Page 1

©ITW Food Equipment Group, LLC

3600 North Point Blvd.

Baltimore, MD 21222

RETAIN THIS MANUAL FOR FUTURE USE

FORM F-38306 (rev. 10-15)

VCRG48-M

MODELS

VCRG24-M

VCRG36-M

VCRG48-M

WCRG24-M

WCRG36-M

WCRG48-M

For additional information on Vulcan or to locate an authorized parts and

service provider in your area, visit our website at www.vulcanequipment.com

INSTALLATION & OPERATION MANUAL

MEDIUM DUTY GAS GRIDDLES

Page 2

IMPORTANT FOR YOUR SAFETY

Improper installation,

adjustment, alteration, service or maintenance

can cause property damage, injury, or death.

Read the installation, operating and maintenance

instructions thoroughly before installing or

servicing this equipment.

THIS MANUAL HAS BEEN PREPARED FOR PERSONNEL QUALIFIED TO

INSTALL GAS EQUIPMENT, WHO SHOULD PERFORM THE INITIAL FIELD

START-UP AND ADJUSTMENTS OF THE EQUIPMENT COVERED BY THIS

MANUAL.

POST IN A PROMINENT LOCATION THE INSTRUCTIONS TO BE FOLLOWED IN

THE EVENT THE SMELL OF GAS IS DETECTED. THIS INFORMATION CAN BE

OBTAINED FROM THE LOCAL GAS SUPPLIER.

IMPORTANT

IN THE EVENT A GAS ODOR IS DETECTED, SHUT

DOWN UNITS AT MAIN SHUTOFF VALVE AND

CONTACT THE LOCAL GAS COMPANY OR GAS

SUPPLIER FOR SERVICE.

FOR YOUR SAFETY

DO NOT STORE OR USE GASOLINE OR OTHER

FLAMMABLE VAPORS OR LIQUIDS IN THE VICINITY OF

THIS OR ANY OTHER APPLIANCE.

IN THE EVENT OF A POWER FAILURE, DO NOT

ATTEMPT TO OPERATE THIS DEVICE.

- 2 -

Page 3

INSTALLATION, OPERATION AND CARE OF

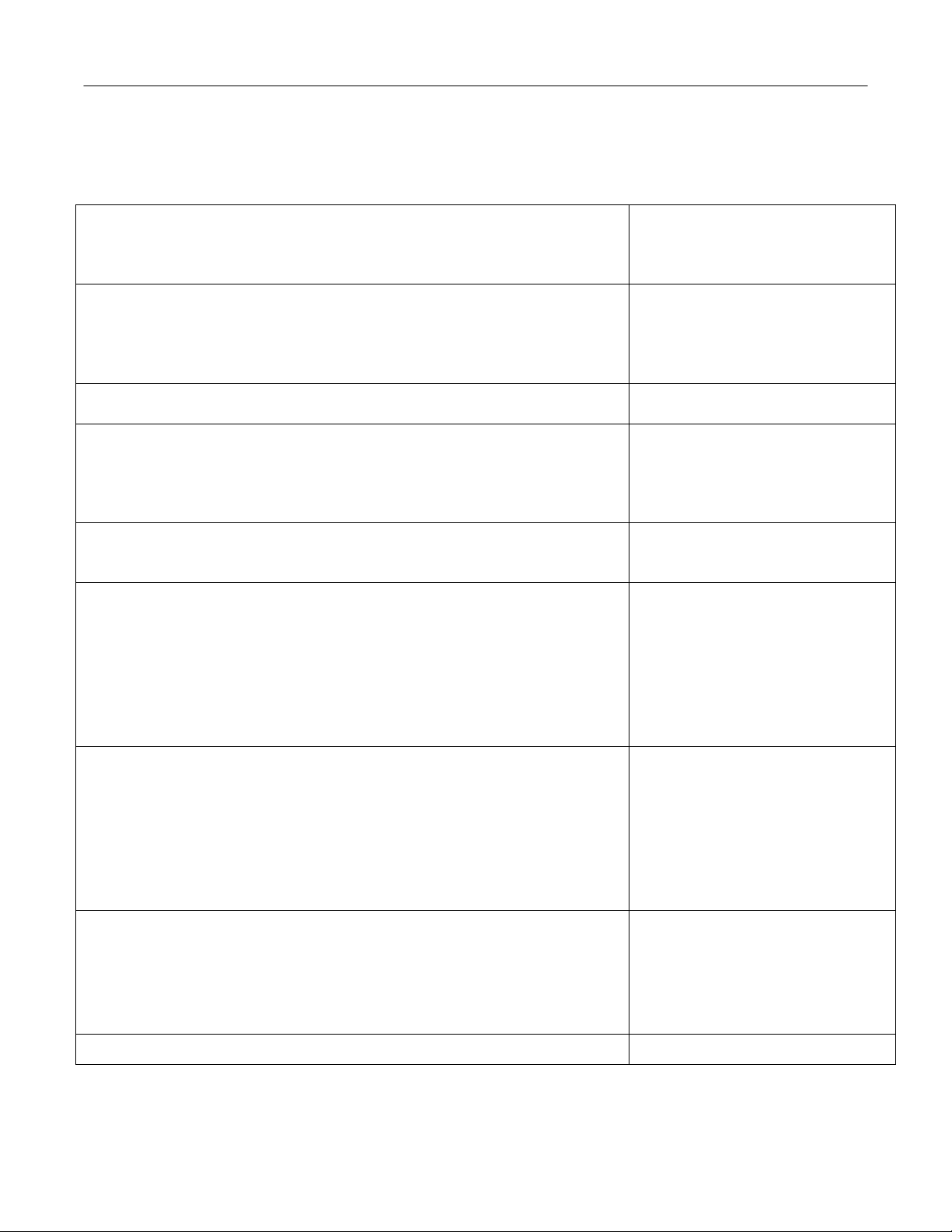

Model

Number Of Burners

BTU/hr Input Rating

VCRG24-M / WCRG24-M

2

50,000

VCRG36-M / WCRG36-M

3

75,000

VCRG48-M / WCRG48-M

4

100,000

MEDIUM DUTY GAS GRIDDLES

GENERAL

Medium Duty Gas Griddles are produced with quality workmanship and materials. Proper

installation, usage and maintenance of your griddle will result in many years of

satisfactory performance.

Thoroughly read this entire manual and carefully follow all of the instructions provided.

INSTALLATION

UNPACKING

This griddle was inspected before leaving the factory. The carrier assumes full responsibility for the

safe delivery upon acceptance of the shipment. Check for possible shipping damage immediately after

receipt.

If the griddle is found to be damaged, complete the following steps:

1. Carrier must be notified within 5 business days of receipt.

2. Carrier’s local terminal must be notified immediately upon discovery (note time, date, and

who was spoken to), and follow up and confirm with written or electronic communication.

3. All original packing materials must be kept for inspection purposes.

4. The griddle cannot have been moved, installed, or modified.

5. Notify Vulcan Customer Service immediately at 800-814-2028.

Carefully unpack your griddle and make sure that no parts are discarded with packaging

material. A pressure regulator designed to operate with the griddle has been supplied and

must be installed before the griddle is placed into service (Refer to GAS PRESSURE

REGULATOR INSTALLATION in this manual).

LOCATION

The installation location must be kept free and clear of combustibles. When installing,

never enclose the bottom of the griddle with a raised curb or other constructions that

would obstruct flow of air into or out of the griddle. Adequate clearance for air openings

into the combustion chamber must be provided. Make sure there is an adequate supply of

air in the room to replace air taken out by the ventilation system.

Do not permit air to blow directly at the griddle. Avoid open windows next to the griddle

wherever possible. Avoid wall-type fans which create air cross-currents within the room.

- 3 -

Page 4

This griddle is Design Certified for installation on a non-com bu s tible counter with 4” l e g s,

COMBUSTIBLE CONSTRUCTION

NON-COMBUSTIBLE CONSTRUCTION

Back:

6”

0”

Sides:

6”

0”

