Page 1

©ITW Food Equipment Group, LLC

3600 North Point Blvd.

Baltimore, MA 21222

RETAIN THIS MANUAL FOR FUTURE USE

FORM F-38308 (09-15)

VCRH36

MODELS

VCRH12

VCRH24

VCRH36

WCRH12

WCRH24

WCRH36

For additional information on Vulcan or to locate an authorized parts and

service provider in your area, visit our website at www.vulcanequipment.com

INSTALLATION & OPERATION MANUAL

MEDIUM DUTY GAS HOTPLATES

Page 2

IMPORTANT FOR YOUR SAFETY

Improper installation,

adjustment, alteration, service or maintenance

can cause property damage, injury, or death.

Read the installation, operating and maintenance

instructions thoroughly before installing or

servicing this equipment.

THIS MANUAL HAS BEEN PREPARED FOR PERSONNEL QUALIFIED TO

INSTALL GAS EQUIPMENT, WHO SHOULD PERFORM THE INITIAL FIELD

START-UP AND ADJUSTMENTS OF THE EQUIPMENT COVERED BY THIS

MANUAL.

POST IN A PROMINENT LOCATION THE INSTRUCTIONS TO BE FOLLOWED IN

THE EVENT THE SMELL OF GAS IS DETECTED. THIS INFORMATION CAN BE

OBTAINED FROM THE LOCAL GAS SUPPLIER.

IMPORTANT

IN THE EVENT A GAS ODOR IS DETECTED, SHUT

DOWN UNITS AT MAIN SHUTOFF VALVE AND

CONTACT THE LOCAL GAS COMPANY OR GAS

SUPPLIER FOR SERVICE.

FOR YOUR SAFETY

DO NOT STORE OR USE GASOLINE OR OTHER

FLAMMABLE VAPORS OR LIQUIDS IN THE VICINITY OF

THIS OR ANY OTHER APPLIANCE.

IN THE EVENT OF A POWER FAILURE, DO NOT

ATTEMPT TO OPERATE THIS DEVICE.

- 2 -

Page 3

INSTALLATION, OPERATION AND CARE OF

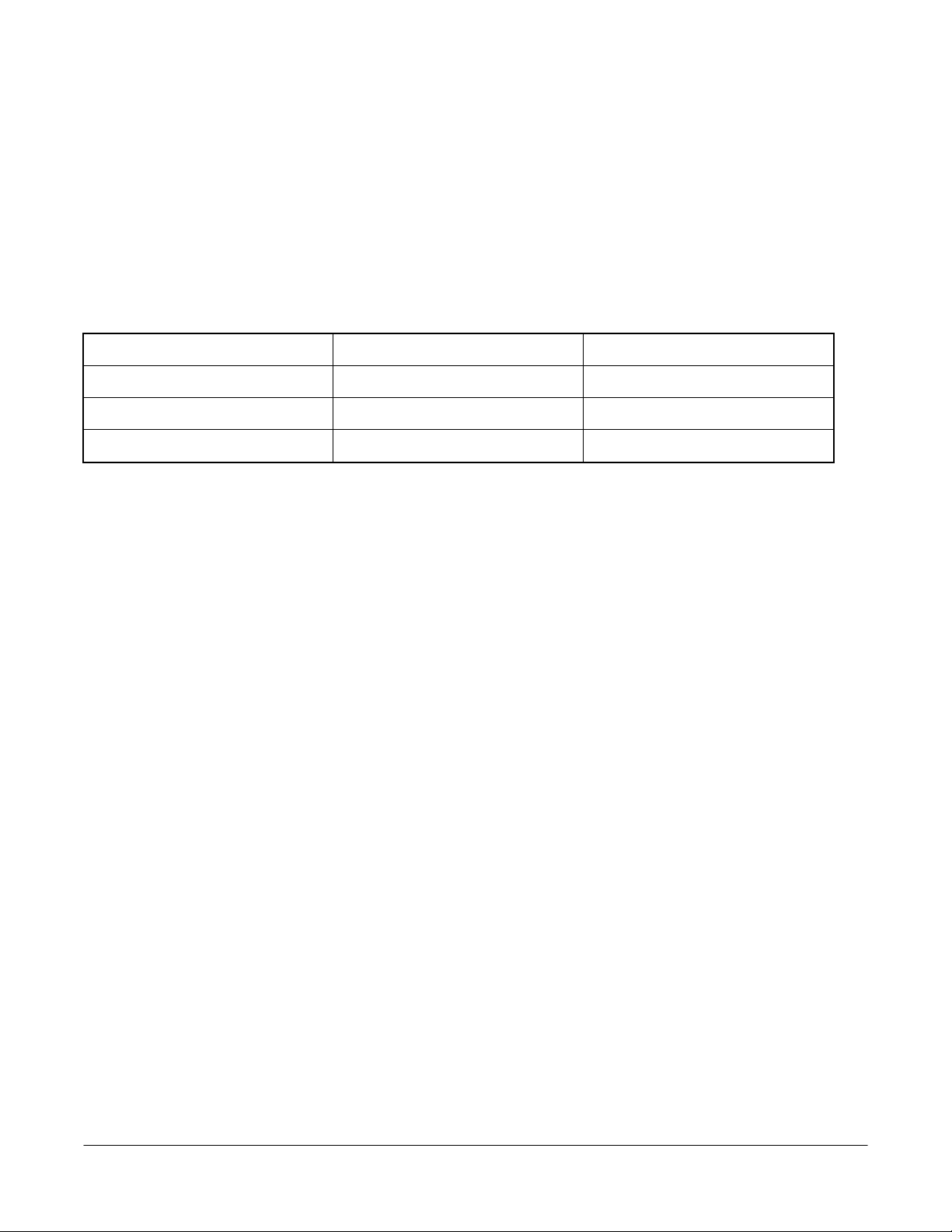

Model

Number Of Burners

BTU/hr Input Rating

VCRH12 / WCRH12

2

50,000

VCRH24 / WCRH24

4

100,000

VCRH36 / WCRH36

6

150,000

MEDIUM DUTY GAS HOTPLATES

GENERAL

Gas Countertop Hotplates are designed for commercial use only and feature fast, efficient

