Resis

tance Range

Min 10R 0R22 0R16

Máx 2M21 10M 10M

Temperature Coefficient

Permissible

film temperature

Dielectric Withstanding Voltage

Historical

+0 /-0,15

+0 /-0,1

min.

+0 /-0,1

±0,05

7

22

77

0.7 1.2 1.5 3.1 1.1 0.8 1.3 2.7

Precision MELF resistor

Advanced MELF technology

Excellent stability in different environmental conditions

Best in class pulse load capability

AEC –

Q200 Qualified

Intrinsic sulfur r

esistance

RoHs & REACH Compliant

ZCM Series Datasheet

SMD Precision Metal Film Resistors | MELF Style

ORDERING CODE-Example

New SAP Part Nr.:

ZCM 207 F K E 07- 1K AA

Serie Power rating Tol. Pack-Code TCR Forming type R Value Special

102 = 0,2W

204 = 0,4W

207 = 1,0W

Historical VTM Part Nr.:

ZC 0207 F K E 07 1K

Type Size Tol. K = Blister tape reel TC Reel diam. R Value

ELECTRICAL SPECIFICATIONS

Type

Historical Part Number SMD - ZC0204

Nominal Power Rating P70 [W] 0,2 0,4 1,0

B = ±0,1%

C = ±0,25%

D = ±0,5%

F = ±1%

G = ±2%

J = ±5%

- = Jumper

K = Blister

tape reel

C = ±15ppm

D = ±25ppm

E = ±50ppm

F = ±100ppm

- = Jumper

APPLICATIONS

Automotive Charger

Alternative Energy Power Supply

07- = 07 inch

(Reel diameter)

or

13- = 13 inch

(Reel diameter)

0R = Jumper AA = Standard

Home Appliances Industrial

FEATURES

ZCM102 ZCM204 ZCM207

AEC - Q200

Qualified

ZC0207

(Other values upon request)

[Ω]

E-Series E24 / E96 / E192

Tolerances ±[%] B = 0,1%, F = 1% B = 0,1% , C = 0,25% , D = 0,5% , F = 1% , G = 2% , J = 5%

IEC60115-1 clause 4.2 ; 4.8

(+20 / -55[°C] and (+20 /

±[10

-6*K-1

] Depends on the value, please check the table below

+125[°C])

Working Temperature Range [ºC] -55 … +125 -55 … +155

(F max.)

Max. Working Voltage [AC or DC]

IEC115-1 clause 4.7 (1[min])

DIMENSIONS [mm]

[ºC] 125 155

150 200 350

RMS

[V]

200 300 500

RMS

Type

P/N:

ZCM102 ZCM204 ZC0204

ZCM207 ZC0207

L Ø D L

2,2

1,1

3,6 +0 /-0,2 1,4 +0 /-0,1 1,8 min. D +0 /-0,15 0,80 ±0,10

5,8 +0 /-0,3 2,2 ±0,2 2,6 min. D +0 /-0,2 1,25 ±0,2

1,2

Ø D1 A

1

D

0,40

Recommended solder pads dimensions

Type

Wave soldering Reflow soldering

I a b c I a b c

ZCM102

ZCM204

ZCM207

1,5 1,5 1,8 4,5 1,7 1,2 1,6 4,1

2,4 2,3 2,6 7,0 2,6 2,0 24 6,6

MASS

(mg)

File Nr. 3900.18-450.113.19 | Revision: 201911 | Page 1 of 6

ZCM S

er

ies Datasheet

ZCM102

ZCM204

ZCM207

ZC0207

0,1 (<211k

Ω

) ;

-

9 h-

1

1000h

-

0.05 (10R

≤1M) 0.05 (10R

≤1M) 8000h

-

0.1 (10R

≤1M) 0.1 (10R

≤1M)

1000h

0,25 (<211k

Ω

) ;

0,5

(>211k

Ω

)

0.15 (<10R) ; 0.1 (10R

≤1M) ; 0.25

0.15 (

≤1M) ; 0.5 (>1M)

8000h

0,5 (<211k

Ω

) ; 1 (>211k

Ω)

0.3 (<10R) ; 0.2 (10R

≤1M) ; 0.5

0.3 (

≤1M) ; 1 (>1M)

1000h

-

0.25 0,25 (≤1M) ; 0,5 (>1M)

8000h

-

0.5 0,5 (

≤1M) ; 1 (>1M)

0.15 (<10R) ; 0.1 (10R

≤1M) ; 0.25

0.3 (<10R) ; 0.2 (10R

≤1M) ; 0.5

-

55~125ºC

-

0,25 0,25

No burning after 30[s]

0.5

3.5

File Nr. 3900.18

-

450.113.

