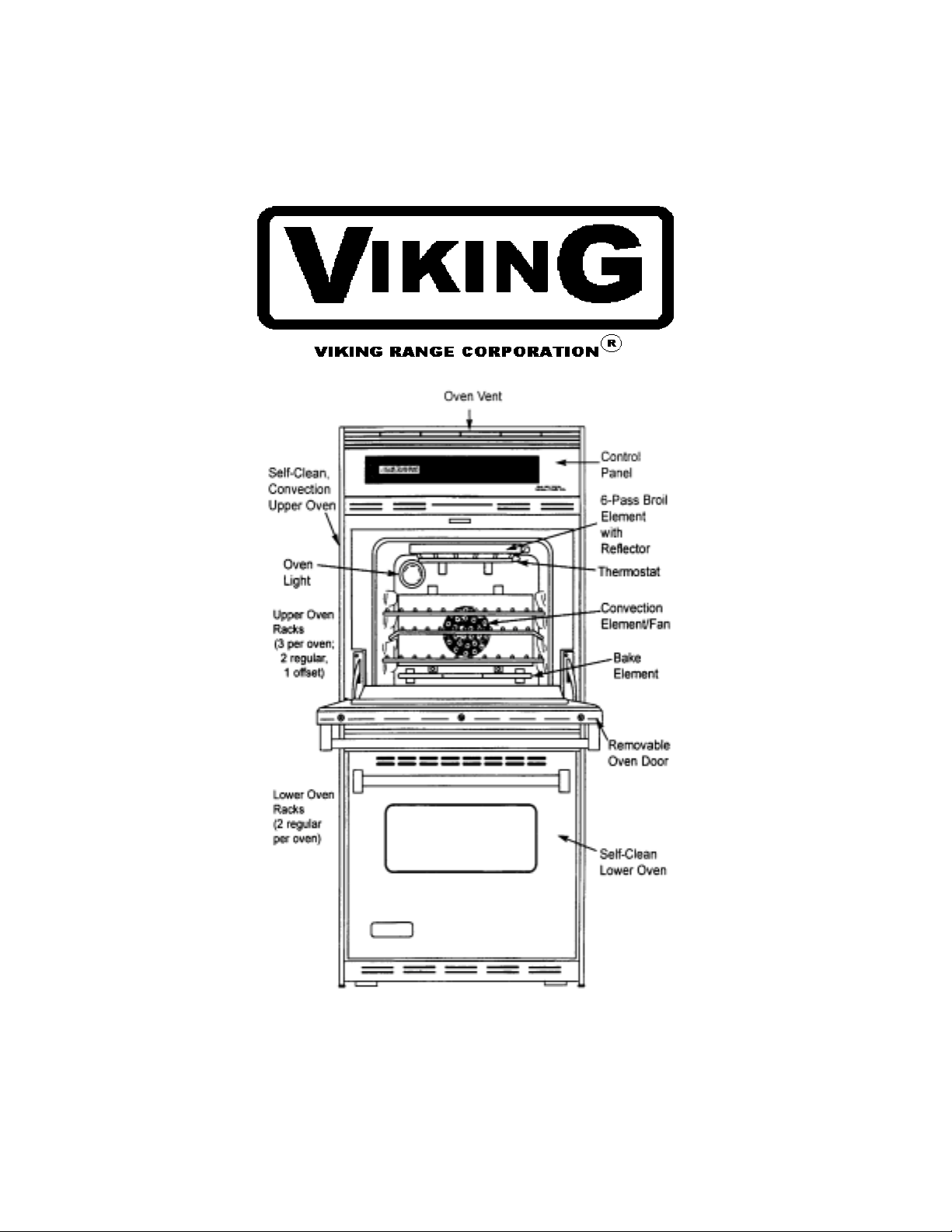

Viking VEDO 273 Service Notebook

SERVICE NOTEBOOK

ELECTRIC WALL OVEN

VEDO 273

VIKING RANGE CORPORATION, P. O. DRAWER 956, GREENWOOD, MS. 38930 - USA

TABLE OF CONTENTS

Important Information.................................... 4

Important Safety Information........................ 5

All Appliances......................................... 5

Self-Cleaning Oven................................. 5

Oven.......................................................... 5

In Case of Fire............................................ 5

Precautions................................................... 5

General Information

Oven Operation--

(Not all models are convection equipped.... 6

Baking Guide.............................................. 6

Prepare to Bake.......................................... 6

Remove Items Stored in Oven................... 7

Oven Racks................................................ 7

Oven Rack Placement................................ 7

Bake Pan Placement.................................. 7

Convection Pan Placement........................ 7

Remove Oven Door.................................. 8

Replacing Oven Light............................... 8

Care and Cleaning

Cleaning Parts........................................... 9

Component Testing Information.................... 10

Testing Procedures

Upper and Lower Limit Control, Limit,

Fan Switch................................................. 11

Oven Temperature Sensor......................... 11

Blower Motor............................................ 11

Auto Latch Motor..................................... 12

Convection Fan Motor.............................. 12

Convection Element Testing..................... 12

Broil Element Testing............................... 12

Bake Element Testing............................... 12

Disassembly Procedures

Removing and Replacing Oven................ 13

Control Panel Assembly........................... 13

Electronic Range Control (ERC).............. 13

Mylar Control Panel................................. 13

Transformer/Relay Board(s)..................... 13

Upper Oven High Limit, Thermal Fan,

Vent High Limit Switches......................... 14

Lower Oven High Limit and Thermal

Fan Switch................................................ 14

Oven Sensor.............................................. 14

Bake Element............................................ 14

Broil Element............................................ 15

Broil Element/Broil Element Reflector.... 15

Convection Heating Element.................... 15

Convection Fan Blade................................... 15

Convection Fan Motor.............................. 15

Upper Oven Door latch/Door Plunger

Light Switch Assembly............................. 15

Lower Oven Doo r Latch/Door Plunger

Light Switch Assembly............................. 15

Oven Light Bulb/Oven Light Socket........ 16

Oven Tank Removal ................................ 16

Oven Door Removal................................. 16

Oven Door Assembly............................... 16

Oven Door Hinges.................................... 17

Blower Motor........................................... 17

Vent Assembly/Smoke Eliminator........... 17

Door Assembly (Exploded View)............ 18

Installation

Packing Material....................................… 19

Oven Location.......................................... 19

Cabinet Opening Double Wall Oven........ 19

Electrical Supply Location....................... 19

Electrical Connection Requirements........ 19

Electrical Connection................................ 20

Place Oven in Wall................................... 20

Removal and Replacement of Oven......... 20

Programming Instructions

Electronic Oven Control Options............. 21

Special Oven Control Functions............... 21

Quick Reference Instructions................... 22

Flashing Display....................................... 23

Setting Electronic Clock........................... 23

Setting Electronic Timer........................... 23

Baking, Convection, or Convection Baking 23

Timed Baking, Convection, or

Convection Baking................................... 23

Delayed Baking, Convection, or

Convection Baking................................... 24

Prepare for Broiling.................................. 24

Broiling or Convection Broiling............... 24

