Page 1

SUPPLEMENT TO OPERATING AND MAINTENANCE MANUAL

This section refers solely to items which are added to Kettles to set them apart as Coffee Urns.

See section on Kettles for items characteristic to both Kettles and Coffee Urns,

ALL MODELS GC - EC & SC SERIES STEAM JACKETED COFFEE URNS

INDEX Page

Operating Instructions ....................................................................................................2-3

Service Procedures ...........................................................................................................4

Wiring Diagram ..................................................................................................................5

Parts Drawing.....................................................................................................................6

Parts list...........................................................................................................................7-8

P. 0. Box 696, Louisville, Kentucky 40201

F-136090

Page 2

COFFEE URNS INSTALLATION

INSTRUCTIONS

1. Follow Installation Instructions for a Vulcan kettle of the same type of heat,

(steam, gas or electric).

2. Plug the electric supply cord for the repour pump into 115 volt, 60 cycle, 1

phase receptacle.

3. For tall urns (due to tall legs or to jacket height) platforms may be desirable

to allow easy removal of the coffee grounds and holder. If platforms are

provided (not supplied by Vulcan-Hart Corporation), they must not interfere

with access to controls or with access for service.

P. 0. Box 696, Louisville, Kentucky 40201 F-136089

Page 3

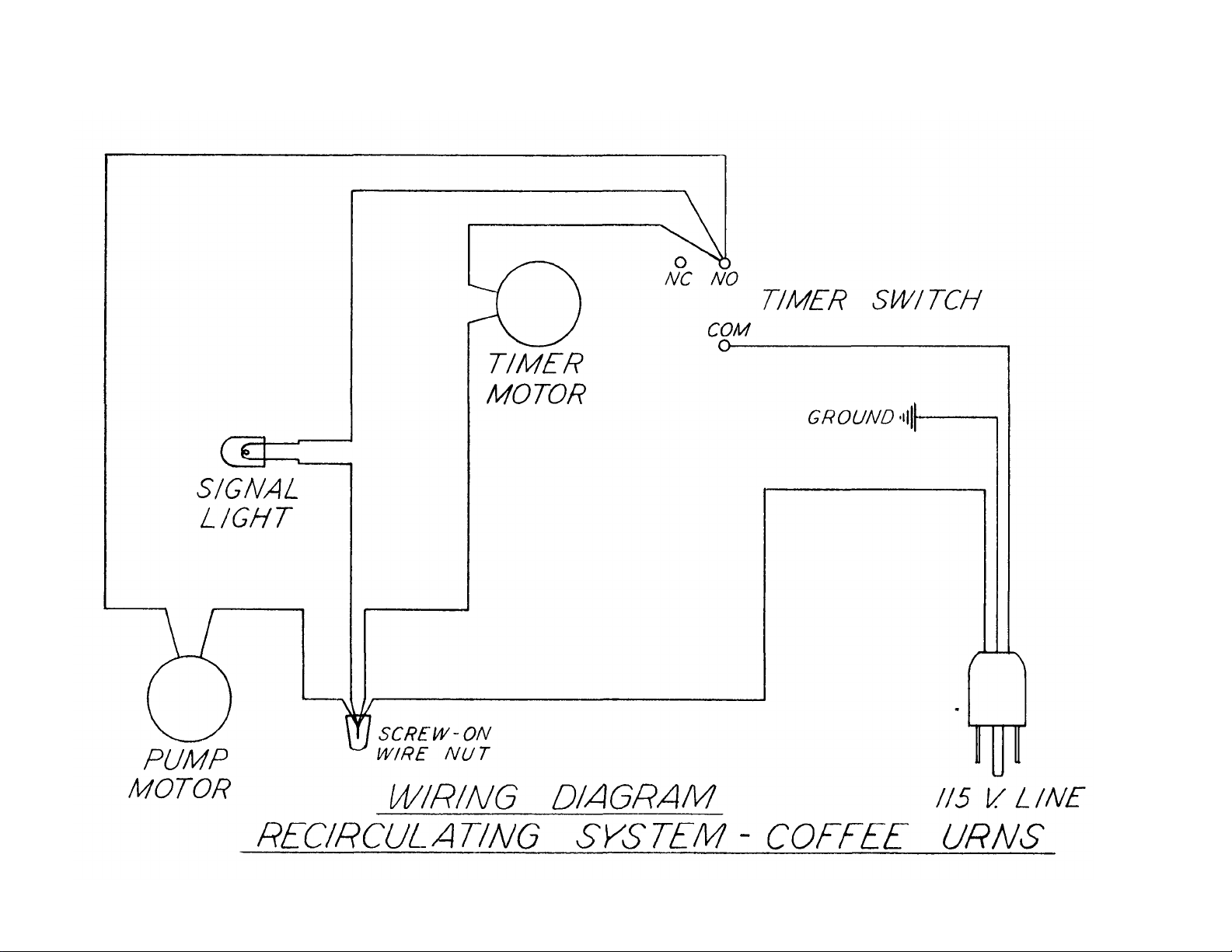

WIRING DIAGRAM E-4059

Page 4

COFFEE URNS

(Steam, Gas or Electric)

Note: Vulcan Coffee Urns are Vulcan Kettles modified to adapt them for the brewing of coffee. Basic instructions are

contained in the Kettle Manual and only those additional instructions required due to the modifications to the unit and

due to its use as a coffee urn are contained herein.

The modifications that adapt the kettle to the brewing of coffee are as follows:

1. Additions of the repour pump and its related piping, and its timer control.

2. Addition of the coffee holder (bag with holding frame or gridded riser, or stainless steel leacher.)

3. Change in type of draw off faucet.

4. Addition of graduated gage glass to show volume of water or brewed coffee.

5. Increased leg heighth to permit draw off faucet to discharge into tall containers.

