Vollrath 72723019, 72729017, 72729019, 7286002, 7286100 Installation Manual

ENGLISH

Operator’s Manual

English, Spanish, French

CAYENNE® HEAT AND LIGHT STRIPS

RegisteR youR pRoduct on-line at www.vollRath.com

Thank you for purchasing this Vollrath Food Processing Equipment. Before operating the equipment, read and familiarize yourself with

the following operating and safety instructions. SAVE THESE INSTRUCTIONS FOR FUTURE REFERENCE. Save the original box and

packaging. Use this packaging to ship the equipment if repairs are needed.

Item No. 17030-1 ml Rev 09/14

safety pRecautions

To ensure safe operation, read the following statements and understand

their meaning. This manual contains safety precautions which are

explained below. Please read carefully.

WARNING

Warning is used to indicate the presence of a hazard that can cause

severe personal injury, death, or substantial property damage if the

warning is ignored.

CAUTION

Caution is used to indicate the presence of a hazard that will or can

cause minor personal injury or property damage if the caution is

ignored.

NOTE

Note is used to notify people of installation, operation, or maintenance

information that is important but not hazard-related.

For Your Safety!

These precautions should be followed at all times. Failure to follow

these precautions could result in injury to yourself and others or damage

the equipment.

To reduce risk of injury or damage to the unit:

Use only grounded electrical outlets or circuits matching the nameplate

rated voltage.

Unit should only be used in a at, level position.

Turn off unit and let it cool before cleaning or moving.

ENGLISH

Do not operate unattended.

unit installation cleaRances

Do not use extension cords, power strips or surge protectors with this

unit.

Install with distances specied in the Unit Installation section of this

manual. Minimum distance to the following surfaces.

Combustible surroundings 5” Sides 2” Top

Non Combustible surroundings 1” Sides 1” Top

Setback from edge of pass-through 8” from any edge

Units that require wiring for installation must follow National Electrical

Code (NEC) standards and local ordinances.

Only use coated light bulbs that meet NSF standards and are

specically designed for foodservice areas. Breakage of bulbs that are

not coated could cause injury or contaminate food.

Do not place materials on or allow combustible materials to come in

contact with unit.

There are no serviceable parts in this unit. Contact a Vollrath

Authorized Service Agent for service.

Authorized service agent must use genuine Vollrath replacement parts.

Failure to do so will void warranty and may cause a safety hazard.

Do not spray controls or outside of unit with liquids or cleaning agents.

Units that require a circuit breaker larger than 20 amps must have

separate circuit for the lighting circuit that is less than 20 amps.

function and puRpose

Heat Strips = These units are intended to be used as a heat source to help

maintain food at safe temperatures until served. They are not intended

or designed to cook raw food or to reheat prepared food. Food must be

prepared and placed in food stations at proper temperatures.

Light Strips = These units are intended to illuminate food serving display

areas or food preparation areas.

unpacking the equipment and initial setup

Carefully remove crating or packaging materials from the unit. Dispose of all

packaging ,materials in an environmentally responsible manner.

WARNING

Fire Hazard.

Do not install unit near combustible material. Do not

place combustible material under or on top of unit.

Discoloration or combustion could occur.

WARNING

Electrical Shock Hazard.

Keep water and other liquids from entering the

inside of the unit. Liquid inside the unit could cause

an electrical shock. Unit must be installed by

qualied personal in accordance with all local and

national ordinances. Do not use a power cord that

has been modied or damaged.

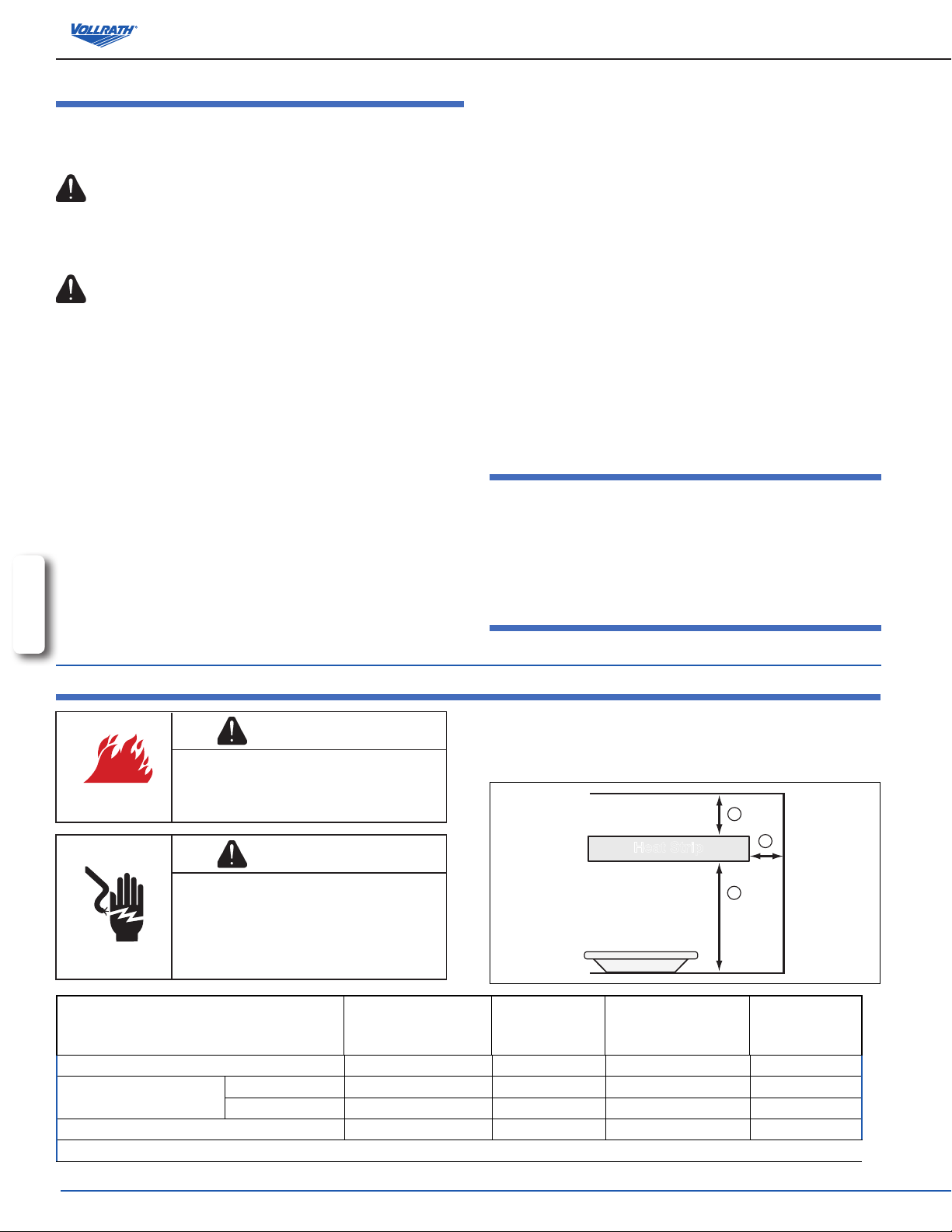

Single

Minimum Clearances

A Top of strip to surface above (minimum)

