Page 1

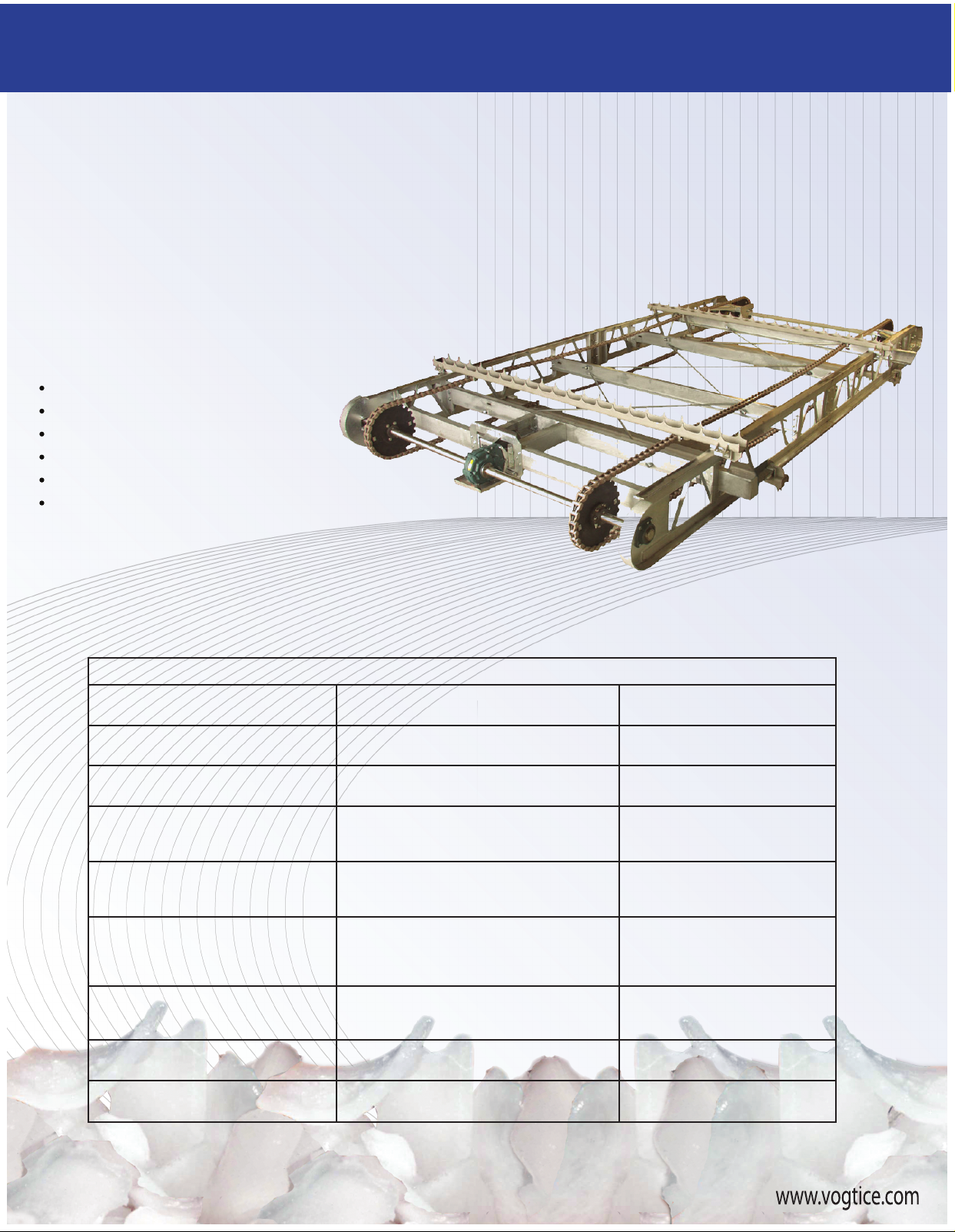

VOGT ICE RAKE 10 to 400 tons of storage

Reputation

From the first automatic sized icemaker in 1938 to

the rapid advancements of controling a rake with

your smart phone Vogt is a name you can trust!

