Workshop Manual

Technical Data

TAD1240GE, TAD1241GE/VE

TAD1242GE/VE, TWD1240VE

>| Ecu - Repair - Manual |<

>| Ecu - Repair - Manual |<

Technical data

Engine

TAD1240GE, TAD1241GE/VE

TAD1242GE/VE, TWD1240VE

Contents

Safety information ................................................ 2

Introduction ......................................................... 2

Important ............................................................ 2

General information ............................................. 5

About the Service Manual ................................... 5

Spare parts ......................................................... 5

Certificated engines ............................................ 5

Technical data ...................................................... 6

References to Service Bulletins .......................... 31

>| Ecu - Repair - Manual |<

Safety information

Group 20

The Service Manual contains technical data,

descriptions and repair instructions relating to the

Volvo Penta products or product versions included in

the list of contents. Make sure you use the right

workshop literature.

Read the safety information, “General

information” and “Repair instructions” carefully

before starting any service work.

Important

The following special warning symbols occur in the

Service Manual and on the product.

WARNING! Warns of the risk of injury and

extensive damage to the product or property,

or that serious functional faults could arise if

the instructions are not followed.

IMPORTANT! Used to draw attention to anything that could cause damage to the product or

property or functional disorders in the same.

NOTE: Used to draw attention to important information

for facilitating work operations or handling.

If work is carried out near an engine that is running, an incautious movement or a dropped tool

could in the worst case lead to bodily harm. Be

mindful of hot surfaces (exhaust pipes, the

turbocharger, charge air pipes, starter elements,

etc.) and hot liquids in lines and hoses on an

engine that is running or has just been stopped.

Before starting the engine, refit all guards and

protective elements that were removed in the

course of carrying out service work.

Make sure that the warning and/or information

decals affixed to the product are always in plain

sight. Replace decals that are damaged or have

been painted over.

Never start the engine unless the air filter is

fitted. The rotating impeller in the turbo could

cause serious injuries. Foreign objects in the inlet line could additionally cause machinery damage.

To provide an overview of the risks you should always

be aware of and the precautionary measures that

should always be adopted, we have listed them here.

Make it impossible for the engine to start. Turn

off the current by means of the main switch (or

switches) and lock it (them) in the OFF position

before starting service work. Affix a warning

sign in the driver’s area.

As a rule, all service work should be carried out

when the engine is stationary. Some work,

including certain adjustments, nonetheless

requires the engine to be running. Approaching

an engine that is running could be dangerous.

Bear in mind that loose-fitting clothes or long

hair may get caught in rotating parts and cause

serious injury.

Never use a starter spray or the like to help start

the engine. It could cause an explosion in the inlet manifold. Danger of injury.

Start the engine in well-ventilated premises only.

If the engine is run in a confined space, exhaust

gases and crankcase gases should be conducted away from the engine bay or workshop area.

Avoid opening the coolant filler cap when the

engine is still hot. Steam or hot coolant could

squirt out while the built-up pressure will be lost.

If necessary, open the filler cap slowly and release the pressure in the cooling system. Be

extremely careful if a cock, plug or coolant line

has to be removed while the engine is still hot.

Steam or hot coolant could squirt out in an unexpected direction.

>| Ecu - Repair - Manual |<

General instructionsGroup 20

Hot oil can cause burns, Avoid getting hot oil on

your skin. Make sure that the lubricating system

is depressurized before starting any work on it.

Never start or run the engine with the oil filler

cap removed as oil under pressure could then

escape.

Stop the engine before doing any work on the

cooling system.

Always use protective goggles when carrying

out work where splinters, grinding sparks and

splashes of acid or other chemicals could occur.

The eyes are especially sensitive and an injury

could result in loss of sight.

Avoid getting oil on your skin. Prolonged or recurring contact with oil can remove the skin’s

natural moisture with irritation, dehydration, eczema and other skin disorders as a result. From

a hygienic point of view, used oil is more harmful than fresh oil. Wear protective gloves and

avoid clothes and rags ingrained with oil. Wash

yourself regularly, particularly before mealtimes.

Use skin lotion intended for this purpose to

avoid dehydration and to facilitate cleansing of

the skin.

WARNING! Under no circumstances should the

engine’s pressure pipes be bent or reshaped.

Damaged pipes must be changed.

All fuels and many chemicals are flammable.

Make sure that they cannot be ignited by a

naked flame or spark. Petrol, certain diluents

and hydrogen from batteries, when mixed with

air in the right proportions, are highly flammable

and explosive. No smoking! Arrange for adequate ventilation and take the necessary safety

measures prior to the start of welding or grinding work in the vicinity. Always keep a fire extinguisher easily accessible at the workplace.

Ensure that rags saturated with oil and fuel, as

well as used fuel and oil filters, are kept in a

safe place prior to their disposal. Under certain

conditions, spontaneous combustion can occur

in oil-ingrained rags. Used fuel and oil filters

comprise environmentally hazardous waste and,

together with used lubricating oil, contaminated

fuel, residual paint, solvents, degreasants and

residual detergents, should be taken to a suitable plant for destruction.

Most chemicals intended for the product (such

as engine and transmission oils, glycol, petrol

and diesel oil) or chemicals for workshop use

(such as degreasants, paints and solvents) are

injurious to the health. Carefully read the instructions on the package. Always follow the

prescribed safety rules (such as the use of respirators, protective goggles, gloves, etc.). Make

sure that other personnel are not exposed without their knowledge to substances that are injurous to health, such as through the air they

breathe. Make provision for good ventilation.

Deal with used and surplus chemicals in the prescribed manner.

Exercise great care when detecting leaks in the

fuel system and testing fuel nozzles. Wear protective goggles. The jets from a fuel nozzle are

under very high pressure and have great penetrative power; the fuel can penetrate deep into

body tissues and cause serious injury. Risk of

blood poisoning.

Batteries should never be exposed to naked

flames or electric sparks. Never smoke near the

batteries. When the batteries are being charged

they give off hydrogen which, when mixed with

air, forms oxyhydrogen gas. This gas is highly

flammable and extremely explosive. A spark,

which can occur if the batteries are connected

incorrectly, could cause a battery to explode

with injury and damage as a result. Do not disturb the connections when attempting to start

(risk of sparks) and do not lean over any of the

batteries.

Never mistake the positive and negative terminals for each other when installing the batteries. If this happens it could cause serious

damage to the electrical equipment. Compare

with the wiring diagram.

>| Ecu - Repair - Manual |<

General instructions

Group 20

Always wear protective goggles when charging

and handling batteries. The battery electrolyte

contains highly corrosive sulphuric acid. If it

gets on your skin, wash the affected area with

soap and plenty of water. If the electrolyte gets

in your eyes, rinse them at once with plenty of

water and see a doctor as soon as possible.

Stop the engine and cut off the current with the

main switch (or switches) before starting to work

on the electrical system.

The clutch should be adjusted with the engine

switched off.

Use the lifting eyes mounted on the engine

when lifting it. Always check that all lifting

equipment is in good condition and that it has

the right capacity for the job (engine weight plus

reversing gear and extra equipment, if any). To

ensure safe handling and to avoid damaging

components mounted on the top of the engine,

it should be lifted using an adjustable lifting

beam or one suitably adapted to the engine. All

chains or cables should run parallel to each

other and as perpendicular as possible to the

top of the engine.

If other equipment that has been connected to

the engine changes its centre of gravity, special

lifting devices may be needed to obtain the right

balance and ensure safe handling.

Never carry out any work on an engine that is

suspended solely from a lifting device (hoist, etc.).

Never work alone when heavy components are

to be removed, not even when a safe lifting device like a lockable block and tackle is used.

Even when a lifting device is used two people

will generally be required, one to handle the lifting device and the other to make sure that the

components go clear and are not damaged when

lifted away.

Always make sure in advance that there is sufficient space for dismantling to be carried out in

the area with no danger of it causing injury or

material damage.

WARNING! Electrical system and fuel system

components on Volvo Penta products are designed and manufactured to minimize the risk of

explosion and fire. The engine must not be run

in environments where they will be surrounded

by explosive media.

