Viking Designer Ruby User Manual

User’ s Guide

KEEPING THE WORLD SEWING™

This household sewing machine is designed to comply with IEC/EN 60335-2-28 and UL1594

IMPORTANT SAFETY INSTRUCTIONS

When using an electrical appliance, basic safety precautions should always be followed, including the following:

Read all instructions before using this household sewing machine.

DANGER – To reduce the risk of electric shock:

• A sewing machine should never be left unattended when plugged in. Always unplug this sewing machine from the

electric outlet immediately after using and before cleaning.

WARNING – To reduce the risk of burns, À re,

electric shock, or injury to person:

• This sewing machine is not intended for use by persons (including children) with reduced physical, sensory or mental

capabilities, or lack of experience and knowledge, unless they have been given supervision or instruction concerning use

of the sewing machine by a person responsible for their safety.

• Children should be supervised to ensure that they do not play with the sewing machine.

• Use this sewing machine only for its intended use as described in this manual. Use only attachments recommended by

the manufacturer as contained in this manual.

• Never operate this sewing machine if it has a damaged cord or plug, if it is not working properly, if it has been dropped

or damaged, or dropped into water. Return the sewing machine to the nearest authorized dealer or service center for

examination, repair, electrical or mechanical adjustment.

• Never operate the sewing machine with any air openings blocked. Keep ventilation openings of the sewing machine and

foot controller free from the accumulation of lint, dust, and loose cloth.

• Keep À ngers away from all moving parts. Special care is required around the sewing machine needle.

• Always use the proper needle plate. The wrong plate can cause the needle to break.

• Do not use bent needles.

• Do not pull or push fabric while stitching. It may deÁ ect the needle causing it to break.

• Wear safety glasses.

• Switch the sewing machine off (“0”) when making any adjustment in the needle area, such as threading needle, changing

needle, threading bobbin, or changing presser foot, etc.

• Always unplug sewing machine from the electrical outlet when removing covers, lubricating, or when making any other

user servicing adjustments mentioned in the instruction manual.

• Never drop or insert any object into any opening.

• Do not use outdoors.

• Do not operate where aerosol (spray) products are being used or where oxygen is being administrated.

• To disconnect, turn all controls to the off (“0”) position, then remove plug from outlet.

• Do not unplug by pulling on cord. To unplug, grasp the plug, not the cord.

• Hold plug when rewinding into cord reel. Do not allow plug to whip when rewinding.

• This sewing machine is provided with double insulation. Use only identical replacement parts.See instructions for

Servicing of Double-Insulated Appliances.

SAVE THESE INSTRUCTIONS

SERVICING OF

DOUBLE INSULATED PRODUCTS

In a double-insulated product, two systems of insulation are provided instead of grounding. No ground means is provided

on a double-insulated product, nor should a means for grounding be added to the product. Servicing of a double-insulated

product requires extreme care and knowledge of the system, and should be done only by qualiÀ ed service personnel.

Replacement parts for a double-insulated product must be identical to those parts in the product. A double-insulated

product is marked with the words ‘DOUBLE INSULATION’ or ‘DOUBLE INSULATED’.

TABLE OF CONTENTS

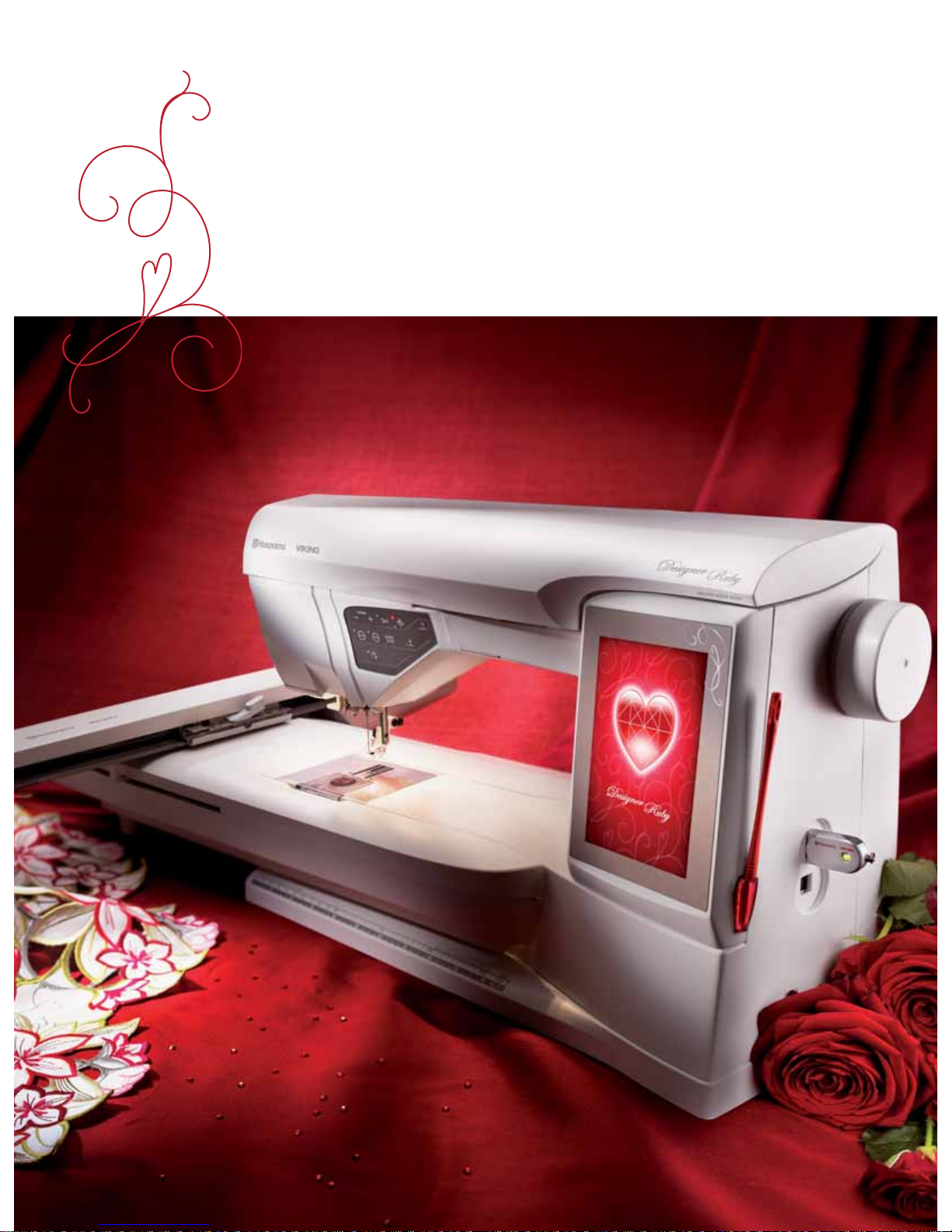

1 Getting to know your machine 1:5

MACHINE OVERVIEW 1:6

Rear Side ...........................................................................1:6

Needle Area ......................................................................1:6

Accessory Tray .................................................................1:7

Parts of the Embroidery Unit .......................................1:7

ACCESSORIES 1:7

Included Accessories ......................................................1:7

Hoops Included ...............................................................1:7

Accessories Included - Not in the Picture ..................1:8

Presser Feet ......................................................................1:8

STITCHES 1:10

2 Set Up 2:1

UNPACKING 2:2

Connect the Power Cord and Foot Control ...............2:2

Pack Away after Sewing .................................................2:2

FREE ARM 2:3

SPOOL PINS 2:3

Horizontal Position .........................................................2:3

Vertical Position ...............................................................2:3

Auxiliary Spool Pin .........................................................2:3

THREADING THE UPPER THREAD 2:4

Needle Threader ..............................................................2:4

Threading for Twin Needle ...........................................2:5

THREAD CUTTER 2:5

THREAD SENSOR 2:5

BOBBIN WINDING 2:6

Bobbin Winding Through the Needle .........................2:6

Bobbin Winding while Embroidering or Sewing .......2:7

INSER TING THE BOBBIN 2:7

CHANGING THE PRESSER FOOT 2:7

CHANGING THE NEEDLE 2:8

NEEDLES 2:8

THREADS 2:9

STABILIZERS 2:9

PICTOGRAM™ PEN 2:9

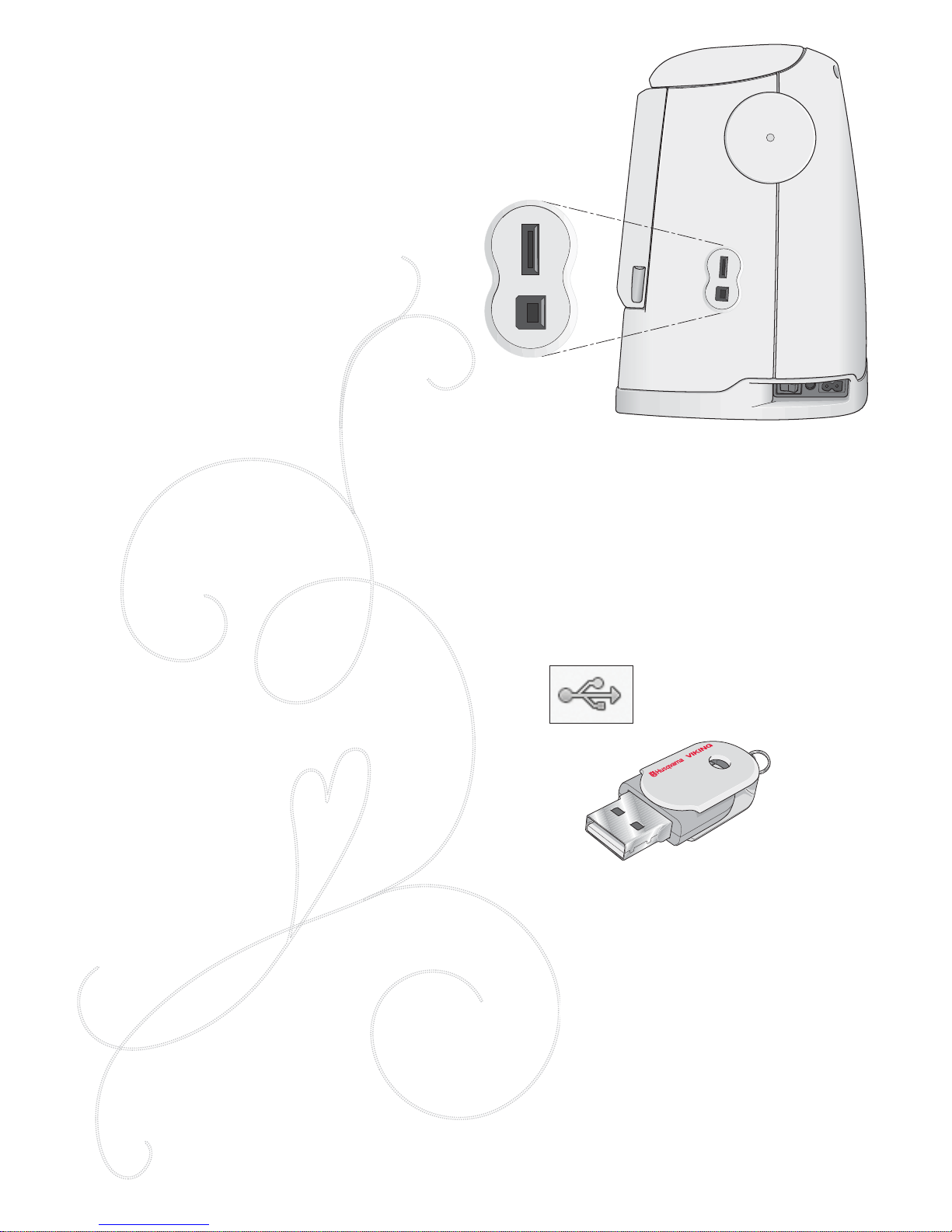

USB PORTS 2:10

USB embroidery stick ...................................................2:10

Connect to and Remove from the USB Port ............2:10

CONNECTING THE MACHINE T O YOUR COMPUTER 2:11

5D™ Embroidery Software ........................................2:11

Installing your Software ...............................................2:11

Install Hardware Drivers and

Connect the Embroidery Machine ...........................2:11

How to Launch the Programs .....................................2:12

Embroidery Machine Communication module ........2:12

How to Update your Machine .....................................2:12

3 Settings & Functions 3:1

INTERACTIVE COLOR TOUCH SCREEN 3:2

COMMON ICONS/FUNCTIONS 3:2

OK .....................................................................................3:2

Cancel ................................................................................3:2

Touch & Hold ..................................................................3:2

TOOLBAR 3:2

START MENU 3:2

SEWING/EMBROIDERY MODE 3:2

QUICK HELP 3:3

EXTENDED TOOLBAR 3:3

STITCH MENU 3:3

How to Select a Stitch ....................................................3:3

FONT MENU 3:3

Selecting a Font ...............................................................3:3

DESIGN MENU 3:4

Selecting a Design ...........................................................3:4

EMBROIDER Y AD VISOR™ 3:4

FILE MANAGER 3:4

SET MENU 3:5

Stitch Settings .................................................................3:5

Sewing Settings ................................................................3:6

Machine Settings..............................................................3:8

Sound Settings .................................................................3:9

Screen Settings .................................................................3:9

INFORMATION MENU 3:10

FUNCTION BUTTONS 3:11

Speed + and - .................................................................3:11

STOP (Monochrome) ..................................................3:11

FIX (Baste) .....................................................................3:11

Reverse ............................................................................3:11

Selective Thread Cutter ................................................3:12

Needle Stop Up/Down (Trim Position) ...................3:12

Start/Stop .......................................................................3:12

EXCLUSIVE SENSOR SYSTEM™ 3:12

Sensor Foot Up and Extra Lift ...................................3:12

Sensor Foot Down and Pivot ......................................3:12

4 Sewing 4:1

SEWING MODE - OVERVIEW OF ICONS 4:2

EXCLUSIVE SEWING ADVISOR™ 4:3

Fabric Selection ...............................................................4:3

Sewing Techniques ..........................................................4:4

Extended SEWING ADVISOR™ ..............................4:4

SELECT A STITCH 4:4

STITCH SETTINGS 4:5

Stitch Settings in SET Menu ..........................................4:6

FREE-MOTION TECHNIQUE 4:7

RAISE AND LOWER THE PRESSER FOOT 4:7

SEWING TECHNIQUES 4:8

Seam ..................................................................................4:8

Overcast ............................................................................4:9

Seam and Overcast ........................................................4:10

Seam/Overcast for Ribbing ........................................4:10

Baste ...............................................................................4:11

Blind Hem ......................................................................4:11

Hem .................................................................................4:12

Perfectly Balanced Sensor One-Step Buttonhole .....4:13

Manual Buttonhole .......................................................4:14

Embroidered buttonhole .............................................4:14

Programmable Button Sew On ...................................4:14

Bartacks...........................................................................4:15

