Page 1

SERVICE MANUAL

V-SERIES HEAVY DUTY

BROILERS, DOUBLE DECK AND

RANGE MATCH MODELS

For a complete listing of models, see the MODELS

section.

- NOTICE -

This Manual is prepared for the use of trained Vulcan Service

Technicians and should not be used by those not properly

qualified.

This manual is not intended to be all encompassing. If you have

not attended a Vulcan Service School for this product, you should

read, in its entirety, the repair procedure you wish to perform to

determine if you have the necessary tools, instruments and skills

required to perform the procedure. Procedures for which you do

not have the necessary tools, instruments and skills should be

performed by a trained Vulcan Service Technician.

The reproduction, transfer, sale or other use of this Manual,

without the express written consent of Vulcan, is prohibited.

This manual has been provided to you by ITW Food Equipment

Group LLC ("ITW FEG") without charge and remains the property

of ITW FEG, and by accepting this manual you agree that you will

return it to ITW FEG promptly upon its request for such return at

any time in the future.

A product of Vulcan-Hart 3600 North Point Blvd Baltimore, MD 21222

F45548 (0715)

Page 2

V-SERIES HEAVY DUTY BROILERS, DOUBLE DECK AND RANGE MATCH MODELS

TABLE OF CONTENTS

GENERAL .................................................................................................. 3

INTRODUCTION ....................................................................................... 3

MODELS ............................................................................................... 3

INSTALLATION, OPERATION AND MAINTENANCE .................................................... 3

RACK POSITION AND GAS SETTING .................................................................. 3

SPECIFICATIONS ...................................................................................... 3

LUBRICATION ......................................................................................... 3

TOOLS ................................................................................................. 3

REMOVAL AND REPLACEMENT OF PARTS ............................................................... 5

MANIFOLD COVER .................................................................................... 5

CONTROL VALVE COVER ............................................................................. 5

CONTROL VALVE ...................................................................................... 5

PILOT TUBE (CERAMIC-RADIANT BURNER) .......................................................... 7

PILOT (INFRARED BURNER) .......................................................................... 7

CERAMIC-RADIANT BURNER ......................................................................... 8

INFRARED BURNER .................................................................................. 10

GAS PRESSURE REGULATOR ....................................................................... 10

RACK SPRINGS ...................................................................................... 10

SERVICE PROCEDURES AND ADJUSTMENTS ........................................................... 12

PILOT FLAME HEIGHT ............................................................................... 12

CERAMIC-RADIANT BURNER AIR SHUTTER ADJUSTMENT ......................................... 12

REGULATOR ADJUSTMENT .......................................................................... 12

INFRARED BURNER ADJUSTMENT .................................................................. 13

INFRARED BURNER FLAME APPEARANCE .......................................................... 13

GAS ORIFICE CHECK ................................................................................ 13

CONTROL VALVE .................................................................................... 14

RACK SPRING TENSION ADJUSTMENT .............................................................. 14

TROUBLESHOOTING ..................................................................................... 15

GENERAL (ALL MODELS) ............................................................................ 15

CERAMIC-RADIANT BURNER ........................................................................ 15

INFRARED BURNER .................................................................................. 16

© VULCAN 2015

F45548 (0715) Page 2 of 16

Page 3

V-SERIES HEAVY DUTY BROILERS, DOUBLE DECK AND RANGE MATCH MODELS - GENERAL

GENERAL

INTRODUCTION

This manual is for the Vulcan V-Series Gas Broilers

which include the double deck broiler models and the

single broiler over the Heavy Duty Range (HDR)

models. Procedures in this manual will apply to all

models unless specified. Pictures and illustrations will

be of model VIB2 - Infrared Broiler over CeramicRadiant Broiler unless otherwise noted.

All of the information, illustrations and specifications

contained in this manual are based on the latest

product information available at the time of printing.