Hold.......................................................... 24

Delayed Slow Baking............................... 25

Defrost...................................................... 25

Dehydration.............................................. 25

Prepare for Self-Clean and

Delayed Self-Clean Cycle......................... 26

Self-Cleaning............................................. 26

Delayed Self-Clean Cycle......................... 26

Adjusting Oven Temperature.................... 26

Service Tones and Codes........................... 26

2

TABLE OF CONTENTS (Continued)

Testing Procedures

Service Information....................................... 27

Quick Test Procedure................................... 27

ERC Warning and Failure Codes................. 27

Temperature Calibration Offset................... 28

Function Switch Connection........................ 28

Check Procedures......................................... 28

Transformer/Relay Board 1 ......................... 28

Double Line Break K6.................................. 28

Bake Relay K4.............................................. 28

Broil Relay K5............................................... 28

Convection Element Relay K2...................... 28

Convection Fan Relay K1............................ 28

Oven Light Relay K10................................. 29

Door Lock Relay K3................................... 29

Display (Filament) Voltage........................... 29

Relay Board 2................................................ 29

Double Line Break K1.................................. 29

Bake Relay K2.............................................. 29

Broil Relay K3.............................................. 29

Door Lock Relay K4..................................... 29

Component Testing Information....................30 Thru 33

Wiring Diagram........................................... 34

3

IMPORTANT INFORMATION

Pride and workmanship go into every product to provide our customers with quality products. It is possible,

however, that during its lifetime a product may require service. Products should be serviced only by a

qualified service technician wh o is familiar with the safety procedures required in the repair and who is

equipped with t he proper tools, parts, te sting i nstrume nts and t he a ppr opr iat e s er vic e m an ual . REVIEW ALL

SERVICE INFORMATION IN THE APPROPRIATE SERVICE MANUAL and TECHNICAL

SHEETS BEFORE BEGINNING REPAIRS.

Important Notice for Consumers and Services

WARNING

To avoid risk of serious injury or death, repairs should not be attempted by an unauthorized personnel,

dangerous conditions (such as exposure to electrical shock) may result.

CAUTION

VIKING will not be responsible for any injury or property damage from improper service

procedures. If performing service on your own product, assume responsibility for any personal

injury or property damage which may result.

To locate an authorized servicer, consult the dealer from whom you purchased this product. For

further assistance, call:

Viking Preferred Service

Phone # 601-451-4133

Address your written correspondence to: Viking Preferred Service

111 Front Street

P. O. Drawer 956

Greenwood, MS. 38935-0956

Recognize Safety Symbols, Words, and Labels

Danger-Immediate hazards which WILL result in severe personal injury or death

Warning-Hazards or unsafe practices which COULD result in severe personal injury

or death

CAUTION-Hazards or unsafe practices which COULD result in minor personal injury

or product or property damage.

4

Important Safety Information

To avoid personal injury , do n ot

sit or stand or lean on oven door.

To avoid risk of elect rica l sh ock ,

personal injury, or death, make

sure your oven has been

properly grounded and always

disconnect it from main power supply before any

servicing.

This appliance contains or

produces a chemical or

chemicals which can cause

death or serious illness and w hich a re know n

to the state of California to cause c ance r, bi rth defe cts

or other reproductive harm .. To reduce th e risk f rom

substances in the fu el or f rom fuel combustion make

sure this appliance is installed, operated, and

maintained according to the instructions in this

booklet.

ALL APPLIANCES

1. Proper installation - Be sure your appliance is

properly installed and grounded by a qualified

technician.

2. Never use appliance for warming or heating the

room.