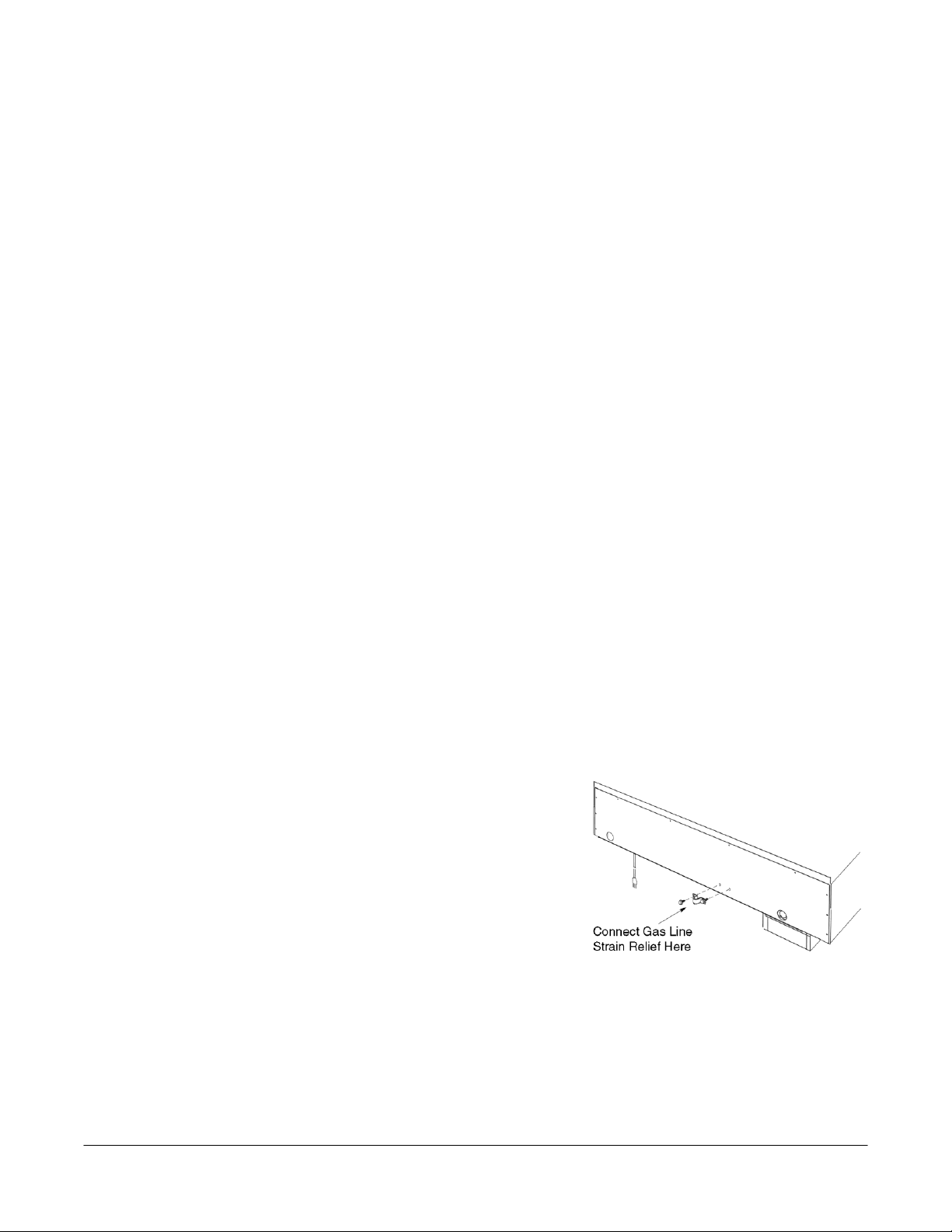

Griddles mounted on stands with casters must use a

flexible connector (not supplied) that complies with the

Standard for Connectors for Movable Gas Appliances

AN SI Z21.6 9 • C S A6.1 6 , and a quick -disconnect device

that complies with Gas Fuel, ANSI Z 2 1. 3 •CSA6.9. I n

addition, adequate means must be provided to limit

movement of the appliance without depending on the

connector and the quick-disconnect device (or its

associated piping) to limit appliance movement. Attach

the restraining device at the rear of the griddle as

shown in Fig. 1.

Fig. 1

or combustible floor with 24” h ig h stand.

INSTALLATION CLEARANCES

INSTALLATION CODES AND STANDARDS

The griddle must be installed in accordance with:

In the United States of America:

1. State and local codes.

2. National Fuel Gas Code, ANSI-Z223.1/NFPA #54 (latest edition). This shall include but

not be limited to: NFPA #54 Section 10.3.5.2 for Venting. Copies may be obtained

from The American Gas Association Accredited Standards Committee Z223, @ 400

N. Capital St. NW, Washington, DC 20001 or the Secretary Standards Council, NFPA,

1 Batterymarch Park Quincy, MA 02169-7471

NOTE: In the Commonwealth of Massachusetts

All gas appliances vented through a ventilation hood or exhaust system equipped with

a damper or with a power means of exhaust shall comply with 248 CMR.

3. NFPA Standard # 96 Vapor Removal from Cooking Equipment, latest edition, available

from the National Fire Protection Association, Batterymarch Park, Quincy, MA 02269.

In Canada:

1. Local codes.

2. CAN/CSA-B149.1 Natural Gas Installation (latest edition)

3. CAN/CSA-B149.2 Propane Installation Code (latest edition), available from the

Canadian Gas Association, 178 Rexdale Blvd., Etobicoke, Ontario, Canada M9W 1R3

GRIDDLES MOUNTED ON STANDS WITH CASTERS

If disconnection of the restraint is necessary, turn off the gas supply before

disconnecting. Reconnect the restraint prior to turning the gas supply on and returning

the griddle to its installation position.

Casters are only supplied on a griddle stand. If the griddle is moved for any reason the

griddle should be re-leveled (see LEVELING in this manual).

- 4 -

Page 5

FLUE CONNECTIONS

Do not obstruct the flow of flue gases from the flue, located at the rear of the griddle. It is

recommended that flue gases be ventilated to the outside of the building through a

ventilation system installed by qualified personnel.

From the termination of the flue to the filters of the hood venting system, a minimum

cle a r a n ce of 1 8” m ust be maintained.

Information on the construction and installation of ventilating hoods may be obtained from

the standard for “Vap o r Removal f rom Cooki ng E q uipment”, NFPA No. 96 ( lat est edition),

available from the National Fire Protection Association, Batterymarch Park, Quincy, MA

02269.

GAS CONNECTIONS

Gas supply connections and any pipe joint compound must be resistant to the

action of propane gases.

Us e a ¾” NPT gas supply lin e for the griddle inlet, lo c a t ed a t the rear of t he g r i d dle. All of

flexible and semi-rigid gas supply lines must comply with the applicable ANSI standard.

To ensure maximum operating efficiency, this appliance must be connected with a gas

supply line of solid pipe or a commercial type Flexible Connector with the net inside

diameter (I.D.) as large as or larger than the gas pipe inlet on this appliance. Codes

require that a gas shutoff valve must be installed in the gas line upstream of the griddle.

Prior to lighting, check all joints in the gas supply line for leaks.

Use soap and water solution. Do not use an open flame.

After checking for leaks all lines receiving gas should be fully purged to remove air.

TESTING THE GAS SUPPLY SYSTEM

When the gas supply pressure exceeds ½ psig (3.45 kPa), the griddle and its individual

shutoff valve must be disconnected from the gas supply piping system.

When the gas supply pressure is ½ psig (3.45 kPa) or less, the griddle should be isolated

from the gas supply system by closing its individual manual shutoff valve.

GAS PRESSURE REGULATOR INSTALLATION

This griddle is supplied with a convertible gas pressure regulator preset at 4” W at er

Column (W.C.) for natural gas. No further adjustment should be required. Install the

regulator as close to the griddle on the gas supply line as possible. Make sure that the

arrow on the underside of the regulator is oriented in the direction of gas flow to the

griddle (Fig. 2 on next page) and the regulator is positioned with the vent plug and

conversion plug cover upright (Fig. 3 on next page).