Always use fuel recommended by Volvo Penta.

See the Owner’s Manual. The use of a poorer

grade of fuel could damage the engine. On a

diesel engine, a poor grade of fuel could lead to

binding of the control rod and overrevving of the

engine with a consequent risk of injury and damage. Poor fuel can also give rise to higher maintenance costs.

Bear in mind the following when cleaning with

high-pressure equipment: never direct the jet of

water on seals, rubber hoses or electrical components. Never use the high-pressure function

when cleaning the engine.

4

>| Ecu - Repair - Manual |<

Group 20

General information

About the Service Manual

This Service Manual contains technical data for the

standard versions of the TAD1240GE, TAD1241GE/VE,

TA1242GE/VE and TWD1240VE engines.

All references from the service manuals containing

repair instructions for the TAD1240GE, TAD1241GE/

VE, TAD1242GE/VE and TWD1240VE engines will be

found in the “Technical data” Service Manual.

The Service Manual is primarily produced for Volvo

Penta’s service workshops and their qualified personnel. It is therefore assumed that persons using the

manual have the necessary basic knowledge and can

carry out work of a mechanical/electrical nature that

forms part of their occupational duties.

Volvo Penta is continuously developing its products

and we therefore reserve the right to introduce

changes and modifications. All the information in this

manual is based on product data available up to the

time of going to press. Any changes of vital importance that have been introduced in product or service

methods after that date will be announced in the form

of Service Bulletins.

Spare parts

Spare parts for the electrical and fuel systems are

subject to different national safety requirements. Volvo

Penta Original Spare Parts meet these require-ments.

All types of damage occurring as a result of using

non-original Volvo Penta spare parts for the pro-duct

in question will not be covered under the terms of

warranty as undertaken by Volvo Penta.

Certificated engines

For engines that are certificated in compliance with

national and regional environmental legislation the

manufacturer undertakes to ensure that the environmental requirements are fulfilled both in new engines

and those already in use. The product must correspond to the specimen product that was approved for

certification. For Volvo Penta as the manufacturer to

be answerable for ensuring that engines in use meet

the stipulated environmental requirements, the following requirements in regard to service and spare parts

must be fulfilled:

€

€ The service intervals and maintenance measures

recommended by Volvo Penta must be followed.

€

€ Only Volvo Penta Original Spare Parts intended

for the certificated engine version may be used.

€

€ Service embracing injection pumps, pump set-

tings and injectors must always be carried out by

an authorized Volvo Penta workshop.

€

€ The engine must not be rebuilt or modified in any

way, except for the accessories and service kits

that Volvo Penta has developed for the engine in

question.

€

€ Installation changes to exhaust pipes and supply

air ducts for the engine bay (ventilation ducts)

must not be made indiscriminately as this could

affect exhaust emission levels.

€

€ Security seals, if any, must not be broken by non-

authorized personnel.

In other respects the general instructions for driving,

operation and maintenance given in the Owner’s Manual are applicable.

IMPORTANT! When spare parts are required,

use only Volvo Penta Original Spare Parts.

If non-original spare parts are used, AB Volvo

Penta will no longer be responsible for ensuring that the engine corresponds to the certificated version.

All types of injury, damage and/or costs arising

due to the use of non-original Volvo Penta Original

Spare Parts for the product in question will not be

covered under the terms of warranty as undertaken by Volvo Penta.

>| Ecu - Repair - Manual |<

5

Technical data

Group 20

General

Type designation .................................................... TAD1240GE TAD1241/42GE TWD1240VE TAD1241/42VE

Number of cylinders ............................................... 6

Cylinder bore ..........................................................131 mm (5.16")

Stroke ....................................................................150 mm (5.91")

Swept volume ........................................................12.13 dm3 (740.20 inch3)

Number of valves ................................................... 24

Direction of rotation (viewed from front) ..................Clockwise

Compression ratio .................................................. 18.5:1 17.5:1 18.5:1 17.5:1

Firing order .............................................................1-5-3-6-2-4

Slow idling speed (rpm) .......................................... 600-1200 600-1200 600-900 600-900

Fast idling speed (rpm)........................................... 1500-1620 1500-1620 2100 1000

........................................................................... /1800-1920 /1800-1920

Highest full-load engine speed (rpm) ...................... 1500/1800 1500/1800 2100 1800

Dry weight (kg) ......................................................1230* 1230* 1270 1230*

........................................................................... (2706 lbs) (2706 lbs) (2794 lbs) (2706 lbs)

*Weight TAD engines without radiator assembly and air filter

Engine block

Cylinder head

Type ..................................................................... One cylinder head for all cylinders with single overhead camshaft

Length ................................................................... 1078 mm (42.44")

Width ..................................................................... 397 mm (15.63")

Height ....................................................................135 mm (5.32")

Max. surface unevenness (bottom surface) .......... 0.1 mm (0.004")

Cylinder head bolts

Number of bolts per cylinder head ......................... 38

Thread size ........................................................... M16

Length ................................................................... 200 mm (7.87")

6

>| Ecu - Repair - Manual |<

Group 20

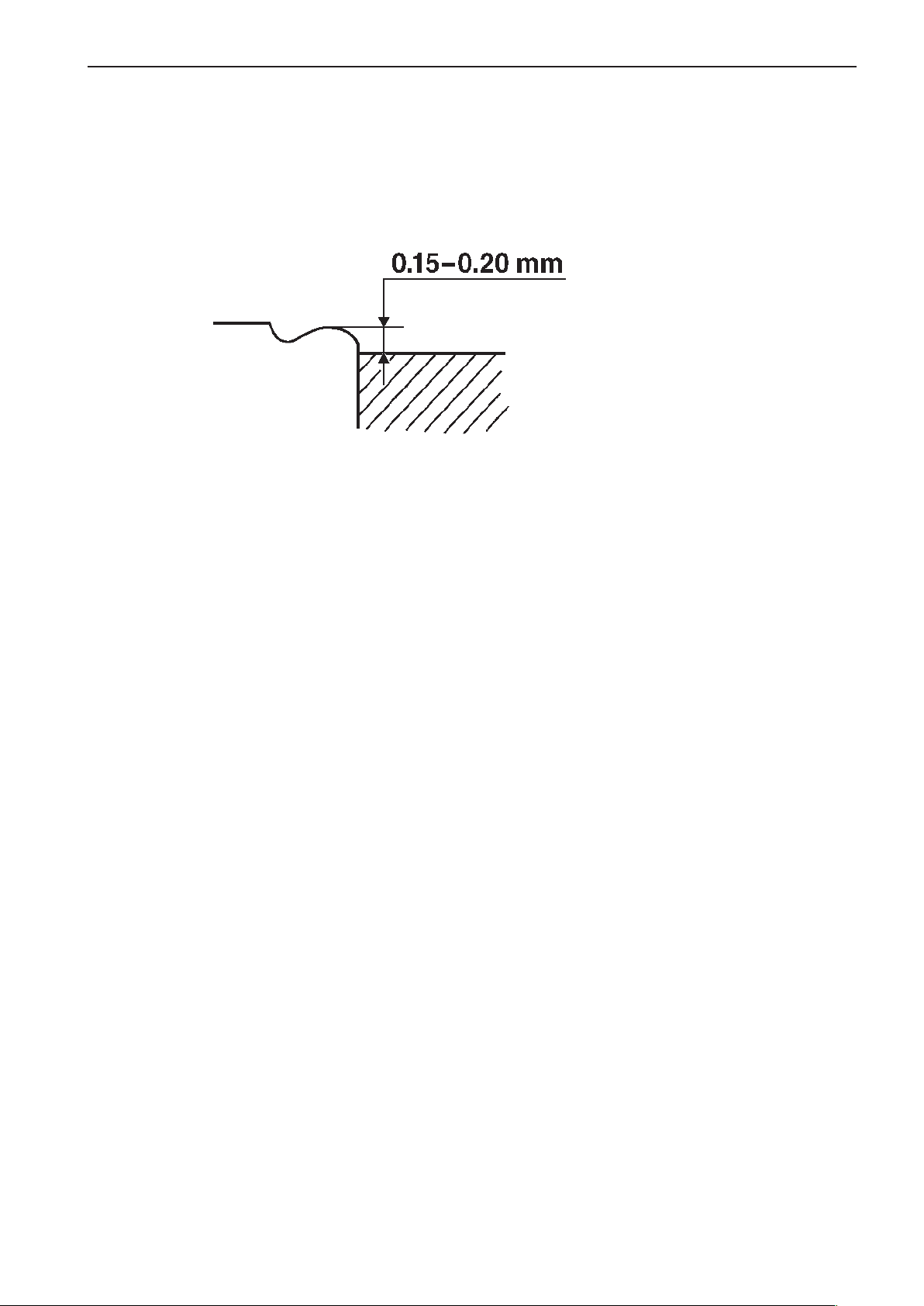

Cylinder liners

Type ...................................................................... Wet, replaceable

