Page 1

Installation Guide

Microwave Built-In Trim Kit

Page 2

Table of Contents

Warnings & Important Information ———————————————————————— 2

Specifications ————————————————————————————————— 3

General Information ——————————————————————————————— 4

Parts Included in the Kit ————————————————————————— 4

Cabinet or Wall Cutout —————————————————————————— 4

Electrical Outlet Location ————————————————————————— 4

Installation ——————————————————————————————————— 5

Mounting Template ——————————————————————————— 5

Bottom Duct Assembly —————————————————————————— 6

Mounting Bracket Assembly ——————————————————————— 6

Cabinet Installation ——————————————————————————— 7

Frame Assembly ————————————————————————————— 7

Side Decoration Assembly (For Surface Mount Only) ————————————— 8

Over Oven Installation —————————————————————————— 8

Performance Checklist ————————————————————————————— 8

IMPORTANT–

• Before beginning, please read these

instructions completely and carefully.

• Be sure to DISCONNECT THE PLUG of the

microwave oven from the electrical outlet

before installing the built-in trim kit. Remove

the turntable from the oven cavity.

• Because the kit includes metal parts, caution

should be used in handling and installation

to avoid the possibility of injury.

• Do not remove permanently affixed labels,

warnings, or plates from the product. This

may void the warranty.

• Please observe all local and national codes

and ordinances.

• The installer should leave these instructions

with the consumer who should retain for local

inspector’s use and for future reference.

Please Read and Follow!

WARNING

This built-in trim kit is designed for use ON LY

with microwave ovens specifying built-in trim

kit RDMTK302 on the rating label on the left

side wall of the oven cavity.

E

2

Page 3

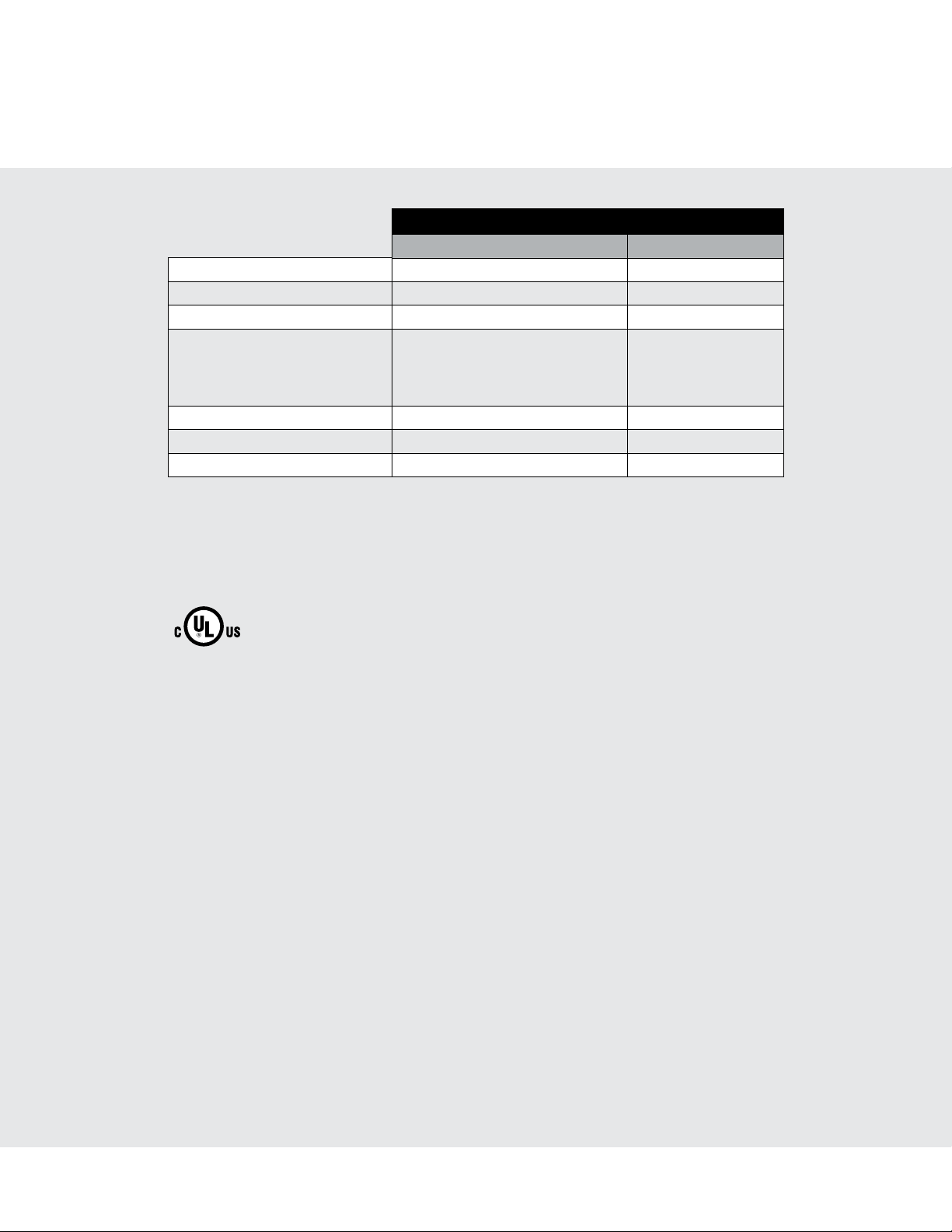

Specifications

Microwave Oven Built-In Trim Kit

RVM320 / CRVM320 RVMTK330

Overall Width 24" (60.9 cm) 29-1/2" (74.9 cm)

Overall Height from Bottom 13-3/8" (33.9 cm) 17-1/4" (43.7 cm)

Overall Depth from Rear 19-1/8" (48.7 cm) NA

Oven Interior Width

Height

Depth

Overall

Electrical Requirements 120VAC/60 Hz NA

Max. Amp Usage 1.5 KW 13 amps NA

Approx. Shipping Wt. 46 lbs. (20.9 kg) 15 lbs. (6.9 kg)

In compliance with standards set by:

FCC – Federal Communications Commission Authorized.

DHHS – Complies with Department of Health and Human Services (DHHS) rule, CFR, Title 21,

Chapter I, Subchapter J.

17-3/8"

10-1/2"

18-5/8"

2.0 cu. ft.

(4 4.1 c m)

(26.6 cm)

(47. 3 c m)

NA

– This symbol on the Rating label means the product is listed by Underwriters

Laboratories, Inc. for use in USA or Canada.