- 5 -

Page 6

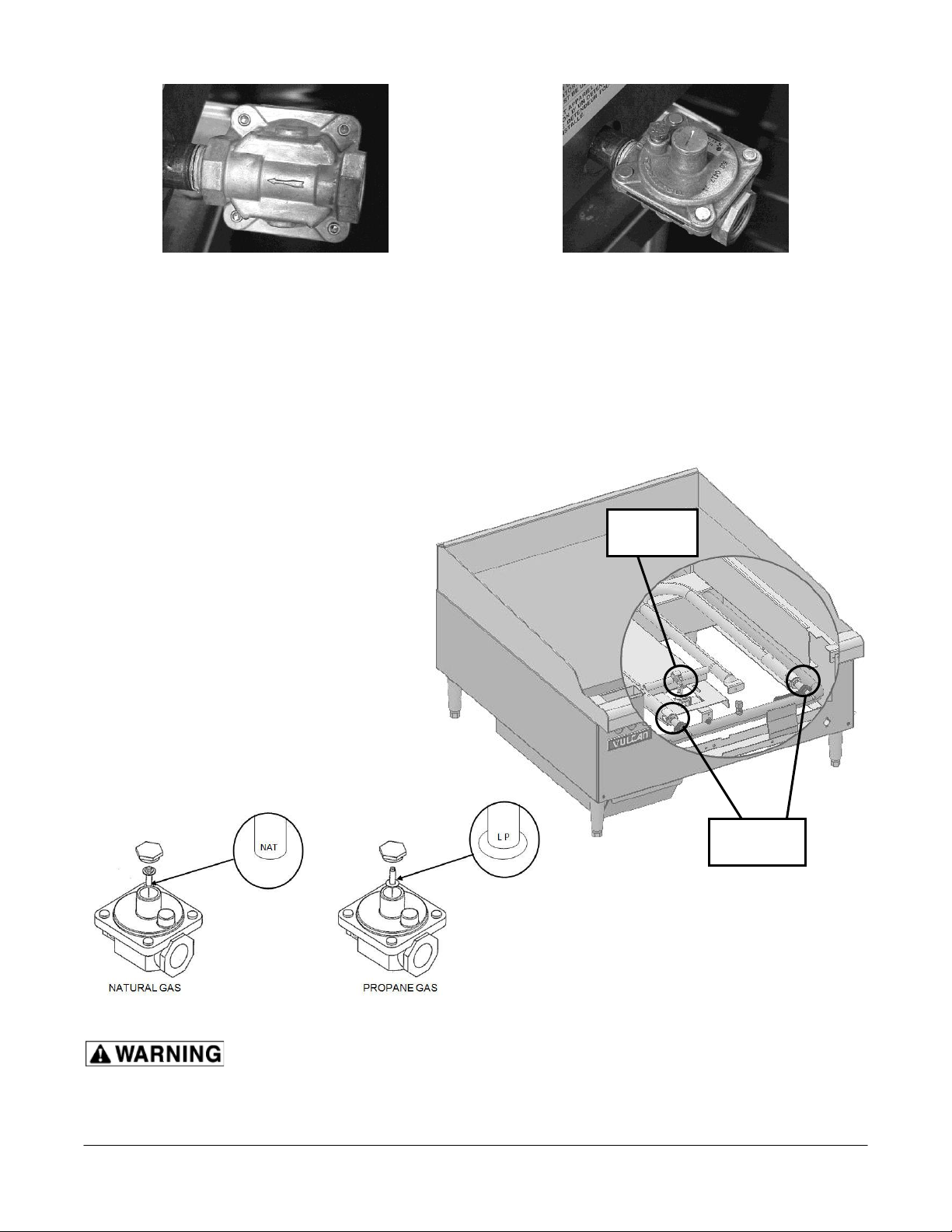

Fig. 2

Fig. 3

The supply pressure (upstream of the regulator) should be 7-9” W.C. for na t ural gas and

To convert to propane, following steps

must be completed:

1. Remove all natural gas burner

orifices and install the provided

propane burner orifices. See Fig. 4

2. Remove all pilot orifices and install

the provided propane pilot orifices.

See Fig 4.

3. Set the regulator to 10” W . C . by

inverting the regulator spring plug.

See Fig 5.

Fig. 4

Fig. 5

BURNER

ORIFICE

PILOT

ORIFICE

11-12” W .C. f or propane gas. At no time should the g r iddle be connected to supply

pressure greater than ½ psig (3.45 kPa) or 14” W. C.

PROPANE GAS CONVERSION

This griddle is shipped from the factory equipped with fixed burner and pilot orifices for

natural gas operation. The burner and pilot orifices required to convert the griddle to

propane gas are shipped with the griddle in the shipping packaging. It is recommended

that a trained gas service technician with the necessary tools, instruments and skills

perform the conversion.

Prior to lighting, check all joints in the gas supply line for leaks.

Use soap and water solution. Do not use an open flame.

- 6 -

Page 7

OPERATION

CONTROL KNOBS

OFF

ON

The griddle and its parts are hot. Use care when operating, cleaning

or servicing the griddle.

BEFORE FIRST USE

Remove all packing material and protective plastic from surfaces of the unit. Before

leaving the factory the griddle is coated with vegetable oil as a rust inhibitor. Remove this

film when the griddle plate is being cleaned prior to its first cooking use. Heat the griddle

to 200-300°F to loosen and melt the coating, then clean the surface with a non-corrosive,

grease dissolving commercial c lean er , following the m anuf a c t u r e r ’ s directions. Rinse

thoroughly and wipe dry with a soft clean cloth. Clean all accessories.

SEASONING THE GRIDDLE

Season the griddle to avoid possible surface corrosion before first use, and after every

cleaning. Heat griddle to a low temperature (300-350°F) and apply a small amount of

cooking oil – about one ounce per square foot of surface. Use a soft lint-free cloth to

spread the oil over the entire griddle surface to create a thin film. Wipe off any excess oil

with a cloth. Repeat the procedure until the griddle has a slick, mirror-like finish. This will

also help reduce the sticking of cooked food product.

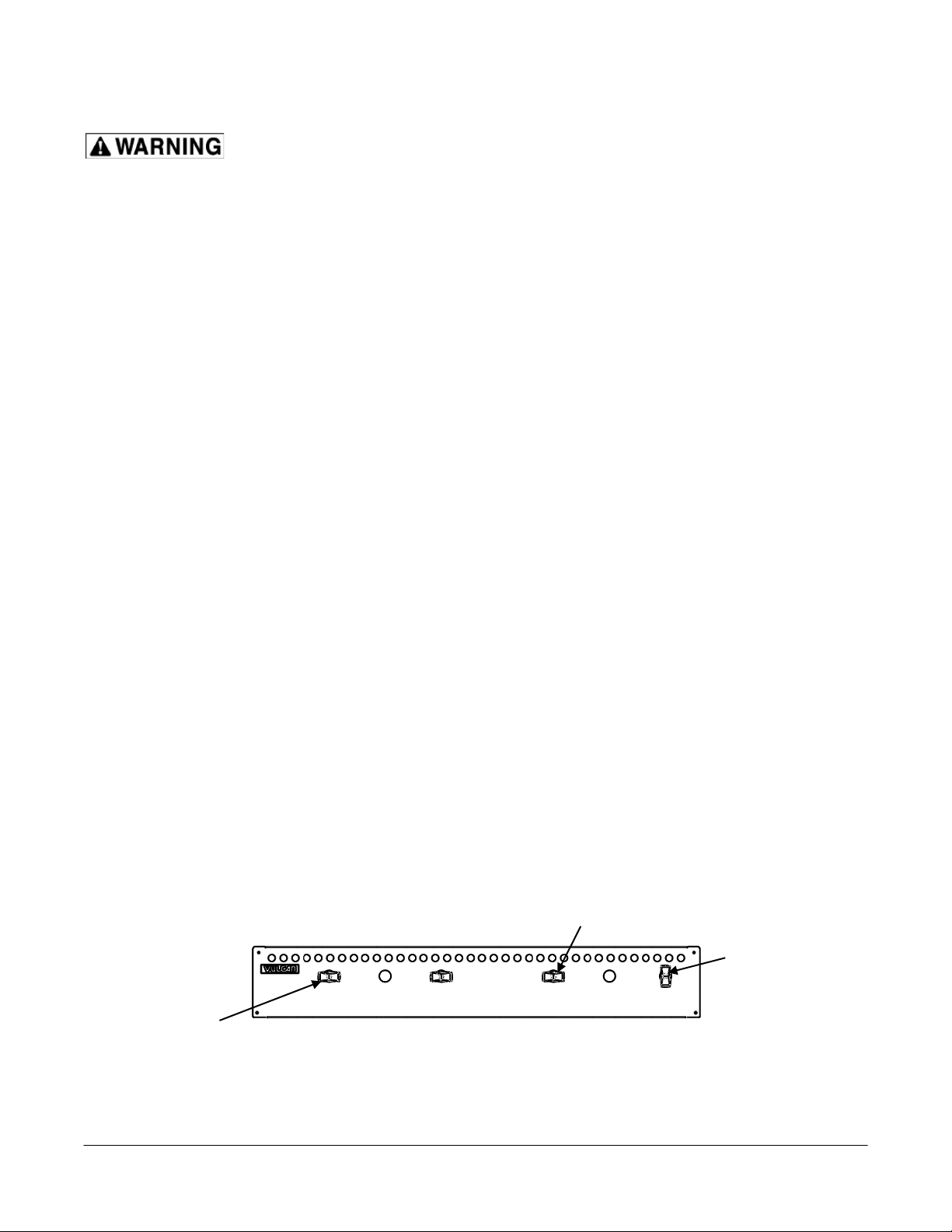

CONTROLS

There is one pi lot for every t wo burners e xcept on t he 36” mo d els. Th e 36” mo de l s have

an odd number of main burners; therefore one of the pilots in these models will control

only one main burner. The pilot burners are off centered ab o ut 1” to th e left of pilot sight

holes and inset approximately 7” f ro m the front panel. See cutaway view on page 8.

The unit is equipped with standing, unmonitored pilots. Gas will flow from the pilots as

soon as the main gas supply to the unit is turned on. The pilots are lit with the use of an

outside ignition source (such as a lit taper, etc). See pilot lighting procedure on page 8.

Ea c h 12” s ect ion of the g r i d dle is indepe n dentl y c ontrol led b y an infinite heat control

valve. Once the pilots are lit, turning the control knob to the ON position will light each

burner. The burners will be in the full ON position when turned all the way to the left.

The burners will be in the full OFF position when turned all the way to the right. See Fig.

6. The height of the burner flame and plate temperature can be adjusted by turning

control knobs while viewing burners through the burner sight holes.