19

|

Revision: 201911

| Page 2

of 6

PERFORMANCE DATE

Type

Historical Part Number

Climatic Category

Short Time Overload

IEC60115-1 clause 4.13

(U=2,5*

, ≤2* U

5 [s])

max,

Single pulse high voltage overload

IEC60115-1 clause 4.27

(U=10* ,Severity 4, 10 pulses 10[µs]/700[µs]

Periodic electric overload

IEC60115-1 clause 4.39

(U=15* ,0.1[s]on, 2.5[s]off,1000 cycles

Failure Rate (Total, max, 60[%] cont. lev.)

Endurance at 70ºC,

IEC60115-1 clause 4.25.1

(U= U

, 1,5[h]ON ; 0,5[h]OFF)

max,

Standard

operation

Power

operation

Standard

operation

Power

operation

Standard

operation

Power

operation

[10

Precision

operation

Standard

operation

Power

operation

±[%]

±[%]

±[%]

±[%]

±[%]

±[%]

- ZC0204

55/155/56

0,15(>211kΩ)

0,03 (≤1M) ; 0,15 (>1M) 0,03 (≤1M) ; 0,15 (>1M)

- 0,05 (≤1M) ; 0,15 (>1M) 0,05 (≤1M) ; 0,15 (>1M)

- 0,15 0,25

- 0,15 0,5

- 0,15 0,15

- 0,3 0,3

]

≤ 0,1

Endurance at upper Category Temp.

IEC60115-1 clause 4.25.3

( 1000[h]

Damp Heat, Steady State

IEC60115-1 clause 4.24

(40±2[°C], 93±3[% r.h.], 56[d])

Damp Heat, Steady State, Accelerated

IEC60115-1 clause 4.37

(85±2[°C], 85±5[%RH], U = 0.3* )

Temperature Cycling

IEC60068-2-14 ; IEC60115-1 clause 4.19

( 30[min] each , 1000 cycles)

Vibration

IEC60068-2-6 ; IEC60115-1 clause 4.22

(10;2000[Hz], ≤1,5[mm] , or ≤200[m/s2] 7,5[h])

Resistance to Soldering Heat

IEC60115-1 clause 4.18

(260±5[°C], 10±1[s])Solder bath method

Electrostatic Discharge

IEC60115-1 clause 4.38 ; IEC61340-3-1

( 3 positives + 3 negatives discharges)

Voltage proof

IEC60115-1 clause 4.7 U

RMS=UINS

, 60 [s]

Flammability

IEC60115-1 clause 4.35, IEC60695-11-5

Needle flame test, 10[s]

Solderability

IEC60068-2-20 ; IEC60115-1 clause 4.17

±0,2

(235±3[ºC] 2

[s],SnAg3Cu

or SnAg

)

Component Resistance to Solvents

IEC60068-2-45 ; IEC60115-1 clause 4.29

(50[ºC] method 2)

±[%]

125ºC 0,25 (<211kΩ) ; 1 (>211kΩ) 0,15 (≤1M) ; 0,5 (>1M)

±[%]

155ºC - 0,3 (≤1M) ; 1 (>1M)

±[%]

±[%]

-55~155ºC

±[%]

±[%]

±[%]

0,5 (<211kΩ) ; 1 (>211kΩ) 0,25 (≤ 1M) ; 1 (>1M) 0,25 (≤ 1M) ; 1 (>1M)

- 0,25 (≤ 1M) ; 2 (>1M) 0,5 (≤ 1M) ; 2 (>1M)

- 0,5 0,5

- 0,05 (≤ 1M) ; 0,1 (>1M) 0,05

0,1 (<211kΩ) ;

0,25(>211kΩ)

0,1 (≤ 10R) ; 0,05 (>10R) 0,1 (≤ 10R) ; 0,05 (>10R)

- 0,5 [2 kV] 0,5 [4 kV]

- No flash over or breakdown

-

- ≥ 95% covered, no visible damage

(>1M)

(>1M)

No visible damage

Resistance to solvents of Marking

IEC60068-2-45 ; IEC60115-1 clause 4.30

(50[ºC] method 1)

Marking

IEC60062

NOTES: MARKING [COLOR CODE]:

•

ZCM204 Color code marking is applied according to IEC 60062 in four bands (E24 series) for 5 % tolerance, or in five bands (E96 or E192 series). Each color band appears as a single solid

line, voids are permissible if at least

•

ZCM207 Color code marking is applied according to IEC 60062 in four (E24 series) or six bands (E96 series). Each color band appears as a single solid line, voids are permissible if at least

2

/

of the band is visible from each radial angle of view. The last color band represents the TCR for resistors with TCR 50 ppm/K and nominal tolerance 1 %.

