Page 1

January 6, 2012

Preaction 328a

TECHNICAL DATA

The Viking Corporation, 210 N Industrial Park Drive, Hastings MI 49058

Telephone: 269-945-9501 Technical Services: 877-384-5464 Fax: 269-818-1680 Email: techsvcs@vikingcorp.com

WITH ELECTRIC RELEASE

1. DESCRIPTION

The 2” Model G-2000P Preaction System with Electric Release can be used as a Single

Interlock Preaction System with Electric Release, or as a Double Interlock Preaction System

with Electric/Pneu-Lectric Release. These preaction systems are commonly used where it isThese preaction systems are commonly used where it is

important to control accidental water discharge due to inadvertent damage to the sprinkler

piping. The small profile, lightweight, pilot operated Viking G-2000P Valve comes completeThe small profile, lightweight, pilot operated Viking G-2000P Valve comes complete

as shown in Figure 8. This pilot-operated externally reset valve also includes an internal

check diaphragm, which eliminates the need for a separate check valve being installed

in the system riser.

A. Viking Supervised Single-In terlock ed Electric Rel ease Preaction Systems

Utilizing the Viking G-2000P Valve.

The system piping is pressurized with air or nitrogen as required by NFPA 13 for supervisory purposes only. Viking recommends a minimum of 15 to 20 PSI (1.0 to 1.4

bar) for supervisory air pressure for single interlock systems (refer to Table 2 for double

interlock systems). This feature serves to prevent undetected leaks on the system piping network. If the system piping or a sprinkler is damaged, the supervisory pressure is

reduced and a “low air” supervisory alarm is activated.

Electrically released preaction systems require a 24 VDC normally closed electric solenoid valve controlled by an approved release control panel with compatible detection

system. In fire conditions, when the detection system operates, the system control

panel energizes the solenoid valve open. When the solenoid opens, the priming water is relieved from the internal prime chamber

assembly. The prime chamber assembly collapses, and water passes through the G-2000P Valve and internal check diaphragm

to the system piping network. The entire sprinkler system fills with water. The sprinkler piping will remain filled with water until a

sprinkler operates.

B. Viking Supervised Double-Interlocked Electric/Pneu-Lectric Release Preaction Systems Utilizing the Viking G-2000P

Valve.

The system piping is pressurized with air or nitrogen to serve both as a means of supervising the integrity of the piping network

and as one portion of the system release operation. This feature serves to prevent undetected leaks on the system piping network. If the system piping or a sprinkler is damaged, the supervisory pressure is reduced and a “low air” supervisory alarm is

activated.

The 24 VDC normally closed electric solenoid and an additional “low air” alarm switch are connected to a compatible release24 VDC normally closed electric solenoid and an additional “low air” alarm switch are connected to a compatible releaseelectric solenoid and an additional “low air” alarm switch are connected to a compatible release

control panel and compatible detection devices. The release control panel is programmed so that a signal from both a release

device and the low air alarm switch must be received before the solenoid is allowed to open. The air pressure switch has two

independently operating connections. The high side is wired as a low air supervisory switch, and the low side is wired as low air

alarm. In fire conditions, a detection device and the low air alarm switch must operate in order to open the solenoid valve. When

the solenoid opens, priming water is relieved from the G-2000P Valve’s internal prime chamber assembly. The prime chamber

assembly is forced open by the system water supply and water passes through the G-2000P Valve and internal check diaphragm

to the system piping network. The entire sprinkler system fills with water.

2” MODEL G-2000P PREACTION

2. LISTING AND APPROVALS

cULus Listed: VLFT

FM Approved: Preaction Sprinkler Systems

3. TECHNICAL DATA

Specifications:

Pressure Rating: 250 PSI (17.2 bar) Water Working Pressure

Factory Hydrostatically Tested to: 500 PSI (34.5 bar)

Friction Loss (Given in feet of Schedule 40 pipe based on Hazen & Williams formula C = 120):

G-2000P Valve - 8.5’

10” Section of Pipe - 1’

Water Supply Control Valve: 1.9’

Model G-2000P Valve Cv Factor: 115.6

Valve Color: Black

Material Specifications:

Refer to Figure 11.

Form No. F_011310

Q = C

Q = Flow

C

= Flow Factor (GPM/1 PSI ∆P)

v

∆P = Pressure Loss through Valve

S = Specific Gravity of Fluid

Viking Technical Data may be found on

The Viking Corporation’s Web site at

http://www.vikinggroupinc.com.

The Web site may include a more recent

edition of this Technical Data Page.

Replaces page 328a-m, dated July 1, 2011.

(Revised the replacement parts list and Figure 11.)

v

√

S

∆P

Page 2

Preaction 328b

January 6, 2012

TECHNICAL DATA

The Viking Corporation, 210 N Industrial Park Drive, Hastings MI 49058

Telephone: 269-945-9501 Technical Services: 877-384-5464 Fax: 269-818-1680 Email: techsvcs@vikingcorp.com

Table 1 - Pipe Capacity for Sizing Air Compressors

Pipe Diameter Capacity

Schedule 40 (1” to 6”)

US International

1” DN25 0.045 0.559 0.049 0.608

1-1/4” DN32 0.078 0.969 0.085 1.043

1-1/2” DN40 0.106 1.316 0.115 1.428

2” DN50 0.174 2.161 0.190 2.360

2-1/2” DN65 0.248 3.080 0.283 3.515

3” DN80 0.383 4.756 0.434 5.390

3-1/2” DN90 0.513 6.370 0.577 7.165

4” DN100 0.660 8.196 0.740 9.190

5” DN125 1.040 12.915 1.144 14.206

6” DN150 1.501 18.640 1.649 20.477

8” DN200 2.660 33.032 2.776 30.472

For Metric Units 1 Ft. = 0.3048 M, 1 Gal. = 3.785L

Ordering Information:

