Page 1

VG40 SHOWN

SERVICE MANUAL

GAS BRAISING PANS

(30 & 40 GALLON)

VG30 ML-126847

VG40 ML-126848

- NOTICE This Manual is prepared for the use of trained Vulcan Service

Technicians and should not be used by those not properly

qualified. If you have attended a Vulcan Service School for this

product, you may be qualified to perform all the procedures

described in this manual.

This manual is not intended to be all encompassing. If you have

not attended a Vulcan Service School for this product, you should

read, in its entirety, the repair procedure you wish to perform to

determine if you have the necessary tools, instruments and skills

required to perform the procedure. Procedures for which you do

not have the necessary tools, instruments and skills should be

performed by a trained Vulcan Service Technician.

Reproduction or other use of this Manual, without the express

written consent of Vulcan, is prohibited.

For additional information on Vulcan-Hart Company or to locate an authorized parts

and service provider in your area, visit our website at www.vulcanhart.com.

A product of VULCAN-HART LOUISVILLE, KY 40201-0696

F25121(February 2003)

Page 2

GAS BRAISING PANS

TABLE OF CONTENTS

GENERAL ................................................................................ 3

Installation, Operation and Cleaning ......................................................... 3

Introduction ............................................................................ 3

Control Panel ...................................................................... 3

Model Designations ................................................................. 3

Tools................................................................................. 3

Specifications ..........................................................................3

REMOVAL AND REPLACEMENT OF PARTS .................................................... 4

Covers and Panels ...................................................................... 4

Power Supply Box Components ............................................................ 5

Temperature Controller .................................................................. 5

Pan Position/Down Limit Switch ............................................................ 6

Thermocouple Probe .................................................................... 8

DC Lift Motor .......................................................................... 9

Gear Reducer ......................................................................... 10

Gas Combination Valve ................................................................. 11

Pilot Burner ........................................................................... 12

Runner Tube .......................................................................... 12

Main Burners ......................................................................... 13

Lid Springs ........................................................................... 13

SERVICE PROCEDURES AND ADJUSTMENTS ................................................. 15

Temperature Controller Calibration ........................................................ 15

Temperature Controller Test ............................................................. 16

Thermocouple Test .................................................................... 16

Spark Ignition Test ..................................................................... 17

Pilot Burner Flame Adjustment............................................................ 18

Flame Sense Current Test ............................................................... 19

Ignition Control Module Test .............................................................. 19

Gas Manifold Pressure Adjustment ........................................................ 20

Main Burners ......................................................................... 21

Inspection ........................................................................ 21

Air Shutter Adjustment .............................................................. 21

DC Motor Controller Test ................................................................ 22

Pan Position/Down Limit Switch Adjustment ................................................. 22

Lid Spring Tension Adjustment............................................................ 23

ELECTRICAL OPERATION .................................................................. 25

Component Function ................................................................... 25

Component Location ................................................................... 26

Ignition Control Module .................................................................. 27

Sequence of Operation .................................................................. 28

Schematic Diagram .................................................................... 30

TROUBLESHOOTING ...................................................................... 31

Gas Heating (Manual Lift or Motorized Lift Option) ............................................ 31

Motorized Lift Option Only ............................................................... 32

CONDENSED SPARE PARTS LIST ........................................................... 32

© VULCAN 2003

F25121 (February 2003) Page 2 of 32

Page 3

GAS BRAISING PANS

GENERAL

INSTALLATION, OPERATION

AND CLEANING

Refer to the Installation & Operation Manual for

specific instructions.

INTRODUCTION

The tilting braising pan (skillet) is a versatile piece of

cooking equipment. It can be used to stew, simmer,

steam, sear, pan fry, grill or saute food products over

an evenly distributed heating surface. Once the

product is fully cooked, the pan can be tilted for ease

of product removal.

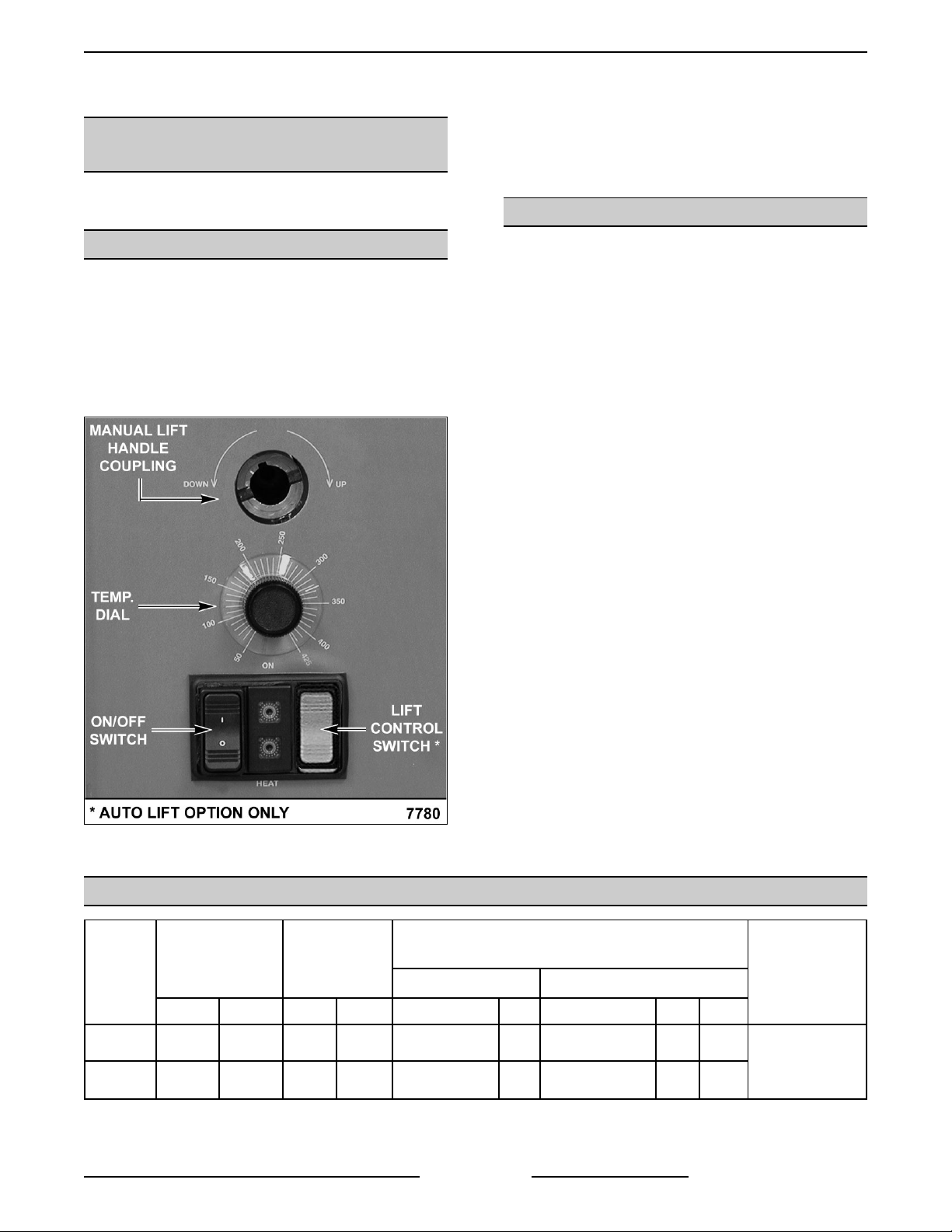

Control Panel

Model Designations

! VG30 - 30 gallon capacity

! VG40 - 40 gallons capacity

TOOLS

Standard

! Standard set of hand tools.

! VOM with an AC current tester and DC micro

amp current tester capable of measuring 0-10

micro amps.

NOTE: Any quality VOM with a sensitivity of

20,000 ohms per volt can be used.

! U-Tube Manometer.

! Temperature tester (thermocouple type) with

surface probe.

Special

! 1 5/8" open end wrench. Used for removing lid

springs and adjusting lid spring tension.

! Field service grounding kit P/N TL- 84919.

MODEL

! RTV sealant Dow Corning 732 or equivalent.

Used for sealing the slot in top cover for the gas

combination valve.

! Pipe thread sealant suitable for natural and

propane gases.

SPECIFICATIONS

INPUT

BTU/HR

NAT. PROP. NAT. PROP. RECOMMEND MIN RECOMMEND MIN MAX

MANIFOLD

PRESSURE

(INCHES W.C.)

NATURAL PROPANE

LINE PRESSURE

(INCHES W.C.)

AMPS (MAX)

@ 120V/60HZ

VG30 90,000 90,000 3.7 10.0 7.0 5.0 11.0 11.0 14.0

VG40 120,000 120,000 3.7 10.0 7.0 5.0 11.0 11.0 14.0

Page 3 of 32

F25121 (February 2003)

