Page 1

Operator’s Manual

Infant Flow

Advance™ System

E.M.E. (Electro Medical Equipment) Ltd.

A subsidiary of VIASYS Healthcare inc.

© Copyright 2004, VIASYS Healthcare Critical Care

777077-101 Revision B June 2004

Page 2

2 Infant Flow Advance™ System

Revision History

Date Revision Pages Changes

December 2003 A All Release

June 2004 B All Release manual in VIASYS Healthcare

template using VIASYS Healthcare Critical

Care nomenclature. Add Appendix C,

Abdominal Respiratory Sensor Placement.

Revise part number list in Appendix B.

777077-101 Revision B June 2004

Page 3

Operator’s Manual 3

Contact and Ordering Information

United States, Latin America, Asia Pacific:

Sales, Service and Clinical Support:

VIASYS Healthcare

Critical Care Division

22705 Savi Ranch Parkway

Yorba Linda, CA 92887

Phone: (714) 283-8444

(800) 381-3552

Fax: (714) 283-8493

www.VIASYShc.com

United Kingdom:

Sales, Service and Clinical Support:

VIASYS Healthcare

3 Welton Rd.

Warwick,

CV34 5PZ

Phone: 01926 490888

Fax: 01926 402262

Europe

Sales and Customer Service Technical Service

VIASYS Healthcare VIASYS Healthcare

Critical Care Division Leibnizstrasse 7

22705 Savi Ranch Parkway D-97204 Hoechburg

Yorba Linda, CA 92887 Germany

Phone: (714) 283-8444 Phone +49 (0) 931 4972 – 0

(800) 381-3552 Fax:+49 (0) 931 4972 –423

e-mail: Support.CC.EU@VIASYShc.com

website: www.VIASYShc.com

777077-101 Revision B June 2004

Page 4

4 Infant Flow Advance™ System

CAUTION

Federal law (USA) restricts this device to sale by or on the order of a physician.

CAUTION

Not suitable for use in the presence of flammable anesthetics.

CAUTION

Always read the Operator’s Manual before applying treatment.

CAUTION

The Infant Flow Advance™ has been designed and tested as a complete system

using Infant Flow™ accessories. Use only approved accessories (Refer to Appendix

B for a list of approved accessories).

CAUTION

Service and/or repair of this instrument is restricted to VIASYS Healthcare authorized

or VIASYS Healthcare Trained Personnel only.

777077-101 Revision B June 2004

Page 5

Operator’s Manual 5

Warranty

The Infant Flow Advance is warranted to be free from defects in material and

workmanship and to meet the published specifications for One (1) year from date of

shipment.

The liability of VIASYS Healthcare, Critical Care Division, (referred to as the

Company) under this warranty is limited to replacing, repairing or issuing credit, at

the discretion of the Company, for parts that become defective or fail to meet

published specifications during the warranty period; the Company will not be liable

under this warranty unless (A) the Company is promptly notified in writing by Buyer

upon discovery of defects or failure to meet published specifications; (B) the

defective unit or part is returned to the Company, transportation charges prepaid by

Buyer; (C) the defective unit or part is received by the Company for adjustment no

later than four weeks following the last day of the warranty period; and (D) the

Company’s examination of such unit or part shall disclose, to its satisfaction, that

such defects or failures have not been caused by misuse, neglect, improper

installation, unauthorized repair, alteration or accident.

Any authorization of the Company for repair or alteration by the Buyer must be in

writing to prevent voiding the warranty. In no event shall the Company be liable to

the Buyer for loss of profits, loss of use, consequential damage or damages of any

kind based upon a claim for breach of warranty, other than the purchase price of any

defective product covered hereunder.

The Company warranties as herein and above set forth shall not be enlarged,

diminished or affected by, and no obligation or liability shall arise or grow out of the

rendering of technical advice or service by the Company or its agents in connection

with the Buyer's order of the products furnished hereunder.

Limitation of Liabilities

This warranty does not cover normal maintenance such as cleaning, adjustment or

lubrication and updating of equipment parts. This warranty shall be void and shall not

apply if the equipment is used with accessories or parts not manufactured by the

Company or authorized for use in writing by the Company or if the equipment is not

maintained in accordance with the prescribed schedule of maintenance.

