Page 1

INSTALLATION &

OPERATION MANUAL

VGL SERIES GAS STEAM KETTLES

MODEL

VGL20

VGL40

VGL60

VGL20E

VGL40E

VGL60E

MODEL VGL40

VULCAN-HART COMPANY, P.O. BOX 696, LOUISVILLE, KY 40201-0696, TEL. (502) 778-2791

FORM 30909 (1-95)

Page 2

IMPORTANT FOR YOUR SAFETY

THIS MANUAL HAS BEEN PREPARED FOR PERSONNEL QUALIFIED TO INSTALL GAS

EQUIPMENT, WHO SHOULD PERFORM THE INITIAL FIELD START-UP AND

ADJUSTMENTS OF THE EQUIPMENT COVERED BY THIS MANUAL.

POST IN A PROMINENT LOCATION THE INSTRUCTIONS TO BE FOLLOWED IN THE

EVENT THE SMELL OF GAS IS DETECTED. THIS INFORMATION CAN BE OBTAINED

FROM THE LOCAL GAS SUPPLIER.

IMPORTANT

IN THE EVENT A GAS ODOR IS DETECTED, SHUT DOWN

UNITS AT MAIN SHUTOFF VALVE AND CONTACT THE

LOCAL GAS COMPANY OR GAS SUPPLIER FOR

SERVICE.

FOR YOUR SAFETY

DO NOT STORE OR USE GASOLINE OR OTHER

FLAMMABLE VAPORS OR LIQUIDS IN THE VICINITY OF

THIS OR ANY OTHER APPLIANCE.

WARNING: IMPROPER INSTALLATION, ADJUSTMENT,

ALTERATION, SERVICE OR MAINTENANCE CAN CAUSE

PROPERTY DAMAGE, INJURY OR DEATH. READ THE

INSTALLATION, OPERATING AND MAINTENANCE

INSTRUCTIONS THOROUGHLY BEFORE INSTALLING OR

SERVICING THIS EQUIPMENT.

IN THE EVENT OF A POWER FAILURE, DO NOT

ATTEMPT TO OPERATE THIS DEVICE.

– 2 –

Page 3

Installation, Operation, and Care of

VGL SERIES GAS STEAM KETTLES

SAVE THESE INSTRUCTIONS FOR FUTURE USE

GENERAL

The VGL Series Gas Steam Kettles use efficient gas heat and thermostat controls to provide superior

cooking performance. The VGL Kettles are intended for commercial use only; not for household use.

If the VGL kettle's model designation ends in E, the unit is provided with electronic ignition instead of

a pilot light. The VGL kettles are stationary, self-contained, and come fully assembled from the factory.