Manual Bartack ..............................................................4:15

4-way Stitches - Menu S ...............................................4:16

8-Way Stitches – Menu T .............................................4:17

Special Sewing Techniques ..........................................4:18

Taper Satin Stitch ..........................................................4:18

Decorative Tapering Stitches .......................................4:18

SEWING POP-UP MESSAGES 4:19

5 Program 5:1

IMPORTANT PROGRAM MODE INFORMATION 5:2

PROGRAM - OVERVIEW OF ICONS 5:2

TO PROGRAM IN SEWING MODE 5:3

TO PROGRAM IN EMBROIDERY EDIT 5:3

EDIT YOUR STITCH OR LETTERING PROGRAM 5:3

Preview..............................................................................5:4

Adjust the Entire Program ............................................5:4

Stitch program commands .............................................5:4

SEWING A STITCH PROGRAM 5:4

TO SAVE A STITCH PROGRAM 5:5

Save to “My Stitches” .....................................................5:5

Save your Program in “My Files” .................................5:5

TO RE-LOAD A STITCH PROGRAM 5:6

PROGRAM POP-UP MESSAGES 5:6

6 Embroidery Set Up 6:1

EMBROIDERY UNIT OVERVIEW 6:2

EMBROIDERY HOOP OVERVIEW 6:2

CONNECT THE EMBROIDERY UNIT 6:2

REMOVE THE EMBROIDERY UNIT 6:3

TO HOOP THE FABRIC 6:3

SLIDE ON THE HOOP 6:4

BUILT-IN DESIGNS 6:4

DESIGNER RUBY™ Sampler Book .........................6:4

GETTING STARTED EMBROIDERING 6:5

7 Embroidery Edit 7:1

MAIN FUNCTIONS IN THE

EXTENDED EMBROIDERY EDIT TOOLBAR 7:2

Load a Stitch ....................................................................7:2

Load a Font ......................................................................7:2

Load a Design ..................................................................7:2

Exclusive EMBROIDERY ADVISOR™ ...................7:2

File Manager.....................................................................7:2

SET Menu ........................................................................7:2

Information Menu ..........................................................7:2

EMBROIDERY EDIT - OVERVIEW OF ICONS 7:3

MY HOOPS 7:3

RESIZE 7:4

Important Resize information .......................................7:5

COLOR EDIT 7:6

Thread Color Change .....................................................7:6

Grid ...................................................................................7:6

2-dimensional/3-dimensional view toggle ..................7:6

EDIT STITCH PROGRAM 7:7

SAVE EDITED DESIGN 7:7

PARK POSITION 7:7

MOVE T O HOOP 7:7

ZOOM 7:7

STITCH-OUT ORDER OF SELECTED DESIGN 7:7

TOUCH FUNCTIONS 7:8

UNDO 7:9

REDO 7:9

MIRROR SIDE-TO-SIDE AND END-TO-END 7:9

DELETE 7:9

DUPLICATE 7:9

HOW TO SELECT DESIGNS 7:10

Advanced selection .......................................................7:10

PROGRAM EMBROIDERY FONTS 7:11

EMBROIDERY EDIT POP-UP MESSAGES 7:12

8 Embroidery Stitch-Out 8:1

TO ENTER EMBROIDERY STITCH-OUT 8:2

EMBROIDERY STITCH-OUT - OVERVIEW OF ICONS 8:2

DESIGN POSITIONING 8:3

How to use Design Positioning ....................................8:4

BASTE IN HOOP 8:6

MOVE HOOP 8:6

FULL SCREEN 8:7

MONOCHROME 8:7

CORNER CHECK 8:7

ZOOM 8:7

REMAINING EMBROIDERY TIME BY COLOR 8:7

THREAD TENSION CONTROL 8:8

STEP STITCH-BY-STITCH CONTROL 8:8

Go to Stitch ......................................................................8:8

RETURN TO EMBROIDERY EDIT 8:8

NUMBER OF STITCHES IN

EMBROIDERY COMBINATION 8:9

NUMBER OF STITCHES IN

CURRENT COLOR BLOCK 8:9

COLOR BLOCK LIST 8:9

FUNCTION BUTTONS IN EMBROIDERY STITCH-OUT 8:10

EMBROIDERY STITCH-OUT POP-UP MESSAGES 8:11

Design Positioning ........................................................8:12

9 File Manager 9:1

FILE MANAGER - OVERVIEW OF ICONS 9:2

AVAILABLE MEMORY 9:2

FILE FORMATS 9:2

BROWSE FILE MANAGER 9:3

List View ...........................................................................9:3

My Designs .......................................................................9:3

My Fonts ..........................................................................9:3

My Files .............................................................................9:3

Built-in designs ................................................................9:3

External Device ...............................................................9:4

Open a Folder ..................................................................9:4

Open a File .......................................................................9:4

Move Up One Folder Level ...........................................9:4

Folder Structure ...............................................................9:4

ORGANIZE 9:5

Create a New Folder .......................................................9:5

Rename a File or Folder .................................................9:5

Move a File or Folder .....................................................9:5

Copy a File or Folder ......................................................9:5

Delete a File or Folder ...................................................9:5

FILE MANAGER POP-UP MESSAGES 9:6

10 Maintenance 10:1

CLEANING THE MACHINE 10:2

TROUBLESHOOTING 10:3

INDEX 10:5

INTELLECTUAL PROPERTY 10:11

1

GETTING TO KNOW YOUR MACHINE

1:6

16

20

24

22

21

23

1

2

5

12

7

3

4

8

10

9

13

6

11

8

17

18

19

14

15

27

26

25

34

33

31

29

32

28

30

1. Lid

2. Pre-Tension Thread guide

3. Thread tension discs

4. Thread take-up lever

5. Thread slots

6. Thread tension disc for bobbin winding

7. Thread cutter

8. LED-lights

9. Needle plate

10. Bobbin cover

11. Button ruler and built-in tape measure

12. Base plate

13. Function button panel

14. Main spool pin

15. Bobbin winding thread guide

16. Auxiliary spool pin

17. Bobbin winder

18. Thread cutter for bobbin winding

19. Bobbin winder lever

20. Handwheel

21. Interactive Color Touch Screen

22. Built-In USB ports

23. Stylus holder

24. ON/OFF switch, connectors for power

cord and foot control

REAR SIDE

25. Handle

26. Free arm

27. Embroidery unit connection socket

NEEDLE AREA

28. Sensor One-Step Buttonhole Foot

socket

29. Built-In needle threader

30. Needle bar

31. Needle clamp

32. Needle thread guide

33. Presser foot bar and presser foot ankle

34. Presser foot

MACHINE OVERVIEW

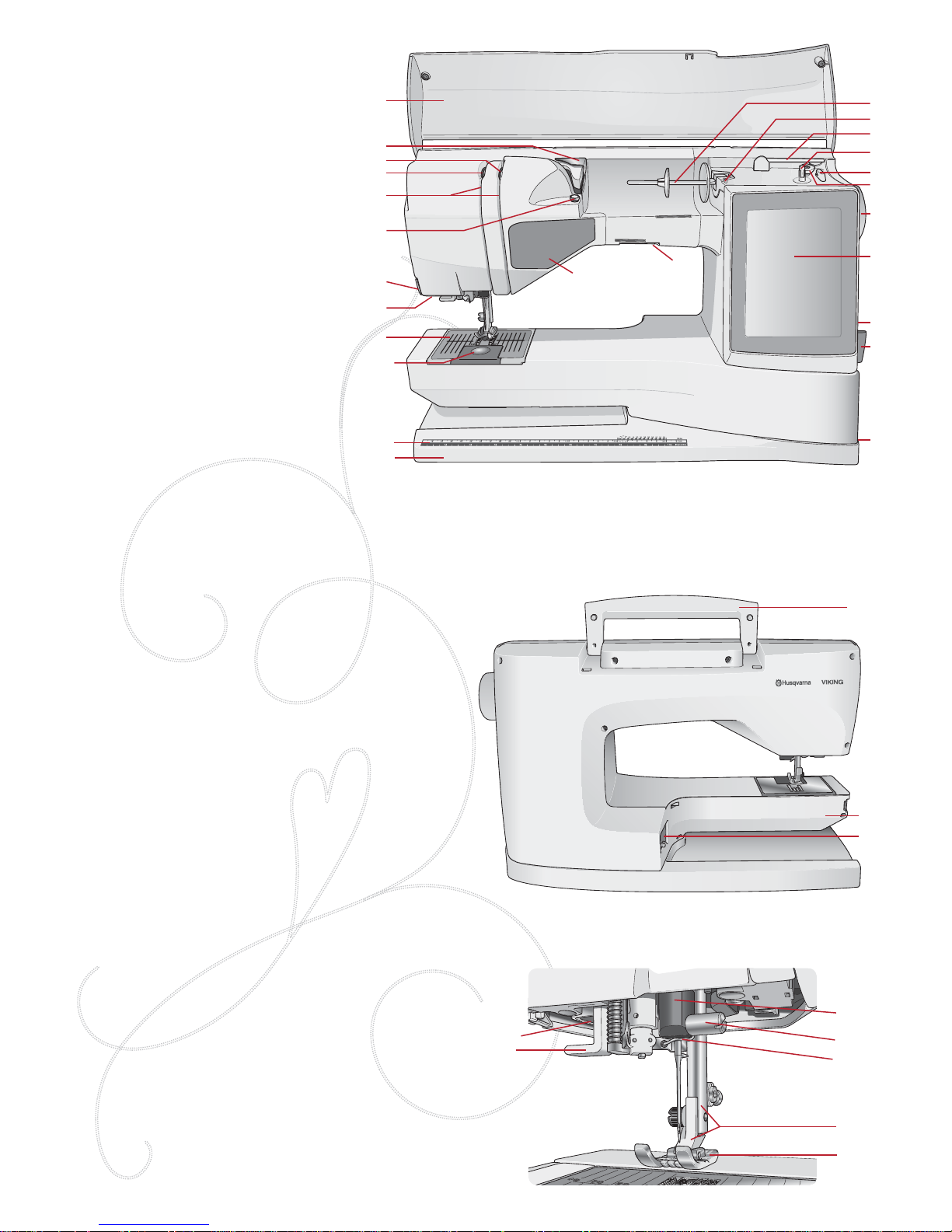

GETTING TO KNOW YOUR MACHINE 1:7

37

38

39

40

41

40

46 47 48 49

43 44 45

50 51 52

53 54 55 56

42

57 58

36

35

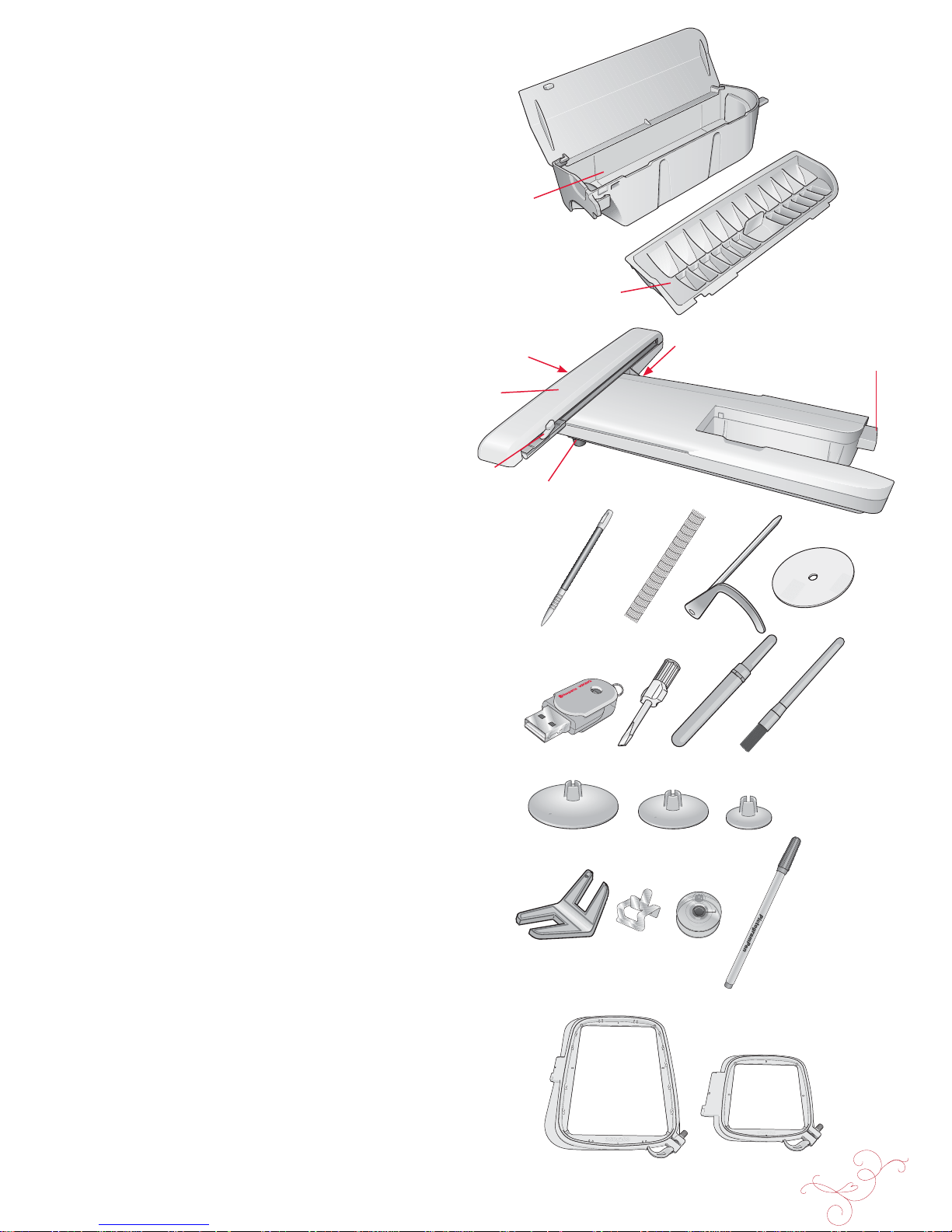

ACCESSOR Y TRA Y

The accessory tray features special compartments for

presser feet and bobbins, plus space for needles and other

accessories. Store the accessories in the tray so that they are

easily accessible.