gas heat. Each burner is controlled by an adjustable gas valve. Cast grates and burners

are easily removed for cleaning when cool.

INSTALLATION

UNPACKING

This hotplate was inspected before leaving the factory. The carrier assumes full responsibility for the

safe delivery upon acceptance of the shipment. Check for possible shipping damage immediately after

receipt.

If the hotplate is found to be damaged, complete the following steps:

1. Carrier must be notified within 5 business days of receipt.

2. Carrier’s local terminal must be notified immediately upon discovery (note time, date, and

who was spoken to), and follow up and confirm with written or electronic communication.

3. All original packing materials must be kept for inspection purposes.

4. The hotplate cannot have been moved, installed, or modified.

5. Notify Vulcan Customer Service immediately at 800-814-2028.

LOCATION

The installation location must be kept free and clear of combustibles. Do not obstruct the

flow of combustion and ventilation air. DO NOT install the hotplate adjacent to open

burners or fryers.

Sufficient air should be allowed to enter the room to compensate for the amount of air

removed by any ventilating system and for combustion of the gas burners. Do not

obstruct the air flow into and around the hotplate. Position the hotplate in its final

location. Check that there are sufficient clearances to service the hotplate and to make

the required gas supply connection(s). Provide 24" clearance at the front for cleaning,

maintenance, service and proper operation.

Minimum clearances to combustible construction are 11" to the back and 11" to the sides.

Minimum clearances to non-combustible walls are 0" to the rear and 0" to the sides.

- 3 -

Page 4

INSTALLATION CODES AND STANDARDS

The hotplate must be installed in accordance with:

In the United States of America:

1. State and local codes.

2. National Fuel Gas Code, ANSI-Z223.1/NFPA #54 (latest edition). This shall include but

not be limited to: NFPA #54 Section 10.3.5.2 for Venting. Copies may be obtained

from The American Gas Association Accredited Standards Committee Z223, @ 400

N. Capital St. NW, Washington, DC 20001 or the Secretary Standards Council, NFPA,

1 Batterymarch Park Quincy, MA 02169-7471

NOTE: In the Commonwealth of Massachusetts

All gas appliances vented through a ventilation hood or exhaust system equipped with

a damper or with a power means of exhaust shall comply with 248 CMR.

3. NFPA Standard # 96 Vapor Removal from Cooking Equipment, latest edition, available

from the National Fire Protection Association, Batterymarch Park, Quincy, MA 02269.

In Canada:

1. Local codes.

2. CAN/CSA-B149.1 Natural Gas Installation (latest edition)

3. CAN/CSA-B149.2 Propane Installation Code (latest edition), available from the

Canadian Gas Association, 178 Rexdale Blvd., Etobicoke, Ontario, Canada M9W 1R3

CASTER EQUIPPED APPLIANCES

Hotplates mounted on stands with casters must use a flexible connector (not supplied)

that complies with the Standard for Connectors for Movable Gas Appliances, ANSI Z21.69

• CS A 6 . 1 6 an d a quick-disconnect device that complies with the Standard for Quick-

Disconnect Devices for use With Gas Fuel, ANSI-Z21.41 • CSA 6.9. In additio n, adequate

means must be provided to limit movement of the hotplate without depending on the

connector and the quick-disconnect device or its associated piping to limit hotplate

movement. Attach the restraining device at the rear of the hotplate. If disconnection of

the restraint is necessary, turn off the gas supply before disconnection. Reconnect the

restraint prior to turning the gas supply on and return the hotplate to its installation

position.

If the Hotplate is installed on casters and is moved for any reason, it is recommended

that it be re-leveled (see LEVELING).

LEVELING

Turn the feet at the bottom of the legs in or out to level the hotplate in the final installed

location. If the hotplate is mounted on the optional stand equipped with casters, position

the hotplate on a level floor.

VENTILATION HOOD

The hotplate should be installed under a suitable ventilation hood. For safe operation and

proper ventilation, keep the space between the hotplate and vent hood free from any

obstructions.