The warranty stated above shall extend for a period of One (1) year from date of

shipment, with the following exceptions:

1. Components for monitoring of physical variables such as temperature,

pressure, or flow are warranted for ninety (90) days from date of receipt.

2. Elastomeric components and other parts or components subject to

deterioration, over which the Company has no control, are warranted for sixty

(60) days from date of receipt.

3. Internal batteries are warranted for ninety (90) days from the date of receipt.

The foregoing is in lieu of any warranty, expressed or implied, including, without

limitation, any warranty of merchantability, except as to title, and can be amended

only in writing by a duly authorized representative of the Company.

777077-101 Revision B June 2004

Page 6

6 Infant Flow Advance™ System

777077-101 Revision B June 2004

Page 7

Operator’s Manual 7

Contents

Revision History....................................................................................2

Contact and Ordering Information ...............................................................................3

Warranty .........................................................................................................................5

Limitation of Liabilities....................................................................................................5

Contents .........................................................................................................................7

Chapter 1: Product Description ...........................................................9

Applications .................................................................................................................10

Intended Use ................................................................................................................10

Chapter 2: Product Specification.......................................................11

ETL Classification........................................................................................................13

EN 60601-1 Classification ...........................................................................................13

Chapter 3: Summary of Warnings and Cautions..............................15

Terms ............................................................................................................................15

Chapter 4: Operating Instructions.....................................................21

Step by Step Instructions............................................................................................22

Chapter 5: Clinical References...........................................................31

Chapter 6: Routine Maintenance........................................................33

Oxygen Analyzer Calibration......................................................................................33

Cleaning........................................................................................................................34

Battery Maintenance....................................................................................................34

Chapter 7: Summary of Symbols.......................................................37

Appendix A: Screen Flow Diagrams.................................................39

Appendix A: Screen Flow Diagrams.................................................39

Appendix B: Approved Accessories .................................................41

Appendix C: Abdominal Respiratory Sensor Placement.................43

Glossary of Terms...............................................................................45

777077-101 Revision B June 2004

Page 8

8 Infant Flow Advance™ System

777077-101 Revision B June 2004

Page 9

Operator’s Manual 9

Chapter 1: Product Description

TM

The Infant Flow Advance

Analyzer, Flow meter and Pressure Manometer with integral alarm systems designed

specifically to be used in conjunction with the Infant Flow

generator, and patient interfaces consisting of a selection of masks and prongs.

Together these products make up the Infant Flow Advance System.

The Infant Flow Advance Driver is assembled in a sheet metal enclosure from

standard and commercial components. These are a Medical Air/Oxygen Blender, a

Flow meter calibrated for mixed gas between 0 and 15 L/min, a galvanic Oxygen

Fuel Cell with associated electronics, a self activating electronic pressure measuring

and limiting system and a power supply.

The Infant Flow Advance Driver is supplied with a pole mount bracket to fit round or

square section poles from 10 to 35 mm (0.4 to 1.4 in) diameter.

The Medical Air and Oxygen gas inlets are standard NIST, DISS or other appropriate

inlets. High-pressure Medical Air and Oxygen hoses must be ordered separately.

Driver is a combined Air/Oxygen Mixer, Oxygen

TM

nasal CPAP circuits,

The patient outlet is an ISO standard 15 mm female taper fitting and the pressure

monitoring inlet is a standard Luer taper fitting. The Oxygen monitor is an integral

part of the driver and does not require any additional external fittings.

The Oxygen monitor uses a galvanic fuel cell sensor which is fitted in a pressure

controlled path to avoid variations in delivered gas pressure altering the measured

value. The gas which is used for the Oxygen analyzer is subsequently vented from

the rear of the Infant Flow Driver.

The Infant Flow Advance™ Driver is designed to supply a periodic or patienttriggered additional flow of oxygen-enriched air to the patient, and to provide an

apnea monitoring and alarm facility when used in conjunction with the appropriate

accessories.

The Infant Flow Advance™ Driver can be used in the following modes:

• Nasal CPAP, via the Infant Flow generator, with or without apnea monitoring

using a respiration sensor that is attached to the patient’s abdomen.

• Pressure Assist (PA), whereby an elevated pressure is intermittently

delivered to the patient via the Infant Flow™ generator. This can be applied

at a variable rate (R) and for varying lengths of time (Ti) and with or without

apnea monitoring using a respiration sensor that is attached to the patient’s

abdomen.

