Page 1

CHOP HOUSE

BROILERS

MODEL

VST4B ML-136590

INSTALLATION &

OPERATION MANUAL

For additional information on Vulcan-Hart or to locate an authorized parts

and service provider in your area, visit our website at www.vulcanhart.com

VULCAN-HART

DIVISION OF ITW FOOD EQUIPMENT GROUP, LLC

WWW.VULCANHART.COM

3600 NORTH POINT BLVD.

BALTIMORE, MD 21222

F-35684 (5-07)

Page 2

IMPORTANT FOR YOUR SAFETY

THIS MANUAL HAS BEEN PREPARED FOR PERSONNEL QUALIFIED TO INSTALL

GAS EQUIPMENT, WHO SHOULD PERFORM THE INITIAL FIELD START-UP

AND ADJUSTMENTS OF THE EQUIPMENT COVERED BY THIS MANUAL.

POST IN A PROMINENT LOCATION THE INSTRUCTIONS TO BE FOLLOWED IN

THE EVENT THE SMELL OF GAS IS DETECTED. THIS INFORMATION CAN BE

OBTAINED FROM THE LOCAL GAS SUPPLIER. IN THE EVENT OF A POWER

FAILURE, DO NOT ATTEMPT TO OPERATE THIS DEVICE.

IMPORTANT

IN THE EVENT A GAS ODOR IS DETECTED, SHUT

DOWN UNITS AT MAIN SHUTOFF VALVE AND

CONTACT THE LOCAL GAS COMPANY OR GAS

SUPPLIER FOR SERVICE.

FOR YOUR SAFETY

DO NOT STORE OR USE GASOLINE OR OTHER

FLAMMABLE VAPORS OR LIQUIDS IN THE

VICINITY OF THIS OR ANY OTHER APPLIANCE.

WARNING

IMPROPER INSTALLATION, ADJUSTMENT,

ALTERATION, SERVICE OR MAINTENANCE CAN

CAUSE PROPERTY DAMAGE, INJURY OR DEATH.

READ THE INSTALLATION, OPERATING AND

MAINTENANCE INSTRUCTIONS THOROUGHLY

BEFORE INSTALLING OR SERVICING THIS

EQUIPMENT.

IN THE EVENT OF A POWER FAILURE, DO NOT

ATTEMPT TO OPERATE THIS DEVICE.

© VULCAN-HART, 2007

— 2 —

Page 3

TABLE OF CONTENTS

INTRODUCTION.............................................................................................................................. 4

GENERAL ...................................................................................................................................4

UNPACKING .............................................................................................................................. 4

INSTALLATION..........................................................................................................................4

LOCATION .................................................................................................................................4

CLEARANCES ........................................................................................................................... 4

INSTALLATION CODES AND STANDARDS ..........................................................................4

LEG STAND ASSEMBLY INSTRUCTIONS .............................................................................5

Required Tools .....................................................................................................................5

BROILER STAND INSTALLATION INSTRUCTIONS ..............................................................5

Required Tools .....................................................................................................................5

CASTER-EQUIPPED BROILERS ............................................................................................. 6

BURNERS & RADIANTS ...........................................................................................................6

GRIDDLE PLATE INSTALLATION ...........................................................................................6

VENTILATION HOOD ...............................................................................................................7

GAS CONNECTION ..................................................................................................................7

GAS PRESSURE REGULATOR INSTALLATION ................................................................... 7

OPERATION .................................................................................................................................... 8

CONTROLS ................................................................................................................................8

LIGHTING THE GAS PILOT .....................................................................................................8

TEMPORARY SHUTDOWN ......................................................................................................8

COMPLETE SHUTDOWN .........................................................................................................8

PREHEATING THE BROILER ..................................................................................................9

GRIDDLE ....................................................................................................................................9

ADJUSTMENTS .........................................................................................................................9

Burner Adjustment ...............................................................................................................9

Grate and Carriage Adjustment ..........................................................................................9

CLEANING .................................................................................................................................9

Broiler Grate .........................................................................................................................9

Griddle ............................................................................................................................... 10

Stainless Steel Surfaces .................................................................................................. 10

MAINTENANCE ............................................................................................................................ 11

VENT SYSTEM ....................................................................................................................... 11

SERVICE AND PARTS INFORMATION ............................................................................... 11

— 3 —

Page 4

GENERAL

INTRODUCTION

Gas fired broilers are designed for commercial

use only and feature fast, efficient gas heat.

Each burner is controlled by an adjustable

on/off gas valve.

Model Number BTU/hr Input

of Burners Rating

3 @ 45,000 ea. 135,000VST4B

UNPACKING

Immediately after unpacking, check for

possible shipping damage. If the broiler is

found to be damaged, save the packaging

material and contact the carrier within 15

days of delivery.

INSTALLATION

Before installing, verify that the type of gas

(natural or propane) and the clearance

dimensions (see below) agree with the

specifications on the rating plate which is

located on right hand side of unit.

Location

The installation location must be kept free and

clear of combustibles. Do not obstruct the

flow of combustion and ventilation air.

Combustible Non-Combustible

Construction Construction

Sides Rear Sides Rear

6 inches 6 inches 0 inches 0 inches

INSTALLATION CODES

AND STANDARDS

The broiler must be installed in accordance

with the following:

In the United States of America:

1. State and local codes.

2. National Fuel Gas Code, ANSI-Z223.1/

NFPA #54 (latest edition). Copies may be

obtained from The American Gas

Association Accredited Standards

Committee Z223, @ 400 N. Capital St. NW,

Washington, DC 20001, or the Secretary

Standards Council, NFPA, 1 Batterymarch

Park Quincy, MA 02169-7471.

3. NFPA Standard #96 Vapor Removal from

Cooking Equipment, late st edit ion,

available from the National Fire Protection

Association, Batterymarch Park, Quincy,

MA 02269.

4. In the Commonwealth of Massachusetts all

gas appliances vented through a ventilation

hood or exhaust system equipped with a

damper or with a power means of exhaust

shall comply with 248 CMR.

Clearances

Check that there are sufficient clearances to

service the broiler and to make the required

gas supply connection(s). Provide 24"

cle arance at t he f ron t for cleaning ,

maintenance, service and proper operation.

— 4 —

In Canada:

1. Local codes.

2. CAN/CSA-B149.1 Natural Gas Installation

(latest edition).

CAN/CSA-B149.2 Propane Installation Code

3.

(latest edition), available from the Canadian

Gas Association, 178 Rexdale Blvd.,

Etobicoke, Ontario, Canada M9W 1R3.

Page 5

LEG STAND ASSEMBLY

INSTRUCTIONS

5. Install the rear non-locking casters into

the remaining two (2) leg assemblies.

