Page 1

SERVICE MANUAL

VC4G & VC6G SERIES FULL SIZE

CONVECTION OVENS

VC4GS ML-126610

VC4GD ML-126611

VC4GC ML-136494

VC6GS ML-126612

VC6GD ML-126613

VC6GC ML-136495

- NOTICE -

This Manual is prepared for the use of trained Vulcan Service

Technicians and should not be used by those not properly

qualified.

This manual is not intended to be all encompassing. If you have

not attended a Vulcan Service School for this product, you should

read, in its entirety, the repair procedure you wish to perform to

determine if you have the necessary tools, instruments and skills

required to perform the procedure. Procedures for which you do

not have the necessary tools, instruments and skills should be

performed by a trained Vulcan Service Technician.

The reproduction, transfer, sale or other use of this Manual,

without the express written consent of Vulcan, is prohibited.

This manual has been provided to you by ITW Food Equipment

Group LLC ("ITW FEG") without charge and remains the property

of ITW FEG, and by accepting this manual you agree that you will

return it to ITW FEG promptly upon its request for such return at

any time in the future.

A product of Vulcan-Hart 3600 North Point Blvd Baltimore, MD 21222

F24682 Rev. C (0315)

Page 2

VC4G & VC6G SERIES FULL SIZE CONVECTION OVENS

TABLE OF CONTENTS

SERVICE UPDATES ....................................................................................... 4

SERVICE UPDATES - VC4G / VC6G ................................................................... 4

GENERAL .................................................................................................. 5

INTRODUCTION ....................................................................................... 5

INSTALLATION ........................................................................................ 5

OPERATION ........................................................................................... 5

CLEANING ............................................................................................. 5

LUBRICATION ......................................................................................... 5

SPECIFICATIONS ...................................................................................... 5

TOOLS ................................................................................................. 6

REMOVAL AND REPLACEMENT OF PARTS ............................................................... 7

COVERS AND PANELS ................................................................................ 7

TOP FRONT COVER ............................................................................... 7

BOTTOM FRONT COVER .......................................................................... 7

CONTROL PANEL ................................................................................. 7

RIGHT SIDE PANEL ................................................................................ 7

CONTROL PANEL COMPONENTS ..................................................................... 8

COMPONENT PANEL COMPONENTS ................................................................. 9

TEMPERATURE PROBE (VC4GD/6GD) ............................................................... 10

GAS BURNER ........................................................................................ 11

GAS ORIFICE ......................................................................................... 12

GAS SOLENOID VALVE .............................................................................. 12

IGNITION CONTROL MODULE ....................................................................... 14

SPARK IGNITER AND FLAME SENSE ................................................................ 15

BLOWER AND MOTOR ............................................................................... 15

OVEN DOORS (SIMULTANEOUS DOORS) ........................................................... 17

ASSEMBLY REMOVAL ........................................................................... 17

DISASSEMBLY ................................................................................... 18

OVEN DOORS AND BEARINGS (INDEPENDENT DOORS) ............................................ 18

DOOR CATCH BALL ASSEMBLY (INDEPENDENT DOORS) ........................................... 19

ROLLER LATCH ASSEMBLY (INDEPENDENT DOORS) ............................................... 19

DOOR WINDOW ...................................................................................... 19

DOOR SWITCH ....................................................................................... 20

MECHANICAL KX THERMOSTAT (VC4GS/6GS) ...................................................... 21

HIGH LIMIT THERMOSTAT ........................................................................... 21

INTERIOR LIGHTS .................................................................................... 22

COOLING FAN ........................................................................................ 22

SERVICE PROCEDURES AND ADJUSTMENTS ........................................................... 24

SOLID STATE TEMPERATURE CONTROL CALIBRATION (VC4GD/6GD) ............................. 24

MECHANICAL THERMOSTAT CALIBRATION (VC4GS/6GS) .......................................... 25

SOLID STATE TEMPERATURE CONTROL TEST (VC4GD/6GD) ...................................... 26

TEMPERATURE PROBE TEST (VC4GD/6GD) ......................................................... 27

GAS PRESSURE ADJUSTMENT (UNITS UP TO FEBRUARY 2015) ................................... 28

GAS VALVE PRESSURE CHECK (UNITS AFTER FEBRUARY 2015) .................................. 29

VERIFICATION OF SPARK AT IGNITOR .............................................................. 30

DOOR SWITCH ADJUSTMENT ....................................................................... 31

BLOWER ADJUSTMENT .............................................................................. 31

DOOR ADJUSTMENT ................................................................................. 31

DOOR STRIKE ADJUSTMENT (INDEPENDENT DOORS) ............................................. 32

DOOR CATCH BALL ADJUSTMENT (INDEPENDENT DOORS) ........................................ 33

DOOR CHAIN ADJUSTMENT (SIMULTANEOUS DOORS) ............................................. 34

INTRODUCTION .................................................................................. 34

PROCEDURE ..................................................................................... 34

COMPUTER CONTROL (VC4GC/VC6GC) ............................................................. 35

F24682 Rev. C (0315) Page 2 of 74

Page 3

VC4G & VC6G SERIES FULL SIZE CONVECTION OVENS

OPERATION ...................................................................................... 35

SETUP MODE .................................................................................... 35

PROBE TEST ..................................................................................... 35

SOLID STATE RELAY TEST ...................................................................... 35

COMPUTER CONTROL CALIBRATION (VC4GC/VC6GC) ............................................. 35

ELECTRICAL OPERATION ................................................................................ 37

COMPONENT FUNCTION ............................................................................ 37

COMPONENT LOCATION ............................................................................. 38

SEQUENCE OF OPERATION ......................................................................... 43

VC4GS, VC6GS WITH ROAST & HOLD OPTION (MECHANICAL KX THERMOSTAT) .............. 43

VC4GD, VC6GD WITH ROAST & HOLD OPTION (SOLID STATE

TEMPERATURE CONTROL) .................................................................. 47

VC4GC, VC6GC (ROAST & HOLD STANDARD ON COMPUTER MODEL) ......................... 53

COOL DOWN CYCLE (COMPUTER CONTROL MODEL) .......................................... 55

SCHEMATICS ............................................................................................ 56

VC4GS, VC6GS MECHANICAL (KX) CONTROLS ..................................................... 56

VC4GS, VC6GS MECHANICAL (KX) CONTROLS, ROAST & HOLD OPTION ........................... 57

VC4GD, VC6GD SOLID STATE TEMPERATURE CONTROL .......................................... 58

VC4GD, VC6GD SOLID STATE TEMPERATURE CONTROL, ROAST & HOLD OPTION ................ 59

VC4GC, VC6GC COMPUTER CONTROL (ROAST & HOLD STANDARD) .............................. 60

WIRING DIAGRAMS ...................................................................................... 61

VC4GS, VC6GS MECHANICAL (KX) CONTROLS ..................................................... 61

VC4GS, VC6GS MECHANICAL (KX) CONTROLS, ROAST & HOLD OPTION ........................... 63

VC4GD, VC6GD SOLID STATE TEMPERATURE CONTROL .......................................... 65

VC4GD, VC6GD SOLID STATE TEMPERATURE CONTROL, ROAST & HOLD OPTION ................ 67

VC4GC, VC6GC COMPUTER CONTROL (ROAST & HOLD STANDARD) .............................. 69

TROUBLESHOOTING ..................................................................................... 71

ALL MODELS ......................................................................................... 71

COMPUTER CONTROL MODELS ONLY .............................................................. 72

ERROR CODES .................................................................................. 73

© VULCAN 2015

Page 3 of 74 F24682 Rev. C (0315)

Page 4

VC4G & VC6G SERIES FULL SIZE CONVECTION OVENS - SERVICE UPDATES

SERVICE UPDATES

SERVICE UPDATES - VC4G / VC6G

March 2015

Updated Photos Added to the Following Data

Modules

• GAS BURNER

• GAS ORIFICE

• GAS SOLENOID VALVE

• ROLLER LATCH ASSEMBLY (INDEPENDENT

DOORS)

• HIGH LIMIT THERMOSTAT

• GAS PRESSURE ADJUSTMENT (units up to

February 2015)

Added New Data Module

• GAS VALVE PRESSURE CHECK (units after

February 2015)

VC4GC AND VC6GC Serial Number Breaks

• SPECIFICATIONS

Updated Data Module

• SOLID STATE TEMPERATURE CONTROL

CALIBRATION (VC4GD/6GD)

F24682 Rev. C (0315) Page 4 of 74

Page 5

VC4G & VC6G SERIES FULL SIZE CONVECTION OVENS - GENERAL

GENERAL

INTRODUCTION

Procedures in this manual will apply to all models unless specified. Pictures and illustrations can be of any model

unless the picture or illustration needs to be model specific.

Models

FEATURES OPTIONS

COOK

MODEL

VC4GS 26.5" Mechanical (KX)

VC6GS 30.5" Mechanical (KX)

VC4GD 26.5" Solid State

VC6GD 30.5" Solid State

VC4GC 26.5" Computer

VC6GC 30.5" Computer

1

Simultaneous doors are optional (with or w/o window).

2

Stainless steel doors w/o window (standard).

3

Stainless steel doors with window (standard).

CAVITY

DEPTH

TEMPERTURE

CONTROL

DOORS

(50/50)

Independent 1

Independent 1

Independent 1

Independent 1

Independent 1

Independent 1

COOK

TIMER

2

1-Hour Dial 5-Hour Dial Optional Optional

2

1-Hour Dial 5-Hour Dial Optional Optional

3

1-Hour Dial 5-Hour Dial Optional Optional

3

1-Hour Dial 5-Hour Dial Optional Optional

24-Hour

3

Digital

24-Hour

3

Digital

TIMER

OR

HOLD

TIMER

Built in Built in Optional

Built in Built in Optional

COOK

BLOWER

&

208/240/60/1

HOLD

INSTALLATION

Refer to the Instructions Manual for detailed

installation instructions on single or stacked ovens.

OPERATION

Refer to the Instructions Manual for specific operating

instructions.

CLEANING

Refer to the Instructions Manual for specific cleaning

instructions.

Page 5 of 74 F24682 Rev. C (0315)

LUBRICATION

• Cavity blower motor has sealed bearings and

requires no additional lubrication.

• Huskey™ TF-1000 grease or equivalent high

temperature Teflon grease.

SPECIFICATIONS

Electrical

Voltage - 120/60/1

Amps - 8.0 Amps

Input BTU Rating

Natural Gas - 44,000 BTU input at 3.5 in. W.C.

Page 6

VC4G & VC6G SERIES FULL SIZE CONVECTION OVENS - GENERAL

Units after Serial Number Break (VC4GD 481835388,

VC6GD 481835406, VC4GD 541077665) Natural

Gas - 50,000 BTU input at 5.0 in. W.C.

Propane Gas - 44,000 BTU input at 10.0 in. W.C.

Units after Serial Number Break (VC4GD 481835394

& 541077965, VC6GD 481835429) Propane Gas 50,000 BTU input at 10.0 in. W.C.

Gas Line Pressures

Natural - Recommend (in. W.C.) 7.0, Min 5.0

Natural - Recommend (in W.C.) 8.0, Min 6.0 for Units

after Serial Number Break (VC4GD 481835388,

VC6GD 481835406, VC4GD 541077665)

Propane - Recommend (in. W.C.) 11.0, Min 11.0 (All

Propane Units)

Maximum 14.0 in. W.C. (Nat. or Prop.)

TOOLS

Standard

• Standard set of hand tools

• VOM with ability to measure micro amp current

VOM with minimum of NFPA-70E CAT III 600V,

UL/CSA/TUV listed. Sensitivity of at least 20,000

ohms per volt. Meter leads must also be rated at

CAT III 600V.

• Gear Puller to remove blower

Special

• Temperature tester (thermocouple type)

• Manometer

F24682 Rev. C (0315) Page 6 of 74

Page 7

VC4G & VC6G SERIES FULL SIZE CONVECTION OVENS - REMOVAL AND REPLACEMENT OF PARTS

REMOVAL AND REPLACEMENT OF PARTS

COVERS AND PANELS

Disconnect the

electrical power to the machine and

follow lockout / tagout procedures.

SHUT OFF THE GAS BEFORE

SERVICING THE UNIT.

Top Front Cover

1. The top front cover is secured with four (4)

screws, two on each side of cover. Remove these

screws then remove the cover from the oven.

Fig. 1

2. Reverse the procedure to install.

Bottom Front Cover

1. The bottom front cover is secured with four (4)

screws, two on each side of cover. Remove these

screws then remove the cover from the oven.

Fig. 3

NOTE: If the oven has a mechanical (KX type)

thermostat, it must be removed from the control panel

first, before removing the control panel.

2. Disconnect the temperature probe leads from the

solid state temperature control.

3. Unplug the wire harness connector to the control

panel components.

4. Reverse the procedure to install.

Right Side Panel

1. Remove the screws which secure the right side

of the top front cover, bottom front cover and

control panel.

2. Remove the remaining six screws securing the

right side panel.

Fig. 2

2. Reverse the procedure to install.

Control Panel

1. Remove three (3) screws on the right side which

secure the control panel then pull the panel away

from the oven.

Page 7 of 74 F24682 Rev. C (0315)

Fig. 4

3. Pull the right side panel out at the bottom then

down to remove.

4. Reverse the procedure to install.

Page 8

VC4G & VC6G SERIES FULL SIZE CONVECTION OVENS - REMOVAL AND REPLACEMENT OF PARTS

CONTROL PANEL COMPONENTS

Disconnect the

electrical power to the machine and

follow lockout / tagout procedures.

Removable Components Procedure

1. Remove the Control Panel.

2. Remove the component being replaced.

3. Reverse the procedure to install the replacement

component, then check oven for proper

operation.