Available since 2010

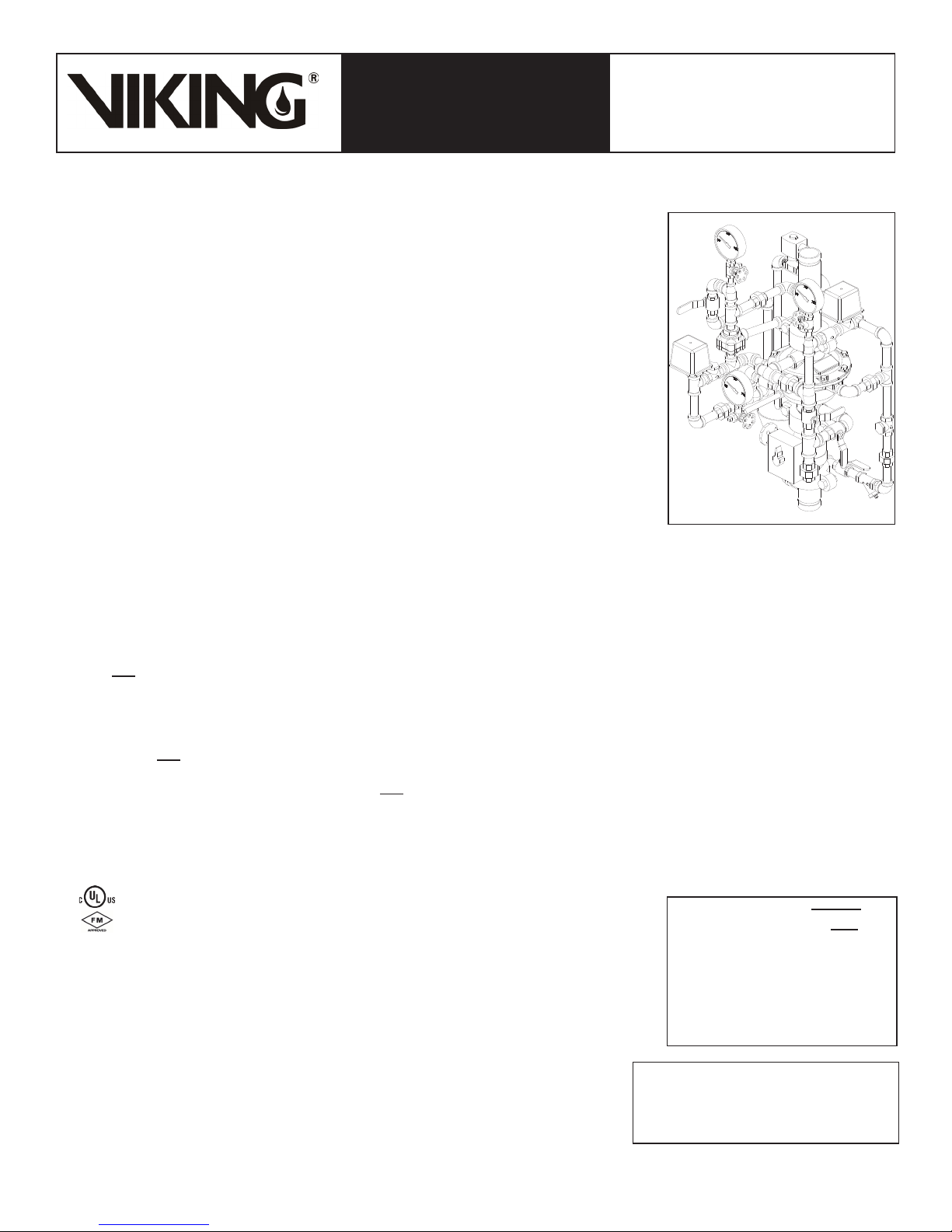

Part Number: Electric Release Preaction Riser Assembly: 16187-1

(Refer to Figure 8)

