Workshop Manual

I

Group 30

4(0)

TAD650VE, TAD660VE,

TAD734GE, TAD750VE, TAD760VE

Group 30 Electrical system

Industrial Engines

TAD734GE, TAD650VE, TAD660VE, TAD750VE,

TAD760VE

Contents

Safety rules ............................................................ 3

General information .............................................. 4

About this Workshop Manual ............................... 4

Spare parts .......................................................... 4

Certified engines .................................................. 4

Repair instructions ................................................ 5

Our common responsibility ................................... 6

Tightening torques ............................................... 6

Special tools ......................................................... 7

EMS 2 - “Engine Management System” .............. 8

General information .............................................. 8

CAN - Controller Area Network ............................. 8

CIU - Control Interface Unit .................................. 9

DCU - Display Control Unit ................................... 9

Fuel control ........................................................ 10

Calculation of fuel quantity ................................. 10

Altitude correction .............................................. 10

Diagnostic function ............................................ 10

Component location ........................................... 11

TAD 650, 660, 750, 760 VE ............................... 11

TAD 734 GE ...................................................... 12

Component description ...................................... 13

Starter motor ...................................................... 13

Alternator ........................................................... 13

Injectors ............................................................. 14

Speed sensor, crankshaft .................................. 14

Speed sensor, camshaft .................................... 14

Sensor, boost pressure/

boost temperature .............................................. 15

Sensor, oil pressure, engine ............................... 15

EGR ................................................................... 15

Coolant temperature sensor ............................... 16

Sensor, common rail pressure (fuel) ................... 16

Sensor, fuel pressure ......................................... 16

Magnetically controlled proportional valve

(MPROP) ........................................................... 17

Water in fuel switch, secondary fuel filter .......... 17

Switch, coolant level .......................................... 17

Preheater ........................................................... 18

Engine control unit, EMS 2 ................................ 18

Repair instructions .............................................. 19

General advice on working with EMS engines .... 19

Electric welding .................................................. 20

Changing the engine control unit ........................ 21

Reprogramming a control unit............................. 22

Programming an empty control unit .................... 23

Fault tracing of cables and connectors ............... 24

Checking the starter motor voltage..................... 26

Checking the charging system ........................... 27

Rail pressure measurement ................................ 28

Malfunctions ........................................................ 29

Fault code information ........................................ 29

FMI table / SAE standard .................................. 30

Manual fault tracing in bus cables ...................... 33

Diagnostic Trouble Codes .................................. 34

MID 128, PID 45

Inlet air heater status ......................................... 34

MID 128, PID 94

Fuel pressure ..................................................... 37

MID 128, PID 97

Water in fuel ....................................................... 43

MID 128, PID 100

Oil pressure ....................................................... 46

MID 128, PID 105

Boost temperature ............................................. 52

MID 128, PID 106

Boost pressure ................................................... 58

7747632 English 03–2007

MID 128, PID 108

Ambient air pressure .......................................... 64

MID 128, PID 110

Coolant temperature ........................................... 66

MID 128, PID 111

Coolant level ...................................................... 72

MID 128, PID 158

Battery voltage................................................... 76

MID 128, PID 164

Rail pressure ...................................................... 78

MID 128, PID 190

Engine speed ..................................................... 84

MID 128 / MID 144, PPID 4

Start input CIU ................................................... 85

MID 128 / MID 144, PPID 6

Engine stop switch ............................................. 87

MID 128, PPID 19

Internal EGR status ........................................... 89

MID 128, PPID 55

EMS temperature ............................................... 93

MID 128, PPID 98

Engine sync acknowledge .................................. 95

MID 128 / 144, PPID 132

Throttle input request failure, DCU/CIU .............. 97

MID 128, SID 1-6

Injector common rail # 1-6 ................................. 100

MID 128, SID 21

Speed sensor camshaft .................................... 105

MID 128, SID 22

Speed sensor, crankshaft .................................110

MID 128, SID 39

Engine starter relay ...........................................115

MID 128, SID 42

Injection control pressure regulator ....................118

MID 128, SID 70

Preheat sense ...................................................122

MID 128, SID 211

5V sensor supply 2 ...........................................124

MID 128, SID 231

Communication fault J 1939 .............................. 126

MID 128, SID 232

5V sensor supply 1 ...........................................129

MID 128, SID 240

Program memory .............................................. 131

MID 128, SID 254

Controller error .................................................. 132

MID 128, PSID 96

Rail pressure system ........................................ 133

MID 128, PSID 97

Rail pressure release valve ...............................137

MID 128 / MID 144, PSID 201

J1939 communication bus ................................ 141

Engine protection .............................................. 144

TAD 650, 660, 750, 760 VE ..............................144

TAD 734 GE .....................................................145

Wiring diagrams .................................................146

Wiring diagram EMS 2:

Vechicle harness TAD 650-760VE ................... 146

Engine harness TAD 650-760VE ......................147

Engine harness TAD 734GE ............................ 148

Wiring diagram DCU .......................................... 149

Wiring diagram CIU ........................................... 150

Technical data ....................................................151

Switch, water in fuel ..........................................151

Sensor, fuel pressure ........................................ 151

Speed sensor, camshaft /

Speed sensor, crankshaft .................................151

Sensor, oil pressure .......................................... 151

Sensor, rail pressure ......................................... 151

Combination sensor,

boost pressure/boost temperature .....................152

Sensor, coolant temperature ............................. 152

Switch, coolant level .........................................152

Alternator .......................................................... 152

Starter motor ..................................................... 152

Index ................................................................... 153

References to Service Bulletins ........................ 153

We reserve the right to make modifications without prior notice.

© 2007 AB VOLVO PENTA

Printed on environmentally compatible paper.

Group 30: Electrical system Safety information

Safety rules

Introduction

This workshop manual contains technical data, descriptions and repair instructions for the Volvo Penta

products or product versions noted in the table of contents. Check that you have the correct Workshop

Manual for your engine.

Read the available safety information, ”General information” and ”Repair instructions” in this workshop

manual before you start to do any service work.

Important!

The following special warning symbols occur in this

book and on the engine.

WARNING! Warns for the risk of personal injury,

property damage or that a mechanical fault can

occur if the instructions are not followed.

IMPORTANT! Is used to call attention to things

which could cause damage or malfunctions to

product or property.

NOTE! Is used to call attention to important information, to facilitate work processes or operation.

Below is a summary of the risks involved and safety

precautions you should always observe or carry out

when performing work on the EMS 2 system.

Before electric welding is done, the connector

on the EMS system must be disconnected.

Disconnect the engine from system voltage by

turning off the main switch.

Disconnect the cable connectors from the control unit.

Reconnect the EMS 2 control module terminal

when the electric welding is finished and the electric welding equipment has been disconnected.

Never do any work on an engine which just

hangs from a lifting device (crane etc.).

The engine must not be run in areas where explosive material or any gases are stored.

Only start the engine in a well-ventilated area. If

the engine is run in a confined space, make

sure that the crankcase ventilation and exhaust

gases can be led away from the workplace.

The battery lockers must never be exposed to

open flames or sparks. Never smoke close to

the batteries. The batteries generate hydrogen

gas when charged, which can form an explosive

gas when mixed with air. This gas mixture is

very flammable and highly explosive. A spark,

which can be caused by incorrect battery connection, can cause a single spark which is sufficient to cause an explosion with resulting damage. Do not shift the connections when attempting to start the engine (spark risk) and do not

lean over any of the batteries. Please refer to

the advice in the instruction book.

Always ensure that the + (positive pole) and –

(negative pole) are securely connected to their

appropriate terminals on the battery. If the batteries are wrongly connected, this can cause

severe damage to the electrical equipment.

Please refer to the wiring diagram.

Always use goggles when charging and handling batteries. Battery electrolyte contains sulfuric acid, which is highly corrosive. If battery

acid comes into contact with your skin, wash it

off at once with a lot of soap and water, and

then get medical help. If battery acid comes

into contact with your eyes, flush your eyes at

once (preferably with an eye shower) with a lot

of clean water, and then get medical help at

once.

Be careful, watch out for the moving components of the engine during function testing and

in operation. Approaching the engine during operation entails a risk of personal injury. Remember that loose clothes or long hair can catch on

rotating components and cause severe injury.

3

Group 30: Electrical system General information

General information

About this Workshop Manual

This workshop manual contains descriptions and repair instructions for the standard versions of the

TAD734GE, TAD650VE, TAD660VE, TAD750 and

TAD760VE engines.

The workshop manual can illustrate tasks done on

any of the engines noted above. This means that the

illustrations and photographs which clarify certain details might not correspond with other engines in some

cases. Repair methods are similar in all important respects, however. If this is not the case, this is noted.

Important differences are noted separately.

The engine designation and number are noted on the

number plate and engine decal. The engine designation and number must always be given in all correspondence about any product.

The workshop manual is produced primarily for the

use of Volvo Penta workshops and service technicians. For this reason the manual presupposes a certain basic knowledge and that the user can carry out

the mechanical/electrical work described to a general

standard of engineering competence.

Volvo Penta constantly improves its products, so we

reserve the right to make modifications without prior

notification. All information in this manual is based on

product data which was available up to the date on

which the manual was printed. Any material changes

introduced into the product or service methods after

this date are notified by means of Service Bulletins.

Spare parts

Spare parts for electrical and fuel systems are subject

to various national safety requirements. Volvo Penta

Original Spare Parts meet these specifications. Any

kind of damage whatsoever, occasioned by use of

non-original Volvo Penta spares for the product in

question, will not be compensated by the warranty offered by Volvo Penta.

Certified engines

When doing service and repair on emission certified engines, it is important to be aware of the following:

Certification means that an engine type has been

checked and approved by the relevant authority. The

engine manufacturer guarantees that all engines made

of the same type are equivalent to the certified engine.

This makes special demands on service and repair

work, as follows:

● Maintenance and service intervals recommended

by Volvo Penta must be complied with.

● Only Volvo Penta original spares may be used.

● Service to injection pumps, pump settings and in-

jectors must always be done by an authorized

Volvo Penta workshop.

● The engine must not be converted or modified,

except for the accessories and service kits which

Volvo Penta has approved for the engine.

● No installation changes to the exhaust pipe and

engine air inlet ducts may be done.

● No seals may be broken by unauthorized personnel.

The general advice in the instruction book about operation, care and maintenance applies.

IMPORTANT! Delayed or inferior care/maintenance, and the use of non-original spares parts

means that Volvo Penta can no longer be responsible for guaranteeing that the engine complies with the certified version.

Damage and/or costs which arise from this will

not be compensated by Volvo Penta.

4

Group 30: Electrical system Repair instructions

Repair instructions

The working methods described in the workshop manual apply to work carried out in a workshop. For this

reason, the engine is lifted out and mounted on an engine support. Unless otherwise stated reconditioning

work which can be carried out with the engine in place

follows the same working method.

The warning signs which occur in the workshop manual

(please refer to “Safety information” for their meanings).

WARNING!

IMPORTANT!

NOTE!

are not comprehensive in any way, since we can not of

course foresee everything, because service work is

done in highly varying circumstances. For this reason,

all we can do is to point out the risks which we believe

could occur due to incorrect work in a well-equipped

workshop, using work methods and tools tested by us.

All operations described in the Workshop Manual for

which there are Volvo Penta Special Tools available

assume that these tools are used when carrying out

the repair. Volvo Penta Special Tools have been developed to ensure the most safe and rational working

methods possible. It is therefore the responsibility of

anyone using other tools or other working methods

than we recommend to determine that there is no risk

of personal injury or mechanical damage or malfunction as a result.

In some cases special safety precautions and user instructions may be required in order to use the tools and

chemicals mentioned in the Workshop Manual. These

rules must always be observed, so there are no special

instructions about this in the workshop manual.

By following these basic recommendations and using

common sense it is possible to avoid most of the

risks involved in the work. A clean work place and a

clean engine will eliminate many risks of personal

injury and engine malfunction.

Above all, when work on fuel systems, lubrication

systems, inlet systems, turbocharger, bearing caps

and seals is done, it is extremely important that no

dirt or other kinds of foreign particles are able to get

in, since this would otherwise cause malfunctions or

shortened repair life.

5

Repair instructions Group 30: Electrical system

Our common responsibility

Each engine consists of a large number of collaborating systems and components. Any deviation of a component from its technical specification can dramatically increase the environmental impact of an otherwise

good engine. For this reason, it is important that the

specified wear tolerances are observed, that systems

which are adjustable are correctly adjusted and that

Volvo Penta Original Spares are used for the engine.

The stated service intervals in the Maintenance

Schedule (see the Owner’s Manual) must be observed.

Some systems, such as the components in the fuel

system, require special expertise and special testing

equipment for service and maintenance. For environmental reasons etc., some components are sealed at

the factory. It is only permissible to work on sealed

components if you are authorized to do such work.

Remember that most chemical products, incorrectly

used, damage the environment. Volvo Penta recommends the use of biodegradable degreasers whenever

engine components are de-greased, unless otherwise

specified in the workshop manual. When working

aboard a boat, be careful to ensure that oils, wash

residue etc. are processed for destruction, and are not

inadvertently discharged with bilge water into the environment.

Tightening torques

The tightening torque for vital fasteners, which should

be tightened with a torque wrench, are listed in “Technical Data: Special tightening torques” and noted in the

job descriptions in the book. All torque specifications

apply to clean screws, screw heads and mating faces.

Torque data stated apply to lightly oiled or dry threads.

If lubricants, locking fluids or sealants are needed on a

fastener, the type of preparation to be used will be noted in the job description and in “Tightening Torques”.

For fasteners where specific torque values are not given, please refer to “Technical data: General tightening

torques”. General torque specifications are target values and the fastener does not need to be tightened with

a torque wrench.

