Page 1

INSTALLATION &

OPERATION MANUAL

VGC SERIES GAS CONVEYOR OVENS

MODELS

VGC3018 ML-126196

VGC3624 ML-114829

VGC3632 ML-114830

VGC4018 ML-126197

VGC4824 ML-114831

VGC4832 ML-114832

VGC6024 ML-114834

VGC6032 ML-114835

VULCAN-HART COMPANY, P.O. BOX 696, LOUISVILLE, KY 40201-0696, TEL. (502) 778-2791

FORM 31057 (5-98)

Page 2

IMPORTANT FOR YOUR SAFETY

THIS MANUAL HAS BEEN PREPARED FOR PERSONNEL QUALIFIED TO INSTALL GAS

EQUIPMENT, WHO SHOULD PERFORM THE INITIAL FIELD START-UP AND

ADJUSTMENTS OF THE EQUIPMENT COVERED BY THIS MANUAL.

POST IN A PROMINENT LOCATION THE INSTRUCTIONS TO BE FOLLOWED IN THE

EVENT THE SMELL OF GAS IS DETECTED. THIS INFORMATION CAN BE OBTAINED

FROM THE LOCAL GAS SUPPLIER.

IMPORTANT

IN THE EVENT A GAS ODOR IS DETECTED, SHUT

DOWN UNITS AT MAIN SHUTOFF VALVE AND

CONTACT THE LOCAL GAS COMPANY OR GAS

SUPPLIER FOR SERVICE.

FOR YOUR SAFETY

DO NOT STORE OR USE GASOLINE OR OTHER

FLAMMABLE VAPORS OR LIQUIDS IN THE

VICINITY OF THIS OR ANY OTHER APPLIANCE.

WARNING

IMPROPER INSTALLATION, ADJUSTMENT,

ALTERATION, SERVICE OR MAINTENANCE CAN

CAUSE PROPERTY DAMAGE, INJURY OR DEATH.

READ THE INSTALLATION, OPERATING AND

MAINTENANCE INSTRUCTIONS THOROUGHLY

BEFORE INSTALLING OR SERVICING THIS

EQUIPMENT.

IN THE EVENT OF A POWER FAILURE, DO NOT

ATTEMPT TO OPERATE THIS DEVICE.

© VULCAN-HART COMPANY, 1998

— 2 —

Page 3

TABLE OF CONTENTS

GENERAL. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Unpacking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Installation Codes and Standards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Ovens Mounted on Casters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Installing Basic Oven . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Installing Stacked Ovens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Leveling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Gas Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Testing the Gas Supply System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Electrical Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Alternate Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Before First Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Lighting Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Using the Oven . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Conveyor Belt Assembling and Disassembling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Cooking Chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Service and Parts Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

— 3 —

Page 4

Installation, Operation and Care of

MODEL VGC SERIES GAS CONVEYOR OVENS

PLEASE KEEP THIS MANUAL FOR FUTURE USE

GENERAL

Vulcan ovens are produced with quality workmanship and material. Proper installation, usage and

maintenance of your oven will result in many years of satisfactory performance.

It is suggested that you thoroughly read this entire manual and carefully follow all of the instructions

provided.

INSTALLATION

Before installing, verify that the electrical service and type of gas supply (natural or propane) agree with

the specifications on the rating plate located on the right front side panel. If the supply and equipment

requirements do not agree, do not proceed with the installation. Contact your dealer or Vulcan-Hart

Company immediately.

UNPACKING

This oven was inspected before leaving the factory. The transportation company assumes full

responsibility for safe delivery upon acceptance of the shipment. Immediately after unpacking, check

for possible shipping damage. If the oven is found to be damaged, save the packaging material and

contact the carrier within 15 days of delivery.

1. Tilt the oven on its back side.

2. Place the oven on a four-wheel dolly.

3. Move oven to its installation position.

4. Remove the oven from the dolly and place on two pieces of 2 x 4 wood.

5. Carefully unpack the oven.

Do not use the door or the handle to lift the oven.

LOCATION

When the crate is turned on its side, the oven will pass through a 34" (86 cm) door opening (or 30" [76 cm]

opening without the crate). Verify that the doors and access routes into the kitchen area will permit

clearance.

The equipment area must be kept free and clear of combustible substances.