35. Space for accessories

36. Removable presser feet and bobbin holder

PARTS OF THE EMBROIDERY UNIT

(type BE 18)

37. Embroidery unit release button (underside)

38. Embroidery arm

39. Embroidery hoop attachment

40. Level adjustment feet

41. Embroidery unit socket

ACCESSORIES

INCLUDED ACCESSORIES

42. Stylus

43. Thread net

44. Edge/ Quilting guide

45. Felt pad (2)

46. USB embroidery stick (1 GB)

47. Screwdriver

48. Seam ripper

49. Brush

50. 2 spool caps, large

(1 attached on the machine at delivery)

51. Spool cap, medium

(attached on the machine at delivery)

52. Spool cap, small

53. Multipurpose tool/ Button reed

54. Hoop clips (16)

55. 11 Bobbins (1 in machine at delivery)

56 PICTOGRAM™ Pen

HOOPS INCLUDED

57. DESIGNER™ Royal Hoop (360x200)

58. DESIGNER™ Splendid Square Hoop (120x120)

1:8

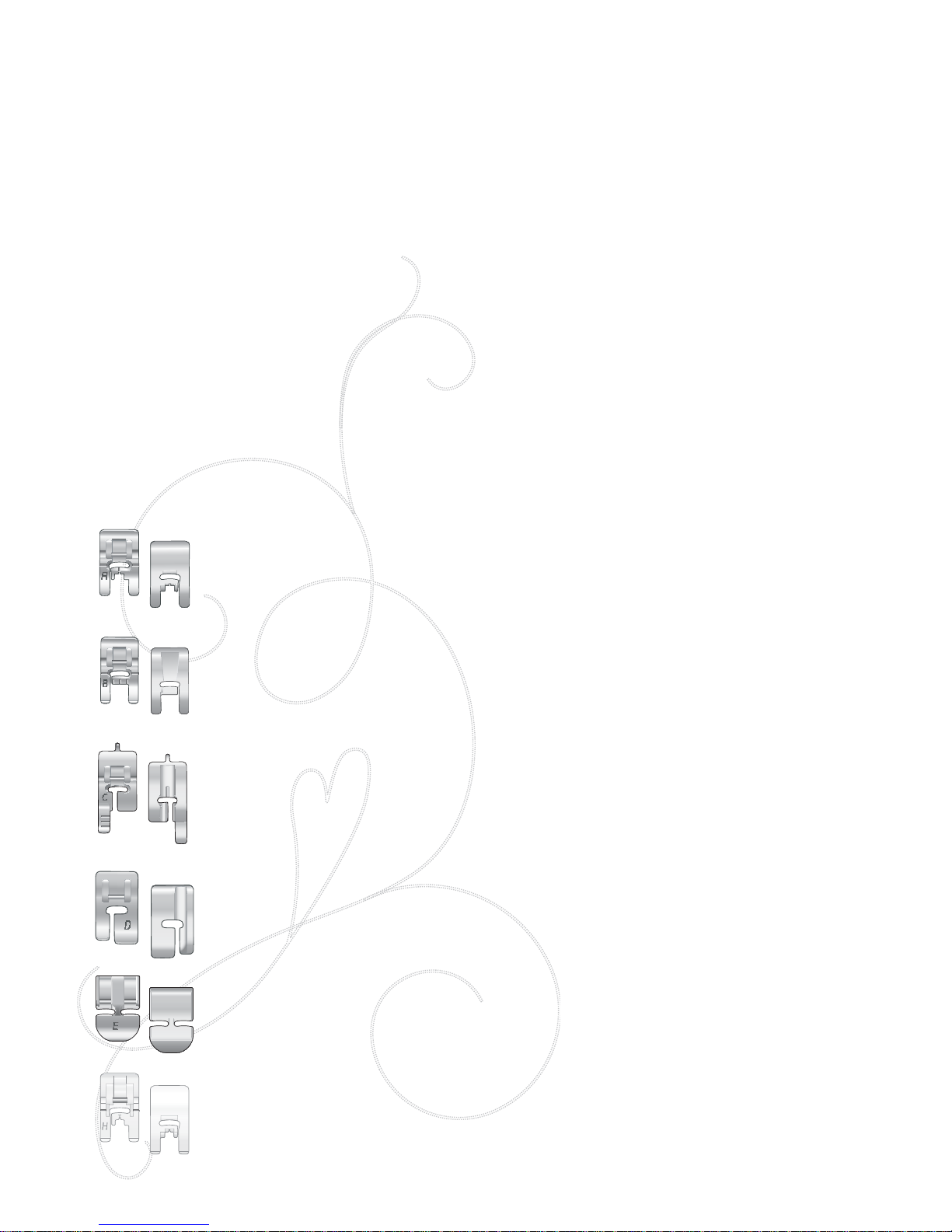

PRESSER FEET

7

Utility Foot A

Snapped onto the machine upon delivery. This foot is used mainly for straight stitching and

zigzag stitching with a stitch length longer than 1.0.

7

Decorative Stitch Foot B

For sewing close zigzag stitches (satin stitches) with less than 1.0 mm stitch length, other utility

stitches or decorative stitches, use this foot. The tunnel on the underside of the foot is designed

to feed smoothly over the stitches.

7

Buttonhole Foot C

For manual buttonholes. This foot has guide lines to determine buttonhole length. The middle

measures a 5/8'' (15 mm) from the fabric edge. The two tunnels on the underside of the foot

ensure a smooth feed over the buttonhole columns. The À nger on the back of the foot holds

cording for corded buttonholes.

Blindhem Foot D

This foot is used for blindhem stitches. The inner edge of this foot guides the fabric. The right

toe of the foot is designed to ride along the hem edge.

7

Zipper Foot E

This foot can be snapped on either to the right or to the left of the needle. This makes it easy to

sew both sides of the zipper. Move needle position to right or left to sew closer to zipper teeth

or for covering large cording.

7

Non-Stick Glide Foot H

This foot, with a non-stick coating underneath, is used when sewing foam, vinyl, plastic, or

leather to keep these materials from sticking to the foot.

ACCESSORIES INCLUDED - Not in the Picture

• 5D™ Embroidery Machine Communication CD

• Carrying Case (attached on the machine upon delivery)

• Scissors

• Foot control

• Power cord

• USB PC cable

• Needles

• Embroidery thread

• Pieces of fabric and stabilizer

• DESIGNER RUBY™ Sampler book

• User’s Guide

• Warranty card

GETTING TO KNOW YOUR MACHINE 1:9

Edging Foot J

This foot is used for overcasting and seam/overcasting, with stitches that have a stitch width

of 5.0 and 5.5 mm. Stitches form over the pin which prevents puckering at the edge of the

fabric.

Quilter’s 1/4” Piecing foot P

This foot is used when piecing quilt blocks. The foot has distance guidelines marks 1/4"

(6 mm) and 1/8" (3 mm) from the needle.

Embroidery/ Darning Foot R

This foot is used for free motion embroidery/quilting/stitching and hoop embroidery.

7

Side Motion Foot S

This foot is used for side-motion/Omnimotion stitches.

7

Decorative Stitch Foot B Transparent

A clear foot for decorative sewing ma kes it easy to match stitches. Same tunnel on the

underside as Presser Foot B.

7

Sensor One-Step Buttonhole Foot

Plug into the machine then enter the desired buttonhole length to sew Sensor One-Step

Buttonholes. The middle mark measures a 5/8" (15 mm) from fabric edge.

Self-Adhesive Glide Plates

Used for Presser Foot C/Sensor One-Step Buttonhole Foot when sewing buttonholes on

plastic-coated fabrics, leather, etc.

1:10

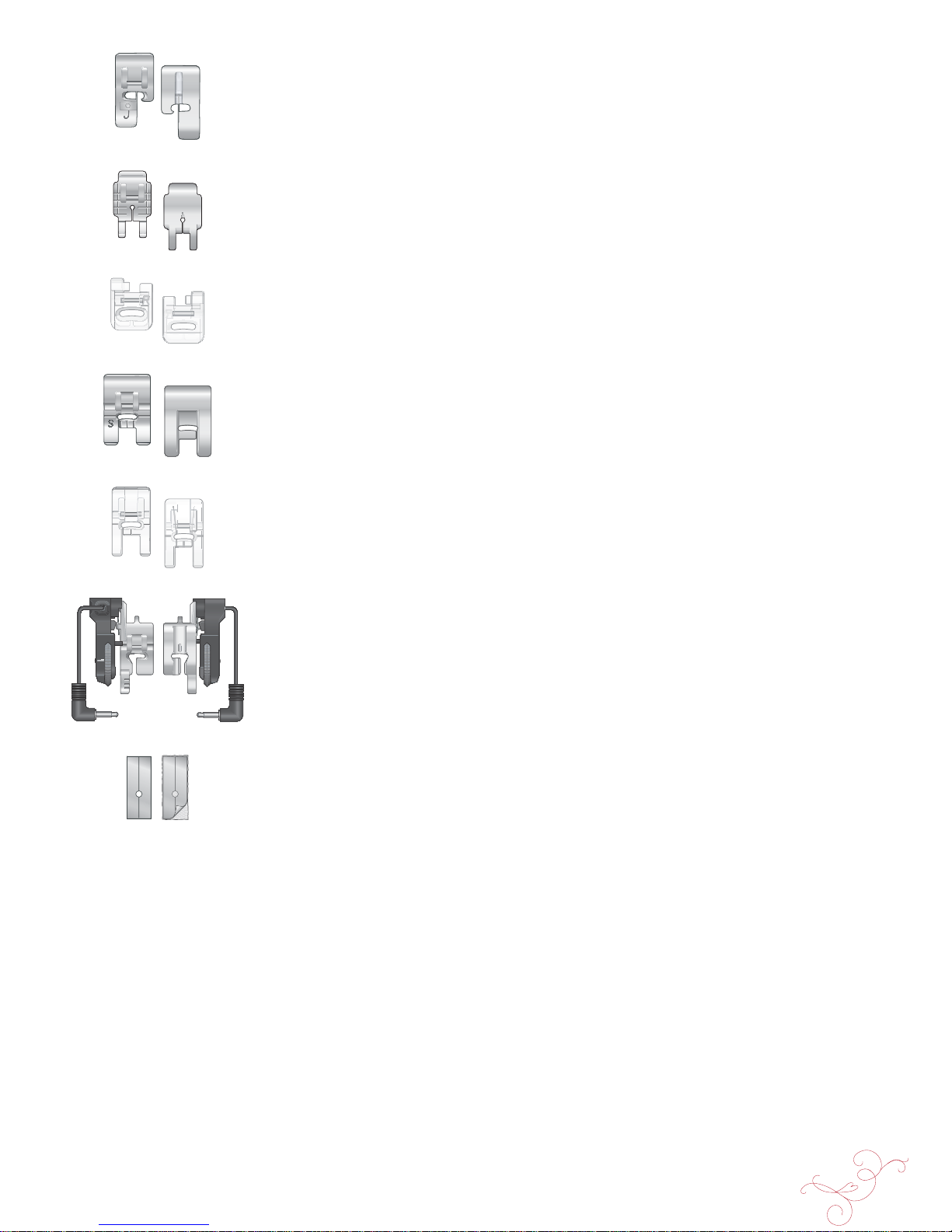

STITCHES

A – Utility Stitches

Stitches for garment sewing and mending.

Stitch Stitch description

Presser

Foot

A1, A2, A3 – Straight Stitch, left, center and right needle position

For all types of sewing. Touch stitch width and Side-to-Side mirror image to select 29 different needle

positions.

A

A4, A5, A6 – Stretch Stitch, left, center and right needle position

For seams in tricot and stretch fabrics.

A

A7, A8, A9 – Reinforced Straight Stitch, left, center and right needle position

Triple and elastic, for reinforced seams. For topstitch, increase the stitch length. 29 different needle

positions.

A

A10, A11, A12 – Zigzag, left, center and right needle position

For sewing on lace, bands and appliqués.

A

A13 – Three Step Zigzag

For overcasting, mending, sewing on patches and elastic. Suitable for light and medium weight fabrics.

A

A14 – Serpentine Stitch

For mending and elastic applications.

A

A15 – Four-Step Zigzag

For overcasting, mending, sewing on patches and elastics on loosely woven fabrics.

A

A16 – Overcast Stitch

Seam and overcast in one step along the edge or trim later. For light stretch and non-stretch fabrics.

J

A17 – Stretch Seam Overcast Stitch

Seam and overcast in one step along the edge or trim later. For medium and medium/heavy stretch

fabrics.

B

A18 – Double Overlock Stitch

Seam and overcast in one step along the edge or trim later. For heavy stretch and heavy woven fabrics.

B

A19 – Overlock Stitch

Seam and overcast in one step along the edge or trim later. For medium stretch fabrics.

B

A20 – Flatlock Stitch

Decorative hems and overlapped seams, belts and bands. For medium/heavy stretch fabrics.

B

A21 – Elastic/Casing Stitch

For overlapped seams in tricot. To sew casing over narrow elastic.

B

A22 – Reinforced Zigzag Stitch

For joining fabric edge to edge or overlapping in leather. For decorative sewing.

B

A23 – Basting Stitch

For joining two pieces of fabric with a long stitch length and reduced tension.

A

A24 – Stretch Blind Hem Stitch

Blind hems in stretch medium and heavy fabrics.

D

GETTING TO KNOW YOUR MACHINE 1:11

Stitch Stitch description

Presser

Foot

A25 – Woven Blind Hem Stitch

Blind hems in medium and heavy woven fabrics.

D

A26 – Shell Edge Stitch

For edgings, sew over the edge on light stretch fabrics, sew woven fabric on bias.

A

A27 – Elastic or Smocking Stitch

Sew over two rows of elastic thread for elastic shirring.

B

A28 – Bridging Stitch

For joining two pieces of fabric with À nished edges and for elastic shirring.

B

A29 – Bartack Stitch

Reinforce pockets, shirts openings, belt loops as well as at lower end of a zipper.

B

A30 – Darning Stitch (Forward and Backward)

Darn and mend small holes in work clothes, jeans, tablecloths and linen towels. Stitch over hole, touch

reverse for continuous darning and auto stop.

A

A31 – Darning Stitch (Side to Side)

For mending small tears.

A

A32 – Reinforced Darning Stitch

Darn and mend work clothes, jeans, table cloths and linen towels. Stitch over hole, touch reverse for

continuous darning and auto stop.

A

A33 – Bartack, Manual

Reinforce pockets, shirts openings, belt loops as well as at lower end of a zipper.

B

A34 – Gathering Stitch

For gathering.

A

A35 – Belt Loop Stitch

For securing belt loops.

A

A36 – Three-Step Zigzag

For overcasting, mending, sewing on patches and elastic. Suitable for light and medium weight fabrics.

J

A37 – Two-Step Zigzag

For joining two pieces of fabric with À nished edges and for elastic shirring.

A

A38 – Straight stitch with FIX

Begins and ends with forward and reverse sewing.

A

A39 – Straight Basting Stitch

Use together with the foot control to baste pieces of the fabric together. Feed the fabric by moving to

the next baste position when sensor foot lifts. Feed teeth lowered automatically.

A

A40 – Zigzag Basting

Use together with the foot control to baste layers of the fabric by moving to the next baste position

when foot lifts.

A

1:12

Stitch Stitch description Presser Foot

B1 – Bartack Buttonhole

For most fabric weights.

Sensor Buttonh.

