Vision Fitness ST700 User Manual

Assembly &

Owner’s Guide

ST700

FUNCTIONAL TRAINER

2

Table of Contents

ASSEMBLY GUIDE OWNER’S GUIDE

ASSEMBLY GUIDE . . . . . . . . . . . . . . . . 4

HARDWARE BAGS . . . . . . . . . . . . . . . . 6

STEP 1: ORANGE BAG . . . . . . . . . . . . . 9

STEP 2: BLUE BAG . . . . . . . . . . . . . . . 10

STEP 3: PINK BAG . . . . . . . . . . . . . . . 11

STEP 4: GREEN BAG . . . . . . . . . . . . . . 12

STEP 5: CABLE #1 . . . . . . . . . . . . . . . 13

STEP 6: CABLE #2 . . . . . . . . . . . . . . . 14

STEP 7: CABLE #3 . . . . . . . . . . . . . . . 15

STEP 8: CABLE #4 . . . . . . . . . . . . . . . 16

STEP 9: BLACK BAG . . . . . . . . . . . . . . 17

STEP 10: YELLOW BAG . . . . . . . . . . . 18

EFFECTIVE RESISTANCE . . . . . . . . . . . 19

RESISTANCE TRAINING BENEFITS

& TIPS, WORKOUT VARIATIONS . . . . . . 20

TRAINING PROGRAMS . . . . . . . . . . . . 21

STRETCHING . . . . . . . . . . . . . . . . . . . 22

INCLUDED ACCESSORIES . . . . . . . . . . 24

FUNCTIONAL TRAINER EXERCISES . . . . 26

MAINTENANCE SCHEDULE . . . . . . . . . . 32

COMMERCIAL WARRANTY . . . . . . . . . . 33

WORKOUT LOGS . . . . . . . . . . . . . . . . 34

3

Assembly &

Owner’s Guide

ST700

FUNCTIONAL TRAINER

To avoid possible damage to this Functional Trainer, please follow these assembly steps in the correct order. Before

proceeding, find your new Functional Trainer serial number located on the side of the right floor support (AC3), and

enter here:

Refer to this number when calling for service, and enter this serial number on your Warranty Card and in your

own records. Be sure to read your Assembly/Owner’s Guide before using your new Functional Trainer.

If any parts, hardware or tools are missing, please call 1.800.335.4348, Extension 12

NOTE: During assembly, it is recommended to ensure that all bolts are in place and partially threaded before completely tightening

any one bolt. During assembly steps 1 thru 4, do not completely tighten any bolts until completion of Step 4.