3

E

Page 4

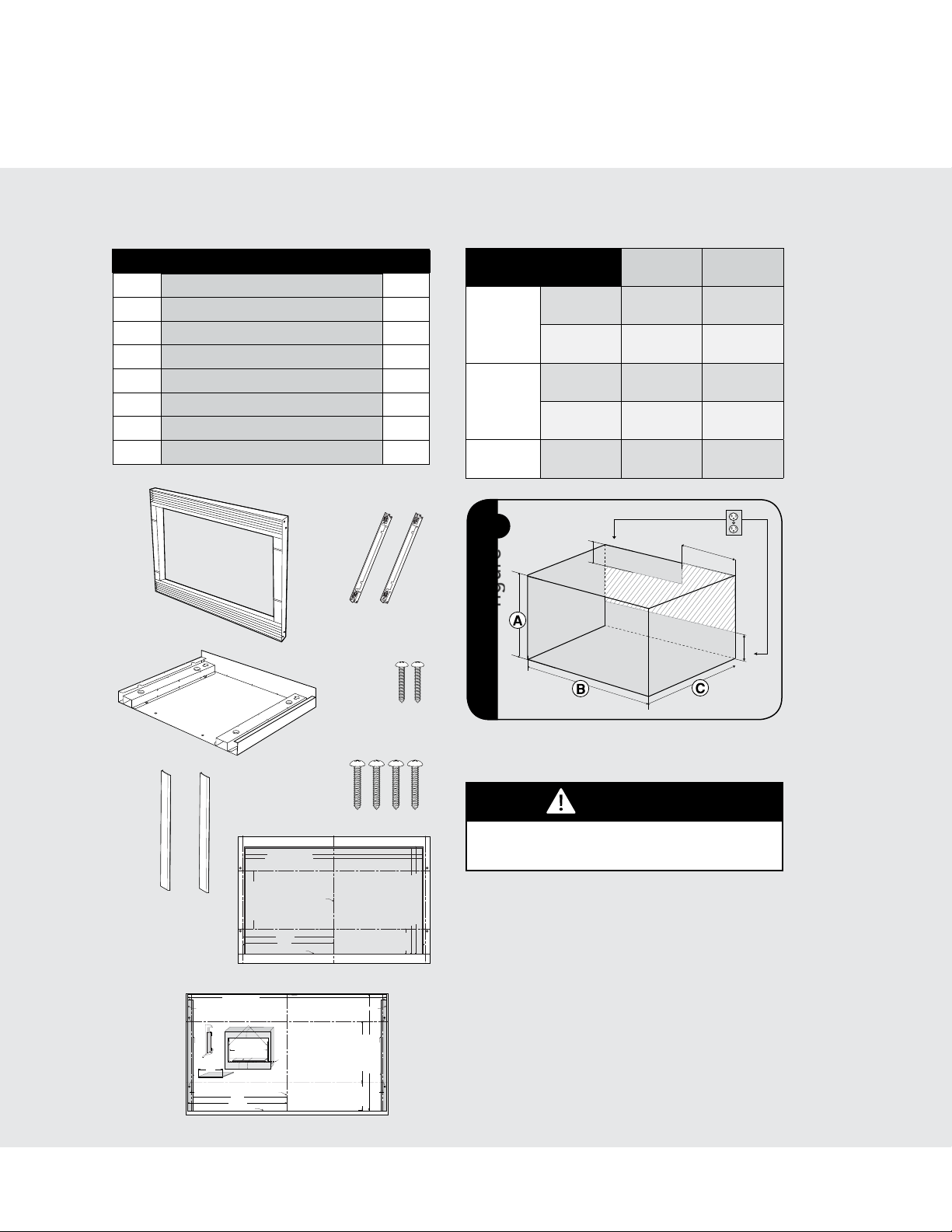

General Information

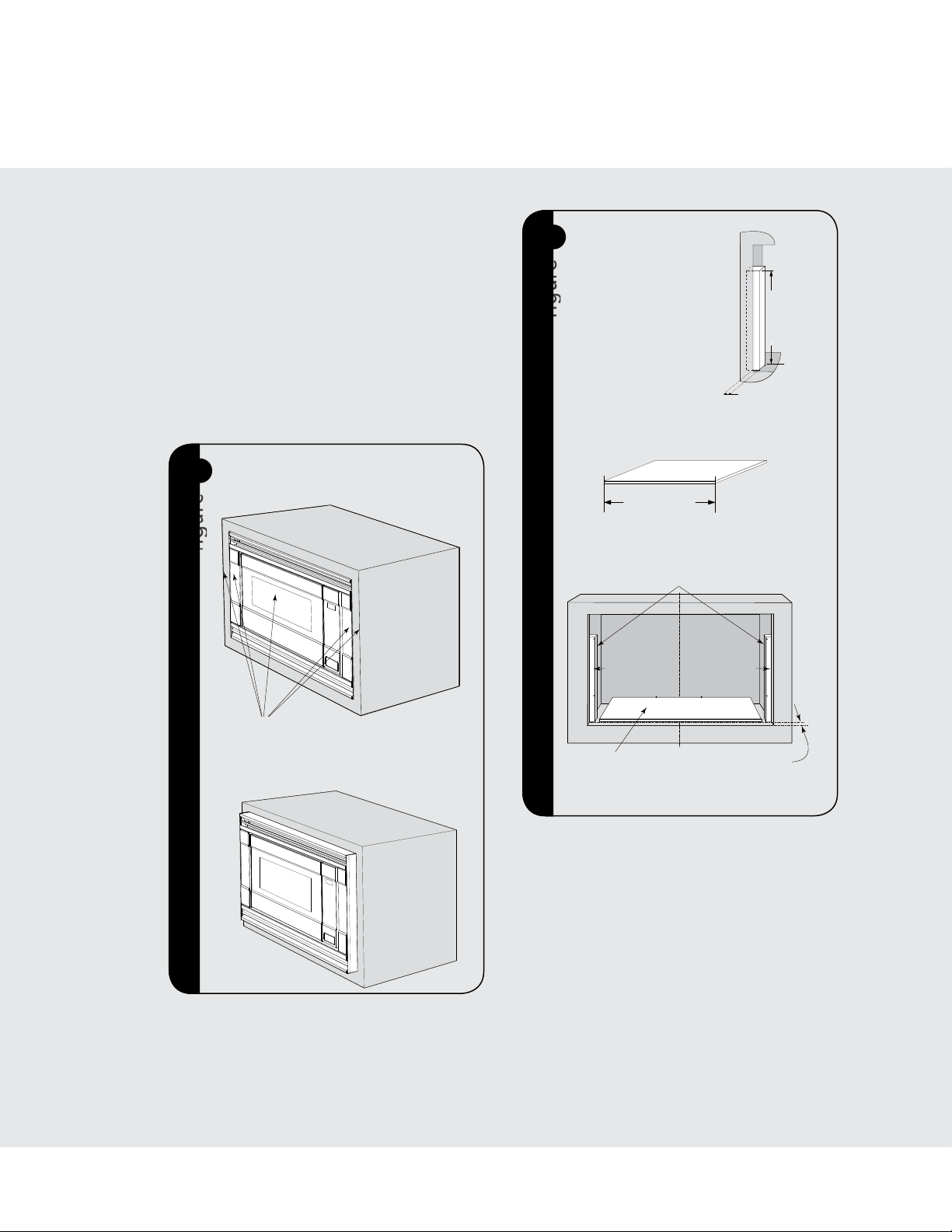

(SURFACE MOUNTING ONLY)

1) Frame Assembly: QTY 1 2) Bottom Duct Assembly: QTY 1

Parts Included in the Kit

Item Part Name QTY

Frame Assembly 1

1

Bottom Duct 1

2

Mounting Bracket 2

3

Screw A :1-3/16" length 2

4

Screw B: 1-3/4" length 4

5

Side Decoration

6

Surface Mounting Template 1

7

Flush Mounting Template 1

8

1

2

(Surface Mount Only)

3

4

Cabinet or Wall Cutout

Cutout Dimensions

Height A

Minimum

Flush

Mount

17-5/16"

(439.8mm)

Width B

Maximum

Minimum

N/A 16-13/16"

29-5/8"

(752.5mm)

2

Depth C

Maximum

Minimum

N/A 28"

20"

(503mm)

1

4"(10.2 cm)

figure

Surface

Mount

16-9/16"

(420.7mm)

(427mm)

27-3/4"

(704.9mm)

(711. 2 mm)

20"

(503mm)

6"(15.2 cm)

4"(10.2 cm)

5

6

7

Maximum Cutout Opening Width 28" (711.2 mm)

Minimum Cutout Opening Width 27-3/4" (704.9 mm)

1. Align the Surface Mounting Template center line with the

center of the cabinet. Align the Floor Line with the bottom

of the cabinet at the desired height. Tape it into place.

2. Predrill 4 holes marked A with a ¹₁₆" drill bit.

Center Line

BUILT-IN TRIM KIT

3. Cut the cabinet opening between the minimum and

maximum cutout opening lines. Be careful to cut precisely

along the Floor Line of the cutout.

4. Remove template from the cabinet.

CABINET CUTOUT LINE

Distance between holes A9.1" (231.2 mm)

Cutout Opening Height 17-5/16" (439.8 mm)

1/4" (6.35 mm)1/4" (6.35 mm)

4-3/16" (106.4 mm)

TINSKB181MRR0

Align Side Spacer-R to this line

SIDE SPACER TEMPLATE - R

BUILT-IN TRIM KIT

SURFACE MOUNTING TEMPLATE

FOR DESIGNER SERIES MICROWAVE OVEN

Distance between holes A9.1" (231.2 mm)

14-1/4" (361.95 mm)

14" (355.6 mm)

1/4"

(6.2 mm)

Floor Line of Cutout Opening

8

E

E

SIDE SPACER TEMPLATE - L

Cutout Opening Width 29-5/8" (752.5 mm)

CABINET CUTOUT LINE

Edges to align Side Spacer Templates (R and L)

13-1/2" min. height

Side Spacer - L Side Spacer - R

13/16" Min.

FIGURE 1

15/16 Max.

Align Side Spacer-L to this line

Side Spacer (2 required)

Must protrude from edge of cabinet

cutout towards center as shown.

