Page 1

Technical Data Manual

Model Nos. and pricing: see Price List

Vacuum tube collector based on the heat pipe principle

For the utilisation of solar energy

VITOSOL r 200-T SPE

Product may not be exactly as shown

VITOSOL 200-T Type SPE

Vacuum tube collector

For the heating of DHW, supplement heating systems

and swimming pool water via heat exchangers as well

as for the generation of process heat.

For installation on pitched and flat roofs, as well as for

freestanding installations.

5693 556 v1.0

Page 2

Product Information

Product Description

Vitosol 200-T, SPE Technical Data

Benefits

■ Highly efficient vacuum tube collector based on the

heat pipe principle for high operational reliability.

Optimized for horizontal installation on flat roofs.

■ Optimized tube spacing prevents shading.

■ Can be universally installed anywhere, either vertically

or horizontally, on roofs as well as for horizontal and

freestanding installation.

■ The absorber areas with a highly selective coating

are integrated into the vacuum tubes and therefore

are not susceptible to contamination.

■ Efficient heat transfer through fully encapsulated

condensers.

■ Tubes can be rotated (up to 45°) for optimum

alignment with the sun, thereby maximizing the energy

utilisation.

■ Dry connection, meaning tubes can be fitted or replaced

when the system is fully operational.

■ Highly effective thermal insulation for minimized heat

losses from the header casing.

■ Easy installation through the Viessmann assembly and

connection systems.

The Vitosol 200-T, type SPE can be installed on sloped

or flat roofs as well as horizontally (laying flat) or

freestanding. On sloped roofs the collectors may be

positioned vertically (tubes at right angles to the roof

ridge) or horizontally (tubes parallel to the roof ridge).

