Page 1

Service Manual

Bear Cub 750PSV

© Copyright 2004, VIASYS Healthcare Critical Care

L2346 Revision B June 2004

Page 2

2 Bear Cub 750PSV

Revision History

Date Revision Pages Changes

June 2003 A All Release

June 2004 B All Release manual in VIASYS Healthcare

template using VIASYS Healthcare Critical

Care nomenclature.

L2346 Revision B June 2004

Page 3

Service Manual 3

Contact and Ordering Information

United States, Latin America, Asia Pacific:

Sales, Service and Clinical Support:

VIASYS Healthcare

Critical Care Division

22705 Savi Ranch Parkway

Yorba Linda, CA 92887

Phone: (714) 283-8444

(800) 381-3552

Fax: (714) 283-8493

www.VIASYShc.com

United Kingdom:

Sales, Service and Clinical Support:

VIASYS Healthcare

3 Welton Rd.

Warwick,

CV34 5PZ

Phone: 01926 490888

Fax: 01926 402262

Europe

Sales and Customer Service Technical Service

VIASYS Healthcare VIASYS Healthcare

Critical Care Division Leibnizstrasse 7

22705 Savi Ranch Parkway D-97204 Hoechburg

Yorba Linda, CA 92887 Germany

Phone: (714) 283-8444 Phone +49 (0) 931 4972 – 0

(800) 381-3552 Fax:+49 (0) 931 4972 –423

e-mail: Support.CC.EU@VIASYShc.com

website: www.VIASYShc.com

L2346 Revision B June 2004

Page 4

4 Bear Cub 750PSV

CAUTION

Federal law (USA) restricts this device to sale by or on the order of a physician.

CAUTION

Not suitable for use in the presence of flammable anesthetics.

CAUTION

Service and/or repair of this instrument is restricted to VIASYS Healthcare authorized

or VIASYS Healthcare Trained Personnel only.

L2346 Revision B June 2004

Page 5

Service Manual 5

Warranty

The Bear Cub 750PSV is warranted to be free from defects in material and

workmanship and to meet the published specifications for One (1) year from date of

shipminent.

The liability of VIASYS Healthcare, Critical Care Division, (referred to as the

Company) under this warranty is limited to replacing, repairing or issuing credit, at

the discretion of the Company, for parts that become defective or fail to meet

published specifications during the warranty period; the Company will not be liable

under this warranty unless (A) the Company is promptly notified in writing by Buyer

upon discovery of defects or failure to meet published specifications; (B) the

defective unit or part is returned to the Company, transportation charges prepaid by

Buyer; (C) the defective unit or part is received by the Company for adjustment no

later than four weeks following the last day of the warranty period; and (D) the

Company’s examination of such unit or part shall disclose, to its satisfaction, that

such defects or failures have not been caused by misuse, neglect, improper

installation, unauthorized repair, alteration or accident.

Any authorization of the Company for repair or alteration by the Buyer must be in

writing to prevent voiding the warranty. In no event shall the Company be liable to

the Buyer for loss of profits, loss of use, consequential damage or damages of any

kind based upon a claim for breach of warranty, other than the purchase price of any

defective product covered hereunder.

The Company warranties as herein and above set forth shall not be enlarged,

diminished or affected by, and no obligation or liability shall arise or grow out of the

rendering of technical advice or service by the Company or its agents in connection

with the Buyer's order of the products furnished hereunder.

Limitation of Liabilities

This warranty does not cover normal maintenance such as cleaning, adjustment or

lubrication and updating of equipment parts. This warranty shall be void and shall not

apply if the equipment is used with accessories or parts not manufactured by the

Company or authorized for use in writing by the Company or if the equipment is not

maintained in accordance with the prescribed schedule of maintenance.

The warranty stated above shall extend for a period of One (1) year from date of

shipment, with the following exceptions:

1. Components for monitoring of physical variables such as temperature,

pressure, or flow are warranted for ninety (90) days from date of receipt.

2. Elastomeric components and other parts or components subject to

deterioration, over which the Company has no control, are warranted for sixty

(60) days from date of receipt.

3. Internal batteries are warranted for ninety (90) days from the date of receipt.

The foregoing is in lieu of any warranty, expressed or implied, including, without

limitation, any warranty of merchantability, except as to title, and can be amended

only in writing by a duly authorized representative of the Company.

L2346 Revision B June 2004

Page 6

6 Bear Cub 750PSV

L2346 Revision B June 2004

Page 7

Service Manual 7

Contents

Revision History .................................................................................... 2

Contact and Ordering Information ...............................................................................3

Warranty .........................................................................................................................5

Limitation of Liabilities.................................................................................................... 5

Contents .........................................................................................................................7

List of Figures ................................................................................................................9

List of Tables................................................................................................................ 11

Chapter 1: Specifications ...................................................................13

Modes............................................................................................................................ 13

Controls ........................................................................................................................13

Alarms...........................................................................................................................15

Monitors........................................................................................................................17

Preset Values ............................................................................................................... 19

Emissions/Susceptibility............................................................................................. 19

Outputs .........................................................................................................................19

Inputs ............................................................................................................................20

Physical Dimension and Shipping Information......................................................... 20

Environmental Specifications..................................................................................... 21

Method of Sterilization/Disinfection ........................................................................... 21

Cleaning........................................................................................................................22

Sterilization...................................................................................................................22

Chapter 2: Theory of Operation .........................................................23

Overview .......................................................................................................................23

Ventilator pneumatics - General description............................................................. 25

Gas Inlet Conditioning................................................................................................. 25

Blender.......................................................................................................................... 25

Flow Control Valve....................................................................................................... 25

AOPR Valve/Sub-Ambient Valve/ Dump Solenoid ....................................................26

Auxiliary Gas Outlet..................................................................................................... 26

Pressure Control System ............................................................................................26

Exhalation Valve .......................................................................................................... 27

Flow Sensor.................................................................................................................. 27

Ventilator Electronics ..................................................................................................27

Power Supply ...............................................................................................................28

Ventilator Software ......................................................................................................28

L2346 Revision B June 2004

Page 8

8 Bear Cub 750PSV

Chapter 3 OVP Recommended Service ........................................... 29

Operational Verification .............................................................................................. 29

Equipment Required.................................................................................................... 29

Test Procedures........................................................................................................... 32

Exterior Inspection and Cleaning............................................................................... 34

Exterior Cleaning ......................................................................................................... 34

Plugs and Cables ........................................................................................................ 34

OVP Checklist .............................................................................................................. 35

Verification Steps......................................................................................................... 35

Chapter 4 Calibration (for software releases 2 and 3 only)........... 37

Introduction .................................................................................................................. 37

Pressure Transducers and Flow Control Valve Calibration .................................... 38

Air and O2 Regulator Balance..................................................................................... 41

Objective...................................................................................................................... 41

Equipment ................................................................................................................... 41

Requirements .............................................................................................................. 41

Chapter 5 Schematics and Assemblies ........................................... 45

Chapter 6 Troubleshooting ............................................................... 69

Chapter 7 Removal & Replacement.................................................. 73

Interior Access ............................................................................................................. 73

Flow Valve Assembly Removal .................................................................................. 74

Control PCB Removal.................................................................................................. 75

Display PCB Removal.................................................................................................. 76

Air/O2 Regulator Removal ........................................................................................... 76

Blender Removal.......................................................................................................... 77

Exhalation Valve Removal .......................................................................................... 78

Chapter 8 Preventive Maintenance................................................... 79

Replacement Parts ...................................................................................................... 79

Recommended Service Procedure............................................................................. 79

Exterior Inspection ...................................................................................................... 80

Interior Inspection........................................................................................................ 80

Specifications............................................................................................................... 80

Calibration and Verification Procedure ..................................................................... 80

Ground Resistance Test.............................................................................................. 81

Current Leakage Test .................................................................................................. 81

Operational Verification Procedure............................................................................ 81

Chapter 9 RS-232 Protocol............................................................... 83

Scope ............................................................................................................................ 83

L2346 Revision B June 2004

Page 9

Service Manual 9

Hardware Definition ..................................................................................................... 83

Pin Assignment............................................................................................................ 83

Software Protocol ........................................................................................................ 84

Continuous Output (Default Mode) .............................................................................. 84

Data Upon Request ..................................................................................................... 84

Data Format................................................................................................................. 84

Chapter 10 Parts List.......................................................................... 93

Chapter 11 Repackaging Instructions ............................................... 95

General.......................................................................................................................... 95

Packaging Instructions ............................................................................................... 95

Procedure ..................................................................................................................... 95

Index ..................................................................................................... 97

List of Figures

Figure 2-1: Top Level Block Diagram ............................................... 23

Figure 2-2: Pneumatics System Schematic ..................................... 24

Figure 3-1: Bear Cub 750PSV US with Patient Circuit ....................33

Figure 5-1: Power Supply Module Assembly (1 of 2) ...................... 45

Figure 5-2: Power Supply Module Assembly (2 of 2) ....................... 46

Figure 5-3: Schematic Diagram, Pneumatic 750PSV .......................47

Figure 5-4: Power Supply PCB Assembly (1 of 3) ............................ 48

Figure 5-5: Power Supply PCB Assembly (2 of 3) ............................ 49

Figure 5-6: Power Supply PCB Assembly (3 of 3) ............................ 50

Figure 5-7: Pneumatic Tubing Diagram............................................. 51

Figure 5-8: Display PCB (1 of 3) ......................................................... 52

Figure 5-9: Display PCB (2 of 3) ......................................................... 53

Figure 5-10: Display PCB (3 of 3)....................................................... 54

Figure 5-11: Control PCB Assembly.................................................. 55

Figure 5-12: Wiring Diagram............................................................... 56

Figure 5-13: Power Supply Schematic ..............................................57

Figure 5-14: Control Schematic PCB (1 of 5) .................................... 58

L2346 Revision B June 2004

Page 10

10 Bear Cub 750PSV

Figure 5-15: Control Schematic PCB (2 of 5).................................... 59