4

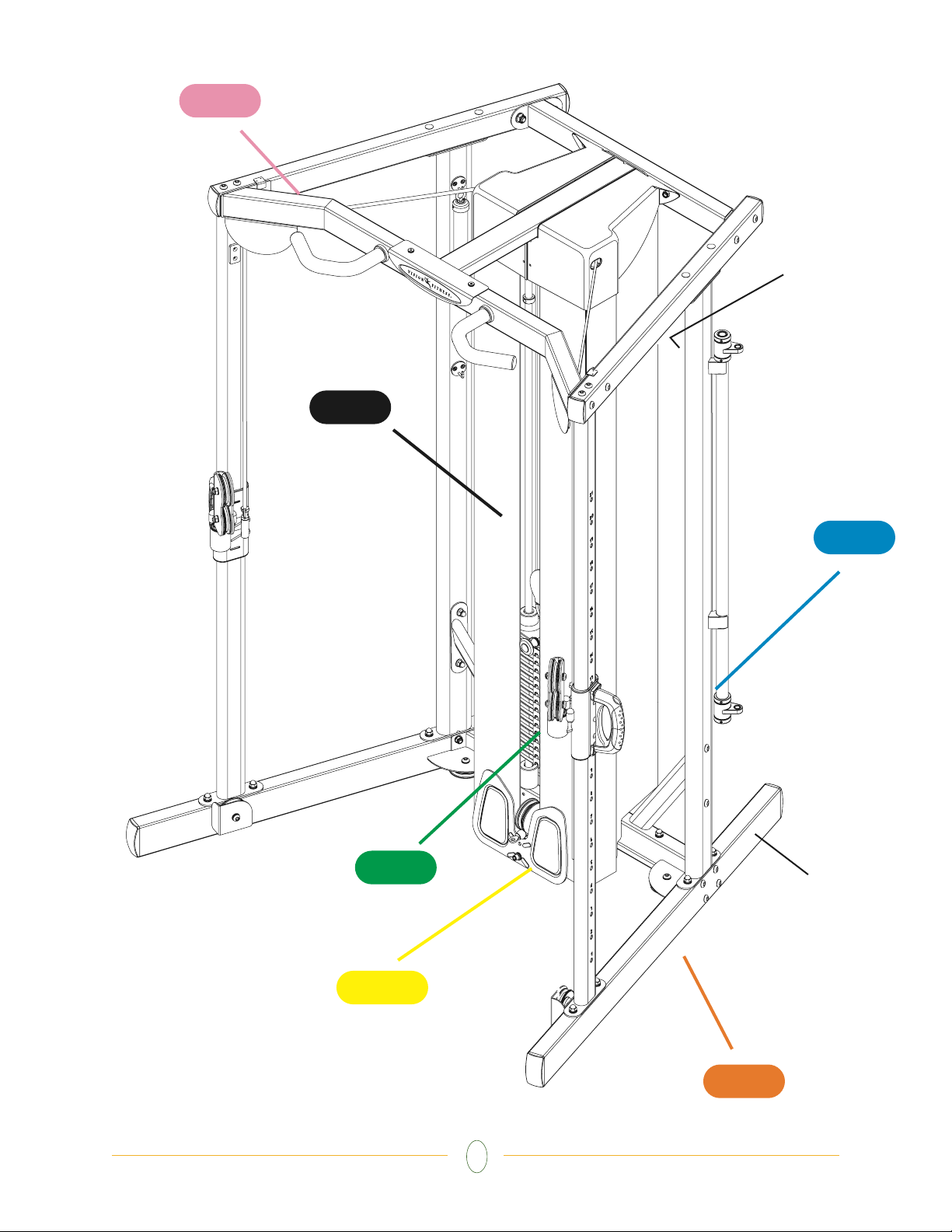

g

STEP

3

General Warnin

Decal

STEP

9

STEP

2

STEP

STEP

10

4

Serial #

STEP

1

5

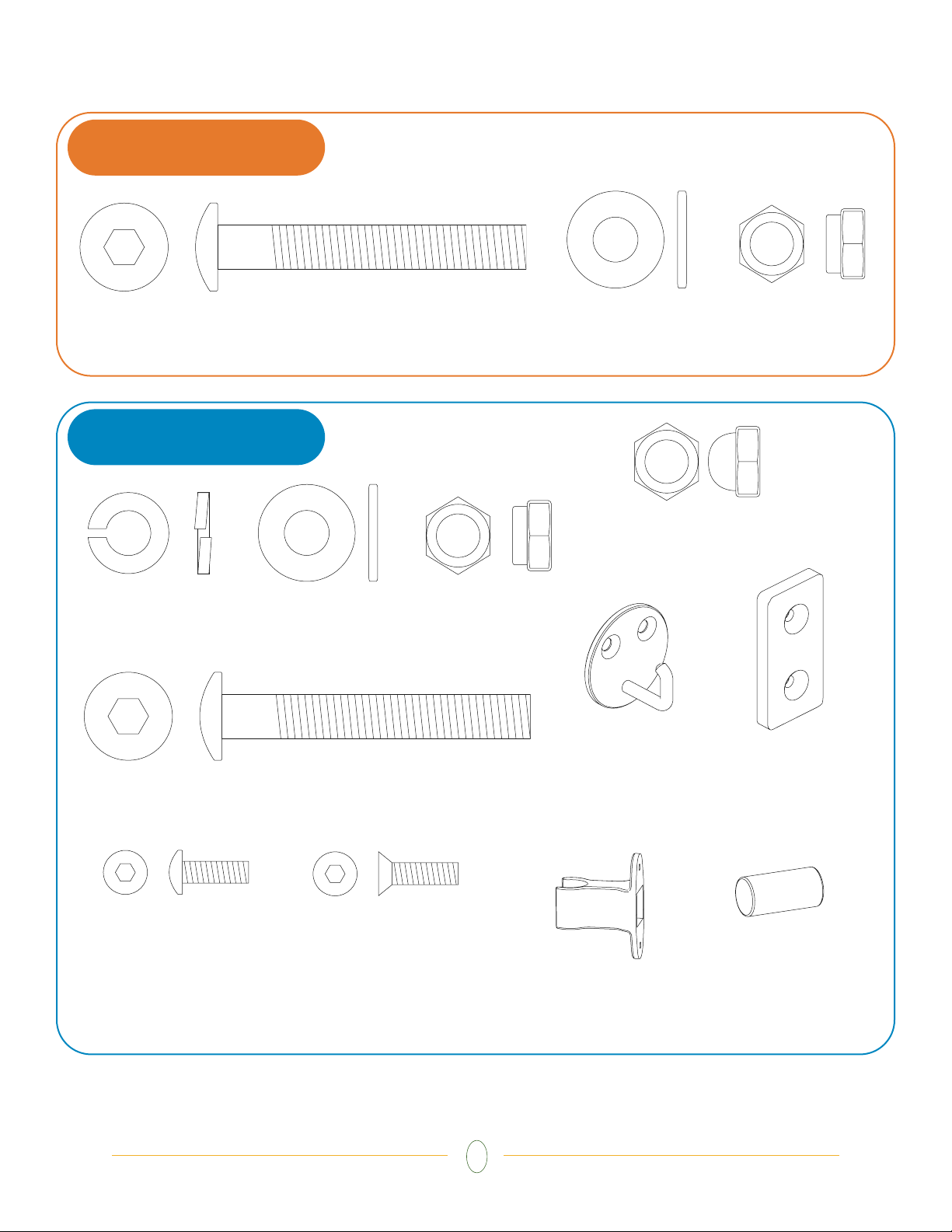

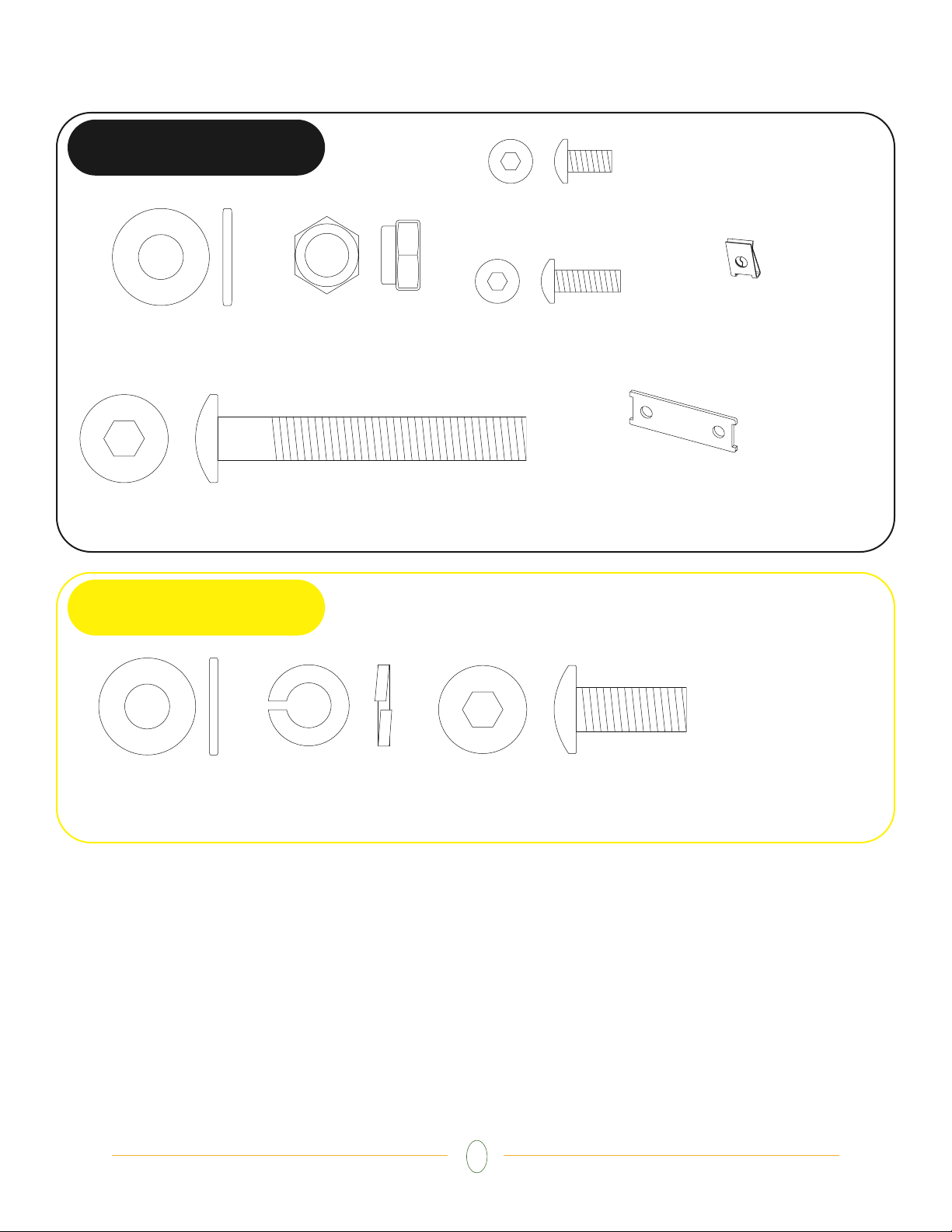

ORANGE BAG

HARDWARE INCLUDED

BLUE BAG

10.2 x 18.4 x 2.5

Lock Washer

Quantity: 13

M10 x 70 Bolt

Quantity: 8

10.2 x 22 x 2

Flat Washer

Quantity: 21

M10 x 70 Bolt

Quantity: 5

M10 Nylon Nut

Quantity: 4

10.2 x 22 x 2

Flat Washer

Quantity: 16

M10 Acorn Nut

Quantity: 12

Accessory

Storage Hook

illustration not to scale

Quantity: 2

M10 Nylon Nut

Quantity: 8

Rubber Stop

illustration not to scale

Quantity: 2

M5 x 15 Bolt

Quantity: 4

M5 x 15 Flathead Screw

Quantity: 8

Snap Hook

illustration not to scale

Quantity: 2

Add-on Weight Storage Post

(illustration not to scale)