Fig. 5

Fig. 6

F24682 Rev. C (0315) Page 8 of 74

Page 9

VC4G & VC6G SERIES FULL SIZE CONVECTION OVENS - REMOVAL AND REPLACEMENT OF PARTS

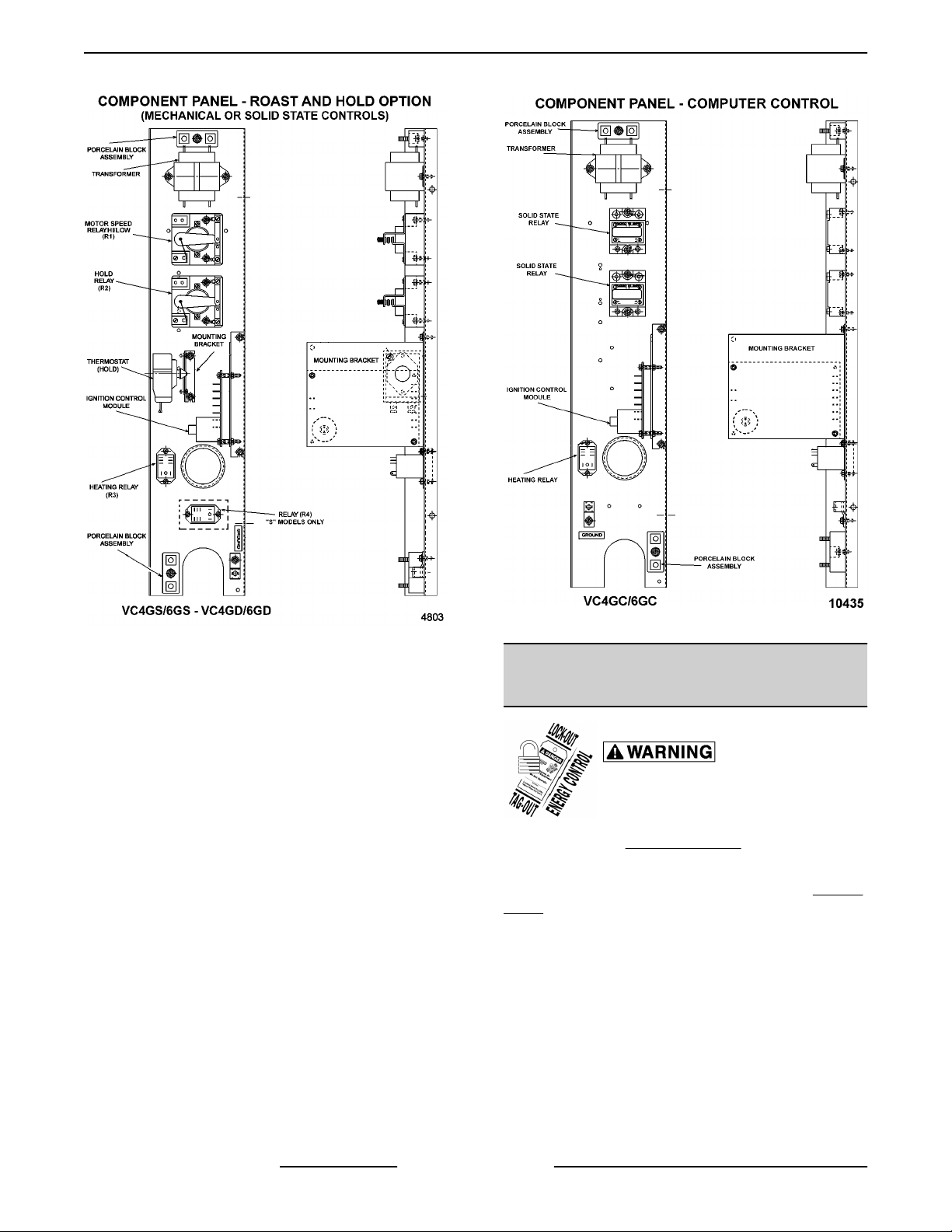

Fig. 7

COMPONENT PANEL

COMPONENTS

Disconnect the

electrical power to the machine and

follow lockout / tagout procedures.

Removable Components Procedure

1. Remove the

NOTE: If right side panel is not accessible, this

component can be serviced by removing the Control

Panel.

2. Disconnect the wire leads to the component

being replaced.

3. Remove the component.

4. Reverse the procedure to install the replacement

component and check oven for proper operation.

Right Side Panel.

Fig. 8

Page 9 of 74 F24682 Rev. C (0315)

Page 10

VC4G & VC6G SERIES FULL SIZE CONVECTION OVENS - REMOVAL AND REPLACEMENT OF PARTS

Fig. 9

Fig. 10

TEMPERATURE PROBE (VC4GD/

6GD)

Disconnect the

electrical power to the machine and

follow lockout / tagout procedures.

1. Remove the

NOTE: If right side panel is not accessible, this

component can be serviced by removing the Control

Panel.

2. Disconnect the probe leads from the solid state

temperature control.

3. Remove the racks and right rack support.

4. Remove the probe guard.

Right Side Panel.

F24682 Rev. C (0315) Page 10 of 74

Page 11

VC4G & VC6G SERIES FULL SIZE CONVECTION OVENS - REMOVAL AND REPLACEMENT OF PARTS

Fig. 11

5. Remove probe by pushing it through the oven

wall and into the control panel area.

Fig. 13

3. Remove the bolts securing the gas manifold to

the oven and place the manifold to the side.

Fig. 12

NOTE: The hole in the oven cavity wall does not line

up straight with the oven cavity outer shell, therefore

the probe must be removed at an angle.

6. Reverse the procedure to install the replacement

probe.

7. Adjust the temperature control as outlined under

SOLID STATE TEMPERATURE CONTROL

CALIBRATION (VC4GD/6GD).

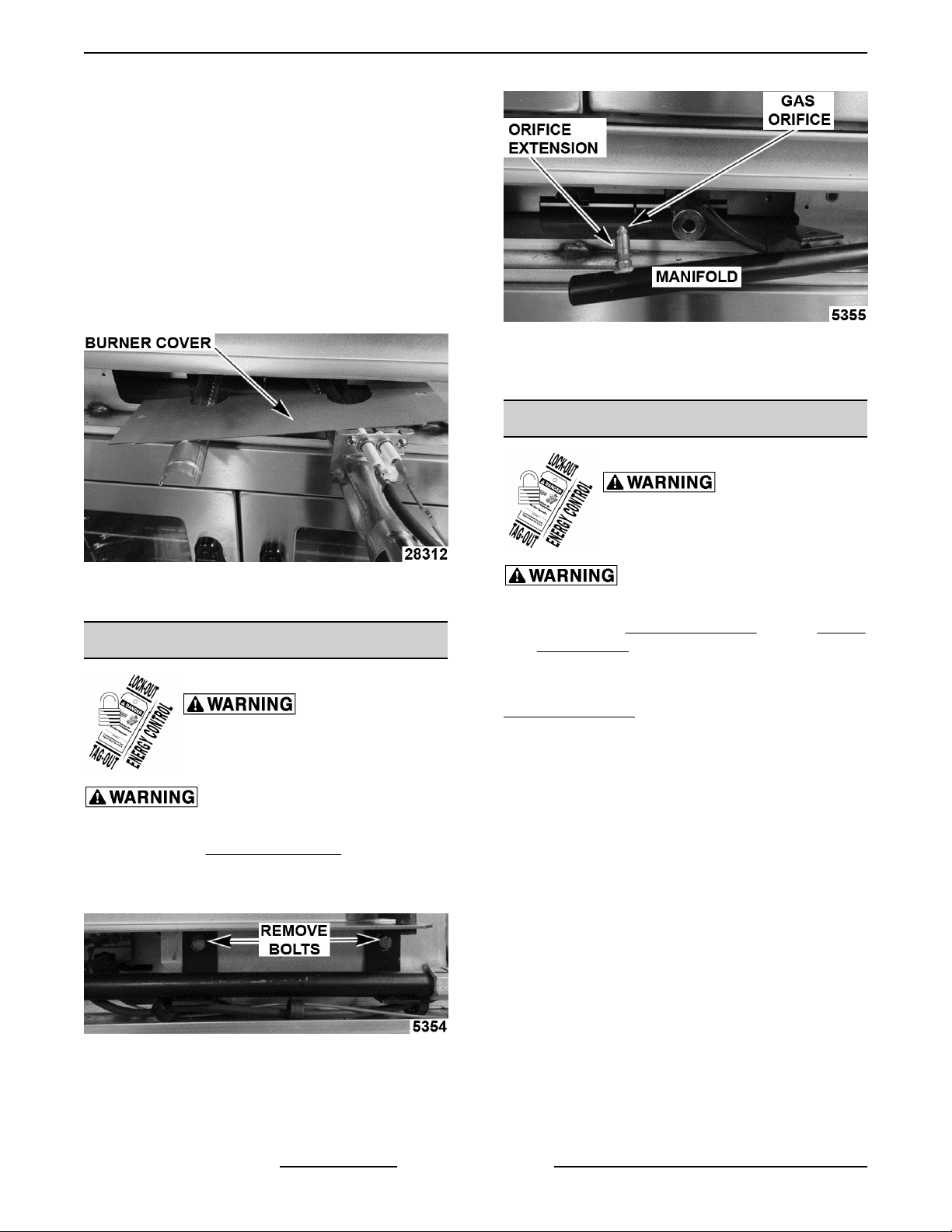

GAS BURNER

Disconnect the

electrical power to the machine and

follow lockout / tagout procedures.

SHUT OFF THE GAS BEFORE

SERVICING THE UNIT.

1. Remove the BOTTOM FRONT COVER.

2. Disconnect the ignition cable and the flame

sense lead wire.

Fig. 14

4. Remove the screws securing the burner cover

then lift out.

Fig. 15

5. Grasp the burner and lift out.

Fig. 16

Page 11 of 74 F24682 Rev. C (0315)

Page 12

VC4G & VC6G SERIES FULL SIZE CONVECTION OVENS - REMOVAL AND REPLACEMENT OF PARTS

6. Reverse procedure to install the replacement

burner.

NOTE: Ensure that burner positioning bracket (U

shaped end) is inserted into slot at the rear of the

burner chamber.

NOTE: When installing current production burner

covers:

• Lay cover flat over burner with openings

aligned behind ignitor.

• Push burner into unit and flip cover 90° up

and align mounting holes.

4. Reverse procedure to install and check for proper

operation.

Fig. 19

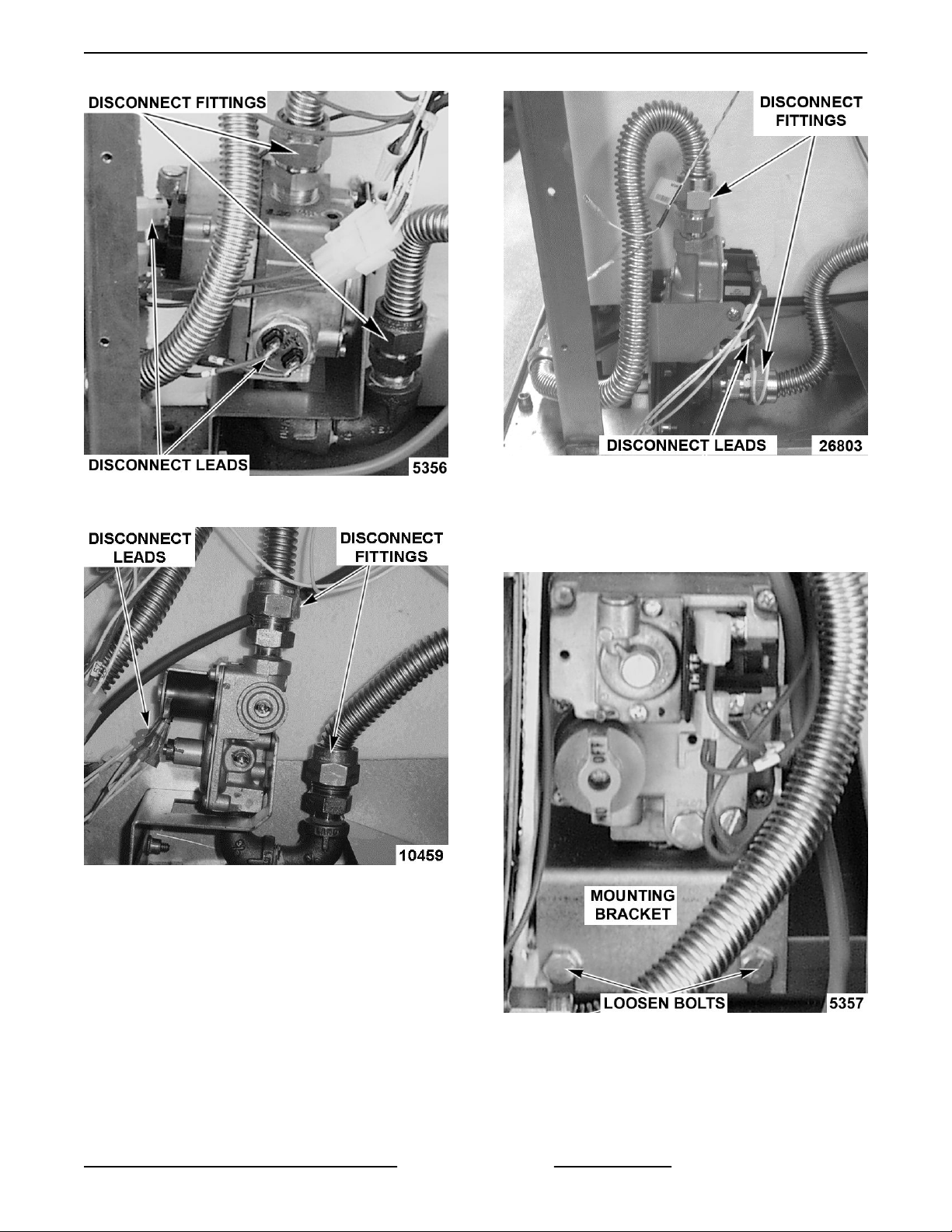

GAS SOLENOID VALVE

Disconnect the

electrical power to the machine and

follow lockout / tagout procedures.

CURRENT PRODUCTION UNIT SHOWN

7. Check for proper operation.

GAS ORIFICE

Disconnect the

electrical power to the machine and

follow lockout / tagout procedures.

SHUT OFF THE GAS BEFORE

SERVICING THE UNIT.

1. Remove the Bottom Front Cover.

2. Remove the bolts securing the gas manifold to

the oven and place the manifold to the side.