Figure 5-16: Control Schematic PCB (3 of 5).................................... 60

Figure 5-17: Control Schematic PCB (4 of 5).................................... 61

Figure 5-18: Control Schematic PCB (5 of 5).................................... 62

Figure 5-19: Display Schematic PCB (1 of 4).................................... 63

Figure 5-20: Display Schematic PCB (2 of 4).................................... 64

Figure 5-21: Display Schematic PCB (3 of 4).................................... 65

Figure 5-22: Display Schematic PCB (4 of 4).................................... 66

Figure 5-23: BEAR CUB 750PSV Overlay (P/N 51-09640-00)........... 67

Figure 6-1: Troubleshooting Decision Tree...................................... 69

Figure 7-1: Cover Removal................................................................. 73

Figure 7-2: Standoff Tube Removal................................................... 74

Figure 7-3: Opening of Front Portion ................................................ 74

Figure 7-4: Flow Valve Assembly ...................................................... 75

Figure 7-5: Control PCB ..................................................................... 75

Figure 7-6: Display PCB ..................................................................... 76

Figure 7-7: Air / O2 Fittings................................................................. 76

Figure 7-8: Air / O2 Regulator Assembly ........................................... 77

Figure 7-9: Oxygen % Knob ............................................................... 77

Figure 7-10: Blender Removal ........................................................... 78

Figure 7-11: Blender Assembly ......................................................... 78

Figure 7-12: Exhalation Valve Assembly .......................................... 78

Figure 8-1: Ventilator Back Panel ...................................................... 81

Figure 11-1: Repacking Procedure.................................................... 96

L2346 Revision B June 2004

Page 11

Service Manual 11

List of Tables

Table 3-1: Standard Settings ............................................................. 30

Table 3-2: Rate.................................................................................... 30

Table 3-3: Exhalation Time and I/E Ratio Table ............................... 30

Table 4-1: Control PCB Transducer Calibration .............................. 38

Table 4-2: Calibration ......................................................................... 39

Table 4-3: Diagnostic Function ......................................................... 40

Table 4-4: Inspiratory Flow Calibration ............................................ 41

Table 4-5: Regulator Balance ............................................................ 42

Table 4-6: Standard Test Settings..................................................... 43

Table 6-2: Troubleshooting ................................................................70

Table 9-1: Pin Assignment.................................................................. 83

Table 9-2: Alternate Pin Assignment ................................................. 84

Table 9-3: Valid Requests Received by the Ventilator .................... 85

Table 9-4: Valid Message Transmitted by the Ventilator ................ 85

Table 9-5: Real Time Data .................................................................. 86

Table 9-6: Adult Ventilator Control Settings .................................... 87

Table 9-7: Adult Ventilator Alarm Settings / Status.........................88

Table 9-8: Adult Ventilator Monitor Status....................................... 89

Table 9-9: Infant Ventilator Control Settings ...................................90

Table 9-10: Infant Ventilator Alarm Settings / Status ...................... 91

Table 9-11: Infant Ventilator Monitor Status .................................... 92

L2346 Revision B June 2004

Page 12

12 Bear Cub 750PSV

L2346 Revision B June 2004

Page 13

Service Manual 13

Chapter 1: Specifications

Modes

A/C

In the Assist/Control position, a mechanical breath is delivered with each inspiratory

effort, provided the patient satisfies the assist sensitivity criteria. If the patient does

not meet the assist sensitivity criteria, the ventilator automaticallydelivers breaths

according to the Ventilator Rate control. Mechanical breaths may then be either

patient initiated (assisted) or ventilator initiated (controlled).

SIMV/IMV

In the SIMV/IMV position, a combination of mechanical and spontaneous breath

types is available. Mechanical breaths, either assisted or controlled, are delivered at

the set ventilator rate while all other breaths are spontaneous. Disabling the assist

sensitivity mechanism. or removing the flow sensor from the ventilator, will cause the

equivalent of IMV mode of ventilation to exist.

CPAP

In the CPAP position, the Base Flow control establishes the continuous flow

available for spontaneous breathing.

STANDBY

The STANDBY position discontinues all electrical controls and functions with the

exception of the charging system for the internal battery.

NOTE

If the ventilator is connected to air and O2 sources, blended gas will circulate while

ventilator is in the STANDBY position, making gas available from the Auxiliary Gas

Outlet. The amount of gas flow circulating is determined by the Base Flow setting.

Controls

Rate

Range: 1 to 150 BPM

Resolution: 1 from 1 to 100BPM

2 from 100 to 150 BPM

Tolerance: Greater of ± 1 BPM or 0.02 seconds applied to the Breath

Interval

L2346 Revision B June 2004

Page 14

14 Bear Cub 750PSV

Inspiratory Time

Range: 0.10 to 3.0 seconds

Resolution: 0.01 from 0.10 to 0.50 seconds

0.02 from 0.50 to 1.70 seconds

0.05 from 1.70 to 3.00 seconds

Accuracy: ± 0.02 seconds from 0.10 to 0.50 seconds

± 0.025 seconds from 0.50 to 3.00 seconds

Inspiratory Flow

Range: 1 to 30 L/min

Resolution: 0.5 L/min from 1 to 10 L/min

1.0 L/min from 10 to 30 L/min

Accuracy: Pressures 0 to 60 cmH2O: ± 0.5 L/min or ± 10% of setting,

whichever is greater.

Pressure 60 to 72 cmH2O: ± 0.5 L/min or + 10%/- 15% of

setting, whichever is greater.

Baseline Flow

Range: 1 to 30 L/min

Resolution: 0.5 L/min from 1 to 10 L/min

1.0 L/min from 10 to 30 L/min

Accuracy:Pressures 0 to 60 cmH2O: ± 0.5 L/min or ± 10% of setting, whichever is

greater.

Pressure 60 to 72 cmH2O: ± 0.5 L/min or + 10%/- 15% of

setting. Whichever is greater

Volume Limit™

Range: 5 to 300 ML

Resolution: 1 ML from 5 to 50 ML

2 ML from 50 to 150 ML

5 ML from 150 to 300 ML

Accuracy: ± 2 ML or ± 10% of setting, whichever is greater

PEEP

Range: 0 to 30 cmH2O

Resolution: 1 cmH2O

Repeatability: ± 1 cmH2O or ± 5%, whichever is greater

L2346 Revision B June 2004

Page 15

Service Manual 15

Inspiratory Pressure

Range: 0 to 72 cmH2O

Resolution: 1 cmH2O from 0 to 30 cmH2O

2 cmH2O from 30 to 72 cmH2O

Repeatability: ± 1 cmH2O or ± 5% whichever is greater. Breath to breath

Manual Breath

Range: X1

Assist Sensitivity

Range: 0.2 to 5.0 L/min

Resolution: 0.2 at 0.2 L/min increasing to 0.5 at 5.0 L/min

Accuracy:Not a calibrated scale, minimum setting accuracy is ± 0.1 L/min

Over Pressure Relief

Range: (Pressure at the patient wye): 15

to 75 cmH2O

Resolution: 2 cmH2O stability (repeatability) ±4 cmH2O

%02 Blending

Range: 21 to 100% Oxygen concentration

Resolution: 1%

Accuracy: ± 3% oxygen

APNEA Interval

Range: 5, 10, 20, or 30 seconds

Accuracy: ± 1 second

Alarms

Alarm Loudness

Range: Min. to Max. 60 to 75 db(A)

High Breath Rate

Range: 3 to 255 BPM

Low PEEP/CPAP

Range: -5 to 30 cmH2O

L2346 Revision B June 2004

Page 16

16 Bear Cub 750PSV

Low Inspiratory Pressure

Range: 1 to 65 cmH2O

Patient Circuit

LED On/Off

Failed to Cycle

LEd On/Off

Low Gas Supply

LED On/Off

Apnea

LED On/Off

Settings Incompatible

LED On/Off

Pressure Settings Incompatible

LED On/Off

Prolonged Inspiratory Pressure

LED On/Off

Flow Sensor

LED On/Off

Low Battery

LED On/Off

Alarm Silence

60 seconds

Visual Reset

Push Button

High Pressure Limit

Range: 10 to 75 cmH2O

L2346 Revision B June 2004

Page 17

Service Manual 17

Line Power

Green/Red LED

Monitors

Total Breath Rate

Range: 0 to 255 BPM

Resolution: 1 BPM from 0 to 100 BPM

2 BPM from 100 to 150 BPM

3 BPM from 150 to 255 BPM

Exhalation Minute Volume

Range: 0 to 30.0 L/min

resolution: 0.01 L/min from o to 1.00 L/min

0.02 L/min from 1 to 2.00 L/min

0.05 L/min from 2 to 5.0 L/min

0.10 L/min from 5 to 10.0 L/min

0.20 L/min from 10 to 30.0 L/min

Accuracy: Accuracy of the exhaled minute volume is a function of both

volume and breath rate. To evaluate the performance of this

monitor the accuracy of both tidal volume and breath rate must

be combined

Exhaled Tidal Volume

Range: 0 to 500 ML

Resolution: 0.1 ML from 0.0 to 99.9 ML

1.0 ML from 100 to 500 ML

Accuracy: ± 1 ML or ± 10%, whichever is greater

% of Tubing Leakage

Range: 0 to 100%

Resolution: 1%

Accuracy: ± 2% or ± 1 ML

Inspiratory Time

Range: 0 to 3.10 seconds

Resolution: 0.01 seconds

Accuracy: ± 0.02 seconds

L2346 Revision B June 2004

Page 18

18 Bear Cub 750PSV

Expiratory Time

Range: 0 to 99.9 seconds

Resolution: 0.01 seconds from 0 to 99.9 seconds

0.10 seconds from 10.0 to 99.9 seconds

Accuracy: ± 0.02 seconds

I:E Ratio

Range: 9.9:1 to 1:9.9

Accuracy: ± 0.1 or ± 20 mseconds, whichever is greater

Peak Inspiratory Pressure

Range: 0 to 99 cmH2O

Resolution: 1 cmH2O

Accuracy: ± 2 cmH2O or ± 5% of reading, whichever is greater

Mean Airway Pressure

Range: 0 to 75 cmH2O

Resolution: 0.5 cmH2O

Accuracy: ± 2 cmH2O or ± 3% of reading, whichever is greater

Inlet O2 Pressure

Range: 0 to 100 PSIG

Resolution: 1 PSIG

Accuracy: ± 5 PSIG

Proximal Airway Pressure

Range: -10 to 100 cmH2O

Resolution: 1 cmH2O

Accuracy: ± 1 cmH2O from -10 to 20 cmH2O

± 2 cmH2O from 20 to 65 cmH2O

± 3 cmH2O from 65 to 100 cmH2O

Hourmeter

Range: 0 to 99,999 hours

Resolution: 0.1 hour

Accuracy: ± 2% of reading

L2346 Revision B June 2004

Page 19

Service Manual 19

Breath Type (Patient Initiated)