Quantity: 1

6

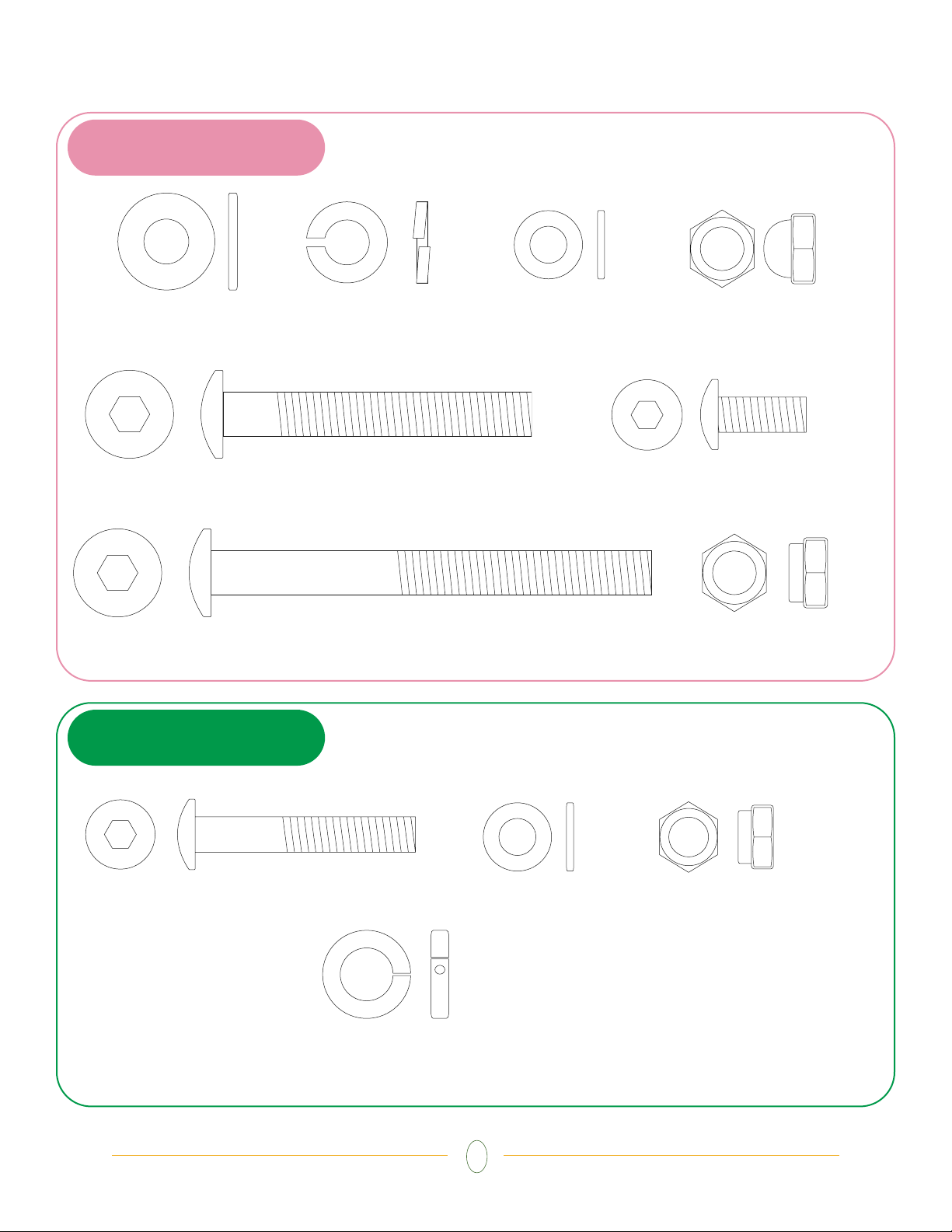

PINK BAG

HARDWARE INCLUDED

10.2 x 22 x 2

Flat Washer

Quantity: 30

M10 x 70 Bolt

GREEN BAG

10.2 x 18.4 x 2.5

Lock Washer

Quantity: 10

Quantity: 12

M10 x 100 Bolt

Quantity: 4

8.4 x 15.5 x 1.6

Flat Washer

Quantity: 2

M10 Acorn Nut

Quantity: 4

M8 x 20 Bolt

Quantity: 2

M10 Nylon Nut

Quantity: 10

M8 x 50

Flat Washer

Quantity: 2

Travel Limiter Ring

illustration not to scale

Quantity: 1

8.4 x 15.5 x 1.6

Flat Washer

Quantity: 4

7

M8 Nylon Nut

Quantity: 2

BLACK BAG

HARDWARE INCLUDED

M5 x 10 Bolt

Quantity: 4

10.2 x 22 x 2

Flat Washer

Quantity: 4

M10 x 70 Bolt

Quantity: 2

YELLOW BAG

M10 Nylon Nut

Quantity: 2

M5 x 15 Bolt

Quantity: 12

Slip-on Nut

illustration not to scale

Quantity: 4

Z19 Connecting Bracket