Dimension Torque

Nm

M5 ................................................. 6

M6 ................................................. 10

M8 ................................................. 25

M10 ............................................... 50

M12 ............................................... 80

M14 ............................................... 140

M16 ............................................... 220

6

Special tools Group 30: Electrical system

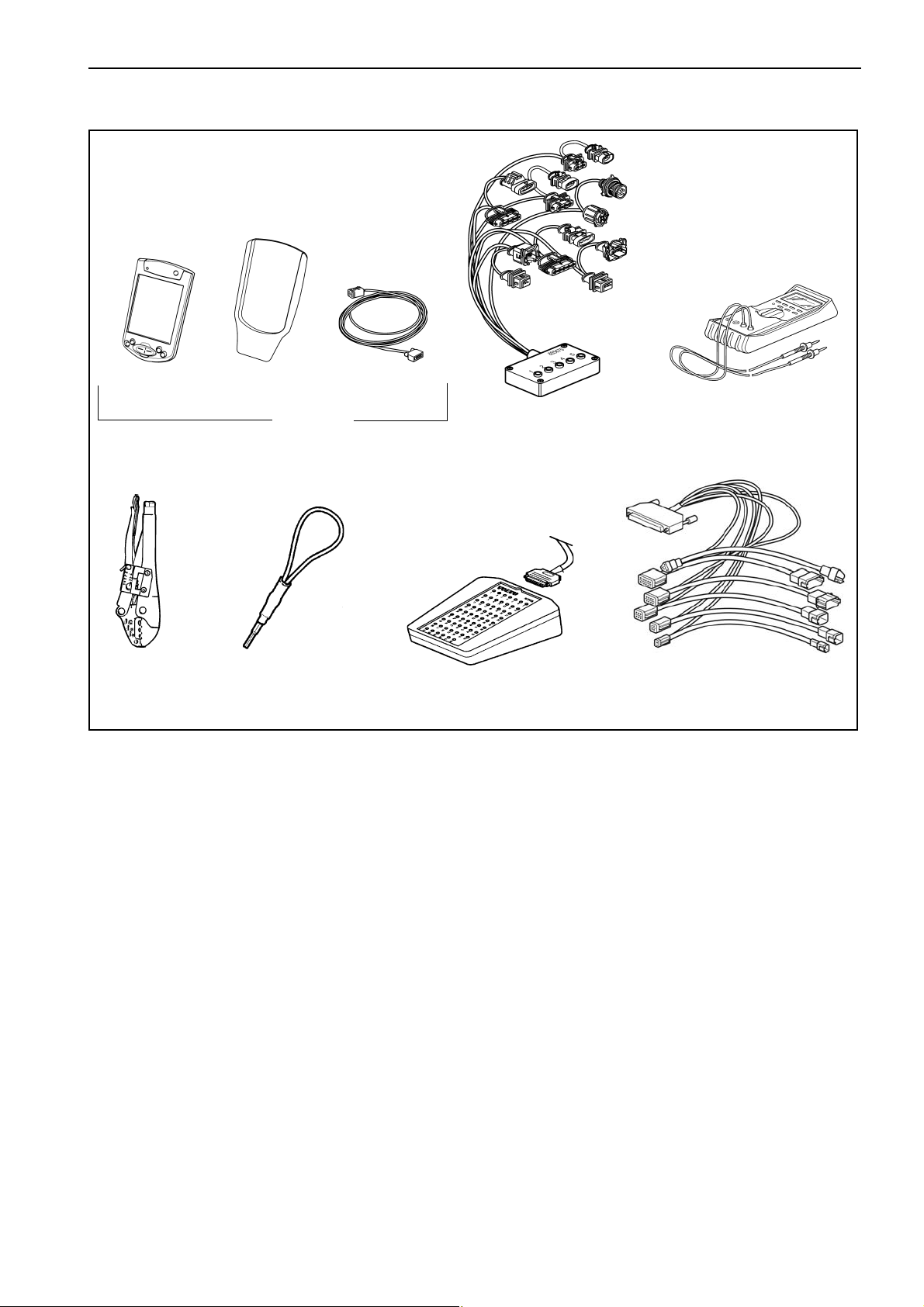

Special tools

3838620 3838621 3838622

383 8619

9999324

9998482

383 8619 VODIA complete diagnostic tool.*

Components:

3838620 VODIA – palmtop computer (PDA) with SD card.

3838621 VODIA – docking station. Used with VODIA PDA

(3838620).

3838622 VODIA – cable with connector. Used with dock-

ing station (3838621) on the engine’s communication connector.

*Note. More detailed information about using the VODIA tool can

be found in the tool’s instruction manual.

885675

9812519

888900169998699

885675 Adapter cable for sensor test

9812519 Multimeter

999 9324 Terminal crimping tool

9998482 Gauge for connector on control unit

9998699 Measurebox

88890016 Adapter cable

7

EMS 2 - “Engine Management System” Group 30: Electrical system

EMS 2 - “Engine Management System”

General information

EMS 2 is an electronic system with CAN communication (Controller Area Network) for diesel engine control. The

system has been developed by Volvo and includes fuel control and diagnostic function.

The system consists of a control module, six injectors, a number of sensors that supply the control module with

measurements, sockets for diagnosis and functional checks. The engine can be connected to a communications

interface consisting of a CAN link and a serial link.

CAN - Controller Area Network

The J1939 CAN link is responsible after all communication between the engine control unit (EMS 2) and a

communication interface (such as CIU/DCU), except

for diagnostics. Diagnostics are managed by the socalled J1708/J1587 link. The CAN link is much faster

than the J1708/J1587 link and has been designed to

connect to other components that support the SAE

J1939 protocol, such as instrument panels and transmissions.

If a fault develops on the CAN link, signals for the engine speed potentiometer, and the start and stop

knobs are taken over by the J1708/J1587 link. However, instrument and indicator lamps are completely

turned off.

If faults occur in both links, the engine starts to idle.

The only way to shut off the engine in this case is to

use the auxiliary stop (AUX-STOP).

8

Group 30: Electrical system EMS 2 - “Engine Management System”

CIU - Control Interface Unit

The CIU is a “translator” between the CAN bus and

the customer’s own control panel. This unit has two

serial communication links, one fast and one slow.

The fast one is a CAN link that features a bus speed

of 250 Kbit/s. All data regarding instruments, indicator

lamps, contacts and potentiometers are controlled by

this bus.

The slower J1708/J1587 link handles diagnostic information for, among other things, the flashing code. The

VODIA diagnosis tool also uses the J1708/J1587 link

to communicate with the system.

DCU - Display Control Unit

DCU is a digital instrument panel that communicates

with the engine control module via the CAN link. DCU

has several functions, such as:

Engine control

– Start, stop, speed control, preheating etc.

Monitoring

– Engine speed, boost pressure, boost temperature,

coolant temperature, oil pressure, oil temperature,

engine hours, battery voltage, instantaneous fuel

consumption and fuel consumption (trip fuel).

Diagnostics

– Shows fault codes in text. Lists previous faults.

Parameter setting

– Idling speed, alarm limit for oil temperature/cool-

ant temperature, droop.

– Preheating for ignition.

Information

– Information about hardware, software and engine

identification.

9

EMS 2 - “Engine Management System” Group 30: Electrical system

Fuel control

The amount of fuel injected into the engine and the injection advance are fully electronically controlled, via

fuel valves in the injectors, once the control unit has

analyzed the engine’s fuel requirements.

This means that the engine always receives the correct volume of fuel in all operating conditions, which

offers lower fuel consumption, minimal exhaust emissions etc.

The control unit monitors and reads the injectors to

ensure that the correct volume of fuel is injected into

each cylinder, and it calculates and set the injection

advance. Control is mainly done with the help of the

speed sensors, fuel pressure sensor and the combined sensor for boost pressure/boost temperature.

The control unit controls the injectors via a signal to

the electromagnetically operated fuel valve in each injector, which can be opened and closed.

Calculation of fuel quantity

The quantity of fuel to be injected into the cylinder is

calculated by the control unit. The calculation determines the time that the fuel valve is open (when the

fuel valve is open fuel is sprayed into the cylinder).

The parameters which govern the amount of fuel injected are:

• Demanded engine speed

• Engine protector functions

• Temperature

• Boost pressure

Altitude correction

The control unit contains an atmospheric pressure

sensor and an altitude compensation function for engines that operate at high altitude. This function limits

the fuel volume in relation to ambient air pressure.

This is to prevent smoke, high exhaust temperature

and to protect the turbocharger from overspeeding.

Diagnostic function

The task of the diagnostic function is to discover and

localize any malfunctions in the EMS 2 system, to

protect the engine and to inform about any problems

that occur.

If a malfunction is discovered, this is announced by

warning lamps, a flashing diagnostic lamp or in plain language on the instrument panel, depending on the equipment used. If a fault code is obtained as a flashing code

or in plain language, this is used for guidance in any fault

tracing. Fault codes can also be read by Volvo’s VODIA

tool at authorized Volvo Penta workshops.

In case of serious disturbances, the engine is shut

down completely or the control module decreases the

power output (depending on the application). Once

again, a fault code is set for guidance in any fault

tracing.

10

Group 30: Electrical system Component location

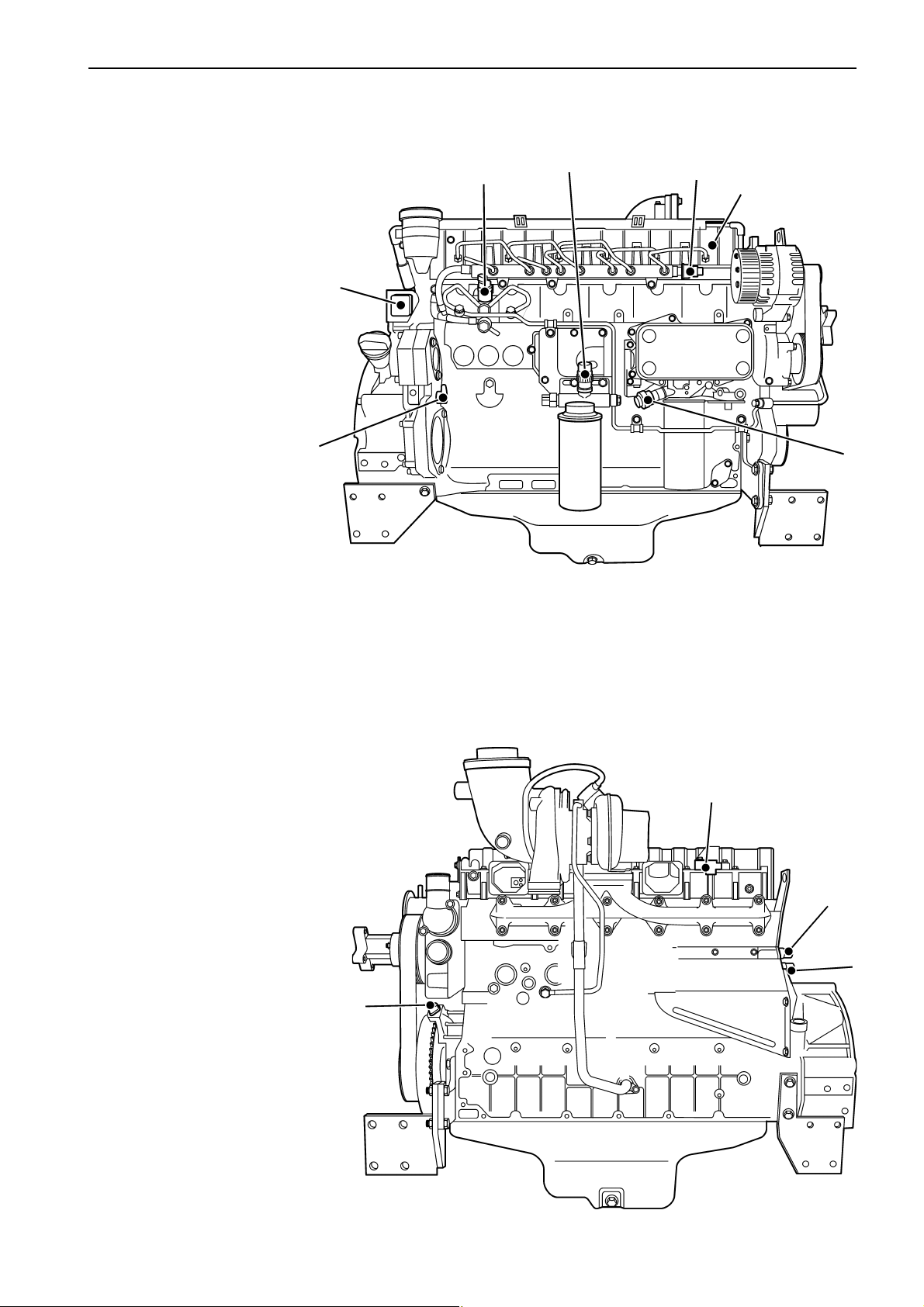

Component location TAD 650, 660, 750, 760 VE

NOTE! Location can differ, depending on engine model.

2

1

1. Speed sensor, camshaft

2. Connection, EMS 2

3. Solenoid controlled proportional valve, high pressure pump – fuel (MPROP)

4. Fuel pressure

5. Fuel pressure in comman rail

6. Glow plugs, one for each injector

7. Oil pressure sensor

8. Boost pressure and temperature

9. Solenoid valve, EGR

10. Coolant temperature

11. Speed sensor, crankshaft

12. Water in fuel (not shown, mounted on primary

fuel filter).