3. Do not leave Children alone - Children should not

be alone or unattended in the area where the

appliance is in use. They should never be allowed

to sit or stand on any part of the appliance.

4. Wear proper apparel - loose fitting or hanging

garments should never be worn while using

appliance.

5. User servicing - Do not repair or replace any part of

the appliance unless specifically recommended in

the manual. All other servicing should be referred

to a qualified technician.

6. Storage in or on appliance - Flammable materials

should not be stored in oven.

7. Do not use water on gre ase fir es - smothe r fire s or

flame, or use dry chemical or foam-type

extinguisher.

8. Use only dry potholders - mois t or dam p potholders

on hot surfaces may result in burns f rom st eam. Do

not let potholders touch burners. Do not use a t owe l

or other bulky cloth.

SELF - CLEANING OVEN

1. Do not clean door gasket. The door gasket is

essential for a good seal. Care should be taken not

to rub, damage, or move the gasket.

2. Do not use oven cleaners. No commercial oven

cleaner or oven liner protective coating of any ki nd

should be used in or around any part of the liner.

3. Clean only parts listed in manual. See CLEANING

section.

4. Before self-cleaning the oven, remove broiler pan,

oven racks, and other utensils.

Oven

1. Use care when opening door, let hot air or steam

escape before removing or replacing food.

2. Do not heat unopened food containers, build-up of

pressure may cause container to burst and result in

injury.

3. Keep oven vent ducts unobstructed.

4. Placement of oven racks. Always place racks in

desired location while oven is cool. If rack is

removed while oven is hot, do not let potholder

contact hot oven.

In Case of Fire

Fires can occur as a result of over cooking or exces sive

grease. Though a fire is unlikely, if one occurs,

proceed as follows:

Oven Fires

1. If you see smoke from oven, do not open oven door.

2. Turn oven control to OFF.

3. As an added precaution, turn off power at main

circuit breaker or fuse box.

4. Turn on vent to remove smoke.

5. Allow food or grease to burn itself out in oven.

6. If smoke and fire persist, call fire department.

7. If there is any damage to components, call repair

service before using oven.

Precautions

• Do not mix household cleaning products. Chemical

mixtures may interact with objectionable or even

hazardous results.

• Do not put plastic items on warm cooking areas.

They may stick and melt.

• Do not use damp sponge or dishcl oth t o clean ov en

when oven is hot. Steam from sponge or dishcloth

can burn.

• Do not leave fat heating unless you remain nearby.

Fat can ignite if overheated by spilling onto hot

surfaces.

