Volkswagen 01P Servicing Manual

2001-03 AUTOMATIC TRANSMISSIONS

Servicing - Eurovan

APPLICATION

TRANSAXLE APPLICATION

IDENTIFICATION

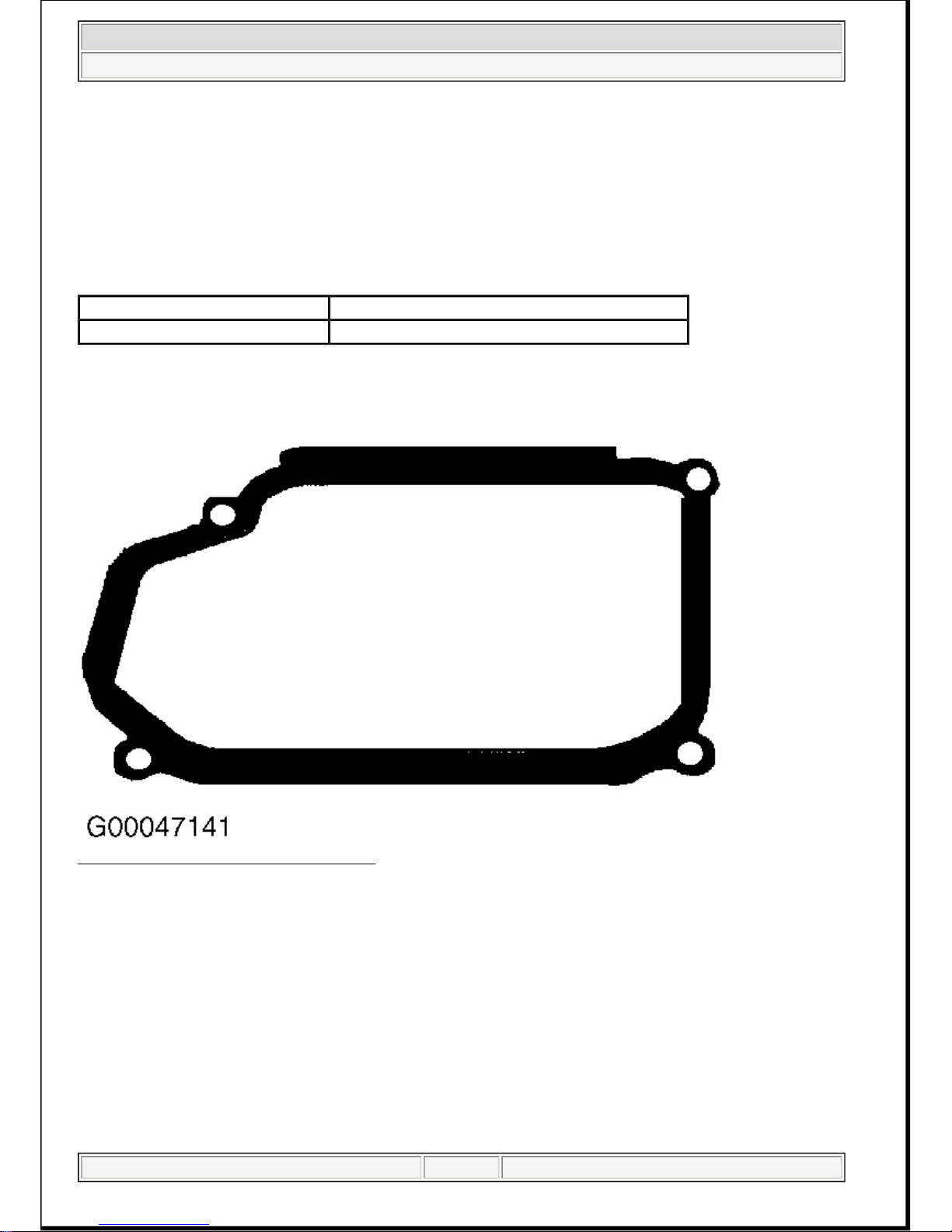

OIL PAN GASKET

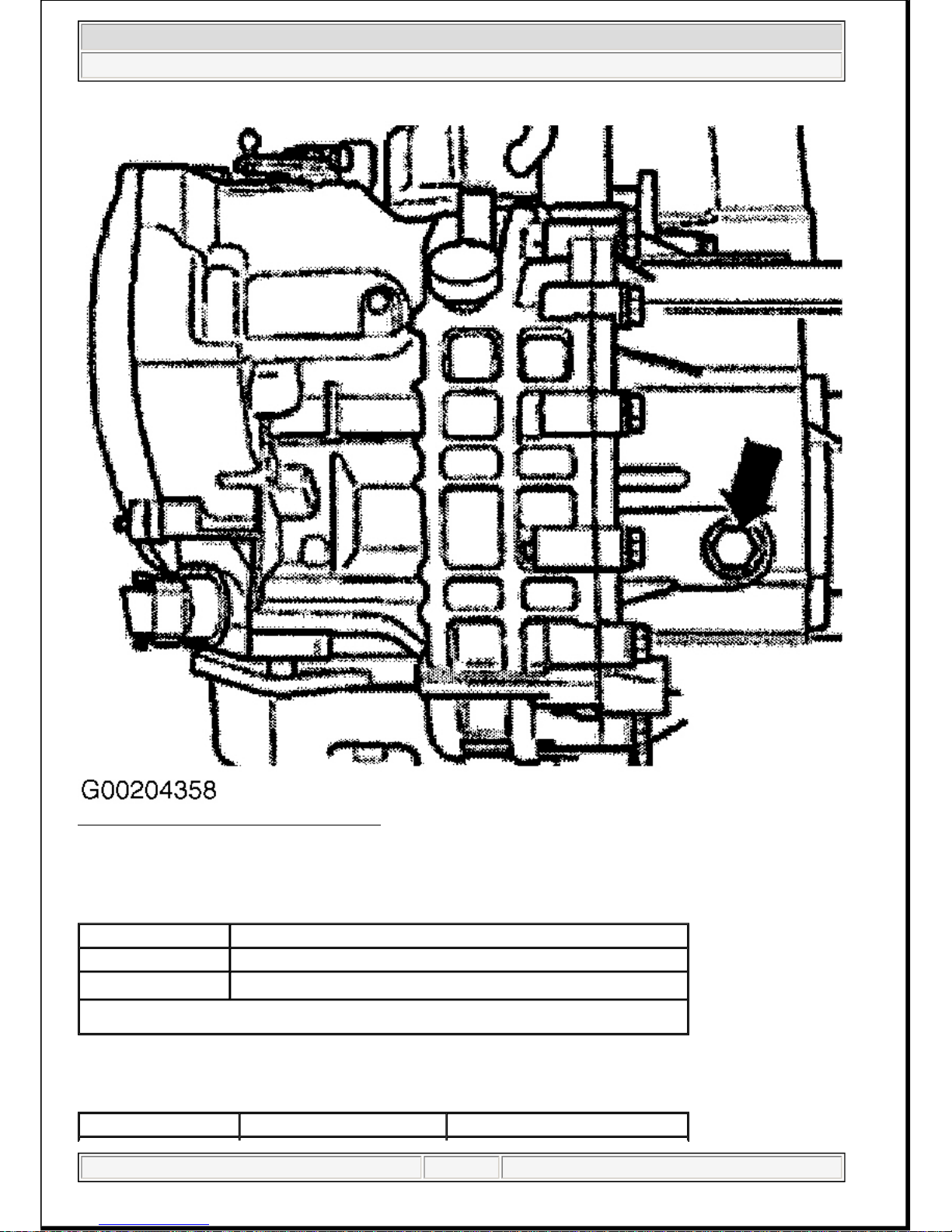

Fig. 1: Identifying Oil Pan Gasket (01P)

Courtesy of VOLKSWAGEN UNITED STATES, INC.

LUBRICATION

SERVICE INTERVALS

Transaxle

Check fluid level at 20,000 mile intervals. Fluid is filled for life except on transaxle with code EQJ. No

changing is required. On transaxles with code EQJ, replace fluid every 40,000 miles.

Final Drive

Check fluid level at 40,000 mile intervals. Fluid is filled for life. No changing is required.

Application Transaxle Model

Eurovan 01P

2003 Volkswagen EuroVan MV

SERVICING - A/T

4 января 2005 г. 1:05:09 Page 1 © 2004 Mitchell Repair Information Company, LLC.

CHECKING FLUID LEVELS

Transaxle

1.