SHUT OFF THE GAS BEFORE

SERVICING THE UNIT.

1. Remove the CONTROL PANEL and the RIGHT

SIDE PANEL.

NOTE: if right side panel is not accessible, this

component can be serviced by removing the

CONTROL PANEL.

2. Disconnect the lead wires.

3. Disconnect the compression fittings to the valve.

Fig. 18

3. Remove the gas orifice from the spud on the

manifold and replace with the correct orifice for

the given altitude.

F24682 Rev. C (0315) Page 12 of 74

Page 13

VC4G & VC6G SERIES FULL SIZE CONVECTION OVENS - REMOVAL AND REPLACEMENT OF PARTS

CURRENT PRODUCTION SHOWN (After February

FIRST GENERATION UNIT SHOWN (Before April

2005)

4. Loosen the bolts securing the valve and bracket

assembly then remove the screws securing the

valve to the bracket.

2015)

SECOND GENERATION UNIT SHOWN (After April

2005 thru February 2015)

Page 13 of 74 F24682 Rev. C (0315)

FIRST GENERATION UNIT SHOWN (Before April

2005)

Page 14

VC4G & VC6G SERIES FULL SIZE CONVECTION OVENS - REMOVAL AND REPLACEMENT OF PARTS

6. Verify gas pressure as outlined under GAS

PRESSURE ADJUSTMENT (for units before

February 2015) and GAS VALVE PRESSURE

CHECK (for units after February 2015) and check

for proper operation.

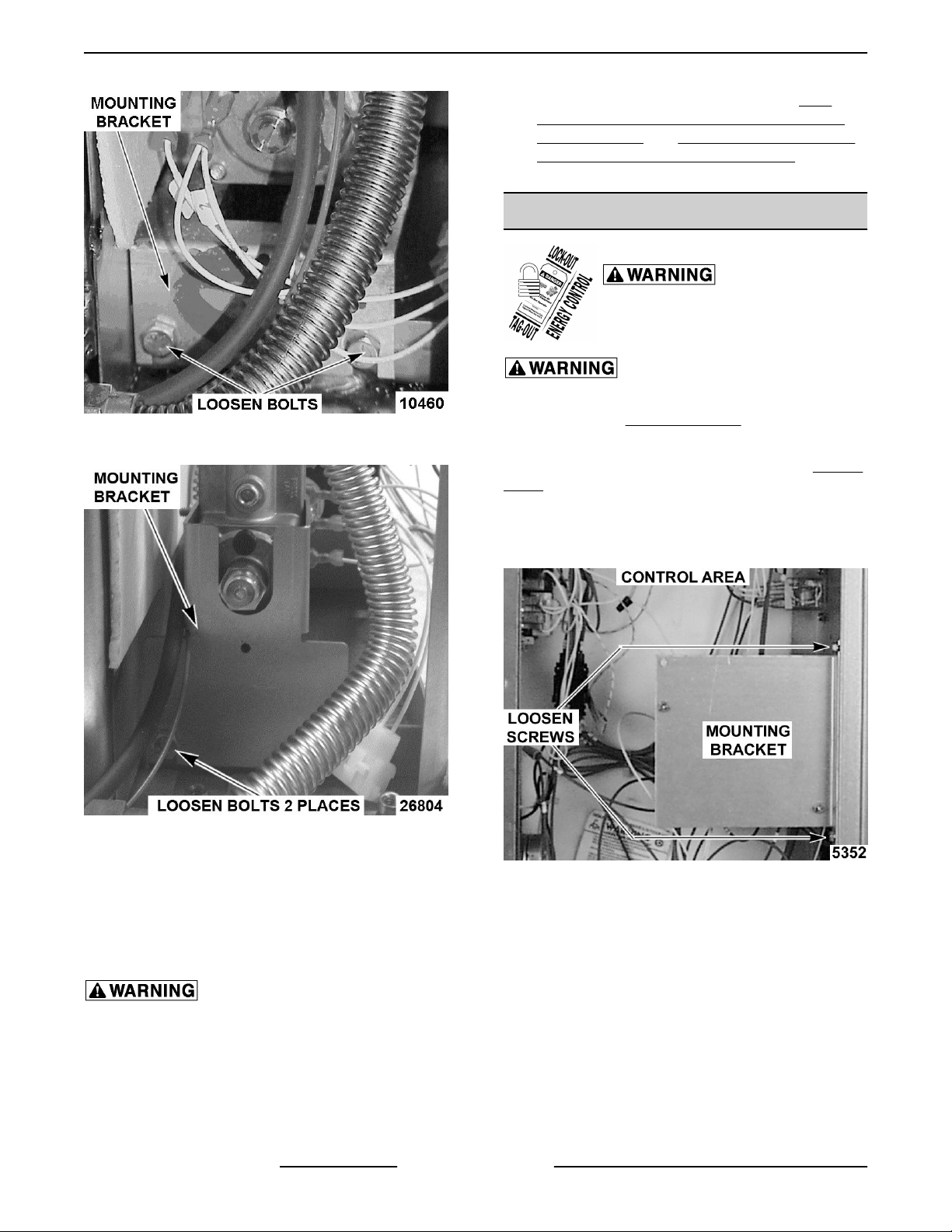

IGNITION CONTROL MODULE

Disconnect the

electrical power to the machine and

follow lockout / tagout procedures.

SHUT OFF THE GAS BEFORE

SERVICING THE UNIT.

SECOND GENERATION UNIT SHOWN (After April

2005 thru February 2015)

CURRENT PRODUCTION SHOWN (After February

2015)

1. Remove the

NOTE: If right side panel is not accessible, this

component can be serviced by removing the Control

Panel.

2. Loosen the screws securing the mounting

bracket to the component panel and remove the

bracket.

Right Side Panel.

5. Reverse the procedure to install the replacement

gas valve.

NOTE: Clean the pipe threads and apply pipe joint

compound to threads. Any pipe joint compound used,

must be resistant to the action of propane gases.

All gas joints disturbed during

servicing must be checked for leaks. Check with a

soap and water solution (bubbles). Do not use an open

flame.

F24682 Rev. C (0315) Page 14 of 74

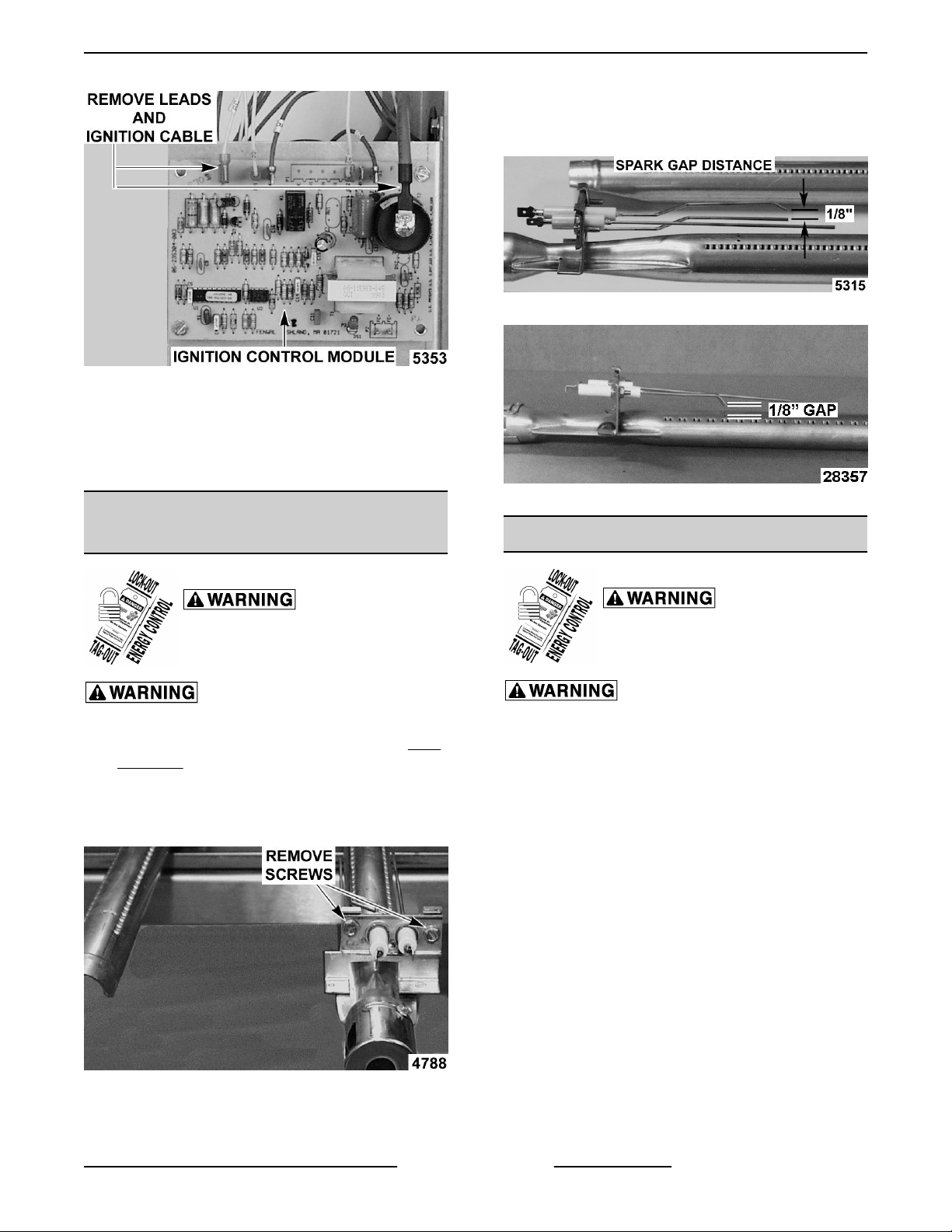

3. Disconnect the lead wires and igniter cable from

Fig. 26

the ignition module board.

Page 15

VC4G & VC6G SERIES FULL SIZE CONVECTION OVENS - REMOVAL AND REPLACEMENT OF PARTS

NOTE: Check to ensure the spark gap distance is

approximately 1/8". If the gap appears to be excessive

or poor sparking is occurring then adjust.

PREVOUS PRODUCTION SHOWN

Fig. 27

4. Remove the ignition module board from the

mounting bracket.

5. Reverse the procedure to install the replacement

ignition module board.

CURRENT PRODUCTION SHOWN

SPARK IGNITER AND FLAME

SENSE

BLOWER AND MOTOR

Disconnect the

electrical power to the machine and

follow lockout / tagout procedures.

SHUT OFF THE GAS BEFORE

SERVICING THE UNIT.

1. Remove the gas burner as outlined under GAS

BURNER.

2. Remove the screws securing the ignitor and

flame sense to burner then remove the

assembly.

Disconnect the

electrical power to the machine and

follow lockout / tagout procedures.

SHUT OFF THE GAS BEFORE

SERVICING THE UNIT.

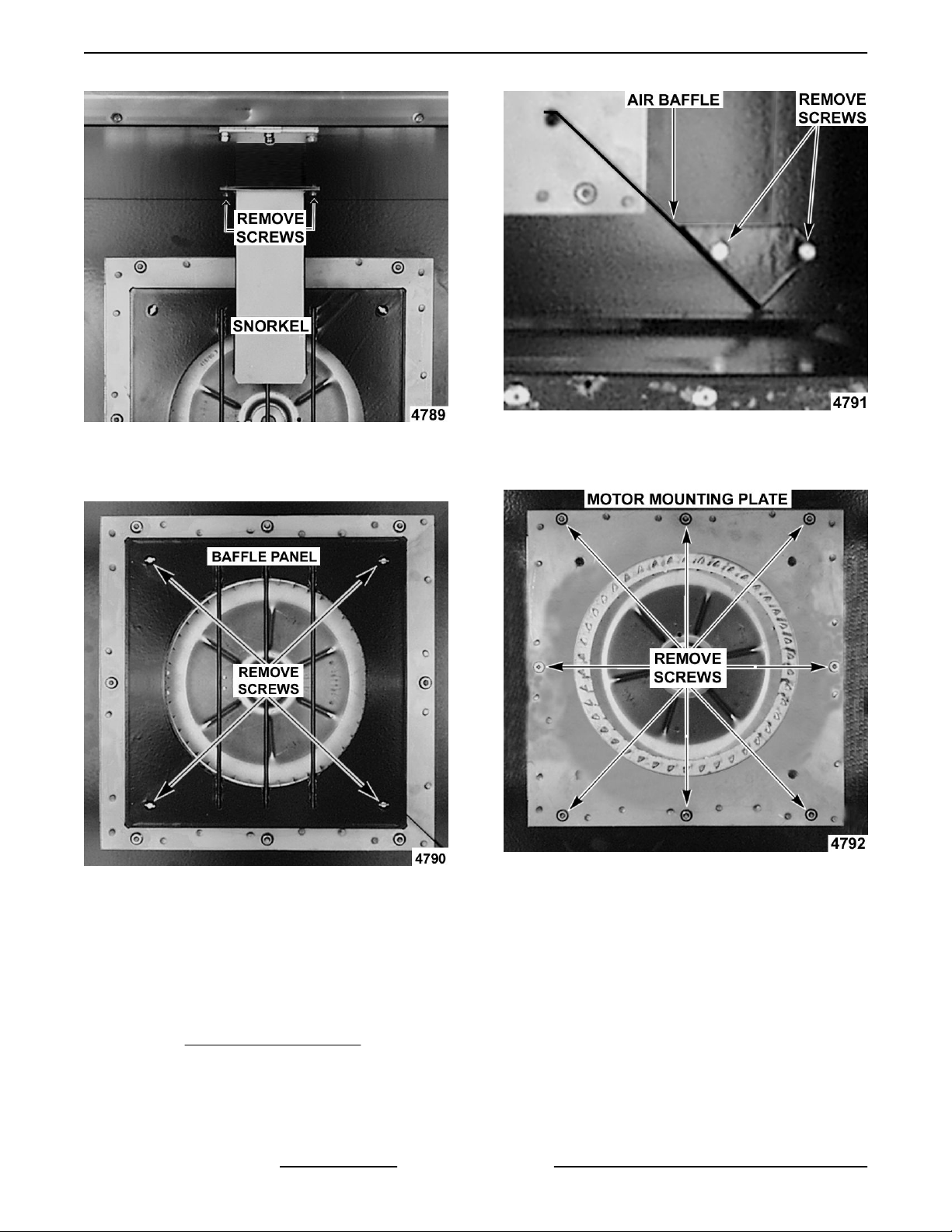

1. Take out the racks and rack supports.

2. Remove screws securing the “snorkel” and

remove the snorkel.

