Page 1

Service Instructions

Please file in Service Binder

5673 650 - 01 04/2015

Please file in Service Binder

Vitocrossal 300 CU3A Quick Start Guide:

INSTRUCTIONS

for use by heating contractor

Vitocrossal 300

CU3A Series 26 to 57

Floor mounted, gas-fired condensing boiler with MatriX gas burner and Lambda Pro control

For operation with natural gas and liquid propane gas

Heating input 19 to 199 MBH

5.6 to 58 kW

VITOCROSSAL 300

Product may not be exactly as shown

IMPORTANT

Read and save these instructions

H

5673 649 - 01 04/2015

Installation Instructions

for use by heating contractor

Vitocrossal 300

CU3A Series 26 to 57

Floor mounted, gas-fired condensing boiler with MatriX gas burner and Lambda Pro control

For operation with natural gas and liquid propane gas

Heating input 19 to 199 MBH

5.6 to 58 kW

VITOCROSSAL 300

5673 648 - 01 04/2015

for future reference.

Product may not be exactly as shown

IMPORTANT

Read and save these instructions

for future reference.

H

Please file in Service Binder

Please file in Service Binder

FOR LPG CONVERSION DETAIL, SEE PAGES 14-15

FOR CODINGS, SEE PAGES 57-70

FOR TROUBLESHOOTING AND FAULT CODES, SEE PAGES 75-86

FOR WIRING DIAGRAM, SEE PAGES 94-95

FOR HEATING/DHW PUMP AND SENSOR WIRING, SEE PAGES 24-38

FOR SYSTEM LAYOUT, SEE PAGES 40-48

Operating Instructions

Vitocrossal 300

CU3A Series 26 to 57

Floor mounted, gas-fired condensing boiler with MatriX gas burner and Lambda Pro control

For operation with natural gas and liquid propane gas

Heating input 19 to 199 MBH

5.6 to 58 kW

VITOCROSSAL 300

With Vitotronic 200 KW6B Controls

H

Installation Instructions

for use by heating contractor

Mixing Valve Extension Module

for one heating circuit with mixing valve

Mixing Valve

Extension Module

Certified as a component

part for Viessmann boilers

5774 472 - 03 04/2015

WARNING

If the information in this manual is not followed

exactly, a fire or explosion may result causing

property damage, personal injury or loss of life.

Do not store or use gasoline or other

fl ammable liquids in the vicinity of this

or any other appliance.

WHAT TO DO IF YOU SMELL GAS

Do not try to light any appliances.

Do not touch any electrical switches,

do not use any phone in your building.

Immediately call your gas supplier

from a neighbor’s phone. Follow

the gas supplier’s instructions.

If you cannot reach your gas supplier,

call the fi re department.

Installation and service must be

performed by a qualifi ed installer,

service agency or the gas supplier.

WARNING

Improper installation, adjustment, and/

or operation could cause carbon monoxide

poisoning resulting in injury or loss of life.

This product must be installed and serviced

by a professional service technician who is

experienced and qualified in hot water boiler

installation and gas combustion.

Product may not be exactly as shown

IMPORTANT

Read and save these instructions

for future reference.

Product may not be exactly as shown

IMPORTANT

Read and save these instructions

for future reference.

FOR PROGRAMMING, SEE PAGES 11-33

QUICK START GUIDE

FOR PUMP AND SENSOR WIRING, SEE PAGE 8

VITOCROSSAL 300, CU3A

For the latest updates on the Quick Start Guide, please visit

9442120 05 / 2015

UNCOMPROMISE.US

UNCOMPROMISE.US

Page 2

Vitocrossal 300 CU3A Quick Start Guide:

VITOCROSSAL CU3A QUICK START GUIDE

ABOUT THIS QUICK START GUIDE: The programming and wiring recommendations in this guide are

intended to enable immediate initial service under the most common conditions; they are not intended to be a

substitute for detailed, site-specific set-up and commissioning. Only for use by trained, licensed heating contractor.

SEE THE INSTALLATION AND SERVICE INSTRUCTIONS FOR IMPORTANT SAFETY INFORMATION.