Fig. 6

- 7 -

Page 8

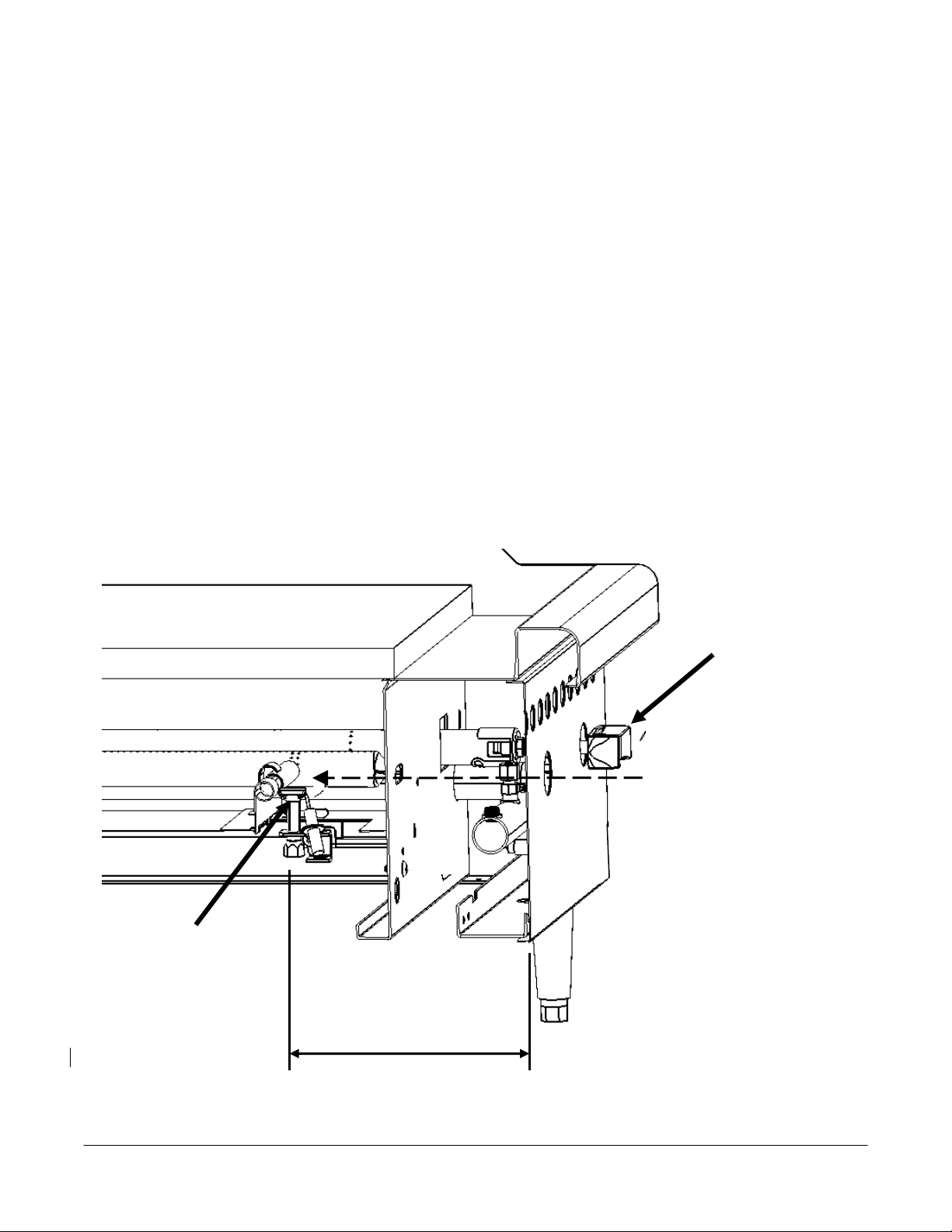

VCRG-M / WCRG-M PILOT LIGHTING PROCEDURE

1. Turn the main gas shut-off valve and all burner control knobs to the OFF position. Wait 5 minutes to

allow any gas that may have accumulated in the burner compartment to escape.

2. Turn the main gas shut-off valve ON.

3. While viewing through the pilot sight hole, you will have to reach under the front of the unit and through

the pilot cutout to ignite the pilots with an outside ignition source(such as a lit taper, etc.). It may be

necessary to adjust the pilot valve to increase gas to the pilot. See Fig. 7 on page 11.

4. Repeat steps until all pilots are lit

5. To light main burners, turn individual burner valves to the ON position.

5. If after completing steps 1-5 main burners do not light, turn off the main gas shut-off valve and

contact an authorized service contractor.

CUTAWAY VIEW

BURNER CONTROL KNOB

PILOT SIGHT HOLE

PILOT BURNER

7”

- 8 -

Page 9

USING THE GRIDDLE

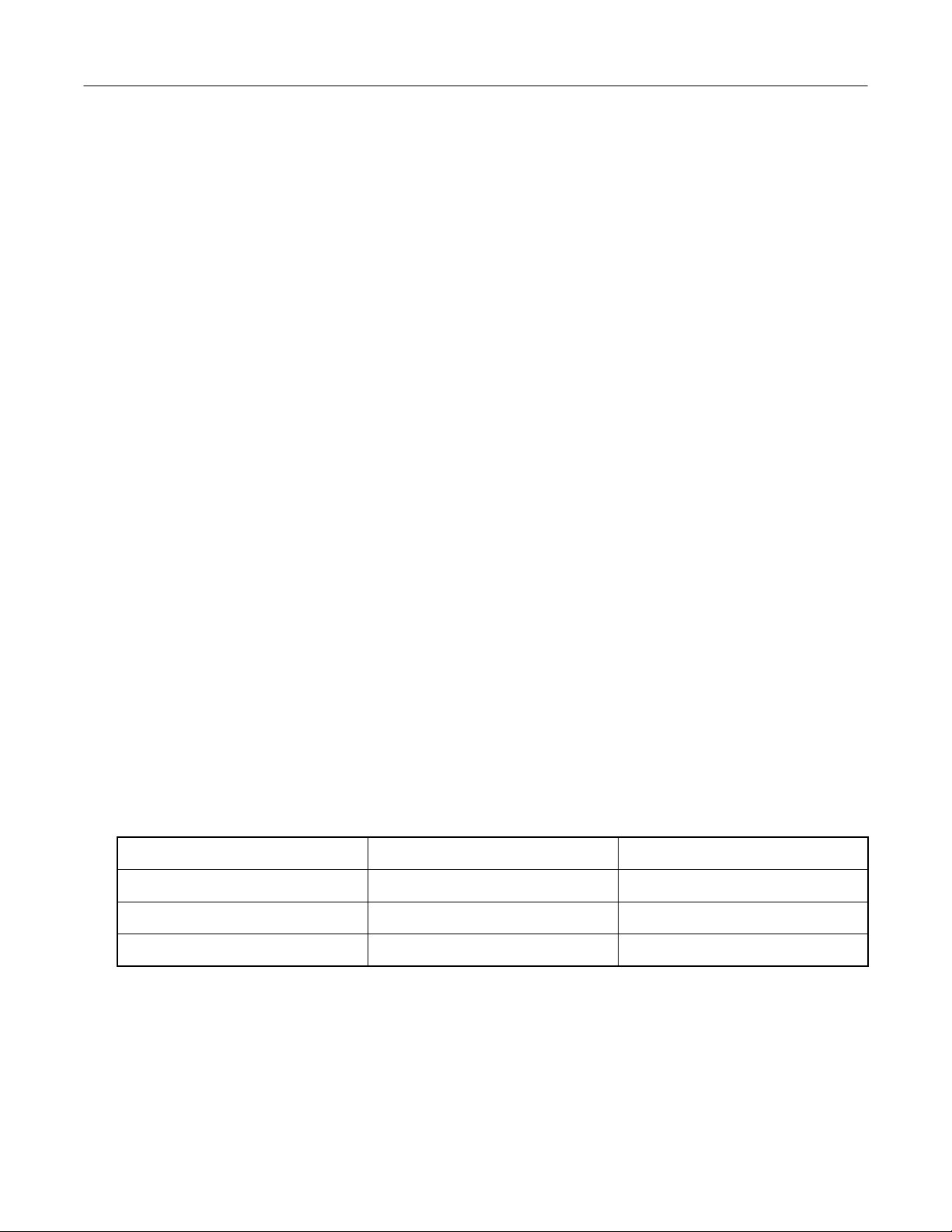

ZONE 1

(300°F)

ZONE 2

(350°F)

ZONE 3

(350°F)

ZONE 4

(400°F)

PRODUCT

Sausage

Eggs (Hard Fried)

Eggs (Scrambled)

Burger (Well Done)

Steak (Well Done)

Chicken Breast

Frozen Foods

Pork Chops

PRODUCT

PRODUCT

Steak (Rare)

Stir Fry Vegetables

Salmon

Fi sh Cakes

Lobster

Scampi

Pancakes

French Toast

Bacon

Omelet

Hash Browns

Canadian Bacon

Eggs (Sunny Side Up)

Boiled Ham

Steak (Medium W ell)

Fresh Burger (Medium W ell)

Small Frozen Burger (Medium W ell)

To preheat, turn the burners on about 20-25 minutes before cooking.

A uniform and systematic approach to loading the griddle will produce the most consistent

product results.

The griddle plate is steel, but the surface is relatively soft and can be scored or dented by

careless use of a spatula or scraper. Be careful not to dent, scratch, or gouge the plate

surface. Do not try to knock off loose food that may be on the spatula by tapping the

corner or the edge of the spatula on the griddle surface.

