Vollrath 40834 Installation Manual

Operator’s Manual

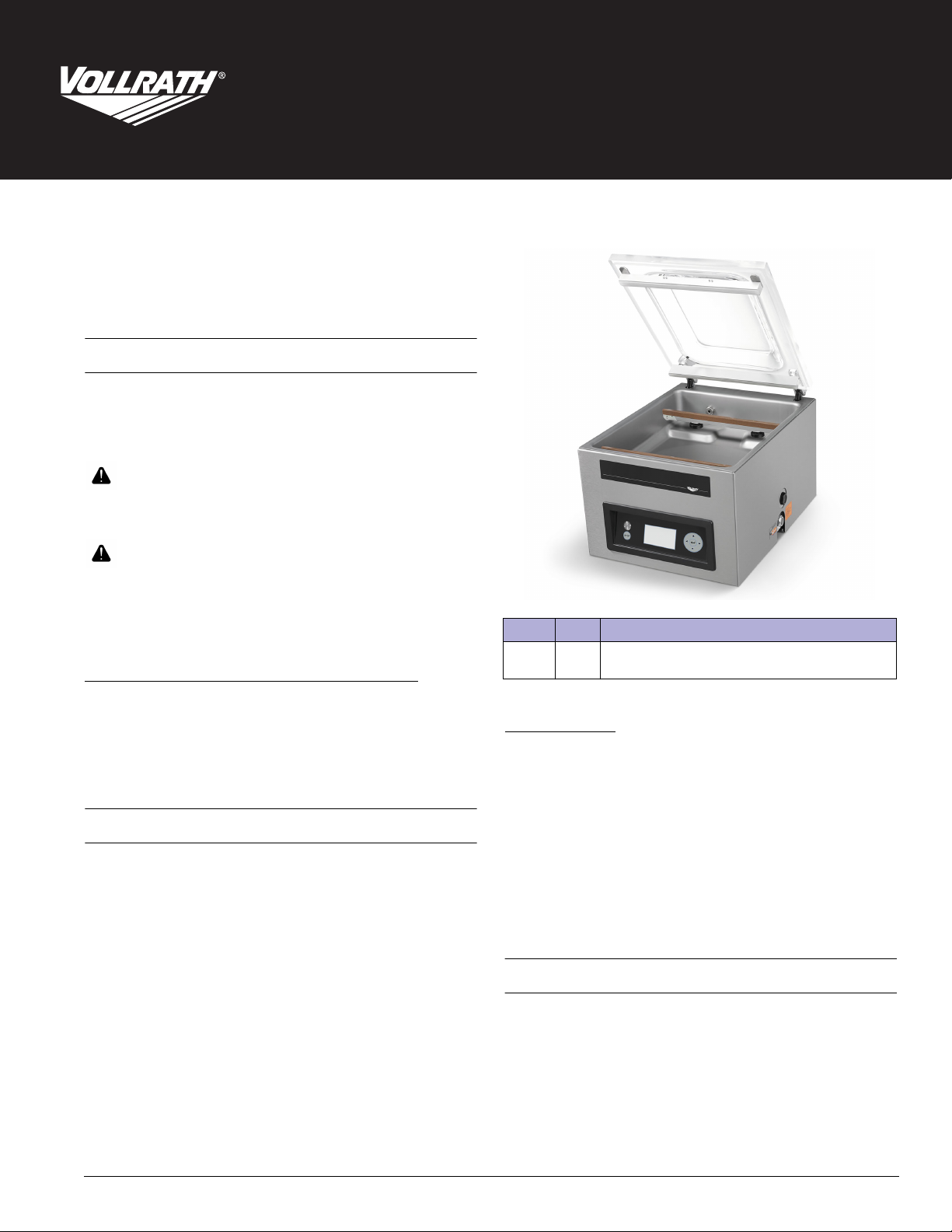

Vacuum Packing Machine with Dual 16" Sealing Bars and Advanced Control System (ACS)

Thank you for purchasing this Vollrath equipment. Before operating the

equipment, read and familiarize yourself with the following operating

and safety instructions. SAVE THESE INSTRUCTIONS FOR FUTURE

REFERENCE. Save the original box and packaging. Use this packaging

to ship the equipment if repairs are needed.

SAFETY PRECAUTIONS

To ensure safe operation, read the following statements and understand

their meaning. This manual contains safety precautions which are

explained below. Please read carefully.

WARNING

Warning is used to indicate the presence of a hazard that will or can

cause severe personal injury or death.

CAUTION

Caution is used to indicate the presence of a hazard that will or can

cause minor or major personal injury if the caution is ignored.

NOTICE: Notice is used to note information that is important but not

hazard-related.

To reduce risk of injury or damage to the equipment:

• Unplug when not in use.

• Keep unit and power cord away from open flames, electric burners

or excessive heat.

• Do not operate unattended.

• Do not operate if unit has been damaged or is malfunctioning in

any way.

FUNCTION AND PURPOSE

This unit is intended to vacuum seal food products in a commercial

kitchen environment. It is not intended for household, industrial or

laboratory use.

Item No. Model Description

40834 VPP16 Vacuum Packing Machine with Dual 16" Sealing Bars

and Advanced Control System (ACS)

Table of Contents

Features and Controls .................................................. page 2

Password-Controlled Access ...................................... page 2

Installation ..................................................................page 2

Operation ..................................................................... page 3

Create Custom Programs and Labels........................... page 4

HACCP Data Log .........................................................page 7

Cleaning ...................................................................... page 7

Maintenance................................................................. page 8

Troubleshooting...........................................................page 10

Maintenance Log.......................................................... page 11

CLEARANCE REQUIREMENTS

• Requires 6" (15 cm) clearance on all sides and 15½" (39.4 cm)

above the machine for the lid to fully open.

• Ambient temperature must be between 41-86 °F (5-30 °C).

NOTICE: Never place the machine near a heat source. This can

damage the lid.

