Page 1

Operator’s Manual

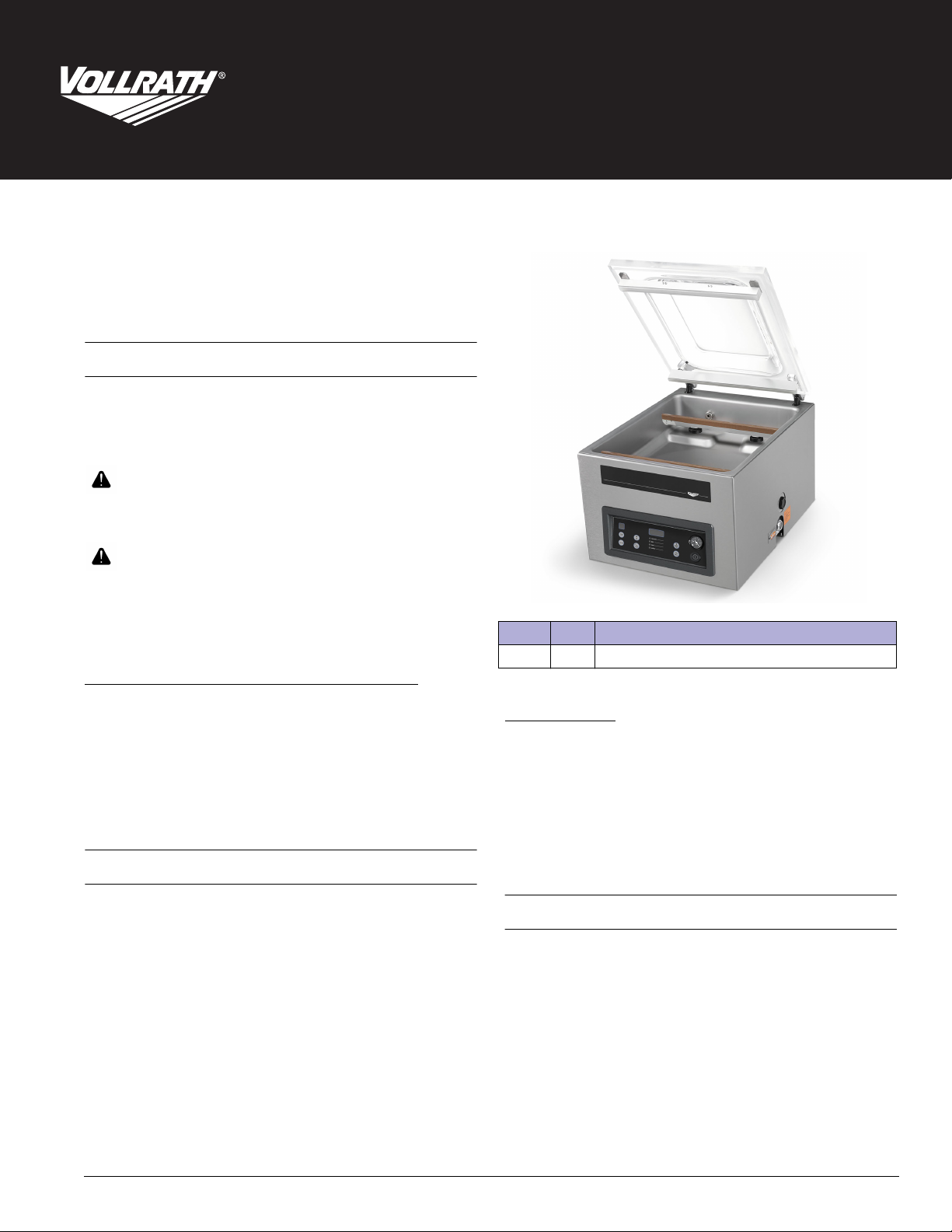

Vacuum Packing Machine with Dual 16" Sealing Bars

Thank you for purchasing this Vollrath equipment. Before operating the

equipment, read and familiarize yourself with the following operating

and safety instructions. SAVE THESE INSTRUCTIONS FOR FUTURE

REFERENCE. Save the original box and packaging. Use this packaging

to ship the equipment if repairs are needed.

SAFETY PRECAUTIONS

To ensure safe operation, read the following statements and understand

their meaning. This manual contains safety precautions which are

explained below. Please read carefully.

WARNING

Warning is used to indicate the presence of a hazard that will or can

cause severe personal injury or death.

CAUTION

Caution is used to indicate the presence of a hazard that will or can

cause minor or major personal injury if the caution is ignored.

NOTICE: Notice is used to note information that is important but not

hazard-related.

To reduce risk of injury or damage to the equipment:

• Unplug when not in use.

• Keep unit and power cord away from open flames, electric burners

or excessive heat.

• Do not operate unattended.

• Do not operate if unit has been damaged or is malfunctioning in any

way.

FUNCTION AND PURPOSE

This unit is intended to vacuum seal food products in a commercial

kitchen environment. It is not intended for household, industrial or

laboratory use.

Item No. Model Description

40833 VP16 Vacuum Packing Machine with Dual 16" Sealing Bars

Table of Contents

Installation ................................................................... page 2

Operation ..................................................................... page 3

Packing Liquid Products ............................................. page 5

Cleaning....................................................................... page 6

Maintenance ................................................................ page 6

Troubleshooting .......................................................... page 8

CLEARANCE AND ENVIRONMENT REQUIREMENTS

NOTICE: Never place the machine near a heat source. This can

damage the lid.

• 6" (15 cm) clearance on all sides and 15½" (39.4 cm) above the

machine for the lid to fully open.

• Ambient temperature must be between 41-86 °F (5-30 °C).

©

2020 The Vollrath Company L.L.C. Part No. 26133-1 ml 2/27/20

Page 2

INSTALLATION

NOTICE: Do NOT tilt the machine. Tilting could allow oil to flow out

of the pump and cause damage to the machine.

NOTICE: Using a voltage other than the nameplate rated voltage will

cause damage to the unit. Incorrect voltage, modification

to the power cord or electrical components can damage

unit and will void the warranty.

NOTICE: Running the machine without oil or insufficient oil will

damage the machine and void the warranty.

1. Remove all packing material and tape, as well as any protective

plastic from the equipment.

2. Clean any glue residue left by the plastic or tape.

3. Place the vacuum pack machine on a flat, level surface.

4. Install the included 4" (10.2 cm) legs. ETL Sanitation requires

machine to be used with included legs.

5. Check the oil gauge window at the back of the machine. Verify the oil

level is between the minimum and maximum fill lines.

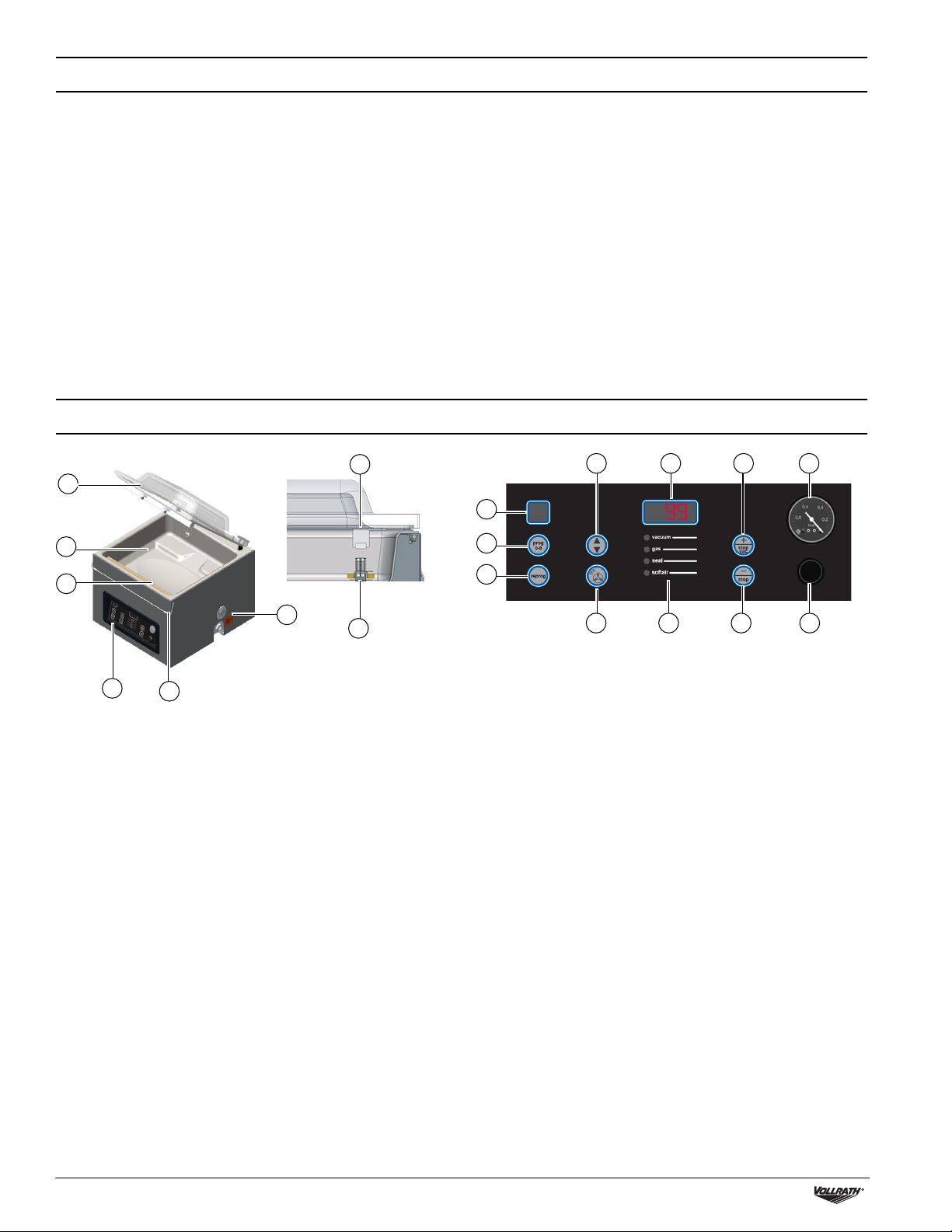

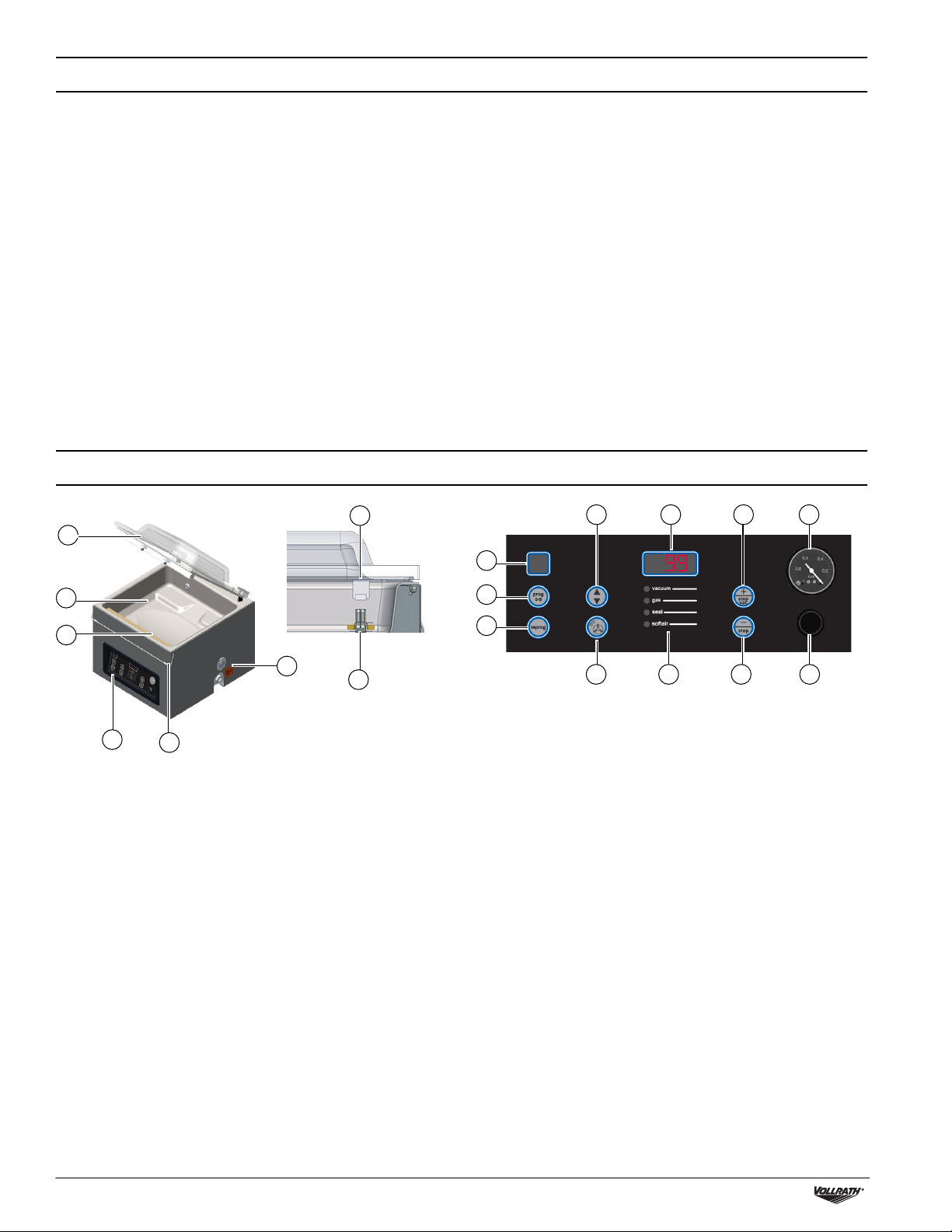

FEATURES AND CONTROLS

6. Plug the power cord into a grounded electrical outlet that matches

the nameplate rated voltage.

7. Run the Pump Conditioning program. See Run the Pump

Conditioning Program on page 6.