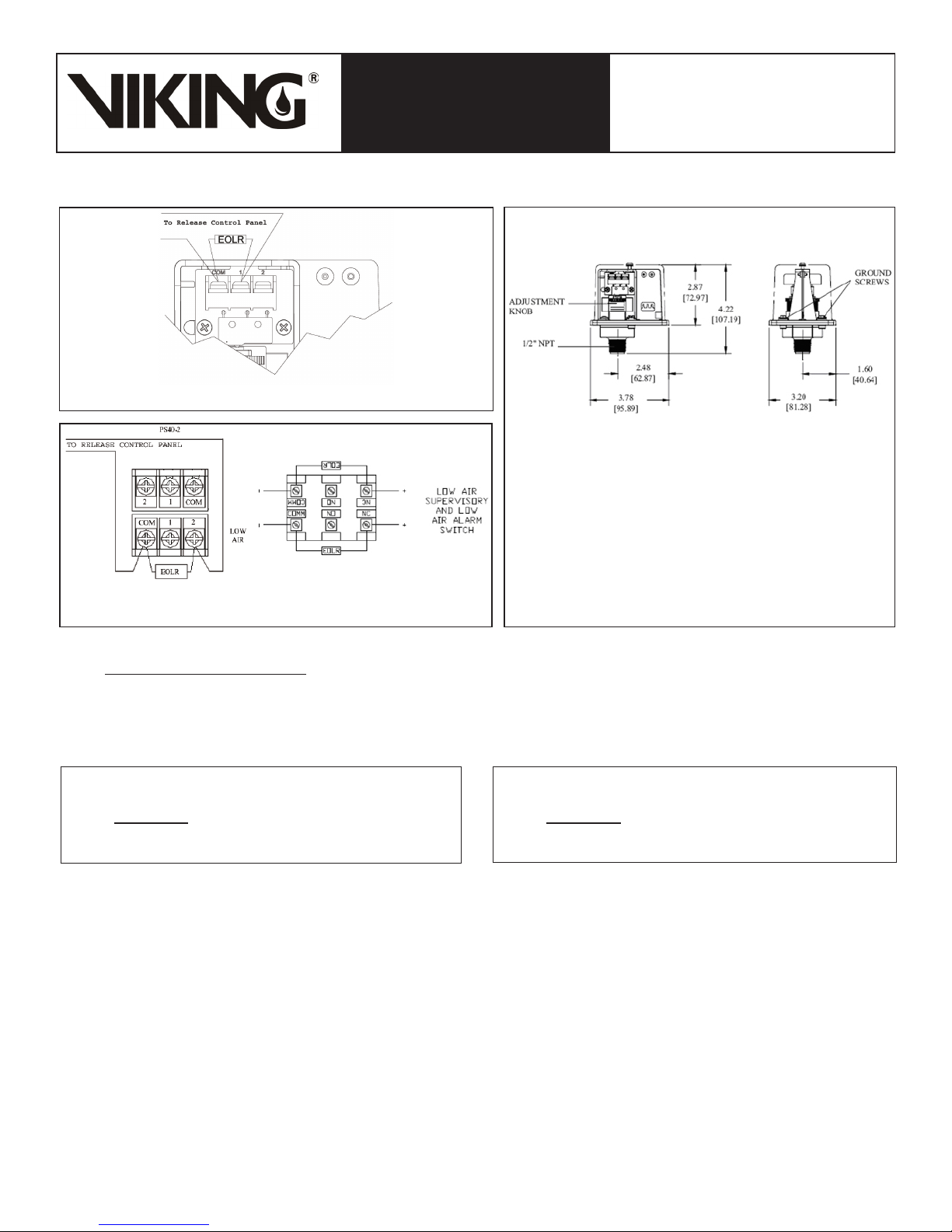

Accessories: (See Figure 9)

Drain Manifold: 16211

Model E-1 Accelerator: 08055

Model LD-1 Anti-Column Device: 14800

Schedule 30 (8”)

Gal / Ft L / m Gal / Ft L / m

Schedule 10

Air Maintenance

Supervisory Switch

Compressor On/Off

Supervisory Switch

Table 3 - Quick Reference Compressor Size

Compressor

Size (HP)

Table 2 - Air Pressure Settings

For Systems with Tank-Mounted Compressors:

Device

Air Pressure

Low Air Alarm

Switch

For Systems with Riser-Mounted Compressors:

Switch

Air Pressure

Low Air Alarm

Switch

1/6 1.0 90

1/3 2.0 180

1/2 3.1 300

1 5.9 600

WITH ELECTRIC RELEASE

Single Interlock Double Interlock

20 PSI (1.4 bar) 30 PSI (2.1 bar)

15 PSI (1.0 bar) 25 PSI (1.7 bar)

-- 20 PSI (1.4 bar)

15 PSI (1.0 bar) /

25 PSI (1.7 bar)

10 PSI (.7 bar) 25 PSI (1.7 bar)

-- 20 PSI (1.4 bar)

Free Air @

40 PSI (2.8 bar)(2.8 bar)

(cfm)

Pump to 40 PSI (2.8 bar)(2.8 bar)

30 PSI (2.1 bar) /

40 PSI (2.8 bar)

Max System Size to

in 30 Minutes (Gal)

2” MODEL G-2000P PREACTION

4. INSTALLATION:

A. General Installation Instructions:

1. For proper operation and approval, the valve must be installed in the vertical position as trimmed from the factory. DO NOT

modify the factory assembled trim except as described in this technical data sheet.

2. A 10” section of pipe is provided with the G-2000P Electric Release Preaction Riser Assembly. Prior to valve maintenance,

this section of pipe may be removed to provide clearance for lifting the cover from the body.

3. The G-2000P Valve must be installed in an area not subject to freezing temperatures or physical damage. If required, provide

a valve house (enclosure) with adequate heat around the valve and trim. Freezing temperatures will damage the G-2000P

Valve. When corrosive atmospheres and/or contaminated water supplies are present, it is the owner’s responsibility to verify

compatibility with the Model G-2000P Valve and associated equipment.

4. The Viking Model E-1 Accelerator should be installed at the location indicated in Figure 1 when required. Note: The accelerator would only be used for Double Interlock Systems.

B. Air Supply Design:

1. Air Compressor Size

Viking recommends a minimum of 15 to 20 PSI (1.0 to 1.4 bar) of supervisory pressure be established within the piping network

for single interlock systems (refer to Table 2 for double interlock systems). While lower pressures are allowed by NFPA 13 for

single interlock preaction systems, maintaining higher air pressure within the system will assist maintenance personnel in finding

and isolating inadvertent or accidental leaks within the system quickly.

NFPA 13 requires that the air supply be capable of filling the entire sprinkler system to its required air pressure within 30 minutes.

A common method of sizing an air compressor is to use the following formula:

Compressor

Size (cfm) =

V x P

7.48 x 14.7 x T

Where:

V = Volume

P = Required Air Pressure

T = Fill time (typically 30 min.)