MODELS

Range Match Broilers on Base (Ceramic-Radiant

Burner)

• VBB1F - Modular (for refrigerated base mount

only)

• VBB1BF - Cabinet Base

• VBB1SF - Standard Oven Base

• VBB1CF - Convection Oven Base

Range Match Broilers on Base (Infrared Burner)

• VIR1F - Modular (for refrigerated base mount

only)

• VIR1BF - Cabinet Base

• VIR1SF - Standard Oven Base

• VIR1CF - Convection Oven Base

Double Deck Broilers

• VIR2 - Infrared Broiler over Infrared Broiler

RACK POSITION AND GAS

SETTING

NOTE: Infrared burner models must use the full gas

setting (knob fully counterclockwise) to achieve the

best burner performance and highest broiler

temperatures. Lower broiler temperatures can be

achieved by using a lower gas setting (knob in the

range just past off but less than fully

counterclockwise). When using a lower gas setting,

the flame should remain lit and be steady across the

entire burner surface.

For information on rack position and gas setting, refer

to F38215 V-Series Heavy Duty range (HDR) Broilers

Operations manual sent with each unit. The manual is

also available online at www.vulcanequipment.com.

SPECIFICATIONS

GAS PRESSURES

• Manifold/Operating Pressure

Natural - 6" W.C.

Propane - 10" W.C.

• Inlet Supply Pressure

Natural - Recommended 7" - 9" W.C. with a

minimum of 7" W.C.

Propane - Recommended 11" - 12" W.C.

with a minimum of 11" W.C.

Maximum 14" W.C. (0.5 PSI) for Natural or

Propane.

• VBB2 - Ceramic-Radiant Broiler over CeramicRadiant Broiler

• VBI2 - Ceramic-Radiant Broiler over Infrared

Broiler

• VIB2 - Infrared Broiler over Ceramic-Radiant

Broiler

INSTALLATION, OPERATION AND

MAINTENANCE

For detailed installation, operation and cleaning

instructions, refer to F38215 V-Series Heavy Duty

range (HDR) Broilers Operations Manual sent with

each unit. The manual is also available online at

www.vulcanequipment.com.

LUBRICATION

Anderson and Forrester (or comparable) valve grease

for burner valve stems. Apply light coat to valve stems.

Valve grease must be insoluble in propane and natural

gas.

TOOLS

Standard

• Standard set of hand tools.

• Manometer.

• Gas leak detection equipment.

• Pipe thread sealant. Any sealant used must be

resistant to the reaction of propane gases.

Page 3 of 16 F45548 (0715)

Page 4

V-SERIES HEAVY DUTY BROILERS, DOUBLE DECK AND RANGE MATCH MODELS - GENERAL

Special

• Pipe tee for checking gas manifold pressure after

the regulator when a pressure tap is not available

in the gas manifold (purchase parts locally).

Assemble the parts and retain for future use on

gas equipment:

• Pipe tee sized for the gas line inlet

connection and pipe fittings (pipe nipples,

reducers etc.) for the connection as

required.

• Hose barb to install in the tee for connecting

manometer hose.