5

GENERAL INFORMATION

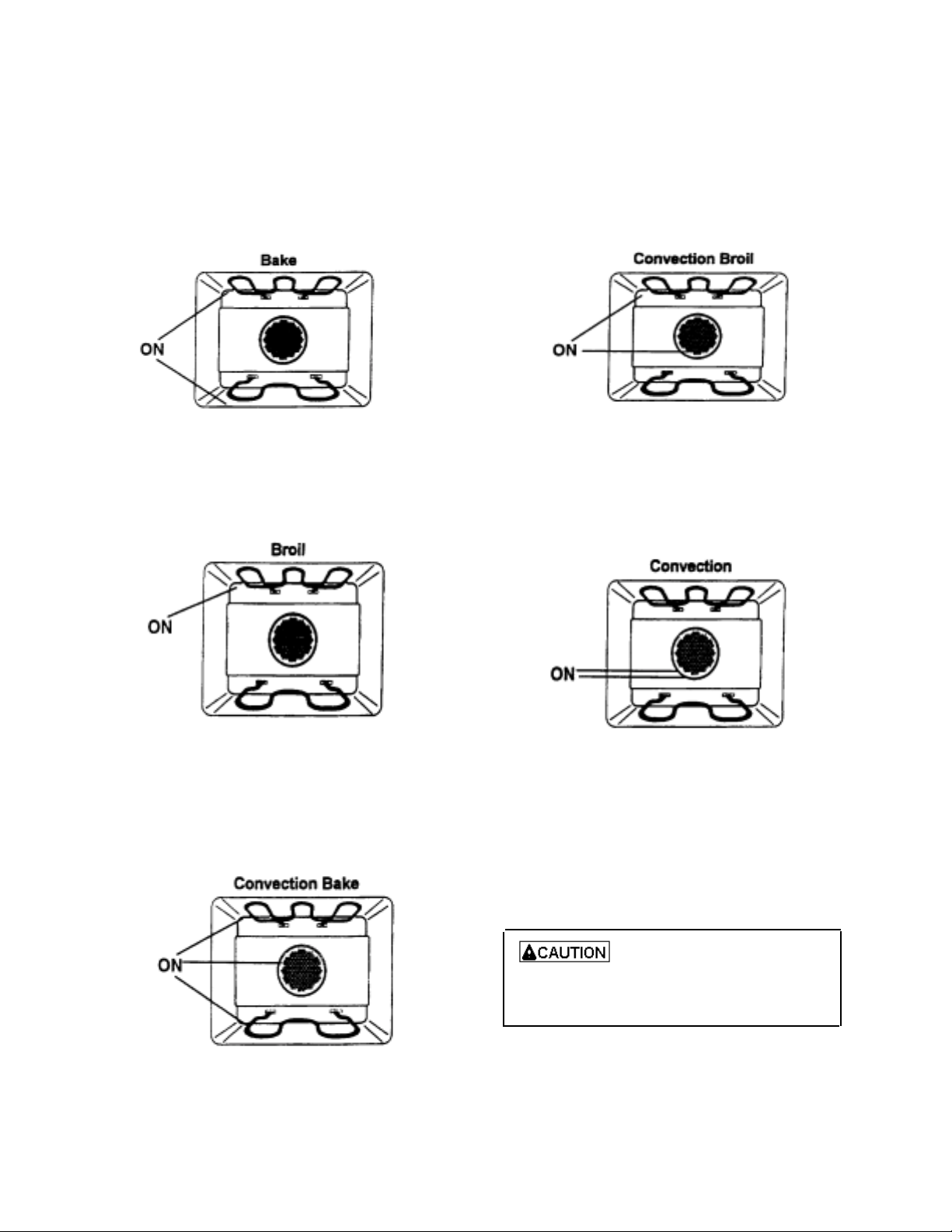

Oven Operation - (not all models are convection

equipped)

Bake

Top and bottom elements operate during bake. Bake

can be used to cook foods which are normally baked.

Oven must be preheated.

Convection Broil

Top elements and fan operate when using convection

broil. Convection broil can be used to cook foods that

are normally broil ed. Oven does not requ ire prehe ati ng

when usi ng convect ion broil. Food does n ot need to be

turned during broiling. Cooks approximately 25%

quicker than broil.

Broil

Top element operates durin g broil. Broil can be use d to

cook foods which are normally broiled. Preheating is

not required when using broil. All foods should be

turned at least once except fish, w hich does not need to

be turned.

Convection Bake

Upper element, lower element, and fan operate during

convection bake. Convection bake should be used for

cooking casseroles and roastin g meats. Oven sh ould be

preheated for best results w hen usin g conv ection bake.

Pans do not need to be staggered. Cooks approximatel y

25% quicker than bake.

Convection

Rear element and fan operate during convection.

Convection should be used for cooking pastries,

souffles, yeast bread, cakes and cook ies. Ov en s h ou ld

be preheated for best results when using convection.

Pans do not need to be staggered. Cooks approximatel y

25% quicker than bake.

Baking Guide

Refer to owners manual, for following

recommendations only as a guide for times and

temperature. Times, rack position, and

temperatures m ay vary depending on conditions

and food type. For best results, alway s ch eck food

at minimum time. When roasting, choose rack

position based on size of food item.

Prepare to Bake

To reduce risk of food poisoning

due to bacterial growth and pro duction of toxins, never hold

meat, milk, fish or eggs for more

than 2 hours before baking.

6

GENERAL INFORMATION

Remove Items Stored in Oven

Remove any pans and ot her co o king ute nsils st or ed i n

oven.