— 4 —

Page 5

When installed, minimum clearance from combustible and non-combustible construction must be 2.5"

(63.5 mm) at the sides and 2.5" (63.5 mm) at the rear.

The installation location must allow adequate clearances for servicing and proper operation.

A minimum front clearance of 36" (914.4 mm) is required.

Do not obstruct the flow of combustion and ventilation air. Adequate clearance for air openings into

the combustion chamber must be provided. Make sure there is an adequate supply of air in the room

to replace air taken out by the ventilating system.

Information on the construction and installation of ventilating hoods may be obtained from the

standard for "Vapor Removal from Cooking Equipment," NFPA No. 96 (latest edition), available from

the National Fire Protection Association, Batterymarch Park, Quincy, MA 02269.

The ventilation hood should extend 6" (152 mm) minimum past the oven on the front, back, and each

side of the conveyor belt.

Exhaust: Approximately 2000 CFM required for double stacked ovens.

Approximately 1500 CFM required for single oven.

Make-up air should be 65% to 80% of the exhaust air rating.

Do not permit fans to blow directly at the oven. Wherever possible, avoid open windows next to the

oven. Avoid wall-type fans which create air cross currents within the room.

INSTALLATION CODES AND STANDARDS

The oven must be installed in accordance with:

In the United States of America:

1. State and local codes.

2. National Fuel Gas Code, ANSI-Z223.1 (latest edition). Copies may be obtained from The

American Gas Association, Inc., 1515 Wilson Blvd., Arlington, VA 22209.

3. National Electrical Code, ANSI/NFPA-70 (latest edition). Copies may be obtained from The

National Fire Protection Association, Batterymarch Park, Quincy, MA 02269.

In Canada:

1. Local codes.

2. CAN/CGA-B149.1 Natural Gas Installation Code (latest edition).

3. CAN/CGA-B149.2 Propane Installation Code (latest edition), available from the Canadian Gas

Association, 178 Rexdale Blvd., Etobicoke, Ontario, Canada M9W 1R3.

4. Canadian Electrical Code, CSA C22.2 No. 3 (latest edition). Copies may be obtained from The

Canadian Standard Association, 178 Rexdale Blvd., Etobicoke, Ontario, Canada M9W 1R3.

— 5 —

Page 6

ASSEMBLY

Ovens Mounted on Legs or Feet

To service the oven when mounted on legs or feet, a minimum clearance of 18" (457 mm) from service

compartment is required.