B Bottom of strip to surface

below

C Side of strip to adjacent surface (minimum)

Setback from front opening on pass through application: maximum of 8" (20.3 cm)

Medium Wattage 11" (27.9 cm) 13" (33.0 cm) 18" (45.7 cm) 20" (50.8 cm)

High Wattage 16" (40.6 cm) 16" (40.6 cm) 24" (60.9 cm) 25" (63.5 cm)

Non-Combustible

Surface

1" (2.5 cm) 2" (5.1 cm) 1" (2.5 cm) 2" (5.1 cm)

1" (2.5 cm) 5" (12.7 cm) 1" (2.5 cm) 5" (12.7 cm)

This unit must be installed by qualied personal in compliance with electrical

codes. The following distances must be kept between the unit and the

surrounding surfaces for safe operation. It is recommended that two (2) or

more people assist with the installation of this unit.

A

C

B

Dual

Combustible

Surface

Single

Combustible

Surface

Heat Strip

Dual

Non-Combustible

Surface

2

OperatOr’s Manual

NOTE:

This unit must be installed in an area that will not be affected by the heat

3. Mount the brackets and unit to a suitable surface using holes (E) and

suitable hardware.

from the unit. Damage to solid surface counter tops or other materials in

the heat zone of this product are not covered under warranty.

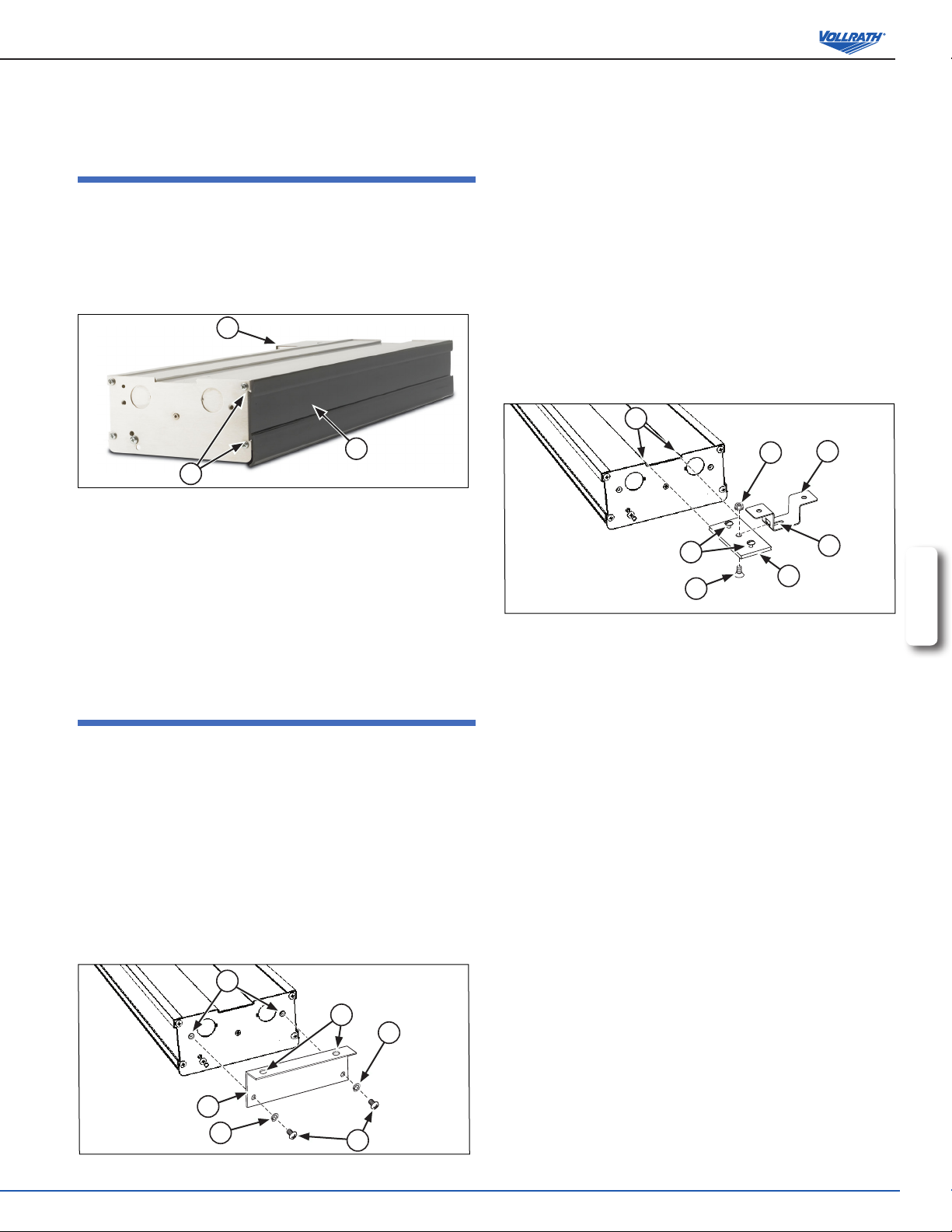

kool-touch® tRim installation

The Kool-Touch® trim option is shipped separately. It will need to be installed

on the unit. We recommend that this option be installed before the unit is

mounted.

1. Beginning on the side that does not have the control box (A), slide the

Kool-Touch® (B) panel into position by starting at one end of the unit. Slide

the Kool-Touch® panel in the channel (C) on the side of the unit until it is in

place. (Ganged units will require two pieces trimmed to t). See Figure 1.

A

centeR mount installation

Top mount brackets may be purchased as an option for direct-wired units.

The brackets are available in 1” height or 2” height. Dual units require

brackets on each unit.