Fig. 28

3. Reverse the procedure to install the assembly

and check for proper operation.

Page 15 of 74 F24682 Rev. C (0315)

Page 16

VC4G & VC6G SERIES FULL SIZE CONVECTION OVENS - REMOVAL AND REPLACEMENT OF PARTS

Fig. 31

3. Remove screws securing baffle panel and

remove the panel.

Fig. 32

4. If replacing:

A. Blower Only - Loosen set screws on blower

hub and using a bearing puller, remove

blower from motor shaft.

1) Reverse procedure to install and adjust

blower position as outlined under

BLOWER ADJUSTMENT.

B. Motor - perform step 4A and continue

procedure.

5. Remove the screws securing the air baffle to the

rear wall at the lower right hand corner.

Fig. 33

6. Remove the nuts that secure the motor mounting

plate to the rear wall.

Fig. 34

7. Place a piece of cardboard on the bottom of the

oven cavity to protect its surface from any

damage during motor assembly removal.

8. Pull the motor assembly into the oven cavity and

place it on the cardboard.

9. Remove the junction box cover from the motor,

disconnect lead wires and remove the conduit.

10. Remove motor mounting bolts and flat washers

then lift the motor from the mounting plate.

11. Position the replacement motor on the motor

mounting plate and install mounting bolts and

washers. Hand tighten mounting bolts only.

F24682 Rev. C (0315) Page 16 of 74

Page 17

VC4G & VC6G SERIES FULL SIZE CONVECTION OVENS - REMOVAL AND REPLACEMENT OF PARTS

12. Reconnect lead wires at the motor, replace

conduit and junction box cover.

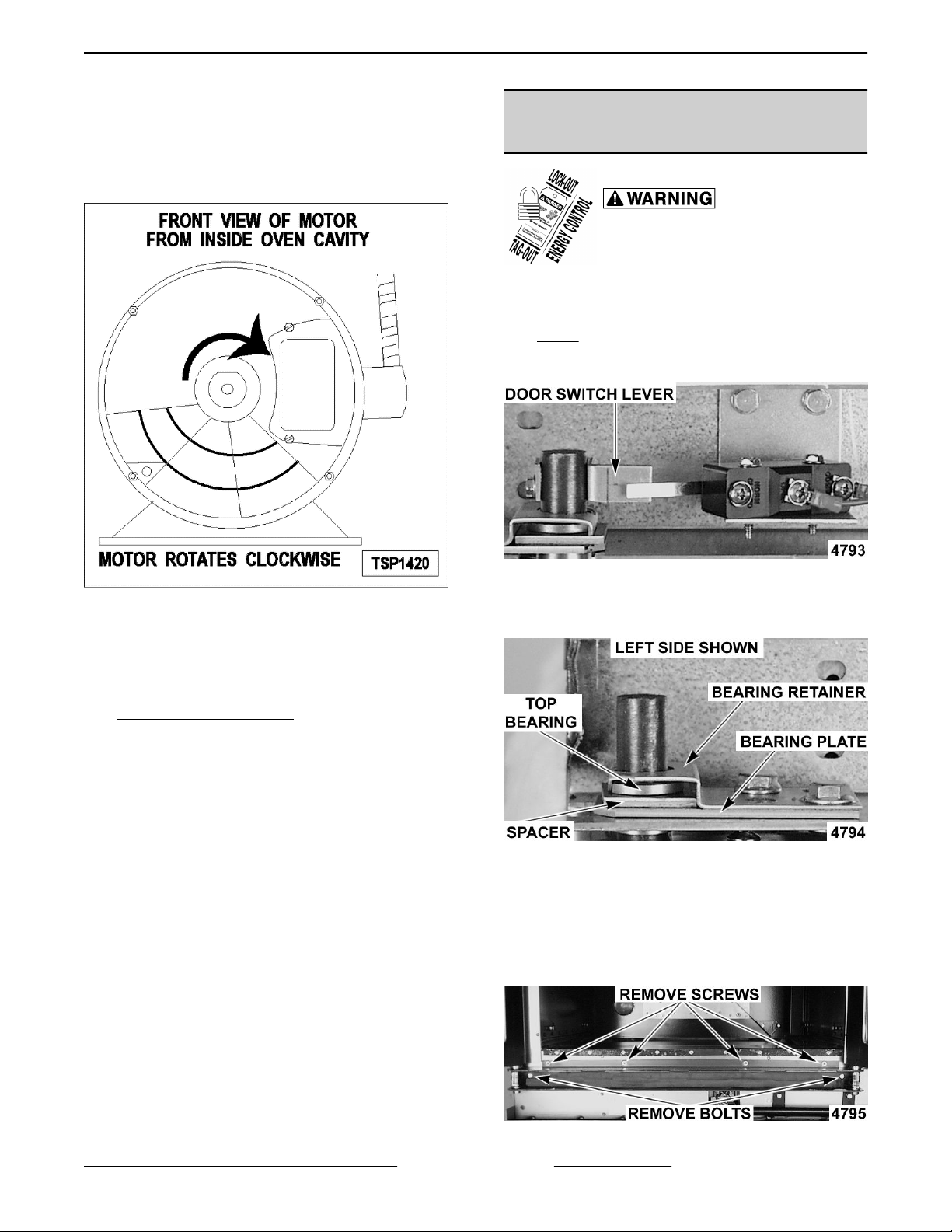

NOTE: Check data plate on motor for wiring

schematic. The motor must rotate clockwise when

viewed from the shaft end.

OVEN DOORS (SIMULTANEOUS

DOORS)

Disconnect the

electrical power to the machine and

follow lockout / tagout procedures.

Assembly Removal

1. Remove the

Cover.

2. Remove the door switch lever.

Top Front Cover and Bottom Front

Fig. 35

13. Slide blower onto motor shaft until hub is flush

with end of shaft then tighten set screws.

14. Adjust motor position until blower is parallel to

motor mounting plate as outlined under

BLOWER ADJUSTMENT.

15. Position motor mounting plate on the rear wall

and secure with nuts and washers.

16. Replace the baffle panel and “snorkel”.

17. Replace the air baffle on the rear wall at the lower

right hand corner.

18. Remove cardboard from the bottom of the oven

cavity.

19. Install rack guides and racks.

20. Check oven for proper operation.

Fig. 36

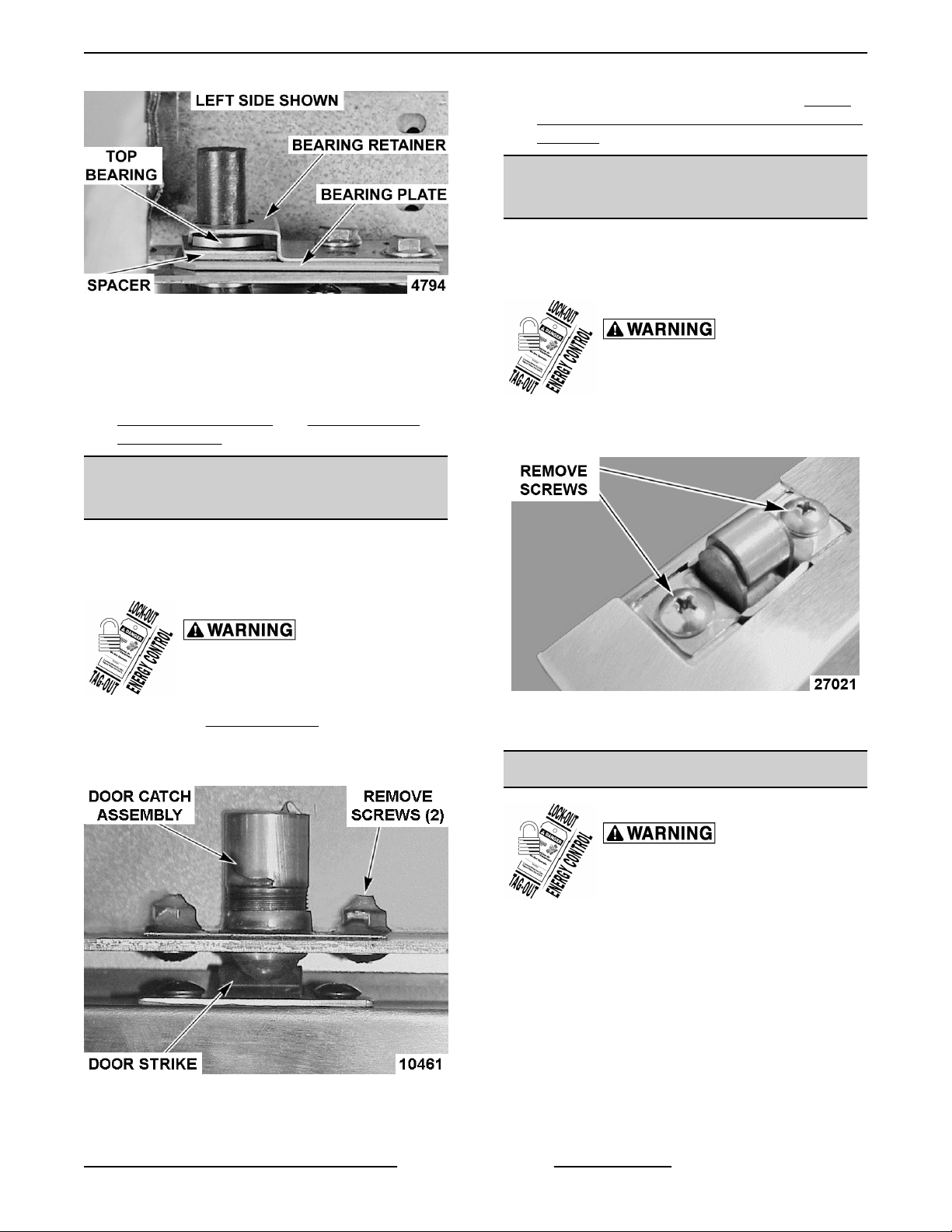

3. Remove the top bearing retainers and top

bearings.

Fig. 37

4. Remove the lower door seal strip to expose the

mounting screws of the door assembly.

A. Remove the two (2) lower sill bolts by the

lower door shaft and the four (4) countersunk screws from the lower sill.

Fig. 38

Page 17 of 74 F24682 Rev. C (0315)

Page 18

VC4G & VC6G SERIES FULL SIZE CONVECTION OVENS - REMOVAL AND REPLACEMENT OF PARTS

NOTE: The door assembly is heavy and will drop

down once the last screw is removed. If removing door

assembly with-out assistance, use caution.

5. Lift up on the door assembly and swing the right

side out then move the assembly to the left to

clear the slots in the upper door sill.

6. Lay the door assembly on a flat cushioned

surface for disassembly.

7. Reverse procedure to install door assembly and

check for proper adjustment as outlined under

DOOR ADJUSTMENT, DOOR CHAIN

ADJUSTMENT (SIMULTANEOUS DOORS) and

DOOR SWITCH ADJUSTMENT.

Disassembly

1. Remove the door assembly as outlined in

"ASSEMBLY REMOVAL".

2. Remove the door chain by loosening one of the

turnbuckles.

3. Loosen the set screw on the sprocket of door

being replaced.

4. Drive out the Spirol pin from the sprocket of door

being replaced.

5. Remove the door from lower sill bearings and

sprocket.

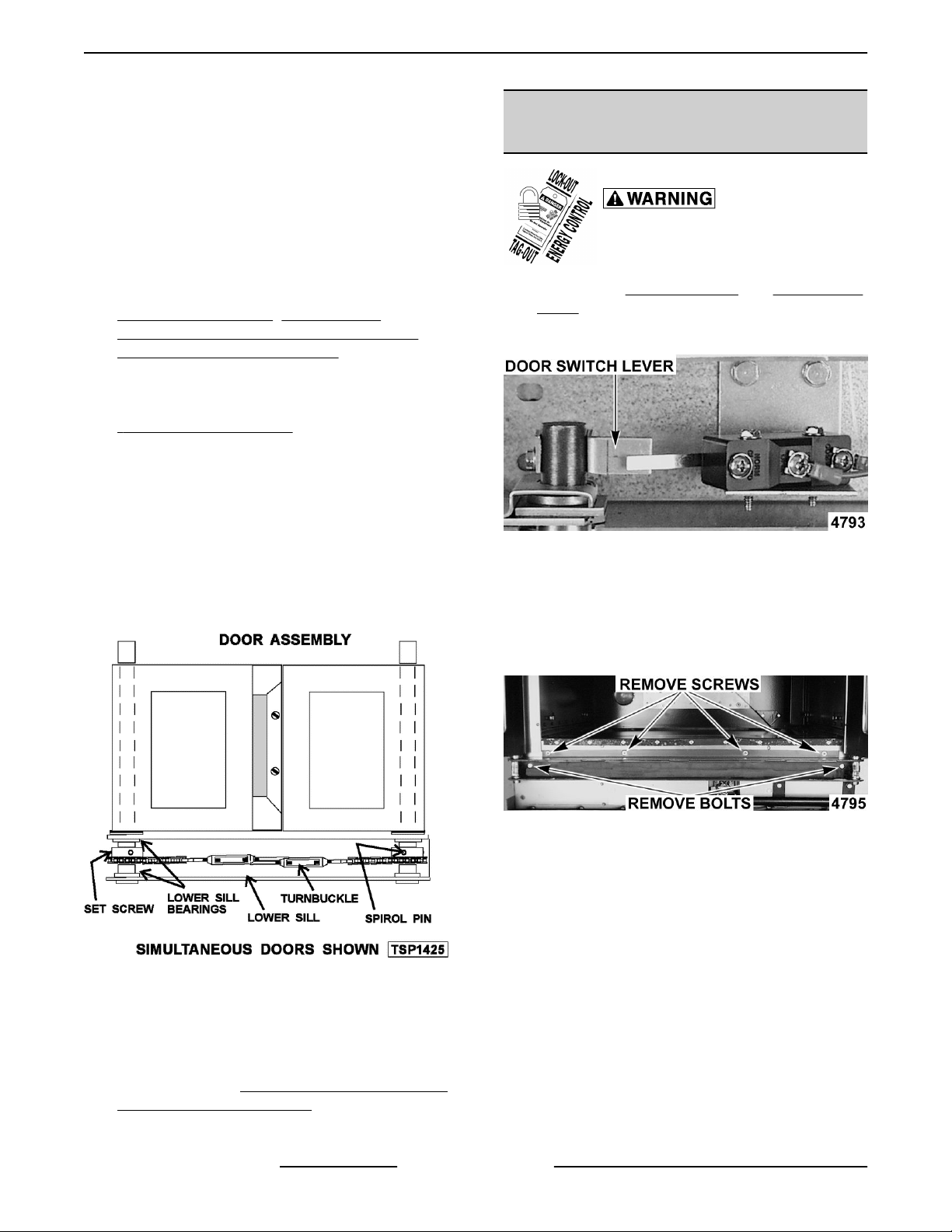

OVEN DOORS AND BEARINGS

(INDEPENDENT DOORS)

Disconnect the

electrical power to the machine and

follow lockout / tagout procedures.