F45548 (0715) Page 4 of 16

Page 5

V-SERIES HEAVY DUTY BROILERS, DOUBLE DECK AND RANGE MATCH MODELS - REMOVAL AND

REPLACEMENT OF PARTS

REMOVAL AND REPLACEMENT OF PARTS

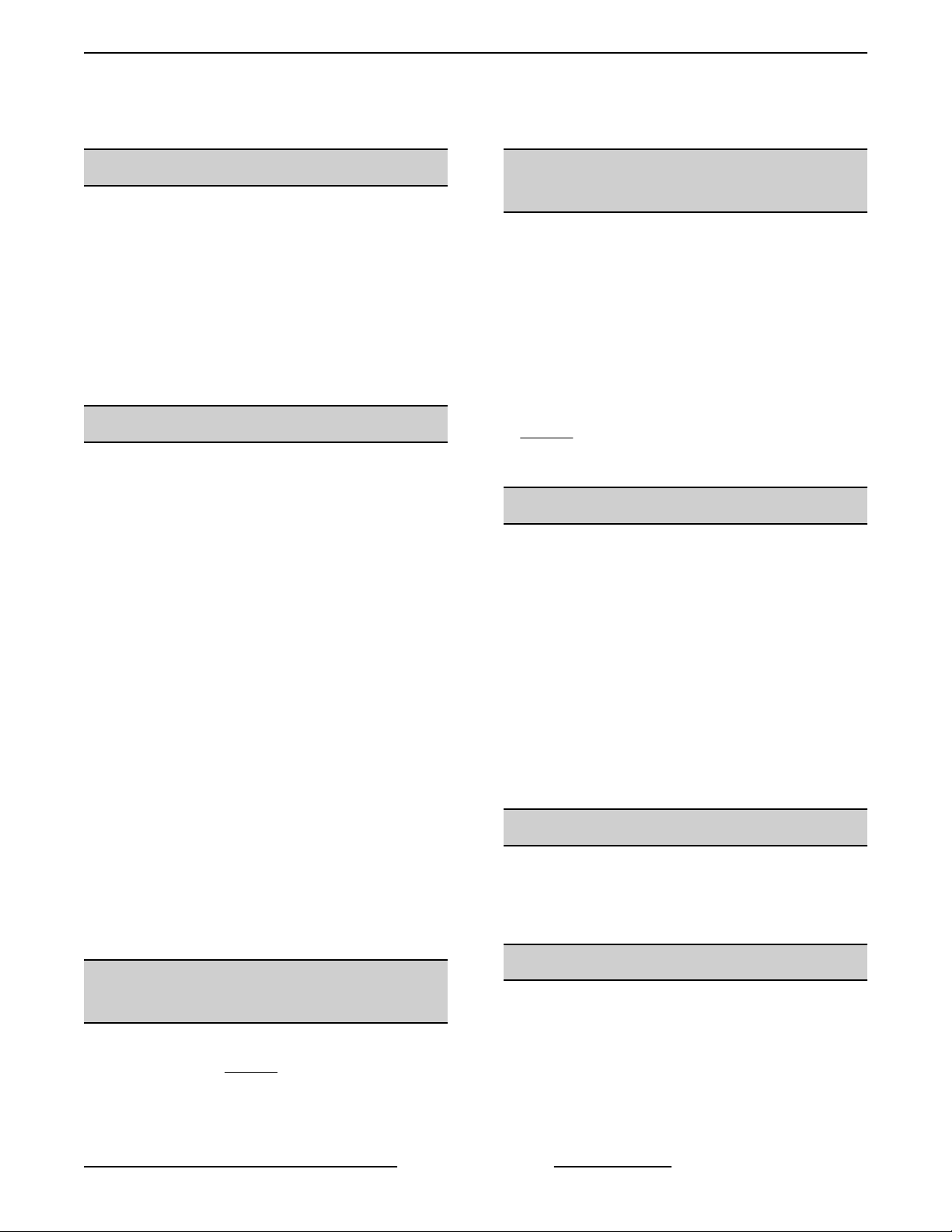

MANIFOLD COVER

1. Remove screws that secure manifold cover and

remove the cover from broiler.