Innovation

Recent improvements in PLC controls, drive train

design and new manufacturing methods make us

the leader in ice storage and handling!

Features:

Superior direct drive rake motor design

Stainless steel drive and idler shafts

Stainless steel material options

Used in USDA approved applications

Customized PLC controls

Want Remote Monitoring - Just ask us!

Feature Advantage Benefit

Automated ice storage & delivery No personnel directly involved in moving ice.

Ice can be stored and delivered

untouched by people.

Capacity ranges from 10 US tons of ice

to 400 US tons

Materials of construction are either

stainless steel, food grade plastic or

galvanized.

Direct drive flite driving

Split drive and idler sprockets (plastic)

Electronic controls for rake system

Rake flite monitor

Drive failure monitor

Avalanche control

Automatic door opening system

In use in USDA inspected facilities Assures acceptance by USDA inspectors

Over 250 CB and 100 Auto Rakes

installed world wide

system

Minimizes number of points for potential ice

contamination

Wide range of sizes and capacities can fit

dimensional and capacity constraints.

No corrosion or contamination of ice is possible

No threat of corrosion, other contamination

Improvement in areas of sanitations and maintenance

Cryogenically treated wear pads

Adjustment required from one end only.

Assures reliable operation and diagnostic

capabilities of equipment.

Allows setting to meet individual needs and

allows changes by customer.

Smooth, easy opening and closing of rake bin

door through the PLC controls or pushing a button

Proven systems and design Longer life and reliability

Safety of workers

Sanitation of ice product

Applicable for any size ice plant

Sanitation of ice product

Ease of maintenance

Improved sanitation of ice product

Maximum up time

User has best control and information

possible on the operation of this

equipment

Automatic operation of delivery system

Proven design to meet sanitation

requirements.

