Page 1

VT-Series

Ice Maker

Model

VT40, VT60, VT80, VT100

Revision Date: 1/04/12

Page 2

NOTICE

This manual is the property of the owner of this particular Vogt

Tube-Ice® machine.

Model #____________________ Serial #____________________.

It is to be left on the premises with this machine at all times. After

start-up, it should be stored in a safe place where it can be readily

available when needed for future reference in maintaining

troubleshooting or servicing.

Failure to comply with this notice will result in unnecessary

inconvenience and possible additional expenses.

This manual is intended as an informational tool for the installation,

operation, maintenance, troubleshooting, and servicing of this

equipment. If an existing situation calls for additional information

not found herein, we suggest that you contact your distributor first.

If further assistance or information is needed, please feel free to

contact the factory at 502-635-3000 or FAX at 502-635-3024.

IMPORTANT: The Warranty Registration/Start-Up Report found in

the front of this manual is to be completed and returned to the factory

promptly after the official start-up.

Please return to: VOGT ICE

, LLC

1000 W. Ormsby Ave.

Louisville, KY 40210

Page 3

FOREWORD

Vogt Ice®, LLC, strives to provide a quality product that is time-tested and will

provide years of dependable service to its customers.

Skilled craftsmen have carefully assembled your Vogt

material components and parts available from the leading vendors and producers of

the highest quality refrigeration equipment in our industry. You have invested in

quality equipment, and we pledge to support your needs and requirements after the

sale.

This manual is provided to aid the service technician and users in the installation,

operation, and maintenance of your equipment. Before attempting to install and

start the machine, the installer should read and understand each section of this

manual.

If, at any time, you encounter conditions that we have not addressed in this manual,

we welcome you to write or call Vogt

immediate attention and reply.

®

Ice, LLC and we will give your questions our

®

VT Series ice maker using

Vogt Ice®, LLC

1000 W. Ormsby Avenue

Suite 19

Louisville, KY 40210

(502) 635-3000

(502) 634-3024 Fax

Page 4

TABLE OF CONTENTS

General Information - Section 1

History of Company............................................................................................. 1-1

Receipt of Your Ice Machine ............................................................................... 1-2

Installation Information - Section 2

Important Safety Notice....................................................................................... 2-1

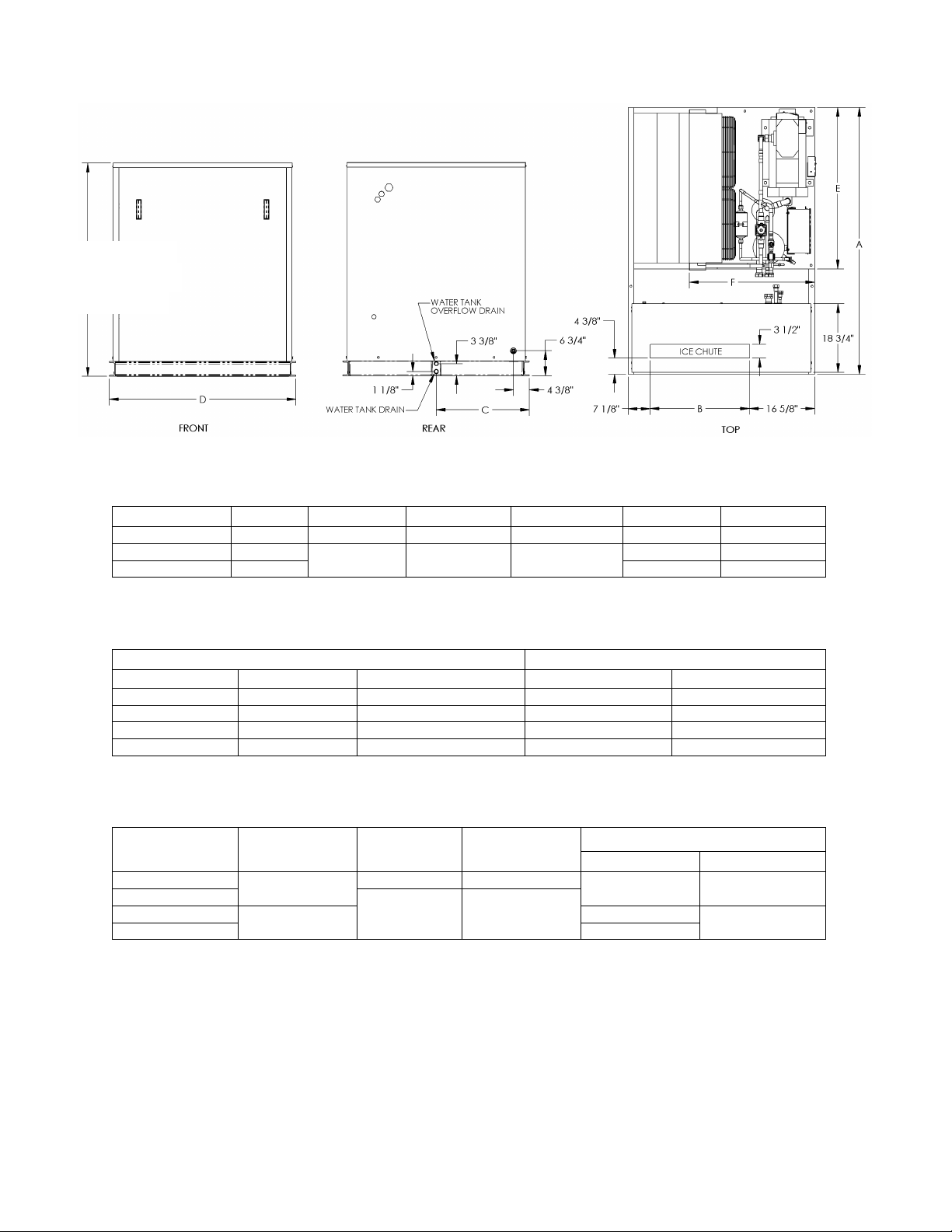

Machine Dimension............................................................................................. 2-2

Machine Weights & Refrigerant Line Sizes.......................................................... 2-2

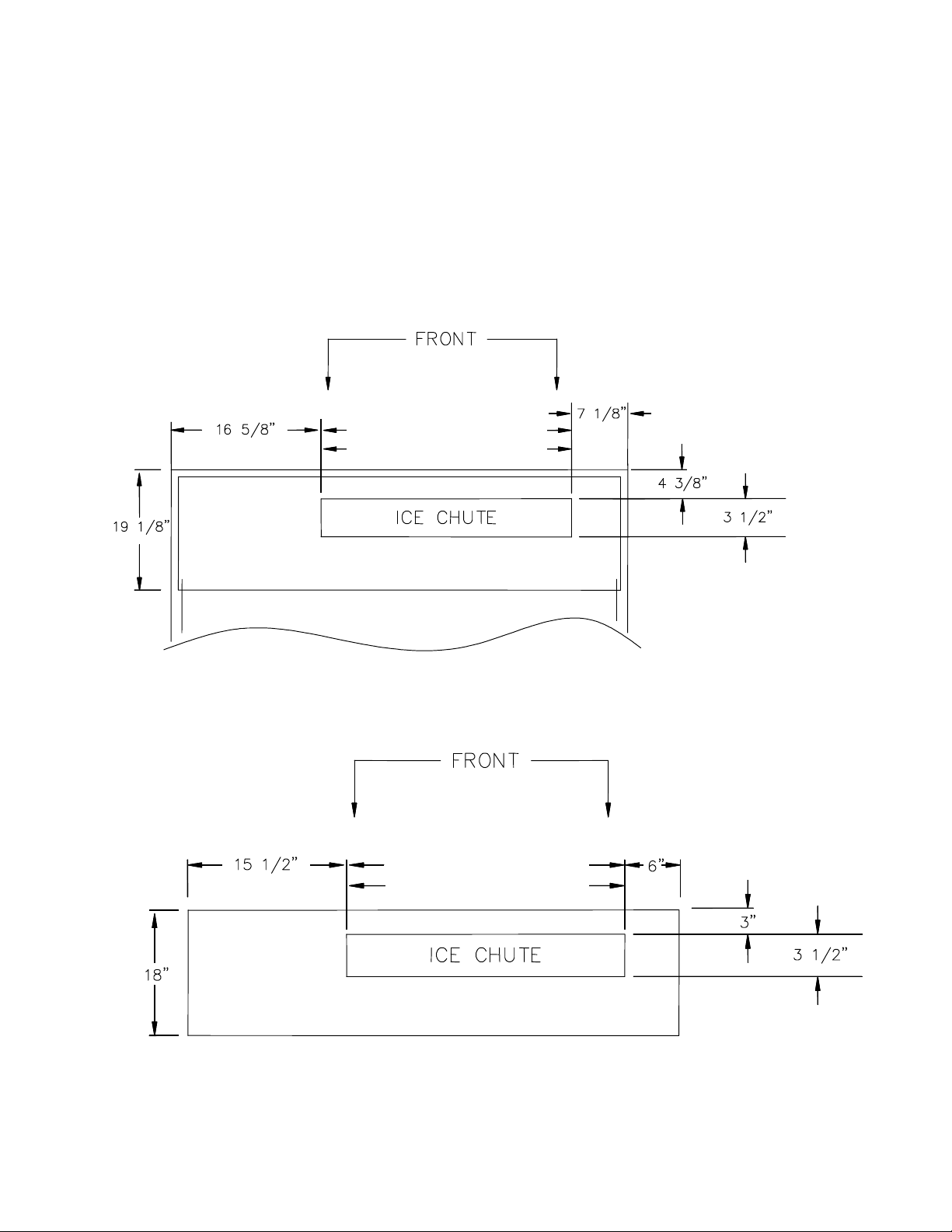

Ice Chute Cutout ................................................................................................. 2-3

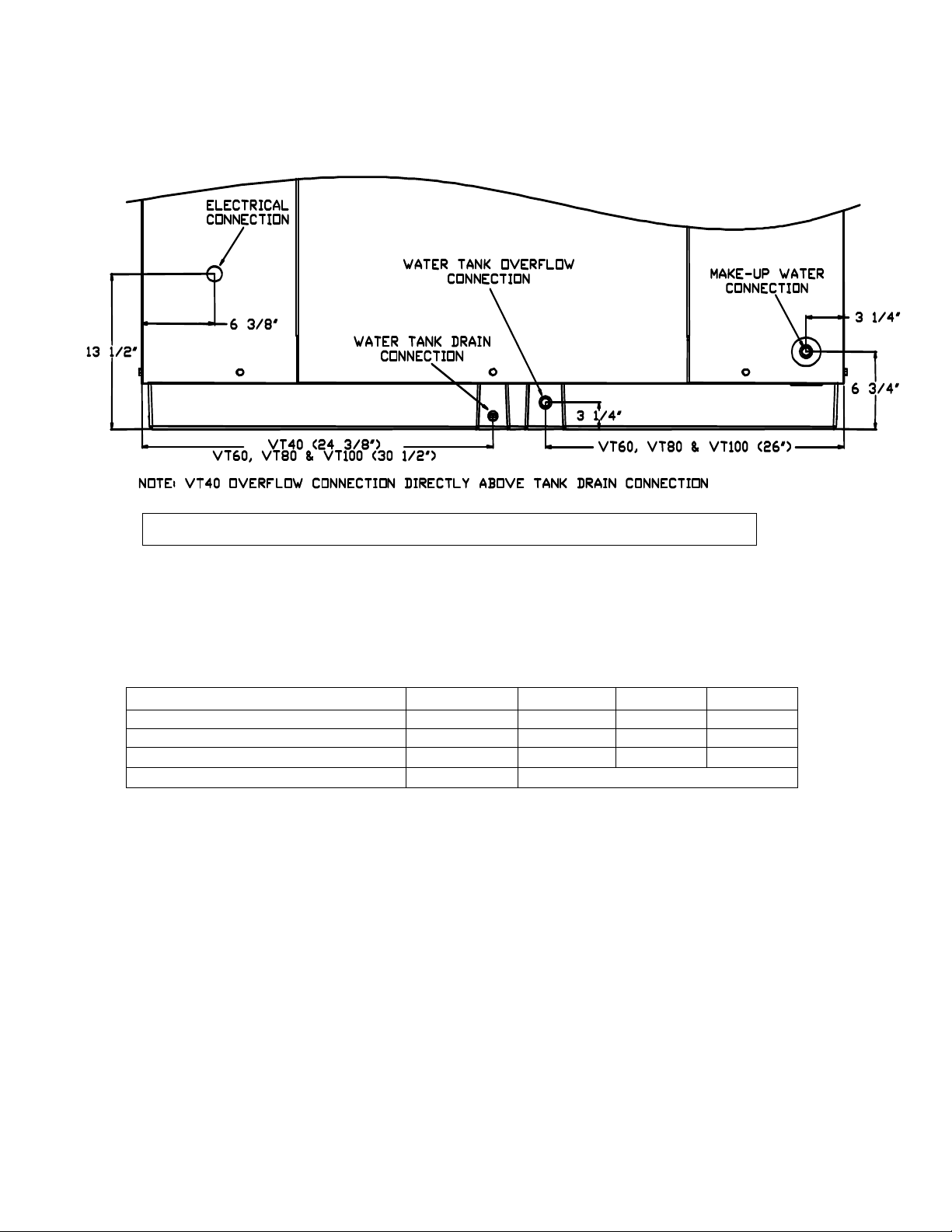

Water Connections.............................................................................................. 2-4

Water Flow Rates / Water Tank Capacity............................................................ 2-4