illustration not to scale

Quantity: 2

10.2 x 22 x 2

Flat Washer

Quantity: 2

10.2 x 18.4 x 2.5

Lock Washer

Quantity: 2

M10 x 25 Bolt

Quantity: 2

8

AC1

AC2

AC3

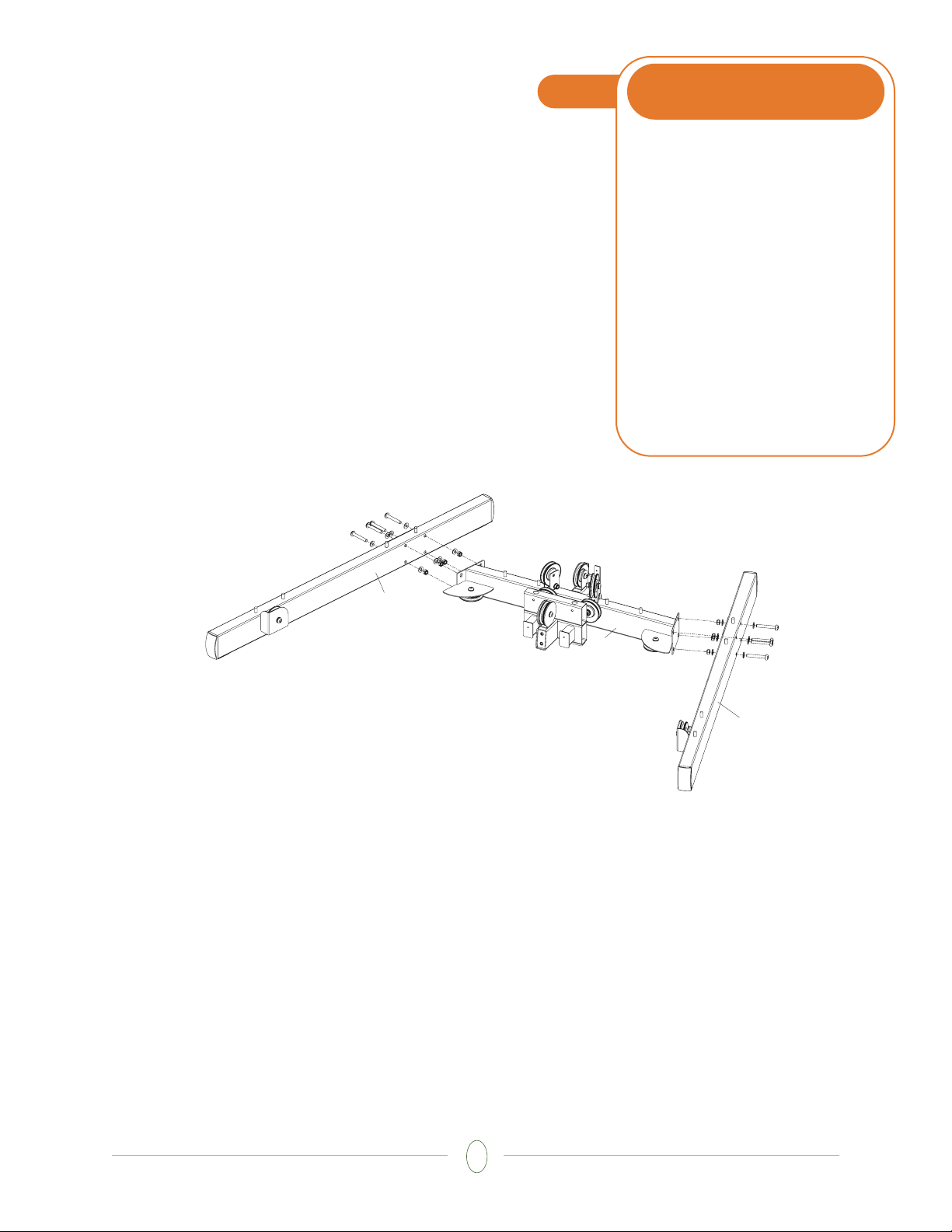

STEP

1

ORANGE BAG

NOTE: During assembly, it is recommended

to ensure that all bolts are in place and

partially threaded before completely tightening

any one bolt. During assembly steps 1 thru

4, do not completely tighten any bolts until

completion of Step 4.

• Lay the center floor support (AC1) on the

ground, floor pads down. Attach left floor

support (AC2) to center floor support by

sliding four bolts (M10x70) with four flat

washers (10.2x22x2) through the holes,

and securing bolts with four more flat

washers (10.2x22x2) and four nylon nuts

(M10). Repeat for attaching right floor

support (AC3).