3

4

5

6

7

8

11

9

10

11

Component description Group 30: Electrical system

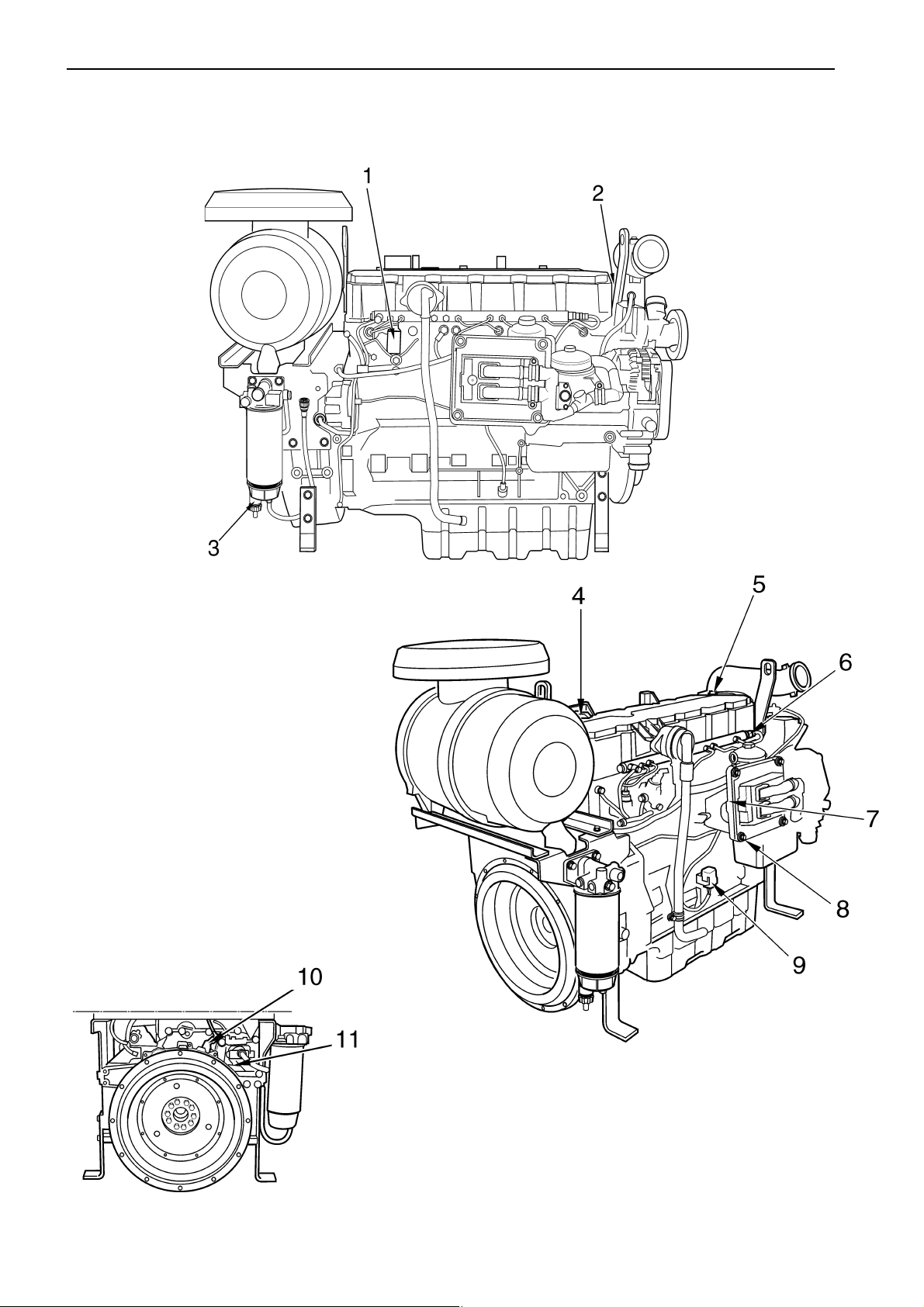

Component location TAD 734 GE

1. Solenoid controlled proportional valve,

high pressure pump – fuel (MPROP)

2. Coolant temperature sensor

3. Water in fuel switch(mounted on primary

fuel filter).

4. Boost pressure and temperature sensor

5. Preheater, intake manifold

6. Fuel pressure in comman rail

7. Fuel pressure sensor

8. Oil pressure sensor

9. Main relay

10. Speed sensor, crankshaft

11. Speed sensor, camshaft

12

Group 30: Electrical system Component description

Component description

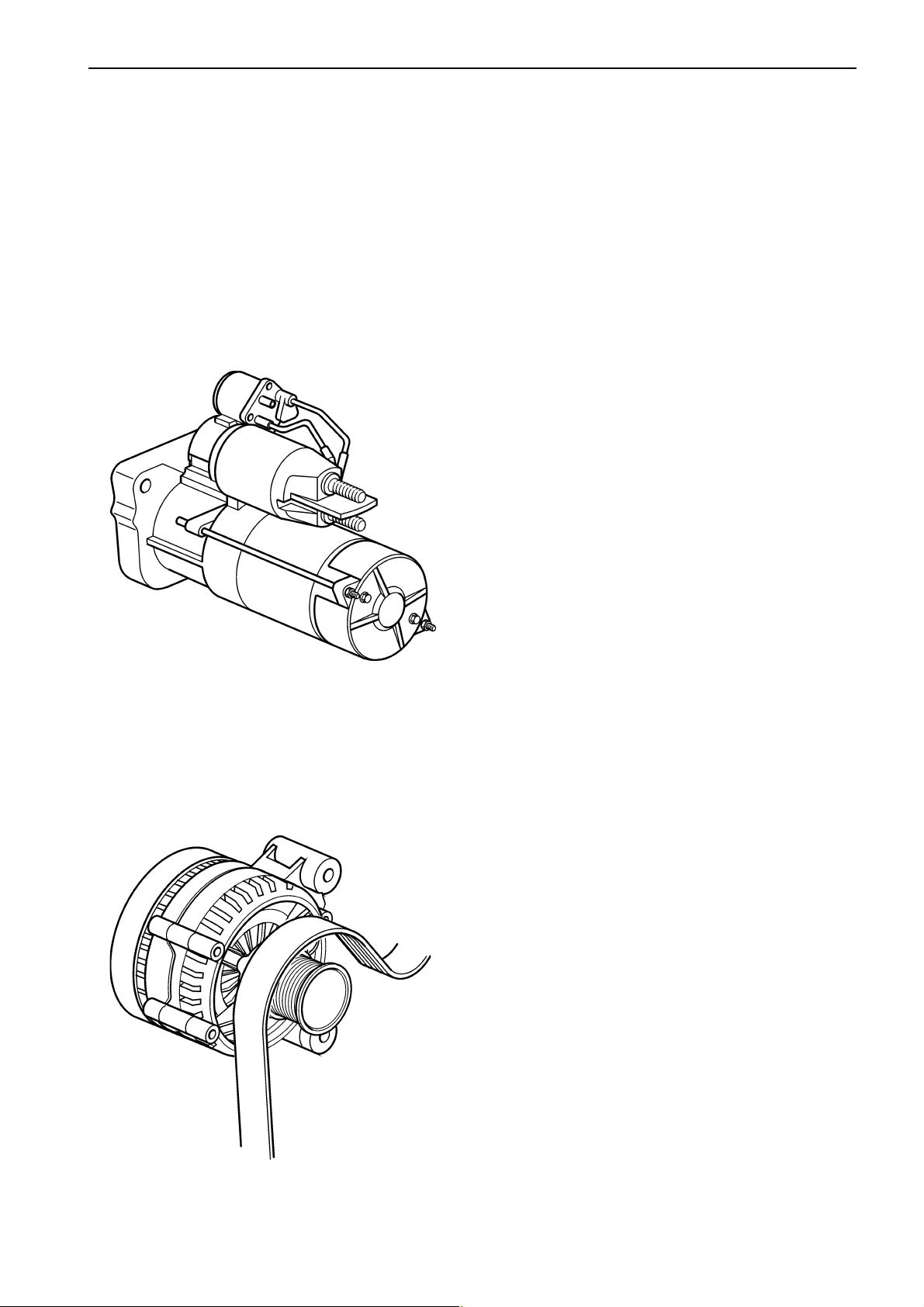

Starter motor

The starter motor is installed in the flywheel housing,

on the left-hand side of the engine. The starter motor

relay is “positive connected”, which means that the relay is connected to battery voltage.

Alternator

The alternator is belt driven and mounted on the front

of the engine, on the right.

13

Component description Group 30: Electrical system

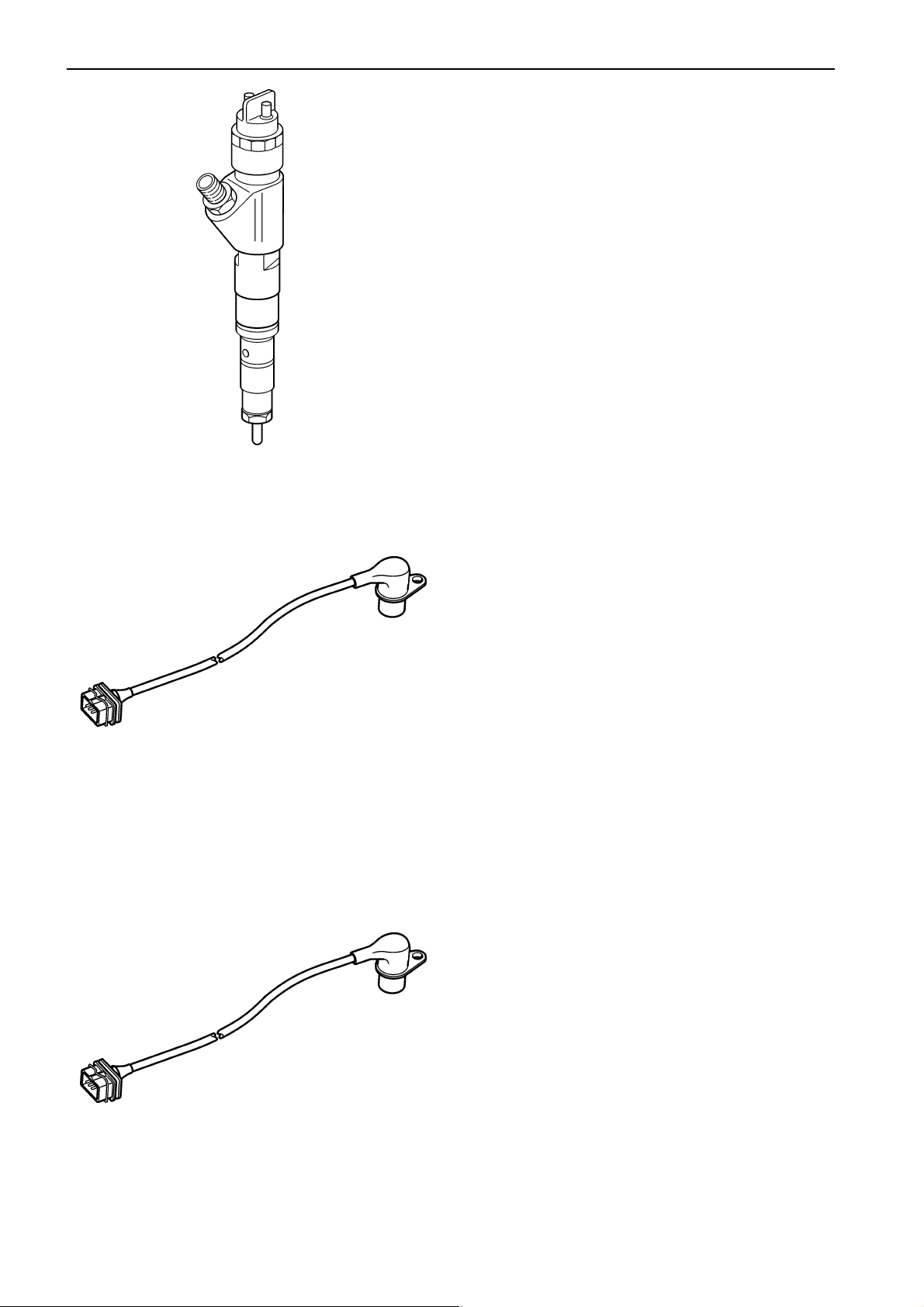

Injectors

The injectors are installed on the cylinder head.

The amount of fuel injected and injection duration is

controlled by the engine control unit, via electromagnetically controlled fuel valves in the injectors. This

means that the engine always receives the correct

volume of fuel in all operating conditions, which offers

lower fuel consumption, minimal exhaust emissions

etc.