©

2020 The Vollrath Company L.L.C. Part No. 26134-1 ml 2/27/20

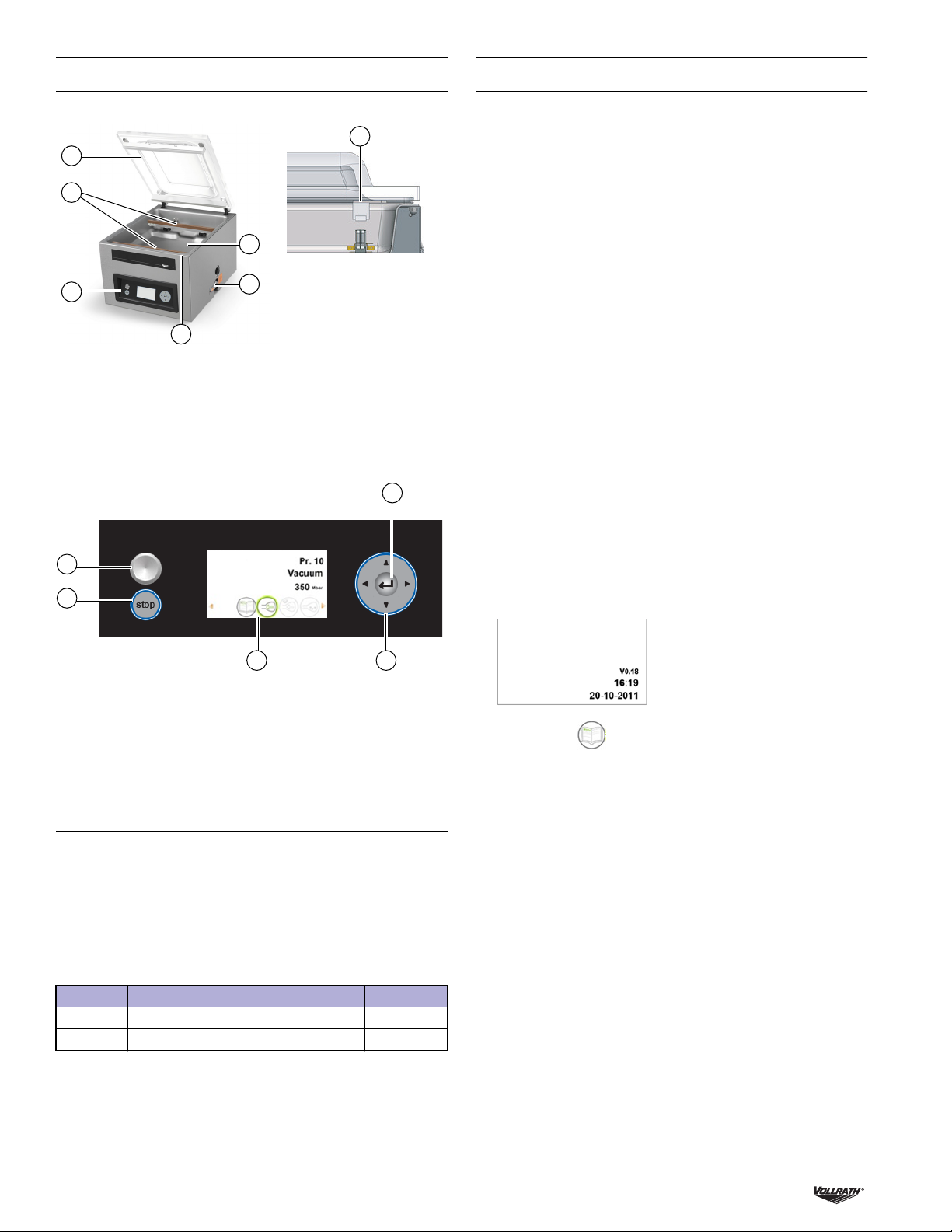

FEATURES AND CONTROLS

INSTALLATION

G

A

B

F

C

D

A Lid E Oil Inspection Window

B Seal Bars F Chamber

C Control Panel G Seal Pad

D Lid Retainer

(not pictured)

A

B

E

NOTICE: Do NOT tilt the machine. Tilting could allow oil to flow out

NOTICE: Using a voltage other than the nameplate rated voltage will

NOTICE: Running the machine without oil or insufficient oil will

1. Remove all packing material and tape, as well as any protective

2. Clean any glue residue left by the plastic or tape.

3. Place the vacuum pack machine on a flat, level surface.

4. Install the included 4" (10.2 cm) legs. ETL Sanitation requires

5. Check the oil gauge window at the back of the machine. Verify the

6. Plug the power cord into a grounded electrical outlet that matches

7. Run the Pump Conditioning program. See Daily Cleaning on

of the pump and cause damage to the machine.

cause damage to the unit. Incorrect voltage, modification

to the power cord or electrical components can damage

unit and will void the warranty.

damage the machine and void the warranty.

plastic from the equipment.

machine to be used with included legs.

oil level is between the minimum and maximum fill lines.

the nameplate rated voltage.

page 7.

Set the Time and Date

E

The default time on the machine may not match your local time. If you

plan to use HACCP logging, it is important to set the correct time. There

are also several date formats from which to choose. Both of these can

be changed in the Settings menu.

1. Turn on the machine.

Press and release the On/Off button. Allow approximately 7-10

seconds for the display to load. The start-up screen will display

information about the software, time and date. For example:

C D

A On/Off Button D Navigation Buttons

B Stop Button E Enter Button

C Display

PASSWORD-CONTROLLED ACCESS

NOTICE: The machine remembers the last password used. To

prevent unauthorized changes, login as User after you

change settings.

The machine has two levels of password-controlled access – owner

mode and user mode. The machine arrives in owner mode. This allows

full-access to all settings and programs. User mode locks the settings

and programs so they cannot be changed. To switch to user mode,

login to the machine using the user code.

Login As Access To Password

User Run programs and adjust printer settings 0000

Owner Change settings and edit programs 1324

2. Press until is highlighted. Press .

3. Enter the owner password 1324. Press .

(Press to select a number. Press to enter to the next number.)

4. Press to enter the Settings menu.

5. Press to 1.3 Date and Time. Press .

2 Vacuum Packing Machine with Dual 16" Sealing Bars and Advanced Control System (ACS) Operator’s Manual

OPERATION

The machine includes 20 default programs. These programs can be

named and the settings customized for specific needs. See Create

Custom Programs and Labels on page 4 for instructions.

NOTICE: Never pack products that can be damaged by vacuum

packaging.

NOTICE: To reduce condensation and corrosion risk for the pump,

cool products before packing.

NOTICE: When packing food, always select a program that includes

Liquid Sensor Control.

NOTICE: Special instructions apply for packing liquid products. See

Packing Liquid Products on page 3.

NOTICE: The machine is designed for a maximum use of five hours

per day.

NOTICE: This machine is not designed for continuous use. Allow 15

seconds between packing cycles.

NOTICE: If the machine has been in use for one hour, stop the

machine and allow it to cool to ambient temperature.

NOTICE: Do NOT tilt the machine. Tilting could enable oil to flow out

of the pump and cause damage to the machine.

Turn On the Machine

1. Rotate the lid retainer so it is not covering the lid. The lid retainer is

used only for securing the lid when the machine is not in use.

2. Press and release the On/Off button and allow approximately 7-10

seconds for the display to load.

3. If the machine has not been used for a while, run the Pump

Conditioning Program. See page 7.

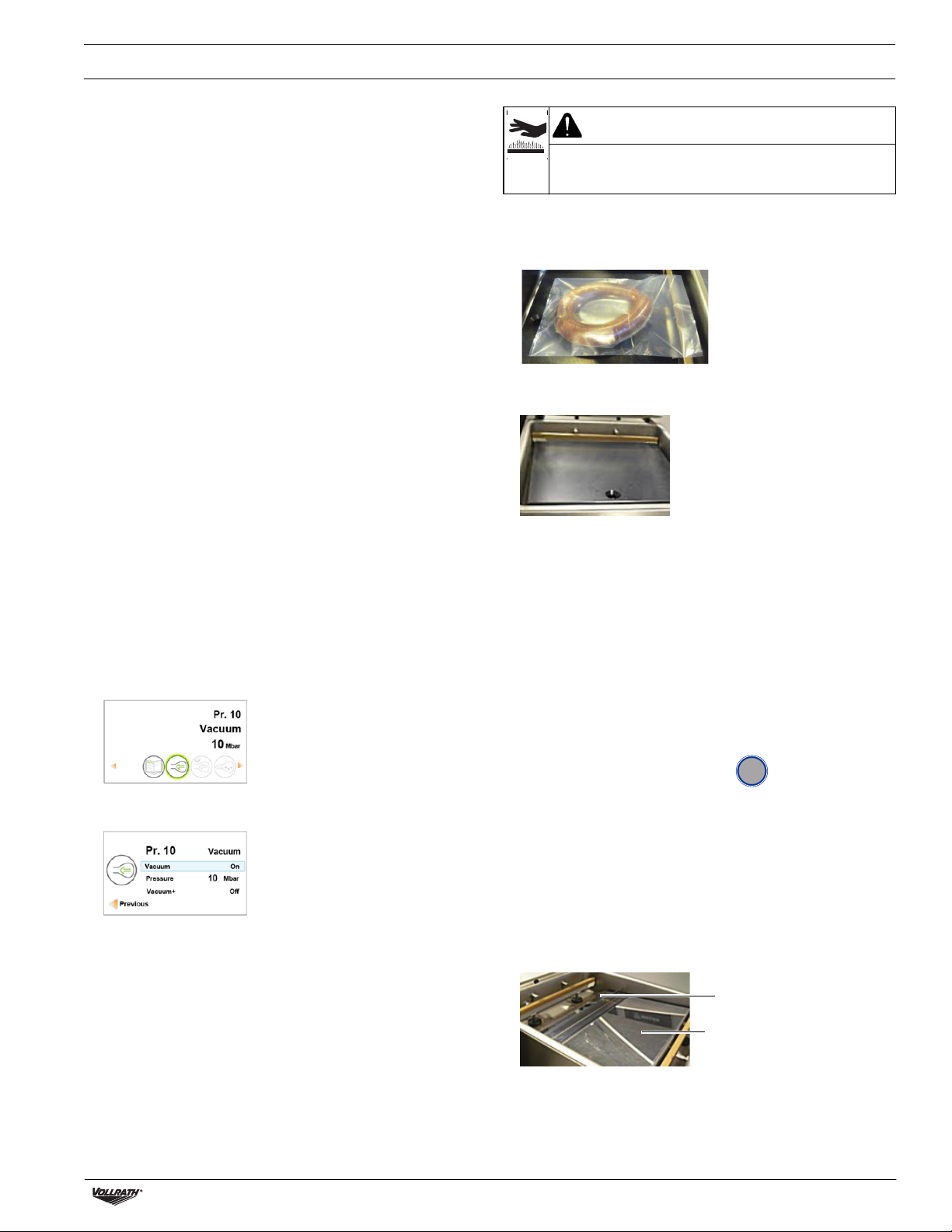

Place the Product in the Chamber

CAUTION

Burn Hazard

Sealing bar may become hot after repeated use. Do not touch

the sealing bar when placing vacuum bags in the chamber.