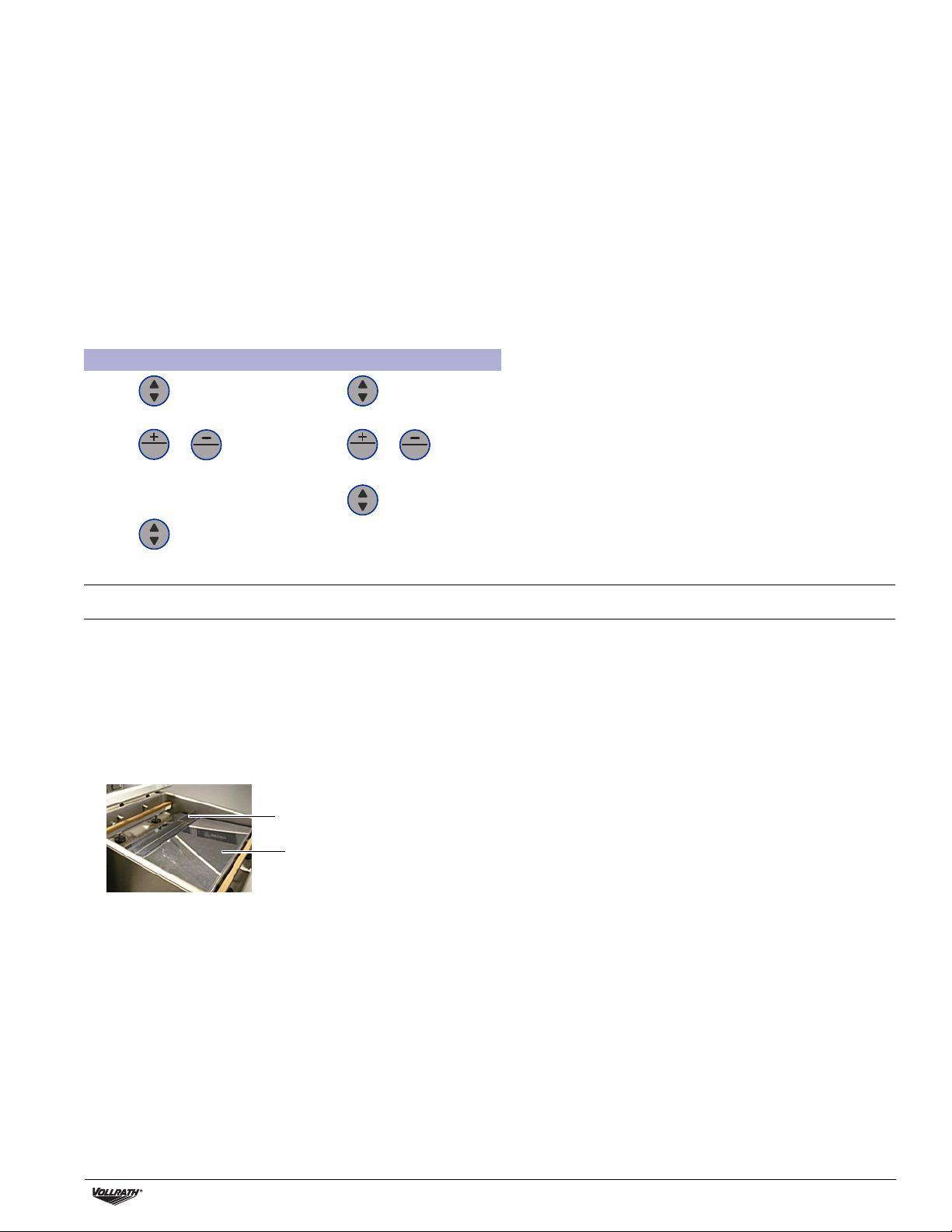

A

B

C

D

A Lid

B Chamber

C Seal Bar

D Control Panel

E Lid Retainer

F Oil Inspection Window

G Seal Pad

E

G

A

B

C

F

H

A Program Display

B Program Button

C Reprogram Button

D Pump Conditioning Program Button

E Function LEDs

F Decrease/Cancel Button. Decreases vacuum pressure, vacuum

plus or seal time. Also cancels the cycle.

G On/Off Button

H Vacuum Gauge

I Increase/Stop Button. Increases vacuum pressure, vacuum plus

or seal time. Also stops the vacuum.

J Display

K Function Select Button

D E GF

HIJK

2 Vacuum Packing Machine with Dual 16" Sealing Bars Operator’s Manual

Page 3

OPERATION

NOTICE: Never pack products that can be damaged by vacuum

packaging.

To reduce condensation and corrosion risk for the pump,

cool products before packing.

When packing food, always select a program that includes

Liquid Sensor Control.

Special instructions apply for packing liquid products. See

Edit Programs on See “Packing Liquid Products” on

page 5.

The machine is designed for a maximum use of five hours

per day.

This machine is not designed for continuous use. Allow 15

seconds between packing cycles.

Do NOT exceed a vacuum time of 60 seconds.

If the machine has been in use for one hour, stop the

machine and allow it to cool to ambient temperature.

Do NOT tilt the machine. Tilting could enable oil to flow out

of the pump and cause damage to the machine.

Place the Product in the Chamber

CAUTION

Burn Hazard

Sealing bar may become hot after repeated use. Do not touch

the sealing bar when placing vacuum bags in the chamber.

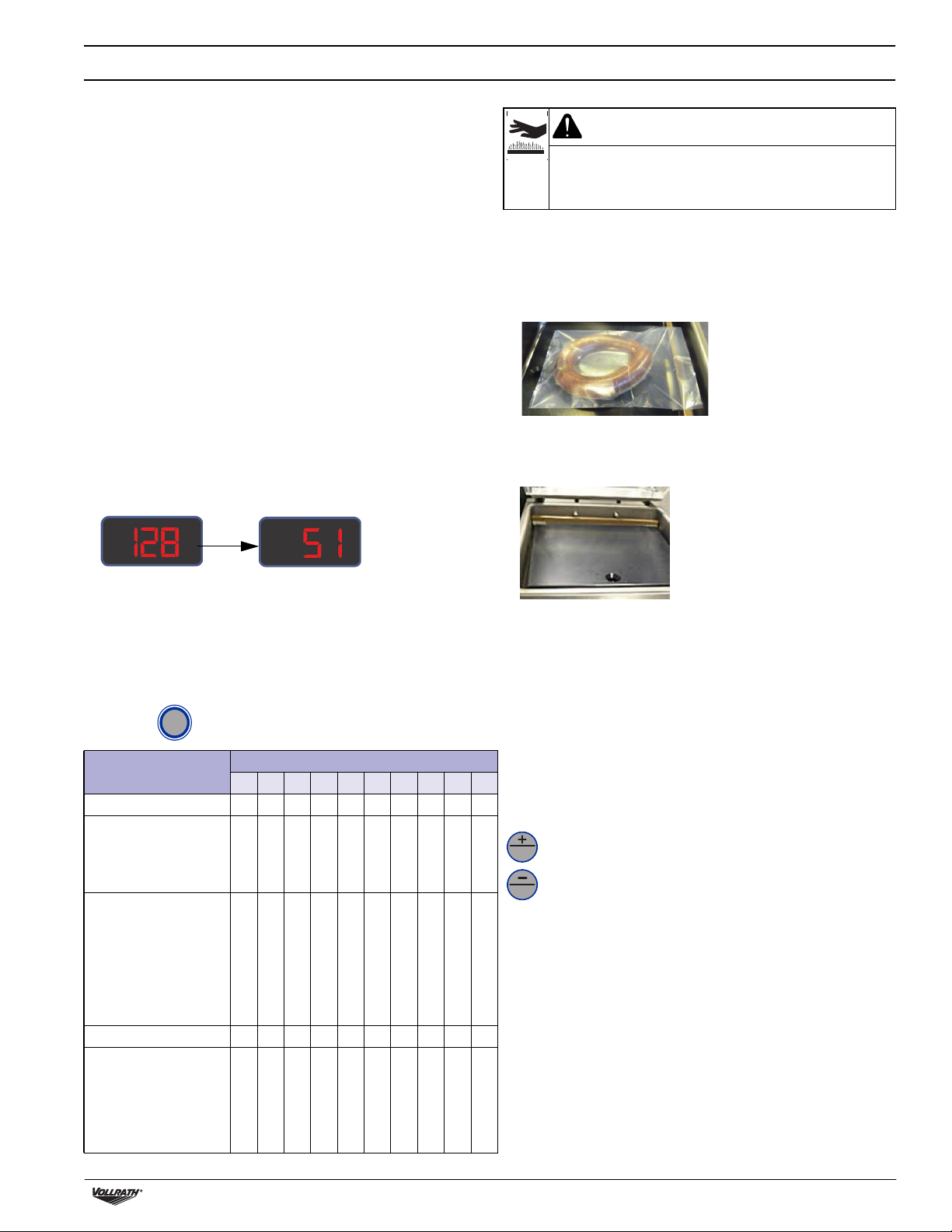

1. Place the food product in a vacuum sealing bag that fits completely

within the chamber.

2. Place the bag in the chamber with the open end over the sealing bar.

Make sure the bag is smooth, without wrinkles or folds. Multiple

vacuum bags can be placed over the sealing bars. Do NOT overlap

vacuum bags.

Turn On the Machine

1. Rotate the lid retainer so it is not covering the lid. The lid retainer is

used only for securing the lid when the machine is not in use.

2. Press the On/Off button.The function display shows codes for the

software revision. For example:

3. If the machine has not been used for a while, run the Pump

Conditioning Program. See page 6.

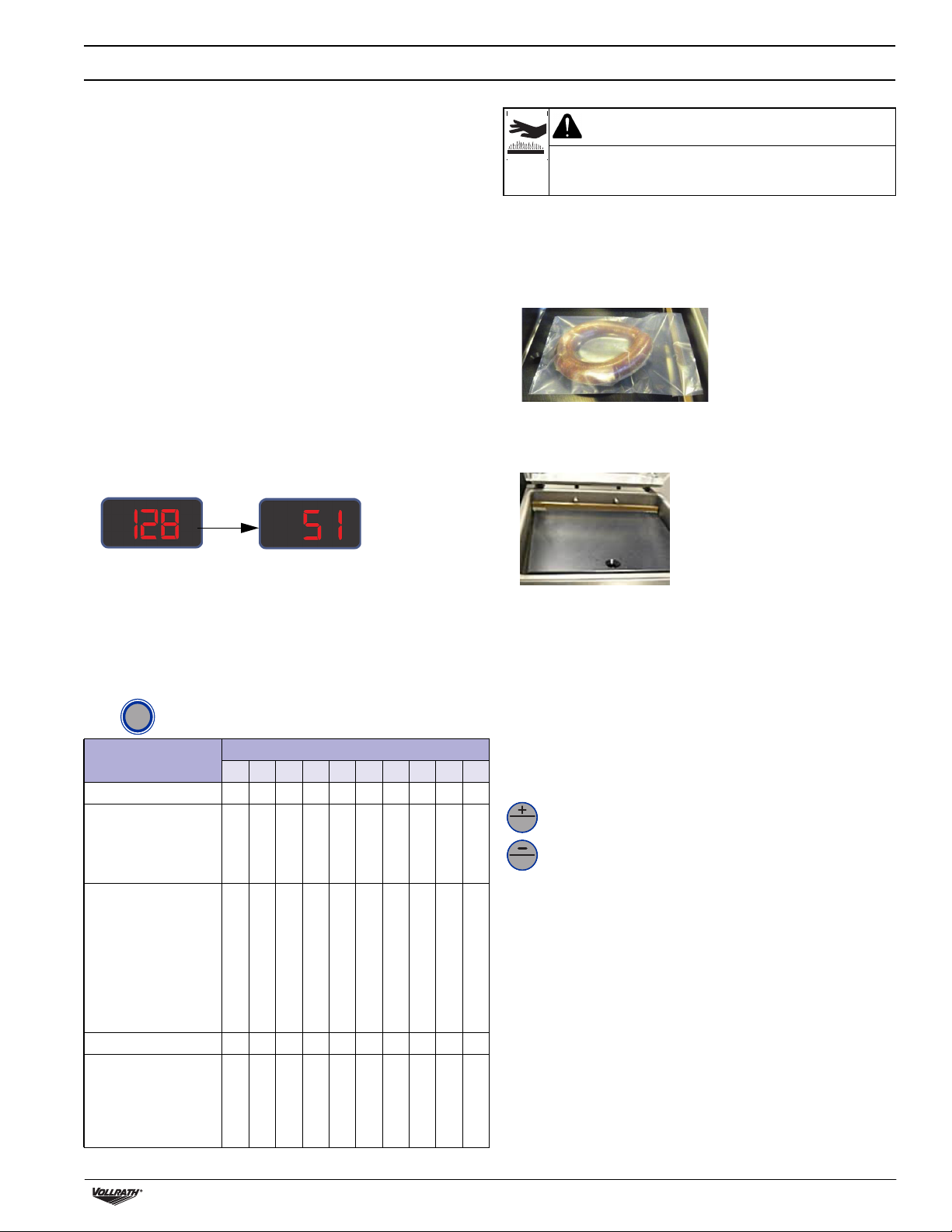

Select a Program

Packing a Food Product: Select a program that includes Liquid Sensor

Control.

Packing a Liquid Product: See important information under Packing

Liquid Products on page 5.

prog

Press until the desired program number shows in the display.