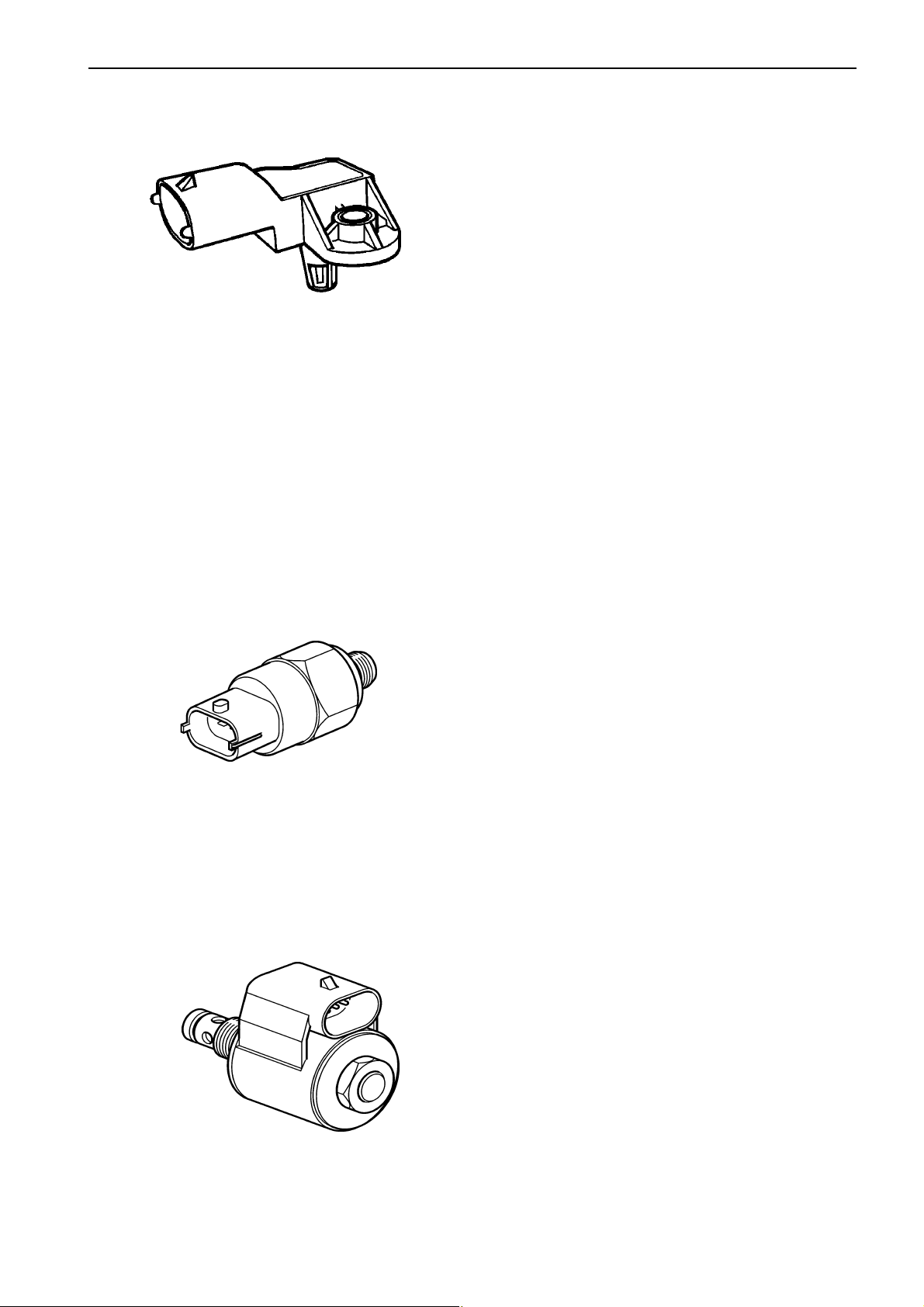

Speed sensor, crankshaft

The engine speed sensor is an inductive sensor.

When the crankshaft rotates impulses are created in

the sensor via a tooth wheel on or behind the torsion

damper. The impulses create a pulse signal in the

sensor that the engine control unit (EMS 2) uses to

calculate the crankshaft’s rpm.

The tooth wheel has a tooth free gap for the EMS 2 to

recognize the crankshafts position.

The signal is sent to the engine control unit, which

calculates the injection in advance and the amount of

fuel to be injected.

Speed sensor, camshaft (camshaft position)

The camshaft sensor is an inductive sensor. When

the camshaft rotates impulses are created in the sensor via a tooth wheel installed on the camshaft. The

tooth has seven teeth, one for each cylinder and one

to determine when cylinder one is to be injected. The

impulses create a pulse signal in the sensor that the

engine control unit (EMS 2) uses to calculate when a

cylinder is in turn for injection.

14

Group 30: Electrical system Component description

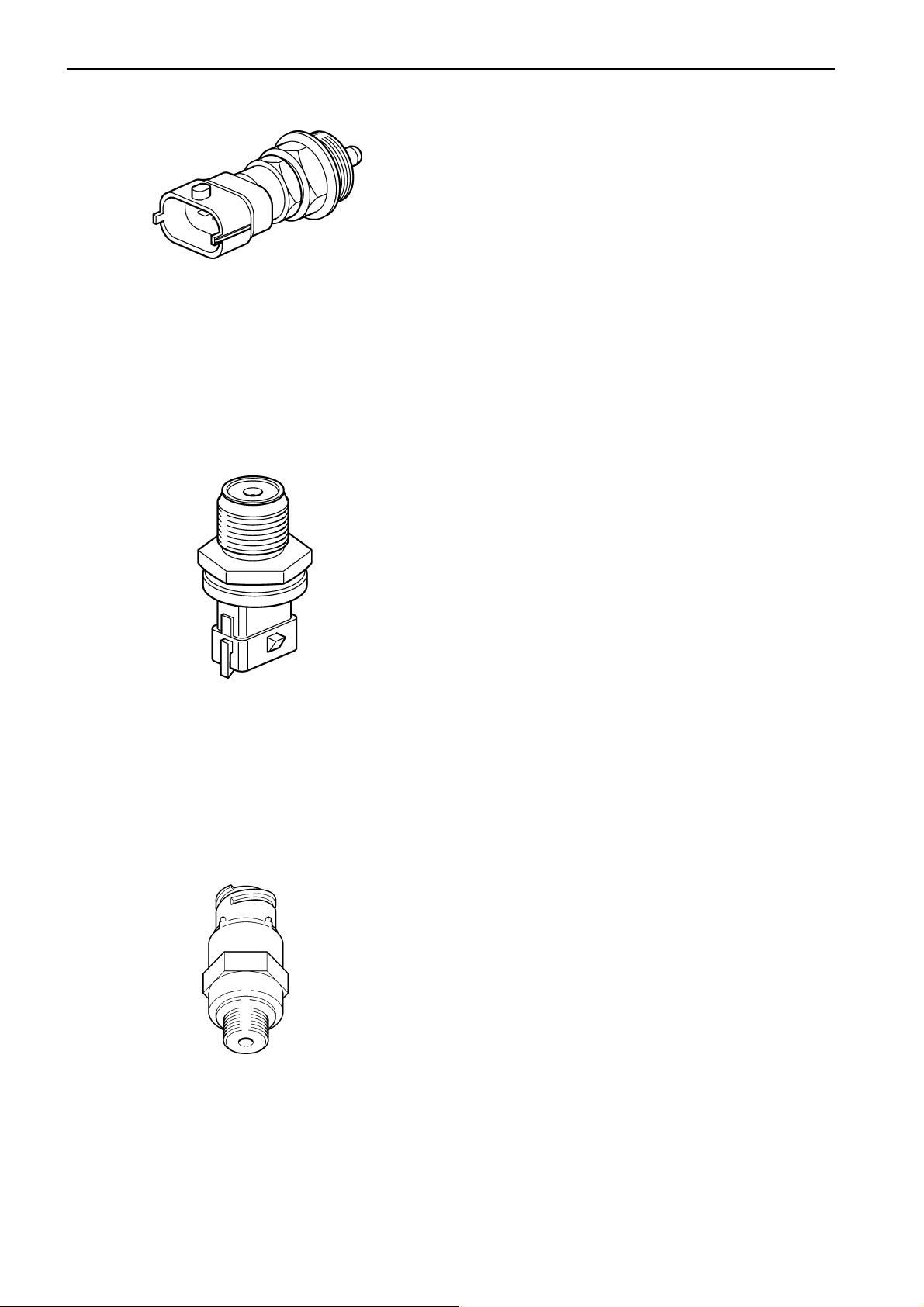

Sensor, boost pressure/ boost

temperature

The boost pressure and the boost temperature are

measured by a combined sensor located on the inlet

manifold on the left of the engine.

The sensor is supplied by a 5 Volt reference voltage

from the engine control module.

The boost pressure sensor measures the absolute

pressure, which is the sum of the boost pressure and

atmospheric pressure (300 kPa thus corresponds to a

boost pressure of 200 kPa when atmospheric pressure is 100 kPa).

The pressure signal is a voltage signal which is proportional to absolute pressure.

The boost temperature sensor consists of a non-linear resistor, whose resistance varies with boost temperature. The resistance falls as the temperature rises.

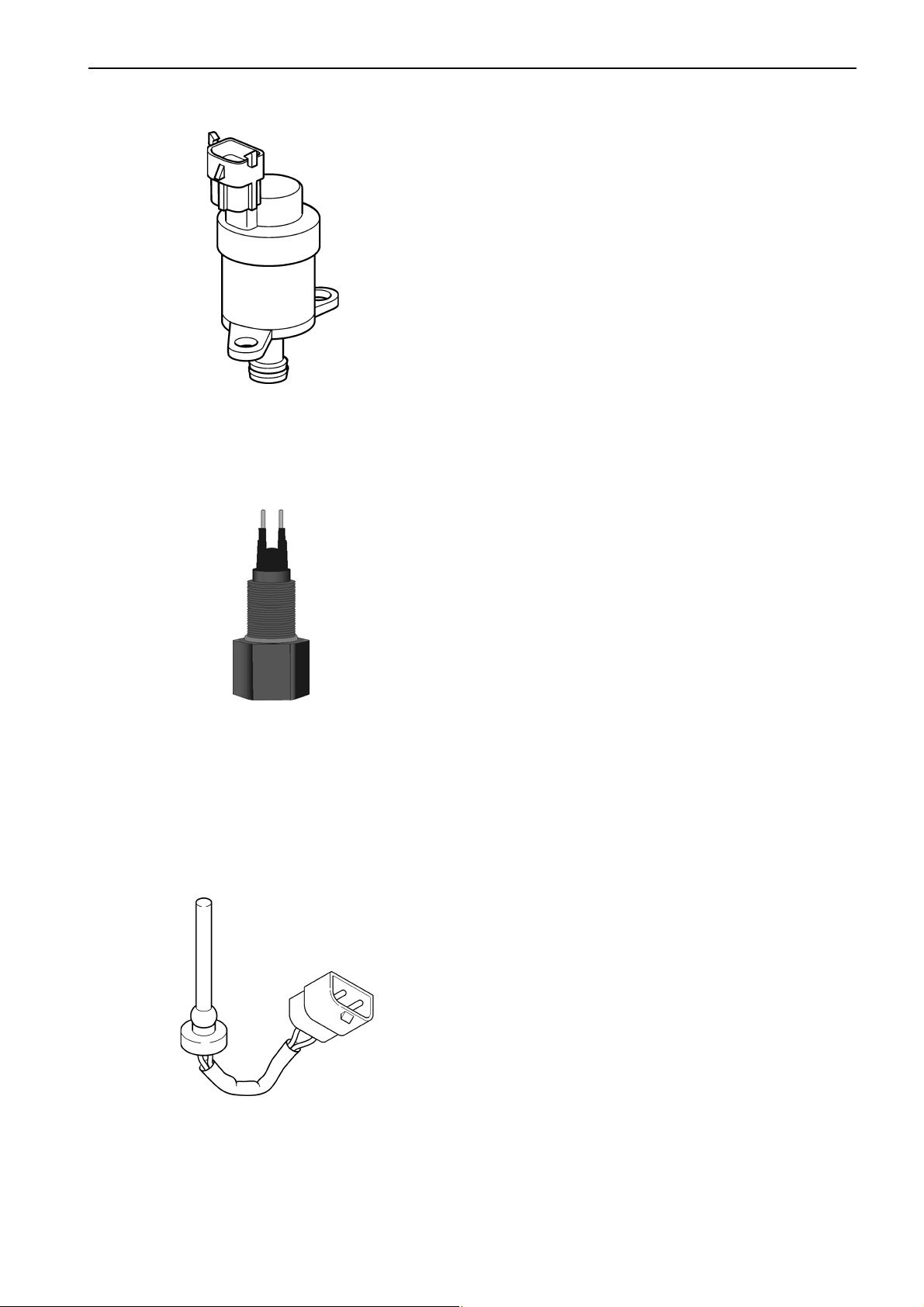

Sensor, oil pressure, engine

Oil pressure is measured by a sensor installed in the

engine block on the right side of the engine.

The sensor measures pressure in the main oil gallery,

and is supplied by a 5 Volt reference voltage from the

engine control module.

The pressure signal is a voltage signal which is proportional to the lubrication oil pressure.

IEGR (only VE engines)

The IEGR valve is a 2-way solenoid valve controlled by

the engine control unit. The IEGR solenoid controls a

oil pressure that effects a control valve which activate

the exhaust gas recirculation function.

15

Component description Group 30: Electrical system

Coolant temperature sensor

The sensor is located on the cylinder head, at the rear

end of the engine.

The sensor senses the engine coolant temperature

and sends the information to the engine control unit.

The sensor consists of a non-linear resistor, whose resistance varies with coolant temperature. The resistance falls as the coolant temperature rises.

Sensor, common rail pressure

(fuel)

The sensor is mounted on the right of the engine, at

the front of the common rail, which distributes fuel to

the injectors.

The rail pressure sensor senses the fuel pressure and

converts this to a voltage which is registered by the

engine control unit.

16

Sensor, fuel pressure

The sensor measures fuel pressure and is located on

the fuel filter bracket. The sensor is an active sensor,

i.e. the sensor requires a supply voltage of +5 Volt.

The sensor provides an output signal whose voltage is

proportional to the pressure that the sensor measures.

Group 30: Electrical system Component description

Magnetically controlled proportional valve (MPROP)

A magnetically controlled proportional valve (MPROP)

controls the high pressure pump to ensure that the

correct fuel pressure (rail pressure) is retained despite

varying engine speed and loading.

The input signal to the valve is a PWM signal whose

pulse width is controlled by the engine control module.

When the current through the valve is changed, this affects the fuel flow, which results in changed rail pressure.

Water in fuel switch, secondary

fuel filter

A switch is located in the water trap under the fuel filter. Its task is to detect whether there is water in the

fuel.

The switch senses the resistance between two pins,

wich are in contact with the fuel. When there is no water in the fuel, the resistance is very high. If there is

any water in the fuel, the resistance falls.

Switch, coolant level

The task of the switch is to discover whether the coolant level in the engine (expansion tank) has become

too low. An alarm signal is sent when the coolant level

is too low.

17

Component description Group 30: Electrical system

Preheater with preheater relay

The preheater is located in the inlet manifold at the left

side of the engine. The preheat relay is located at the

engines left side beneath the preheater.