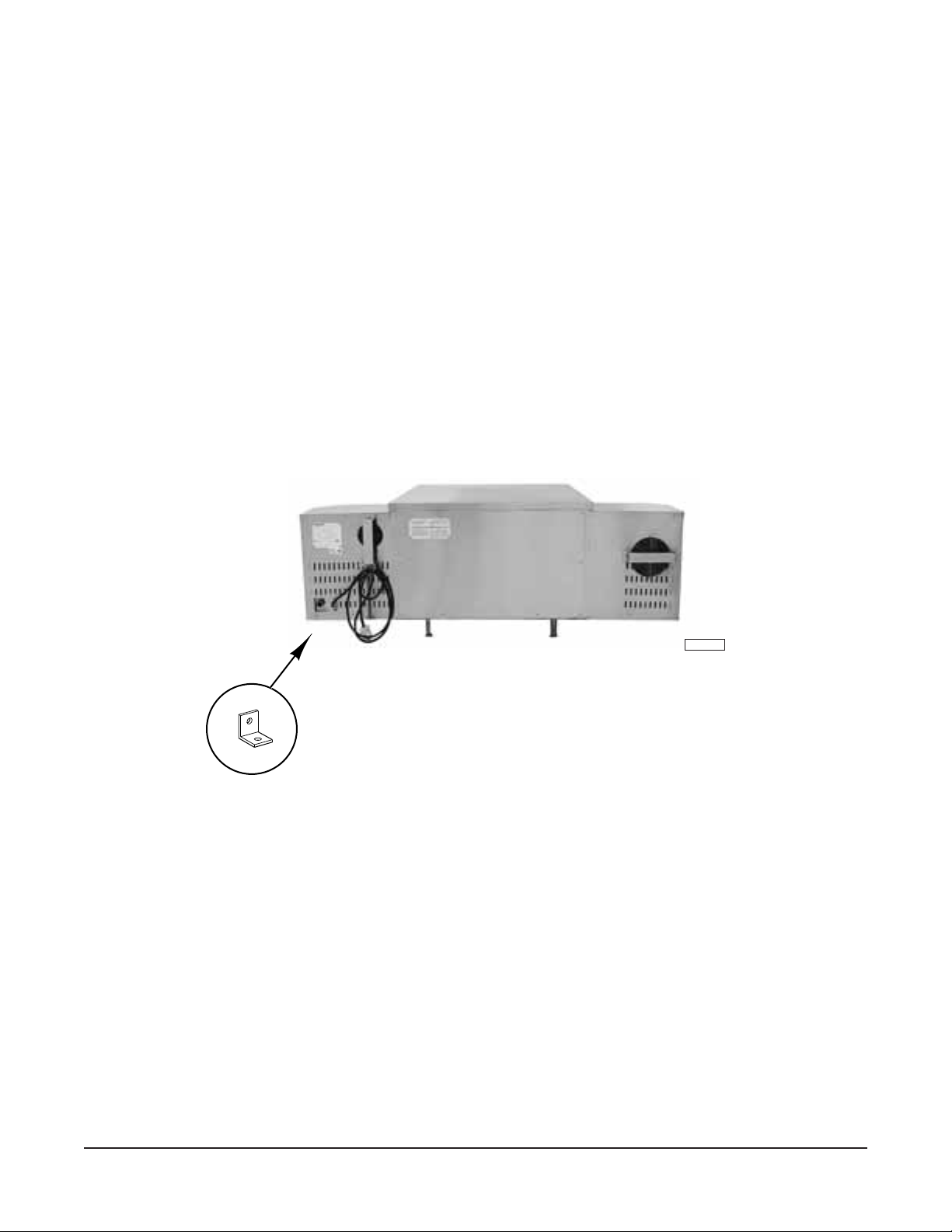

Ovens Mounted on Casters

NOTICE: In order to be able to service this appliance, it must be installed with the casters supplied,

a connector complying with ANSI Z21.69 or CAN/CGA-6.16, and a quick-disconnect device complying

with ANSI Z21.41 or CAN1-6.9. It must also be installed with restraining means to guard against

transmission of strain to the connector, as specified in the appliance manufacturer's installation

instructions.

Attach the restraining device at the rear of the oven (Fig. 1).

If disconnection of the restraint is necessary, turn off the gas supply before disconnection. Reconnect

this restraint prior to turning the gas supply on and returning the oven to its installation position.

PL-41122

CONNECT GAS

LINE STRAIN

RELIEF HERE

Fig. 1

Installing Basic Oven

1. Attach the front legs by screwing them into the bottom of the oven.

2. Tilt oven forward resting it on the front legs.

3. Lift the oven from the rear.

4. Once the oven is lifted, attach the back legs.

5. The oven is now ready to be placed in its operating position.

Installing Stacked Ovens

After basic oven is installed, lift the top oven and place it on top of the bottom oven. No fasteners are

required; the weight of the oven will keep it in place.

— 6 —

Page 7

LEVELING

Casters for this oven are of the non-adjustable type. Therefore, the floor must be level. If floor surface

is not level, the oven will experience cooking problems.

GAS CONNECTIONS

Gas supply connections and any pipe joint compound must be resistant to the action of propane gases.

3

Location of the

⁄4" gas inlet is at the back of the oven on the lower right side.

Codes require that a gas shutoff valve (available from Vulcan-Hart) must be installed in the gas line

ahead of the oven.

Connect gas supply. Make sure the pipes are clean and free of obstructions.

The ovens are equipped with fixed burner orifices which coincide with installation elevation.

Natural gas and propane gas are preset at the factory for proper operation. Store line pressures are

preset for 7" W.C. (Water Column) (1.75 kPa) for natural gas and 11" W.C. (2.75 kPa) for propane gas.

WARNING: PRIOR TO LIGHTING, CHECK ALL JOINTS IN THE GAS SUPPLY LINE FOR LEAKS.

USE SOAP AND WATER SOLUTION. DO NOT USE AN OPEN FLAME.

After piping has been checked for leaks, all piping receiving gas should be fully purged to remove air.