NOTE:

For units longer than 72”, a minimum of three (3) mounting points

consisting of the two ends and the center of the unit must be used.

1. Access the area the unit will be mounted in and mark the location the

center mount brackets will be mounted. Make sure the material the unit

will be mounted to will support the weight of the unit.

2. The brackets must be located near the ends of the unit for greatest

stability.

3. Mount the hanging bracket (A) with the “T” slot cutout, in the locations

identied in step 1. Figure 3.

D

B

C

Figure 1. Installation of Kool-Touch® Panels.

2. The side of the unit that has the control box will need to be trimmed.

Measure the area that is to be covered by the Kool-Touch® panel.

3. Mark the length to be covered on the Kool-Touch® panel.

4. Place a damp soft cloth under the end of the Kool-Touch® panel to be cut

to prevent the Kool-Touch® panel from scratching or slipping while it is

being cut.

5. Using a hacksaw with a ne metal or plastic blade, slowly cut the panel to

length.

6. Install the panel on the unit in the same manner as the opposite side.

unit installation - diRect wiRe mounting

Figure 3. Installing Center Mount Brackets.

4. Loosen the two screws (B) located in the center of the at channel

plates (C) far enough so they do not protrude out of the bottom of the

plate.

5. Slide the channel plates (C) into the channel (D) on the top of the unit.

6. Measure the distance from the center points of the hanging brackets

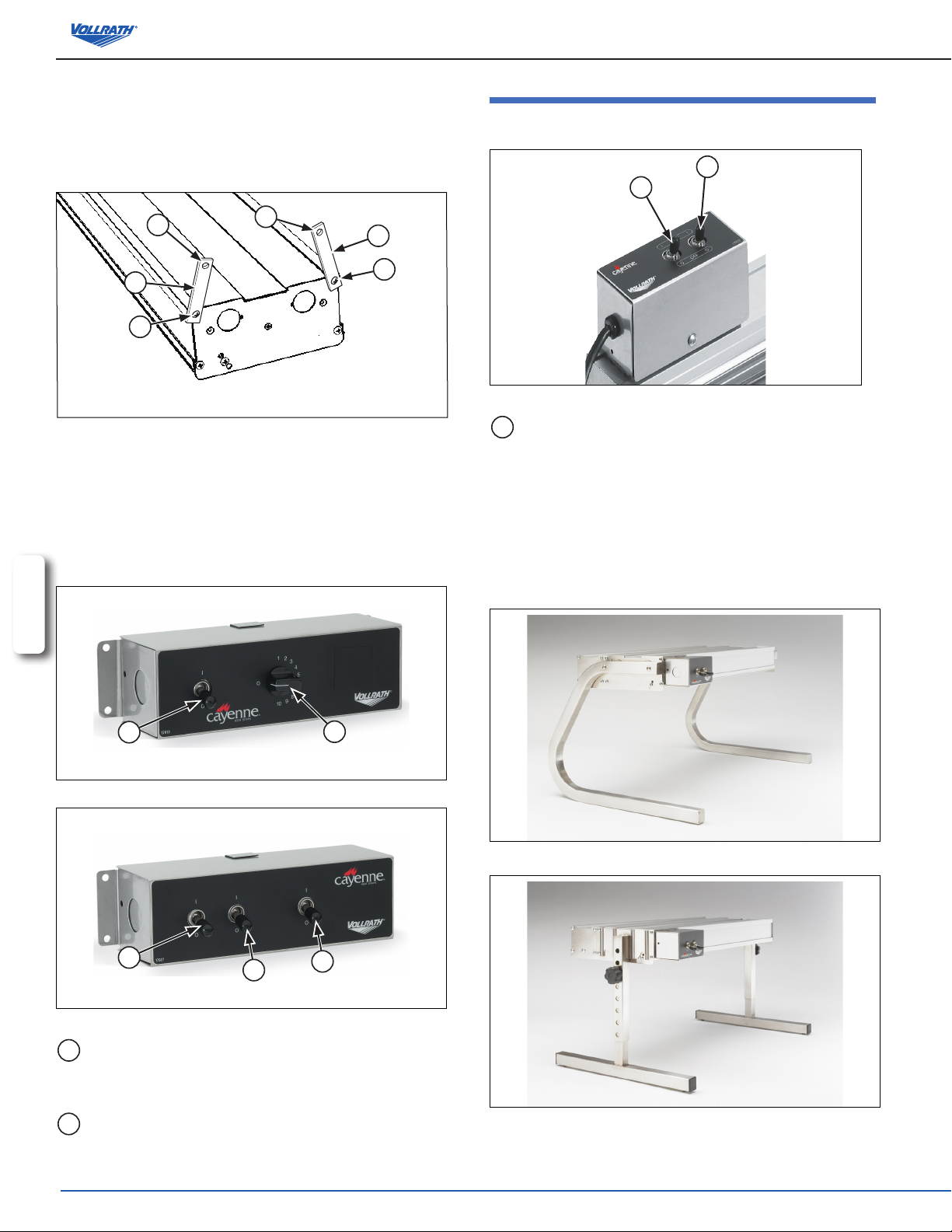

top mount installation

Top mount brackets may be purchased as an option for direct-wired units. The

brackets are available in 1” height or 2” height. Dual units require two sets of

brackets.

NOTE:

Top mount brackets may not be used with units longer than 72”.

1. Access the area the unit will be mounted in and mark the location the

center mount brackets will be mounted. Make sure the material the unit

will be mounted to will support the weight of the unit.

2. Secure the top mount bracket (A) to the mounting holes (B) using

lockwashers (C) and screws (D). Repeat on the other end. See Figure 2.

(A) and slide the channel plates (C) in the channel (D) on the top of the

unit so the center screws (E) in the channel plate (C) match the distance

between the center of the “T” slot (G) in the brackets (A).

7. Tighten the two outside screws (B) in the channel plate (C) to lock the

channel plate in position.

8. Loosen the nut (F) in the center of the channel plate (C) but DO NOT

REMOVE.

9. Raise the unit and align the nut (F) in the center of the channel plate (C)

with the “T” in the bracket (A) mounted in step 2.

10. Slide the nut (F) through the “T” slot and TIGHTEN THE NUT to keep the

unit in place. THE NUT MUST BE TIGHTENED TO PREVENT THE UNIT

FROM SLIPPING OUT OF THE BRACKET.

F

B

E

A

G

C

ENGLISH

B

A

C

Figure 2. Installing Top Mount Brackets.

chain mount installation

E

C

D

NOTE: Units over 72” in length, must use the center mounting point.