Prior to checking ATF level, ensure all fuses are okay. Battery voltage must be at least 11.5 volts.

Ground connections on engine, transaxle and body must be okay. All electrical components must be

switched off. Transaxle ATF temperature must not be above about 86°F (30°C). Vehicle must be on

level surface and selector lever must be in "P" position.

2. Connect VAG 1924 ATF filling system to vehicle. Remove noise insulation tray. Connect vehicle

diagnostic, testing and information system VAS 5051. Select "08 - read measured value blocks" on

the touch screen. Select display group 005 via "Measured value block" and "Change display group

number". The first display zone shows the ATF temperature. The ATF temperature must not be more

than about 86°F (30°C) at the start of test.

3.

Connect VAG Scan Tool (1551) and enter address word "02 Transmission electronics" and advance

until "Select function XX" is indicated on display. Measure ATF temperature in measured value

block.

4. Press keys 0 and 8. (The function "Read measured value block" is selected with 08). Confirm entry

with key Q. Press keys 0 0 5. (005 selects the "Display group number 005"). Confirm entry with key

Q. The first display zone shows the ATF temperature. The ATF temperature must not be more than

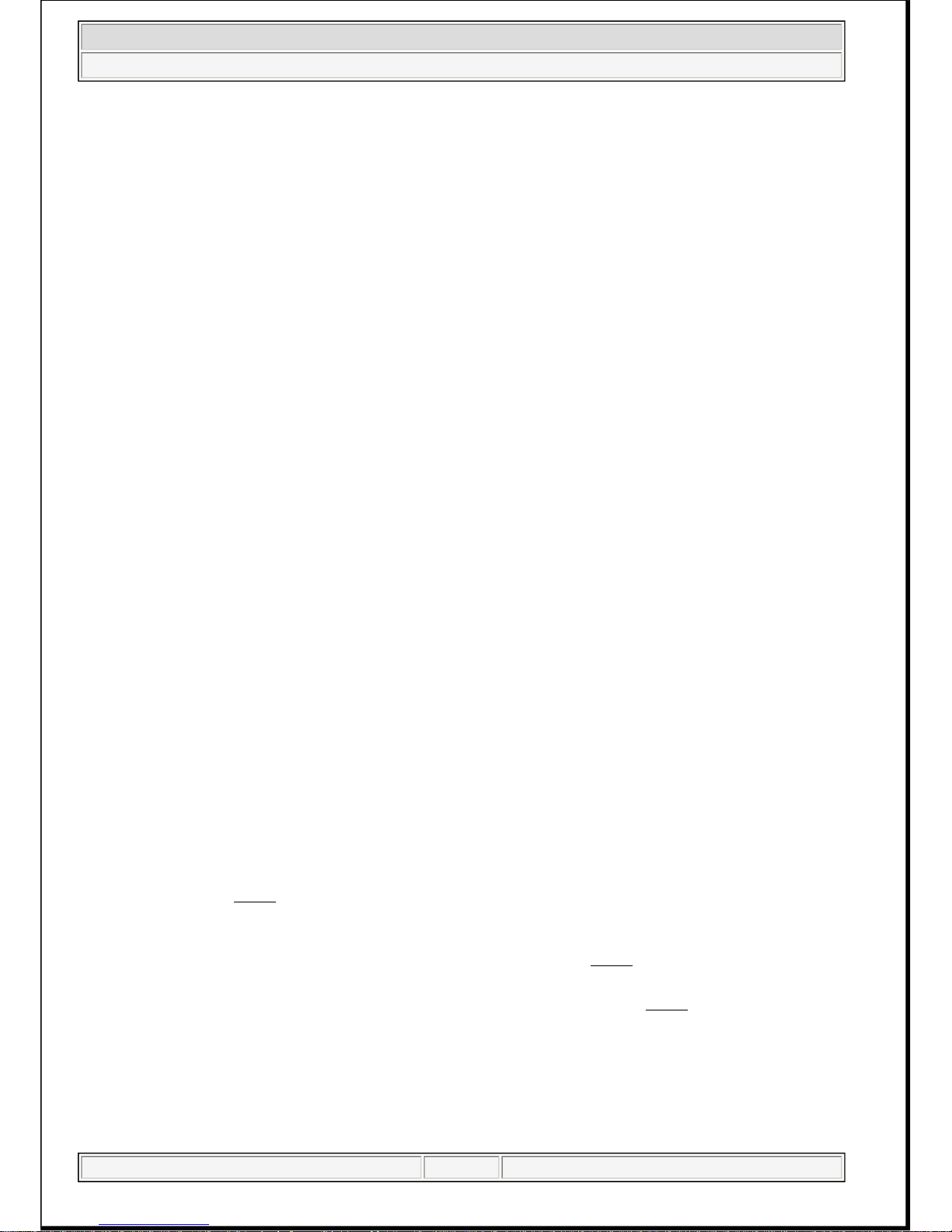

about 86°F (30°C) at the start of test. Start engine. Raise and support vehicle. Place drip tray under the

transaxle. Bring ATF to test temperature of 95-113°F (35-45°C). Remove ATF level plug (A) from

the oil pan. See

Fig. 2

.

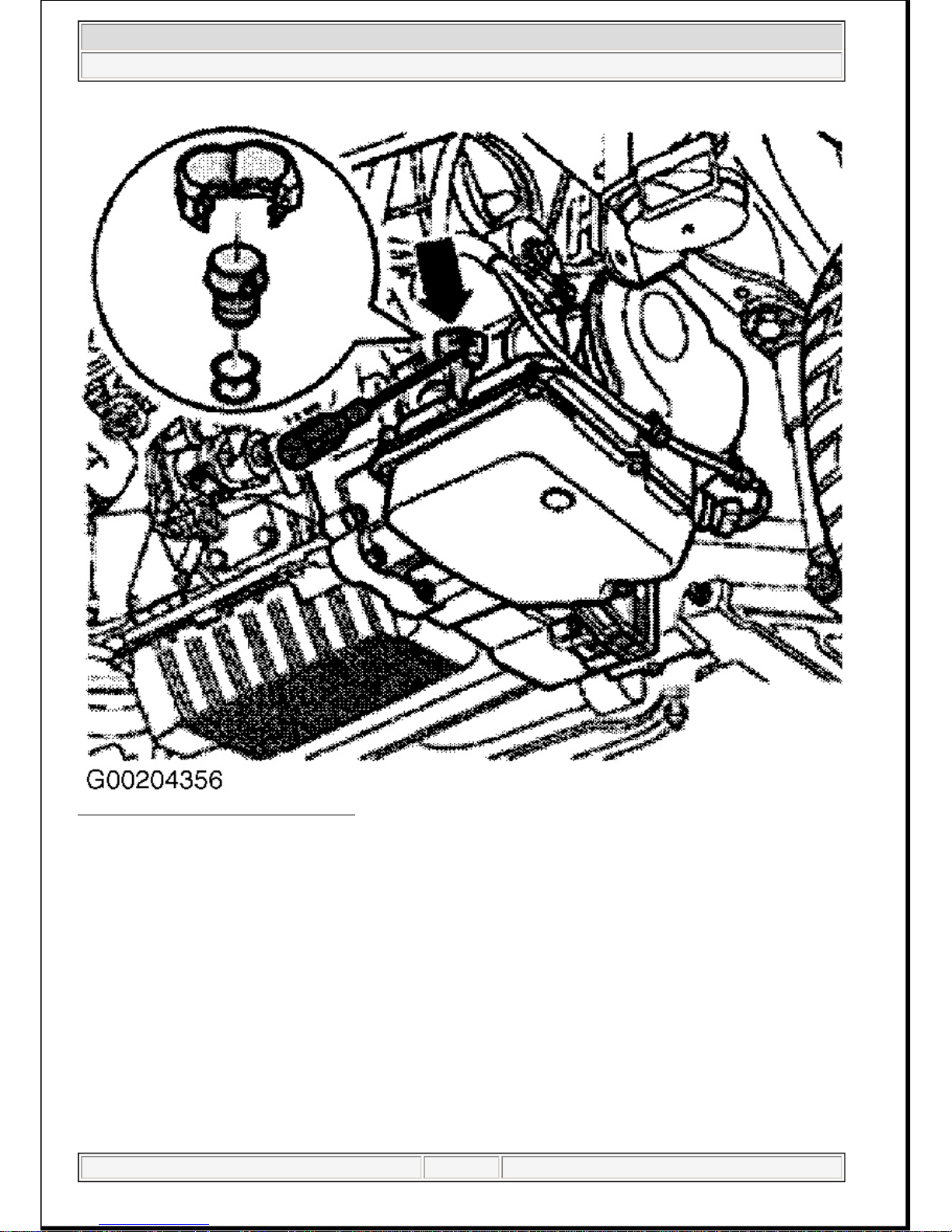

5. The ATF present in the overflow pipe (2) will run out. If ATF drips out of hole, ATF does not need to

be topped off. Install NEW seal (1) to level plug and tighten to 11 ft. lbs. (15 N.m). ATF check is