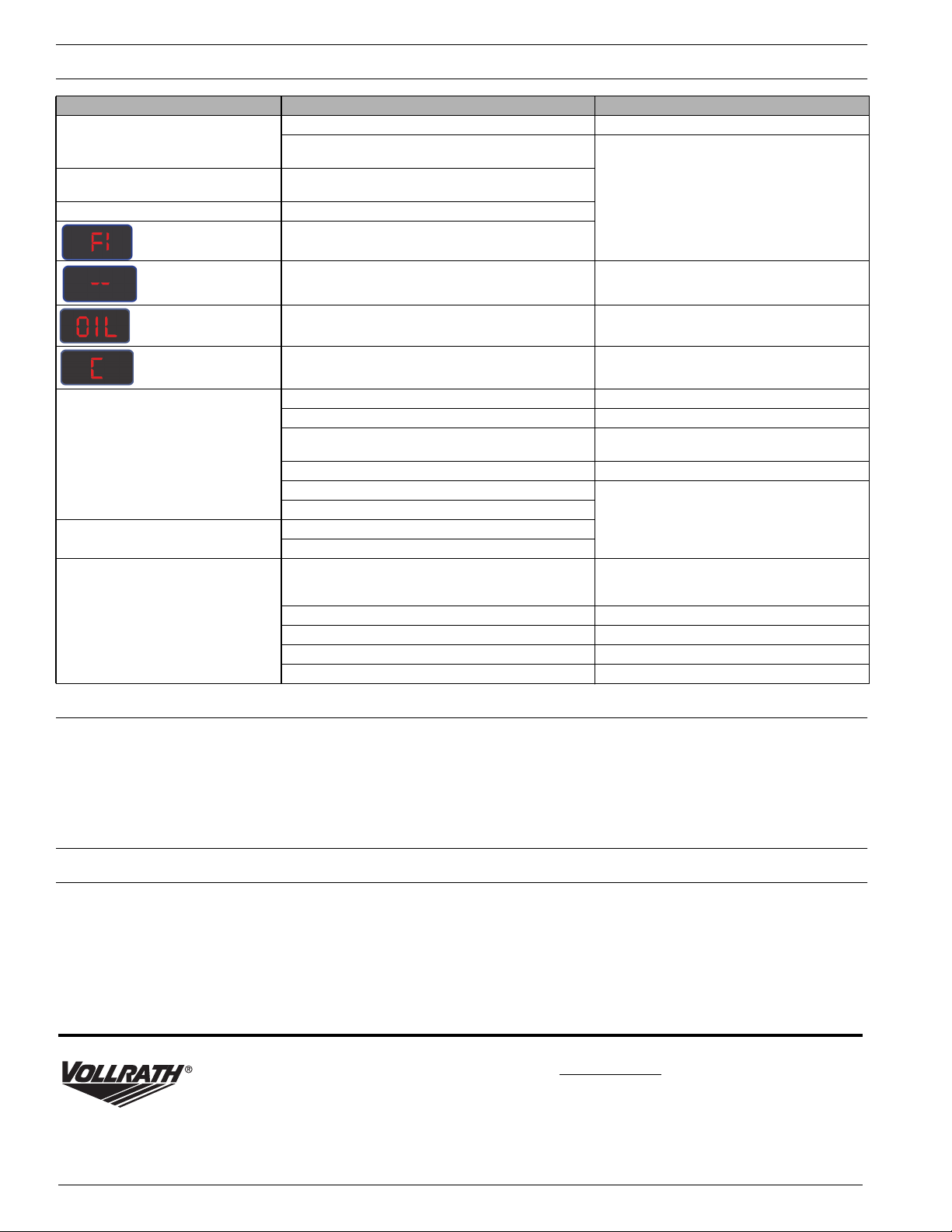

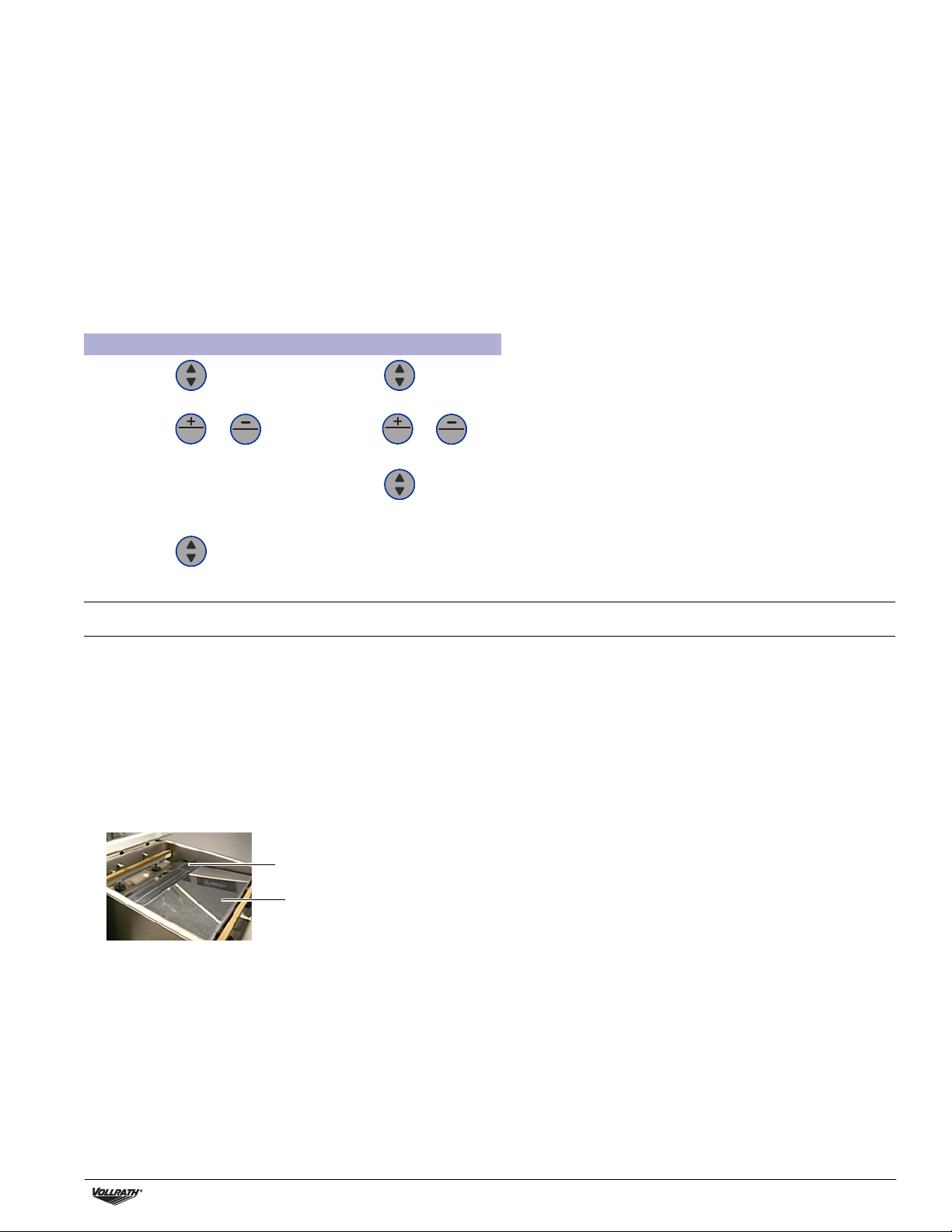

Function

0-9

Program

0 1 2 3 4 5 6 7 8 9

Vacuum Pressure % 99 90 99 99 99 80 90 50 90 60

Vacuum Plus

Extends the vacuum

cycle to enable air

trapped in the product

to escape the bag.

H2O Liquid Sensor

Control

Use when packing food.

Detects the boiling

point, stops the vacuum

and advances to the next

step to produce a better

quality product and

prevent the pump from

taking on liquids.

Sealing (seconds) 2.5 2.5 2.5 2.5 2.5 2.5 2.5 2.5 2.5 2.5

Soft-Air (seconds)

Gently forms the bag to

protect delicate

products or prevent

damage to the bag from

sharp edges on product.

15 OFF 15 10 10 OFF OFF OFF OFF OFF

OFF ON OFF OFF OFF OFF OFF OFF OFF OFF

3 3 2 2 2 OFF OFF 2 OFF OFF

3. For small products, place one or more insert plates under the

product. This fills empty space in the chamber, which reduces the

cycle time.

Run the Program

1. Close the lid. Do not use the lid retainer. Using the lid retainer during

a packing cycle will interfere with the cycle. The cycle automatically

starts.

2. The lid opens when the cycle is complete.

3. Remove the packed product.

4. Wait 15 seconds before packing another product.

Stop a Cycle

The machine can be stopped before a packing cycle is complete.

stop

Stops the vacuum function and continues to the next function.

vac

Stops and cancels the program.

stop

Vacuum Packing Machine with Dual 16" Sealing Bars Operator’s Manual 3

Page 4

OPERATIONS (CONTINUED)

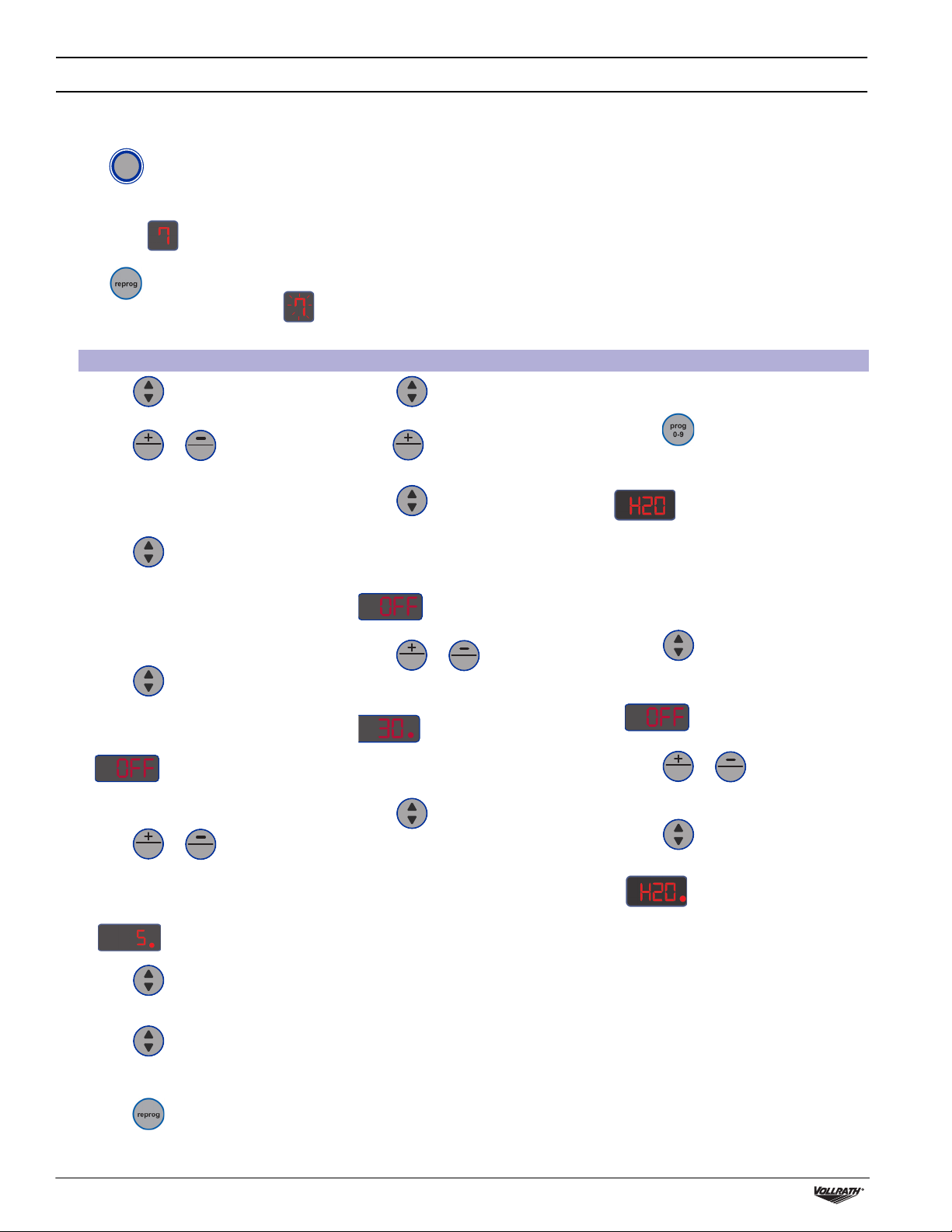

Edit Programs

1. Select a program to edit. Programs 1 through 9 can be customized. Program 0 cannot be changed.

prog

Press

until the number of the program to be edited is shown in the program display.

For example:

2. Reprogram.

Press to edit the program.

The program number begins to flash:

3. Select a function to edit (continues onto next page).

0-9

Vacuum Pressure Percentage Vacuum Time H2O Liquid Sensor Control

1. Press until the Vacuum LED

illuminates.

1. Press until the Vacuum LED

illuminates.

Use this function when packing liquid.

1. Turn on H2O Liquid Sensor Control.

Press to turn the function on or off.

2. Press or to set a vacuum

stop

vac

stop

pressure.

2. Press to reduce the vacuum pressure

to OFF.

stop

vac

When H2O is turned on the function display

shows:

• The recommended minimum is 50%.

• To use Vacuum Plus, Vacuum Pressure

must be set to 99%.

3. Press to confirm the setting.

4. To edit the Vacuum Plus function, continue

with the steps for Vacuum Plus.

3. Press once to enter Vacuum Time

function.

The Vacuum LED remains illuminated. The

function display shows:

2. To edit the H2O Plus function, continue with

the steps for H2O Plus.

H2O Plus

1. Turn on H2O Plus.

Vacuum Plus

1. Turn on Vacuum Plus.

Press

4. Press or to set the number of

stop

vac

stop

seconds. A red dot indicates Vacuum Time is

active.

Press until the Vacuum LED

illuminates and the function display shows:

until the Vacuum LED illuminates and the

function display shows:

2. Set the time.

stop

Press or

vac

stop

• The recommended maximum is 60 seconds.

5. Press to confirm the setting.

2. Press to confirm the setting. A red

stop

Press or to set the time,

vac

stop

in tenths of a second.

dot after H2O indicates H2O Plus is active.

to set the number of seconds.

A red dot indicates Vacuum Plus is active.

3. Press to confirm the setting.

4. Edit another function in the current program.

Press .

5. Save changes and exit the current program.

Press .

4 Vacuum Packing Machine with Dual 16" Sealing Bars Operator’s Manual

Page 5

Sealing Time Soft-Air Time

1. Press until the Seal LED

illuminates.

2. Press or to set the

stop

vac

stop

number of seconds.

1. Press until the Soft -Air

LED illuminates.

2. Press or to set the

stop

vac

stop

number of seconds.

• 2.0 to 2.5 seconds is recommended for most bags.

3. Press to confirm the

setting.

3. Press to confirm the

setting.

PACKING LIQUID PRODUCTS

Special care needs to be taken when vacuum packing liquid or moist

products.

1. Cool foods before packing. Hot food quickly reaches the boiling

point, which can lead to an insufficient seal.