3.0

Page 4

GAS BRAISING PANS - REMOVAL AND REPLACEMENT OF PARTS

REMOVAL AND REPLACEMENT OF PARTS

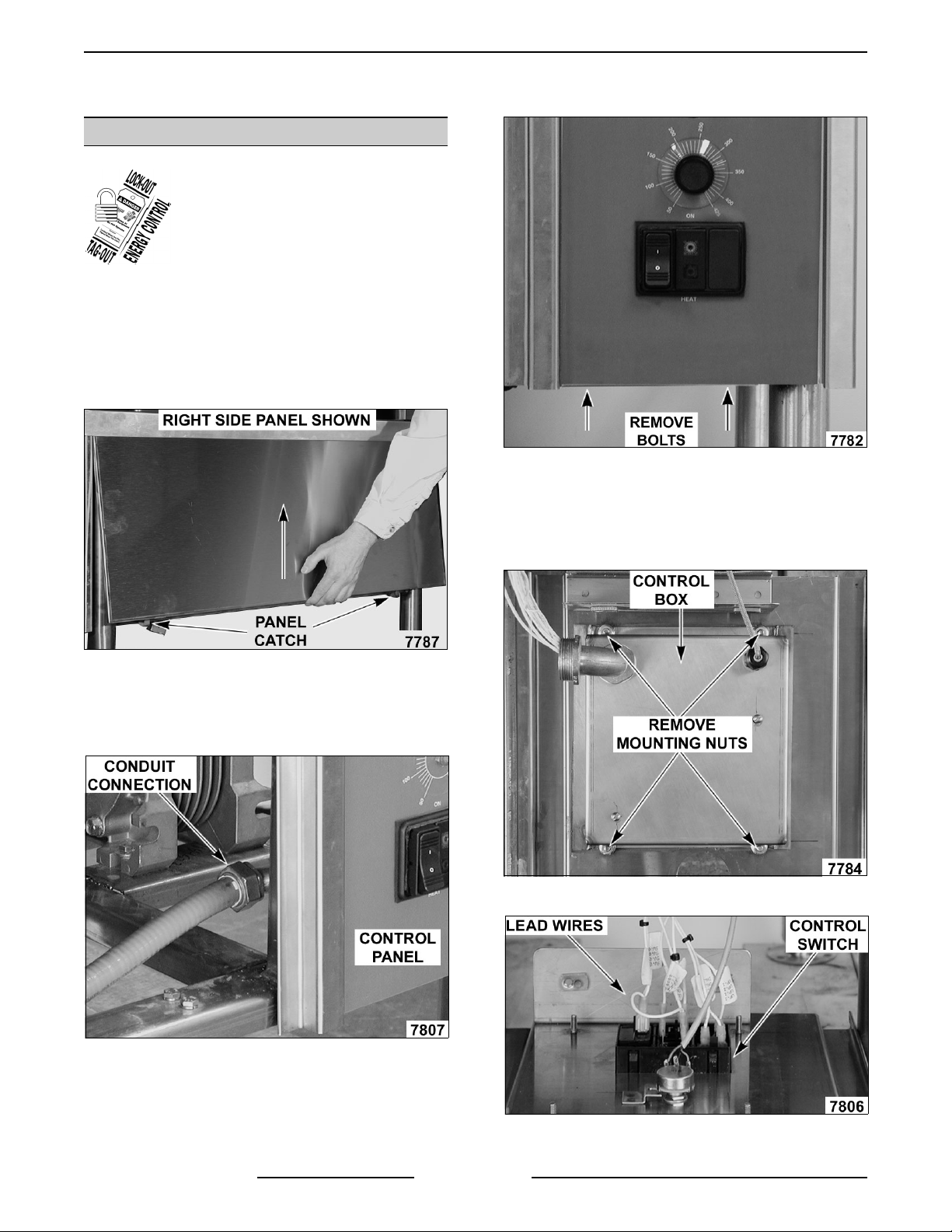

COVERS AND PANELS

WARNING: DISCONNECT THE

ELECTRICAL POWER TO THE

MACHINE AND FOLLOW LOCKOUT /

TAGOUT PROCEDURES.

Front, Rear & Side Panels

1. Lift up on the bottom edge of panel until it clears

the catch.

2. Tilt outwards and allow the panel to drop down.

3. Reverse procedure to install.

5. Tilt bottom of control panel outwards and pull

down.

Control Panel

1. Remove front panel.

2. Disconnect conduit from control box.

NOTE: The control panel should be supported to

remove lead wire strain.

6. Remove control box from control panel.

7. Disconnect lead wires from control switch.

3. Remove manual lift crank handle (if installed).

4. Remove bolts securing control panel to braising

pan frame. Bolts are recessed in the frame

channel.

F25121 (February 2003) Page 4 of 32

Page 5

GAS BRAISING PANS - REMOVAL AND REPLACEMENT OF PARTS

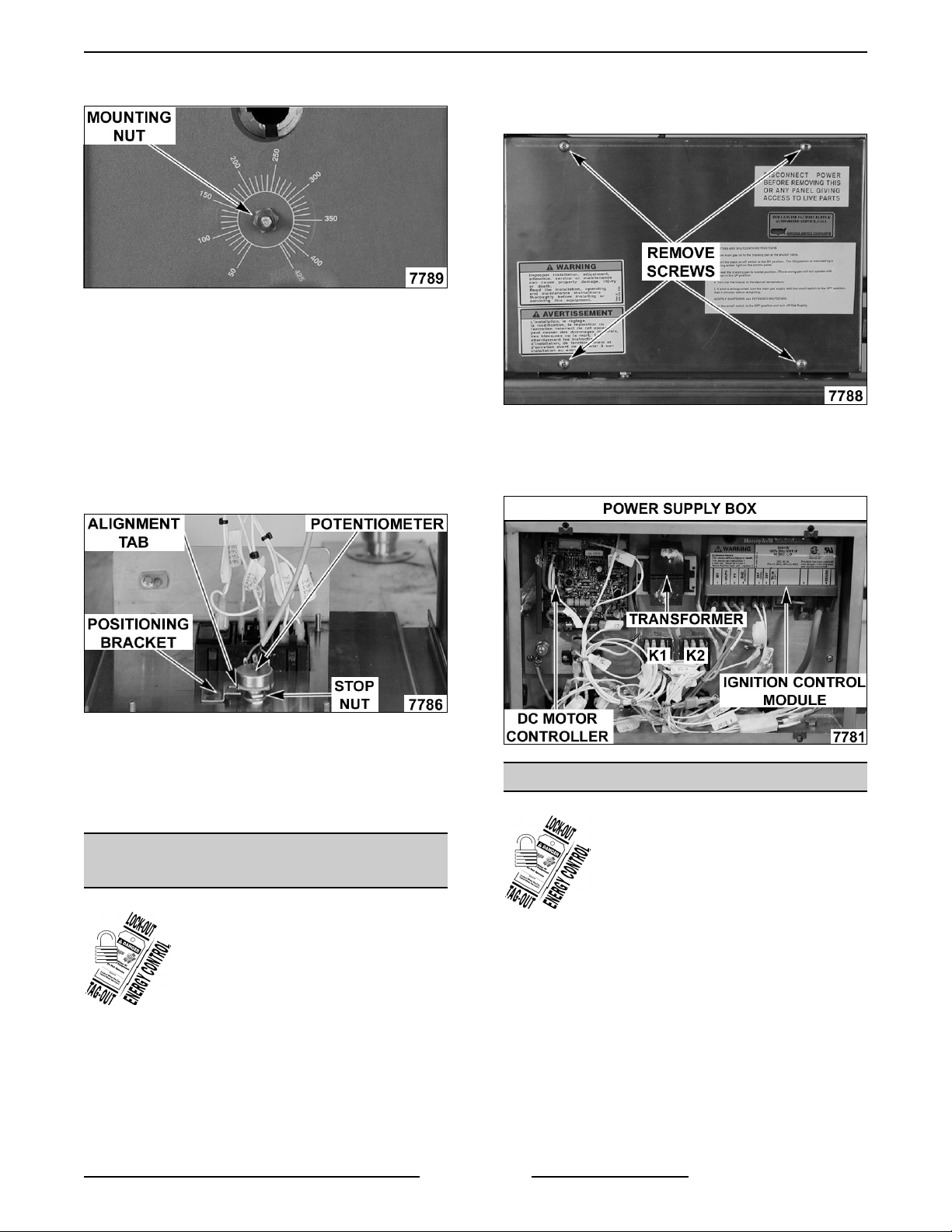

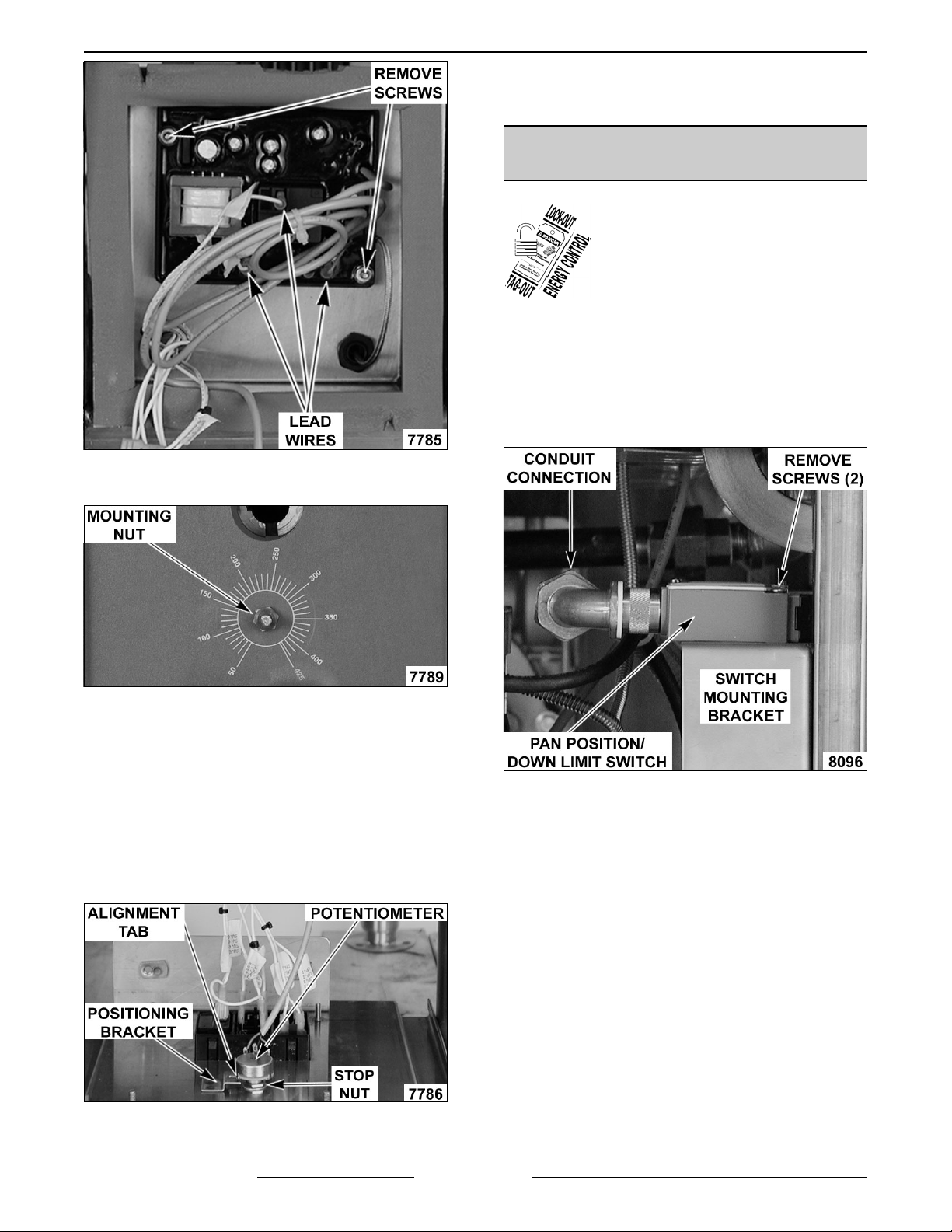

8. Pull temperature dial from potentiometer shaft

and remove mounting nut.

9. Control panel is removed.

10. To install.

A. Align tab on potentiometer with positioning

bracket on panel.

B. Install mounting nut and tighten.

C. Adjust stop nut on potentiometer body (as

necessary) to ensure a water tight seal on

mounting nut.

D. Attach temperature dial.

1. Remove front panel as outlined under

COVERS AND PANELS.

2. Remove power supply box cover.

3. Remove the component being replaced.

4. Reverse procedure to install the replacement

component then check for proper operation.

11. Reverse procedure from step 6 to complete the

installation.

12. Check calibration as outlined under

TEMPERATURE CONTROLLER

CALIBRATION.

POWER SUPPLY BOX

COMPONENTS

WARNING: DISCONNECT THE

ELECTRICAL POWER TO THE

MACHINE AND FOLLOW LOCKOUT /

TAGOUT PROCEDURES.