24" min. width

Bottom Spacer centered with cabinet cutout

27-7/8" max. width

FIGURE 3

FIGURE 2

Bottom Spacer (1 required) ¹₄" plywood

14" (355.9 mm)

14-13/16" (376.2 mm)

FLOOR LINE OF CUTOUT OPENING

CENTER LINE

1-9/16" (39.7 mm)

Bottom and Side

Spacer (R and L) Offset

CABINET CUTOUT LINE

FLUSH MOUNTING TEMPLATE

FOR DESIGNER SERIES MICROWAVE OVEN

1. Align the Flush Mounting Template center line with the center of the

cabinet. Align the Floor Line with the bottom of the cabinet at the

desired height. Tape it in place.

2. Cut the cabinet opening along the three Cabinet Cutout Lines and

the Floor Line.

3. Install two Side Spacers (see FIGURE 1) and one Bottom Spacer (see

FIGURE 2) as specified in FIGURE 3. Be sure to offset all three spacers

by 1⁹₁₆" from the front surface of the cabinet.

4. Cut out the Side Spacer Templates (R and L) and align the indicated

edge to the corresponding Side Spacer (see FIGURE 3). Be careful to

align the Floor Line to the bottom edges of the Side Spacers.

5. Predrill two holes indicated “A“ in Side Spacer - R with a ¹₁₆" drill bit.

6. Predrill two holes indicated ”B“ in Side Spacer - L with a ¹₁₆" drill bit.

7. Remove template from the cabinet.

Electrical Outlet Location

CAUTION

Outlet should NOT be in the shaded area as

indicated on figure 1.

NOTES:

Maximum Cutout Opening Height 16-13/16" (427 mm)

Minimum Cutout Opening Height 16-9/16" (420.7 mm)

3-15/16" (100 mm)

TINSKB180MRR0

• IftheDepth(C)dimensionisgreaterthan21"

1/4"

(6.2 mm)

(53.3cm), the outlet location may be in any

areaontherearwall.

• Theooroftheopeningshouldbeconstructed

ofplywoodstrongenoughtosupporttheweight

oftheovenandoorload(approximately100

pounds).Theoorshouldbelevelforproper

operation of theoven. Be sureto check the

localbuildingcodeasitmayrequirethatthe

openingbee n cl o sedwithside,ceilingandrear

partition.Theproperfunctioningoftheoven

doesnotrequiretheenclosure.

4

4

Page 5

Installation

b. Surface Mount Configuration -

Microwave Oven and Frame Assembly

protrude from the surface of the cabinet.

Illustration 2

a. Flush Mount Configuration -

Microwave Oven and Frame Assembly

glass are flush with the cabinet

Mounting Template

Determine which mounting method to use

based on the required configuration. See figure

2A for FLUSH MOUNT and 2B for SURFACE

MOUNT.

Align the template corresponding to the required

mounting method to the center of the cabinet.

Make sure that the template is level with the

floor. Tape it into place. Cut the cabinet opening

along the lines specified on the template. Leave

template taped in place.

FLUSH MOUNT CONFIGURATION—

A

2

figure

Microwave Oven and Frame Assembly glass

are flush with the cabinet.

3

SIDE SPACER—2

A

REQUIRED. Must

protrude from edge of

cabinet cutout towards

center as shown.

figure

13-1/2" m in.

13/16" min.

15/16" max.

BOTTOM SPACER—1

B

REQUIRED. 1/4" plywood.

24" min. width

27-7/8" max. width

C

EDGES TO ALIGN SIDE SPACER

TEMPLATES (R and L)

Side Spacer (L) Side Spacer (R)

Indicated surfaces are flush.

SURFACE MOUNT CONFIGURATION

B

—Microwave Oven and Frame Assembly

protrude from the surface of the cabinet.

For SURFACE MOUNT, predrill 4 holes marked “A” with a

1/16" drill bit. Remove template from the cabinet. Go to

Bottom Duct Assembly.

BOTTOM SPACER

CENTERED with

CABINET CUTOUT

For FLUSH MOUNT, two (2) side spacers and one (1) bottom

spacer are required. Spacers are not included in the kit and

must be fabricated by installer. See figures 3A and B for

spacer requirements. Make sure that all three spacers are

offset from the front of the cabinet by 1-9/16".

1-9/16" (39.7 mm)

BOTTOM and SIDE

SPACER (R and L) offset

Cut out the Side Spacer Templates (R and L)

from the Flush Mounting Template. Align the

indicated edges to the corresponding right and

left side spacers as shown in figure 3. Make sure

to align the bottom edges of the side spacer

templates to the floor of the cabinet opening.

Predrill two (2) holes marked “A” on Side Spacer

Template – R and two (2) holes marked “B” on

Side Spacer Template – L with 1/16" drill bit.

Remove templates from the cabinet.

5

E

Page 6

Installation

Illustration 6 - for Flush Mount

Illustration 7 - for Surface Mount

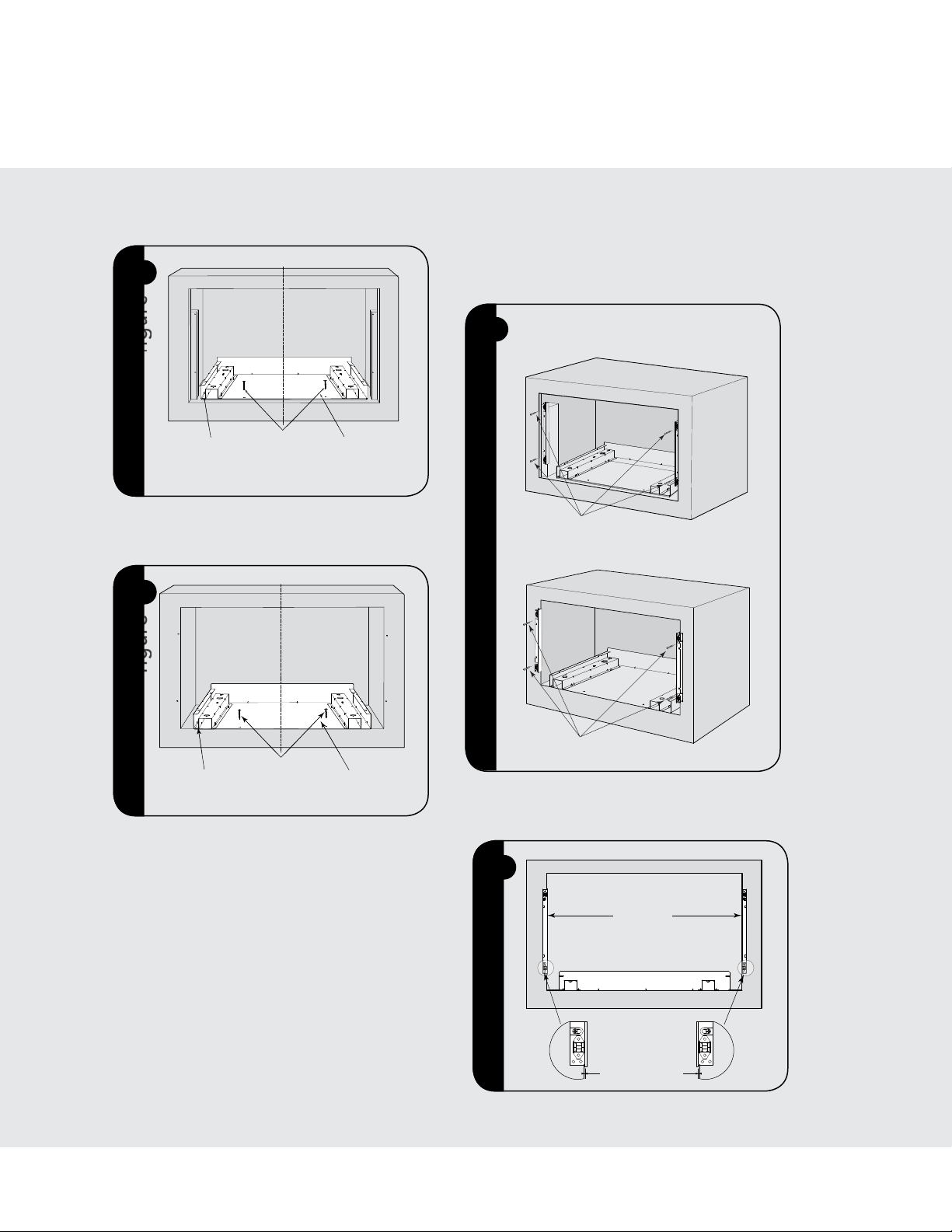

Bottom Duct Assembly

4

CENTER THE

BOTTOM DUCT

figure

MAKE BOTTOM FLANGE

FLUSH WITH BOTTOM

SPACER

Place the Bottom Duct in the cabinet opening. For FLUSH

MOUNT, it will rest on the bottom spacer centered with

the cabinet. See figure 4.