2. Reverse procedure to install.

Fig. 1

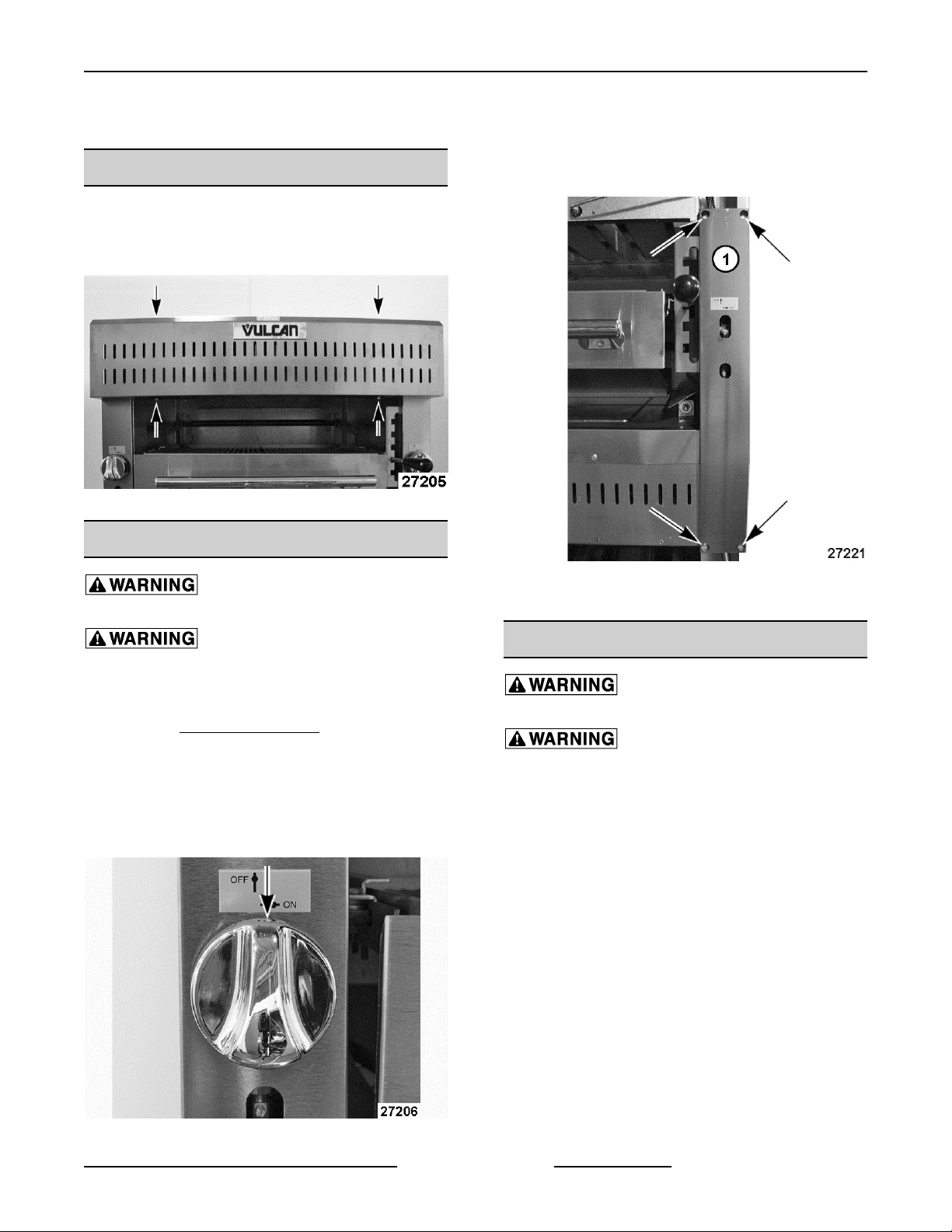

CONTROL VALVE COVER

Shut off the gas before servicing the

unit.

3. Remove screws securing the control valve cover

[1] to broiler.

Fig. 3

4. Reverse procedure to install.

All gas joints disturbed during

servicing must be checked for leaks. Check with a

soap and water solution (bubbles). Do not use an open

flame.

1. Remove MANIFOLD COVER.

NOTE: When servicing the upper broiler on a double

deck unit, the manifold cover on the lower broiler must

also be removed.

2. Loosen set screw and remove knob from control

valve.

CONTROL VALVE

Shut off the gas before servicing the

unit.

All gas joints disturbed during

servicing must be checked for leaks. Check with a

soap and water solution (bubbles). Do not use an open

flame.

Accessing Control Valve

• Upper Broiler (double stack or single unit over

range) - The side panel must be removed as

outlined in the procedure. The rear of panel is

secured to the broiler frame with screws. The

bottom lip of the panel and the top lip of the panel

at the both corners are an interference fit.

• Lower Broiler (double stack or finishing oven on

top) - The side panel can only be pulled away

from broiler at the bottom of panel. The rear of

panel is secured to broiler frame with screws. The

bottom lip of the panel at the front and rear are

an interference fit. The top lip of the panel is

secured to the broiler frame with screws.

Fig. 2

NOTE: When servicing the upper broiler on a double

deck unit, the manifold cover on the lower broiler must

also be removed.

Page 5 of 16 F45548 (0715)

Page 6

V-SERIES HEAVY DUTY BROILERS, DOUBLE DECK AND RANGE MATCH MODELS - REMOVAL AND

REPLACEMENT OF PARTS

1. Remove MANIFOLD COVER.

2. Remove CONTROL VALVE COVER.

3. Remove side panel (left or right):

A. Loosen several screws securing brace [1]

Fig. 4 to broiler frame near the side panel to

remove. The upper front right of the broiler

is shown in Fig. 4.

Fig. 6

D. Remove side panel from broiler.

Fig. 4

B. At rear of broiler, loosen screws securing

the flue back panel [1] Fig. 5 to broiler frame

then lift panel off broiler.

NOTE: The mounting holes in the flue back panel Fig.

5 are keyed to allow for easy panel removal without

having to remove all the screws that are also securing

the back panel Fig. 6 to broiler frame.