AC2

AC1

AC3

9

AQ1

Weight Storage Post

AD2

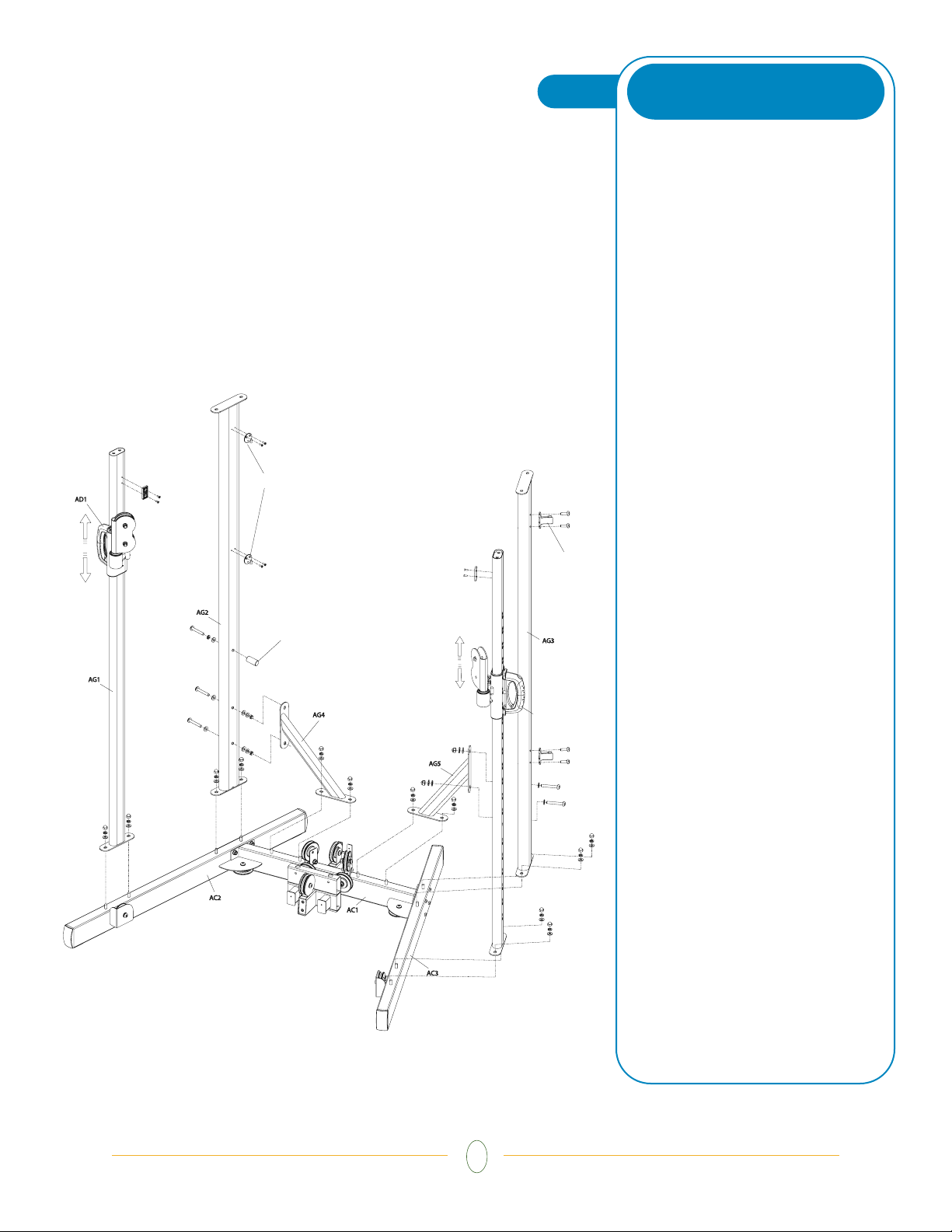

STEP

Q18

2

BLUE BAG

• Place the chrome front upright (AG1)

over the protruding bolt ends on front of

left floor support (AC2), making sure numbers and holes are facing outward.

Secure using a flat washer (10.2x22x2),

lock washer (10.2x18.4x2.5), and an

acorn nut (M10) on each bolt end. Slide

the left adjustment handle (AD1) onto the

upright from the top, keeping the handle

on the side with the holes. Repeat this

process for the front upright assembling

AD2 to it on the right floor support (AC3).

Attach a rubber stop to the holes provided

at the top of the left and right chrome tube

using four flathead screws (M5x15).

• Take the left rear upright (AG2) and

stand it over the protruding bolts on the left

floor support (AC2) , making sure the

horizontal holes face inward of the

machine. Secure using a flat washer

(10.2x22x2), lock washer (10.2x18.4x2.5),

and an acorn nut (M10) on each bolt end.

Repeat this process for right rear upright

(AG3) on the right floor support (AC3).

Make sure the horizontal holes face the

outside. Attach two accessory hooks

(AQ1) to the left rear upright (AG2) with

four flathead screws (M5x15). Attach the

weight storage post with a lock washer

(10.2x18.4x2.5), a flat washer

(10.2x22x2), and a bolt (M10x70).

Attach the two plastic snap hooks (Q18)

to the outside of the right rear upright (AG3)

with four round head bolts (M5x15).

10

• Place the left stabilizer support (AG4)

over the protruding bolt ends on left side

of center floor support (AC1). Do not

secure that connection until later. Slide two

bolts (M10x70) with flat washers

(10.2x22x2) through holes in left rear

upright (AG2) and stabilizer support. Slide

another flat washer onto each bolt and

secure using an nylon nut (M10). Now,

secure the stabilizer to the protruding bolt

ends using a flat washer (10.2x22x2),

lock washer (10.2x18.4x2.5) and an

acorn nut (M10). Repeat this process for

the right stabilizer support (AG5).