Required Tools

7/16" Socket

Philips Head Screw Driver

13/16" Open End Wrench

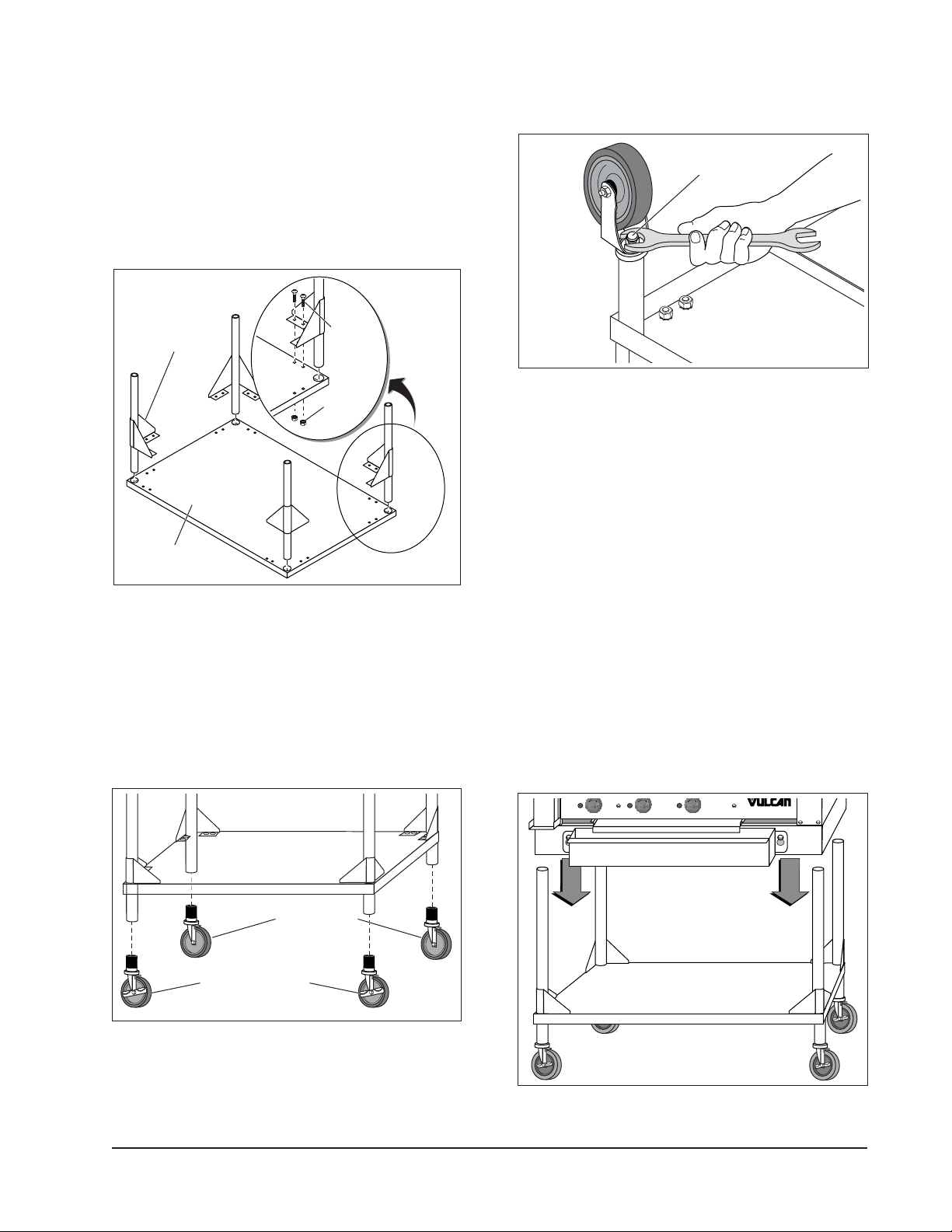

Leg

assembly

Shelf

Screw

Nut

w/

Lock

washer

Figure 1

1. Insert short end of leg into top of shelf

(Fig. 1).

2. Secure into place with one (1) screw, one

(1) lock washer, and one (1) nut per hole.

3. Repeat leg installation with three (3)

remaining legs.

Tighten nut

Figure 3

6. Secure all four (4) casters by tightening

down the nut on the underside of the

caster.

7. Ensure the two locking casters are located

on the same side of the stand. This will

now be the front of the broiler.

BROILER STAND INSTALLATION

Required Tools

13/16" Open End Wrench

1. Lower Broiler onto the four (4) legs of the

stand, supporting from under the body

bottom (Fig. 4).

Non-locking

casters

(rear)

Locking casters

(front)

Figure 2

4. Install the two (2) front locking casters into

the short end of the leg assembly (Fig. 2).