Foot /C

B2 – Round-End Buttonhole

For blouses and children’s garments.

Sensor Buttonh.

Foot /C

B3 – Medium Reinforced Buttonhole

For medium fabrics.

C

B4 – Heirloom Buttonhole

For hand look on À ne and delicate fabrics.

Tip: For jeans buttonholes, increase length and width of the buttonhole. Use thicker thread.

Sensor Buttonh.

Foot /C

B5 – Rounded Heirloom Buttonhole

For hand look on À ne and delicate fabrics.

Sensor Buttonh.

Foot /C

B6 – Keyhole Buttonhole

Square end for tailored jackets, coats, etc.

Sensor Buttonh.

Foot /C

B7 – Heavy Duty Buttonhole

With reinforced bartacks.

Sensor Buttonh.

Foot /C

B8 – Leather Buttonhole (Straight Stitch)

For leather and suede.

A

B9 – Bound Buttonhole (Straight Stitch)

With extra cutting space for bound buttonholes.

A

B10 – Automatic Button Sewing

For sewing on buttons

-

B11 – Round Eyelet

For belts, laces, etc.

B

B12 – Decorative Fashion Buttonhole

For most fabric weights.

Sensor Buttonh.

Foot /C

B - Buttonhole Stitches

Different styles of buttonholes, eyelets and button sewing.

GETTING TO KNOW YOUR MACHINE 1:13

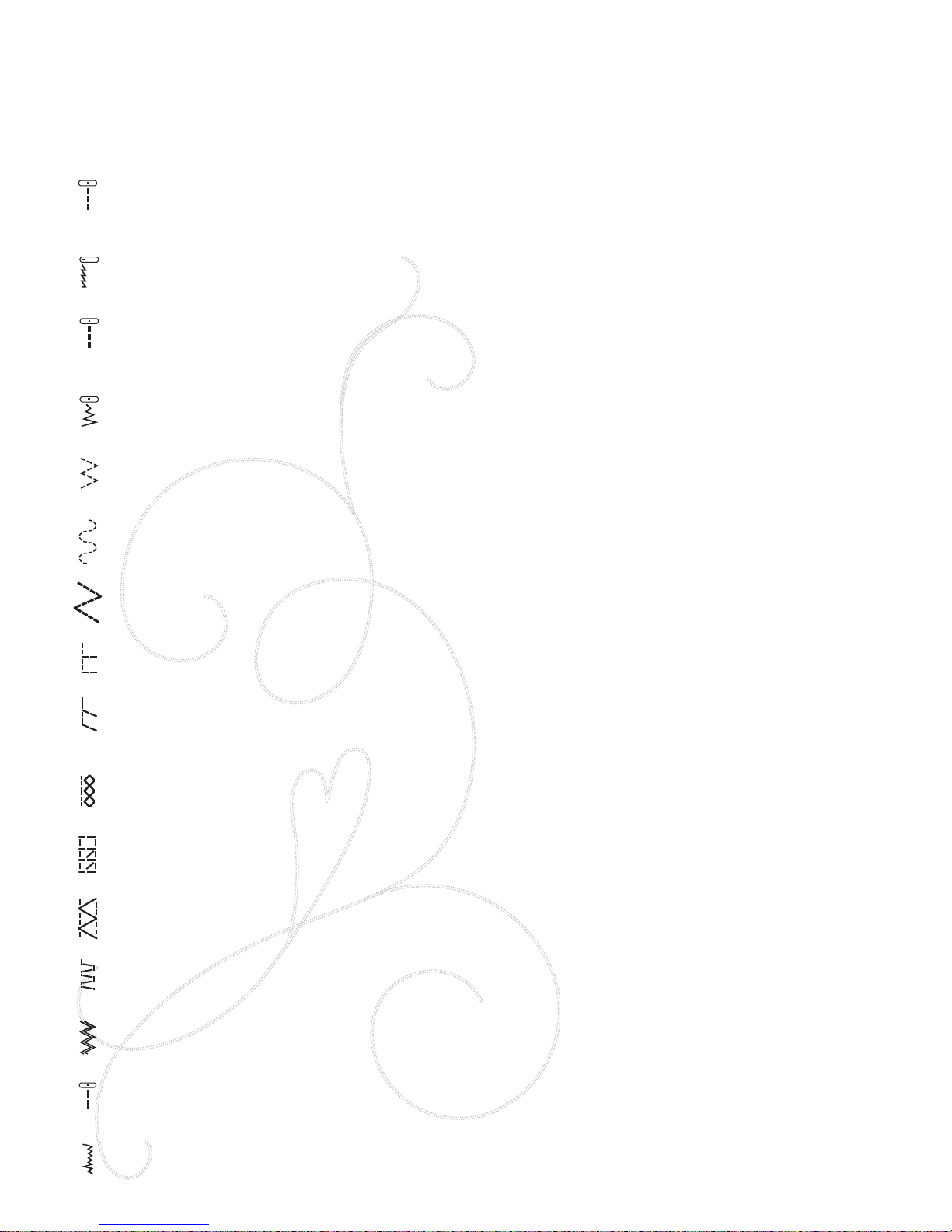

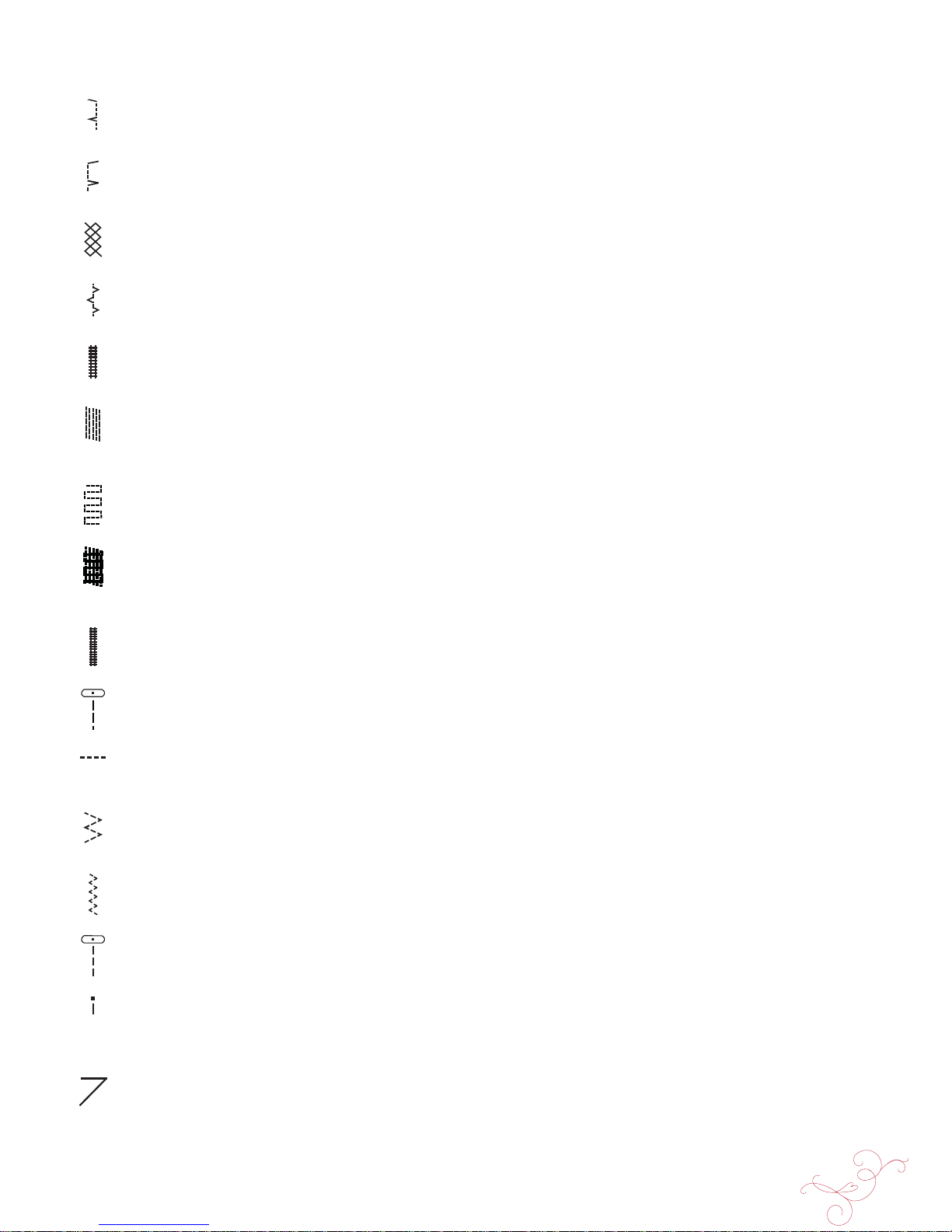

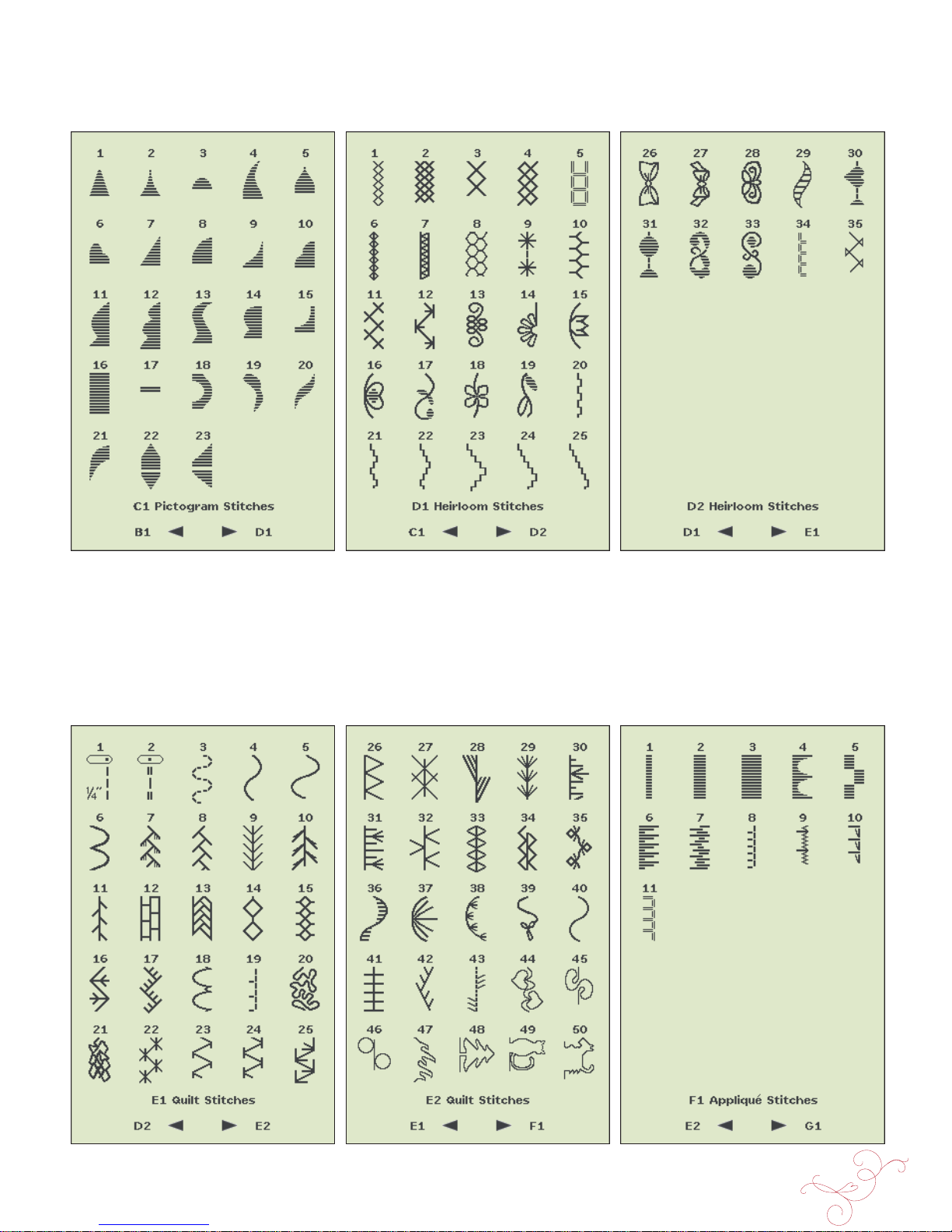

C - Pictogram Stitches

Pictogram satin elements to program

original satin stitch designs.

D - Heirloom Stitches

For hemstitching, smocking and sewing

on lace and trims.

E - Quilt Stitches

Stitches for all types of quilting

techniques.

F - Appliqué Stitches

For sewing appliqués with different

effects.