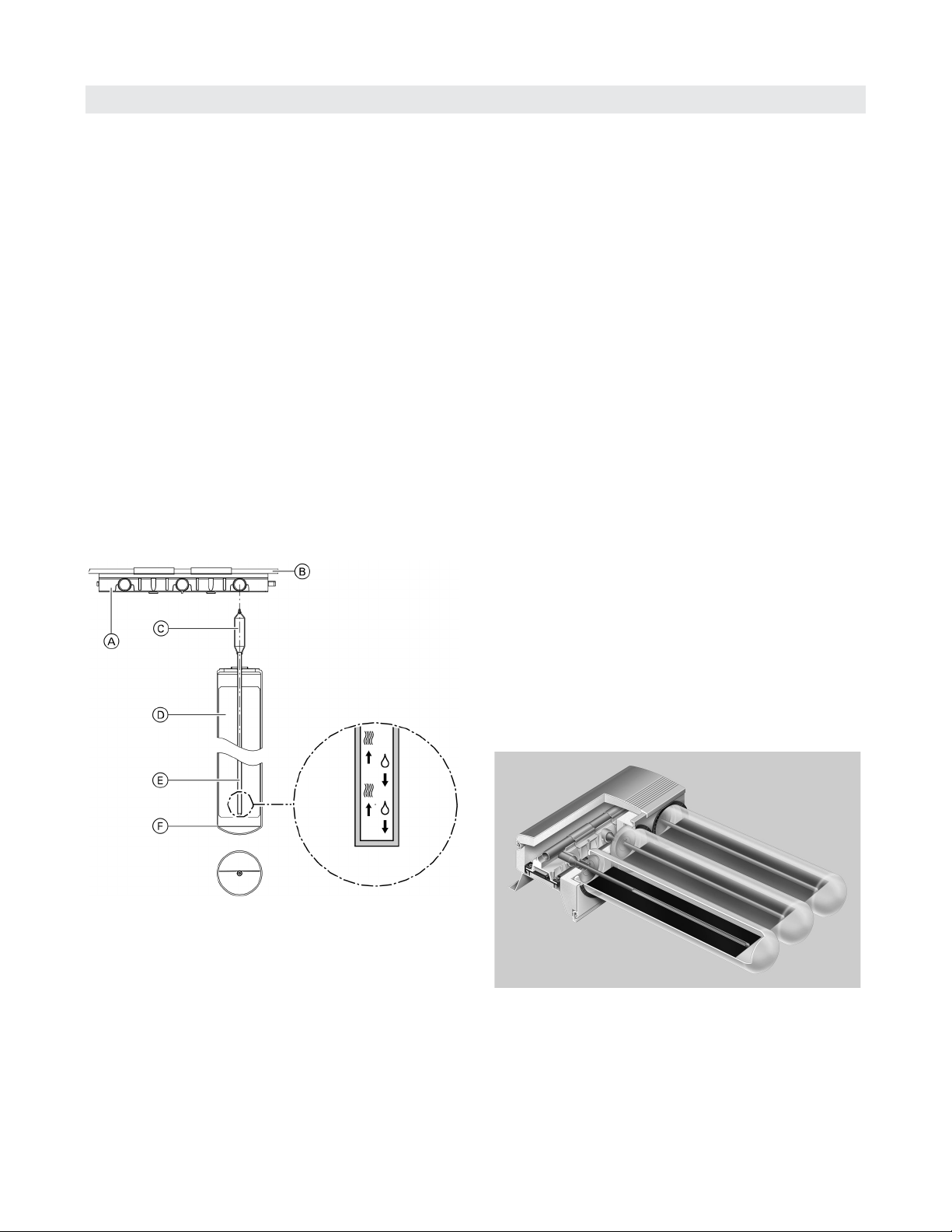

A highly selectively coated metal absorber is incorporated

inside each vacuum tube. It ensures high absorption of

insolation and low emissions of thermal radiation.

A heat pipe filled with an evaporation liquid is arranged

on the absorber. The heat pipe is connected to the

condenser. The condenser is located inside a heat

exchanger designed as a block made from aluminium

and copper.

The system is referred to as a “dry connection”,

i.e. tubes can be rotated and replaced even when the

system is filled and is pressurised. The heat is transferred

from the absorber to the heat pipe. This causes the liquid

to evaporate. The vapor rises into the condenser. Heat is

transferred by the heat exchanger with its copper

manifold, inside which lies the condenser, to the

heat transfer medium streaming past, and the vapor

condenses. The condensate returns back down into

the heat pipe and the process repeats.

The angle of inclination must be greater than zero to

guarantee circulation of the evaporator liquid in the

heat exchanger. Deviations from south can be partially

compensated for by rotating the vacuum tubes.

Up to 215 ft

to form one collector array. For this purpose, the standard

delivery includes flexible connection pipes with O-rings.

A connection set with clamping ring fittings enables the

collector array to be readily connected to the pipes of the

solar circuit. The collector temperature sensor is fitted

into a sensor well inside the collector header casing.

2

(20 m2) absorber area can be connected

Legend

A Heat exchanger block made from aluminium and copper

B Copper manifold

C Condenser

D Absorber

E Heat pipe

F Evacuated glass tube

The Vitosol 200-T, type SPE vacuum tube collector is

available in the following versions:

■ 1.63 m

■ 3.26 m2 with 18 tubes.

2

2

2

with 9 tubes

Delivered condition

Packed in separate boxes:

■ Vacuum tubes, 9 pieces per box

■ Header casing with tube retainer rails

5693 556 v1.0

Page 3

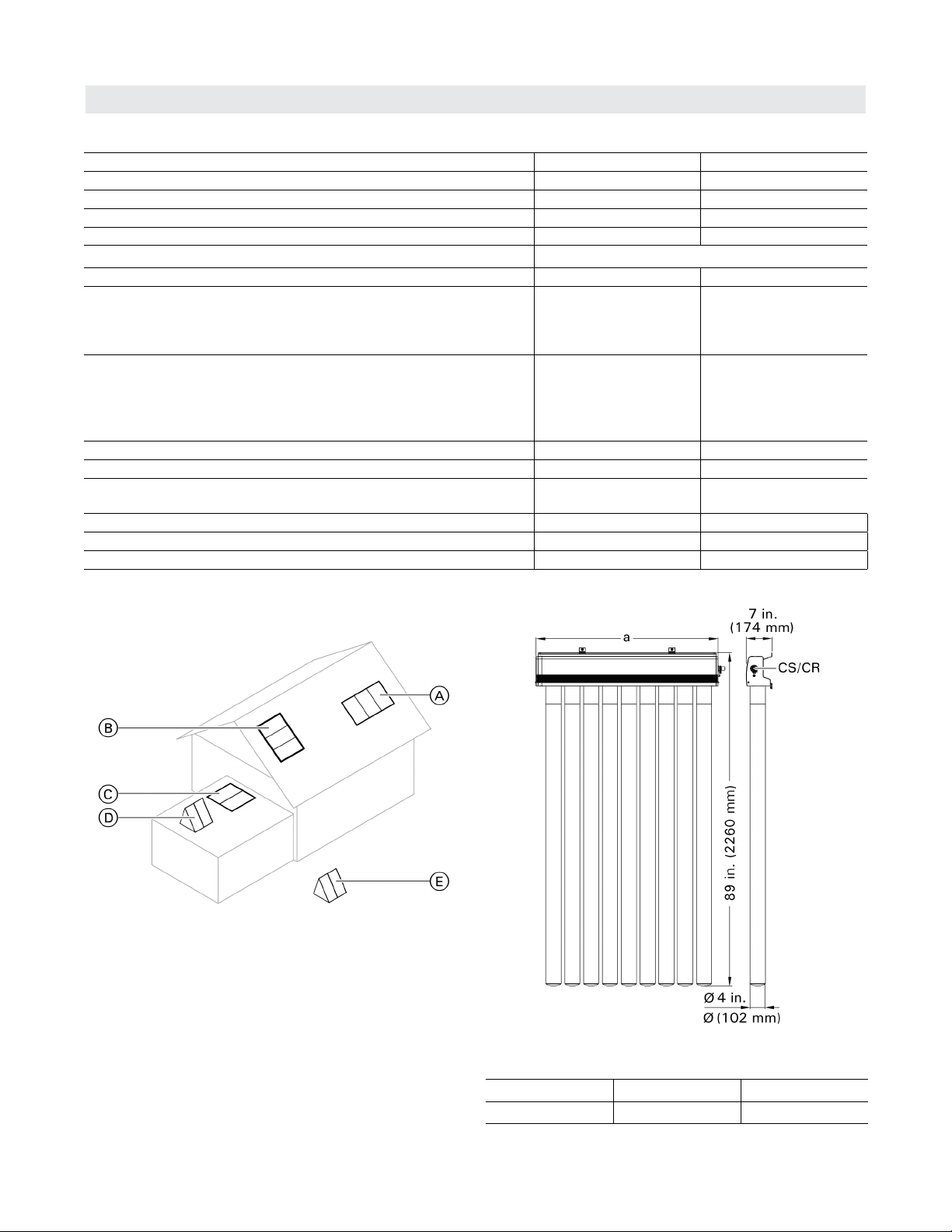

Vitosol 200-T, SPE Technical Data

Specification

Product Information

Vitosol 200-T 1.63 m

2

3.26 m

Number of tubes 9 18

2

Gross area ft

Absorber area ft

Aperture area ft

Installation position (see figure below)

(m2) 28.63 (2.66) 57.26 (5.32)

2

(m2) 17.55 (1.63) 35.10 (3.26)

2

(m2) 18.84 (1.75) 37.57 (3.49)

A, B, C, D, E, F

Spacing between collectors in. (mm) 1.73 (44) 1.73 (44)

Dimensions

Width

Height

Depth

in. (mm)

in. (mm)

in. (mm)

48 (1220)

89 (2260)

6.85 (174)

94 (2390)

89 (2260)

6.85 (174)

The following values apply to the absorber area:

(as tested by TUV testing laboratories in Europe)

– Optical efficiency

– Heat loss factor k1

– Heat loss factor k2

k1 W/(m

k1 W/(m2 · K2)

Thermal capacity kJ/(m

2

%

· K)

73

1.21

0.0075

2

· K) 8.4 8.4

73

1.21

0.0075

Weight lb(kg) 126 (57) 249 (113)

Liquid content

USG (L) 0.124 (0.47) 0.243 (0.92)

(heat transfer medium)

Permissible operating pressure psig (bar) 87 (6) 87 (6)

Maximum stagnation temperature °F (°C) 518 (270) 518 (270)

Connection Ø in. (Ø mm) ¾ (22) ¾ (22)

2

Tested quality

The collectors meet the requirements of the “Blue Angel”

eco-label to RAL UZ 73.