Figure 4

— 5 —

Page 6

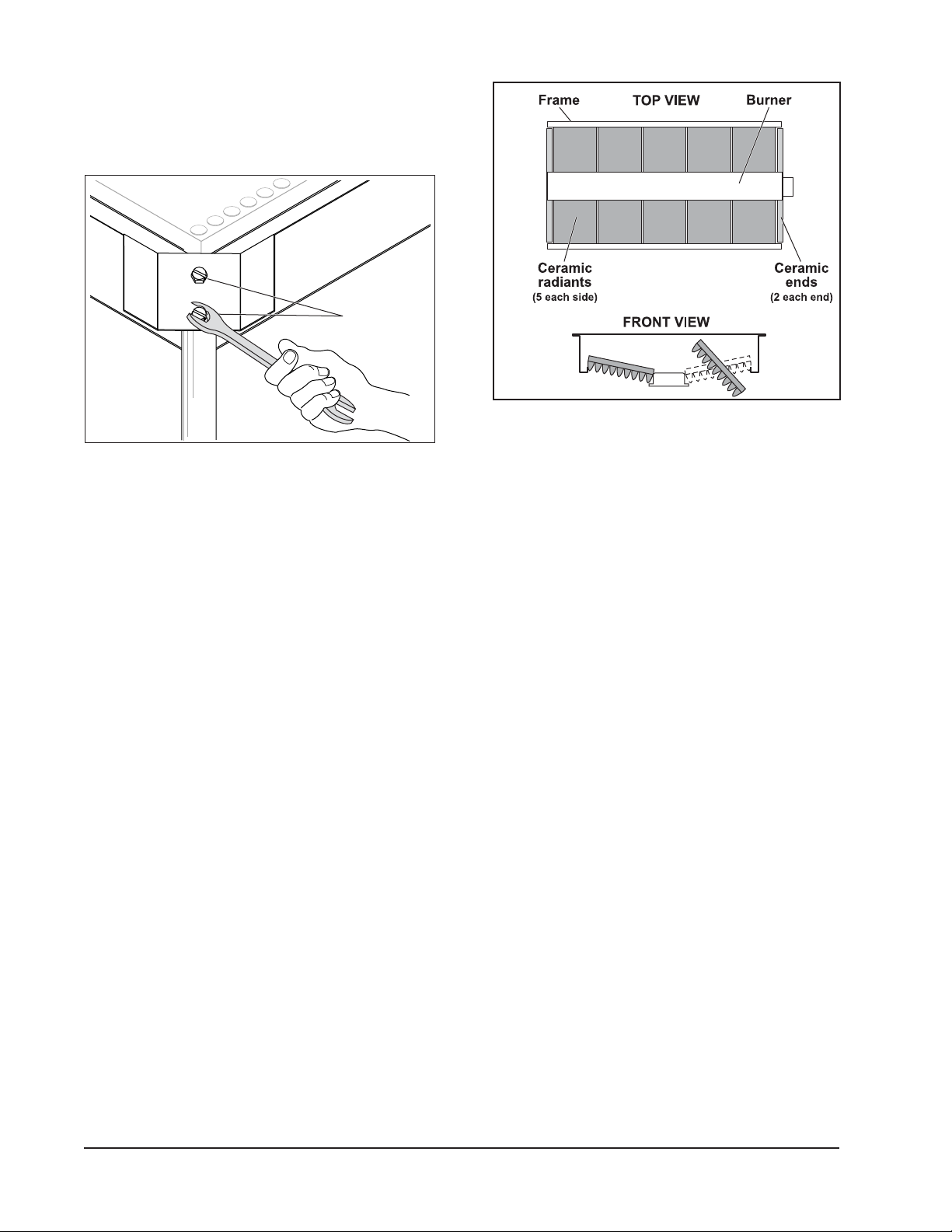

2. Install two (2) hex head bolts per leg

assembly to secure broiler body onto leg

stand (Fig. 5). (Apply lock-tight to bolt

threads.)

Hex-head

Bolts

Figure 5

CASTER-EQUIPPED BROILERS

Broilers mounted on stands with casters must

use a flexible connector (not supplied) that

complies with the Standard for Connectors

for Movable Gas Appliances, ANSI Z21.69

CSA 6.16 and a quick-disconnect device that

complies with the Standard for QuickDisconnect Devices for use with Gas Fuel,

ANSI-Z21-41.CSA 6.9. In addition, adequate

means must be provided to limit movement of

the broiler without depending on the connector

and the quick-disconnect device or its

associated piping to limit broiler movement.

Attach the restraining device at the rear of the

broiler. If disconnection of the restraint is

necessary, turn off the gas supply before

disconnection.

Figure 6

GRIDDLE PLATE INSTALLATION

Put the griddle plate on top of the broiler. Duh.

.

BURNERS & CERAMIC BRICKS

a) Insert ceramic radiant brick ends at each

corner of the burner frame. Four are required

for each burner (Fig. 6).

b) Tilt ceramic radiant sideways to clear

burner and frame assembly, then lower

radiant into position with one flange resting

on burner ledge and one flange resting on

frame ledge.

c) Install the remaining radiants so 5 radiants

are located on each side of the burner.

— 6 —

Page 7

VENTILATION HOOD

The broiler should be installed under a suitable

ventilation hood. For safe operation and proper

ventilation, keep the space between the broiler

and vent hood free from any obstructions.

GAS CONNECTION

The data plate indicates the type od gas and

pressure rate the unit is equipped to burn. DO

NOT connect to any other gas type.

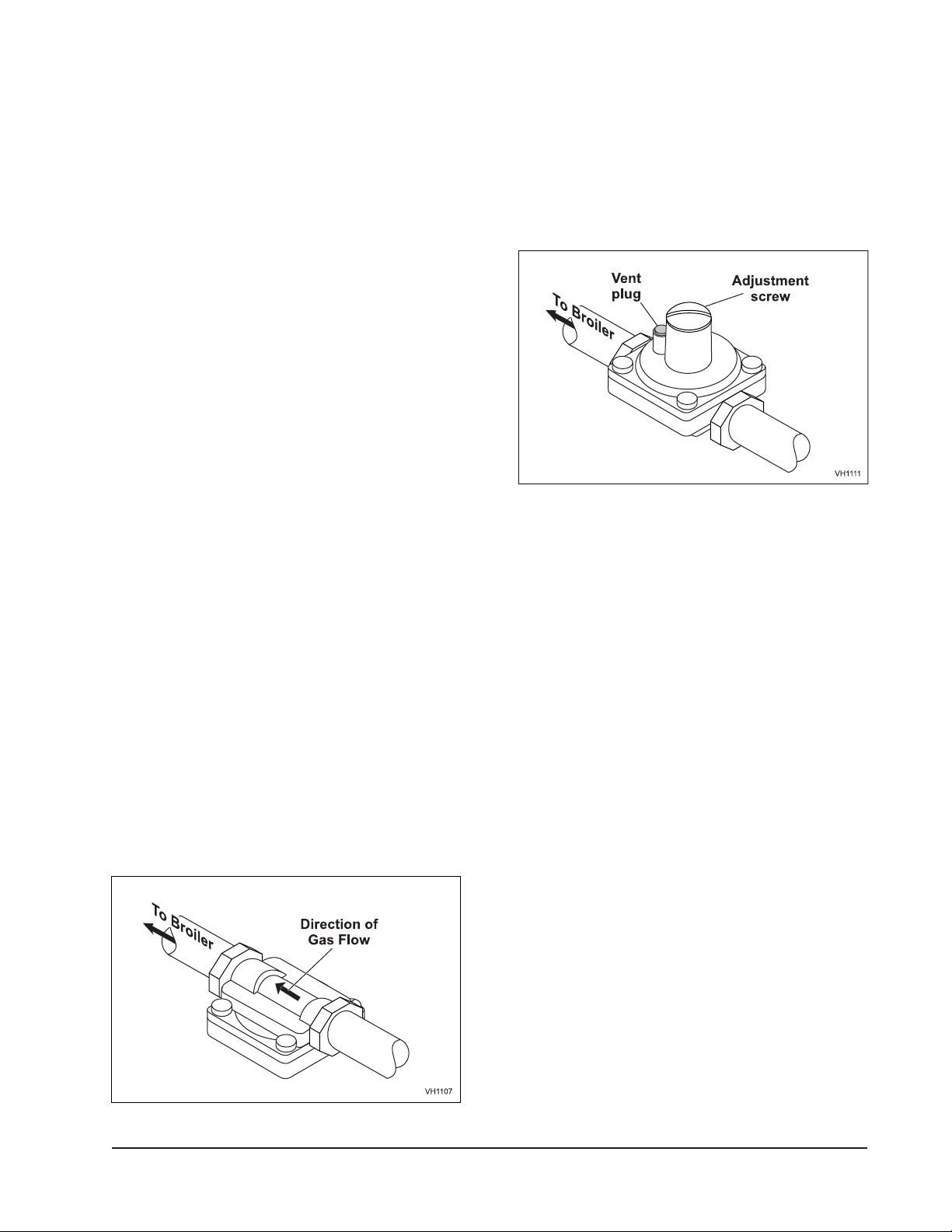

GAS PRESSURE REGULATOR

INSTALLATION

A pressure regulator is supplied and must be

installed outside the broiler when making the

gas supply connection. The regulator is preset

at the factory for 6" W.C. (Water Column) for

Natural Gas; 10" W.C. for Propane. No further

adjustment should be required.

Install the regulator as close to the broiler on

the gas supply line as possible. Make sure

that the arrow on the underside of the regulator

is oriented in the direction of gas flow to the

broiler (Fig. 7 and the regulator is positioned

with the vent plug and adjustment screw

upright (Fig. 8).