7.48 = gal. / ft.

14.7 = atmospheric pressure

3

Example:

System volume as determined by table 1 = 750 gallons

Required Air pressure = 20 PSI (1.4 bar) (Single Interlock

System)

Compressor Size (cfm) =

(750 x 20)

7.48 x 14.7 x 30

= 4.5 cfm

Therefore, the compressor shall be capable of providing 5 cfm.

Page 3

January 6, 2012

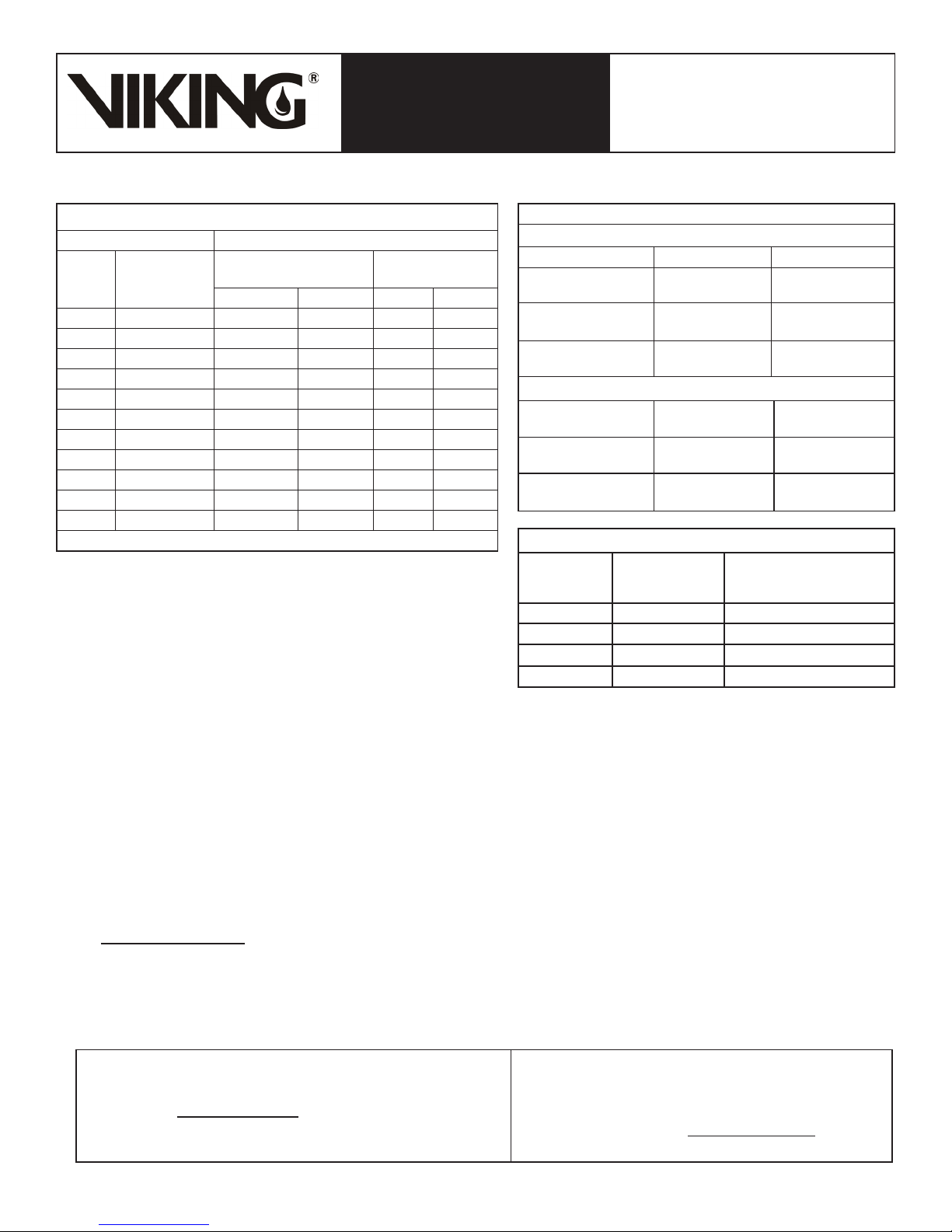

Tank Mounted Air Riser Mounted Air

Riser Mounted Air

Compressor

Tank Mounted Air

Compressor

Pressure

Relief

Valve

Viking Model D-2 Air Maintenance

Device

Warning - Do not allow pressures

in excess of 175 psi from reaching

the AMD.

Nitrogen

Regulator*

Pressure

Relief

Valve

Nitrogen

Bottle*

Nitrogen Air Supply Option

* Not provided by

Viking

Compressor Option

Compressor Option

Preaction 328c

TECHNICAL DATA

The Viking Corporation, 210 N Industrial Park Drive, Hastings MI 49058

Telephone: 269-945-9501 Technical Services: 877-384-5464 Fax: 269-818-1680 Email: techsvcs@vikingcorp.com

WITH ELECTRIC RELEASE

2” MODEL G-2000P PREACTION

Figure 1 - Air Supply Options

Page 4

Preaction 328d

January 6, 2012

TECHNICAL DATA

The Viking Corporation, 210 N Industrial Park Drive, Hastings MI 49058

Telephone: 269-945-9501 Technical Services: 877-384-5464 Fax: 269-818-1680 Email: techsvcs@vikingcorp.com