Tested in accordance with Solar KEYMARK, EN 12975

and SRCC 0G-100

5693 556 v1.0

CR Collector return

CS Collector supply

Vitosol 200-T 1.63 m

2

3.26 m

a in. (mm) 48 (1220) 94 (2390)

2

3

3

Page 4

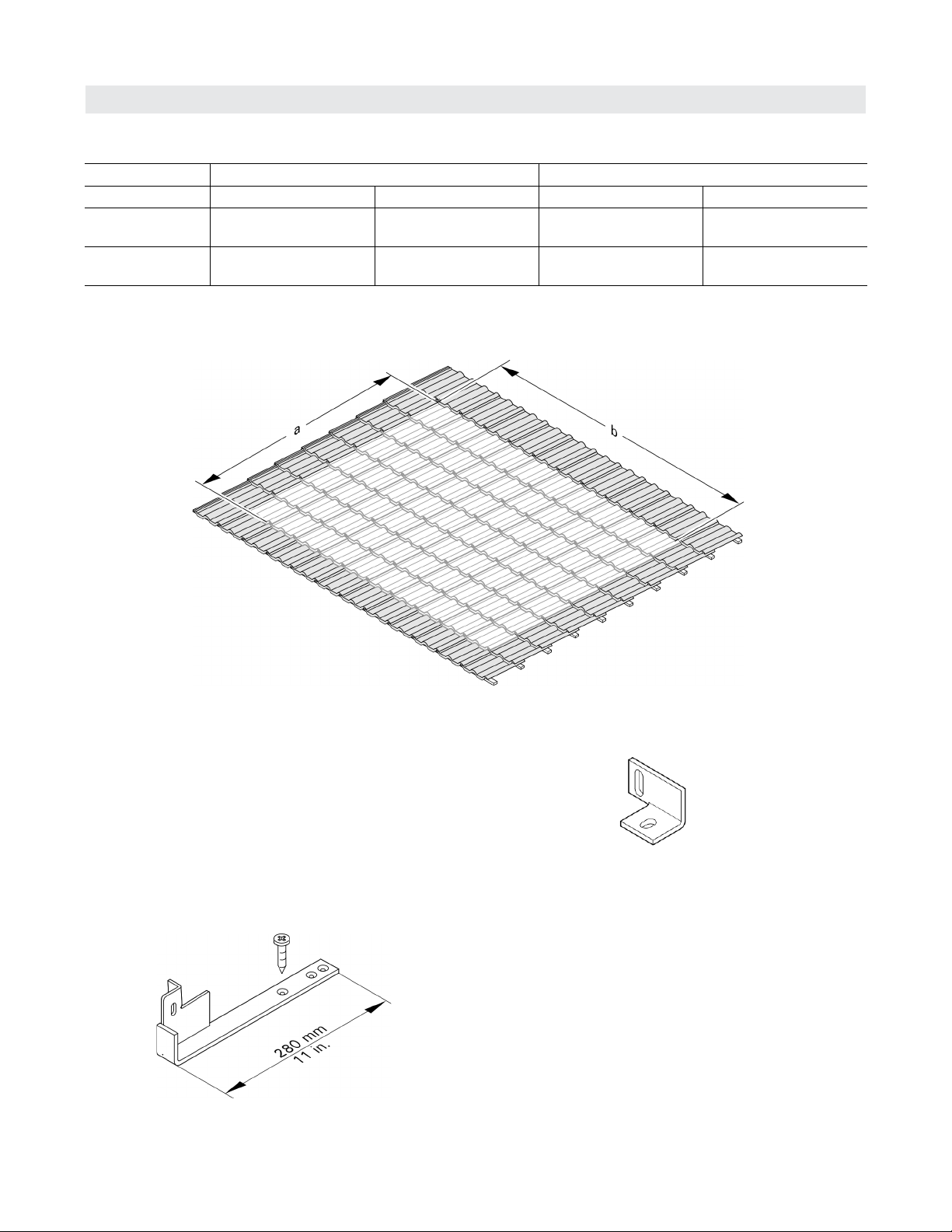

Design Information

Installation on Sloped Roofs

Required roof area

Vitosol 200-T

Vertical installation Horizontal installation Vertical installation Horizontal installation

a in.

(mm)

b in.

(mm)

* space between collectors if multiple units are installed in an array.