1:14

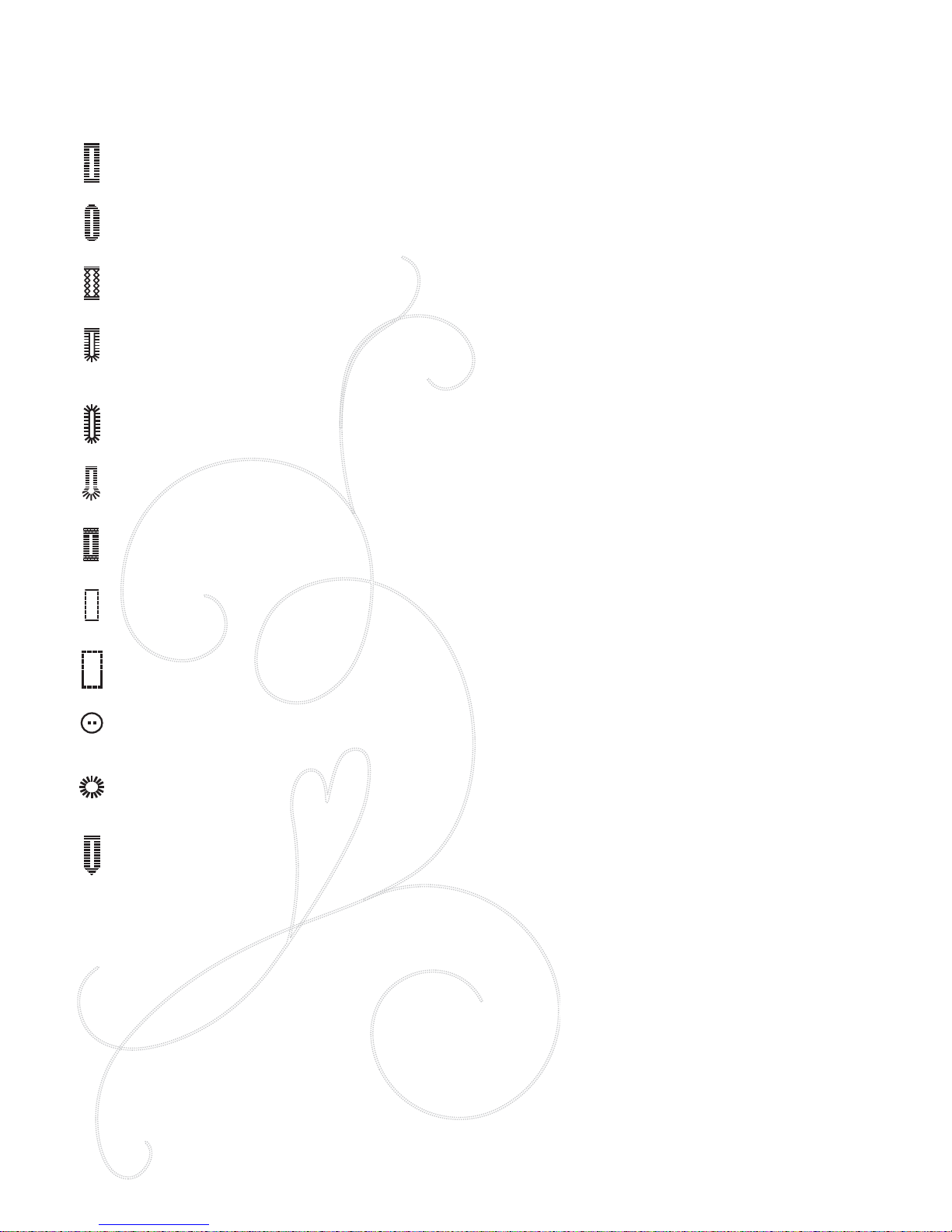

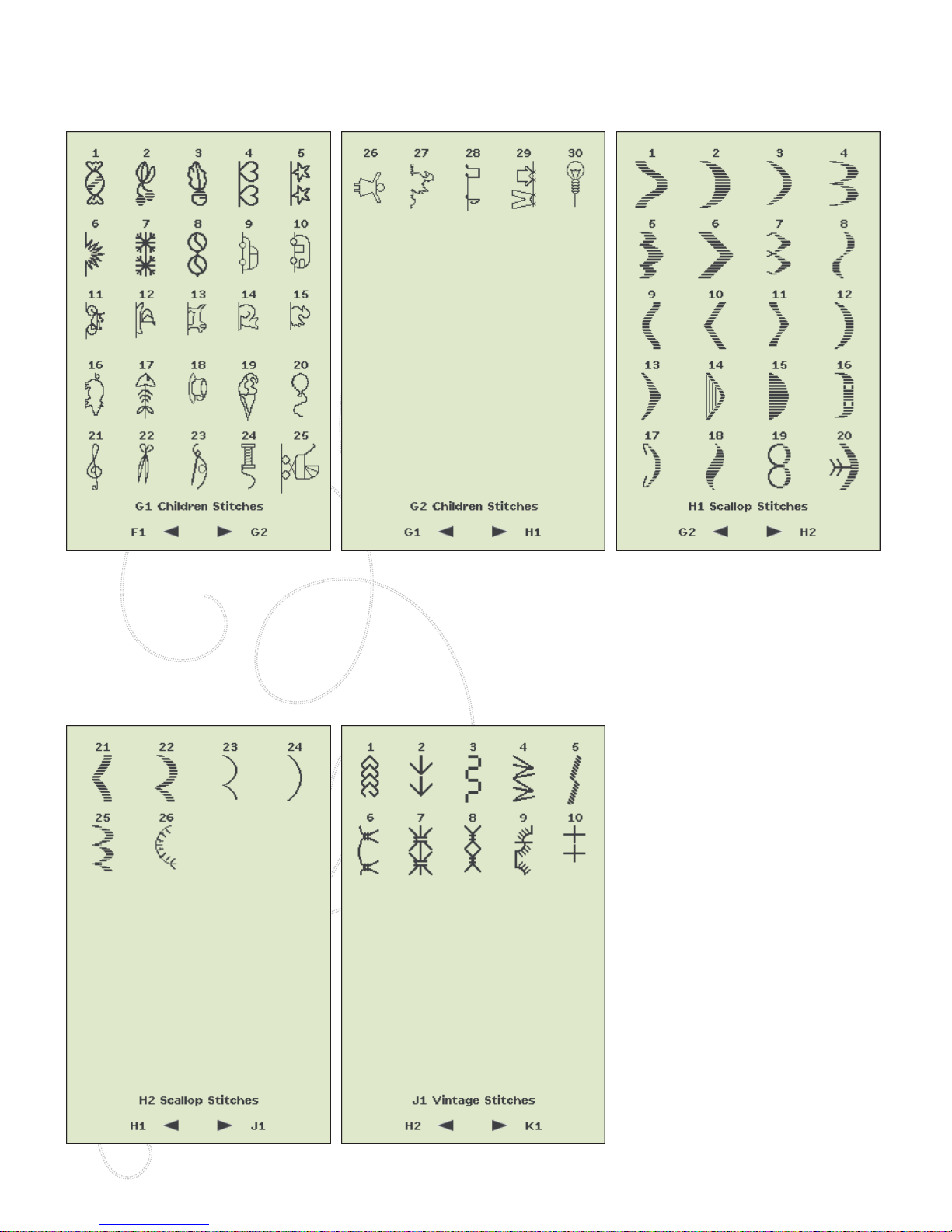

G - Children Stitches

Stitches suitable for sewing on

children’s clothes and projects.

H - Scallop Stitches

Create scallop details and À nish edges

with beautiful scallop stitches.

J - Vintage Stitches

A selection of quilt stitches for crazy

patch quilting and decorative stitching.

GETTING TO KNOW YOUR MACHINE 1:15

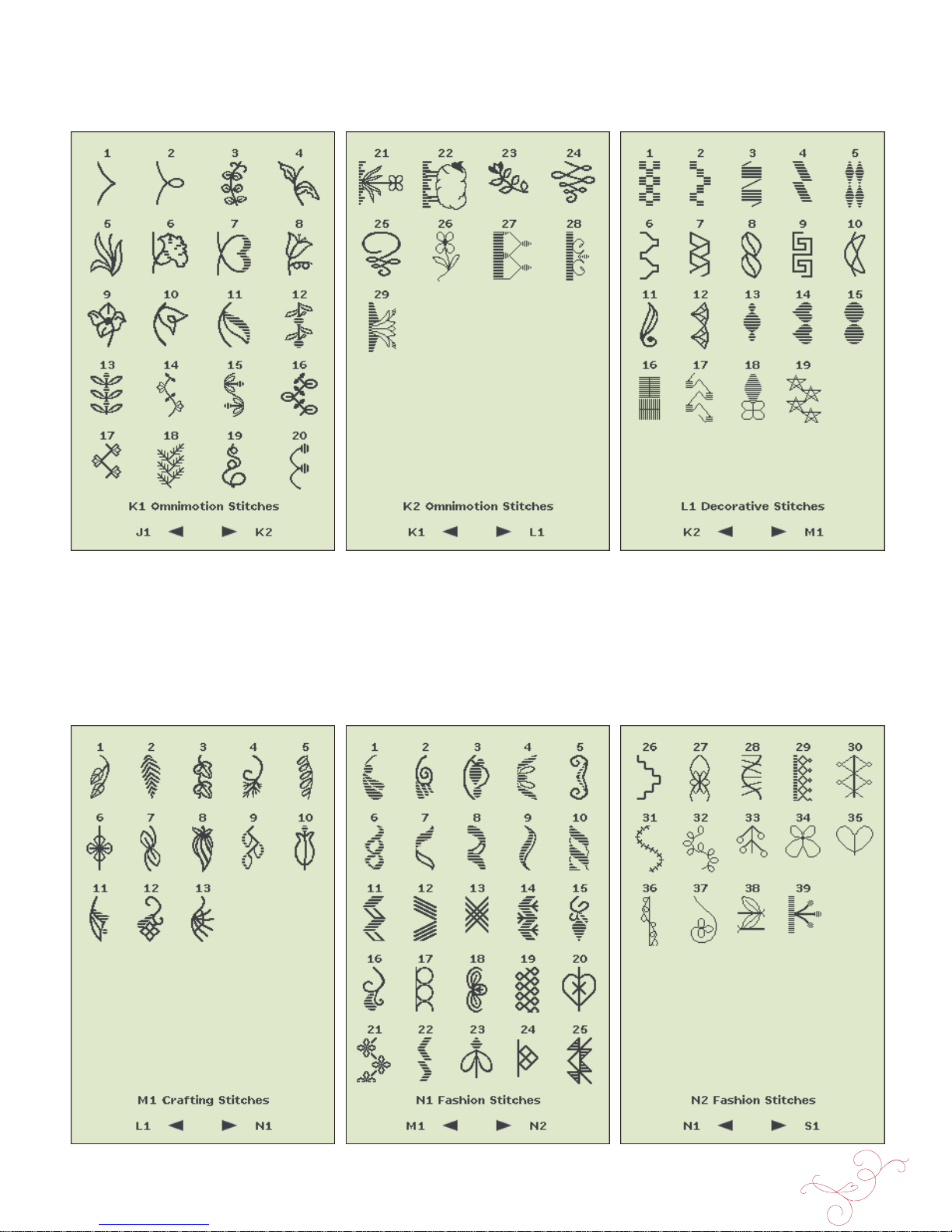

K - Omnimotion Stitches

Program these stitches into an unlimited number of

combinations. Stitches are formed with side motion. The stitch

width can be up to 40 mm wide or more.

L - Decorative Stitches

For decorative sewing.

M - Crafting Stitches

For decorative stitches to embellish

crafts.

N - Fashion Stitches

Fashion stitches to decorate clothing

and accessories.

1:16

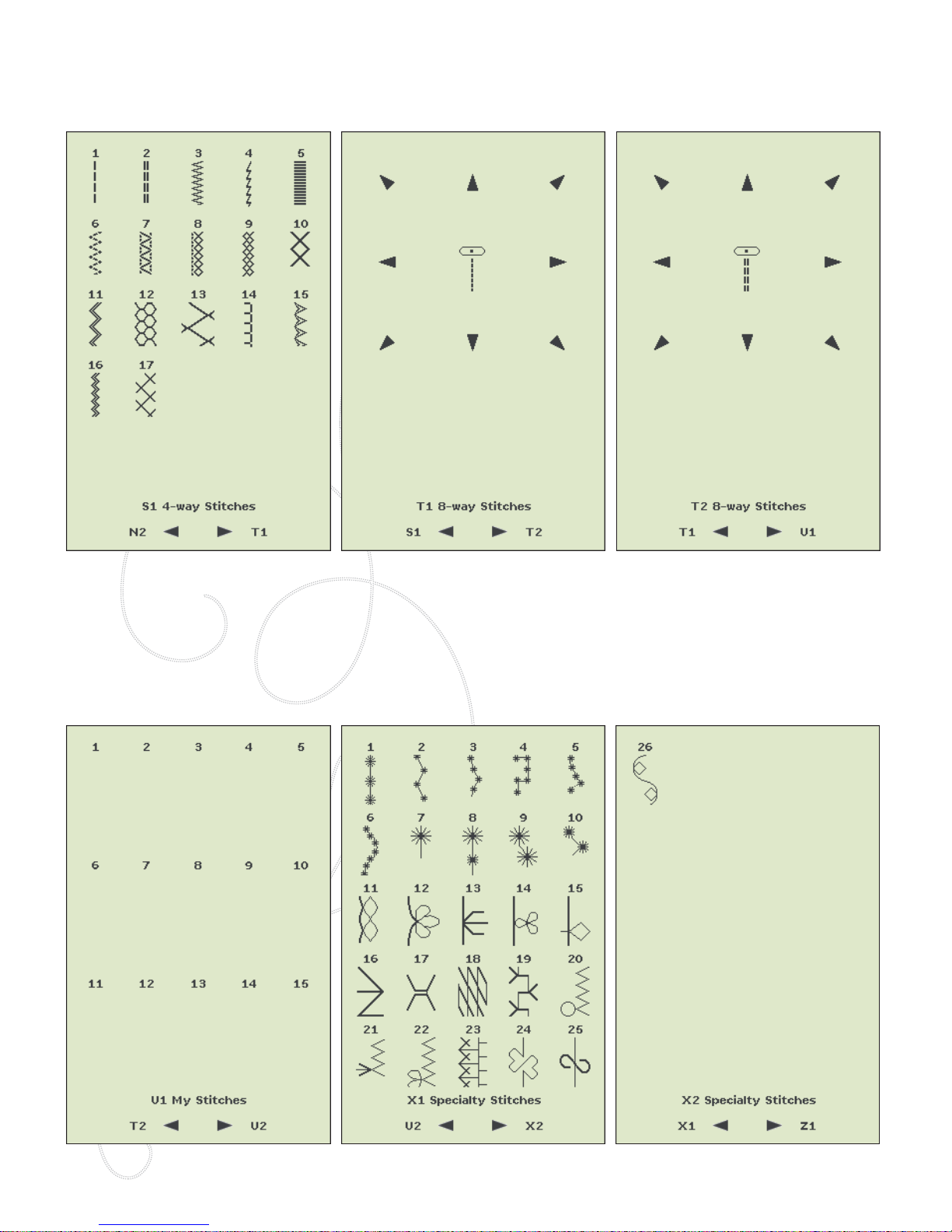

S - 4-way Stitches

For directional sewing and patching

using the free arm

T - 8-way Stitches

Straight stitch and reinforced straight

stitch in eight different directions

without turning the fabric.

U - My Stitches

Save your own personally adjusted and

favorite stitches and stitch programs.