5

figure

SCREW A

BOTTOM DUCT

CENTER THE

BOTTOM DUCT

Mounting Bracket Assembly

Position the mounting brackets to align with the

predrilled holes that were drilled with the mounting

template.

6

A

figure

figure

B

FLUSH MOUNT BRACKET

SCREW B

SURFACE MOUNT BRACKET

E

SCREW A

MAKE BOTTOM FLANGE

FLUSH WITH CABINET

For SURFACE MOUNT, the Bottom Duct will rest on the

floor of the opening. See figure 5.

BOTTOM DUCT

Align the Bottom Duct to the center of the

opening with the bottom flange securely flush

with the bottom spacer (for FLUSH MOUNT) or

the cabinet (for SURFACE MOUNT).

Secure the Bottom Duct Assembly with the two (2)

SCREWS A. See figures 4 and 5 respectively.

SCREW B

The enclosed ends of the mounting brackets should face

inwards. Check that they are vertical and then secure loosely

with four (4) Screws B. See figure 6.

7

27-1/2"

(698.5mm)

figure

figure

EQ. EQ.

6

Page 7

Installation

CABINET INSTALL FRAME INSTALL CABINET INSTALL

Align the mounting brackets horizontally by sliding

them back and forth along the screw slots until

the brackets are exactly 27-1/2" apart and equal

distance from the cabinet sides. See figure 7.

Once the brackets are correctly positioned,

securely tighten the four (4) screws B.

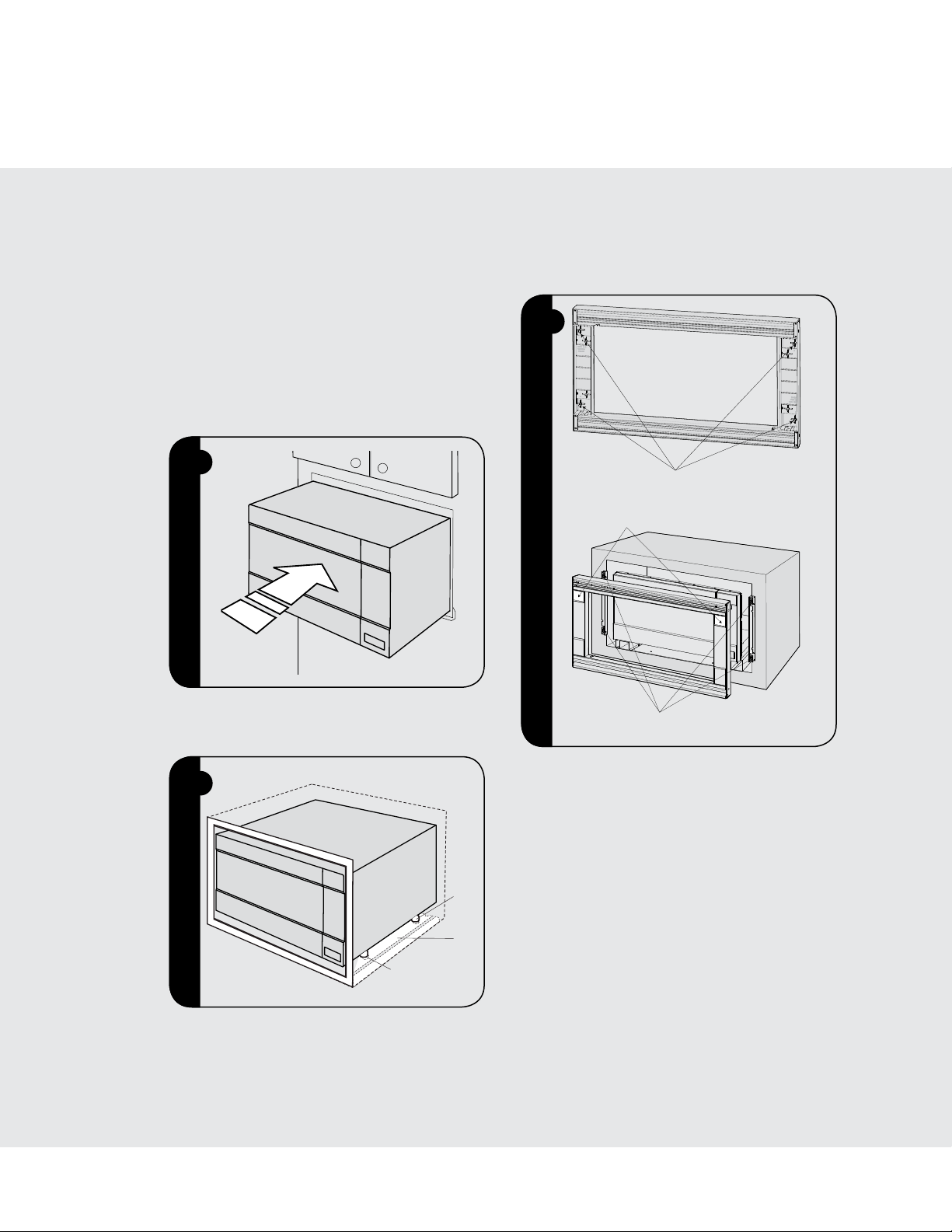

Cabinet Installation

Place the oven adjacent to the wall or cabinet

opening. Plug the power cord into the electrical

outlet.

8

figure

figure

Frame Assembly

Turn over FRAME ASSEMBLY to locate the 4 ball

studs.

!

figure

figure

4 BALL STUDS ON BACK OF FRAME ASSEMBLY

SMALL STAINLESS DECORATIONS ON TOP

Carefully guide the assembled oven into the prepared

opening. Slide the oven onto the Bottom Duct Assembly.

9

figure

figure

Avoid pinching the cord between the oven and the wall.

Adjust the position of the oven so that the feet of the oven

are fitted into the recesses of the Bottom Duct Assembly.

See figure 8.

S

ee figure 9.

BOTTOM

ASSEMBLY

DUCT RECESS

FOOT

DUCT

Position the FRAME ASSEMBLY with the small

stainless decorations on top. Align the 4 ball studs

with the 4 snap attachments at both ends of the

MOUNTING BRACKETS.

Secure the FRAME ASSEMBLY by firmly pushing

it onto the Mounting Brackets engaging the four

(4) snap attachments. See figure !.

SNAP ATTACHMENT LOCATIONS ON

MOUNTING BRACKETS

7

E

Page 8

Installation

Side Decoration Assembly

(For Surface Mount Only)

"

figure

ALIGN TOP

SURFACE OF SIDE

DECORATION TO

TOP SURFACE OF

FRAME ASSEMBLY

FRONT INNER EDGE

OF SIDE DECORATION

FRONT SIDE EDGE OF FRAME ASSEMBLY

Peel the backing off the tape on the backside of

the SIDE DECORATIONS. Align the front inner

edge of the side decorations to the front side

edge of the FRAME ASSEMBLY.

Align the top surface of the side decorations to the

top surface of the FRAME ASSEMBLY. Secure the

side decorations by pressing them firmly against

the side of the FRAME ASSEMBLY. See figure ".

Over Oven Installation

#

figure

figure

2" (5.1 CM) FOR 30" W LOWER OVEN

Performance Checklist

1. Make sure the unit has been installed according

to all of the Installation Instructions and the

required Mounting Template.

2. Plug in the power cord.

3. Keep the Use & Care Manual and Installation

Manual.

Viking Range, LLC

111 Front Street

Greenwood, Mississippi 38930 USA

(662) 455-1200

For product information

call 1-888-845-4641

E

8

Page 9

Guide d’installation

Kit de garniture à encastrer pour

four à micro-ondes

Page 10

Table des matières

Avertissements et Information importante ————————————————————— 10

Spécifications ————————————————————————————————— 11

Information générale

Pièces comprises dans le kit ——————————————————————— 12

Découpe de l’armoire ou du mur ————————————————————— 12

Emplacement de la prise électrique ———————————————————— 12

Installation —————————————————————————————————— 13

Gabarit de fixation ———————————————————————————— 13

Pose du conduit inférieur ————————————————————————— 14

Brides de fixation ———————————————————————————— 14

Installation dans l’armoire ————————————————————————— 15

Cadre de porte ————————————————————————————— 15

Décorations latérales (pour fixation en surface uniquement) —————————— 16

Installation au dessus d’un four —————————————————————— 16

Liste de contrôle du rendement ————————————————————————— 16

IMPORTANT–

• Prière de lire attentivement toutes ces

directives avant de commencer.