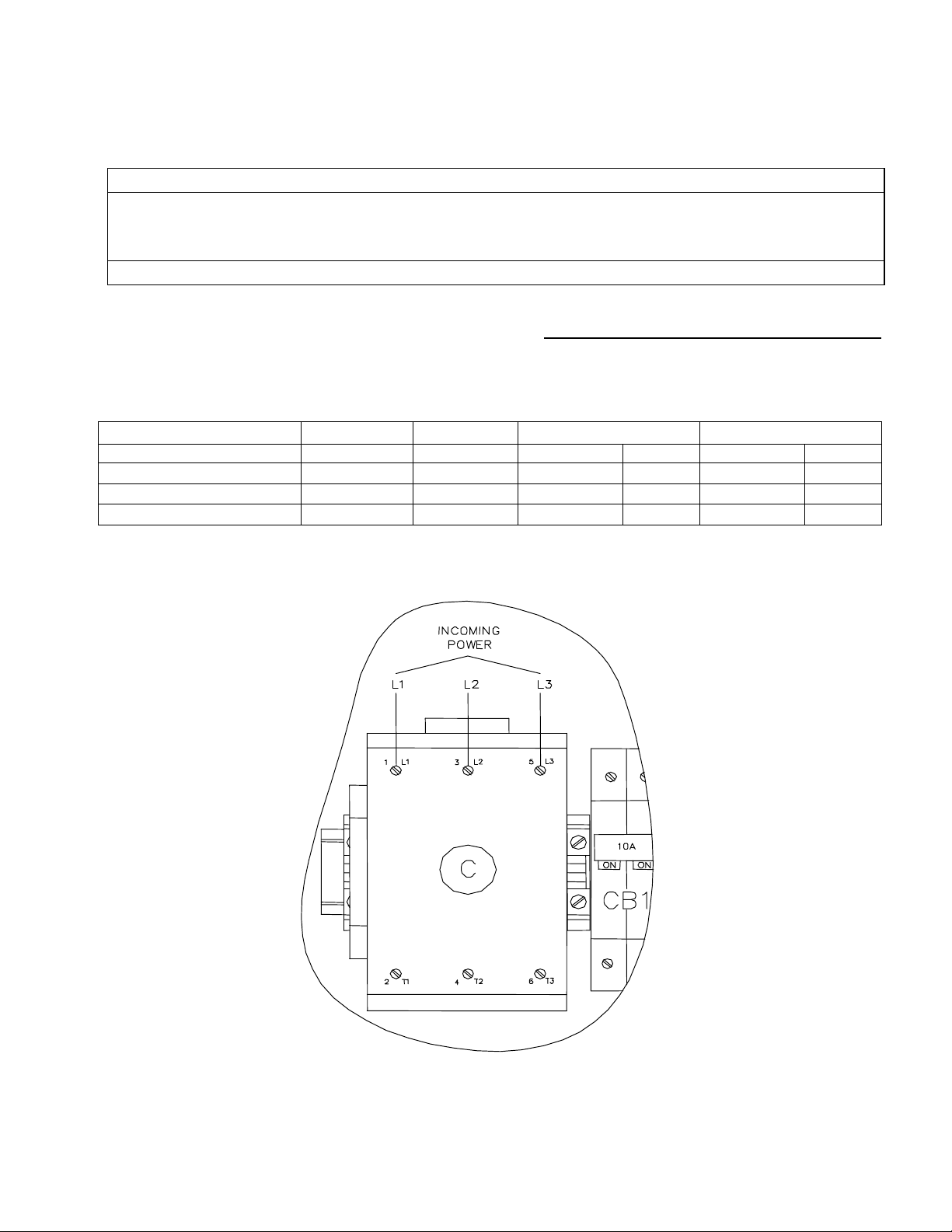

Electrical Connections......................................................................................... 2-5

Air Cooled Condenser Electrical Connections .................................................... 2-6

Lowside Electrical Connections..............................................................................2-6

Air Cooled Condenser Installation ....................................................................... 2-7

Air Cooled Condenser Wiring ............................................................................. 2-9

Storing Ice – Bin Thermostat Mounting ............................................................. 2-12

Model Specifications and Wiring Diagrams - Section 3

Model Specifications ........................................................................................... 3-1

Model Number Structure .................................................................................... 3-2

Initial Startup - Section 4

Startup Procedure ............................................................................................... 4-1

Circuit Breakers & Lowside Control Panel Front.................................................. 4-2

Service Valve Locations ...................................................................................... 4-3

Adding Refrigerant .............................................................................................. 4-4

Suction Line Access Port..................................................................................... 4-4

Removing Refrigerant ......................................................................................... 4-5

Electrical Controls - Section 5

Explanation of Controls........................................................................................ 5-1

Startup & Standby Mode ..................................................................................... 5-1

Freeze Mode ...................................................................................................... 5-1

PLC & Freezer Timer .......................................................................................... 5-1

Harvest Mode ...................................................................................................... 5-2

Harvest Hold Pressure Switch

Clean Mode......................................................................................................... 5-3

Fault Mode & Faults Designations ....................................................................... 5-3

PLC Input / Output Table..................................................................................... 5-4

Electrical Schematic

Electrical Schematic

Lowside Electrical Schematic .............................................................................. 5-7

Lowside Control Panel Layout ............................................................................ 5-8

Condensing Unit Electrical Schematic

Condensing Unit Control Panel Layout

Condensing Unit Electrical Schematic

Condensing Unit Control Panel Layout

(Standard)

(CE)

(Increasing Harvest)

............................................................................ 5-5

..................................................................................... 5-6

(Standard)

(Standard)

(CE)

....................................................... 5-11

(CE)

............................................... 5-2

................................................. 5-9

.............................................. 5-10

...................................................... 5-12

Page 5

Maintenance - Section 6

Preventive Maintenance ..................................................................................... 6-1

Preventive Maintenance Program ....................................................................... 6-2

Air Cooled Condenser Cleaning .......................................................................... 6-3

Compressor Oil ................................................................................................... 6-3

Chopper Gear Reducer Oil.................................................................................. 6-4

Water Distributor ................................................................................................. 6-4

Troubleshooting - Section 7

Machine Fault Light ............................................................................................ 7-1

Control Power Light ............................................................................................ 7-1

PLC ..................................................................................................................... 7-2

Damaged Bin Control Sensor .............................................................................. 7-2

Machine Inoperative ............................................................................................ 7-3

Machine “Freeze-Up”........................................................................................... 7-4

Additional Troubleshooting ................................................................................. 7-5

Service Operations - Section 8

Principle Of Operation ........................................................................................ 8-1

Pressure Switches .............................................................................................. 8-2

CoreSense

Bin Control

PLC

Compressor......................................................................................................... 8-6

TXV & Solenoid Valve ......................................................................................... 8-7

Adjusting TXV...................................................................................................... 8-8

Inlet Pressure Regulator...................................................................................... 8-8

Water Tank Parts ............................................................................................... 8-9

Chopper Assembly ........................................................................................... 8-10

Evaporator Housing Covers .............................................................................. 8-11

Freeze Cycle Piping Schematic

Harvest Cycle Piping Schematic

Freeze Cycle Piping Schematic

Harvest Cycle Piping Schematic

Freeze Cycle Piping Schematic

Harvest Cycle Piping Schematic

Replacement Parts List .................................................................................... 8-18

(Programmable Logic Controller)

(Copeland Compressor Protection

(Electronic Temperature Control)

...................................................................... 8-5

(No Hot Gas Loop)

(No Hot Gas Loop)

(With Hot Gas Loop)

(With Hot Gas Loop)

(With Suction Stop Valve)

(With Suction Stop Valve)

)........................................................ 8-3

........................................................... 8-4

............................................ 8-12

........................................... 8-13

.......................................... 8-14

......................................... 8-15

......................................8-16

..................................... 8-17

Options and Accessories - Section 9

Voltage Monitor

Remote Switch

(Wagner Model DTP-3)

(Includes Ice/Off/Clean selector switch, start button & fault light)

...................................................................9-1

...........9-3

Page 6

Vogt® VT Service Manual 1-1

General Information

1. General Information

H

ISTORY OF COMPANY

Henry Vogt Machine Co. was founded as a small machine shop in Louisville, Kentucky in

1880. In 1938, Vogt built the first Tube-Ice® machine and revolutionized the ice-making

industry. Our first “sized-ice” machine quickly replaced the old can-ice plants, which required

much hard labor and large amounts of floor space for freezing, cutting, and crushing ice by

hand.

Today, Vogt Ice

making equipment.

Preview

that we have learned in over a century of ice machine manufacturing.

Furnished with your machine is the “Certificate of Test”--the report of operating data that is a

record of the unit’s satisfactory operation on our factory test floor.

This manual is designed to assist you in the installation, start-up, and maintenance of your

unit. Your VT® machine will give you many years of service when you install it, maintain it,

and service it properly.

Please read your manual carefully before attempting installation, operation, or servicing of this

piece of equipment.

If you have additional questions, please call your distributor. Also, feel free to phone the

factory direct at (502) 635-3000 or 1-800-853-8648.

, LLC carries on the tradition as one of the world’s leading producers of ice-

Vogt VT Series ice machines are built with the skill in engineering and fabrication

Page 7

1-2 Vogt® VT Service Manual

General Information

Receipt Of Your Ice Machine

! CAUTION !

Only service personnel experienced in refrigeration and

qualified to work on high amperage electrical equipment should

be allowed to install or service this VT ice machine.

Eye protection should be worn by all personnel

working on or around the VT machine.

It is very important that you are familiar with and adhere to

all local, state, and federal, etc. ordinances and laws regarding

the handling, storing, and use of R404A.

! CAUTION !

Inspection.

note it on the shipper’s papers (i.e., the trucker’s Bill of Lading). Immediately make a separate written

request for inspection by the freight line’s agent. Any repair work or alteration to the machine without the

permission of the Vogt Ice can void the machine’s warranty. You should also notify your Vogt distributor or

the factory.

Safety Tags and Labels.

or applied to various areas of the machine. They provide important information necessary for safe and

efficient operation of your equipment.

As soon as you receive your machine, inspect it for any damage. If damage is suspected,

Be sure to read and adhere to all special tags and labels attached to valves

Page 8

Vogt® VT Service Manual 2-1

Installation Instructions

2. Installation Information

Important Safety Notice.

backgrounds of electrical, refrigeration and mechanical experience. Any attempt to repair major equipment

may result in personal injury and property damage. The manufacturer or seller cannot be responsible for

the interpretation of this information, nor can it assume any liability in connection with its use.

Special Precautions To Be Observed When Charging Refrigeration Systems.

technically-qualified persons, experienced and knowledgeable in the handling of refrigerant and operation

of refrigeration systems, should perform the operations described in this manual. All local, federal, and

EPA regulations must be strictly adhered to when handling refrigerants.

If a refrigeration system is being charged from refrigerant cylinders, disconnect each cylinder when empty

or when the system is fully charged. A gage should be installed in the charging line to indicate refrigerant

cylinder pressure. The cylinder may be considered empty of liquid R404A refrigerant when the gage

pressure is 25 pounds or less, and there is no frost on the cylinder. Close the refrigerant charging valve

and cylinder valve before disconnecting the cylinder. Loosen the union in the refrigerant charging line-carefully to avoid unnecessary and illegal release of refrigerant into the atmosphere.

This information is intended for use by individuals possessing adequate

Only

! CAUTION !

Immediately close system charging valve at commencement of defrost or thawing

cycle if refrigerant cylinder is connected. Never leave a refrigerant cylinder

connected to system except during charging operation. Failure to observe either

of these precautions can result in transferring refrigerant from the system to the

refrigerant cylinder, over-filling it, and possibly causing the cylinder to rupture

because of pressure from expansion of the liquid refrigerant brought on by an

increase in temperature.

! CAUTION !

Always store cylinders containing refrigerant in a cool place. They should never be exposed to

temperatures higher than 110°F and should be stored in a manner to prevent abnormal mechanical shocks.

Also, transferring refrigerant from a refrigeration system into a cylinder can be very dangerous and is not

recommended.

! CAUTION !

It is not recommended that refrigerant be transferred from a refrigeration system

directly into a cylinder. If such a transfer is made, the refrigerant cylinder must be

an approved, CLEAN cylinder--free of any contaminants or foreign materials--and

must be connected to an approved recovery mechanism with a safety shutoff

sensor to assure contents do not exceed net weight specified by cylinder

manufacturer or any applicable code requirements.

! CAUTION !

Page 9

2-2 Vogt® VT Service Manual

Installation Instructions

58" - VT40, VT60

& VT80

71" - VT100

Unit "A" "B" "C" "D" "E" "F"

VT40 72 5/8" 27" 24 3/8" 50 3/4" 44" 34"

VT60 89" 39 1/2" 30 1/2" 63 1/4" 57.5 68"

VT80 & VT100 44 7/8" N/A N/A

Model Lowside Condensing Unit Model Skid Mounted

VT40 520 lbs. 975 lbs. VT-40 1,525 lbs.

VT60 650 lbs. 1330 lbs. VT-60 2290 lbs.

VT80 1,475 lbs. 375 lbs. (condenser) VT-80 ----------

VT100 1,850 lbs. 400 lbs. (condenser) VT-100 ----------

Suction Hot Gas Liquid

Model Line Line Line

VT40 1 3/8 OD 7/8 OD 5/8 OD N/A N/A

VT60 1 1/8 OD 7/8 OD

VT80 1 5/8 OD 1 1/8 OD 7/8 OD

VT100 1 3/8 OD

Note: Split systems will be supplied with Rota-lock adapters to connect the highside to the lowside

Machine Clearances:

machine. This will provide sufficient area for service and air flow.

FIGURE 2-1

Ice Machine Dimensions

TABLE 2-1

Ice Machine Dimensions

Remote Weights Skid Mounted Weights

TABLE 2-2

Weight Of Machines

TABLE 2-3

Refrigerant Line Sizes

A minimum three (3) feet of clearance is recommended around entire ice

Remote Condenser

Discharge Liquid Return

Evaporator Installation:

Mount evaporator section (lowside) on storage area capable of sustaining its

weight and secure by thru bolting.

Note: Ambient at the lowside should remain between 50º

not drop below 40º

F. Machine may experience problems if operated outside of these ranges.

F

–105º

F. Makeup wa

ter temperature should

Page 10

Vogt® VT Service Manual 2-3

Installation Instructions

Piping Installation:

Use ACR refrigeration tubing and nitrogen purge during brazing to prevent formation

of copper oxide. For piping runs exceeding 25’, consult a reliable piping manual (Copeland, Heatcraft, or Vilter)

for proper pipe sizing. Heat sink all ball valves and remove Schrader valve core prior to brazing. Pressure test

piping for leaks. Evacuate lines to 500 microns prior to starting machine.

Chute Location:

bin. Place ice machine on ice storage unit and bolt in place. Machine must be level front to back and side

to side for proper operation.