1. Place the food product in a vacuum sealing bag that fits completely

within the chamber.

2. Place the bag in the chamber with the open end over the sealing

bar. Make sure the bag is smooth, without wrinkles or folds.

3. For small products, place one or more insert plates under the

product. This fills empty space in the chamber, which reduces the

cycle time.

4. Multiple vacuum bags can be placed over the sealing bars. Do NOT

overlap vacuum bags.

Select a Program

Packing a Food Product: Select a program that includes Liquid Sensor

Control.

Packing a Liquid Product: See important information under Packing

Liquid Products on page 3.

1. Press or to select a program.

Press or to view the functions in the program.

2. Press to view the settings of a function. For descriptions of the

functions, please see page 4

.

Run the Program

1. Close the lid. Do NOT use the lid retainer. Using the lid retainer

during a packing cycle will interfere with the cycle.

2. The program automatically starts.

3. The lid opens when the last function is complete.

4. Remove the packed product.

5. Wait 15 seconds before packing another product.

Stop a Cycle

• Stop the vacuum function and continue to the next function,

press .

• Stop and cancel the entire cycle Press

stop

Packing Liquid Products

Special care needs to be taken when vacuum packing liquid or moist

products.

• Cool foods before packing. Hot food quickly reaches the boiling

point, which can lead to an insufficient seal.

NOTICE: Hot products create condensation, which can damage

1. Use the included incline plate and magnetic positioning bars to

the pump.

position the bag so the liquid is below the sealing bar. Magnetic

bars are shipped attached to the underside of the incline plate.

Magnetic bar

Incline plate

2. Use a program that includes the Liquid Sensor Control function.

This will prevent the product from boiling.

NOTICE: Boiling will increase the amount of moisture that enters

3. Run the Pump Conditioning Program at the end of the work day.

Vacuum Packing Machine with Dual 16" Sealing Bars and Advanced Control System (ACS) Operator’s Manual 3

the pump, which can lead to corrosion.

See page 7.

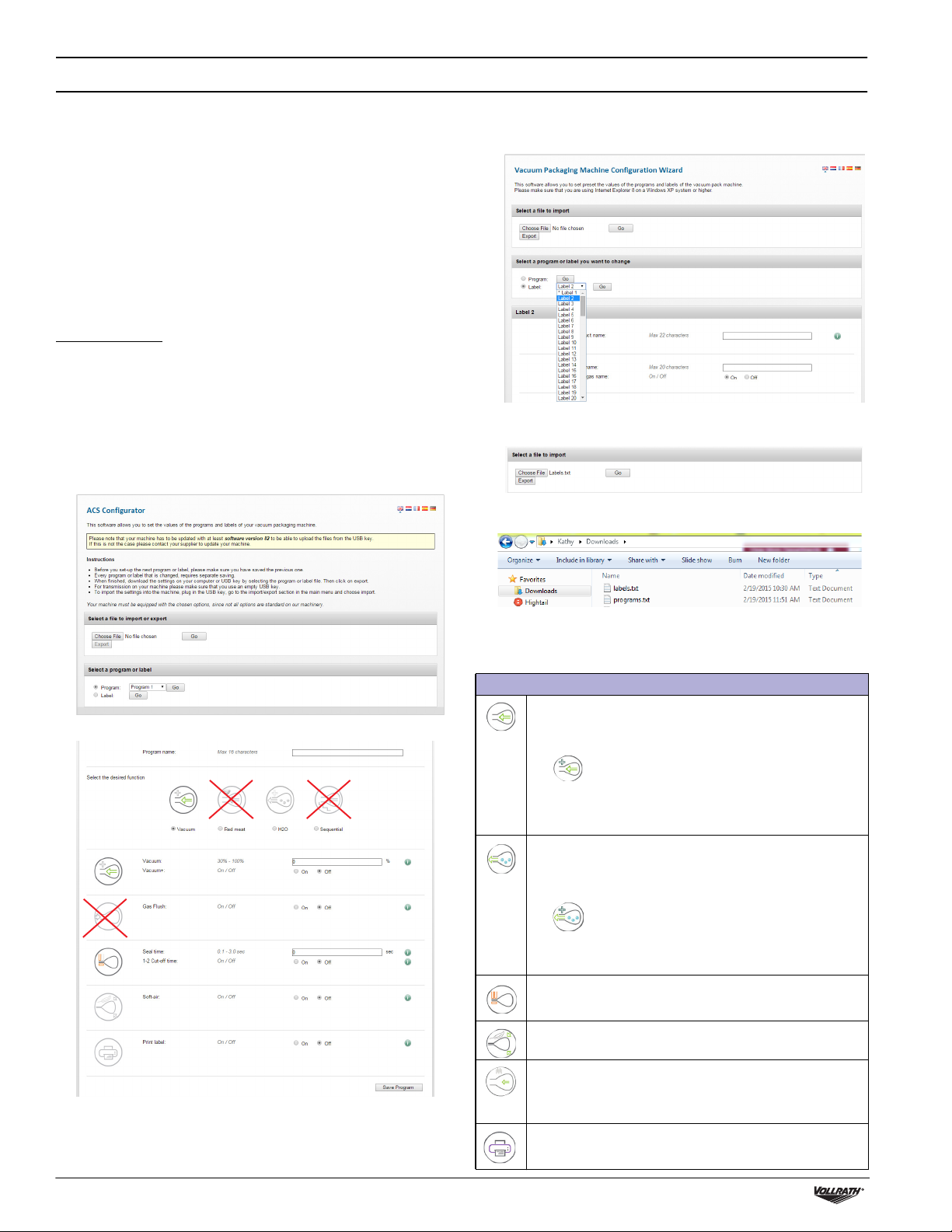

CREATE CUSTOM PROGRAMS AND LABELS

The default programs can be customized to fit your specific needs.

• If you have access to a computer, use the online ACS Configurator

Tool to create your custom programs and labels.

• If you do not have access to a computer, use the control panel on the

machine to create programs. See Create Programs Using the Control

Panel on page 5.

