Volvo Truck Quality Manual

1 Introduction

1

2 Parking

2

3 General requirements

3

4

4 Loading / unloading operation

5

Transport by jockeys

6

5 Securing / lashing / support onboard carrier

7

6 Loading / unloading operation Lo/Lo

8

7 Damages

9

Quality audits

1

Issue 2/2010-01-01

VLC Dept 73400 Fle-122

1

Table of contents

1 Introduction 4

2 Parking 5

2.1 Parking requirements 5

2.2 Parking routines 5

2.3 Distances between parked vehicles 6

2.4 Slippery prevention 6

2.5 Snow & ice 6

3 General requirements 7

Trucks related

3.1 Tow / jump start 7

3.2 Starting with starting cables 8

3.3 Mechanical problems 10

3.4 Start the engine 10

3.5 Batteries 13

3.6 Central locking 15

3.7 Gearboxes 17

3.8 Ad Blue (Urea solution) 19

3.9 Air suspension 21

3.10 Airbag 22

Driver related

3.11 Clothing 22

3.12 Drawing / marking / attaching 22

3.13 Miscellaneous 24

3.14 Some driving advice 25

4 Loading / unloading operation Ro/Ro 26

4.1 Distances between stowed trucks 26

4.2 Preparation of ship / trailer 26

4.3 Driving behaviour in port area or terminal 27

4.4 Driving behaviour onboard ship 27

4.5 Parking routines onboard ship 28

4.6 Stowing onboard ship 28

4.7 Lashing / unlashing routine 29

4.8 General condition 29

4.9 Ramps and loading platform 29

4.10 Lashing equipment 30

4.11 Attachment of lashing sling 31

4.12 Lashing of trucks 31

5 Transport by jockeys 33

5.1 General 33

5.2 Driving behaviour 33

5.3 Mechanical problems 33

Issue 2/2010-01-01

VLC Dept 73400 Fle-122

Page 2 of 47

2

6 Securing / lashing / support onboard carrier 34

6.1 Introduction to this chapter 34

6.2 Wheel chocks 34

6.3 Wheel lashings 34

6.4 Lashing on tyres 35

6.5 Lashing on rims 35

6.6 Lashing around the axles 35

6.7 Lashing around the rear stabilizer 34

6.8 Use of supports 34

6.9 Securing carrier ramps 37

6.10 Lashing 37

6.11 Dismounting of parts 38

7 Loading / unloading operation Lo/Lo 43

7.1 Introduction to this chapter 43

7.2 Lifting instructions 43

7.3 Lashing methods for trucks piggyback 45

8 Damages 46

9 Quality audits 46

Issue 2/2010-01-01

VLC Dept 73400 Fle-122

Page 3 of 47

3

INTRODUCTION

1

These requirements are valid for all kind of distribution activities of Volvo Trucks including

loading/unloading as well as other types of handling performed in ports, stopovers or

terminals. The instruction applies to all Volvo Logistics contracted parties.

These requirements also apply for all other brands which are handled under the

responsibility of Risk Management Department.

These requirements are Volvo’s minimum demands.

Each transport company can issue their own requirements, but must be in accordance with

Volvo’s. If any kind of handling instruction are issued a copy must be sent to Volvo

Logistics Risk Management Dept.

Please note that these requirements do not in any way supersede the regulations

stipulated by various authorities.

Random inspections and planned audits will be made continuously within all areas,

terminals, ports, carriers, and vessels.

Detected remarks will be reported to the responsible persons at the contracted party.

The contracted party is responsible for ensuring that all involved personnel is notified and

aware of these requirements.

All product training for personnel should be stated in writing.

Training records must be maintained and updated, and to be handed

over to Volvo Logistics upon request.

The handling instruction provided by VLC will be updated on an

ongoing basis. Always search at Volvo Logistics website for the latest edition available

VOLVO LOGISTICS CORPORATION

Risk Management Department

http://www.volvo.com/logistics/global/en-gb

Issue 2/2010-01-01

VLC Dept 73400 Fle-122

4

Page 4 of 47

2 Parking

2.1 Parking requirements

All parking areas and roadways:

• must be well separated from other activities

• must be free from any object that may damage the vehicles

• must be cleaned up regularly

• must be covered with hard surface, asphalt or similar

• must be well drained

• must be fenced, guarded and well litt

• must be equipped with an efficient drive-through protection to

prevent theft

• must have alarm system or camera surveillance

• must be pot hole free

• all vegetation must be systematically removed from the compounds and their

immediate surroundings

• must be divided into separate areas dedicated to :

Truck storage and truck loading / unloading

The trucks should be parked away from sources of emission that could contaminate them.

When parking in loadlines we recommend that all trucks are parked with the driver side

wheels on the marked line in order to get straight rows.

2.2 Parking routines

Make sure that;

• parking brake is in on-position

• transmission is in N position

• all windows, doors etc. are closed

• wiper blades are in rest position

• ignition and all electric devices are switched off

• electric main switch is in off-position

• key in ignition or according to respective yards routine

Issue 2/2010-01-01

VLC Dept 73400 Fle-122

5

Page 5 of 47

2.3 Distances between parked vehicles

Minimum distances between parked trucks :

- Between sides 1 metre (40 inches)

- Between vehicles lengthwise minimum 30 cm (12 inches)

Driver’s door must be opened into an open space.

2.4 Slippery prevention

Avoid using stone chips for slippery prevention. Salt to be used with caution, avoid salt at

parking areas. Ports located in areas, requiring slippery prevention, must have valid and

updated routines for this. Used slippery prevention material such as sand must be cleaned

up as soon as the weather allows it.

2.5 Snow and ice

Snow on parking areas must be removed before the vehicles are parked. Snow to be taken

away with proper equipment. Rotating brushes or snow throwers are not to be used close

to the vehicles.

Issue 2/2010-01-01

VLC Dept 73400 Fle-122

6

Page 6 of 47

3

General requirements

3.1 Tow/jump start

It is absolutely forbidden to use trucks aimed for distribution for towing or to jump-start a

non-starter. If the battery is low, use help-batteries or battery from a service car.

Non-starter should only be handled by authorized personnel and follow instructions.

Issue 2/2010-01-01

VLC Dept 73400 Fle-122

7

Page 7 of 47

3.2 Starting with starting cables

1 Turn the ignition key to 0 position.

2 Make sure that the help start battery

has 24 V total voltage or 24 V system

voltage.

3 Switch the engine of the “assisting

vehicle” off, and make sure that the

vehicles do not touch one another.

4 Connect one of the clamps on the red

cable to the positive terminal on the help

battery. The positive pole is marked in

red, P or +.

5 Connect the other clamp on the red

cable to the positive terminal on the

battery of the vehicle that needs help.

The positive pole is marked in red, P

or +.

6 Connect one clamp on the black cable

to the negative terminal of the help

battery marked in blue, N or -.

7 Connect the other clamp on the black

cable to a place - an earth - some

distance from the battery of the vehicle

which needs help.

8 Start the engine of the “assisting

vehicle”. Let the engine run for some

minutes at a higher idle speed than

normal (about 1000 rpm).

9 Start the engine on the other vehicle.

10 Remove the clamp on the black cable

from the earth point.

11 Remove the clamp on the black cable

from the negative terminal on the help

battery.

12 Remove the red cable.

Do not use a start help unit as these can

supply extremely high voltages which can

damage control units

CAUTION

Note: After the truck has been started by using starting cables, the batteries should

be charged using a battery charger. It takes about 20 hours to fully charge a battery.