Engine control unit, EMS 2

The engine control unit checks and controls the injectors, to ensure that the correct volume of fuel is injected into each cylinder at the right time. It also controls

the high pressure pump via the proportional valve

(MPROP) to ensure that the system always has the

correct fuel pressure (rail pressure).

The control unit also calculates and adjusts the injection advance. Regulation is mainly done with the aid of

the engine speed sensor and the combined sensor for

boost pressure/boost temperature.

The EMS 2 system processor is located in the control

unit, protected from water and vibration.

The processor receives continuous information about:

Engine speed

•

Throttle

•

Oil pressure

•

Boost pressure /temperature

•

Fuel pressure (common rail pressure)

•

Fuel alarm, “water in fuel”

•

Camshaft position

•

Coolant temperature

•

18

The information provides information about current operation conditions and allows the processor to calculate

the correct fuel volume, monitor engine status etc.

Group 30: Electrical system Repair instructions

Repair instructions

General advice on working

with EMS engines

The following advice must be followed to avoid

damage to the engine control unit and other electronics.

IMPORTANT! The system must be disconnect-

ed from system voltage (by cutting the current

with the main switch) and the starter key(s) must

be in the 0 position when the engine control

module connectors are disconnected or connected.

● Never disconnect the current with the main

switches when an engine is running.

● Never undo a battery cable when the engine is

running.

● Turn the main switches off or disconnect the bat-

tery cables during quick charging of the batteries.

● NOTE! During normal trickle charging, it is not

necessary to turn the main switches off.

● Only batteries may be used for start help. A help

start device can produce a very high voltage and

damage the control unit and other electronics.

● If a connector is disconnected from a sensor, be

very careful to avoid allowing the contact pins to

come into contact with oil, water or dirt.

19

Repair instructions Group 30: Electrical system

Electric welding

1. NOTE! Cut the current with the main switch.

IMPORTANT! The system must be disconnect-

ed from system voltage when the engine control

module connectors are disconnected or connected.

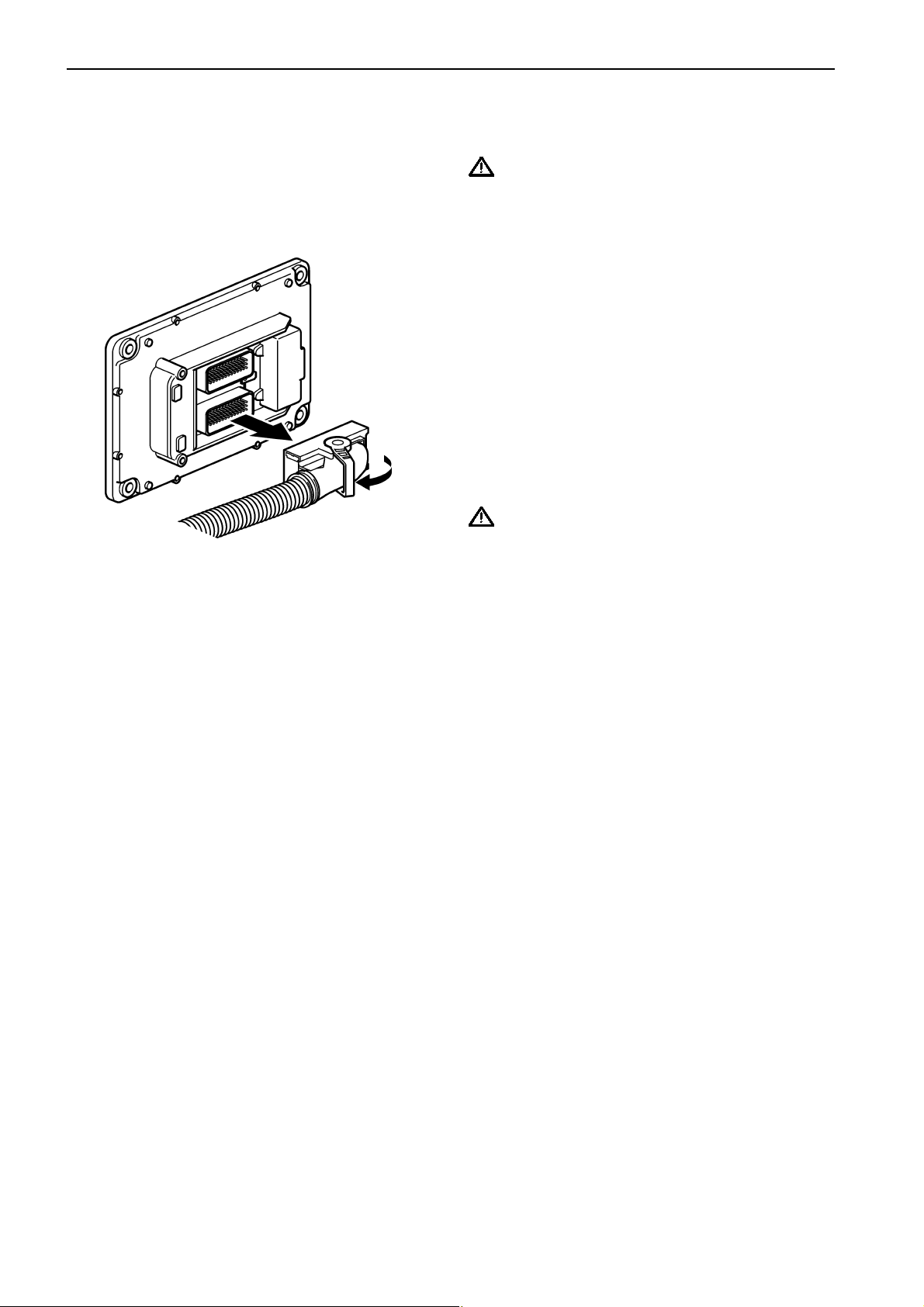

2. Undo the two connectors from the engine control

unit before any electric welding starts. Turn the

locking arm down at the same time as the connector is pulled outwards.

3. Disconnect all connections to the alternator.

Connect the welder earth clamp to the component

to be welded, or as close as possible to the weld

site. The clamp must never be connected to the

engine or in such a way that current can pass

through a bearing.

IMPORTANT! After welding is completed, the

disconnected components, such as alternator

cables and battery cables must be connected in

the correct order.

The battery cables must always be connected

last.

20

Group 30: Electrical system Repair instructions

Changing the engine control

unit

1. NOTE! Cut the current with the main switch.

IMPORTANT! The system must be disconnect-

ed from system voltage when the engine control

module connectors are disconnected or connected*.

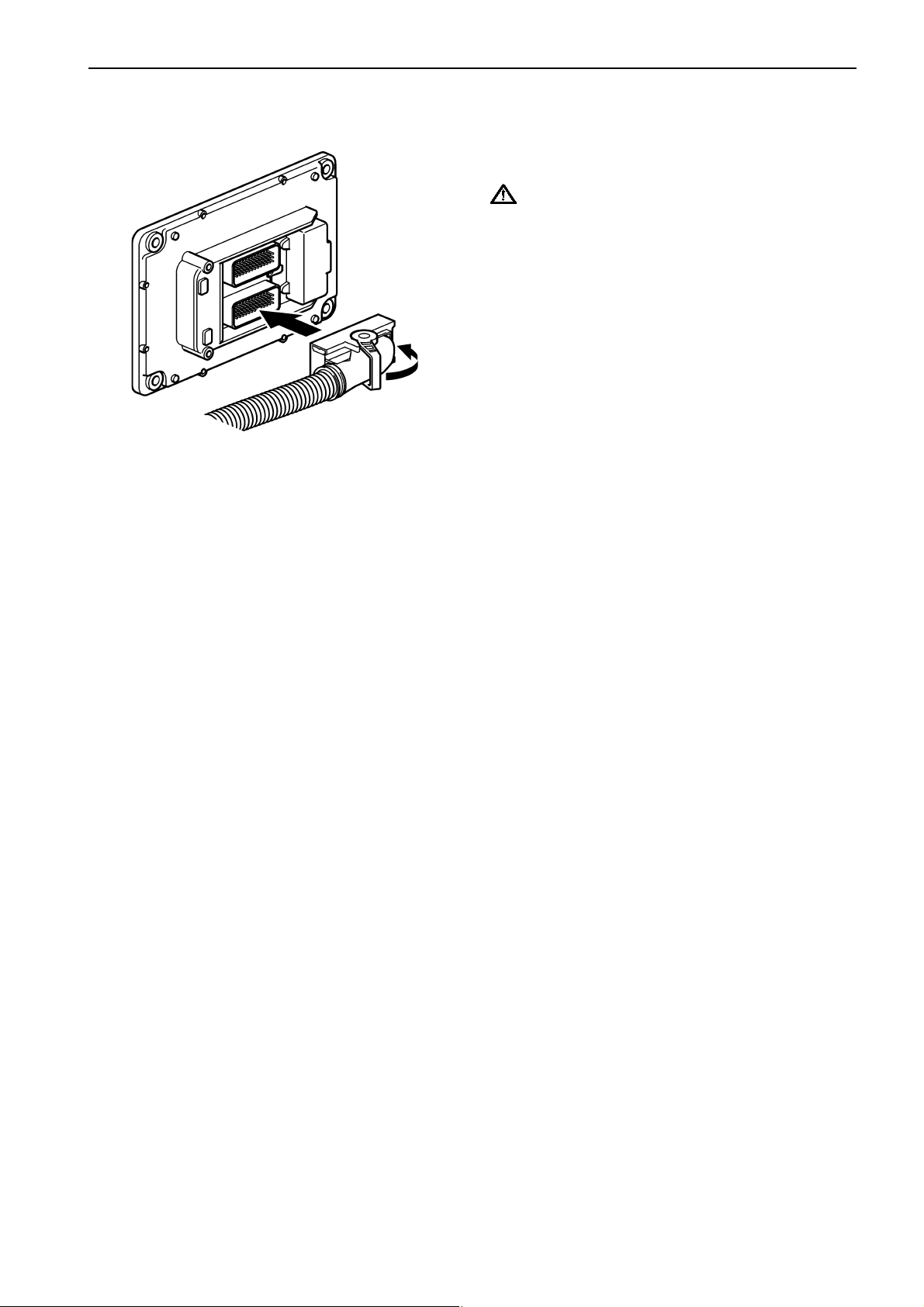

2. Remove the two connectors from the engine control unit. Turn the locking arm down at the same

time as the connector is pulled outwards

3. If the new engine control unit has recently been

programmed:

Start the engine and check whether any fault

codes related to the engine control unit occur.

21

Repair instructions Group 30: Electrical system

Reprogramming a control unit

IMPORTANT! The CHASSIS ID number must

be readily available to allow the software to be

downloaded.

Action:

1. Log in to Volvo Penta Partner Network’s website:

www.vppn.com

2. Choose “VODIA” in the left-hand menu.

3. Choose “ECU programming” in the left-hand

menu.

4. Follow the instructions under “Download software”. Choose the control units to be reprogrammed and click the “Download” button. The

software for the control units is now downloaded

to the PDA*.

* Note. PDA = “Personal Digital Assistant” (palmtop computer).

5. Take a look under “Settings”, “Software information” in VODIA to check that the software has

been downloaded.

8. The next control unit is the vehicle ECU.

Select “Electrical system and instruments” in the

VODIA menu.

Select “MID 144 ECU, programming”.

VODIA will guide you through the entire programming process.

9. NOTE! Programming must be reported back to

Volvo Penta within 28 days. Log in to Volvo Pen-

ta Partner Network’s web site:

www.vppn.com

10. Choose “VODIA” in the left-hand menu.

11. Choose “Report software” in the left-hand menu.

12. Follow the instructions for “Report software/parameter”. Click “Report software/parameter”.

6. Connect the VODIA to the engine (control unit) to

be programmed.

7. Start with the engine control unit.

Select “Engine with mounting and equipment” in

the VODIA menu.

Select “MID 128 Control unit, programming”.

VODIA will guide you through the entire programming process.

22

Group 30: Electrical system Repair instructions

Programming an empty

control unit

When a new engine control unit is installed, where no

software has been downloaded, the control unit must

be programmed.

The new control unit must have the same part number

as the old control unit. If the control units do not have

the same part number, it will not be possible to program the new control unit until a “Conversion kit” has

been ordered from Volvo Penta.

If the control units have the same part number, the

new control unit can be programmed as usual. Please

refer to “Programming a control unit”.

If the part numbers do not coincide – proceed as possible:

1. Have both part numbers available.

2. Log in to Volvo Penta Network’s web site:

www.vppn.com

3. Choose “VODIA” in the left-hand menu.

4. Choose “Conversion kit” in the left-hand menu. A

new page, “Conversion kit / Accessory kit”, opens

up.

5. Click the text “Available conversions kits” which

is shown in bold face.

6. A new window opens. Follow the instructions given in the window.

7. Return to the “Conversion kit / Accessory kit”

page and follow the instructions to order a new

“conversion kit”.

8. Volvo Penta’s database is now updated. It can

take about a minute before a confirmation is sent.

9. Programing of the control unit can now start.

Please refer to “Programming a control unit”.