- 4 -

Page 5

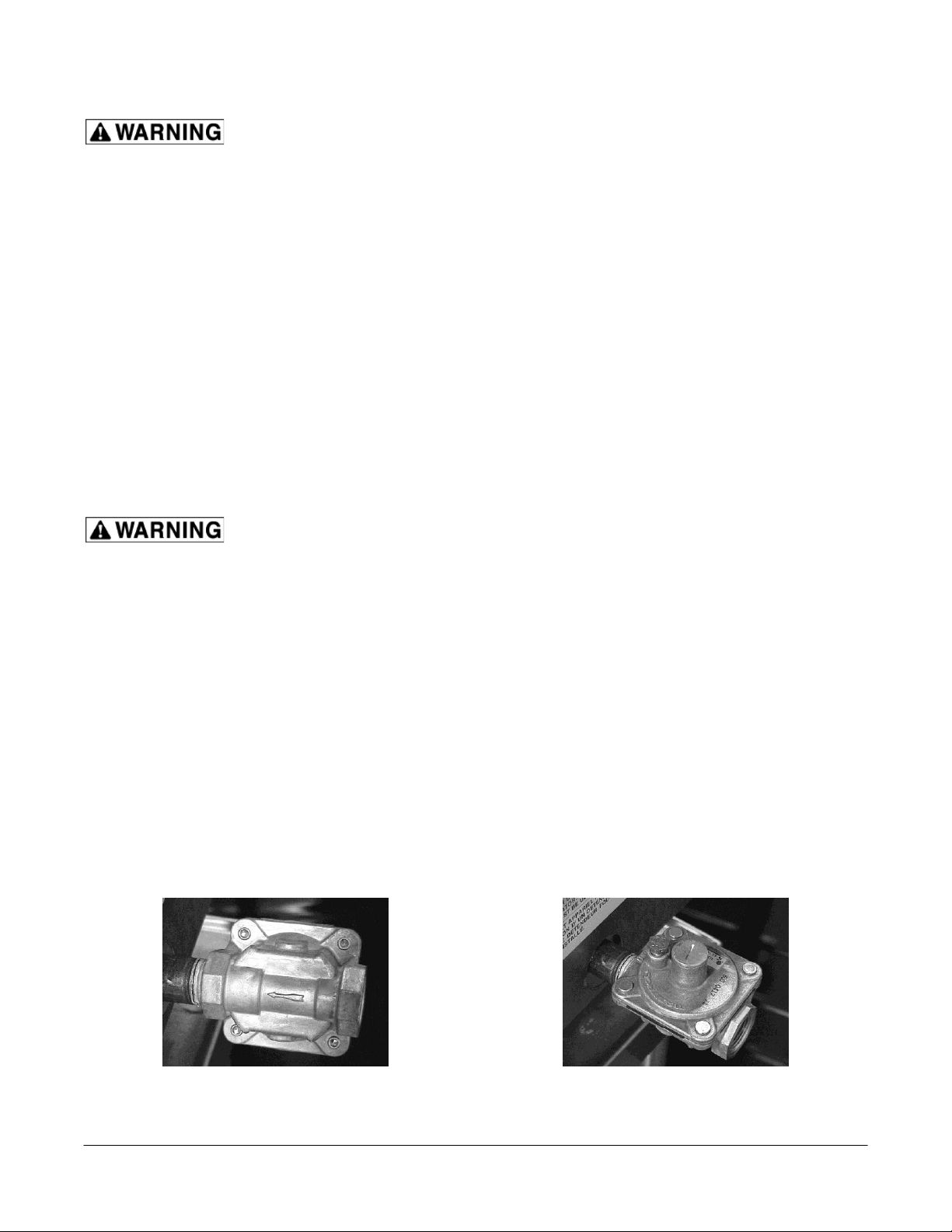

GAS CONNECTIONS

Fig. 1

Fig. 2

Gas supply connections and any pipe joint compound must be

resistant to the action of propane gases.

Purge the supply line to clean out any dust, dirt, or any foreign matter before connecting

the line to the unit.

Codes require that a gas shut-off valve be installed in the gas line ahead of the

appliance. The gas supply line must be at least the equivalent o f ¾” iron pipe.

An adequate gas supply is necessary. Undersized or low pressure lines will restrict the

volume of gas required for satisfactory performance. A minimum supply pressure of 7"

W.C. for natural gas and 11" W.C. for propane gas is recommended. With all units

operating simultaneously, the manifold pressure on all units should not show any

appreciable drop.

When testing the gas supply piping system, if test pressures exceed ½ psig (3.45 kPa),

the appliance and its individual shutoff valve must be disconnected from the gas supply

piping system. When test pressures are ½ psig (3.45 kPa) or less, the appliance must be

isolated from the gas supply piping system by closing its individual manual shut-off valve

during any pressure testing of the system.

Prior to lighting, check all joints in the gas supply line for leaks.

Use soap and water solution. Do not use an open flame.