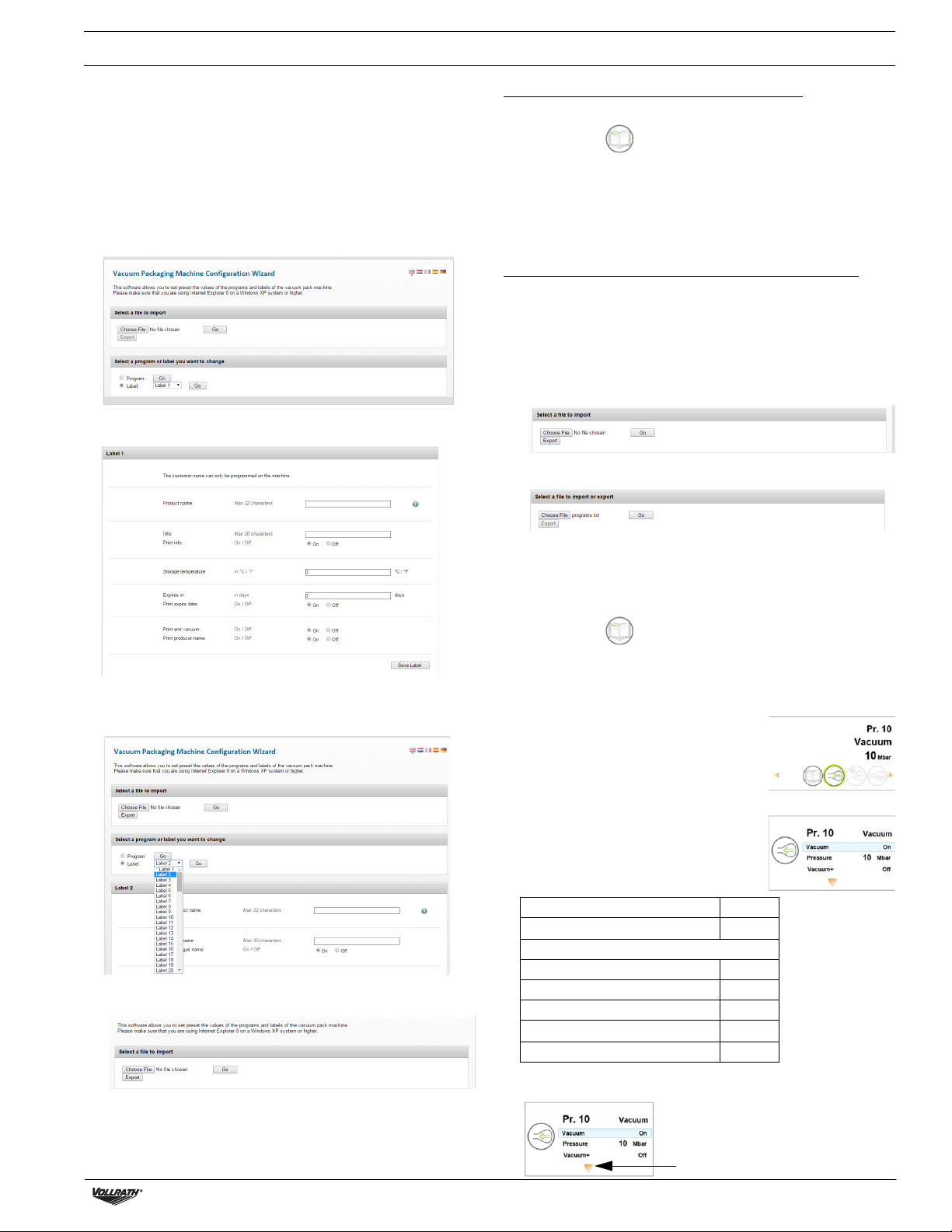

Create Programs and Labels with ACS Configurator

• A USB stick (not included) is required.

The ACS Configurator provides an easy-to-use interface for creating

custom programs and labels. Download and save the programs and

labels to a USB stick for transferring to the machine.

Create Programs

You can create new programs or edit the default programs on the

machine. To edit the default programs, you must first download the

programs from the machine. See Edit Programs or Label Data Using

the ACS Configurator on page 5. To create new programs, continue

below.

1. Start a web browser such as Internet Explorer or Chrome.

2. Go to http://www.acs-configurator.com

3. Select Program and Program 1. Click Go.

5. Click Save. An asterisk in front of the program indicates it has been

saved.

6. To create another program select Program 2. Press Go.

7. Enter and save data for each program.

8. Click Export to save the programs to your computer.

9. The file “programs.txt” will be saved to the downloads folder on

your computer.

4. Edit functions in Program 1.

NOTICE: The Red Meat, Gas Flush, Sequential Vacuum and Cut-

off functions are not available on this Vacuum Packing

Machine. Settings for these functions are not used when

the program is loaded into the machine.

10. Copy the file “programs.txt” to a USB stick.

NOTICE: Do not rename “programs.txt.” Programs will not load

into the machine if the name has been changed.

Function Descriptions

Final Vacuum Pressure % – Sets vacuum to reach a set

pressure.

• Recommended minimum is 50%.

Vacuum + – Extends the vacuum cycle to enable air

trapped in the product to escape the bag.

• To use this function, Final Vacuum Pressure must be

set to 99.8%.

Liquid Control – Use when packing food. Detects the boiling

point, stops the vacuum and advances to the next step to

produce a better quality product and prevents damage to the

pump from moisture in the product.

Liquid Control + – Similar to Vacuum +.

Extends the vacuum cycle to enable air trapped in the

product to escape the vacuum bag.

Sealing Time – Sets the seal time.

• 2.0 to 2.5 seconds recommended for most bags.

Soft-Air – Gently forms the bag to protect delicate products or

prevent damage to the bag from sharp edges on product.

Tenderize – Uses vacuum pressure to quickly marinate food.

Set pressure and marinate time. Can only be programmed

through the control panel. Not available in the ACS

Configurator.

Print – Select a label to print with a program.

4 Vacuum Packing Machine with Dual 16" Sealing Bars and Advanced Control System (ACS) Operator’s Manual

CREATE CUSTOM PROGRAMS AND LABELS (CONTINUED)

Create Label Data

• Label printer, USB cable and labels are required to print labels, but

are not included.

Use the online configurator tool to enter data for labels. Download and

save label data to a USB stick for loading into the machine. Label data

can include: product name, description, storage temperature, expiration

date, vacuum pressure and the name of person who packed the

product.

1. Start a web browser such as Internet Explorer or Chrome.

2. Go to http://www.acs-configurator.com

3. Select Label and Label 1. Click Go.

4. Enter the data for Label 1.

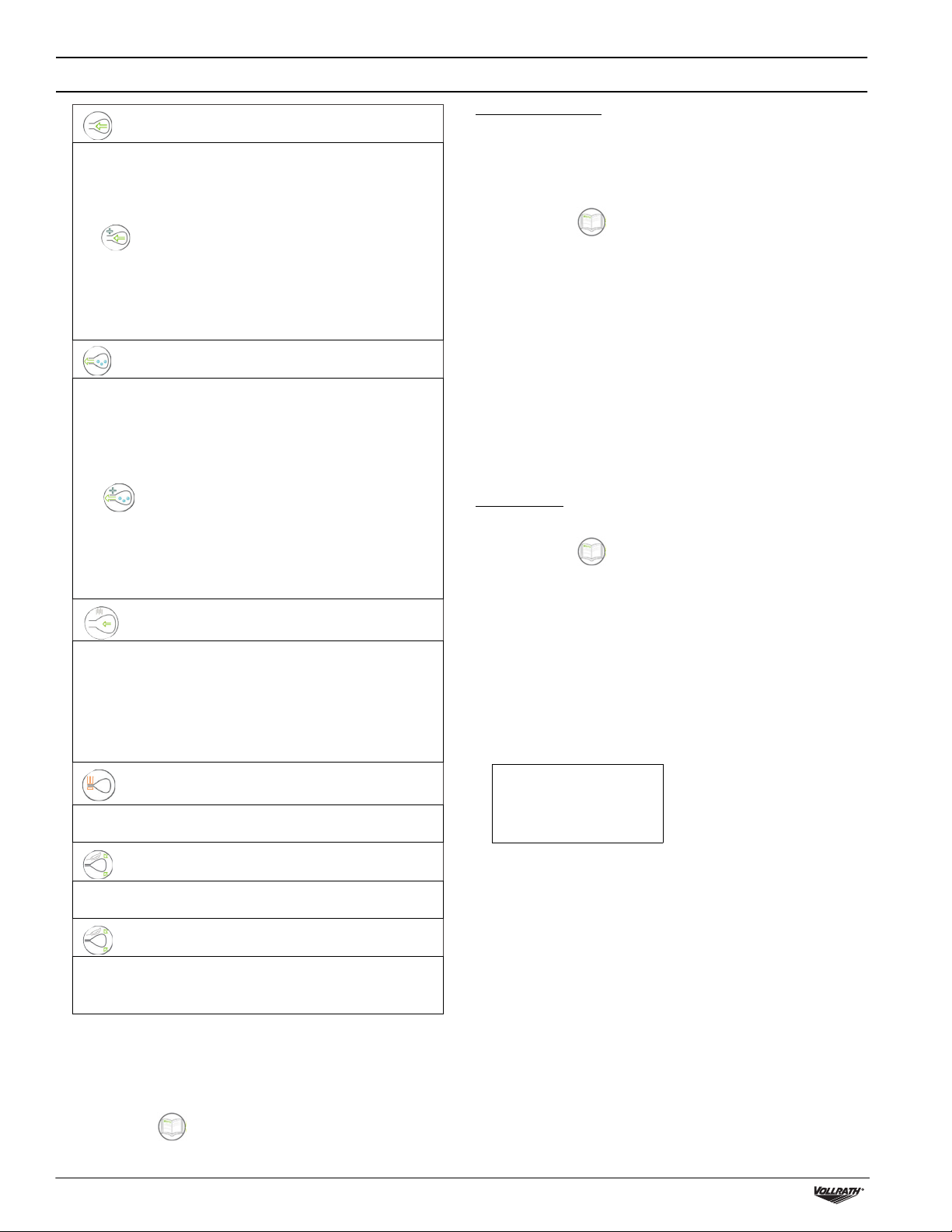

Load Program and Label Data into the Machine

1. Insert the USB stick into the USB port at the back of the machine.

2. Press until is highlighted. Press .

3. Enter the owner password 1324. Press to select a number.

Press to enter to the next number. Press .