Figure 8

Use the 1/8" pipe tap on the burner manifold

for checking pressure. Make sure the gas

piping is clean and free of obstructions, dirt,

and piping compound.

An adequate gas supply is necessary.

Undersized or low pressure lines will restrict the

volume of gas required for satisfactory

performance. The recommended maximum

supply pressure (upstream of the regulator) is

7" W.C. for natural gas and 11" W.C. for propane

gas. With all units operating simultaneously,

the manifold pressure on all units should not

show any appreciable drop. At no time should

the broiler be connected to supply pressure

greater than 1/2 psig (3.45 kPa) or 14" W.C.

CAUTION: All gas supply connections

and any pipe joint compound

must be resistant t o the

action of propane.

Purge the supply line to clean out any dust,

dirt, or foreign matter before connecting the

line to the unit.

Codes require that a gas shutoff valve be

installed in the gas line ahead of the broiler.

The gas supply line must be at least the

equivalent of 3/4" iron pipe.

When testing the gas supply piping system, if

test pressures exceed 1/2 psig (3.45 kPa), the

broiler and its individual shutoff valve must be

disconnected from the gas supply piping system.

When test pressures are 1/2 psig (3.45 kPa) or

less, the broiler must be isolated from the gas

supply piping system by closing its individual

manual shutoff valve during any pressure testing

of the system.

Figure 7

WARNING: PRIOR TO LIGHTING, CHECK

ALL JOINTS IN THE GAS

SUPPLY LINE FOR LEAKS.

USE SOAP AND WATER

SOLUTION. DO NOT USE

AN OPEN FLAME.

— 7 —

Page 8

OPERATION

WARNING: THE BROILER AND ITS

PARTS ARE HOT. USE

CARE WHEN OPERATING,

CLEANING, OR SERVICING

THE BROILER.

CONTROLS

OFF ONOFF ON

Access hole to

pilot adjustment

Figure 9

The broiler is a free vented appliance. All

products of combustion and the heat generated

by the burners pass through the grates. When

meat is placed on the grates, this blocks the

venting and causes a temperature buildup. The

broiler operates most efficiently with valves

turned down to 1/3 or 1/2.

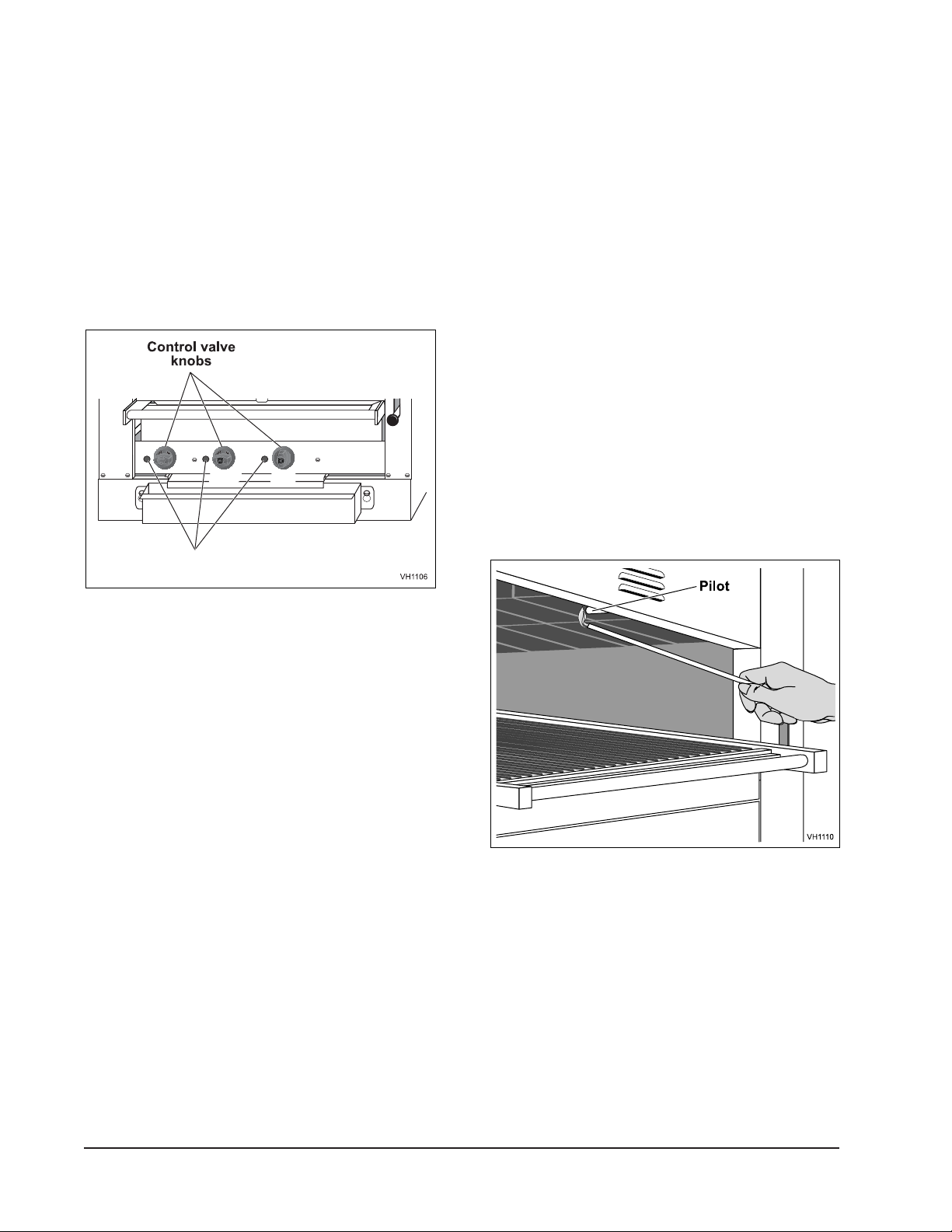

LIGHTING THE GAS PILOT

1. Turn the individual burner gas valves off

and wait 5 minutes

2. Turn the incoming main gas supply valve

on. Light pilots through grate area by

extending a taper to the pilot lighter tube

up under the broiler area (Fig. 10).

3. To light the burners, turn the individual

burner valves on.

All orifices are of the fixed type and require no

adjustment.

Standing pilots should be adjusted via the

pilot adjustment valve to provide a slight yellow

tip on the flame. Pilots may be lighted by

extending a taper to the pilot lighter tube up

under the broiler area.

When broiling, turn burner control valves to 1/3

or 1/2 to prevent overheating.

Air shutters on the main burners must be

individually adjusted to provide a blue flame.

All traces of yellow should be adjusted out of

the burner flame. (See burner adjustment.)

When the grate is hot, scrape it with a wire

brush to keep the grate clean. Do not allow

debris to accumulate on the grate.

Turn flame to low setting during slack periods

to conserve energy.

Figure 10

TEMPORARY SHUTDOWN

Turn burner valves off.

COMPLETE SHUTDOWN

For complete shutdown, turn the main gas

supply valve off. (Make sure all individual

burner valves are off before relighting.)

— 8 —

Page 9

PREHEATING THE BROILER

Air Shutter Adjustment

Allow the broiler to preheat for 30 minutes.