4. Disconnect compression nut [1] Fig. 7 above the

control valve for the burner gas supply.

5. Disconnect flexible tubing compression nut [2]

Fig. 7 from the pilot valve adjustment fitting.

6. Separate union fitting [3] Fig. 7 at the bottom of

control valve to remove the valve.

Fig. 5

C. For the side panel being removed, remove

screws at the rear that are securing the back

panel [1] Fig. 6 and side panel to broiler

frame. Arrows shown in Fig. 6 are pointing

to the rear screw locations for right side

panel removal.

F45548 (0715) Page 6 of 16

7. Note locations then remove pipe fittings from

sealant that is suitable for use with propane gases.

8. Install pipe fittings on replacement valve.

Fig. 7

control valve.

Clean pipe threads and apply thread

Page 7

V-SERIES HEAVY DUTY BROILERS, DOUBLE DECK AND RANGE MATCH MODELS - REMOVAL AND

REPLACEMENT OF PARTS

9. Reverse procedure to install replacement valve.

10. Check for proper operation.

PILOT TUBE (CERAMIC-RADIANT

BURNER)

Shut off the gas before servicing the

unit.

All gas joints disturbed during

servicing must be checked for leaks. Check with a

soap and water solution (bubbles). Do not use an open

flame.

1. Remove MANIFOLD COVER.

2. Remove screws securing pilot tube mounting

bracket to broiler.

5. Reverse procedure to install and check for proper

operation.

PILOT (INFRARED BURNER)

Shut off the gas before servicing the

unit.

All gas joints disturbed during

servicing must be checked for leaks. Check with a

soap and water solution (bubbles). Do not use an open

flame.

1. Remove

2. Disconnect compression fitting [1] Fig. 10 for pilot

gas tubing.

3. Remove screw [2] Fig. 10 and lock washer nut [3]

Fig. 11 securing pilot to mounting bracket.

MANIFOLD COVER.

Fig. 8

3. Pull the pilot tube assembly Fig. 9 away from

broiler. There are 3 pilot tubes on each assembly.

4. Disconnect compression nut Fig. 9 from the pilot

tube fitting and remove the tube.

Fig. 9

When disconnecting compression nut

from the pilot tube fitting, support the fitting to prevent

damage to pilot tubing.

Fig. 10

Page 7 of 16 F45548 (0715)

Page 8

V-SERIES HEAVY DUTY BROILERS, DOUBLE DECK AND RANGE MATCH MODELS - REMOVAL AND

REPLACEMENT OF PARTS

Fig. 11

4. Reverse procedure to install and check for proper

operation.

CERAMIC-RADIANT BURNER

Shut off the gas before servicing the

unit.

1. Remove

2. Remove CONTROL VALVE COVER next to rack

lift assembly handle.

3. Adjust rack assembly to the lowest position to

access the burners.

Use care when handling.

4. Lift ceramic bricks [1] Fig. 12 off the support rails

[2] Fig. 12 for each burner [3] Fig. 12. There are

6 ceramic bricks for each of the 3 burners (18

bricks total).

MANIFOLD COVER.

Ceramic bricks can easily be damaged.

Fig. 12

5. Remove screws securing pilot tube mounting

brackets [1]

13. Position pilot tube assemblies out of the way

to the sides.

6. Remove screws securing manifold bracket [1]

Fig. 14 to burner support [2] Fig. 14. Allow

bracket to drop down out of the way.

Fig. 13 to burner support [2] Fig.

Fig. 13

7. Loosen screws [1] Fig. 15 (qty 6) by several turns

F45548 (0715) Page 8 of 16

Fig. 14

that secure the burner support [2] and brace [3]

Fig. 15 to broiler frame.

Page 9

V-SERIES HEAVY DUTY BROILERS, DOUBLE DECK AND RANGE MATCH MODELS - REMOVAL AND

REPLACEMENT OF PARTS

NOTE: Leave the burner support screws installed.

The burner support is necessary to hold the burners

in place during removal procedure.

Fig. 15

8. Remove screws [1] Fig. 16 (qty 6) securing

burner support [2] Fig. 16 to broiler frame.