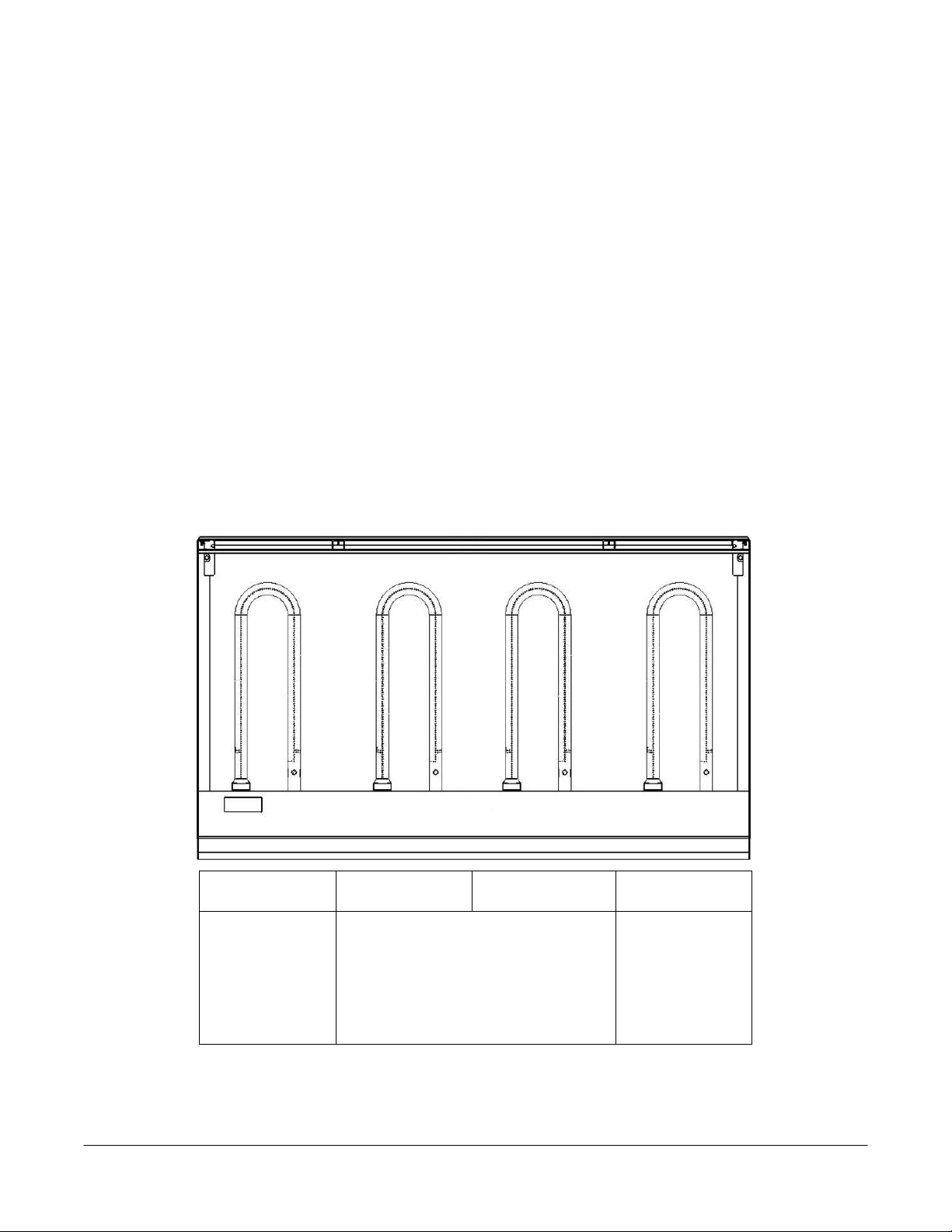

ZONE COOKING

This griddle features a tubular U-shaped burner in each 12” section, each controlled by

independent valves. Each 12” section is a se p ar a t e cooking zone, an d allows cooki n g a

wide variety of products over a single griddle plate. The chart below is a suggested usage

of zone cooking.

When zone cooking, it is suggested that you start with your lowest temperature setting at

either side of the griddle, increasing the zone temperature as you move up the zone line.

These zone cooking guidelines will vary depending on product temperatures, size and

shape. This guide should be adjusted to suit your product and operational cooking

preference.

- 9 -

Page 10

CLEANING THE GRIDDLE

Empty the grease drawer as needed throughout the day and regularly clean at least once

daily.

Clean the griddle regularly. A clean griddle always looks better, lasts longer and performs

better. To produce evenly cooked, perfectly browned griddle products keep the griddle

plate clean and free of carbonized grease. Carbonized grease on the surface hinders the

transfer of heat from the griddle surface to the food, resulting in spotty browning and loss

of cooking efficiency. Carbonized grease tends to cling to griddle foods, giving them a

highly unsatisfactory and unappetizing appearance.

To keep the griddle clean and operating at peak efficiency, follow these procedures:

AFTER EACH USE

Clean the griddle with a wire brush of flexible spatula.

ONCE PER DAY

Thoroughly clean the griddle back splash, sides and front. Remove, empty and wash the

grease drawer in the same manner as an ordinary cooking utensil.

ONCE PER WEEK

Clean the griddle surface thoroughly. Use a griddle stone, screen, or Scotch Bright pad

on the surface as necessary. Rub with the grain of the metal while the griddle is still

warm (not hot). A detergent may be used on the plate surface to help clean it, but be sure

the detergent is thoroughly removed by flushing with clear water.

After removal of detergent the surface of the plate the griddle should be seasoned

according to the instructions in this manual.

Clean stainless steel surfaces with a damp cloth and polish with a soft dry cloth. To

remove discoloration, use a griddle cleaner.

If the griddle usage is very high, consider conducting this weekly cleaning procedure

more than once per week.

LEVELING

The griddle must be level (side-to-side and front-to-back) during operation to ensure

proper performance. Improper leveling can result in uneven temperature distribution, cold

spots, and possibly damaged components.

1. Place a level on the griddle.

2. Adjust legs by turning the bullet feet at the bottom of each leg. Using pliers or a

crescent wrench, turn the feet counter-clockwise to increase height, and clockwise to

decrease height until leveling is achieved. Do not extend the legs more than 1-¾”.

- 10 -

Page 11

PILOT ADJUSTMENT

PILOT ADJUSTMENT SCREW

FIG. 7

Using a flathead screwdriver, turn the slotted hex-head pilot adjustment screw clockwise

to decrease the flame, and counterclockwise to increase the flame. See Fig. 7.

SHUTDOWN OF GRIDDLE WITH STANDING PILOT SYSTEM

1. Turn burner control knobs to the OFF position to cut off burners.

2. The pilots will remain lit as long as the main gas supply is on.

EXTENDED SHUTDOWN

1. Shut off the main gas supply valve.

2. Apply a heavy coat of vegetable oil over the griddle plate to inhibit rust.

- 11 -

Page 12

MAINTENANCE

The griddle and its parts are hot. Use care when operating, cleaning

or servicing the griddle.

LUBRICATION

All valves must be checked and lubricated periodically. Check with your service agency

for details.

VENT

Daily, when the griddle is cool, check the flue and clear any obstructions.

SERVICE AND PARTS INFORMATION

Contact the Service Contractor in your area to obtain service and parts information. For a

complete listing of Service and Parts depots refer to or www.vulcanequipment.com.

When calling for service, the following information should be available from the appliance

identification plate: Model Number, Serial Number and Gas Type.

- 12 -

Page 13

TROUBLESHOOTING

PROBLEM

POSSIBLE CAUSES

Burner does not come on

when the control knob is

turned on

1. Problem with gas valve. (Call for service)

2. Pilot burner not lit. (Call for service)

3. Low gas pressure. (Call for service)

Pilot burner will not light

1. Manual gas valve not turned on.

2. Obstructed pilot orifice. (Call for service)

3. Pilot gas turned off at pilot. Adjust pilot to allow gas flow.

4. Low gas pressure. (Call for service)

Pilot burner will not stay

lit

1. Obstructed or wrong size pilot orifice. (Call for service)

2. Gas supply not purged of air. Open pilot valve until air is

purged.

3. Air blowing pilot out. (Call for service)

4. Low gas pressure. (Call for service)

Fat appears to smoke

excessively

1. Temperature set too high.

2. Moisture in food may be turning into steam

Food sticks to griddle or

burned around edges or

contains dark specs

1. Temperature set too high.

2. Griddle surface requires cleaning and/or seasoning.

3. Surface under food not covered with enough cooking oil.

Food under-cooked inside

1. Temperature set too low.

2. Food not cooked for long enough time.

Food tastes greasy or has

objectionable off-flavor

1. Food itself may have off-flavor.

2. Food stored improperly before cooking.

3. Too much griddle fat used.

4. Temperature set too low.

Noticeable build-up of

gum on griddle

1. Temperature set too high.

2. Griddle surface needs cleaning and/or seasoning.

3. Too much griddle fat used.

- 13 -

Page 14

NOTES

- 14 -

Page 15

- 14 -

REMARQUES

Page 16

- 13 -

PROBLÈME

CAUSES POSSIBLES

Le brûleur ne s’ouvre pas

lorsque le bouton de

commande est ouvert

1. C’est un problème avec la soupape à gaz (Contactez le

service à la clientèle).

2. La veilleuse du brûleur n’est pas allumée. (Contactez le

service à la clientèle).

3. La pression du gaz est basse. (Contactez le service à la

clientèle).

La veilleuse n’est pas

allumée

1. La soupage manuelle du gaz n’est pas ouverte.

2. L’orifice de la veilleuse d’allumage est obstrué.

(Contactez le service à la clientèle).

3. La veilleuse du gaz est fermée. Réglez la veilleuse

d’allumage pour permettre la circulation du gaz.