• Veiller à DÉBRANCHER LA FICHE du four

à micro-ondes de la prise électrique avant

d’installer la garniture à encastrer. Retirer la

table tournante de la cavité du four.

• Le kit comprend des parties métalliques, il

faut faire attention lors de la manipulation

et de l’installation pour éviter éventuelles

blessures.

• Ne pas retirer de façon permanente les

étiquettes, les mises en garde ou les plaques

fixées au produit. Cela pourrait annuler la

garantie.

• Veuillez observer tous les codes et règlements

locaux et nationaux.

• L’installateur devra laisser ces directives au

client qui devra les conserver pour l’usage

d’un inspecteur local et pour référence

ultérieure.

Prière de lire et d’observer!

AVERTISSEMENT

Ce kit à encastrer est conçu pour être utilisé

uniquement avec les fours à micro-ondes

spécifiant kit à encastrer RDMTK302 sur

l’étiquette des spécifications nominales sur la

paroi gauche de la cavité du four.

F

10

Page 11

Specifications

Four à micro-ondes

RVM320 / CRVM320 RVMTK330

Largeur hors tout 24 po (609 mm) 29-1/2 po (749 mm)

Hauteur hors tout depuis le bas 13-3/8 po (339 mm) 17-1/4 po (437 mm)

Profondeur hors tout depuis l’arrière 19-1/8 po (487 mm) S/O

Intérieur du four Largeur

Hauteur

Profondeur

Hors tout

Alimentation électrique 120VAC/60 Hz S/O

Max. Ampèrage max. 1,5 KW 13 amps S/O

Poids approx. à l’expédition. 46 lb. (20,9 kg) 15 lb. (6,9 kg)

En conformité avec les normes établies par :

FCC – Autorisé par la Federal Communications Commission.

DHHS – Conforme au règlement du Department of Health and Human Services (DHHS), CFR, Titre

21, Chapitre I, Souschapitre J.

– Ce symbole sur l’étiquette des spécifications nominales signifie que le produit est sur la liste

des Underwriters Laboratories, Inc. pour une utilisation aux É.-U. ou au Canada.

17-3/8 po

10-1/2 p o

18-5/8 po

2 pi3

(441 mm)

(266 mm)

(473 mm)

(0,04 m3)

Kit de garniture à

encastrer

S/O

11

F

Page 12

Information générale

(SURFACE MOUNTING ONLY)

1) Frame Assembly: QTY 1 2) Bottom Duct Assembly: QTY 1

Pièces comprises dans le kit

Numéro Nom de pièce Qté

Cadre de porte 1

1

Conduit inférieur 1

2

Bride de fixation 2

3

Vis A : longueur 1-3/16 po (30,2 mm) 2

4

Vis B : longueur 1 3/4 po (44,5 mm) 4

5

1

2

Décorations latérales (pour fixation

6

en surface uniquement)

Gabarit de fixation en surface 1

7

Gabarit de fixation encastrée 1

8

3

4

2

Découpe de l’armoire ou

du mur

Dimensions de la

découpe

Hauteur A

Largeur B

Profondeur C

1

Minimum

Maximum

Minimum

Maximum

Minimum

4 po (102 mm)

figure

Fixation

encastrée

17-5/16 po

(4 3 9, 8 mm)

Fixation en

surface

16-9/16 po

(420,7 mm)

N/A 16 -13 /16p o

(427 mm)

29-5/8 po

(752,5 mm)

27-3/4 po

(704,9 mm)

N/A 28 po

(711, 2 mm)

20po

(503mm)

20po

(503mm)

6 po (15,2 mm)

4 po (102 mm)

5

6

7

Maximum Cutout Opening Width 28" (711.2 mm)

Minimum Cutout Opening Width 27-3/4" (704.9 mm)

1. Align the Surface Mounting Template center line with the

center of the cabinet. Align the Floor Line with the bottom

of the cabinet at the desired height. Tape it into place.

2. Predrill 4 holes marked A with a ¹₁₆" drill bit.

Center Line

BUILT-IN TRIM KIT

FLUSH MOUNTING TEMPLATE

FOR DESIGNER SERIES MICROWAVE OVEN

3. Cut the cabinet opening between the minimum and

maximum cutout opening lines. Be careful to cut precisely

along the Floor Line of the cutout.

4. Remove template from the cabinet.

CABINET CUTOUT LINE

Distance between holes A9.1" (231.2 mm)

Cutout Opening Height 17-5/16" (439.8 mm)

1/4" (6.35 mm)1/4" (6.35 mm)

4-3/16" (106.4 mm)

TINSKB181MRR0

Align Side Spacer-R to this line

SIDE SPACER TEMPLATE - R

BUILT-IN TRIM KIT

SURFACE MOUNTING TEMPLATE

FOR DESIGNER SERIES MICROWAVE OVEN

Distance between holes A9.1" (231.2 mm)

14-1/4" (361.95 mm)

14" (355.6 mm)

1/4"

(6.2 mm)

Floor Line of Cutout Opening

8

SIDE SPACER TEMPLATE - L

Cutout Opening Width 29-5/8" (752.5 mm)

CABINET CUTOUT LINE

Edges to align Side Spacer Templates (R and L)

13-1/2" min. height

Side Spacer - L Side Spacer - R

13/16" Min.

FIGURE 1

15/16 Max.

Align Side Spacer-L to this line

Side Spacer (2 required)

Must protrude from edge of cabinet

cutout towards center as shown.

24" min. width

Bottom Spacer centered with cabinet cutout

27-7/8" max. width

FIGURE 3

FIGURE 2

Bottom Spacer (1 required) ¹₄" plywood

14" (355.9 mm)

14-13/16" (376.2 mm)

FLOOR LINE OF CUTOUT OPENING

CENTER LINE

1-9/16" (39.7 mm)

Bottom and Side

Spacer (R and L) Offset

CABINET CUTOUT LINE

1. Align the Flush Mounting Template center line with the center of the

cabinet. Align the Floor Line with the bottom of the cabinet at the

desired height. Tape it in place.

2. Cut the cabinet opening along the three Cabinet Cutout Lines and

the Floor Line.

3. Install two Side Spacers (see FIGURE 1) and one Bottom Spacer (see

FIGURE 2) as specified in FIGURE 3. Be sure to offset all three spacers

by 1⁹₁₆" from the front surface of the cabinet.

4. Cut out the Side Spacer Templates (R and L) and align the indicated

edge to the corresponding Side Spacer (see FIGURE 3). Be careful to

align the Floor Line to the bottom edges of the Side Spacers.

5. Predrill two holes indicated “A“ in Side Spacer - R with a ¹₁₆" drill bit.

6. Predrill two holes indicated ”B“ in Side Spacer - L with a ¹₁₆" drill bit.

7. Remove template from the cabinet.

F

Emplacement de la prise

électrique

MISE EN GARDE

La prise NE doit PAS se trouver dans l’aire

ombrée comme indiqué à l’Illustration 1.

Maximum Cutout Opening Height 16-13/16" (427 mm)

Minimum Cutout Opening Height 16-9/16" (420.7 mm)

3-15/16" (100 mm)

TINSKB180MRR0

NOTES :

1/4"

(6.2 mm)

• Silaprofondeur(C)dépasse53,3cm(21po),

l’emplacement de la prise peut être situé

n’importeoùsurlemurarrière.

• Leplancher de l’ouverture doit être en

contreplaquéassezfortpoursupporterlepoids

dufouretsa proprecharge(environ45,5kg

[100 lb]).Ildoit êtreà unniveau convenable

pourl’utilisationdu four. Veillerà vérierle

codelocaldubâtiment,carilpourraitexiger

que l’ouverture soit fermée par une cloison

latérale,arrièreetunplafond.Lefourn’apas

besoind’êtreenclospourfonctionner.

12

Page 13

Installation

b. Surface Mount Configuration -

Microwave Oven and Frame Assembly

protrude from the surface of the cabinet.

Illustration 2

a. Flush Mount Configuration -

Microwave Oven and Frame Assembly

glass are flush with the cabinet

Installation

Gabarit de fixation

Déterminer la méthode de fixation selon la

configuration requise. Voir la figure 2A pour la

fixation ENCASTRÉE et 2B pour la fixation en

SURFACE.

Aligner le gabarit correspondant à la méthode de

fixation requise avec le centre de l'armoire. Veiller

à ce que le gabarit soit horizontal. Coller en place

avec du ruban adhésif. Découper l'ouverture de

l'armoire selon les lignes indiquées sur le gabarit.

Laisser le gabarit en place.