Using drawing and table below, determine ice machine location so that it is centered on

39 1/2” (VT60, VT80 & VT100)

27” (VT40)

Skid Mounted

39 1/2” (VT60, VT80 & VT100)

27” (VT40)

Split System

FIGURE 2-2

Ice Chute Cutout Location

Page 11

2-4 Vogt® VT Service Manual

Installation Instructions

Makeup water, water tank drain and water tank overflow are ½” FPT connections

FIGURE 2-3

VT Lowside Water and Electrical Connections – Rear View

Makeup Water Flow VT40 VT60 VT80 VT100

Usage - Gallons /100 lbs of Ice 12 12 12 12

Flow rate – Gallons / minute 0.38 0.54 0.67 0.80

Flow rate – Gallons / hour 22.5 32.5 40.0 48.0

Water Tank Capacity – Gallons 6 7

Note: Water usage and flow rates base on 70°F water with no blowdown

TABLE 2-4

MakeUp Water Requirements / Flow Rates

Page 12

Vogt® VT Service Manual 2-5

Installation Instructions

Wiring And Electrical Connection.

! WARNING !

Only service personnel experienced in refrigeration and qualified to work with high

voltage electrical equipment should be allowed to install or work on the Vogt® VT

Series Ice machine.

! WARNING !

Main Power:

Refer to the table below to properly size wiring connections. A fused disconnect switch must be provided

near the condensing unit of the ice machine. Connect 3 phase power to compressor contactor L1, L2, L3 for

operation of the VT ice machine and its controls. If one phase (leg) of the 3 phase power is higher or lower

(“Wild”), it should be connected to terminal #L2. Connect the “Ground” wire to the “Ground” terminal provided.

Electrical Data VT40 VT60 VT80 VT100

Volts/ Phase/ Hertz

Total F.L.A.

Minimum Circuit Ampacity

Maximum Fuse Size

Power for the entire ice machine will be supplied at the condensing unit.

208/230-3-60 208/230-3-60 208/230-3-60 460-3-60 208/230-3-60 460-3-60

46.1 56.4 67.2 32 80.6 38.7

54.0 66.9 80.4 38.6 97.1 47

85 110 135 65 165 80

TABLE 2-5

Electrical Requirements

FIGURE 2-4

Main Power Connection

Page 13

2-6 Vogt® VT Service Manual

400/460V, 3PH, 50/60HZ

SWIT

CH

CONDENSER

Installation Instructions

Air Cooled Condenser Wiring:

condensing unit control panel terminal block to the air cooled condenser control panel.

Note: 400/460V VT-80 & VT100’s run 3 #14 AWG wires from terminals L6, L7& L8 to air cooled condenser.

Standard Voltage Machine

200/230V,3PH, 50/60HZ

Run two #14 AWG wires from the terminals T4 and T5 on the

AIR COOLED

CONDENSER

TO LOWSIDE

VT-80 & VT-100

AIR COOLED

TO LOWSIDE

FIGURE 2-5

Condensing Unit Terminal Blocks

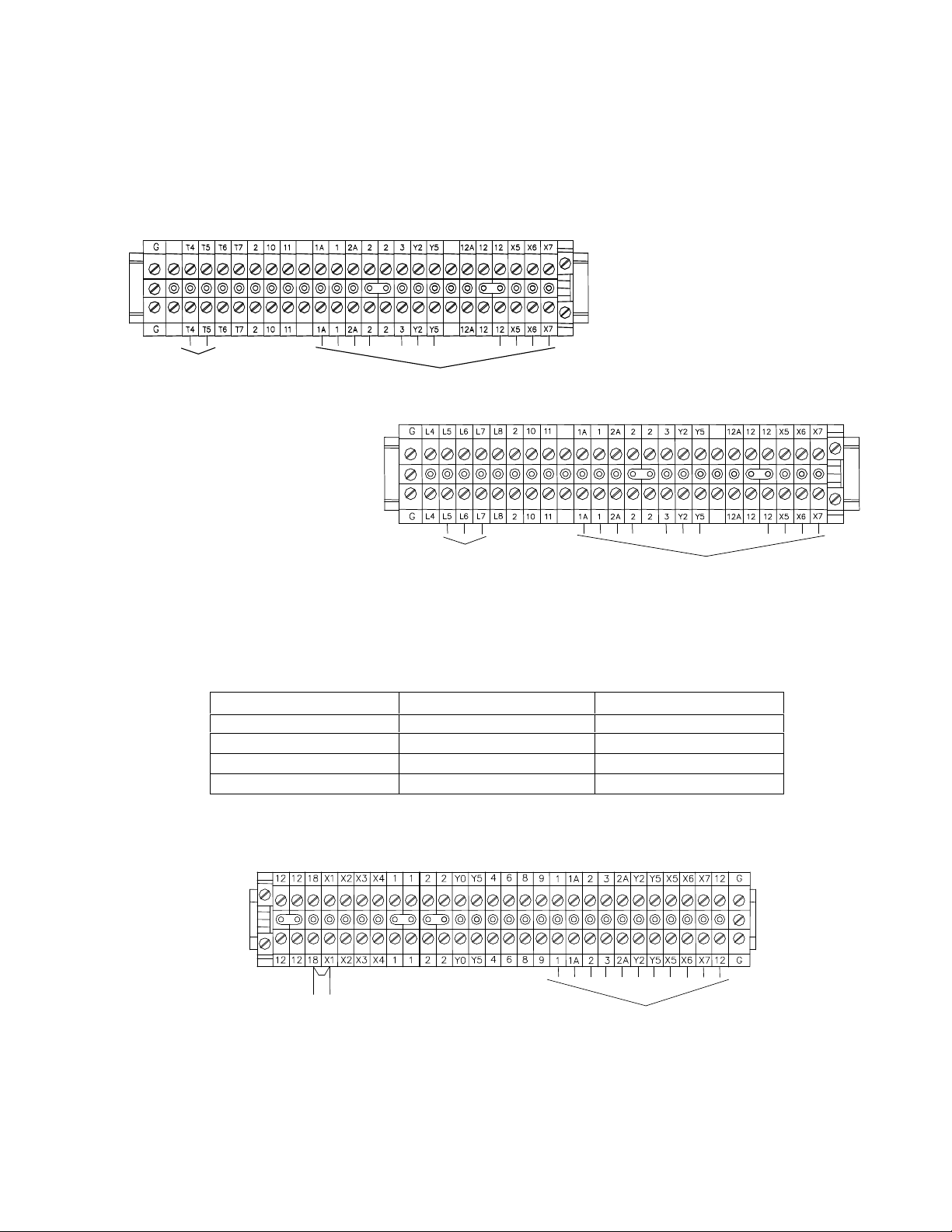

Lowside Electrical Connections:

terminal block to the condensing unit (highside) control panel terminal block.

Run 11 #14 AWG or larger wires run from the Lowside control panel

Number of wires Wire Size

5 16 (Red) 1, 2, 3, Y2, Y5

4 16 (Blue) X5, X6, X7, 12

2 14 (Black) 1A, 2A

1 14 (Green) GND

(AWG)

Wire #

Note: Machine is supplied with a remote “on/off” connection on the lowside terminal block. If a remote

TABLE 2-6

Lowside to Highside Wire

REMOTE “ON/OFF”

TO LOWSIDE

FIGURE 2-6

Lowside Unit Terminal Block

“On/Off” switch is used, remove jumper between #18 & #X1 and connect switch to these terminals.

Page 14

Vogt® VT Service Manual 2-7

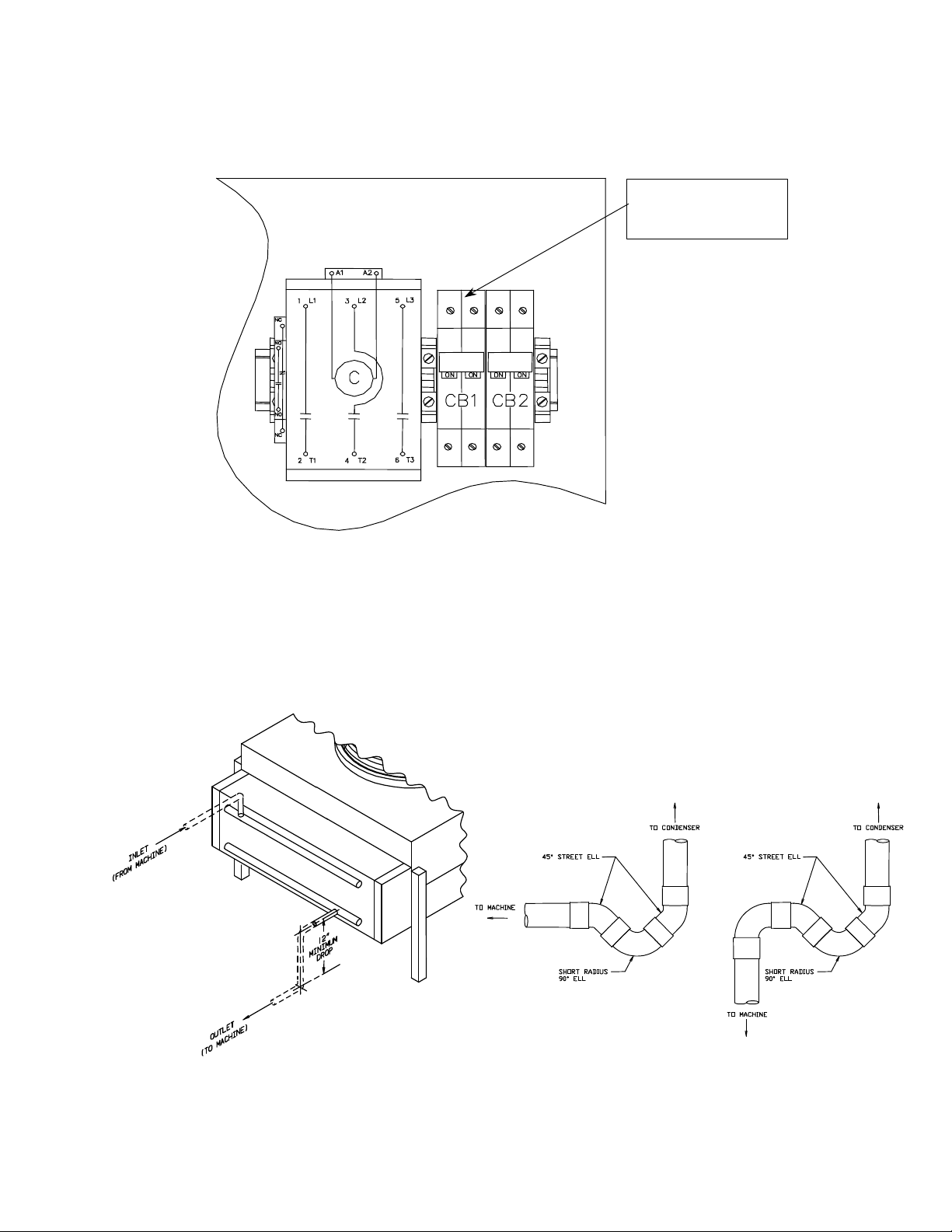

10A 15A

CB1 supplies power

Installation Instructions

Power is supplied to the lowside through circuit breaker (CB1) located in the condensing unit control panel.

See diagram below.

Condensing unit control panel

to lowside unit

FIGURE 2-7

Condensing Unit Circuit Breakers (200/230V)

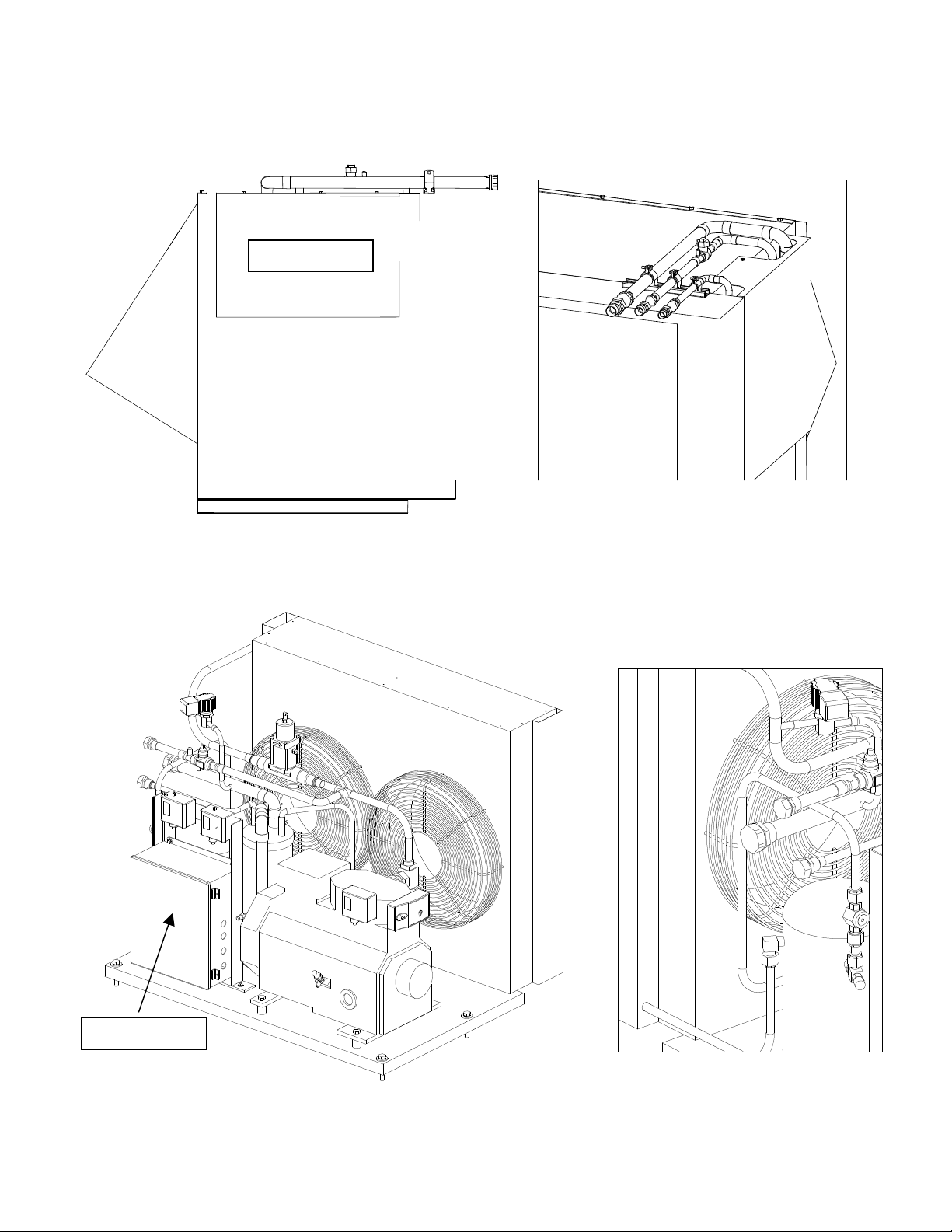

Air Cooled Condenser Installation (VT80 & VT100):

are trapped internally. A trap leaving the compressor is not necessary. On vertical runs a short radius “P” trap

should be installed every 15’ to 20’ of vertical rise to facilitate oil flow. Horizontal runs should be sloped in

direction of refrigerant flow 1” for every 20’ of run. The condenser should be securely mounted in a place

capable of sustaining its weight.