4. La pression du gaz est basse. (Contactez le service à la

clientèle).

La veilleuse d’allumage ne

reste pas allumée

1. L’orifice de la veilleuse d’allumage est obstrué ou n’a pas

la bonne dimension. (Contactez le service à la clientèle).

2. L’alimentation en gaz n’a pas été vidée de son air. Ouvrez

la soupape de la veilleuse jusqu’à ce que l’air soit évacué.

3. Il y a de l’air qui sort de la veilleuse. (Contactez le service

à la clientèle).

4. La pression du gaz est basse. (Contactez le service à la

clientèle).

Le gras semble causer de la

fumée de façon excessive

1. La température est trop haute.

2. L’humidité dans la nourriture peut se transformer en

vapeur

La nourriture colle sur la

plaque ou brûle sur les

bouts ou a des taches

foncées

1. La température est trop haute.

2. La surface de la plaque nécessite un nettoyage ou un

rodage.

3. La surface sous la nourriture n'a pas été assez enduite

d’huile végétale.

La nourriture n’est pas

assez cuite à l’intérieur

1. La température est trop basse.

2. La nourriture n’a pas été cuite assez longtemps.

La nourriture goûte le gras

ou a un goût altéré

désagréable

1. La nourriture elle-même a un goût altéré.

2. La nourriture a été gardée dans de mauvaises conditions

avant la cuisson.

3. Il y a trop de gras utilisé sur la plaque

4. La température est trop basse.

Accumulation visible de

gomme sur la plaque

1. La température est trop haute.

2. La surface de la plaque a besoin d’un nettoyage ou d’un

rodage.

3. Il y a trop de gras utilisé sur la plaque

DÉPANNAGE

Page 17

- 12 -

de série et le type de gaz.

disponibles sur la plaque d'identification de l'appareil : le numéro du modèle, le numéro

Lorsque vous appelez pour du service, les renseignements suivants devraient être

www.vulcanequipment.com.

l’entretien et les pièces. Pour une liste des bureaux des services et des pièces, consultez

Contactez le service à la clientèle de votre région pour obtenir des renseignements sur

RENSEIGNEMENTS SUR L’ENTRETIEN ET LES PIÈCES

toute obstruction.

Quotidiennement, lorsque la plaque chauffante est refroidi, vérifiez le conduit et retirez

VENTILATION

la clientèle pour de plus amples détails.

On doit vérifier et lubrifier toutes les soupapes régulièrement. Contactez votre service à

LUBRIFICATION

chauffante.

attention lorsque vous employez, nettoyez ou vous vous servez la plaque

La plaque chauffante et ses pièces sont chaudes. Faites

ENTRETIEN

Page 18

- 11 -

VIS DU RÉGLAGE DE LA VEILLEUSE D’ALLUMAGE

FIG. 7

2. Mettez une généreuse couche d’huile végétale sur la plaque pour empêcher la rouille.

1. Fermez le robinet principal d’alimentation en gaz.

FERMETURE PROLONGÉE

principale en gaz est ouverte.

2. Les veilleuses d’allumage resteront allumées aussi longtemps que l'alimentation

1. Fermez les boutons de commande pour éteindre les brûleurs.

FERMETURE DE LA PLAQUE AVEC SYSTÈME DE VEILLEUSES PERMANENTES

7.

et dans le sens contraire des aiguilles d'une montre pour augmenter la flamme. Voir Fig.

la veilleuse d’allumage dans le sens des aiguilles d'une montre pour diminuer la flamme

À l’aide d’un tournevis à tête plate, tournez la vis à tête hexagonale f endue de réglage de

RÉGL AGE DE LA VEILLEUSE D’ALLUMAGE

Page 19

- 10 -

jusqu’à ce que l a m ise à ni vea u so it ef fect ué e. Ne pas allonger les pattes plus de 4 cm .

augmenter la hauteur et dans le sens des aiguilles d'une montre pour diminuer la hauteur

d’une clé à molette , tournez les pieds dans le sens contraire des aiguilles d'une montre pour

2. Ré glez les pattes en to urn ant les pieds en b as de chaque patte. À l’a ide d’une pince -étau ou

1. Placez un niveau sur la plaque chauffante.

composants endommagés.

peut provoquer une répartition de la température inégale, des zones froides et possiblement des

quand vous l'utilisez pour assurer une performance adéquate. Une mise à niveau inadéquate

La plaque chauf fant e do it être mise à niveau (d’ u n c ôté à l’autr e et du devant vers l’arrièr e)

MISE À NIVEAU

hebdomadaire de net toyag e plus d’u ne f ois par sem aine .

Si vous utilisez très souvent la plaque chauffante, songez à effectuer cette procédure

Pour enlever la décoloration, utilisez un nettoyant pour plaque chauffante.

Nettoyez la surface en acier inoxydable avec un linge humide et polissez avec un linge sec doux.

ce manuel.

Après avoir enlevé le détersif, la surface de la plaque devrait être rodée selon les instructions de

de l'eau claire.

de la plaque pour vous aider à nettoyer, mais assurez-vous qu’il n'e n res te plus en rinçan t avec

pendant la plaque est encore tiède (pas chaude). Vous pouvez utiliser un détersif sur la surface

une toile ou un tampon Scotch Bright sur la surface au besoin. Frottez avec le grain métallique

Nettoyez à fond la surface de la plaque chauffante. Utilisez une pierre pour plaque chauffante,

UNE FOIS PAR SEMAINE

Retirez, videz e t l avez le tir oir à gra iss e d e l a m êm e f aç on q u’u n ust ens il e de cuis ine ord inai re.

Nettoyez à fond le dos antiéclaboussement, les côtés et le devant de la plaque chauffante.

UNE FOIS PAR JOUR

Nettoyez la plaque chauffante avec une brosse métallique d'une spatule de plastique .

APRÈS CHAQUE UTILISATION

procédures :

Pour garder la plaque cha uff ante propre et l ’util iser à un rend em ent opt imum, suivez ces

très insatisfaisante et peu appétissante.

gras carbonisé a tendance à adhérer aux aliments cuits sur plaque, leur donnant une apparence

nourriture, provoquant du brunissement par endroits et de la perte d’eff icac ité de cuisson . Le

carbonisé sur la surface empêche le transfert la chaleur de la surface de la plaque à la

façon uniforme et parfaitement grillés, garder la plaque propre et sans gras carbonisé. Le gras

aspect, dure plus longtemps et a une meilleure performance. Pour obtenir des aliments cuits de

Nettoyez régulièrement la plaque chauffante Une plaque chauffante propre a toujours un meilleur

moins une fois par jour.

Videz le tiroir à graisse au besoin tout au long de la journée et le nettoyez régulièrement au

NETTOYAGE DE LA PLAQUE CHAUFFANTE

Page 20

- 9 -

ZONE 1

(300°F)

ZONE 2

(350°F)

ZONE 3

(350°F)

ZONE 4

(400°F)

PRODUIT

Saucisse

Oeufs (poêlés)

Oeufs (brouillés)

Hamburger (bien

cuit)

Bifteck (bien cuit)

Poitrine de poulet

Aliments congelés

Côtelette de porc

PRODUIT

PRODUIT

Bifteck (saignant)

Légumes sautés

Saumon

Galettes de poisson

Homard

Langoustine

Crêpes

Pain doré

Bacon

Omelette

Pommes de terre

rissolées

Bacon de dos

Oeufs (au miroir)

Jambon blanc

Bifteck (médium)

Hamburger (médium)

Petit hamburger congelé (médium)

devrait être réglé selon votre préférence de produits et de fonctionnement lors de la cuisson.

les zones de cuisson varieront selon les températures, la taille et la forme du produit. Ce guide

zones au fur et à mesure que vous vous déplacez tout au long de celles-ci. Ces directives pour

la plus basse température d'un côté ou l'autre de la plaque et d'augmenter la température des

Lorsque vous utilisez les zones de cuisson, nous vous suggérons de commencer par celle qui a

démontre un usage suggéré des zones de cuisson.

permet la cuisson d’un grand nombre de produ its sur une se ule plaque. Le graphique ci -dessous

par des soupapes indépendantes. Chaque section de 30 cm est une zone de cuisson séparée et

La plaque a un brûleur tubulaire en forme de U dans chaque section de 30 cm, chacun contrôlé

ZONES DE CUISSON

spatule en tappant sur le coin ou le bout de la spatule sur la surface de la plaque.

ou percer la surface de la plaque. Ne pas essayer de retirer la nourriture qui se retrouve sur la

un m au vais usage d'une spatule ou d’un gr at toir . Faites attention de ne pas boss eler , égratigner

La plaque est en acier, mais la surface est relativement douce et peut être rayée ou bosselée par

plus constants.

Un approche uniforme et méthodique pour remplir la plaque chauffante produira les résultats les

Pour préchauffer, ouvrez les brûleurs environ 20 à 25 minutes avant la cuisson.

UTILISATION LA PLAQUE CHAUFFANTE

Page 21

- 8 -

PROCÉDURE D’ALLUMAGE DE LA VEILLEUSE VCRG-M / WCRG-M

1. Fermez le robinet d’arrêt principal du gaz et tous les boutons de commande du brûleur. Attendez 5

minutes pour permettre à tout gaz accumulé dans le compartiment des brûleurs de s’échapper.