LED

Test

Push Button

Battery

LED On/Off

Preset Values

Minimum Expiratory Time 150 milliseconds

Maximum Inspiratory Time 3.10 seconds

Maximum settable I:E Ratio 4:1

Model 9300

Classification Class 1

Degree of Protection

Electric Shock Type B

Harmful Ingress of Water None (Ordinary Equipment)

Degree of Safety of Application

in Presence of Flammable Anesthetics None

Mode of Operation Continuous

Emissions/Susceptibility

This ventilator has been tested to conform to the following specifications:

MIL-STD-461D:1993,MIL-STD-462D:1993, EN55011:1991, IEC 1000-4-2:1994, IEC

1000-4-3:1994, IEC 1000-4-4:1994, IEC 1000-4-5:1994, QUASI-STATIC:1993.

This ventilator is designed and manufactured to comply with the safety requirements

of IEC 601-1, IEC 601-2-12, CAN/CSA-C22.2 No. 601.1-M90, and UL 2601-1.

Outputs

Digital

(see chapter 9) RS-232 Bi-Directional

Analog

Proximal Pressure -10 to 100 cmH2O, 1 cmH2O/25 mv

L2346 Revision B June 2004

Page 20

20 Bear Cub 750PSV

Proximal Inspiratory/Expiratory Flow -40 (expiratory) to 40 (inspiratory) L/min,

1 L/min/50 mv

Breath Phase 1 “Logic” signal; 0, 5V

Remote Nurse Call 0.5 amps max at 24 vdc max

Pneumatic

Auxiliary Blended Gas Outlet 7 to 17 psig, 0 to 8 L/min

Inputs

Electrical

Supply Ratings

Voltage: 100V 80 to 110 VAC

120V 96 to 132 VAC

220V* 176 to 242 VAC

240V 192 to 264 VAC

Current: 100V 1.0 A maximum

120V 1.0 A maximum

220V 0.5 A maximum

240V 0.5 A maximum

Frequency: 100V 50/60 Hz

120V 50/60 Hz

220V 50/60 Hz

240V 50/60 Hz

Fuses: 100/120V T 0.5 A, 5 x 20 mm

230/240V T 0.25 A, 5 x 20 mm

* For 220V operation, set the power entry module selector switch to 230V setting.

Pneumatic

Oxygen and Air 30 to 80 psig, 50 L/min Supply Ratings

Physical Dimension and Shipping Information

Ventilator Weight 27 lbs., 12 kg

Graphics Display Weight 5.5 lbs.

Pedestal Stand Weight 9 lbs.

Compressor Weight 110 lbs.

L2346 Revision B June 2004

Page 21

Service Manual 21

Ventilator Dimensions 13.5" W x 10" D x 11" H

Graphics Display Dimensions 13" W x 2.5" D x 9.5" H

Pedestal Stand Dimensions 24" x 40.5" H

Compressor Dimensions 22"W x 21.5"D x 36" H

Shipping Weight Including Ventilator 38 lbs.

Graphics Display 11 lbs.

Pedestal Stand 12 lbs.

Compressor 122 lbs.

Shipping Dimensions

Ventilator 18" W x 18" D x 19" H

Graphics Display 16" W x 13" D x 11" H

Pedestal Stand 25" W x 5" D x 45" H

Compressor 26" W x 22" D x 40" H

Environmental Specifications

Temperature

Storage and Shipping -40 to 158 ºF (-40 to 70 ºC)

Checkout and Operating 50 to 104 ºF (10 to 40 ºC)

Altitude

Checkout, Operating,

Transport and Storage 0 to 9,000 feet (14.7 to 10.5 PSIA/760 to 543 mm Hg)

Humidity

Storage and Shipping 0 to 99% Relative Humidity — Non-condensing

Checkout and Operating 0 to 95% Relative Humidity — Non-condensing

Method of Sterilization/Disinfection

NOTE

See also the BEAR CUB™ 750PSV Infant Ventilator Instruction Manual Cleaning

and Maintenance (chapter 8)

L2346 Revision B June 2004

Page 22

22 Bear Cub 750PSV

Cleaning

External Surfaces

All external surfaces of the ventilator shall be able to be wiped clean with the

following compounds:

A. Isopropyl Alcohol

B. Chlorine Compounds Maximum Concentration: 1:10

C. Quaternary Ammonium Compounds Maximum Concentration: 1:500

NOTE

These compounds are diluted by volume in water.

Sterilization

All parts of the ventilator that can come in contact with the patient expiratory gas and

all parts of the breathing circuit external to the ventilator shall be sterilizable or

disposable.

Methods of Sterilization

Ethylene oxide, maximum temperature 130 ºF (54 ºC)

Steam sterilization, maximum temperature 250 ºF (121 ºC)

Liquid Sterilization

1. Cidex

Minimum sterilization cycles before part replacement:

1. Patient Circuit, Exhalation Manifold:

Ethylene Oxide 240 cycles

Steam Sterilization 240 cycles

Liquid Sterilization 240 cycles

2. Flow Sensor:

Ethylene Oxide 6 months

Liquid Sterilization 6 months

Pasteurization (using mesh bag) 6 months

3. All other sterilization components:

Ethylene Oxide 120 cycles or 1 year

Steam Sterilization 120 cycles or 1 year

Liquid Sterilization 120 cycles or 1 year

L2346 Revision B June 2004

Page 23

Service Manual 23

Chapter 2: Theory of Operation

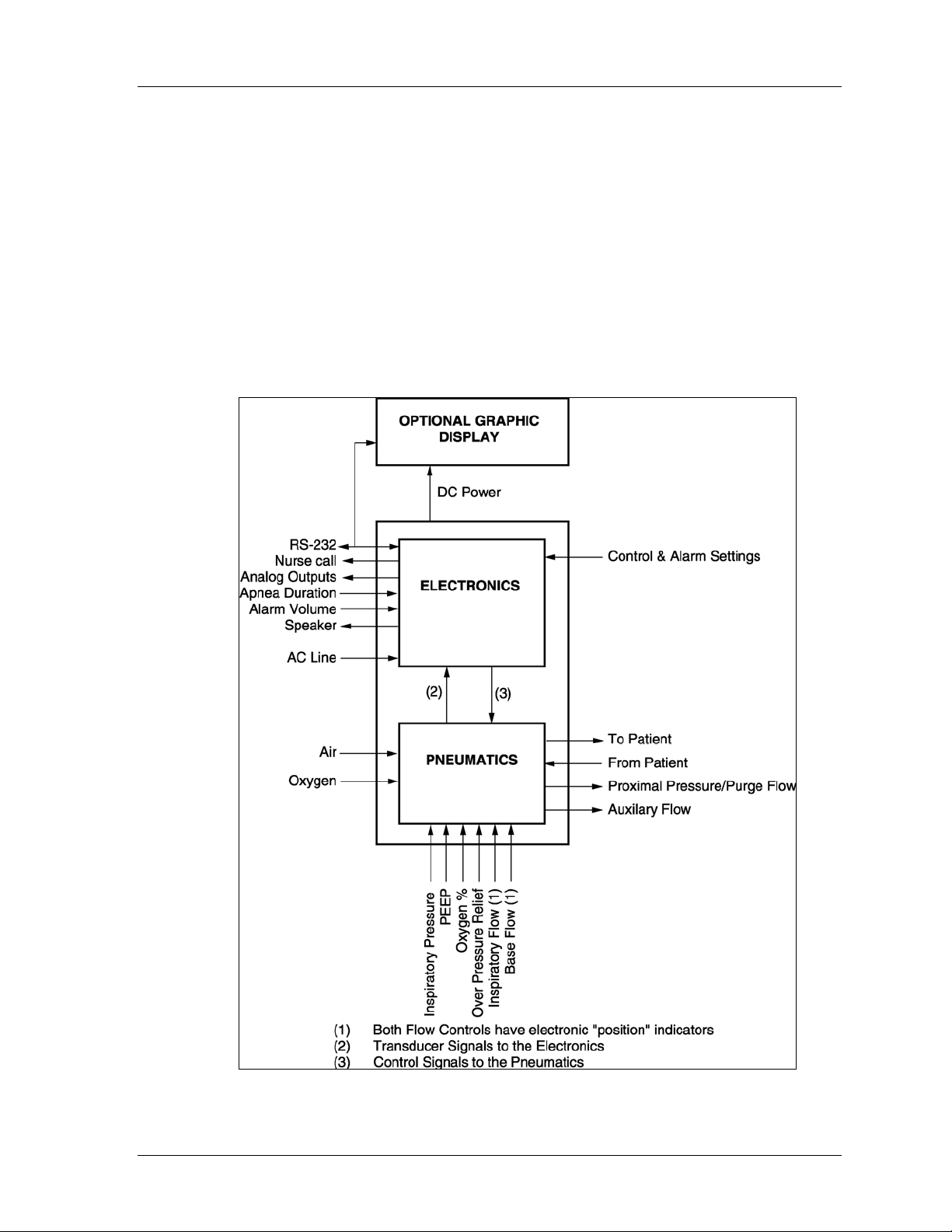

Overview

This chapter describes the operating theory of the BEAR CUB™ 750PSV Infant

Ventilator. The BEAR CUB™ 750PSV ventilator can be classified as a microprocessor controlled, time cycled, pressure limited, dual flow, neonatal/pediatric

critical care ventilator. Breaths are initiated either by the ventilator (controlled), by

patient activity (assisted), or by the operator (manual).

