Viking Designer Series, VIV300, VIV600, VIV1200, VEV900 Installation Manual

...

Viking Installation Guide

Designer Series

Built-In 18” H. Hoods

Viking Range Corporation

111 Front Street

Greenwood, Mississippi 38930 USA

2

NNOOTTEE:: IIFF IINNSSTTAALLLLIINNGG HHOOOODD WWIITTHH

WWAARRMMIINNGG SSHHEELLFF PPAANNEELL,, IINNSSTTAALLLL

WWAARRMMIINNGG SSHHEELLFF PPAANNEELL FFIIRRSSTT..

IIMMPPOORRTTAANNTT --

PPLLEEAASSEE RREEAADD AANNDD FFOOLLLLOOWW

•Before beginning, please read these instructions

completely and carefully.

•Do not remove permanently affixed labels, warnings, or

plates from the product. This may void the warranty.

•Please observe all local and national codes and

ordinances. If no local codes are applicable, wire in

accordance with the National Electrical Code,

ANSI/NFPA 70-1990.

••CChheecckk wwiitthh aa qquuaalliiffiieedd aanndd ttrraaiinneedd iinnssttaalllleerr oorr llooccaall

ccooddeess ffoorr mmaakkeeuupp aaiirr rreeqquuiirreemmeenntt,, iiff aannyy..

•

TThhee iinnssttaalllleerr sshhoouulldd lleeaavvee tthheessee iinnssttrruuccttiioonnss wwiitthh tthhee

ccoonnssuummeerr wwhhoo sshhoouulldd rreettaaiinn ffoorr llooccaall iinnssppeeccttoorr’’ss uussee aanndd

ffoorr ffuuttuurree rreeffeerreennccee..

This hood is for residential installation only and is not

designed for installation over a commercial product.

Make sure power is off at the main circuit breaker or fuse

box before making connections.

TToo aavvooiidd rriisskk ooff ffiirree,,

eelleeccttrriicc sshhoocckk,, oorr iinnjjuurryy ttoo ppeerrssoonnss,, ttuurrnn ooffff tthhee eelleeccttrriicciittyy

ttoo tthhee hhoooodd ffrroomm tthhee ppoowweerr ssuuppppllyy bbeeffoorree sseerrvviicciinngg oorr

cclleeaanniinngg..

Viking Range hoods are equipped with variable speed

controls for blowers. These units will not function with a

single

speed ventilator. All Viking Range ventilator kits are

designed specifically for use with Viking Range hoods.

Use of

any non-Viking Range ventilator kit will void the hood

warranty.

WWAARRNNIINNGG

TTOO RREEDDUUCCEE TTHHEE RRIISSKK OOFF FFIIRREE,, EELLEECCTTRRIICCAALL SSHHOOCCKK,,

OORR IINNJJUURRYY TTOO PPEERRSSOONNSS,, OOBBSSEERRVVEE TTHHEE FFOOLLLLOOWWIINNGG::

1. Installation work and electrical wiring must be done by

qualified person(s) in accordance with all applicable

codes and standards, including fire-rated construction.

2. Sufficient air is needed for proper combustion and

exhausting of gases through the flue (chimney) of fuel

burning equipment to prevent back drafting. Follow

the heating equipment manufacturer’s guideline and

safety standards such as those published by the

National Fire Protection Association (NFPA), and the

American Society for Heating, Refrigeration and Air

Conditioning Engineers (ASHRAE), and the local code

authorities.

3. When cutting or drilling into wall or ceiling, do not

damage electrical wiring and other hidden utilities.

4. Ducted fans must always be vented to the outdoors.

5.

WWAARRNNIINNGG!!::

To reduce the risk of fire, use only metal

ductwork.

6.

CCAAUUTTIIOONN!!::

To reduce risk of fire and to properly

exhaust air, be sure to duct air outside. Do not vent

exhaust air into spaces within walls or ceilings, or into

attics, crawl spaces, or garages.

