow

the instructions provided with the product. Perform

work in a well ventilated area.

Descaler

The descaler is accessible through the hand hole

opening. It is a coiled wire wound around a solid

cylindrical core, and hangs by an open loop from the

shell’s horizontal stay rod, about 4" from the front of

the shell. If the wire is eaten through, or if the core of

the descaler is eaten away to half its original size, a

new descaler should be installed. To install a new

descaler, stretch its wire coil so that the descaler

hangs with its core completely below the minimum

water level in the generator, but hanging free. The

descaler must not contact the bottom of the generator

shell, or the electric heating elements or regenerator

steam coils (if applicable).

Low Water Cutoff/Automatic Fill Control

The steam generator is equipped with level sensing

probes and relays for controlling the flow of feed

water to the boiler and to turn off the heat source when

the level is too low.

The low level control is a simple series circuit with a

transformer, secondary coil, relay coil, electrode,

metal boiler and water. When water is below the low

level cutoff electrode probe, the circuit is open and the

coil is deactivated. When the water level is at or

above the electrode probe, the circuit is closed by a

path through the liquid from the probe to the metal

boiler. The relay coil and the n.o. relay contacts 7 &

8 transfer positions, activating the heating contactor,

or combination control, or solenoid valve.

The differential level control relay coil activates and

the n.c. contacts 3 & 4 transfer positions once the

water level reaches the top probe.

The relay coil will deactivate when the water level

goes below the low level probe. This is achieved by

holding the circuit closed with the use of an additional

lower electrode probe through the n.o. contacts 7 & 8

on the relay. The relay activates when the water level

reaches the top high level electrode probe, but does

not deactivate until the level recedes below the low

level electrode probe.

Drain completely and thoroughly flush shell with fresh

water, repeating several times to be sure all traces of

the lime removing agent are flushed away.

34

Loose electrical connections may prevent the heat

from coming on or may cause the boiler to overfill.

Accumulation of boiler scale on or near the sensing

probes may cause them to retain water on the insulator

surface. This may prevent the boiler from filling or

cause dry firing. DRY FIRING WILL RESULT IN

DAMAGE TO HEATING ELEMENTS OR TO THE

BOILER SHELL.

Page 35

With the probe wire removed, check the probes and

contactors in the following manner:

1. With an ohmmeter, check the probe at wire

connection and shell. There should be no

resistance present when the boiler is empty. If

resistance is present, remove and clean the

probes. Also check for a cracked insulator, then

reinstall probes and check. You should read

continuity between the probes and shell only

when the boiler shell is full

of water.

2. Check low level and differential contactors. With

a voltmeter, check across terminals 1 & 2. Meter

should read 115 V. Across terminals 9 & 10, you

should read 350 V. Using a jumper wire, jump

terminals 9 & 10. Contactor should engage. If

contactor does not engage, replace contactor.

3. Remove sensing probe. First remove the bolted

cover over the sensor cluster. Then remove the

wire from the probe and unscrew the probe with a

wrench. Be careful to note the location of each

probe and the number of the wire connected to it.

Incorrectly connected wires will cause the controls

to malfunction.

4. Clean probe thoroughly, removing ALL deposits

from the insulator. Do not use an abrasive on the

insulator; use a soft cloth.

5. Inspect through the probe socket for the presence

of water. Water must drain from the probe

housing. If in doubt, pour water into the housing

and observe that it drains quickly. If the housing

fails to drain, remove the housing or housing

cover and clean the interior mechanically.

Water Level Gauge Assembly

Close the valve at the top and at the bottom of the

gauge assembly. Unscrew the packing nuts at the top

and bottom of the glass tube. Slide the glass tube up

until the bottom of the tube is clear of the fitting. When

reinstalling the tube, use new sealing washers. Do

not overtighten the packing nuts; it could break the

gauge glass. Check that both top and bottom valves

are fully open.

Pressure Switches

WARNING: DISCONNECT ELECTRICAL POWER

SUPPLY BEFORE REMOVING BOILER CONTROL

BOX COVER.

There are two pressure switches located inside the

boiler control box. One pressure switch is the cycling

or primary control; the other is the high limit control.

They are identical switches, differing only in their

settings. Each one is identified by a label attached to

the switch case. The labels show the proper setting

for:

Cycling Switch: Off at 10 psi and on at 8 psi

High Limit Switch: Off at 15 psi and on at 6 psi

There are two square head slotted adjustment screws

which project through the top of the switch case and

a dial with pointers that indicate the approximate

setting. The adjustment screw directly above the dial

changes both the cut-out (off) and the cut-in (on)

points. Set it first to give the proper OFF setting.