Ice making systems with remote condensers

FIGURE 2-8

Condenser Piping (VT80 & VT100) and Recommended Traps

Page 15

2-8 Vogt® VT Service Manual

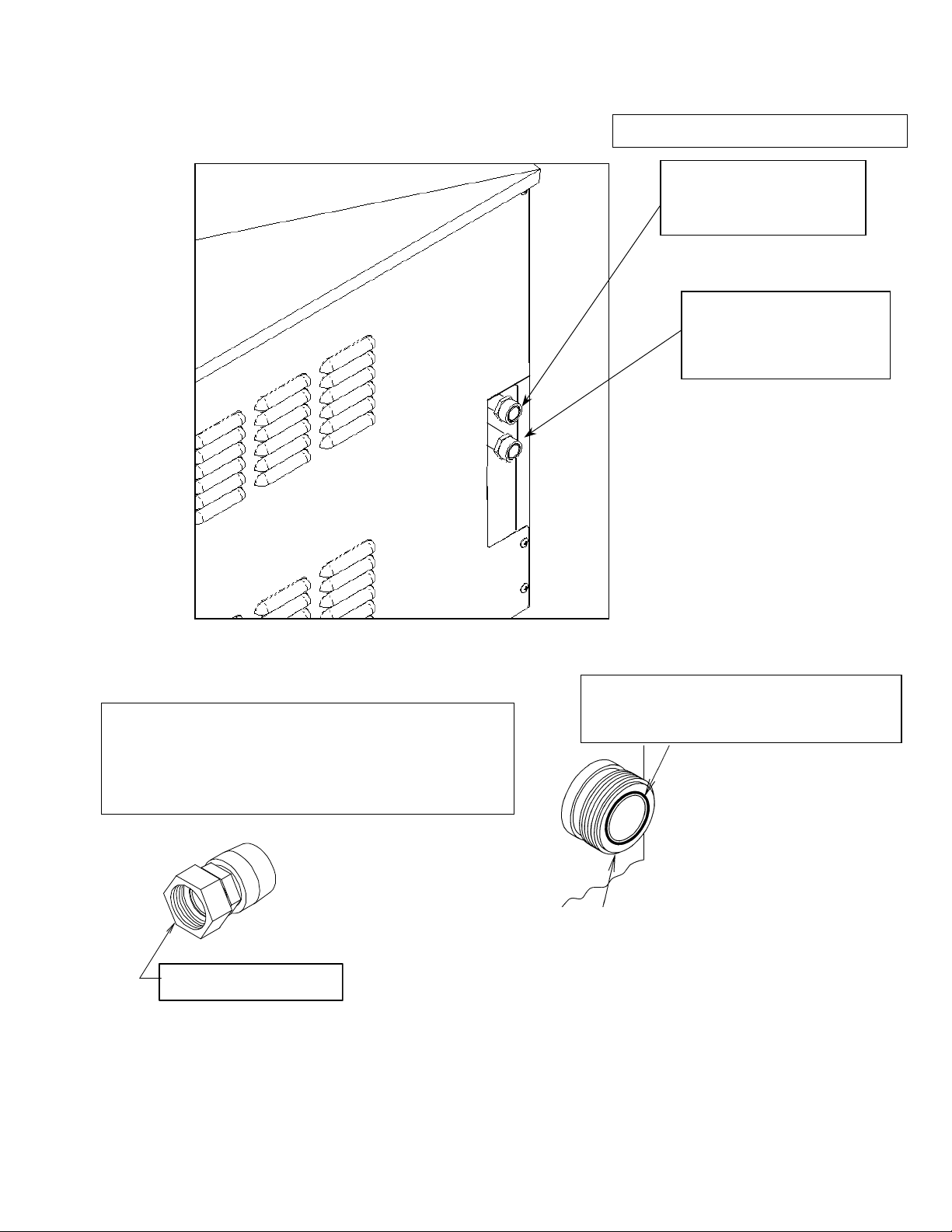

Note: Rota

supplied with machine

Note: Rota

12 F x 7/8” Sweat (Solder)

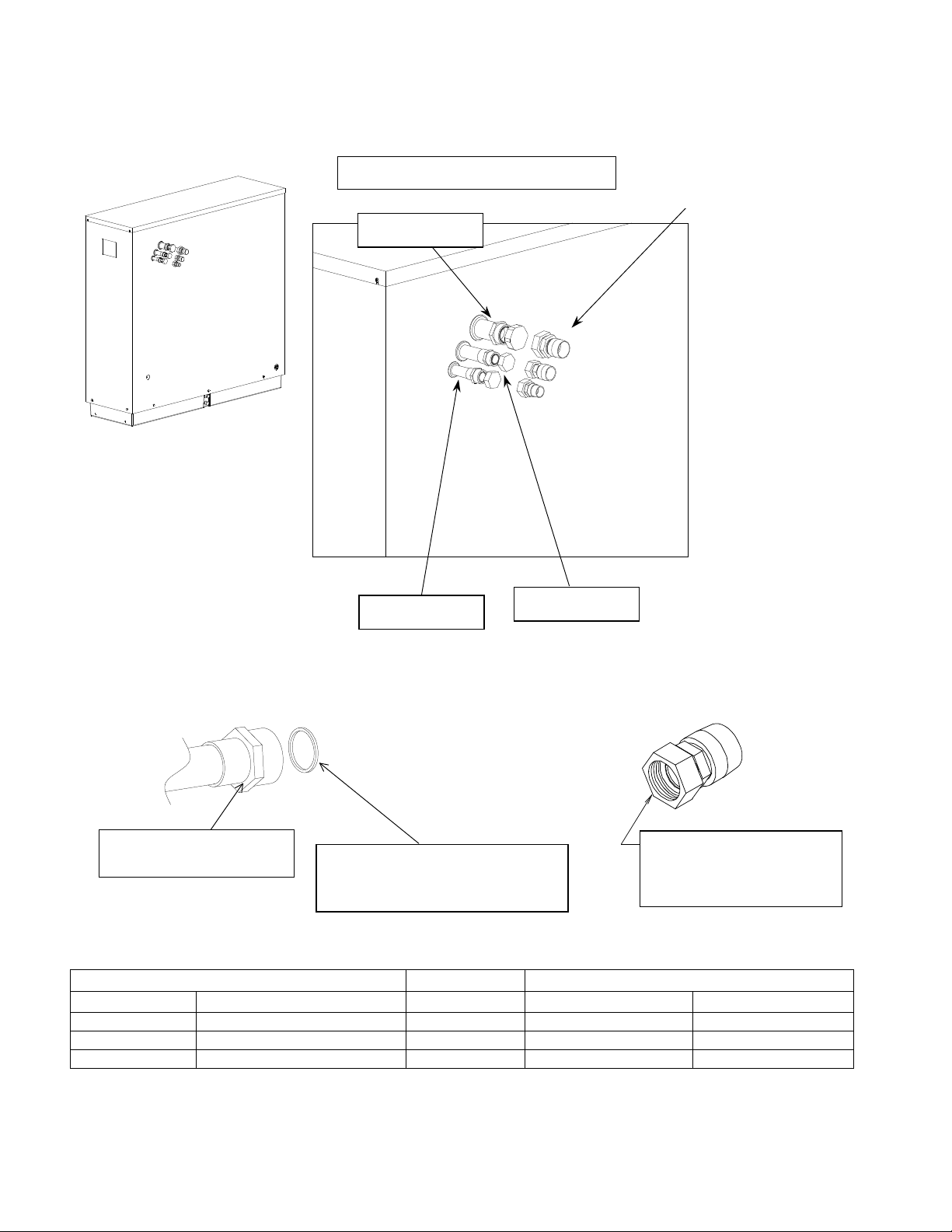

Installation Instructions

Must solder with 45% silver solder

Female Rota-lock Adapters:

12A2396A0701 – for 1 ¼” (Return Line from condenser)

12A2396A0601 – for 1 ¾”-12 F x 1 3/8” Sweat (Solder)

(Discharge to condenser)

Liquid return from

Teflon Seal

12A2600T01 (for 1 1/4”-12 thread fitting)

12A2600T03 (for 1 3/4”-12 thread fitting)

Air Cooled Condenser

(7/8” line)

Discharge gas to

Air Cooled Condenser

VT80 - 1 1/8”

VT100 – 1 3/8”

Rota-lock Adapter

-lock male

adapter on ice machine

-lock adapters

FIGURE 2-10

VT80 & VT100 Condenser Refrigerant Line Connections

Page 16

Vogt® VT Service Manual 2-9

Installation Instructions

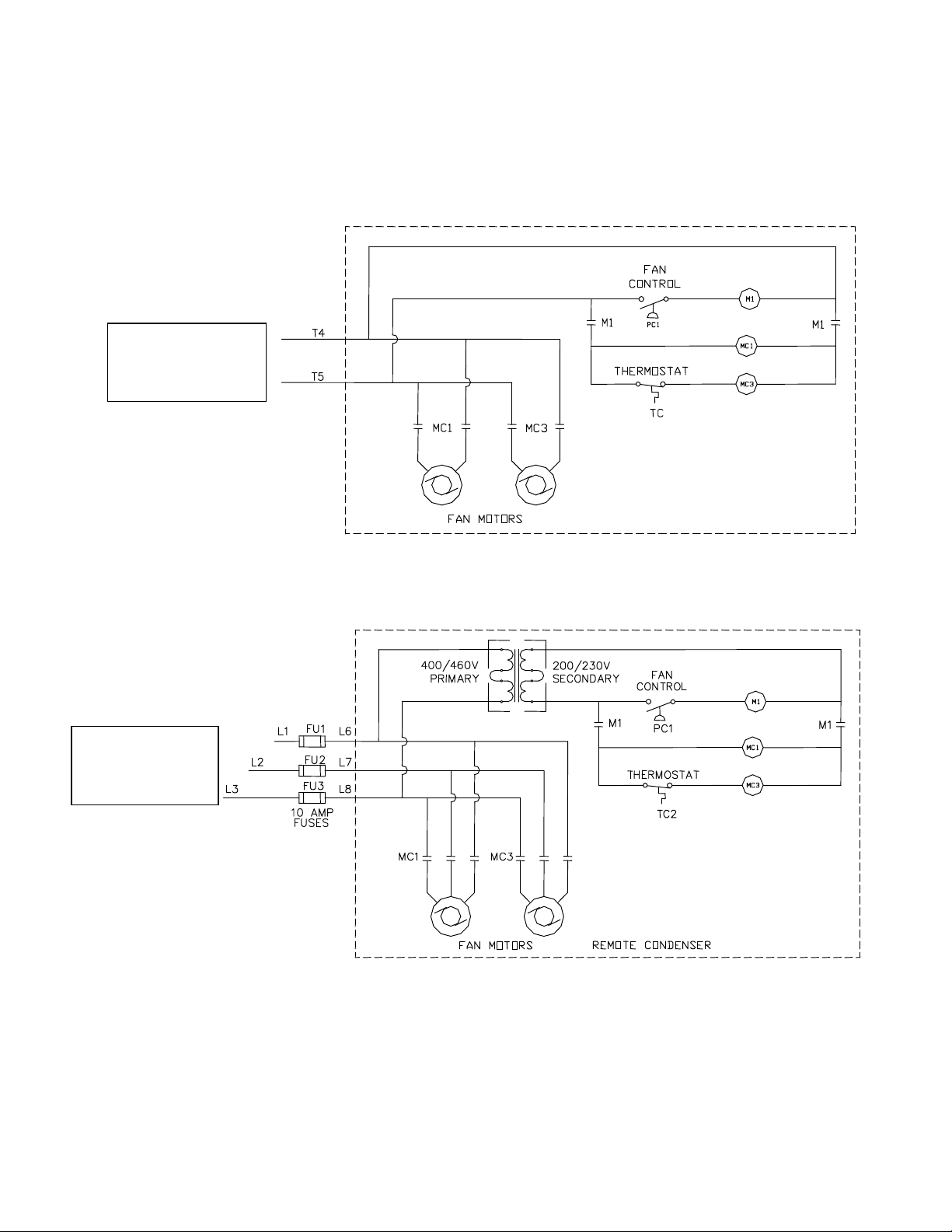

Air Cooled Condenser:

Run two #14 AWG wires and a ground wire from the condensing unit control panel to the Air Cooled

condenser control panel.

To Ice Machines

condensing unit

control panel

To Ice

Machines

condensing unit

VT80 & VT100 Remote Air Cooled Condenser Wiring

The air cooled condenser will be wired to the condensing unit control panel.

208/230V

460V

FIGURE 2-11

Note: Fan control pressure switch is located in air cooled condenser control panel on VT80 & VT100’s with

remote condensers. On VT40’s and VT60’s, fan control pressure switch is location on condensing unit

(highside).