1. Remove the

Cover.

2. Remove the door switch lever.

3. Remove the lower door seal strip to expose the

mounting screws of the door assembly.

4. Remove the two (2) lower sill bolts by the lower

door shaft and the four (4) counter-sunk screws

from the lower sill.

Top Front Cover and Bottom Front

Fig. 40

NOTE: The door assembly is heavy and will drop

down once the last screw is removed. If removing door

assembly with-out assistance, the ignition cable,

flame sense lead and gas manifold should also be

removed to avoid damage to these components.

5. Tilt the top of the door slightly forward and lift the

Fig. 39

A. Door assembly parts are now accessible for

inspection and/or replacement if necessary.

6. Reverse procedure to re-assemble the door

assembly parts and check for proper adjustment

as outlined under DOOR CHAIN ADJUSTMENT

(SIMULTANEOUS DOORS).

F24682 Rev. C (0315) Page 18 of 74

6. Lay the door flat to prevent damage.

7. The top and bottom bearings are now accessible

Fig. 41

door up until the bottom of the door shaft clears

the opening in the sill.

for inspection and/or replacement if needed.

A. If bearings are OK, proceed to step 8.

B. If replacing the top bearing, remove the top

bearing retainer and top bearing.

Page 19

VC4G & VC6G SERIES FULL SIZE CONVECTION OVENS - REMOVAL AND REPLACEMENT OF PARTS

4. Adjust the ball catch as outlined under DOOR

CATCH BALL ADJUSTMENT (INDEPENDENT

DOORS).

ROLLER LATCH ASSEMBLY

(INDEPENDENT DOORS)

NOTE: For units with serial number starting with 48

made after 8/12/07 and serial number starting with 54

made after 8/26/07.

Fig. 42

C. If replacing the bottom bearing, remove it

from the door shaft or the lower sill opening.

8. Reverse procedure to install door assembly and

check for proper adjustment as outlined under

DOOR ADJUSTMENT and DOOR SWITCH

ADJUSTMENT.

electrical power to the machine and

follow lockout / tagout procedures.

1. Remove the screws that attach roller latch

assembly to door.

Disconnect the

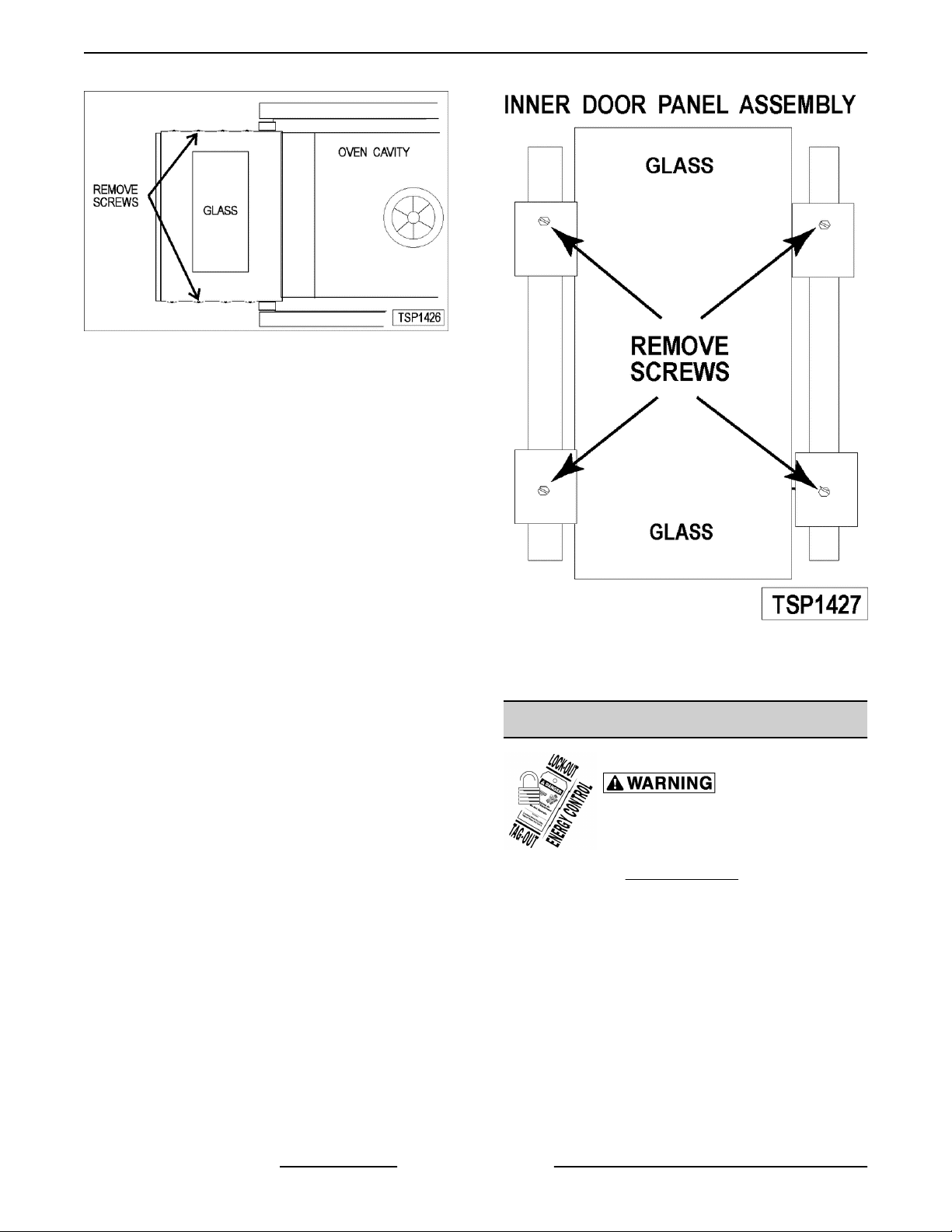

DOOR CATCH BALL ASSEMBLY

(INDEPENDENT DOORS)

NOTE: For units with serial number starting with 48

made before 8/13/07 and serial number starting with

54 made before 8/27/07.

Disconnect the

electrical power to the machine and

follow lockout / tagout procedures.

1. Remove the

2. Remove the screws that secure the door catch

assembly.

FRONT COVER.

Fig. 44

2. Reverse procedure to install.

DOOR WINDOW

Disconnect the

electrical power to the machine and

follow lockout / tagout procedures.

1. Remove the screws at the top and bottom of

door.

Fig. 43

3. Reverse procedure to install.

Page 19 of 74 F24682 Rev. C (0315)

Page 20

VC4G & VC6G SERIES FULL SIZE CONVECTION OVENS - REMOVAL AND REPLACEMENT OF PARTS

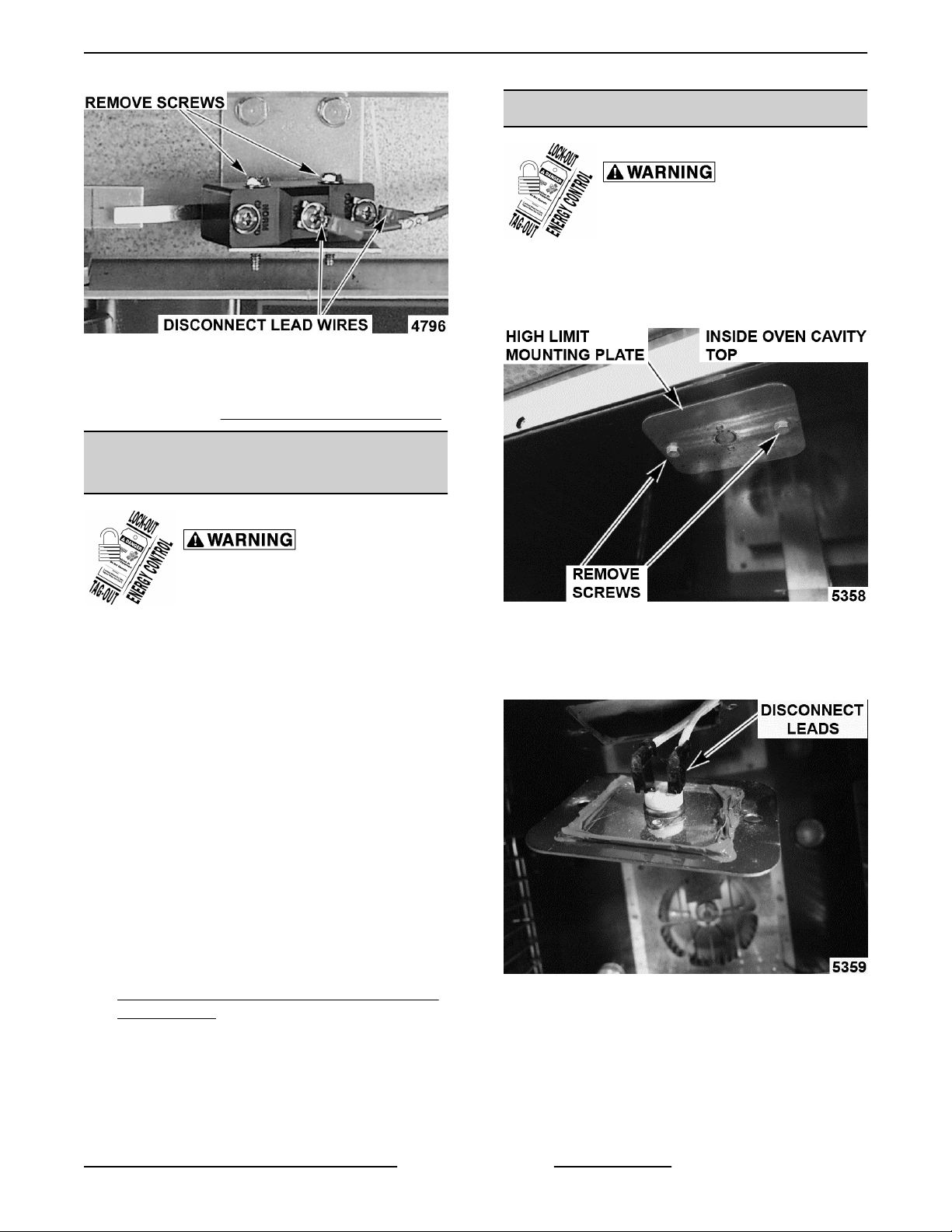

Fig. 45

2. Independent doors:

A. Remove the door handle then remove the

outer door panel.

B. Lift out the inner door panel and window

assembly.

NOTE: Left door only - remove door seal from the

inside edge of the door.

3. Simultaneous doors:

A. If replacing window on the left door, remove

the handle from the front of the door then

remove door seal from the inside edge of the

door.

1) Lift out the inner door panel and

window assembly.

2) If replacing window on the right door,

remove the screws along the inside

edge (if applicable) of the door then

remove the inner door panel and

window assembly.

4. Remove the screws securing the window “tabs”

to the door bracket and lift the window assembly

out from the door frame.

Fig. 46

5. Reverse procedure to install the replacement

window.

DOOR SWITCH

Disconnect the

electrical power to the machine and

follow lockout / tagout procedures.

1. Remove the

2. Disconnect the lead wires to the door switch.

3. Remove the switch.

Top Front Cover.