An alternator can never charge the battery to 100%; in favourable circumstances a

maximum level of 90% can be achieved. Refer to the “Electrical system” section in

the “Driver’s Manual, maintenance” for more information.

Issue 2/2010-01-01

VLC Dept 73400 Fle-122

8

Page 8 of 47

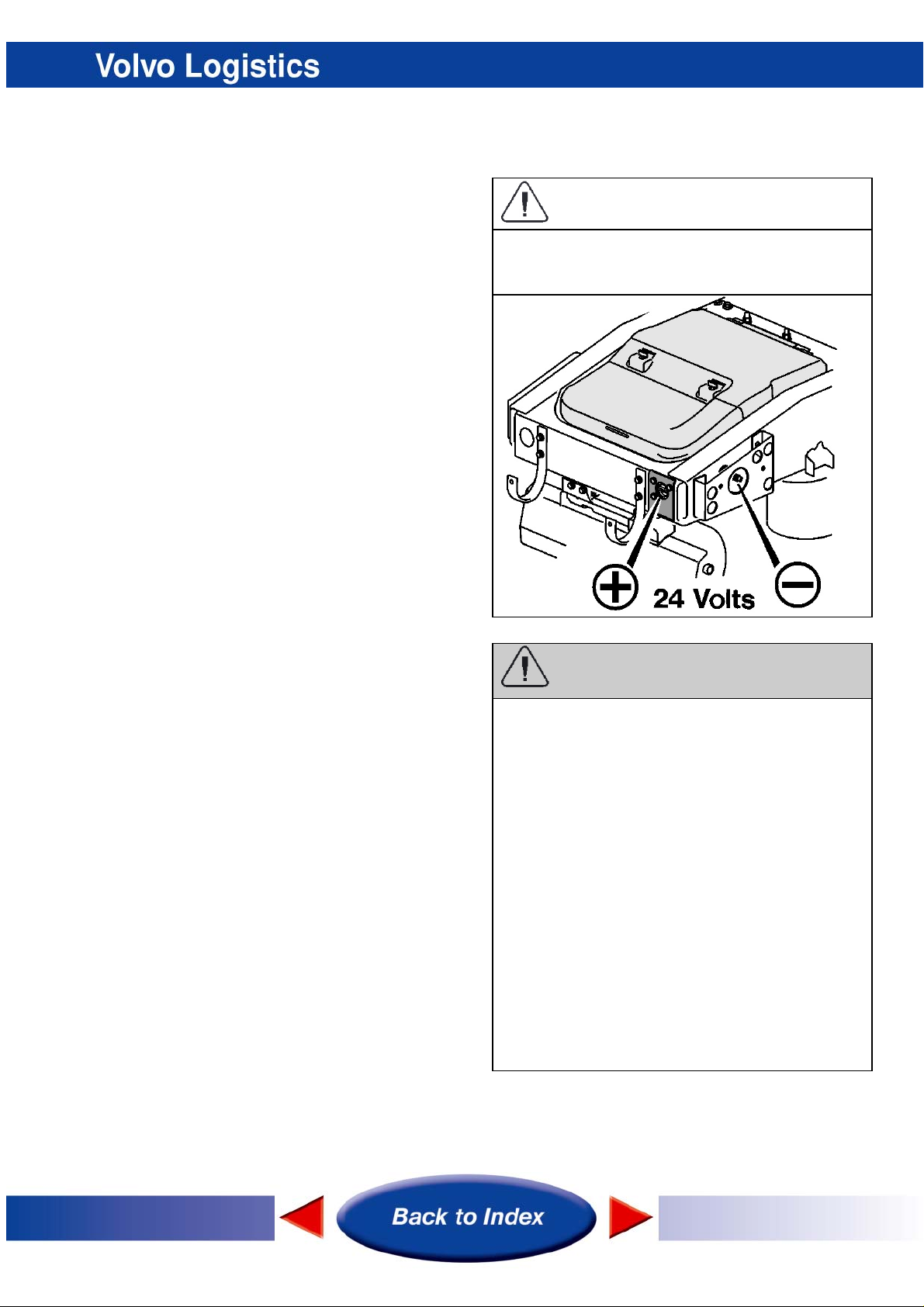

Starting with starting cables, battery box at the rear

Always use another vehicle or other batteries

to help start the engine

The starting cables should be able to handle

1000 A for at least 30 seconds.

1 Turn the ignition key to 0 position.

2 Make sure that the help start battery

has 24 V total voltage or 24 V system

voltage.

3 Switch the engine of the “assisting

vehicle” off, and make sure that the

vehicles do not touch one another.

4 Connect one of the clamps on the red

cable to the positive terminal on the help

battery. The positive pole is marked in

red, P or +.

5 Connect the other clamp on the red

cable to the positive terminal on the

battery of the vehicle that needs help.

The positive pole is marked in red, P

or +.

6 Connect one clamp on the black cable

to the negative terminal of the help

battery marked in blue, N or -.

7 Connect the other clamp on the black

cable to a place - an earth - some

distance from the battery of the vehicle

which needs help.

8 Start the engine of the “assisting

vehicle”. Let the engine run for some

minutes at a higher idle speed than

normal (about 1000 rpm).

9 Start the engine on the other vehicle.

10 Remove the clamp on the black cable

from the earth point.

11 Remove the clamp on the black cable

from the negative terminal on the help

battery.

12 Remove the red cable.

Note: After the truck has been started by using

starting cables, the batteries should

be charged using a battery charger. It takes

about 20 hours to fully charge a battery.

An alternator can never charge the battery

to 100%; in favourable circumstances a

maximum level of 90% can be achieved.

Refer to the “Electrical system” section in

the “Driver’s Manual, maintenance” for

more information.

Issue 2/2010-01-01

VLC Dept 73400 Fle-122

Do not use a start help unit as these can

supply extremely high voltages which can

damage control units.

Batteries contain oxyhydrogen gas which

is very explosive. A spark, which can

ignite if you connect the starting cables

incorrectly, or if they are moved around

during the starting procedure, is

sufficient

for the battery to explode and cause

serious damage and injury. Batteries

contain sulphuric acid, which can cause

serious corrosion damage. If the acid

gets

in your eyes, skin or clothes, rinse with

large amounts of water. If the acid gets

in

your eyes, get medical attention at once.

Do not lean over the batteries.

CAUTION

WARNING

9

3.3 Mechanical problems

If a mechanical problem occurs during distribution at harbour or terminal

contact Volvo Action Service.