Sealing surface height above block surface ...........0.15–0.20 mm (0.006–0.0079")

Number of sealing rings per cylinder liner ............... 4

Technical data

Pistons

Height above cylinder block surface ....................... 0.05-0.45 mm (0.002–0.018")

Diameter, combustion chamber .............................. 89 mm (3.5")

Depth, piston bowl ................................................. 18.55 mm (0.73") (E=17.5:1) 17.14 (E=18.5:1)

Number of ring grooves .........................................3

Front marking ........................................................Arrow pointing forwards

Gudgeon pin diameter ........................................... 55 mm (2.17")

Piston rings

Compression rings

Number .................................................................. 2

Piston ring clearance in groove:

upper compression ring ....................................... Trapezoidal section, no clearance

lower compression ring, vertical .......................... 0.05-0.08 mm (0.002–0.0031")

Piston ring gap:

upper compression ring ....................................... 0.425-0.575 mm (0.0167–0.0226")

wear tolerance .................................................. 1 mm (0.04")

lower compression ring ....................................... 0.8 mm (0.032")

wear tolerance .................................................. 1.3 mm (0.051")

Oil control ring

Number .................................................................. 1

Width, incl. spring ..................................................4.3 mm (0.17")

Piston ring clearance, vertical ................................ 0.03-0.08 mm (0.0012–0.0031")

Piston ring gap ....................................................... 0.35-0.75 mm (0.014–0.03")

>| Ecu - Repair - Manual |<

7

Technical data

Valve mechanism

Valves

Valve head diameter

Inlet .................................................................... 40 mm (1.58")

Exhaust .............................................................. 40 mm (1.58")

Stem diameter

Inlet .................................................................... 7.960–7.975 mm (0.3134–0.3140")

Exhaust .............................................................. 7.947–7.962 mm (0.3129–0.3135")

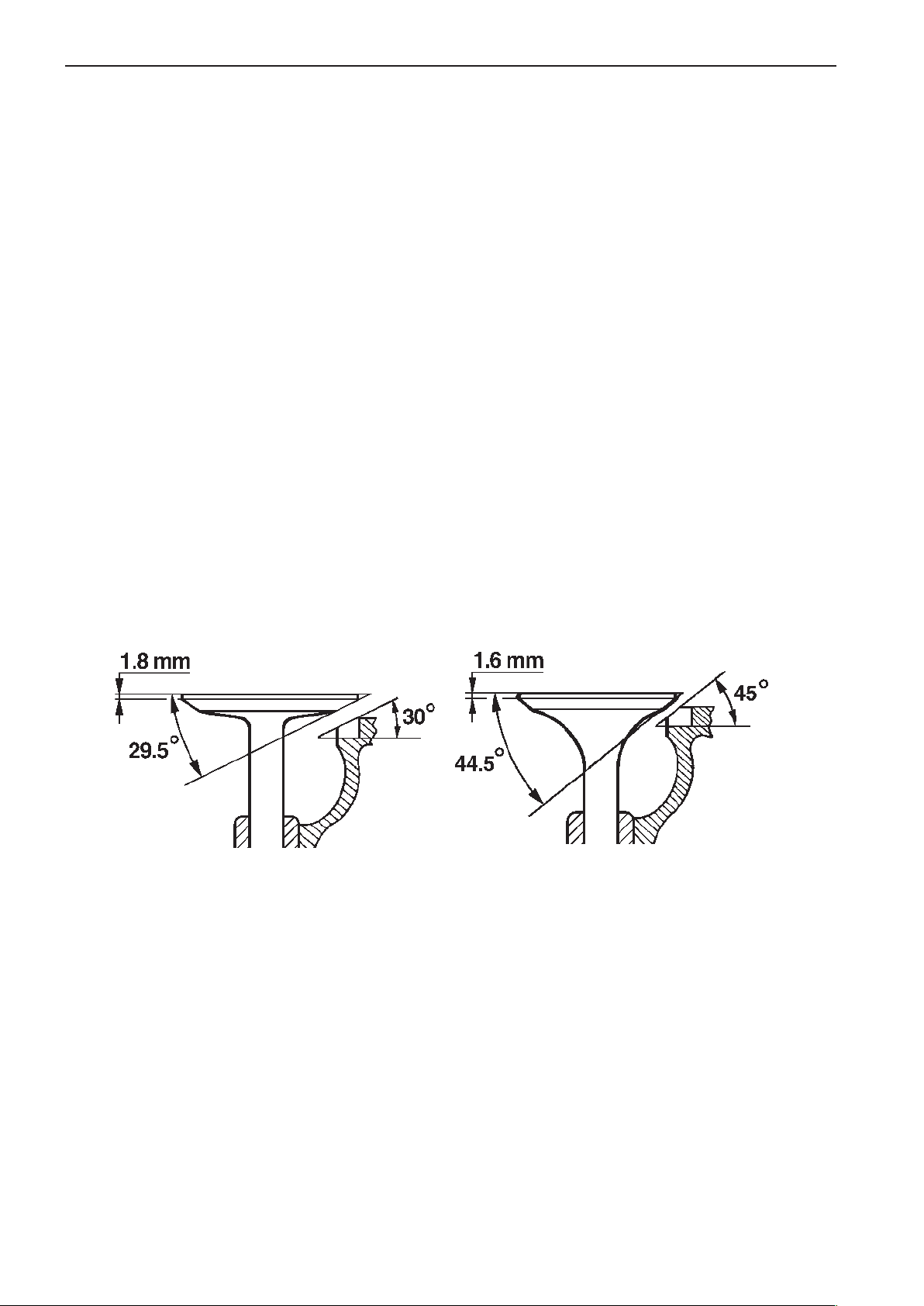

Valve face angle

Inlet .................................................................... 29.5°

Exhaust .............................................................. 44.5°

Valve head face, (see illustration below)

Inlet (new valve) .................................................. Min.1.8 mm (0.07")

wear tolerance ..................................................... 1.4 mm (0.055")

Exhaust (new valve) ........................................... Min.1.6 mm (0.063")

wear tolerance ..................................................... 1.2 mm (0.0472")

Seat angle in cylinder head

Inlet .................................................................... 30°

Exhaust .............................................................. 45°

The valve seat should be ground down until

the distance from the valve head (new valve)

to the cylinder head surface is:

Inlet ...................................................................... 0.9–1.4 mm (0.035–0.055")

wear tolerance ..................................................... Max. 1.5 mm (0.06")

Group 20

Exhaust .............................................................. 1.2–1.7 mm (0.047–0.067")

wear tolerance ..................................................... Max. 1.8 mm (0.071")

If the distance is greater the valve seats

must be changed.