1. The unit is shipped with mounting tabs (A) located on each end of

the unit. For units that are longer than 72”, three (3) mounting points

consisting of the two ends and the center of the unit must be used. See

Figure 4.

2. Loosen the screws (B) holding the mounting tabs in place but do not

remove. Rotate tabs (A) to an upright position and the attach chain to

holes (C). The chain must support each side of each end of the unit

evenly.

OperatOr’s Manual

3

3. Hang chain from an appropriate hanging point directly over the area to be

kept warm. Make sure the hanging point is adequate for the total weight of

unit installation - coRded mounting

the unit and chain.

4. Adjust height of the unit making sure it is level and each point is supporting

on BoaRd toggle contRols

the weight of the unit evenly.

5. Tighten screws (B) to secure the mounting tabs.

A

A

C

A

B

C

A

B

Figure 4. Chain Mount Installation.

Remote mounting of contRol(s)

NOTE: Installations must be in accordance with National Electrical Code

(NEC) regulations.

Control boxes must be mounted securely to surfaces using proper hardware.

Mount the control box(es) in such a way they will not be bumped or accidently

switched on or off.

ENGLISH

Figure 7. On Board Toggle Control with Switches

A

ON/OFF Toggle Switch. Move the toggle switch to the up

position for “ON”. Move the toggle switch to the down position

for “OFF”.

mounting options

NOTE: UL requires all cord and plug heat strips, from all

manufacturers be mounted on legs. All heat strips are custom ordered

and therefore cannot be cancelled or returned per Vollrath Terms and

Conditions.

A

B

Figure 5. Control Panel with Switch and Innite Control.

A

A

A

Figure 6. Control Panel with Switches

A

ON/OFF Toggle Switch. Move the toggle switch to the up position

for “ON”. Move the toggle switch to the down position for “OFF”.

The switch(es) may operate a heating element(s) or light(s).

B

INFINITE HEAT CONTROL. Rotate the INFINITE HEAT

CONTROL off zero “0” to turn control on. Rotate to desired heat.

Figure 8. Stainless Steel C-Leg Stand - 13” (33 cm)

Figure 9. Stainless Steel T-Leg Stand -

Adjustable 8 to 15” (22.8 to 38.1 cm)

4

OperatOr’s Manual

opeRation

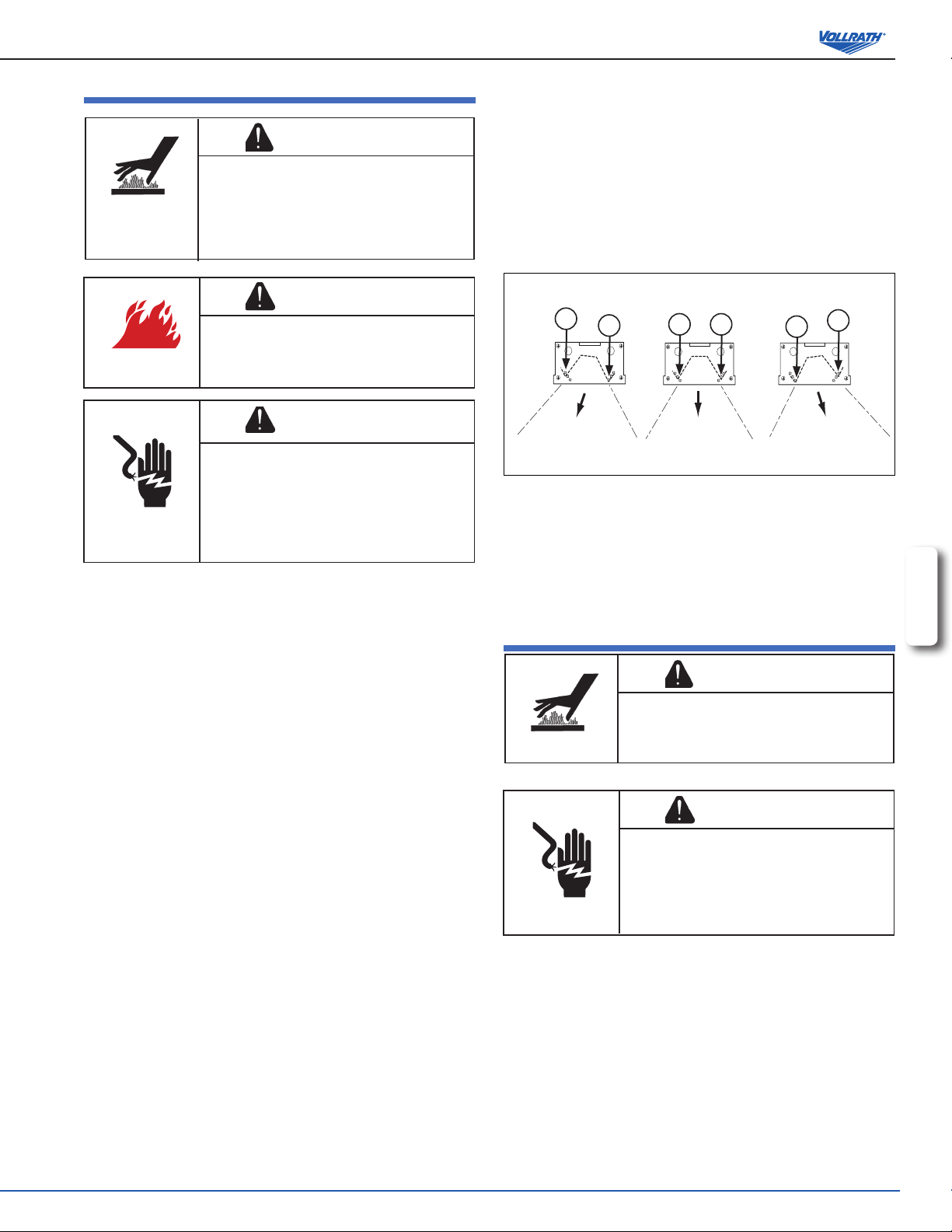

adjusting the heat ReflectoR

The heat strip units have been equipped with a directional heat reector to

allow the heat zone to be directed to best suite each application.

WARNING

Burn Hazard.

Do not touch heating surfaces, liquid, or while unit

is heating or operating.

and liquids can burn skin. Use gloves, mitts or

pot holders if it is necessary to handle hot pans,

plates and equipment.