CCAAUUTTIIOONN

For general ventilating use only. Do not use

to exhaust hazardous or explosive materials

and vapors.

WWAARRNNIINNGG

TO REDUCE THE RISK OF FIRE, ELECTRICAL SHOCK,

OR INJURY TO PERSONS, RANGEHOODS MUST BE

INSTALLED WITH THE VENTILATORS THAT ARE

SPECIFIED ON THEIR CARTON INDICATING

SUITABILITY WITH THIS MODEL. OTHER VENTILATORS

CANNOT BE SUBSTITUTED.

WWAARRNNIINNGG

TTOO RREEDDUUCCEE TTHHEE RRIISSKK OOFF AA RRAANNGGEETTOOPP GGRREEAASSEE

FFIIRREE::

1. Never leave surface units unattended at high

setting. Boilovers cause smoking and greasy

spillovers that may ignite. Heat oils slowly on

low or medium settings.

2. Always turn hoon ON when cooking at high

heat or when cooking flaming foods.

3. Clean ventilating fans frequently. Grease should

not be allowed to accumulate on fan or filter.

4. Use proper pan size. Always use cookware

appropriate for the size of the surface element.

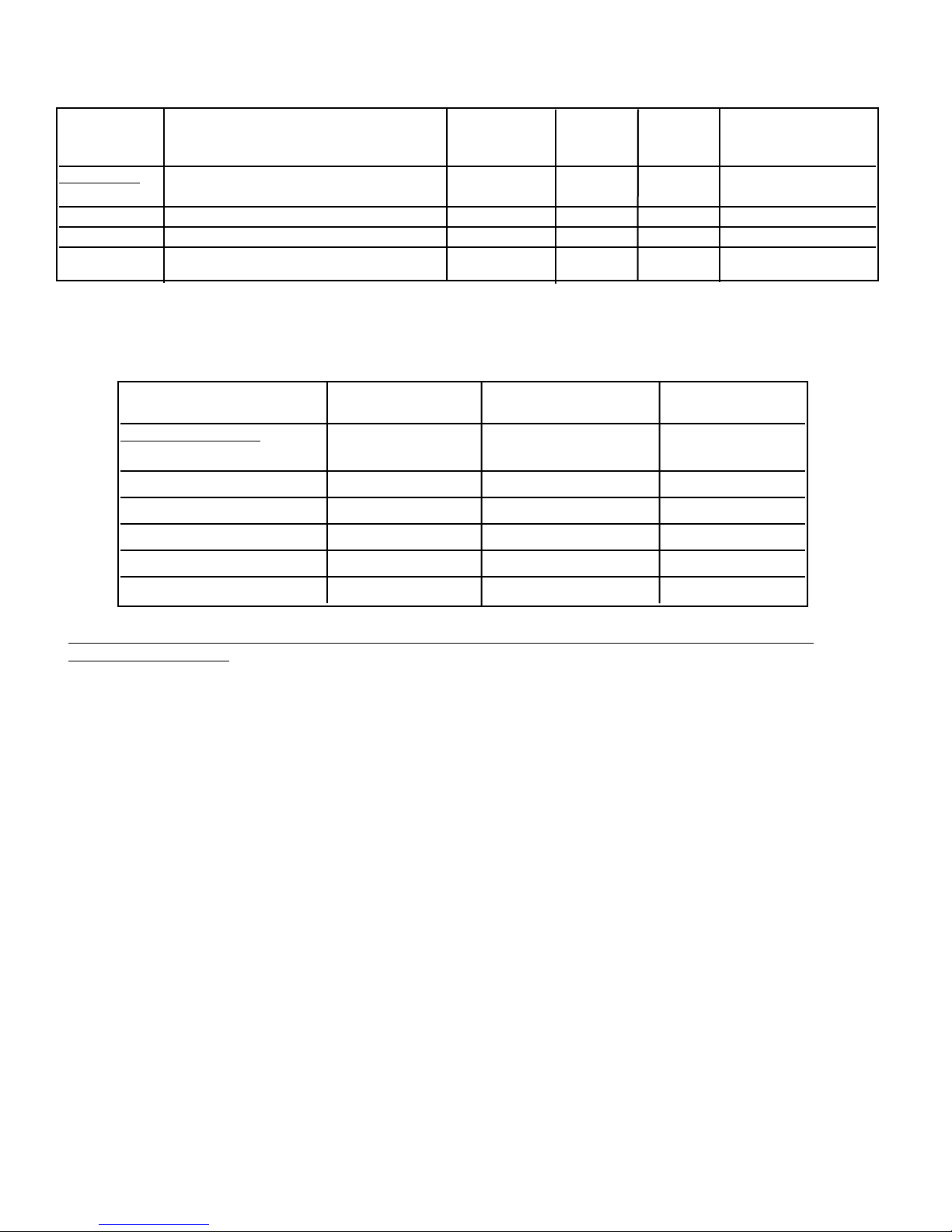

BBAASSIICC SSPPEECCIIFFIICCAATTIIOONNSS

IINNTTEERRIIOORR AANNDD EEXXTTEERRIIOORR PPOOWWEERR HHOOOODDSS

RREECCOOMM.. NNUUMMBBEERR OOFF 112200VVAACC//6600HHzz

DDEESSCCRRIIPPTTIIOONN CCFFMM

11

HHAALLOOGGEENN FFIILLTTEERRSS SSPPAACCEERRSS MMAAXX.. AAMMPPSS

33

((iinntt..--iinntteerriioorr;; eexxtt--eexxtteerriioorr

LLIIGGHHTTSS

((IInntteerriioorr//EExxtteerriioorr))

1188”” HH.. WWaallll

30”W.* 300 int/600 int./1200 int./900 ext./1200 ext. 2 2 0 2.4/4.6/6.6/6.6/3.9