• Triggered PA (trPA), whereby an elevated pressure is intermittently delivered

to the patient via the Infant Flow™ generator. This is triggered by the

patient’s own respiratory effort by using a respiration sensor that is attached

to the patient’s abdomen and for varying lengths of time (Ti). Apnea

monitoring is a feature of this mode and a back-up rate (Rb) is available.

777077-101 Revision B June 2004

Page 10

10 Infant Flow Advance™ System

Applications

Applications are prescribed by the clinician depending on the needs of the patient.

Intended Use

The Infant Flow Advance System consisting of a driver and generator plus nasal

CPAP prongs and masks, is intended for the provision of periodic and patient

triggered bi-Level CPAP. The system is for use in hospitals, hospital-type facilities

and intra-hospital transport environments.

777077-101 Revision B June 2004

Page 11

Operator’s Manual 11

Chapter 2: Product Specification

This manual describes the operation and routine maintenance of the M674 models of

the Infant Flow Advance™ Driver when fitted with Version 1.00 software and above.

Identification of the particular version of software fitted in the equipment may be

made at power-up. When the Infant Flow Advance Driver is turned on, the 7 segment

displays show first three "8"s, then blanks, then the software version number as part

of the start-up procedure.

• Gas supply - Nominal 50 PSI (3.5 bar) clean, dry Medical Air and Oxygen.

• Range - Minimum 30 psig (2.1 bar), maximum 80 psig (5.6 bar). Maximum

differential pressure 30 psig (2.1 bar).

• Power Supply – 95-135 Vac, 0.30A, 50-60 Hz or 200-265 Vac, 0.15A,

50-60 Hz. Internal lead acid battery (2 hours running time when fully

charged).

CAUTION

Equipment must be used with approved power supplies. Refer to Appendix B for a

list of approved accessories.

• Power and Battery status indicators – indicates connection to an external

power source and the battery status.

- Top indicator shows green when an external 12V DC power source is

connected and indicates the battery is being charged.

- The full battery indicator shows green when the battery is fully charged.

- The low battery indicator shows red when the battery is low. With this

LED illuminated, approximately 15 minutes of power remain before a

complete discharge of the battery occurs.

• Dimensions: 11in (27.5 cm) x 8.5 in (22.25 cm) x 5.5 in (13.75 cm)

(excluding gas inlets, patient outlets and mounting bracket)

• Weight: 16 lbs (7.2 kg)

• Air/Oxygen Mixer - Range 21 to 100% Oxygen, accuracy ± 3% of selected

output

• Flow meter - Range 0 to 15 L/min, accuracy ± 5% of selected output

• Pressure relief valve - 2 systems incorporated

- Patient safety - automatic electronic valve system pre-set to vent to

ambient at 11 cmH2O.

- System and delivery circuit safety - mechanical internal relief valve pre-

set at 205 cmH2O.

• Manometer - Range, 0 to 12 cmH

• Oxygen Monitor – Range, 0 to 100% Oxygen, accuracy ± 2% of span.

777077-101 Revision B June 2004

O, accuracy ± 1 cmH2O.

2

Page 12

12 Infant Flow Advance™ System

• Alarm System - Four separate alarm systems are provided all of which are

automatic. The electronic alarms are set after 2 minutes of operation without

operator intervention although the operator can manually set or reset them if

required.

1 Supply gases failure: If the differential pressure between the two inlet

gases falls outside of the limit of 20 PSI (1.4 bar) or one gas fails

completely, an alarm will sound and the gas at the higher pressure only

will be delivered to the patient.

2 High patient pressure: An audible and visual high pressure alarm is

pre-set at 11 cmH

relieving solenoid which instantly reduces the pressure in the patient

circuit to near zero. The pressure is restored after 3 seconds, but will be

reduced to near zero should the cause of the alarm condition still exist. A

second high pressure alarm with audible and visual indication is set 3

cmH

O above the measured CPAP pressure.

2

3 Low patient pressure: An audible and visual low pressure alarm is set

at 2 cmH

O below the measured CPAP pressure or at 0 cmH2O if this

2

would otherwise be negative.