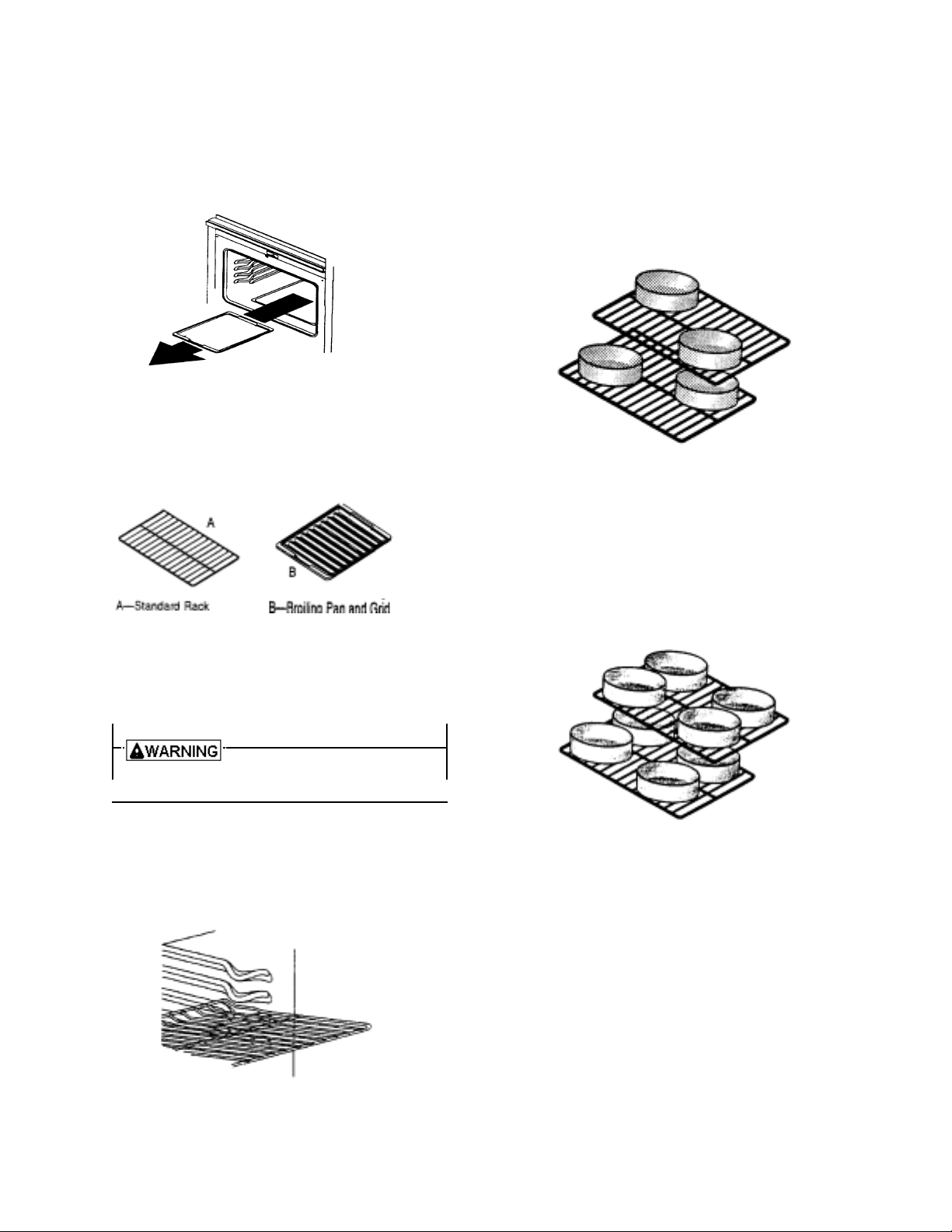

Oven Racks

Use Standard rack for normal baking and broiling.

Oven Rack Placement

Position oven rack before turning oven on.

To avoid damaging oven liner or

creating fire, do not line oven bottom

or racks with foil.

1. Pull rack forward to stop position.

2. Raise front edge of rack and pull until rack is out of oven.

3. Place rack in new rack position.

• Curved edge of rack must be toward rear of oven.

Bake Pan Placement

• Keep pans and baking sheets 2 inches from oven walls.

• Stagger pans placed on different racks so one is not

directly over the other.

Convection Pan Placement

Baking pans and cookie sheets should not touch side or rear

walls of oven. If pans are placed on different racks, they can

be placed directly over each other. Convection baking

circulates air around oven providing even browning on all

rack positions. When using convection, oven can be loaded

on all racks with excellent baking results.

7

GENERAL INFORMATION

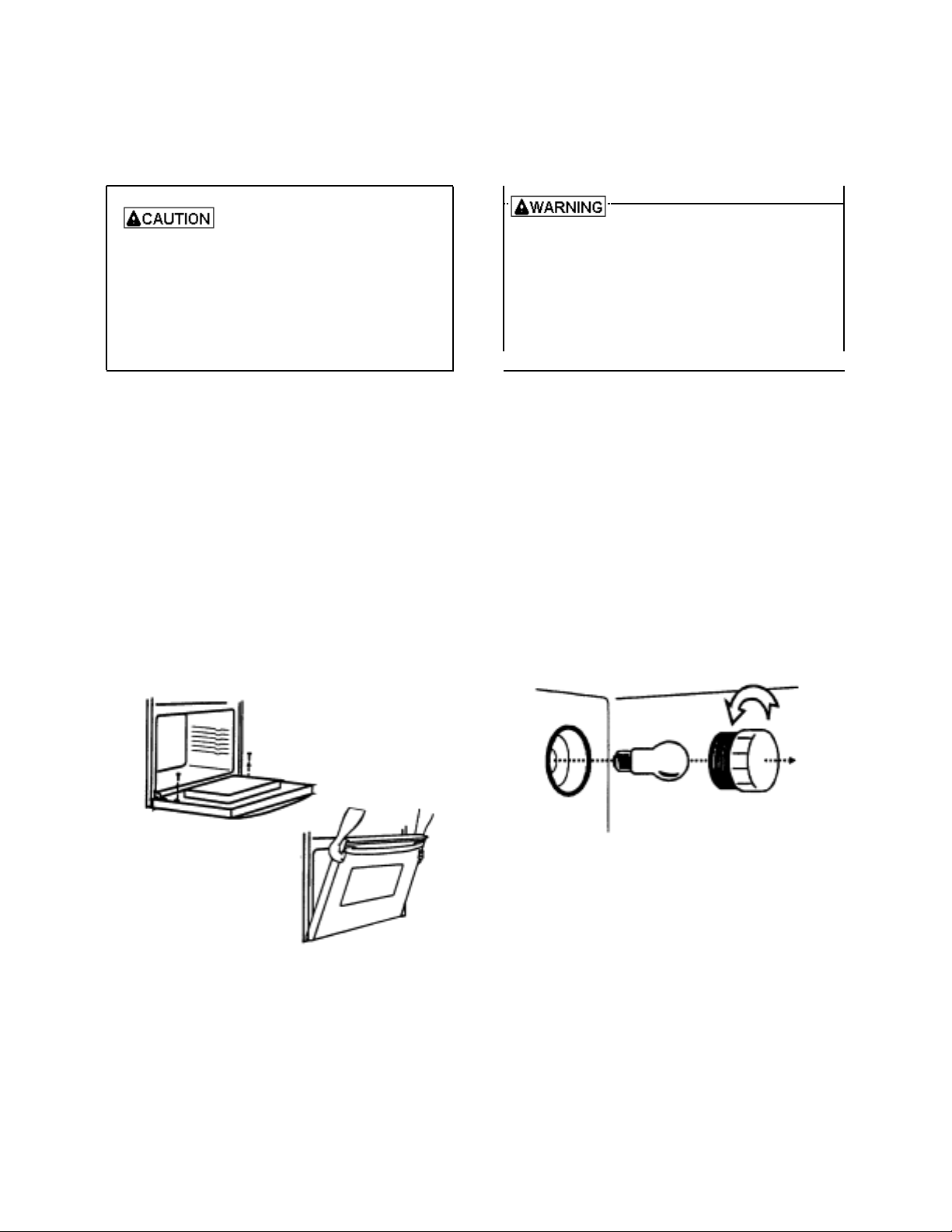

Removing Oven Door

To avoid personal injury or property

damage, handle ov en door w ith care .