36”W.*

300 int/600 int./1200 int./900 ext./1200 ext. 2 2 1 2.4/4.6/6.6/6.6/3.9

42”W.* 600 int./1200 int./900 ext./1200 ext. 2 3 0 4.6/6.6/6.6/4.0

48”W.

1200 int./1200 ext./1500 ext. 3 3 0 7.0/4.3/5.1

AAPPPPRROOXXIIMMAATTEE RREECCOOMMMMEENNDDEEDD MMAAXX.. DDUUCCTT

MMOODDEELL NNUUMMBBEERR CCFFMM

11

DDUUCCTT SSIIZZEE RRUUNN

22

((fftt..))

FFoorr UUssee wwiitthh hhooooddss::

VIV300 (interior) 300 7” round 50

VIV600 (interior) 600 7” round 50

VIV1200 (interior) 1200 10” round 50

VEV900 (exterior) 900 10” round 50

VEV1200 (exterior) 1200 10” round 50

VEV1500 (exterior) 1500 10” round 75

PPRROOPPEERR IINNSSTTAALLLLAATTIIOONN//DDUUCCTTIINNGG IISS EEXXTTRREEMMEELLYY IIMMPPOORRTTAANNTT TTOO EENNSSUURREE MMAAXXIIMMUUMM PPEERRFFOORRMMAANNCCEE FFRROOMM AANNYY

VVEENNTTIILLAATTIIOONN PPRROODDUUCCTT

1. •All CFMs stated are based on tests at .1 static pressure: without applying static pressure, CFM would be greatly

overstated.

2. •Duct run length is for general reference only; for longer duct runs, increase duct size and contact a qualified and trained

installer.

•Straight runs and gradual turns are best; for example, each 90

o

elbow is equivalent to 5-10 feet (1.52 - 3.05 cm) of

straight run.

•Never use flexible duct; it creates back pressure/air turbulence and greatly reduces performance.

•Proper performance is dependent upon proper ducting; make sure that a qualified and trained installer is used.