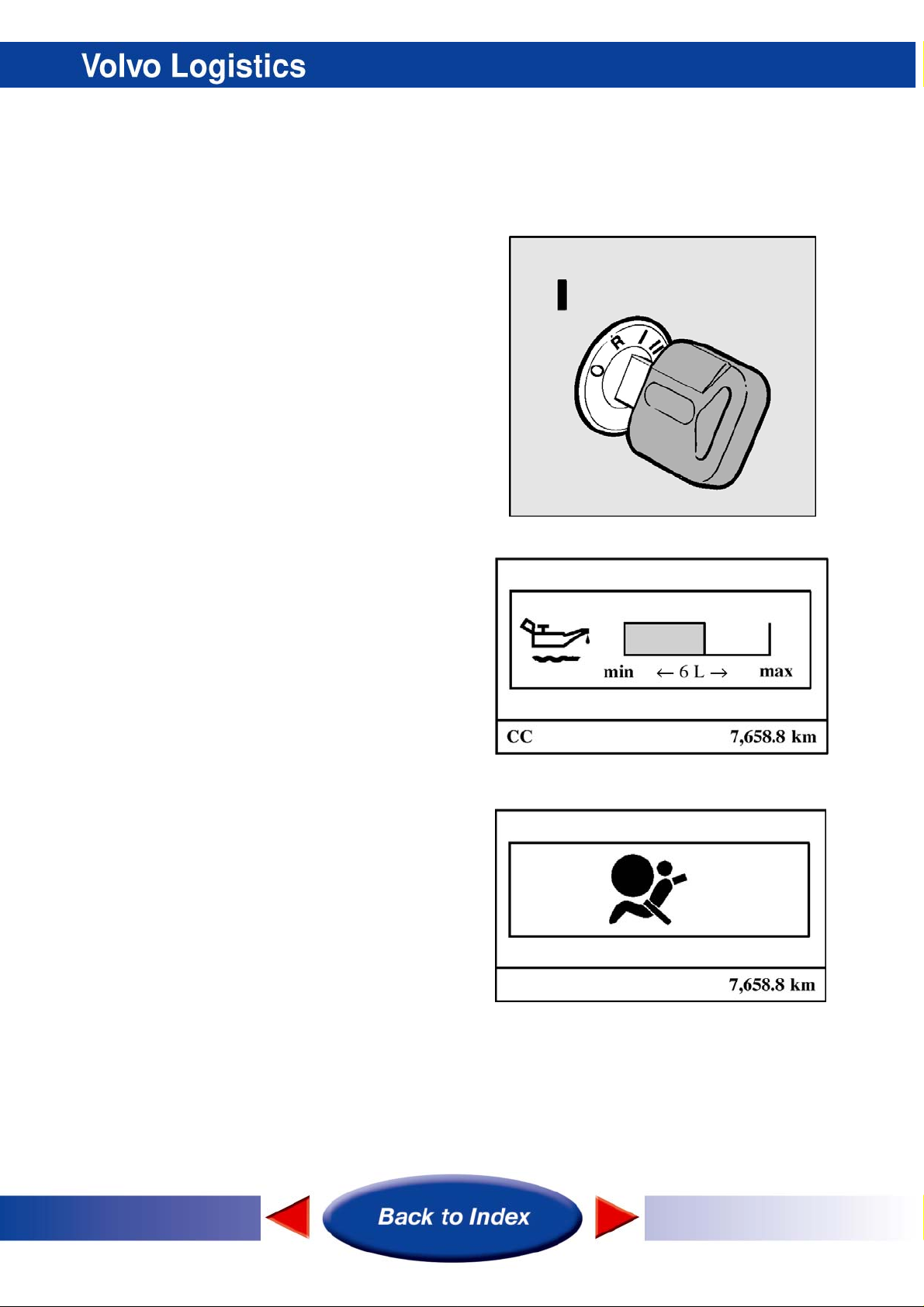

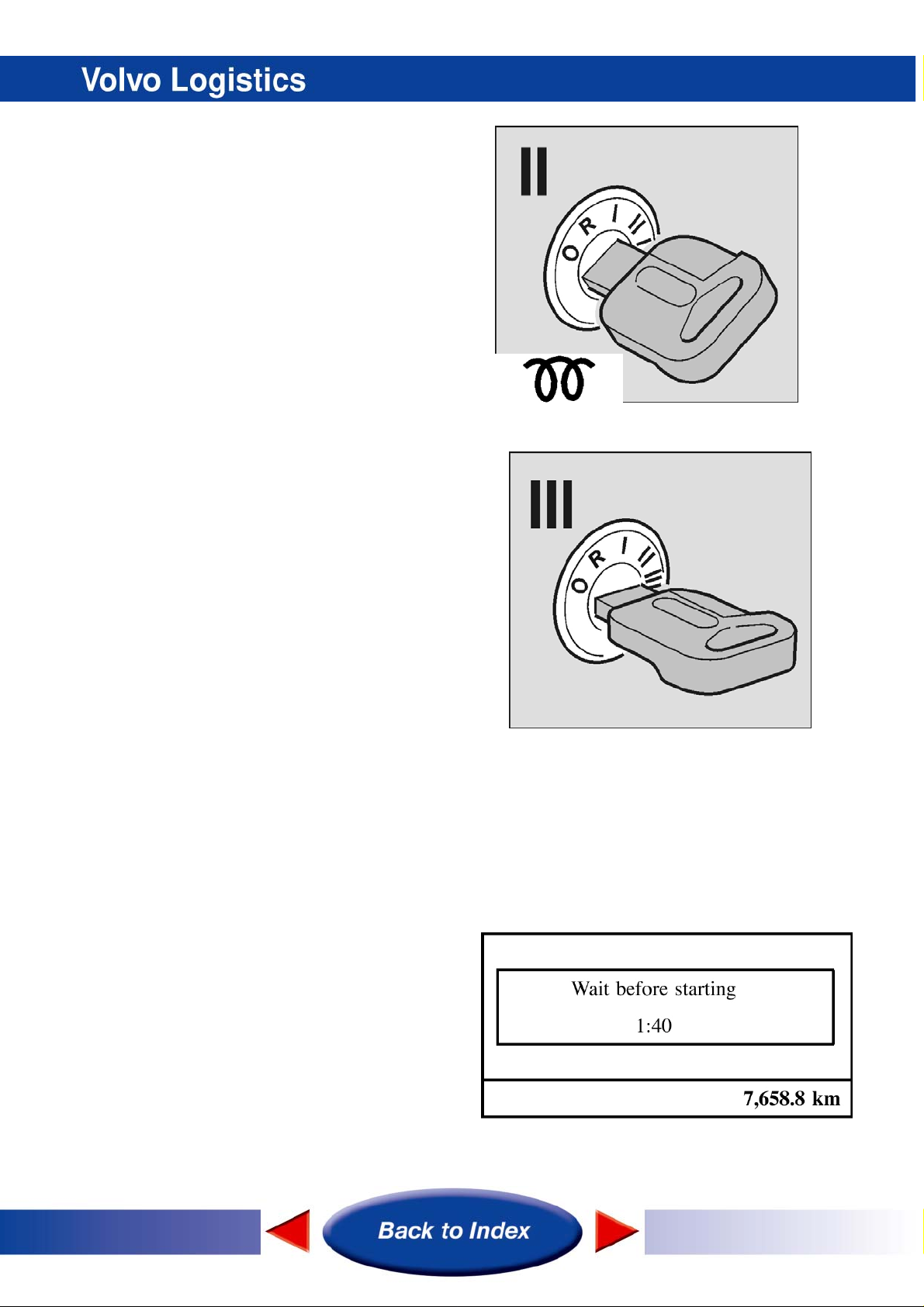

3.4 Start the engine

1 Turn on the main switch.

2 Check that

• the parking brake is applied

• the gearbox is in neutral

• the auxiliary brake is in position 0

3 Turn the starter key to the drive position

Note: If the key is turned straight from

the off position to the start position on

trucks with D13 engines, there is a delay of

about one second before the starter motor is

activated. During this time the starter motor

shows no response as it is activated via

EMS. When the key is turned from ignition

position to start, there is no delay.

4 The display shows the engine oil level.

If the engine has been running during the

last 20 minutes, nothing is shown. The value

shown under the graph is the difference

between the engine max and min oil volumes.