CAUTION: Certain components in this system

are subject to damage by electrostatic discharge

during field repairs. A field service grounding kit

is available to prevent damage. The field service

grounding kit must be used anytime a control

board is handled.

Page 5 of 32

TEMPERATURE CONTROLLER

WARNING: DISCONNECT THE

ELECTRICAL POWER TO THE

MACHINE AND FOLLOW LOCKOUT /

TAGOUT PROCEDURES.

1. Remove control box from the control panel as

outlined under COVERS AND PANELS.

2. Disconnect lead wires from temperature

controller.

3. Remove temperature controller from control

box.

F25121 (February 2003)

Page 6

GAS BRAISING PANS - REMOVAL AND REPLACEMENT OF PARTS

4. Pull temperature dial from potentiometer shaft

and remove mounting nut.

7. Check calibration as outlined under

TEMPERATURE CONTROLLER

CALIBRATION.

PAN POSITION/DOWN LIMIT

SWITCH

WARNING: DISCONNECT THE

ELECTRICAL POWER TO THE

MACHINE AND FOLLOW LOCKOUT /

TAGOUT PROCEDURES.

1. Remove front and left side panels as outlined

under COVERS AND PANELS.

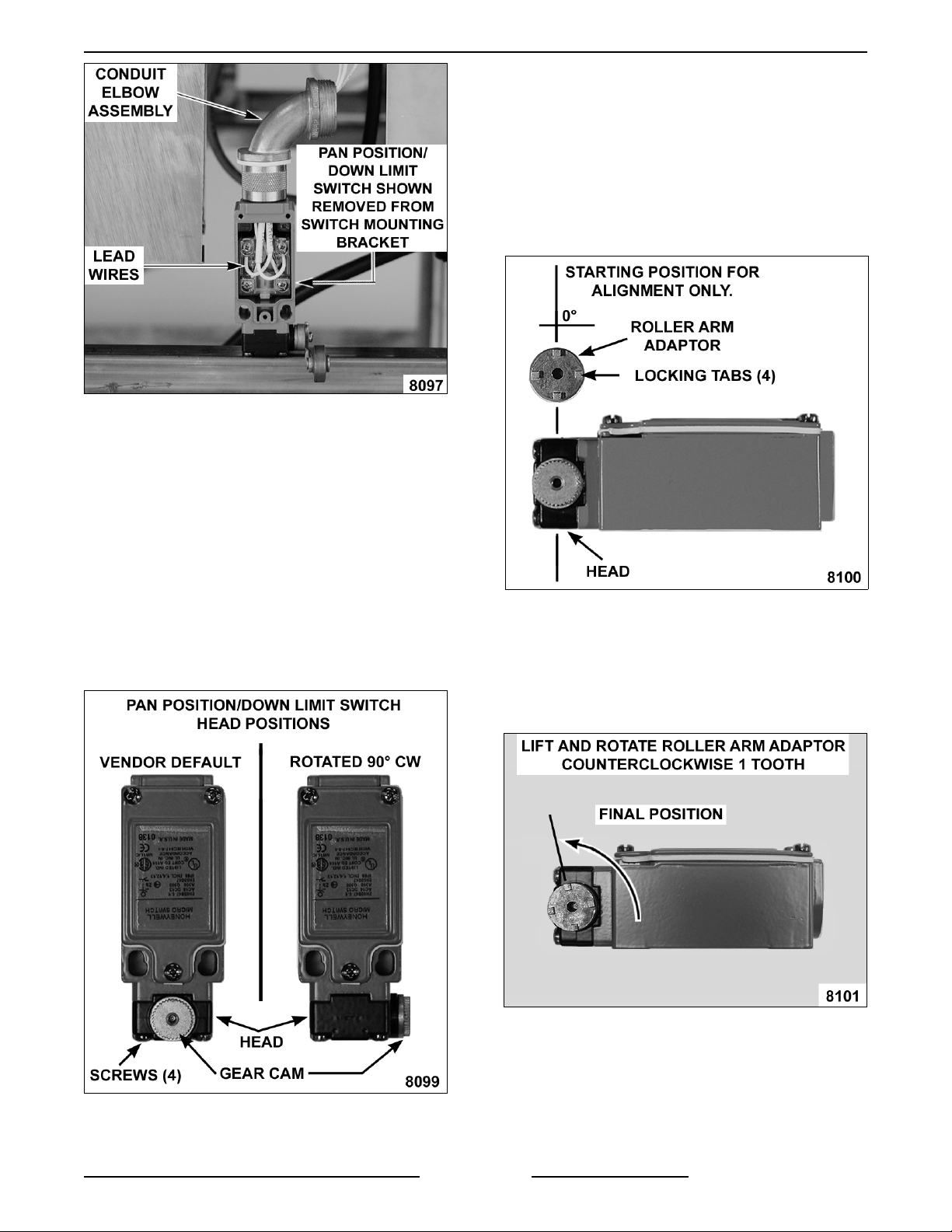

2. Disconnect conduit and remove pan

position/down limit switch from switch mounting

bracket.

LEFT SIDE VIEW SHOWN

5. To install:

A. Align tab on potentiometer with positioning

bracket on panel.

B. Install mounting nut and tighten.

C. Adjust stop nut on potentiometer body (as

necessary) to ensure a water tight seal on

mounting nut.

D. Attach temperature dial.

6. Reverse procedure from step 3 to complete the

installation.

3. Remove cover from switch.

4. Disconnect lead wires and pull wires thru

conduit elbow assembly.

5. Remove conduit elbow assembly from switch.

F25121 (February 2003) Page 6 of 32

Page 7

GAS BRAISING PANS - REMOVAL AND REPLACEMENT OF PARTS

NOTE: When installing, replace the o-ring seal

(provided) inside the brass fitting and re-use conduit

elbow assembly.

6. To install:

C. Place switch on its side with the head to

the left and gear cam pointing up.

D. Align roller arm adaptor with the four

locking tabs pointing up and position one

of the tabs at 0°.

NOTE: The 0° position of the roller arm locking tab

is the starting point for alignment only. The locking

tab cannot remain at the 0° position.

SIDE VIEW SHOWN

A. Position the switch with the head pointing

toward installer and gear cam pointing up.

NOTE: The plunger on the head is spring loaded

and will push the head away from switch body when

the last screw is removed.

B. Remove screws securing the head to

switch body, rotate 90° clockwise and

tighten screws to secure.

TOP VIEW SHOWN

E. Place roller arm adaptor on the gear cam

to engage the teeth. Lift the adaptor until

the teeth just slightly disengage from the

gear cam. Rotate the roller arm adaptor

counterclockwise 1 tooth, re-engage teeth

and release the adaptor.

Page 7 of 32

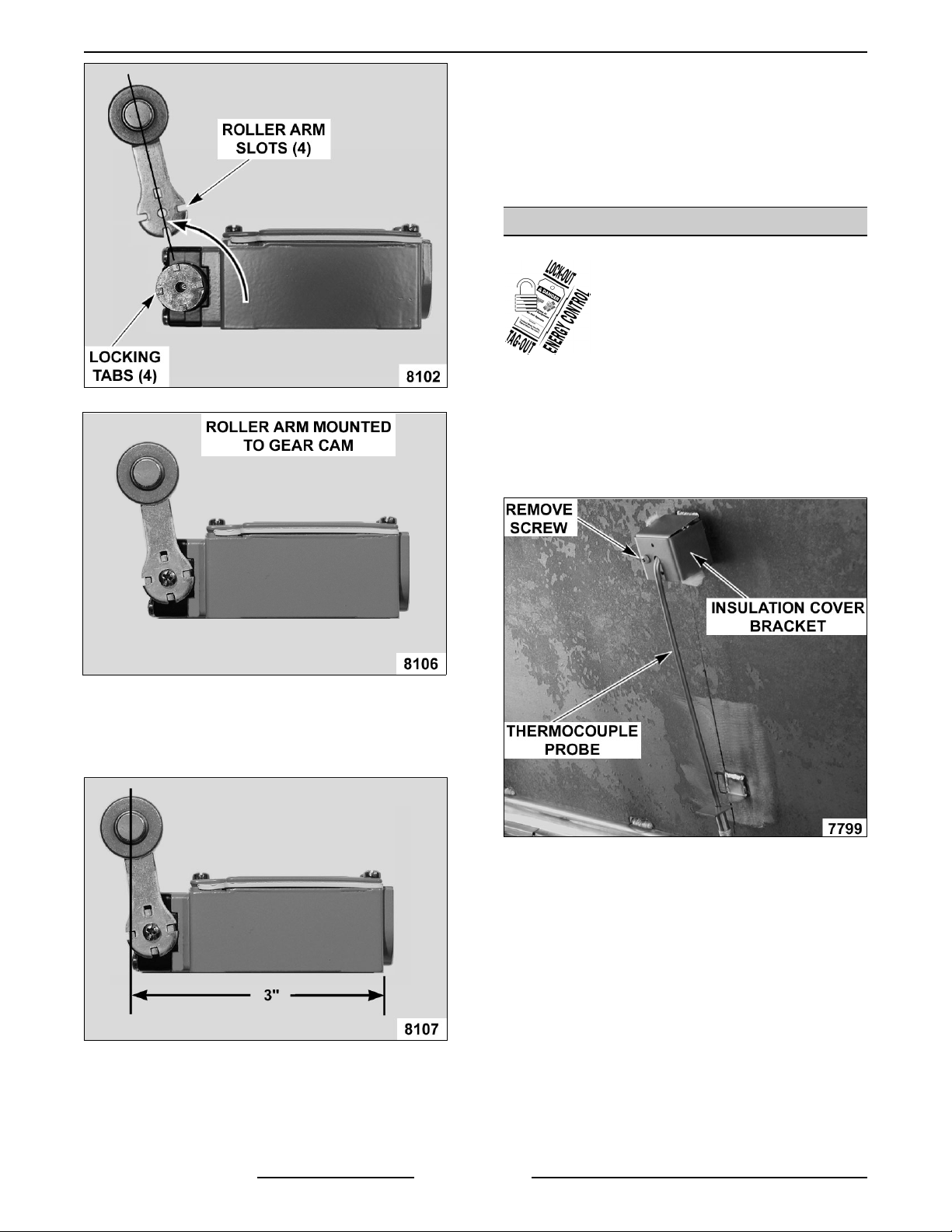

F. Align the roller arm slots with the four

locking tabs on the roller arm adaptor and

tighten mounting screw to secure.

F25121 (February 2003)

Page 8

GAS BRAISING PANS - REMOVAL AND REPLACEMENT OF PARTS

7. Reverse procedure from step 5 to complete the

installation.

8. Adjust pan position/down limit switch on switch

mounting bracket as outlined under PAN

POSITION SWITCH ADJUSTMENT in

SERVICE PROCEDURES AND

ADJUSTMENTS.

THERMOCOUPLE PROBE

WARNING: DISCONNECT THE

ELECTRICAL POWER TO THE

MACHINE AND FOLLOW LOCKOUT /

TAGOUT PROCEDURES.