Valve clearances, cold engine, setting value

Inlet .................................................................... 0.2 mm (0.008")

Exhaust .............................................................. 0.5 mm (0.020")

Valve clearance, cold engine, check value

Inlet .................................................................... 0.15–0.25 mm (0.006–0.010")

Exhaust .............................................................. 0.45–0.55 mm (0.018–0.022")

8

>| Ecu - Repair - Manual |<

Group 20

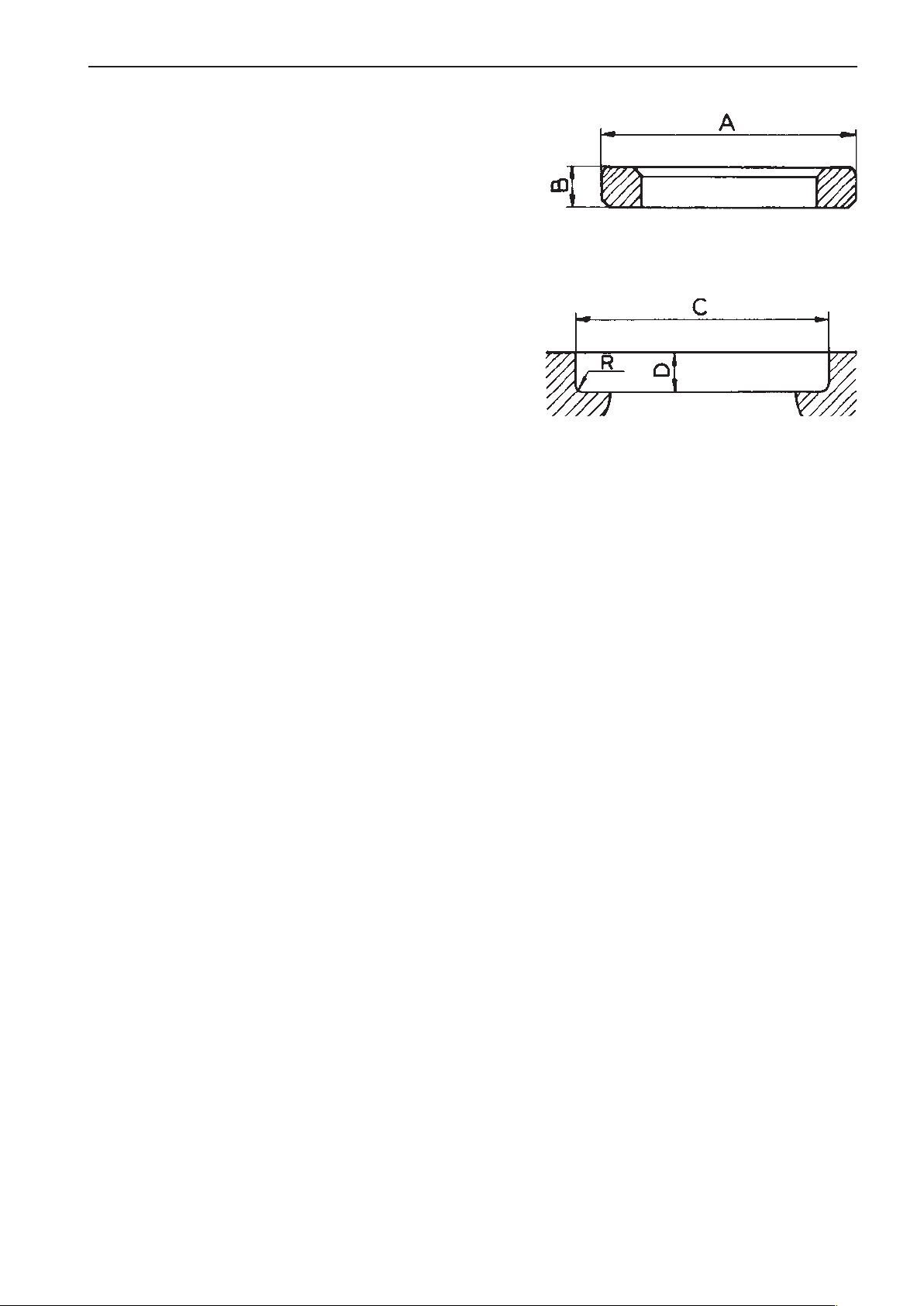

Valve seats

Outer diameter (dimension A) Standard:

Inlet .................................................................... 43.1 mm (1.697")

Exhaust .............................................................. 43.1 mm (1.697")

Oversize:

Inlet .................................................................... 43.3 mm (1.710")

Exhaust .............................................................. 43.3 mm (1.710")

Height (dimension B):

Inlet .................................................................... 8.4-8.6 mm (0.331–0.339")

Exhaust .............................................................. 7.9-8.1 mm (0.311–0.319")

Valve face seat

Diameter (dimension C) standard:

Inlet .................................................................... 43 mm (1.69")

Exhaust .............................................................. 43 mm (1.69")

Diameter (dimension C) oversize:

Inlet .................................................................... 43.200–43.225 mm (1.701–1.702")

Exhaust .............................................................. 43.200–43.225 mm (1.701–1.702")

Depth (dimension D):

Inlet .................................................................... 11.2±0.1 mm (0.441±0.004")

Exhaust .............................................................. 11.2±0.1 mm (0.441±0.004")

Seat bottom radius (dimension R):

Inlet. max. .......................................................... 0.8 mm (0.032")

Exhaust, max. .................................................... 0.8 mm (0.032")

Dimension between valve head and

cylinder head surface:

Inlet .................................................................... 0.9–1.4 mm (0.035–0.055")

Exhaust .............................................................. 1.2–1.7 mm (0.047–0.067")

Technical data

Valve guides

Length:

Inlet .................................................................... 83.2–83.5 mm (3.28–3.29")

Exhaust .............................................................. 83.2–83.5 mm (3.28–3.29")

Inner diameter:

Inlet .................................................................... 8.0 mm (0.032")

Exhaust .............................................................. 8.0 mm (0.032")

Height above cylinder head spring plane:

Inlet .................................................................... 26.5±0.4 mm (1.04±0.016")

Exhaust .............................................................. 18.5±0.4 mm (0.73±0.016")

Clearance, valve stem - guide:

Inlet .................................................................... 0.03–0.05 mm (0.001–0.002")

Wear tolerance ...................................................0.2 mm (0.008"

Exhaust .............................................................. 0.04-0.07 mm (0.002–0.003")

Wear tolerance ...................................................0.3 mm (0.012"

1

Max. permissible clearance between valve stem and valve guide:

(according to the method described in ”Service Manual Engine Group 21: valve guides, inspection”)

)1

)1

>| Ecu - Repair - Manual |<

9

Technical data

Valve springs

Valve springs, exhaust/inlet

Valve springs:

Length without load ............................................. 72-73 mm (2.8-2.9")

With 600 N (61.2 kgfm (134.6 lbs)) load ..............56 mm (2.2")

With 1076 N (109.7 kgfm (241.3 lbs)) load........... 43 mm (1.7")

Rigid length max. ................................................ 41 mm (1.6")

Inner valve spring (exhaust):

Length without load ............................................. 67-68 mm (2.6-2.7")

With 243 N (24.8 kgfm (54.6 lbs)) load ................ 52 mm (2.1")

With 447 N (45.6 kgfm (100.3 lbs)) load ..............39 mm (1.5")

Rigid length max. ................................................ 36 mm (1.4")