5 If the truck has air bags, the symbol for

this is shown on the display.

Issue 2/2010-01-01

VLC Dept 73400 Fle-122

10

Page 10 of 47

6 Check that all the instrument panel lamps

are working

7 If the engine has pre-heating, turn the start

key to pre-heating position and release the

key

8 Wait until the pre-heating symbol goes out.

9 Start the engine

Run the starter motor by holding the key

in the start position for a maximum of

30 seconds. If the engine has not started

within 30 seconds: Turn the key to the radio

position and wait for 15 seconds before

trying to start again.

The following applies for D13: Run the

starter motor by holding the key in the start

position. If the engine does not start, the

starting attempt will be automatically shut

off after 15 seconds. A new attempt can be

made by turning the key back to 0 position

and then again to start position.

Note: The starter motors on the D12 and

D13 engines have automatic overheating

protection.

If the overheating protection cuts in on trucks

with a D12 engine, the starter motor must

cool down for 3 -15 minutes before a new

attempt can be made.

If the overheating protection cuts in on trucks

with a D13 engine, a message is displayed to

verify this. The message shows how long the

starter motor must be allowed to cool before

it will be possible to try to start the truck

again, usually 10–15 minutes.

Issue 2/2010-01-01

VLC Dept 73400 Fle-122

11

Page 11 of 47

10 Hold down the brake pedal for a few

seconds to enable the cruise control

The air suspension is activated first after

the parking brake is released or if the air

suspension control box is used.

If the temperature of the coolant is below

50 C when the engine is switched on, the

engine speed will be limited to 1000 rpm for

15 seconds

Warming up

Warm the engine up by driving with low

engine speed rather than running the

engine while stationary. Avoid revving up

excessively and high engine speed.

After starting let the clutch out in order to

warm up the gearbox. The oil pump in the

gearbox will begin working and will quickly

attain working temperature.

Note: It is especially important that the

gearbox is warmed up if the outside

temperature is below 0 C.

WARNING

Do not use start gas. An explosion can

cause considerable damage.

Blocking valve

If the pressure in the braking system is too

low, for example if the truck has been parked

for a long period of time, the blocking valve

must be pushed in for the parking brake to be

released. Before the blocking valve can be

pushed in the pressure in the braking system

must exceed about 5 bar.

Issue 1/2008-06-01

Issue 2/2010-01-01

VLC Dept 73400 Fle-122

VLC Dept 73400 Fle-122

6

12

Page 12 of 47

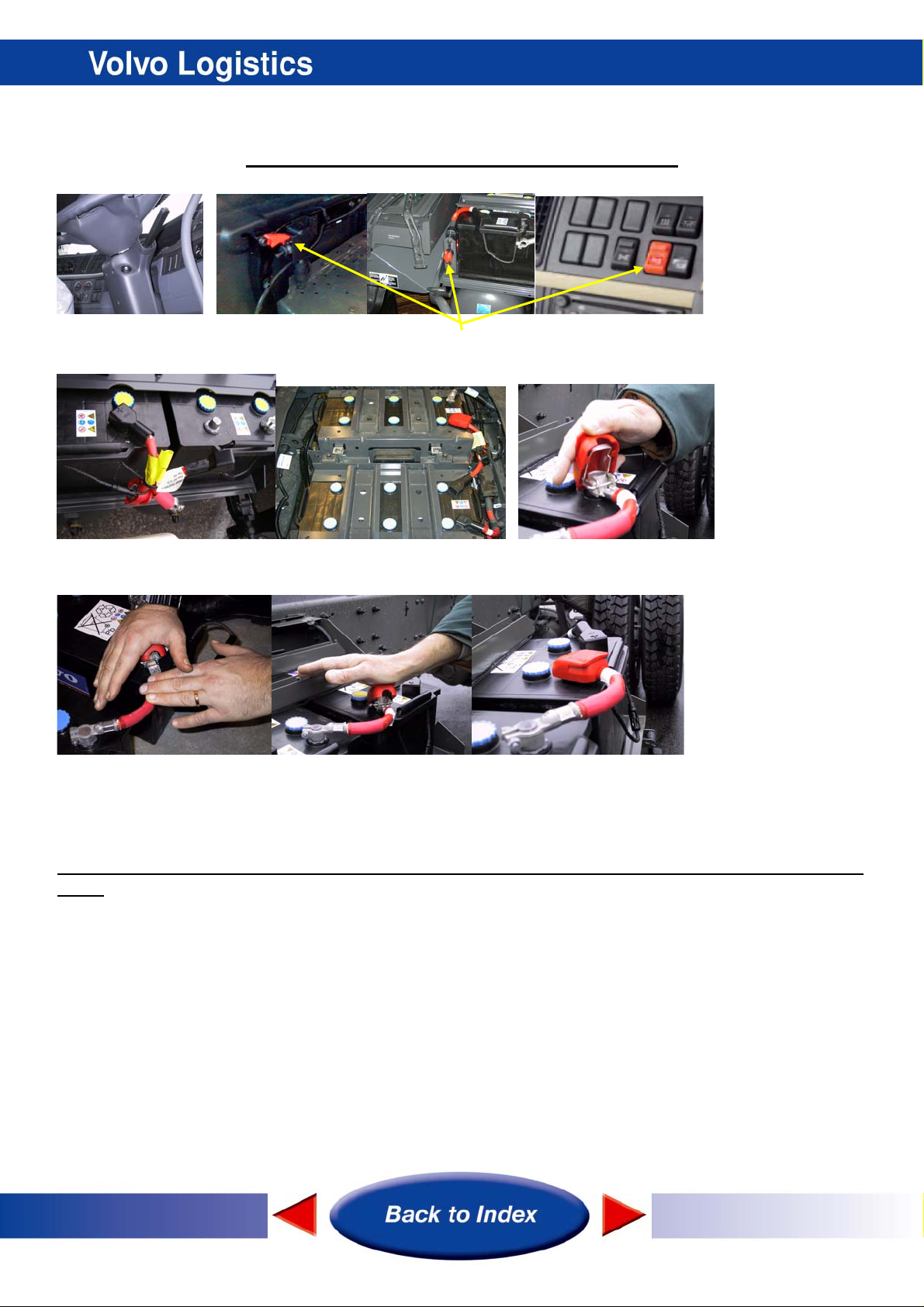

3.5 Batteries

Before start the vehicle = reconnect the batteries

Verify that ignition and main switches are placed in off mode before re-connecting batteries

Battery boxes found at side of the frame or rear end of frame. Re-connect Press down to bottom

Important!! Press down the cable Lock secure Correct position

Always disconnect the electrical main switch when parking the truck

Disconnect the quick-lock at battery if the truck is parked/stored/stowed/transported more then 36

hours

Issue 2/2010-01-01

VLC Dept 73400 Fle-122

Page 13 of 47

13

A

NOTE For Euro 4/5 trucks!

The UREA pump in the after-treatment system needs 90 seconds to empty the UREA hoses!

This is needed to avoid that the UREA is freezing and consequently damages the system!

Wait 90 seconds = UREA pump stops Æ then disconnect the battery cable!