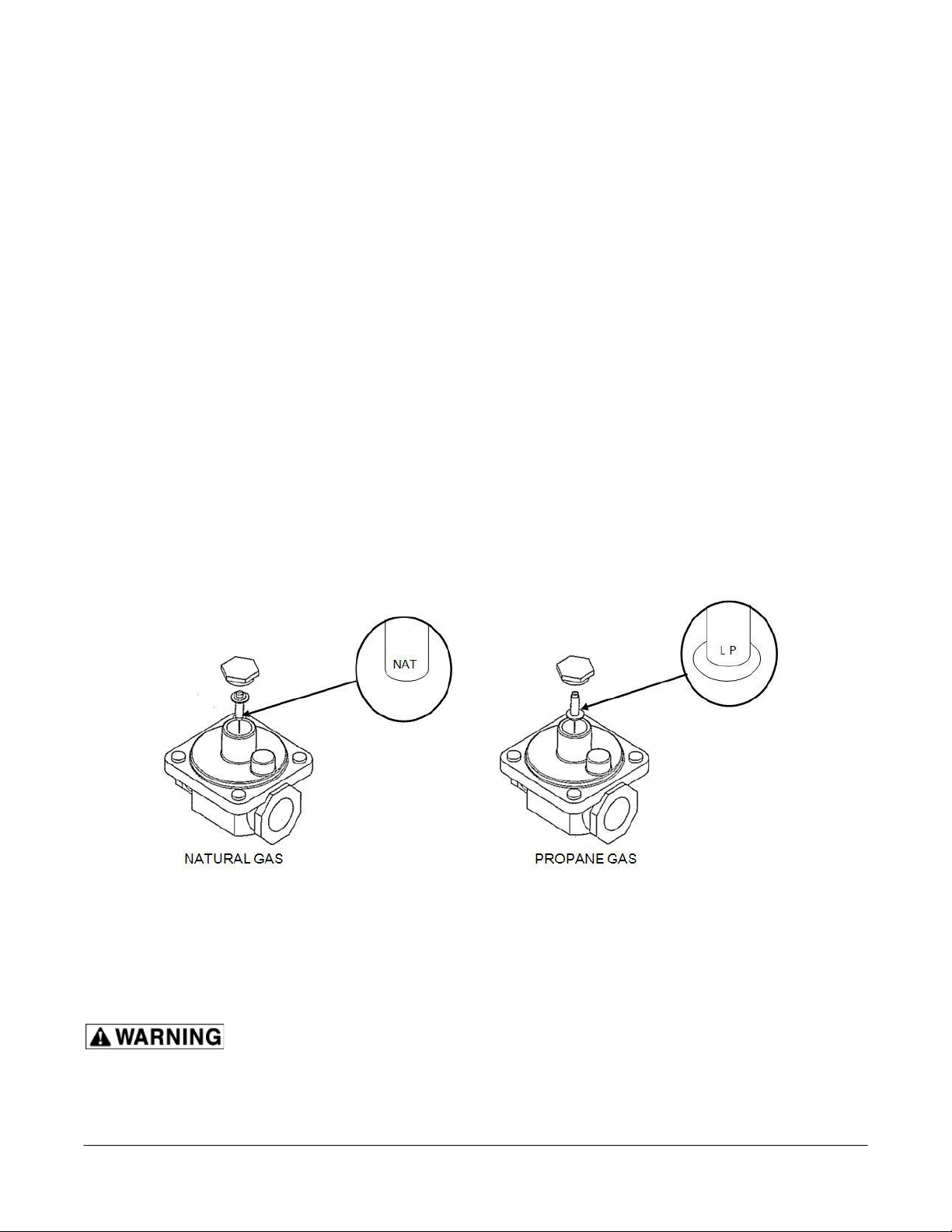

GAS PRESSURE REGULATOR INSTALLATION

This hotplate is supplied with a convertible gas pressure regulator preset at 4” W at er

Column (W.C.) for natural gas. No further adjustment should be required.

Install the regulator as close to the hotplate on the gas supply line as possible. Make sure

that the arrow on the underside of the regulator is oriented in the direction of gas flow to

the hotplate (Fig. 1) and the regulator is positioned with the vent plug and the conversion

plug cover upright(Fig. 2).

- 5 -

Page 6

The minimum supply pressure (upstream of the regulator) should be 7-9 ” W.C. for n atural

Fig. 3

gas and 11-12” W. C . for propane gas. At no time should the hotplate be connected to

suppl y p r e ssure greater than ½ psig (3.45 kPa) or 14” W . C.

PROPANE GAS CONVERSION

This hotplate is shipped from the factory equipped with fixed burner orifices for natural

gas operation. The burner orifices required to convert the hotplate to propane gas are

shipped with the hotplate in the shipping packaging. It is recommended that a trained gas

service technician with the necessary tools, instruments and skills perform the

conversion.

To convert to propane, following steps must be completed:

1. Remove all natural gas burner orifices and install the provided propane burner orifices.

2. Set the regulator to 10” W.C. by inverting the r egulator spring p lug . See Fig. 3.

Prior to lighting, check all joints in the gas supply line for leaks.

Use soap and water solution. Do not use an open flame.

- 6 -

Page 7

OPERATION

CONTROL KNOBS

OFF

ON

PILOTS

Fig. 4

Fig. 5

The hotplate and its parts are hot. Use care when operating,

cleaning or servicing the hotplate.

CONTROLS

There is one pilot for every two burners. The hotplate is equipped with standing,

unmonitored pilots. Gas will flow from the pilots as soon as the main gas supply to the

unit is turned on. See pilot lighting procedure below.

Each burner is independently controlled by an infinite heat control valve. Once the pilots

are lit, turning the control knob to the ON position will light each burner. The burners will

be in the full ON position when the control knobs are turned all the way to the left. The

burners will be in the full OFF position when the control knobs are turned all the way to

the right. See Fig 4.

LIGHTING INSTRUCTIONS

1. See Fig 5. Turn main gas shut-off valve

and all burner control knobs to the OFF

position and wait 5 minutes to allow

any accumulated gas to escape.

2. Remove the front row of grates.

3.Turn main gas shut-off valve ON.

Light the pilot between each two main

burners. Pilot can be accessed under

the grate support beam running from

left to right. Adjust the pilot valve

screw(See Fig.6 on page 8) until the

pilot flame has a slight yellow tip.

4.To light burners, turn individual burner

valves to the ON position.

5. If burners fail to light, turn all valves

and the main gas shut-off to the OFF

position and contact an authorized

service contractor.

- 7 -

Page 8

PILOT ADJUSTMENT

Fig. 6

Pilot adjustment screw

Using a flathead screwdriver, turn the slotted hex-head pilot adjustment screw clockwise

to decrease the flame, and counterclockwise to increase the flame. See Fig. 6.