23

Repair instructions Group 30: Electrical system

Fault tracing of cables and

connectors

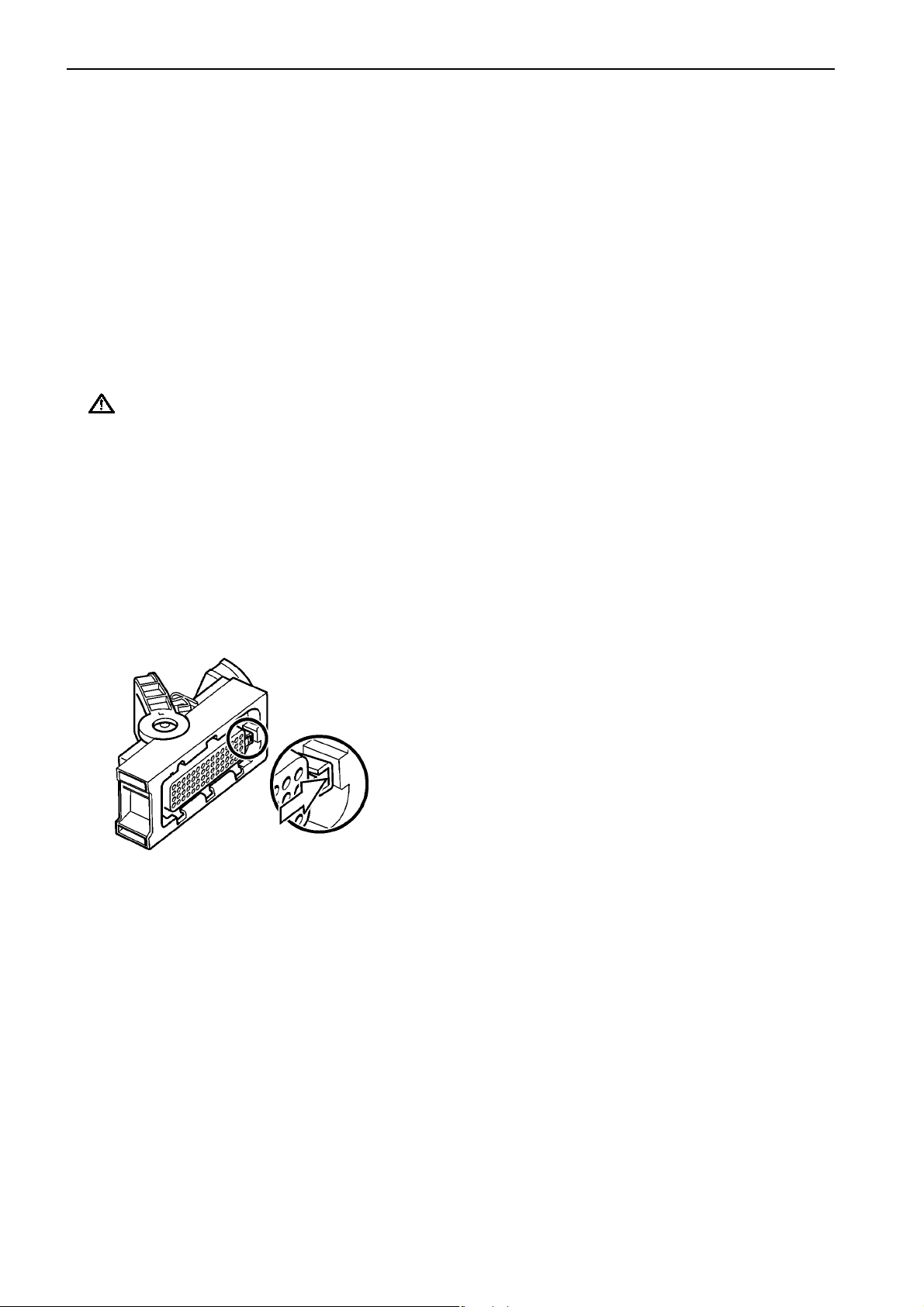

Special tools: 9812519, 9998482

Check all connectors visually

Check the following:

l Look for oxidation which can impair contact in con-

nectors.

l Check that terminals are undamaged, that they are

correctly inserted into their connectors, and that

the cable is correctly terminated in the terminal.

● Check that there is good mechanical contact in the

connector. Use a loose pin to check this.

IMPORTANT! The multi-pin connectors for

the engine control unit must only be checked

with gauge 9998482.

● Carefully insert gauge 999 8482 into the multi-pin

connector. Pull and push the connector in and out

a few times and feel whether the terminal socket

grasps the tool. If the terminal socket does not

grasp, or if it feels slack, the connection pins

should be changed. Please refer to ”Joining electrical cables for multi-connector” Check the secondary locking in the connector.

Contact problems

Intermittent contact or temporary recurring faults can

be difficult to fault trace, and are frequently caused by

oxidation, vibration or poorly terminated cables.

Wear can also cause faults. For this reason, avoid disconnecting a connector unless it is necessary.

Other contact problems can be caused by damage to

pins, sockets and connectors etc.

Shake cables and pull connectors during measurement, to find where the cable is damaged.

Contact resistance and oxidation

Resistance in connectors, cables and junctions

should be close to 0 Ω. A certain amount of resistance

will occur, however, because of oxidation in connectors.

If this resistance is too great, malfunctions occur. The

amount of resistance that can be tolerated before malfunctions occur varies, depending on the load in the

circuit.

Open circuit

● If possible, shake the cables and pull the connec-

tors during measurement to discover whether the

cable harness is damaged.

● Check that the cables are not damaged. Avoid

clamping cables in tight bends close to the connector.

● Check the function of the secondary locking.

Possible reasons for faults could be chafed or broken

cables, or connectors which have come undone.

Use the wiring schedule to check the cable harnesses

which are relevant to the function. Start off with the

most probable cable harness in the circuit.

Check the following:

● Disconnect the relevant connector at each end of

the cable harness.

● Use multimeter 9812519 to measure the resis-

tance between the ends of the cable.

Nominal value close to 0 Ω.

● If possible, shake the cables and pull the connec-

tors during measurement to discover whether the

cable harness is damaged.

● Check the next cable harness in the wiring sched-

ule if no fault has been found.

24

Group 30: Electrical system Repair instructions

Joining electrical cables for

connectors

Special tools: 9808648, 999 9324

Repair kit: 1078054

1

Disconnect the connector from the engine control unit

or from the power supply unit, please refer to ”Control

unit, changing”.

Undo the connector, to gain access to the cable leading to the pin which is to be changed.

2

Undo the pin catch.

3

Remove the pin with tool no. 9808648.

NOTE! Only remove one pin at a time.

4

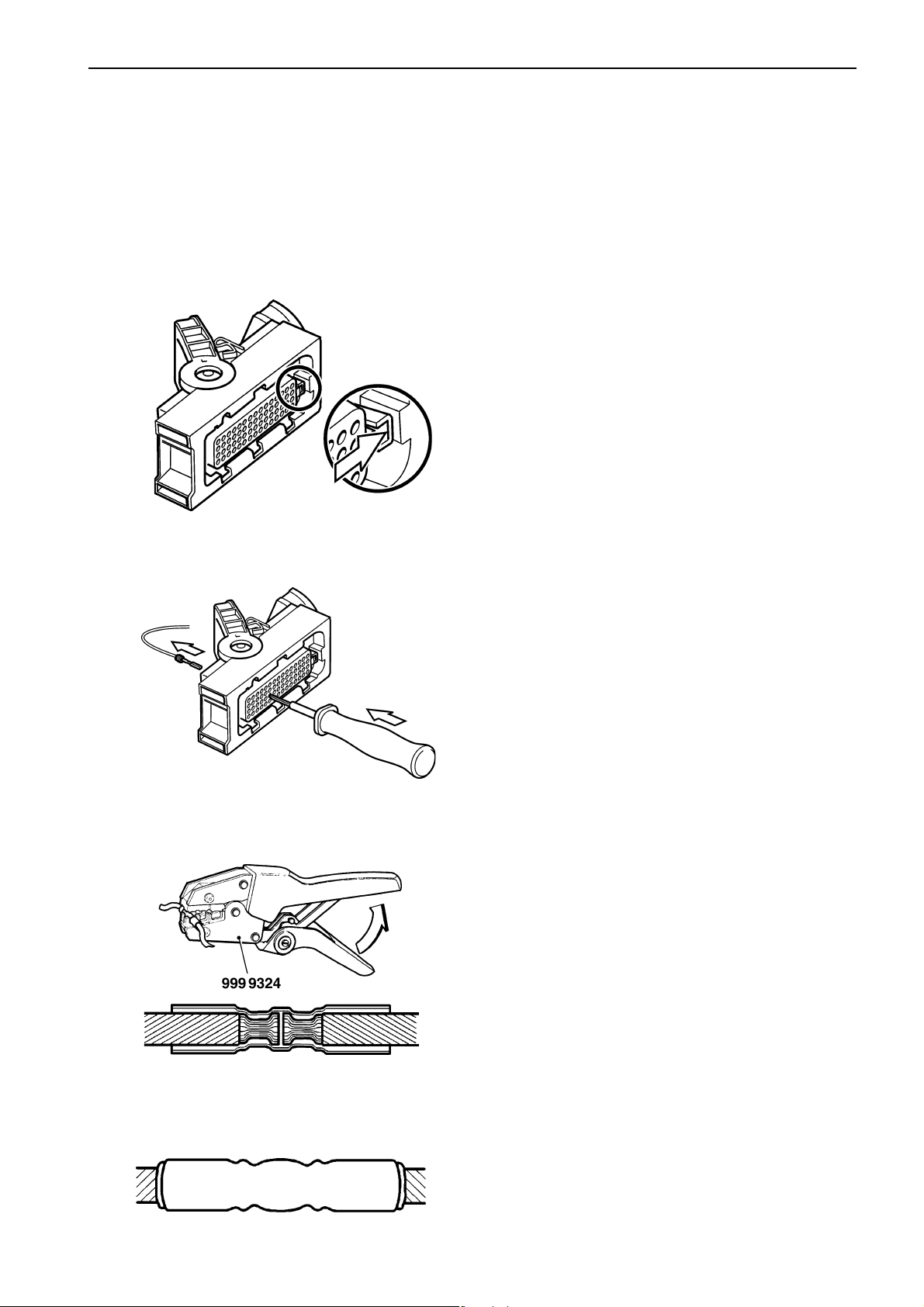

Cut off the cable and the pin which is to be changed.

Join the cable with the new one, using repair kit

10.78054. Use cable crimping tool no. 999 9324.

5

Carefully heat the joint with a hot air gun, to make the

insulation shrink and seal tightly.

25

Repair instructions Group 30: Electrical system

6

Put the pin back in the right place in the connector before removing the next pin, if several pins are to be

changed. Check that the locking tongue locks the pin

in the connector.

7

Install the cables with insulation and tie wraps in the

connector, in the reverse order to disassembly.

8

Install the connector in the reverse order to disassembly.

9

Check that the connector and the mating connector on

the engine control unit or power supply unit are clean

and dry.

10

Join up the multi-pin connector. Please refer to ”Control unit, changing” for advice on joining up the connector.

11

Start the engine and check carefully that no fault

codes occur.

Checking the starter motor

voltage

Special tools: Multimeter 981 2519

General

If battery voltage falls below 24.7 V*, the starter motor

will not be able to crank the engine at normal speed.

A fully charged battery has an open circuit voltage of

about 25.4 V.

* Note. Measured on the batteries.

Voltage measurement, check

1

Check that the battery voltage is at least 24.7 V* when

unloaded by using multimeter 9812519 to measure

between the battery poles.

* Note. Measured on the batteries.

26

2

Turn the main switch on.

3

Check that the voltage between terminal B+ on the starter motor and battery negatives connection point is the

same as the battery voltage.

Group 30: Electrical system Repair instructions

Checking the charging system

Special tools: 9812519

Generally about alternators:

The voltage output from an alternator must be limited

to prevent the elecrolyte in the battery to evaporate.

The alternator output is regulated (limited) by the voltage regulator in the alternator. The maximum current

that the alternator can deliver at regulated voltage output depends on the alternator revolution. When the engine is started an excitation current is needed to

“wake up” the alternator.

NOTE! It is the consumers (batteries included) which

decides the output current from the alternator.

Measurements

1. Engine off.

2. Use multimeter 9812519 to do a voltage measurement over the battery. The nominal voltage over a

full loaded battery is approx. 25.4V.

3. Engine on. Run at 1500 rpm.

4. Use multimeter 9812519 to do a voltage measurement over the battery. The nominal charging voltage over the battery should be approx. 27.8-

28.6V.

Fault tracing charging system

Battery

1. Check that all connectors at the battery is correct

assembled.

2. Check the conditions of the cables to the battery.

3. Check the water level in the battery.

4. Check, if possible, the specific gravity of all cells.

when no charge

1. Check the alternator belt tension.

2. Check that all connectors at the alternator and at

the battery is correct assembled.

3. Check the conditions of all cables in the charging

system.

4. Regulator fault, try another alternator.

when undercharge

1. Check the alternator belt tension.

2. Check that all connectors at the alternator and at

the battery is correct assembled.

3. Check the conditions of all cables in the charging

system.