Timing

Group 20

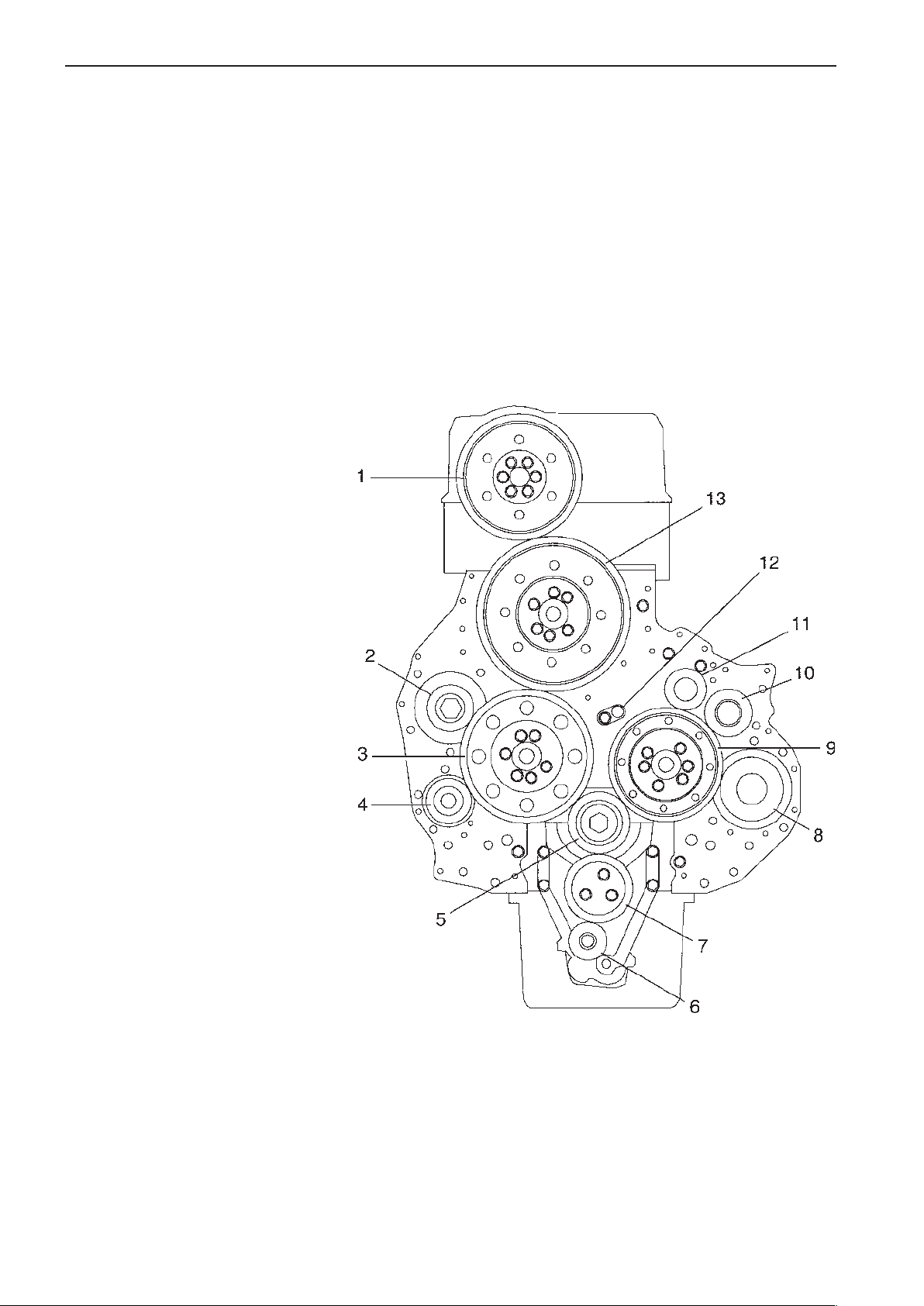

1. Drive, camshaft (z=76)

2. Drive, compressor (z=29)

3. Idler (z=83)

4. Drive, coolant pump (z=27)

5. Drive, crankshaft (z=38)

6. Drive, lubricating oil pump (z=23)

7. Idler (z=44)

8. Drive, hydraulic pump (z=39)

9. Idler (z=71)

10. Drive to belt and fuel pump (z=27)

11. Drive, servo pump (z=23)

12. Spray nozzle, drive lubrication

13. Idler, adjustable (z=97)

Flank clearance, adjustable intermediate gear (13) .. 0.05–0.17 mm (0.0020–0.0067")

Intermediate gear shaft journal, diameter ............... 99.99±0.01 mm (3.937±0.0004")

Intermediate gear bush, diameter ........................... 100.04±0.01 mm (3.939±0.0004")

Radial clearance for intermediate, max. diameter ...0.03–0.07 mm (0.0012–0.0028")

Axial clearance for intermediate gear ..................... 0.07–0.17 mm (0.0028–0.0067")

10

>| Ecu - Repair - Manual |<

Group 20

Technical data

Camshaft

Checking camshaft setting. The engine should be cold and the No. 1 cylinder valves should be adjusted to a

clearance of 0. At a flywheel position of 6° ATDC the No. 1 cylinder inlet valve should have opened 1.6±0.3 mm

(0.063±0.012").

When checking this the timing mechanism must be rotated in the right direction (clockwise viewed from the front)

to take up any backlash.

NOTE: Do not forget to adjust the valve clearance back to the correct value after the test.

Drive ...................................................................... Gears

Number of bearings ................................................ 7

Diameter of journals, standard ................................ 70 mm (2.76 ")

Diameter of journals, undersize:

0.25 .................................................................... 69.720–69.780 mm (2.7449–2.7472")

0.50 .................................................................... 69.470–69.530 mm (2.7350–2.7374")

0.75 .................................................................... 69.220–69.280 mm (2.7252–2.7276")

Wear tolerances

Axial clearance, max. ............................................ 0.35 mm (0.0014")

Radial clearance, max............................................ 0.01 mm (0.0004")

Valve lift:

Inlet .................................................................... 13.1 mm (0.516")

Exhaust .............................................................. 13.1 mm (0.516")

Unit injector (stroke) ...............................................17 mm (0.669")

Camshaft bearings

Camshaft bearing thickness, standard: .................. 1.9 mm (0.075")

Oversize:

0.25 .................................................................... 2.0 mm (0.079")

0.50 .................................................................... 2.2 mm (0.087")

0.75 .................................................................... 2.3 mm (0.091")

Diameter, camshaft bearing housings:

Bearings 1-7 ........................................................ 73.9 mm (2.91")

>| Ecu - Repair - Manual |<

11

Technical data

Crank movement

Crankshaft

Length .................................................................... 1203 mm (47.36")

Crankshaft axial clearance1.................................... 0.10–0.40 mm (0.0039–0.0157")

Main bearing radial clearance1................................ 0.01–0.15 mm (0.0004–0.0059")

Max. permissible ovality

of main bearing journals and crankpins .................. 0.08 mm (0.003")

Max. permissible conicity

of main bearing journals and crankpins .................. 0.05 mm (0.002")

Max. runout of centre bearing ................................. 0.15 mm (0.006")

1

The dimensions apply to oiled parts

Group 20

Main bearing journals

Diameter (Ø) for machining, standard ..................... 108.0 mm (4.25")

Undersize:

0.25 mm (0.010") ................................................107.73–107.75 mm (4.2413–4.2421")

0.50 mm (0.020") ................................................107.48–107.50 mm (4.2315–4.2323")

0.75 mm (0.030") ................................................107.23–107.25 mm (4.2216–4.2224")

1.00 mm (0.040") ................................................106.98–107.0 mm (4.2118–4.2126")

1.25 mm (0.050") ................................................106.73–106.75 mm (4.2020–4.2027")

Surface finish, main bearing journal ....................... Ra 0.25

Surface finish, radius ............................................. Ra 0.4

Width, thrust bearing journal (A) standard ............... 47.0 mm (1.85")

Oversize:

0.2 mm (0.008") (thrust bearing 0.1) .................... 47.175–47.225 mm (1.8573–1.8592")

0.4 mm (0.016") (thrust bearing 0.2) .................... 47.375–47.425 mm (1.8652–1.8651")

0.6 mm (0.024") (thrust bearing 0.3) .................... 47.575–47.625 mm (1.8730–1.8750")

Fillet radius (R)....................................................... 3.75–4.00 mm (0.148–0.158")

Thrust washers (thrust bearing)

Width (B) standard ................................................. 3.1–3.2 mm (0.122–0.126")

Oversize:

0.1 mm (0.004") .................................................. 3.2–3.3 mm (0.126–0.130")

0.2 mm (0.008") .................................................. 3.3–3.4 mm (0.130–0.134")

0.3 mm (0.012") .................................................. 3.4–3.5 mm (0.134–0.138")

12

>| Ecu - Repair - Manual |<

Group 20

Main bearing shells

Type ...................................................................... replaceable