The top level block diagram (figure 2-1) graphically illustrates the overall structure of

the ventilator.

Figure 2-1: Top Level Block Diagram

L2346 Revision B June 2004

Page 24

24 Bear Cub 750PSV

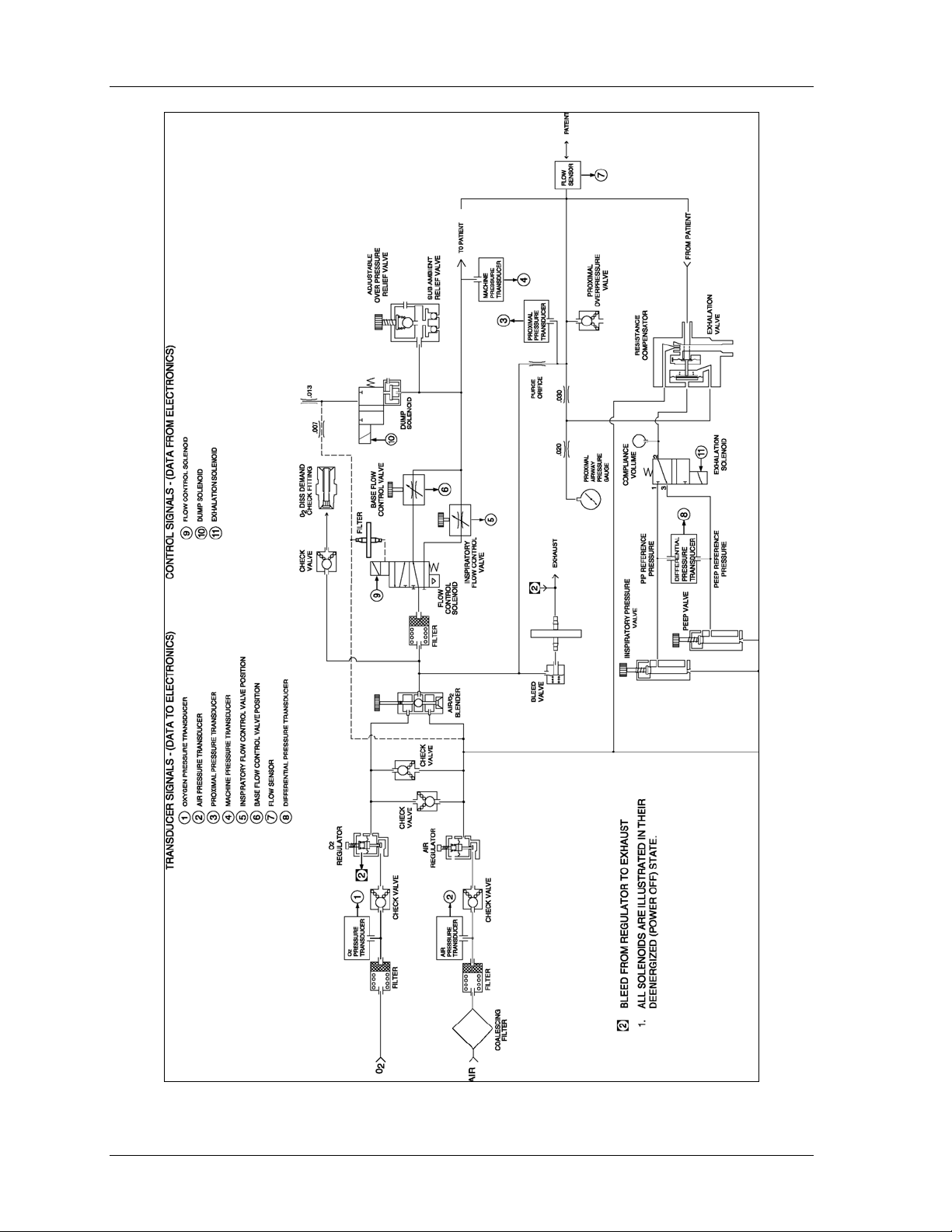

Figure 2-2: Pneumatics System Schematic

L2346 Revision B June 2004

Page 25

Service Manual 25

Ventilator pneumatics - General description

Figure 2-2 shows the schematic diagram of the BEAR CUB™ 750PSV Pneumatics

System. The pneumatics interface to the electronics is achieved using various

actuators (solenoids) and transducers. The Pneumatics System consists of eight (8)

main subsystems: Gas Inlet and Conditioning, Oxygen Blender System, Flow

Control, Sub-Ambient/Overpressure Relief system, Exhalation Valve/Pressure

Control, Pressure Monitoring, the Proximal Airway Purge System, and the Auxiliary

Gas Outlet.

Gas Inlet Conditioning

Compressed air and oxygen sources, supplied in the pressure range of 30 to 80

psig, are connected to the standard DISS male-threaded fittings on the back panel of

the ventilator.

Incoming air passes through a coalescing filter housed in the Air Inlet Water Trap.

Particulate matter down to .3 micron in size, and aerosols down to .75 micron, are

trapped. Both gases, air and O2, pass through sintered metal filters.

Supply pressures are monitored and displayed by the ventilator via pressure

transducers and the system electronics. The system will trigger an alarm if either Air

or O

pressure drops below 24(±2) psig, and the alarm will reset when the pressures

2

are above 30 psig.

From the Air Inlet Water Trap and internal filters, the air and oxygen enter the in-line,

one way Check Valves which prevent flow from exiting through an inlet if that source

is removed.

Blender

Air and O2 pressure are regulated to 17 psig and are balanced to each other for

accurate blending of gases in the O

In the event of a failure of either of the supply gases, one of a pair of crossover

check valves will open to permit continued operation. Oxygen blending will not be

maintained in this condition, and the patient gas flow and pressure may decrease, by

less than 10%, depending on settings.

To ensure accurate oxygen blending at low patient flow rates, a bleed valve

maintains a minimum flow through the blender.

Flow Control Valve

blender.

2

Two flow control valves are switched by a solenoid valve to create Inspiratory and

Base Flow. Each valve controls flow from 1 to 30 L/min. Each flow control valve is

geared to a potentiometer. The potentiometer provides an electronic signal to the

microprocessor; this flow is then displayed on the front panel corrected to set

barometric pressure.

L2346 Revision B June 2004

Page 26

26 Bear Cub 750PSV

NOTE

The Inspiratory Flow and Base Flow displayed on the Front Panel are independent of

the flow readings taken by the flow sensor.

AOPR Valve/Sub-Ambient Valve/ Dump Solenoid

Maximum pressure to the patient can be limited using the Adjustable/Over Pressure

Relief valve. The mechanical, user adjustable, pressure relieving valve can be set

from 15 cmH

breathe air through the Sub-Ambient valve.

A Dump Solenoid is activated upon detection of an obstruction in the expiratory leg

of the patient circuit. Activation of the solenoid opens the Dump Valve to the

atmosphere. The solenoid is controlled by software which monitors system

pressures. Depending upon flow rate, patient circuit pressure will drop to 5 cmH

or less.

O to 75 cmH2O. A patient effort of -3 cmH2O allows the patient to

2

O

2

Auxiliary Gas Outlet

The auxiliary gas outlet provides blended gas for use with a nebulizer, or for manual

ventilation. The connection of auxiliary gas is achieved via a DISS O

inhibit overpressure in the system due to a mistaken connection to high pressure

oxygen supply, a check valve in line allows only one direction of flow. Auxiliary gas

flow levels can range from 0 to 8 L/min. This flow will not be interrupted by a

disruption in electrical power (therefore, use of a manual resuscitation bag could be

initiated if needed).

Pressure Control System

The BEAR CUB™ 750PSV Infant Ventilator ventilates the patient between two

pressure levels: Positive End Expiratory Pressure (PEEP) and Peak Inspiratory

Pressure (PIP). Inspiratory Pressure must always be above the PEEP pressure for

ventilation to occur. The PIP pressure is manually set by the user at a level of 0 to

72 cmH

cmH

exhalation assist jet venturi compensates for flow resistance in the exhalation limb of

the patient circuit to allow 0 cmH2O PEEP setting at up to 10 L/min of Base Flow (to

less than 4 cmH

be set appropriately to prevent negative patient circuit pressures.

The patient circuit has a proximal airway line for monitoring patient pressure. This

proximal airway line provides a link to the control electronics and software. It also

functions as a pneumatic servo control line to the exhalation valve. Only tubing that

is 1/8 inch in diameter is to be used in the proximal airway system. Any other

diameter tube may cause patient circuit pressure to become less stable.

O (measured at the patient wye). The PEEP valve can be set from 0 to 30

2

O. A solenoid valve switches reference pressure to the Exhalation Valve. An

2

O at 20 L/min). At low levels of Base Flow, the PEEP control must

2

fitting. To

2

A purge flow (100ml/min) of blended gas through the proximal airway tube is used to

prevent the migration of moisture and patient contamination into the ventilator.

L2346 Revision B June 2004

Page 27

Service Manual 27

Exhalation Valve

The Exhalation Valve regulates flow out of the patient circuit. Exhaled patient gases

flow through the expiratory leg of the patient circuit, past the Exhalation Valve

diaphragm and seat, and out to the atmosphere. The Exhalation Valve is a

pneumatic servo controlled regulator. Within the Exhalation Valve, Proximal pressure

and Control pressure (which alternates between PIP and PEEP reference pressure

depending on the breath phase) are separated by a Control diaphragm. If Control

pressure is higher than Proximal pressure, the Control diaphragm will move the

control pin to close the Exhalation Valve diaphragm. When Proximal pressure

equals PIP/PEEP Control pressure, the diaphragm will open slightly to maintain the

PIP/PEEP level. At exhalation, Control pressure drops to PEEP reference pressure

which causes the Control diaphragm to retract the control pin opening the Exhalation

Valve diaphragm. Proximal pressure then drops to the PEEP level and stabilizes.