Page 2

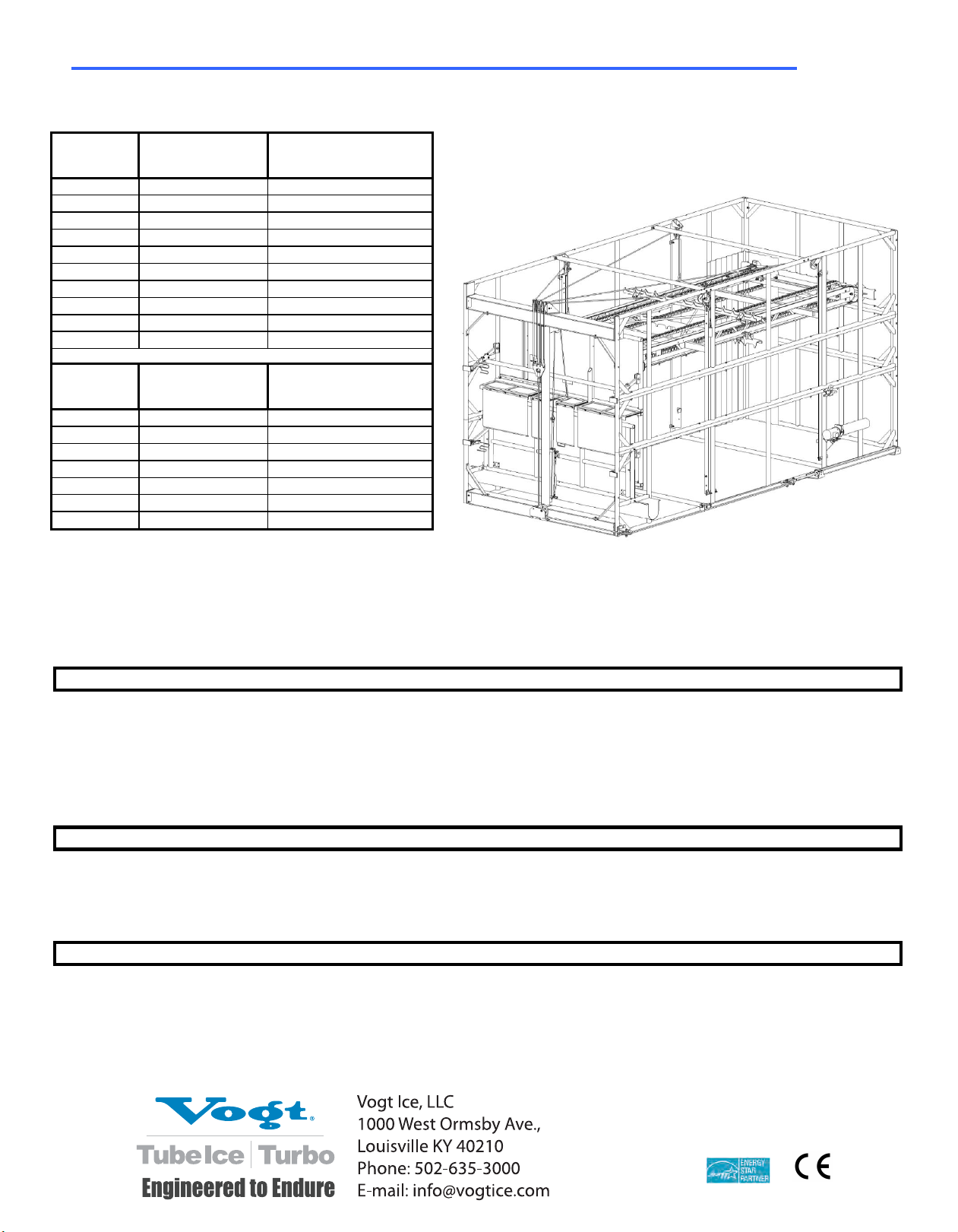

VOGT ICE RAKES

CB RAKE

CB10 10 17'0" X 9'11" X 9'0"

CB20 20 24'9" x 11'6" x 9'0"

CB30 30 24'9" x 11'6" x 11'10"

CB38 38 24'9" x 11'6" x 13'6"

CB50 50 24'9" x 11'6"x 16'4"

CB31 31 29'9" x 14'0" x 9'0"

CB49 49 29'9" x 14'0" x 11'10"

CB59 59 29'9" x 14'0" x 13'6"

CB75 75 29'9" x 14'6" x 16'4"

CB87 87 29'9" x 16'6" x 16'4"

AUTORAKE

(BIN SIZE)

15' x 30' 162 38'2" x 17'11" x H"

15' x 35' 189 43'2" x 17'11" x H"

20' x 35' 252 43'2" x 22'11" x H"

20' x 40' 288 48'2" x 22'11" x H"

20' x 45' 324 52'9" x 22'11" x H"

20' x 50' 360 58'2" x 22'11" x H"

20' x 55' 396 63'2" x 22'11" x H"

CAPACITY

(US TONS)

CAPACITY

up to (US TONS)

DIMENSIONS

(L x W x H)

DIMENSIONS

(L x W x H)

(CB Rake Assembly Shown)

Standard Features

● PLC Controls

● Automatic Hydraulic Door-Auto Rake ● UL508a Control Panel

● Soft Start Feature ● Stainless Steel Drive & Idler Shafts ● Avalanche Control Algorithm

● Plastic Chain & Sprockets ● Single Point Power w/Disconnect

● Hydraulic Hoist Assembly

● Hoist Lower Limit Switch ● Corrugated Aluminum Bin Liner ● Direct Drive Motor

Rake Options

● Additional Starters for Control of Auxillary Equipment ● 50 hz Application

● Split Frame, for Shipment in 20' Container (CB 20, 30, 38 & 50 only) ● CE Approval

● Front Mounted Hydraulics ● Remote Monitoring

Rake Bin Liner and Stainless Steel Options

● H.D.P.E. Bin & Door Liner ● Stainless Steel Girders

● Stainless Steel Bin & Door Liner ● Stainless Steel Chain

● Stainless Steel Flites ● Stainless Steel Sprockets

10/2012

Loading...

Loading...