NOTICE: Hot products create condensation, which can damage

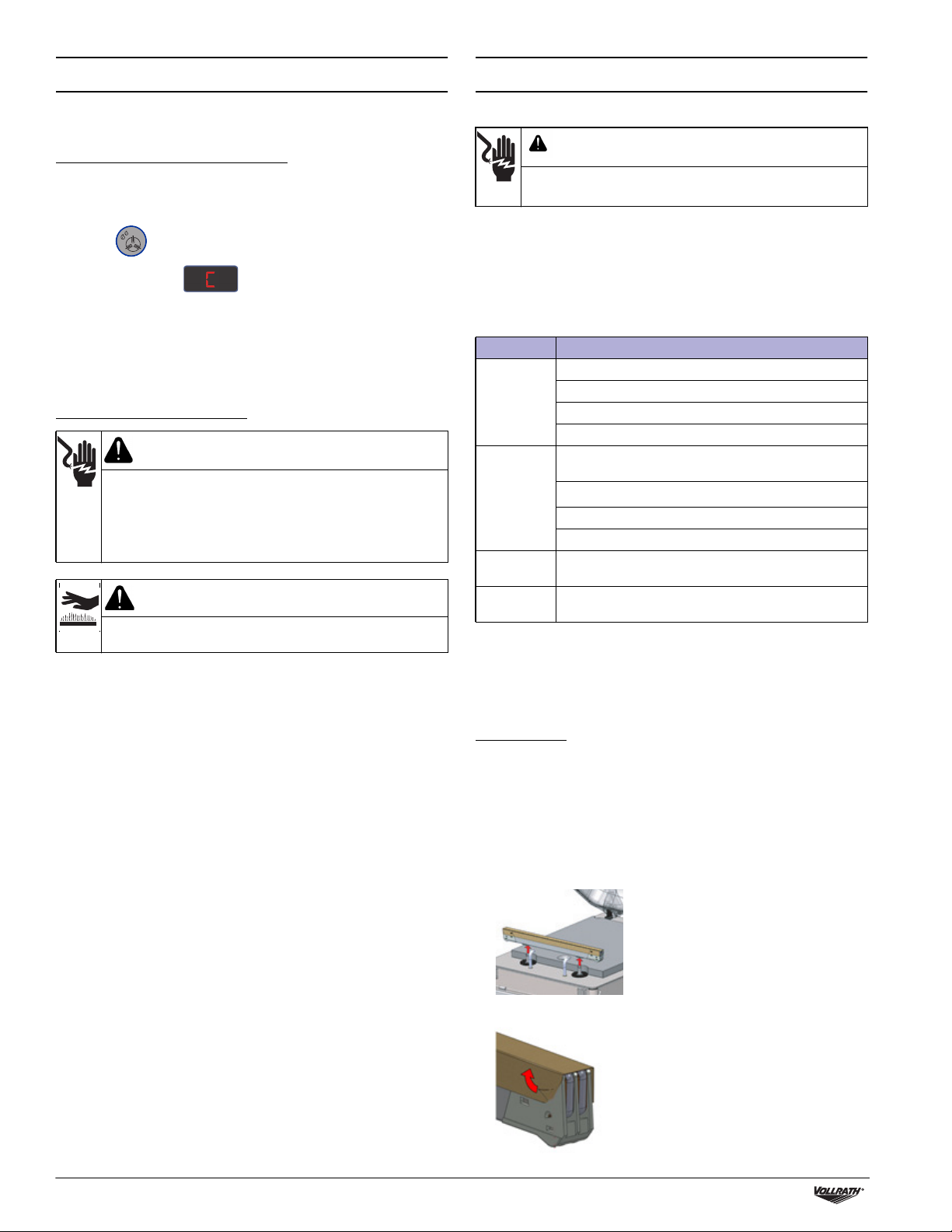

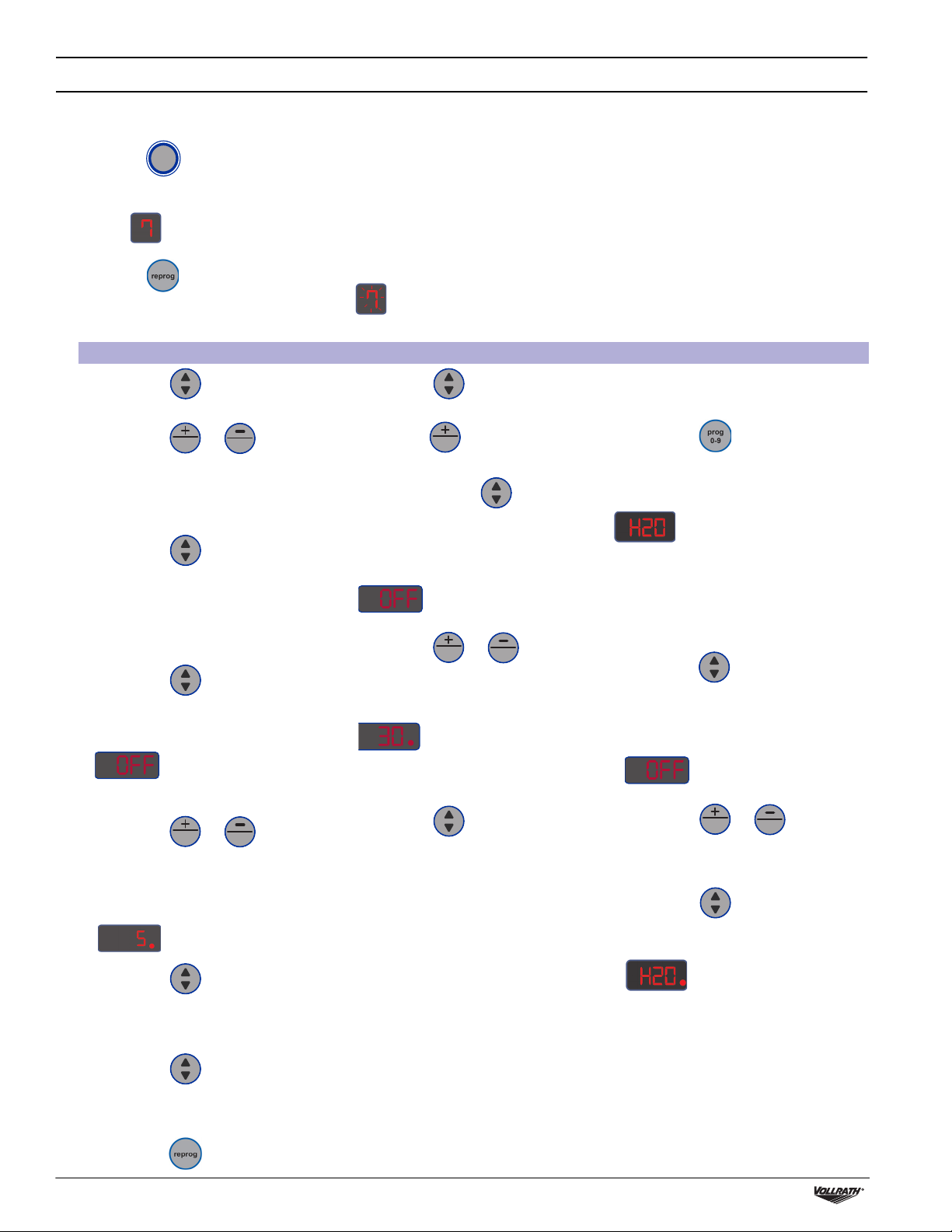

2. Use the included incline plate and magnetic positioning bars to

position the bag so the liquid is below the sealing bar. Magnetic bars

are shipped attached to the underside of the incline plate.

the pump.

Magnetic positioning bar

Incline plate

3. Use a program that includes the Liquid Sensor Control function. This

will prevent the product from boiling.

NOTICE: Boiling will increase the amount of moisture that enters

the pump, which can lead to corrosion.

Vacuum Packing Machine with Dual 16" Sealing Bars Operator’s Manual 5

Page 6

CLEANING

Daily

Run the Pump Conditioning Program

The Pump Conditioning Program removes any moisture that may have

accumulated in the pump. During the program, the pump and oil reach

operating temperature, which evaporates any moisture in the pump.

1. Press .

2. The display shows .

3. Close the lid.

4. The program starts. Moving dots appear on the display.

5. The program runs for approximately 15 minutes. Do not interrupt

the program. If the program is interrupted, it must be run again to

ensure completion.

Clean the exterior and interior

WARNING

Electrical Shock Hazard

Keep water and other liquids from entering the inside of the

equipment. Liquid inside the equipment could cause an

electrical shock. Do not spray water or cleaning products.

Liquid could contact the electrical components and cause a

short circuit or an electrical shock.

CAUTION

Burn Hazard

Allow equipment to cool before moving or cleaning.

NOTICE: Do not use cleaners containing ammonia, alcohol, acetone

NOTICE: Do not use paper towels, abrasive materials, scratching

NOTICE: Do not use WD-40

1. Unplug the machine. Allow it to cool.

2. Wipe the vacuum chamber, lid, sealing bar, silicone holder and

3. Thoroughly wipe off any mild soap or chemical cleaners. Residue

or dry cleaning products. Cleaners with these chemicals

will damage Plexiglas

will damage the finish.

cleansers, razor blades, brushes, steel wool or scouring

pads, such as Scotch Brite™ pads.These will damage the

finish.

cleaning products. These will damage the finish.

exterior with a soft, lint free or microfiber cloth and warm water, or

a mixture of warm water and a small amount of mild dish

detergent.

could corrode the surface of the unit.

®

, acrylic and other plastics. These

®

or petroleum, industrial or commercial

MAINTENANCE

WARNING

Electrical Shock Hazard

Unplug unit before servicing.

NOTICE: All maintenance must be performed by a qualified service

NOTICE: Do NOT tilt the machine. Tilting could enable oil to flow out

The following maintenance schedule is only a guideline. Actual

maintenance needs will vary depending on machine use. Inspect your

machine regularly.

Interval Procedure

Weekly Check the oil by viewing the Oil Inspection Window.

Every six

months

Yearly Inspect the oil exhaust filter. Contact Vollrath Technical

Every four

years

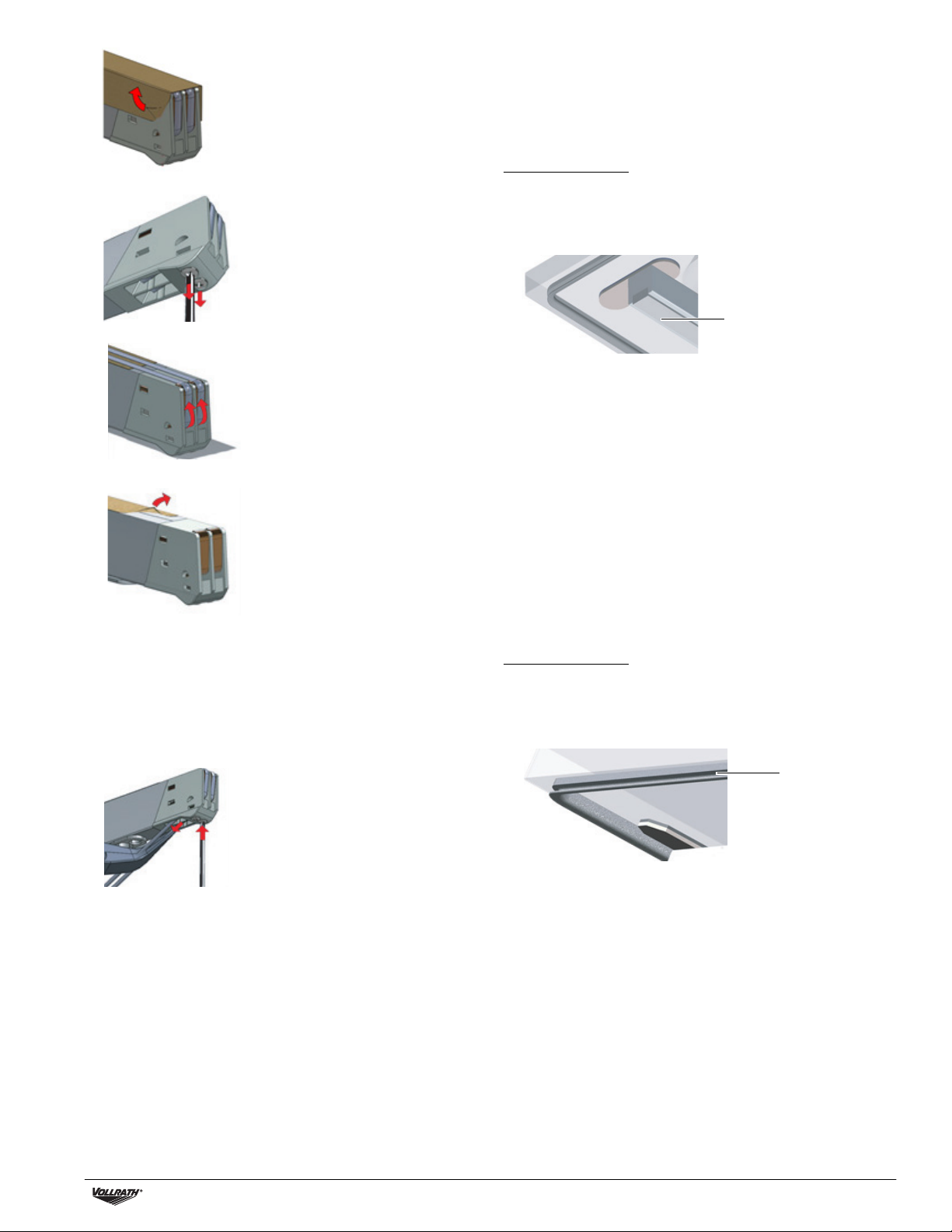

Replace the Sealing Wires and Teflon® Tape

Check the sealing bar for damage. Replace the Teflon tape or sealing

wires if the seal quality is no longer sufficient or if the Teflon tape or

seal wires are worn.

Tools Needed:

• Phillips screwdriver

• Tensioning tool or pliers

• Scissors

• Lint-free cleaning cloth

• Replacement Teflon tape

• Replacement sealing wire

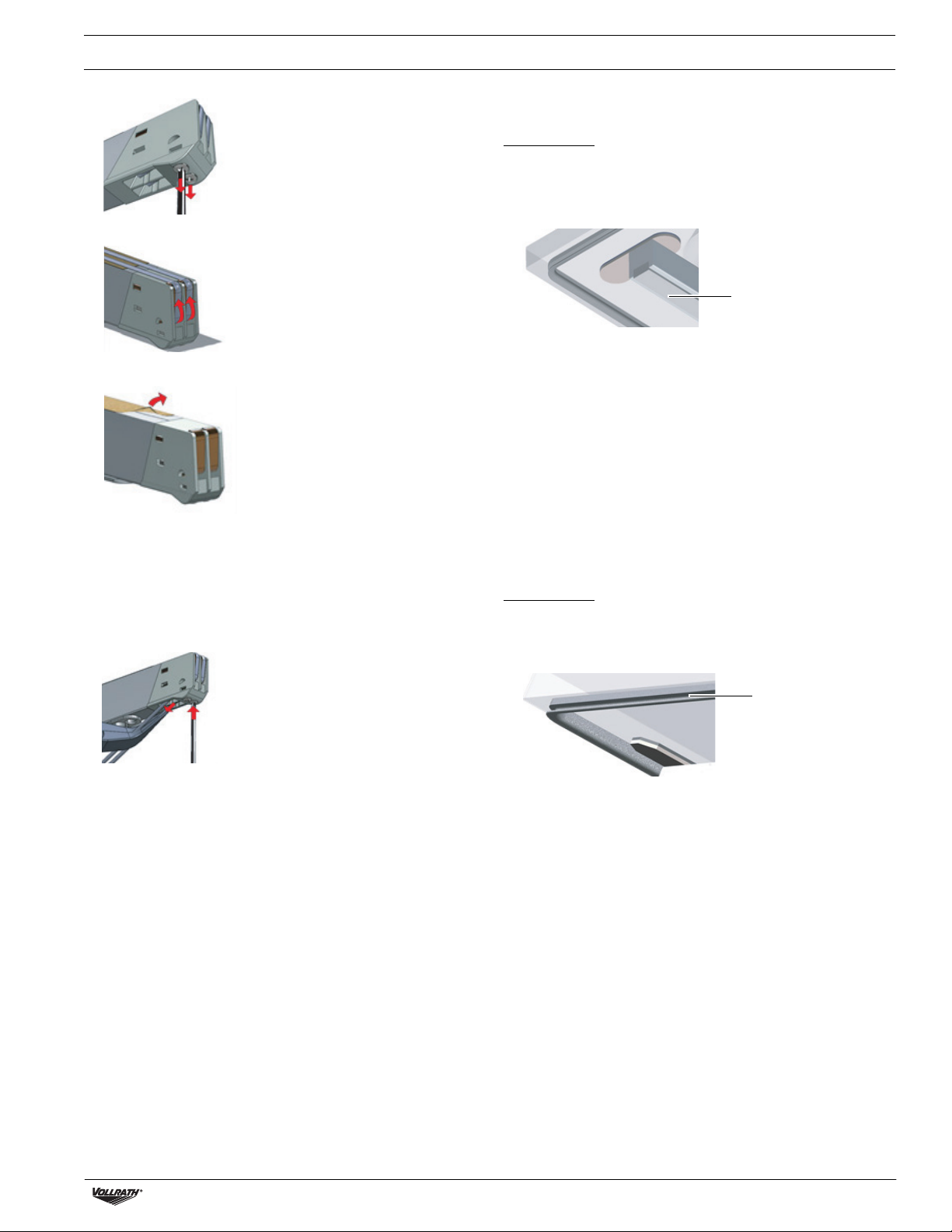

1. Pull up on the sealing bar to remove it from the machine.

technician.

of the pump and cause damage to the machine.