X - Specialty Stitches

Sew special techniques including candlewicking and edging. Extra accessories

may be needed. Use Quick Help for detailed information

GETTING TO KNOW YOUR MACHINE 1:17

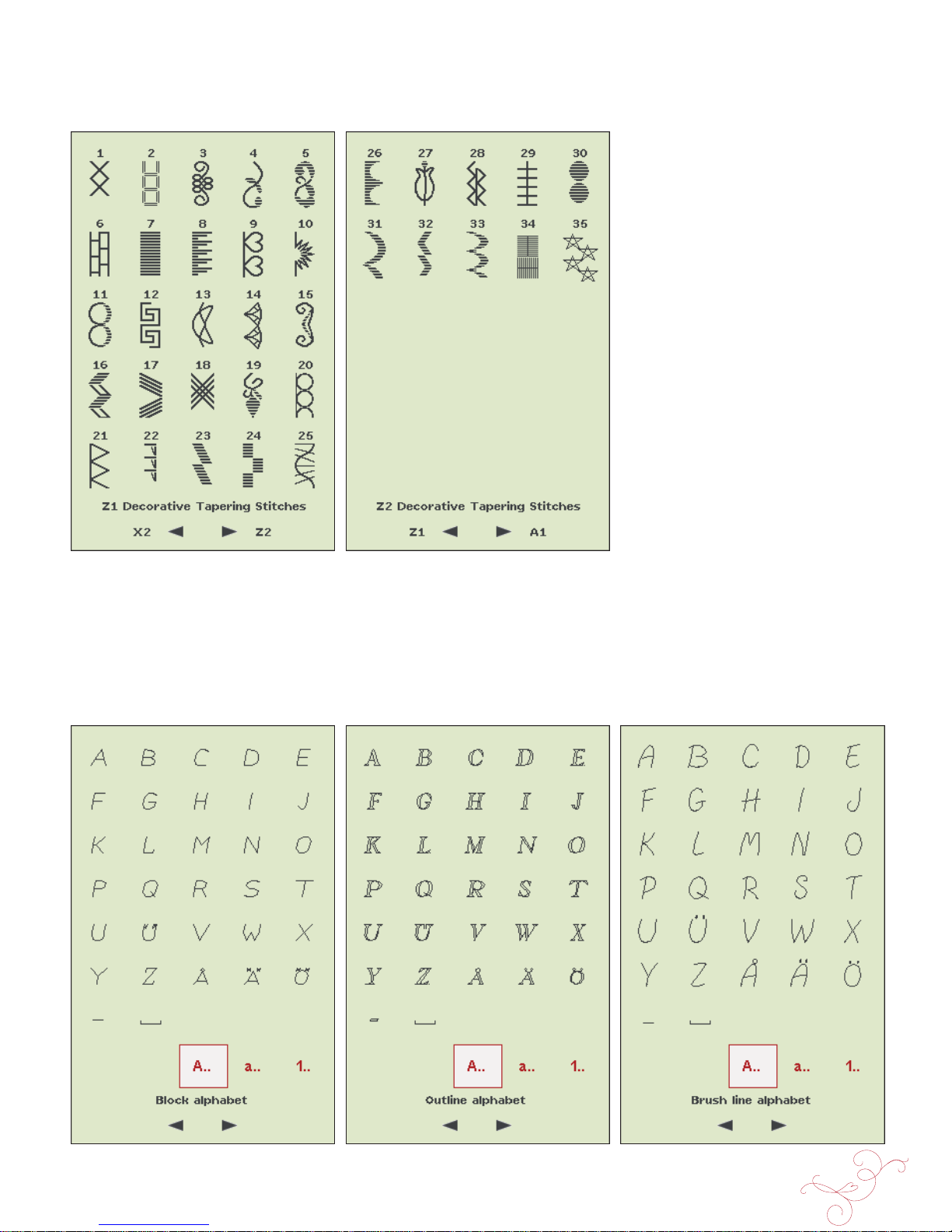

Block Alphabet Outline block Alphabet Brush Line Alphabet

Z - Decorative T apering Stitches

Decorative stitches with tapering.

1:18

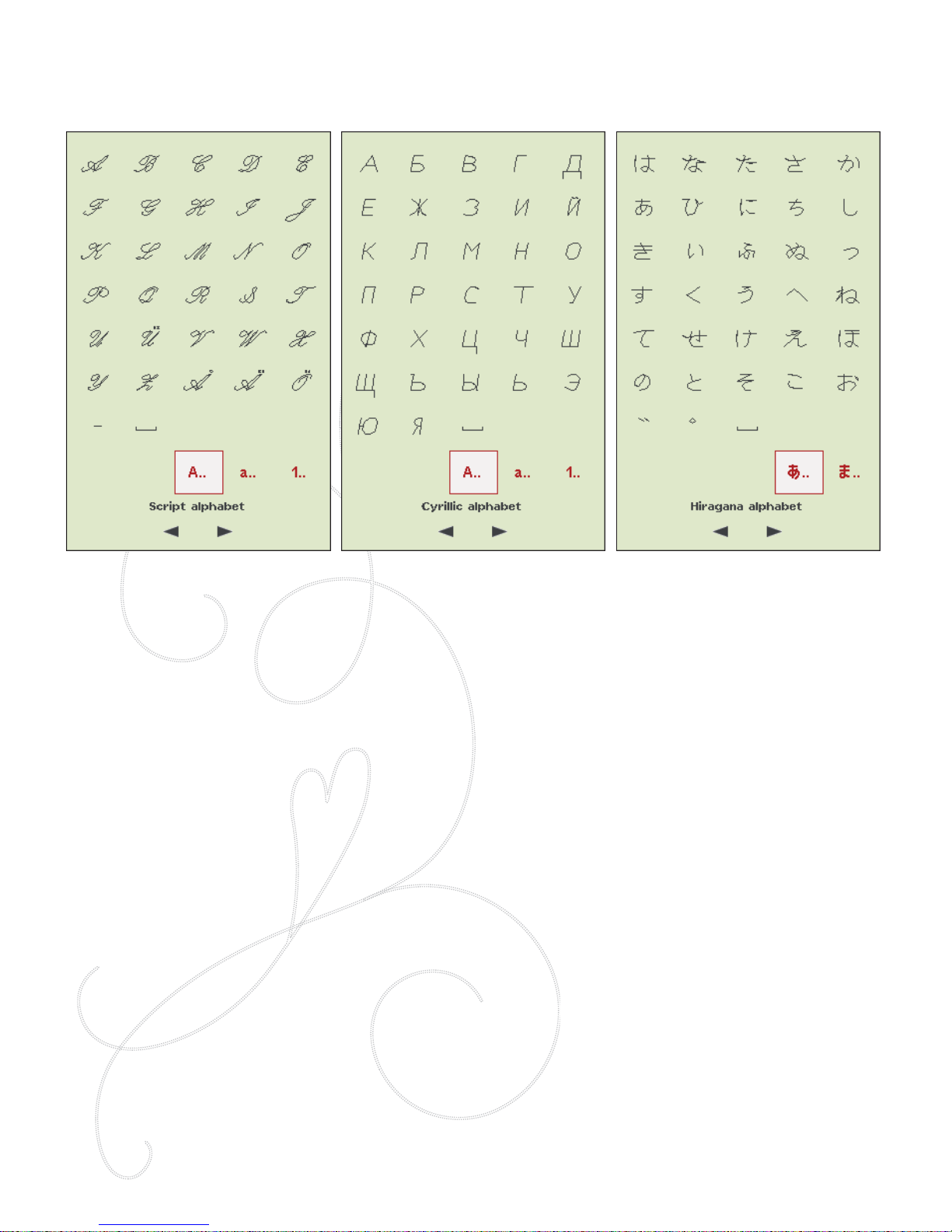

Script Alphabet Cyrillic Alphabet Hiragana Alphabet

SET UP

2

2:2

OFF

ON

312

UNPACKING

1. Place the box on a steady, Á at surface. Lift off the

machine carrying case. Lift your machine out of the

box and remove the outer packaging.

2. Remove all other packing material and the plastic bag.

CONNECT THE POWER CORD AND FOOT

CONTROL

Among the accessories you will À nd the power cord and

the foot control.

Note: Before plugging in the foot control, check to ensure that it is type

“FR5” (see underside of foot control).

1. Pull out the cord from the foot control. Connect the

foot control cord to the front socket on the bottom

right side of the machine (1).

2. Connect the power cord to the rear socket on the

bottom right side of the machine (2).

3. Press the ON/OFF switch to ON to turn on power

and light (3).

For the USA and Canada

This sewing machine has a polarized plug (one blade wider

than the other). To reduce the risk of electric shock, this

plug is intended to À t in a polarized outlet only one way. If

the plug does not À t fully in the outlet, reverse the plug. If

it still does not À t, contact a qualiÀ ed electrician to install

the proper outlet. Do not modify the plug in any way.

P ACK A W A Y AFTER SEWING

1. Press the ON/OFF (3) switch to OFF.

2. Unplug the cord from the wall socket and then from

the machine (2).

3. Unplug the foot control cord from the machine (1).

Pull the cord gently and release. The cord will retract

itself into the foot control.

4. Place all accessories in the accessory tray. Slide the tray

on to the machine, behind the free arm.

5. Place the foot control in the space above the free arm.

6. Place the hard cover over your machine.

SET UP 2:3

FREE ARM

Slide the accessory tray to the left when you wish to

remove it and use the free arm.

Use the free arm to facilitate sewing trouser legs and sleeve

hems.

To replace the accessory tray, slide it onto the machine until

it À ts in place.

SPOOL PINS

Your machine has two spool pins; a main spool pin and

an auxiliary spool pin. The spool pins are designed for all

types of thread. The main spool pin is adjustable and can

be used both in a horizontal position (the thread reels off

the spool) and a vertical position (the thread spool rotates).

Use the horizontal position for regular sewing threads and

the vertical position for specialty threads.

HORIZONTAL POSITION

Place a spool cap and the thread spool on the spool pin.

Make sure that the thread reels over the top. Slide on a

second spool cap, slightly larger than the thread spool.

The Á at side of the spool cap should be pressed À rmly

against the spool. There should be no space between the

spool cap and the thread spool.

VERTICAL POSITION

Lift the spool pin up and all the way to the right. Lock

the spool pin in the vertical position by slightly pressing it

down. Slide on the large spool cap. For spools smaller than

the medium size spool cap or when using specialty threads,

place a felt pad under the thread spool to prevent the

thread from reeling off too fast. For larger spools, the felt

pad is not needed.

Do not place a spool cap on top of the vertical spool pin as

it may prevent the spool from rotating.

Note: When the spool pin is used in the vertical position, the thread

tension might need to be adjusted manually.

AUXILIARY SPOOL PIN

The auxiliary spool pin is used when winding a bobbin

from a second spool of thread or for a second spool when

sewing with a twin needle.

Lift the auxiliary spool pin up and to the left. Slide on

the large spool cap. For spools smaller than the medium

size spool cap, place a felt pad under the thread spool to

prevent the thread from reeling off too fast. For larger

spools, the felt pad shall not be used.

2:4

A

B

CD

E

F

G

F

G

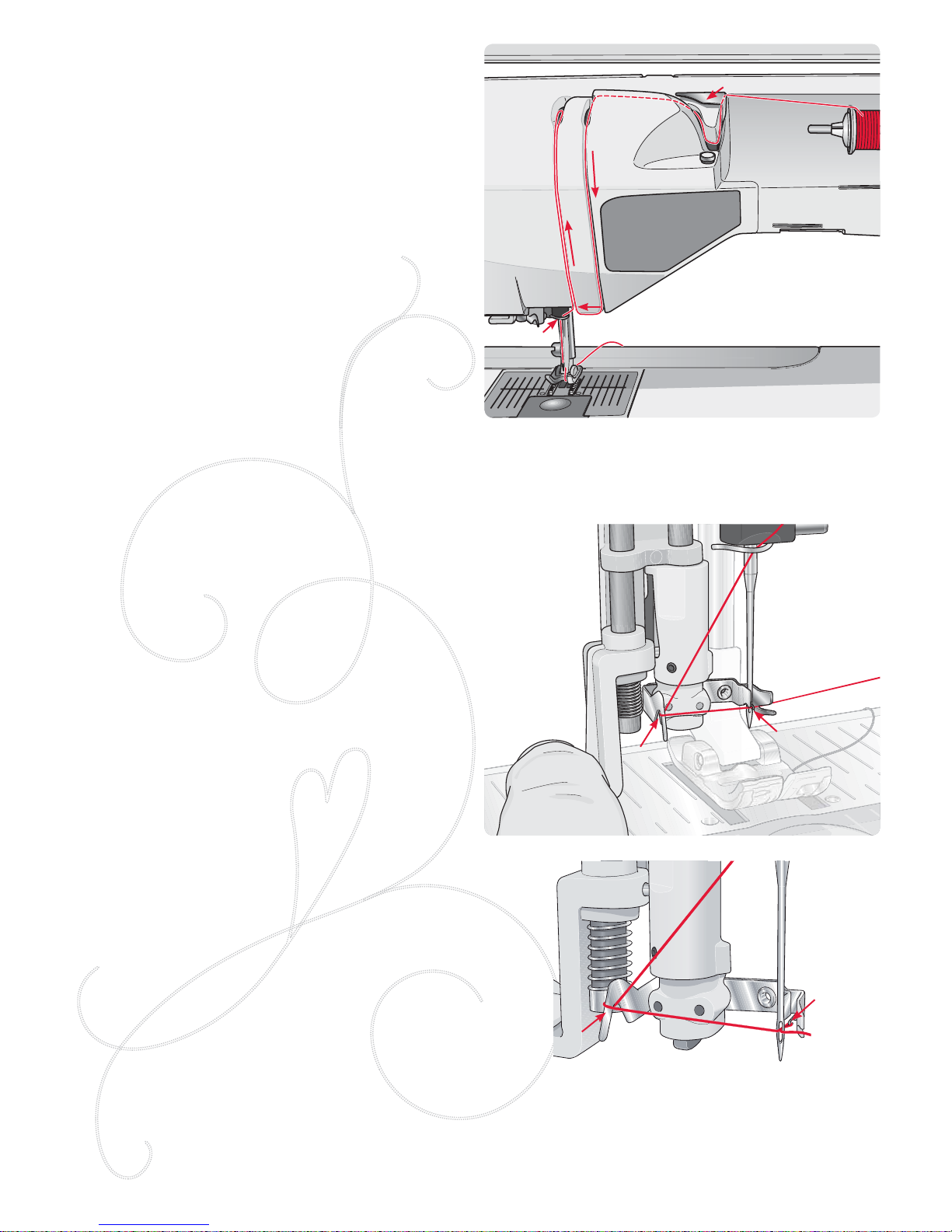

THREADING THE UPPER THREAD

Make sure that the presser foot is raised and the needle is in

the up position.

1. Place the thread on the spool pin and the spool cap on

the spool as described on page 2:3.

2. Spool pin in horizontal position:

Bring the thread over and behind the pre-tension

thread guide (A) and under the thread guide (B).

Spool pin in vertical position:

Instead of bringing the thread into the pre-tension

guide (A), bring it directly under the thread guide (B).

3. Bring the thread down between the thread tension

discs (C).

4. Continue threading in the direction indicated by the

arrows. Bring the thread from the right into the slot on

the take-up lever (D).

5. Take the thread down and behind the last guide just

above the needle (E).

NEEDLE THREADER

The needle threader allows you to thread the needle

automatically. The needle must be in the up position to use

the Built-In needle threader. We also recommend lowering

the presser foot.

1. Use the handle to pull the needle threader all the way

down. The threader hook (G) swivels through the

needle eye.

2. Place the thread from the back over the hook (F) and

under the thread hook (G).

3. Let the needle threader gently swing back. The hook

pulls the thread through the needle eye and forms

a loop behind the needle. Pull the thread loop out

behind the needle.

Note: The needle threader is designed to be used for size 70-120

needles. You cannot use the needle threader for needles size 60 or

smaller, the wing needle, twin needle, triple needle or when the Sensor

One-Step buttonhole foot is attached. There are also some optional

accessories that require manual threading of the needle.

When threading the needle manually, make sure that the needle

is threaded from front to back. The bobbin cover can be used as a

magnifying glass to make threading easier.