11. Adjust rack assembly to the middle position.

12. Remove cotter pin from all three burners.

Fig. 18

Fig. 16

9. Reach underneath burner support to access the

support rails [1] Fig. 17 (qty 6) that hold the

ceramic bricks in place. Remove screws (qty 2)

Fig. 17 securing each support rail to the rear of

burner support. Top view shown in Fig. 17.

Fig. 17

Fig. 19

13. Grasp the bottom of burner support in between

the burners and pull out on the burner support to

disengage burners. The front of burners will drop

down onto the 2 x 4's. Ensure the burner air

shutters are not catching in the burner support

opening to prevent removal.

10. Provide support for burners from inside the

cooking area by stacking two 2 x 4's

approximately 24" long onto the broiler grid.

Position 2 x 4's underneath the burners near the

front.

Fig. 20

14. Lift the burner being replaced off the rear pin and

pull toward the front to remove from broiler.

15. Remove burner support rails [1] Fig. 21 from

each side of burner [2] Fig. 21 being replaced.

Page 9 of 16 F45548 (0715)

Page 10

V-SERIES HEAVY DUTY BROILERS, DOUBLE DECK AND RANGE MATCH MODELS - REMOVAL AND

REPLACEMENT OF PARTS

6. Check for proper operation.

GAS PRESSURE REGULATOR

Shut off the gas before servicing the

unit.

All gas joints disturbed during

servicing must be checked for leaks. Check with a

soap and water solution (bubbles). Do not use an open

flame.

Clean pipe threads and apply thread

sealant that is suitable for use with propane gases.

NOTE: Gas pressure regulator should be installed as

close to the broiler inlet gas connection as possible.

Fig. 21

16. Install burner support rails on replacement

burner.

17. Reverse procedure to install.

18. Perform CERAMIC-RADIANT BURNER AIR

SHUTTER ADJUSTMENT.

INFRARED BURNER

Shut off the gas before servicing the

unit.

1. Remove

2. Adjust rack assembly to the lowest position.

3. From inside the broiler cooking area, remove

wire Fig. 22 securing burner to mounting bracket.

MANIFOLD COVER.

1. Thread regulator [1] Fig. 23 onto pipe hand tight

with arrow on regulator pointing in direction of

gas flow to the broiler.

Fig. 23

2. Tighten regulator securely in horizontal position

with the regulator adjustment upward [2] Fig.

23. Regulator adjustment is below the closing

nut.

NOTE: Regulator will not function properly without

adjustment screw pointing upward.

3. Connect main gas supply line to gas pressure

4. Adjust regulator as outlined in REGULATOR

Fig. 22

4. Lift burner up at the rear and slide it away from

gas orifice to remove from broiler.

5. Reverse procedure to install replacement burner.

NOTE: When installing, secure the burner with wire.

F45548 (0715) Page 10 of 16

NOTE: Springs should be replaced in pairs for proper

operation of the rack lift assembly.

1. Raise the rack lift assembly to its highest position

regulator inlet.

ADJUSTMENT.

RACK SPRINGS

on stop bracket to relieve spring tension.

Page 11

V-SERIES HEAVY DUTY BROILERS, DOUBLE DECK AND RANGE MATCH MODELS - REMOVAL AND

REPLACEMENT OF PARTS

2. Loosen spring tension adjusting nuts to remove

any remaining tension on springs.

Fig. 24

3. Remove springs from the lifting arm mechanism

and eye bolt.

4. Reverse procedure to install.

5. Perform RACK SPRING TENSION

ADJUSTMENT.

Page 11 of 16 F45548 (0715)

Page 12

V-SERIES HEAVY DUTY BROILERS, DOUBLE DECK AND RANGE MATCH MODELS - SERVICE PROCEDURES

AND ADJUSTMENTS

SERVICE PROCEDURES AND ADJUSTMENTS

PILOT FLAME HEIGHT

1. Locate the pilot adjustment screws below the

burner control knobs (one on each side) on the

front of broiler. It is not necessary to remove the

control valve cover as the adjustment access

holes are provided in the panel.

Fig. 25

2. Locate the pilots at the top of the broiler heating

area.

To correct this condition, loosen the shutter screw Fig.

26 and rotate the air shutter Fig. 27 open until the

flame begins to lift from the burner, then close the

shutter slightly and tighten the shutter screw. A proper

flame should be blue in color, well-defined and seated

on the burner port. A white-blue flame is a result of

excessive primary air.