DR Remote control El main switch manual main switch

1. Ignition OFF 2. Switch OFF the main switch (ADR inside the cab) lock the doors with remote or key.

(If equipped with main-switch)

3. Open cap lock switch 4. Put cable in between the batteries, put on the battery box cover

Incorrect position Correct position

5. Do NOT leave the cap lock open!!! 6. Cable is fixed between the batteries

Issue 2/2010-01-01

VLC Dept 73400 Fle-122

14

Page 14 of 47

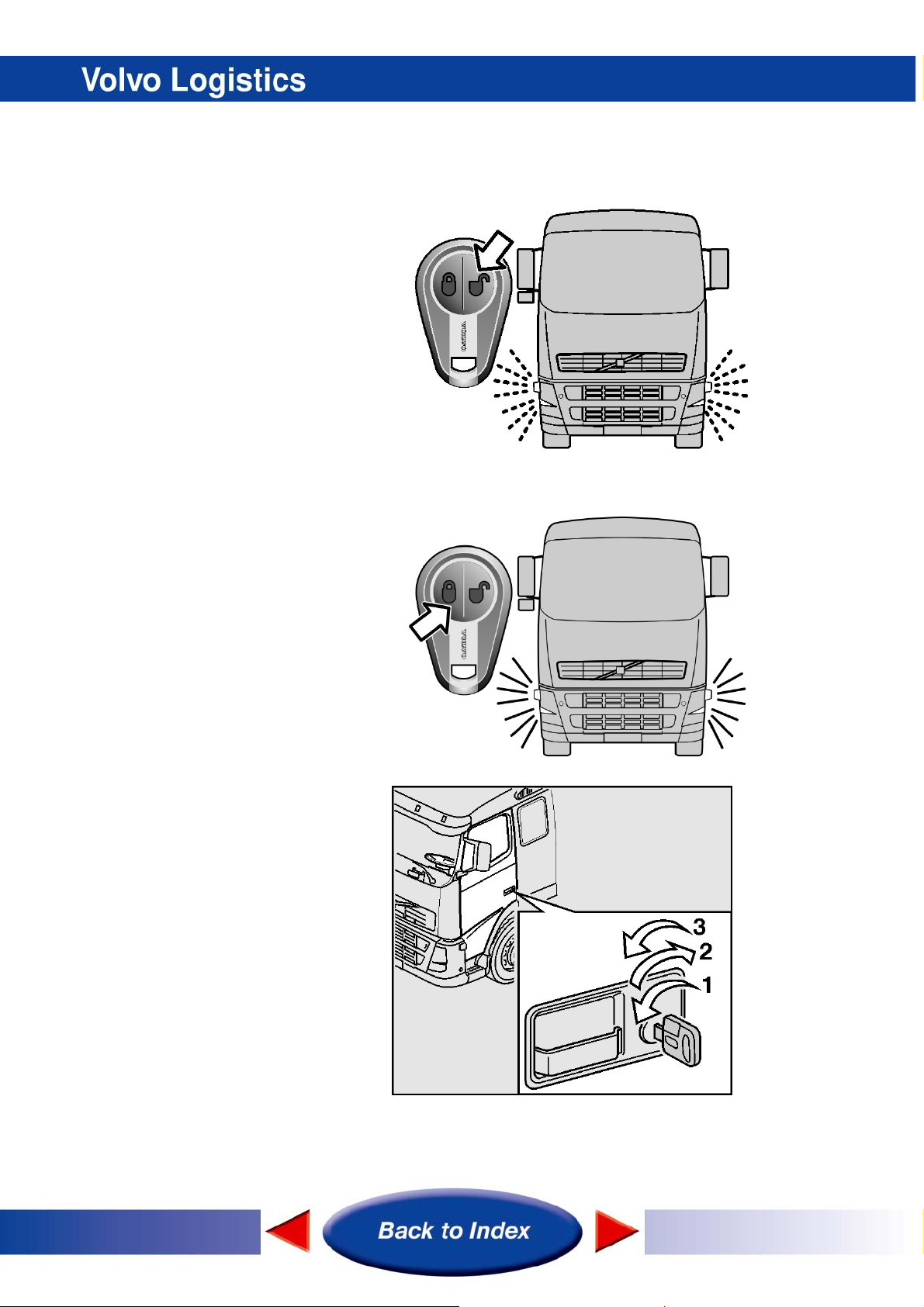

3.6 Central locking

Unlock with the sender

Unlock the driver’s door

Press the symbol for UNLOCK

The indicators will flash

Unlock the passenger door

1 Unlock the driver’s door using

UNLOCK

The indicators will flash

2 Press the symbol for UNLOCK again

The indicators will flash

Lock with the sender

Press the symbol for LOCK

The flashers light up

Unlock with the key

1 Unlock

A door is unlocked

2 Lock

3 Unlock again

Both doors are unlocked

Issue 2/2010-01-01

VLC Dept 73400 Fle-122

15

Page 15 of 47

Main switch at key unit

Turn on the main switch

Press the symbol for UNLOCK

or

Set the key at start position

Note: This only applies to trucks with

electrically-controlled main switches.

Switch off the main supply

1 Lock the door, press the symbol for

LOCK

2 Press the symbol for LOCK twice

consecutively

The main supply is switched off

Note: This only applies to trucks with

electrically-controlled main switches.

Issue 2/2010-01-01

VLC Dept 73400 Fle-122

16

Page 16 of 47

p

g

3.7 Gearboxes

1. The engine can only be started with the gear in N-position.

2. Switch on the ignition key. Wait until the gear display on the instrument panel turns

on.

3. Start the engine. Wait until the red warning light for the air

pressure turns out.

4. Press the brake pedal and release the parking brake.

5. Select D-position for forward driving or R for reverse.

If it is a ZF-model, keep the brake pedal depressed while selecting D or R.

6. Press down the accelerator pedal gently.

The gear will only be in operation when pressing down the accelerator. This is

important when starting up or down hills.

7. The gear must be in neutral position when ignition key is switched to “0”.

Gear selector

The gear selector is fixed to the seat

and the gear lever can be tilted to allow

the driver to move freely around the

cab without being hindered by the lever.

Starting instructions

Put the gear lever in neutral or tilted position or the engine will not start.

When the air pressure to the gearbox is too low, a warning will be displayed automatically.

An icon will appear on the display at the same time as the information lamp comes on. Wait

until the lamp has gone out

before driving off.

Stopping the vehicle

When the vehicle is stationary:

• Apply the parking brake.

• Move the gear lever to N, neutral.

• Stop the engine.

Note! The parking brake must always be applied when the vehicle is

parked or if the driver leaves the driver’s seat for any other reason.

Issue 2/2008-01-01

Issue 1/2003-01-01

VLC Dept 73400 Fle-122

VLC Dept 7140 Fle-103

Information

lam

Icon for low air pressure

to

ear-box

17

26

Page 17 of 47

In case of gearbox malfunction

If a gearbox malfunction occurs that prevents you from driving the

vehicle, activate limp-home mode and drive on.

Note! The limp-home function should only be used for short distances.

The function is activated by pressing button L on the gear selector housing and moving the

gear lever to A at the same time.

The following functions are affected:

• automatic mode is not available

The following gears can be used:

• reverse 1

• forward 1, 3 and 5

To engage reverse gear, move the lever to R. Move the lever back to

A again to drive forwards. It is not necessary to press the L button again.

The limp-home function will be disengaged when the ignition is turned off.

Issue 2/2010-01-01

VLC Dept 73400 Fle-122

18

Page 18 of 47

3.8 AdBlue (Urea solution)

The engines are fitted with an exhaust gas cleaning system which cleans the exhaust using

AdBlue urea solution. AdBlue is injected into the exhaust system at a point between the

turbocharger and the silencer, which has an inbuilt SCR catalytic converter. The catalytic

converter is used to reduce emissions of nitrogen oxides and particulates.