BEFORE BEGINNING THE QUICK START PROCESS:

1. Verify that power (120/1/60 wth earth ground, properly polarized) is supplied to the #4 0

connections on the POWER /PUMP INTERFACE and MIXING CONTROL, if used.

2. Verify that the fuel gas supply is available (4”-14”WC Nat, 10”-14”WC LPG) and that air has been purged from the piping.

3. Verify boiler/system water fill and purge.

4. Verify proper venting and combustion air supply.

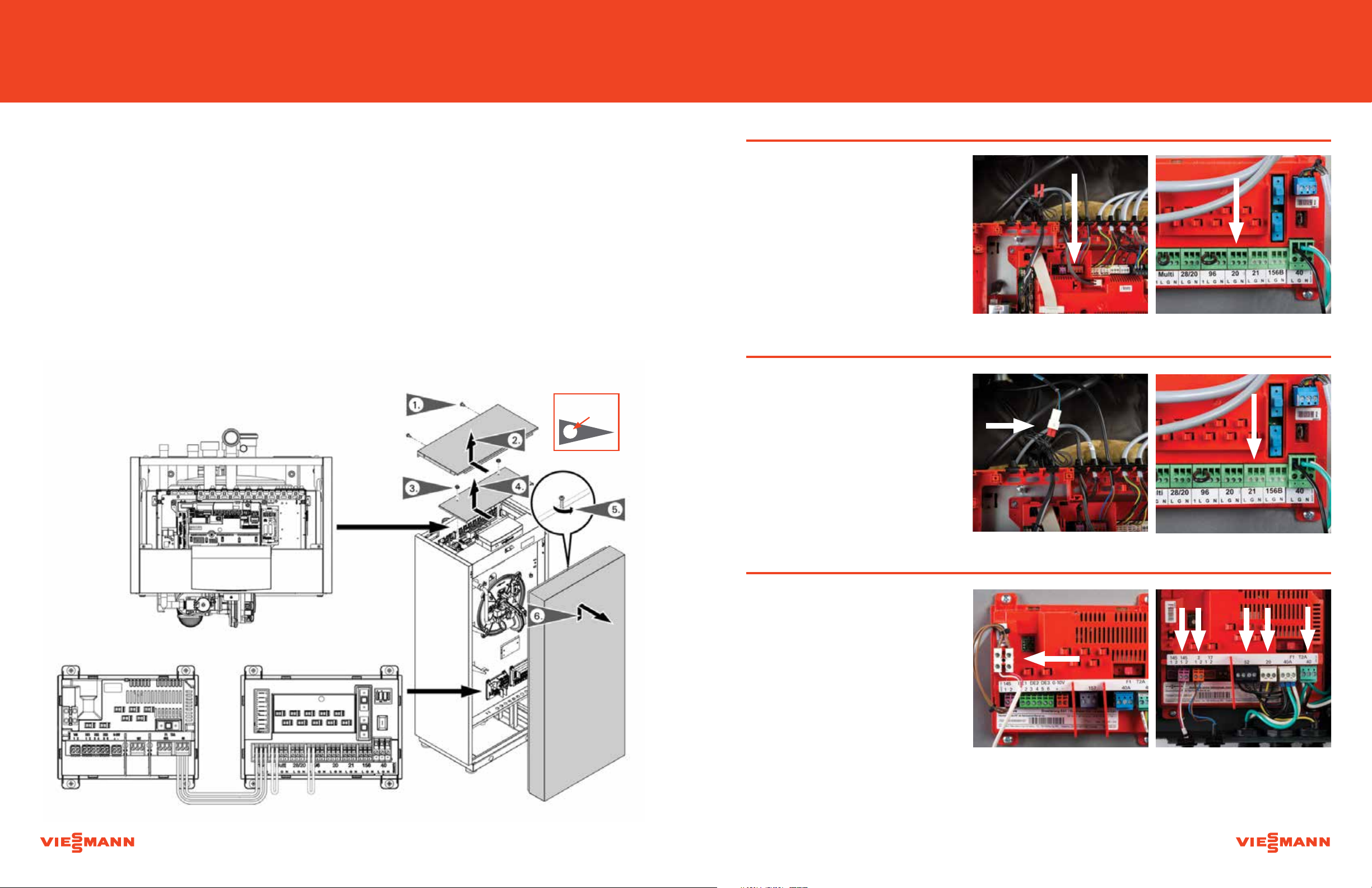

ACCESS TO THE CU3A WIRING:

BOILER

CONTROL

REMOVE FASTENERS 1 - 6

Remove fastners

in order.