CLEANING

Grates may be immersed in commercial cleaning compound overnight. In the morning,

rinse with hot water to remove any residues of cleaning compound. Thoroughly dry and

apply a cooking oil to prevent rusting.

Burner ports and burner rest should be thoroughly cleaned. Venturi must be free from

grease and lint. When cleaning, do not insert a pick into the burner port holes – soap and

water will normally do the job. Heavy spattering or spill-over may require cleaning with a

mild oven cleaner. After cleaning, rinse with clean water and dry with a dry cloth. Be sure

to apply a thin coat of cooking oil for protection after cleaning.

Stainless steel surfaces may be cleaned using damp cloth with mild detergent and water

solution.

Places where fat, grease, or food can accumulate must be cleaned regularly.

- 8 -

Page 9

MAINTENANCE

The hotplate and its parts are hot. Use care when operating,

cleaning or servicing the hotplate.

LUBRICATION

All valves must be checked and lubricated periodically. Check with your service

contractor for details.

VENT SYSTEM

At least twice a year the exhaust hood (venting system) should be examined and cleaned.

SERVICE

Contact your local Service Contractor for any repairs or adjustments needed on this

equipment. For a complete listing of Service and Parts depots refer to

www.vulcanequipment.com .

When calling for service, the following information should be available from the appliance

identification plate: Model Number and Serial Number.

- 9 -

Page 10

TROUBLESHOOTING

Burner does not come on A. Problem with gas valve. (Call for service).

when the control knob is B. Pilot burner not lit.

turned on C. Low gas pressure. (Call for service)

Too much heat A. Burner valves adjusted too high

B. Faulty ventilation

C. Overrated gas pressure

D. Improperly adjusted burner

Uneven heat side to side A. Burner valves improperly adjusted

B. Appliance is not level side to side

C. Improperly adjusted burner

Uneven heat front to back A. Appliance is not level front to back

B. Faulty ventilation

C. Improperly adjusted burner

Pilot burner will not stay lit A. Pilot flame is set too low. Adjust pilot to allow for gas flow.

B.Obstruction in pilot orifice

C. Low gas pressure. (Call for Service).

Yellow burner flames A. Open burner shutters until flames are blue

Lifting burner flames A. Close burner shutters until flames touch burner

Fluctuating gas pressure A. Check for clogged vent on regulator

- 10 -

Page 11

- 10 -

Le brûleur ne s’ouvre pas lorsque

le bouton de De commande est

ouvert

A. C’est un problème avec l a soupape à gaz (Contactez le

service à la clientèle).

B. La veilleuse d u brûleur n’est pas allumée

C. La pression du gaz est basse.(Contactez le service à la

clientèle).

Trop de chaleur

A. Les soupapes des brûleurs sont réglées trop haut

B. La ventilation est défectueuse

C. La pression du gaz est surestimée

D. Le brûleur est mal réglé

Chaleur inégale d’un côté à

l’autre

A. Les soupapes des brûleurs sont mal réglées

B. L’appareil n’es t pas au niveau d ’un côté à l’au tre

C. Le brûleur est mal réglé

Chaleur inégale de l’avant ver

l’arrière

A. L’appareil n’es t pas au niveau d e l’avant vers l’arrière

B. La ventilation est défectueuse

C. Le brûleur est mal réglé

La veilleuse d’allumage ne reste

pas allumée

A. La veilleuse d’allumage est r églée trop bas. Réglez la

ve illeuse d’allum age pour permettre la circulation d u gaz.

B. Obstruction d e l’orifice de la veilleuse d’all umage

C. La pression du gaz est basse. (Contactez le service à la

clientèle).

Les flammes des brûleurs sont

jaunes

A. Ouvrez les obturateurs des brûleurs jusqu’à ce que les flammes

redeviennent bleues.

Les flammes des brûleurs sont

trop élévées

A. Fermez les obturateurs des sont trop élévées brûleurs jusqu’à ce

que les flammes touchent le brûleur.

La pression du gaz varie

A. Vérifiez si la prise d'air du régulateur est bouchée

DÉPANNAGE

Page 12

- 9 -

sur la plaque d'identification de l'appareil : le numéro du modèle et le numéro de série.

Lorsque vous appelez pour du service, les renseignements suivants devraient être disponibles

www.vulcanequipment.com.

cet équipement. Pour une liste des bureaux des services et des pièces, consultez

Contactez votre service à la clientèle local pour toute réparation ou tout réglage nécessaire sur

SERVICE

fois par année.

La hotte à évacuation (système de ventilation) devrait être examinée et nettoyée au moins deux

SYSTÈME DE VENTILATION

clientèle pour de plus amples détails.

On doit vérifier et lubrifier toutes les soupapes régulièrement. Contactez votre service à la

LUBRIFICATION

attention lorsque vous employez, nettoyez ou entretenez la plaque de cuisson.

La plaque de cuisson et ses pièces sont chaudes. Faites

ENTRETIEN

Page 13

- 8 -

Fig. 6

Vis de réglage de la

veilleuse d’allumage

nettoyés.

Les endr oits où la gr ais se ou la nour riture peu vent s’acc umuler doi ven t être régulièrement

solution d’eau et d’un savon do ux.