• Door is heavy and can be damaged if dropped.

• Avoid placing hands in hinge area when door is

removed. Hinge c an snap closed and pi nch hands.

• Do not scratch or chip glass, or twist door.

Glass may break suddenly.

• Replace door glass if damaged.

• Do not lift door by handle.

1. Open door fully.

2. Remove screws .

• Oven doors are attached with a screw on each

side of oven door.

3. Close door to first stop, grasp door firmly on each

side and lift upward until door is off hinges.

• Do not lift door by handle, glass or handle can

break.

• Only push hinges closed once oven door is

removed if necessary. Use both hands when

closing hinge. Hinge snaps closed.

Replacing Oven light

To avoid risk of burns or electrical

shock, disconnect electrical supply to oven

before cha nging light bulb.

• Before repla cing light bulb make sure bulb and

lens are cool.

• Wear protective gloves.

• Do not operate oven without bulb and lens cov er

in place.

1. Disconnect electrical supply.

2. Remove oven door if desired.

3. Unscrew light bulb cover (counterclockwise) located

in rear of oven cavity. Then turn light bulb

counterclockwise to remove.

4. Replace light bulb with 120 volt, 40 watt appliance

bulb.

• Do not over tighten bulb or cover. They may be

difficult to remove later.

5. Replace light bulb cover and oven door before use.

6. Reconnect power supply.

8

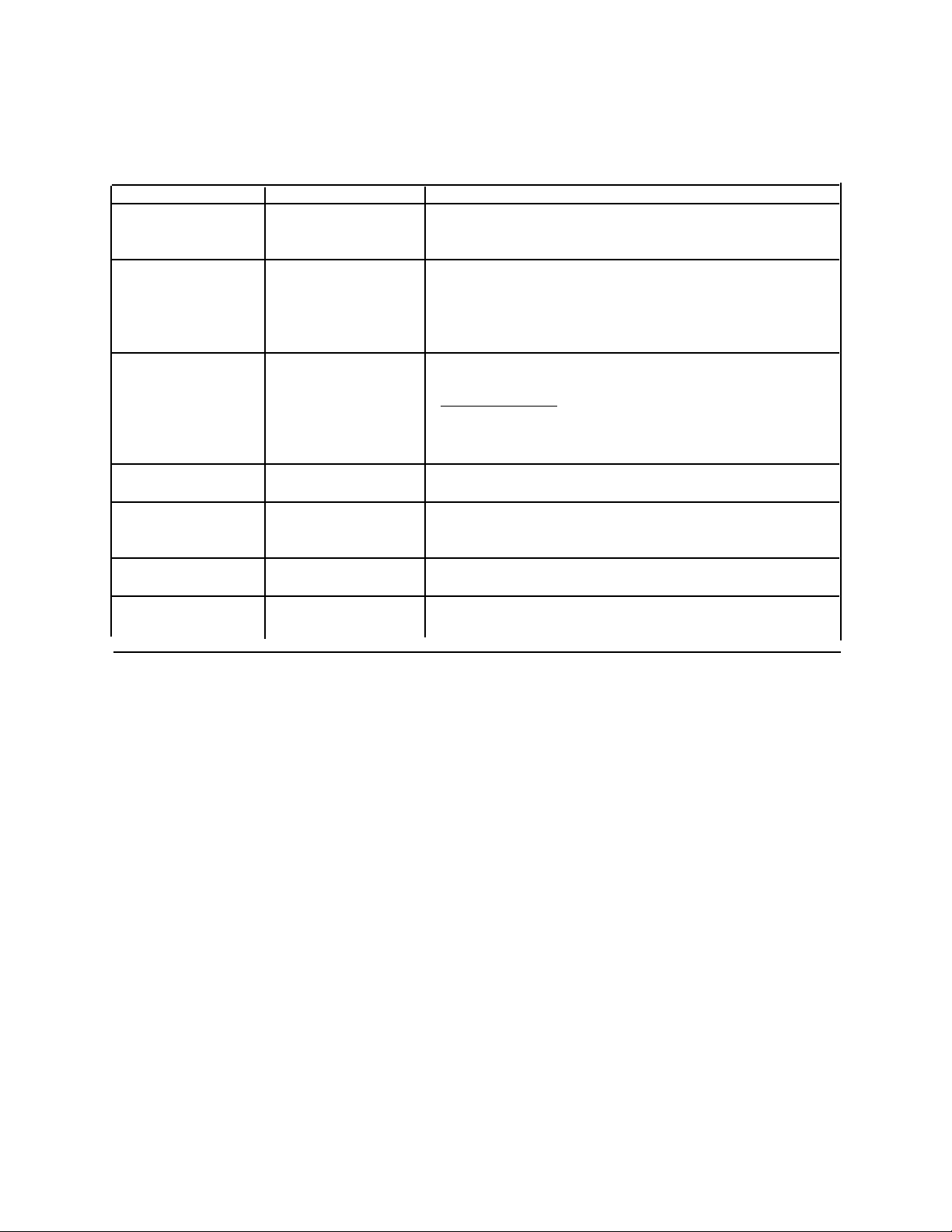

CARE AND CLEANING

Cleaning Oven Parts

Part Material to Use General Directions

Heating elements Do not clean. Any food on element will burn off.