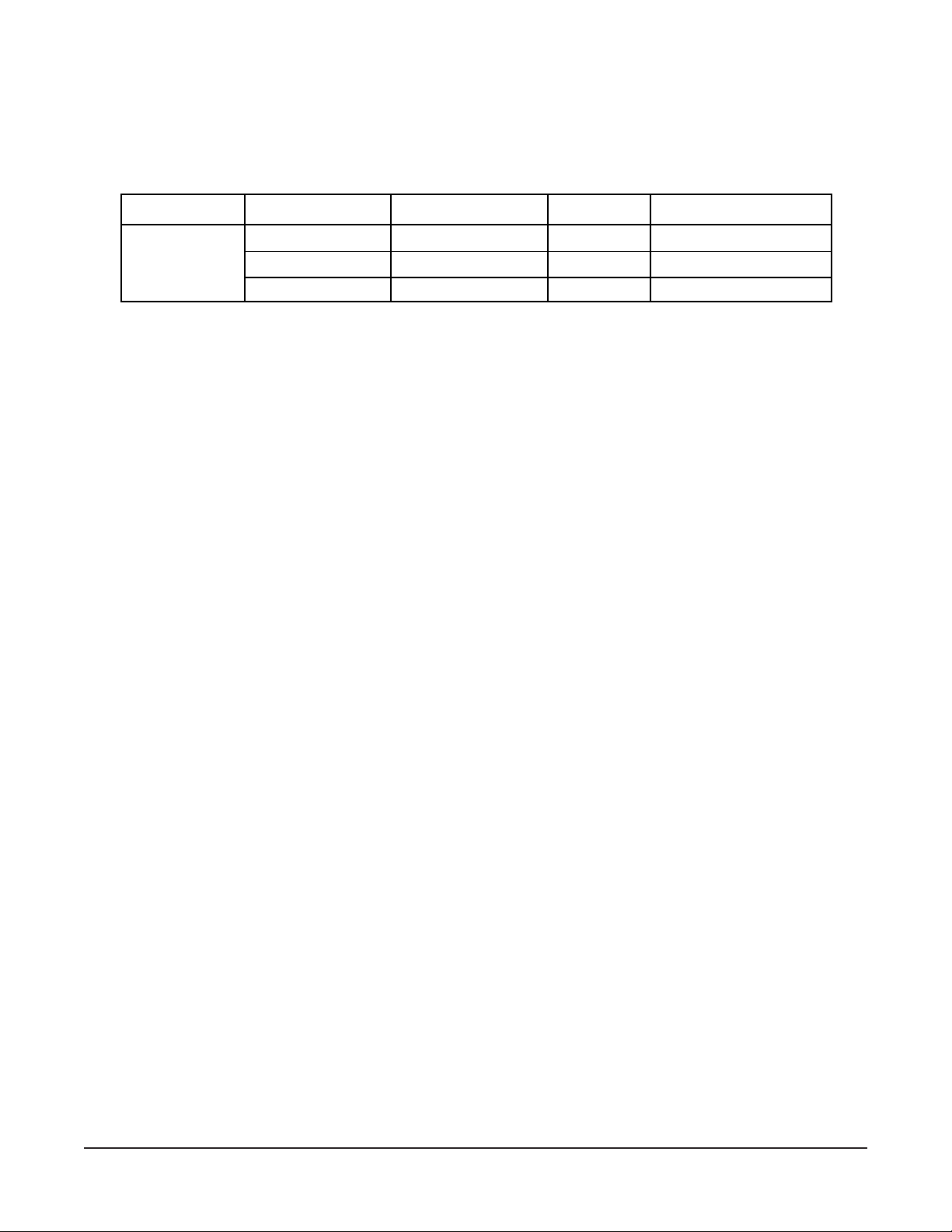

CAPACITY and GAS RATINGS

Model VGL20,VGL20E VGL40,VGL40E VGL60,VGL60E

Capacity

BTU Rating

20 gallons 40 gallons 60 gallons

100,000 BTU/hr 100,000 BTU/hr 130,000 BTU/hr

INSTALLATION

UNPACKING

Uncrate carefully. Immediately after unpacking, check for possible shipping damage. If the steam

kettle is found to be damaged, save the packaging material and contact the carrier within 15 days of

delivery.

Before installing, verify that the gas (natural or propane), the elevation from sea level, and the electrical

supply agree with the specifications on the rating plate which is located on the lower right side. NOTE:

if this kettle is being installed above 2000 feet altitude, contact your Vulcan-authorized service office

to assure that the proper orifice size for your elevation has been installed.

LOCATION

The installation location must be kept free and clear of combustibles. Clearance from combustible

construction must be a minimum of 6 inches from the sides, 2 inches from the back (at the flue box),

and 6 inches from the floor (as provided by legs). Provide adequate clearances for cleaning,

maintenance, service and proper operation.

The installation of the appliance should not obstruct the flow of combustion and ventilation air.

Sufficient air should be allowed to enter the room to compensate for the amount of air removed by any

ventilating system and for combustion of the gas burners. Do not permit fans to blow directly on the

appliance and avoid open windows at the sides or back. Avoid wall type fans which create air cross

currents within the room. Do not obstruct the air flow into and around the appliance. Do not obstruct

the flow of flue gases from the flue duct located on the rear of the appliance. It is recommended that

the flue gases be ventilated to the outside of the building through a suitable and properly installed

ventilation system.

– 3 –

Page 4

LEVELING THE APPLIANCE

To level the kettle, use a spirit level in all directions on the top of the kettle with the lid up.