F24682 Rev. C (0315) Page 20 of 74

Page 21

VC4G & VC6G SERIES FULL SIZE CONVECTION OVENS - REMOVAL AND REPLACEMENT OF PARTS

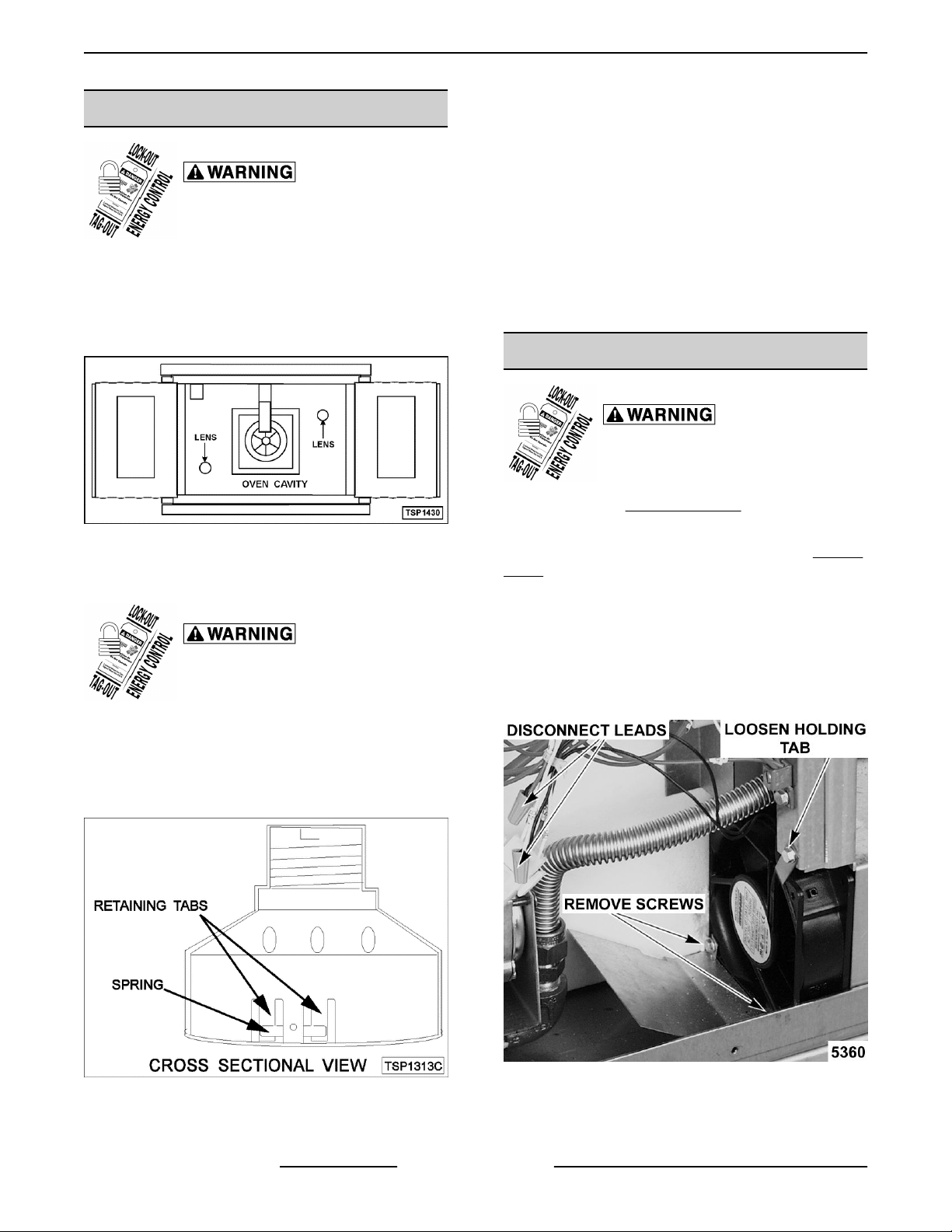

HIGH LIMIT THERMOSTAT

Disconnect the

electrical power to the machine and

follow lockout / tagout procedures.

1. Take out racks from the oven.

2. Remove the high limit thermostat cover/mounting

plate from inside the oven cavity at the top.

Fig. 47

4. Reverse procedure to install the replacement

switch and check for proper adjustment as

outlined under DOOR SWITCH ADJUSTMENT.

MECHANICAL KX THERMOSTAT

(VC4GS/6GS)

Disconnect the

electrical power to the machine and

follow lockout / tagout procedures.

1. Remove the racks and right rack support.

2. Remove the thermostat knob and mounting

screws from the control panel and then remove

the control panel.

3. Remove the probe guard from the oven cavity

wall.

NOTE: When installing, the probe should not extend

beyond the probe guard.

4. Remove the thermostat bulb from the oven cavity

by pushing it through the oven wall and into the

control panel area.

NOTE: The hole in the oven cavity wall does not line

up straight with the oven cavity outer shell, therefore

the probe must be removed at an angle.

5. Reverse the procedure to install.

6. Adjust the thermostat as outlined under

MECHANICAL THERMOSTAT CALIBRATION

(VC4GS/6GS).

Fig. 48

3. Disconnect lead wires from high limit thermostat

then remove high limit thermostat from cover/

mounting plate.

Fig. 49

NOTE: Remove the old RTV from the cover and

mating surfaces inside the oven cavity and apply new

RTV before installing.

4. Reverse procedure to install.

Page 21 of 74 F24682 Rev. C (0315)

Page 22

VC4G & VC6G SERIES FULL SIZE CONVECTION OVENS - REMOVAL AND REPLACEMENT OF PARTS

INTERIOR LIGHTS

Disconnect the

electrical power to the machine and

follow lockout / tagout procedures.

Lamp

1. Remove the racks.

2. Unscrew the glass lens for the light being

replaced then unscrew the bulb.

Fig. 50

3. Replace bulb then reverse the procedure to

install.

Disconnect the

electrical power to the machine and

follow lockout / tagout procedures.

Lamp Assembly

3. Depress the retaining tabs and pull the socket out

from the oven, far enough to disconnect the lead

wires.

4. Remove the socket from the oven.

5. Attach the lead wires to the replacement socket.

6. Insert the socket into the hole in the oven and

push until the socket is held in place by the

retaining tabs.

7. Install the light bulb and lens.

8. Check for proper operation.

COOLING FAN

Disconnect the

electrical power to the machine and

follow lockout / tagout procedures.

1. Remove the Right Side Panel.

NOTE: If right side panel is not accessible, this

component can be serviced by removing the Control

Panel.

Disconnect the lead wires to the fan motor by

removing wire nuts.

2. Remove the screws securing the air deflector to

the fan then loosen the tab screw holding the fan

to the component panel. Rotate the tab so that

the fan will clear and remove the fan.

1. Remove the lens and bulb.

2. Remove the springs from the retaining tabs (2

places) on the socket.

Fig. 51

3. Reverse the procedure to install the replacement

F24682 Rev. C (0315) Page 22 of 74

Fig. 52

fan and check for proper operation.

Page 23

VC4G & VC6G SERIES FULL SIZE CONVECTION OVENS - REMOVAL AND REPLACEMENT OF PARTS

NOTE: The fan must be installed so air is pulled from

the rear of the oven and blown into the control area.

The arrow on the fan body indicates “air flow” direction

and should be pointing toward the controls.

NOTE: Ensure fan is seated “squarely” against the air

tube and the oven bottom.

NOTE: The air deflector should be angled upwards

at approximately 30 degrees to properly direct the air

flow.

Page 23 of 74 F24682 Rev. C (0315)

Page 24

VC4G & VC6G SERIES FULL SIZE CONVECTION OVENS - SERVICE PROCEDURES AND ADJUSTMENTS

SERVICE PROCEDURES AND ADJUSTMENTS

Certain procedures in this section require electrical test or measurements while

power is applied to the machine. Exercise extreme caution at all times and follow Arc Flash

procedures. If test points are not easily accessible, disconnect power and follow Lockout/Tagout

procedures, attach test equipment and reapply power to test.

SOLID STATE TEMPERATURE

CONTROL CALIBRATION (VC4GD/

6GD)

UNITS BEFORE JUNE 2013

1. Place a thermocouple in the geometric center of

the oven cavity.

2. Set the ON-OFF-COOL DOWN switch to ON.

3. Set the temperature control dial to 350°F.

4. Allow the oven temperature to stabilize (normally

3 cycles).

5. Record the temperature at which the Heat lamp

goes OFF and comes ON for at least two

complete heating cycles.

6. Calculate the differential by subtracting the

temperature indicated when the lamp goes out

from the temperature indicated when the lamp

comes on.

Differential = Heat lamp OFF - Heat lamp ON

Example: 360° (lamp off) - 340° (lamp on) =

20°

A. The differential calculated should be less

than 20°F.

7. Calculate the average temperature by adding the

temperature indicated when the lamp goes out to

the temperature indicated when the lamp comes

on and dividing this answer by 2.

[Temp. (lamp off) + Temp. (lamp on)] ÷ 2 =

Average Temp. Example: (360° + 340°) ÷ 2 =

350°

A. If the average temperature is less than 10°F

from the dial setting, the thermostat is

properly calibrated.

B. If the average temperature is more than

10°F from the dial setting, the thermostat

calibration must be adjusted.

1) Loosen the temperature control knob

set screw and remove the knob from

the stem.

2) Loosen temperature control mounting

screws only enough to rotate the

control.

a. Place thumb and forefinger on the

head of the mounting screws,

apply pressure and slightly rotate

the screw heads (body of control)

in the slot. Rotate clockwise to

increase temperature and

counterclockwise to decrease.

1) If the differential is less than 20°F, the

temperature control circuit is

functioning properly.

a. Proceed to

2) If the differential is more than 20°F:

a. Check the temperature probe as

outlined under TEMPERATURE

PROBE TEST (VC4GD/6GD).

b. If the probe is functioning properly

then temperature control is

malfunctioning.

a) Install a replacement

F24682 Rev. C (0315) Page 24 of 74

Step 7.

temperature control and

check calibration.

NOTE: Allow the oven to cycle at least two times

between adjustments before performing the

calculation.

b. Center the stem in the opening

and re-tighten the temperature

control mounting screws.

c. Replace knob and re-tighten set

screw.

d. Rotate the knob to the lowest

temperature setting then back to

350°F.

e. Repeat the average temperature

calculation in Step 7.

Page 25

VC4G & VC6G SERIES FULL SIZE CONVECTION OVENS - SERVICE PROCEDURES AND ADJUSTMENTS

a) If the average temperature

still differs more than 10°F

from the dial setting, adjust

the thermostat calibration

until the average

temperature is within

tolerance.

C. If the above adjustment cannot be obtained,

replace the temperature control and check

calibration.

UNITS AFTER JUNE 2013

1. Place a thermocouple in the geometric center of

the oven cavity.

2. Set the ON-OFF-COOL DOWN switch to ON.

3. Set the NORMAL - GENTLE BAKE switch to

NORMAL.

4. Set the temperature control dial to 350°F.

5. Allow the oven temperature to stabilize (normally

3 cycles).

6. Record the temperature at which the Heat lamp

goes OFF and comes ON for at least two

complete heating cycles.

7. Calculate the differential by subtracting the

temperature indicated when the lamp goes out

from the temperature indicated when the lamp

comes on.

Differential = Heat lamp OFF - Heat lamp ON

Example: 360° (lamp off) - 340° (lamp on) =

20°

A. The differential calculated should be less

than 20°F.

1) If the differential is less than 20°F, the

temperature control circuit is

functioning properly.

a. Proceed to STEP 8.

2) If the differential is more than 20°F:

a. Check the temperature probe as

outlined under TEMPERATURE

PROBE TEST.

b. If the probe is functioning properly

then temperature control is

malfunctioning.

a) Install a replacement

temperature control and

check calibration.

8. Calculate the average temperature by adding the

temperature indicated when the lamp goes out to

the temperature indicated when the lamp comes

on and dividing this answer by 2.

[Temp. (lamp off) + Temp. (lamp on)] ÷ 2 =

Average Temp. Example: (360° + 340°) ÷ 2 =

350°

A. If the average temperature is less than 10°F

from the dial setting, the thermostat is

properly calibrated.

B. If the average temperature is more than

10°F from the dial setting, the thermostat

calibration must be adjusted.

1) Loosen the temperature control knob

set screw and remove the knob from

the stem.

2) Access the adjustment potentiometer

located at the 3 o'clock position.

a. Turn clockwise to increase,

counterclockwise to decrease

temperature

b. Repeat the average temperature

calculation in STEP 8.

NOTE: Allow the oven to cycle at least two times

between adjustments before performing the

calculation.

a) If the average temperature

still differs more than 10°F

from the dial setting, adjust

the thermostat calibration

until the average

temperature is within

tolerance.

C. If the above adjustment cannot be obtained,

replace the temperature control and check

calibration.

MECHANICAL THERMOSTAT

CALIBRATION (VC4GS/6GS)

1. Place a thermocouple in the geometric center of

the oven cavity.

2. Set the ON-OFF-COOL DOWN switch to ON.

3. Set the thermostat dial to 350°F.

4. Allow the oven temperature to stabilize (normally

3 cycles).

5. Record the temperature when the thermostat

cycles OFF and ON for at least three complete

cycles.

Page 25 of 74 F24682 Rev. C (0315)

Page 26

VC4G & VC6G SERIES FULL SIZE CONVECTION OVENS - SERVICE PROCEDURES AND ADJUSTMENTS

6. Calculate the differential by subtracting the

temperature indicated when heat lamp goes out

from temperature indicated when heat lamp

comes on.

Differential = Heat lamp OFF - Heat lamp ON

Example: 360° (lamp off) - 340° (lamp on) 20°

A. The differential calculated should be less

than 30°F.

1) If the differential is less than 30°F, the

thermostat is functioning properly.

a. Proceed to Step 7.

2) If the differential is more than 30°F, the

thermostat is malfunctioning.

a. Install a replacement thermostat

and check calibration.

7. Calculate the average temperature by adding the

temperature indicated when the heat lamp goes

out to the temperature indicated when the heat

lamp comes on and dividing this answer by 2.

[Temp. (lamp off) +Temp. (lamp on)] ÷ 2 =

Average Temp.

Example: 360° 340° ÷ 2 350°

A. If the average temperature is less than 15°F

from the dial setting, the thermostat is

properly calibrated.

B. If the average temperature is more than

15°F of the dial setting, the thermostat

calibration must be adjusted.

1) Remove the thermostat knob.

2) Hold the thermostat shaft and turn the

inner set screw clockwise to decrease

temperature or counterclockwise to

increase temperature (¼ turn = 35°(F).

8. Replace the knob and repeat Step 7 until the

average temperature is within tolerance.

NOTE: Allow the oven to cycle at least two times

between adjustments before performing the

calculation.

9. If the above adjustment can not be obtained,

install a replacement thermostat and check

calibration.

Fig. 53

SOLID STATE TEMPERATURE

CONTROL TEST (VC4GD/6GD)

Certain procedures in

this section require electrical test or

measurements while power is applied

to the machine. Exercise extreme

caution at all times and follow Arc Flash

procedures. If test points are not easily

accessible, disconnect power and

follow Lockout/Tagout procedures,

attach test equipment and reapply

power to test.

1. Remove the RIGHT SIDE PANEL.

NOTE: If right side panel is not accessible, this

component can be serviced by removing CONTROL

PANEL.

2. Place a thermocouple in the geometric center of

NOTE: Oven temperature must be below 450°F.

F24682 Rev. C (0315) Page 26 of 74

the oven cavity.

Page 27

VC4G & VC6G SERIES FULL SIZE CONVECTION OVENS - SERVICE PROCEDURES AND ADJUSTMENTS

NOTE: If oven is equipped with "Cook and Hold"

option, set to Cook (normal cooking) before

continuing.