Les surfaces en ac ier inox yda ble peuven t être nettoyées à l’aide d’u n linge humide et d’une

d'appliquer une mince couche d’huile de c u isson afin de pr otéger après l e nettoyage.

fours. Apr ès le nettoyage, rincez avec l’eau propre et essu ye z avec un linge s ec. Ass urez -vous

ou des d ébordements abond ants nécessitent un netto ya ge à l’ai de d’un pr oduit pour nettoyer les

des orifices de combustion – le savon et l’eau s’en char geront normalement. Des éclaboussures

doit être libre de graisse et de poussière. Lors du nettoyage, ne pas insérer de pic dans les trous

Les orifices de combustion et le support des brûleurs devraient être nettoyés à fond. Le venturi

cuisson afin de prévenir la rouille.

de l'eau c haude po ur enlever t out résid u du dé ter sif. R incez à f ond et m ettez de l’huile de

Les grilles peuvent tremper dans un détersif commercial toute la nuit. Au matin, rincez-les avec

NETTOYAGE

sens contraire des aiguilles d'une montre pour augmenter la flamme. Voir Fig. 6.

veilleuse d’allum age dans le sens des aigui lles d'une montre pour d iminuer la flamm e et da ns le

À l’aide d’un tournevis à tête plate, tournez la vis à tête hexagonale fendue de réglage de la

RÉGLAGE DE LA VEILLEUSE D’ALLUMAGE

Page 14

- 7 -

BOUTONS DE COMMANDE

FERMÉ

OUVERT

Fig. 4

Veilleuses

d’allumage

Fig. 5

du gaz et contactez un service à la clientèle autorisé.

les soupapes ainsi que le robinet d’arrêt principal

5. Si les brûleurs ne s’allument pas, fermez toutes

individuelles des brûleurs.

4. Pour allumer les brûleurs, ouvrez les soupapes

de la veilleuse ait une légère pointe jaune.

(voir Fig. 6 à la page 8) jusqu’à ce que la flamme

Réglez la vis de la soupape de la veilleuse

des grilles allant de gauche à droite.

à la veilleuse d'allumage sous le bras support

principaux brûleurs. On peut avoir accès

Allumez la veilleuse entre chacun des deux

3. Ouvrez le robinet d’arrêt principal du gaz.

2. Retirez la rangée avant des grilles.

à tout gaz accumulé de s’échapper.

et attendez 5 minutes pour permettre

et tous les boutons de commande

1. Voir Fig. 5. Fermez le robinet d'arrêt principal

INSTRUCTIONS D'ALLUMAGE

la droite. Voir Fig. 4.

bout vers

complètement à la position FERMÉ lorsq ue les boutons de command e seront tournés jusqu’au

boutons de commande seront tourn és jusqu’au bout vers l a gauche. Les brûle urs seront

allumera chaque brûleur. Les brûleurs seront complètement à la position OUVERT lorsque les

Une fois que les veilleuses sont allumées, tourner le bouton de commande à la position OUVERT

Chaque brûleur est contrôlé indépendamment par une soupape de réglage infini de la chaleur.

veilleuse ci-dessous.

l’alimentation princ ipale en gaz de l’appareil est ouverte. Voir la procédure d’a ll umage de la

d’allumage permanentes non contrôlées. Le gaz circulera à partir des veilleuses dès qu e

Il y a un e veil le use d’ allumage pour d eux br ûl eurs. La plaqu e de cuisson est munie de v eilleuses

COMMANDES

attention lorsque vous employez, nettoyez ou entretenez la plaque de cuisson.

La plaque de cuisson et ses pièces sont chaudes. Faites

EMPLOI

Page 15

- 6 -

Fig. 3

utiliser une flamme nue.

d’alimentation en gaz pour les fuites. Utilisez une solution d’eau et savon. Ne pas

Avant l’allumage, vérifiez tous les joints dans la conduite

2. Placez le régulateur à 25 cm CE en retournant le tampon de ressort du régulateur. Voir Fig. 3.

combustion pour le propane fournis .

1. Retirez tous les orifices de combustion pour le gaz naturel et installez les orifices de

Pour convertir au propane, les étapes suivantes doivent être remplies :

nécessaires effectue la conversion.

technicien qualifié du service de gaz avec les outils, les instruments et les compétences

gaz pro pane s ont li vrés a vec l a plaqu e de cuisson dans l’em ballage. O n rec ommande qu’un

du gaz naturel. Les orifices de combustion nécessaires pour convertir la plaque de cuisson au

Cette pla que de cuisso n est livrée de l’usine munie d' orifices de com bustion fix es pour l’em ploi

CONVERSION DU GAZ PROPANE

CE.

moment être connectée à une pression d’ali mentation supér ieure à ½ ps i (3,45 kPa) ou 36 cm

le gaz naturel et de 28 à 30 cm CE pour le gaz propane. La plaque de cuisson ne devrait à aucun

La pression d'alimentation minimum (en amont du régulateur) devrait être de 18 à 23 cm CE pour

Page 16

- 5 -

Fig. 1

Fig. 2

avec le bouchon d’aération ainsi que le couvercle de la prise de conversion (Fig. 2)

direction de la circulation du gaz à la plaque de cuisson (Fig.1) et que le régulateur est placé

d’alimentation en gaz. Assure z-vous que la flèche au-dessous du régulateur est orientée dans la

Installez le régulateur aussi près que possible de la plaque de cuisson sur la conduite

nécessaire.