WITH ELECTRIC RELEASE

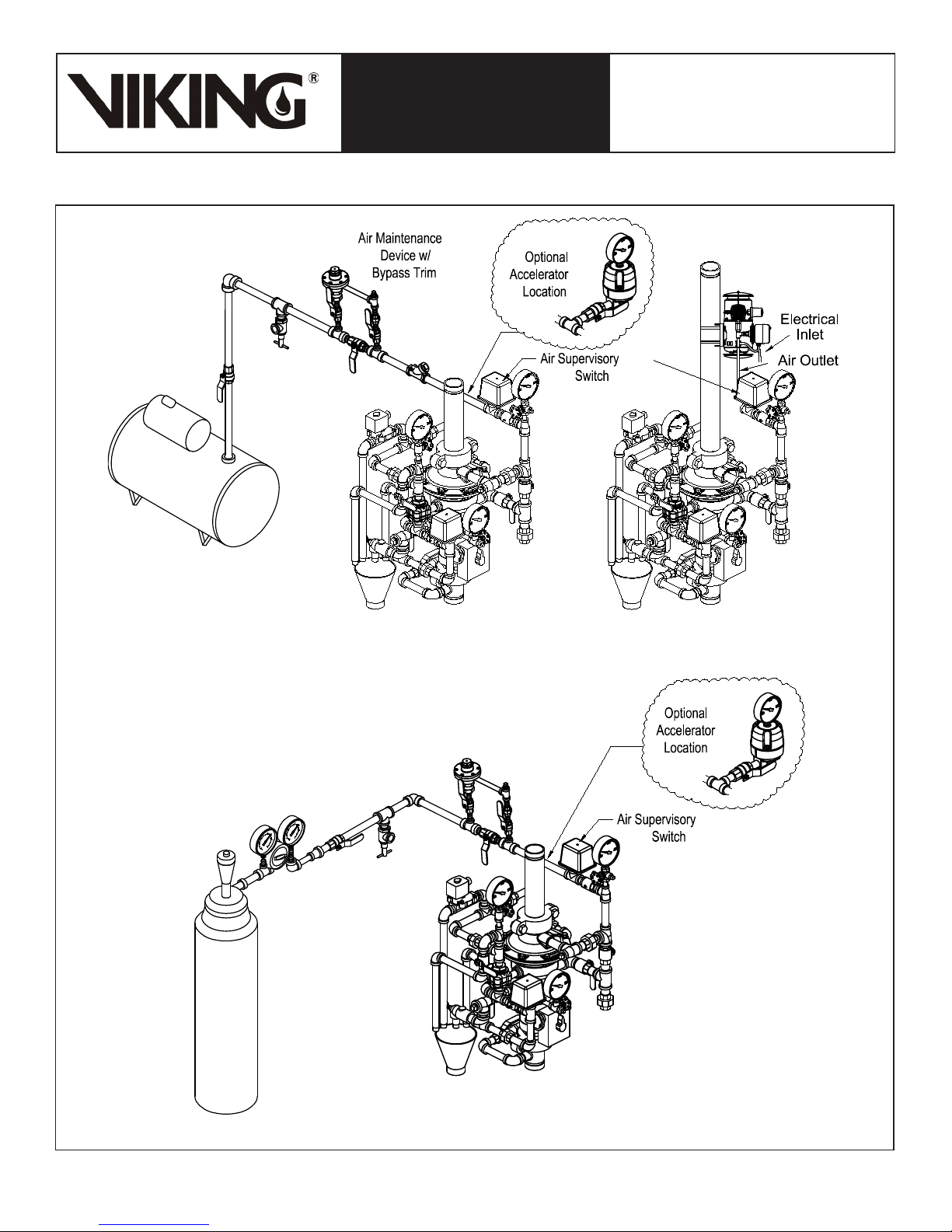

Figure 2 - Alarm Pressure Switch Wiring

(Alarm Pressure Switch should be set to 5 PSI (0.34 bar)

FIELD ADJUSTMENTS:

Alarm Pressure Switch: The operating point of the switch can be

adjusted to any point between 4 PSI (0.27 bar) and 8 PSI (0.55 bar)

by turning the adjustment knob(s) clockwise to raise the actuation

point or counter-clockwise to lower the actuation point.

Air Supervisory Switch: The operating point of the switches can

be adjusted to any point between 10 PSI (0.7 bar) and 60 PSI

(4.1 bar) by turning the adjustment knob(s) clockwise to raise the

actuation point or counter-clockwise to lower the actuation point.

2” MODEL G-2000P PREACTION

Single Interlock

Double Interlock

Figure 3 - Air Supervisory Switch Wiring

The high and low switches are adjusted independently.

Figure 4 - Pressure Adjustment

NOTE: Viking recommends tank-mounted air compressors for Double Interlock Electric/Pneu-Lectric Release Preaction Systems.

2. Nitrogen Cylinder Gas Supply (See Figure 1)

Nitrogen may be used in place of air compressors. Nitrogen is supplied in pressurized cylinders in various sizes and pressures.

Some of the most common are 122 Cu. Ft. at 1,900 PSI (3,455 L at 131 bar), 225 Cu. Ft. at 2,100 PSI (6,372 L at 145 bar), and

280 Cu. Ft. at 2,300 PSI (7,930 L at 159 bar).

When nitrogen cylinders are used as a primary air supply, spare cylinders should be furnished and located at the valve location.

To determine the approximate amount of nitrogen to be furnished, the following formula may be used:

English Units

Vs x P

Vc =

C. Air Supply Installation:

D. Pressure Switch Wiring:

Wire the Alarm Pressure Switch (PS10) and Air Supervisory Switch (PS40), and adjust pressure settings as shown in Figures 2 - 4.