1. Access temperature controller as outlined under

TEMPERATURE CONTROLLER .

2. Disconnect thermocouple lead wires.

3. Raise the pan to the full tilt position.

4. Remove insulation cover bracket.

G. Verify roller arm position on switch.

1) Measure the distance from the rear of

the switch body to the center of the

roller. The distance should be 3".

H. If distance is ok, proceed to step 7.

I. If distance is not ok, adjust the roller arm

position (as necessary) to obtain the 3"

roller arm dimension.

5. Loosen lock nut and remove threaded probe

from pan.

F25121 (February 2003) Page 8 of 32

Page 9

GAS BRAISING PANS - REMOVAL AND REPLACEMENT OF PARTS

6. Reverse procedure to install and check for

proper operation.

NOTE: When installing: Route thermocouple wire in

the same manner thru the metal clamps on the hinge

& frame. Tighten thermocouple just until it touches

the pan; do not over tighten or damage to the

thermocouple may occur.

NOTE: Lead wires can be identified by label or

marking on the wire.

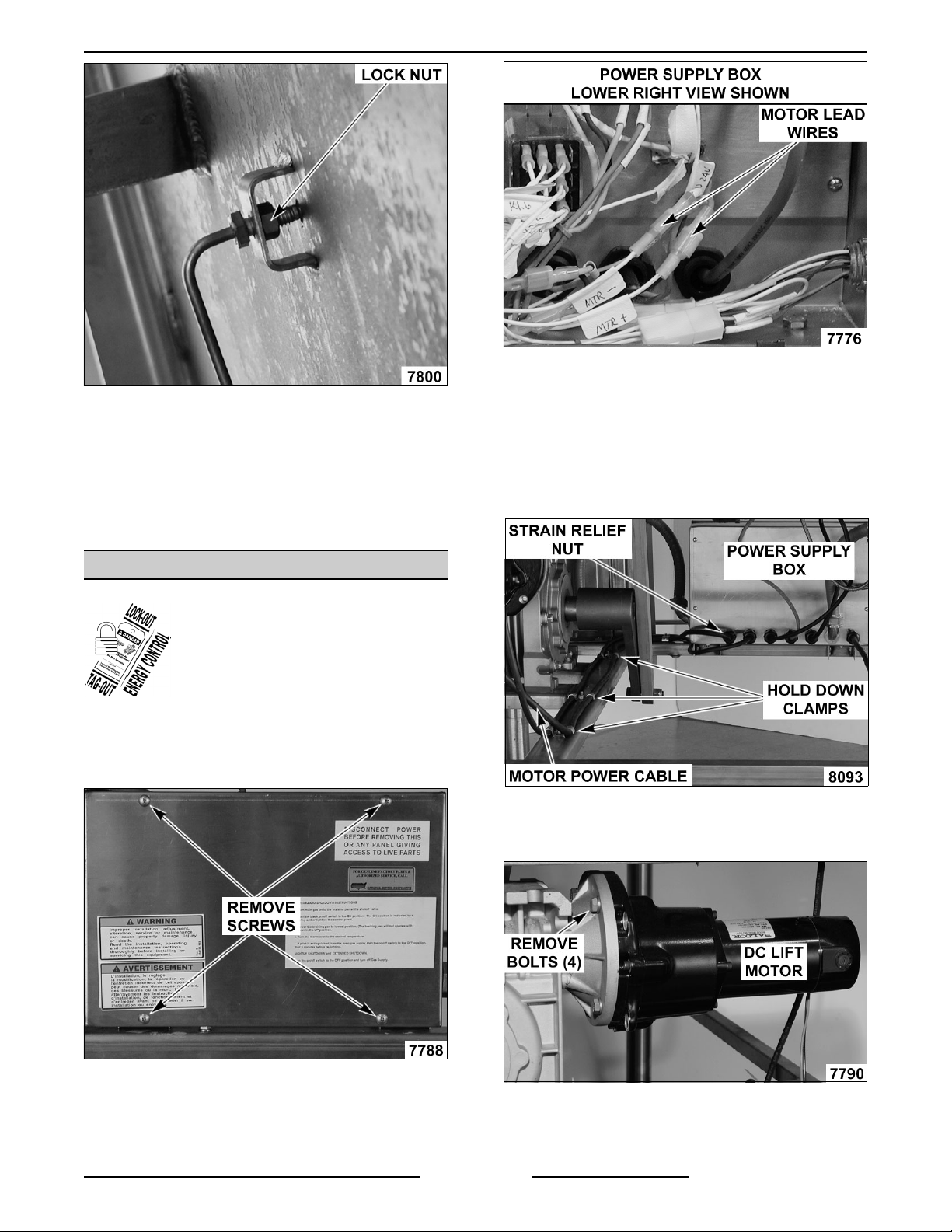

4. Loosen the strain relief nut and the hold down

clamps for the motors' power cable. Pull the

cable thru the strain relief opening and remove

the cable form underneath the clamps.

VG30 REAR VIEW SHOWN

DC LIFT MOTOR

WARNING: DISCONNECT THE

ELECTRICAL POWER TO THE

MACHINE AND FOLLOW LOCKOUT /

TAGOUT PROCEDURES.

1. Remove front, rear and right side panels as

outlined under COVERS AND PANELS.

2. Remove power supply box cover.

5. Remove motor mounting bolts from gear

reducer flange.

6. Remove motor from gear reducer.

3. Disconnect DC lift motor lead wires labeled

MTR+ (positive) & MTR - (negative).

Page 9 of 32

F25121 (February 2003)

Page 10

GAS BRAISING PANS - REMOVAL AND REPLACEMENT OF PARTS

7. To install:

A. With drive key on shaft, install motor to

gear reducer.

B. Route and secure the motors' power cable

and re-connect motor lead wires.

C. Replace power supply box cover and side

panels.

8. Check for proper operation.

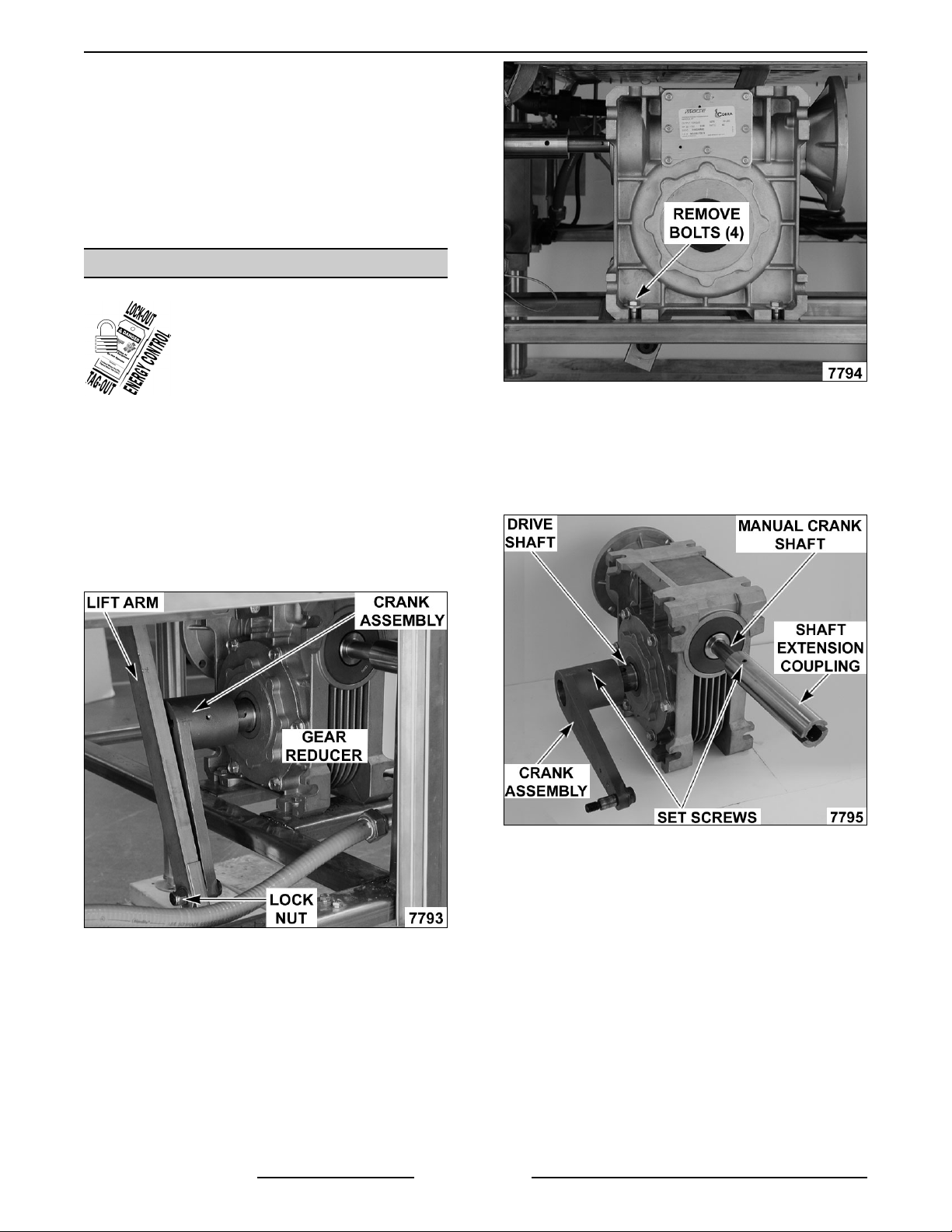

GEAR REDUCER

WARNING: DISCONNECT THE

ELECTRICAL POWER TO THE

MACHINE AND FOLLOW LOCKOUT /

TAGOUT PROCEDURES.

1. Remove right side and rear panels as outlined

under COVERS AND PANELS.

2. Lower the pan (use motorized pan lift or manual

crank).

3. If DC lift motor is installed, remove motor as

outlined under DC LIFT MOTOR.

4. Remove lock nut securing crank assembly to lift

arm.

6. Loosen set screw on crank assembly and

remove the assembly from drive shaft.

7. Loosen set screw on shaft extension coupling

and remove the coupling from manual crank

shaft.

8. To install:

5. Remove bolts securing gear reducer to braising

pan frame then remove gear reducer.

F25121 (February 2003) Page 10 of 32

A. With drive key on drive shaft, install crank

assembly and tighten set screw against

key.

B. With drive key on manual crank shaft,

install shaft extension coupling and tighten

set screw against key.

C. Place gear reducer in its mounting location

on frame. Position gear reducer so the

shaft extension coupling is aligned with the

opening in control panel; and the lift arm is

vertical and parallel to the crank assembly

when connected.

Page 11

GAS BRAISING PANS - REMOVAL AND REPLACEMENT OF PARTS

NOTE: On the bottom lift arm bushing, the bushing

head must

crank assembly to create approximately 1/32"

spacing.