Inspect the seal bar for wear.

Inspect the seal pad under the lid for wear.

Inspect the lid gasket and lid.

Replace the oil in the vacuum pump. Contact Vollrath

Technical Services.

®

Replace the sealing wires and Teflon

Replace the seal pad under the lid.

Replace the lid gasket.

Services.

Replace the lid, gas springs and seal cylinder

membranes. Contact Vollrath Technical Services.

tape.

2. Remove the Teflon tape that protects the sealing wires.

6 Vacuum Packing Machine with Dual 16" Sealing Bars Operator’s Manual

Page 7

MAINTENANCE (CONTINUED)

3. Remove the screws on the bottom side of the seal bar.

4. Remove the sealing wires.

Replace the Seal Pad

Inspect the pad for roughness. Replace if areas of the pad are rough.

Tools Needed:

• Replacement seal pad

• Scissors

1. Remove the worn pad from the holder.

Seal pad

5. Remove the Teflon tape from the sealing bar.

6. Clean the sealing bar with a lint-free cloth.

7. Cut a piece of replacement Teflon tape to the same length as the

sealing bar.

8. Apply the replacement tape to the sealing bar.

9. Cut new sealing wires to the length of the sealing bar, plus about 6"

(15 cm).

10.Attach one wire to one side of the seal bar by tightening the screw.

11.Pull the wire across the sealing bar straight and tight.

12.Attach it by tightening the screw.

13.Repeat steps 10 through 12 for the second wire.

14.Trim the wires.

15.Cut a piece of Teflon tape the same length of the sealing bar, plus

about 2" (5 cm).

16.Apply the tape smoothly over the sealing wires on the sealing bar.

17.Trim the tape.

18.Place the sealing bar back in the machine. Verify that the sealing bar

is properly snapped into the holder.

2. Cut a new piece of seal pad the same length as the old one. A pad

that is too short or too long will cause sealing problems.

3. Place the new pad in the holder. Ensure that the pad is completely

and evenly placed in the groove.

4. Place the new piece in the silicone holder. Ensure that the silicone

rubber is completely and evenly placed in the groove.

Replace the Lid Gasket

The lid gasket ensures the vacuum chamber is completely sealed

during the packing cycle. This is essential to achieve maximum

vacuum. The lid gasket wears due to the extreme pressure differences

and must be replaced regularly.

Tools Needed:

• Replacement gasket

• Scissors

1. Remove the worn gasket.

Lid gasket

2. Cut a new piece of gasket slightly longer than the old one. Position

the new gasket so the lip faces downward and outward.

3. Press the gasket into the slot evenly.

4. Trim the gasket so the ends come tightly together to prevent

leakage. The ends must be cut off straight. If the lid gasket is too

short or too long, it can cause problems when closing the lid or

leakage may occur.

Vacuum Packing Machine with Dual 16" Sealing Bars Operator’s Manual 7

Page 8

TROUBLESHOOTING

Problem Might be Caused By Course of Action

The control panel does not illuminate. The machine is not connected to an electrical outlet. Connect the machine to the power supply.

• The main fuse is burned out.

• The circuit board fuse is burned out.

The control panel is on but there is no

activity after closing the lid.

The lid does not open automatically. The gas spring is damaged.

Final vacuum is not sufficient. The set vacuum time is too short. Extend the vacuum time.

The machine extracts air too slowly. The oil exhaust filter is saturated.

Vacuum bag is not sealed correctly. The vacuum bag is placed incorrectly on the sealing bar. Place the vacuum bag neatly and smoothly on

• The lid micro switch may need to be adjusted.

• The control transformer fuse is burned out.

• The lid micro switch may need adjusting.

• The pump may require technical services.

The lid may have not opened correctly. Check the lid.

The machine use has reached a scheduled oil change. Contact Vollrath Technical Services.

The pump conditioning program needs to be run. See the instructions on page 6.

There is too little oil in the vacuum pump. Contact Vollrath Technical Services.

The extraction hole at the back of the vacuum chamber

is partially covered by the vacuum bag during extraction.

The lid gasket is worn. Replace the lid gasket.

The oil is contaminated. Contact Vollrath Technical Services.

The oil exhaust filter is saturated.

The pump’s extraction filter is blocked.

The sealing time is too long or too short. Adjust the sealing time longer or shorter.

The seal pad under the lid is damaged or worn. Replace the seal pad.

The Teflon tape is damaged. Replace the Teflon tape.

The vacuum bag opening is not clean. Clean the vacuum bag’s opening.

Contact Vollrath Technical Services.

Place the vacuum bag closer to the sealing bar.

the sealing bar. Ensure that the opening of the

bag is always within the vacuum chamber.

SERVICE AND REPAIR

Serviceable parts are available on Vollrath.com.

To avoid serious injury or damage, never attempt to repair the unit or replace a damaged power cord yourself. Do not send units directly to

The Vollrath Company LLC. Please contact Vollrath Technical Services for instructions.

When contacting Vollrath Technical Services, please be ready with the item number, model number (if applicable), serial number, and proof of

purchase showing the date the unit was purchased.

WARRANTY STATEMENT FOR THE VOLLRATH CO. L.L.C.

This warranty does not apply to products purchased for personal, family or household use, and The Vollrath Company LLC does not offer a written

warranty to purchasers for such uses.

The Vollrath Company LLC warrants the products it manufactures or distributes against defects in materials and workmanship as specifically

described in our full warranty statement. In all cases, the warranty runs from the date of the end user’s original purchase date found on the receipt.

Any damages from improper use, abuse, modification or damage resulting from improper packaging during return shipment for warranty repair will

not be covered under warranty.

For complete warranty information, product registration and new product announcement, visit www.vollrath.com.

The Vollrath Company, L.L.C.

Technical Services

techservicereps@vollrathco.com

Induction Products: 800.825.6036

Countertop Warming Products: 800.354.1970

Toasters: 800-309-2250

All Other Products: 800.628.0832

www.vollrath.com

1236 North 18th Street

Sheboygan, WI 53081-3201 U.S.A.

Main Tel: 800.624.2051 or 920.457.4851

Main Fax: 800.752.5620 or 920.459.6573

Customer Service: 800.628.0830

Canada Customer Service: 800.695.8560

©

2020 The Vollrath Company L.L.C. Part No. 26133-1 ml 2/27/20

Page 9

Appareil à emballer sous vide avec deux barres de soudage 16" (40,6 cm)

Merci d’avoir acheté cet appareil Vollrath. Avant d’utiliser cet appareil,

lisez et familiarisez-vous avec le mode d’emploi et les consignes

d’utilisation qui suiven. CONSERVEZ CES INSTRUCTIONS POUR

RÉFÉRENCE ULTÉRIEURE. Conservez l’emballage et le carton d’origine.

L'emballage devra être réutilisé pour expédier l’appareil si une

réparation est nécessaire.

CONSIGNES DE SÉCURITÉ

Pour garantir un fonctionnement sûr, lisez les avertissements suivants

et comprenez leur signification. Ce manuel contient des consignes de

sécurité, présentées ci-dessous. Lisez-les attentivement.

AVERTISSEMENT

Un avertissement permet d'indiquer la présence d'un danger qui

causera ou peut causer des blessures personnelles graves ou la mort.

Manuel d'utilisation

ATTENTION

Une mise en garde indique la présence d'un danger qui causera ou

pourra causer des blessures mineures ou majeures si elle est ignorée.

Un avis met en évidence des informations qui sont importantes mais

sans rapport avec un danger.

Pour réduire le risque de blessures et d'endommagement

de l'appareil :

• Débranchez l’appareil lorsque vous ne comptez pas l’utiliser.

• Tenez les plaques à induction et leur cordon d’alimentation à l’écart

des flammes nues, des brûleurs électriques ou d’une chaleur

excessive.

• N'utilisez pas l'appareil sans surveillance.

• N’utilisez pas l’appareil s’il a été endommagé ou s’il fonctionne mal.

FONCTION ET OBJET

Cet appareil est destiné à l'emballage sous vide des produits

alimentaires dans une cuisine commerciale. Il n'est pas destiné à une

utilisation domestique, industrielle ou en laboratoire.

Num. d’art. Modelé Description

40833 VP16 Appareil à emballer sous vide avec deux barres

de soudage 16" (40.6 cm)

Table des matières

Installation ................................................................... page 2

Mode d'emploi ............................................................. page 3

Emballage de produits liquides ................................... page 5

Nettoyage.....................................................................page 6

Maintenenance.............................................................page 6

Dépannage .................................................................. page 8

EXIGENCES EN MATIÈRE DE DÉGAGEMENT

ET DE CONDITIONS AMBIANTES

AVIS : Ne placez jamais l'appareil près d'une source de

chaleur sous peine d'endommager le couvercle.

• Laissez un dégagement de 6" (15 cm) sur tous les côtés et

de 15½" (39,4 cm) au-dessus de l'appareil pour permettre

l'ouverture complète du couvercle.

• La température ambiante doit être comprise entre

41 et 86 °F (5 et 30 °C).

©

2020 The Vollrath Company L.L.C. Num. d’art. 26133-1 ml 2/27/20

Page 10

INSTALLATION

AVIS : NE BASCULEZ PAS l'appareil. Son inclinaison risque

d'entraîner l'écoulement d'huile de la pompe et

d'endommager l'appareil.

AVIS : L’utilisation d’une tension différente de la tension

nominale indiquée sur la plaque signalétique

endommagera l’appareil. Une tension incorrecte, la

modification du cordon d'alimentation ou les composants

électriques risquent d'endommager l'appareil et d'annuler

la garantie.

AVIS : Le fonctionnement de la machine sans huile ou avec de

l'huile en quantité insuffisante endommagera l'appareil

et annulera la garantie.

1. Enlevez tout le matériel d'emballage et le ruban adhésif, ainsi que le

plastique de protection.

2. Nettoyez les résidus de colle du plastique ou du ruban adhésif.

3. Placez l'appareil à emballer sous vide sur une surface horizontale

et plane.

4. Installez les pieds de 4" (10,2 cm) inclus. La marque ETL Sanitation

exige l'utilisation de l'appareil avec les pieds fournis.

FONCTIONS ET COMMANDES

5. Vérifiez la jauge d'huile à l'arrière de la machine. Vérifiez que le

niveau d'huile se situe entre les lignes de remplissage minimum

et maximum.

6. Branchez l'appareil sur une prise de terre correspondant à la

tension nominale indiquée sur la plaque signalétique.

7. Exécutez le programme de conditionnement de la pompe.

Voir « Exécutez le programme de conditionnement de la pompe »

à la page 6 dans ce manuel.

A

B

C

D

A Couvercle

B Chambre

C Barre de soudage

D Panneau de commande

E Dispositif de retenue du couvercle

F Regard d'huile

G Protection de barre de soudage

E

G

A

B

C

F

H

A Affichage du programme

B Touche Programme

C Touche Reprogrammer

D Touche Programme de conditionnement de la pompe

E Voyants de fonction

F Touche Moins/Annuler. Permet de diminuer la dépression,

le temps de mode Vide Plus ou le temps de soudage.

Permet aussi d'annuler le cycle.

G Touche Marche/Arrêt

H Vacuomètre

I Touche Plus/Arrêt. Permet d'augmenter la dépression,

le temps de mode Vide Plus ou le temps de soudage.

Permet aussi d'arrêter le vide.

J Affichage de fonction

K Touche de sélection de fonction

D E GF

HIJK

2 Manuel d'utilisation de l'appareil à emballer sous vide avec deux barres de soudage 16" (40,6 cm)

Page 11

MODE D'EMPLOI

AVIS : N'emballez jamais des produits pouvant être abîmés par

l'emballage sous vide.

Pour réduire la condensation et le risque de corrosion pour

la pompe, faites refroidir les produits avant d'emballer.

Pour emballer des aliments, sélectionnez toujours un

programme incluant la fonction Capteur de liquide.

Des instructions spéciales s'appliquent pour l'emballage

de produits liquides. Référez-vous à « Emballage de

produits liquides»àlaVoir « Emballage de produits

liquides », à la page 5.

L'appareil est conçu pour une utilisation de cinq heures

maximum par jour.

Cet appareil n'est pas destiné à une utilisation continue.

Comptez 15 secondes entre les cycles d'emballage.

Ne dépassez pas un temps de mise sous vide de

60 secondes.

Si l'appareil est utilisé depuis une heure, arrêtez-le

et laissez-le refroidir à température ambiante.

NE BASCULEZ PAS l'appareil. Son inclinaison risque

d'entraîner l'écoulement d'huile de la pompe et

d'endommager l'appareil.

Mise en marche de l'appareil

1. Tournez le dispositif de retenue du couvercle de manière à ce qu'il ne

couvre pas le couvercle. Le dispositif de retenue du couvercle sert

seulement à fixer le couvercle lorsque l'appareil n'est pas utilisé.

2. Appuyez sur la touche Marche/Arrêt.L'affichage de la fonction

indique le numéro de version du logiciel. Exemple :

Mise en place du produit dans la chambre

ATTENTION

Risque de brûlure

La barre de soudage peut surchauffer après une utilisation

répétée. Ne la touchez pas en mettant les sacs en place dans la

chambre.

1. Placez le produit alimentaire dans un sac d'emballage sous vide qui

tient complètement dans la chambre.

2. Placez le sac dans la chambre en plaçant le côté ouvert pardessus la

barre de soudage. Assurez-vous que le sac est lisse, sans froissures

ou plis. Plusieurs sacs sous vide peuvent être placés sur la barre de

soudage. NE CHEVAUCHEZ PAS les sacs sous vide.