Urea solution is sold under the trademark AdBlue. It is a colourless liquid consisting of a

mixture of urea and distilled water. It may have a slight smell of ammonia. The

concentration of urea in AdBlue is 32.5%. AdBlue follows DIN standard 70070 and is the

only urea solution approved by Volvo for use in Volvo trucks with Euro 4 engines.

AdBlue may also be sold and marketed under other brand names, depending on the

distributor, and can be used as long as it meets DIN standard 70070.

AdBlue is highly corrosive and can damage electrical connectors. If AdBlue gets

into electrical connectors or wiring, they must be replaced. Cleaning electrical

items is not enough.

AdBlue is not toxic but it should be handled with care. If AdBlue is accidentally spilled on

the truck, rinse the area with water and dry off with paper or a rag. The solution can be

aggressive when warm and can therefore damage, for example, nearby electrical

connectors, electrical wiring and hoses if spilled. AdBlue freezes at approx. -11 C, but this

is not a problem, as the SCR system is heated. The truck can be started and driven

normally.

CAUTION

Trucks with ADR

Bear in mind that the ADR switch is only

for use in emergencies. When the engine

is switched off, a process begins to pump

clean the AdBlue nozzle and supply lines.

This process takes about 90 seconds and

during this time the ADR switch must be

switched on. It is especially important to do

this in cold weather as there is a risk of the

solution freezing. The cleaning process is

not carried out if the ADR switch is used

before or during the process.

Issue 2/2010-01-01

VLC Dept 73400 Fle-122

CAUTION

AdBlue that has been modified or replaced by another liquid that does

not comply with DIN 70070 will lose its intended cleaning effect on the

exhaust gases and may damage the SCR system.

19

Idling

To safeguard the power supply, trucks with

Euro 4 engines have a faster idling speed in

cold weather. The engine electronic control

system determines when the increased idling

speed needs to be applied; it cannot be

activated manually by the driver. Because

of this, if the truck is equipped with I-shift,

CAUTION

Never put AdBlue into the fuel tank.

This can damage the engine and

the fuel system..

it is especially important, when idling, to

engage neutral while the truck is stationary

with the engine running. This is to prevent

overloading the clutch and gearbox.

Issue 2/2010-01-01

VLC Dept 73400 Fle-122

20

Page 20 of 47

3.9 Air suspension

If there is a problem with ground clearence for trucks , see how

to increase ground clearence with air suspension.

There are three different types of air suspensions

- Fixed level (not possible to adjust)

- Automatic level (possible to adjust)

- Manual level (only rear axle, not to be used)

All three types, warning lights for air pressure must be off before driving.

Automatic level

If the warning light on the instrument panel for air suspension

still is on, despite correct air pressure, check the control box,

located behind the driver seat.

- Switch 1 always to be in driving position.

It is possible to increase the height of the chassis. This is only to be

done just before passing critical ramps and similar where there is low

ground clearance.

No driving in port area with air suspension in high position.

1. Put switch 1 on the control box

to high position.

2. Switch 2 always in centre

position (only some types).

3. Press button 3 until the truck

reach highest position.

Do not forget to restore switch 1 to driving position after passing critical

low ground clearance point. Maximum speed 10 km/h

Issue 2/2010-01-01

VLC Dept 73400 Fle-122

21

3.10 Airbag

Some trucks are equipped with airbags. If so, than the centre of the steering wheel will be

marked with “SRS”.

Always use the safety belts when driving an Volvo truck. The use of saftey belts are

mandatory when driving trucks equipped with airbags.

3.11 Clothing

Clothes, gloves and shoes must be clean to avoid

dirtying the trucks interior. All buttons and zippers

must be covered. No tools or similar in pockets.

3.12 Drawing / marking / attaching

Writing on the trucks with any material is forbidden, as well as attaching stickers to the

trucks painted surfaces apart from rapguard. Required sticker may be applied with care to

the front window but not in the range of vision.

No rubber bands, metal hooks, wires or other material to be attached directly to the trucks.

Issue 2/2010-01-01

Issue 1/2010-01-01

VLC Dept 73400 Fle-122

VLC Dept 73400 Fle-122

22

27

Page 22 of 47

Rubber bands are only allowed to attach the lengthplate

Issue 2/2010-01-01

VLC Dept 73400 Fle-122

23

Page 23 of 47

3.13 Miscellaneous

Eating, drinking and smoking inside or next to the trucks is not

allowed. Passengers are not allowed inside the truck.

Do not open the sunroof and do not turn on radio equipment.

It’s not allowed to remove any protection from the trucks. It’s not allowed using cellphones

during loading/unloading operation.

When folding the mirrors this must be done with care. The folded mirror may not be in

contact with the door.

When entering and leaving the truck do not cause damages to painted parts close to the

footstep.

Issue 2/2010-01-01

VLC Dept 73400 Fle-122

24

Page 24 of 47

3.14 Some driving advice

1 Check after starting, and occasionally

when driving, that the instruments show

normal values. If a warning lamp lights up

when driving, stop and check the reason.

2 Always use 1st gear to pull away or alt.

Crawl gear with as low engine speed as

possible (700–800 rpm).

3 Never race a cold engine! Avoid long

periods of idling.

4 Never cover the radiator! Check the

coolant level regularly and always use the

correct coolant. Also check the hoses and

belt tension. Do not drive with a leaking

radiator or heating system.

5 Never drive away until the brake

system warning lamps have gone out.

Do not forget to release the parking

brake.

6 Try not to turn when the front wheels are

impeded by a kerb or such like. The

power steering and the tyres can be

damaged.

7 Do not rest your foot on the clutch

pedal. Do not slip the clutch

unnecessarily. Using a too high gear can

cause unnecessary clutch wear.

8 Do not change gear when the power

take-off is engaged. (Applies to gearbox

mounted power take-offs on manual

gearboxes.)

9 The reverse gear is unsynchronized. Shift

to LOW range before engaging reverse.

In good driving conditions it is possible to

reverse with HIGH range engaged.

Note: Changing between HIGH and LOW

range when reversing is not permissible.

First select HIGH or LOW range and then

select reverse.

10 Use the engine brake when decending

hills and during gentle braking. Avoid

having the engine brake constantly

applied on slippery roads.

11 Use the differential lock on slippery

roads.

WARNING

Do not turn corners on firm roads with the

differential lock engaged.

12 Let the engine idle for at least 1 minute

after hard driving, before switching it

off. This avoids heat stress in the engine

and involuntary coolant loss.

13 Check the function of the air drier by

draining the primary tank or one of the

circuit tanks every week.

14 Always use the correct fuel and the

correct oil.

15 Close the rear shelf hatches before

driving off.

16 The lid on the tachograph should always

be closed.

Issue 2/2010-01-01

VLC Dept 73400 Fle-122

25

Page 25 of 47

3

4 LOADING/UNLOADING OPERATION

It’s forbidden to transport trucks with mounted roofspoiler in

backward position

4.1 Distances between stowed trucks

Minimum distances

- Between vehicles lengthwise 10 cm or 4 inches.

- Between lowest part of the truck and carrier superstructure

minimum 6 cm or 2.4 inches.

The driver must always be able to open the driver’s door into an open

space.

Make sure no deformations are made to the loaded truck.