TESTING THE GAS SUPPLY SYSTEM

When gas supply pressure exceeds

be disconnected from the gas supply piping system. When gas supply pressure is

1

/2 psig (3.45 kPa), the oven and its individual shutoff valve must

1

/2 psig (3.45 kPa)

or less, the oven should be isolated from the gas supply system by closing its individual manual shutoff

valve.

ELECTRICAL CONNECTIONS

WARNING: ELECTRICAL AND GROUNDING CONNECTIONS MUST COMPLY WITH THE

APPLICABLE PORTIONS OF THE NATIONAL ELECTRICAL CODE AND/OR OTHER LOCAL

ELECTRICAL CODES.

WARNING: APPLIANCES EQUIPPED WITH A FLEXIBLE ELECTRIC SUPPLY CORD ARE

PROVIDED

WITH A THREE-PRONG GROUNDING PLUG. IT IS IMPERATIVE THAT THIS PLUG BE

CONNECTED INTO A PROPERLY GROUNDED THREE-PRONG RECEPTACLE. IF THE

RECEPTACLE IS NOT THE PROPER GROUNDING TYPE, CONTACT AN ELECTRICIAN. DO NOT

REMOVE THE GROUNDING PRONG FROM THIS PLUG.

The oven is equipped with a power supply cord for service at 120 volts and 20 amps. A 20 amp

receptacle and service is required for proper operation of the oven.

Do not connect the oven to electrical supply until after gas connections have been made.

— 7 —

Page 8

OPERATION

WARNING: THE OVEN AND ITS PARTS ARE HOT. BE VERY CAREFUL WHEN OPERATING,

CLEANING OR SERVICING THE OVEN.

CONTROLS (Fig's. 2 and 3)

TEMPERATURE DISPLAY

READ SET POINT BUTTON

TIME RANGE

SWITCH

POWER SWITCH

Fig. 2

LOAD INDICATOR LIGHT

TIME DISPLAY

BELT SWITCH

TIME KNOB

PL-41147-1

Temperature Display — Displays actual oven cavity temperature during cooking cycle.

Read Set Point Button — Push to display set temperature.

Load Indicator Light — When lit, indicates that the heat is being provided to the oven.

Time Display — Displays actual cooking time in minutes and tenths of minutes.

Time Range Switch — Use to set cook time range from 2 to 8 minutes, 8 to 15 minutes, or 15

to 20 minutes. Switch must be on cook time range desired in order to

change belt speed.

— 8 —

Page 9

Belt Switch — Push switch to ON to start the conveyor belt; push to OFF to stop the

conveyor belt.

Power Switch — Push to ON to start the oven; push to OFF to stop the oven. When the

power switch is pushed to ON, ignition occurs automatically.

Time Knob — After the Time Range Switch has been set to the desired time range,

turn the knob clockwise to increase the cook time or counterclockwise

to decrease the cook time until it reaches the time desired on the time

display.

CYCLE TIME

MAN. RESET PROP. BAND

Fig. 3

SET POINT

DOOR FLAP

PL-41124-1

Cycle Time — This is a service control only. Do not touch this control.

Man. Reset — This is a service control only. Do not touch this control.

Set Point — Set point adjustment control. To adjust the set point, locate the Set

Point knob behind the door flap. Press the Read Set Point button so

that the set point is displayed, and at the same time, turn the Set Point

knob until the desired set point temperature appears in the digital

display. Release the Read Set Point button. Do not make any other

adjustments to this control.

Prop. Band — This is a service control only. Do not touch this control.

— 9 —

Page 10

ALTERNATE CONTROLS (Fig. 4)

SET POINT

TEMPERATURE DISPLAY

SET POINT

INDICATOR

LIGHT

SET POINT ARROWS

TIME DISPLAY

TIME RANGE

SWITCH

POWER SWITCH

CONTROL CIRCUIT FUSE

BELT SWITCH

TIME KNOB

DRIVE MOTOR FUSES

PL-41123-1

Fig. 4

Temperature Display — Displays actual oven cavity temperature during cooking cycle.

Set Point — Push to display set temperature.

Set Point Arrows — Press the Set Point button so that the set point is displayed, and at the

same time, press the Set Point Arrows up or down until the desired set

point temperature appears in the digital display. Release the Set

Point button. The actual oven cavity temperature will display.