3. Pour les petits produits, placez une ou plusieurs assiettes sous le

produit. Ceci permet de combler le vide dans la chambre et donc de

réduire le temps de cycle.

3. Si l'appareil reste inutilisé pendant un certain temps, exécutez le

programme de conditionnement de la pompe. Voir page 6.

Sélection d'un programme

Emballage d'un produit alimentaire : sélectionnez un programme

incluant la fonction Capteur de liquide.

Emballage d'un produit liquide : lisez les informations importantes

de la section Emballage de produits liquides, à la page 5.

prog

Appuyez sur jusqu'à ce que le numéro de programme souhaité

s'affiche.

Fonction

Dépression (%)

Vide Plus

Prolonge le cycle de vide

pour permettre à l'air

piégé dans le produit

de s'échapper du sac.

Capteur de liquide H2O

S'utilise pour

l'emballage d'aliments.

Détecte le point

d'ébullition, arrête le vide

et passe à l'étape suivante

pour produire un produit

de meilleure qualité et

empêcher la pompe

d'aspirer des liquides.

Soudage (secondes)

Soft-Air (secondes)

Moule doucement le

sac pour protéger les

produits fragiles ou éviter

l'endommagement du sac

causé par les bords

coupants du produit.

0-9

Programme

0 1 2 3 4 5 6 7 8 9

99 90 99 99 99 80 90 50 90 60

15 ARR 15 10 10 ARR ARR ARR ARR ARR

ARR MAR ARR ARR ARR ARR ARR ARR ARR ARR

2,5 2,5 2,5 2,5 2,5 2,5 2,5 2,5 2,5 2,5

3 3 2 2 2 ARR ARR 2 ARR ARR

Exécution du programme

1. Fermez le couvercle. N'utilisez pas le dispositif de retenue du

couvercle. L'utilisation du dispositif de retenue du couvercle durant

un cycle d'emballage interférera avec le cycle. Le cycle démarre

automatiquement.

2. Le couvercle s'ouvre une fois le cycle terminé.

3. Enlevez le produit emballé.

4. Attendez 15 secondes avant d'emballer un autre produit.

Arrêt d'un cycle

L'appareil peut être arrêté avant la fin d'un cycle d'emballage.

stop

Arrête la fonction de vide et passe à la fonction suivante.

vac

Arrête et annule le programme.

stop

Manuel d'utilisation de l'appareil à emballer sous vide avec deux barres de soudage 16" (40,6 cm) 3

Page 12

MODE D'EMPLOI (SUITE)

Modification de programmes

1. Sélectionnez un programme à modifier. Les programmes1à9peuvent être personnalisés. Le programme 0 ne peut pas être modifié.

prog

Appuyez sur

jusqu'à ce que le numéro du programme à modifier s'affiche dans l'affichage du programme.

Exemple :

2. Reprogrammez.

Appuyez sur pour modifier le programme.

Le numéro du programme commence à clignoter :

3. Sélectionnez une fonction à modifier (suite à la page suivante).

Pourcentage de dépression Temps de vide Capteur de liquide H2O

1. Appuyez sur jusqu'à ce que

le voyant vacuum s'allume.

0-9

1. Appuyez sur jusqu'à ce que le

voyant vacuum s'allume.

Utilisez cette fonction pour emballer un

liquide.

1. Activez le capteur de liquide H2O.

2. Appuyez sur ou pour définir

stop

vac

stop

la dépression.

• Le minimum recommandé est de 50 %.

• Pour utiliser le mode Vide Plus, la

dépression doit être réglée à 99 %.

3. Appuyez sur pour confirmer le

réglage.

4. Pour modifier la fonction Vide Plus,

passez à la procédure pour Vide Plus.

Vide Plus

1. Activez le mode Vide Plus.

Appuyez sur

jusqu'à ce que le voyant vacuum s'allume

et que l'affichage de la fonction indique :

2. Réglez le temps.

Appuyez sur ou

stop

vac

stop

pour définir le nombre de secondes.

2. Appuyez sur pour couper la

stop

vac

dépression.

3. Appuyez une fois sur pour accéder

à la fonction Temps de vide.

Le voyant vacuum reste allumé.

L'affichage de la fonction indique :

4. Appuyez sur ou pour définir

stop

vac

stop

le nombre de secondes. Un point rouge

indique que la fonction Temps de vide

est activée.

• Le temps maximum recommandé est

de 60 secondes.

5. Appuyez sur pour confirmer

le réglage.

Appuyez sur pour activer ou

désactiver la fonction.

Lorsque le capteur de liquide H2O est activé,

l'affichage de la fonction indique :

2. Pour modifier la fonction H2O Plus,

passez à la procédure pour H2O Plus.

H2O Plus

1. Activez le mode H2O Plus.

Appuyez sur jusqu'à ce que le voyant

vacuum

s'allume et que l'affichage de la fonction

indique :

Appuyez sur ou pour définir

le temps

stop

vac

stop

en dixièmes de seconde.

Un point rouge indique que le mode

Vide Plus est activé.

2. Appuyez sur pour confirmer le

réglage. Un point rouge après H2O indique

que le mode H2O Plus est activé.

3. Appuyez sur pour confirmer le

réglage.

4. Modifiez une autre fonction dans le

programme en cours.

Appuyez sur .

5. Enregistrez les modifications et quittez

le programme en cours.

Appuyez sur .

4 Manuel d'utilisation de l'appareil à emballer sous vide avec deux barres de soudage 16" (40,6 cm)

Page 13

Temps de soudage Temps Soft-Air

1. Appuyez sur jusqu'à ce

que le voyant seal s'allume.

2. Appuyez sur ou

stop

vac

stop

pour définir le nombre de

1. Appuyez sur jusqu'à ce

que le voyant softair s'allume.

2. Appuyez sur ou pour

stop

vac

stop

définir le nombre de secondes.

secondes.

• Un temps de 2 à 2,5 secondes

est recommandé pour la

3. Appuyez sur pour

confirmer le réglage.

plupart des sacs.

3. Appuyez sur pour

confirmer le réglage.

EMBALLAGE DE PRODUITS LIQUIDES

Il faut faire tout particulièrement attention lors de l'emballage sous vide

de liquides ou de produits humides.

1. Laissez refroidir les aliments avant de les emballer. Les aliments

chauds atteignent rapidement le point d'ébullition, ce qui peut se

solder par un soudage insuffisant.

AVIS : Les produits chauds créent de la condensation, ce qui

2. Utilisez la plaque inclinée fournie et les barres de positionnement

aimantées pour positionner le sac de sorte que le niveau de liquide

soit en dessous de la barre de soudage. Les barres aimantées sont

expédiée attachées sous la plaque inclinée.

peut endommager la pompe.

Barre de positionnement aimantée

Plaque inclinée

3. Utilisez un programme incluant la fonction Capteur de liquide. Ceci

empêchera le produit de bouillir.

AVIS : L'ébullition augmentera la quantité d'humidité qui entre

dans la pompe, ce qui peut entraîner la formation de

rouille.

Manuel d'utilisation de l'appareil à emballer sous vide avec deux barres de soudage 16" (40,6 cm) 5

Page 14

NETTOYAGE

MAINTENANCE

AVIS : NE BASCULEZ PAS l'appareil. Son inclinaison risque

d'entraîner l'écoulement d'huile de la pompe et

d'endommager l'appareil.

AVIS : Si l'appareil est inutilisé pendant plus d'un mois, la pompe

doit être vidée de son huile. L'humidité dans l'huile risque

de corroder la pompe.

Une fois par jour

Exécutez le programme de conditionnement de la pompe

Le programme de conditionnement de la pompe élimine toute humidité

ayant pu s'accumuler dans la pompe. Durant le programme, la pompe

et l'huile atteignent la température de fonctionnement ce qui entraîne

l'évaporation de l'humidité dans la pompe.

1. Appuyez sur .

2. apparaît sur l'affichage.

3. Fermez le couvercle.

4. Le programme démarre. Des points en mouvement apparaissent

sur l'affichage.

5. Le programme s'exécute pendant 15 minutes environ.

N'interrompez pas le programme. Si le programme est interrompu,

il devra être réexécuté pour arriver jusqu'à son terme.

Nettoyez l'extérieur et l'intérieur

AVERTISSEMENT

Risque d’électrocution

Empêchez toute infiltration d'eau et d'autres liquides dans

l'appareil. L'infiltration de liquide dans l'appareil risque de

causer une électrocution. Ne vaporisez pas d'eau ou de

produits nettoyants. Du liquide risque d’entrer en contact avec

les composants électriques et de causer un court-circuit ou

une décharge électrique.

AVERTISSEMENT

Risque d’électrocution

Débranchez l'appareil avant toute maintenance.

AVIS : Toute la maintenance doit être effectuée par un agent

AVIS : NE BASCULEZ PAS l'appareil. Son inclinaison risque

Le calendrier de maintenance suivant est seulement fourni à titre de

référence. Les besoins de maintenance réels varient selon l'utilisation

de l'appareil. Inspectez régulièrement votre appareil.

Fréquence Procédure

Une fois

par semaine

Tous les

six mois

Une fois

par an

Tous les

quatre ans

Remplacement des fils de soudure et du ruban

en Teflon®

technique qualifié.

d'entraîner l'écoulement d'huile de la pompe et

d'endommager l'appareil.

Vérifiez le niveau d'huile par le regard.

Inspectez l'usure de la barre de soudage.

Inspectez l'usure de la protection de la barre de

soudage sous le couvercle.

Inspectez le joint du couvercle et le couvercle.

Remplacez l'huile dans la pompe à vide. Contactez

le support technique Vollrath.

Remplacez les fils de soudure et le ruban en Teflon

Remplacez la protection de la barre de soudage sous

le couvercle.

Remplacez le joint du couvercle.

Inspectez le filtre à huile. Contactez le support

technique Vollrath.

Remplacez le couvercle, les ressorts à gaz et les

membranes du cylindre de soudage. Contactez le

support technique Vollrath.

®

.

ATTENTION

Risque de brûlure

Laissez refroidir l'appareil avant de le manipuler ou de le laver.

AVIS : Ne pas utiliser de nettoyants contenant de l'ammoniaque,

AVIS : Ne pas utiliser d'essuie-tout, de matériaux abrasifs,

AVIS : Ne pas utiliser de WD-40

1. Débranchez l'appareil. Laissez-le refroidir.

2. Essuyez la chambre à vide, le couvercle, la barre de soudage, le

3. Essuyez bien tout résidu de savon doux ou de nettoyants

6 Manuel d'utilisation de l'appareil à emballer sous vide avec deux barres de soudage 16" (40,6 cm)

de l'alcool, de l'acétone ou des produits de nettoyage à

sec. Les nettoyants contenant ces agents chimiques

abîmeront le Plexiglas

sous peine d'endommager le fini.

nettoyants qui rayent, lames de rasoir, brosses, laine

d'acier ou tampons à récurer, comme du Scotch Brite™,

sous peine d'endommager le fini.

de pétrole, industriel ou commercial sous peine

d'endommager le fini.

support en silicone et l'extérieur avec un chiffon microfibre non

pelucheux doux et de l'eau chaude, ou un mélange d'eau chaude et

d'une petite quantité de liquide vaisselle doux.

chimiques. Les résidus risquent de corroder la surface de

l’appareil.

®

, l'acrylique et autres plastiques

®

ou un produit nettoyant à base

Vérifiez l'état de la barre de soudage. Remplacez le ruban en Teflon et

les fils de soudage si la qualité de la soudure n'est plus suffisante ou si

le ruban en Teflon ou les fils de soudage sont usés.

Outils nécessaires :

• Tournevis cruciforme

• Outils de tension ou pinces

• Ciseaux

• Chiffon de nettoyage non pelucheux

• Ruban en Teflon de rechange

• Fil de soudage de rechange

1. Tirez la barre de soudage vers le haut pour l'enlever de l'appareil.

Page 15

2. Enlevez le ruban en Teflon qui protège les fils de soudage.

3. Enlevez les vis sous la barre de soudage.

4. Enlevez les fils de soudage.

5. Enlevez le ruban en Teflon de la barre de soudage.

Remplacement de la protection

de la barre de soudage

Inspectez la rugosité de la protection de la barre de soudage.

Remplacez si des zones de la protection de la barre de soudage

sont rugueuses.

Outils nécessaires :

• Protection de la barre de soudage de rechange

• Ciseaux

1. Enlevez la protection usée du support.

Protection de barre

2. Coupez un bout de protection de barre de soudage neuve à la

même longueur que l'ancien. Un bout trop court ou trop long

causera des problèmes de soudage.

3. Placez la protection neuve dans le support. Assurez-vous qu'elle

est complètement et uniformément placée dans la rainure.

4. Placez le bout neuf dans le support en silicone. Assurez-vous que

le caoutchouc de silicone est complètement et uniformément

placée dans la rainure.

6. Nettoyez la barre de soudage avec un chiffon non pelucheux.

7. Coupez un bout de ruban en Teflon de rechange à la même

longueur de la barre de soudage.

8. Appliquez le ruban de rechange à la barre de soudage.

9. Coupez le fils de soudage neufs à la longueur de la barre de

soudage, plus 6" (15 cm) environ.

10. Attachez un fil à une extrémité de la barre de soudage en serrant

la vis.

11. Tirez le fil à travers la barre de soudage bien droit et tendu.

12. Attachez-le en serrant la vis.

13. Répétez les étapes 10 à 12 pour le second fil.

14. Élaguez les fils.

15. Coupez un bout de ruban en Teflon à la longueur de la barre de

soudage, plus 2" (5 cm) environ.

16. Appliquez le ruban en le lissant bien sur les fils de soudage sur la

barre de soudage.

17. Élaguez le ruban.

18. Remettez la barre de soudage dans l'appareil. Assurez-vous que la

barre de soudage s'est correctement enclenchée dans le support.

Remplacement du joint du couvercle

Le joint du couvercle garantit que la chambre à vide est complètement

soudée durant le cycle d'emballage. Ceci est essentiel pour atteindre le

vide maximum. Le joint du couvercle s'use en raison des différences de

pression extrêmes et doit être régulièrement remplacé.

Outils nécessaires :

• Joint de rechange

• Ciseaux

1. Enlevez le joint usé.

Joint du couvercle

2. Coupez un nouveau bout de joint légèrement plus long que l'ancien.

Positionnez le nouveau joint de sorte à tourner le rebord vers le bas

et l'extérieur.

3. Pressez le joint uniformément dans la fente.

4. Élaguez le joint pour que les bouts serrent bien au point de contact

afin d'empêcher les fuites. Les bouts doivent être coupés droit.

Le joint du couvercle est trop court ou trop long, ce qui peut causer

des problèmes lors de la fermeture du couvercle ou des fuites.