Units with legs — adjust the bottom foot in each leg to overcome an uneven floor.

INSTALLATION CODES AND STANDARDS

The steam kettle must be installed in the United States in accordance with: 1) State and local codes;

2) National Fuel Gas Code, ANSI-Z223.1, latest edition, available from American Gas Association,

1515 Wilson Boulevard, Arlington, VA 22209; and 3) National Electrical Code, ANSI/NFPA No. 70,

latest edition, and with NFPA Standard #96,

Vapor Removal from Cooking Equipment

, latest edition,

available from the National Fire Protection Association, Batterymarch Park, Quincy, MA 02269.

VENTILATION HOOD

The steam kettle must be installed under a suitable ventilation hood.

PRESSURE RELIEF VALVE

The pressure relief valve is located at the right rear of the unit. This area should be kept clear and

should not be in an area where operators will normally stand. The elbow on the relief valve should be

3

turned toward the floor. A maximum 3 foot,

/4" diameter pipe may be used to extend to the floor, but

must not be piped directly to a drain — it must vent to the atmosphere.

PRESSURE GAUGE

Check the pressure gauge on the front panel before operating. If the pressure gauge does not indicate

20 to 30 inches of mercury column vacuum, contact your authorized Vulcan-authorized servicer to reestablish the vacuum.

WATER CONNECTION

Steam kettles equipped with an optional water fill valve should be connected to the water supply line

1

(minimum

⁄4") at the 1⁄4" NPT internal threaded fitting on the valve. Units with dual (hot and cold)

valves must have the hot water line connected to the side with the hot water valve (red) and cold water

line to the cold water valve (blue). Plastic or rubber hose is not recommended as it may melt against

the hot kettle side.

– 4 –

Page 5

GAS CONNECTION

The data plate on the lower right side of the kettle indicates the type of gas your unit is equipped to burn.

DO NOT connect to any other gas type.

A 1" NPT line is provided at the rear for the connection. Each kettle is equipped with an internal

pressure regulator which is set for 4" W.C. manifold pressure for natural gas or 10" W.C. for propane

1

gas. Use the

/8" pipe tap on the burner manifold for checking pressure.

An adequate gas supply is necessary. Undersized or low pressure lines will restrict the volume of gas

required for satisfactory performance. A maximum supply pressure of 8" W.C. for natural gas and 13"

W.C. for propane gas is recommended. With all units operating simultaneously, the manifold pressure

on all units should not show any appreciable drop. Fluctuations of more than 25% on natural gas, and

10% on propane gas, will create pilot problems and affect burner operating characteristics. Contact

your gas company for correct supply line sizes.

Purge the supply line to clean out any dust, dirt, or any foreign matter before connecting the line to the

unit.

Caution: The pipe thread compound used when installing pipes must be a type that is resistant

to the action of liquified petroleum or propane gases.

Codes require that a gas shut-off valve be installed in the gas line prior to the kettle. Make sure the

pipes are clean and free of obstructions, dirt, and piping compound.

TESTING THE GAS SUPPLY PIPING

1

When test pressures exceed

/2 psig (3.45 kPa) the steam kettle and its individual shut-off valve must

be disconnected from the gas supply piping system during any pressure testing of the system. When

1

test pressures are

/2 psig (3.45 kPa) or less, the kettle must be isolated from the gas supply piping

system by closing its individual shut-off valve during any pressure testing of the system.

WARNING: PRIOR TO START-UP, CHECK ALL JOINTS IN THE GAS SUPPLY LINE FOR LEAKS.

USE SOAP AND WATER SOLUTION. DO NOT USE AN OPEN FLAME.

Do not connect the kettle to the electrical supply until after the gas connection has been made.

– 5 –

Page 6

ELECTRICAL CONNECTION

Refer to the electrical diagram attached to the inside of the front panel and to ELECTRICAL DATA.