10 cm de c olonne d’ea u (CE) pour le gaz naturel. Auc un réglage supplémentair e ne devra it être

Cette plaque de cuisson est offerte avec un régulateur de pression du gaz convertible préréglé à

INSTALLATION DU RÉGULATEUR DE PRESSION DU GAZ

une flamme nue.

d’alimentation en gaz pour l es fu ites. Utilisez une solution d’eau et savon. Ne pas utilise r

Avant l’al lumage, vér ifiez tous le s joints d ans la con duite

d’arrêt individu el durant tout ess ai de la pression de la tuyauterie.

moins, l’ap pareil do it être isolé de la tuyauterie de l ’a limentation en ga z en fermant s on robin et

tuyauterie de l’ alimentation en gaz. Lorsq ue les pressions d’essai sont de ½ ps i (3,45 kPa) ou

psi (3,45 k Pa), l’app areil et s on robinet d’arrêt ind ividuel doi vent être déconnectés de la

Lorsque vous évaluez la tuyauter ie de l’alimentation en gaz, si les pressi ons d’essai excèdent ½

d’admission sur tous les éléments n e devrait pas démontrer une b aisse notable.

CE pour le gaz propane. Avec tous les éléments fonctionnant en même temps, la pression

recommande une pression d'alimentation minimum de 18 cm CE pour le gaz naturel et de 28 cm

basse pression limiteront le volume de gaz nécessaire pour une performance satisfaisante. On

Une alimentation adéquate en gaz est requise. Des conduites de dimension insuffisante ou à

2 cm.

l’appareil. La condu ite d’alimentation en gaz do it êtr e au moins l’équiva le nt d’un tu yau en fer de

Les codes exigent qu’un robinet d’arrêt du ga z soit in stallé dans la c onduite de ga z à l’avant de

étranger avant d e la connecter à l’appareil.

Toutes les connexions et toute pâte à joints doivent résister à

Vider la conduite d’ali mentation pour la net t oyer de toute poussièr e, s aleté ou tout autre corps

l’action du gaz p ropane.

CONNEXIONS DU GAZ

Page 17

- 4 -

hotte à évacuation libre de toute obstruction.

emploi sécuritaire et une ventilation adéquate, laissez un espace entre la plaque de cuisson et la

La plaque de cuisson devrait être installée sous une hotte de ventilation appropriée. Pour un

HOTTE DE VENTILATION

plancher droit.

montée sur des supports optionnels munis de roulettes, placez la plaque de cuisson sur un

cuisson à niveau dans son emplacement d'installation définitif. Si la plaque de cuisson est

Tournez les pieds de chaqu e patte vers l’intérieur ou vers l’extérieur afin de mettr e la plaque de

MISE À NIVEAU

une autre, on rec ommande qu’e lle soit mise à niveau une autre f ois (MISE À NIV EAU).

Si la plaque de cuisson est installée sur des roulettes et est déplacée pour une raison ou pour

l’alimentation e n gaz et replacez l a plaque de cuiss on à l'endroit où elle doit êtr e installée.

fermez l’a limentation en ga z avant le débr anchement. Rebranchez le d ispositif a vant d’ou vrir

retenue à l’arr ière de la plaque de cuisson. Si le dé branchement du dispositif est nécessaire,

dispositif de prise à démontage rapide ou de leurs conduites associées. Attachez le dispositif de

apportées pour limiter le mouvement de la plaque de cuisson sans dépendre du connecteur et du

for use With Gas Fuel, ANSI-Z 21.41 • CS A 6.9. De plus, des mesures appro priées doivent être

un dispositif de prise à démontage rapide qui est conforme à la norme Quick-Disconnect Devices

qui est conforme à la norme Connectors f or Mova ble Gas Appliances, ANSI Z 21 .69 • CSA 6.16 et

Les plaques de cuisson sur pieds avec roulettes doivent employer un raccord flexible (non fourni)

APPAREILS MUNIS DE ROULETTES

l’Association Ca nadienne du Ga z, 178 boul. Rexdale, Etobicoke, Ontario, Canada M9W 1R3

3. Code d'installation du propane CAN/CSA-B149.2 (dernière édition), disponible auprès de

2. Code d'installation du gaz naturel CAN/CSA-B149.1 (dernière édition)

1. Codes locaux.

Au Canada :

auprès de la National Fire Protection Association, Batterymarch Park, Quincy, MA 02269.

3. La norme NFPA no 96 Vapor Removal from Cooking Equipment, dernière édition, disponible

qui doit être conforme à 248 CMR.

d'échappement muni d’une clef de réglage ou avec une moyenne potentielle d’échapp ement

Tous les appareils d'utilisation du gaz aéré grâce à une hotte de ventilation ou un système

REMARQUE : Dans l’État du Massachus etts

Batterymarch Park Quincy, MA 02169-7471

N. Capital St. NW, Washington, DC 20001 ou le Secretary Standards Council, NFPA, 1

copies auprès de l’ American G as Associatio n Accredite d S tandards Committee Z223, à 400

sans être limité à : NFPA No54 Section 10.3.5.2 pour la ventilation. Vous pouvez obtenir des

2. National Fuel Gas Code, ANSI-Z223.1/NFPA No54 (dernière édition). Cela doit comprendre

1. Codes locaux et d’état.

Aux États-Unis d'Amérique :

La plaque de cuisson doit être installée conformément à :

CODES ET NORMES D’INSTALLATION

Page 18

- 3 -

Modèle

Nombre de brûleurs

Débit calorifique BTU/h

VCRH12 / WCRH12

2

50 000

VCRH24 / WCRH24

4

100 000

VCRH36 / WCRH36

6

150 000

de 0 cm de chaque côté.