Outer diameter (C) ................................................. 113.0 mm (4.45")

Thickness (D) standard .......................................... 2.5 mm (0.098")

Oversize:

0.25 mm (0.010") ................................................ 2.6–2.7 mm (0.102–0.106")

0.50 mm (0.020") ................................................ 2.7–2.8 mm (0.106–0.110")

0.75 mm (0.030") ................................................ 2.8–2.9 mm (0.110–0.114")

1.00 mm (0.040") ................................................ 2.9–3.0 mm (0.114–0.118")

1.25 mm (0.050") ................................................ 3.1–3.2 mm (0.122–0.126")

Crankpins

Diameter (Ø) for machining, standard ..................... 92.0 mm (3.62")

Undersize:

0.25 mm (0.010") ................................................ 91.73–91.75 mm (3.6114–3.612")

0.50 mm (0.020") ................................................ 91.48–91.50 mm (3.6016–3.6024")

0.75 mm (0.030") ................................................ 91.23–91.25 mm (3.5917–3.5925")

1.00 mm (0.040") ................................................ 90.98–91.00 mm (3.5819–3.5827")

1.25 mm (0.050") ................................................ 90.73–90.75 mm (3.5720–3.5728")

Surface finish, crankpin ......................................... Ra 0.25

Surface finish, radius ............................................. Ra 0.4

Width (A) thrust bearing journal .............................. 56.9–57.0 mm (2.240–2.244")

Fillet radius (R) (5.25–5.5) ...................................... 3.75–4.00 mm (0.148–0.158")

Technical data

Big-end bearing shells

Outside diameter (B) .............................................. 96.85 mm (3.8130")

Thickness (C) standard .......................................... 2.39–2.40 mm (0.0941–0.0945")

Oversize:

0.25 mm (0.010") ................................................ 2.51–2.52 mm (0.0988–0.0992")

0.50 mm (0.020") ................................................ 2.64–2.65 mm (0.1039–0.1043")

0.75 mm (0.030") ................................................ 2.76–2.77 mm (0.1087–0.1091")

1.00 mm (0.040") ................................................ 2.89–2.90 mm (0.1138–0.1142")

1.25 mm (0.050") ................................................ 3.01–3.02 mm (0.1185–0.1189")

Diameter, bearing shell seat (D) ............................. 96.84–96.85 mm (3.8126–3.8130")

>| Ecu - Repair - Manual |<

13

Technical data

Group 20

Connecting rod

Length, centre-to-centre (E) .................................... 260 mm (10.236")

Marking:

Connecting rod and cap1........................................ 1 to 6

”FRONT” on the shank to face ...............................Forwards

Connecting rod bush inside diameter (G) ................ 55 mm (2.165")

Axial clearance, big-end - crankshaft, max.2.......... 0.35 mm (0.014")

Big-end bearing, radial clearance, max.2................. 0.10 mm (0.004")

Straightness, max. deviation per 100 mm (3.94")

measured length .................................................... 0.06 mm (0.002")

Warping, max. deviation per 100 mm (3.94")

measured length .................................................... 0.15 mm (0.006")

1

Marking on same side

2

The measurements apply to oiled parts

Flywheel. fitted

Max. permissible axial runout,

test radius 150 mm (5.91") ...................................... 0.20 mm (0.008")

Number of teeth on starter ring ...............................153

Sensor grooves on flywheel ...................................3 x 18

14

>| Ecu - Repair - Manual |<

Group 20

Lubricating system

Oil grade Fuel sulphur content in per cent by weight

up to 0.5 % 0.5 - 1.0 % more than 1.0 %

Oil change interval: in operation whichever reached first

Technical data

VDS-3 600 hours or 12 months 300 hours or 12 months 150 thours or 12 months

VDS-2 and ACEA: E7

VDS-2 and ACEA: E5

VDS-2 and Global DHD-1

VDS-2 and API: CI-4

VDS-2 and API: CH-4

VDS and ACEA: E3

2)

2)

2)

2)

2)

2)

400 hours or 12 months 200 hours or 12 months 100 hours or 12 months

ACEA: E7, E5, E4 200 hours or 12 months 100 hours or 12 months 50 hours or 12 months

API: CI-4, CH-4, CG-4

NOTE! Mineral based oil, either fully or semi-synthetic, can be used on condition that it complies with the quality

requirements above.

NOTE! For 6 and 7-liter engines equipped with low profile type oil pans, the oil change interval must be halved.

1)

If the sulfur content is > 1.0% by weight, use oil with TBN > 15

2)

The engine oil must fullfil both requirements. For markets outside Europe, API: CG-4 and CH-4 can be used instead of

ACEA: E3.

VDS = Volvo Drain Specification

ACEA = Association des Constructeurs Européenne d’Automobiles

API = American Petroleum Institute

Global DHD = Global Diesel Heavy Duty

TBN = Total Base Number

Viscosity

The viscosity should be selected from the adjacent

table. Note: the temperatures refer to constant outside

air temperature.

* Refers to synthetic or synthetic-based oil.

Oil

Change volume including changing three filters:

For horizontal installation ....................................... 35 litres (9.2 US gal)

Oil pressure

Operating engine speed 1100 rpm or higher ........... 400–550 kPa (58–80 psi)

Idling speed, minimum ........................................... 175 kPa (25 psi)

Oil filters

Number .................................................................. 3

Full-flow filter (tightened 1/2–3/4 turn after fitting) ... 2

Bypass filter (tightened 3/4–1 turn after fitting) ....... 1

Oil pump

Type ...................................................................... Gear driven

>| Ecu - Repair - Manual |<

15

Technical data

Oil valves

Group 20

1. Safety valve

Marking ..................................................................Yellow

Safety valve opening pressure ............................... 700 kPa (101 psi)

2. Delivery valve, oil cooler

Marking ..................................................................124

Delivery valve, oil cooler, opening pressure ........... 300 kPa (43 psi)

3, 5. Overflow valve, oil filter, full-flow/by-pass

Marking on spring................................................... Blue/yellow

Overflow valve, oil filter, opening pressure ............. 110 kPa (16 psi)

Free length .............................................................68.8 mm (2.71")

Loaded with 25–29 N (2.5–2.9 kgf (5.5–6.4 lbs)) .....40.0 mm (1.58")

4. Piston cooling valve

Marking ..................................................................Orange

Piston cooling valve, opening pressure .................. 200 kPa (29 psi)

6. Pressure reducing valve

Marking ..................................................................Blue

Pressure reducing valve, opening pressure ............ 480 kPa (70 psi)

16

>| Ecu - Repair - Manual |<

Group 20

Fuel system

Technical data

Injection order

Injection order ........................................................1-5-3-6-2-4

Feed pump

Feed pressure after fuel filter at 1000 rpm, min. ..... 350 kPa (51 psi)

Feed pressure after fuel filter at full load, min. ....... 350 kPa (51 psi)

Overflow valve

Opening pressure ................................................... 400–450 kPa

(58–65 psi)

Sensor spacing

Camshaft ............................................................... 0.3–1.0 mm (0.012–0.040")

Flywheel ................................................................ 0.75–2.1 mm (0.030–0.083")

Unit injectors

Prestress (setting with gauge) ................................68.9±0.1 mm (2.712±0.004")

>| Ecu - Repair - Manual |<

17

Technical data

Group 20

Inlet and exhaust system

Engine ................................................................... TAD1240GE TAD1241GE/VE

TWD1240VE TAD1242GE/VE

Turbocharger

Manufacturer and type ........................................... 3K/Warner K31 3971 QXAKB K31 3971 QXAKB

24.20 DCAYD 27.20 DCAYD

Lubrication system ................................................ Force-feed lubrication

Max. permissible axial clearance ........................... 0.16 mm (0.0063")

Max. permissible radial clearance

(turbocharger side) ................................................ 0.45 mm (0.0177")

Pressure drop indicator

Air filter TAD1240-42GE TAD1241-42VE

TWD1240VE

Level for indication (vacuum) ................................. 500 mm (19.7") w.g.