AB4

AB4

AB2

AB1

AB3

B21

AB5

AB2

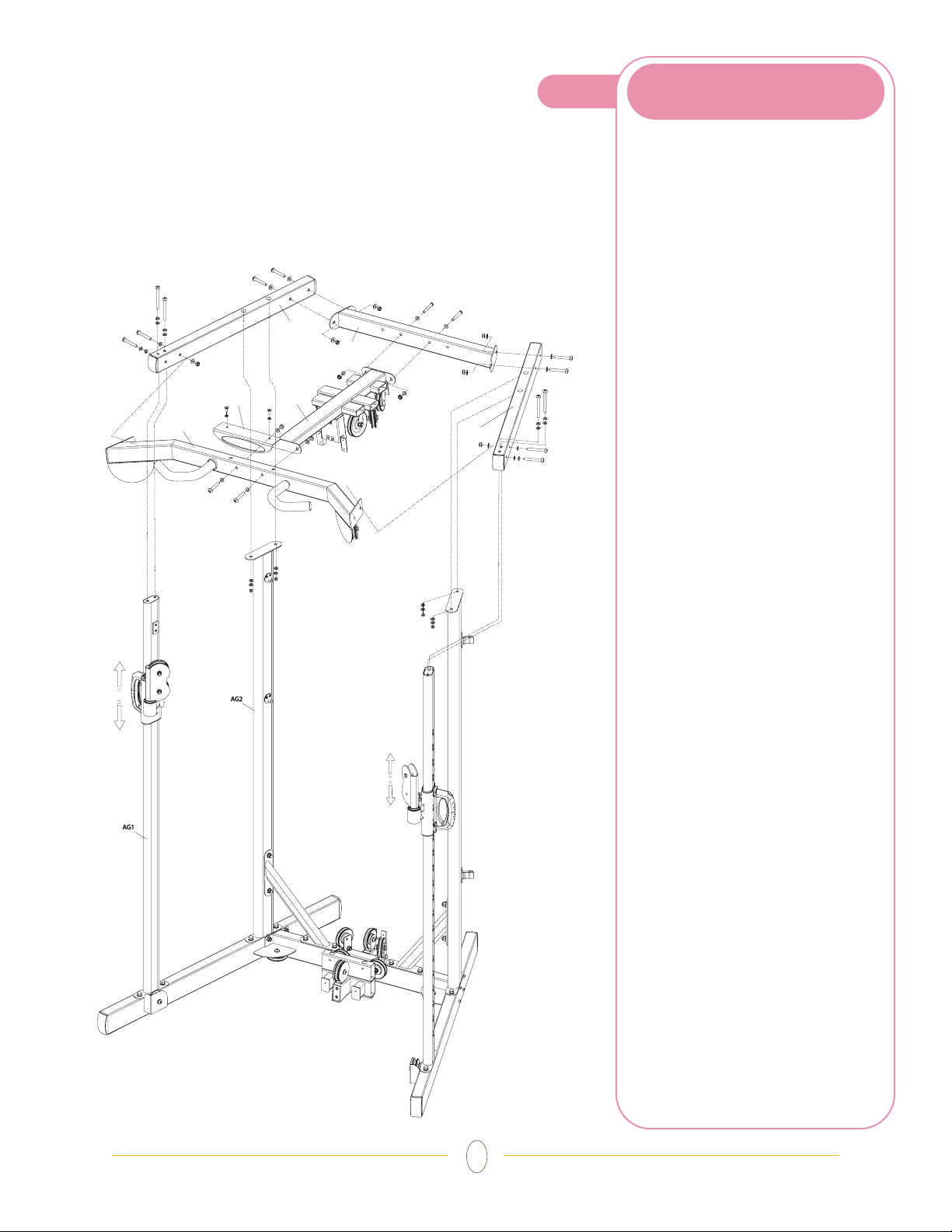

STEP

3

PINK BAG

• Place the top left frame (AB4) on the left

side uprights (AG1 & AG2), with the

protruding bolt ends going through holes

in the left rear upright (AG2). Slide a flat

washer (10.2x22x2) and lock washer

(10.2x18.4x2.5) over each bolt end, and

secure with an acorn nut (M10). Secure

two bolts (M10x100) with a lock washer

(10.2x18.4x2.5) and a flat washer

(10.2x22x2) through holes over the top of

front chrome upright (AG1). Repeat this

process for top right frame (AB5).

• Place the top rear frame (AB2) up

against the back of the top left and right

frames (AB4 & AB5). Insert two bolts

(M10x70) with flat washers (10.2x22x2)

through the holes on both sides of top

AB3

B21

AB1

AB5

frames, and secure the connection with

another flat washer on each bolt, and a

nylon nut (M10).

• Take the top center pulley support (AB1)

with the pulley bracket side down, place

the holes on the short end over the middle

holes in top rear frame (AB2). Secure in

place by sliding two bolts (M10x70) with

flat washers (10.2x22x2) through the

holes. Slide another flat washer onto each

bolt and tighten with a nylon nut (M10).

• Grab the top front frame (AB3) and

align the holes in the center with the holes

in top center pulley support (AB1). Slide

two bolts (M10x70) with flat washers

(10.2x22x2) through the holes, placing

another flat washer onto the bolts and

securing with a nylon nut (M10). To connect

to both left and right top frames (AB4 &

AB5), slide a bolt (M10x70) with a lock

washer (10.2x18.4x2.5) and flat washer

(10.2x22x2) through the front holes in the

connection points (See diagram for

clarification). For other hole, use a bolt

(M10x70) with a flat washer (10.2x22x2)

and connect other side of bolt using another

flat washer and a nylon nut (M10).