completed. Ensure sealing plug (3) and cap (4) remain closed. See

Fig. 3

. If only the ATF present in

the overflow pipe runs out of hole, top off ATF.

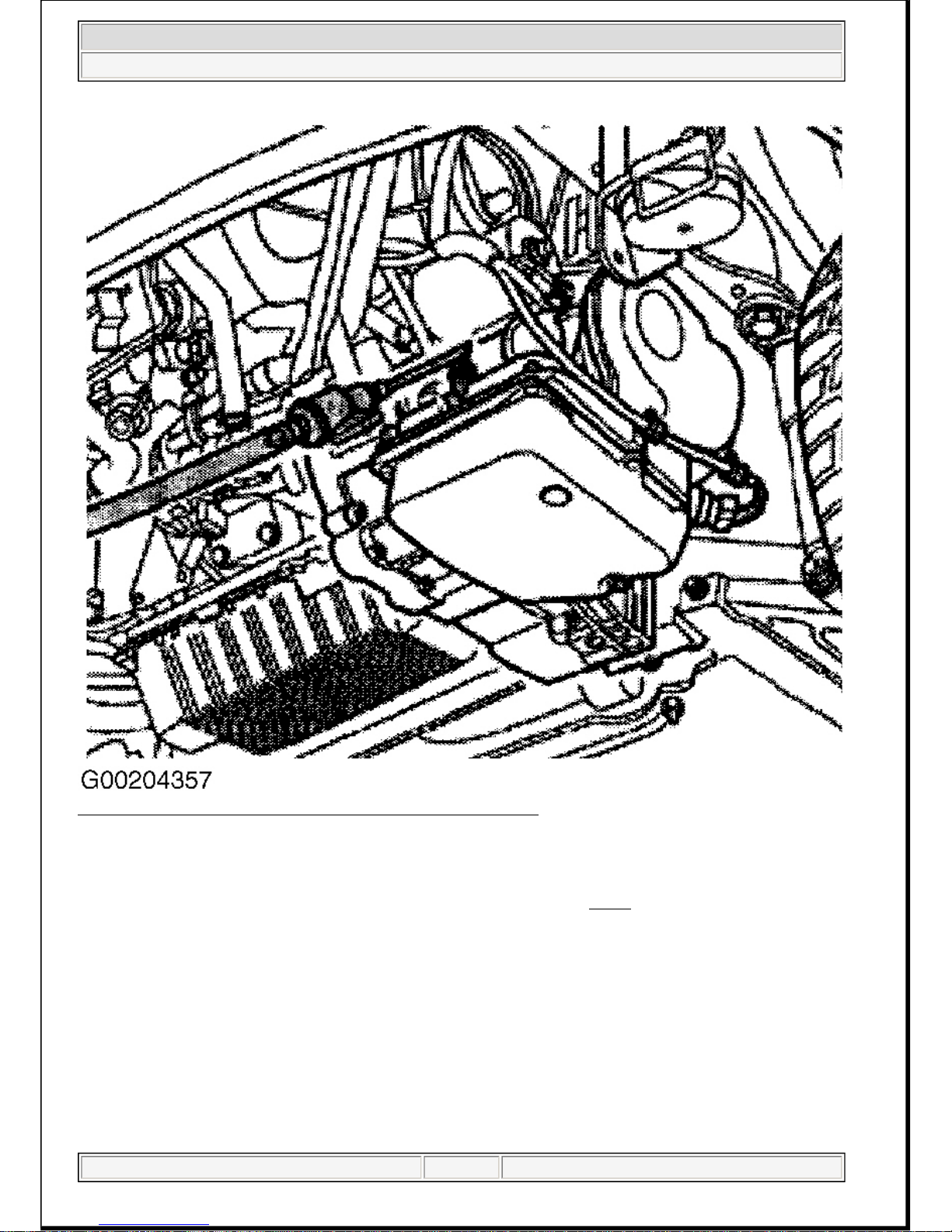

6. To top off ATF, pry off plug securing cap (arrow) with a screwdriver. See

Fig. 4

. The securing cap

locking device will be destroyed when doing this, so always replace securing cap. Pull plug out of

filler pipe. On some transaxles, a cap with a spring retainer is installed. This cap can be used again.