OPERATING INSTRUCTIONS

See the "Notes for Operators" in the Kettle Manual. These all apply to the coffee urns excepting the cautions regarding the plug

type draw-off faucet used only on kettles.

SUGGESTED PROCEDURE FOR BREWING COFFEE

1. Turn heat on and if unit is thermostat controlled-gas and electric urns are always thermostat controlled-set thermostat dial

to 10.

2. Charge desired volume (up to brewing capacity but not less than one half of this capacity,) of water into the urn. The

graduated gage glass at the front of the urn shows the volume of water in the urn. Charging with hot water will shorten

the time required to heat the water.

3. Close cover and allow urn to bring water to a rolling boil. Then turn heat off (or set thermostat dial to 4 or 5).

4. Raise the cover, place the coffee holder in position and charge the proper amount of ground coffee (about one pound of

coffee to each 21/2 gallons of water).

Note: If a coffee bag is used, it must be wetted before its first use and

should be kept immersed in cold water when not in use. Once wetted,

never allow the bag to dry.

5. Close the cover, connect the union-in repour piping, open the observation hole cover, turn timer dial to desired brewing

time and press button at center of the timer dial to start the brewing cycle.

? 2 ?

Page 5

COFFEE URNS

SUGGESTED PROCEDURE FOR BREWING COFFEE (Continued)

6. At end of brewing time, allow approximately 5 minutes for coffee grounds to drain, then disconnect union at top of

vertical portion of repour line, open cover and remove holder and coffee grounds it holds.

7. Close cover, connect union and set timer dial to approximately 5 minutes to thoroughly mix brew. Brewed coffee is now

ready.

NOTES:

When timer dial is set to desired brewing time and button in center of dial is pressed to start the brewing cycle, the pointer on

dial will remain at the preset value. (Pointer does not return to 0.) To change this preset interval, the timer dial must be reset

manually.

The grind of coffee, the blend of coffee beans, the grade of coffee bag (if used), the gallons of water per pound of coffee

charged, and the length of the brewing cycle are all variables which affect the type of brew obtained. Individual tastes vary

widely as to the end result desired such that we can not offer specific recommendations covering these variables. Your coffee

vendor will offer valuable assistance to you in tailoring your procedure to produce the type of brew you desire.