2. Ouvrez le robinet d’arrêt principal du gaz.

3. Tout en surveillant par le trou de regard de la veilleuse, vous devez atteindre le dessous à l’avant de

l’appareil et la fente de la veilleuse pour l’allumer à l’aide d’une source d'inflammation extérieure (telle

qu’une tige pour allumer les bougies, etc.). Il peut être nécessaire de régler la soupape de la veilleuse

pour augmenter le gaz. Voir Fig. 7 à la page 11.

4. Répéter les étapes jusqu’à ce que toutes les veilleuses soient allumées.

5. Pour allumer les brûleurs principaux, ouvrez les soupapes individuelles des brûleurs.

6. Si les brûleurs principaux ne s’allument pas après avoir complété les étapes 1 à 5, fermez le robinet

d’arrêt principal du gaz et contactez le service à la clientèle autorisé.

VUE DE COUPE

BOUTONS DE COMMANDE

TROU DE REGARD

VEILLEUSE D’ALLUMAGE 18 cm

Page 22

- 7 -

BOUTONS DE COMMANDE

FERMÉ

OUVERT

Fig. 6

regard.

plaque en tournant les boutons de commande tout en surveillant les brûleurs par leurs trous de

droite. Voir Fig. 6. On peut régler la hauteur de la flamme des brûleurs et la température de la

brûleurs sero nt complètement à la p os ition FERMÉ lor squ’ ils seront tour nés jusqu’au bout vers la

complètement à la p osition OUVERT lorsqu ’ils seront tournés jusqu’au bout vers la gauc he . Les

bouton de commande à la position OUVERT allumera chaque brûleur. Les brûleurs seront

soupape de réglage infini de la chaleur. Une fois que les veilleuses sont allumées, tourner le

Chaque section de 30 cm de la plaque chauffante est contrôlée indépendamment par une

allumer les bou gies, et c.). Voir la proc édur e d’ allum age de la veil leus e à la p age 8.

veilleuses sont al lum ées à l’aide d’une source d'inf lamm ation extérieure (te lle qu’une ti ge pour

partir des veilleuses dès qu e l’a li mentation pri ncip ale e n ga z de l’ap pare il es t ouverte. Les

L’appareil est muni de veilleuses d’allum ag e perman en tes non contrôlé es. Le ga z circulera à

environ 18 cm du panneau avant. Voir la vue de coupe à la page 8.

d'allumage sont centrées à 8 cm à gauche des trous de regard des veilleuses et incrustées à

veilleuses d’allum age de ces modè les con trôl er a seu lem ent un brûleur princ ipa l. Les veilleu ses

modèles de 91 cm ont un nombre inhabituel de brûleurs principaux; par conséquent, une des

Il y a une veilleuse d’ allum age p our de ux brûl eurs e xcepté sur les modèles de 91 cm. Les

COMMANDES

aliments cuits qui collent.

jusqu’à ce que la plaque chauffant e ait un fini lisse , lustr é. Cela vous aidera aussi à réduir e les

de produire une mince pellicule. Essu yez tout excès d’huile avec un linge. Répétez la proc édur e

doux no n peluch eux pour répartir l’hu ile sur la totalité de la s urf ac e de la plaque chauffante afin

une petite quantité d’huile de cuisson – une once par pied carré de la surface. Utilisez un chiffon

utilisation et après le nettoyage. Chauffez la plaque à basse température (149-177°C) et mettez

Rodez la plaque chauffante pour éviter la possible corrosion de la surface avant la première

RODAGE DE LA PLAQUE CHAUFFANTE

Rincez à fond et essuyez avec un linge doux propre. Nettoyez tous les accessoires.

surface avec un nettoyant commercial dissolvant les graisses, selon les directives du fabricant.

cuisine. Chauffez la plaque à 93-149°C pour desserrer et faire fondre la couche, puis nettoyez la

Retirez cette pellicule lors du nettoyage de la plaque chauffante avant la première utilisation en

Avant de quitter l’us ine , la plaque chauffan te est enduite d'hu ile végét ale en tant qu'antir oui lle.

Retirez tout le mat érie l d ’em balla ge e t la pr otect ion en plast iqu e des surfaces d e l ’app are il.

AVANT LA PREMIÈRE UTILISATION

attention lorsque vous employez, nettoyez ou vous vous servez la plaque chauffante.

La plaque chauffante et ses pièces sont chaudes. Faites

EMPLOI

Page 23

- 6 -

Fig. 2

Fig. 3

Pour convertir au propane, les étapes

suivantes doivent être remplies :

1. Retirez tous les orifices de combustion

pour le gaz naturel et installez les

orifices de combustion pour le propane

fournis. See Fig. 4

2. Retirez tous les orifices de veilleuse

pour le gaz naturel et installez les

orifices de veilleuse pour le propane

fournis. Voir Fig. 4.

3. Placez le régulateur à 25 cm CE en

retournant le tampon de ressort du

régulateur. Voir Fig. 5.

Fig. 4

Fig. 5

ORIFICE de

veilleuse

ORIFICE

DE

COMBUSTION

open flame.

d’alimentation en gaz pour les fuites. Use soap and water solution. Do not use an

Avant l’allumage, vérifiez tous les joints dans la conduite

instruments et les compétences nécessaires effectue la conversion.

l’emballage. On recommande qu’un techn icien qualif ié du serv ice de gaz avec les outi ls, les

nécessaires pour convertir la plaque chauffante au gaz propane sont livrés avec celle-ci dans

d’allumage pour l’emploi du ga z naturel. Les or if ices de combustion et de veilleuse d’allumage

Cette p laq ue chauff ante est livrée de l’us ine mu nie d'orifices fixes de combustion et de veilleuse

CONVERSION DU GAZ PROPANE

CE.

moment être connectée à une pression d’ali mentation supérieure à ½ psi (3 ,45 kPa) ou 36 cm

naturel et de 28 à 30 cm CE pour le gaz propane. La plaque chauffante ne devrait à aucun

La pression d'alimentation (en amont du régulateur) devrait être de 18 à 23 cm CE pour le gaz

Page 24

- 5 -

conversion à droite (Fig. 3 à la page suivante).

le régulateur es t placé avec le bouchon d’aération ainsi que le couverc le de la pr is e d e

dans la direction de la circulation du gaz à la plaque chauffante (Fig.2 à la page suivante) et que

conduite d’alim entat ion en gaz. Assur ez-vous que la flèche au-dessous du régulateur est orientée

nécessaire. Installez le régulateur aussi près que possible de la plaque chauffante sur la

10 cm de colonne d’eau (CE) pour le gaz naturel. Aucun réglage suppl ém entair e ne devrait être

Cette plaque chauffante est offerte avec un régulateur de pression du gaz convertible préréglé à

INSTALLATION DU RÉGULATEUR DE PRESSION DU GAZ

manuel individuel.

chauffante devrait être isolée du système d’alimentation en ga z en ferm ant son robinet d’arr êt

Lorsque la pr essi on de l’ a lim enta tio n e n gaz est de ½ psi (3 ,45 kPa) o u m oins , la p laq ue

gaz.

son robinet d’arrêt in div iduel doivent êtr e débranchés du systèm e de tuyauterie d’alimentation en

Lorsque la pression de l’alimentation en gaz ex cè de ½ psi (3,4 5 kPa), la pla que chauff ant e et

ÉVALUATION DU SYSTÈME D'ALIMENTATION EN GAZ

entièrement vidé es pou r e nlever l’ air.

Après avoir vérifié s'il y a des fuites, toutes les conduites recevant du gaz devraient être

une flamme nue.

d’alimentation en g az pour les fuites. Ut ili sez une so luti on d’eau et savon . Ne pas uti lise r

Avant l’allumage, vérifiez tous les joints dans la conduit e

robinet d’arrêt d u gaz s oit i nstal lé dans la co nduite de gaz en am ont d e la p laq ue c ha uff ant e.

lar ge ou plus large que l’e ntré e du tu yau de ga z s ur cet ap par ei l. Les codes exigent qu e le

non perforé ou un raccord flexible de type commercial ayant un diamètre intérieur (Di) net aussi

fonctionnement, cet appareil doit être connect é à une conduite d’alimentation en gaz d’un tuyau

rigides do iven t être co nf orm es à la norme AN SI applicable. Pour assurer l’efficacité maximum du

située à l'arrière de la plaque. Toutes les conduites d'alimentation en gaz flexibles et semi-

Utilisez une condu ite d’alim ent ation en gaz NPT de 2 cm pour l’entrée de la plaque chauffante,

Toutes les conn ex io ns et tout e p ât e à jo ints d oi vent rés ist er à l ’act ion du g az pr op ane.

CONNEXIONS DU GAZ

auprès de la National Fire Protection Association, Batterymarch Park, Quincy, MA 02269.

la norme « Vapor Removal from Cooking Equipment », NFPA no 96 , dernière édition, disponible

Les renseignements sur la construction et l'installation des hottes à évacuation sont décrits dans

hotte à évacuation.