Manuel d'utilisation de l'appareil à emballer sous vide avec deux barres de soudage 16" (40,6 cm) 7

Page 16

DÉPANNAGE

Problème Cause possible Mesure corrective

Le panneau de commande ne

s'allume pas.

Le panneau de commande est

allumé, mais il n'y a pas d'activité

après la fermeture du couvercle.

Le couvercle ne s'ouvre pas

automatiquement.

L'appareil n'est pas branché sur une prise électrique. Branchez l'appareil sur une prise électrique.

• Le fusible principal a grillé.

• Le fusible de la carte de circuits a grillé.

• Le réglage du microcommutateur est peut-être

nécessaire.

• Le fusible du transformateur de commande a grillé.

Le ressort à gaz est endommagé.

• Le réglage du microcommutateur est peut-être

nécessaire.

• La pompe exige peut-être une réparation.

Le couvercle ne s'est peut-être pas ouvert correctement. Vérifiez le couvercle.

Contactez le support technique Vollrath.

L'utilisation de l'appareil a atteint la vidange d'huile

programmée.

Le programme de conditionnement de la pompe doit être

exécuté.

Le vide final n'est pas suffisant. Le temps de vide défini est trop court. Prolongez le temps de vide.

Il n'y a pas assez d'huile dans la pompe à vide. Contactez le support technique Vollrath.

Le trou d'extraction à l'arrière de la chambre à vide est

partiellement couvert par le sac sous vide durant

l'extraction.

Le joint du couvercle est usé. Remplacez le joint du couvercle.

L'huile est contaminée. Contactez le support technique Vollrath.

Le filtre à huile est saturé.

La machine extrait l'air trop

lentement.

Le sac sous vide est mal soudé. Le sac sous vide est mal placé sur la barre de soudage. Placez correctement le sac sous vide sur la barre de

Le filtre à huile est saturé.

Le filtre d'extraction de la pompe est bouché.

Le temps de soudage est trop long ou trop court. Ajustez le temps de soudage.

La protection de la barre de soudage sous le couvercle est

abîmée ou usée.

Le ruban en Teflon est abîmé. Remplacez le ruban en Teflon.

L'ouverture du sac sous vide n'est pas propre. Nettoyez l'ouverture du sac sous vide.

Contactez le support technique Vollrath.

Voir les instructions à la page 6.

Rapprochez le sac sous vide de la barre de soudage.

soudage, sans plis. Assurez-vous que l'ouverture du

sac est toujours dans la chambre à vide.

Remplacez-la.

SAV ET RÉPARATIONS

Des pièces détachées sont disponibles sur Vollrath.com.

Pour éviter toute blessure grave ou tout dommage sévère, n’essayez jamais de réparer l'appareil ou de remplacer vous-même un cordon

d’alimentation endommagé. N’envoyez aucun appareil directement à la Vollrath Company LLC. Pour des instructions, contactez les services

techniques de Vollrath.

Lorsque vous contacterez les services techniques de Vollrath, tenez-vous prêt à fournir le numéro d'article, le numéro de modèle (s'il y a lieu),

le numéro de série et le justificatif d’achat indiquant la date d’achat de l’appareil.

GARANTIE DE THE VOLLRATH CO. L.L.C.

Cette garantie ne s'applique pas aux produits achetés pour un usage personnel, familial ou ménager, et The Vollrath Company LLC ne propose

aucune garantie écrite aux acheteurs pour de telles utilisations.

The Vollrath Company L.L.C. garantit que les produits qu'elle fabrique et distribue seront dépourvus de vices de matériaux et de malfaçons,

comme indiqué dans notre déclaration complète de garantie. Dans tous les cas, la garantie entre en vigueur à la date d'achat par l'utilisateur

initial indiquée sur le reçu. Tous les dommages subis lors d’une utilisation impropre ou abusive, ou résultant d’une modification ou d'un emballage

inadapté lors d’un renvoi du produit pour une réparation sous garantie ne seront pas couverts par la garantie.

Pour des informations complètes sur la garantie, l'enregistrement des produits et l'annonce de nouveaux produits, consultez www.vollrath.com.

The Vollrath Company, L.L.C.

Services techniques

techservicereps@vollrathco.com

Produits à induction : 800.825.6036

Réchauds de comptoir : 800.354.1970

Tous les autres produits : 800.628.0832

www.vollrath.com

1236 North 18th Street

Sheboygan, Wi 53081-3201 États-Unis

Standard : 800.624.2051 ou 920.457.4851

Télécopieur : 800.752.5620 ou 920.459.6573

Service clientèle : 800.628.0830

Service clientèle Canada : 800.695.8560

©

2020 The Vollrath Company L.L.C. Num. d’art. 26133-1 ml 2/27/20

Page 17

Manual para operadores

Máquina de envasado al vacío con barras de sellado dobles de 16" (40,6 cm)

Gracias por comprar este equipo Vollrath. Antes de usar el equipo, lea y

familiarícese con las siguientes instrucciones de operación y seguridad.

CONSERVE ESTAS INSTRUCCIONES COMO REFERENCIA PARA EL

FUTURO. Conserve la caja y embalado originales. Deberá utilizarlos

para devolver el equipo en caso de que requiera reparaciones.

PRECAUCIONES DE SEGURIDAD

Para garantizar una operación segura, lea las siguientes afirmaciones y

comprenda su significado. Este manual contiene precauciones de

seguridad que se explican a continuación. Léalas atentamente.

ADVERTENCIA

Advertencia se usa para indicar la presencia de un peligro que

provocará o puede provocar lesiones graves o letales.

PRECAUCIÓN

Precaución se usa para indicar la presencia de un peligro que provocará

o puede provocar lesiones personales o daños materiales leves si se

ignora el aviso.

AVISO: Aviso se usa para señalar información importante

no relacionada con peligros.

Para disminuir el riesgo de lesiones personales o daños

al equipo:

• Desenchúfelo cuando no esté en uso.

• Mantenga la unidad y el cable eléctrico lejos de llamas expuestas,

quemadores eléctricos o calor excesivo.

• No lo deje funcionando solo.

• No opere la unidad si se ha dañado o si funciona defectuosamente

de algún modo.

FUNCIÓN Y PROPÓSITO

Esta unidad está diseñada para sellar al vacío alimentos en un entorno

de cocina comercial. No está diseñada para uso doméstico, industrial ni

de laboratorio.

Núm. art. Modelo Descripción

40833 VP16 Máquina de envasado al vacío con barras

de sellado dobles de 16" (40,6 cm)

Contenido

Instalación ................................................................... página 2

Funcionamientos.......................................................... página 3

Envasado de productos líquidos ................................. página 5

Limpieza....................................................................... página 6

Mantenimiento ............................................................ página 6

Solución de problemas ............................................... página 8

REQUISITOS AMBIENTALES Y DISTANCIADO

AVISO: Nunca coloque la máquina cerca de una fuente de calor,

ya que puede dañar la tapa.

• Espacio libre de 6" (15 cm) en todos los lados y 15½" (39,4 cm)

sobre la máquina para que la tapa se abra completamente.

• La temperatura ambiente debe estar entre 41-86 °F (5-30 °C).

©

2020 The Vollrath Company L.L.C. Núm. pieza 26133-1 ml 2/27/20

Page 18

INSTALACIÓN

AVISO: NO incline demasiado la máquina, ya que el aceite podría

salirse de bomba y dañar la máquina.

AVISO: Usar un voltaje distinto del indicado en la placa

identificatoria dañará la unidad. Usar un voltaje

incorrecto, o modificar el cable eléctrico o los

componentes electrónicos puede dañar la unidad e

invalidará la garantía.

AVISO: Hacerfuncionar la máquina sin aceite o aceite insuficiente

dañará la máquina y anulará la garantía.

1. Retire del equipo todo el material y cinta de embalado, así como el

plástico protector.

2. Limpie todo residuo adhesivo que haya quedado del plástico o la

cinta.

3. Coloque la máquina de envasado al vacío en una superficie plana y

nivelada.

4. Instale las patas de 4" (10,2 cm) que se incluyen. La higienización

ETL exige que la máquina se use con las patas incluidas.

5. Revise la mirilla de aceite en la parte posterior de la máquina.

Verifique que el nivel de aceite esté entre las líneas de llenado

mínimo y máximo.

CARACTERÍSTICAS Y CONTROLES

6. Enchufe el cable eléctrico en un tomacorriente con puesta a tierra

cuyo voltaje nominal corresponda al indicado en la placa

identificatoria.

7. Ejecute el programa de acondicionamiento de la bomba. Consulte la

sección Ejecute el programa de acondicionamiento de la bomba

página 4 en este manual.

A

B

C

D

A Tapa

B Cámara

C Barra de sellado

D Panel de control

E Retén de la tapa

F Mirilla de aceite

G Almohadilla de sellado

E

G

A

B

C

F

H

A Visor de programas

B Botón de programas

C Botón de reprogramar

D Botón del programa de acondicionamiento de la bomba

E Indicadores LED de funciones

F Botón de disminuir/cancelar. Disminuye la presión de vacío,

vacío adicional o tiempo de sellado. También cancela el ciclo.

G Botón de encendido/apagado

H Vacuómetro

I Botón de aumentar/detener. Aumenta la presión de vacío, vacío

adicional o tiempo de sellado. También detiene el vacío.

J Visor

K Botón para seleccionar funciones

D E GF

HIJK

2 Manual para operadores de máquinas de envasado al vacío con barras de sellado dobles de 16" (40,6 cm)

Page 19

FUNCIONAMIENTO

AVISO: Nunca empaquete productos que puedan ser dañados por

el envasado al vacío.

Para reducir el riesgo de condensación y corrosión de la

bomba, enfríe los productos antes de envasarlos.

Al envasar alimentos, siempre seleccione un programa

que incluya el control del sensor de líquido.

Hay instrucciones especiales para el envasado de

productos líquidos. Consulte “Envasado de productos

líquidos” en la página 5.

La máquina está diseñada para un uso máximo de cinco

horas al día.

No está diseñada para uso continuo. Permita 15 segundos

entre los ciclos de envasado.

NO exceda un período de vacío de 60 segundos.

Si la máquina ha estado en uso durante una hora,

deténgala y deje que se enfríe a temperatura ambiente.

NO incline demasiado la máquina, ya que el aceite podría

salirse de bomba y dañar la máquina.

Encender la máquina

1. Gire el retén de la tapa de modo que este no la cubra. El retén se usa

solo para asegurar la tapa cuando la máquina no está en uso.

2. Pulse el botón de encendido/apagado.El visor de funciones muestra

los códigos de la revisión del software. Por ejemplo:

Colocar el alimento en la cámara

PRECAUCIÓN

Peligro de quemaduras

La barra de sellado puede calentarse después del uso repetido.

No toque la barra cuando coloque bolsas de vacío en la

cámara.

1. Coloque el alimento en una bolsa de sellado al vacío que calce

completamente dentro de la cámara.

2. Coloque la bolsa en la cámara con el extremo abierto sobre la barra

de sellado. Cerciórese de que la bolsa esté lisa, sin arrugas ni

pliegues. Se pueden colocar múltiples bolsas de vacío sobre las

barras de sellado. NO traslape las bolsas de vacío.

3. Para productos pequeños, coloque una o más placas de inserción

debajo del producto. Esto llena el espacio vacío en la cámara, lo cual

agiliza los ciclos.

3. Si la máquina no se ha utilizado durante un tiempo, ejecute el

programa de acondicionamiento de la bomba. Consulte la sección

página 6Limpieza.

Seleccionar un programa

Envasado de alimentos: Seleccione un programa que incluya el control

del sensor de líquido.

Envasado de un producto líquido: Encontrará información importante

en la sección Envasado de productos líquidos en la página 5.

prog

Pulse hasta que en el visor aparezca el número del programa

deseado. [APA = Apagado (OFF), ENC = Encendido (ON)]

Función

0-9

Vacuum Pressure %

Vacuum Plus

Extiende el ciclo de vacío

para permitir que el aire

atrapado en el producto

escape de la bolsa.

H2O Liquid Sensor

Control

Úselo al envasar

alimentos.

punto de ebullición,

detiene el vacío y avanza

al siguiente paso para

producir un producto de

mejor calidad y evitar que a

la bomba ingresen líquidos.

Detecta el

Sealing (segundos)

Soft-Air (segundos)

Forma la bolsa con

suavidad para proteger

productos delicados o

evitar dañar la bolsa con

los bordes afilados del

producto.

Programa

0 1 2 3 4 5 6 7 8 9

99 90 99 99 99 80 90 50 90 60

15 APA 15 10 10 APA APA APA APA APA

APA ENC APA APA APA APA APA APA APA APA

2,5 2,5 2,5 2,5 2,5 2,5 2,5 2,5 2,5 2,5

33222

APA APA

2

APA APA

Ejecutar el programa

1. Cierre la tapa. No use el retén de la tapa. Si lo usa durante un ciclo

de envasado interferirá con el ciclo. El ciclo se inicia

automáticamente.

2. La tapa se abre cuando se completa el ciclo.

3. Retire el producto envasado.

4. Espere 15 segundos antes de envasar otro producto.

Detener un ciclo

La máquina se puede detener antes de que se complete un ciclo de

empaque.

stop

Detiene la función de vacío y continúa con la función siguiente.

vac

Detiene y cancela el programa.

stop

Manual para operadores de máquinas de envasado al vacío con barras de sellado dobles de 16" (40,6 cm) 3

Page 20

FUNCIONAMIENTO (CONTINUACIÓN)

Editar programas

1. Seleccionar un programa para editar. Los programas del 1 al 9 se pueden personalizar. El programa 0 no se puede cambiar.

prog

Pulse

hasta que en el visor de programas aparezca el número del programa que se va a editar.

Por ejemplo:

2. Reprogramar.

Pulse para editar el programa.

El número del programa comienza a destellar:

3. Seleccione una función para editar (continúa en la página siguiente).

0-9

Porcentaje de presión de vacío Tiempo de vacío Control del sensor de líquido H2O

1. Pulse hasta que se ilumine el LED

de vacío.

1. Pulse hasta que se ilumine el LED de

vacío.

Use esta función al envasar líquidos.

1. Encienda el control del sensor de líquido

H2O

2. Pulse o para fijar una presión

stop

vac

stop

de vacío.

• El mínimo recomendado es 50%.

• Para utilizar el vacío adicional, la presión

de vacío debe fijarse en 99%.

3. Pulse para confirmar el ajuste.

4. Para editar la función Vacío adicional,

continúe con los pasos para el vacío

adicional.

Vacío adicional

1. Encienda la función Vacío adicional.

Pulse

hasta que el LED de vacío se ilumine y el

visor de funciones muestre:

2. Fije el tiempo.

stop

Pulse o

vac

stop

para fijar la cantidad de segundos.

Un punto rojo indica que está activa la

función Vacío adicional.

2. Pulse para reducir la presión de vacío

stop

vac

a fin de apagarla.