Flow Sensor

The BEAR CUB™ 750PSV Infant Ventilator flow sensor reads gas flow while

sensing flow direction. The flow is calibrated to 37 °C, ambient pressure, and

assumes 100% humidity. Inhaled flows, exhaled flows, and volumes are monitored

with control electronics through the flow sensor. The flow sensor enables the

ventilator to trigger a breath based upon inspired flow. The patient effort (in L/min)

required to initiate a breath can be adjusted (.2 to 5 L/min) using the assist sensitivity

setting. The flow sensor also enables the ventilator to display on the front panel the

percentage of endotracheal tube leak based upon inhaled and exhaled volume

measurements.

The flow sensor operates on the principle of hot wire anemometry. The hot wire flow

sensing system is a constant temperature device. The bidirectional operation is

achieved with two platinum wires. The two wires are positioned in the same plane

with a pin installed between them. The upstream wire will cool more rapidly than the

downstream wire. Therefore more current will be required to maintain a constant

preset temperature. The electronics interprets this higher current in the upstream

wire to determine both flow and flow direction. This measured flow rate is then

integrated over time by the ventilator’s microprocessor to yield inhaled and exhaled

volumes.

The flow sensor reads from 0.2 to 40 L/min, calibrated from 0.2 to 25 L/min, and

indicates to 40 L/min. Each Flow Sensor Cable Assembly contains an electronic

memory circuit (an E2PROM) which stores calibration data for the unit. Therefore,

the sensor will function with the electronic circuit of any BEAR CUB™ 750PSV Infant

Ventilator without the need for a system calibration.

Ventilator Electronics

The major components of the electronics system include the Display PCB, the

Control PCB, and the Power Supply.

L2346 Revision B June 2004

Page 28

28 Bear Cub 750PSV

The Display circuit board is the user interface for the ventilator electronics. Ventilator

controls and alarms are set by the clinician, and Monitors feed current ventilator

status back to the display.

The Control circuit board includes the Monitor MCU and Control MCU. The Control

board drives the system solenoids which control breath phase, flow, and pressure.

This is achieved using front-panel settings from the display board, as well as

incorporating its own real-time pressure and flow readings. The Control board also

enables bidirectional (digital) communication to the optional Graphic Display in order

to chart ventilator data. Also, analog outputs proportional to pressure and flow, plus

a breath phase signal are provided to the back panel. The electronics to drive and

read the flow sensor are also contained on the Control PCB.

Power Supply

The Power Supply converts the AC line voltage to DC voltages for the electrical

system. AC line voltages of 100, 120, 230, and 240 volts (at frequencies from 50 to

60 Hertz) can be used as input power. Five DC voltages are used in the ventilator

electronics: 5, 7, 10, -10 and 22 VDC. All power levels that are high enough to pose

an ignition hazard in the presence of oxygen concentrations greater than 21% are

housed in a separate enclosure from the rest of the system. If input power fails, a 12

volt rechargeable, sealed, lead-acid battery is included to provide a minimum of 30

minutes of ventilator operation. A two-level battery charger circuit is contained on

the Power Supply PCB in order to keep the battery on continuous charge whenever

the ventilator is plugged into an AC outlet.

Ventilator Software

The BEAR CUB™ 750PSV Infant Ventilator is a shared processor system,

incorporating two Motorola 68HC11 microcontroller units (MCU), the Monitor and the

Controller. Each processor, and thereby its software, have specific and duplicated

tasks. Each processor is based on a 2.5 m-sec timer interrupt, referred to as a ‘tick.’

The Controller directs basic control of the ventilator based on operational settings

communicated from the Monitor MCU, as well as on pressure transducer, and flow

sensor data read on its own 8 bit Analog to Digital (A/D) converter. The Monitor has

the following functions: (1) reads the front panel switches, back panel switches, and

potentiometers, (2) monitors ventilator performance as well as the performance of

the Controller MCU, (3) transmits front panel status to the Controller, (4) receives

performance data back from the Controller, and (5) transmits display data and

annunciator status to the front panel.

During power-up, both processors perform RAM (Random Access Memory), and

ROM (Read Only Memory) tests to verify integrity of these two memory systems.

Solenoid and Control Potentiometer continuity are also tested during power-up by

the Control and Monitor processors respectively. Continuous communication checks

between the two processors are used to verify functionality of each sub-system. If

an error is detected, either processor has the ability to shutdown the ventilator while

enabling the audible and visual Failed to Cycle alarms. These systems, among

others, are provided to reduce the possibility of a software/hardware error leading to

an undetected hazardous condition.

L2346 Revision B June 2004

Page 29

Service Manual 29

Chapter 3 OVP Recommended Service

Operational Verification

Operational Verification should be performed between patient use or a minimum of

once each month. Verification may be done by a qualified operator, Allied Healthcare

Trained Hospital Service Technician or Allied Healthcare Technician. Verification is

intended to be done in the hospital. If done by an Allied Healthcare Technician,

there will be a charge.

Certain procedures such as a verification of the alarm circuits should be performed at

least once every 24 hours that the unit is in clinical use. Refer to the BEAR CUB™

750PSV Infant Ventilator instruction manual for details.

Do not use the ventilator unless it passes all the steps in the Operational Verification

Procedure.

Equipment Required

Infant Test Lung P/N 52000-40027

Patient Circuit P/N 50000-01147

Oxygen Analyzer

Rubber Stopper

Stop Watch

CAUTION

If any of the following procedures fail to producer the results as outlined in this

document, disconnect the ventilator and contact your authorized VIASYS Healthcare

service technician.

L2346 Revision B June 2004

Page 30

30 Bear Cub 750PSV

Table 3-1: Standard Settings

Mode SIMV

Rate 30 BPM

Inspiratory Pressure 40 cmH2O

Inspiratory Flow 15 L/min

PEEP/CPAP 0 cmH2O

Inspiratory Time 0.8 seconds

Base Flow 5 L/min

Assist Sensitivity MAX

O2% 21%

Apnea 10 seconds

Low PEEP/CPAP Alarm -3 cmH2O

Volume Limit™ 300 ml

High Pressure Limit 50 cmH2O

Low Inspiratory Pressure Alarm 30 cmH2O

High Breath Rate Alarm 40 BPM

Table 3-2: Rate

Set Rate Inspiratory Time Using stop watch verify Breath Rate

10 BPM 3 seconds 10 ± 2 BPM

40 BPM 1 second 40 ± 3 BPM

80 BPM 0.4 seconds 80 ± 4 BPM

120 BPM 0.1 seconds 120 ± 6 BPM

Table 3-3: Exhalation Time and I/E Ratio Table

Rate Set Inspiratory time Verify Exhalation

Time

10 BPM 3.00 seconds 3.0 ± 0.4 sec 1:1.0 ± 0.3

75 BPM 0.40 seconds - - - - - - - - 1:1.0 ± 0.3

Verify I/E Ratio

150 BPM 0.10 seconds - - - - - - - - 1:3.0 ± 0.4

L2346 Revision B June 2004

Page 31

Service Manual 31

WARNINGS

The following warnings must be read and understood before performing the

procedures described in this chapter.

• Under no circumstances should this medical device be operated in the presence

of flammable anesthetics or other volatile materials due to a possible explosion

hazard.

• Liquid spilled or dripped into the unit may cause damage to the unit or result in

an electrical shock hazard.

• Oxygen vigorously accelerates combustion. To avoid violent ignition, do not use

any gauges, valves, or other equipment that has been exposed to oil or grease

contamination.

• Do not release this medical device if any alarm/alert function is inoperative. To do

so could result in a malfunction without warning, possibly resulting in personal

injury, including death or property damage. Refer the unit to a Allied Healthcare

Authorized Service Technician or a Allied Healthcare Trained Hospital Service

Technician.

• All tubing and fittings used to connect high pressure gas (air and oxygen) from

the source to the test equipment and from the test equipment to the device being

tested must be capable of withstanding a minimum supply pressure of 100 psi

(7.03 kg/cm2). The use of tubing and fittings not capable of withstanding this

pressure could cause the tubing to rupture, resulting in personal injury or

property damage.

• When verifying the operation of this medical device, do not breathe directly from

the machine. Always use a fresh bacterial filter and test circuit. A hazard to the

health of the service person may result.

• If any of the following procedures cannot be verified as outlined in this document,

do not use this device on a patient and refer it to Allied Healthcare or a Allied

Healthcare Authorized Service Facility or a Allied Healthcare Trained Hospital

Service Technician.

CAUTIONS

• Do not sterilize the ventilator. The internal materials are not compatible with

sterilization techniques.

• Do not use MEK or Trichloroethylene, as damage to surface may result. Do not

allow any liquid to spill or drip into the ventilator.

• Circuit boards are subject to damage by static electricity. Do not touch

components, circuit, or connector fingers with hands. Handle only by edges.

Before using any test equipment [electronic or pneumatic] for calibration procedures

[other than operational verification], the accuracy of the instruments must be verified

by a testing laboratory. The laboratory master test instruments must be traceable to

the NIST (National Institute of Standards Technology) or equivalent. When variances

exist between the indicated and actual values, the calibration curves [provided for

each instrument by the testing laboratory] must be used to establish the actual

L2346 Revision B June 2004

Page 32

32 Bear Cub 750PSV

correct values. This certification procedure should be performed at least once every

six months. More frequent certification may be required based on usage and

environment.

Test Procedures

1. Set up the ventilator with a standard infant test circuit. Plug the end of circuit

with rubber stopper.

2. Set the ventilator to standard settings per Table A. Ensure overpressure relief

valve is set to maximum pressure. Connect air, oxygen, and AC power to

ventilator.