chaque côté. Les espaces minimums pour les parois non combustibles sont de 0 cm à l’arrièr e et

Les espaces minimums pour les parois non combustibles sont de 28 cm à l’arr ière et de 28 cm de

espace libre de 61 cm à l’av ant pour le nett oyage, l’entret ien et l’emploi a déquat.

de cuisson et effectuer la(les) con nexion(s) nécessair e(s) d’alimentation en gaz. Prévoyez un

emplacement final. Assurez-vous qu ’il y a suf fisamment d’espace l ibre pour entretenir la pl aque

circulation de l’air à l’intérieur et autour de la plaque de cuisson . Plac ez l e br ûleur dans son

tout système de ventilation et pour la combustion des brûleurs de gaz. Ne pas obstruer la

Suf fisamment d’air devrait entr er dans la pièce afin de com penser la quantit é d'air enlevé par

friteuses ou de brûleurs ouverts.

flux de la combustion ainsi que l'air de ventilation. NE PAS installer la plaque de cuisson près de

Le lieu de l’installa tion doit être maint enu sans présence de combustibles. N e pas o bstruer le

EMPLACEMENT

5. Avisez le Service à la clientèle de Vulcan immédiatement en faisant le (800) 814-2028.

4. Les plaques de cuisson ne doit pas avoir été déplacé, installé ou modifié.

3. Pour f ins d’inspection, tout le matérie l d’emballage or iginal doit êtr e c o nservé.

suivi en confirmant les faits par écrit ou par communication électronique.

découverte des dommages ( indiquez l’heur e, la date et à qui vous avez p arlé) et assurez l e

2. Les gens du terminus local du transporteur doivent être avisés immédiatement lors de la

1. Le transporteur doit être averti dans les 5 jours ouvrables suivant la réception.

suivantes :

S’il s’avère que les plaques de cuisson a été endommagé, veuillez suivre les procédures

livr aison, vérifi ez s’il a effecti vement subi des dommages pen dant le transport.

transporteur prend l’entière respo nsabilité de le livrer en tou te sécur it é. Imm édiatement après la

Les plaques de c uisson a ét é inspecté a vant de quit ter l’usine. En acceptant sa livraison, le

DÉBALLAGE

INSTALLATION

lor squ’ils sont r efroidis.

à gaz réglable. Les grilles moulées et les brûle urs s’en lèvent fac ilement pour le netto yag e

et offrent une chaleur au gaz rapide, efficace. Chaque brûleur est contrôlé par une soupape

Les plaques de cuisson au gaz de comptoir sont conçues à des fins commerciales seulement

GENERAL

PLAQUES DE CUISSON AU GAZ À FONCTION MOYENNE

INSTALLATION, EMPLOI ET ENTRETIEN DES

Page 19

- 2 -

Une installation, un

ajustement, une modification, un service ou un entretien

inapproprié peut causer du dommage matériel, une

blessure ou la mort. Lire minutieusement les

instructions d’installation, d’emploi et d’entretien avant

d’installer ou de se servir cet équipement.

DE FAIRE FONCTIONNER CET APPAREIL.

EN CAS DE PANNE DE COURANT, NE PAS TENTER

APPAREIL OU TOUT AUTRE APPAREIL.

VAPEURS OU LIQUIDES INFLAMMABLES À PROXIMITÉ DE CET

NE PAS ENTREPOSER OU UTILISER DE L’ESSENCE OU AUTRES

POUR VOTRE SÉCURITÉ

SERVICE.

FOURNISSEUR DE G AZ LOC AL AFI N D’OBTENIR DU

CONTACTEZ VOTRE COMPAGNIE DE GAZ OU VOTRE

FERMEZ LES UNITÉS DU ROBINET D'ARRÊT PRINCIPAL ET

AU CAS OÙ UNE ODEUR DE GAZ SERAIT DÉTECTÉE,

IMPORTANT

DEMANDER CES RENSEIGNEMENTS AU FOURNISSEUR DE GAZ LOCAL.

SUIVIES AU CAS OÙ UNE ODEUR DE GAZ SERAIT DÉTECTÉE. VOUS POUVEZ

PLACEZ DANS UN ENDROIT IMPORTANT LES INSTRUCTIONS QUI DOIVENT ÊTRE

RÉGL AGES INITI AUX DE L’ÉQUIPEMENT DONT IL S’AGIT DANS CE MANUEL.

IMPORTANT POUR VOTRE SÉCURITÉ

ÉQUIPEMENT AU GAZ, QUI DOIT EFFECTUER LA MISE EN MARCHE ET LES

CE MANUEL A ÉTÉ CONÇU POUR LE PERSONNEL APTE À INSTALLER UN

Page 20

©ITW Food Equipment Group, LLC

3600 North Point Blvd.

Baltimore, MA 21222

GARDER CE MANUAL POUR UNE UTILISATION FUTURE

FORMULAIRE F-38308 (09-15)

VCRH36

MODELS

VCRH12

VCRH24

VCRH36

WCRH12

WCRH24

WCRH36

Pour obtenir des renseignements supplémentaires au sujet de Vulcan-Hart

ou pour trouver un fournisseur de pièces et service autorisé dans votre

région, veuillez visiter notre site web à www.vulcanequipment.com

MANUEL D’INSTALLATION ET D’EMPLOI POUR

PLAQUES DE CUISSON AU GAZ À FONCTION MOYENNE

Loading...

Loading...