3. Set the temperature control to the maximum

setting.

4. Check machine data plate for correct voltage to

oven. Refer to diagram below for proper terminal

locations and voltages before checking the

control. Use the correct terminals for the

corresponding voltage.

5. Turn the power switch to ON.

1) If input voltage to the internal relay is

correct, proceed to step 8. If input

voltage to the internal relay is not

present, problem is not with the

temperature control. See

TROUBLESHOOTING.

2) If output voltage from the internal relay

is correct proceed to step 8. If output

voltage from the internal relay is not

correct, check temperature probe as

outlined under TEMPERATURE

PROBE TEST (VC4GD/6GD).

8. Set the temperature control to the minimum

setting.

NOTE: Oven temperature must be above 300°F.

9. Check for zero (0) volts AC across terminals

OUTPUT RELAY terminal (right side) to 120VAC

or OUTPUT RELAY terminal (right side) to

208-240VAC for no output from the internal relay.

A. If correct, temperature control is functioning

properly.

B. If incorrect, check temperature probe as

outlined under TEMPERATURE PROBE

TEST (VC4GD/6GD).

Fig. 54

6. Check for proper voltage across terminals COM

AC to 120VAC or COM AC to 208-240VAC for

power to the control.

A. If correct, proceed to step 7.

B. If incorrect, problem is not with the

temperature control. See

TROUBLESHOOTING.

7. Check relay voltages on the board:

A. For 120VAC controls - check across

OUTPUT RELAY terminal (left side) to

120VAC terminal for input to the internal

relay. Check across OUTPUT RELAY

terminal (right side) to 120 VAC for output

from the internal relay.

B. For 208-240VAC controls - check across

OUTPUT RELAY terminal (left side) to

208-240VAC terminal for input to the

internal relay. Check across OUTPUT

RELAY terminal (right side) to 208-240VAC

for output from the internal relay.

1) If temperature probe is OK:

a. Turn the power switch OFF.

Disconnect the

electrical power to the machine and

follow lockout / tagout procedures.

b. Replace the temperature control

and check calibration as outlined

SOLID STATE

under

TEMPERATURE CONTROL

CALIBRATION (VC4GD/6GD).

TEMPERATURE PROBE TEST

(VC4GD/6GD)

Disconnect the

electrical power to the machine and

follow lockout / tagout procedures.

NOTE: The temperature probe used in conjunction

with the Solid State Temperature control is an RTD

(resistance temperature detector) of the Thermistor

Page 27 of 74 F24682 Rev. C (0315)

Page 28

VC4G & VC6G SERIES FULL SIZE CONVECTION OVENS - SERVICE PROCEDURES AND ADJUSTMENTS

type. As temperature increases the resistance value

decreases.

1. Remove the Right Side Panel.

NOTE: If right side panel is not accessible, this

component can be serviced by removing the Control

Panel.

2. Place a shielded thermocouple in the geometric

center of the oven cavity and determine the

temperature in the oven cavity.

3. Remove the probe lead wires from the solid state

temperature control.

4. Test the probe with an ohmmeter.

A. If the measured resistance values are inside

the given tolerance then the probe is

functioning properly.

B. If the measured resistance values are

outside the given tolerance then replace the

probe and retest.

1) Check oven for proper operation.

5. Reverse procedure to install.

FIRST GENERATION UNIT SHOWN (Before April

2005)

TEMP (°F) OHMS* TEMP (°F) OHMS*

77 90,000 360 822

240 4,077 380 656

260 3,016 400 529

280 2,266 425 424

300 1,726 450 334

320 1,332 475 266

340 1,041

(*) Resistance in ohms ± 10%

GAS PRESSURE ADJUSTMENT

(units up to February 2015)

Disconnect the

electrical power to the machine and

follow lockout / tagout procedures.

1. Turn gas supply off at manual shutoff valve.

SECOND GENERATION UNIT SHOWN (After April

2005 thru February 2015)

4. Install hose barb adapter and attach manometer

tube.

2. Remove the

NOTE: If right side panel is not accessible, this

component can be serviced by removing the Control

Panel.

3. Remove the plug from the manifold pressure

port.

F24682 Rev. C (0315) Page 28 of 74

Right Side Panel.

Page 29

VC4G & VC6G SERIES FULL SIZE CONVECTION OVENS - SERVICE PROCEDURES AND ADJUSTMENTS

8. Turn the set screw to obtain the proper gas

pressure (clockwise = pressure increase;

counterclockwise = pressure decrease).

NOTE: Accurate gas pressure adjustments can only

be made with the gas on and the burner lit.

PRESSURE READING (IN W.C.)

GAS

TYPE

Natural 3.5 7.0 5 14

Propane 10 11.0 11 14

NOTE: If the incoming line pressure to the valve is

less than the minimum stated, then the manifold

pressure can not be set correctly.

MANIFOLD

RECOMMEND MIN MAX

LINE

GAS VALVE PRESSURE CHECK

(units after February 2015)

FIRST GENERATION UNIT SHOWN (Before April

2005)

SECOND GENERATION UNIT SHOWN (After April

2005 thru February 2015)

Disconnect the

electrical power to the machine and

follow lockout / tagout procedures.

1. Turn gas supply off at manual shutoff valve.

2. Remove the

NOTE: If right side panel is not accessible, this

component can be serviced by removing the

CONTROL PANEL.

3. Remove the plug from the manifold pressure

port.

RIGHT SIDE PANEL.

5. Remove adjustment screw cap from the gas

valve and turn gas supply to the oven back on.

6. Plug the unit in and turn the power switch ON.

7. Set the temperature control to its highest setting

and allow burner to ignite.

NOTE: The burner must be lit during test and

adjustment.

Page 29 of 74 F24682 Rev. C (0315)

Fig. 59

Page 30

VC4G & VC6G SERIES FULL SIZE CONVECTION OVENS - SERVICE PROCEDURES AND ADJUSTMENTS

4. Install hose barb adapter and attach manometer

tube.

5. Turn gas supply to the oven back on.

6. Plug the unit in and turn the power switch ON.

7. Set the temperature control to its highest setting

and allow burner to ignite.

NOTE: The burner must be lit during test.

NOTE: Accurate gas pressure readings can only be

made with the gas on and the burner lit.

PRESSURE READING (IN W.C.)

GAS

TYPE

Natural 5.0 8.0 6 14

Propane 10 11.0 11 14

NOTE: If the incoming line pressure to the valve is

less than the minimum stated, then the manifold

pressure will not be maintained.

NATURAL GAS

• If the incoming pressure to the valve is between

MANIFOLD

RECOMMEND MIN MAX

6”WC and 14” for Natural gas and the manifold

pressure is not maintaining 5” WC, and the cap

is correctly positioned, replace the valve.

LINE

YOUR HANDS FOR THIS TEST. THE MANUAL GAS

VALVE MUST BE CLOSED.

3. Clamp the ignition cable in a manner that will

position the end of the cable 3/16" from the oven

frame (bare metal surface).

NOTE: It is critical that the cable be held 3/16" away

from the surface of the oven frame or sparking may

not occur even though the sparking circuit is

functioning properly.

Fig. 60

DO NOT HOLD THE WIRE WITH

PROPANE

• 11”WC and 14” for Propane gas and the manifold

pressure is not maintaining 10” WC, and the cap

is correctly positioned, replace the valve.

VERIFICATION OF SPARK AT

IGNITOR

Disconnect the

electrical power to the machine and

follow lockout / tagout procedures.

SHUT OFF THE GAS BEFORE

SERVICING THE UNIT.

1. Remove the

2. Disconnect the high voltage "ignition cable" from

the spark ignitor.

Bottom Front Cover.

Fig. 61

4. Plug the oven in and set the temperature control

to the maximum setting.

5. Turn the power switch ON.

6. Sparking should occur after a 4 second delay, for

a duration of 7 seconds then repeat twice after a

15 second purge time. Arching from the ignition

cable to the oven frame should be observed.

F24682 Rev. C (0315) Page 30 of 74

Page 31

VC4G & VC6G SERIES FULL SIZE CONVECTION OVENS - SERVICE PROCEDURES AND ADJUSTMENTS

DOOR SWITCH ADJUSTMENT

Disconnect the

electrical power to the machine and

follow lockout / tagout procedures.

1. Remove the Top Front Cover.

2. Door operation:

A. Independent doors - The switch actuator

should be operated by the switch lever when

the right door is between 1" and 1 ½" from

being closed.

B. Simultaneous doors - The switch actuator

should be operated by the switch lever when

the right door is ½" from being closed.

3. If adjustment is necessary, bend the switch

actuator to obtain the proper setting.

3. Adjust the motor position until the blower is

parallel to and 1/4 inch away from the motor

mounting plate. Check for squareness of the

blower to the motor mounting plate at the top,

bottom, left and right of the blower.

A. If the blower is square then tighten motor

mounting bolts and proceed to Step 4.

B. If the blower is not square continue

adjusting until proper spacing is achieved

then tighten motor mounting bolts.

NOTE: If necessary, place shims between motor and

frame.

Fig. 62

4. Install the top front cover

5. Apply power to the oven and check for proper

operation.

BLOWER ADJUSTMENT

Disconnect the

electrical power to the machine and

follow lockout / tagout procedures.

SHUT OFF THE GAS BEFORE

SERVICING THE UNIT.

Fig. 63

4. Reverse the procedure to install.

DOOR ADJUSTMENT

Disconnect the

electrical power to the machine and

follow lockout / tagout procedures.

1. Check the doors to make sure they have an equal

gap between them and that the vertical edge of

the door is parallel to the vertical door seal. If the

doors are not positioned in this manner, adjust

the doors as described.

1. Remove the blower motor and mounting

assembly by following steps 1 through 8 as

outlined under

2. Loosen the motor mounting bolts.

BLOWER AND MOTOR.

Page 31 of 74 F24682 Rev. C (0315)

Page 32

VC4G & VC6G SERIES FULL SIZE CONVECTION OVENS - SERVICE PROCEDURES AND ADJUSTMENTS

4. Move the door until proper alignment is achieved

then tighten the screws on the upper door

bearing hardware.

5. Repeat step 3 and 4 on the opposite door, if

necessary.

DOOR STRIKE ADJUSTMENT

(INDEPENDENT DOORS)

NOTE: For units with serial number starting with 48

made after 8/12/07 and serial number starting with 54

made after 8/26/07.

Disconnect the

electrical power to the machine and

follow lockout / tagout procedures.

Fig. 64

2. Remove the Top Front Cover.

3. Loosen the screws that secure the upper door

bearings and related hardware, just enough to

allow door movement.

1. Remove

2. Open the doors and inspect door strike for proper

shape.

A. Replace if bent. Do not bend strike plate.

B. If adjustment is necessary, loosen

Top Front Cover.

fasteners, close doors and insure contact

between door inner surface and upper

horizontal seal. Slide door strike plate until

contact with roller latch is made. Tighten

strike plate fasteners.

3. Open and close the doors several times while

Fig. 65

F24682 Rev. C (0315) Page 32 of 74

Fig. 66

observing the roller latch and strike plate

operation.

A. Replace roller latch if malfunctioning as

outlined under ROLLER LATCH

ASSEMBLY (INDEPENDENT DOORS)

and adjust as outlined in this procedure.

Page 33

VC4G & VC6G SERIES FULL SIZE CONVECTION OVENS - SERVICE PROCEDURES AND ADJUSTMENTS

4. Each oven door should open with a force of 8 to

25 pounds when pulled at the handle. The

adjustments must allow the doors to remain

closed during normal operation and allow

opening without exertion by the user.

DOOR CATCH BALL ADJUSTMENT

(INDEPENDENT DOORS)

NOTE: For units with serial number starting with 48

made before 8/13/07 and serial number starting with

54 made before 8/27/07.

Disconnect the

electrical power to the machine and

follow lockout / tagout procedures.

1. Remove

2. Open the doors and inspect door strike for proper

shape.

Top Front Cover.

4. Apply lubricant at the top of the door catch

assembly to lubricate the internal spring. See

LUBRICATION.

Fig. 68

5. Close the doors and check them for proper

alignment.

A. Doors should be centered and parallel at the

top and bottom in the oven cavity opening

as outlined under DOOR ADJUSTMENT.

Fig. 67

A. Replace if bent and adjust as outlined in this

procedure.

3. Open and close the doors several times while

observing the catch ball operation.

A. Replace if malfunctioning and adjust as

outlined in this procedure.

NOTE: Shims may be required under the door strike,

before the proper door tension adjustment can be set.

6. Open right side door and view the left side catch

ball and door strike position. Ensure catch ball is

resting upon the angular surface of door strike.

Repeat on opposite door.

NOTE: If catch ball is striking the flat surface on door

strike, shims will be required under the door catch

assembly.

NOTE: The catch ball should make contact near the

center of door strike.

A. If adjustment is necessary, loosen mounting

screws then slide door strike from front to

back until roller ball rests upon the angular

surface of the door strike. Tighten screws

and check operation.

B. If proper adjustment cannot be achieved,

add shims beneath the door strike. Repeat

step 6.

NOTE: DO NOT BEND THE DOOR STRIKE.

7. Each oven door should open with a force of 8 to

25 pounds when pulled at the handle. The

adjustment must allow the doors to remain

closed during normal operation and allow

opening without exertion by the user.

NOTE: The amount of tension on catch ball

determines the opening force of door.

A. Adjust catch ball tension as follows:

Page 33 of 74 F24682 Rev. C (0315)

Page 34

VC4G & VC6G SERIES FULL SIZE CONVECTION OVENS - SERVICE PROCEDURES AND ADJUSTMENTS

1) Turn set screw inside the catch

assembly housing clockwise to

increase tension on catch ball and

counterclockwise to decrease tension

on catch ball.

Fig. 69

E. When the doors are opened, the

turnbuckles will move away from each other.

F. The stop cable must be positioned where it

moves freely and does not get pinched.

3. Position door chain assembly to factory setting if

the conditions in step 2 are not met.

2) Continue adjustment until proper door

operation is achieved.