3. Press the TEST button, verify all indicators and digits illuminate.

4. Verify rates per Table B. While doing rate verification you will get a rate alarm.

Press the alarm silence button. Verify that the audible alarm is silenced and

the silence is canceled after 60 seconds ± 10%. Return to standard settings.

Set mode to Assist Control.

5. Verify Exhalation Time and I:E Ratio per Table C. Return to standard settings.

6. Adjust Inspiratory Pressure to 25 cmH

alarm.

7. Increase Inspiratory Pressure to 50 cmH

limit.

8. Return Inspiratory Pressure to 40 cmH

verify that the Low Pressure and High Pressure LEDs are canceled.

9. Occlude patient circuit limb going to the exhalation valve. Verify that a

prolonged inspiratory alarm occurs.

10. Increase ventilator rate to 45 BPM. Verify that the High Rate alarm activates.

11. Decrease rate to 4 BPM. Verify that the apnea alarm activates.

12. Set ventilator rate to 70 BPM. Verify that the Incompatible Setting alarm

activates. Return rate to 30 BPM.

13. Push the Pressure Selector button to read air pressure. Verify reading is within

5 PSI of input pressure.

14. Push the Pressure Selector button to read O

within 5 PSI of O

supply pressure.

2

15. Disconnect air supply. Verify that the Low Gas Supply alarm activates.

Reconnect air supply.

16. Disconnect O2 supply. Verify that the Low Gas Supply alarm activates.

17. Disconnect the air supply. Verify that the fail to cycle alarm activates.

Reconnect the air and O

18. Connect an O

analyzer inline. Verify that the FIO2 is within ± 3% at the

2

supplies.

2

following settings: 21%, 60%, 100%. Remove O

19. Adjust the rate to 10 BPM. Turn the Low PEEP/CPAP alarm to 5 cmH

Verify that the Low PEEP/CPAP alarm activates. Return the Low PEEP/CPAP

alarm to -3 cmH

O.

2

O. Verify activation of Low Pressure

2

O. Verify High Pressure alarm and

2

O. Push the Visual Reset button and

2

Pressure. Verify reading is

2

analyzer.

2

O.

2

L2346 Revision B June 2004

Page 33

Service Manual 33

20. Disconnect the AC power. Verify that the audible alarm activates and the line

power LED illuminates red within 10 seconds. Push the Visual Reset button.

Verify that the audible alarm is canceled and the unit continues to function.

Reconnect the AC power.

21. Connect the circuit to the infant test lung. Set the Volume Limit to 25ml. Verify

That the tidal Volume readout is 25 ml ± 20%.

22. Disconnect the Flow Sensor cable from the ventilator. Verify that the flow

sensor alarm activates, assist sensitivity window is blank, and that the

monitored volume and volume limit displays show dashes. Reconnect the flow

sensor cable, verify audible alarm cancels, assist sensitivity window

illuminates, and volume digits return.

23. Turn Assist Sensitivity to MIN. Squeeze and release the patient circuit. Verify

that the unit will assist and that Patient Initiated LED is illuminating.

24. Disconnect the patient circuit from the test lung. Verify that both audible and

visual Low Inspiratory Pressure alarms are activated. Verify that the Alarm

Loudness can be varied from minimum to maximum, but the alarm cannot be

turned off.

Figure 3-1: Bear Cub 750PSV US with Patient Circuit

L2346 Revision B June 2004

Page 34

34 Bear Cub 750PSV

Exterior Inspection and Cleaning

Inspect all cords, connectors, and fittings. Inspect the case for any cracks or other

damage.

Exterior Cleaning

1. Before any cleaning of the ventilator, disconnect WALL AC.

2. Clean the exterior of the ventilator with an appropriate bactericidal or

germicidal agent. Clean all external panels and surfaces before and after each

patient use and as often as necessary to keep them clean. Use only those

cleaning materials that have been approved by your department. Care should

be exercised not to allow any liquid to penetrate the inside of the ventilator.

CAUTION

Do not use cleaning agents that contain phenols, ammonium chloride, chloride

compounds, or more than 2% glutaraldehyde. These agents may damage the

ventilator’s plastic components and front panel overlay.

Plugs and Cables

Plugs and cables may be wiped down with an appropriate bactericidal or germicidal

agent.

L2346 Revision B June 2004

Page 35

Service Manual 35

OVP Checklist

This checklist is for use during the BEAR CUB™ 750PSV operational verification procedure.

Serial Number Hour meter reading Today’s date

Service Location Service Organization

Address

City/State/Zip City/State/Zip

Contact Contact

Phone ( )

Address

Phone ( )

Verification Steps

STEP PASS FAIL STEP PASS FAIL

Indicator Verification O2 Pressure Reading

Verification

Breath Rate Verification Low Gas Supply

Verification(Air)

Alarm Silence, Reset Verification Low Gas Supply Verification

(O2)

Exhalation Time, I:E Ratio

Verification

Low Pressure alarm Verification FIO2 verification (21%, 60%,

High Pressure alarm/Limit

Verification

Pressure LED reset AC power loss verification

Prolonged Inspiratory alarm

verification

High Rate alarm verification Flow Sensor alarm

Apnea alarm verification Patient Triggering verification

Incompatible setting alarm

verification

Fail to Cycle alarm

verification

100%)

Low PEEP/CPAP alarm

verification

Tidal Volume Limit

verification

verification

Alarm loudness verification

Air Pressure reading verification

WARNING

Do not release the ventilator for use if it does not pass all of the verification

procedures specified in the checklist. To do so could result in personal injury

including death or property damage. Refer the ventilator to a VIASYS trained

service technician for appropriate repair and/or calibration.

Signature _________________________________________

PROCEDURE COMPLETE

L2346 Revision B June 2004

Page 36

36 Bear Cub 750PSV

L2346 Revision B June 2004

Page 37

Service Manual 37

Chapter 4 Calibration

(for software releases 2 and 3 only)

Introduction

The information in this chapter is intended for use by a factory trained service

technician. Before opening the console or removing assemblies to perform

calibration, a reference should be made to the Operators Manual and all chapters of

this Service Manual to ensure that the ventilator is being properly utilized.

WARNINGS

• The calibration procedures contained in this chapter must be completed when

any part/assembly has been removed and/or replaced. Failure to do so could

result in ventilator malfunction and injury or death to the patient.

• After calibration and/or replacement of any assembly(ies), always perform the

Operational Verification Procedure (Chapter 3), then allow a "BURN-IN" period

and repeat the Operational Verification Procedure.

• Oxygen vigorously accelerates combustion. DO NOT use any gauges, valves or

other equipment that has been exposed to oil or grease contamination to avoid

violent ignition.

• Hazardous voltages exist within the ventilator. Always observe appropriate

safety precautions when working on the ventilator while the machine is

connected to an electrical power source to prevent possible accidental injurious

electrical shock.

• When high pressure gas sources are connected to the ventilator, always use

extreme caution when attempting to measure internal pressures. Abnormal

conditions may exist where measured pressures exceed the burst pressure of

the gauge, resulting in possible injury.

NOTE

The Operational Verification Procedure (OVP) is always performed prior to use of

this chapter.

CAUTION

• Before using any test equipment (electronic or pneumatic) for calibration

purposes (other than operational verification), the accuracy of the instruments

must be certified by a testing laboratory. The laboratory master test instruments

must be traceable to the US Bureau of Standards or equivalent. When variances

exist between the indicated and actual values, the calibration curves (proved by

the testing laboratory) must be used to establish the actual correct values. This

certification procedure should be performed at least once every six months. More

frequent certification may be required based on usage and environment.

L2346 Revision B June 2004

Page 38

38 Bear Cub 750PSV

NOTE

If problems are incurred in obtaining the calibration performance, refer to

Troubleshooting (Chapter 6) or contact your dealer or VIASYS Healthcare Service

Facility.

Pressure Transducers and Flow Control Valve Calibration

Turn OFF the ventilator and disconnect tubing to the Pressure Transducers on the

Control PCB. Press and hold the diagnostic switch on the Control PCB while turning

the ventilator ON to enter Transducers and Flow Calibration routines. Throughout

calibration, the TEST key is for advancing the calibration number; VISUAL RESET is

for backing to previous calibration, and the MANUAL BREATH key is for recording

calibration data. The calibration number and message are displayed in the Breath

Rate and Monitored Time/I:E Ratio windows respectively. Data (when applicable) is

displayed in the Monitored Pressure window. Refer to the following (See table 4-1)

to calibrate the transducers on the Control PCB:

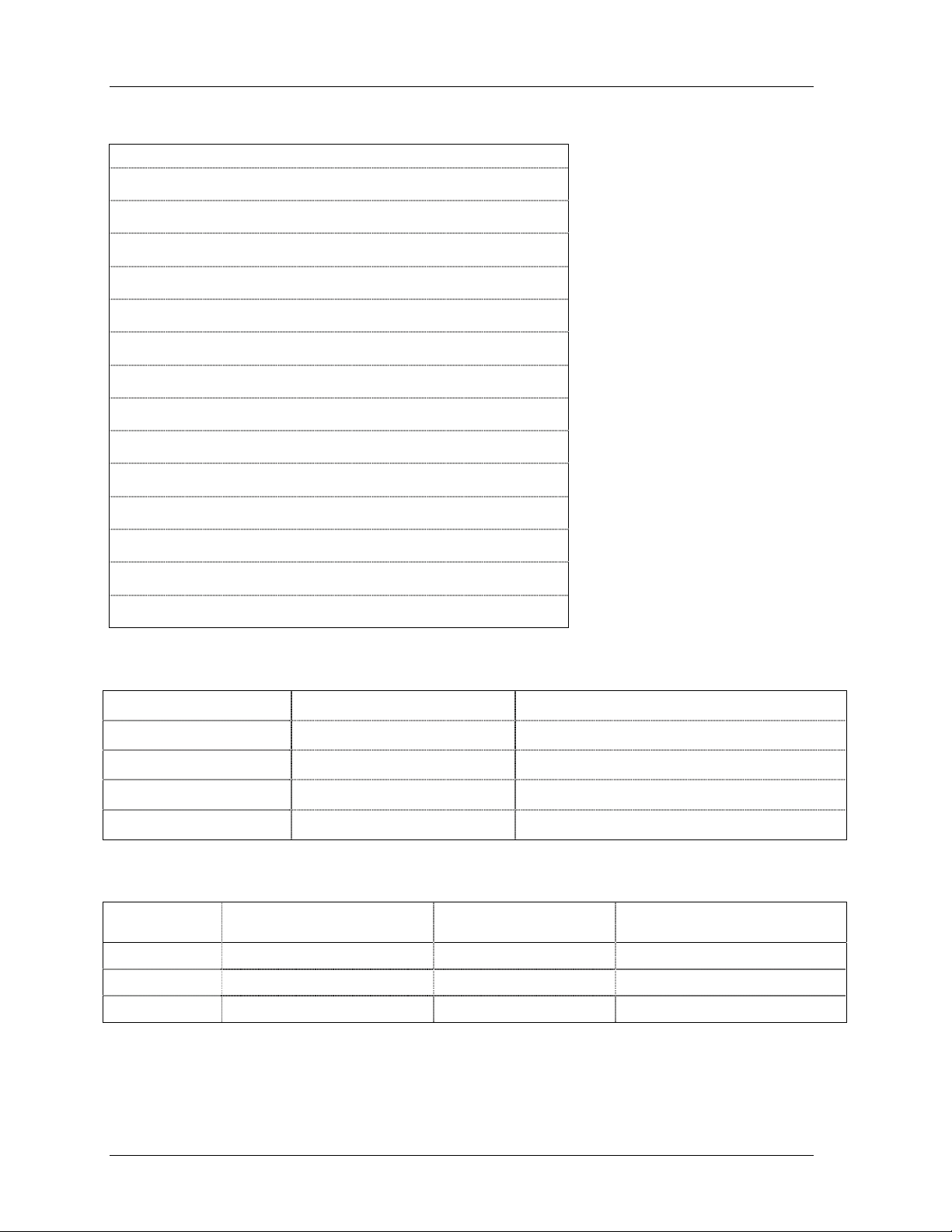

Table 4-1: Control PCB Transducer Calibration

Transducer Calibration Number Message Input Static Pressure

Machine (port B) d00 nP00 0 cmH2O

d01 nP40 40 ± 0.2 cmH2O

Differential (port B) d02 dP00 0 cmH2O

d03 dP40 40 ± 0.2 cmH2O

Proximal (port B) d04 pP00 0 cmH2O

d05 pP40 40 ± 0.2 cmH2O

O2 (A2) d06 0P00 0 PSIG

d07 0P40 40 ± 0.2 PSIG

AIR (A1) d08 AP00 0 PSIG

d09 AP40 40 ± 0.2 PSIG

NOTE

The 40 cm/psi settings were 70 cm/psi prior to monitor firmware 511-02803-00.

When calibrating the pressure transducers, both pressure points (i.e. 0 and 40

cm/psi) must be read and the 0 cm/psi reading must be obtained first.

1. Check the accuracy of the five pressure transducers per table 4.2. The

window shows the pressure readings monitor pressure.

2. Press the TEST key to advance the calibration number to the Display Set

Altitude Test, then press the MANUAL BREATH key until the number in the

PRESSURE window indicates the altitude at which the Flow Control valve

calibration is to be performed (expressed in units of 100 ft). Then advance to

the next test number and power down.

3. Re-connect tubing to the transducers on the Control PCB; apply Air and O2

(approximately 50 psi) to UUT. Use an RT-200 to measure flow at the TO

L2346 Revision B June 2004

Page 39

Service Manual 39

PATIENT port. To calibrate the Flow Control Valve, press the TEST key to

advance the calibration number; then set flow as specified and press the

MANUAL BREATH key to record data. Calibrate Base Flow, then Calibrate

Inspiratory Flow.

Table 4-2: Calibration

Transducer Calibration Number Message Input Static Pressure

Differential (port B) d10 0 ± 1 0 cmH2O

d10 50 ± 1 50 ± 0.5 cmH2O

Machine (port B) d11 0 ± 1 0 cmH2O

d11 50 ± 1 50 ± 0.5 cmH2O

Proximal (port B) d12 0 ± 1 0 cmH2O

d12 50 ± 1 50 ± 0.5 cmH2O

AIR (A1) d13 50 ± 2 50 ± 0.2 PSI

O2 (A2) d14 50 ± 2 50 ± 0.2 PSI

NOTE

The pressure display occasionally flickering 1 digit beyond the tolerance is

acceptable.

L2346 Revision B June 2004

Page 40

40 Bear Cub 750PSV

Table 4-3: Diagnostic Function

NUMBER FUNCTION

00 Calibrate pmach @ 0 cmH2O

01 Calibrate pmach @ 40 cmH2O

02 Calibrate pdelta @ 0 cmH2O

03 Calibrate pdelta @ 40 cmH2O

04 Calibrate proxp @ 0 cmH2O

05 Calibrate proxp @ 40 cmH2O

06 Calibrate O2p @ 0 cmH2O

07 Calibrate O2p @ 40 cmH2O

08 Calibrate airp @ 0 cmH2O

09 Calibrate airp @ 40 cmH2O

10 Display pdelta

11 Display pmach

12 Display proxp

13 Display airp

14 Display O2p

15 Display/Set Altitude

16 Calibrate Base Flow @ 1 L/min*

17 Calibrate Base Flow @ 2 L/min*

18 Calibrate Base Flow @ 5 L/min*

19 Calibrate Base Flow @ 15 L/min*

20 Calibrate Base Flow @ 25 L/min*

21 Calibrate Base Flow @ 30 L/min*

22 Calibrate Insp Flow @ 1 L/min*

23 Calibrate Insp Flow @ 2 L/min*

24 Calibrate Insp Flow @ 5 L/min*

25 Calibrate Insp Flow @ 15 L/min*

26 Calibrate Insp Flow @ 25 L/min*

27 Calibrate Insp Flow @ 30 L/min*

*±0.5 L/min

NOTE

Diagnostic numbers can only be accessed by depressing the diagnostic switch on

the Control PCB while turning the Ventilator ON.

L2346 Revision B June 2004

Page 41

Service Manual 41

Table 4-4: Inspiratory Flow Calibration

Flow Flow Flow Flow Flow Flow Flow Flow Flow

Sea Level 500 feet 1000 feet 1500 feet 2000 feet 2500 feet 3000 feet 3500 feet 4000 feet

2.00± .02 2.02± .02 2.04± .02 2.05± .02 2.08± .02 2.10± .02 2.12± .02 2.14± .02 2.16± .02

5.00± .03 5.05± .03 5.10± .03 5.14± .03 5.19± .03 5.24± .03 5.29± .03 5.33± .03 5.38± .03

15.00± .1 15.1± .1 15.3± .1 15.4± .1 15.5± .1 15.7± .1 15.8± .1 15.9± .1 16.1± .1

25.00± .2 25.2± .2 25.4± .2 25.6± .2 25.8± .2 26.0± .2 26.2± .2 26.4± .2 26.6± .2

30.00± .2 30.2± .2 30.5± .2 30.7± .2 30.9± .2 31.2± .2 31.4± .2 31.6± .2 31.9± .2

Flow Flow Flow Flow Flow Flow Flow Flow Flow

Sea Level 4500 feet 5000 feet 5500 feet 6000 feet 6500 feet 7000 feet 7500 feet 8000 feet

2.00± .02 2.18± .02 2.20± .02 2.23± .02 2.26± .02 2.29± .02 2.31± .02 2.34± .02 2.37± .02

5.00± .03 5.44± .03 5.5± .1 5.6± .1 5.6± .1 5.7± .1 5.8± .1 5.8± .1 5.9± .1

15.00± .1 16.2± .1 16.4± .1 16.6± .1 16.7± .1 16.9± .1 17.1± .1 17.3± .1 17.5± .1

25.00± .2 26.9± .2 27.1± .2 27.4± .2 27.7± .2 28.0± .2 28.3± .2 28.6± .2 28.9± .2

30.00± .2 32.1± .2 32.4± .2 32.7± .2 33.0± .2 33.4± .2 33.8± .2 34.1± .2 34.5± .2

Air and O2 Regulator Balance

Objective

To define the calibration requirements for balancing the Air and O2 Regulators.

Equipment

Pressure gauge, 0 - 30 psig, ± 1/4% F.S.

Differential pressure gauge, 2 - 0 - 2 cmH

3% F.S.

Requirements

Regulator and Bleed Valve Adjustment:

Set up per Standard Test Settings except set MODE to STANDBY

Set O

Set O

Patient circuit may be omitted

Blender as noted (Table 4-5)

2

supply pressure to 50 psi

2

O, ± 5% F.S. Flow meter, 0 - 10 L/min, ±

2

L2346 Revision B June 2004

Page 42

42 Bear Cub 750PSV

Table 4-5: Regulator Balance

O

Blender

Component

Air Regulator 100% 17.0 ± 1 psig

O2 Regulator 60%

Bleed Valve 60%

Air Regulator 60%

O2 Regulator

Bleed Valve

2

Setting

Requirement

Adjust O

regulator to obtain a

2

pressure balance with the air

regulator within 2 cmH2O.

With Base Flow Control Valve

set to minimum, Bleed Valve

exhaust shall equal 3.5 - 5.5

L/min.

Increase Base Flow rate to

maximum.

Regulators shall remain

balanced within 2 cmH

2

O.

Bleed Valve Flow drops to less

than .25 L/min.