The rate of repouring is controlled by the size of orifice hole in the metering disc assembled inside the shower head. Three

discs are supplied, one with a 5/32" orifice hole, one with a 11/64" orifice hole, and one with a 3/16" orifice hole. Use the disc

with the largest orifice hole possible without causing flooding with your selected operating conditions. One of the metering

discs may be modified to provide a larger or smaller orifice hole if such is found desirable. For your information, flow rates are

approximately as follows:

With 5/32" orifice hole disc - 1.6 gal/min.

With 11/64" orifice hole disc - 1.9 gal/min.

With 3/16" orifice hole disc - 2.3 gal/min.

With metering disc omitted - 7. 6 gal/min.

We suggest a brewing time of 15 to 25 minutes.

Clean and flush the urn immediately after use. The pipe lines and pump are cleaned by using the pump to circulate the cleaning

solution. Prompt, careful cleaning is essential to assure absence of any build up which could adversely affect the taste of the

brew. Periodically, as found necessary in your operation, dismantle the pump, the repour piping and the faucet and clean them

thoroughly.

One pound of ground coffee will absorb and retain approximately one quart of water. Therefore, for each 10 gallons of water

charged, you will get approximately 9 gallons of brewed coffee.

- 3 -

Page 6

COFFEE URNS

Service Instructions

TO REPLACE TIMER:

Remove four (4) screws from corners of timer face plate and pull timer unit forward out of box.

TO REPLACE SIGNAL LIGHT:

Remove eight (8) screws around edges of box. The front should then be slipped out of box. Remove two (2) screws from either

side of signal light. Note position of bar of signal light and gasket. Replace with parts in same position, bar against back

surface of metal ring on light and gasket around light and between metal ring and inner surface of timer box wall.

TO REPLACE PUMP PARTS:

Remove tube between faucet flange and pump body. Disconnect tube nut at discharge opening of pump-body. Remove two

thumb nuts on the pump body and pull pump body forward.

TO REPLACE IMPELLER:

Strike impeller sharply in counter-clockwise direction with soft instrument, such as a rawhide mallet or block of wood, to

disengage from locking pin of shaft. Pull forward to remove.

TO REPLACE "O" RING GASKET:

Remove gasket from groove in inboard head. This service indicated when leak is observed which cannot be stopped by

tightening thumb nuts on pump body. The impeller need not be removed to perform this service.

TO ADJUST OR REPLACE SHAFT SEAL:

This service is indicated when a drip is observed from drain hole in bottom of bracket housing. Remove impeller by following

aforementioned directions, then slip inboard head forward and off of shaft. Loosen set screw in adjusting collar and slip collar

and seals forward slightly. Tighten set screw and remove inboard head. When inboard head is seated solidly in bracket, the

rubber shaft seal should be compressed 1/32 inch.

TO REPLACE PUMP MOTOR:

Follow instruction for replacing pump parts above. Remove impeller, inboard head and rotary seal from pump. Remove three

cap nuts from front of bracket housing and slip motor out from rear of housing. Loosen set screw in impeller shaft to remove it

from pump shaft. Reassemble in reverse order.

TO REPLACE PIPE LINE GASKETS:

Disengage union nut, remove old gasket from female portion of joint and snap in new gasket.

Note: When re-engaging union nut on any gasketed joint, be careful not to

overtighten. Over tightening will contribute to rapid breakdown of the

gaskets.

TO REPLACE SEAT CUP IN DRAW-OFF FAUCET:

Unscrew complete black plastic bonnet and pull out of faucet body. Pull seat cup off of bonnet assembly. When reassembling,

be careful to have mushroom end of shaft properly seated in recessed portion of bottom of seat cup.

- 4 -

Page 7

WIRING DIAGRAM E-4059

Page 8

PARTS DRAWING H-3922

- 6 -

Page 9

PARTS LIST

ITEM PART NO. REQ'D PART NAME

1 3919 1 Draw-off Faucet

2 3917 1 Flange

3 3918 1 Gasket - Flange

4 3497 2 Flange Mntg. Screw (5/8-18 NF x 1" LG. Hex. Hd.)

5 3750 3 1 1/2" Snap-Tite Gasket

6 3745 3 1 1/2" To 1" Ferrule

7 3775 3 1 1/2" Nut

8

3923-2

9 4382 1 Motor - 1/3 HP., 60 CY. 11 1 PH., 115V.