100

Special attention must be given to systems employing a bottled-gas supply. Because only a limited amount of gas is available,

small leaks, which normally would go unnoticed in systems being supplied by mechanical compressors, can become critical to

the system’s overall performance. If the system is to function at temperatures as low as -40 °F (-40 °C), and, if bottled nitrogen

is the gas supply, the system is particularly susceptible to leakage, and special care should be taken to ensure against leaks

throughout the entire system.

1. Install the required air supply as described in section 4.B. The size of the compressor and amount of air required should be

determined in accordance with Tables 1 - 3. The air or nitrogen supply to the preaction system must be clean, dry, and oil free.

2. Automatic air supplies must be regulated, restricted, and from a continuous source. A Viking Air Maintenance Device should

be installed on each system equipped with a tank-mounted compressor, plant air, or nitrogen. For compressors with a capacity

less than 5.5 ft3/min at 10 PSI (0.154 m(0.154 m3/min at 0.69 bar), NFPA 13 does not require an air maintenance device. In addition, NFPA 13 does not require an air maintenance device. In addition,

an air maintenance device should not be used with riser mounted compressors as this can lead to compressor “short cycling”.

Viking recommends that a tank-mounted compressor with air maintenance device be used. This can become critical whenThis can become critical when

accelerators are installed on the system.

Where:

Vc = Volume of Cylinder (ft3)

P = Required Nitrogen Pressure (PSI)

V = Volume of System (gal)

Vc =

Vs x P

108

Metric Units

Where:

Vc = Volume of Cylinder (L)

P = Required Nitrogen Pressure (bar)

V = Volume of System (L)

Page 5

January 6, 2012

Preaction 328e

TECHNICAL DATA

The Viking Corporation, 210 N Industrial Park Drive, Hastings MI 49058

Telephone: 269-945-9501 Technical Services: 877-384-5464 Fax: 269-818-1680 Email: techsvcs@vikingcorp.com

WITH ELECTRIC RELEASE

2” MODEL G-2000P PREACTION

Figure 5 - Trim Components

E. Hydrostatic Test:

The Preaction System, including Sprinkler Piping and Sprinklers shall be hydrostatically tested at 200 PSI (13.8 bar) and maintained

for 2 hours, in accordance with NFPA 13. Systems normally subjected to working system pressures in excess of 150 PSI (10.3 bar)

shall be tested at a pressure of 50 PSI (3.45 bar) in excess of system working pressure.

F. Placing the Valve in Service: (Refer to Figure 5)

When the Preaction System is ready to be placed in service, verify that the electric release system has been reset and in normal condition.

1. Verify that the control valve connected to the G-2000P Valve is closed.

2. Verify required air pressure is established on the piping system.

3. Open the prime vlave, emergency release valve, and flow test valve.

4. Slowly open the water supply main control valve. Wait until water exits the emergency release valve, and then CLOSE the

emergency release valve.

5. Close the prime valve and observe the prime pressure gauge for at least 15 seconds. If the gauge pressure drops, check the

prime line and drip check-make sure the leak is fixed before proceeding to the next steps. Finally, RE-OPEN the priming valve

and verify required prime pressure has been established.

6. Slowly open the control valve connected to the G-2000P Valve.

7. When water exits the flow test valve, CLOSE the flow test valve.

8. Then fully open the control valve connected to the G-2000P Valve.

9. Verify that no water flows from the drip check when the plunger is pushed.

10. Make sure all valves on the trim are in their normal operating positions.

11. Reset the release control panel to clear any supervisory alarms.

12. Notify Authorities Having Jurisdiction and those in the affected area that the system is in service.

13. The system is now fully operational.

NOTE: If the system has operated or if water has entered the system, allow enough time to drain all water from the pip-

ing system before following the above steps.

G. Operational Test:

An operational test shall be performed on the system in accordance with NFPA 13. Refer to Section 6 for Inspection and Operation

Test Procedures.

Page 6

Preaction 328f

January 6, 2012

TECHNICAL DATA

The Viking Corporation, 210 N Industrial Park Drive, Hastings MI 49058

Telephone: 269-945-9501 Technical Services: 877-384-5464 Fax: 269-818-1680 Email: techsvcs@vikingcorp.com

WITH ELECTRIC RELEASE

5. OPERATION

A. In the Set position:

Air pressure is introduced into the sprinkler piping for supervisory purposes only for single interlock systems. For double interlock

systems, air pressure is used for supervisory purposesair pressure is used for supervisory purposes and as one of the two initiation actions of the cross-zoned solenoid. PrimePrime

water is routed to the normally closed solenoid valve and to the prime chamber. When prime water enters the prime chamber, the

prime chamber assembly is pressurized, causing it to expand downward onto the water seat.

2” MODEL G-2000P PREACTION

Figure 6 - Set Position

Page 7

January 6, 2012

Preaction 328g

TECHNICAL DATA

The Viking Corporation, 210 N Industrial Park Drive, Hastings MI 49058

Telephone: 269-945-9501 Technical Services: 877-384-5464 Fax: 269-818-1680 Email: techsvcs@vikingcorp.com

B. Activation of Release System (Single Interlock System):

When the detection system operates, the normally closed solenoid valve is powered open. Prime water is drained from the prime

chamber, causing the G-2000P Valve to open, filling the sprinkler piping with water. Water from the intermediate chamber of the

G-2000P Valve pressurizes the sensing end of the PORV causing the PORV to open. The open PORV prevents water pressure

from building in the prime chamber should the solenoid close.