ELECTRICAL DATA

MODEL Volts / Hz / Ph Standard / Optional Amps Circuit Requirement

115 / 60 / 1 Standard 2.0 15 Amp Cord/Plug

VGL Series

208 / 60 / 1 or 3 Optional 1.0 Hard wire

236 / 60 / 1 or 3 Optional 1.0 Hard wire

Cord Connected Steam Kettles

WARNING: THE SUPPLY CORD ON THE STEAM KETTLE IS PROVIDED WITH A GROUNDING

PLUG. THE OUTLET TO WHICH THIS PLUG IS CONNECTED MUST BE PROPERLY GROUNDED.

IF THE RECEPTACLE IS NOT THE PROPER GROUNDING TYPE, CONTACT AN ELECTRICIAN.

Hard Wire Connected Steam Kettles

WARNING: ELECTRICAL AND GROUNDING CONNECTIONS MUST COMPLY WITH THE

APPLICABLE PORTIONS OF THE NATIONAL ELECTRICAL CODE AND/OR OTHER LOCAL

CODES.

WARNING: DISCONNECT THE ELECTRICAL POWER SUPPLY AND PLACE A TAG AT THE

DISCONNECT SWITCH INDICATING THAT YOUR ARE WORKING ON THE CIRCUIT.

Units equipped for 208 or 236 volt / 60 Hz, single- or three-phase electrical service, are factory

equipped with a transformer. To connect supply wires, remove the cover from the transformer box at

the right rear of the unit. Route supply wires and ground wire through the hole in the cover with a strain

relief fitting. Connect wires to the primary transformer terminals as required by your power supply

voltage. Connect ground wire to the ground lug. Replace cover. Three-phase units are wired as

above, using only two supply wires. The third supply wire is not connected and must be properly

terminated.

PERFORMANCE CHECK

The following items should be checked at installation by a qualified service technician.

1. Verify correct gas type.

2. Verify correct voltage, cycle and phase.

3. Gas pressure.

4. Internal gas connections.

5. Internal electrical connections.

6. Pilots — adjustment and ignition.

7. Burners — adjustment and ignition.

8. Thermostat — cycle for operation check.

9. Gas supply valve — check for operation.

10. Check hinge and lid assembly.

11. Draw-off valve — check operation.

12. Advise user on cleaning procedures.

– 6 –

Page 7

USING THE GAS CONTROL (Kettles with Pilot Lights)

A. Lighting

1. Turn thermostat to lowest position and turn the power switch OFF.

2. Open control panel access door.

3. Turn dial on combination control to pilot position. NOTE: Any gas service valves exterior to the

unit should be open.

4. Remove shield which fits over the burners for access to the pilot, which is located on the right

side of the left burner, approximately 6" into the combustion chamber. Depress dial on the

combination control while lighting the pilot burner. Hold dial in for 30 - 45 seconds, until the pilot

remains lit when the dial is released. A lit taper is recommended for easy access in lighting the

pilot burner.

On units recently installed, the pilot line will require "bleeding". Consequently, the pilot may not

ignite immediately and it may be necessary to keep the combination control dial depressed until

sufficient gas reaches the pilot to keep it burning. After "bleeding" wait 5 minutes before

attempting ignition.

5. Turn combination control dial ON.

B. Shut Down

1. Standby

a. Turn combination control to "pilot" position.

2. Complete

a. Depress lightly and turn combination control dial OFF.

b. Turn thermostat to lowest position.

c. Turn power switch OFF.

d. Turn any gas service valves supplying gas OFF.

C. Relighting

1. Shut off all gas (turn combination control OFF.)

2. Wait 5 minutes.

3. Repeat "lighting" instructions in section A above.

– 7 –

Page 8

USING THE GAS CONTROL (Kettles with Electronic Ignition)

Units equipped with electronic ignition do not require "lighting" the pilot with a match.

A. Lighting

1. Turn thermostat to lowest position and turn the power switch OFF.

2. Open control panel access door.

3. Turn dial on combination control to ON position by rotating the control knob counterclockwise

to "stop" on black line. Depress control knob completely and release, then continue to rotate

to ON. (NOTE: Any gas service valves exterior to the unit should be open.)

4. Turn power switch ON.

After step 4 there will be a 2 minute and 10 second delay before the kettle will attempt ignition. At this

time the spark igniter will begin sparking at the pilot until the pilot is ignited, or for 50 seconds (an

audible clicking sound will be evident).