Note that grease runs forward and drops into

the trough at the front of the broiler before

draining into the grease drawer.

GRIDDLE

The griddle can be used for heating as

required. Griddle heat is controlled by the

broiler burner valves.

ADJUSTMENTS

Burner Adjustment

The efficiency of the broiler depends on a

delicate balance between the supply of air

and the volume of gas so that complete

combustion is achieved. Whenever this

balance is d isturbed, poor op erating

characteristics occur.

All burner air shutters are adjusted at the plant

but may need to be readjusted depending on

gas mixtures and altitudes at each location.

Start broiler burners and let them run for

15 minutes. Check each burner flame for

approx. a 1" high flame with a little yellow tip on

the ends.

If flame is larger or smaller than 1" the burner

shutter must be adjusted. One burner at a time,

loosen shutter screw and open slowly until flame

reaches approx. 1" high. Retighten screw.

Repeat on remaining burners needing adjustment.

Grate and Carriage Adjustment

If carriage tension is too strong, turn adjusting

nuts counterclockwise. If one side of the grate

is lower than the other side, turn adjusting nut

on the low side clockwise to level (Fig. 12).

The air supply is controlled by an air shutter on

the front of the burners. The air shutter openings

should be increased until the flame on the

burner begins to “lift.” The air shutter should

then be closed slightly and locked in place. A

yellow streaming flame indicates insufficient air

(Fig. 11). This condition could be corrected by

increasing the air shutter opening.

Adjustment should be made with the grate irons

in place and allowance for product weight.

The adjusting nut is accessible from the front

as shown in Fig. 12.

Grate and carriage adjustments should be

done by authorized service personell only.

Figure 11

Figure 12

— 9 —

Page 10

CLEANING

Broiler Grate

Scrape grate thoroughly after each use so

grease flows to drip pan. Ensure that the

grease drawer remains uninhibited. This

prevents flare-ups.

Dispose of grease regularly. Do not allow

drawer to overflow.

After being allowed to cool to at least 200°F,

grates may be removed and immersed in

commercial cleaning compound overnight. In

the morning, rinse with hot water to remove

any residues of cleaning compound.

Grease Chutes

The lower broiler grease can and the left

side griddle grease chute can be removed

for cleaning (use wire brush).

Avoid rubbing with steel pads, wire brushes or

scrapers that can leave iron deposits on stainless

steel. Instead, use plastic scouring pads or soft

cloths. For stubborn stains, always rub parallel

to the polish lines or with the grain.

Hard water will leave deposits that promote rust

on stainless steel. Treated water from softeners

or certain filters can eliminate these mineral

deposits. Other deposits from food or lubrication

must be properly removed by cleaning. Use

mild detergent and non-chloride cleaners. Rinse

thoroughly and wipe dry. Where appropriate,

apply a polish recommended for stainless steel

(such as Benefit or Super Sheen) for extra

protection and luster.

Griddle

Clean using mild detergent and griddle screen

as needed.

Stainless Steel Surfaces

There are four things that will break down

stainless steel and allow corrosion to develop:

1) abrasion

2) deposits

3) water

4) chlorides

— 10 —

Page 11

MAINTENANCE

WARNING: THE BROILER AND ITS

PARTS ARE HOT. USE

CARE WHEN OPERATING,

CLEANING, OR SERVICING

THE BROILER.

VENT SYSTEM

At least twice a year, the exhaust hood (venting

system) should be examined and cleaned.

SERVICE AND PARTS INFORMATION

To obtain service and parts information

concerning this model, contact Vulcan-Hart

or refer to our website:

for a complete listing of Authorized Service

and Parts depots.

When calling for service, have the model number

and serial number available.

www.vulcanhart.com

— 11 —

Page 12

F-35684 (5-07)

— 12 —

PRINTED IN U.S.A.

Page 13

IMPRIMÉ AUX ÉTATS-UNIS

— 12 —

F-35684 (5-07)

GRILLOIRS AU GAZ

Page 14

— 11 —

GRILLOIRS AU GAZ

numéro de modèle et le numéro de série.

Lors d’un appel de service, avoir en main le

www.vulcanhart.com).

pièces autorisées, visiter notre site Web à l’adresse :

de nos succursales de service de l’entretien et de

Vulcan-Hart le plus près (pour une liste complète

communiquer avec le service de l’entretien

des renseignements sur les pièces de rechange,

Pour l’entretien de cet appareil ou pour obtenir

DE RECHANGE

APPAREIL.

L’ENTRETIEN DE CET

LE NETTOYAGE ET

LORS DE L’EXPLOITATION,

EXTRÊME PRUDENCE

CHAUDS. EXERCER UNE

COMPOSANTS SONT

SERVICE DE L’ENTRETIEN ET PIÈCES

ENTRETIEN

le conduit d’évacuation.

Au moins deux fois l’an, vérifier et nettoyer

VENTILATION

AVERTISSEMENT : LE GRILLOIR ET SES

Page 15

— 10 —

inoxydable, (tel que Benefit ou Super Sheen).

si nécessaire un poli recommandé pour l’acier

supplémentaire et un beau lustre, appliquer

Rincer à fond et essuyer. Pour une protection

doux et un nettoyant ne contenant aucun chlorure.

des aliments ou de la graisse. Utiliser un détergent

Bien nettoyer les autres dépôts provenant

filtreurs permet d’éliminer ces dépôts de minéraux.

à l’aide d’un agent adoucissant ou de certains

la rouille sur l’acier inoxydable. Une eau traitée

Une eau dure laissera des dépôts qui provoquent

aux lignes du poli ou dans le sens du grain.

taches tenaces, toujours frotter parallèlement

en plastique ou un chiffon doux. Pour les

inoxydable. Utiliser plutôt un tampon à récurer

pourraient laisser des dépôts de fer sur l’acier

une brosse métallique ou une racle qui

Éviter de frotter avec un tampon en acier,

4) Les chlorures

3) L’eau

2) Les dépôts

1) L’abrasion

inoxydable et provoquer la corrosion.

Quatre facteurs peuvent endommager l’acier

Surfaces en acier inoxydable

besoin.

plaque à frire ainsi que le tamis de la grille au

À l’aide d’un détergent doux, nettoyer la

Plaque à frire

pour la nettoyer (utiliser une brosse métallique).

Enlever la rainure de récupération de graisse

GRILLOIRS AU GAZ

Page 16

NETTOYAGE

— 9 —

compound.

tout résidu de nettoyant.any residues of cleaning

matin, les rincer avec de l’eau chaude pour enlever

Figure 11

composé de nettoyant commercial pour la nuit. Le

(200 °F), les enlever et les immerger dans un

Après avoir refroidi les grilles à au moins 99 °C

le tiroir de propreté déborder.

Vider la graisse régulièrement. Ne pas laisser

les flambées.

que rien n’entrave le tiroir de propreté. Ceci prévient

que la graisse tombe dans la lèchefrite. S’assurer

Gratter la grille à fond après chaque usage pour

Grille du grilloir

Surgazage ou ventilation insuffisante.