4 Failure to deliver correct Oxygen concentration: Audible and visual

alarms are provided at ± 5% of the measured FiO

of the alarms with an upper maximum limit of 101% and a lower

minimum limit of 20%. There is a low hazard warning at 18% Oxygen or

below. Additionally, the Infant Flow Advance has the following

characteristics:

O. This alarm automatically activates a pressure

2

at the time of arming

2

• Variable augmented flow: 0 to 5 L/min of the mixed gas

• Pressure display with time: 0 to 10 cm H

O; accuracy: 10% of full

2

scale

• Timing accuracy: 1% of setting

• Input connection: 8-way self-locking socket for Transducer Interface

• Apnea alarm indicator (red)

• Breath indicator (yellow) – indicates inspiration when the Transducer

Interface and abdominal respiratory sensor are properly fitted.

• Environment: Keep dry and do not expose to direct sunlight.

- Temperature

Operating: 50 to 104 ºF (10 to 40 ºC)

Storage: 32 to 122 ºF (0 to 50 ºC)

- Humidity

Operating : <90% non condensing

Storage: <90% non condensing

- Atmospheric Pressure

Storage: 8.7 to 20.3 PSI (0.6 to 1.4 bar)

777077-101 Revision B June 2004

Page 13

Operator’s Manual 13

ETL Classification

With respect to applicable requirements of Standard for Safety Medical Electrical

Equipment, UL 60601-1 1

General Instructions No. 1, CAN/CSA C22.2 No. 601.1-M90.

st

Ed. 04/25/03 and General Requirements for Safety

EN 60601-1 Classification

Equipment is Class 1 and internally powered, IPX0 Protected, and uses Type B and

Type BF applied parts.

Equipment not suitable for use in presence of flammable anesthetics.

NOTE

For use of Model M674A in Australia and New Zealand, Power supply Part Number

777223 must be used. This replaces Power Supply 674-037. With Power Supply Part

Number 777223 in use, M674A equipment is Class 2 and internally protected, and

uses Type B applied parts.

NOTE

Although the Infant Flow™ Advance meets the requirements of current EMC/RFI

legislation, this does not guarantee immunity from all sources of radiated energy.

Some mobile telephones and other products containing radio transmitting

components may cause malfunction of the Infant Flow™ Advance and should not be

used in the vicinity of the device.

777077-101 Revision B June 2004

Page 14

14 Infant Flow Advance™ System

777077-101 Revision B June 2004

Page 15

Operator’s Manual 15

Chapter 3: Summary of Warnings and

Cautions

The Infant Flow Advance System consisting of a driver and generator plus nasal

CPAP prongs and masks, is intended for the provision of periodic and triggered biLevel CPAP. The system is for use in hospitals, hospital-type facilities and intrahospital transport environments.

This equipment has been tested and found to comply with the limits for medical

devices in IEC 601-1-2:1994. These limits are designed to provide reasonable

protection against harmful interference in a typical medical installation.

This equipment generates, uses and can radiate radio frequency energy and, if not

installed and used in accordance with the instructions, may cause harmful

interference to other devices in the vicinity. VIASYS Healthcare makes no guarantee

that interference will not occur in a particular installation.

If this equipment does cause harmful interference to other devices, which can be

determined by turning the equipment off and on, the user is encouraged to try to

correct the interference by one or more of the following measures:

- Reorient or relocate the receiving device.

- Increase the separation between the equipment.

- Connect the equipment into an outlet on a circuit different from that to

which the other device(s) are connected.

- Consult the manufacturer or field service technician for help.

The Infant Flow Advance Driver is a medical device intended for use only by or under

the order of a physician.

Personnel operating this equipment are responsible for reading and thoroughly

understanding all product documentation provided. The warning, caution and note

statements listed below must be thoroughly read and understood prior to use of this

device. These statements may be repeated throughout the product documentation

as needed and have special significance as follows:

Terms

WARNING - Means there is a possibility of personal injury to the operator or patient.

CAUTION - Indicates there is a possibility of damage to the product or other

equipment attached to it.

NOTE - Notes are used to call attention to statements pertaining to more efficient or

convenient operation or service of the equipment.

777077-101 Revision B June 2004

Page 16

16 Infant Flow Advance™ System

Warnings

• Whenever a patient is attached to respiratory care equipment constant

attendance is required by qualified personnel. The use of an alarm or

monitoring system does not give absolute assurance of warning for every

form of malfunction that may occur with the system. In addition, some

problems may require immediate attention.