After a total of 3 minutes the unit will lockout, shutting off all gas although the spark igniter will continue

to spark. When the pilot is ignited the spark igniter will automatically stop and within 30 to 60 seconds

main burner gas will come on if the thermostat is turned on. New installations (where there may be a

considerable amount of air in the gas line) may require the unit to be turned off and immediately back

on numerous times after each 3 minute lockout period until the air is purged from the gas line.

B. Shut Down

1. Standby

a. Turn power switch OFF.

2. Complete

a. Turn power switch OFF.

b. Turn dial on combination control from ON to black line, depress knob slightly and continue

rotating to OFF.

c. Place thermostat on lowest setting.

d. Turn any main gas service valves supplying gas to OFF.

C. Relighting

1. Turn power switch ON.

It should be noted that the pilot and electronic ignition do not cycle with the thermostat. A standing pilot

is automatically established and monitored each time the power switch is turned on. If the pilot is ever

extinguished by a momentary external interruption, the spark igniter will automatically relight it after

a 2 minute and 10 second purge period without disturbing the cooking cycle, unless lockout occurs.

– 8 –

Page 9

OPERATION

3

3

3

3

3

WARNING: THE STEAM KETTLE AND ITS PARTS ARE HOT. USE CARE WHEN OPERATING,

CLEANING, AND SERVICING THE STEAM KETTLE.