CONFIGURATION POUR FIXATION

A

2

figure

ENCASTRÉE—Le four à microondes et le

verre du cadre de porte sont encastrés dans

l’armoire.

3

ENTRETOISE

A

LATÉRALE—2. Doit

dépasser du bord de la

découpe de l’armoire

vers le centre comme

figure

illustré.

13/16 po (20,6 mm) min

15/16 po (23,8 mm) max

ENTRETOISE INFÉRIEURE—1.

B

Contreplaqué 1/4 po (6,35 mm)

Largeur min 24 po

27-7/8" max. width

C

Entretoise

Side Spacer (L) Side Spacer (R)

Latérale (G)

13-1/2 po

13-1/2" m in.

13/16" min.

15/16" max.

24" min. width

(609 mm)

BORDS POUR ALIGNER LES GABARITS

EDGES TO ALIGN SIDE SPACER

D’ENTRETOISE LATÉRALE (D et G)

TEMPLATES (R and L)

Largeur max 27-7/8 po

(708 mm)

Entretoise

Latérale (D)

min

(342,9 mm)

Les surfaces indiquées affleurent.

SURFACE MOUNT CONFIGURATION

B

—Le four à microondes et le verre du cadre de

porte font saillie de la surface de l’armoire.

Pour la fixation en surface, percer 4 trous marqués « A »

avec un foret de 1/16 po (1,6 mm). Enlever le gabarit de

l’armoire Aller au conduit inférieur.

Entretoise inférieure

BOTTOM SPACER

Centrée avec la

CENTERED with

CABINET CUTOUT

Découpe de l’armoire

Pour la fixation encastrée, il faut deux (2) entretoises

latérales et une (1) entretoise inférieure. Les entretoises

ne sont pas fournies dans le kit et doivent être fabriquées

par l’installateur. Voir figures 3A et B pour les exigences

d'entretoise. Veiller à ce que les trois entretoises dépassent

de 1-9/16 po (39,7 mm) à l'avant de l'armoire.

1-9/16 po (39,7 mm)

1-9/16" (39.7 mm)

Déport d’entretoises

BOTTOM and SIDE

SPACER (R and L) offset

Inférieure et Latérales

(D et G)

Découper les gabarits d’entretoise latérale (D et

G) du gabarit de montage encastré. Aligner les

bords indiqués aux entretoises droite et gauche

correspondantes comme l’illustre la figure 3.

Veiller à aligner les bords inférieurs des gabarits

d'entretoise latérale avec le plancher de l'ouverture

de l'armoire. Percer deux (2) trous marqués « A »

sur un gabarit D d'entretoise latérale et deux (2)

trous marqués « B » sur un gabarit G d'entretoise

latérale avec un foret de 1/16 po (1,6 mm).

Enlever les gabarits de l'armoire.

13

F

Page 14

Installation

Illustration 6 - for Flush Mount

Illustration 7 - for Surface Mount

Conduit inférieur

4

CENTRER LE

CENTER THE

CONDUIT

BOTTOM DUCT

figure

FAIRE AFFLEURER LA

BRIDE INFÉRIEURE AVEC

L'ENTRETOISE INFÉRIEURE

Placer le conduit inférieur dans l’ouverture de l’armoire.

Pour le montage encastré, il reposera sur l’entretoise

inférieure centrée dans l’armoire. Voir figure 4.

5

figure

INFÉRIEUR

VIS A

CENTER THE

CENTRER LE

BOTTOM DUCT

CONDUIT IN-

FÉRIEUR

CONDUIT

INFÉRIEUR

Brides de fixation

Placer les brides de fixation pour les aligner avec

les trous percés à l’aide du gabarit.

6

A

figure

figure

B

BRIDE FIXÉE ENCASTRÉE

VIS B

BRIDE FIXÉE EN SURFACE

VIS A

FAIRE AFFLEURER LA BRIDE

INFÉRIEURE AVEC L’ARMOIRE

Pour la fixation en surface,le conduit inférieur reposera sur

le plancher de l’ouverture. Voir figure 5.

CONDUIT

INFÉRIEUR

Aligner le conduit inférieur au centre de l’ouverture

avec la bride inférieure affleurant l’entretoise

inférieure (pour la FIXATION ENCASTRÉE) ou

l’armoire (pour la FIXATION EN SURFACE).

Fixer le conduit inférieur avec deux VIS A

(2-3/16 po [ 55,6 mm]). Voir figures 4 et 5

respectivement.

VIS B

Les extrémités encastrées des brides de fixation doivent

faire face à l’intérieur. Vérifier qu’elles sont verticales et les

fixer à demi avec quatre (4) VIS B. Voir figure 6.

7

27-1/2 po

(698,5 mm)

figure

figure

EQ. EQ.

F

14

Page 15

Installation

CABINET INSTALL FRAME INSTALL CABINET INSTALL

Aligner les brides de fixation horizontalement en

les faisant glisser vers l'avant et l'arrière le long

des fentes de vis jusqu'à ce que les brides soient

exactement séparées de 27-1/2 po (698,5 mm)

et à égale distance des côtés de l'armoire. Voir

figure 7.

Une fois les brides correctement placées, bien les

fixer avec quatre (4) vis B.

Installation dans l'armoire

Placer le four près de l'ouverture du mur ou de

l'armoire. Brancher le cordon d'alimentation dans

la prise électrique.

8

figure

figure

Cadre de porte

Retourner le CADRE DE PORTE pour repérer les

quatre pivots à rotule.

!

figure

figure

QUATRE PIVOT À ROTULE À L’ARRIÈRE DU CADRE DE PORTE

PETITES DÉCORATIONS EN ACIER INOX SUR LE DESSUS

EMPLACEMENT DES FIXATIONS À PRESSION

Guider avec précaution le four assemblé dans l'ouverture

préparée. Faire glisser le four sur le conduit inférieur. Voir

figure 8.

9

figure

figure

ÉVIDEMENT DANS

Éviter de pincer le cordon entre le four et le mur. Ajuster la

position du four de façon à ce que ses pattes entrent dans

les évidements du conduit d'évacuation. Voir figure 9.

PATTE

CONDUIT

INFÉRIEUR

LE CONDUIT

Placer le cadre de porte avec les petites décorations

en acier inox sur le dessus. Aligner les quatre

pivots à rotule avec les fixations à pression aux

deux extrémités des BRIDES DE FIXATION.

Bien fixer le cadre de porte en le poussant

fermement sur les brides de fixation en engageant

les quatre (4) fixations à pression. Voir figure !.

SUR LES BRIDES DE FIXATION

15

F

Page 16

Installation

Installation

Décorations latérales

(pour fixation en surface uniquement)

"

figure

ALIGNER LA SUR-

FACE SUPÉRIEURE

DE LA DÉCORA-

TION LATÉRALE

AVEC LA SURFACE

SUPÉRIEURE DU

CADRE DE PORTE

BORD INTÉRIEUR

AVANT DE LA DÉC-

ORATION LATÉRALE

BORD INTÉRIEUR AVANT DU CADRE DE PORTE

Retirer le papier dorsal du ruban au verso des

DÉCORATIONS LATÉRALES. Aligner le bord

intérieur avant des décorations latérales avec le

bord intérieur avant du CADRE DE PORTE.

Installation au dessus d'un

four

#

figure

figure

5,1 CM (2 po) POUR UN FOUR INFÉRIEUR DE

91,4 CM (30 po) DE LARGE

Liste de contrôle

Aligner la surface supérieure de la décoration

latérale avec la surface supérieure du CADRE DE

PORTE. Fixer les décorations latérales en pressant

fermement contre le côté du CADRE DE PORTE.

Voir figure ".

Viking Range, LLC

111 Front Street

Greenwood, Mississippi 38930 USA

(662) 455-1200

Pour plus d'information sur le produit,

Composer le 1-888-845-4641

1. Veiller à ce que l'appareil soit installé selon

les instructions et avec le bon gabarit de

fixation.

2. Brancher le cordon d'alimentation.

3. Conserver le mode d'emploi et d'entretien et

le manuel d'installation

F

F

16

Page 17

Guía de instalación

Juego de molduras para empotrado

del Microondas

S

Page 18

Tabla de Contenido

Advertencias e información importante —————————————————————— 18

Especificaciones ———————————————————————————————— 19

Información general ——————————————————————————————— 20

Partes incluidas en el juego ———————————————————————— 20

Abertura del gabinete o pared —————————————————————— 20

Ubicación del tomacorriente eléctrico ——————————————————— 20

Instalación ——————————————————————————————————— 21

Plantilla de montaje ——————————————————————————— 21

Conjunto de ducto inferior ———————————————————————— 21

Ensamblaje del soporte de montaje ———————————————————— 22

Instalación en gabinete —————————————————————————— 23

Instalación del marco —————————————————————————— 23

Instalación de la decoración lateral ———————————————————— 24

Instalación de la decoración lateral ———————————————————— 24

Lista de control de ejecución ——————————————————————————— 24

IMPORTANTE–

• Antes de comenzar, lea estas instrucciones

completa y detalladamente.