Page 17

2-10 Vogt® VT Service Manual

supplied for both lowside

Must solder w

ith 45% silver

Installation Instructions

Note: Rota-lock fittings

and highside

Suction Line

Liquid Line

Hot Gas Line

FIGURE 2-12

VT Lowside Connections

Rota-lock Fitting

(on lowside & condensing unit)

Teflon Seal

12A2600T01 (for 1 1/4”-12 thread fitting)

12A2600T03 (for 1 3/4”-12 thread fitting)

Rota-lock Adapter

1 3/8” IDS X 1 3/4”-12 Threads

1 1/8” IDS X 1 1/4”-12 Threads

7/8” IDS X 1 1/4”-12 Threads

Rota-lock Adapter Teflon Seal

Part # Description Part # VT40 VT60

12A2396A0501 1 1/8” IDS X 1 1/4”-12Thrd 12A2600T01 N/A Hot Gas Line

12A2396A0601 1 3/8” IDS X 1 3/4”-12Thrd 12A2600T03 Suction Line Suction Line

12A2396A0701 7/8” IDS X 1 1/4”-12Thrd 12A2600T01 Liquid & Hot Gas line Liquid Line

Where Used

Note: See Refrigerant Line Size TABLE 2-3 for line sizes

TABLE 2-5

Rota-lock Adapters

Page 18

Vogt® VT Service Manual 2-11

Installation Instructions

Control Panel

Control Panel

FIGURE 2-13

VT60 Condensing Unit Connections

FIGURE 2-14

VT40 Condensing Unit Connections

Page 19

2-12 Vogt® VT Service Manual

Installation Instructions

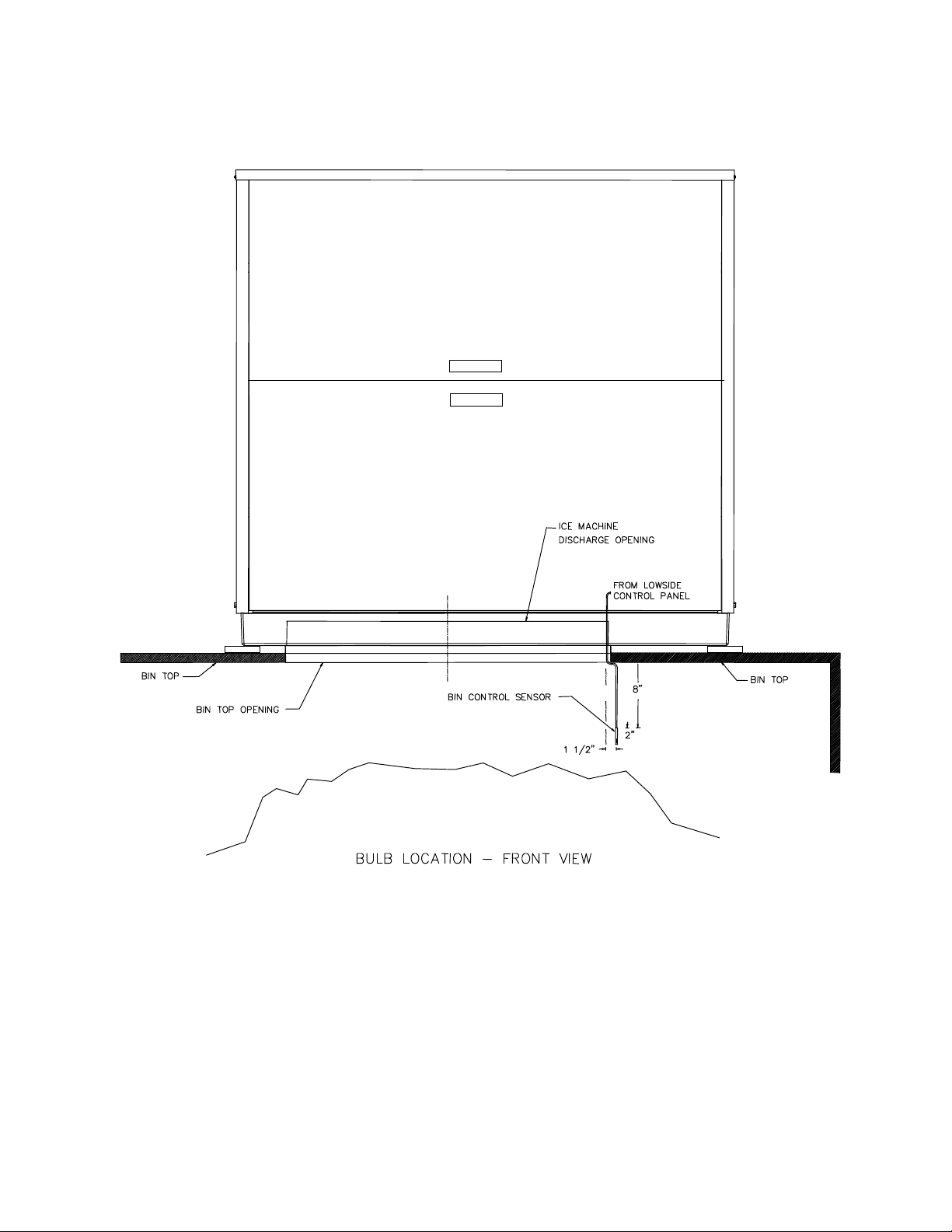

Storing Ice.

The sensor should be mounted on the right side of the bin approximately 8” –12” from the top of the bin.

When storing ice in a bin, make sure the bin control sensor is mounted in the bin properly.

FIGURE 2-15A

Bin Control Sensor Installation

Page 20

Vogt® VT Service Manual 2-13

STAINLESS

NOTE: Use

front of angle to

protect probe

Installation Instructions

STEEL

ANGLE

FIGURE 2-15B

Bin Control Sensor Installation

Ice Bin Capacity.

into a bin, it will pile up and slope naturally at about a 45° angle. This natural slope should be taken into

account when locating the bin thermostat sensor (or other bin level control) and when calculating the normal

bin capacity. If the ice is spread out by hand in the bin for maximum storage capacity, make sure a hazard

is not created by allowing ice to back up into the chute and jamming the cutter. Always allow enough room

below the chute for at least one harvest.

VT40 = 25-30 lbs. / cycle

VT60 & VT80 = 35-40 lbs. / cycle

VT100 = 47-52 lbs. / cycle

Crushed ice weighs approximately 35 pounds per cubic ft. (35 lb/ft3). As ice drops

Page 21

2-14 Vogt® VT Service Manual

Installation Instructions

Blank

Page 22

Vogt® VT Service Manual 3-1

Model Specifications

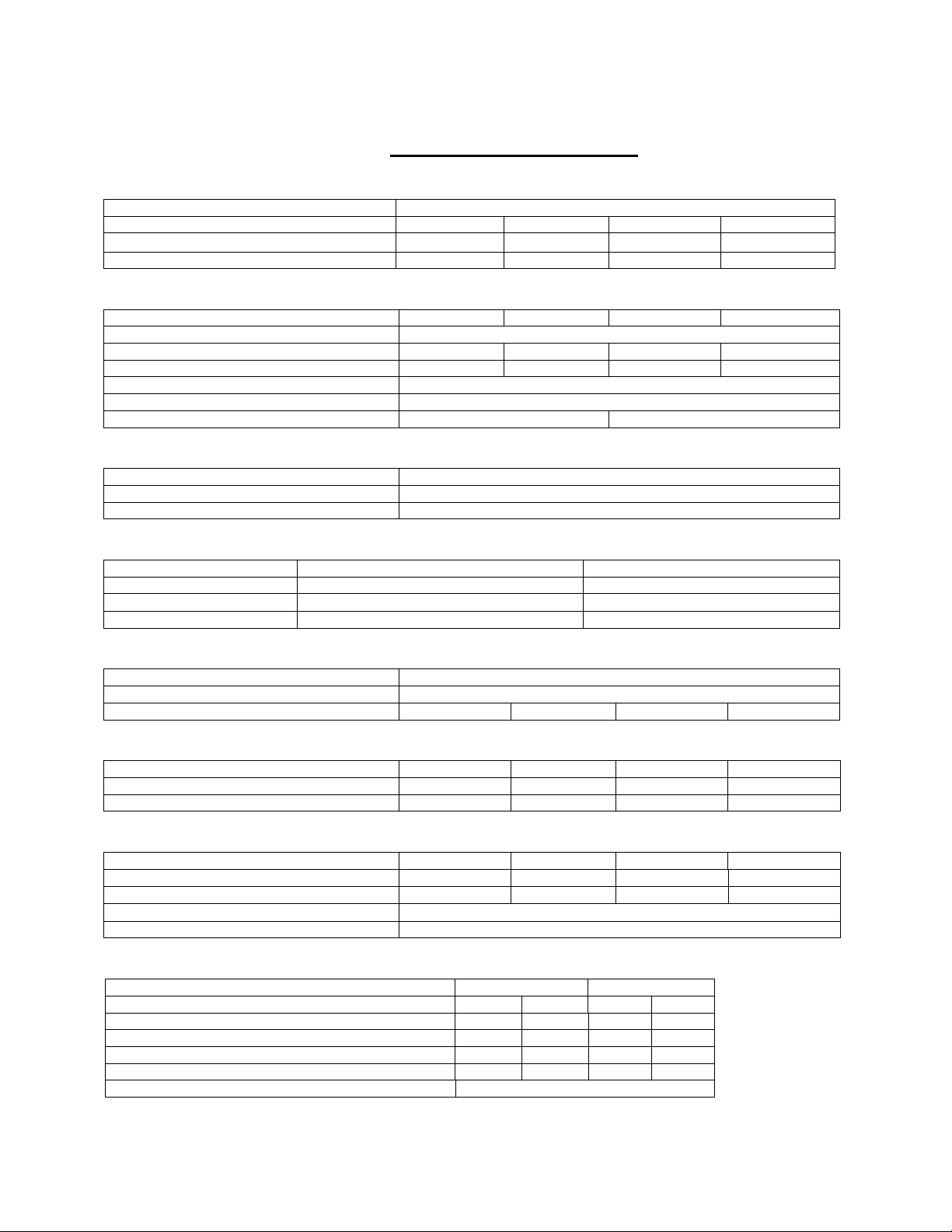

3. Model Specifications

Electric VT-40 VT-60 VT-80 VT-100

Volts/ Phase/ Hertz 208/230-3-60

Total F.L.A. Rating 46.1 56.4 67.2 80.8

Minimum Circuit Ampacity 54.0 66.9 80.4 97.3

Maximum Circuit Breaker 90 110 135 165

Compressor

Compressor 5.5 HP 7 HP 10 HP 12.5 HP

Voltage Range

Nameplate Amp Rating

Locked Rotor Amp Rating

Oil (Suniso) – Mineral (R22) 3GS

Oil (Copeland) – Synthetic (R404A) Ultra 32 – 3MAF or Mobil EAL Arctic 22 CC

Oil – amount

Chopper Motor

HP 1/2 HP

Voltage 230 V

FLA 3.7 A

Water Pump Motor

Hartell Anjon (CE approved)

HP 1/12 HP 1/5 HP (144W)

Voltage 208-230V 115V

FLA 0.85 A 1.2A

Condenser Fan Motors

HP 2 @1/2 HP

Voltage 208-230 V

FLA (Total for both motors) 8.4 A 8.2 A 8.4 A 8.6 A

Field Connections

Suction 1 3/8 ODS 1 3/8 ODS N/A N/A

Hot Gas 7/8 ODS 1 1/8 ODS 1 1/8 ODS 1 1/8 ODS

Liquid 5/8 ODS 7/8 ODS 7/8 ODS 7/8 ODS

General Info

Sight Glass (Sporlan) SA 15U SA 17S SA 17S SA 17S

Filter Drier (Sporlan) C-415 RC-4864 RC-4864 RC-4864

Refrigerant Charge 16 lbs. 32 lbs. 35 lbs. 40 lbs.

Inlet Water Line ½” FPT

Water Tank Drain & Water Tank Overflow ½” FPT

Control Settings

R22 R404A

Cut-in Cut-out Cut-in Cut-out

Fan Switch (PSIG) 220 200 250 230

Low Pressure Safety (PSIG) 20 10 20 10

Harvest Hold Pressure Control 45 60 65 80

High Pressure Safety (PSIG) Manual 300 Manual 350

Oil Pressure Control (Differential) 9 PSIG (Manual Reset)

Listed refrigerant charges are for close coupled and skid mounted machines as tested.

Remote installations of extended length will require additional refrigerant.

Note: Electrical data based on air cooled units

(Copeland® Discus®)

(208/230)

(Initial Charge / Recharge - oz)

187-253

(RLA)

31.5 42.0 52.6 66

(LRA)

161.0 215.0 278 374

(Marathon)

(Remote Condensing Units Only)

(approximate)

125 / 115 135 / 125

Page 23

3-2 Vogt® VT Service Manual

“RC”

–

Remote Air

"H" – High

-

side

“K” – 12.5HP

"21"

-

230-1-60

Product Variation Codes

Model Specifications

Vogt Ice Vertical Tube

Model Number Structure

G

VT

– P

B

6

F

AC

26

H

Basic Model

“VT” – Vertical Tube

Nominal Capacity

in 1000’s of lbs

“4” – 4000 lbs

“6” – 6000 lbs

“8” – 8000 lbs

“10” – 10000 lbs

Configuration

"P" – Package

"L" – Low-side

Refrigerant

"F" - R22

"H" – R404A

Revision Level

A letter assigned to indicate

major revisions within any one

family series.

Electrical Codes

"26" - 208/230-3-60

"46" - 460-3-60

"25" - 200-3-50

"45" - 400-3-50

“35” – 380-3-50

Condenser

“NC” – No Condenser

"AC" – Air Cooled

"WC" – Water Cooled

“SW” – Sea Water

00

Compressor Size

“0” – No Compressor

“F” – 5 ½HP

“G” – 7HP, 3cyl, 2120 CFH

“H” – 7HP, 4cyl, 2380 CFH

“J” – 10HP

(

A number or letter designator assigned to specific variations within a family.)

“01” – CE Approved, no skins

"00 or Blank" – Standard Product

“NS” – No skins (on condensing unit)

“WS” – With skins (on condensing unit)

“RS” – Remote Start Switch

Skin

(casing)

“G” – Galvannealed

“S” – Stainless Steel

Material

Page 24

Vogt® VT Service Manual 4-1

CAUTION !!! Make sure Lower Evaporator Housing Cover is

!!!