Tighten the two front center bolts.

11

• Attach the top front frame cover (B21) to

the top front frame (AB3) using two

bolts (M8x20) and two flat washers

(8.4x15.5x1.6).

STEP

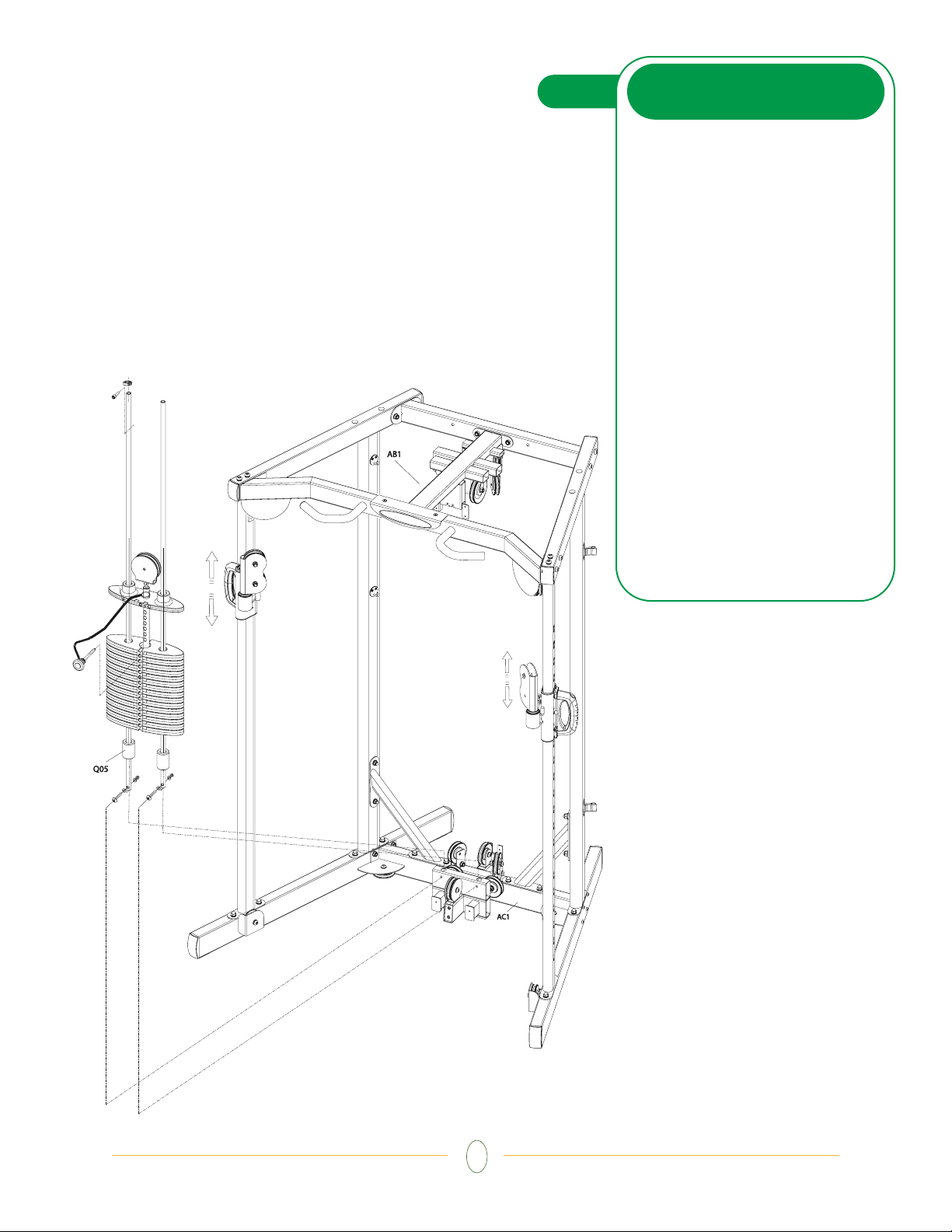

4

GREEN BAG

• Place the two rubber bumpers (Q05)

over the holes for the guide rods in center

floor support (AC1). With the horizontal

holes at the bottom, slide the guide rods

through the rubber bumpers and into center

floor support. Let the guide rods tilt forward.

Slide each of the 15 weight plates over

both of the guide rods on top of one another.

Place the header weight plate over both

guide rods on top of other weight plates.

Slide a travel limiter ring on the left guide

rod, tightening the ring 10.5” (bottom

edge of ring) from the top.

• Make sure rubber guide rod sleeves are

in place in top holes of the center pulley

support(AB1). Lift the guide rods up until

holes in guide rods are lined up with holes

in center floor support. Slide a bolt

(M8x50) with a flat washer (8.4x15.5x1.6)

through each guide rod, securing bolt with

another flat washer and nylon nut (M8).

Tighten all hardware (horizontal hardware

first, then vertical hardware).

12

Loading...

Loading...