WITH ELECTRIC RELEASE

2” MODEL G-2000P PREACTION

Figure 7a - Activation of Release System - Single Interlock System

Page 8

Preaction 328h

January 6, 2012

TECHNICAL DATA

The Viking Corporation, 210 N Industrial Park Drive, Hastings MI 49058

Telephone: 269-945-9501 Technical Services: 877-384-5464 Fax: 269-818-1680 Email: techsvcs@vikingcorp.com

C. Fire Condition (Double Interlock System):

In a fire condition, operation of the detection system activates the first initiating circuit in the release control panel, causing an

alarm to activate. When a sprinkler operates, air pressure escapes from the sprinkler piping. The air supervisory switch activates

the second initiating circuit in release control panel. When BOTH initiating circuits have been activated, the release control panel

energizes solenoid valve open. With the solenoid valve open, prime water is drained from the prime chamber, causing the G2000P Valve to open, filling the sprinkler piping with water. Water from the intermediate chamber of the Model G-2000P Valve

pressurizes the sensing end of the PORV causing the PORV to open. The open PORV prevents water pressure from building in

the prime chamber should the solenoid close.

WITH ELECTRIC RELEASE

2” MODEL G-2000P PREACTION

Figure 7b - Fire Condition - Double Interlock System

Page 9

January 6, 2012

Preaction 328i

TECHNICAL DATA

The Viking Corporation, 210 N Industrial Park Drive, Hastings MI 49058

Telephone: 269-945-9501 Technical Services: 877-384-5464 Fax: 269-818-1680 Email: techsvcs@vikingcorp.com

WITH ELECTRIC RELEASE

6. INSPECTION AND OPERATIONAL TEST

NOTICE: THE OWNER IS RESPONSIBLE FOR MAINTAINING THE FIRE PROTECTION SYSTEM AND DEVICES IN PROPER

OPERATING CONDITION. It is imperative that the system is inspected and tested on a regular basis in accordance with NFPA 25.

The frequency of the inspections may vary due to contaminated water supplies, corrosive water supplies, corrosive atmospheres, as

well as the condition of the air supply to the system. For minimum maintenance and inspection requirements, refer to NFPA 25. In addition, the Authority Having Jurisdiction may have additional maintenance, testing, and inspection requirements that must be followed.

Viking does not require internal inspection of the valve as part of routine inspection and testing. Internal maintenance is generally only

required for valve repairs and internal component replacement.

WARNING: Any system maintenance that involves placing a control valve or detection system out of service may eliminate the fire

protection capabilities of that system. Prior to proceeding, notify all Authorities Having Jurisdiction. Consideration should be given to

employment of a fire patrol in the affected areas.

A. Low Air Pressure Alarm Test: (Refer to Figure 5)

Quarterly testing of low air alarms is recommended.

To Test Sprinkler System “Low Air Supervisory” Alarm:

1. To prevent operation of the Model G-2000P Valve and filling the system with water during the test, DO NOT operate the electric

detection system during test. Consider closing the main water supply control valve.

2. Partially open the sprinkler system main drain or test connection.

3. Verify that low air alarms operate within an acceptable time period and continue without interruption.

4. Close the main drain or test connection .

5. Establish the supervisory air pressure to the recommended pressure.

6. Reset the system release control panel. The supervisory alarms should stop.

When testing is complete, return the system to service following steps 1 through 8 below.

B. Full Flow Trip Test: (Refer to Figure 5)

Performance of a trip test is recommended annually during warm weather. Consider coordinating this test with operation testing of

the detectors.

CAUTION! PERFORMANCE OF THIS TEST WILL CAUSE THE G-2000P VALVE TO OPEN AND THE SPRINKLER SYSTEM TO

FILL WITH WATER.

To Trip Test the Electrically Controlled Preaction System:

1. Notify the Authority Having Jurisdiction and those in the area affected by the test.

2. Trip the G-2000P Valve by performing option “a” or “b” below.

Operate the electric release control system according to the manufacturer’s instructions (for the Single Interlock or

a.

Double Interlock System) and open the sprinkler system test connection (for Double Interlock Systems).and open the sprinkler system test connection (for Double Interlock Systems)..

Operate the emergency release valve.

b.

3. The G-2000P Valve should open, filling the sprinkler system with water. Water flow alarms should operate.

4. Open the sprinkler system main drain valve or sprinkler system test valve to verify adequate flow.

When Trip Testing is complete:

5. Perform steps 1 through 16 of section 4.F - PLACING THE SYSTEM IN SERVICE to return the system to service.

6. Notify the Authority Having Jurisdiction and those in the affected area that testing is complete.

2” MODEL G-2000P PREACTION

7. MAINTENANCE

Viking does not require an internal inspection of the G-2000P Valve unless there is an indication of damage to internal components.

A. Taking the system out of service: (Refer to Figure 5)

1. Close the water supply main control valve, placing the system out of service.

2. Open the flow test valve located in the base of the G-2000P Valve.

3. Close the air (or nitrogen) supply to the preaction system piping.

4. Close the priming valve.

5. Relieve all air pressure from the preaction system piping. If the system has operated, open the main drain valve to allow the

system to drain completely.

B. Removing the Cover from the Body: (Refer to Figures 1 & 11)

1. Remove the 2” coupling from the top of the G-2000P Valve.

2. Remove the 10” section of pipe directly above the G-2000P Valve.G-2000P Valve. Valve.

3. Remove the air supply line from the air supervisory switch.

4. Remove the 3/4” union below the main drain.

Page 10

Preaction 328j

January 6, 2012

TECHNICAL DATA

The Viking Corporation, 210 N Industrial Park Drive, Hastings MI 49058

Telephone: 269-945-9501 Technical Services: 877-384-5464 Fax: 269-818-1680 Email: techsvcs@vikingcorp.com

5. Remove the 8 cover screws (8).

6. The cover and trim that is still connected may now be removed from the body. (It may be necessary to pry the valve open as

the diaphragm may bond itself to the cover and body over time.)