Unacceptable

4.2 Preparation of ship / trailer

- All roadways, ramps and decks should be free from lashings and

other material that could cause damage to the vehicles.

- All ramps and loading platforms must be adjusted to fit the

measurements of the vehicles

Issue 1/2008-01-01

Issue 2/2010-01-01

VLC Dept 73400 Fle-122

VLC Dept 73400 Fle-122

Page 26 of 47

26

9

4.3 Driving behaviour in port area or terminal

Maximum speed limit in port, terminal, loading and unloading area 30

km/hour or 20 miles/hour.

Maximum speed limit when using sand or stone chips for

slippery prevention 20 km/hour or 10 miles/hour.

Keep extra long distance between vehicles to avoid stone

chipping.

4.4 Driving behaviour onboard ship

When driving on ramps and decks all vehicles must be driven at a low

speed and according to respective shipping lines’ regulations.

The speed should always be reduced at the beginning and end of ramps.

Decks and ramps can be slippery. Keep a safe distance to other

vehicles.

Issue 2/2010-01-01

VLC Dept 73400 Fle-122

27

Page 27 of 47

LASHING/STOWING ONBOARD SHIP

4.5 Parking routines onboard ship

Make sure that;

• parking brake is in on-position

• transmission is in N position

• all windows, doors etc. are closed

• wiper blades are in rest position

• door mirrors are folded inwards

• ignition and all electric devices are switched off

• electric main switch is in off-position

• key in ignition or according to respective shipping line’s routine

Battery disconnected if according to 3.5

4.6 Stowing onboard ship

No vehicles to be parked on the ship’s weatherdeck.

Stowing should be done according to shipping lines procedure and be

performed in a way that makes unloading as easy as possible.

No vehicles should be reversed during unloading.

Vehicles always to be separated from other cargo. No vehicles parked

between or under trailers, machinery etc.

The driver must always be able to open the drivers door into an open

space. Never park vehicles with their wheels upon floor chains, fixed

lashing eyelets or any other objects.

Note: Minimum distance when stowing piggybacked trucks is

40 cm (16 inches) between sides and 50 cm (20 inches) lengthwise.

Issue 1/2008-01-01

Issue 2/2010-01-01

VLC Dept 73400 Fle-122

VLC Dept 73400 Fle-122

Page 28 of 47

12

28

4.7 Lashing/unlashing routine

Lashing/unlashing must always be done by a separate gang.

Lashing operations must be done simultaneously with the loading.

No lashing to be done afterwards. Lashing material to be moved

between parked vehicles below bumper or spoiler level.

Do not lean against the vehicles and do not use bumpers as support

when rising.

4.8 General condition

Decks and ramps must be regularly cleaned. Leakage from hydraulic

equipment will not be accepted. Loose lashing material, trailer bars and

other equipment must be removed and secured.

4.9 Ramps and loading platforms

Ramps and decks must be constructed in such a way that there is no

risk of damaging the vehicles.

All ramps must have rounded and soft approach and be at an angle of

no more than 8 degrees.

All pillars and other obstacles located close to vehicles must be covered

with protective material or marked with zebra tape.

Transverse open space, over which the wheels of the truck are to pass,

should never exceed 15 cm or 6 inches, respective 5 cm or 2 inches in

height.

Small ramps must be used to avoid below problems.

Issue 2/2010-01-01

VLC Dept 73400 Fle-122

29

Page 29 of 47

4.10 Lashing equipment

Only special lashing equipment for securing heavy vehicles may be

used. All straps, tensioners and hooks should be intact.

Damaged or worn out lashing equipment must be replaced.

Example of a recommended lashing sling for trucks.

It is only allowed to use torsion bars and chains for lashing trucks.

Hooks are never to be attached directly into the chassis. Soft sling must

be used around the chassis axle or the chain must be protected with a

fibre tube when in contact with the chassis.

Fixed lashing equipment, such as floor chains and eyelets, should be

designed and attached in such a way that they do not damage tyres

and rims.

Not permanently fixed lashing equipment, such as loose chains,

must be removed before operation starts.

Issue 1/2008-01-01

Issue 2/2010-01-01

VLC Dept 73400 Fle-122

VLC Dept 73400 Fle-122

Page 30 of 47

15

30

4.11 Attachment of lashing sling

Always try to get an angle of 45 degrees measured horizontally from

the lashingpoint and an angle of 30 degrees measured vertically from

the lashingpoint. Lashing never to be in contact with the truck so it can

cause damages.

4.12 Lashing of trucks

All lashings must be done in such a way that the vehicle is not damaged.

Precautions must be taken, not to lash around steering parallel stay,

tubes or electrical cables or any other not approved lashing point.

No chains around axles, use soft slings or protect the

chain with fibre tubes.

Lashing methods for single trucks

Lash around axles according to figure.

Trucks may also be lashed around rear stabilizer as shown below.

Note: Lashings as above must regularly be checked/tightened during

the voyage. Possible air leakage from air suspension will lower the

chassis and the lashing will slack.

Issue 1/2008-01-01

Issue 2/2010-01-01

VLC Dept 73400 Fle-122

VLC Dept 73400 Fle-122

Page 31 of 47

16

31

Lashing methods for trucks on flats:

If there is a need to lash the trucks to the ships deck, it must be

done according to “lashing methods for trucks and “lashing

methods for piggybacked trucks”.

Issue 2/2010-01-01

VLC Dept 73400 Fle-122

Page 32 of 47

32

5

5 TRANSPORT BY JOCKEYS

5.1 General

Follow Volvo’s requirements in this instruction as well as reading the

truck instruction booklet.

It’s not allowed to bring passengers during transport.

Smoking is not accepeted inside the trucks.

Plastic protection for driver´s seat may be removed during driving.

Replace plastic protection upon delivery.

5.2 Driving behaviour

Drive with care and follow the driving instructions.

Note a truck without superstructure has a very low rear axle pressure,

which will affect brake distance and stability.

In case of work deviations, please drive slowly to avoid chippings.

Behave like a gentleman; remember that you are representing Volvo.

Avoid driving in convoy, if impossible always use sufficient distance.

5.3 Mechanical problems

If a mechanical problem occurs during transport, contact the receiver for

instructions.

When impossible to reach the receiver contact Volvo Action Service.

Issue 2/2010-01-01

VLC Dept 7140 Fle-103

33

Page 33 of 47

6 SECURING / LASHING / SUPPORT ONBOARD

6 CARRIER

6.1 Introduction to this chapter

There are different regulations depending on the country in which the

transport takes place. The general rule is that all vehicles must be

secured on the carrier. The securing must be done by a combination of

wheel chocks and lashings.

It is the transporters´ responsibility to make sure that each countries

legal regulations are followed and that loaded vehicles can not move

during transport.

Avoid spinning wheels during loading and unloading operation.

6.2 Wheel chocks

Each chassis must be secured with at least 2 or 4 wheel chocks,

depending upon local regulations. The wheel chocks must be properly

fixed to the loading platform. Design and size of the wheel chock must be

appropriate for trucks.

6.3 Wheel lashings

All lashings must be done in such a way that the vehicle is not damaged.

Precautions must be taken, not to lash around steering parallel stay,

tubes or electrical cables or any other not approved lashing point.

Thighterners should be placed/used in such a way that no damages

occurs. Lashings must be maintained and replaced on a regular basis.

Chains or unprotected hooks never to be attached or in

contact with the vehicle.