9. Reverse procedure from step 5 to complete the

10. Check for proper operation.

be positioned between the lift arm and the

installation.

GAS COMBINATION VALVE

5. Disconnect lead wires from gas combination

valve.

6. Disconnect pilot tube from gas combination

valve.

WARNING: DISCONNECT THE

ELECTRICAL POWER TO THE

MACHINE AND FOLLOW LOCKOUT /

TAGOUT PROCEDURES.

WARNING: SHUT OFF THE GAS SUPPLY

BEFORE SERVICING THE UNIT.

WARNING: ALL GAS JOINTS DISTURBED

DURING SERVICING MUST BE CHECKED FOR

LEAKS. CHECK WITH A SOAP AND WATER

SOLUTION (BUBBLES). DO NOT USE AN OPEN

FLAME.

1. Remove front, rear and left side panels as

outlined under COVERS AND PANELS.

2. Remove screw from the top cover of gas

combination valve box.

3. Remove silicone sealant around the gas pipe

and the slot in top cover then remove the

cover.

NOTE: When installing, clean the areas and apply

silicone sealant.

4. Remove U-bolt securing gas valve box to gas

pipe then remove box.

7. Separate gas pipe union (near manifold),

remove U-bolt securing gas pipe to braising

pan frame (at rear of pan) then remove the gas

combination valve and piping assembly.

8. Remove pipe from gas combination valve.

9. Reverse procedure to install.

NOTE: When installing, clean gas pipe threads and

apply pipe joint compound to threads. Any pipe joint

compound used must

propane gases.

be resistant to the action of

Page 11 of 32

F25121 (February 2003)

Page 12

GAS BRAISING PANS - REMOVAL AND REPLACEMENT OF PARTS

10. Check for proper operation.

PILOT BURNER

WARNING: DISCONNECT THE

ELECTRICAL POWER TO THE

MACHINE AND FOLLOW LOCKOUT /

TAGOUT PROCEDURES.

WARNING: SHUT OFF THE GAS SUPPLY

BEFORE SERVICING THE UNIT.

WARNING: ALL GAS JOINTS DISTURBED

DURING SERVICING MUST BE CHECKED FOR

LEAKS. CHECK WITH A SOAP AND WATER

SOLUTION (BUBBLES). DO NOT USE AN OPEN

FLAME.

1. Raise the pan to the full tilt position.

2. Remove pilot burner mounting bracket from the

burner box pan.

3. Disconnect ignitor cable from ignitor/flame

sense electrode on the pilot burner.

4. Remove pilot burner from pilot mounting

bracket.

5. Disconnect pilot tube from pilot burner.

7. Reverse procedure to install and check for

proper operation.

RUNNER TUBE

WARNING: DISCONNECT THE

ELECTRICAL POWER TO THE

MACHINE AND FOLLOW LOCKOUT /

TAGOUT PROCEDURES.

6. To remove gas orifice from pilot burner for

inspection or cleaning, disconnect the pilot tube

compression fitting from pilot burner body.

A. The gas orifice is inserted into pilot burner

body and should drop out when

compression fitting is removed. If

necessary, lightly tap on pilot burner body

to free the gas orifice.

CAUTION: If orifice is clogged with debris, clean

with air or non-flammable liquid only.

WARNING: SHUT OFF THE GAS SUPPLY

BEFORE SERVICING THE UNIT.

WARNING: ALL GAS JOINTS DISTURBED

DURING SERVICING MUST BE CHECKED FOR

LEAKS. CHECK WITH A SOAP AND WATER

SOLUTION (BUBBLES). DO NOT USE AN OPEN

FLAME.

1. Raise the pan to the full tilt position.

2. Loosen screw on each runner tube clamp and

rotate the clamp away from runner tube.

3. Lift runner tube from mounting bracket and off

F25121 (February 2003) Page 12 of 32

of the gas orifice.

Page 13

GAS BRAISING PANS - REMOVAL AND REPLACEMENT OF PARTS

NOTE: Runner tube slides onto the gas orifice.

When installing, ensure runner tube is fully seated

onto gas orifice.

4. To remove gas orifice for inspection or

cleaning, disconnect the gas supply tube

compression fitting at the manifold.

5. Remove gas orifice from elbow fitting.

CAUTION: If orifice is clogged with debris, clean

with air or non-flammable liquid only.

6. Reverse procedure to install and check for

proper operation.

MAIN BURNERS

WARNING: DISCONNECT THE

ELECTRICAL POWER TO THE

MACHINE AND FOLLOW LOCKOUT /

TAGOUT PROCEDURES.

3. Lift burner at rear to clear the locating pin hole

and slide burner toward the rear of burner box

pan to clear the orifice.

4. To remove gas orifice for inspection or

cleaning, remove the gas orifice from the elbow

fitting.

CAUTION: If orifice is clogged with debris, clean

with air or non-flammable liquid only.

5. Reverse procedure to install and adjust air

shutter as outlined under MAIN BURNERS.

NOTE: When installing, ensure locating pin is in the

hole for proper

attached.

positioning and hold down wire is re-

LID SPRINGS

WARNING: DISCONNECT THE

ELECTRICAL POWER TO THE

MACHINE AND FOLLOW LOCKOUT /

TAGOUT PROCEDURES.

1. Lower the lid to the full down position.

NOTE: For spring tension to be set correctly, both

the left and right side springs must be replaced.

2. Remove spring covers by prying up at the

bottom. The covers are held in place by tabs on

the bottom of cover.

RIGHT SIDE REAR VIEW SHOWN

WARNING: SHUT OFF THE GAS SUPPLY

BEFORE SERVICING THE UNIT.

WARNING: ALL GAS JOINTS DISTURBED

DURING SERVICING MUST BE CHECKED FOR

LEAKS. CHECK WITH A SOAP AND WATER

SOLUTION (BUBBLES). DO NOT USE AN OPEN

FLAME.

1. Raise the pan to the full tilt position.

2. Remove the hold down wire from main burner.

Page 13 of 32

3. Place a 1 5/8" wrench on the lid spring lock nut

and apply a downward force until locking pin

can be removed. Continue to hold lock nut in

place.

Caution: Do not release wrench while locking pin

is removed or damage to the braising pan may

occur.

F25121 (February 2003)

Page 14

GAS BRAISING PANS - REMOVAL AND REPLACEMENT OF PARTS

A. Slowly release downwards force to remove

spring tension.

B. Rotate lid spring lock nut to the next hole

position then replace locking pin. Continue

until all spring tension is removed, one

position at a time.

C. Remove bolts securing the inside lid

bearing housing to the lid support bracket.

4. To install:

A. Slide the spring onto the lid spring

mandrel. Insert spring into locator hole on

the lid spring retainer.

B. Slide the lid spring lock nut onto the lid

spring mandrel. Insert spring into locator

hole on the lid spring lock nut.

C. Replace

lid bearing housing.

5. Replace spring on the opposite side.

6. Adjust spring tension as outlined under LID

SPRING TENSION ADJUSTMENT IN

SERVICE PROCEDURES AND

ADJUSTMENTS.

D. Remove lid bearing housing

, lid spring lock

nut and the spring, from spring mandrel.

F25121 (February 2003) Page 14 of 32

Page 15

GAS BRAISING PANS - SERVICE PROCEDURES AND ADJUSTMENTS

SERVICE PROCEDURES AND ADJUSTMENTS

WARNING: CERTAIN PROCEDURES IN THIS SECTION REQUIRE ELECTRICAL TEST OR MEASUREMENTS

WHILE POWER IS APPLIED TO THE MACHINE. EXERCISE EXTREME CAUTION AT ALL TIMES. IF TEST

POINTS ARE NOT EASILY ACCESSIBLE, DISCONNECT POW ER AND FOLLOW LOCKOUT / TAGOUT

PROCEDURES, ATTACH TEST EQUIPMENT AND REAPPLY POWER TO TEST.

TEMPERATURE CONTROLLER

CALIBRATION

than

than

NOTE: Verify condition of thermocouple as outlined

under THERMOCOUPLE TEST before proceeding.

1. At the geometric center on the pan cooking

surface, clean an area approximately 3" inches

in diameter.

2. Apply a thin layer of fresh cooking oil to the

cleaned area and place a temperature sensing

disk on the pan cooking surface.

3. Turn on/off switch on and set temperature dial

to 250°F.

4. Monitor the heat light (red) on the control panel.

When temperature controller is calling for heat,

light will be on. If temperature controller is

satisfied, light will be off.

A. Allow the temperature controller to cycle

three times to stabilize the pan

temperature.

B. Record the temperature when the

temperature controller cycles off and on for

the next three cycles.

5. Calculate the differential by subtracting the

temperature indicated when heat light goes out

from temperature indicated when heat light

comes on.

A. If the average temperature is less

10°F of the dial setting, temperature

controller is properly calibrated.

B. If the average temperature is more

10°F of the dial setting, temperature

controller calibration must

7. Using the temperature scale on the overlay as a

guide, align the edge on a short piece of tape to

the temperature calculated in step 6 and apply

tape to knob as a reference point.

8. Remove temperature dial from shaft.

9. Loosen screws on the back of dial.

A. Hold the knob and rotate dial to the edge of

the tape used for reference. This

adjustment offsets the indicated

temperature on the dial to the actual

temperature measured.

NOTE: With knob facing user, a clockwise

rotation increases temperature and a counterclockwise rotation decrease temperature.

B. Hold the dial & knob together to maintain

the adjusted setting and tighten screws.

be adjusted.

A. The differential calculated should be less

than 20°F.

1) If the differential is less

temperature controller is functioning

properly.

a. Proceed to average temperature.

2) If the differential is more

the temperature controller is

malfunctioning.

a. Install a replacement

temperature controller and check

calibration.

6. Calculate the average temperature by adding

the temperature indicated when the heat lamp

goes out to the temperature indicated when the

heat lamp comes on & divide this answer by 2.

than 20°F,

than 20°F,

10. Replace temperature dial on shaft.

11. Turn the temperature dial to the lowest setting

Page 15 of 32

then back to 250°F.

F25121 (February 2003)

Page 16

GAS BRAISING PANS - SERVICE PROCEDURES AND ADJUSTMENTS

12. Repeat the average temperature calculation for

up to three attempts. Allow the pan to cycle at

least two times between adjustments before

performing the calculation.

13. If calibration is unsuccessful, the controller may

be malfunctioning and cannot be adjusted

properly. Install a replacement temperature

controller and check calibration.

TEMPERATURE CONTROLLER

TEST

NOTE: The controller is powered whenever supply

power is connected to the machine.

7. Disconnect lead wire labeled "HT.0" from the

COM terminal on the controller.

8. Verify 24VAC between the disconnected "HT.0"

lead wire and ground.

A. If correct, re-connect lead wire to COM

terminal and proceed to step 9.

B. If incorrect, check transformer and the

on/off switch for proper operation.

9. Disconnect lead wire labeled "HT.1" from the

N.O. terminal on the controller.

10. Verify 24VAC between N.O. terminal on the

temperature controller and ground.