Hot food, surfaces, steam

1. Turn the switch(es) to the “OFF” position(s). Allow the unit to cool

completely before continuing.

2. Make sure unit is cool. This is for safety and the reector can be moved

more easily when the unit is at room temperature.

3. Remove the small screws (A) from the holes on the end alignment

plates. There is one screw on each side of the end plate that secures the

reector. See Figure 10.

WARNING

Fire Hazard.

Do not install unit near combustible material. Do not

place combustible material under or on top of unit.

Discoloration or combustion could occur.

WARNING

Electrical Shock Hazard.

Keep water and other liquids from entering the

inside of the unit. Liquid inside the unit could cause

an electrical shock. Unit must be installed by

qualied personal in accordance with all local and

national ordinances. Do not use a power cord that

has been modied or damaged.

NOTE: Certain containers such as foam or plastic may melt if left in the

heat zone. Also, food left in the heat zone may begin to dry if left in the

heat zone for an extended time.

1. Make sure there are no combustible materials in contact or near the

food-warming unit.

2. Turn the heat switch(es) to the “ON”position or set the INFINITE HEAT

CONTROL to desired setting. Allow the unit to preheat for approximately

15 minutes before placing food in the heat zone.

3. If the unit is equipped with lights, switch the lights on.

4. Place food items to be kept warm in the heat zone. Regularly check the

food temperature. Adjust controls as necessary. See Note:

NOTE:

Monitor food temperature closely for food safety. The United States

Public Health Service recommends that hot food be held at a minimum

of 140 ºF (60 ºC) to help prevent bacteria growth. Maintain correct water

level and temperature setting. Periodically remove food container and

check the water level. Add water in needed.

5. When not in use turn the heat switch(es) to the “OFF” position or rotate

the innite heat control to the zero (0) position. Turn the lights to the

“OFF” position.

Figure 10. Reector Positions.

4. Pivot the reector in the desired direction.

5. There are 3 alignment screw holes to choose from that are located on

the outside end of the unit. Align the screw hole in the reector end

with the appropriate hole in the end plate for the desired direction of the

reector.

6. Place the screws in the appropriate location and tighten.

cleaning

1. Turn the power switch(es) off. Turn the light switch(es) off. Allow the unit

to completely cool.

2. Wipe the unit exterior with a clean damp cloth.

3. Do not use abrasive materials, scratching cleansers or souring pad to

clean the unit. These can damage the nish.

4. Thoroughly wipe off any mild soap or chemical cleaners. Residue could

corrode the surface of the unit.

A

A

A

A

A

A

ENGLISH

WARNING

Burn Hazard.

Hot surfaces can burn the skin

completely before cleaning.

. Allow unit to cool

WARNING

Electrical Shock Hazard.

Do not spray unit or controls with liquid or cleaning

product.

Liquid could enter the electrical compartment and

cause a short circuit or electric shock.

OperatOr’s Manual

5

tRouBleshooting

All procedures are to be carried out by qualied individuals. This may include Vollrath Authorized Service Agents or special trained personnel adhering to

local codes.

Problem It might be caused by Course of Action

Unit is switched “ON” but there is no heat.

The unit is on, but low heat.

Lights or switches burn out after a short

time.

ENGLISH

No power to the unit.

Defective switch. Replace the switch.

Wiring or heating element problem.

Unit is mounted too high above the

heating zone.

Excess cold air circulation around

heating zone or unit.

Incorrect power supply (low). Check that the power supply matching the nameplate rated voltage.

Check mounting height. If unit is to

low, the unit will over heat.

Check that there is power to the outlet. Reset circuit breaker if

necessary.

Check that all wire are good. Check that the element connection is

good. Check element and replace if necessary.

Re-mount unit lower, placing heat closer to heating zone. See Unit

Installation Clearances chart on page 2.

Restrict or redirect air movement away from heating zone or unit.

Check that the unit is mounted as specied in the Unit Installation

Clearances chart on page 2. If unit is not at the correct height,

remount unit.