4. Select Import/Export. Press .

5. Select Import Data from USB to copy the programs and labels into

the machine. Press .

Edit Programs or Label Data Using the ACS Configurator

• You can use the ACS Configurator to edit existing programs or

labels. If the programs or labels are in the machine, export the

information to a USB stick. Reverse the procedure for Loading

Programs and Label Data into the Machine.

1. Start a web browser such as Internet Explorer or Chrome.

2. Go to http://www.acs-configurator.com

3. Click Choose File.

4. Navigate to the location of the “programs.txt” or “labels.txt” file

containing the label data. Click Open.

5. Click Save. An asterisk in front of the label indicates the data has

been saved.

6. To enter data for another label, select

7. Enter and save data for each label.

8. Click Export to save the labels to your computer.

9. The file “labels.txt” will be saved to your computer.

10. Save “labels.txt” to a USB stick.

NOTICE: Do not rename “labels.txt.” The labels will not load into

the machine if the file has a different name.

Label 2. Press Go.

5. Click Go to load your label data into the configurator.

Create Programs Using the Control Panel

1. Enter programming mode.

Press until is highlighted. Press .

Enter the owner password 1324.

(Press to select a number. Press to enter to the next number.)

Press .

2. Select a program to edit.

Press or to scroll through

programs.

Press to select the program.

Confirm the owner password.

3. Select a function to edit.

Press or to view functions.

Press to select the function.

4. Edit the settings in a function.

Select a setting or

Edit the selected setting

Change the setting

Increase

Decrease

Go to previous or next character

Confirm the change

Go back

A downward pointing arrow at the bottom of a screen indicates

more options. Press to see the options.

or

More options

Vacuum Packing Machine with Dual 16" Sealing Bars and Advanced Control System (ACS) Operator’s Manual 5

CREATE CUSTOM PROGRAMS AND LABELS (CONTINUED)

Name the Programs

Vacuum Pressure

1. Set the vacuum pressure.

• Recommended minimum is 50%.

• To use Vacuum+, vacuum pressure must be set to 99.8%.

2. To edit the Vacuum + function, continue below.

Vacuum +

1. Turn on Vacuum Plus.

2. Set the time.

When Vacuum + is selected the plus sign in the program ICON is

highlighted blue.

Liquid Control

Settings in Liquid Control override any settings in Vacuum

function.

1. Turn Liquid Control On.

2. Set the vacuum pressure.

3. To edit the Liquid Control + function, continue below.

The default programs are named Pr. 1 through Pr. 20. You can change

the program names to be more descriptive. For example, Fish, Soup,

Steak, Cheese, Vacuum 85%, etc. The new program names display at

the program select level. But the default name displays when viewing

the details of the functions in the program.

1. Press until is highlighted. Press .

2. Enter the owner password 1324.

3. Press to enter the Settings menu.

4. Press to 1.7 Program Names. Press .

5. Press to Select a Program. Press .

6. Press or to select a program number. Press .

7. Press to Name. Press .

8. Use arrow buttons to enter a name.

9. Press .

10. To name another program, press .

11. Login using the user password 0000 to prevent unauthorized

(Press to select a number. Press to enter to the next number.)

changes to the machine.

Liquid Control +

1. Turn on Liquid Control +.

2. Set the Liquid Control + Time.

When Liquid Control + is selected the plus sign in the program

ICON is highlighted blue.

Tenderize (Marinate)

NOTICE: When using the Tenderize function you must also turn

on Liquid Control.

Tenderize will vacuum to the pressure set in the Tenderize function

or until Liquid Control detects boiling.

1. Turn Tenderize On.

2. Set a vacuum pressure.

3. Set the time.

Sealing Time

1. Set the number of seconds.

• 2.0 -2.5 seconds recommended for most bags.

Soft Air

1. Turn Soft Air On or OFF.

2. Set the time.

Print

1. Turn label print On or Off.

2. Select which label to print.

3. Set the number of labels to print per cycle.

Create Labels

Enter the data you wish to print on labels.

1. Press until is highlighted. Press .

2. Enter the owner password 1324.

(Press to select a number. Press to enter to the next number.)

3. Press Enter to enter the Settings menu.

4. Press to 1.1 Printer. Press .

5. Press to Set Labels.

6. Enter the label data.

7. To create another label, press .

8. Login using the user password 0000 to prevent unauthorized

changes to the machine.

Tip:

To enter: Press

Lowercase letter

Uppercase letter

5. Edit another function in the current program.

Press .

6. Exit owner mode and return to user mode.

This will prevent unauthorized changes to settings and programs.

Press until is highlighted. Press .

Enter the user password 0000 and press .

6 Vacuum Packing Machine with Dual 16" Sealing Bars and Advanced Control System (ACS) Operator’s Manual

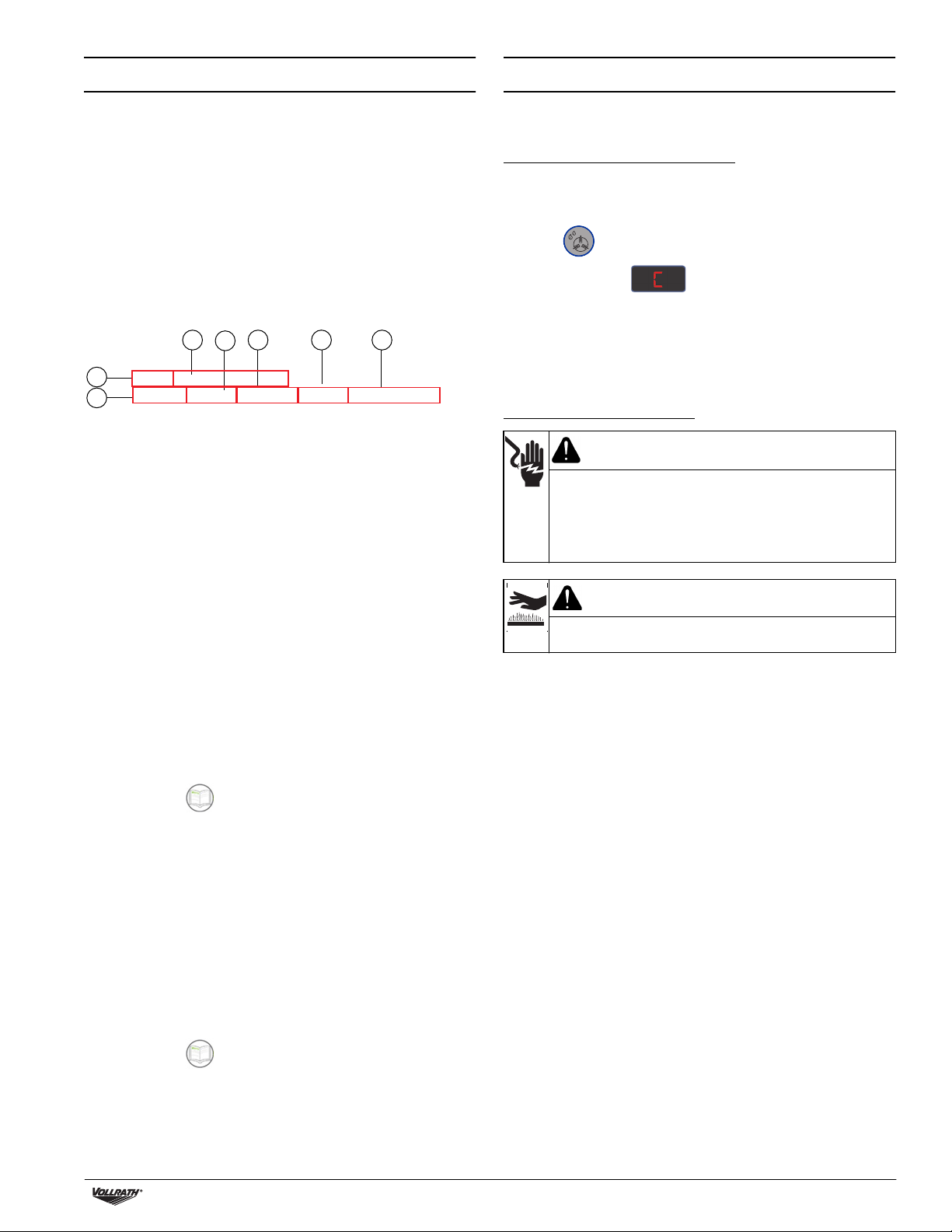

HACCP DATA LOG

The machine can log HACCP information. Each entry in the log

contains: date, time, user, selected programs and settings, selected

label and number of cycles.