3. Pulse una vez para ingresar a la

función Tiempo de vacío.

El LED de vacío permanece iluminado. El

visor de funciones muestra:

4. Pulse o para fijar la cantidad

stop

vac

stop

de segundos. Un punto rojo indica que está

activa la función Tiempo de vacío.

• El máximo recomendado es de 60

segundos.

5. Pulse para confirmar el ajuste.

Pulse para encender o apagar la

función.

Cuando se enciende H2O, el visor de

funciones muestra:

2. Para editar la función H2O adicional,

continúe con los pasos para H2O adicional.

H2O adicional

1. Encienda la función H2O adicional.

Pulse hasta que se ilumine el LED de

vacío

y el visor de funciones muestre:

stop

Pulse o para fijar el tiempo

vac

stop

en décimas de segundo.

2. Pulse para confirmar el ajuste. Un

punto rojo después de H2O indica que está

activa la función de H2O adicional.

3. Pulse para confirmar el ajuste.

4. Editar otra función en el programa actual.

Pulse .

5. Guarde los cambios y salga del programa

actual.

Pulse .

4 Manual para operadores de máquinas de envasado al vacío con barras de sellado dobles de 16" (40,6 cm)

Page 21

Tiempo de sellado Tiempo de aire suave

1. Pulse hasta que se ilumine

el LED de sellado.

2. Pulse o para fijar

stop

vac

stop

la cantidad de segundos.

1. Pulse hasta que se ilumine

el LED de aire suave.

2. Pulse o para fijar

stop

vac

stop

la cantidad de segundos.

• Se recomiendan 2.0 a 2.5

segundos para la mayoría de

las bolsas.

3. Pulse para confirmar

el ajuste.

3. Pulse para confirmar el

ajuste.

ENVASADO DE PRODUCTOS LÍQUIDOS

Se debe tener especial cuidado al envasar al vacío productos líquidos o

húmedos.

1. Enfríe los alimentos antes de envasarlos. Los alimentos calientes

alcanzan rápidamente el punto de ebullición, lo que puede dar lugar

a un sellado insuficiente.

AVISO: Los productos calientes crean condensación,

2. Use la placa de inclinación y las barras de posicionamiento

magnéticas que se incluyen para colocar la bolsa de modo que el

líquido esté debajo de la barra de sellado. Las barras magnéticas se

envían unidas al lado inferior de la placa de inclinación.

lo cual puede dañar la bomba.

Barra magnética de posicionamiento

Placa de inclinación

3. Use un programa que incluya la función de control del sensor de

líquido. Ello evitará que hierva el producto.

AVISO: La ebullición aumentará la cantidad de humedad que

entra en la bomba, lo cual puede dar lugar a la

corrosión.

Manual para operadores de máquinas de envasado al vacío con barras de sellado dobles de 16" (40,6 cm) 5

Page 22

LIMPIEZA

MANTENIMIENTO

AVISO: NO incline demasiado la máquina, ya que el aceite podría

AVISO: Si la máquina estará inactiva durante más de un mes, el

salirse de la bomba y dañar la máquina.

aceite debe drenarse de la bomba. La humedad en el

aceite podría corroer la bomba.

Diariamente

Ejecute el programa de acondicionamiento de la bomba

El programa de acondicionamiento elimina la humedad que pueda

haberse acumulado en la bomba. Durante el programa, la bomba y el

aceite alcanzan la temperatura de funcionamiento, lo cual evapora la

humedad de la bomba.

1. Pulse .

2. El visor muestra .

3. Cierre la tapa.

4. Se inicia el programa. Aparecen puntos en movimiento en el visor.

5. El programa se ejecuta durante aproximadamente 15 minutos. No

interrumpa el programa, ya que deberá ejecutarlo nuevamente para

garantizar su finalización.

Limpie el exterior e interior

ADVERTENCIA

Peligro de descarga eléctrica

Evite que ingrese agua o cualquier otro tipo de líquido al

interior del equipo, ya que ello podría causar una descarga

eléctrica. No lo rocíe con agua ni productos de limpieza. El

líquido podría hacer contacto con los componentes eléctricos

y causar un cortocircuito o una descarga eléctrica.

PRECAUCIÓN

Peligro de quemaduras

Deje que el equipo se enfríe antes de moverlo o limpiarlo.

AVISO: No use limpiadores que contengan amoniaco, alcohol,

AVISO: No use toallas de papel, materiales abrasivos,

AVISO: No use WD-40

1. Desenchufe la máquina. Deje que se enfríe.

2. Limpie la cámara de vacío, la tapa, la barra de sellado, el soporte de

3. Elimine totalmente los restos de detergente o limpiadores químicos

acetona o productos de limpieza en seco. Los limpiadores

con estos químicos dañarán el Plexiglas

otros plásticos, y dañarán el acabado.

limpiadores que rayen, hojas de afeitar, cepillos, lana de

acero ni esponjas metálicas, tales como almohadillas

Scotch Brite™, ya que dañarán el acabado.

®

industriales o comerciales, ya que dañarán el acabado.

silicona y el exterior con un paño suave, sin pelusas o de microfibra

y agua tibia, o con una mezcla de agua tibia y una pequeña cantidad

de detergente suave para loza.

suaves, ya que los residuos podrían corroer la superficie de la

unidad.

ni petróleo, ni productos de limpieza

®

, el acrílico y

ADVERTENCIA

Peligro de descarga eléctrica

Desenchufe la unidad antes de darle servicio.

AVISO: Todo el mantenimiento debe ser realizado por un técnico

AVISO: NO incline demasiado la máquina, ya que el aceite podría

El siguiente programa de mantenimiento es solo una pauta. Las

necesidades reales de mantenimiento variarán según el uso de la

máquina. Inspeccione su máquina regularmente.

Intervalo Procedimiento

Semanalmente

Semestralmente

Anualmente

Cada cuatro

años

Reemplace los alambres de sellado

y la cinta Teflon

Inspeccione la barra de sellado por si está dañada. Reemplace la cinta

de teflón o los alambres de sellado si la calidad del sello ya no es

suficiente o si la cinta de teflón o los alambres de sellado están

desgastados.

Herramientas necesarias:

• Destornillador Phillips

• Herramienta tensora o alicates

• Tijeras

• Paño de limpieza sin pelusa

• Cinta de teflón de repuesto

• Alambre de sellado de repuesto

1. Tire hacia arriba de la barra de sellado para extraerla de la máquina.

de servicio calificado.

salirse de bomba y dañar la máquina.

Verifique el nivel de aceite observando por

la mirilla de aceite.

Inspeccione la barra de sellado por si está

desgastada.

Inspeccione la almohadilla de sellado debajo

de la tapa por si está desgastada.

Inspeccione la tapa y su junta.

Reemplace el aceite en la bomba de vacío.

Comuníquese con los Servicios de asistencia

técnica de Vollrath.

Reemplace los alambres de sellado y la cinta

®

Teflon

.

Reemplace la almohadilla de sellado debajo

de la tapa.

Reemplace la junta de la tapa.

Inspeccione el filtro de escape de aceite.

Comuníquese con los Servicios de asistencia

técnica de Vollrath.

Reemplace la tapa, los resortes de gas y las

membranas del cilindro de sellado. Comuníquese

con los Servicios de asistencia técnica de Vollrath.

®

6 Manual para operadores de máquinas de envasado al vacío con barras de sellado dobles de 16" (40,6 cm)

Page 23

2. Retire la cinta de teflón que protege los alambres de sellado.

Reemplace la almohadilla de sellado

Inspeccione las almohadillas por si están rugosas. Reemplace la

almohadilla si tiene áreas rugosas.

Herramientas necesarias:

• Almohadilla de sellado de repuesto

• Tijeras

3. Retire los tornillos en la parte inferior de la barra de sellado.

4. Retire los alambres de sellado.

5. Retire la cinta de teflón de la barra de sellado.

6. Limpie la barra de sellado con un paño sin pelusa.

7. Corte un pedazo de cinta de teflón de repuesto a la misma longitud

que la barra de sellado.

8. Coloque la cinta de repuesto en la barra de sellado.

9. Corte alambres de sellado nuevos según el largo de la barra de

sellado, más unas 6" (15 cm).

10. Fije un alambre a un lado de la barra de sellado apretando el

tornillo.

1. Retire del soporte la almohadilla desgastada.

Almohadilla de sellado

2. Corte una almohadilla de sellado nueva del mismo largo que la

anterior. Una almohadilla demasiado corta o excesivamente larga

causará problemas de sellado.

3. Coloque la almohadilla nueva en el soporte. Cerciórese de que la

almohadilla esté colocada completa y uniformemente en la ranura.

4. Coloque la pieza nueva en el soporte de silicona. Cerciórese de que

la goma de silicona esté colocada completa y uniformemente en la

ranura.

Reemplace la junta de la tapa

La junta de la tapa garantiza que la cámara de vacío esté

completamente sellada durante el ciclo de envasado. Esto es esencial

para lograr el vacío máximo. La junta de la tapa se desgasta debido a

las diferencias extremas de presión y debe reemplazarse regularmente.

Herramientas necesarias:

• Junta de repuesto

• Tijeras

1. Retire la junta desgastada.

Junta de la tapa

11. Tire del alambre por la barra de sellado en forma recta y firme.

12. Fíjelo apretando el tornillo.

13. Repita los pasos 10 al 12 para el segundo alambre.

14. Corte los alambres.

15. Corte un trozo de cinta de teflón del mismo largo de la barra de

sellado, más unas 2" (5 cm).

16. Aplique la cinta suavemente sobre los alambres de sellado en la

barra de sellado.

17. Corte la cinta.

18. Vuelva a colocar la barra de sellado en la máquina. Verifique que la

barra de sellado esté encajada correctamente en el soporte.

Manual para operadores de máquinas de envasado al vacío con barras de sellado dobles de 16" (40,6 cm) 7

2. Corte una junta nueva un poco más larga que la anterior. Coloque la

junta nueva de manera que el reborde quede hacia abajo y afuera.

3. Presione uniformemente la junta en el surco.

4. Recorte la junta de modo que los extremos se junten

herméticamente para evitar fugas. Los extremos deben cortarse

rectos. Si la junta de la tapa es demasiado corta o larga, puede

causar problemas al cerrarse la tapa o pueden producirse fugas.

Page 24

SOLUCIÓN DE PROBLEMAS

Problema Podría deberse a Curso de acción

El panel de control no se ilumina. La máquina no está conectada a un tomacorriente. Conéctela al suministro eléctrico.

• El fusible principal está fundido.

• El fusible del tablero de circuitos está fundido.

El panel de control está encendido pero

no hay actividad tras cerrarse la tapa.

La tapa no se abre automáticamente. El resorte de gas está dañado.

• Es posible que deba ajustarse el microinterruptor de la tapa.

• El fusible del transformador de control está fundido.

• Es posible que deba ajustarse el microinterruptor de la tapa.

• Es posible que la bomba requiera servicios técnicos.

Es posible que la tapa no se haya abierto correctamente. Revise la tapa.

Comuníquese con los Servicios de

asistencia técnica de Vollrath.

El uso de la máquina ha alcanzado un cambio de aceite

programado.

Debe ejecutarse el programa de acondicionamiento de la bomba. Consulte las instrucciones en la página 6.

El vacío final no es suficiente. El tiempo de vacío fijado es demasiado corto. Extienda el tiempo de vacío.

Hay muy poco aceite en la bomba de vacío.

El orificio de extracción en la parte posterior de la cámara de

vacío está parcialmente cubierto por la bolsa de vacío durante la

extracción.

La junta de la tapa está desgastada. Reemplace la junta.

El aceite está contaminado. Comuníquese con los Servicios de

El filtro de escape de aceite está saturado.

La máquina extrae el aire muy

lentamente.

La bolsa de vacío no está sellada

correctamente.

El filtro de escape de aceite está saturado.

El filtro de extracción de la bomba está bloqueado.

La bolsa de vacío está colocada incorrectamente en la barra de

sellado.

El tiempo de sellado es demasiado largo o demasiado corto. Aumente o disminuya el tiempo de sellado.

La almohadilla de sellado debajo de la tapa está dañada o

desgastada.

La cinta de teflón está dañada. Reemplácela.

La abertura de la bolsa de vacío no está limpia. Limpie la abertura.

Comuníquese con los Servicios de

asistencia técnica de Vollrath.

Comuníquese con los Servicios de

asistencia técnica de Vollrath.

Coloque la bolsa de vacío más cerca de la

barra de sellado.

asistencia técnica de Vollrath.

Coloque la bolsa de vacío ordenada y

suavemente en la barra de sellado.

Cerciórese de que la abertura de la bolsa

esté siempre dentro de la cámara de vacío.

Reemplace la almohadilla de sellado.

SERVICIO Y REPARACIÓN

En Vollrath.com encontrará las piezas que puedan ser reparadas.

Para evitar lesiones o daños materiales graves, no trate de reparar la unidad ni reemplazar un cable eléctrico por su cuenta. No envíe las unidades

directamente a The Vollrath Company LLC. Pida instrucciones a los Servicios de asistencia técnica de Vollrath.

Al comunicarse con los servicios, esté listo para proporcionar el número de artículo, número de modelo (si corresponde), número de serie y el

comprobante de compra que muestre la fecha en que adquirió la unidad.

CLÁUSULA DE GARANTÍA DE THE VOLLRATH CO. L.L.C.

El período de garantía para las estufas de inducción serie Ultra es de 2 años.

Esta garantía no se aplica a los productos adquiridos para uso personal, familiar ni doméstico, y The Vollrath Company LLC no ofrece una garantía

por escrito a los compradores para dichos usos.

The Vollrath Company LLC garantiza los productos que fabrica o distribuye contra defectos en materiales y fabricación, según se especifica en

nuestra cláusula de garantía completa. En todos los casos, la garantía rige desde la fecha de compra original del usuario final que aparece en el

recibo. La garantía no cubrirá ningún daño que resulte del uso indebido, abuso, modificación o daños causados por el embalado incorrecto durante

la devolución para obtener servicio de reparación dentro del período de vigencia de la garantía.

Para obtener información de garantía, inscripción de productos y anuncios de productos nuevos, visite www.vollrath.com.

The Vollrath Company, L.L.C.

Servicios de asistencia técnica:

techservicereps@vollrathco.com

Productos de inducción: 800.825.6036

Productos de calentamiento para mostrador:

800.354.1970

Todos los demás productos: 800.628.0832

www.vollrath.com

1236 North 18th Street

Sheboygan, WI 53081-3201 EE. UU.

Tel. principal: 800.624.2051 ó 920.457.4851

Fax principal: 800.752.5620 ó 920.459.6573

Servicio al cliente: 800.628.0830

Servicio al cliente en Canadá: 800.695.8560

©

2020 The Vollrath Company L.L.C. Núm. pieza 26133-1 ml 2/27/20

Loading...

Loading...