1.

FOR HEATING ONLY:

CONNECT #1 OUTDOOR SENSOR TO SCREW

TERMINALS X3, 1 + 2 ON BOILER CONTROL

USE #20 ON THE POWER/PUMP INTERFACE

TO POWER SINGLE-ZONE HEATING PUMP

DIRECTLY. ON ZONED SYSTEMS, USE #20

TO POWER ZR (REMOVE ZC-ZR JUMPER)

ON SWITCHING RELAY PROVIDED BY

OTHERS

TO ADD DOMESTIC HOT WATER:

CONNECT THE #5 DHW SENSOR TO THE RED

#5 PLUGS ON THE BOILER CONTROL. DHW

OPERATION WILL BE AUTO-ENABLED IN THE

CONTROL PROGRAM.

USE A SEPARATE DHW PUMP; POWER IT

WITH #21 ON THE POWER/PUMP INTERFACE

WIRING CONNECTIONS

BOILER CONTROL

POWER/PUMP INTERFACE

EA1 EXTENSION

POWER/PUMP INTERFACE

TO ADD A MIXING VALVE:

CONNECT THE PURPLE #145 ON THE MIXING

VALVE EXTENSION TO THE #145 KM BUS

ON THE BOILER’S EA1 EXTENSION USING

18/2 WIRE

CONNECT THE #2 SUPPLY SENSOR TO #2 ON

THE MIXING VALVE EXTENSION. CONNECT

THE MIXING VALVE MOTOR TO #52 ON THE

MIXING VALVE EXTENSION

POWER THE MIXING PUMP WITH #20 ON

THE MIXNG VALVE EXTENSION

BOILER CONTROL

EA1 EXTENSION MIXING VALVE EXTENSION

POWER/PUMP INTERFACE

(OPTIONAL)

Page 3

Vitocrossal 300 CU3A Quick Start Guide:

LPG CONVERSION

START

FROM THE HOME SCREEN

Press

1

Then Press OK and

together for 4 seconds.

1. Set adusting screw to position 2

2. Turn power switch on.

3. Program for LPG operation

4. Refer to SERVICE INSTRUCTIONS, pages 14-15

for important safety information and

pressure check.

2

Press OK and together for 4 seconds

5

Press OK

8

3

Press OK

6

Press until you see :

9

4

Press until you see :

7

Press OK

10

LEGEND

Takes you to the previous step in the menu or cancels

a setting that has been started

Cursor keys to scroll through the menu or to set values

Press until you see :

Press OK

Press until you see :

OK Confirms your selection or saves the setting

? Calls up help or additional information on the selected menu

Calls up the extended menu

11

Press OK then 4 times

12

DONE

Page 4

Vitocrossal 300 CU3A Quick Start Guide:

PROGRAMMING

Setting Time, Date, and Heating Curve for heating circuit #1 (High Temp)

START

1

Press Press 3 times

4

Press OK

2

5

Press or to set time Press or to set date

Press Press Press OK Press OK

3

Press OK

6

Setting Domestic Hot Water Operation

DHW operation is auto-enabled with the connection of the #5 tank sensor and

DHW temperature is set to 122F.

Setting the Heating Curve for mixing circuit #2 (Low Temp)

START

1

Press

2

Press 7 times

3

Press OKPress OK Press (RIGHT)

7

Press 4 times

10

Press 2 times

Press OK

13

Press 3 times

8

11

14

Press OK

Press OK

Press 7 times

9

Press Press OK

12

Press OK

15

4

Press 5 times Press 3 timesPress OK Press OK

Refer to OPERATING INSTRUCTIONS for more programming options.

5

6

DONE

Press OK

Press 4 times

Press OK

Press 3 times

DONE

Loading...

Loading...