! CAUTION !!!!

Initial Startup

4. Initial Startup

START-UP PROCEDURE

Prior to start-up, the following items should be checked:

1.

Make sure all packing has been removed from the lowside unit. To do this, you must remove the upper

and lower evaporator housing covers. Remove to upper casing first, then the lower. (See Figure 4-1)

put back on machine before power is applied.

2. Open all service and ball valves. (Figure 4-4 & 4-5)

3. Check that bin switch is installed correctly. (Figure 2-5)

4. Check voltage and verify with nameplate.

5. Verify adequate water supply and water level of two (2”) inches.

6. Verify Ice/Off/Clean selector switch on the lowside unit is in the “Off” position.

7. Energize unit two (2) hours prior to starting to energize crankcase heater.

8. Ensure that circuit breakers in condensing unit control panel are in the “on” position. (Figure 4-2)

Note: “Control Power” Light will be ON when power is supplied to Lowside

At completion of above eight (8) items, machine is ready to run. Place selector switch in “Clean” position

and check water flow. (If the pump does not come on, press the green “Manual Harvest” button). Place

selector switch in “Ice” position and press “Manual Harvest” button. The machine will start in a harvest mode

then proceed to the Freeze mode. Observe machine operation. Make no changes to any settings on

machine for six (6) cycles. Verify pressures settings conform to service manual information. Do not trust

pressure control scales.

Never Operate Machine with Lower

Evaporator Housing Cover Removed.

Disconnect Power to machine before

removing lower evaporator cover.

Upper Evaporator

Housing Cover

Lower Evaporator

Housing Cover

FIGURE 4-1

Evaporator Housing Covers (Upper & Lower)

Page 25

4-2 Vogt® VT Service Manual

Selector Switch

Manual Harvest

Lowside unit control panel

CB2

-

Condenser

Fans

Control Circuit Power Light

Initial Startup

Condensing unit control panel

CB1 -

Lowside

Circuit Breakers (200/230V machines)

Light will be “on” if power is being

supplied from the Highside

FIGURE 4-2

(Start)

“Ice / Off / Clean”

FIGURE 4-3

Lowside Control Panel Front

Page 26

Vogt® VT Service Manual 4-3

Initial Startup

VT40

Compressor Discharge

Service Valve

Compressor Suction

Service Valve

VT60

Hot Gas Line Ball Valve

Liquid Line Ball Valve

Receiver Service Valve

Hot Gas Line Ball Valve

Liquid Line Ball Valve

Receiver Service Valve

Compressor Discharge

Service Valve

FIGURE 4-4

Service and Ball Valve Locations

Compressor Suction

Service Valve

Page 27

4-4 Vogt® VT Service Manual

Initial Startup

Compressor Suction

Service Valve

Sight Glass

Compressor Discharge

Service Valve

Service and Ball Valve Locations

VT80 & VT100

FIGURE 4-5

Liquid line Ball Valve

Condenser Ball Valves

(Hot gas & liquid return)

Adding Refrigerant / System Charging:

glass during the ice making cycle. When the fans cycle off, the sight glass should clear in 8 to 10 seconds.

If it takes longer than 10 seconds to clear the glass, the unit is undercharge. Add refrigerant to

system at compressor suction port or the ¼” access fitting on suction line. (See Figure 4-6)

If the glass clears in less than 8 seconds, the unit is overcharged. Remove refrigerant from system

following EPA standards.

Note: Do not charge to a full sightglass. Do not charge in a harvest cycle.

If packaged unit is totally out of refrigerant, add amount specified on machines nameplate.

To charge the system with cycling fans, observe sight

Suction Line – 1/4”

access “T” with

shrader valve

FIGURE 4-6

Access port for adding refrigerant

Page 28

Vogt® VT Service Manual 4-5

VT60

VT40

Initial Startup

Removing Refrigerant:

removed from suction line ¼” access port (See Figure 4-7). For quicker removal, liquid refrigerant may be

reclaimed from the liquid line.

VT80/VT100 – access port on liquid line ball valve

VT60 – access port on receiver rota-lock valve

VT40 – access port in liquid line

To remove refrigerant from an overcharged system, refrigerant gas may be

Note: Follow all EPA regulations and guidelines when handling refrigerant.

Liquid line Ball Valve

VT80 & VT100

with ¼” access port

Receiver Service Valve – rotalock

valve with ¼” access port

Liquid line Ball Valve

with ¼” access port

FIGURE 4-7

Access Fitting for Removing Refrigerant

Page 29

4-6 Vogt® VT Service Manual

Initial Startup

Blank

Page 30

Vogt® VT Service Manual 5-1

Electrical Controls

5. Electrical Controls

CONTROLS

Explanation.

PLC controls the sequence of events and monitors the ice machine functions. The operational sequences of

the VT-Series ice machine can be described best as a series of six different modes. Each mode identifies

and defines a sequence of events that occur while in that mode and thereby cause it to move to the next

mode. Only one mode is active at a time.

Start-Up Mode.

machine at the time of installation, after a power interruption, or after a machine fault. During Start-up, the

machine will not start for two hours. This gives the crankcase heater time to boil any refrigerant out of the

compressor. The start-up mode may be bypassed at any time by pressing the “Manual Harvest” (Start)

button to immediately advance to the standby mode.

NOTE: While the machine is in the Start-Up Mode, the Fault Indicator light will remain “on” (will not be

blinking).

If the power has been turned off to the machine, make sure the compressor

crankcase is warm and there is no liquid refrigerant in with the oil before

The VT-Series ice machine is controlled by a PLC (Programmable Logic Controller). The

The start-up mode is a function which prevents the premature automatic starting of the

! CAUTION !

restarting the unit.

! CAUTION !

Standby Mode.

switches in the control circuit and at the proper time decides which mode to advance to next.

Note: R404A machines are pumped down while in the Standby mode. If the pressure comes back up after

3 minutes, (the low pressure switch “closes”), the machine will go to the Pumpdown Mode.

Freeze Mode (Freeze Cycle).

this time, liquid feed valve is energized (R404A machines only) and the circulating water pump and

compressor are running. The freeze time is determined by the PLC analog timer (0-3.5 min) plus 5 minutes.

(Minimum freeze cycle time = 5 minutes, maximum freeze cycle time = 8.5 minutes)

The standby mode is a decision making mode. It monitors the position of all the various

The freeze mode is active during the normal ice making cycle. During

Freeze cycle Timer (PLC analog pot)

Turn Clockwise to increase freeze time

Minimum Freeze Time = 5 min

Maximum Freeze Time = 8.5 min

PLC: FX1s

PLC: FXos

FIGURE 5-1

PLC – Programmable Logic Controllers

Page 31

5-2 Vogt® VT Service Manual

Electrical Controls

Harvest Mode (Thaw Cycle).

mode. At this time, the circulating water pump stops and the liquid feed valve closes (R404A machines

only). After five seconds, the “D” (thaw gas) solenoid valves open and the chopper motor starts. On split

VT40’s & VT60’s, the hot gas loop valve energizes and VT80 & VT100 the suction stop valve energizes

when the chopper starts and thaw gas valves open. When the suction pressure reaches the set point on the

Harvest Hold (HH) pressure switch (PLC input #2 light will turn “off”), the harvest timer will begin to time.

The harvest timer is an internal timer in the PLC set for 45 seconds.

The harvest mode is terminated by the PLC thaw (harvest) timer at which time the machine will begin

another freeze cycle. The harvest mode can also be terminated manually by pushing in the “Manual Harvest

(Start)” button.

Increasing Harvest Time

(See Figure 5-2) This will increase the time it takes for the suction pressure to reach the set-point on the

switch, thereby increasing the harvest time.

Cut-In Setting

Clockwise – Lowers setting

set @ 45 psi (R22)

set @ 60 psi (R404A)

The harvest mode is normally initiated at the termination of the freeze

– To increase the harvest cycle time, raise the HH pressure switch cut-out setting.

Cut-out Setting

Clockwise – Raises setting

set @ 65 psi (R22)

set @ 80 psi (R404A)

FIGURE 5-2

Harvest Hold Pressure Switch

(located on top of lowside control panel)

Long Harvest Cycle Safety

the HH pressure switch set-point within 3 minutes, the machine will shut down and go to the Fault Mode.

NOTE: If the “Selector Switch” switch is in the “Off” position or the bin control is satisfied the machine will

complete the Freeze, Harvest and Pumpdown cycle before shutting off (standby mode). Machines with R22

do not go through a pumpdown cycle before shutting off.

– The PLC monitors harvest cycle time. If the suction pressure does not reach

Pumpdown Mode

go through a Pumpdown cycle before shutting off. During the Pumpdown cycle the water pump and

compressor are “on” and the liquid feed solenoid valve is “closed”. The machine will run in the Pumpdown

mode until the Low pressure safety switch “opens”. After shutting off on low pressure, the machine will go to

the Standby mode.

Note: If the suction pressure does not reach the cut-out point on the low pressure switch within 2 minutes,

the machine will fault out on a “Pumpdown Fault”.

Continuous Pumpdown

remain pumped down. After a 3 minute delay, if the pressure comes up in the freezer and the low pressure

safety switch “closes” (pressure gets above 20 psig), the compressor will come “on” and pump the machine

down.

(R404A machines only)

(R404A machines only). While in the Standby mode, the machine will

.

All R404A machines have a liquid feed solenoid valve and

Page 32

Vogt® VT Service Manual 5-3

Fault Indicator Light

Flashes to indicate the

Control Circuit Power Light

Light will be “on” if power is being

Electrical Controls

Clean Mode.

During this mode only the water pump will run.

The water pump can be stopped by simply moving the “Selector Switch” from the “Clean” to the “Off”

position. To restart the water pump, move the “Selector Switch” back to the “Clean” position and press the

“Manual Harvest (Start)” button. Ice machine cleaning solution can be circulated though the tubes to

accomplish the cleaning procedure. If the water pump is left to run in the clean mode for more than two

hours, the PLC will shut the machine off. The clean mode can be resumed by pushing the “Manual Harvest”

button.

NOTE: Running in Clean mode for extended period of time can cause excessive pressure to build up in the

freezer.

At the termination of the clean mode, the machine can be returned to ice making mode by putting the

“Selector Switch” in the “Ice” position and pressing the “Manual Harvest” button.

The “Clean” mode is considered to be a maintenance or service function of the machine.

Fault Mode.

aspects of the operation. One of the functions of the PLC is to shut down the machine when a problem

arises and send a signal to the fault indicator light located on the front of the electrical panel. (Figure 5-3)

The red light will blink 1 to 6 times when a problem has caused the machine to shut down.

See table below for the description of the fault modes.

The VT Series is equipped with a PLC (programmable logic controller) that controls all

# Description

1 Low Suction Pressure Auto

2 High Discharge Pressure Manual

3 Low Oil Pressure Manual

4 Long Harvest Cycle N/A

5 Cutter Motor Auto

6 Pumpdown Fault N/A

Solid Power Failure N/A

Switch Reset

(Auto or Manual)

TABLE 5-1

PLC Fault Codes

supplied from the Highside

fault that occurred

FIGURE 5-3

Lowside Control Panel Front

Page 33

5-4 Vogt® VT Service Manual

PLC: FX

s

PLC: FXos

Electrical Controls

PLC Inputs PLC Outputs

#

0 Current Sensing Relay (CSR) for cutter motor

1 “On” Switch & Bin control (in series)

2 Harvest Hold (HH) Pressure Switch

3 Start / Manual Harvest Switch

4 “Clean” Switch

5 High Pressure safety (“off” when tripped)

6 Low Pressure safety (“off” when tripped)

7 Oil Safety / Compressor OL (VT80 & VT100)

1

Description

#

0 Machine Fault Indicator Light

1 Liquid Feed Solenoid (R404A machine only)

2 Compressor

3 N/A

4 Water Pump

5 Cutter / "D" valve / Defrost loop valve or

Suction Stop valve (VT80 & VT100)

Description

FIGURE 5-4

PLC Inputs & Outputs

Page 34

Vogt® VT Service Manual 5-5

Electrical Controls

FIGURE 5-5

Standard Complete Electrical Schematic - 208/230V (Air Cooled)

Page 35

5-6 Vogt® VT Service Manual

Electrical Controls

FIGURE 5-5A

CE Rated VT100 Electrical Schematic – 200-220V / 400-440V (Water Cooled)

Page 36

Vogt® VT Service Manual 5-7

Electrical Controls

FIGURE 5-6

Air Cooled Condenser Wiring (200-240V/400-460V)

Page 37

5-8 Vogt® VT Service Manual

MELSEC FX

OS

-

14MR-ES

Electrical Controls

E-STOP

MITSUBISHI

Lowside Control Panel Parts

BC 12A2117G09 Ice Bin Control

CB3/CB4 12A7515E21 Control Circuit Breaker – 2 pole (3 Amp)

CSR 12A7507S07 Current Sensing Relay (cutter/chopper motor)

CU 12A7516E23 Cutter Motor Contactor

E-STOP 12A7500E75 Contact Block/Mounting Latch, 1NC (CE Machine only)

12A7500E130 Push Button, Push-Pull

P 12A7516E23 Pump Motor Contactor

PB1 12A7500E56 Manual Harvest (Start) Button

12A7500E75 Contact Block, 1 N.O. (for Manual Harvest Button)

PLC 12A7536M01 Programmable Logic Controller

HH 12A2117B03 Harvest Hold Pressure Switch – Open on Rise

SS 12A7500E61 3 Position Selector Switch

12A7500E73 Contact Block, 2 N.O. (for Selector Switch)

TB N/A Terminal Block

1LT 12A7520E33 Machine Fault Indicator Light, 250V, Red

2LT 12A7520E34 Control Power Indicator Light, 250V, Amber

FIGURE 5-7

Lowside Control Panel Layout

Page 38

Vogt® VT Service Manual 5-9

Electrical Controls

FIGURE 5-8

Standard Condensing Unit Electrical Schematic – 208-240V (Air Cooled)

Page 39

5-10 Vogt® VT Service Manual

Electrical Controls

Condensing Unit Control Panel Parts

CB1 12A7515E18 Lowside Circuit Breaker, 2 pole (10Amp)

CB2 12A7515E19 AC Fan motors Circuit Breaker, 2 pole (15Amp)

TB N/A Terminal Block

C 12A7516E29 VT40 Compressor Contactor, 43Amp

12A7516E30 VT60/80/100 Compressor Contactor, 72Amp

12A7518E30 Auxiliary Contact, 1 N.O./1 N.C.