• Asegúrese de DESCONECTAR el horno

microondas del tomacorriente eléctrico

antes de instalar el juego de moldura para

empotrado. Retire el plato giratorio de la

cavidad del horno.

• El juego incluye partes de metal por lo que

debe manipularlo e instalarlo con precaución

para evitar el riesgo de lesiones.

• No retire las etiquetas, advertencias o placas

permanentes del producto. Esto puede anular

la garantía.

• Cumpla todos los códigos y normas locales

y nacionales.

• El instalador debe devolver estas instrucciones

al cliente quien debe conservarlas para uso

del inspector local y para referencias futuras.

¡Lea y siga con atención!

ADVERTENCIA

Este juego de molduras para empotrado

está diseñado para uso exclusivo con hornos

microondas que especifique el juego de

molduras para empotrado RDMTK302 en la

etiqueta de potencia en la cavidad del horno.

S18S

18

Page 19

Especificaciones

Horno microondas

RVM320 / CRVM320 RVMTK330

Ancho total 24" (60.9 cm) 29-1/2" (74.9 cm)

Altura total desde la parte

inferior

Profundidad total desde la

parte posterior

Parte interna del horno Ancho

Requisitos eléctricos 120VCA/60 Hz NA

Cap. máx. en amperios 1.5 KW 13 amps NA

Peso de despacho aprox. 46 lbs. (20.9 kg) 15 lbs. (6.9 kg)

Cumple con las normas establecidas por:

FCC – Autorizada por la Comisión Federal de Comunicaciones.

DHHS – Cumple con la norma del Departamento de Salud y Servicios Humanos (DHHS), CFR,

Título 21, capítulo I, subcapítulo J.

13-3/8" (33.9 cm) 17-1/4" (43.7 cm)

19-1/8" (48.7 cm) NA

Altura

Profundidad

Ancho total

17-3/8"

10-1/2"

18-5/8"

2.0 pies

cúbicos

(4 4.1 c m)

(26.6 cm)

(47. 3 c m)

Juego de molduras

para empotrado

NA

– Este símbolo en la etiqueta de potencia indica que el producto está aprobado por

Underwriters Laboratories, Inc. para uso en los EE.UU. o Canadá.

19

S

Page 20

Información general

(SURFACE MOUNTING ONLY)

1) Frame Assembly: QTY 1 2) Bottom Duct Assembly: QTY 1

Partes incluidas en el juego

Artículo

1

2

3

4

5

6

7

8

1

2

Nombre de la parte

CANT.

Conjunto del marco 1

Conjunto del ducto inferior 1

Soporte de montaje 2

Tornillo A :1-3/16” de largo 2

Tornillo B: 1-3/4” de largo 4

Decoración lateral (Sólo superficie

de montaje)

Plantilla para montaje en superficie 1

Plantilla para montaje al ras 1

3

4

2

Abertura del gabinete o pared

Dimensiones de

recorte

Altura A

Ancho B

Profundidad C

1

4"(10.2 cm)

figura

Mínimo

Máximo

Mínimo

Máximo

Mínimo

Brindas

Montaje

17-5/16"

(439.8mm)

Superficie

Montaje

16-9/16"

(420.7mm)

N/A 16-13/16"

(427mm)

29-5/8"

(752.5mm)

27-3/4"

(704.9mm)

N/A 28"

(711. 2 mm)

20"

(503mm)

20"

(503mm)

6"(15.2 cm)

4"(10.2 cm)

5

6

7

Maximum Cutout Opening Width 28" (711.2 mm)

Minimum Cutout Opening Width 27-3/4" (704.9 mm)

1. Align the Surface Mounting Template center line with the

center of the cabinet. Align the Floor Line with the bottom

of the cabinet at the desired height. Tape it into place.

2. Predrill 4 holes marked A with a ¹₁₆" drill bit.

Center Line

BUILT-IN TRIM KIT

FLUSH MOUNTING TEMPLATE

FOR DESIGNER SERIES MICROWAVE OVEN

3. Cut the cabinet opening between the minimum and

maximum cutout opening lines. Be careful to cut precisely

along the Floor Line of the cutout.

4. Remove template from the cabinet.

CABINET CUTOUT LINE

Distance between holes A9.1" (231.2 mm)

Cutout Opening Height 17-5/16" (439.8 mm)

1/4" (6.35 mm)1/4" (6.35 mm)

4-3/16" (106.4 mm)

TINSKB181MRR0

Align Side Spacer-R to this line

SIDE SPACER TEMPLATE - R

BUILT-IN TRIM KIT

SURFACE MOUNTING TEMPLATE

FOR DESIGNER SERIES MICROWAVE OVEN

Distance between holes A9.1" (231.2 mm)

14-1/4" (361.95 mm)

14" (355.6 mm)

1/4"

(6.2 mm)

Floor Line of Cutout Opening

8

SIDE SPACER TEMPLATE - L

Cutout Opening Width 29-5/8" (752.5 mm)

CABINET CUTOUT LINE

Edges to align Side Spacer Templates (R and L)

13-1/2" min. height

Side Spacer - L Side Spacer - R

13/16" Min.

FIGURE 1

15/16 Max.

Align Side Spacer-L to this line

Side Spacer (2 required)

Must protrude from edge of cabinet

cutout towards center as shown.

24" min. width

Bottom Spacer centered with cabinet cutout

27-7/8" max. width

FIGURE 3

FIGURE 2

Bottom Spacer (1 required) ¹₄" plywood

14" (355.9 mm)

14-13/16" (376.2 mm)

FLOOR LINE OF CUTOUT OPENING

CENTER LINE

1-9/16" (39.7 mm)

Bottom and Side

Spacer (R and L) Offset

CABINET CUTOUT LINE

1. Align the Flush Mounting Template center line with the center of the

cabinet. Align the Floor Line with the bottom of the cabinet at the

desired height. Tape it in place.

2. Cut the cabinet opening along the three Cabinet Cutout Lines and

the Floor Line.

3. Install two Side Spacers (see FIGURE 1) and one Bottom Spacer (see

FIGURE 2) as specified in FIGURE 3. Be sure to offset all three spacers

by 1⁹₁₆" from the front surface of the cabinet.

4. Cut out the Side Spacer Templates (R and L) and align the indicated

edge to the corresponding Side Spacer (see FIGURE 3). Be careful to

align the Floor Line to the bottom edges of the Side Spacers.

5. Predrill two holes indicated “A“ in Side Spacer - R with a ¹₁₆" drill bit.

6. Predrill two holes indicated ”B“ in Side Spacer - L with a ¹₁₆" drill bit.

7. Remove template from the cabinet.

S20S

Ubicación del

tomacorriente eléctrico

PRECAUCIÓN

El tomacorriente NO debe estar en el área

sombreada como se indica en la figura 1.

Maximum Cutout Opening Height 16-13/16" (427 mm)

Minimum Cutout Opening Height 16-9/16" (420.7 mm)

3-15/16" (100 mm)

TINSKB180MRR0

NOTAS:

• Siladimensióndeprofundidad(C)esmayora21”

1/4"

(6.2 mm)

(53.3 cm),la ubicación del tomacorriente puede

estarencualquieráreadelaparedposterior.

• El piso de la abertura debe estar construido de

maderalaminadalosucientementeresistentepara

soportarelpesodelhornoylacapacidaddecarga

(aproximadamente 100libras).Elpisodebeestar

nivelado para una correcta operación del horno.

Asegúrese devericarel código deconstrucción

local ya que puede requerir cercar la abertura

con tabiques laterales, superior y posterior.El

funcionamiento apropiadodel horno norequiere

delcercado.

20

Page 21

Instalación

b. Surface Mount Configuration -

Microwave Oven and Frame Assembly

protrude from the surface of the cabinet.

Illustration 2

a. Flush Mount Configuration -

Microwave Oven and Frame Assembly

glass are flush with the cabinet

Plantilla de montaje

Determine el método de montaje a usar en base

a la configuración requerida. Vea la figura 2A

para MONTAJE AL RAS y 2B para MONTAJE

EN SUPERFICIE.