Add dimension b for each additional collector.

98.4

(2500)

57.9 + 1.75*

(1470 + 44*)

1.63 m

2

57.9 + 1.75*

(1470 + 44*)

98.4

(2500)

Vitosol 200-T, SPE Technical Data

98.4

(2500)

104 + 1.75*

(2640 + 44*)

3.26 m

2

104 + 1.75*

(2640 + 44*)

98.4

(2500)

Installation with roof brackets

■ This method of fixing can be applied universally on

all common roof covers.

■ The fixing system comprises roof brackets, mounting

rails, clamping brackets and screws.

■ Forces are applied to the roof structure in various ways,

including via the roof brackets and the roof cover. Roof

covers can be very different. Consequently, damage

cannot be completely excluded in the case of applied

loads.

4

4

Mounting bracket

Note: During installation, e.g. on sheet steel roofs,

the mounting rails are secured directly on to

the mounting brackets with T-bolts.

Use on-site fixing options to secure the brackets,

to the substructure.

5693 556 v1.0

Page 5

Vitosol 200-T, SPE Technical Data

Installation on Sloped Roofs

Horizontal installation

Design Information

(continued)

Legend

A Header casing

B Mounting rail

C Tube retainer

D Mounting bracket

E Roof bracket

F Vacuum tube

Vertical installation

Legend

A Vacuum tube

B Clamping bracket

C Tube retainer

D Mounting rail

E Roof bracket

F Header casing

G Mounting plate

5693 556 v1.0

5

5

Page 6

Design Information

Installation on Flat Roofs

Vitosol 200-T, SPE Technical Data

When installing collectors, maintain the minimum

clearances towards the roof edge in accordance with

DIN 1055.

If the roof size necessitates a split array, ensure that

sections of the same size are created. The collectors can

be secured on any solid substructure or on concrete slabs.

When installing collectors on concrete slabs, secure them

with additional ballast against slippage, tipping and lifting.

Slippage is the movement of the collectors on the roof

surface due to wind, because of insufficient friction

between the roof surface and the collector fixing system.

Collectors can be secured by guy ropes or by being fixed

to other roof structures.

Vertical tube installation (elevated)

Collector supports with fixed angle of inclination

Legend

A Footplates

B Rear support

C Collector support

Angle of

inclination

a in.

(mm)

Ballast and max. load on the substructure

Calculation in accordance with DIN 1055-4, 3/2005

and DIN 1055-5, 7/2005 or applicable local codes.

Two support slabs each, both A and B are required

for every collector.

Ballast weight requirements, as well as the calculation of

additional live loads (due to installation of solar collectors),

must be evaluated by a professional structural engineer.

Combination x in. (mm) y in. (mm)

1.63 m2/1.63 m223.6/23.6 (600/600) 25.4 (644)

1.63 m2/3.26 m223.6/47.2 (600/1200) 37.4 (949)

2

3.26 m

/3.26 m247.2/47.2 (1200/1200) 48.6 (1234)

30° 45° 60°

95

(2413)

86.6

(2200)

72.36

(1838)

Note: For calculating z, see page 7.

66

5693 556 v1.0

Page 7

Vitosol 200-T, SPE Technical Data

Installation on Flat Roofs

Design Information

(continued)

Determining the collector row clearance z

At sunrise and sunset (when the sun is very low),

shading cannot be avoided when collectors are arranged

behind one another. To keep the reduction in yield within

acceptable parameters, observe specific row clearances

(dimension z). When the sun is at its highest on the

shortest day of the year (21.12), the rows at the back

should be free of shading. The angle of the sun β (at

midday) on 21.12. must be used to calculate

the row clearance.

Example:

Toronto is approximately located on latitude 43° north.

In the northern hemisphere, this value is calculated as

follows:

Angle β = 90° - 23.5° - latitude

= 90 - 23.5 - 43 =23.5

h = 2260 mm

α = 45°

β = 23.5°

z = sin (180°– (α+β))

h sin β

z = 2260 mm · sin (180° – 68.5°)

sin 23.5°

z = 208 in. (5273 mm)

z = Distance between collector rows

h = Collector height (for dimensions see “Specification”

for the relevant collector)

α = Angle of collector inclination

β = Angle of the sun

5693 556 v1.0

7

7

Page 8

Design Information

Installation on Flat Roofs

A Support slabs A

B Support slabs B

Vitosol 200-T, SPE Technical Data

Horizontal installation (non-elevated)

Yield can be optimized by rotating the vacuum tubes to

45° to the horizontal plane. The collector must be sloped

greater than 0°.