FIGURE 5-8A

Standard 208-240V Condensing Unit Control Panel (Air Cooled)

Page 40

Vogt® VT Service Manual 5-11

Electrical Controls

FIGURE 5-9

CE Rated VT100, 200-220V/400-440V Condensing Schematic (Water Cooled)

Page 41

5-12 Vogt® VT Service Manual

Electrical Controls

PART # DESCRIPTION QTY PART # DESCRIPTION QTY

C 12A7516E29 CONTACTOR, 3 POLE, 43A 1 CB5 12A7515E21 CIRCUIT BREAKER, 2 POLE 1

12A7516E30 CONTACTOR, 3 POLE, 72A * DS 12A2790H07 DISCONNECT HANDLE 1

12A7518E30 AUX CONTACT, 1 NO/1 NC 1 12A2790D07 DISCONNECT, 63A, DOOR MNT 1

CB1 12A7515E18 CIRCUIT BREAKER, 10A, 2 POLE, 1 (400/440V MACH)

(200/220V MACH) 12A2790D11 DISCONNECT, 100A, DOOR MNT

12A7515E35 CIRCUIT BREAKER, 8A, 2 POLE, (200/220V MACH)

(400/440V MACH) FU1- 12A7504E12 FUSE, 10A, 600V, TD, CLASS CC 3

CB2 12A7515E19 CIRCUIT BREAKER, 10A, 2 POLE, 1 FU3 (AC, 400/440V ONLY)

(AC, 200/220V MACH) * PLF 12A7527S06 POWER LINE FILTER, 10A 1

* NOTE: CE UNITS ONLY * TF2 12A7519E38CE TRANS, 250VA, 200/400VAC PRI, 1

120VAC SEC

FIGURE 5-9A

CE Rated VT100, 200-220V/400-440V Condensing Unit Control Panel (Water Cooled)

Page 42

Vogt® VT Service Manual 6-1

Maintenance

6. Maintenance

Preventive Maintenance

For The Manager Who Depends Upon This Machine

For Efficient Operation.

“Preventive Maintenance” simply means that you or a delegated employee makes a daily

visual check of your Vogt Ice machine. Here is what to look for and why:

Daily checklist:

1. Is the machine running or is the bin full

2. Bin doors kept closed

3. Thermostat sensor in bracket

4. Does all ice discharge during harvest

5. Cleanliness

6. Unusual noises

Why?

production of ice for your facility. When you are aware of the proper operating conditions

and observe them on a daily basis, changes in these conditions can alert you to changes

in the operation of the machine which may require maintenance--long before a service

situation arises.

When you make these simple observations on a daily basis, you insure the smooth

Note To Manager or Owner:

The following page is a complete Preventative Maintenance Schedule that should be

performed each 90 days. The Preventative Maintenance page may be copied and given

to your service person. It should be signed, dated, and returned to you for permanent

record.

Page 43

6-2 Vogt® VT Service Manual

Maintenance

Preventive Maintenance Program

Model # _________ Serial # _____________ Date___________

Customer/Address ___________________________________

___________________________________

Mgr. Name _______________ Service Tech Name_____________

The following service performed and checked:

Scale condition of water tank & tubes (good - fair - poor)

All drains freely draining (water tank, drip pan, ice bin)

Ice machine cleaner circulated through system

AC condenser clean (if applicable)

Voltage at machine (actual reading) L1-L2 _____, L2-L3_____, L1-L3______

Compressor amps (halfway through the freeze cycle) L1_____ L2_____ L3_____

Cutter motor amps (cutting ice) _____

Water pump amps _____

AC condenser motor amps (if applicable) _____

Crankcase heater heating

Refrigerant charge (okay - high - low)

Leak checked system ______ leaks found & repaired

Compressor oil level (i.e, 1/4 - 1/2 - 3/4 - low - high)

PSIG, low pressure switch set @ 10 psi

PSIG, high pressure switch set @ 300 psi (R22) / 350 psi (R404A)

Bin stat(s) installed and operate properly

Make-up water float valve adjusted okay

________ _ Suction PSIG at end of freeze

________ Suction PSIG during harvest (high/low)

________ PSIG, Discharge pressure regulator (Water cooled only)

________ Discharge PSIG at end of freeze

________ °F/°C at machine

________ °F/°C outside ambient (at condenser if applicable)

________ °F/°C make-up water temperature

________ Freeze cycle time (minutes)

________ Harvest cycle time (minutes)

________ First ice out (seconds)

________ All ice out (seconds)

________ Pounds of ice per cycle

Capacity check: ice # per cycle X (1440 / total cycle time (min)) = lbs./24 hrs.

Remarks

Last maintenance performed (approx. date) ___/___/___

:

_______________________________________________________

____________________________________________________________

____________________________________________________________

Page 44

Vogt® VT Service Manual 6-3

Suction Screen

Maintenance

Air-Cooled Condenser Cleaning.

the fin face of the condenser. A vacuum cleaner, compressed air, or a brush may be used to remove any

accumulation of loose dirt from the fin section of the condenser.

For the removal of more severe accumulations of dirt or foreign materials, a detergent-type cleaner can be

used. This cleaning agent can be supplied by your local refrigeration supply house. Follow the

manufacturer’s instructions when using a liquid cleaner.

If fins have been damaged, they should be straightened with the proper fin comb.

Compressor Oil.

should be watched carefully for the first hour to make certain the proper lubrication is being maintained. The

oil may become low in the crankcase on an initial start-up if the electrical current has been interrupted to the

machine, thus de-energizing the compressor crankcase heater.

Before starting the machine again, the heater should be energized for a time period of at least two hours to

evaporate refrigerant that may have condensed in the crankcase during the shutdown period. If the oil level

is low after start-up, it should begin to return after a short period of operation.

The oil level should be checked frequently, particularly during the start-up operation, to see that a sufficient

amount of oil remains in the crankcase. While it is important to observe the oil splash during operation, the

true level can be obtained only when the compressor is stopped. With the compressor idle, the oil level

should be between 1/2 to 3/4 of the sight glass, but not above the top of the sightglass.

In starting and charging the unit, the oil sight glass in the crankcase of the compressor

Visual inspection will indicate if dirt is accumulating and clogging

Although the machine was shipped with the oil charge, which was originally added for the test operation, it

may be necessary to add some oil when or if new refrigerant is added to the system.

An oil pump should be used to force any oil that may be required into the system. Oil may be added to the

compressor of all units through the compressor oil charging port. Air should be purged from the oil pump

discharge line by forcing some oil through the line before tightening the charging port.

R22 - Dual Inhibited Suniso 3GS (Viscosity 150) or equal.

R404A - Ultra 32 – 3MAF, Mobil EAL Arctic 22 CC or equal.

See page 3-1 for amount.

Oil Pump

Oil Pump

Oil Sight Glass

Crankcase Heater

Oil Charging valve

FIGURE 6-1

Copeland Discus Compressor (VT80)

Page 45

6-4 Vogt® VT Service Manual

Maintenance

Chopper Gear Reducer Oil.

of a leak. It should be level with the plugged opening in the side of the gear housing. Use Mobile 600W

cylinder oil or equal.

Gear Reducer Vent Plug

The oil level for the gear reducer should be checked if there is evidence

Gear Reducer

FIGURE 6-2

Gear Reducer

Water Distributor.

water supply tube by removing the hose clamp. The water distributor may be soaked in ice machine cleaner.

Make sure all holes are free of dirt and calcium buildup.

At times it may be necessary to clean the plastic water distributor. Remove the

Hose Clamp

1” Tubing

FIGURE 6-3

Water Distributor

Page 46

Vogt® VT Service Manual 7-1

Fault Indicator Light

the

Control Power Light

CB2

-

Condenser Fans

Troubleshooting

7. Troubleshooting

The VT Series ice machine is equipped with a PLC (programmable logic controller) that controls all aspects

of the machines operation. One function of the PLC is to shut down the machine when a machine fault

occurs. By continuously monitoring the High and Low pressure safety switches, the harvest cycle time, and

the oil pressure, the PLC can determine if a problem exists.

Machine Fault Light -

harvest cycle" fault or an oil pressure fault, the machine will not automatically restart. When a "fault" occurs,

the PLC sends a signal to the fault indicator light located on the control panel door.

if the machine shuts off due to a high pressure fault, low pressure fault, a "long

Flashes to indicate

fault that occurred

Is “On” when power is

supplied to

lowside

FIGURE 7-1

Lowside Control Panel Front

# Description Switch Reset

1 Low Suction Pressure

2 High Discharge Pressure

3 Low Oil Pressure

4 Long Harvest Cycle N/A

5 Chopper Motor Fault N/A

6 Pumpdown Fault N/A

Solid Power Failure

Auto

Manual

Manual

N/A

(Auto or Manual)

TABLE 7-1

PLC Fault Codes

Control Power Light – if the machine is shut off and the “Control Power” light on the lowside unit is not

, check the 3A circuit breaker (CB3/CB4) in the lowside control panel. If after resetting the breaker, the

“On”

control light still does not come on, check the 10A breaker (CB1) in the condensing unit control panel.

CB1 -

Lowside

Lowside Unit Control Panel

Condensing Unit Control Panel

FIGURE 7-2

Control Panel

Page 47

7-2 Vogt® VT Service Manual

Troubleshooting

# Description

Inputs 0 Current Sensing Relay (chopper)

1 “On” Selector Switch/Bin Control

2 HH Pressure Switch

3 Manual Harvest (Start) Button

4 Clean Switch

5 High Pressure Safety Switch

6 Low Pressure Safety Switch

7 Oil Safety / Compressor OL

Freeze cycle Timer (PLC analog pot)

Turn Clockwise to increase freeze time

Minimum Freeze Time = 5 min

Maximum Freeze Time = 8.5 min

# Description

(VT80 & VT100)

Outputs

0 Fault Indicator light

1 Liquid Feed Solenoid (R404A machines only)

2 Compressor

3 N/A

4 Water Pump

5 Chopper/Hot Gas Valve/Defrost Loop

or Suction Stop valve (VT80 & VT100)

TABLE 7-2

PLC Inputs/Outputs

PLC Input

Lights

PLC Output

Lights

FIGURE 7-3

PLC (FX

1s

)

Damaged Bin Control Sensor –

control to shut the machine off when the bin is full, one of the first things to check is the Bin Control sensor.

If the sensor is bad or has been damaged, “EP” will be displayed. See 8-3 for more details.

If the machine is not running and it uses the electronic temperature

EP

“EP” on display designates

a damaged

or bad probe

Sensor – can be replaced if damaged

FIGURE 7-3

Electronic Bin Control

Page 48

Vogt® VT Service Manual 7-3

Troubleshooting

MACHINE INOPERATIVE

No Electrical Power:

crankcase heater should be energized two (2) hours prior to starting.

Note: If no power to the lowside unit, check 10A breaker in condensing unit electrical enclosure.

High Pressure Safety:

pressures to determine that compressor discharge pressure is within operating limits. If fans do not come

“on”, check circuit breaker in condensing unit control panel. For water cooled units, verify water supply and

water regulating valve setting.

Low Pressure Safety:

point. If tripped, install gauges observe operating pressures to determine that compressor suction pressure is

within operating limits. If suction pressure is low, check machine refrigerant charge.

Note: When the machine starts after a power failure or after the machine has cycled off on bin control or the

“on/off/clean” selector switch, the PLC do not look at the low pressure switch for 90 seconds.

Compressor Motor Overload Protector

2011)

:

Machines are equipped with a compressor protection device that opens in the event compressor

temperature or amperage reaches an extreme that could damage compressor. The device automatically

resets after compressor has cooled. CoreSense must be reset.

(Note: On VT80 & V100 Only). Note: This sensor is in series with the oil pressure safety switch. Fault #3 can

be either compressor motor overload or oil pressure.

CAUTION: If machine is off on motor overload protector, control cycle timer and

other components will continue to function although the compressor is off. The

machine or any of its components can start without warning causing serious injury.

Bin Control Open:

Faulty Remote Off/On Switch:

Compressor Contactor Defective:

are supplied with power. Check contactor coil for open winding.

Oil Failure Switch

pressure safety switch. Check compressor oil level. If oil level in sightglass, check oil pressure.

Note: Verify proper operation of crankcase heater. Cold starts can cause oil loss.

Chopper Failure:

circuit will detect the absence of motor current and shut the machine off. See Machine “Freeze-Up”.

Check main electrical fused disconnect or circuit breaker. If power has been off,

Reset high pressure control switch. If tripped, install gauges observe operating

This switch will automatically reset when pressure comes up to the “cut-in” set

(Sentronic before March 2011, CoreSense after March

Adjust thermostat bin control as required. See page 8-3 for bin control error code.

Replace if necessary.

Check wiring to line contactor to determine that "L" terminals

(Sentronic before March 2011, CoreSense after March 2011): Reset Sentronic oil

If the chopper motor fails to come on, the current sensing relay in the chopper motor

Page 49

7-4 Vogt® VT Service Manual

CAUTION: Clearing “freeze

-

ups” should be done using only water. Use of

any foreign objects (example: hammer or screw driver) may damage tube

This

Troubleshooting

MACHINE “FREEZE-UP”

The following situations may cause machine “freeze-up”:

1. Harvest hold switch is improperly set

2. Improper fan control setting

3. Low head pressure limiting available gas for defrost

4. Dirty, scratched, or dented evaporator surface

5. Chopper motor or motor contactor defective

6. Interruption of electric service

7. Off on low pressure and reset without clearing tubes.

8. Low pressure safety switch improperly adjusted, causing termination prior to harvest.

9. Loss of water pressure.

10. Defective hot gas solenoid valve.

11. TXV not adjusted properly or functioning properly. Ice freezing too far up tube.

Note: If ice is freezing too high (onto the top flange holding the evaporator) the ice may not drop

from the evaoprator tubing. See page 8-6 for adjusting TXV.