••CChheecckk wwiitthh aa qquuaalliiffiieedd aanndd ttrraaiinneedd iinnssttaalllleerr oorr llooccaall ccooddeess ffoorr mmaakkeeuupp aaiirr rreeqquuiirreemmeenntt,, iiff aannyy..

3. •Max. amp rating for hoods includes recommended ventilator kit rating; all products must be hard wired direct with 2wire with ground.

**11220000 CCFFMM ((oorr 11550000 CCFFMM iiff aapppplliiccaabbllee)) eexxtteerriioorr vveennttiillaattoorr sshhoouulldd bbee uusseedd wwhheenn iinnssttaalllleedd oovveerr

rraannggeess/

/rraannggeettooppss wwiitthh ggaass ggrriillll..

3

4

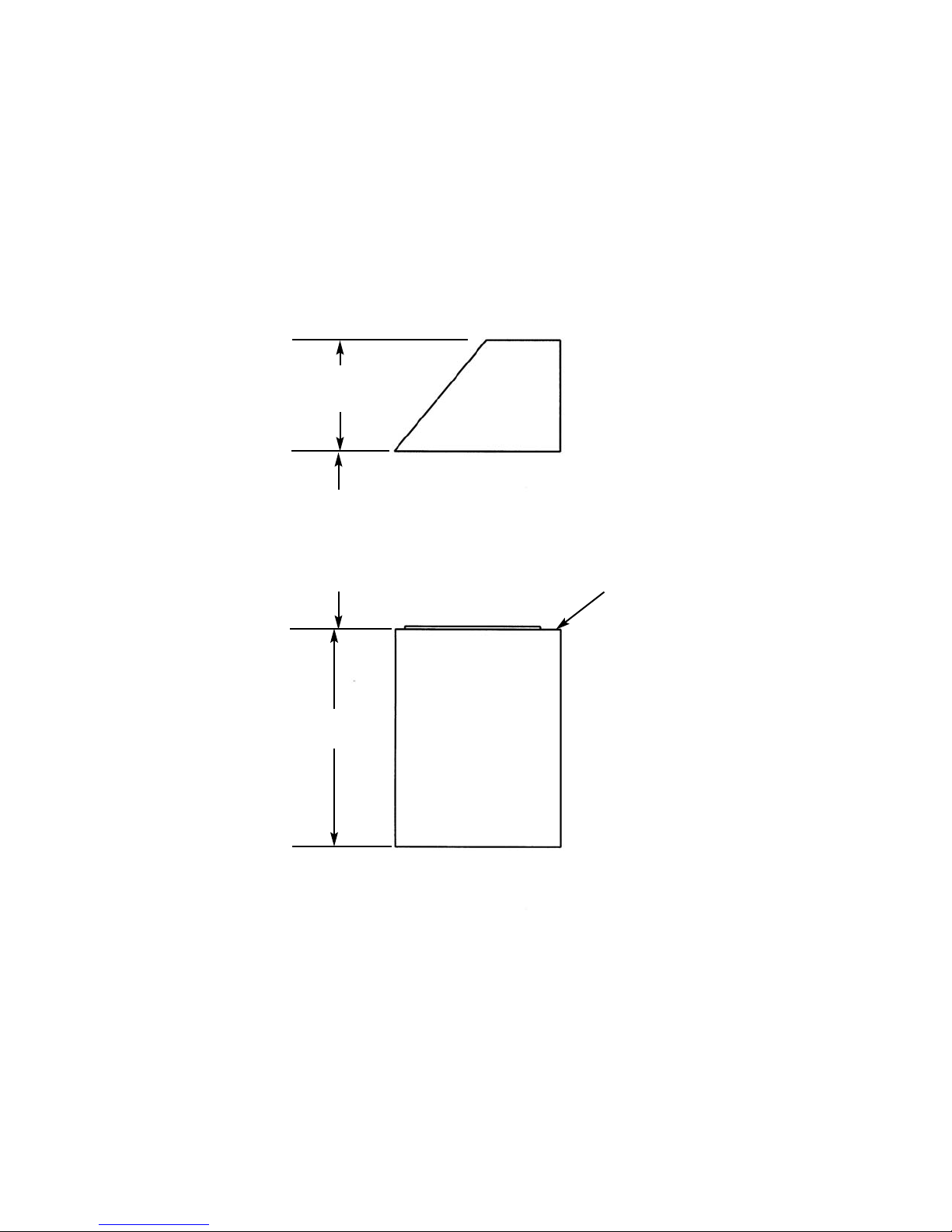

HHEEIIGGHHTT OOFF HHOOOODD

The bottom of the hood should be 30” (76.2 cm) min. to 36” (91.4 cm) max. above the countertop. This would

typically result in the bottom of the hood being 66” (167.6 cm) to 72” (182.9 cm) above the floor. For best

performance, it is recommended that the bottom of the hood be 30” (76.2 cm) to 33” (83.8 cm) above the

countertop. These dimensions provide for safe and efficient operation of the hood.

CClleeaarraannccee DDiimmeennssiioonnss

18”

(45.7 cm)

30”

(76.2 cm) Min.

36”

(91.4 cm) Max.

36”

(91.4 cm)

CCoouunntteerrttoopp

5

PPRREEPPAARRIINNGG FFOORR HHOOOODD IINNSSTTAALLLLAATTIIOONN

Plan where the ductwork will be located. See pages 8-11 for rough-in dimensions. Install proper-sized duct work, and

roof or wall cap for the type of blower you are using. Recommended hood locations for the most common

installations are shown on page 2.

Adjust your measurements for various heights of ceilings, soffits,

cabinets, or ranges/rangetops.

Roof Cap

7” Round

Duct

Roof Cap

10”

Round

duct

Duct Cover

or Soffit

Duct Cover

or Soffit

300 or 600 CFM

Interior-Power - Typical Ductwork

1200 CFM

Interior-Power - Typical Ductwork

Exterior Blower

10” Round

Duct

Duct

Cover

or Soffit

12”

(30.5 cm)

900, 1200, or 1500 CFM

Exterior-Power - Typical Ductwork

12”

(30.5 cm)