Issue 1/2008-01-01

Issue 1/2008-01-01

Issue 2/2010-01-01

VLC Dept 73400 Fle-122

VLC Dept 73400 Fle-122

VLC Dept 73400 Fle-122

20

23

Page 34 of 47

34

Page 35 of 47

6.4 Lashing on tyres

6.5 Lashing on rims

6.6 Lashing around the axles

(Note: Not allowed on alloy wheels.)

Issue 2/2010-01-01

VLC Dept 73400 Fle-122

Page 36 of 47

35

6.7 Lashing around the rear stabilizer

For trucks with air suspension it is also allowed to lash around the rear

stabilizer. It´s not allowed to lash in the rear crossmember.

Note: Lashings as above must regularly be checked/tightened during

the transport. Possible air leakage from air suspension will

lower the chassis and the lashing will slack.

6.8 Use of supports

All supports must be covered with rubber or wood surface. Steel to steel

contact between support and truck is not accepted.

If no sufficient distance remains after lowering the truck with air

suspension it is allowed to place supports underneath axles or stabilizer.

Issue 2/2010-01-01

VLC Dept 73400 Fle-122

Page 37 of 47

36

6.9 Securing carrier ramps

If there is a need to secure the carrier upper ramp/deck, it is allowed to

place support between this ramp/deck upon the chassis on the truck

underneath.

Approved locations for supports are fifth wheel, upon tyres or frame.

A rubber mat should be used as protection.

6.10 Lashing

Lashing of ramps must be done to the carrier itself.

Issue 2/2010-01-01

VLC Dept 73400 Fle-122

37

Page 38 of 47

6.11 Dismounting of parts

Following items are allowed to dismount:

- Spare wheel

- Spoiler transport mounted on the chassis

- Rear light including console

- Roof section for air inlet

- Antennas

- Rear fenders

- Under run protections

- Wheel housing including console

- Upper part vertical exhaust pipe

Dismounting of other parts only after approval from Risk Management

Department.

When dismounting parts, never climb/stand upon fuel, airtanks or painted

surfaces on the cab.

Always use tools with correct dimensions, no adjustable spanners.

When dismounting consoles fixed with bolts in threaded holes, always

remount the bolts. This to protect the threads.

Small parts to be stored on the passenger side.

All parts to be packed in a proper way to avoid damages, both on the

part itself and the cab interior.

Bigger parts to be mounted/secured on the chassis.

This is to be done in such a way that the parts or the chassis will not be

damaged. It is also important that all parts are secured on the chassis in

a safe way to avoid losing parts during transport.

Always use soft lashings for securing. Use plastic/cardboard/rubber mats

between parts and the chassis. Scraped off paint or scratches on the

part or the chassis is not accepted. When moving transport mounted roof

spoiler, there must be two persons for lifting to avoid damages.

It is not allowed to remove transport protections from inside the cab.

Issue 2/2010-01-01

VLC Dept 73400 Fle-122

Page 39 of 47

38

Dismounting & remounting mudguards

PICTURES

Dismounting :

• joint can be loosened

Remounting :

• joint is tightened

INFORMATIONS

with a wrench key

at140Nm with a standard

angle nut runner.

Issue 2/2010-01-01

VLC Dept 73400 Fle-122

Page 40 of 47

39

Dismounting & remounting air intake

PICTURES INFORMATIONS

Dismounting :

Remounting

Angle nutrunner

Upper air intake part

• Hardware can be

loosened with an

angle nutrunner :

a. Qty 1 (Nut

M8x9,4)

b. Qty 1 (Screw

PT6*35)

c. Qty 4 (Screws

PT6*25/ 2 on

each side)

• Drain for evacuating

water from snow /

rain is present inside

2 pipes. No further

protection is

required.

:

• Caution when

remounting parts:

i. Electrical tools may

damage threads

ii. Ensure parts are

properly connected

prior to be tighten

• Tight parts with an

angle nutrunner

a. Qty 1 (Screw

PT6*35) : 3 Nm

b. Qty 4 (Screws

PT6*25/ 2 on

each side) : 3

Nm

c. Qty 1 (Nut

M8x9,4) : 24 Nm

Issue 2/2010-01-01

VLC Dept 73400 Fle-122

40

Page 41 of 47

Dismounting & remounting rear bumper

PICTURES INFORMATIONS

Dismounting :

• joint can be loosened with a

pistol grip impact nutrunner or

a standard angle nut runner

Remounting :

• joint is tightened at140Nm with

a standard angle nut runner.

Issue 2/2010-01-01

VLC Dept 73400 Fle-122

Page 42 of 47

41

Dismounting & remounting rear light brackets

PICTURES

INFORMATIONS

Dismounting :

• joint can be loosened with a

pistol grip impact nutrunner or

a standard angle nut

runner

• when dismounting rear lamp,

protect connectors from

corrosion or else. For

example, lamp connectors

P/N 1079283 can be used.

Remounting :

• joint is tightened at140Nm

with a standard angle nut

runner.

Issue 2/2010-01-01

VLC Dept 73400 Fle-122

42

Page 43 of 47

7 LOADING/UNLOADING OPERATION LO/LO

7.1 Introduction to this chapter.

It is the shipping lines responsibility to make sure that wires etc. used for

lifting operations have the right strength.

Lifting is to be done with lifting devices attached to the front wheels. See

figure below (lifting devices to be mounted by the factories).

7.2 Lifting instructions

Spreader must always be used. Wires never to be in contact with the

truck cab or the truck superstructure. Wires around frame work to be

protected with a soft fibre tube. Do not damage electrical wires and

pneumatic tubes.

Issue 2/2010-01-01

VLC Dept 73400 Fle-122

43

Page 44 of 47

Issue 2/2010-01-01

VLC Dept 73400 Fle-122

44

Page 45 of 47

Lashing methods for trucks piggyback:

Lash around front and rear axle according to figure below.

It is allowed to attach lashing (not

hooks/chains) to the rims on the

upper chassis. Use soft sling or

protect the hook/chain with fibre

tubes. This method is only to be

used if it is impossible to reach the axles.

Note: All lashing from upper trucks must be regularly checked/tightened

during the voyage. Possible air leakage from suspension will lower the chassis

Issue 2/2010-01-01

VLC Dept 73400 Fle-122

Page 46 of 47

45

8 DAMAGES

All vehicles must be checked before entering the vehicles.

If a transit damage is found, a Vehicle Condition Report must be filled out.

Instructions for assessment of transit damages can be find at

Volvo Logistics / Risk Management Department website.

Major damages such as transport accidents, total loss or other severe damage, theft,

fire, vandalism etc. must be reported immediately to Risk Management Department at

Volvo Logistics. This in order for VLC to decide if the vehicle should continue it’s voyage

to final destination or be returned to the place of loading.

In case of broken windscreens and/or flat tyres the transport company must take action

to avoid further damage, i.e. cover broken windscreens and replace flat tyres.

9 Quality audits

Volvo Logistics reserves the right to audit all operations, at any time, to check that the

handling instructions provided by Volvo Logistics are followed.

Anyone with contract to Volvo Logistics that uses a subcontractor are responsible for that

the handling instruction are followed. Audit regarding a subcontractor will be turned to

contract holder or responsible person at company audited.

When an audit result is considered not approved, VLC will request an actionplan.

The result from audits / inspections will be registred and statistics will be performed and

are available from Risk Management Department at Volvo Logistics.

Issue 2/2010-01-01

VLC Dept 73400 Fle-122

46

Page 47 of 47

Loading...

Loading...