3

Zero ohm jumpers are marked with one centered black band.

2

/

of the band is visible from each radial angle of view. The last color band for tolerance is approximately 50 % wider than the other bands.

3

Marking visible , no visible damage

Color code

ZCM S

er

ies Datasheet

ZCM102

ZCM204

ZCM207

OPERATION MODE

STANDARD

PRECISION

STANDARD

POWER

PRECI

SION STANDARD

POWER

Rated Power dissipation P

[W] 0,2 0,07 0,25 0,4 0,125 0,4 1,0

Operating temp. range [ºC]

-55 to 125

-10 to 85

-55 to 125

-55 to 155

-10 to 85

-55 to 125

-55 to 155

Permissible film temperature

ϑ

F Max [ºC]

125 85 125 155 85 125 155 Resistance range

10R –

2M21 10R – 1M

R22 – 1M

R22 –

10M 100R –

511K 1R0 – 1M

1R0 – 1M

1000h

≤0,5 ≤0,05 ≤0,15 ≤0,25 ≤0,05 ≤0,15 ≤0,25 8000h

≤1

≤0,1 ≤0,3 ≤0,5 ≤0,1 ≤0,3 ≤0,5 225 0

00h - ≤0,25 ≤0,75 - ≤0,25 ≤1,0 -

ZCM102

Resistance range

Tolerance

TCR E-Series

0R16 … 0R91

± 5%

- 0R22 … 0R91

± 2% 10R…2M21

0R82… 10M

1R… 10M

± 1%

E24 / E96

-

10R… 1M65

1R… 2M21

± 0,5%

E24 / E192

-

10R… 1M65

43R… 1M

± 0,5%

- 22R… 1M65

43R… 1M

± 0,25%

100R

… 100K

22R… 1M65

43R… 1M

± 0,1%

- 10R… 221K

100R… 511K

± 0,5%

- 22R… 221K

100R… 511K

± 0,25%

100R

… 100K

43R… 221K

100R… 511K

± 0,1%

Jumper

I

= 2A Jumper

I

= 3A Jumper

I

= 5A

≤ 10 mΩ

File Nr. 3900.18

-

450.113.

19

|

Revision: 201911

| Page 3

of 6

TEMPERATURE COEFFICIENT

Notes :

ZCM204 - The color of the body coating is light green for jumpers and for a temperature coefficient of ±50 ppm/K or ±100 ppm/K, pink for ±25 ppm/K, or violet for ±15 ppm/K.

ZCM207 - TCR ±10 ppm/K and ±5 ppm/K in resistance range 100Ω to 100kΩ on request.

•

Zero ohm jumper - Are marked with one centered black band.

•

NOTES: RESISTOR BODY COLOR CODE:

The body coating color is light green for jumpers and for a temperature coefficient of ±50 or 100 [ppm], pink for ±25[ppm] and violet for ±15[ppm]

- 0R22 … 0R91

max

ZCM204 ZCM207

MAXIMUM RESISTANCE CHANGE AT RATED DISSIPATION

max

± 100 ppm/K E24

± 50 ppm/K

± 25 ppm/K E24 / E192

± 15 ppm/K E24 / E192

max

70

Max. Resistance drift [%]

[ΔR/R]

A suitable low thermal resistance of the circuit board assembly must be safeguarded in order to maintain the film temperature of the resistors within the specified

limits.