Le gaz traverse l’extrémité des briques de céramique.

du chariot

du chariot

la tension

Ressort de

d’une montre

des aiguilles

dans le sens

tourner l’écrou

Pour élever,

Figure 12

ressort de tension

Écrou de réglage du

RÉGLAGES

tel qu’illustré dans la Figure 12.

L’écrou réglable est accessible vers l’avant

bon endroit en tenant compte du poids du produit.

Effectuer le réglage en plaçant les fers de grille au

PLAQUE À FRIRE

aiguilles d’une montre pour niveler (Fig. 12).

de réglage sur le côté inférieur dans le sens des

la grille est inférieur à l’autre côté, tourner l’écrou

contraire des aiguilles d’une montre. Si un côté de

tourner les écrous de réglage dans le sens

de la grille. Si la tension du chariot est trop forte,

Pour un meilleur fonctionnement, régler le chariot

augmentant l’ouverture de l’obturateur d’air.

insuffisance d’air (Fig. 11). Ceci peut être corrigé en

Une flamme jaune continue indique qu’il y a une

l’obturateur d’air doucement et le verrouiller en place.

flamme sur le brûleur commence à s’élever. Fermer

ouvertures de l’obturateur d’air jusqu’à ce que la

placé en avant des brûleurs. Augmenter les

Le débit d’air est contrôlé par un obturateur d’air

fonctionnement ne sont pas aussi bonnes.

cet équilibre est perturbé, les caractéristiques de

l’alimentatio n en air et le volume de gaz. Lorsque

grilloir repose sur un équilibre délicat entre

Afin que la combustion soit complète, l’efficacité du

Réglage du brûleur

est contrôlée par les robinets du brûleur du grilloir.

aliments tel que requis. La chaleur de la plaque

La plaque à frire peut être utilisée pour chauffer les

de propreté.

l’avant du grilloir avant de se vidanger dans le tiroir

et retombe dans la rainure de récupération à

minutes. Noter que la graisse circule vers l’avant

Laisser réchauffer le grilloir pendant 30

GRILLOIRS AU GAZ

Réglage de la grille et du chariot

PRÉCHAUFFAGE DU GRILLOIR

Page 17

— 8 —

OFF ON

ARRÊT COMPLET

ARRÊT TEMPORAIRE

Figure 10

burner valves are off before relighting.)

à OFF (arrêt) avant d’allumer à nouveau.

tous les robinets individuels du brûleur sont

gaz principal à OFF (arrêt). (S’assurer que

Pour un arrêt complet, mettre le robinet de

Mettre les robinets du brûleur à OFF (arrêt).

conserve energy.

à un bas réglage pendant les périodes creusesto

Pour conserver l’énergie, tourner la flamme

Ne pas laisser de débris s’accumuler sur la grille.

d’une brosse métallique pour la garder propre.

Lorsque la grille est chaude, la gratter à l’aide

le surchauffage.

régulation du brûleur de 1/3 à 1/2 pour prévenir

Pour la cuisson sur le gril, tourner les vannes de

(Se référer à la section Réglage du brûleur).

Régler pour éliminer toute trace de flamme jaune.

individuellement.

les obturateurs d’air des brûleurs principaux

Pour obtenir une flamme bleue, régler tous

de la veilleuse placé sous le grilloir.

une bougie pour rejoindre le tube d’allumage

la flamme soit jaune. Pour les allumer, utiliser

vanne de réglage jusqu’à ce que la pointe de

Les veilleuses permanentes se règlent par la

aucun réglage.

Tous les orifices sont fixes et ne requièrent

Veilleuse

Figure 9

individuels du brûleur à ON (marche).

3. Pour allumer les brûleurs, mettre les robinets

MARCHE

OFF ON

la veilleuse qui est placé sous le brûleur.

bougie pour rejoindre le tube d’allumage de

veilleuses à travers la grille en utilisant une

principale à ON (marche). Allumer les

2. Mettre le robinet d’alimentation d’entrée

brûleur à OFF (arrêt) et attendre 5 minutes.

1. Mettre les robinets de gaz individuels du

ALLUMAGE DE LA VEILLEUSE AU GAZ

tournés à 1/3 ou à 1/2.

plus efficacement lorsque les robinets de gaz sont

et la température augmente. Le grilloir fonctionne

des viandes sur les grilles, la ventilation est bloquée

par les brûleurs passent par les grilles. En plaçant

les produits de combustion et la chaleur générée

Le grilloir est un appareil de ventilation libre. Tous

L’ENTRETIEN DU GRILLOIR.

DU NETTOYAGE OU DE

LORS DE L’EXPLOITATION,

EXTRÊME PRUDENCE

BRÛLURES. EXERCER UNE

PEUVENT CAUSER DES

LES COMPOSANTS CHAUDS

pilot adjustment

de la veilleuse

Trou d’accès au réglage

Access hole to

ARRÊT

de régulation

Boutons de vanne

COMMANDES

AVERTISSEMENT :

FONCTIONNEMENT

GRILLOIRS AU GAZ

Page 18

FLAMME NUE.

SE SERVIR D’UNE

AUCUNE FUITE. NE PAS

QU’ILS NE PRÉSENTENT

POUR S’ASSURER

LA CONDUITE DE GAZ

TOUS LES JOINTS DE

SAVONNEUSE DANS

CIRCULER DE L’EAU

À L’ALLUMAGE, FAIRE

AVERTISSEMENT : AVANT DE PROCÉDER

robinet d’arrêt individuel.

l’appareil de la conduite de gaz en fermant son

est égale ou inférieure à 3,45 kPa (1/2 psig), isoler

de la conduite de gaz. Lorsque la pression d’essai

débrancher le grilloir et son robinet d’arrêt individuel

à 3,45 kPa (1/2 psig) lors d’essais de pression,

Si la pression de la conduite de gaz est supérieure

diamètre.

l’équivalent d’un tuyau de 19 mm (3/4 po) de

devant le grilloir. La conduite de gaz devrait être

un robinet d’arrêt dans la conduite de gaz du grilloir

Conformément aux exigences des codes, installer

de raccorder la conduite d’alimentation à l’appareil.

toute poussière, saleté ou corps étranger avant

Purger la conduite d’alimentation pour enlever

à l’action du gaz propane.

joints de tuyaux doivent résister

de la conduite de gaz et la pâte à

ATTENTION : Tous les raccords d’alimentation

Figure 8

— 7 —

l’écoulement du gaz

Direction de

Vers le grilloir

réglage soient à la verticale (Fig. 8).

que le bouchon de ventilation et la vis de

que le régulateur est positionné de façon à ce

l’écoulement du gaz vers le brûleur (Fig. 7) et

régulateur est orientée dans la direction de

S’assurer que la flèche sur la sous-face du

du grilloir sur la conduite d’alimentation en gaz.