• HACCP can only be turned On or Off by the owner. Once it is turned

on, data can be logged by logging into the machine using the

following codes: owner: 1324, user 2: 3821, user 3: 5718, user 4:

6982, user 5: 9217. The generic user code 0000 cannot be used.

• A new entry is started each time a different user logs in or when

programs and program settings are changed.

• The HACCP log can hold up to 100 entries.

• Log data is saved as a .txt file and can be exported to a USB stick.

• After exporting the data, the log will automatically be cleared.

C E F G

D

B

User:hm started 28-3-2013 16:42

Program 2=, Vac:98%, Seal:0.3 sec, Labelnr.:1, Amount of cycles:2

A

User:he started 28-3-2013 16:43

Program 1=, Vac:99.8% Seal:0.4 sec, Labelnr.:1, Amount of cycles:1

User:hm started 28-3-2013 16:44

Program 3=, Vac:90%, Seal:2.5 sec, Labelnr.:1, Amount of cycles:2

User: started 28-3-2013 16:45

Program 3=, Vac:95% Seal:2.5 sec, Labelnr.:1, Amount of cycles:1

A The program number used.

B The initials of the person who has logged in.

If no initials are entered in the settings, nothing is displayed here

(see the last entry of the sample log).

C Start time and date of the production.

D The maximum vacuum reached for the package.

E The seal time used.

F The label printed with this package.

G The total number of operating cycles.

Turn On HACCP Logging

Use the control panel to turn on HACCP. Before logging HACCP data,

set your machine to your local time and preferred date format.

1. Press until is highlighted. Press .

2. Enter the owner password 1324.

(Press to select a number. Press to enter to the next number.)

3. Press to enter the Settings menu.

4. Turn on HACCP.

5. Assign user initials to each User (Pin Code) (optional).

Select a User (Pin Code).

Press to Name to enter user initials.

6. Log into the machine as owner or with one of the HACCP PINs.

CLEANING

Daily

Run the Pump Conditioning Program

The Pump Conditioning Program removes any moisture that may have

accumulated in the pump. During the program, the pump and oil reach

operating temperature, which evaporates any moisture in the pump.

1. Press .

2. The display shows .

3. Close the lid.

4. The program starts. Moving dots appear on the display.

5. The program runs for approximately 15 minutes. Do not interrupt

the program. If the program is interrupted, it must be run again to

ensure completion.

Clean the exterior and interior

WARNING

Electrical Shock Hazard

Keep water and other liquids from entering the inside of the

equipment. Liquid inside the equipment could cause an

electrical shock. Do not spray water or cleaning products.

Liquid could contact the electrical components and cause a

short circuit or an electrical shock.

CAUTION

Burn Hazard

Allow equipment to cool before moving or cleaning.

NOTICE: Do not use cleaners containing ammonia, alcohol, acetone

NOTICE: Do not use paper towels, abrasive materials, scratching

NOTICE: Do not use WD-40

1. Unplug the machine. Allow it to cool.

2. Wipe the vacuum chamber, lid, sealing bar, silicone holder and

3. Thoroughly wipe off any mild soap or chemical cleaners. Residue

or dry cleaning products. Cleaners with these chemicals

will damage Plexiglas

will damage the finish.

cleansers, razor blades, brushes, steel wool or scouring

pads, such as Scotch Brite™ pads.These will damage the

finish.

cleaning products. These will damage the finish.

exterior with a soft, lint free or microfiber cloth and warm water, or

a mixture of warm water and a small amount of mild dish

detergent.

could corrode the surface of the unit.

®

, acrylic and other plastics. These

®

or petroleum, industrial or commercial

Export HACCP Data

1. Insert a USB stick into the USB port on the back of the machine.

2. Press until is highlighted. Press .

3. Enter the owner password 1324.

(Press to select a number. Press to enter to the next number.)

4. Press to enter the Settings menu.

5. Select Import/Export menu. Press .

6. Select Export data.

Vacuum Packing Machine with Dual 16" Sealing Bars and Advanced Control System (ACS) Operator’s Manual 7

MAINTENANCE

WARNING

Electrical Shock Hazard

Unplug unit before servicing.

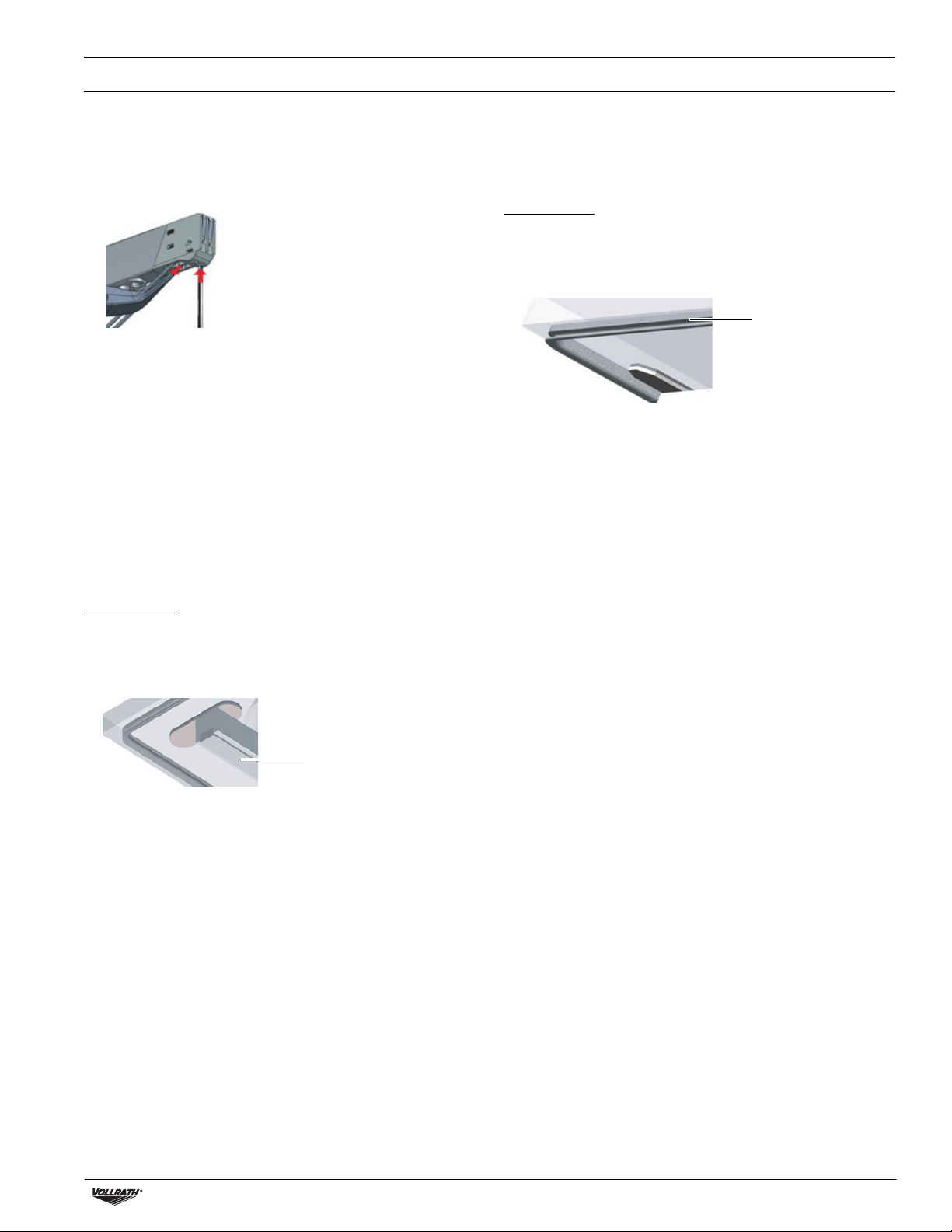

3. Remove the screws on the bottom side of the seal bar.

NOTICE: The machine must be moved or transported in an upright

NOTICE: Do NOT tilt the machine. Tilting could enable oil to flow out

The following maintenance schedule is only a guideline. Actual

maintenance needs will vary depending on machine use. Inspect your

machine regularly.

Interval Procedure

Weekly Check the oil by viewing the Oil Inspection Window.