Set Point Indicator Light — When lit, indicates that the heat is being provided to the oven. When

set point is reached, light will go off.

Time Display — Displays actual cooking time in minutes and tenths of minutes.

Time Range Switch — Use to set cook time range from 2 to 8 minutes, 8 to 15 minutes, or 15

to 20 minutes. Switch must be on cook time range desired in order to

change belt speed.

— 10 —

Page 11

Belt Switch — Push switch to ON to start the conveyor belt; push to OFF to stop the

conveyor belt.

Power Switch — Push to ON to start the oven; push to OFF to stop the oven. When the

power switch is pushed to ON, ignition occurs automatically.

Time Knob — After the Time Range Switch has been set to the desired time range,

turn the knob clockwise to increase the cook time or counterclockwise

to decrease the cook time until it reaches the time desired on the time

display.

Control Circuit Fuse — 25 Amp. / 250V. Time delay.

Drive Motor Fuses — 375 ma / 250V.

BEFORE FIRST USE

Clean the protective metal oils from all surfaces of the oven. Use a non-corrosive, grease dissolving

commercial cleaner, following manufacturer's directions. Rinse thoroughly with a clean damp cloth

and wipe dry with a soft clean cloth. DO NOT hose down the oven. Do not use this oven if it's controls

have been wet. Contact your Vulcan-Hart servicer.

LIGHTING INSTRUCTIONS

Turning the Oven On

The burner control is a solid state device that automatically ignites and monitors the pilot flame. To

turn the oven on, turn the gas combination valve (Fig. 5) to ON, push the Power Switch to ON, and set

the oven temperature to desired temperature.

GAS COMBINATION

CONTROL VALVE

Fig. 5

PL-41125-1

If the burner fails to light within 90 seconds, the burner control will shut off the gas combination valve

and will lock out. To reset the burner control for restart, push the Power Switch to OFF and then to ON.

If the burner still fails to light, turn the oven off and wait for 5 minutes before restarting. If lockout occurs

again, contact your local Vulcan authorized servicer.

— 11 —

Page 12

Turning the Oven Off

Turn Power Switch to OFF.

Extended Shutdown

Turn Power Switch to OFF. Turn gas combination valve to OFF. Turn main gas shutoff valve to OFF.

USING THE OVEN

When power is applied to the oven, it will begin operating at the factory set temperature of 525°F

(273°C). The actual oven cavity temperature will appear in the temperature display and the Load

Indicator Light will indicate if the heat is on. To reset the set temperature, see SET POINT on page 9

or 10.

To read the temperature set point, press and hold the Read Set Point or Set Point button. The set point

will appear in the temperature display.

If the conveyor belt stalls, the time display will indicate "O.L." and the belt will automatically stop.

Remove the blockage and reset the control by moving the Belt Switch up and down. The time should

be indicated on the display again and the drive motor should restart.

On each end of the oven is a baffle (Fig. 6) which can be adjusted higher or lower to accommodate the

height of the product being cooked. To raise or lower the baffles, use insulated gloves and loosen the

two thumb screws (Fig. 6),

readjust baffle height, then retighten the two thumb screws.

BAFFLE

THUMB SCREWS

PL-41126-1

Fig. 6

Loading and Unloading the Oven

Place product in utensils (if required) and set utensils or products on the entrance end of the belt, but

not in the oven tunnel. Remove utensils or products from the oven after they completely clear the oven

tunnel.

— 12 —

Page 13

Air Distribution Panels

The oven is equipped with a top and a bottom air distribution panel. These panels regulate the quantity

of air on the top and bottom of the product that is being cooked. They have been adjusted at the factory

for proper baking performance. Some products may need additional panel adjustments. This should

be done by a Vulcan-Hart authorized servicer.

CLEANING

WARNING: DISCONNECT ELECTRICAL POWER SUPPLY BEFORE CLEANING.

Daily

Clean the outside of the oven daily by wiping with a clean damp cloth.

Avoid using abrasive powders or pads; these cleaners may damage the finish.