Installer le régulateur aussi près que possible

(1/2 psig) ou 3,48 kPa (14 po) de colonne d’eau.

pression d’alimentation plus élevée que 3,45 kPa

temps, le grilloir ne devrait être branché à une

devrait pas indiquer de baisse sensible. En aucun

tubulure d’alimentation de tous les appareils ne

les appareils simultanément, la pression de la

le gaz propane. Même en faisant fonctionner tous

d’eau pour le gaz naturel et de 2,74 kPa (11 po) pour

du régulateur) est de 1,74 kPa (7 po) de colonne

d’alimentation maximale recommandée (en amont

pour une performance satisfaisante. La pression

trop basse peut restreindre le volume de gaz requis

Une conduite de pression trop petite ou une pression

Une alimentation en gaz adéquate est nécessaire.

et de composant dans la tuyauterie.

et exempte de toute obstruction, de poussière

S’assurer que la canalisation de gaz est propre

(1/8 po) sur la tubulure d’alimentation du brûleur.

Pour vérifier la pression, utiliser un tuyau de 3 mm

Vers le grilloir

Figure 7

GRILLOIRS AU GAZ

ventilation

Bouchon de

Vers le grilloir

de 2,49 kPa (10 po) pour le gaz propane.

(6 po de colonne d’eau) pour le gaz naturel et

en usine à une pression de sortie de 1,49 kPa

de l’alimentation en gaz. Le régulateur est réglé

installé à l’extérieur du grilloir lors du raccordement

Un régulateur de pression est fourni et doit être

DE PRESSION DE GAZ

INSTALLATION D’UN RÉGULATEUR

Page 19

— 6 —

à aucun autre type de gaz.

nominale requis pour chauffer. NE PAS raccorder

avant) indique le type de gaz et la pression

NIVELAGE

La plaque signalétique (dans le bas du panneau

Placer le grilloir sur un plancher à niveau.

Le grilloir est monté sur un support muni de roulettes.

Figure 6

VUE DE FACE

chaque côté)

en céramique (2 de

Extrémités des briques

BRANCHEMENT DU GAZ

hotte de ventilation exempt de toute obstruction.

ventilation, garder l’espace entre le grilloir et la

adéquate. Pour plus de sécurité et une bonne

Installer le grilloir sous une hotte de ventilation

HOTTE DE VENTILATION

de chaque côté)

à éléments radiants (5

Briques en céramique

NIVELAGE).

à nouveau (se référer à la section

une autre, il est conseillé de la niveler

et doit être déplacé pour une raison ou

Nota : Si le grilloir est installé sur des roulettes

position d’exploitation.

l’alimentation en gaz et de remettre l’appareil en

l’appareil. Le rattacher avant de rétablir

retenue, couper l’alimentation en gaz de

s’avère nécessaire de détacher le dispositif de

dispositif de retenue à l’arrière du grilloir. S’il

sur la tuyauterie pour le garder immobile. Fixer le

ou le raccord à débranchement rapide, ni même

l’appareil sans devoir compter sur le connecteur

nécessaires pour limiter le mouvement de

CSA 6.9. En plus, prendre les moyens

rapide conforme aux normes ANSI-Z21.41 •

au gaz mobile et d’un raccord à débranchement

CSA 6.16 sur les connecteurs des appareils

Vulcan) conforme aux normes ANSI-Z21.69 •

munir d’un connecteur flexible (non fourni par

Si l’appareil doit être installé sur des roulettes, se

Brûleur

VUE EN PLAN

Bâti

soient placés de chaque côté du brûleur.

restantes de façon à ce que cinq briques

la pièce d’appui du bâti.

pièce d’appui du brûleur et un rebord sur

emplacement en plaçant un rebord sur la

brûleur et le bâti, puis les abaisser à leur

chaque brûleur (Fig. 6).

brûleur. Quatre briques sont requises pour

à éléments radiants à chaque coin du bâti du

CÉRAMIQUE

BRÛLEURS ET BRIQUES EN

Figure 5

c) Installer les briques à éléments radiants

Bolts

hexagonale

Hex-head

Boulons à tête

b) Les pencher latéralement pour dégager le

(a) Insérer l’extrémité des briques en céramique

GRILLOIRS SUR ROULETTES

de la colle-frein sur le filetage.)

le support de patte (Fig. 5). (Appliquer

par patte pour fixer le bâti du grilloir dans

2. Installer deux boulons à tête hexagonale

GRILLOIRS AU GAZ

Page 20

— 5 —

Tighten nut

Figure 4

Figure 2

(front)

(avant)

Roulettes

(rear)

(arrière)

casters

non-verrouillables

Non-locking

Roulettes

(Fig. 4).

support en y appuyant le dessous du bâti

1. Abaisser le grilloir sur les quatre pattes du

Clé à fourches 21 mm (13/16 po)

Outils requis

INSTALLATION DU SUPPORT DU GRILLOIR

de la patte (Fig. 2).

dans la petite extrémité de l’assemblage

verrouillables

Locking casters

pattes.

rondelle-frein et d’un écrou par trou.

le haut de la tablette (Fig. 1).

4. Installer les deux roulettes verrouillables avant

3. Faire la même chose pour les trois autres

2. Fixer en place à l’aide d’une vis, d’une

1. Insérer la petite extrémité de la patte dans

Figure 3

Serrer l’écrou

Figure 1

Griloir.

support. C’est maintenant le devant du

sont placées sur le même côté que le

7. S’assurer que les deux roulettes verrouillables

en dessous de la roulette.

6. Fixer les quatre roulettes en serrant l’écrou

Nut

Écrou

washer

frein

Lock

Rondelle-

Vis

Screw

restantes.

arrière dans l’assemblage de deux pattes

PATTES

5. Installer les roulettes non-verrouillables

Shelf

Tablette

assembly

des pattes

Leg

Assemblage

Clé à fourches de 21 mm (13/16 po)

Tournevis à pointe cruciforme (Philips)

Douille de 11 mm (7/16 po)

Outils requis

ASSEMBLAGE DU SUPPORT DE

GRILLOIRS AU GAZ

Page 21

— 4 —

M9w 1R3.

Rexdale Blvd., Etobicoke, Ontario, Canada

de la Canadian Gas Association, 178

on peut se procurer un exemplaire auprès

au gaz propane (dernière édition), dont

d’installation des appareils fonctionnant

3. Norme CAN/CSA-B149.2 du Code

(dernière édition).

des appareils fonctionnant au gaz naturel

2. Norme CAN/CSA-B149.1 du Code d’installation

1. Codes locaux.

Au Canada :

doivent satisfaire à la norme CMR 248.

de moyens d’échappement de la puissance

d’échappement muni d’un registre d’air ou

hotte de ventilation ou d’un système

appareils au gaz ventilés à l’aide d’une

4. Dans l’État du Massachusetts, tous les

Batterymarch Park, Quincy, MA 02269.

National Fire Protection Association,

se procurer un exemplaire auprès de la

cuisson, dernière édition, dont on peut

des vapeurs provenant des appareils de

3. Norme NFPA N° 96 sur la dispersion

MA 02169-7471.