Alinee la plantilla correspondiente al método

de montaje necesario en el centro del gabinete.

Asegúrese de que la plantilla esté nivelada con

la base. Asegúrelo con cinta adhesiva. Corte la

abertura del gabinete a lo largo de las líneas

señaladas en la plantilla. Deje la plantilla pegada

en el lugar.

CONFIGURACIÓN PARA MONTAJE

A

2

figura

AL RAS — El horno microondas y el vidrio

del conjunto del marco están alineados con

el gabinete.

3

figura

SPACER LADO—2

A

NECESARIO. Debe

sobresalir del borde de

corte hacia el centro

del gabinete como se

muestra.

FONDO SPACER—1 SOLICITAN.

B

1 / 4 "de madera contrachapada.

24" min. anchura

24" min. width

27-7/8" max. width

27-7/8" máx. anchura

BORDES PARA ALINEA

EDGES TO ALIGN SIDE SPACER

LAS PLANTILLAS DE LOS

C

TEMPLATES (R and L)

ESPACIADORES LATERALES (R Y L)

Espaciador

Side Spacer (L) Side Spacer (R)

lateral - L

Espaciador

lateral - R

13-1/2" m in.

13/16" min.

13/16" min.

15/16" max.

15/16" máx.

Las superficies indicadas están alineadas.

CONFIGURACIÓN DE LA SUPERFICIE

B

DE MONTAJE — El horno microondas y el

conjunto del marco sobresalen de la superficie

del gabinete.

For SURFACE MOUNT, predrill 4 holes marked “A” with a

1/16" drill bit. Remove template from the cabinet. Go to

Bottom Duct Assembly.

1-9/16" (39.7 mm)

BOTTOM SPACER

Espaciador inferior

CENTERED with

centrado con el

CABINET CUTOUT

recorte del gabinete

Para MONTAJE AL RAS, instale dos (2) espaciadores laterales

y un (1) espaciador inferior como se muestra en la figura 3 A y

B. Los espaciadores no están incluidos en el juego y deben ser

fabricados por el instalador. Los requisitos para el espaciador

se indican en la Plantilla para montaje al ras. Asegúrese que los

tres espaciadores estén equilibrados desde la parte frontal del

gabinete por 1-9/16".

1-9/16" (39.7 mm)

Compensación para

BOTTOM and SIDE

espaciador lateral e

SPACER (R and L) offset

inferior (R y L)

Recorte las plantillas del espaciador lateral (R y

L) de las plantillas de montaje al ras. Alinee los

bordes indicados con los espaciadores izquierdo

y derecho correspondientes como se muestra

en la figura 3. Asegúrese de alinear los bordes

inferiores de las plantillas de los espaciadores

laterales a la base de la abertura del gabinete. Pretaladre (2) agujeros marcados “A” en la plantilla

del espaciador lateral – R y dos (2) agujeros

marcados “B” en la plantilla del espaciador lateral

– L con una broca 1/16".

Retire las plantillas del gabinete.

21

S

Page 22

Illustration 6 - for Flush Mount

Illustration 7 - for Surface Mount

Instalación

Conjunto del Ducto Inferior

4

CENTRE EL

CENTER THE

DUCTO INFERIOR

BOTTOM DUCT

figura

TORNILLO A

COLOQUE LA BRIDA INFERIOR AL

RAS CON EL GABINETE

Coloque el Ducto inferior en la abertura del gabinete. Para

MONTAJE AL RAS, se apoyará en el espaciador inferior

centrado con el gabinete. Vea la figura 4.

5

figura

CONJUNTO DEL

DUCTO INFERIOR

CENTER THE

CENTRE EL DUCTO

BOTTOM DUCT

INFERIOR

Ensamblaje del soporte de

montaje

Coloque los soportes de montaje para que se

alineen con los agujeros taladrados preparados

con la plantilla de montaje.

SOPORTE PARA MONTAJE AL RAS

A

6

figura

TORNILLO B

SOPORTES PARA MONTAJE EN

B

SUPERFICIE

S

TORNILLO A

COLOQUE LA BRIDA INFERIOR AL RAS

CON EL GABINETE

Para MONTAJE EN SUPERFICIE, el ducto inferior se

apoyará en la base de la abertura. Vea la figura 5.

CONJUNTO DEL

DUCTO INFERIOR

Alinee el ducto inferior al centro de la abertura

con la brida inferior colocada firmemente al ras

con el espaciador inferior (para MONTAJE AL RAS)

o el gabinete (para MONTAJE EN SUPERFICIE).

Asegure el conjunto del ducto inferior con los

dos (2) TORNILLOS A. Vea las figuras 4 y 5

respectivamente.

TORNILLO B

Los extremos cerrados de los soportes de montaje deben

quedar hacia dentro. Verifique que estén en posición

vertical y después asegúrelos de forma suelta con los

cuatro (4) tornillos B. Vea la figura 6.

7

27-1/2"

(698.5mm)

figura

EQ EQ.

22

Page 23

CABINET INSTALL FRAME INSTALL CABINET INSTALL

Instalación

Alinee los soportes de montaje horizontalmente

deslizándolos hacia atrás y hacia adelante a través

de las ranuras de los tornillos hasta que los soportes

tengan una distancia exacta de 27-1/2" entre sí y

una distancia igual desde los lados del gabinete.

7

Vea la figura

Una vez que los soportes estén posicionados

correctamente, apriete firmemente los cuatro (4)

tornillos B.

.

Instalación en gabinete

Coloque el horno al lado de la abertura de la pared

o gabinete. Conecte el cordón de alimentación al

tomacorriente eléctrico.

8

figurafigura

Conjunto del marco

Voltee el CONJUNTO DEL MARCO localice los 4

montantes redondos.

!

figura

CUATRO UBICACIONES DE LOS MONTANTES REDONDOS

EN LA PARTE POSTERIOR DEL CONJUNTO DEL MARCO

PEQUEÑAS DECORACIONES INOXIDABLES EN LA PARTE

SUPERIOR

UBICACIONES DE LAS MUESCAS A PRESIÓN EN LOS

Guíe con cuidado el horno ensamblado dentro de la

abertura preparada. Deslice el horno sobre el conjunto

del ducto inferior. Vea la figura 8.

9

BASE

CONJUNTO

DE DUCTO

INFERIOR

CAVIDAD DEL DUCTO

Evite que el cable quede entre el horno y la pared. Ajuste

la posición del horno de modo que las patas del horno

encajen en las ranuras del conjunto del ducto de escape.

Vea la figura

9.

Coloque el CONJUNTO DEL MARCO con las

pequeñas decoraciones inoxidables en la parte

superior. Alinee los cuatro montantes redondos

con los 4 accesorios a presión en ambos extremos

de los SOPORTES DE MONTAJE.

Asegure el CONJUNTO DE MARCO presionando

firmemente sobre los soportes de montaje

colocando los cuatro (4) accesorios a presión.

Vea la figura !.

SOPORTES DE MONTAJE

23

S

Page 24

Instalación

Instalación de la

decoración lateral

(Sólo para montaje en superficie)

"

figura

ALÍNEE LA SUPER-

FICIE SUPERIOR DE

LA DECORACIÓN

LATERAL A LA SU-

PERFICIE SUPERIOR

DEL CONJUNTO

DEL MARCO

BORDE INTERIOR

FRONTAL DE LA

DECORACIÓN LATERAL

BORDE LATERAL FRONTAL DEL CONJUNTO DEL MARCO

Retire la cinta de refuerzo de la parte posterior

de las DECORACIONES LATERALES. Alinee

el borde interior frontal de las decoraciones

laterales al borde lateral frontal del CONJUNTO

DEL MARCO.

Alinee la superficie superior de las decoraciones

laterales a la superficie superior del CONJUNTO

DEL MARCO. Asegure las decoraciones laterales

presionándolas firmemente contra el lado del

CONJUNTO DEL MARCO. Vea la figura ".

Instalación sobre el horno

#

figura

2" (5.1 CM) PARA HORNO INFERIOR DE

30" DE ANCHO

Lista de control de

ejecución

1. Asegúrese de que la unidad ha sido instalada

de acuerdo con todas las instrucciones de

instalación y la plantilla de montaje necesaria.

2. Enchufe el cable de alimentación.

3. Conserve el Manual de uso y cuidado y el

Manual de instalación

Viking Range, LLC

111 Front Street

Greenwood, Mississippi 38930 EE.UU.

(662) 455-1200

Para mayor información sobre

productos, llame al 1-888-845-4641

TINSKB179MRR0

S

24

F20971

Loading...

Loading...