4. Regulator fault, try another alternator.

when overcharge

1. Probably regulator fault, try another alternator.

27

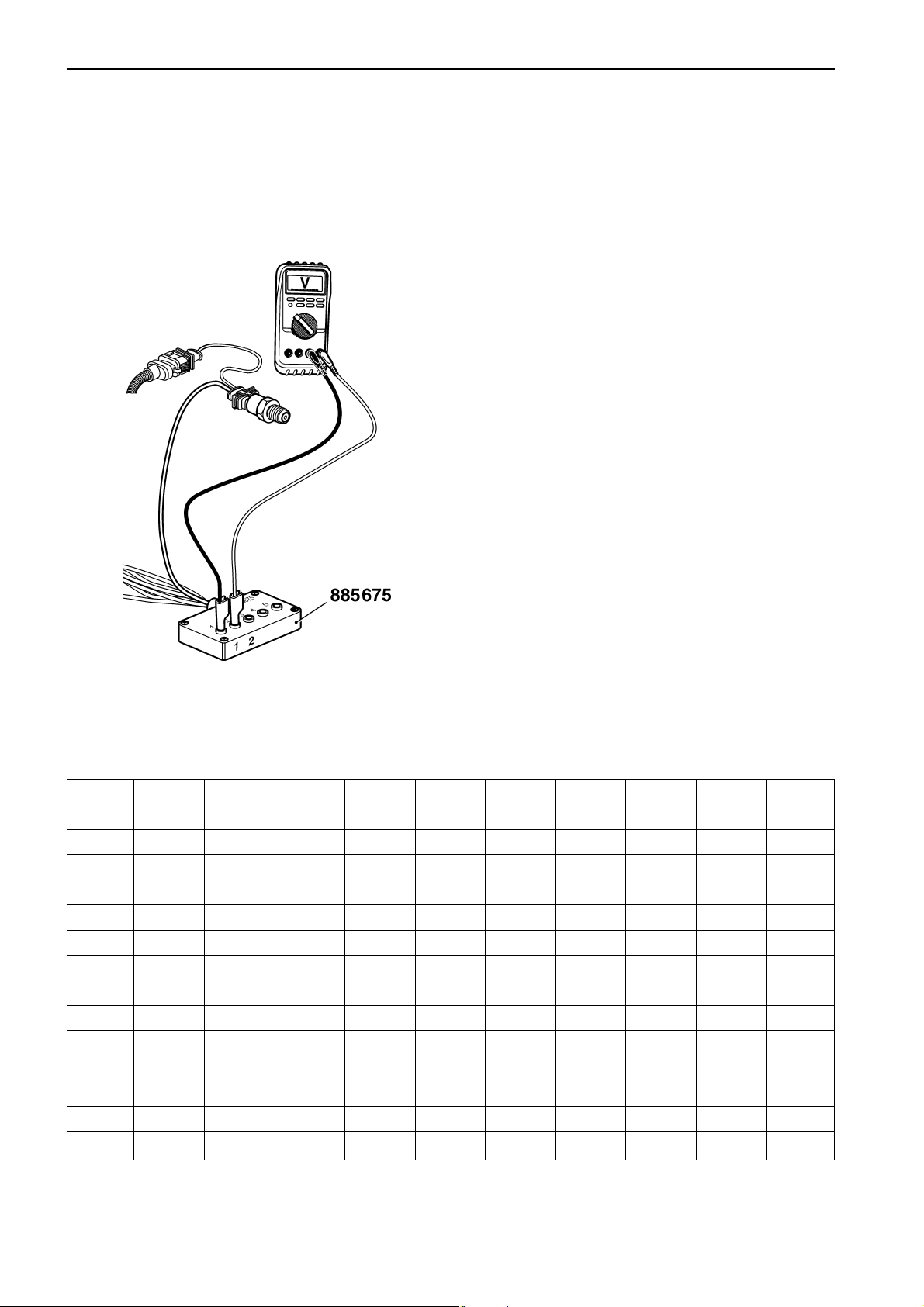

Repair instructions Group 30: Electrical system

Rail pressure measurement

This measurement is used for measuring the rail pressure. For example if the engine doesn’t start this measurement can show the rail pressure while the engine

is cranking. If it is air in the system the rail pressure

could be too low for the engine control unit to activate

injection.

1. NOTE! Starter key in position 0.

2. Undo the connector from the sensor.

3. Connect adapter cable (885675) between the sensor and the engine control unit.

4. Use multimeter (9812519) for voltage measurement. Connect the COM from the multimeter to

measurement point 1. Connect V from the multimeter to measurement point 2.

5. NOTE! Starter key in position I. The multimeter

should now show 0.5 Volt which is equal to 0Mpa

(0bar).

6. When cranking the engine, read the voltage value

on the multimeter and look in the table which pressure the voltage equals.

NOTE! To activate injection a rail pressure of at least

25 MPa (250 bar) is demanded.

Voltage 0.5 0.95 1.0 1.1 1.2 1.3 1.4 1.5 1.6 1.7

MPa 0 20.3 22.5 27.0 31.5 36.0 40.5 45.0 49.5 54.0

Bar 0 203.0 225.0 270.0 315.0 360.0 405.0 450.0 495.0 540.0

Voltage 1.8 1.9 2.0 2.1 2.2 2.3 2.4 2.5 2.6 2.7

MPa 58.5 63.0 67.5 72.0 76.5 81.0 85.5 90.0 94.5 99.0

Bar 585.0 630.0 675.0 720.0 765.0 810.0 855.0 900.0 945.0 990.0

Voltage 2.8 2.9 3.0 3.1 3.2 3.3 3.4 3.5 3.6 3.7

MPa 103.5 108.0 112.5 117.0 121.5 126.0 130.5 135.0 139.5 144.0

Bar 1035.0 1080.0 1125.0 1170.0 1215.0 1260.0 1305.0 1350.0 1395.0 1440.0

Voltage 3.8 3.9 4.0 4.1 4.2 4.3 4.4 4.5

MPa 148.5 153.0 157.5 162.0 166.5 171.0 175.5 180.0

Bar 1485.0 1530.0 1575.0 1620.0 1665.0 1710.0 1755.0 1800.0

28

Group 30: Electrical system Malfunctions

Malfunctions

Fault code information

• MID - Message Identification Description:

The MID consists of a number which designates

the control unit that sent the fault code message.

(e.g. the engine control unit).

• PID - Parameter Identification Description:

The PID consists of a number that designates a

parameter (value) to which the fault code relates

(oil pressure, for example).

• PPID - Proprietary PID:

The same as the PID, but this is a Volvo-specific

parameter.

• SID - Subsystem Identification Description:

The SID consists of a number that designates a

component to which the fault code relates

(injector, for example).

• PSID - Proprietary SID:

The same as the SID, but this is a Volvo-specific

component.

• FMI - Failure Mode Identifier:

FMI indicates the type of fault (please refer to the

FMI table below).

• SPN - Suspect Parameter Number

29

Malfunctions Group 30: Electrical system

FMI table

SAE standard

FMI Display text SAE text

0 “Value too high” Valid data, but above the normal working range

1 “Value too low” Valid data, but below the normal working range

2 “Faulty data” Intermittent or faulty data

3 “Electrical fault” Abnormally high voltage or short circuit to higher voltage

4 “Electrical fault” Abnormally low voltage or short circuit to lower voltage

5 “Electrical fault” Abnormally low current or open circuit

6 “Electrical fault” Abnormally high current or short circuit to battery negative

7 “Mechanical fault” Faulty response from mechanical system

8 “Mechanical or electrical fault” Abnormal frequency

9 “Communication fault” Abnormal updating rate

10 “Mechanical or electrical fault” Abnormally large variations

11 “Unknown fault” Unidentified fault

12 “Component fault” Faulty unit or component

13 “Faulty calibration” Calibration values outside the limits

14 “Unknown fault” Special instructions

15 Data valid but above normal operating range - least severe level

16 Data valid but above normal operating range - moderately severe level

17 Data valid but above normal operating range - least severe level

18 Data valid but above normal operating range - moderately severe level

19 Received network data in error

20 Reserved for SAE assignment

21 Reserved for SAE assignment

22 Reserved for SAE assignment

23 Reserved for SAE assignment

24 Reserved for SAE assignment

25 Reserved for SAE assignment

26 Reserved for SAE assignment

27 Reserved for SAE assignment

28 Reserved for SAE assignment

29 Reserved for SAE assignment

30 Reserved for SAE assignment

31 Condition exist

30

Group 30: Electrical system Malfunctions

Volvo-specific for injectors

(MID 128, SID 1–6)

FMI Help

3 Short circuit to battery voltage, injector low voltage side

4 Short circuit to battery negative, injector low voltage or high voltage side

5 Open circuit in injector circuit

7 Mechanical system not responding properly

12 Low injector hold current

General advice

NOTE!

The following must be done before fault tracing continues, to avoid changing functional

sensors:

● If there is an active/inactive fault code.

Remove the connector from the sensor. Check

that there is no oxidation and that the connector

pins are not damaged.

If there is a fault, please refer to the instructions

in chapter “Fault tracing of cables and connectors”.

NOTE! Some fault codes become inactive when the

engine is stopped. Start the engine to check whether

the fault code is still inactive with the engine running.

● After an action with the connector

Put the connector* back. Check if the fault code

becomes inactive.

Check faults that could be related to that specific sensor.

If the fault remains, measure the cables and

sensors to check them, as instructed.

*NOTE! No grease in the connector.

31

Malfunctions Group 30: Electrical system

Network

The system has two types of communication buses.

CAN

A data link (CAN bus) links the nodes to each other.

CAN (“Controller Area Network”) is an industrial standard for distributed systems.

The CAN bus consists of a pair of copper conductors

which are twisted 30 times per meter. The nodes communicate via the CAN bus and they form a network together, which exchanges information and benefits

from each other’s services.

The CAN bus is a serial bus and is the primary control

bus.

J1587

The communication bus, J1587, is also used for accessories and for diagnostics.

This is a serial bus in accordance with standard SAE

J1708.

32

Group 30: Electrical system Malfunctions

Manual fault tracing in bus

cables

Special tools:

Multimeter ..................................................... 9812519

IMPORTANT! Cut the current with the main

switch before the cables are disconnected.

Use the multimeter to check the bus cables. The conductors in the bus cables should not be in contact

with each other.

Disconnect a bus cable at each end and measure the

resistance between the pins to check this. The multimeter should show infinite resistance between each

pin. If the resistance is less than infinite, there is a

fault.

Measuring the engine cables

Two types of measurement are done on the engine

cable harness, both resistance measurement and voltage measurement.

The measurements are done to ensure that no open

circuits or short circuits occur.

If there is an open circuit, the resistance is infinite,

and if there is a short circuit, it is close to zero. The

resistance values given in the workshop manual are

approximate, and should be regarded as guidelines.

NOTE!

When resistance measurement is done, the engine

should be stopped and system voltage should be

cut off with the main switch.

All resistance measurement is done at +20°C

(68°F) and with a cold engine.

33

Diagnostic Trouble Codes Group 30: Electrical system

Diagnostic Trouble Codes

MID 128, PID 45

Inlet air heater status

MID 128: Engine control unit

FMI 3: The voltage exceeds the normal value or is

short circuited to higher voltage.

FMI 4: The voltage is less than the normal value or

is short circuited to lower voltage.

FMI 5: The current is less than the normal value or

is open circuited.

FMI Fault code explanation

3, 4, 5 Faulty sensor / Faulty sensor circuit

Fault indication

DCU: Engine warning in DCU display.

CIU: Flash code

Flash code

Electrical fault: 5.4

Value fault: None

Symptom

FMI 3, 5: Preheat relay never activated. White

smoke for cold start. Start problems in

cold climate.

FMI 4: Induction air is hot. Preheat relay is im-

possible to turn off. Preheat fuse will

break.

34

Group 30: Electrical system Diagnostic Trouble Codes

Circuit description

In cold climate the intake air need too be preheated.

This is either done for GE engines by the preheater

which is located in the inlet manifoldor or for VE engines by the glowplugs that are mounted in the cylin-

pre-heat relay

derhead. The preheat function is activated/deactivated

by the engine control unit via the preheat relay. When

the preheat function is activated B25 alter its potential

and the relay activates. B7 is a sense cable which

senses that the voltage supply to the preheater is correct.

Fault tracing

FMI 3 Abnormally high voltage or short

circuit to higher voltage

Possible reason:

• Short circuit to B+ in cable harness between EMS

2 and preheat relay.

Suitable action:

1. Check cable harness and connectors between

EMS 2 and preheat relay.

FMI 4 Abnormally low voltage or short

circuit to lower voltage

Possible reason:

• Short circuit to battery negative in cable harness

between EMS 2 and preheat relay.

Suitable action:

1. Check cable harness and connectors between

EMS 2 and preheat relay.

35

Diagnostic Trouble Codes Group 30: Electrical system

FMI 5 Abnormally low current or open

circuit

Possible reason:

• An open circuit in cable harness between EMS 2

and preheat relay.

Suitable action:

1. Check the contact pressure in socket 25 in the

engine connector B.

2. Check cable harness and connectors between

EMS 2 and preheat relay.

Measurements

NOTE! If any of the measurements shows an abnor-

mal value, check the wiring to and from the engine

control unit and the preheat relay.

Checking the wiring:

1. NOTE! Cut the current with the main switch.

2. Remove connector B from the EMS 2.

3. Connect the B connector to brakeout cable

9990014 with measurebox 9998699.

4. Use multimeter 9812519 to do a resistance mea-

surement.

Measurement points on box Nominal value

7 (preheat sense) - R ≈ 0 Ω

one of the preheat connectors

25 (relay activation) - R ≈ 0 Ω

one of the preheat connectors

60 (relay +) - R ≈ 0 Ω

one of the preheat connectors

36

Group 30: Electrical system Diagnostic Trouble Codes

MID 128, PID 94

Fuel pressure

MID 128: Engine control unit

FMI 1: The sensor value is valid but below the nor-

mal working range.

FMI 3: The voltage exceeds the normal value or is

short circuited to higher voltage.

FMI 5: The current is less than the normal value or

is open circuited.

FMI 7: Mechanical fault. The system responds in-

correctly.

FMI Fault code explanation

1 Fuel pressure is too low

3, 5 Faulty sensor / Faulty sensor circuit

7 Fuel pressure is critically low

Fault indication

DCU: Engine warning in DCU display.

CIU: Flash code

Flash code

Electrical fault: 3.6

Value fault: 3.8

Symptom

None

Circuit description

splice

splice

engine

interface

Note! Only TAD 650, 660, 750, 760 has an engine interface. On

TAD 734 the wiring to the EMS 2 is the same but without any engine interface.

fuel pressure

The sensor is an active sensor, i.e. the sensor must

receive operating voltage. Pin B17 on the engine control unit provides pin 1 on the sensor with an operating

voltage of +5 Volt. Pin 4 on the sensor is connected to

battery negative via pin B18 on the engine control unit.

The output signal from the pressure sensor, pin 2 on

the sensor to pin B16 on the EMS 2, is a voltage signal that is proportional to the fuel pressure.