6

OperatOr’s Manual

Black

White

Optional

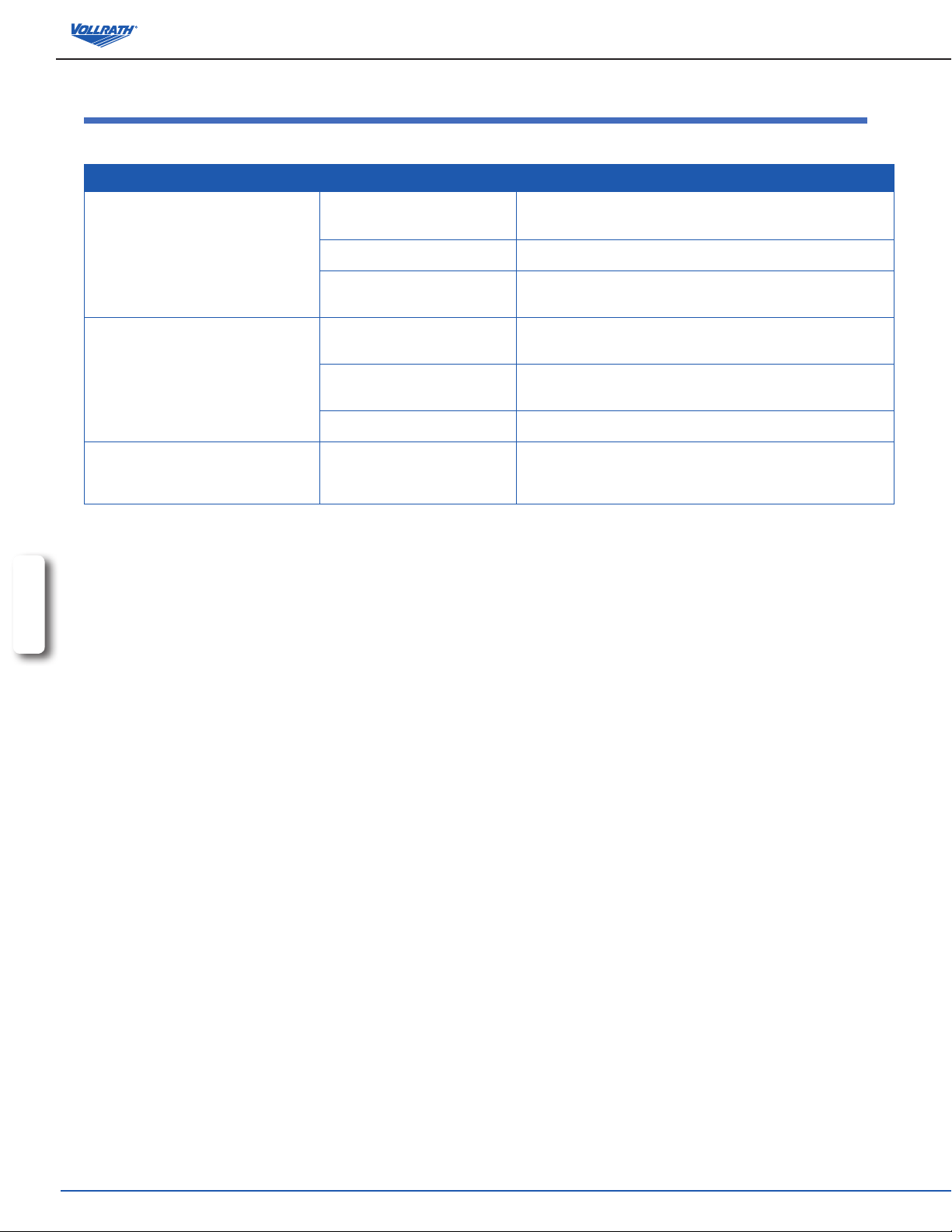

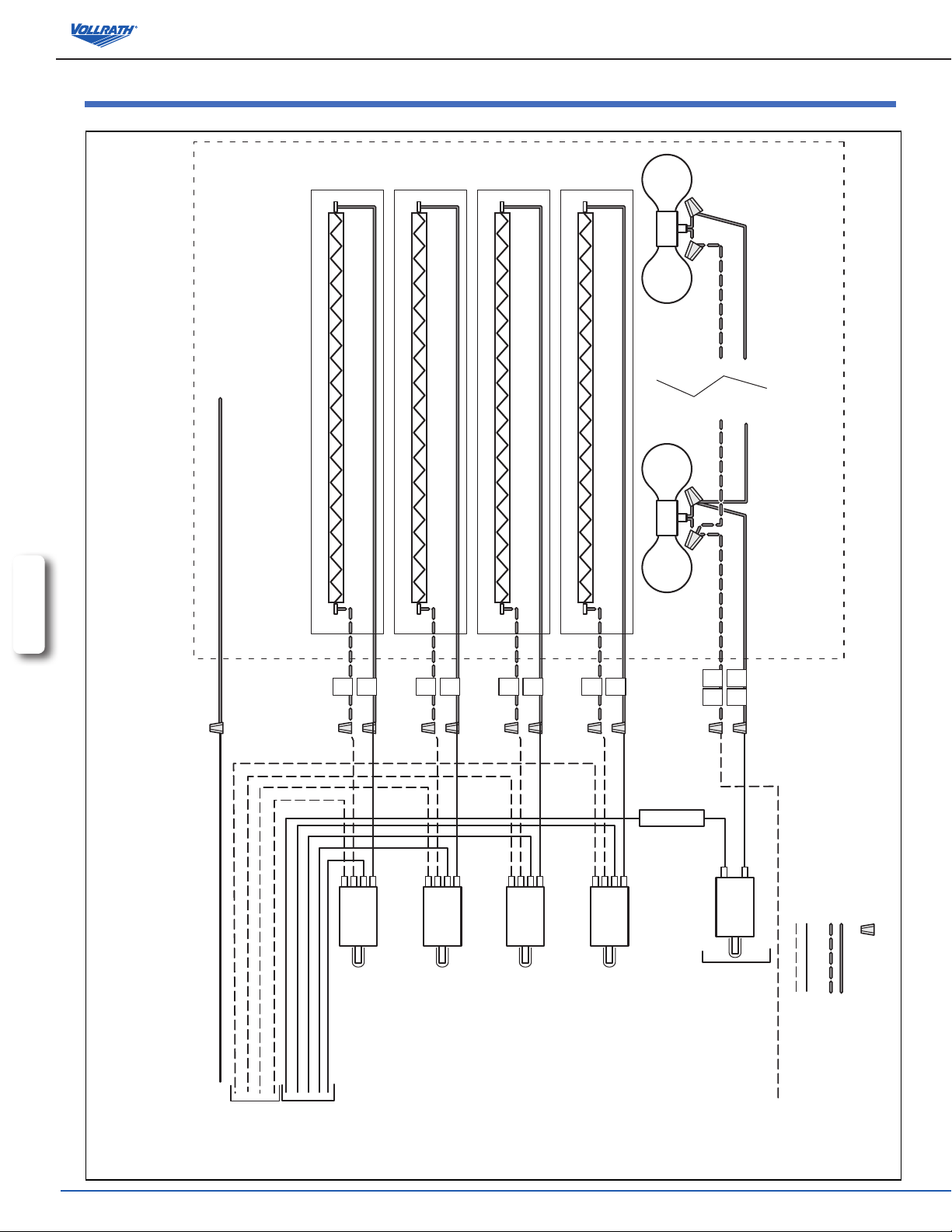

120 Volt Heater W/Infinate Control Assembly Wiring Diagram

electRical diagRam 120 volt heateR ~ infinite contRol

Ground Wire

Heater AssemblyControl Assembly

Heating Element #1

Heating Element #2

120 Volt Optional Lights

Heating Element #3

Heating Element #4

120V

120V

Up to 6 Light Fixtures Wired in Parellel

Green

ENGLISH

1

2

3

Relay

Power

4

5

6

7

Relay

Power

8

1 1

1 2

Ceramic Wire Nuts

200 °C Temprature Rated Wire

450 °C Temprature Rated Wire

Fuse

above 16 Amps

Use W/Lighted units

Green

N

L2

H1

H2

L1

P2 P1

L1

Light

Switch

OperatOr’s Manual

7

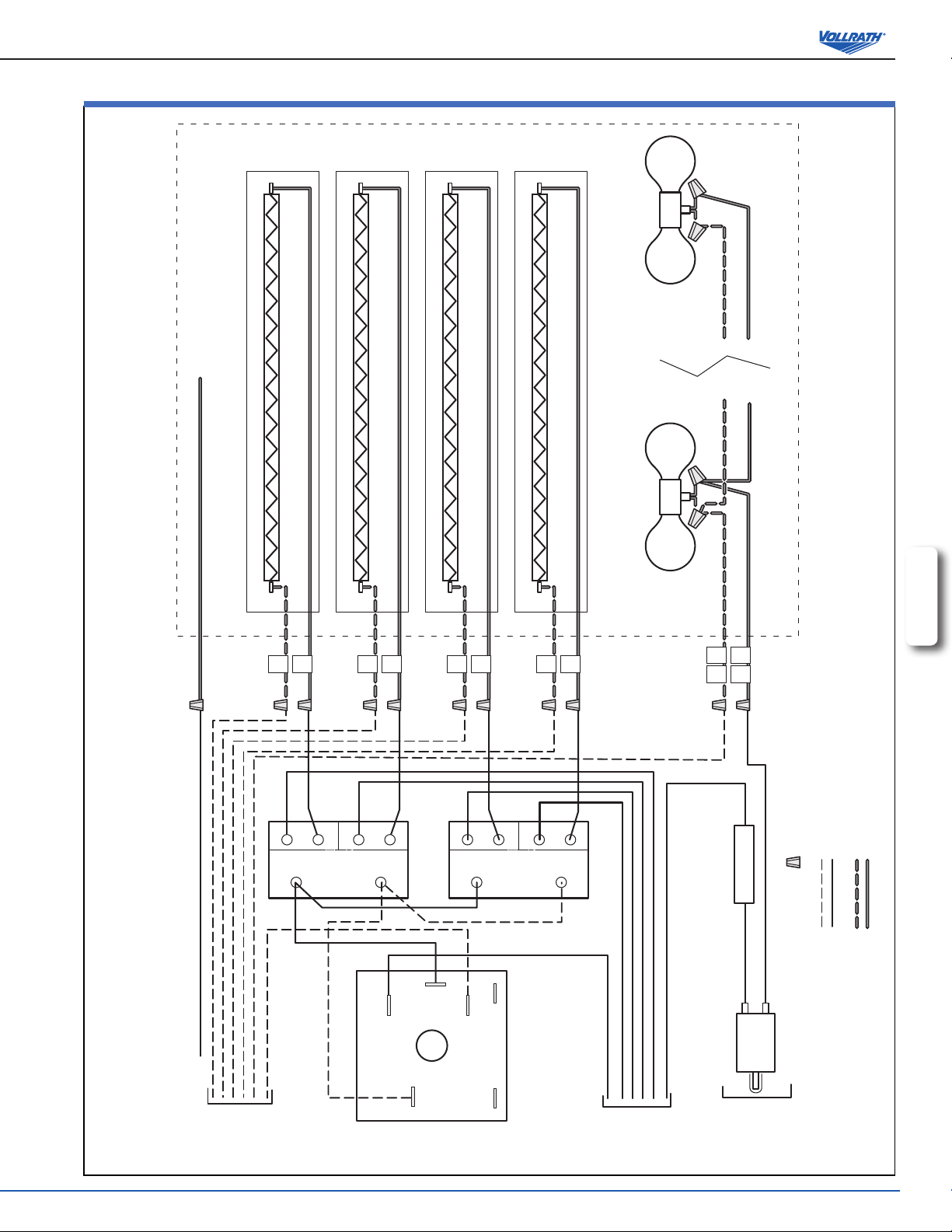

1 1

1 2

1

2

3

4

5

6

7

8

120V

120V

120 Volt Optional Lights

Up to 6 Light Fixtures Wired in Parellel

Heating Element #1