Exhaust back pressure

Exhaust back pressure, max................................. 10 kPa 15 kPa

(1.5 psi) (2,2 psi)

Cooling system

General

Type ......................................................................Overpressure, closed

Pressure cap valve opens at ................................. 75 kPa (11 psi)

Capacity (engine) .................................................. 20 litres (5.3 US gal)

Capacity (engine + radiator and hoses) ................. 44 litres (11.6 US gal)

Thermostat TAD1240-42GE TWD1240VE

TAD1241-42VE

Type ......................................................................Piston thermostat

Number.................................................................. 1

Opening temperature ............................................. 82° C 75° C

(187°F) (167°F)

Coolant filter

Number.................................................................. 1

Coolant pump

Type ......................................................................Geared centrifugal pump

18

>| Ecu - Repair - Manual |<

Group 20

Technical data

Coolant

Type ...................................................................... Volvo Penta Coolant

Consisting of ..........................................................Ethylene glycol + corrosion inhibiting additives

Colour .................................................................... Blue-green

Mixed with .............................................................. Pure water

IMPORTANT! Coolant must be mixed with pure water, use distilled - de-ionized water. The water must fulfill the requirements specified by Volvo Penta, see “Water quality”.

IMPORTANT! Coolant must be used all year round. This applies even if there is never any risk for frost , to

ensure that the engine has an adequate protection against corrosion. Using anti-corrosion aditive exclusively

is not permitted in Volvo Penta’s engines. Never use water by itself as coolant.

Future warranty claims on the engine and additional equipment may be rejected if an unsuitable coolant has

been used or if the instructions concerning coolant mixing have not been followed.

Water quality

ASTM D4985:

Total solid particles ...................................... < 340 ppm

Total hardness: ............................................ < 9.5° dH

Chloride ......................................................... < 40 ppm

Sulfate ........................................................... < 100 ppm

pH value........................................................ 5,5– 9

Silica (acc. ASTM D859) .............................. < 20 mg SiO2/l

Iron (acc. ASTM D1068) .............................. < 0.10 ppm

Manganese (acc. ASTM D858) ................... < 0.05 ppm

Conductivity (acc. ASTM D1125) ................ < 500 µS/cm

Organic content, CODMn (acc. ISO8467) .... < 15 mg KMnO4/l

>| Ecu - Repair - Manual |<

19

Technical data

Tightening torques

General tightening torques Nm (kgfm)

M6 standard bolt 8.8 .............................................. 10±1.5 (1.0±0.15)

M8 standard bolt 8.8 .............................................. 24±4 (2.4±0.4)

M10 standard bolt 8.8 ............................................ 48±8 (4.8±0.8)

M12 standard bolt 8.8 ............................................ 85±15 (8.5±1.5)

M14 standard bolt 8.8 ............................................ 140±25 (14.0±2.5)

Special tightening torques Nm (kgfm) Angle tightening

Group 21

Front engine mounting, crossmember (M14) .......... 180±15 (18.0±1.5)

Front engine mounting (M16) .................................. 220±35 (22.0±3.5)

Rear engine mounting, flywheel housing (M16) ....... 220±35 (22.0±3.5)

Main bearings

Stage 1 .................................................................. 150±20 (15.0±2.0)

Stage 2 .................................................................. 120°±5°

Big-end cap ............................................................ 275±12 (27.5±1.2)

Flywheel

(see tightening diagram ”Flywheel” page 22) ........... 245 +24.5

Flywheel housing ................................................... 140±14 (14.0±1.4)

Vibration damper, inner (2 socket cap screws)

Stage 1 .................................................................. 60±5 (6.0±0.5)

Stage 2 .................................................................. 90°±5°

Vibration damper outer or Pulley

(10 bolts, see tightening diagram

”Outer vibration damper” page 24)

Stage 1 .................................................................. 60±5 (6.0±0.5)

Stage 2 .................................................................. 90°±5°

Rocker cover (see tightening diagram

”Rocker cover” page 22) ......................................... 20±2 (2.0±0.2)

Stud, rocker cover ................................................. 40±3 (4.0±0.3)

Cylinder head (see tightening diagram

”Cylinder head” page 23)

Stage 1 .................................................................. 60±10 (6.0±1.0)

Stage 2 (check tightening) ..................................... 60±10 (6.0±1.0)

Stage 3 .................................................................. 90°±5°

Stage 4 .................................................................. 90°±5°

Clean-out plugs, cylinder head ............................... 60±10 (6.0±1.0)

Lock nut, valve adjustment bolt ............................. 38±4 (3.8±0.4)

- 0

+25

- 0

+2,5

Group 20

20

>| Ecu - Repair - Manual |<

Group 20

Special tightening torques

Bolts for camshaft bearing caps should be tightened in 5 stages, see tightening diagram “Bearing caps, camshaft/

rocker arm shaft” page 23.

Timing cover, upper (see tightening diagram ”Timing cover, upper” page 25)

Timing gear incl. toothed wheel (see tightening diagram ”Timing gear” page 25)

Nm (kgfm) Angle tightening

Timing plate (see ”Timing plate” page 24) ............. 34±4 (3.4±0.4)

Group 22

Oil nozzle in timing gear

(see ”Timing gear” page 25).................................... 34±4 (3.4±0.4)

Oil cooler, retaining bolts ........................................ 27±4 (2.7±0.4)

Cover, oil cooler (see tightening diagram

”Cover, oil cooler” page 27) ................................... 24±4

Delivery oil pipe (see ”Delivery oil pipe” page 26) .. 180° new pipe 60° used pipe

Bolt, piston cooling nozzle

(see Piston cooling nozzle” page 26) ...................... 24±4 (2.4±0.4)

Drain plug, oil sump ............................................... 60±10 (6.0±1.0)

Technical data

Group 23

Bolt, retaining yoke, unit injector

(new copper sleeve)

First tightening

Stage 1 .................................................................. 20±5 (2.0±0.5)

Stage 2 .................................................................. 180°±5°

Undo the bolt for the unit injector retaining yoke

before the second tightening

Second tightening

Stage 1 .................................................................. 20±5 (2.0±0.5)

Stage 2 .................................................................. 60°±5°

Bolt, retaining yoke, unit injector

(old copper sleeve)

Stage 1 .................................................................. 20±5 (2.0±0.5)

Stage 2 .................................................................. 60°±5°

Lock nut for adjusting screw, unit injector .............. 52±4 (5.2±0.4)

Nut, connection, unit injector .................................. 1.5±0.5 (0.15±0.05)

Clamping and tightening torques for fuel lines

(see ”Fuel lines” page 28).

IMPORTANT! Pay attention and do NOT tighten the nut for the electrical

connections (on the unit injector) to a higher torque than specified above.

>| Ecu - Repair - Manual |<

21

Technical data

Tightening diagram

Flywheel

Group 20

Rocker cover

22

>| Ecu - Repair - Manual |<

Group 20

Cylinder head

Technical data

Bearing caps, camshaft/rocker arm shaft

NOTE: Tightening in stage 2 should be carried out gradually to ensure that the rocker arm shaft bottoms against

the bearing housings without bending.

NOTE: In stage 4 undo the marked bolts before continuing to stage 5. If the rocker arm shaft has been loosened

or removed, only the bolts retaining the shaft should be tightened according to the diagram on refitting.

>| Ecu - Repair - Manual |<

23

Technical data

Timing plate

Group 20

Centre the plate using tool 9998267. No special tightening sequence for marked bolts.

Outer vibration damper

24

>| Ecu - Repair - Manual |<

Group 20

Timing cover, upper

Technical data

Timing

>| Ecu - Repair - Manual |<

25

Technical data

Piston cooling nozzle

NOTE: The piston cooling nozzle retaining bolt has a

friction coating and can be used only once.

IMPORTANT! Incorrect piston cooling always

leads to seizing of the piston or pistons. If it is

suspected that the piston cooling nozzle could

be damaged or deformed it must be changed.