Remove the crumb trays on each side of the oven (Fig. 7) and clean in a sink as you would any normal

utensil. Also remove the center crumb tray (Fig. 7) and clean it. To remove the center crumb tray:

1. Remove the front panel by grasping each side of the door handle and lifting up.

2. Swing the bottom of the front panel out. Lower panel and pull away.

3. Before removing the crumb tray, loosen the conveyor belt (see Conveyor Belt Removal in this

manual) and brush away the crumbs under the belt.

4. After cleaning the center crumb tray, replace the tray and replace the front panel by reversing the

procedure.

Replace right-hand and left-hand crumb trays.

CRUMB TRAYS

PL-41127-1

Fig. 7

— 13 —

Page 14

Conveyor

To maintain proper belt tension the conveyor belt will have to be adjusted to remove any slack in the

belt.

1. To tension the belt, locate the two adjustment screws (Fig. 8) on the right hand end (facing machine)

of the conveyor assembly. Loosen the nuts on the inside of the of the conveyor rack and turn the

adjusting screws clockwise to increase belt tension. Be sure to adjust both screws an equal

amount.

2. Retighten the nuts on the inside of the conveyor rack.

When the conveyor belt adjustment is at its maximum and the belt is still slack, remove one link from

the belt.

1. Locate the conveyor belt splicing strand and remove it as shown in the

ASSEMBLING AND

DISASSEMBLING (Fig. 12).

CONVEYOR BELT

2. Remove one conveyor link and set the tension screws at their minimum by turning them

counterclockwise. Adjust both screws an equal amount.

3. Reinstall the splicing strand as shown in the

CONVEYOR BELT ASSEMBLING AND

DISASSEMBLING (Fig. 12), and readjust the belt tensions with the adjusting screws.

Two ways to remove the conveyor for cleaning:

1. Conveyor Belt Removal

a. Loosen belt tension screws at the end of the belt track (Fig. 8).

b. Locate the wide end-hooks of the splicing strands where the belt should be disconnected.

To remove splicing strands, follow the directions shown in CONVEYOR BELT ASSEMBLING

c.

DISASSEMBLING in this manual.

AND

d. To replace belt, reverse this procedure.

BELT TENSION SCREWS

Fig. 8

— 14 —

PL-41128-1

Page 15

2. Conveyor Assembly Removal

a. Remove conveyor crumb trays (see Fig. 7).

b. Remove cover where conveyor shaft enters the left-hand control box (Fig. 9).

REMOVE COVER

PL-41129-1

Fig. 9

c. Lift up the drive end of the conveyor assembly and slide the conveyor assembly into the oven

tunnel to remove the tension on the drive chain.

d. Slip the drive chain off the conveyor drive sprocket (Fig. 10).

Fig. 10

— 15 —

PL-41130

Page 16

e. Pull the entire conveyor assembly from the oven (Fig. 11).

Fig. 11

f. Take conveyor assembly to cleaning area.

g. To replace conveyor assembly, reverse this procedure.

PL-41131

Weekly

CAUTION: Intake fans and slots on the back of the oven and control box must be cleaned

weekly. Any obstructions may cause motor damage.

Use a long bristle brush to clean these areas.

— 16 —

Page 17

CONVEYOR BELT ASSEMBLING AND DISASSEMBLING (Fig. 12)

Install the conveyor belt so that it always runs in

the direction indicated by this arrow — the closed

end of the loop toward the direction of travel.

The arrows in the belt illustrate the movement of

the splicing strand between steps.

When bending the splicing strand, try to limit

bending to straight portions of the strand rather

than in the "Z" bend area.

1

2

3

Splice one side completely before starting the

other side.

After completely splicing the belt, it is advisable to

go along the width of the belt straightening the

spliced-in strand.

Depending upon the width of the belt, there might

be one, two, or three splicing strands.

4

5

6

7

— 17 —

PL-52997

Fig. 12

Page 18

COOKING CHART

The times and temperatures shown in this chart are suggested only. Experiment with your food

products to determine the cooking temperatures and times that give you the best results.

TYPE OF APPROX. TIME TEMP.