A. If correct, internal relay "HEAT" contacts

are functioning properly. Reconnect lead

wire to the N.O. terminal.

B. If incorrect, install a replacement

temperature controller and check for

proper operation.

THERMOCOUPLE TEST

1. Access the temperature controller as outlined

in REMOVAL AND REPLACEMENT OF

PARTS.

1. Lower the pan to the full down position.

2. Access the temperature controller as outlined in

REMOVAL AND REPLACEMENT OF PARTS.

3. Re-connect power to the machine.

4. Verify temperature controller is receiving

120VAC at terminals L1 & L2, polarity is correct

and machine is properly grounded.

5. Turn on/off switch on and set temperature dial

to 250/F.

6. Verify heat light (red) comes on and main

burners light.

A. If heat light and main burners come on but

turn off within 10 seconds, verify condition

of thermocouple as outlined under

THERMOCOUPLE TEST.

NOTE: Temperature controller will de-energize

internal relay if the circuitry detects an open

thermocouple.

B. If heat light and main burners do not

on, verify internal relay "HEAT" contacts

are operating properly.

come

2. Remove thermocouple lead wires from

temperature controller.

3. Check the thermocouple for resistance.

A. If meter reads an overload (OL) condition

(open), or zero ohms (short) replace the

thermocouple and check temperature

controller for proper operation.

4. If resistance is measured, thermocouple is

good.

F25121 (February 2003) Page 16 of 32

Page 17

GAS BRAISING PANS - SERVICE PROCEDURES AND ADJUSTMENTS

SPARK IGNITION TEST

If the ignition control module is not generating a

spark or the spark is not sufficient to light pilot

burner, perform the following test.

1. Lower the pan to the full down position, turn the

on/off switch on and set the temperature dial to

call for heat.

B. Inspect the ignitor electrode and ground

clip for contaminates, or corrosion. Clean

those surfaces as necessary.

C. The spark gap between the ignitor/flame

sense electrode and the ground clip should

be 0.120" ± 0.020". If the gap is outside of

this dimension, bend the ground clip as

necessary, to make the adjustment.

2. Verify the ignition control module is receiving

24VAC between terminals 5 & 6.

A. If voltage is present, turn the on/off switch

off and proceed to step 3.

B. If voltage is not present, see schematic

diagram.

3. Disconnect power to the machine.

WARNING: SHUT OFF THE GAS SUPPLY

BEFORE SERVICING THE UNIT.

WARNING: ALL GAS JOINTS DISTURBED

DURING SERVICING MUST BE CHECKED FOR

LEAKS. CHECK WITH A SOAP AND WATER

SOLUTION (BUBBLES). DO NOT USE AN OPEN

FLAME.

4. Verify all electrical connections (including

ground) on the ignition control module are

secure.

5. Access the pilot burner as outlined in

REMOVAL AND REPLACEMENT OF PARTS.

6. Verify the ground connection on pilot burner

mounting bracket is clean and secure. The pilot

burner should have good metal to metal contact

to the pilot mounting bracket.

D. Check the ignitor cable connection for

tightness and damaged insulation. If the

ignitor cable appears to be damaged, then

install a replacement ignitor cable.

8. Install pilot burner and connect ignitor cable.

9. Disconnect main valve (MV) lead wire from

terminal 1 on the ignition control module.

7. Remove pilot burner and check the following:

A. Inspect the ceramic insulator on the

ignitor/flame sense electrode for cracks or

evidence of exposure to extreme heat,

which can permit leakage to ground. If

either of these conditions exist, then install

a replacement pilot burner.

NOTE: Removal of lead wire prevents main burners

from lighting with the pan raised and the pan

position/down limit switch manually operated.

10. Reconnect power to the machine and turn the

Page 17 of 32

gas supply on.

F25121 (February 2003)

Page 18

GAS BRAISING PANS - SERVICE PROCEDURES AND ADJUSTMENTS

11. Turn on/off switch on and set the temperature

dial to call for heat.

12. Manually operate pan position/down limit switch

and observe spark from ignitor.

A. If spark from ignitor is present and lights

the gas for pilot burner, and pilot burner

remains lit, then the system is working

properly.

B. If pilot burner lights but does not maintain

an adequate flame during the trial for

ignition (90 seconds):

D. If ignitor is still not sparking, turn the on/off

switch off, disconnect power to the

machine and turn the gas supply off.

13. Install a replacement ignition control module

and check for proper operation.

PILOT BURNER FLAME

ADJUSTMENT

1. Turn the on/off switch off.

2. Raise the pan to the full tilt position.

3. Remove left side panel as outlined under

COVERS AND PANELS.

4. Access the ignition control module as outlined

under POWER SUPPLY BOX COMPONENTS

IN REMOVAL AND REPLACEMENT OF

PARTS.

5. Disconnect main valve (MV) lead wire from

terminal 1 on the ignition control module.

NOTE: Removal of lead wire prevents main burners

from lighting with the pan raised and the pan

position/down limit switch manually operated.

6. Reconnect power to the machine.

7. Turn on/off switch on and set the temperature

dial to call for heat.

8. Manually operate pan position/down limit switch

and observe pilot burner flame.

1) Check pilot burner orifice for clogging.

CAUTION: If orifice is clogged with debris, clean

with air or non-flammable liquid only.

2) Check pilot burner flame adjustment

as outlined under SERVICE

PROCEDURES AND

ADJUSTMENTS.

C. If spark from ignitor is present but does not

light the pilot gas before ignition control

module locks out, there may not be

enough gas in the supply line for ignition.

Release the pan position/down limit switch

to remove power and re-set the module.

Wait 5 minutes between ignition tries for

unburned gas to vent.

Manually operate pan position/down limit

switch and sparking should resume. The

module may need to be re-set several

times before ignition takes place.

1) If pilot burner ignition is successful,

release the pan position/down limit

switch, turn the on/off switch to off

and re-connect main valve (MV) lead

wire on the ignition control module.

A. If flame envelops 3/8" to 1/2" of the

ignitor/flame sense electrode, pilot burner

is adjusted properly.

B. If flame is outside of the specified range,

release the pan position/down limit switch

and

continue with procedure.

9. Remove adjustment screw cap to access the

pilot burner flame adjustment screw.

F25121 (February 2003) Page 18 of 32

Page 19

GAS BRAISING PANS - SERVICE PROCEDURES AND ADJUSTMENTS

4. Set VOM to micro amp scale (DC) and connect

the black meter lead (-) to the asterisk (*)

terminal and red meter lead (+) to terminal 8.

10. Manually operate pan position/down limit switch

and observe pilot burner flame.

A. To increase pilot flame, turn the screw

counterclockwise. To decrease pilot flame,

turn the screw clockwise

11. Once the pilot flame

correctly, release the pan position

switch, turn the on/off switch off and replace the

adjustment screw cap.

12. Re-connect main valve (MV) lead wire from

terminal 1 on the ignition control module.

13. Lower the pan to the full down position and

check for proper operation.

has been adjusted

.

/down limit

FLAME SENSE CURRENT TEST

NOTE: You must complete the SPARK IGNITION

TEST prior to checking flame sense current.

If pilot burner lights but will not maintain flame,

perform the following test.

1. Turn the on/off switch off.

2. Access the ignition control module as outlined

under POWER SUPPLY BOX COMPONENTS

IN REMOVAL AND REPLACEMENT OF

PARTS.

5. Turn on/off switch on and set the temperature

dial to call for heat.

6. With pilot burner lit, meter reading should be

above 1.0 micro amp (minimum) and steady.

A. If reading is greater than or equal to 1.0

micro amp then flame sense current is

within tolerance.

1) Turn on/off switch off and replace

jumper wire.

B. If reading is less than 1.0 micro amp and

the condition of the ignitor/flame sense has

been verified as good, turn on/off switch

off.

7. Install a replacement ignition control module

and check for proper operation.

IGNITION CONTROL MODULE

TEST

3. Remove jumper wire between terminals marked

with an asterisk (*) & 8.

Page 19 of 32

1. Lower the pan to the full down position, turn the

on/off switch on and set the temperature dial to

call for heat.

F25121 (February 2003)

Page 20

GAS BRAISING PANS - SERVICE PROCEDURES AND ADJUSTMENTS

2. Ignition control module is energized and trial

for ignition starts (90 seconds).

A. Verify 24VAC between terminals 5 & 6.

1) If voltage is not present, see

schematic diagram.

3. Pilot valve (PV) contacts close to energize the

pilot valve coil, allowing gas flow to the pilot

burner.

A. Verify 24VAC between terminals 2 & 3.

1) If voltage is not present, replace

ignition control module and check for

proper operation.

4. At the same time, spark voltage is sent from

terminal 9 to the ignitor/flame sense electrode

and sparking begins.

The pilot burner lights, pilot flame is sensed,

spark voltage from terminal 9 is removed and

sparking stops. Main valve (MV) contacts close

to energize main valve coil, allowing gas flow

to the runner tube and main burners.

A. Verify 24VAC between terminals 1 and 2.

1) If voltage is not present, replace

ignition control module and check for

proper operation.

5. With pilot burner lit, the runner tube lights and

main burners light.

GAS MANIFOLD PRESSURE

ADJUSTMENT

WARNING: SHUT OFF THE GAS SUPPLY

BEFORE SERVICING THE UNIT.

GAS PRESSURE (INCHES W.C.)

Gas

Type

Natural 3.7 7.0 5.0

Propane 10.0 11.0 11.0

NOTE: If the incoming line pressure is less

the minimum stated, then the manifold pressure

cannot be set correctly.

1. Lower the pan to the full down position.

2. Remove front panel as outlined under COVERS

3. Access the gas combination valve as outlined in

4. Remove 1/8" NPT pipe plug on the outlet side

5. Install a hose barb adaptor at the port and

Manifold

Recommended Min Max

AND PANELS in REMOVAL AND

REPLACEMENT OF PARTS.

REMOVAL AND REPLACEMENT OF PARTS.

of the gas valve (manifold pressure tap).

attach a manometer.

Line

14.0

than

6. As long as the temperature controller is calling

for heat and the ignition control module is

sensing a sufficient flame sense current, the

pilot valve (PV) and main valve (MV) contacts

will remain closed.

NOTE: If pilot burner does not immediately light, the

ignition control module continues sparking for 90

seconds, then locks out power to the gas

combination valve (pilot valve and main valve

remain closed). The module remains locked out

until the on/off switch is cycled to reset the system

re-start the ignition trial cycle.

6. Turn gas supply, gas combination valve and

on/off switch to on.

A. Set the temperature dial to call for heat.

B. Verify main burners light.

7. Observe manometer pressure reading and

compare to the gas pressure table.

A. If other appliances are connected to the

same gas line, turn them all on and check

manometer pressure reading again. If a

pressure drop of 1/2" W.C. or more is

observed, then the gas supply needs to be

checked by the gas line installer or the

local gas company for adequate sizing.

B. If adjustment is necessary, continue with

procedure.