Broiler pan and grid Soap and a non- Drain fat, cool pan and grid slightly. (Do not let soiled pan and

abrasive plastic grid stand in oven to cool.) Sprinkle with soap. Fill the pan

scouring pad. with warm water. Let pan and grid stand for a few minutes.

Wash or scour if necessary. Rinse and dry. The broiler pan

and grid may also be cleaned in the dishwasher.

Inside oven door Soap and water Clean the outside of the door and the window area with warm

soapy water.

Oven Door Gasket

Do not clean the braided oven door gasket. Gasket should not

be moved while cleaning. Avoid getting any cleaning material

on gasket.

Outside finish Soap and water Wash all glass with cloth dampened in soapy water. Rinse and

polish with a dry cloth.

Oven interior Soap and water Cool before cleaning. Frequent wiping with m ild soap and w ater

surfaces prolongs time between self - cleanings. Be sure to rinse

thoroughly. Clean excess spills b efore self - cleaning.

Control panel Soap and water Wash with cloth dampened in soapy water. Rinse and polish

with a dry cloth.

Oven racks Soap and water For heavy soil, cle an by hand and rinse racks thoroughly for

ease in cleaning. Be sure racks are dry before replacing.

9

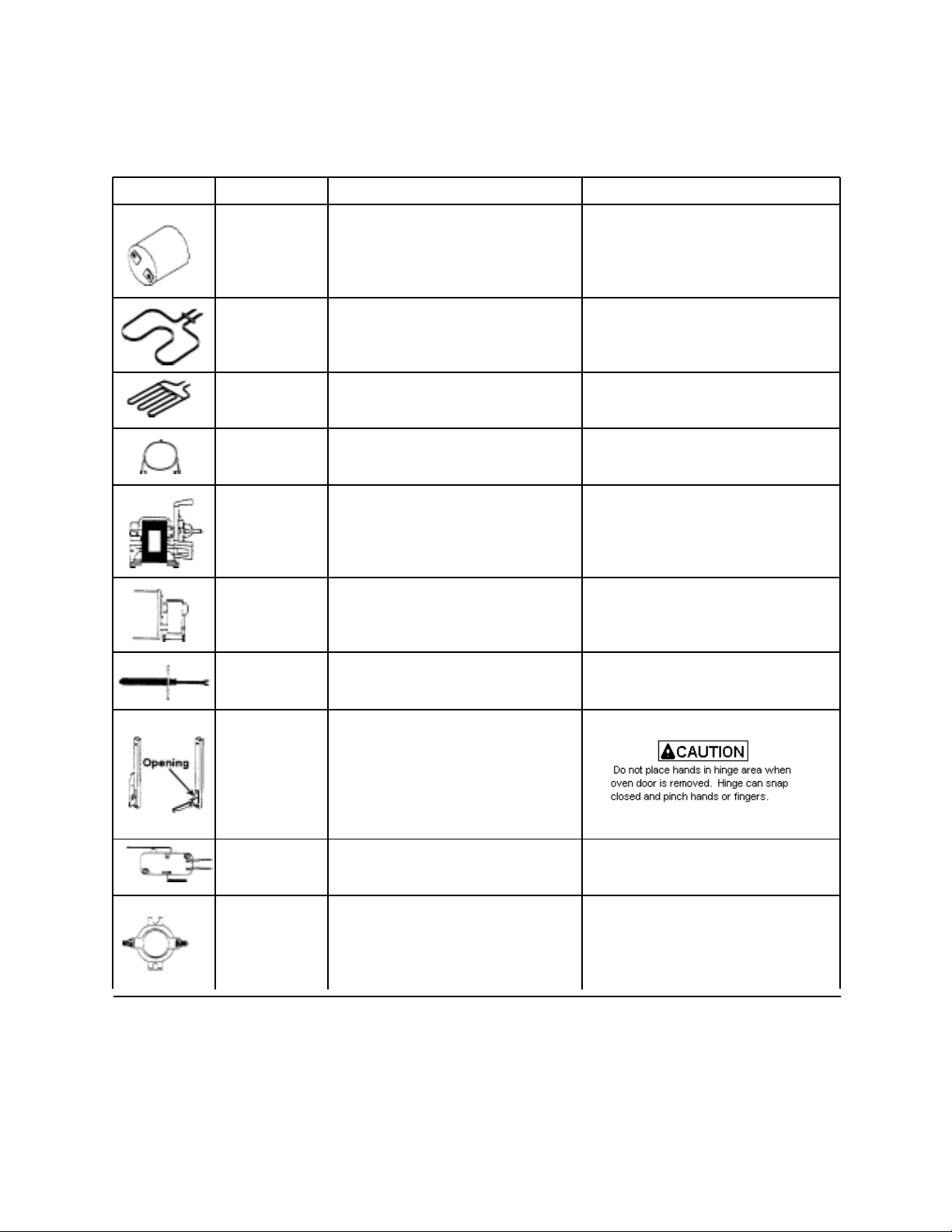

COMPONENT TESTING INFORMATION

To avoid risk of electrical shock, per sonal injur y, or death, discon nect power to oven befor e servicing, u nless tes ting

requires it.