NFPA, 1 Batterymarch Park, Quincy,

auprès du Secretary Standards Council,

Capital St. NW, Washington, DC 20001 ou

Standards Committee Z223 au 400 N.

l’American Gas Association Accredited

peut se procurer un exemplaire auprès de

édition) du National Fuel Gas Code dont on

2. Norme ANSI/Z223.1/NFPA N° 54 (dernière

1. Codes locaux

Aux États-Unis :

aux exigences suivantes :

L’installation du grilloir doit être conforme

INSTALLATION

DÉBALLAGE

3 à 45 000 ch. 135 000VST4B

est requis devant l’appareil.

Un dégagement minimal de 610 mm (24 po)

entretien et leur fonctionnement appropriés.

suffisamment espacé pour permettre leur

Les grilloirs doivent se trouver dans un endroit

Dégagements requis

des brûleurs découverts ou friteuses.

la combustion. NE PAS installer le grilloir près

la circulation de l’air nécessaire à l’aération et à

trouver à proximité de l’appareil. Ne pas obstruer

Aucune substance combustible ne doit se

Placer le grilloir à l’emplacement prévu.

Emplacement

de récupération de la graisse inférieure.

la plaque signalétique placée derrière la rainure

ci-dessous) correspondent aux spécifications de

ainsi que les dimensions de dégagement (voir

type de gaz (naturel ou propane) de l’immeuble

Avant de procéder à l’installation, s’assurer que le

dans les 15 jours suivant la date de réception.

matériel d’emballage et aviser le transporteur

transport. En cas de dommages, conserver le

vérifier s’il n’a pas été endommagé lors du

Immédiatement après avoir déballé l’appareil,

NORMES

CODES D’INSTALLATION ET

152 mm(6 po) 152 mm(6 po) Aucun Aucun

Côtés Arrière Côtés Arrière

combustible incombustible

Construction Construction

brûleurs BTU/h

Modèle Nombre de Débit

par un robinet de gaz réglable marche/arrêt.

rapide et efficace. Chaque brûleur est commandé

commercial seulement et procurent un chauffage

Les grilloirs au gaz sont conçus pour un usage

GÉNÉRALITÉS

INTRODUCTION

GRILLOIRS AU GAZ

Page 22

— 3 —

SERVICE DE L’ENTRETIEN ET PIÈCES DE RECHANGE ................................................ 11

SYSTÈME DE VENTILATION................................................................................................ 11

ENTRETIEN .................................................................................................................................. 11

Surfaces en acier inoxydable........................................................................................... 10

Plaque à frire..................................................................................................................... 10

Grille du grilloir.....................................................................................................................9

NETTOYAGE .............................................................................................................................9

Réglage de la grille et du chariot........................................................................................9

Réglage du brûleur ..............................................................................................................9

RÉGLAGES................................................................................................................................9

PLAQUE À FRIRE .....................................................................................................................9

PRÉCHAUFFAGE DU GRILLOIR.............................................................................................9

ARRÊT COMPLET.....................................................................................................................8

ARRÊT TEMPORAIRE..............................................................................................................8

ALLUMAGE DE LA VEILLEUSE AU GAZ................................................................................8

COMMANDES............................................................................................................................8

EXPLOITATION...............................................................................................................................8

INSTALLATION D’UN RÉGULATEUR DE PRESSION DE GAZ ...........................................7

BRANCHEMENT DU GAZ ........................................................................................................6

HOTTE DE VENTILATION........................................................................................................6

BRÛLEURS ET ÉLÉMENTS RADIANTS .................................................................................6

NIVELAGE..................................................................................................................................6

GRILLOIRS MUNIS DE ROULETTES ......................................................................................6

Outils requis .........................................................................................................................5

INSTALLATION DU SUPPORT DE GRILLOIR .......................................................................5

Outils requis .........................................................................................................................5

ASSEMBLAGE DU SUPPORT DE PATTES ...........................................................................5

CODES D’INSTALLATION ET NORMES .................................................................................4

DÉGAGEMENTS REQUIS........................................................................................................4

EMPLACEMENT........................................................................................................................4

INSTALLATION..........................................................................................................................4

DÉBALLAGE ..............................................................................................................................4

GRILLOIRS AU GAZ

GÉNÉRALITÉS ..........................................................................................................................4

INTRODUCTION..............................................................................................................................4

TABLE DES MATIÈRES

Page 23

— 2 —

© COMPAGNIE VULCAN-HART, 2007

FONCTIONNER CET APPAREIL.

EN CAS DE PANNE DE COURANT, NE PAS FAIRE

INSTALLATION OU TOUT ENTRETIEN.

ET D’ENTRETIEN AVANT DE PROCÉDER À TOUTE

INSTRUCTIONS D’INSTALLATION, DE FONCTIONNEMENT

DES BLESSURES ET MÊME LA MORT. LIRE LES

PEUVENT CAUSER DES DOMMAGES MATÉRIELS,

ET L’ENTRETIEN INCORRECTS DE CET APPAREIL

L’INSTALLATION, LE RÉGLAGE, LA MODIFICATION

AVERTISSEMENT

APPAREIL.

PROXIMITÉ DE CET APPAREIL OU DE TOUT AUTRE

AUTRE LIQUIDE OU VAPEUR INFLAMMABLE À

NE PAS RANGER NI UTILISER DE L’ESSENCE NI TOUT

MESURE DE SÉCURITÉ

L’ENTRETIEN.

AVEC LE FOURNISSEUR DE GAZ ATTITRÉ POUR

AVEC LA COMPAGNIE DE GAZ LA PLUS PRÈS OU

LE ROBINET D’ARRÊT PRINCIPAL ET COMMUNIQUER

EN CAS D’ODEURS DE GAZ, ÉTEINDRE L’APPAREIL PAR

IMPORTANT

PROCURER CES INFORMATIONS CHEZ LE FOURNISSEUR DE GAZ LE PLUS PRÈS.

PERSONNE AYANT RESPIRÉ LES GAZ QUE CET APPAREIL DÉGAGE. ON PEUT SE

AFFICHER À UN ENDROIT VISIBLE LES PREMIERS SOINS À ADMINISTRER À TOUTE

DES APPAREILS CONCERNÉS DANS CE MANUEL.

EFFECTUER LE DÉMARRAGE INITIAL CHEZ LE CLIENT DE MÊME QUE LE RÉGLAGE

AUTORISÉ À INSTALLER DES APPAREILS FONCTIONNANT AU GAZ ET À

CE MANUEL A ÉTÉ PRÉPARÉ À L’INTENTION D’UN PERSONNEL QUALIFIÉ ET

MESURES DE SÉCURITÉ IMPORTANTES

GRILLOIRS AU GAZ

Page 24

F-35684 (5-07)

BALTIMORE, MD 21222

3600 NORTH POINT BLVD.

et de service autorisé le plus près, visiter notre site Web à l’adresse : www.vulcanhart.com

Pour de plus amples détails concernant Vulcan-Hart ou pour repérer le détaillant de pièces

WWW.VULCANHART.COM

UNE DIVISION DE GROUPE ITW ÉQUIPEMENT ALIMENTAIRE, LLC

VULCAN-HART

VST4B ML-136590

MODÈLE

AU GAZ

GRILLOIRS

ET MODE D'EMPLOI

MODE D'INSTALLATION

Loading...

Loading...