NOTE: The factory default air shutter positions are

half open natural; full open propane.

Fig. 26

3. Monitor the pilots flame and burner lighting. Pilot

is in adjustment when it will stay on continually

and lights the burners without delayed ignition.

Approximate pilot flame height:

A. Ceramic-Radiant Burner - 1/2" bubble

extending from the end of pilot tube.

B. Infrared Burner - 3/4" from each side of the

pilot tee.

4. If adjustment is necessary, rotate the screw

clockwise to decrease and counterclockwise to

increase flame height.

CERAMIC-RADIANT BURNER AIR

SHUTTER ADJUSTMENT

The efficiency of the burner depends on a delicate

balance between the air supply and volume of gas.

Whenever this balance is disturbed, poor operating

characteristics and excessive gas consumption may

occur. An air shutter on the front of the burner controls

the gas mixer balance. A yellow streaming flame on

the burner is an indication of insufficient primary air.

Fig. 27

REGULATOR ADJUSTMENT

Shut off the gas before servicing the

unit.

NOTE: Regulators come preset, but should be

checked anytime one is installed. Before adjusting

regulator, check incoming gas line pressure. Incoming

pressure must be 7-14" W.C. for natural gas and

11-14" W.C. for propane gas. If incoming pressure is

not correct, have the gas source checked and

adjusted as necessary. Make sure the regulator is

F45548 (0715) Page 12 of 16

Page 13

V-SERIES HEAVY DUTY BROILERS, DOUBLE DECK AND RANGE MATCH MODELS - SERVICE PROCEDURES

AND ADJUSTMENTS

mounted in the horizontal position with the arrow

pointing in the direction of gas flow. See GAS

PRESSURE REGULATOR under REMOVAL AND

REPLACEMENT OF PARTS.

See data plate for manifold pressure setting

information. Clean vent cap [1] Fig. 28 before

adjusting.

Fig. 29

B. Insert a flat edge screwdriver through the

top of the regulator. While watching the

manometer, turn the adjusting screw

clockwise to increase pressure and

counterclockwise to decrease pressure until

the proper gas pressure is achieved.

Fig. 28

1. Connect manometer to measure gas manifold

pressure.

A. Install a tee with hose barb connection on

the outlet side of the regulator. See

TOOLS. Connect the opposite end of tee to

the incoming gas supply for the machine.

2. Turn gas supply on and light all pilots on the

machine.

3. Open all valves to the full on position to light

burners and check manometer reading. The

reading should be 6" W.C. for natural gas and 10"

W.C. for propane gas. Tolerance is ±0.3" W.C.

4. If manifold pressure is not correct, adjust the

regulator as follows.

A. Remove the regulator closing nut [1] Fig.

29.

C. Install the regulator closing nut.

D. Turn gas supply off.

E. Remove manometer and tee from gas line.

Clean pipe threads and apply thread

sealant that is suitable for use with propane gases.

F. Apply thread sealant to gas line pipe threads

and re-install regulator.

INFRARED BURNER ADJUSTMENT

The only adjustment for the Infrared burner is the gas

manifold pressure. Verify the pressure is set correctly

as outlined under REGULATOR ADJUSTMENT.

INFRARED BURNER FLAME

APPEARANCE

When the Infrared burner first lights you should see a

small rolling blue flame, which will clear up after the

burner warms. Once warm, a low profile orange flame

is the best description of the Infrared burner flame. In

some cases, if the burner is operating correctly, you

may not be able to see the actual flame. Instead you

will see the glow of the ceramic bricks in the burner.

GAS ORIFICE CHECK

If burner operation seems poor and other systems

have been checked, remove MANIFOLD COVER to

access the gas and air inlet for the Ceramic-Radiant

Page 13 of 16 F45548 (0715)

Page 14

V-SERIES HEAVY DUTY BROILERS, DOUBLE DECK AND RANGE MATCH MODELS - SERVICE PROCEDURES

AND ADJUSTMENTS

burner Fig. 30 or Infrared burner Fig. 31. Inspect the

following:

• Gas orifice alignment - orifice should be centered

in the venturi opening and perpendicular to the

burner.

• Check gas orifice for blockage or damage. If dirty,

clean with air or water only.

• Verify gas orifice is correct for the altitude.