8. Remove adjustment screw cap to access the

pressure adjustment screw.

A. To increase pressure, turn the screw

clockwise

screw counterclockwise

. To decrease pressure, turn the

.

F25121 (February 2003) Page 20 of 32

Page 21

GAS BRAISING PANS - SERVICE PROCEDURES AND ADJUSTMENTS

NOTE: Accurate gas pressure adjustments can only

be made with the gas on and the main burners lit.

9. Set pressure as listed in gas pressure table.

10. Once the correct pressure has been set, turn

the on/off switch off, replace the adjustment

screw cap and pipe plug.

11. Check for proper operation.

MAIN BURNERS

CAUTION: To prevent discoloration of the

cooking surface, and possible pan warpage at

temperature settings above 250°F, do not

operate the braising pan unless the cooking

surface is covered with water or a thin layer of

cooking oil.

5. Allow burners to remain lit for at least five

minutes.

6. Observe each burners< flame thru the opening

in the front of the burner box.

A. If the flame is blue, air shutter is adjusted

properly. A slight tinge of orange in the

flame is acceptable.

B. If the flame is yellow tipping, this indicates

too little primary air (oxygen) for proper

combustion. The heating efficiency is

reduced, and the amount of soot (carbon)

generated as a by-product is increased.

Continue with procedure to adjust.

7. Loosen screw on the air shutter for the burner

being adjusted. Closing the air shutter will

decrease

the shutter will increase

primary air to the burner and opening

primary air the burner.

FRONT VIEW OF BURNER AIR SHUTTER

SHOWN

Inspection

1. Access the main burners as outlined in

REMOVAL AND REPLACEMENT OF PARTS.

2. Inspect burners for clogged ports or

obstructions around air shutter. Clean the

burner (as necessary) using a soft bristle

brush.

3. Inspect gas orifice for clogging. If clogs are

found, remove the orifice and clean with air or

non-flammable liquid only.

NOTE: If the orifice was removed, be sure to install

the orifice in the same location. The outside burners

use a slightly larger orifice than the center burner(s).

Air Shutter Adjustment

1. Verify the gas manifold pressure as outlined

under GAS MANIFOLD PRESSURE

ADJUSTMENT.

2. Turn the on/off switch off.

3. Remove the control panel as outlined in

REMOVAL AND REPLACEMENT OF PARTS

to gain viewing access to the right side burner.

8. Monitor the burner flame and set the air shutter

opening as follows:

A. Adjust the air shutter (as necessary) to

obtain a blue flame. A slight tinge of

orange in the flame is acceptable.

B. After the air shutter adjustment is made,

tighten the set screw.

9. Adjust the remaining burners as necessary.

4. Turn the on/off switch on and set the

temperature dial to call for heat.

Page 21 of 32

F25121 (February 2003)

Page 22

GAS BRAISING PANS - SERVICE PROCEDURES AND ADJUSTMENTS

DC MOTOR CONTROLLER TEST

A. If voltage is present but pan does not raise,

refer to MOTORIZED LIFT OPTION ONLY

under TROUBLESHOOTING.

B. If voltage is not present and the fuse is ok,

turn the on/off switch off and disconnect

power to the machine.

11. Instal a replacement DC motor controller and

check for proper operation.

PAN POSITION/DOWN LIMIT

SWITCH ADJUSTMENT

NOTE: Do not use the motorized lift (if installed) for

this procedure.

1. Turn the on/off switch off.

2. Remove front and left side panels as outlined

under COVERS AND PANELS.

3. Insert the manual crank handle.

4. Raise the pan to the full tilt position.

5. Verify roller arm position on switch.

A. Measure the distance from the rear of the

switch body to the center of the roller. The

distance should be 3".

1. Lower the pan to the full down position.

2. Raise the lid to the full open position.

3. Access the DC motor controller as outlined

under POWER SUPPLY BOX COMPONENTS

in REMOVAL AND REPLACEMENT OF

PARTS.

4. Set VOM to measure AC volts and connect

meter leads at L1 & L2 on the controller.

5. Turn the on/off switch to on.

6. Verify 120VAC at L1 & L2 on the controller

when the lift control switch (momentary) is

operated to raise & lower the pan.

A. If voltage is present but pan does not raise

& lower, proceed to step 7.

B. If voltage is not present refer to

MOTORIZED LIFT OPTION ONLY under

TROUBLESHOOTING.

7. Disconnect power to the machine.

8. Set VOM to measure DC volts and connect

VOM leads to terminals A + (positive) & A (negative) on the controller.

SIDE VIEW SHOWN

B. If distance is ok, proceed to step 6.

C. If distance is not ok, position the roller arm

as outlined under PAN POSITION/DOWN

LIMIT SWITCH in REMOVAL AND

REPLACEMENT OF PARTS.

6. Lower the pan to the full down position. The

roller should make contact with the hinge and

operate the switch.

9. Re-connect power to the machine.

10. Verify 90VDC (approximate) from the DC motor

controller when the lift control switch

(momentary) is operated to raise & lower the

pan.

F25121 (February 2003) Page 22 of 32

7. Verify pan position/down limit switch N.O.

contacts are closing.

A. Turn the on/off switch on and set the

temperature dial to call for heat.

B. Heat light (red) comes on and main

burners light.

Page 23

GAS BRAISING PANS - SERVICE PROCEDURES AND ADJUSTMENTS

1) If main burners do not light, verify

24VAC input to the switch, and that

the voltage is output from the switch.

2) If voltage is present on the output

side of the switch, the switch is

functioning properly.

3) If voltage is not present, install a

replacement pan position/down limit

switch and repeat this procedure to

adjust.

8. Verify pan position/down limit switch N.O.

contacts are opening.

A. Slowly raise the pan until the heat light

and burners go out then stop.

B. At the rear of the pan, measure the

distance from the bottom of the pan skirt

to the flat surface covering the frame.

1) Distance should be 2.25" to 2.50".

LEFT SIDE VIEW SHOWN

LEFT SIDE VIEW SHOWN

B. Adjust mounting switch bracket up or

down (as necessary) to obtain the rear

pan dimension of 2.25" to 2.50".

11. Repeat steps 5 thru 9 to check for proper

operation.

LID SPRING TENSION

ADJUSTMENT

NOTE: For reference, this is approximately 5

angular degrees.

9. If heat light and main burners go out and the

measured distance is within the acceptable

range, switch is adjusted properly. If both

conditions are not satisfied, adjustment is

necessary.

10. To Adjust:

A. Loosen screws on the mounting switch

bracket.

1. Raise the lid and release at several positions

thru the range of travel.

A. If lid remains in place, no adjustment is

necessary.

B. If lid does not remain in place (springs up

or falls down), continue with procedure.

NOTE: For spring tension to be set correctly, each

spring must be adjusted the same amount.

2. Remove spring covers by prying up at the

bottom. The covers are held in place by tabs on

the bottom of cover.

RIGHT SIDE REAR VIEW SHOWN

Page 23 of 32

F25121 (February 2003)

Page 24

GAS BRAISING PANS - SERVICE PROCEDURES AND ADJUSTMENTS

3. To adjust:

A. Place a 1 5/8" wrench on the lid spring lock

nut and apply a downward force until

locking pin can be removed. Continue to

hold lock nut in place.

CAUTION: Do not release wrench while locking

pin is removed or damage to the braising pan

may occur.

B. Apply additional downward force to

increase

downwards force to decrease

tension.

C. Rotate lid spring lock nut to the next hole

position then replace locking pin. Adjust

the spring tension, one position at a time.

D. Repeat tension adjustment on the opposite

spring.

4. Repeat step 1 to verify adjustment. Make

additional adjustments as necessary.

spring tension; or slowly release

spring

F25121 (February 2003) Page 24 of 32

Page 25

GAS BRAISING PANS - ELECTRICAL OPERATION

ELECTRICAL OPERATION

COMPONENT FUNCTION

BRAISING PAN CONTROLS

Temperature Controller .... Monitors thermocouple input (type E) and regulates braising pan temperature. An

external set point potentiometer is used for temperature adjustments.

Transformer ............. Supplies 24VAC for heating circuit. If motorized pan lift option is installed,

supplies 24VAC for lift control circuit.

ON/OFF Switch .......... Controls 24VAC to the gas heating circuit. If motorized pan lift option is installed,

controls power to lift circuit.

Power On Light (Amber) . . . Indicates on/off switch is turned on.

Heat Light (Red) .......... Indicates temperature controller is calling for heat and pan is down.

Pan Position/

Down Limit Switch ........ N.O. contacts function as pan position switch to power the gas heating circuit

when pan is down. Removes power from gas heating circuit when pan is raised.

The N.C. contacts are used for the down limit switch (motorized lift option only).

Ignition Control Module . . . Controls and monitors gas heating. Energizes pilot valve coil to supply gas to

pilot, generates spark to light gas at the pilot, monitors the presence of flame and

energizes the main valve coil upon a call for heat.

Ignitor/Flame Sense

Electrode ................ Ignites pilot burner and senses the presence of a flame. The Igniter/Flame Sense

is a component of the pilot burner.

Gas Combination

Valve ................... Allows gas flow to the pilot burner when pilot valve coil is energized; and gas flow

to the runner tube & main burners when main valve coil is energized. Also,

regulates gas manifold pressure.

MOTORIZED PAN LIFT OPTION CONTROLS

DC Motor Controller ....... Controls DC lift motor operation for raising & lowering of the pan, and provides

motor acceleration control each time the controller is powered. The controller

outputs approximately 90VDC to power the motor.

DC Lift Motor ............. Operates gear reducer to raise or lower the pan. When the correct voltage

polarity is applied thru K1 contacts, motor rotates CW to raise pan. W hen reverse

voltage polarity is applied thru K2 contacts, motor rotates CCW to lower the pan.

Lid Switch ............... Supplies 24VAC power to lift control switch. Used to ensure lid is open before pan

can be raised.

Lift Control Switch

(Momentary On/Off/On) .... Energizes K1 relay coil thru up limit switch contacts (N.C.) to raise the pan.

Energizes K2 relay coil thru down limit switch contacts (N.C.) to lower the pan.

The switch positions are: Center neutral (starting) position off; Momentary on lower pan; Momentary on - raise pan.

Up Limit Switch .......... Removes power from K1 relay coil when pan reaches full tilt (pan travel stops).

Pan Position/

Down Limit Switch ........ N.C. contacts function as down limit switch to remove power from K2 relay coil

when pan is lowered to the down position (pan travel stops). The N.O. contacts

are used for the pan position switch.

K1 "Up" Relay (3PDT) ..... Supplies power to motorized lift circuit to raise the pan when 24VAC coil is

energized.

K2 "Down" Relay (3PDT) . . . Supplies power to motorized lift circuit to lower the pan when 24VAC coil is

energized by the lift control switch. The voltage polarity to the DC motor is

reversed thru K2 contacts to turn motor CCW and lower the pan.