Clearing a “freeze-up can be accomplished by placing “On/Off/Clean” selector switch in the “Clean”

position and circulating water over the tubes.

surface. If tube is dented or scratched, ice will not release properly.

will void the evaporator warranty.

Page 50

Vogt® VT Service Manual 7-5

Troubleshooting

ADDITIONAL TROUBLESHOOTING

Low Suction Pressure - Possible causes include:

1. Evaporators froze up

2. Plugged drier

3. Low refrigerant charge

4. Moisture causing freezing @ TXV

5. Low water circulation

6. Faulty TXV

7. Bad hot gas solenoid valve

High Head Pressure - Possible causes include:

1. Plugged condenser

2. Faulty fan motor

3. Faulty fan cycle switch

4. Faulty thermostat at condenser (allowing only one fan to run)

5. Refrigerant overcharge

6. Non condensable present.

7. Electric interruption to condenser (Remote condenser only)

Compressor Oil Pressure Fault - Possible causes include:

1. Faulty oil pressure sensor or module (Sentronic/CoreSense)

2. Clogged oil pump suction screen

3. Low compressor oil

4. Low compressor superheat

Compressor Runs But Condenser Fan Does Not:

1. Faulty fan cycle switch

2. Faulty fan motor

3. Blocked fan blade

4. Electric interruption to condenser (circuit breaker located in condensing unit control panel)

Compressor Will Not Run, Water Pump Runs:

1. Open compressor overload (on VT-40 & VT-60 only)

2. Defective compressor

3. Faulty compressor contactor

Water Pump Will Not Run, Compressor Runs:

1. Faulty pump

2. Electric service interrupted to pump - pump contactor

Pump and Compressor Run with Insufficient Water on the Evaporators:

1. Water system needs cleaning

2. Faulty pump

3. Inadequate water supply

4. Obstructed float assembly

5. Improper float adjustment

Chopper motor Fault:

1. Bad chopper motor

2. Bad chopper motor contactor

3. Machine Froze up

Page 51

7-6 Vogt® VT Service Manual

Troubleshooting

Blank

Page 52

Vogt® VT Service Manual 8-1

Freeze

Harvest

Service Operations

8. Service Operations

PRINCIPLE OF OPERATION

The Vogt® VT Series line of ice making machines from Vogt® Tube Ice®, LLC, combines state-of-the-art

technology and efficiency with a reputation for quality and reliability developed over four decades of

manufacturing.

In the Vogt® VT Series icemaker, ice is produced on both walls of vertically suspended cylindrical tubes with

recirculating water. As ice is produced, makeup water is fed to the water tank via float valve. Freeze time

and harvest time are controlled by a Programmable Logic Controller (PLC).

In freeze cycle, the liquid feed valve is “open” (R404A machines only) and the compressor and water pump

are “on”. At the end of the Freeze cycle, the PLC initiates the Harvest cycle were the hot gas solenoid

valves and chopper motor are energized, and the water pump is turned “off” and liquid feed valve “closed”.

Bin control or remote on/off switch will allow machine to complete a freeze and harvest cycle prior to

interrupting operation. For R404A machines, the machine will go thru a Pumpdown before cycling off.

FIGURE 8-1

Piping Schematic

Page 53

8-2 Vogt® VT Service Manual

Service Operations

Pressure Switches

High Pressure Safety: 12A2117H01 (Penn)

This switch terminates operation of machine when high compressor discharge pressure occurs.

Settings

Low Pressure Safety: 12A2117B08

This switch terminates operation of machine when low suction pressure occurs.

Note: When the machine starts after a power failure or after the machine has cycled off on bin control or the

“on/off/clean” selector switch, the plc do not look at the low pressure switch for 90 seconds.

Settings

Fan Control Switch:

This switch cycles the condenser fan motors to maintain proper discharge pressure.

Settings

Harvest Hold Switch: 12A2117B03 (Penn)

This switch stops harvest timer (holds machine in harvest) until the suction pressure comes up to the switch

sets set point. Note: In low ambient conditions, the harvest time may be increased by raising the switch Cutout setting to 70-75 psig.

Settings

Cut-out (“Off”) 65 PSIG (R22) / 80 PSIG (R404A)

: Cut-Out (“Off”) 300 PSIG (R22) / 350 PSIG (R404A). Manual Reset

: Cut-out (“Off”) 10 PSIG (R22 & R404A)

Cut-in (“On”) 20 PSIG. (R22 & R404A)

: Cut-in (“On”) 220 PSIG (R22) / 250 PSIG (R404A)

Cut-out (“Off”) 200 PSIG (R22) / 230 PSIG (R404A)

: Cut-In (“On”) 45 PSIG (R22) / 60 PSIG (R404A)

Condenser Fan Control Switch, Low Pressure Safety & Harvest Hold Switch

High Pressure Safety Switch

(Penn)

12A2117F05 (Penn)

/ 12A2117H01CE (Danfoss – for CE machines)

12A2117H01CE - Danfoss switch wiring

FIGURE 8-2A

/ 12A2117B03CE (Danfoss – for CE machines)

/ 12A2117B03CE (Danfoss – for CE machines)

12A2117B03CE - Danfoss switch wiring

FIGURE 8-2B

Page 54

Vogt® VT Service Manual 8-3

Service Operations

Oil Failure Switch:

This device monitors the compressor oil pump differential pressure. If oil pressure drops below 7-9 psig for a

period of two minutes, the Sentronic module will open the control circuit contact and shut the machine off.

Factory set @ 7-9 psig (Manual reset)

CoreSense: Replaces Copeland Sentronic Oil Pressure Safety module on all Discus compressor and the

Electronic Motor Protector module in 4D & 6D compressors. Note: 2D & 3D compressor will still have

Internal Line Break overload protection.

The oil pressure monitoring portion of the CoreSense will act very similar to the Sentronic Oil Pressure

Safety switch. A current transformer (CT) in the compressor junction box determines when the compressor

is running and starts monitoring oil pressure.

The CoreSense module has power applied at all times to allow for more detailed fault notification. An LED

will flash when a fault occurs. The number of flashes will identify the fault condition.

# of Flashes Condition

1 Oil Pressure

2 Motor Protection Trip

3 Discharge Temperature (optional add-on)

4 Current Sensor Fault

5 Communication Error

12A2117A05 (Copeland Sentronic) On compressors manufactured before March 2011.

FIGURE 8-3

Copeland CoreSense

Page 55

8-4 Vogt® VT Service Manual

Service Operations

Bin Control (Ranco Electronic Temperature Control)

With the Ranco electronic temperature control the ice must come in contact with the sensor to shut the

machine off. The sensor should be installed in the bin using the standard bin thermostat mounting bracket.

Three quarters of the sensor (black part) should hang below the bottom of the bracket.

Programming the Sensor

1) Press the “SET” button to enter the sensors setup mode

2) Select between “C”- Celsius and “F” - Fahrenheit

Use the up ▲or down ▼ key to select “F”

3) Press the “SET” button to set the Set point (S1 will be blinking)

Use the up ▲ or down ▼ key to set the temperature at 38

4) Press the “SET” button to set the Differential (DIF 1 will be blinking)

Use the up ▲ or down ▼ key to set the differential at 2

5) Select between “C1”- Cooling mode and “H1” - Heating mode

Use the up ▲ or down ▼ key to select “C1”

Machine will shut off when temperature drops to 38

Note: The sensor will automatically exit the programming mode if no keys are depressed for a period of

thirty seconds. Any settings that have been input to the control will be accepted at that point.

°

F

°

F

°

F and come on when temperature reaches 40°F.

FIGURE 8-4

Electronic Temperature Control - Part # 12A 2117G09

Error Messages

E1 – Appears when either the up ▲ or down ▼ key is pressed when not in the programming mode.

To correct: If the E1 message appears even when no keys are being pressed, replace the control.

E2 – Appears if the control settings are not properly stored in memory.

To correct: Check all settings and correct if necessary.

EP – Appears when the probe is open, shorted or sensing a temperature that is out of range.

To correct: Check to see if the sensed temperature is out of range. If the sensor is subject to

a known ambient temperature between -30

the damaged probe.

EE – Appears if the EEPROM data has been corrupted.

To correct: This condition cannot be field repaired. Replace the control.

ο

F and 220οF, and displays the EP code, replace

Note: Electronic Temperature Control #: 12A2117G09 / Replacement Sensor #: 12A2117G0901

Page 56

Vogt® VT Service Manual 8-5

Service Operations

PLC (Programmable Logic Controller).

(Programmable Logic Controller). The PLC controls the sequence of events and monitors the ice machine

functions. The operational sequences of the VT-Series ice machine can be described best as a series of six

different modes. Each mode identifies and defines a sequence of events that occur while in that mode and

thereby cause it to move to the next mode. Only one mode is active at a time.

The VT-Series ice machine is controlled by a PLC

Freeze cycle Timer (PLC analog pot)

Turn Clockwise to increase freeze time

Minimum Freeze Time = 5 min

Maximum Freeze Time = 8.5 min

FIGURE 8-5

PLC (Programmable Logic Controller)

# Description

Inputs 0

Current Sensing Relay (chopper)

“On” Selector Switch/Bin Control

1

HH Pressure Switch

2

Manual Harvest (Start) Button

3

Clean Switch

4

High Pressure Safety Switch

5

Low Pressure Safety Switch

6

Oil Press Safety /Comp Motor OL

7

# Description

Outputs

0

1

2

3

4

5

Suction Stop Valve (VT80 & VT100)

TABLE 8-1

PLC Inputs/Outputs

Fault Indicator light

Liquid Feed Solenoid (R404A machines only)

Compressor

N/A

Water Pump

Chopper/Hot Gas Valve/Defrost Loop valve or

Page 57

8-6 Vogt® VT Service Manual

Discharge

Service Operations

Service

Valve

Oil Pump

Suction

Service

Valve

Oil Charging Valve

Oil Pump Inlet Screen

Crankcase Heater

Oil Pressure

Safety Switch

Oil Sightglass

FIGURE 8-6

Copeland Discus Compressor (10HP Shown)

Description Refrigerant Vogt # Copeland #

Compressor VT-40 (5 1/2HP) R22 12A2110A117 3DB3F33K0-TFC-100

R404A 12A2110A130 3DB3F33KE-TFC-100

Crankcase Heater 100 W (insert type) 12A7509E12 518-0028-01

Oil Pressure safety switch Sentronic

VT-60 (7 HP) R22 12A2110A110 3DS3F46K0-TFC-100

R404A 12A2110A131 3DS3F46KE-TFC-100

VT-80 (10 HP) R22 12A2110A122 4DL3F63K0-TSK-253

R404A 12A2110A128 4DL3F63KE-TSK-253

VT100 (12 1/2 HP) R22 12A2110A125 4DT3F76K0-TSK-253

R404A 12A2110A129 4DT3F76KE-TSK-253

R22/R404A

12A2117A05 585-1066-02

TABLE 8-2

Compressor / Compressor Parts

Page 58

Vogt® VT Service Manual 8-7

Line

Regulator Valve

Defrost Loop

Valve

Pressure Switch

Service Operations

Defrost (hot gas)

Solenoid Valve

TXV

Flow

Liquid Line

Solenoid

(404A only)

Harvest Hold (HH)

Hot gas to

Condenser

Hot gas to

evaporators

To

Suction

Inlet Pressure

Note: Suction Stop Valve

Defrost loop valve

Suction Stop Valve

used on VT80 & VT100 only

used on Split VT40 & VT60 only

Description

Defrost Solenoid Valve (Hot gas valve) 1/2” Solenoid valve 12A4200A406 Sporlan

Defrost Loop Valve (Split VT40 & 1/2” (N.C.) Rebuild Kit 12A4199V53 Sporlan

VT60) Coil 12A2105C16 Sporlan

Suction Stop Valve – N.O. (VT80 & 1 5/8” Solenoid valve 12A4200A1104 Sporlan

VT100) 1 5/8” (N.O.) Rebuild Kit 12A4199V47 Sporlan

Coil (for N.O. valve) 12A2105C04 Sporlan

Liquid Line Solenoid Valve 5/8” Extended End (VT40) 12A4200A0504 Sporlan

(R404A machines only) 7/8” Standard length, B25S (VT60-100) 12A4200A0707 Sporlan

7/8” valve, B19S (after 4/2011) 12A4200A0708 Sporlan

5/8” (N.C.) Rebuild Kit 12A4199V38 Sporlan

7/8” (N.C.) Rebuild Kit – for B25S valve 12A4199V39 Sporlan

7/8” (N.C.) Rebuild Kit – for B19S valve 12A4199V43 Sporlan

Inlet Pressure Regulator Valve 1 1/8” Regulator valve 12A4200N0903 Parker

TXV R22 Machines 12A4200C0305 Sporlan

R404A Machines VT40, 60 & 80 12A4200C0320 Sporlan

VT100 12A4200C0321 Sporlan

Vogt # Manufacture

TABLE 8-3

TXV, Regulator Valve & Solenoid Valves

Page 59

8-8 Vogt® VT Service Manual

Seal /Locking

Service Operations

Adjusting TXV:

flange. Freezing too high on the evaporator may cause ice to hang up on tubes and not release properly.

To lower ice level, the TXV can be closed by running the stem in. Do this by turning the TXV stem clockwise

as shown below. (looking up at the valve stem)

Note: Close TXV ¼ turn at a time. Observe several cycles before making further changes.

Ice should start forming on the evaporator tubes approximately two inches from the top

Close TXV – clockwise (freeze lower on tubes)

Remove TXV cap

If ice is not freezing high enough on the evaporator tubes, the TXV can be opened by backing the stem out.

Do this by turning the TXV stem counter-clockwise. (looking up at the valve stem)

Note: Check expansion valve inlet strainer before opening valve. Clean strainer if necessary.

Open TXV ¼ turn at a time. Observe several cycles before making further changes.

Expansion Valve

Inlet Strainer

Expansion Valve inlet screen/strainer

can be accessed by removing nut

FIGURE 8-7

Adjusting TXV

Inlet Pressure Regulator:

The purpose of this valve is to maintain head pressure during the harvest cycle. (Set point = 160-170 psig)

This regulator valve is used on the split VT40, split VT60, VT80 and VT100.

Nut