C. Removing / Replacing the Check Diaphragm: (Refer to Figure 11)

1. The check diaphragm (7) may be lifted from the valve body (1).

2. If necessary, replace the check diaphragm (7).

D. Inspecting the Prime Chamber and Coupling for Leaks: (Refer to Figure 5)

If desired, it is possible to set the Model G-2000P Valve and inspect for leaks with the cover removed.

1. Slowly open the prime valve.

2. With prime water established, partially open the main water supply control valve.

3. Visually inspect the inside of the G-2000P Valve for leaks.

4. Close the water supply control valve.

E. Removing / Replacing the Prime Coupling: (Refer to Figure 11)

1. Open the 1/2” union on the prime line.

2. Using a wrench on the flats of the coupling (6), remove the coupling (6) from the valve body (1).

3. Inspect the coupling (6) and O-rings (5). Replace if necessary,, using the instructions in O-Ring Replacement Bulletin

F_120611.

F. Removing / Replacing the Prime Chamber Assembly: (Refer to Figure 11)

1. The prime chamber assembly (4) is now held in place by two flanges on the outside diameter of the assembly. Slide the prime

chamber assembly (4) toward the prime line and remove from the body (1).

2. Inspect and replace if necessary.

3. Inspect the seat. The seat should be clean and free of foreign material. If the seat is damaged, the G-2000P Valve must be

replaced.

G. Re-Assembling the Valve: (Refer to Figure 11)

1. Place the prime chamber assembly (4) in the valve body (1). Make sure the two flanges are positioned in the groove.

2. Thread the prime coupling (6) into the valve body (1). Make sure the end of the prime coupling (6) is inserted into the prime

chamber assembly (4).

3. Lay the check diaphragm (7) into the valve body (1).

4. Position the cover onto the valve body (1), and install and tighten the cover screws (8).

5. Re-install any trim that was removed.

6. Place the valve in service by following the steps in Section 4.F.

WITH ELECTRIC RELEASE

2” MODEL G-2000P PREACTION

8. AVAILABILITY

The Viking Model G-2000P Valve is available through a network of domestic and international distributors. See the Viking Corp. Web

site for closest distributor or contact The Viking Corporation.

Page 11

January 6, 2012

Preaction 328k

TECHNICAL DATA

The Viking Corporation, 210 N Industrial Park Drive, Hastings MI 49058

Telephone: 269-945-9501 Technical Services: 877-384-5464 Fax: 269-818-1680 Email: techsvcs@vikingcorp.com

WITH ELECTRIC RELEASE

Part Number 16187-1:

1 Model G-2000P Valve

1 Model G-2000P Electric Release Trim

(Includes NC Solenoid)

1 10” Section of Schedule 10 Pipe and

Coupling

1 Air Pressure Supervisory Switch

(PS40-2A)

1 Alarm Pressure Switch (PS10-2A)

1 Water Supply Control Valve

2” MODEL G-2000P PREACTION

Figure 8 - 16187-1 Assembly

Accessories:

08055 Model E-1 Accelerator

14800 Model LD-1 Anti-Column Device

16211 Drain Manifold

Figure 9 - Optional

Accessories

Page 12

Preaction 328l

January 6, 2012

TECHNICAL DATA

The Viking Corporation, 210 N Industrial Park Drive, Hastings MI 49058

Telephone: 269-945-9501 Technical Services: 877-384-5464 Fax: 269-818-1680 Email: techsvcs@vikingcorp.com

WITH ELECTRIC RELEASE

2” MODEL G-2000P PREACTION

Figure 10 - Installation Dimensions

Page 13

January 6, 2012

Preaction 328m

TECHNICAL DATA

The Viking Corporation, 210 N Industrial Park Drive, Hastings MI 49058

Telephone: 269-945-9501 Technical Services: 877-384-5464 Fax: 269-818-1680 Email: techsvcs@vikingcorp.com

WITH ELECTRIC RELEASE

2” MODEL G-2000P PREACTION

Figure 11 - Model G-2000P Valve Components List / Replacement Parts

Item No. Part No. Description Material No. Req’d

1 -- Body 65-45-12 Ductile Iron 1

2 -- Seat UNS-C11000 Copper or UNS-S30400 Stainless Steel 1

3 -- Anaerobic Adhesive -- 1

4 16063 Prime Chamber Assembly Brass, EPDM, Nitrile, 304 Stainless Steel, Bronze Alloy 1

5 * O-Rings EPDM and Nitrile 2 or 3**

6 16062 Coupling UNS-S17400 Stainless Steel 1

7 15932 Check Diaphragm EPDM 1

8 08091 3/8-16 x 1” HHS UNS-S30400 Stainless Steel 8

9 -- Cover 65-45-12 Ductile Iron 1

10 -- Data Plate Aluminum 2

11 -- Tack Alloy Carbon Steel 4

-- Replacement part is not available.

* Indicates part is available only in a Sub-Assembly, as indicated below.

5 17443 O-Ring Replacement Kit (**Refer to O-Ring Replacement Bulletin Form No. F_120611 for instructions.)

Form No. F_011310

Sub-Assembly

Replaces page 328a-m, dated July 1, 2011.

(Revised the replacement parts list and Figure 11.)

Loading...

Loading...