SET UP 2:5

B

A

C

A

B

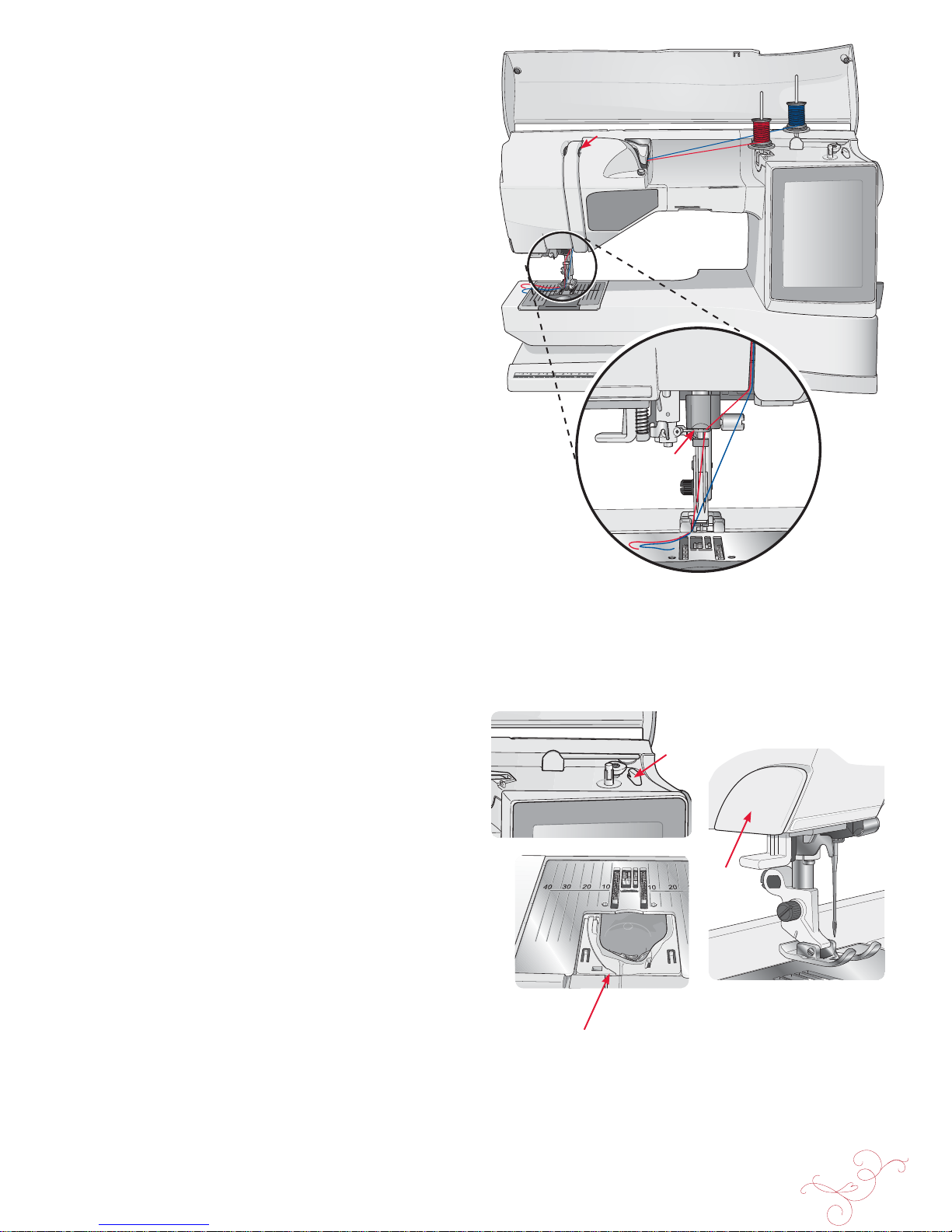

THREADING FOR TWIN NEEDLE

Replace the sewing needle with a twin needle. Make

sure the presser foot is raised and the needle is in the up

position.

1. Lift the spool pin up and all the way to the right.

Lock the spool pin in the vertical position by slightly

pressing it down. Slide on the large spool cap. For

spools smaller than the medium size spool cap, place a

felt pad under the thread spool.

2. Place the À rst thread spool on the spool pin. The

spool should rotate in a clockwise direction when the

thread reels off the spool.

3.

LEFT NEEDLE: Thread the machine as described on page

2:4. Check to ensure that the thread lies between the

left thread tension discs (A). Thread the left needle

manually.

4. Pull out the auxiliary spool pin and slide on the large

spool cap. For spools smaller than the medium size

spool cap, place a felt pad under the thread spool.

5. Place the second thread on the spool pin. The second

spool should rotate in a counterclockwise direction

when the thread reels off the spool.

6.

RIGHT NEEDLE: Thread the machine as before but this

thread should lie between the right thread tension discs

(A) and outside the needle thread guide (B). Thread

the right needle manually.

Note: Activate and choose the correct needle width in Sewing Settings

in SET Menu to prevent damage on the needle or the presser foot.

THREAD CUTTER

There are three thread cutters on your machine. The À rst

one is close to the bobbin winder spindle (A) for cutting

the thread before and after winding. The second one is

next to the bobbin area (B) for cutting the bobbin thread

after placing it in the machine. The third one is on left side

of the machine (C) for manually cutting top and bobbin

threads. Pull both threads into the cutter from the back to

the front and pull down quickly.

THREAD SENSOR

If the upper thread breaks or bobbin thread runs out,

the machine stops and a pop-up message appears on the

screen.

If upper thread breaks: Re-thread the machine and touch

OK on the pop-up message. If bob bin thread runs out,

replace it with a full bobbin and continue sewing.

2:6

A

B

C

D

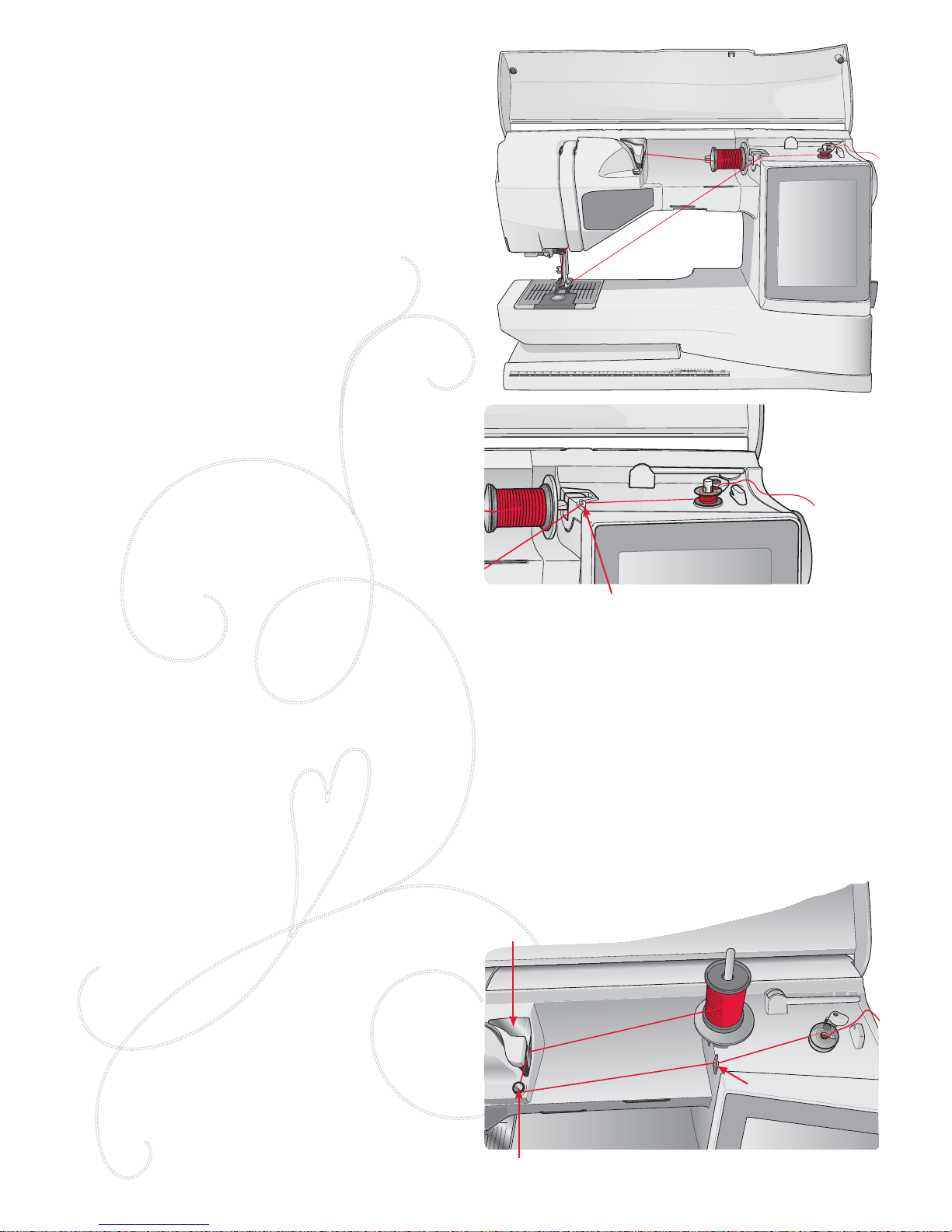

BOBBIN WINDING

BOBBIN WINDING THR OUGH THE NEEDLE

Make sure that the presser foot and the needle are in the up

position.

1. Place an empty bobbin on the bobbin spindle on the

top of the machine. The bobbin only À ts on one way,

with the logo facing up. Use only original HUSQVARNA

VIKING® bobbins.

2. Thread the machine with the main spool pin in the

horizontal position.

Note: If the thread spool is too large to be in horizontal

position, wind the bobbin as described under “Winding Specialty

Threads” below.

3. Bring the thread up from the needle, under the presser

foot and up to the right through thread guide (A).

Note: Use a metal presser foot when bob bin winding from the

needle.

4. Guide the thread through the hole in the bobbin from

the inside to the outside.

5. Push the bobbin winder lever towards the bobbin to

wind. A pop-up message appears on screen. To adjust

winding speed drag the arrow on the slider with your

stylus. Stop and start the bobbin winding with the

on-screen buttons. Hold the end of the thread À rmly

when starting to wind. Once the bobbin begins to

wind, cut the excess thread.

Note: It is important that you cut the thread end close to the bobbin.

When the bobbin is full, the bobbin winder lever will

move back and the winding will stop automatically.

The pop-up message closes. Remove the bobbin and

cut the thread using the bobbin winding thread cutter.

Winding Specialty Threads

We do not recommend winding speciality threads such as

“invisible” or other stretchy threads, metallic or Á at metallic

threads through the needle.

Always wind these threads at minimum speed.

1. Place an empty bobbin on the bobbin spindle at the

front of the machine. The bobbin only À ts on one way,

with the logo facing up. Use only original HUSQVARNA

VIKING® bobbins.

2. Place the large spool cap and a felt pad under the

spool on the main spool pin set in the vertical position.

3. Bring the thread over the Pre-Tension Thread guide

(B) and down around the thread tension disc (C), then

through thread guide (D) as illustrated.

4. See Bobbin Winding Through the Needle, step 4-5.

Note: When using earlier version of HUSQVARNA VIKING®

bobbins that do not have a hole, wind several turns of thread on the

bobbin to get started.

SET UP 2:7

1

2

43

F

G

AB

C

D

E

BOBBIN WINDING WHILE EMBROIDERING OR

SEWING

1. Raise the auxiliary spool pin. Place the large spool cap,

felt pad and thread spool on the spool pin.

2. Bring the bobbin thread around the thread tension

disc (A) and through the thread guide (B) as illustrated.

3. Guide the thread through the hole in the bobbin from

the inside to the outside.

4. Push the bobbin winder lever towards the bobbin to

wind. A pop-up message appears on screen. To adjust

winding speed drag the arrow on the slider with your

stylus. Stop and start the bobbin winding with the

on-screen buttons. Hold the end of the thread À rmly

when starting to wind.

When the bobbin is full, the bobbin winder lever will

move back and the winding willl stop automatically.

The pop-up message closes. Remove the bobbin and

cut the thread using the bobbin winding thread cutter.

Note: Make sure that the thread does not touch the cap of the

horizontal spool pin when winding the bobbin. If it does, place the cap

and spool higher on the vertical spool pin.

INSER TING THE BOBBIN

1. Remove the bobbin cover by sliding it towards you.

2. Place the bobbin in the bobbin case. It drops in only

one way with the logo facing up. The thread unreels

from the left of the bobbin. The bobbin will then

rotate counter-clockwise when you pull the thread.

3. Place your À nger on the bobbin to keep it from

turning as you pull the thread À rmly to the right and

then to the left into the tension spring (C) until it

“clicks” into place.

4. Continue threading around (D) and to the right of the

thread cutter (E). Slide on the bobbin cover (F). Pull

the thread to the left to cut (G).