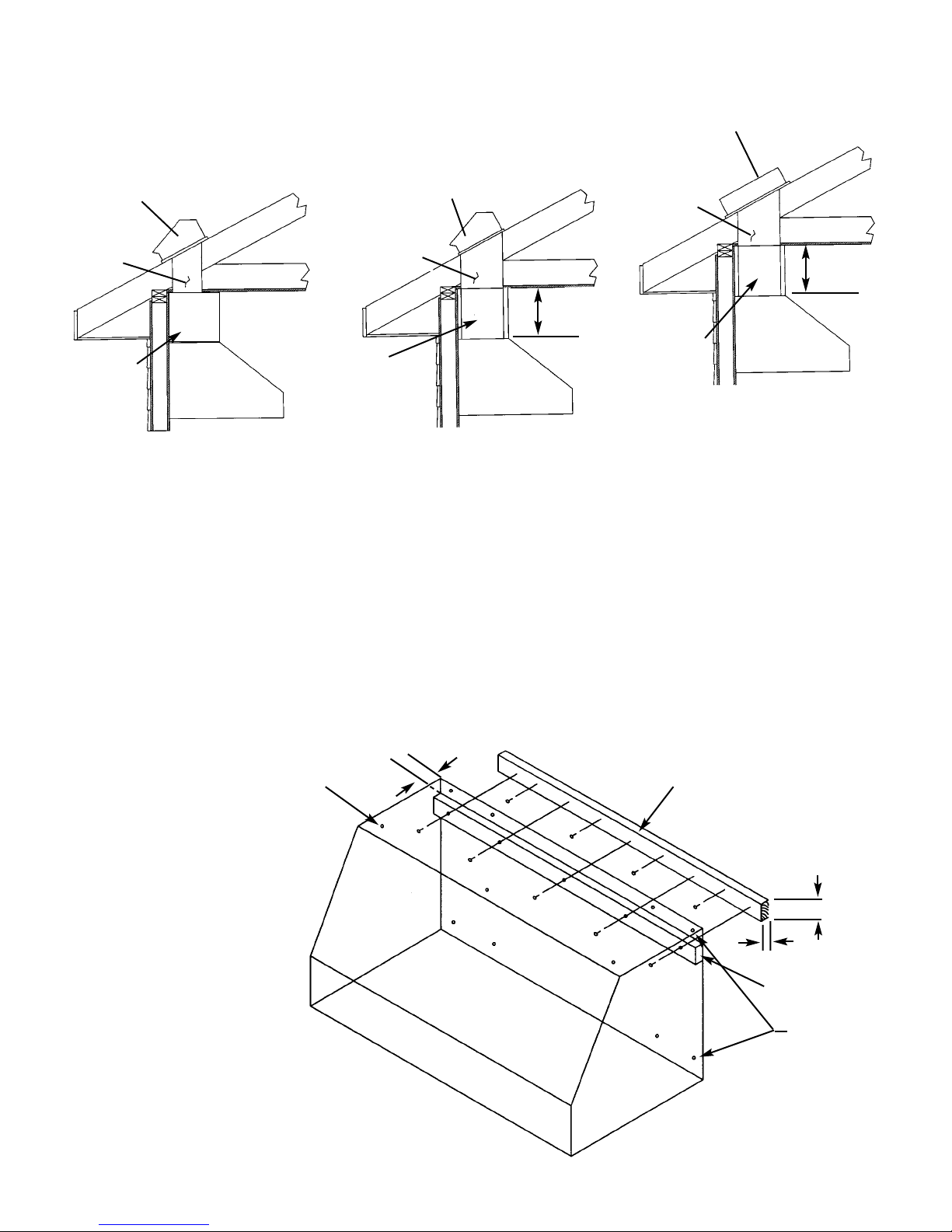

IINNSSTTAALLLLIINNGG HHOOOODD CCAANNOOPPYY

Center the wood strip (acquired locally - see drawing for dimensions) and attach to wall. Using the slot located on

the backside of the canopy, place the hood onto the wood strip. Secure the hood to strip with mounting screws

provided. Make sure that the wood strip mounting screws are driven into the framing and not just the drywall. Use

additional mounting screws (and wall anchors if necessary) in the other holes.

NNOOTTEE:: BBEECCAAUUSSEE OOFF

TTHHEE WWEEIIGGHHTT OOFF TTHHEE

HHOOOODD -- MMAAKKEE SSUURREE

TTHHAATT TTHHEE WWOOOODD SSTTRRIIPP

MMOOUUNNTTIINNGG SSCCRREEWWSS

AARREE DDRRIIVVEENN IINNTTOO TTHHEE

FFRRAAMMIINNGG AANNDD NNOOTT

JJUUSSTT TTHHEE DDRRYYWWAALLLL.. IITT

MMAAYY BBEE NNEECCEESSSSAARRYY TTOO

DDRRIILLLL AADDDDIITTIIOONNAALL

HHOOLLEESS IINN TTHHEE C

CAANNOOPPYY

FFOORR PPRROOPPEERR

AALLIIGGNNMMEENNTT..

EELLEECCTTRRIICCAALL SSUUPPPPLLYY

Run 120 VAC electrical power cable from service panel to installation location. See “Basic Specifications” on page 13

for the maximum amp requirements.

To p

Mounting

Holes

Wood Strip

(acquired locally- 1

1

/2” x

3

/4”)

Slot for Wood

Strip

Rear Mounting

Holes

11/

2”

(3.8 cm)

3

/4”(1.9 cm)

113/16”

(4.6 cm)

Loading...

Loading...