Page 25 of 32

F25121 (February 2003)

Page 26

GAS BRAISING PANS - ELECTRICAL OPERATION

COMPONENT LOCATION

F25121 (February 2003) Page 26 of 32

Page 27

GAS BRAISING PANS - ELECTRICAL OPERATION

IGNITION CONTROL MODULE

The ignition control module is energized when 24 volts is applied between terminals 5 & 6.

The module outputs 24 volts from terminals 2 & 3 to the pilot valve coil (PV) on the gas combination valve,

allowing gas flow to the pilot burner.

At the same time, the module generates a spark voltage output of approximately 13K at terminal 9 to begin

sparking at the ignitor/flame sense electrode.

The sparking will continue until an adequate pilot flame sense current is sensed by the module or for a maximum

of 90 seconds.

NOTE: If pilot is not established within the 90 second ignition trial time, the ignition module locks out by removing

power to the gas combination valve. The system remains locked out until the on/off switch is cycled to reset the

system and re-start the ignition trial cycle.

With the pilot burner lit, a flame sense current in DC micro amps is rectified thru the ignitor cable back to

terminal 9.

When the module senses a sufficient pilot flame current, the module outputs 24 volts from terminal 1 & 2 to

energize the main valve coil (MV) on the gas combination valve, allowing gas flow to the runner tube and main

burners.

When power to the ignition control module is removed, the output voltages are also removed. The pilot valve coil

(PV) and the main valve coil (MV) on the gas combination valve are de-energized and close. Gas flow to the pilot

burner, runner tube and main burners stop and all burners go out.

Page 27 of 32

F25121 (February 2003)

Page 28

GAS BRAISING PANS - ELECTRICAL OPERATION

SEQUENCE OF OPERATION

Refer to schematic diagram AI1341 for the electrical

sequence of operation. Manual pan lift is the

standard configuration.

Heating

1. Conditions.

A. 120VAC to braising pan, polarity is correct,

and is properly grounded.

1) Temperature controller energized.

2) 24VAC transformer energized.

B. Temperature dial at lowest setting

(potentiometer fully CCW).

NOTE: Temperature controller internal relay

"HEAT" contacts remain open (N.O.).

C. Pan temperature is below 200/F.

D. On/off switch off.

E. Pan position/down limit switch N.O.

contacts closed (pan down).

F. Gas supply on.

G. Gas combination control valve on.

2. Turn on/off switch on.

A. Indicator light (amber) comes on.

3. Set the temperature dial to call for heat.

A. Internal relay on temperature controller is

energized and the "HEAT" contacts close

(N.O.).

1) Heat light (red) comes on.

2) Ignition control module.

NOTE: If pan is raised 2.25" to 2.50" at the rear,

pan position/down limit switch N.O. contacts will

open and de-energize the heating circuit.

4. Refer to IGNITION CONTROL MODULE.

5. Braising pan reaches set point temperature.

A. Internal relay on temperature controller is

de-energized and the "HEAT" contacts

open (N.O.).

1) Heat light (red) goes out.

2) Power is removed from the ignition

control module.

6. Braising pan will continue to cycle with the

temperature controller until the pan is raised or

the on/off switch is turned off.

Motorized Pan Lift (Option)

Refer to the dashed line sections labeled

"MOTORIZED LIFT OPTION" on the schematic

diagram for the integration of the motorized pan lift

components into the sequence of operation.

1. Conditions.

A. 120VAC to braising pan, polarity is correct,

and is properly grounded.

B. 24VAC transformer energized.

C. On/off switch off.

D. Lift control switch off (center position).

E. Lid switch N.O. contacts closed (lid

opened).

F. Up limit switch N.C. contacts closed (pan

position is less than full tilt).

G. Pan position/down limit switch N.O.

contacts closed; and

N.C. contacts open

(pan down).

NOTE: The pan position/down limit

contained in the same switch body. Both sets of

DPST contacts are utilized.

2. Turn on/off switch on.

A. Indicator light (amber) comes on.

NOTE: If the temperature dial is set to call for

heat, the ignition trial starts and module begins

sparking.

3. Operate the lift control switch to raise the pan

(momentary on - raise).

A. K1 relay coil is energized thru the up limit

switch N.C contacts.

1) K1 4/7 N.O. contacts close.

2) K1 9/6 N.O. contacts close.

3) K1 8/5 N.O. contacts close.

B. 120VAC to DC motor controller thru K1 4/7

N.O. contacts.

1) 90VDC output is activated at terminals

A + (positive) and A - (negative). DC

lift motor powered thru K1 9/6 N.O.

contacts, K1 8/5 N.O. contacts and

pan raises.

4. When the pan is raised 2.25" to 2.50" at the

rear, pan position/down limit switch contacts

change state. The N.O contacts open to remove

power from the heating circuit; and the N.C

contacts close. Power is then available for K2

relay coil thru the N.C. set of contacts.

switch are

F25121 (February 2003) Page 28 of 32

The pan can still be raised or lowered thru its

travel range by operating the lift control switch.

Release switch to stop pan travel.

Page 29

GAS BRAISING PANS - ELECTRICAL OPERATION

5. Pan reaches full tilt position, the up limit switch

N.C. contacts open and K1 relay coil is deenergized.

A. The three sets of K1 contacts return to

N.O. position. Power is removed from the

DC motor controller, the DC lift motor and

pan travel stops.

6. Operate the lift control switch to lower the pan

(momentary on - lower).

A. K2 relay coil is energized thru the down

limit switch N.C contacts.

1) K2 4/7 N.O. contacts close.

2) K2 9/6 N.O. contacts close.

3) K2 8/5 N.O. contacts close.

B. 120VAC to DC motor controller thru K2 4/7

N.O. contacts.

1) 90VDC output is activated at terminals

A + (positive) and A - (negative). DC

lift motor powered thru K2 9/6 N.O.

contacts, K2 8/5 N.O. contacts and

pan lowers.

7. After the pan leaves the full tilt position, the up

limit switch N.C. contacts close. The direction of

pan travel can then be reversed by un-operating

the switch (pan travel stops) then operating the

switch to raise the pan.

8. Pan reaches full down position, down limit

switch N.C. contacts open and K2 relay coil is

de-energized.

A. The three sets of K2 contacts return to

N.O. position. Power is removed from the

DC motor controller, the DC lift motor and

pan travel stops.

Page 29 of 32

F25121 (February 2003)

Page 30

GAS BRAISING PANS - ELECTRICAL OPERATION

SCHEMATIC DIAGRAM

F25121 (February 2003) Page 30 of 32

Page 31

GAS BRAISING PANS - TROUBLESHOOTING

TROUBLESHOOTING

GAS HEATING (MANUAL LIFT OR MOTORIZED LIFT OPTION)

SYMPTOMS POSSIBLE CAUSES

No spark to ignite pilot burner gas, power on

light is lit.

Spark at ignitor but pilot burner does not light. 1. Gas combination valve off or inoperative.

Pilot burner lights but will not maintain flame. 1. Ignitor/flame sense lead wire connections malfunction.

Main burner(s) do not light or will not

maintain flame.

Braising pan does not heat, power on light is

lit.

Braising pan does not heat, power on light is

not lit.

Excessive or low heat. 1. Temperature probe malfunction.

1. Pan not fully lowered or pan position/down limit switch

malfunction.

2. Temperature dial not set to call for heat or temperature

controller malfunction.

3. Ignitor cable open or grounded (short).

4. Ignitor spark gap distance incorrect.

5. Shorted electrode or an improper ground on

ignitor/flame sense.

6. Ignition module not grounded or inoperative.

2. Gas supply off or insufficient gas pressure.

3. Ignitor spark gap distance incorrect.

4. Pilot burner orifice obstructed.

5. Ignition Module malfunction.

2. Improper ground on pilot burner or ignitor/flame sense;

or ignitor/flame sense malfunction.

3. Pilot burner misaligned or Ignitor/flame sense

malfunction.

4. Gas pressure not within specified range.

5. Incorrect polarity from transformer to Ignition module.

6. Ignition Module malfunction.

1. Gas pressure incorrect.

2. Runner tube - gas orifice obstructed or malfunction.

3. Main burner - gas orifice obstructed or malfunction.

4. Main Burner(s) incorrect air shutter position or burner

malfunction.

5. Gas combination valve malfunction.

1. Temperature controller malfunction.

2. Pan position/down limit switch malfunction.

3. Ignition module malfunction.

4. Gas combination valve malfunction.

5. Interconnecting wiring malfunction.

1. Main circuit breaker off or power not connected.

2. On/off switch off or malfunction.

3. Transformer inoperative.

4. Interconnecting wiring malfunction.

2. Temperature controller malfunction.

3. Gas pressure incorrect.

4. Gas orifice obstructed or incorrect.

Page 31 of 32

F25121 (February 2003)

Page 32

GAS BRAISING PANS - CONDENSED SPARE PARTS LIST

MOTORIZED LIFT OPTION ONLY

SYMPTOM POSSIBLE CAUSES

Pan will not raise. 1. Lid switch open (lid not opened) or malfunction.

2. Transformer inoperative.

3. On/off switch off or malfunction.

4. Lift control switch malfunction (momentary on - raise).

5. Up limit switch malfunction.

6. K1 relay malfunction.

7. DC motor controller - Fuses open or controller malfunction.

8. DC Lift motor inoperative.

9. Gear reducer malfunction.

Pan will not lower. 1. Lid switch open (lid not opened) or malfunction.

2. Pan position is below 2.25" to 2.50" at the rear. Raise pan to

return pan position/down limit switch N.C. contacts to closed

position.

3. Transformer inoperative.

4. On/off switch off or malfunction.

5. Lift control switch malfunction (momentary on - lower).

6. Down limit switch malfunction.

7. K2 relay malfunction.

8. DC motor controller - Fuses open or controller malfunction.

9. DC Lift motor inoperative.

10. Gear reducer malfunction.

CONDENSED SPARE PARTS LIST

VG30 & VG40 GAS BRAISING PANS

PART NUMBER DESCRIPTION NOTE

854534-1 Board, Temperature

854537-1 Switch, Control (Manual Lift)

417980-1 Module, ignitor

411500-12 Transformer, 120-24

854517-1 Switch, Limit (Pan Position/Down limit)

854512-1 Thermocouple (E-Type)

844129-1 Pilot, Burner (Nat) Elect. Ign.

844129-2 Pilot, Burner (LP) Elect. Ign.

844130-1 Cable, Ignitor

844133-1 Valve, Combo Gas (Nat), Elect. Ign.

844133-2 Valve, Combo Gas (LP), Elect. Ign.

BRAISING PANS WITH MOTORIZED LIFT OPTION

PART NUMBER DESCRIPTION NOTE

854495-1 Switch, Control

854671-1 Controller, Speed

854545-1 Relay (24VAC)

411496-F1 Switch, Micro (Lid)

854717-1 Switch, Micro (Up Limit)

854653-1 Motor, Gear

F25121 (February 2003) Printed in U.S.A.

Loading...

Loading...