Heating Element #2

Heating Element #3

Heating Element #4

Light

Switch

Use Fuse W/Lighted

units above 16 Amps

L1

Black

Ground Wire

Green

Green

N

White

Optional

Heater AssemblyControl Assembly

Ceramic Wire Nuts

450 °C Temprature Rated Wire

200 °C Temprature Rated Wire

120 Volt Heater W/Toggle Switch Control Assembly Wiring Diagram

electRical diagRam 120 volt heateR ~ switch contRol

ENGLISH

8

OperatOr’s Manual

Optional

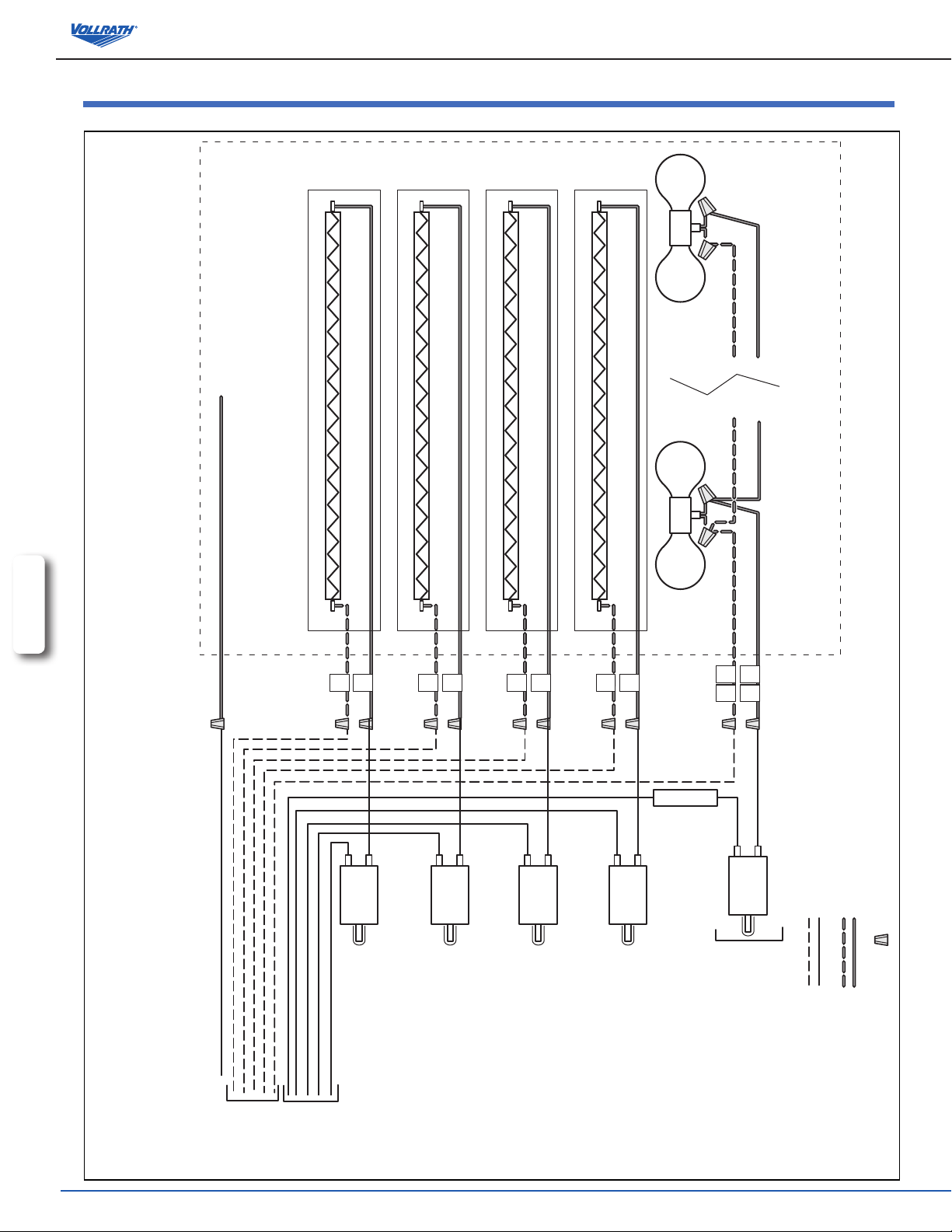

208 - 240 Volt Heater W/Infinate Control Assembly Wiring Diagram

electRical diagRam 208 - 240 volt heateR ~ infinite contRol

Ground Wire

Heater AssemblyControl Assembly

Heating Element #1

Heating Element #2

Heating Element #3

120V

120 Volt Optional Lights

Heating Element #4

120V

Up to 6 Light Fixtures Wired in Parellel

Green

ENGLISH

200 °C Temprature Rated Wire

Ceramic Wire Nuts

450 °C Temprature Rated Wire