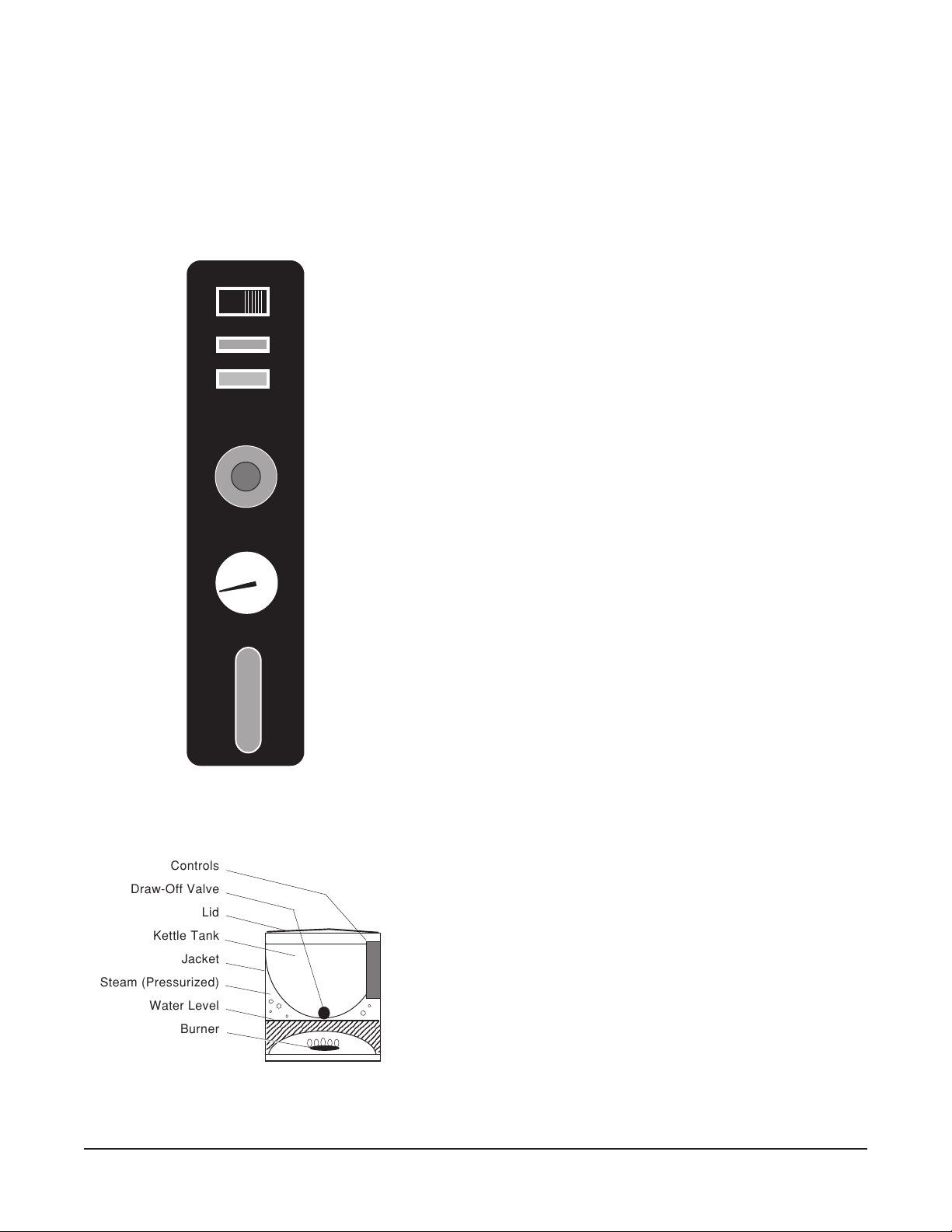

CONTROLS (Figs. 1, 2)

Main Power Switch — Turns main power ON or OFF.

Switch must be turned ON to heat the kettle. Turn the

switch OFF when the kettle will not be in use for long

periods.

OFF

POWER

ON

COOKING

Controls

Draw-Off Valve

Lid

Kettle Tank

Jacket

Steam (Pressurized)

Water Level

Burner

LOW WATER

COOK TEMP.

▼

OFF

OFF

PRESSURE

WATER LEVEL

Fig. 1

Fig. 2

234567890123456789012

234567890123456789012

234567890123456789012

234567890123456789012

234567890123456789012

(Red) Cooking Light — This light is on whenever the

main burner gas is on. On units with electronic ignition,

this light may be on without the burners being on if the

standing pilot becomes extinguished — see page 8.

(Amber) Low Water Light — All kettles are supplied with

sufficient distilled water inside the pressurized jacket. If

at any time the water level falls below that required for

proper operation, the kettle will not heat and this light will

come on. Contact your Vulcan-authorized servicer to

have water added to the jacket and to have the vacuum

pressure re-established.

Thermostat — Sets the kettle's internal operating

temperature (150 – 285°F) or OFF.

Pressure Gauge — Indicates the internal operating

pressure of the kettle. When cold, the gauge should

indicate 25 to 30 inches mercury column vacuum. If it

does not, contact your Vulcan-authorized servicer. Under

normal operation with the kettle empty (and the thermostat

set to 285°F) the pressure shall reach 38 psig. When

loaded the pressure may be considerably less.

Water Level (Sight Glass) — Indicates the minimum and

maximum water level in the pressurized internal portion

of the kettle. If the water level falls below the minimum

level, contact your Vulcan-authorized servicer.

Pressure Relief Valve — This device is located inside

and prevents the internal kettle pressure from exceeding

50 psig. It should never be tampered with.

Draw-Off Valve — Allows you to empty the contents of

the kettle into a suitable container. USE CARE WHEN

HANDLING HOT FOOD. Soups with large chunks may

need to be ladled.

– 9 –

Page 10

DAILY OPERATION

Daily operation should consist of turning on the power switch and setting the thermostat for the desired

temperature.

It is recommenced the kettle be preheated empty prior to use. Milk or egg based products should be

placed in the kettle before heating, however, to prevent sticking. The kettle is preheated when the

cooking light goes off for the first time.

At the end of each day, or if the kettle will not be used for some time, shut the unit down by turning the

power switch OFF.

Clean as required or on a daily basis. Refer to Cleaning, page 11.

On standing pilot units the burner will ignite as soon as both the power switch and the thermostat are

turned on.

On electronic ignition units, turning on the power switch initiates a pilot lighting sequence. For the first

2 minutes and 10 seconds nothing will happen. After 2 minutes and 10 seconds the spark igniter will

begin sparking. The spark igniter will spark until the pilot is ignited. After a total of 3 minutes (or 50

seconds after the spark igniter begins) lockout will occur. Lockout shuts down all pilot (and main

burner) gas flow although the spark igniter will continue to spark. The power switch must be turned

off and back on to restart the pilot lighting sequence once lockout has occurred.