Illustration Component Test Procedure Results

Oven light socket Test continuity of receptacle terminals. Indicates continuity with bulb screwed in.

Measure voltage at oven light. 120 VAC, see wiring diagram for terminal

identification.

If no voltage is present at oven light,

check wiring.

Bake element Disconnect wire terminals and test

voltage to terminals. 240 VAC

Test continuity of element. Indicates continuity.

Broil element Disconnect wire terminals and test

voltage to terminals. 240 VAC

Test continuity of element. Indicates continuity.

Convection Disconnect wire terminals and test

element voltage to terminals. 240 VAC

Test continuity of element Indicates continuity

Convection Verify supply voltage. 120 VAC

motor Disconnect wiring and check Continuity at wire terminals.

fan continuity of motor at the terminals, No continuity from wire terminals to

and verify terminals are not shorted chassis.

to chassis.

Blower motor Verify supply voltage. 120 VAC

Disconnect wiring and check continuity Continuity at terminals.

of motor at the terminals, and verify No continuity from wire terminals to

terminals are not shorted to chassis. chassis.

Heraeus sensor Measure resistance Approximately 1100Ώ at room

temperature 75°F.

Hinge Carefully open the hinge fully, and

insert a wooden dowel or screwdriver

bit into opening. Remove top and

bottom screws securing hinge. Slide

hinge top toward rear of unit and guide

hinge out through frame opening or

storage drawer.

Door lock Switch connection in following position

switch or Unlocked COM-NO=Open, COM-NC=Closed

light switch Locked / Actuated COM-NO=Closed COM-NC=Open

Controls if Verify proper operation. Normally Open

equipped with: 042045 Control limit upper oven Open at 220°F, Closes at 170°F

042056 Fan switch Open at 120°F, Closes at 150°F

042066 Limit switch Open at 90°F, Closes at 100°F

31852801 Control limit lower oven Open at 240°F, Closes at 210°F

10

TESTING PROCEDURES

To avoid risk of electrical shock, personal

injury, or death, disconnect power to unit

before servicing, unless testing requires it.

Upper and Lower Limit Control, Limit, Fan Switch

Upper limit control 200°F 170°F

Lower limit control 120°F 150°F

Limit switch 90°F 100°F

Fan switch 240°F 210°F

Open Close

1. Turn off power to range.

Control.

Following is approximate resistance:

75°F -- 1082 ohms

350°F -- 1656 ohms

550°F -- 2056 ohms

880°F -- 2686 ohms

Sensor resistance can be checked by removing the

sensor interconnect harness plug from the ERC and

inserting ohmmeter leads into the harness connector

plug. A resistance reading of approximately 1100 ohms

should be indicated at ambient room temperature

(75°F). If a higher resistance is in dicated then remove

sensor from oven, disconnect sensor from harness at

plug, and recheck sensor resistance to assure that the

problem is in the sensor and not in the interconnect

harness or due to a bad connection.

2. Remove oven from wall cutout.

3. Remove screws securing cabinet top shield to outer

cabinet wrapper shield.

4. Disconnect wires from switch terminal conn ecti ons.

5. Attach ohmmeter leads to switch terminals. At

ambient room temperature (70°F.) continuity should

be indicated.

Oven Temperature Test

The following procedures should be used to verif y oven

temperature calibration.

• Verify oven door is adjusted and sealing properly.

• Do not cover the oven racks or oven bottom with

foil.

1. Acquire a 8 1/2x 11 inch piece of aluminum foil.

2. Fold the aluminum foil five times, doubling the

thickness with each fold.

3. After the fifth fold, place the thermocouple tip into

the center of the foil and fold over the

thermocouple. Fold the ends of the foil sides to

NOTE: Sensor resistance will increase if held in your

hand.

1. Disconnect power to oven.

2. Disconnect sensor harness plug from ERC.

3. Connect meter leads into harness connector plug,

resistance should be approximately 1100 ohms at

room temperature 75°F.

• If a higher resistance is indicated remove sensor

from oven. Dis connect sens or from har nes s at th e

plug, recheck sensor resistance to assure the

problem is in the sensor and not in the

interconnecting harness, or due to a bad

connection.

NOTE: Sensor resistance will increase if held in your

hand.

Blower Motor

attach foil to thermocouple.

4. Place the oven rack in the center of the oven cavity.

Position thermocouple on the center of the rack.

5. Turn oven to 350°F and allow to cycle for 25 to 30

minutes. Oven should cycle between 330°F to

370°F.

Oven Temperature Sensor

Detail testing can be accomplished as follows: The

oven temperature sensor is mounted in the oven cavity

and electrically connected to the Electronic Range

Fan may come on at any time to cool components.

1. Turn off power to oven.

2. Remove oven from wall cutout.

3. Remove screws securing outer cabinet top shield to

outer cabinet wrapper shield.

4. Disconnect wires from motor terminal connectors.

5. Attach ohmmeter leads to terminal tabs on motor.

6. A resistance of ohms should be indicated but may

vary with each motor tested. This test is to check

the motor winding fo r a n o p en o r shor te d winding.

If zero or infinite ohms is indicated, the motor

11

Loading...

Loading...