• The abdominal respiratory sensor is used only to enable features associated

with the Pressure Assist (PA) and Triggered PA (trPA) modes on the

Advance driver. When using the abdominal respiratory sensor, always use an

additional, external device for monitoring of the respiratory rate and detection

of apneic episodes as well as an appropriate monitor for continuous SaO

monitoring.

• Blender alarms must be corrected swiftly as the Oxygen concentration which

was selected for the patient will not be delivered during an alarm/bypass

situation.

• The gas blender incorporated in this product is designed to mix Air and

Oxygen only. Do not modify the inlets to accommodate other source gases

such as anesthesia gases.

2

• Liquid water or other contaminants in either gas supply, particularly the air

supply, will cause malfunction of this equipment and equipment connected to

it.

• Oxygen vigorously accelerates combustion. To avoid explosion hazard do

not use any instrument or other equipment that may have been exposed to oil

or grease contamination.

• The gas failure alarm will not function if both supply gases are below 30 psig

(2.1 bar).

• Leaving the humidifier refill bag above the height of the Infant Flow™

Advance Driver can cause the pole and stand assembly to be mechanically

unstable. Always place the water refill bag at a lower level than the chamber

after filling of the chamber has been completed. The shut off clamp must be

fully closed at all times other than when filling the chamber.

• Nasal CPAP treatment in general can cause nasal irritation, septal distortion,

skin irritation and pressure necrosis. Adherence to the recommended usage

instructions for the Infant Flow Advance accessories may reduce the

incidence of these complications.

• Do not overload the pole and stand. The stand’s maximum net load is approx.

22 lbs (10 kg); including the 4.4 lb (2 kg) humidifier mounted on the supplied

bracket, the 15.9 (7.2 kg) Infant Flow Advance Driver mounted at a maximum

of 10.2 in (260) mm above the stand handle, two bags of water (4.4 lb / 2 kg)

in the basket, associated gas hoses, and patient breathing circuit.

• Do not use conductive patient circuits with the Infant Flow Advance.

• The Infant Flow Advance™ must only be operated with the supplied

approved AC adaptor (refer to appendix B for a list of approved accessories).

777077-101 Revision B June 2004

Page 17

Operator’s Manual 17

• When filling the humidifier, do not move the stand; moving or transporting the

stand while re-filling may cause the whole assembly to over-balance.

• Disconnect power supply before servicing.

Cautions

• Federal Law (USA) restricts this device to sale by or on the order of a

physician.

• Not suitable for use in the presence of flammable anesthetics.

• Always read the Operator’s Manual before applying treatment.

• The Infant Flow Advance™ has been designed and tested as a complete

system using Infant Flow™ accessories. Use only approved accessories

(Refer to Appendix B for a list of approved accessories).

• Service and/or repair of this instrument is restricted to VIASYS Healthcare

authorized or VIASYS Healthcare Trained Personnel only.

• The precision gas blender incorporated in this product may become non-

functional or damaged if used without the protective water trap and filters

provided.

• Always reset the alarms after changing patient settings.

• Remove any liquid in the manometer line; any obstruction leads to inaccurate

readings of pressure.

• The 5 mark indicates the connection between the Transducer Interface and

the Driver only. It does not indicate correct positioning of the abdominal

respiratory sensor.

• The power switch on this unit does not isolate the unit from the external

power supply. Disconnect the external power supply to ensure isolation.

• Remove primary battery if equipment is to be stored without use for long

periods of time.

• Equipment must be used with approved power supplies. Refer to Appendix B

for a list of approved accessories.

• Verify that this device has been authorized for use by qualified personnel.

• Disconnect the mains power supply before removing covers.

• Do not immerse any part of this device or gas or steam sterilize it. Damage

will result.

Notes

• For use of Model M674A in Australia and New Zealand, Power supply Part

Number 777223 must be used. This replaces Power Supply 674-037. With

Power Supply Part Number 777223 in use, M674A equipment is Class 2 and

internally protected, and uses Type B applied parts.

777077-101 Revision B June 2004

Page 18

18 Infant Flow Advance™ System

• VIASYS Healthcare recommends the use of a heated humidifier which

utilizes a heater wire in the inspiratory limb for enhanced patient safety.