Turning the screw clockwise increases the pressure.

Then set the second adjustment screw to give the

proper ON setting.

To check the wiring, remove the switch cover (held in

place by one captive screw). If wiring is correct and

an adjustment of the setting does not correct the

problem, replace the control. DO NOT attempt to

disassemble the switch or its operating mechanism.

High Limit Thermostat

Remove thermostat and inspect flat surface of

thermostat for corrosion or rust. Replace if rusted.

Clean thermostat mounting and thermostat surfaces

before remounting or replacing. A good metal-tometal contact is essential for proper functioning of the

thermostat. This service must be performed at least

once a year.

On gas boilers, the high limit thermostat is located on

the face of the boiler close to the sight glass on the

right. For access, remove the approximately 2" x 2"

metal cover placed over the thermostat.

35

Page 36

On electric boilers, the high limit thermostat is located

behind the contactor box cover. On electric boilers

with two heating elements, the thermostat is connected

to one of the heating element lugs. On electric boilers

with four heating elements, the thermostat is located

between the center pair of elements at the top of the

elements.

Steam Supply Solenoid

Fill Solenoid Valve

It is not necessary to remove the valve body from the

supply line to disassemble it. Remove the retaining cap

and remove coil assembly. Unscrew the stem from the

valve body. All parts are now accessible for inspection

and cleaning. Do not reuse damaged or worn parts.

Pay careful attention to proper orientation and

placement of parts during reassembly.

The magnetic coil of a solenoid valve is removed from

the valve by removing the snap catch at the center

top. Unions are provided to allow easy removal of the

valve bodies. The solenoid valves must be removed

to disassemble them.

Remove the two screws and remove the inlet part of

the body, the compression spring on the back of it and

the plastic part now exposed.

Unscrew and remove the plunger tube. Remove the

plunger (the valve blade is pinned to the lower end of

the plunger). The plastic seat at the exhaust side of

the valve blade may now be removed from the body.

This is a direct acting valve.

The blade must be clean and the blade mating surfaces

of the plastic seat members must be flat and

undamaged. The plunger and plunger tube must be

clean and the plunger must slide freely in the tube.

The compression spring which fits in the hole in the

top of the plunger must be clean and move freely.

Removing the Generator Assembly

Turn off the gas and electrical supplies and close the

water inlet valve. Drain the generator. Remove the

screws holding any control box which would obstruct

removal of the boiler through the front of the generator

base.

Disconnect the 1⁄4” diameter water inlet tubing.

Disconnect the wire and conduit from the low water

cut-off probes, high limit thermostat, and the automatic

blow down valve (if so equipped). Uncouple the union

on the steam outlet and blow down the lines.

Remove all the screws holding the flue and flue

collector to the generator. Remove the anchor screws

holding the generator to the frame. Slide the generator

forward. The burner box, anchored only by the

generator, must be prevented from sliding forward

with the generator.

Water is Not Being Supplied to Boiler

Turn steamer ON. Check that water supply is available

to the steamer. If after 20 minutes no water can be

observed in the water level gauge sight glass, then

check for a problem with the water solenoid valve or

water level control float and/or probe.

The water level control probe may be covered by

scalant, thereby falsely indicating sufficient water is

present in the boiler. Detach, remove and thoroughly

clean the water level control assembly to remove scalants

and lime build-up. This condition indicates extremely

poor water quality being supplied to the boiler. Water

must be cleared up immediately with a proper water

conditioner to avoid complete breakdown of the steamer.

Water may be draining through an open boiler

blowdown solenoid valve as quickly as it is fed to the

boiler. Loose wiring or a burned out coil may prevent the

valve from closing. This valve contains a movable blade

and when closed, the blade reacts as a guillotine which

should be free to move fully down into the valve pocket

(projection at bottom of valve) so that the pierced hole

in the blade aligns perfectly with the body opening. If

debris has accumulated in the bottom of the valve

pocket, then the blade will not be able to move into the

pocket completely.

If the valve coil needs to be replaced, remove valve

from cooker body and remove retaining clip at top of

solenoid. Grasp cover and housing (green) intact

with coil inside and slide off from valve. Unscrew

projecting tube from top of valve body and remove

internal mechanism together with blade assembly.