If the pilot blows out during operation, the unit will go through the same sequence to re-ignite itself.

Once the pilot is ignited, another 15 to 45 seconds is required to heat the flame switch before main

burner gas will flow if the thermostat is turned on.

OPERATOR TIPS

For easier cleaning add cold water to the kettle immediately after removing contents.

When preparing foods containing vinegar or tomatoes, or those which have a high salt content, clean

the kettle immediately after using to prevent pitting.

Do not use salt to clean the kettle. This will scratch the surface.

If using saltwater to cook shellfish, be sure to rinse and wash the kettle thoroughly.

Bring milk and egg products slowly up to temperature in a cold kettle to prevent product adhering to

the sides.

When planning actual cooking capacity, allow room at top for stirring without spilling.

When preparing milk-based products do not preheat the kettle. This will prevent the milk from sticking

to the sides.

When preparing puddings from a mix, place the powder in a cold kettle, add a small amount of the liquid,

and stir to form a thin paste. Turn on the kettle and add the remainder of the liquid. Continue per recipe

instructions.

When browning meat bring the kettle up to temperature before adding. This seals the juices in the

meat.

– 10 –

Page 11

CLEANING

WARNING: DISCONNECT ELECTRICAL POWER BEFORE CLEANING.

Clean inside the kettle daily by wiping with a clean damp cloth. Clean the exterior daily with soap and

detergent and water. Rinse thoroughly and wipe dry with a soft clean cloth.

Monthly — Clean around burner air mixers, louvered panels and pilots if grease or lint have

accumulated.

SPECIAL CLEANING PROCEDURES

Cleaning Stainless Steel — To remove normal dirt, grease or product residue from stainless steel,

use ordinary soap and water (or detergent); apply with a sponge or cloth. Dry thoroughly with a clean

cloth. Never use vinegar or any corrosive cleaner.

To remove grease and food spatter or condensed vapors that have baked on the equipment, apply

cleanser to a damp cloth or sponge and rub cleanser on the metal in the direction of the polishing lines

on the metal. Rubbing cleanser as gently as possible in the direction of the polished lines will not mar

the finish of the stainless steel. NEVER RUB WITH A CIRCULAR MOTION. Soil and burnt deposits

which do not respond to this procedure can usually be removed by rubbing the surface with ScotchBrite

scouring pads or stainless steel scouring pads. Do not use ordinary steel wool or steel scouring pads

as any particles left on the surface will rust and further spoil the appearance of the finish. Never use

a wire brush, metal scraper, file or other steel tools. Surfaces which are marred collect dirt more rapidly

and become more difficult to clean. Marring also increases the possibility of corrosive attack.

Refinishing may then be required.

Removing Heat Tint — Darkened areas sometimes appear on stainless steel surfaces where the area

has been subjected to excessive heat. Heat tint can normally be removed by the stainless steel

cleaning procedure, however, tint which does not respond to this procedure calls for a vigorous

scouring in the direction of the polish lines using ScotchBrite scouring pads or a stainless steel scouring

pad in combination with a powdered cleanser. Heat tint action may be lessened by not applying or by

reducing heat to equipment during slack periods.

All food contact surfaces must be thoroughly drained and flushed prior to cooking in the kettle.

Control Panel — The textured control panel should be cleaned with a damp cloth moistened in warm

soapy water. Never use an abrasive cloth or steel wool. Never use cleaning solvents with a

hydrocarbon base.

Vent System — At least twice a year the exhaust hood (venting system) should be examined and

cleaned.

Tips for Efficient Operation — Turn kettle off when not in use. Limit preheat times. Use the lid

whenever possible. Follow proper cleaning and maintainance procedures.

Operational Performance Check — To bring 12 gallons of water from 60°F to 212°F, starting the

kettle from a cold start, should take about 28 to 32 minutes.

SERVICE

Contact your local Vulcan-authorized servicer for any repairs or adjustments needed on this equipment.

– 11 –

Page 12

FORM 30909 (1-95) PRINTED IN U.S.A.

– 12 –

Loading...

Loading...