37

Diagnostic Trouble Codes Group 30: Electrical system

Fault tracing

FMI 1 Fuel pressure is too low

Conditions for fault code:

The fuel pressure alarm depends on the engine revo-

lution.

Suitable action:

1. Check fuel level.

2. Open all fuel cocks and check that no leakage

occurs.

3. Check drive belt adjustment.

4. Change all fuel filters. (pre- and fine filter)

5. Check that no fuel hose is squeezed or folded.

6. Check function of fuel pressure sensor by control

measuring the fuel pressure. (see workshop manual)

7. Check fuel feed pump.

8. Change fuel pressure release valve. (see workshop manual)

FMI 3 Abnormally high voltage or short

circuit to higher voltage

Conditions for fault code:

The voltage on pin B16 on the EMS 2 is more than

4,75 Volt.

Possible reason:

• An open circuit in fuel sensor negative cable.

• Short circuited fuel sensor signal cable to 5V volt-

age or to battery voltage.

• Faulty sensor.

Suitable action:

1. Check contact pressure in socket 18 in the engine

connector B. Also check contact pressure in connector at fuel pressure sensor.

2. Check cable harness and connectors between fuel

sensor and EMS 2.

3. Check function of fuel pressure sensor.

38

Group 30: Electrical system Diagnostic Trouble Codes

FMI 5 Abnormally low current or open

circuit

Conditions for fault code:

The voltage on pin B16 on the EMS 2 is less than

0.07 Volt.

Possible reason:

• An open circuit in fuel sensor 5V supply cable.

• An open circuit in fuel sensor signal cable.

• Short circuited sensor signal cable to battery neg-

ative.

• Faulty sensor.

Suitable action:

1. Check contact pressure in socket 16 and 17 in

the engine connector B. Also check contact pressure in connector at fuel pressure sensor.

2. Check cable harness and connectors between fuel

sensor and EMS 2.

3. Check function of fuel pressure sensor.

FMI 7 Critically low pressure

Conditions for fault code:

The fuel pressure alarm depends on the engine revolution.

Suitable action:

1. Check fuel level.

2. Open all fuel cocks and check that no leakage occurs.

3. Check drivebelt adjustment.

4. Change all fuel filters. (pre- and fine filter)

5. Chech that no fuel hose is squeezed or folded.

6. Check functionof fuel pressure sensor by control

measuring the fuel pressure. (see workshop manual)

7. Check fuel feed pump.

8. Change fuel pressure release valve. (see workshop

manual)

39

Diagnostic Trouble Codes Group 30: Electrical system

Measurements

NOTE! If any of the measurements shows an abnor-

mal value, check the wiring to and from the engine interface.

Supply cable

• NOTE! Turn ignition off.

• Disconnect the connector from the sensor

• Connect adapter cable 885675 to the cable har-

ness connector to the engine control unit.

• Use multimeter 9812519 for voltage measure-

ment.

• Turn ignition on.

Measurement points Nominal value

1– 4 U ≈ 5V

Negative cable:

• NOTE! Cut the current with the main switch.

• Disconnect the connector from the sensor

• Connect adapter cable 885675 to the cable har-

ness connector to the engine control unit.

• Use multimeter 9812519 to do resistance mea-

surement against the engine control unit.

Measurement points Nominal value

4 – Battery negative R ≈ 0 Ω

The point of connection for battery negative on the engine

40

Group 30: Electrical system Diagnostic Trouble Codes

Signal cable:

• NOTE! Cut the current with the main switch.

• Disconnect the connector from the sensor

• Connect adapter cable 885675 to the cable har-

ness connector to the engine control unit.

• Use multimeter 9812519 to do resistance mea-

surement against the engine control unit.

Measurement points Nominal value

4 – 2 R ≈ 80 - 120 kΩ

NOTE! Measurement is done to eliminate short circuiting or breaks in the cable to the engine control

unit.

41

Diagnostic Trouble Codes Group 30: Electrical system

Checking fuel pressure sensor

• NOTE! Turn ignition off.

• Disconnect the connector from the sensor

• Connect adapter cable 885675 between the sen-

sor and the engine control unit.

• Use multimeter 9812519 for voltage measure-

ment.

• Turn ignition on.

Measurement points Nominal value

4 – 2 U ≈ 0,5 V

(at normal atmospheric pressure)

Output voltage, V

Component specification

Working range: 0 – 7 bar = 0 – 700 kPa

Supply voltage: 5,00 +/- 0,25 VDC

Nominal output voltage at 25 °C and at supply voltage

5,00 VDC:

0,5 VDC at 0 bar = 0 kPa

4,5 VDC at 7 bar = 700 kPa

Fuel pressure, kPa

42

Group 30: Electrical system Diagnostic Trouble Codes

MID 128, PID 97

Water in fuel

MID 128: Engine control unit

FMI 0: The sensor value is valid but above the nor-

mal working range.

FMI 3: The voltage exceeds the normal value or is

short circuited to higher voltage.

FMI 4: The voltage is less than the normal value or

is short circuited to lower voltage.

FMI Fault code explanation

0 Water in fuel

3, 4 Faulty sensor / Faulty monitor circuit

Fault indication

DCU: Engine warning in DCU display

CIU: Flash code

Flash code

Electrical fault: 2.9

Value fault: 2.1

Symptom

None

splice

water in

fuel

Circuit description

A monitor is located in the water trap under the fuel filter. Its task is to detect whether there is water in the

fuel.

The monitor senses the resistance between two pins,

wich are in contact with the fuel. When there is no water in the fuel, the resistance is very high. If there is

any water in the fuel, the resistance falls.

At a threshold resistance (water has been detected),

the monitor’s output signal (yellow cable) to the engine

control unit pin B8 will be pulled down to zero.

43

Diagnostic Trouble Codes Group 30: Electrical system

Fault tracing

FMI 0 Water in fuel

Conditions for fault code:

Water in the fuel trap has been detected.

Suitable action:

1. Empty the water trap.

2. Check function of water in fuel monitor.

FMI 3

Conditions for fault code:

The voltage signal on B8 is too high.

Possible reason:

• The cable connected to B8 is short circuited to

battery voltage.

Suitable action:

1. Check cable harness and connectors between water in fuel monitor and EMS 2.

FMI 4

Conditions for fault code:

The voltage signal on B8 is too low.

Possible reason:

• Short circuit between both cables to the water in

fuel monitor.

• The cable connected to B8 is short circuited to

battery negative.

Suitable action:

1. Check cable harness and connectors between water in fuel monitor and EMS 2.

44

Group 30: Electrical system Diagnostic Trouble Codes

Measurements

Supply cable:

• NOTE! Turn ignition off.

• Disconnect the connector from the monitor

• Use multimeter 9812519 for voltage measurement

• NOTE! Turn ignition on.

Measurement points Nominal value

Yellow conductor – U ≈ Battery voltage x 0.8

Black conductor

Negative cable:

• NOTE! Cut the current with the main switch.

• Disconnect the connector from the monitor

• Use multimeter 9812519 to do resistance mea-

surement against the engine control unit.

Measurement points Nominal value

Black conductor – R ≈ 0 Ω

Battery negative

Checking water in fuel monitor

1. Disconnect the connector to the water in fuel monitor.

2. Use multimeter 9812519 to do a resistance measurement towards the monitor.

Measurement points Nominal value

1 – 2 Monitor immersed R ≈ 0 Ω

in water

1 – 2 Monitor immersed R ≈∞ Ω

in fuel

45

Diagnostic Trouble Codes Group 30: Electrical system

MID 128, PID 100

Oil pressure

MID 128: Engine control unit

FMI 1: The sensor value is valid but below the nor-

mal working range.

FMI 3: The voltage exceeds the normal value or is

short circuited to higher voltage.

FMI 5: The current is less than the normal value or

is open circuited.

FMI Fault code explanation

1 Oil pressure is too low

3, 5 Faulty sensor / Faulty sensor circuit

Fault indication

DCU: Engine warning in DCU display.

CIU: Flash code

Flash code

Electrical fault: 3.1

Value fault: 6.6

Symptom

FMI 1: Power is reduced due to error torque map if

engine protection parameter is activated.

46

Group 30: Electrical system Diagnostic Trouble Codes

Circuit description

The sensor is an active sensor, i.e. the sensor must

splice

splice

Note! Only TAD 650, 660, 750, 760 has an engine interface. On

TAD 734 the wiring to the EMS 2 is the same but without any engine interface.

oil pressure

receive operating voltage. Pin B17 on the engine control unit (EMS 2) provides pin 1 on the sensor with an

operating voltage of +5 Volt. Pin 3 on the sensor is

connected to battery negative via pin B18 on the EMS

2.

The output signal from the pressure sensor, pin 2 on

the sensor to pin B11 on the EMS 2, is a voltage signal that is proportional to the oil pressure (after the oil

filters).

Fault tracing

FMI 1 Oil pressure is too low

Conditions for fault code:

Oil pressure depends on the engine revolution. Oil

pressure exceeds the set value of the engine protection parameter.

Possible reason:

• Too low engine oil level.

• Blocked oil filter.

• Oil leakage.

• Faulty oil pressure sensor.

Suitable action:

1. Check engine oil level and quality of the oil.

2. Change engine oil and oil filter to prevent blocked

oil filter.

3. Check that no engine oil leakage occurs.

4. Check function of oil pressure sensor by control

measuring the engine oil pressure (see workshop

manual Group 21-26).

47

Diagnostic Trouble Codes Group 30: Electrical system

FMI 3 Abnormally high voltage or short

circuit to higher voltage

Conditions for fault code:

The voltage on pin B11 on the EMS 2 is more than

4.95 Volt.

Possible reason:

• Short circuit between signal cable and 5V supply

to oil pressure sensor.

• Faulty sensor.

Suitable action:

1. Check cable harness and connectors between oil

pressure sensor and EMS 2.

2. Check function of oil pressure sensor.

FMI 5 Abnormally low current or open

circuit

Conditions for fault code:

The voltage on pin B11 on the EMS 2 is less than 0.07

Volt.

Possible reason:

• An open circuit in 5V supply cable to oil pressure

sensor.

• An open circuit in signal cable to oil pressure sen-

sor.

• Short circuit between signal cable and battery

negative to oil pressure sensor.

• Faulty sensor.

Suitable action:

1. Check contact pressure in socket 11 and 17 in

engine connector B. Also check contact pressure

in connector at oil pressure sensor.

2. Check cable harness and connectors between oil

pressure sensor and EMS 2.

3. Check function of oil pressure sensor.

48

Group 30: Electrical system Diagnostic Trouble Codes

Measurements

NOTE! If any of the measurements shows an abnor-

mal value, check the wiring to and from the engine interface.

Supply cable:

• NOTE! Turn ignition off.

• Remove the connector from the sensor.

• Connect adapter cable 885675 between the sen-

sor and engine control unit.

• Use multimeter 9812519 for voltage measurement

• NOTE! Turn ignition on.

Measurement points Nominal value

1 – 3 U ≈ 5 V

Negative cable:

• NOTE! Cut the current with the main switch.

• Disconnect the connector from the sensor

• Connect adapter cable 885675 to the cable har-

• Use multimeter 9812519 to do resistance mea-

The point of connection for battery

negative on the engine

ness connector to the engine control unit.

surement against the engine control unit.

Measurement points Nominal value

3 – Battery negative R ≈ 0 Ω

49

Diagnostic Trouble Codes Group 30: Electrical system

Signal cable:

• NOTE! Cut the current with the main switch.

• Disconnect the connector from the sensor

• Connect adapter cable 885675 to the cable har-

ness connector to the engine control unit.

• Use multimeter 9812519 to do resistance mea-

surement against the engine control unit.

Measurement points Nominal value

2 – 3 R ≈ 80 -120 kΩ

NOTE! Measurement is done to eliminate short circuiting or breaks in the cable to the engine control

unit.

50

Group 30: Electrical system Diagnostic Trouble Codes

Checking the oil pressure sensor

NOTE! Turn ignition off.

•

• Disconnect the connector from the sensor

• Connect adapter cable 885675 between the sen-

sor and the engine control unit.

• Use multimeter 9812519 for voltage measurement

• Turn ignition on.

Measurement points Nominal value

2 – 3 U ≈ 0,5 V (at normal

atmospheric pressure)

Output voltage, V

Component specification

Working range: 0 – 7 bar = 0 – 700 kPa

Supply voltage: 5,00 +/- 0,25 VDC

Nominal output voltage at 25 °C and at supply voltage

5,00 VDC:

0,5 VDC at 0 bar = 0 kPa

4,5 VDC at 7 bar = 700 kPa

Oil pressure, kPa

51

Diagnostic Trouble Codes Group 30: Electrical system

MID 128, PID 105

Boost temperature

MID 128: Engine control unit

FMI 0: The sensor value is valid but above the nor-

mal working range.

FMI 4: The voltage is less than the normal value or

is short circuited to lower voltage.

FMI 5: The current is less than the normal value or

is open circuited.

FMI Fault code explanation

0 Boost temperature is too high

4, 5 Faulty sensor /

Faulty sensor circuit

Fault indication

DCU: Engine warning in DCU display.

CIU: Flash code

Flash code

Electrical fault: 3.2

Value fault: 6.2

Symptom

FMI 0: Engine is derated if engine protection pa-

rameter is activated.

FMI 4, 5: Pressure set to 40° C.

52

Group 30: Electrical system Diagnostic Trouble Codes

Circuit description

The boost temperature sensor consists of a thermistor

splice

splice

engine

interface

Note! Only TAD 650, 660, 750, 760 has an engine interface. On

TAD 734 the wiring to the EMS 2 is the same but without any engine interface.

Boost air and

temperature

which forms a closed circuit with an internal resistor in

the engine control unit (EMS 2), via the engine interface. The thermistor resistor changes in a non-linear