• The gas failure alarm/bypass will activate when the first gas is connected and

will reset upon connection of the second supply gas.

• We recommend that the temperature be set between 36 °C (96.8 °F) and

37 °C (98.6 °F) but never higher than 37 °C (98.6 °F) for inspired gases.

• Due to local regulations these options are not available in all markets.

• It is recommended that hospital personnel responsible for the Performance

Verification Test maintain records of their activities and identify equipment

authorized for use.

• Although the Infant Flow™ Advance meets the requirements of current

EMC/RFI legislation this does not guarantee immunity from all sources of

radiated energy. Some mobile telephones and other products containing

radio transmitting components may cause malfunction of the Infant Flow™

Advance and should not be used in the vicinity of the device.

• The Infant Flow Advance is an integral system consisting of the Driver

(including air-oxygen blender, monitor and oxygen analyzer), electronics

module with screen display and the Infant Flow nasal CPAP Generator.

These components can only be used as a system. The Infant Flow Advance

should not be used for any other type CPAP or ventilation system. The Infant

Flow nasal CPAP Generator should not be used with any other delivery

system.

• It is advisable to leave the Infant Flow Advance connected to a power source

whenever possible. This will ensure maximum battery life for transport

applications. (It may take up to 16 hours to charge a fully discharged

battery).

• The additional flow available through the Infant Flow Advance module should

be turned to zero prior to set-up.

• Certain modes are not available unless the Transducer Interface is attached

to the unit and will not operate unless an abdominal respiratory sensor is

attached to the patient.

• The graphics displayed on the screen are a representation of the manometer

LED’s on the front of the Infant Flow Driver.

• ‘Pressure Assist’ can work with or without the Transducer Interface fitted (ie

with and without Apnea monitoring).

• The ‘bell symbol’ will not be shown on the screen if the Transducer

Interface is not attached to the Infant Flow Advance.

• During set-up of any mode the user can return to the Treatment Selection

Screen by selecting ‘’ key.

• The over and under pressure alarms are set and detect pressure over a

period of time. In the Pressure Assist modes, the mean pressure over the

timed period will be higher than just CPAP. The alarms should therefore be

set around this average.

777077-101 Revision B June 2004

Page 19

Operator’s Manual 19

• The duration of the single Pressure Assist will be the default value of Ti

unless changed through the PA Set-Up screen.

• The LED on the Transducer Interface and the Infant Flow Advance™ will

flash simultaneously when a patient breath is detected. If either LED does

not illuminate, fit an alternative Transducer Interface, or contact your local

VIASYS Healthcare representative.

• The ball in the Flowmeter will ‘bounce’ during operation in the PA and trPA

modes. This is a normal occurrence during these modes. For pressure

reading see the LED display.

• Battery Maintenance for extended storage: remove the battery from the

equipment and charge to 100%. Charge the battery every month if stored at

temperatures below 60 °F (15.5 °C). If stored in an area above 60 °F

(15.5 °C), charge every two weeks.

• All of the functional accessories supplied by VIASYS Healthcare for use with

the Infant Flow™ driver are for single patient use only. These accessories

include the Infant Flow™ generator, delivery breathing circuits, humidification

chambers, silencer/bacteria filters and fixation bonnets. Under no

circumstances should sterilization or re-use of these products be attempted.

• A complete list of service parts can be found in the Service Manual.

777077-101 Revision B June 2004

Page 20

20 Infant Flow Advance™ System

777077-101 Revision B June 2004

Page 21

Operator’s Manual 21

Chapter 4: Operating Instructions

The Infant Flow Advance provides a virtually constant CPAP pressure irrespective of

patient demand or expiratory flows via the specially designed driver, generator, and

nasal interface. The Infant Flow generator is subject to a direct relationship between

controlled enriched gas flow and Nasal CPAP pressure.

A nomogram illustrating the general relationship between constant airway pressure

and flow settings is shown below. Example: 8 L/min will provide in the order of

5 cmH

of more than 10% from that illustrated in the nomogram and, in particular, at

pressures below 2 cmH

CPAP

cmH

O Nasal CPAP. Please note that actual devices may demonstrate tolerances

2

O.

2

O

2

Fresh gas flow

L/min

Figure 1 - Flow Pressure Nomogram for the Infant Flow Advance

CAUTION

Verify that this device has been authorized for use by qualified personnel.