Ceramic-Radiant Burner Orifice

the valve is being closed. When inspecting valve,

always apply a light amount of valve grease at the

base of the valve stem. See LUBRICATION. If valve

grease does not improve rotation of the valve, or

damage is found, replace the CONTROL VALVE as

outlined under REMOVAL AND REPLACEMENT OF

PARTS.

RACK SPRING TENSION

ADJUSTMENT

1. Raise the rack lift assembly to its highest position

on stop bracket to relieve spring tension.

2. Access spring tension adjusting nuts from the

front of broiler.

Fig. 30

Infrared Burner Orifice

Fig. 31

CONTROL VALVE

Shut off the gas before servicing the

unit.

Inspect the control valve for smooth rotation,

noticeable wear and any possible damage. The

burner flame should increase smoothly as the valve is

opened (highest setting) and decrease smoothly as

Fig. 32

3. Tighten nut [1] to adjust rack spring tension.

Adjust both springs equally so there is

approximately 5/8" of thread above the nut.

Spring tension is properly adjusted when the rack

assembly can be comfortably raised and lowered

by the operator using one hand.

Fig. 33

4. If additional rack spring tension is required,

tighten each nut an additional 2-3 turns and recheck.

5. Check for proper operation.

F45548 (0715) Page 14 of 16

Page 15

V-SERIES HEAVY DUTY BROILERS, DOUBLE DECK AND RANGE MATCH MODELS - TROUBLESHOOTING

TROUBLESHOOTING

GENERAL (ALL MODELS)

GENERAL

SYMPTOM POSSIBLE CAUSE

1. Incorrect gas type.

Pilot does not remain lit.

Slow to heat or not hot enough.

Broiler temperature too hot.

SYMPTOM POSSIBLE CAUSE

2. Incorrect gas pressure.

3. Pilot burner not adjusted properly.

4. Pilot burner blocked or Incorrect pilot orifice.

1. Incorrect gas type.

2. Low gas pressure.

3. Regulator adjustment or malfunction.

4. Control valve malfunction.

1. Incorrect gas type.

2. Regulator adjustment or malfunction due to high gas

pressure.

3. Control valve malfunction.

CERAMIC-RADIANT BURNER

CERAMIC-RADIANT BURNER

1. Orifice incorrect size or dirty.

2. Air shutter not adjusted correctly or dirty.

Flame too yellow.

Low burner flame (all burners).

Low burner flame (individual burner). 1. Air mixture incorrect.

Flame floats on burner.

Page 15 of 16 F45548 (0715)

3. Incorrect gas pressure.

4. Incorrect gas type.

5. Orifice not aligned properly in venturi.

6. Appliance not venting properly.

1. Regulator adjustment or low gas pressure.

2. Incorrect gas type.

1. Inadequate air supply.

2. Restricted exhaust flue.

Page 16

V-SERIES HEAVY DUTY BROILERS, DOUBLE DECK AND RANGE MATCH MODELS - TROUBLESHOOTING

INFRARED BURNER

NOTE: Grease laden air is detrimental to the life of the Infrared burner. If a technician sees a broiler with Infrared

burner mounted in a location close to a fryer or charbroiler, please recommend to the customer to move the broiler

away from the grease laden air source to prolong the life of the Infrared burner.

INFRARED BURNER

SYMPTOM POSSIBLE CAUSE

1. Orifice incorrect size or dirty.

2. Incorrect gas pressure.

3. Incorrect gas type.

Flame not orange.

Burner not lighting properly or incorrect burner flame

appearance due to clogged ports.

Tiles falling out of the burner.

4. Orifice not aligned properly in venturi.

5. Appliance not venting properly.

6. Clogged burner ports.

7. Burner malfunction.

1. Broiler with Infrared burner is located too close to a

fryer or charbroiler and the grease laden air is

causing burner ports to clog. If burner ports are

found to be clogged, install a replacement burner.

See NOTE at top of page.

1. Burner ports are clogged from the broiler operating

too close to a fryer or charbroiler that is creating

grease laden air. Clogged burner ports create poor

burner performance and cause the burner housing

to overheat and warp allowing the tiles to fall out of

burner. If tiles are missing, install a replacement

burner. See NOTE at top of page.

F45548 (0715) Page 16 of 16

Loading...

Loading...