1

2

3

Relay

Power

L2

4

H2

5

L1

6

7

Relay

Power

8

1 1

1 2

Fuse Use W/Lighted

units above 16 Amps

White Nuetral Wire

Green

L1

Red

H1

P2 P1

L2

Black

Light

Switch

OperatOr’s Manual

9

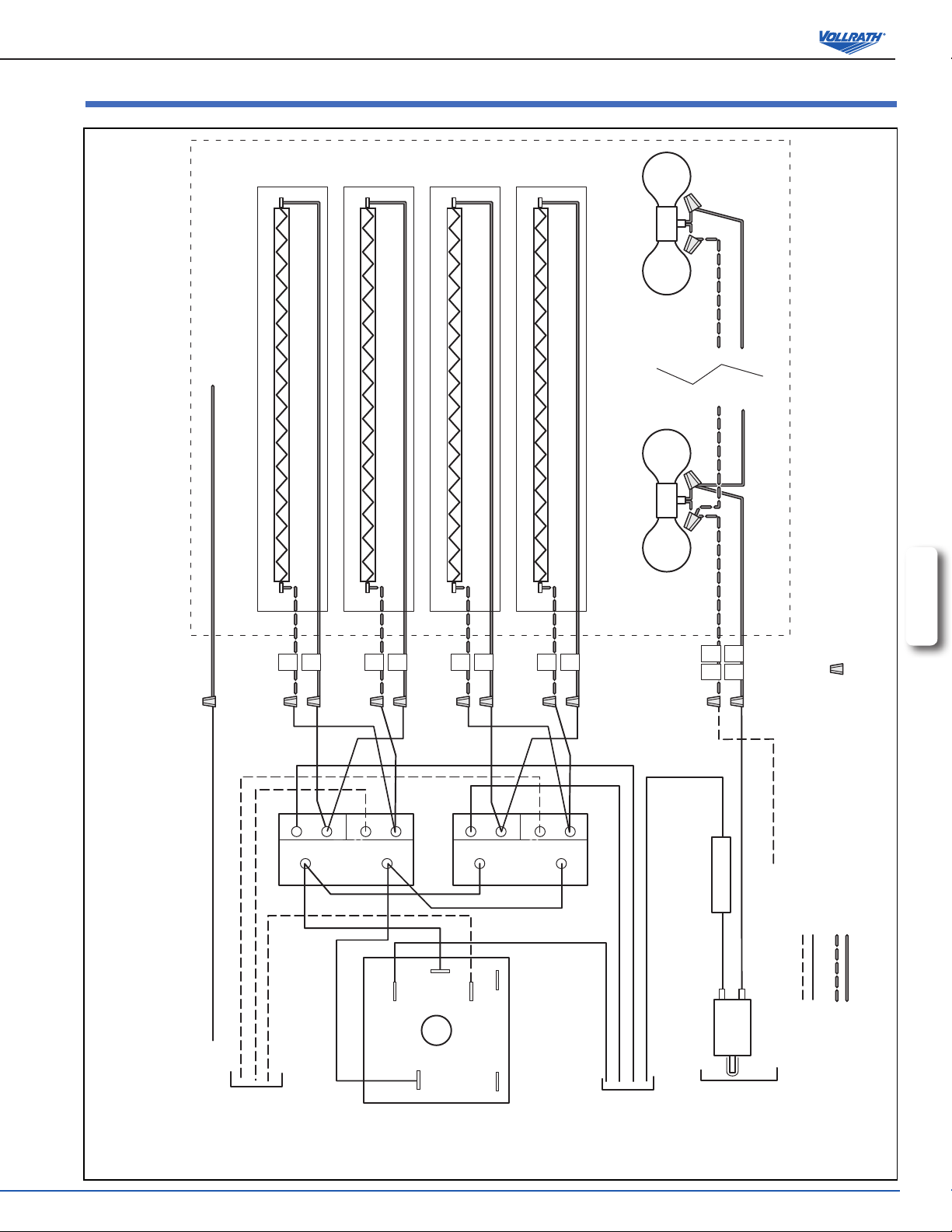

1 1

1 2

1

2

3

4

5

6

7

8

120V

120V

120 Volt Optional Lights

Up to 6 Light Fixtures Wired in Parellel

Heating Element #1

Heating Element #2

Heating Element #3

Heating Element #4

Light

Switch

Use Fuse W/Lighted

units above 16 Amps

L2

Black

Ground Wire

Green

Green

L1

White

Optional

Heater AssemblyControl Assembly

Ceramic Wire Nuts

450 °C Temprature Rated Wire

200 °C Temprature Rated Wire

208 - 240 Volt Heater W/Toggle Switch Control Assembly Wiring Diagram

electRical diagRam 208 - 240 volt heateR ~ switch contRol

ENGLISH

10

OperatOr’s Manual

notes

ENGLISH

OperatOr’s Manual

11

Loading...

Loading...