FOOD PRODUCT (IN MIN.) (°F) / (°C)

ITALIAN Pizza (par baked dough) 4 to 4.5 510 / 265

Pizza (fresh dough) 5.5 to 6.5 510 / 265

Pizza (thick pan type) 7.5 to 8.5 510 / 165

Calzone (fresh dough) 5 to 6 510 / 265

Pastas (precooked to gratin) 5 to 6 510 / 265

BREADS & SUBS Garlic Bread 2.5 to 3.5 510 / 265

Bread Sticks 2.5 to 3.5 510 / 265

Submarine Sandwiches 2.5 to 3.5 510 / 265

BAKERY Dinner Rolls (par baked) 4 to 4.5 390 / 199

Dinner Rolls (fresh) 7.5 to 8.5 390 / 199

Bagels (fresh) 12 to 13 390 / 199

Croissants (par baked) 4 to 4.5 390 / 199

Croissants (fresh) 9 to 10 390 / 199

Muffins (fresh) 12 to 13 390 / 199

Biscuits and Cookies (fresh) 4.5 to 6.5 390 / 199

MEAT & POULTRY Chicken Wings (precooked) 5.5 to 6.5 510 / 265

Chicken Wings (fresh) 18 to 20 390 / 199

Chicken Breasts (boneless) 5.5 to 6.5 510 / 265

B.B.Q. Ribs (fresh) 18 to 20 390 / 199

Hamburger Patties (fresh) 5.5 to 6.5 510 / 265

FISH & SEAFOOD Shrimp (fresh) 4.5 to 5.5 510 / 265

Fish Filets (fresh) 6.5 to 7.5 510 / 265

Tuna Steak (fresh) 8.5 to 9.5 510 / 265

Salmon Steak (fresh) 6 to 7.5 510 / 265

MEXICAN Burritos and Enchiladas 2.5 to 3.5 475 / 246

Nachos Assorted Styles 2.5 to 3.5 475 / 246

EGGS Souffles and Omelettes 5.5 to 6.5 510 / 265

Quiches 9 to 10 390 / 199

— 18 —

Page 19

MAINTENANCE

WARNING: THE OVEN AND ITS PARTS ARE HOT. BE VERY CAREFUL WHEN OPERATING,

CLEANING OR SERVICING THE OVEN.

WARNING: DISCONNECT ELECTRICAL POWER SUPPLY BEFORE PERFORMING ANY

MAINTENANCE ON THE OVEN.

INSPECTION

The oven should be inspected at least annually by a Vulcan-Hart authorized servicer. More frequent

cleaning may be required due to oven grease vapors, dust, etc. It is imperative that control

compartments, burners, and circulating air passageways of the oven be kept clean.

SERVICE AND PARTS INFORMATION

To obtain service and parts information concerning this oven, contact the Vulcan-Hart Service Agency

in your area (refer to listing supplied with the oven), or Vulcan-Hart Company Service Department at

the address or phone number shown on the front cover of this manual.

— 19 —

Page 20

TROUBLESHOOTING

PROBLEM

Power switch is on and oven

will not operate.

Burner is on but oven does

not start.

Speed control shows "OL".

Conveyor belt does not turn.

Conveyor belt jumps.

Burner does not ignite.

POSSIBLE CAUSES

1. Gas combination valve is in

the OFF position.

1. Temperature controller

setting not properly

adjusted.

2. Problem with thermocouple.

1. Conveyor belt is stuck.

1. Problem with speed control.

2. Gear loose.

1. Chain too loose.

1. Gas combination valve is in

the OFF position.

ACTION

Turn the valve to ON.

Adjust temperature controller.

Contact your Vulcan servicer.

Check the belt.

Contact your Vulcan servicer.

Contact your Vulcan servicer.

Adjust belt tension screws

evenly

Turn the valve to ON.

(see Fig. 8).

Cooking is not even.

Oven gives off gas odors.

Oven is operating,

temperature controller is on,

and the burner goes off.

Excessive vibrations of the

circulating motor.

2. Problem with centrifugal

switch or gas valve.

1. Improper adjustment of the

fingers.

1. Improper adjustment of the

burner flame.

1. Axial fan problem.

2. Fan circulating motor is

overloaded or overheated.

1. Blower cage is unbalanced.

Contact your Vulcan servicer.

Contact your Vulcan servicer.

Contact your Vulcan servicer.

Contact your Vulcan servicer.

Contact your Vulcan servicer.

Contact your Vulcan servicer.

FORM 31057 (5-98) PRINTED IN U.S.A.

— 20 —

Loading...

Loading...