CAUTION

Remove any liquid in the manometer line; any obstruction leads to inaccurate

readings of pressure.

777077-101 Revision B June 2004

Page 22

22 Infant Flow Advance™ System

Step by Step Instructions

1 Firmly mount the Infant Flow Advance™ on either the pole and stand or the rail

system with all of the ancillary equipment such as the heated humidifier.

Check the integrity of the driver, the Transducer Interface and all ancillary

equipment prior to operation.

NOTE

VIASYS Healthcare recommends the use of a heated humidifier which utilizes a

heater wire in the inspiratory limb for enhanced patient safety.

2 Connect the medical air and oxygen hoses to the driver and then to the high

pressure source.

NOTE

The gas failure alarm/bypass will activate when the first gas is connected and will

reset upon connection of the second supply gas.

3 Connect the power cord for the Infant Flow Advance Driver to a suitable outlet.

Do not switch on the driver at this point.

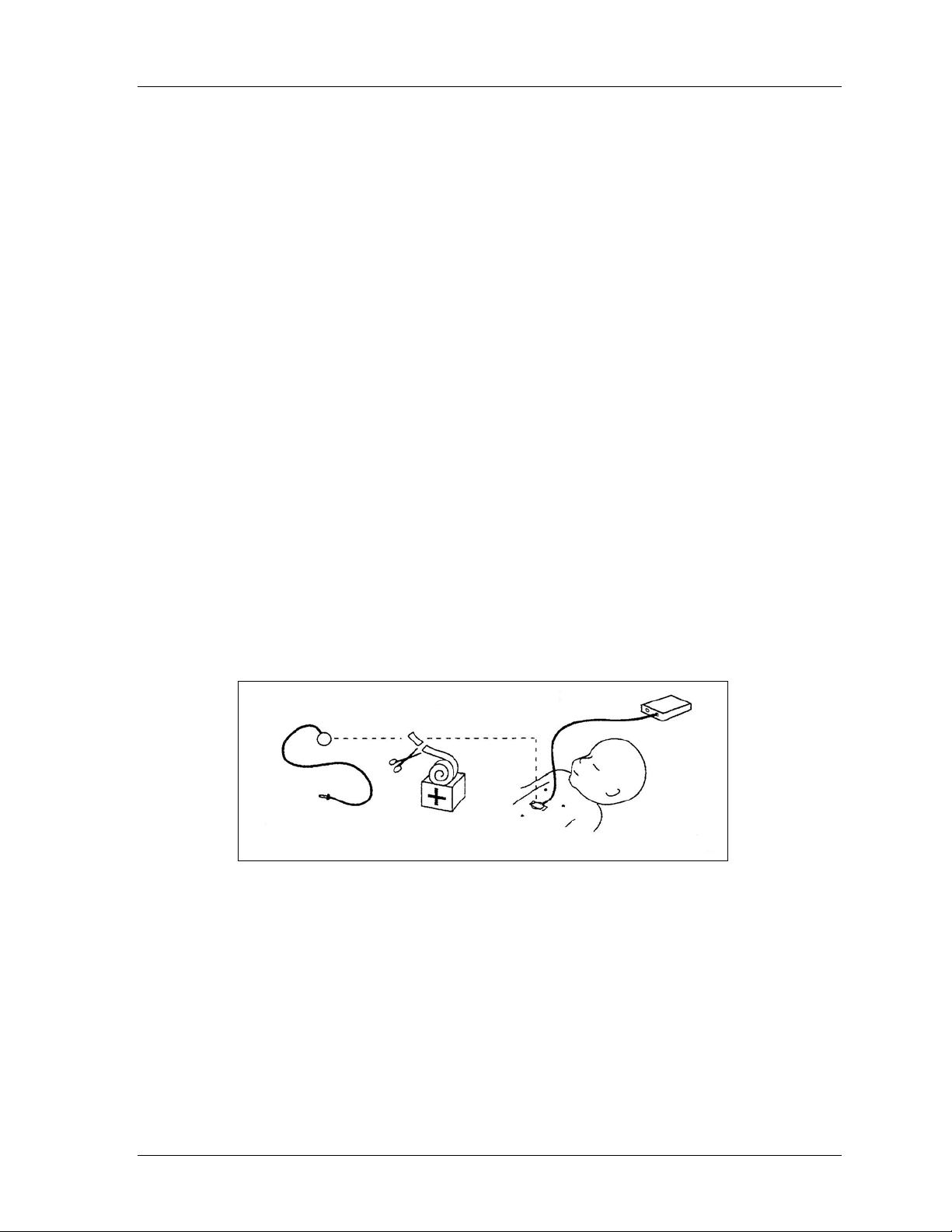

4 Connect the patient circuit and Infant Flow Generator as shown in Figure 2.

777077-101 Revision B June 2004

Page 23

Operator’s Manual 23

It is a Department of Health recommendation than an Oxygen Analyzer be used

at ALL TIMES when Oxygen Enriched Gases are being administered.

Figure 2 - Set Up Infant Flow Advance System

This figure is a general indication of how the various devices would be

interconnected in a typical setup. The actual configuration will vary dependent on the

type of ancillary equipment used.

WARNING

Liquid water or other contaminants in either gas supply, particularly the air

supply, will cause malfunction of this equipment and equipment connected to

it.

5 Set the desired delivery temperature on the heated humidifier and switch it on.

777077-101 Revision B June 2004

Page 24

24 Infant Flow Advance™ System

NOTE

We recommend that the temperature be set between 36 °C (96.8 °F) and 37 °C

(98.6 °F) but never higher than 37 °C (98.6 °F) for inspired gases.

6 Select the appropriate sized bonnet. Full instructions on placement of the

bonnet and fixation may be found on the instruction leaflet included with the

bonnets and generator.

• Use the forehead and the nape of the neck as reference points when

measuring the infant’s head to determine the proper bonnet size.

• Too small a bonnet may cause it to ride up, putting tension on the patient

interface, distorting the infant’s nose.

• Too large a bonnet may allow it to slide down over the infant’s eyes and

release the interface from the infant’s nose.

7 Open a Generator set and attach it to the circuit. Select the largest size