Ballast and maximum load on the substructure

Calculation in accordance with DIN 1055-4, 3/2005 and

DIN 1055-5, 7/2005 or applicable local codes.

Two support slabs each, both A and B are required for

every collector.

Ballast weight requirements, as well as the calculation of

additional live loads (due to installation of solar collectors),

must be evaluated by a professional structural engineer.

88

5693 556 v1.0

Page 9

Vitosol 200-T, SPE Technical Data

Installation Examples

Take venting into account when engineering the collector

array.

Note: Max. 215 ft

be connected in series to form a single array.

2

(20 m2) absorber collector area can

Design Information

Vertical installation on sloped roofs, horizontal installation

or installation on supports

Single row installation; connection from the left or right

[215 ft2 ([202)

A Collector temperature sensor

Installation in several rows, connection from the left or right

Horizontal installation on a sloped roof

1 collector array

With this type of connection, the “Evacuated tube

collector” function at the SCU control must be enabled.

A Collector temperature sensor

2 or more collector arrays

A Collector temperature sensor

With this type of connection, the “Evacuated tube

collector” function at the SCU control must be enabled.

A Collector temperature sensor

5693 556 v1.0

9

9

Page 10

Design Information

Pressure Drop

Pressure Drop

Vitosol 200-T, SPE Technical Data

Relative to water, corresponds to Tyfocor LS at

approximately 140° F (60° C).

Note: For multiple collector arrays, use the total flow

for the whole array to calculate the pressure drop.

A 1.63 m

B 3.26 m

10

Flow Rate

2

2

5693 556 v1.0

Page 11

Vitosol 200-T, SPE Technical Data

Flow Rate

Design Information

SPE collectors have minimum required flow rates (lowflow mode), and maximum flow rates (high-flow mode).

The collectors must operate within this range, and the

designer must choose a flow rate based on the specific

parameters of the system.

Individual collector flow rates

Flow High flow mode

USG/min (L/min)

Model 1.63m2 (9 tube collector) 0.47 (1.8) 0.35 (1.33) 0.26 (1.0)

Model 3.26 m2 (18 tube collector) 0.95 (3.6) 0.70 (2.65) 0.53 (2.0)

Recommended collector array flow rates

Flow High flow mode

USG/min (L/min)

9 tube collector array (model 1.63m

18 tube collector array (model 3.26 m

27 tube collector array* 1.4 (5.4) -- --

36 tube collector array* 1.9 (7.2) -- --

45 tube collector array* 2.4 (9.0) -- --

54 tube collector array* 2.9 (10.8) -- --

72 tube collector array* -- 2.8 (10.6) --

90 tube collector array* -- 3.5 (13.3) 2.7 (10.0)

108 tube collector array* -- -- 3.2 (12.0)

* Collector arrays are combinations of collector model 1.63m2 and/or model 3.26 m

2)

2)

High-flow mode

High-flow mode results in low temperature spread across

the collectors, but may require bigger pump and pipe sizes

for large systems. High-flow mode is best suited for small

scale systems consisting of less than 60 tubes.

Medium and low-flow modes

Medium and low-flow modes result in smaller pipe and

pump sizes, but higher temperature spread across the

collectors. Low-flow and medium-flow modes should

be used for larger collector arrays consisting of greater

than 60 tubes, to avoid high friction losses and high fluid

velocities within the collector, and reduce the size of

supply and return piping requirements.

Use the charts below to determine the required flow rate,

based on the size of the collector or collector array.

Medium flow mode

USG/min (L/min)

Medium flow mode

USG/min (L/min)

0.47 (1.8) -- --

0.95 (3.6) -- --

2.

Low flow mode

USG/min (L/min)

Low flow mode

USG/min (L/min)

5693 556 v1.0

11

Page 12

12

5693 556 v1.0

Vitosol 200-T, SPE Technical Data

Technical information subject to change without notice. Printed on environmentally friendly

(recycled and recyclable) paper.

Loading...

Loading...