Every six

months

Yearly Inspect the oil exhaust filter. Contact Vollrath Technical

Every four

years

position.

of the pump and cause damage to the machine.

Inspect the seal bar for wear.

Inspect the seal pad under the lid for wear.

Inspect the lid gasket and lid.

Replace the oil in the vacuum pump. Contact Vollrath

Technical Services.

®

Replace the sealing wires and Teflon

Replace the seal pad under the lid.

Replace the lid gasket.

Services.

Replace the lid, gas springs and seal cylinder

membranes. Contact Vollrath Technical Services.

tape.

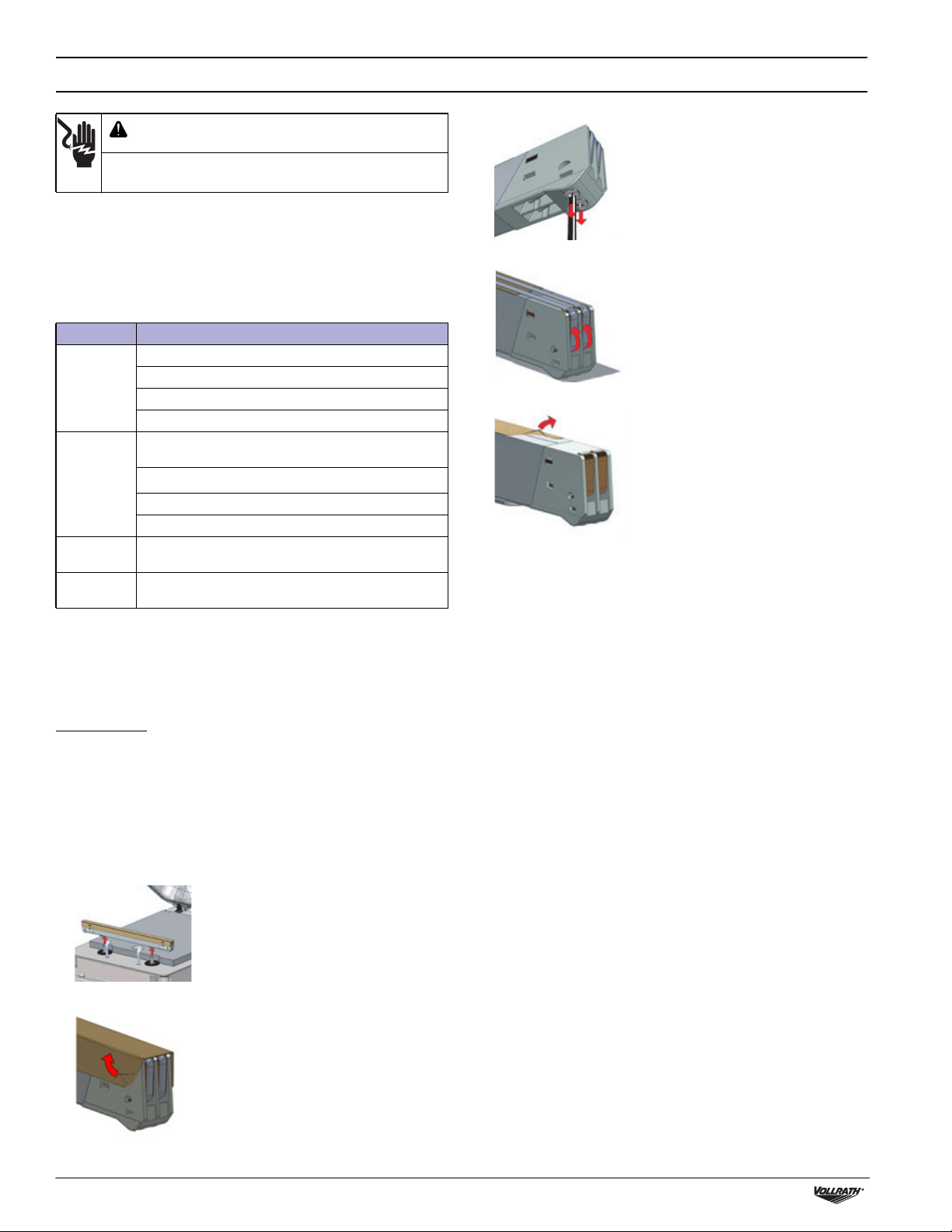

Replace the Sealing Wires and Teflon®Tape

Check the sealing bar for damage. Replace the Teflon tape or sealing

wires if the seal quality is no longer sufficient or if the Teflon tape or

seal wires are worn.

4. Remove the sealing wires.

5. Remove the Teflon tape from the sealing bar.

6. Clean the sealing bar with a lint-free cloth.

Tools Needed:

• Phillips screwdriver

• Tensioning tool or pliers

• Scissors

• Lint-free cleaning cloth

• Replacement Teflon tape

• Replacement sealing wire

1. Pull up on the sealing bar to remove it from the machine.

2. Remove the Teflon tape that protects the sealing wires.

8 Vacuum Packing Machine with Dual 16" Sealing Bars and Advanced Control System (ACS) Operator’s Manual

MAINTENANCE (CONTINUED)

7. Cut a piece of replacement Teflon tape to the same length as the

sealing bar.

8. Apply the replacement tape to the sealing bar.

9. Cut new sealing wires to the length of the sealing bar, plus about 6"

(15 cm).

10. Attach one wire to one side of the seal bar by tightening the screw.

11. Pull the wire across the sealing bar straight and tight.

12. Attach it by tightening the screw.

13. Repeat steps 10 through 12 for the second wire.

14. Trim the wires.

15. Cut a piece of Teflon tape the same length of the sealing bar, plus

about 2" (5 cm).

16. Apply the tape smoothly over the sealing wires on the sealing bar.

17. Trim the tape.

18. Place the sealing bar back in the machine. Verify that the sealing

bar is properly snapped into the holder.

Replace the Lid Gasket

The lid gasket ensures the vacuum chamber is completely sealed

during the packing cycle. This is essential to achieve maximum

vacuum. The lid gasket wears due to the extreme pressure differences

and must be replaced regularly.

Tools Needed:

• Replacement gasket

• Scissors

1. Remove the worn gasket.

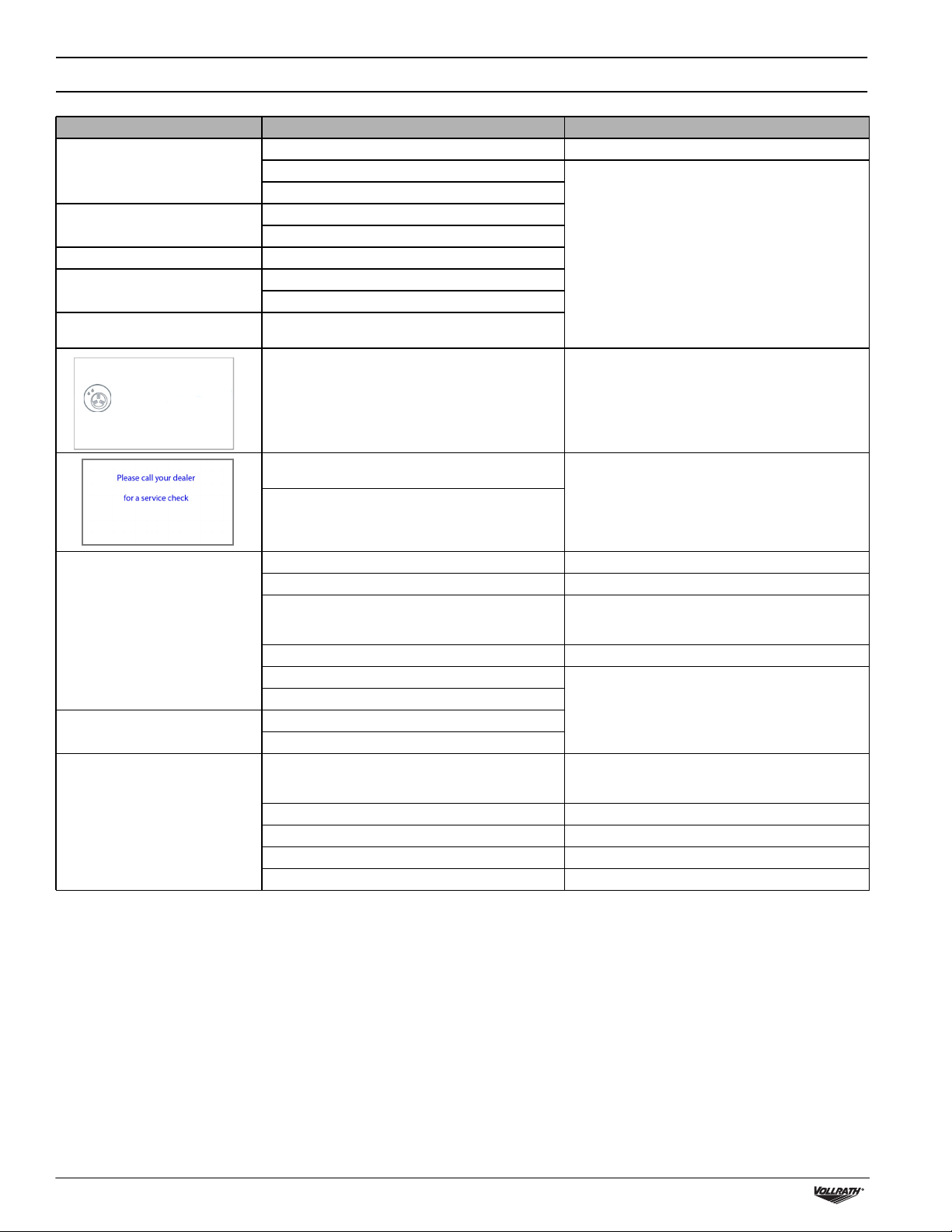

Lid gasket

2. Cut a new piece of gasket slightly longer than the old one. Position

the new gasket so the lip faces downward and outward.

3. Press the gasket into the slot evenly.

4. Trim the gasket so the ends come tightly together to prevent

leakage. The ends must be cut off straight. If the lid gasket is too

short or too long, it can cause problems when closing the lid or

leakage may occur.

Replace the Seal Pad

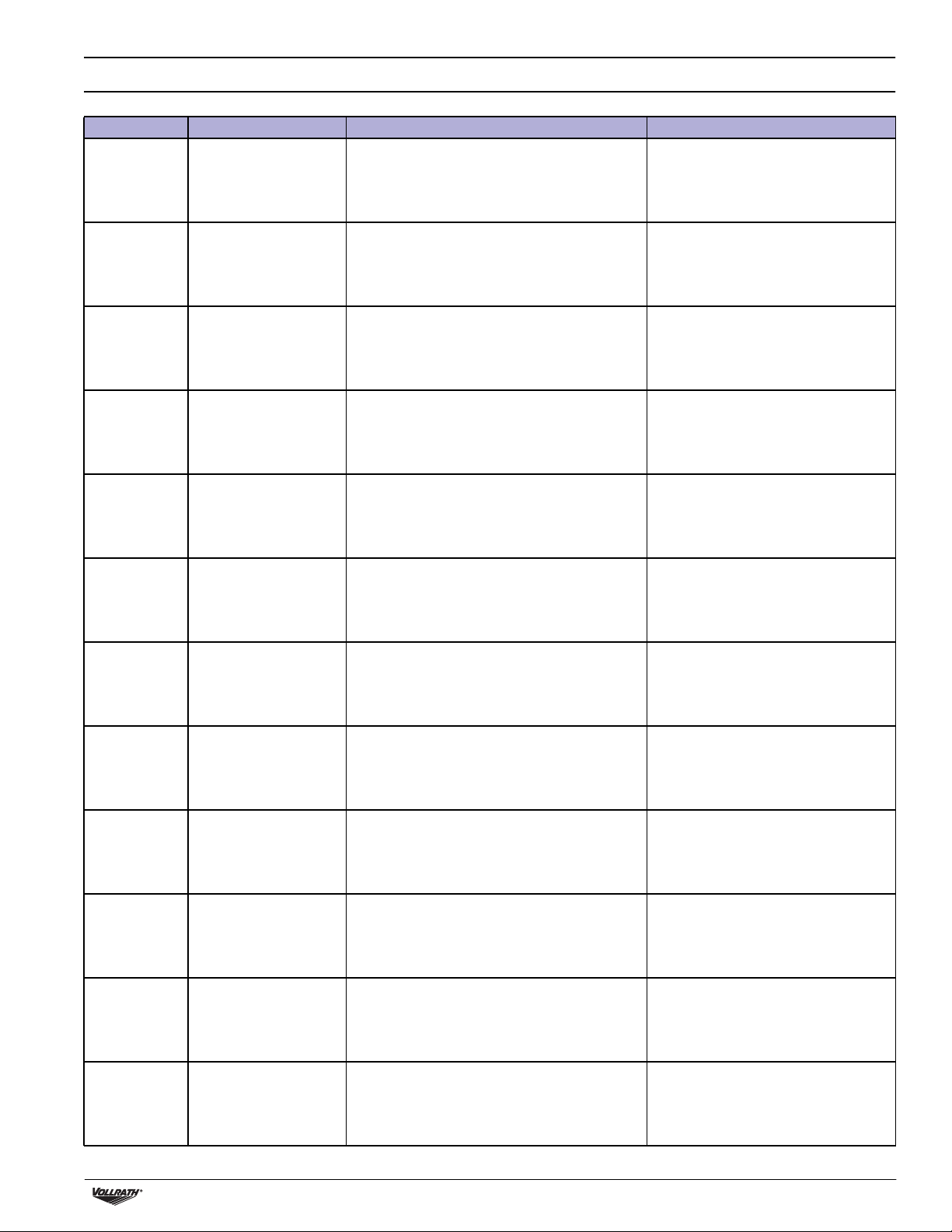

Inspect the pad for roughness. Replace if areas of the pad are rough.

Tools Needed:

• Replacement seal pad

• Scissors

1. Remove the worn pad from the holder.

Seal pad

2. Cut a new piece of seal pad the same length as the old one. A pad

that is too short or too long will cause sealing problems.

3. Place the new pad in the holder. Ensure that the pad is completely

and evenly placed in the groove.

4. Place the new piece in the silicone holder. Ensure that the silicone

rubber is completely and evenly placed in the groove.

Vacuum Packing Machine with Dual 16" Sealing Bars and Advanced Control System (ACS) Operator’s Manual 9

TROUBLESHOOTING

Problem Might be Caused By Course of Action

The control panel does not

illuminate.

The control panel is on but there is

no activity after closing the lid.

The lid does not open automatically. The gas spring is damaged.

F1 in display The lid micro switch may need adjusting.

F2 in display The printed circuit board or liquid control sensor has

The machine is not connected to an electrical outlet. Connect the machine to the power supply.

The main fuse is burned out.

The circuit board fuse is burned out.

The lid micro switch may need to be adjusted.

The control transformer fuse is burned out.

The pump may require technical services.

malfunctioned.

Contact Vollrath Technical Services.

The pump conditioning program needs to be run.

Use the pump cleaning program

The oil in the pump needs to be checked and or needs

to be changed.

Machine usage has reached a scheduled maintenance

point.

Final vacuum is not sufficient. The set vacuum time is too short. Extend the vacuum time.

There is too little oil in the vacuum pump. Contact Vollrath Technical Services.

The extraction hole at the back of the vacuum

chamber is partially covered by the vacuum bag

during extraction.

The lid gasket is worn. Replace the lid gasket.

The oil is contaminated.

The oil exhaust filter is saturated.

The machine extracts air too slowly. The oil exhaust filter is saturated.

The pump’s extraction filter is blocked.

Vacuum bag is not sealed correctly.

The vacuum bag is being placed incorrectly on the

sealing bar.

The sealing time is too long or too short. Adjust the sealing time longer or shorter.

The seal pad under the lid is damaged or worn. Replace the seal pad.

The Teflon tape is damaged. Replace the Teflon tape.

The vacuum bag opening is not clean. Clean the vacuum bag’s opening.

Run the pump conditioning program. See “Pump

Conditioning Program” on page 7.

Contact Vollrath Technical Services.

Place the vacuum bag closer to the sealing bar.

Contact Vollrath Technical Services.

Place the vacuum bag neatly and smoothly on the

sealing bar. Ensure that the opening of the bag is

always within the vacuum chamber.

10 Vacuum Packing Machine with Dual 16" Sealing Bars and Advanced Control System (ACS) Operator’s Manual

MAINTENANCE LOG

Date Company Maintenance Performed Comments

Vacuum Packing Machine with Dual 16" Sealing Bars and Advanced Control System (ACS) Operator’s Manual 11

Loading...

Loading...