10 3819 3 Motor Stud

11 3694 1 Bracket Housing

12 3776 3 Motor Stud Nut

13 3809 1 Impeller Shaft

14 3704 1 Adjusting Collar

15 3805 1 Rubber Seal

16 3806 1 Rotary Seal

17 3761 1 Inboard Head

18 3748 1 "0" - Ring Gasket

19 3760 1 Impeller

20 3777 1 Outboard Head

21 3820 2 Head Stud

22

23 3678 1 Pump Mounting Plate

24 3679 4 Pump Mntg. Screw (5/8 – 11 NC x 3/4" LG. Ilex. Hd.)

25

26 3696 1 Pipe Hanger

27 3774 3 1" Nut

28 3743 3 1 " Ferrule

29 3749 3 1 " Snap-Tite Gasket

30 3725 1 1" Elbow - 90°

31

3924-9 or 1 " “ - 60 "

32 3726 1 Flanged Elbow - 90°

33 3747 3 Rubber Gasket - Shower Head

34 3895

35 3897

36

3896-2

37 3810

38 3493-6

39 3493-7 1 Drain Cock

3923-1 Or 1 Flange To Pump Tubing - 30 Gal.

Or 1

3923-3 Or 1 " “ - 60 "

3923-4 1 " “ - 75, 100 & 125 Gal.

3924-1 1 Pump outlet Tubing - 30 Gal.

3924-2 or “ “ “ - 45 "

3924-3 or 1 “ “ “ - 60 "

3924-4 3924-5 or ^ “ “ “ - 100"

3924-6 or 1 “ “ “ - 125"

3924-7 1 Shower Head Inlet Tubing - 30 Gal.

3924-8 or 1 “ “ - 45 "

3924-10 or 1 " “ - 75, 100 & 125 Gal.

2 Head Stud Nut

or 1 “ “ “ - 75”

1

1

3896-1

1

1

3896-3

1

1

1

“ “ -45”

Tin Gasket - Shower Head

Disc Hold-Down Strip

Metering Disc - 5/32" Hole

“ “ 11/64" Hole

“ “ 3/16" Hole

Shower Head

Lower Gauge Glass Faucet

- 7 -

Page 10

PARTS LIST (cont.)

ITEM PART NO. REQ'D PART NAME

40 3493-5 1 Rubber Seal

41 3493-4 1 Washer

42 3493-2 1 Compression Nut

43

44

45 2665 1 Angle Nut

3912-1 1 Gauge Glass - 30 Gal.

3912-2 1 “ “ - 45, 60 & 75 Gal.

3912-3 or 1 “ “ - 100 Gal.

3912-4 or 1 “ “ - 125 "

3911-1 or1 Graduated Angle Ass'y. - 30 Gal.

3911-2

3911-3 Or 1 “ “ - 100 Gal.

3911-4 Or 1 “ “ - 125 "

3794 1 Motor & Pump Ass'y,, - Complete

“ “ - 45, 60 & 75 Gal.

TIMER PARTS (NOT SHOWN IN DRAWING)

3894 1 Timer - Recirculating System

3393-R 1 Signal Light - Red.

3674 1 Signal Light Bracket

3483 1 Signal Light Gasket

2462 Bracket & Timer Mntg. Screw

3484 " " " Lockwasher

FAUCET PARTS (NOT SHOWN IN DRAWING)

4073 Seat Cup (Sealing Membrane)

BAG HOLDER PARTS (NOT SHOWN IN DRAWING)

Model C-30

3955-1 - Bag Holder

3938-1 - Locking Ring

4065-1 - Lift Bar

3684 - Coffee Bag

Model C-45

3955-2 - Bag Holder

3938-2 - Locking Ring

4065-2 - Lift Bar

3685 - Coffee Bag

Model C-60

3955-3 - Bag Holder

3938-3 - Locking Ring

4065-3 - Lift Bar

3686 - Coffee Bag

Models C-75, C-100 & C-125

3955-4 - Bag Holder

3938-4 - Locking Ring

4065-4 - Lift Bar

3686 - Coffee Rag

- 8 -

Loading...

Loading...