ZCM S

er

ies Datasheet

File N

r. 3900.18

-

450.113.19

|

Revision: 201911

| Page 4

of 6

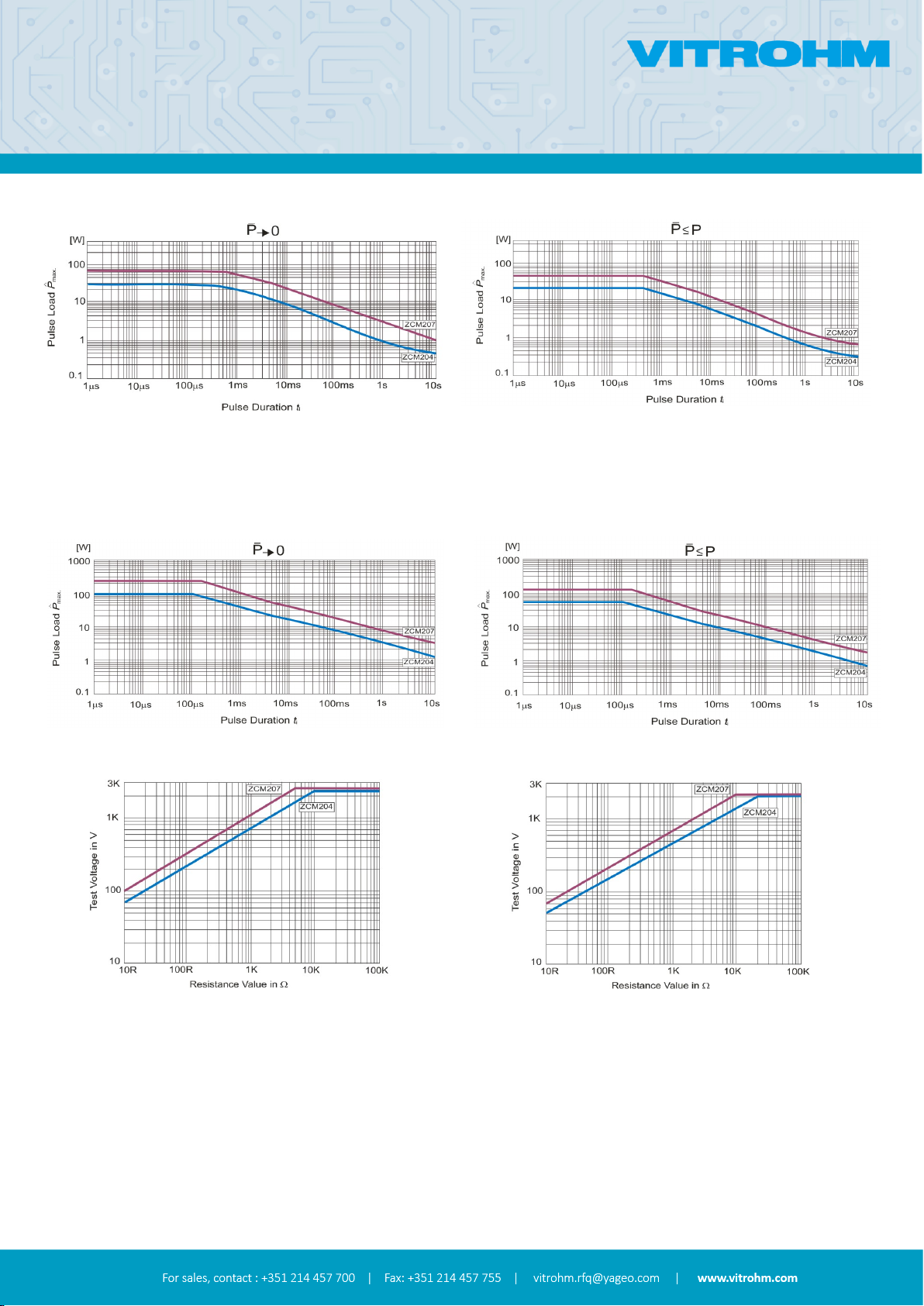

PERFORMANCE GRAPH’s

Derating – Precision Operation Derating – Standard Operation

Derating – Power Operation Non- Linearity

Current Noise Pulse Voltage

ZCM S

er

ies Datasheet

File Nr. 3900.18

-

450.113.

19

|

Revision: 201911

| Page 5

of 6

Single Pulse for R < 10Ω Continuous Pulse for R < 10Ω

Single Pulse for R ≥ 10Ω Continuous Pulse for R ≥ 10Ω

Single Pulse (1.2/50 [µs]) Single Pulse (10/700 [µs])

ZCM S

er

ies Datasheet

W1

W2

Packaging

File Nr. 3900.18-450.113.

19

|

Revision: 201911 | Page 6

of 6

PACKAGING - Blister tape

The type ZCM is packed in antistatic blister tape according to IEC60286-3, type 2a, packing details described below,

Type A0 B0 F W D1 T2

ZCM102 1,3±0,1 2,47±0,1 3,5±0,05 8,0.±0,3/-0,1 1,0 ≤ 1,65

ZCM204 1,55±0,1 3,7±0,1 3,5±0,05 8,0.±0,3 1,0 ≤ 1,8

ZCM207 2,40±0,1 6,0±0,1 5,5±0,05 12,0.±0,3 1,5 ≤ 2,7

Type

ZCM102 8,4

[±1,5]

+1,5/-0

[max]

14,4

ZCM204 8,4 14,4

ZCM207 12,4 18,4

Type

[dimensions]

ZCM102

ZCM204 3000

07(inch)

Blister tape

Quantity

[pcs]

3000

ZCM207 1500

ZCM204

ZCM207 7500

13(inch)

Blister tape

10000

Loading...

Loading...