DOOR CHAIN ADJUSTMENT

(SIMULTANEOUS DOORS)

Introduction

When the oven doors are in proper adjustment, as the

doors come together, the right door will lead the left

door in closing by about 1/4 inch. The doors will feel

like they are self closing the last ½ inch of travel.

Procedure

1. Remove the Bottom Front Cover .

2. Close doors and check door chain for factory

setting.

A. Turnbuckles should be 5 to 5 ½ inches

apart.

B. Short eye bolt should be connected to the

end of the chain that goes to the front of the

sprocket.

C. 2 links of the chain should not be engaged

at the rear of the sprocket.

Fig. 70

4. If right door does not lead the left door in closing:

A. Loosen locknuts on both turnbuckles.

B. Loosen left turnbuckle.

C. Tighten right turnbuckle.

D. Tighten locknuts on both turnbuckles.

5. If the right door leads the left door by more than

3/8 inch:

A. Loosen locknuts on both turnbuckles.

B. Loosen right turnbuckle.

C. Tighten left turnbuckle.

D. Tighten locknuts on both turnbuckles.

6. Check door for proper operation.

NOTE: The locknuts must be tight during testing or

the adjustment will not hold.

D. Chain must be tight enough that the doors

move simultaneously when opened or

closed.

7. Install the lower front cover.

F24682 Rev. C (0315) Page 34 of 74

A. If doors do not close properly, repeat Step

4, 5 and 6.

B. If doors operate properly, continue to step 7.

Page 35

VC4G & VC6G SERIES FULL SIZE CONVECTION OVENS - SERVICE PROCEDURES AND ADJUSTMENTS

COMPUTER CONTROL (VC4GC/

VC6GC)

Operation

Refer to the Instructions Manual for specific operating

instructions.

Setup Mode

NOTE: Use the setup mode to verify that the control

is configured to the factory settings which result in the

proper operation of the oven. If the CAL1 parameter

is other than zero, determine if it is still needed before

resetting to zero. See COMPUTER CONTROL

CALIBRATION (VC4GC/VC6GC).

Changing the C_F, InP1, rL1 & rH1

parameters will default all menus.

1. Use this key sequence to access the setup mode.

Up arrow; Rack 1; Temperature; Temperature;

Down arrow; Rack 1

Fig. 71

2. Once in the setup mode the display will alternate

between the parameter and programmed data.

• To change data to the factory setting, use

the arrow keys.

• To select the next parameter, press the

Rack 1 key.

• After the last Parameter and Data is viewed,

press the Rack 1 key a final time to exit the

setup mode and return to operations mode.

The current set point temperature will be

displayed.

• After 1 minute of no key activations, the

control will return to operation mode.

3. Listed are the parameters and data you should

find.

MENU

Celsius_Fahrenheit C_F F

Guard Band gb 4000

Temperature

Compensation

Input Type 1 InP1 J

Range Low 1 rL1 75

ALTERNATING ON DISPLAY

PARAMETER DATA

tcnP OFF

MENU

Range High 1 rH1 500

Hysteresis HYS1 3

Calibration Offset CAL1 0

Exit Setup Mode

and return to

Operation Mode.

Probe Test

1. Set the control to 350°F.

2. Access the back of the control panel to

disconnect the probe lead wires.

3. Install a jumper wire across the probe terminals.

This will simulate room temperature.

A. If the heat light comes on and the actual

temperature is room temperature, replace

the probe.

B. If the heat light does not come on or the

actual temperature is not room temperature,

replace the control.

Solid State Relay Test

1. Remove the Right Side Panel.

2. Set the temperature to 350°F or high enough to

keep the heat ON for several minutes.

3. Check for +5 VDC on input side of SSR

(terminals 3 & 4).

A. If +5 VDC is present, continue to step 4.

B. If no voltage is present, computer control is

not functioning properly.

4. Check for 120 VAC at load side of SSR (terminals

1 & 2).

A. If no voltage is present, solid state relay is

not functioning properly.

1) Replace the SSR and check for proper

operation.

B. If 120 VAC is present, component is

functioning properly.

5. Re-assemble oven and check for proper

operation.

ALTERNATING ON DISPLAY

PARAMETER DATA

set point temperature is

displayed or if call for heat,

dashes (----) displayed.

COMPUTER CONTROL

CALIBRATION (VC4GC/VC6GC)

1. Place a thermocouple in the geometric center of

the oven cavity.

Page 35 of 74 F24682 Rev. C (0315)

Page 36

VC4G & VC6G SERIES FULL SIZE CONVECTION OVENS - SERVICE PROCEDURES AND ADJUSTMENTS

2. Press the set key then temperature key to enter

the temperature set mode.

A. The display will alternate between the term

"StPt" (set point) and the current oven

temperature setting.

B. Press the up or down arrow keys to make

the proper selection.

C. Press the set key again to save the change

and exit the temperature set mode.

3. Allow the oven temperature to stabilize (normally

3 cycles).

4. Set the ON-OFF-COOL DOWN switch to ON.

A. If the set point temperature is 350°F,

proceed to step 4.

B. If the set point temperature is other than

350°F, proceed to step 3 to change the

temperature.

5. Compare the controls set point temperature to

the thermocouple meter reading when the heat

light goes out.

1) Adjust the calibration offset value as

outlined in step 6, until the cycling

temperature is within tolerance.

B. If the above adjustment cannot be obtained,

replace the computer control and check for

proper operation.

A. A temperature variance more than 5°F

indicates an adjustment is needed.

1) To make the adjustment, proceed to

step 6.

2) If temperature variance is less than

5°F, computer control is functioning

properly.

6. Enter the .

A. Advance through the menu until CAL1

(Calibration Offset) appears.

1) If the thermocouple reading is higher

than set point temperature, press the

down arrow key and enter a negative

offset value that is equal to the number

of degrees above the 5°F tolerance.

2) If the thermocouple reading is lower

than set point temperature, press the

up arrow key and enter a positive offset

value that is equal to the number of

degrees below the 5°F tolerance.

3) Exit the setup mode.

7. Allow the oven to cycle at least two times

between adjustments.

A. If the temperature variance still differs

more than 5°F from the set point, verify the

correct calibration offset value was entered

and retained.

F24682 Rev. C (0315) Page 36 of 74

Page 37

VC4G & VC6G SERIES FULL SIZE CONVECTION OVENS - ELECTRICAL OPERATION

ELECTRICAL OPERATION

COMPONENT FUNCTION

Power Switch (S1) ... Determines the mode of operation; ON, OFF, or COOL DOWN.

Oven Light Switch (S2)

........................

Fan Speed Switch Hi/

Low (S3) .............

Function Switch (S3) ... Selects the cooking mode of the oven between Normal ROAST or ROAST & HOLD and

Buzzer ............... Signals the end of a Normal ROAST cycle (normal cooking) when time expires on the

Normal Roast Timer ... Counts the ROAST time (normal cooking) of the product and signals the buzzer at the

Roast & Hold Timer ... When the function switch (S3) is set to ROAST & HOLD, this timer must used for ROAST

Door Switch .......... Allows the oven to operate when the doors are closed but stops the oven from operating

Controls the oven cavity lights.

Controls blower motor speed between Hi and Low settings. Available on standard models

VC4GS/6GS or VC4GD/6GD. On models with the ROAST & HOLD option (S3) becomes

the Function Switch.

is used in conjunction with the ROAST & HOLD timer during ROAST & HOLD cooking.

The selected mode also determines the fixed blower speed of Hi for Normal ROAST and

Low for ROAST & HOLD. In ROAST & HOLD mode only, energizes the hold relay (R2).

Available on models with ROAST & HOLD option only. On Standard models (S3)

becomes the Function Switch.

Normal ROAST timer.

end of the cycle. On ROAST & HOLD models only, when the function switch (S3) is set

to Normal ROAST, this timer is used.

& HOLD cooking. When the ROAST (then hold) time expires and the function switch is

set to ROAST & HOLD, this timer is used to transfer control of the oven temperature to

the Hold thermostat. Available on models with Roast & Hold option only.

when the doors are opened.

Blower Motor ........ Operates the oven cavity blower (convection fan). Also, an internal centrifugal switch on

the motor is utilized to allow the connection of power to the heat relay (R3) when the

motor is at operating speed.

Motor Speed Relay

(R1) ..................

Hold Relay (R2) ...... Hold relay (R2) supplies power to the Hold thermostat for maintaining the fixed hold

Transformer (T1) ..... Provides 24VAC power to the ignition control module and heating circuit.

Solid State

Temperature Control

(VC4GD/6GD) ........

High Limit Thermostat ...Protects the oven from temperatures above 550°F by removing power from the 1st valve

Computer Control

(VC4GC/6GC) ........

Supplies power to the blower motor through (R1) relay contacts. Available on models

with Cook & Hold option only.

temperature in the oven cavity, after the ROAST & HOLD time expires.

Monitors temperature sensor and regulates the oven cavity temperature by controlling

the heat relay (R3) through the blower motor centrifugal switch contacts.

(safety) on the dual solenoid gas valve which stops the flow of gas to the burner. Auto

resets at 500°F.

Monitors temperature sensor and regulates the oven cavity temperature by controlling

the heat relay (R1) through the blower motor centrifugal switch contacts. Also, counts the

ROAST time (normal cooking) of the product and signals the electronic alarm at the end

of the cycle. If ROAST & HOLD mode is selected, when the ROAST (then hold) time

expires, the oven heating stops and the oven enters HOLD mode. Once the oven cavity

temperature drops to 150°F, the heat comes back on and the oven cycles at this

temperature to hold the cooked product. Roast & Hold is standard on computer models.

Page 37 of 74 F24682 Rev. C (0315)

Page 38

VC4G & VC6G SERIES FULL SIZE CONVECTION OVENS - ELECTRICAL OPERATION

SSR1 & SSR2 (VC4GC/

6GC) .................

Ignition Control

Module ...............

Igniter/Flame Sense ... Ignites the gas and senses the presence of a flame. The flame presence generates a

Power On Light ...... Lit whenever the power switch (S1) is turned to ON or Cool Down mode.

Heat Light ............ Lit whenever temperature control is calling for heat.

No Ignition Light ..... Lit when power is turned ON, during ignition trial & gas purge time and when no flame is

Temperature Probe ... Senses the oven temperature for the solid state temperature control or the computer

When SSR1 is energized by computer control, connects power to blower motor for Hi fan

speed operation in normal ROAST mode. In ROAST & HOLD Mode only, SSR1 is deenergized and SSR2 is energized by computer control and connects power to blower

motor for Low fan speed operation.

Controls the gas ignition cycle - Energizes the 2nd valve (main) on the dual solenoid gas

valve, generates spark for burner ignition, monitors the presence of a flame and controls

the No Ignition light. The ignition times are: 4 second self diagnostic test (initial power

ON); 7 second ignition trial; 3 ignition trials with a 15 second purge between each trial.

micro-amp "flame sense" current that is monitored by the ignition control module. A flame

sense current of 0.7 micro amp (minimum) is required to maintain burner ignition.

detected by flame sensor. If the oven fails to ignite after 3 attempts, it will remain lit until

power is reset.

control. On VC4GD/6D models, converts the temperature into a resistance valve which

is monitored by the temperature control board. The probe is an RTD (resistance

temperature detector) of the Thermistor type. As temperature increases the resistance

value decreases. On VC4GC/6C models, the probe is a J type thermocouple.

Gas Valve (Dual

Solenoid) .............

Cooling Fan .......... Circulates cooler air from rear of oven forward to cool components in the control area.

Mechanical

Temperature Control

KX thermostat

(VC4GS/6GS) .........

Hold Thermostat (KX) ...Holds the oven cavity temperature at 160°F after ROAST (then hold) time expires. For

Allows gas flow to the burner when the 1st valve (safety) and 2nd valve (main) solenoid

coils are both energized.

Regulates the oven cavity temperature by controlling the heat relay (R3) through the

blower motor centrifugal switch contacts. On ROAST & HOLD models only, power is first

connected through one set of (R4) normally closed contacts (N.C.) then through the

centrifugal switch contacts on the motor.

the oven to operate on the Hold thermostat, the ROAST & HOLD timer must be used and

the Function Switch (S3) must be set to. Available on models with Roast & Hold option

only.

COMPONENT LOCATION

Fig. 72

F24682 Rev. C (0315) Page 38 of 74

Page 39

VC4G & VC6G SERIES FULL SIZE CONVECTION OVENS - ELECTRICAL OPERATION

VC4GS/6GS - Plug, Socket and Components (Standard Controls)

Page 39 of 74 F24682 Rev. C (0315)

Page 40

VC4G & VC6G SERIES FULL SIZE CONVECTION OVENS - ELECTRICAL OPERATION

VC4GD/6GD - Plug, Socket and Components (Standard Controls)

F24682 Rev. C (0315) Page 40 of 74

Page 41

VC4G & VC6G SERIES FULL SIZE CONVECTION OVENS - ELECTRICAL OPERATION

VC4GS/6GS, VC4GD/6GD - Plug, Socket and Components (Roast & Hold Option)

Page 41 of 74 F24682 Rev. C (0315)

Page 42

VC4G & VC6G SERIES FULL SIZE CONVECTION OVENS - ELECTRICAL OPERATION

VC4GC/6GC - Plug, Socket and Components (Roast & Hold Standard)

F24682 Rev. C (0315) Page 42 of 74

Page 43

VC4G & VC6G SERIES FULL SIZE CONVECTION OVENS - ELECTRICAL OPERATION

SEQUENCE OF OPERATION

VC4GS, VC6GS With Roast & Hold Option

(Mechanical KX Thermostat)

Schematic diagram 5304 will be used to explain the

electrical sequence of operation for both the Normal

ROAST cycle (normal cooking) and the ROAST &

HOLD cycle.

Normal Roast Cycle

1. Conditions.

A. Oven connected to correct voltage.

1) L1 (HOT) to power switch (S1).

2) L2 (NEUTRAL or SECOND LINE) to

one side of the following components:

power ON light, heat light, oven cavity

lights, buzzer, ROAST timer motor

(normal cooking), ROAST & HOLD

timer motor, heat relay coil (R3),

convection fan motor common (C),

transformer primary (T1), relay coil

(R4), motor speed (Hi/Low) relay coil

(R1), hold relay coil (R2) and the