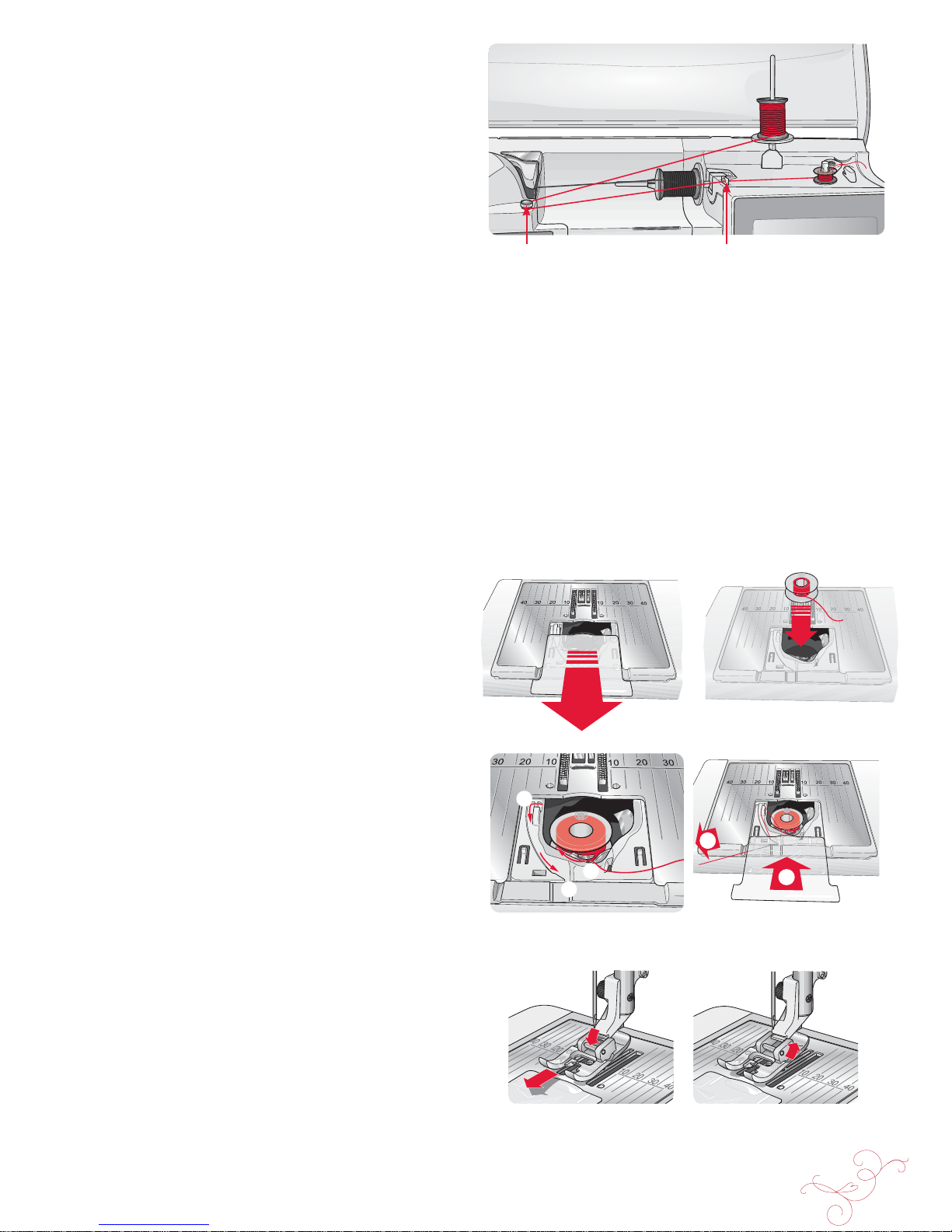

CHANGING THE PRESSER FOOT

1. Make sure that the needle is in the highest position.

Pull the presser foot down and towards you.

2. Line up the cross pin on the foot with the gap in the

presser foot ankle.

3. Push the foot into the clip until the foot snaps into

place.

2:8

CHANGING THE NEEDLE

1. Use the hole in the multipurpose tool to hold the

needle.

2. Loosen the needle screw.

3. Remove the needle.

4. Insert the new needle using the multipurpose tool.

Push the new needle upwards with the Á at side away

from you until it will go no further.

5. Tighten the needle screw.

NEEDLES

The sewing machine needle plays an important role in

successful sewing. Use only quality needles. We recommend

needles of system 130/705H. The needle package included

with your machine contains needles of the most frequently

used sizes.

Universal Needle (A)

Universal needles have a slightly rounded point and come in

a variety of sizes. For general sewing in a variety of fabric

types and weights.

Stretch Needle (B)

Stretch needles have a special scarf to eliminate skipped

stitches when there is a Á ex in the fabric. For knits,

swimwear, Á eece, synthetic suedes and leathers.

Embroidery Needle (C)

Embroidery needles have a special scarf, a slightly rounded

point and a slightly larger eye to avoid damage to thread

and materials. Use with metallic and other specailty threads

for embroidery and decorative sewing.

Denim Needle (D)

Denim needles have a sharp point to penetrate tightly

woven fabrics without deÁ ecting the needle. For canvas,

denim, microÀ bers.

Wing Needles (E)

The Wing needle has wide wings on the side of the needle

to poke holes in the fabric when sewing entredeux and

other hemstitches on natural À ber fabrics.

Note: Change the needle often. Always use a straight needle with a

sharp point (F).

A damaged needle (G) can cause skipped stitches, breakage

or snapping of thread. A damaged needle can also damage

the needle plate.

Do not use asymmetrical twin needles (H) since they may

damage your sewing machine.

F

G

H

ABC ED

SET UP 2:9

THREADS

There are many threads on the market today developed for

different purposes.

All Purpose Sewing Thread

All purpose sewing thread is made of synthetic, cotton or

cotton covered polyester. This type of thread is used for

sewing garments and projects.

Embroidery Thread

Embroidery thread is made of various À bers: rayon,

polyester, acrylic or metallic. These threads create a smooth

glossy appearance for embroidery and other decorative

stitching.

When embroidering, use embroidery bobbin thread

because it is a À ne weight and will not build up under

embroidery.

Note: When using a metallic or a Á at À lm thread for embroidering,

you may need to use a needle with a larger eye and lower the

embroidery speed. Thread the sewing machine with the spool in the

vertical position.

T ransparent Thread

Transparent thread, also called monoÀ lament thread, is

single clear synthetic thread. It is used for quilting and

other decorative sewing. Thread the sewing machine with

the spool in the vertical position. When winding a bobbin,

wind at slow speed and wind the bobbin half full.

Note:

Some fabrics have excess dye which can cause discoloration on

other fabrics or on your sewing machine. This discoloration may be

very difÀ cult or impossible to remove.

Fleece and denim fabric, especially red and blue, often contain excess

dye.

If you suspect that your fabric/ready-to-wear garment contains a

lot of excess dye, always pre-wash it before sewing/embroidering to

prevent discoloration of your machine.

STABILIZERS

Tear-Away Stabilizers

Tear-away stabilizers are used with stable woven fabrics.

Place underneath fabric for decorative stitching or hoop

with the fabric when embroidering. Tear away excess

stabilizer after stitching.

Iron-on T ear -Awa y

Iron-on tear-away is a totally stable stabilizer that has a slick

side that will iron on to fabric. It is recommended for knits

and all unstable fabrics. Fuse it to the wrong side of the

fabric before decorative stitching or hooping. Tear away

excess stabilizer after stitching.

Cut-Away Stabilizer

Cut-away stabilizer does not tear so the excess has to be cut

away. It is recommended for knits and all unstable fabrics,

especially for hoop embroidery.

Water Soluble Stabilizer

Water soluble stabilizer is placed on top of the fabric when

embellishing/embroidering napped and looped fabrics

such as terry cloth. When embroidering cutwork, use it

underneath the fabric. Place your work in water to dissolve

the excess stabilizer. It is available in different thicknesses.

Disintegrating Stabilizer

Disintegrating stabilizer is a stable, loosely woven fabric

that is used for techniques such as cutwork and to crochet

off the fabric edge. The stabilizer disappears with heat.

Sticky Stabilizer

Sticky stabilizer is used for hoop embroidery when the

fabric is too delicate or too small to be hooped. Hoop the

sticky stabilizer with the paper side up. Remove the paper

and stick the fabric onto the sticky surface. Tear away sticky

stabilizer after stitching.

PICTOGRAM™ PEN

Use an air or water soluble marking pen for embroidery and

Pictograms on all types of fabrics. The color disappears

after a few hours. You can also use cold water to completely

remove the markings. Make sure that all markings are

removed before ironing or washing with soap or detergent.

2:10

OFF

ON

USB PORTS

Your machine has two USB ports: one to connect the

sewing machine to your computer, and one to connect

either your USB embroidery stick, optional CD-drive,

optional USB hub or optional mouse.

USB EMBROIDERY STICK

Your machine comes with a USB embroidery stick. Use

the stick to store designs and other À les, or to move À les

between the computer and sewing machine.

CONNECT TO AND REMOVE FROM THE USB

PORT

Insert the USB embroidery stick or other devices in the

upper port. The USB plugs can only be inserted one way –

do not force them into the ports!

The USB PC cable packed with your machine

(P/N:412 62 59-04) plugs in to the lower port. No other

cable should be used in this port. Connect the other end of

the cable to your PC.

Note: Install the Embroidery Machine Communication CD before

connecting the machine to your PC.

To remove, carefully pull the USB embroidery stick or the

plug of the USB cable out straight.

Using the USB embroidery stick

The External Device icon in File Manager is only activate

when a device is connected to the machine USB port.

When loading from or saving to the USB embroidery stick

an hourglass appears on the screen.

Note: Do not remove the USB embroidery stick when the hourglass is

shown on the screen or while the À le manager is shown. Removing the

stick at that time can damage the À les on your USB embroidery stick.

Note: The USB embroidery stick provided with the machine can be

left in the machine when putting on the hard cover. Make sure that the

cover of the USB stick is turned downwards.

External Device icon

SET UP 2:11

CONNECTING THE MACHINE

TO YOUR COMPUTER

Your machine comes with an Embroidery Machine

Communication CD (attached inside the back cover of

this User´s Guide). This CD should be installed before the

machine is connected to your computer for the À rst time.

When the software on the CD is installed and the machine

and the computer are connected, via the USB cable, you

can easily move designs or other À les to your machine.

Note: Your computer must be running

Windows® 7/Vista or Windows® XP.

5D™ EMBROIDERY SOFTWARE

Computer Connection

The Embroidery Machine Communication module is

automatically installed. This is required to use the Send

To features in any 5D™ Embroidery System module, and

Send Multiple in 5D™ Organizer.

5D™ QuickFont

Create font À les (.vf3) for your HUSQVARNA VIKING®

DESIGNER RUBY™ sewing and embroidery machine from

most TrueType® or OpenType® fonts on your computer.

5D™ Organizer

Find your designs and pictures easily. Browse them in

different sizes and print selected groups as full worksheets

or thumbnail catalogs. Conv ert your designs between major

embroidery formats , to pictures or desktop w allpaper for y our

computer.

INST ALLING YOUR SOFTWARE

If you own other HUSQVARNA VIKING® 5D™

Embroidery System software, you may need to install

the 5D™ Embroidery System 9.2 (or higher version)

Update instead of installing the Embroidery Machine

Communication Software. Then add the HUSQVARNA

VIKING® DESIGNER RUBY™ sewing and embroidery

machine from the Machine Manager in 5D™ ConÀ gure,

as described in Step 5. Continue with Step 6 to install

hardware drivers.

1. Ensure your embroidery machine is disconnected from

your computer.

2. Ensure you are logged onto your computer with a user

name that is an administrator on the computer, then

install your software from the CD provided.

3. Insert your CD. In Windows® 7/ Vista, an AutoPlay

message may appear, asking what you wish to do with

the CD. Click the option to Run Menu.exe. Select your

desired language, and select the “Install Embroidery

Machine Communication Software” option from the

menu.

4. Follow the instructions in the Installation Wizard.

When asked to enter your Installation Code, enter the

following number: 9200.

5. In the 5D™ ConÀ gure Wizard under MyMachines

select your machine type: HUSQVARNA

VIKING® DESIGNER RUBY™ sewing and

embroidery machine. Under Send I or Send 2 select

HUSQVARNA VIKING® DESIGNER RUBY™

sewing and embroidery machine. It is recommended to

set the Embroidery Machine Communication module

to start automatically when starting Windows.

Note: You can À nd more detailed information about the installation

in the 5D™ Embroidery System Getting Started Guide, in the folder

‘UserGuides’ on the CD.

REGISTER YOUR 5D™ SOFTWARE

After À nishing the software installation, you can select

to register your software by clicking on Register in the

menu. Create an account and enter your details to receive

customized 5D™ newsletters.

Important!

During the registration process you will be given an option

to enter which sewing and embroidery machine(s) you

own. This is NOT a product or warranty registration. The

machine information entered here is only used to customize

5D™ Software newsletters. For product and warranty

registration, go to the HUSQVARNA VIKING® web site

at www. husqvarnaviking. com.

To register later, select the Register button in 5D™

ConÀ gure at any time.

INSTALL HARDWARE DRIVERS AND

CONNECT THE EMBROIDERY MACHINE

Windows® 7/ Vista

6. From the main menu of your CD, click the Install

Drivers option for your version of Windows® 7/

Vista.

If the following User Account Control message appears: ‘A program

needs your permission to continue’, click the Continue button.

7. During the installation process a security message may

appear, asking ‘Would you like to install this device

software?’ Click Install to continue. Click Finish on the

last page.

8. You may now connect your embroidery machine to

your computer. A message will appear and you will be

informed when your embroidery machine is ready to

be used.

Windows® XP

6. From the main menu of your CD, click the Install

Drivers option for Windows® XP.

Drivers are only available for 32-bit Windows® XP.

2:12

7. During the installation process, if existing drivers are

found, you will be informed that drivers have been

removed and that the computer must be restarted.

Click OK to restart the computer. Installation will

resume after the computer has restarted.

8. At the end of the installation, you will be prompted

to connect your embroidery machine. Click Finish on

the last page. Leave your 5D™ Embroidery System

software CD in your computer.

9. The Found New Hardware wizard will appear. Select

‘No, not at this time’ on the À rst page, then click

Next. Select ‘Install the software automatically’, then

click Next. A warning will appear that the drivers are

not signed. This is normal and should not be a cause

for concern. Click Continue Anyway, and the driver

installation will complete automatically.

HOW T O LAUNCH THE PR OGRAMS

Shortcuts on the Desktop

1. Double-click on the Shortcut to the 5D™ Embroidery

System program folder. A list of the programs appears.

2. Double-click on 5D™ Organizer, 5D™ QuickFont or

5D™ ConÀ gure to launch it.

Alternatively use the Start Menu to open modules under

Start, All Programs, 5D™ Embroidery System.

EMBROIDERY MACHINE

COMMUNICATION MODULE

The Embroidery Machine Communication module must

be active (

or ) to use your embroidery machine

with your computer. The icons are found in the lower

right corner of your computer screen. If the Embroidery

Machine Communication module is not active, it may be

started from the Send tab of 5D™ ConÀ gure.

Viewing and Printing PDF Guides

To À nd all the Reference and Sample Guides for your 5D™

Embroidery System software, go to Start, All Programs,

5D™ Embroidery System then choose Reference Guides

or Sample Guides. Choose the relevant folder, then select

the desired PDF Guide. Double-click on the desired name

to launch the relevant .pdf À le if you have Adobe Acrobat

installed on your computer. To install the Acrobat Reader,

insert the 5D™ Embroidery System CD and select that

option from the menu that appears.

HOW T O UPDA TE YOUR MACHINE

Be sure to consult the web site at www.husqvarnaviking .com

and/or your local authorized HUSQVARNA VIKING®

dealer for updates and upgrades for your machine and

User’s Guide.

You can update your machine using the USB embroidery

stick or the USB cable packed with your machine (P/N:412

62 59-04).

Updating Instructions

1. Open 5D™ ConÀ gure and connect your machine to

your computer.

2. Follow the instructions on the screen to update your

machine.

Updating using the HUSQVARNA VIKING® USB

Embroidery stick

• Go to the HUSQVARNA VIKING® web site at

www. husqvarnaviking.com to À nd information about

available updates.

• Follow the update wizard to prepare your USB

embroidery stick for the update.

• To set your machine in update mode, press and hold

the Needle Stop Up/Down button and the Sensor

Foot Up button while turning on the machine. Follow

the instructions on the sewing machine screen to

update from your USB Embroidery stick.

• When the update is completed the machine will restart

automatically.

Loading...

Loading...