7.

NOTE:

V

W ATF (G 052 162 A2) is Light Yellow in color.

NOTE: In the following procedures, letters and numbers in parenthesis are shown in

illustrations.

NOTE: When ATF level is checked, the seal on the level plug must always be

replaced. VAG Scan Tool (1551) and Diagnosis Cable (1551/1) are

required to check ATF fluid level. Scan tool is used to measure ATF

temperature. Follow aftermarket scan tool manufacturer instructions (if

applicable) to check AFT temperature.

NOTE: The following detailed test procedures are described for VAG Scan Tool

(1551).

NOTE: An insufficient amount of ATF, as well as filling ATF to excess, affects

2003 Volkswagen EuroVan MV

SERVICING - A/T

4 января 2005 г. 1:05:10 Page 2 © 2004 Mitchell Repair Information Company, LLC.

Fill transaxle with ATF using VAG 1924 ATF filling system until ATF runs out of level hole. See

Fig. 5

. Install NEW seal (1) to level plug and tighten to 11 ft. lbs. (15 N.m). See

Fig. 3

. Install

sealing plug (3) on filler pipe until the spring retainer lock locates, or install plug on filler pipe and

secure with a NEW cap. See

Fig. 3

and

Fig. 4

. Lock cap in place. The cap secures the sealing plug.

Fig. 2: Removing ATF Level Plug From Oil Pan

Courtesy of VOLKSWAGEN UNITED STATES, INC.

the function of the transaxle.

2003 Volkswagen EuroVan MV

SERVICING - A/T

4 января 2005 г. 1:05:10 Page 3 © 2004 Mitchell Repair Information Company, LLC.

Fig. 3: Locating Plug Seal, Overfill Pipe, Sealing Plug & Cap

Courtesy of VOLKSWAGEN UNITED STATES, INC.

2003 Volkswagen EuroVan MV

SERVICING - A/T

4 января 2005 г. 1:05:10 Page 4 © 2004 Mitchell Repair Information Company, LLC.

Fig. 4: Prying Off Plug Securing Cap

Courtesy of VOLKSWAGEN UNITED STATES, INC.

2003 Volkswagen EuroVan MV

SERVICING - A/T

4 января 2005 г. 1:05:10 Page 5 © 2004 Mitchell Repair Information Company, LLC.

Fig. 5: Filling Transaxle Using VAG 1924 ATF Filling System

Courtesy of VOLKSWAGEN UNITED STATES, INC.

Final Drive

Raise and support vehicle. Remove filler plug on side of final drive. See

Fig. 6

. Gear oil level should be at

lower edge of hole. If fluid is required, add G 50, SAE 75W-90 synthetic gear oil (G 052 145 S2). Install

filler plug and tighten to 15 ft. lbs. (20 N.m).

2003 Volkswagen EuroVan MV

SERVICING - A/T

4 января 2005 г. 1:05:10 Page 6 © 2004 Mitchell Repair Information Company, LLC.

Fig. 6: Checking Final Drive Fluid Level

Courtesy of VOLKSWAGEN UNITED STATES, INC.

RECOMMENDED FLUIDS

RECOMMENDED FLUIDS

FLUID CAPACITIES

TRANSAXLE FLUID CAPACITY

Application Fluid Type

Transaxle VW ATF (G 052 162 A2)

Final Drive

(1)

G 50, SAE 75W-90 (G 052 145 S2)

(1)

Synthetic oil.

Application Refill - Qts. (L) Dry-Fill - Qts. (L)

2003 Volkswagen EuroVan MV

SERVICING - A/T

4 января 2005 г. 1:05:10 Page 7 © 2004 Mitchell Repair Information Company, LLC.

Loading...

Loading...