L2346 Revision B June 2004

Page 43

Service Manual 43

Table 4-6: Standard Test Settings

CONTROLS

Mode Assist/Control

PEEP/CPAP Pressure 0 cmH2O

Inspiratory Pressure (PIP) 20 cmH2O

Ventilator Rate 30 BPM

Inspiratory Time 1.00 second

Volume Limit 300 mL

Base Flow 5 L/min

Inspiratory Flow 15 L/min

Assist Sensitivity Mid Range

ALARMS

Low PEEP/CPAP Alarm -5 cmH2O

High Breath Rate Alarm 255 BPM

Low Inspiratory Pressure Alarm 5 cmH2O

High Pressure Limit Alarm 75 cmH2O

FRONT OF VENTILATOR

Humidifier VH-820 chamber, no water

Patient Circuit Standard Allied Infant Circuit

Patient Resistance Rp 20

Patient Compliance C3

Endotracheal Tube None

Auxiliary Pressure Relief Fully closed (CW)

REAR OF VENTILATOR

Alarm Loudness Control Minimum

RS-232 Interface Open

Analog Output Open

Remote Nurses call Open

APNEA Alarm 30 seconds

Display Power Outlet Open

AC Line Voltage 120 VAC

O2 Supply >35 PSI

Air Supply >35 PSI

L2346 Revision B June 2004

Page 44

44 Bear Cub 750PSV

L2346 Revision B June 2004

Page 45

Service Manual 45

Chapter 5 Schematics and Assemblies

Figure 5-1: Power Supply Module Assembly (1 of 2)

L2346 Revision B June 2004

Page 46

46 Bear Cub 750PSV

Figure 5-2: Power Supply Module Assembly (2 of 2)

L2346 Revision B June 2004

Page 47

Service Manual 47

Figure 5-3: Schematic Diagram, Pneumatic 750PSV

L2346 Revision B June 2004

Page 48

48 Bear Cub 750PSV

Figure 5-4: Power Supply PCB Assembly (1 of 3)

L2346 Revision B June 2004

Page 49

Service Manual 49

Figure 5-5: Power Supply PCB Assembly (2 of 3)

L2346 Revision B June 2004

Page 50

50 Bear Cub 750PSV

Figure 5-6: Power Supply PCB Assembly (3 of 3)

L2346 Revision B June 2004

Page 51

Service Manual 51

Figure 5-7: Pneumatic Tubing Diagram

L2346 Revision B June 2004

Page 52

52 Bear Cub 750PSV

Figure 5-8: Display PCB (1 of 3)

L2346 Revision B June 2004

Page 53

Service Manual 53

Figure 5-9: Display PCB (2 of 3)

L2346 Revision B June 2004

Page 54

54 Bear Cub 750PSV

Figure 5-10: Display PCB (3 of 3)

L2346 Revision B June 2004

Page 55

Service Manual 55

Figure 5-11: Control PCB Assembly

L2346 Revision B June 2004

Page 56

56 Bear Cub 750PSV

Figure 5-12: Wiring Diagram

L2346 Revision B June 2004

Page 57

Service Manual 57

Figure 5-13: Power Supply Schematic

L2346 Revision B June 2004

Page 58

58 Bear Cub 750PSV

Figure 5-14: Control Schematic PCB (1 of 5)

L2346 Revision B June 2004

Page 59

Service Manual 59

Figure 5-15: Control Schematic PCB (2 of 5)

L2346 Revision B June 2004

Page 60

60 Bear Cub 750PSV

Figure 5-16: Control Schematic PCB (3 of 5)

L2346 Revision B June 2004

Page 61

Service Manual 61

Figure 5-17: Control Schematic PCB (4 of 5)

L2346 Revision B June 2004

Page 62

62 Bear Cub 750PSV

Figure 5-18: Control Schematic PCB (5 of 5)

L2346 Revision B June 2004

Page 63

Service Manual 63

Figure 5-19: Display Schematic PCB (1 of 4)

L2346 Revision B June 2004

Page 64

64 Bear Cub 750PSV

Figure 5-20: Display Schematic PCB (2 of 4)

L2346 Revision B June 2004

Page 65

Service Manual 65

Figure 5-21: Display Schematic PCB (3 of 4)

L2346 Revision B June 2004

Page 66

66 Bear Cub 750PSV

Figure 5-22: Display Schematic PCB (4 of 4)

L2346 Revision B June 2004

Page 67

Service Manual 67

Figure 5-23: BEAR CUB 750PSV Overlay

(P/N 51-09640-00)

L2346 Revision B June 2004

Page 68

68 Bear Cub 750PSV

L2346 Revision B June 2004

Page 69

Service Manual 69

Chapter 6 Troubleshooting

Figure 6-1: Troubleshooting Decision Tree

L2346 Revision B June 2004

Page 70

70 Bear Cub 750PSV

A

Table 6-2: Troubleshooting

Symptom Possible Causes Corrective Action

Failed To Cycle

Alarm

Low PEEP/CPAP

and Low Inspiratory

Pressure Alarms

Faulty or Out of

Specification.

Pressure Limit

Control Does Not

Function Correctly.

Pressure Limit Not

Within

Specifications.

No Delivered

Inspiratory Flow.

Base and/or

Inspiratory Digital

Flow Readings Do

Not Agree With

Actual Measured

Flow.

PEEP/CPAP Levels

Will Not Adjust.

Oxygen

Percentages Are Not

Within Specification.

1. Air and Oxygen

Pressure Have

Decreased Below 24 ± 2

PSIG.

2. Power Supply Failure.

3. System Supply Failure.

4. System Software

Failure.

1. Verify Inlet Air and O

Entering The Ventilator. Verify

Calibration of Air and Pressure

Transducers On Control PCB.

2. Verify Power Supply Voltages At

The 15 Pin Header Connection

Labeled Tp1 On The Control PCB

Per The Table Below. If Out of

Pressure

2

Specification, Replace Power

Supply.

Voltage Test Pt Ground Pt

+5.0 VDC TP1-1 T1P-13

± 5% (4.75-5.25) VDC

+7.0 VDC TP1-6 TP1-7

± 5% (6.65-7.35) VDC

+10.0 VDC TP1-8 TP1-9

± 5% (9.5-10.5) VDC

-10.0 VDC TP1-10 TP1-9

± 5% (10.5) VDC

-15% (8.5) VDC

3. Remove and Replace Control PCB.

4. Remove and Replace System

EEPROM (U-18 On Control PCB)

1. Calibration Pressure

Transducer.

2. Defective Pressure

Transducer.

1. Calibration Pressure

Transducer.

2. Defective Control PCB.

3. Defective Pressure Limit

Valve.

1. Defective Flow Control

Solenoid Valve.

2. Defective Control PCB.

1. Calibrate Pressure Transducer Per

chapter 4 of This Manual.

2. Remove and Replace Control PCB.

1. Calibrate Pressure Transducer Per

chapter 4 of This Manual.

2. Remove and Replace Control PCB.

3. Remove and Replace Pressure

Valve.

1. Remove and Replace Flow Control

Valve Assembly

2. Remove and Replace Control PCB.

1. Flow Valve Calibration. 1. Perform Flow Valve Calibration Per

chapter 4 of This Manual.

1. Defective PEEP Valve. 1. Remove and Replace PEEP Valve

Assembly.

1. Air/O

Differential

2

Pressure Greater Than ±

2 CmH

2.

O.

2

ir and/or O

2

1. Perform Differential Pressure

Calibration Per chapter 4 of This

Manual.

2. Replace Air and/or Oxygen

L2346 Revision B June 2004

Page 71

Service Manual 71

p

Symptom Possible Causes Corrective Action

Regulator(S) Defective.

3. Defective Oxygen

Blender.

4. Defective Cross-Over

Check Valve.

Front Panel

Control(S) Will Not

Adjust.

Base and Inspiratory

Flow Cycles But No

Pressure Building

During Inspiration.

No Flow Out of TO

PATIENT Outlet.

Pressure Settings

Incompatible Alarm.

Ventilator Will Not

Turn On.

Audible Alarm Does

Not Activate.

Flow Sensor Alarm. 1. Flow Sensor Not

"Settings

Incompatible" Alarm;

E.Fl. or E.Pl

Flashing.

Inspiratory Pressure

Too Low.

1. Defective Front Panel

Potentiometer(S).

1. Defective Dump

Solenoid Valve.

2. Defective Control PCB.

3. Adjustable Overpressure

Relief Valve Setting.

1. Inspiratory Pressure

Level Set Below

Peep/Cpap Level.

2. Control PCB Has Lost

Calibration Data.

3. Defective Control PCB.

1. Internal Battery Not

Connected.

2. Internal Battery

Discharged Below

Minimum Operating

Voltage.

3. Internal Battery

Defective.

4. Ventilator Not Plugged

In To Wall Ac Power.

1. Wiring Connection.

2. Defective Alarm

Speaker.

3. Defective Control Pcb.

Connected.

2. Flow Sensor Not

Installed In Patient

Circuit.

3. Occluded Flow Sensor

and/or Endotracheal

Tube.

4. Defective Flow Sensor.

1. Incompatible Volume

Limit Setting.

1. Control Pin In Exhalation

Valve Sticking.

2. Defective Exhalation

Valve Diaphragm.

3. Defective Exhalation

Regulator.

3. Replace Oxygen Blender.

4. Replace Defective Check Valve.

1. Remove and Replace Display PCB.

1. Remove and Replace Dump

Solenoid Valve.

2. Remove and Replace Control PCB.

3. Evaluate/Adjust Valve Setting.

1. Evaluate Pressure Limit and

PEEP/CPAP Level Settings.

2. Calibration Control PCB Per chapter

4 of This Manual.

3. Remove and Replace Control PCB.

1. Connect Internal Battery.

2. Re-Charge Internal Battery Connect

Ventilator Power Cord To A Wall AC

Outlet.

3. Remove and Replace Internal

Battery.

4. Connect Ventilator Power Cord To

A Wall AC Outlet.

1. Verify Connection of P1 of Audible

Alarm Cable To J1 of Controller

Pcb.

2. Remove and Replace Alarm

Speaker Sub-Assembly.

3. Remove and Replace Control Pcb.

1. Connect Flow Sensor To Both

Ventilator Connector and 4 Way