Un espace minimum de 46 cm doit maintenu à partir de la fin du conduit aux filtres du système de

de l'édifice à l'aide d'un système de ventilation installé par du personnel compétent.

de la plaque chauffante. On recommande que les gaz de combustion soient aspirés à l'extérieur

Ne pas obstruer la circulati on des gaz de combustion proven an t des conduits, situés à l’arrière

CONNEXIONS DES CONDUITS

Page 25

- 4 -

CONSTRUCTION COMBUSTIBLE

CONSTRUCTION INCOMBUSTIBLE

Derrière :

15 cm

0 cm

Côtés :

15 cm

0 cm

Les plaques chauffantes sur supports avec roulettes doivent

employer un raccord flexible (non fourni) qui est conforme à

la norme Connectors for Movable Gas Appliances, ANSI

Z21.69 • CS A 6. 16 et un dispositif de prise à démontage

rapide qui est conforme à la norme Gas Fue l, ANSI Z21.3 •

CSA 6.9. De plus, des mesures appropriées doivent être

apportées pour lim it er le mouvement l’appareil sans

dépendre du connecteur et du dispositif de prise à

démontage rapide ou de leurs conduites associées. Attachez

le dis posit if de retenue à l’arrière de la plaque chauffante tel

qu’illustré dans la F ig. 1.

Fig. 1

pour quelque raison que ce soit.

chauffante à niveau une autre fois (voir MISE À NIVEAU dans ce manuel) si elle est déplacée

Les roulettes seulement fournies pour les modèles avec supports. On devrait mettre la plaque

chauffante à l'endroit où elle doit être installée.

débrancher. Rebranchez le dispositif avant d’ouvrir l’a lim ent ati on en ga z et replace z la plaqu e

Si le débr anc hem ent du dispos itif est nécessa ire, fermez l ’alim en tati on en gaz avant de

PLAQUES CHAUFFANTES MONTÉES SUR SUPPORTS AVEC ROULETTES

l’Association Ca nadi en ne d u G az, 1 78 b oul . Rexdale, Etobicoke, Ontario, Canada M9W 1R3

3. Code d'installation du propane CAN/CSA-B149.2 (dernière édition), disponible auprès de

2. Code d'installation du gaz naturel CAN/CSA-B149.1 (dernière édition)

1. Codes locaux.

Au Canada :

auprès de la National Fire Protection Association, Batterymarch Park, Quincy, MA 02269.

3. La norme NFPA no 96 Vapor Removal from Cooking Equipment, dernière édition, disponible

qui doit être conforme à 248 CMR.

d'échappement muni d’ une clef de réglage ou avec une moyenne potentiell e d’échappem en t

Tous les appareils d'utilisation du gaz aérés grâce à une hotte de ventilation ou un système

REMARQUE : D ans l’É tat du Mass ach use tts

Batterymarch Park Quincy, MA 02169-7471

N. Capital St. NW, Washington, DC 20001 ou le Secretary Standards Council, NFPA, 1

copies auprès de l’American Gas Assoc iatio n Accredited Standards Committee Z223, à 400

sans être limité à : NFPA No54 Section 10.3.5.2 pour la ventilation. Vous pouvez obtenir des

2. National Fuel Gas Code, ANSI-Z223.1/NFPA No54 (dernière édition). Cela doit comprendre

1. Codes locaux et d ’ét at.

Aux États-Unis d'Amérique :

La plaque chauffante doit être installée conformément à :

CODES ET NORME S D ’INS TALLATION

ESPACES À PRÉVOIR DURANT L'INSTALLATION

Page 26

- 3 -

Modèle

Nombre de brûleurs

Débit calorifique BTU/h

VCRG24-M / WCRG24-M

2

50 000

VCRG36-M / WCRG36-M

3

75 000

VCRG48-M / WCRG48-M

4

100 000

61 cm.

combustible avec pattes de 10 cm ou sur un plancher combustible avec supports élevés de

Cette plaque chauff ante est une conc ep tio n hom ologu ée pour l’installation sur un compto ir no n

courants d’air en bi ais à tr a ver s la pi èce.

de la plaque chauffante là où c’es t possible. Évitez les ventilateurs de typ e mural qui cr ée nt des

Empêchez l’air de circu ler directement s ur la pla que chauffante. Évitez d’o uvr ir de s fenêtres près

remplacer l'air sorti par le système de ventilation.

combustion. Assurez-vous q u ’il y ait s uf fisa mment d'alimentatio n en air dans la pièc e a fin de

chauffante. On doit donner suffisamment d'espace pour les ouvertures d'air de la chambre de

constructions qui pourrait obstruer la c ircu lat ion de l’air à l’ intér ieur ou à l’ex tér ieur de la plaque

ne jamais entourer le bas de la plaque chauffante avec une bordure en relief ou autres

Le lieu de l’installation doit être maintenu san s présence de combust ibl es. Lors de l’installat ion,

EMPLACEMENT

INTALLATION DU RÉGULATEUR DE PRESSION DU GAZ dans ce manuel).

été fourni et doit être installé avant que la plaque chauffante soit mise en service (Consultez

avec l’emballage. Un régulate ur de pressio n conçu pour fonct ion ner a vec la plaque chauf fant e a

Déballez soigneusement votre plaque chauffante et assurez-vous qu’aucun e partie n’ a été jetée

5. Avisez le Service à la clientèle de Vulcan immédiatement en faisant le (800) 814-2028.

4. Le gril ne doit pas avoir été déplacé, installé ou modifié.

3. Pour fins d’inspection, tout le matériel d’emballage original doit être conservé.

écrit ou par communication électronique.

dommages (indiquez l’heure, la date et à qui vous avez parlé) et assurez le suivi en confirmant les faits par

2. Les gens du terminus local du transporteur doivent être avisés immédiatement lors de la découverte des

1. Le transporteur doit être averti dans les 5 jours ouvrables suivant la réception.

S’il s’avère que le gril a été endommagé, veuillez suivre les procédures suivantes :

dommages pendant le transport.

responsabilité de le livrer en toute sécurité. Immédiatement après la livraison, vérifiez s’il a effectivement subi des

Ce gril a été inspecté avant de quitter l’usine. En acceptant sa livraison, le transporteur prend l’entière

DÉBALLAGE

INSTALLATION

Lisez entièrement ce manuel et suivez attentivement toutes les instructions données.

plaque chauffante vous apporteront de nombreuses années de performance satisfaisante.

l'exécution et des matériaux. L’installation , l’utilisation et l’entretien adéquats de votre

Les plaques chauffantes à fonction moyenne sont produites avec une qualité de

GÉNÉRAL

PLAQUES CHAUFFANTES AU GAZ À FONCTION MOYENNE

INSTALLATION, EMPLOI ET ENTRETIEN DES

Page 27

- 2 -

Une installation, un

ajustement, une modification, un service ou un

entretien inapproprié peut causer du dommage

matériel, une blessure ou la mort. Lire

minutieusement les instructions d’installation,

d’emploi et d’entretien avant d’installer ou

d’entretenir cet équipement.

DE FAIRE FONCTIONNER CET APPAREIL.

EN CAS DE PANNE DE COURANT, NE PAS TENTER

APPAREIL.

À PROXIMITÉ DE CET APPAREIL OU TOUT AUTRE

OU AUTRES VAPEURS OU LIQUIDES INFLAMMABLES

NE PAS ENTREPOSER OU UTILISER DE L’ESSENCE

POUR VOTRE SÉCURITÉ

DE GAZ LOCAL AFIN D’OBTENIR DU SERVICE.

COMPAGNIE DE GAZ OU VOTRE FOURNISSEUR

D'ARRÊT PRINCIPAL ET CONTACTEZ VOTRE

DÉTECTÉE, FERMEZ LES UNITÉS DU ROBINET

AU CAS OÙ UNE ODEUR DE GAZ SERAIT

IMPORTANT

LOCAL.

POUVEZ DEMANDER CES RENSEIGNEMENTS AU FOURNISSEUR DE GAZ

ÊTRE SUIVIES AU CAS OÙ UNE ODEUR DE GAZ SERAIT DÉTECTÉE. VOUS

IMPORTANT POUR VOTRE SÉCURITÉ

PLACEZ DANS UN ENDROIT IMPORTANT LES INSTRUCTIONS QUI DOIVENT

RÉGLAGES INITIAUX DE L’ÉQUIPEMENT DONT IL S’AGIT DANS CE MANUEL.

ÉQUIPEMENT AU GAZ, QUI DOIT EFFECTUER LA MISE EN MARCHE ET LES

CE MANUEL A ÉTÉ CONÇU POUR LE PERSONNEL APTE À INSTALLER UN

Page 28

©ITW Food Equipment Group, LLC

3600 North Point Blvd.

Baltimore, MD 21222

GARDER CE MANUAL POUR UNE UTILISATION FUTURE

FORMULAIRE F-38306 (rév. 10-15)

VCRG48-M

MODELS

VCRG24-M

VCRG36-M

VCRG48-M

WCRG24-M

WCRG36-M

WCRG48-M

Pour obtenir des renseignements supplémentaires au sujet de Vulcan-Hart

ou pour trouver un fournisseur de pièces et service autorisé dans votre

région, veuillez visiter notre site web à www.vulcanequipment.com

MANUEL D’INSTALLATION ET D’EMPLOI

PLAQUE CHAUFFANTE AU GAZ À FONCTION MOYENNE

Loading...

Loading...