This applies to new nozzles also. Always check

that the piston cooling nozzle is correctly located in the hole in the cylinder block and that the

retaining plate lies flat against the cylinder block.

If the piston cooling nozzle is not correctly fitted, engine breakdown when under load will be

the immediate result.

Delivery oil pipe

Tighten to ”0 clearance” and then angle tighten 60º for

a used delivery oil pipe and 180º for a new delivery oil

pipe.

Group 20

26

>| Ecu - Repair - Manual |<

Group 20

Cover, oil cooler

Always use locating pins when positioning the cover on the engine.

Technical data

1 Insert screws A and B to align the cover.

2 Tighten screws C and D.

3 Insert all screws, tighten the screws in numerical order from the center outwards, in accordance with the

diagram (1 - 4).

4 Check screws C and D for tightness.

>| Ecu - Repair - Manual |<

27

Technical data

Fuel lines TAD

Group 20

A. Banjo bolt 34±4 Nm (25±3 lbf. ft)

B. Nipple 14±3 Nm (10±2.2 lbf. ft)

C. Overflow valve 55±5 Nm (41±3.7 lbf. ft)

D. Banjo bolt 35±4 Nm (26±3 lbf. ft)

E. Nut 65±5 Nm (48±3.7 lbf. ft)

F. Nut 65±5 Nm (48±3.7 lbf. ft)

G. Banjo bolt 15±2.5 Nm (11±1.8 lbf. ft)

1 H. Bolt 55±5 Nm (41±3.7 lbf. ft)

28

>| Ecu - Repair - Manual |<

Group 20

Fuel lines TWD

Technical data

A. Overflow valve 55±5 Nm (41±3.7 lbf ft)

B. Banjo bolt 35±5 Nm (26±3.7 lbf ft)

C. Nut 65±5 Nm (48±3.7 lbf ft)

D. Nut 65±5 Nm (48±3.7 lbf ft)

E. Banjo bolt 15±2 Nm (11±1.5 lbf ft)

1 F. Banjo bolt 34±4 Nm (25±3 lbf ft)

2 G. Hose connection 55±5 Nm (41±3.7 lbf ft)

>| Ecu - Repair - Manual |<

29

Exhaust manifold

Stage 1. Tighten bolts 1 to 10 Nm (0.7 to 7.4 lbf.ft) (max.)

Stage 2. Tighten bolts 2 to 10 Nm (1.5 to 7.4 lbf.ft) (max.)

Stage 3. Tighten bolts 3 to 52 ±4 Nm (2.2 to 38 ±3 lbf.ft)

Stage 4. Tighten bolts 2 to 52 ±4 Nm (1.5 to 38 ±3 lbf.ft)

Group 20

Stage 5. Tighten bolts 4 to 52 ±4 Nm (3.0 to 38 ±3 lbf.ft)

Stage 6. Tighten bolts 1 to 52 ±4 Nm (0.7 to 38 ±3 lbf.ft)

Intercooler (TWD)

Tightening diagram

Tightening is done in two stages, in accordance with the tightening diagram.

Stage 1. Insert all of the screws; screw them down until they touch the surface.

Stage 2. Tighten the screws in accordance with the tightening diagram, to a torque of 20 ±2 Nm (14.7 ±1.5 lb. ft.).

30

>| Ecu - Repair - Manual |<

Group 20

References to Service Bulletins

Group No. Date Concerning

.........................................................................................................................................................................................

.........................................................................................................................................................................................

.........................................................................................................................................................................................

.........................................................................................................................................................................................

.........................................................................................................................................................................................

.........................................................................................................................................................................................

.........................................................................................................................................................................................

.........................................................................................................................................................................................

.........................................................................................................................................................................................

.........................................................................................................................................................................................

.........................................................................................................................................................................................

.........................................................................................................................................................................................

.........................................................................................................................................................................................

.........................................................................................................................................................................................

.........................................................................................................................................................................................

.........................................................................................................................................................................................

.........................................................................................................................................................................................

.........................................................................................................................................................................................

.........................................................................................................................................................................................

.........................................................................................................................................................................................

.........................................................................................................................................................................................

.........................................................................................................................................................................................

.........................................................................................................................................................................................

.........................................................................................................................................................................................

.........................................................................................................................................................................................

.........................................................................................................................................................................................

.........................................................................................................................................................................................

.........................................................................................................................................................................................

.........................................................................................................................................................................................

.........................................................................................................................................................................................

.........................................................................................................................................................................................

.........................................................................................................................................................................................

.........................................................................................................................................................................................

>| Ecu - Repair - Manual |<

31

Group 20

Notes

.........................................................................................................................................................................................

.........................................................................................................................................................................................

.........................................................................................................................................................................................

.........................................................................................................................................................................................

.........................................................................................................................................................................................

.........................................................................................................................................................................................

.........................................................................................................................................................................................

.........................................................................................................................................................................................

.........................................................................................................................................................................................

.........................................................................................................................................................................................

.........................................................................................................................................................................................

.........................................................................................................................................................................................

.........................................................................................................................................................................................

.........................................................................................................................................................................................

.........................................................................................................................................................................................

.........................................................................................................................................................................................

.........................................................................................................................................................................................

.........................................................................................................................................................................................

.........................................................................................................................................................................................

.........................................................................................................................................................................................

.........................................................................................................................................................................................

.........................................................................................................................................................................................

.........................................................................................................................................................................................

.........................................................................................................................................................................................

.........................................................................................................................................................................................

.........................................................................................................................................................................................

.........................................................................................................................................................................................

.........................................................................................................................................................................................

.........................................................................................................................................................................................

.........................................................................................................................................................................................

.........................................................................................................................................................................................

.........................................................................................................................................................................................

.........................................................................................................................................................................................

.........................................................................................................................................................................................

32

>| Ecu - Repair - Manual |<

Group 20

Notes

.........................................................................................................................................................................................

.........................................................................................................................................................................................

.........................................................................................................................................................................................

.........................................................................................................................................................................................

.........................................................................................................................................................................................

.........................................................................................................................................................................................

.........................................................................................................................................................................................

.........................................................................................................................................................................................

.........................................................................................................................................................................................

.........................................................................................................................................................................................

.........................................................................................................................................................................................

.........................................................................................................................................................................................

.........................................................................................................................................................................................

.........................................................................................................................................................................................

.........................................................................................................................................................................................

.........................................................................................................................................................................................

.........................................................................................................................................................................................

.........................................................................................................................................................................................

.........................................................................................................................................................................................

.........................................................................................................................................................................................

.........................................................................................................................................................................................

.........................................................................................................................................................................................

.........................................................................................................................................................................................

.........................................................................................................................................................................................

.........................................................................................................................................................................................

.........................................................................................................................................................................................

.........................................................................................................................................................................................

.........................................................................................................................................................................................

.........................................................................................................................................................................................

.........................................................................................................................................................................................

.........................................................................................................................................................................................

.........................................................................................................................................................................................

.........................................................................................................................................................................................

.........................................................................................................................................................................................

.........................................................................................................................................................................................

>| Ecu - Repair - Manual |<

33

Group 20

34

>| Ecu - Repair - Manual |<

Report form

Do you have any complaints or other comments about this manual. Please

make a copy of this page, write your comments down and send them to us. The

address is at the bottom. We would prefer you to write in English or Swedish.

From: ............................................................................

......................................................................................

......................................................................................

......................................................................................

Refers to publication:.............................................................................................................................................

Publication No.: ............................................................. Date of issue: .................................................................

Proposal/motivation: ..............................................................................................................................................

..............................................................................................................................................................................

..............................................................................................................................................................................

..............................................................................................................................................................................

..............................................................................................................................................................................

..............................................................................................................................................................................

..............................................................................................................................................................................

..............................................................................................................................................................................

..............................................................................................................................................................................

Date: ................................................................

Signed: .............................................................

AB Volvo Penta

Technical Information

Dept. 42200

SE-405 08 Göteborg

Sweden

>| Ecu - Repair - Manual |<

>| Ecu - Repair - Manual |<

7741112 English 05–2006

Loading...

Loading...