Next, unscrew both assembly bolts and split brass

body of valve, removing loose internal parts. Flush

and clean pocket thoroughly. Reassemble all parts in

reverse order of disassembly. Energize valve with

120 volt power, and if valve fails to close, replace coil.

Reconnect all plumbing.

36

Page 37

Boiler Blowdown Solenoid Valve Does Not Drain

If your steamer has an automatic blowdown drain

valve, when the blowdown button is depressed, the

boiler blowdown valve opens. If your steamer has a

manual blowdown drain valve, close it. The water

contained in the boiler, being under pressure, should

be blown through this valve and be noticeably visible

exhausting out the steamer drain. If the blowdown

operation appears to function sluggishly or not at all,

considerable scalant may be lodged in the drain pipe

and/or the valve. Disconnect the valve from the drain

line and inspect both the valve and the drain pipe

fixed to the boiler. If considerable scalant or lime

build-up is apparent, then not only the valve, but also

the boiler and water level control must be thoroughly

cleaned. Refer to “Water Is Not Being Supplied To

Boiler” for cleaning procedure of valve and “Removal

of Scalants from Boiler.”

Boiler Achieves Pressure Slower Than Normal

If the boiler requires more than 15 minutes to achieve

normal operating pressure (6 to 7 psi), then assume

that heavy build-up of scalant has completely coated

the interior of the boiler. The insulating effect of the

scalant hampers heat transfer.

The pilot burner flame is controlled by an adjustable

valve (under cap screw behind the dial of the

combination control valve). Turn clockwise to

decrease pilot flame. Pilot flame should be a steady

blue flame which envelopes the thermocouple tip.

Pilot flame should be about 1" long. A pilot orifice

fitting is located at the bottom of the pilot and is the

hexagon fitting to which the gas supply tubing to the

pilot is attached.

The main burners are lanced port steel burners (5 or

7 burners, depending on the unit) and have adjustable

air shutters. Fixed orifice-type hoods are used to

establish the gas flow to each burner. Set each

burner air shutter opening just large enough to

eliminate any yellow tip in the burner flame.

Pilot, Thermocouple or Main Burners

To remove the pilot assembly, disconnect thermocouple

and pilot gas supply tubing from the combination control

valve and remove the two screws holding the pilot to

its bracket.

To remove main burners, lift burner and move it to the

rear to clear the orifice hood, then lower front end of

burner and bring it forward under the manifold pipe.

Unbolt and remove the hand hole cover plate and

gasket assembly. Examine interior of boiler, and if

scalant and/or lime build-up is apparent, follow

procedure for removal of scalants from boiler.

If considerable scalant is evident, then both the boiler

blowdown solenoid valve and the water level control

must also be examined.

GAS GENERATORS

The pilot thermocouple supplies power to the gas

valve. A gas pressure regulating valve is an integral

part of the gas control valve and is set for 3.5" Water

Column for natural gas and 10" Water Column for

propane gas. Limited adjustment is provided by a

screw under the cap screw located at the top of the

control body. Turn the screw clockwise to increase

the gas pressure to the main burner.

If pilot keeps going out, first check visually for proper

pilot flame. Check to see that unusually strong floor

drafts are not interfering with proper heating of the

thermocouple by the pilot flame. If the pilot flame is

not the proper height, adjust it. If adjustment does not

result in a pilot flame of proper size, then gas is not

flowing properly to the pilot. Check for a plugged pilot

orifice, a kinked or plugged pilot gas supply tube, a

problem in the combination control valve, or for low or

high gas supply pressure. The pilot operates at gas

supply pressure. The pressure regulator in the

combination control valve regulates only the pressure

of gas to the main burner.

If the pilot flame is correct and there are no drafts,

then the problem is in the thermocouple or the

combination control valve. Check the thermocouple

with a millivoltmeter. If a meter is not available,

replace thermocouple with a new one as a check. The

connection of the tubing from the thermocouple tip to

the control valve is an electrical connection and must

be clean. Do not use any sealing compound on the

threads. With a wrench, tighten the nut finger tight

plus 1⁄4 turn. DO NOT OVERTIGHTEN this nut. To

check a thermocouple with a millivoltmeter, make a

closed circuit check first (an adapter is required).

Closed circuit reading should be 13 to 26 MV.

37

Page 38

Blow pilot flame out. The reading when the protection