interface that will fit the infant’s nares (for prongs) or around the nose (for

masks). When fitted correctly, nasal prongs should be inside the nares with

some space existing between the prong and the nose. The generator

assembly should not be pulling up on or causing distortion to the infant’s nose.

8 Attach the prongs or mask interface to the Generator.

9 Switch on the Infant Flow Advance™ using the on/off switch at the rear of the

Infant Flow™ driver.

- The Breath and Apnea alarm indicator lamps are illuminated briefly when

the equipment is first powered. If either lamp is not working, do not use

the equipment.

- All the elements of the display are exercised at switch-on so that the

operation of the display can be checked, and the software version can be

viewed.

- The display presents the Pre-treatment Set-up screen after two seconds

(see Appendix for typical screen displays).

10 Occlude the patient interface.

11 Turn the gas flow to 8 L/min using the knob under the flow meter and verify

that the pressure reads 5 cmH

leaks if 5 cmH

O is not achieved. The flow meter indicator may take up to 3

2

seconds to settle after a step change in flow has occurred.

12 Once the CPAP pressure is set, the button under the CPAP icon should be

pressed. The flashing ‘?’ will change to a '9’

13 Set the required FiO

using the O2% graduated control.

2

14 Set the Pressure Assist characteristics by:

O. Check breathing circuit and connections for

2

• Adjusting the flow by using the knob above the transducer connection to the

right of LED display. Check the additional pressure on the graphic display.

• Once set to the desired level, the button under the PA icon should be pressed

and the flashing ‘?’ will change to a ‘9’.

777077-101 Revision B June 2004

Page 25

Operator’s Manual 25

15 The button under the patient icon should be pressed when the Interface and

sensor have been properly attached or when the user has decided that this

option is not required. The flashing ‘?’ will change to a ‘9’.

CAUTION

The 5 mark indicates the connection between the Transducer Interface and the

Driver only. It does not indicate correct positioning of the abdominal respiratory

sensor.

16 Fit the generator to the patient and bonnet. Ensure that the correct size

interface is selected and that the entire assembly is properly fitted to the infant.

Use the largest size interface that fits the infant’s nares or around the infant’s

nose to form a seal.

17 When properly set, the prongs should be inside the nares. There should be

some space between the prong set and the infant’s nose. The prongs should

not be pulling up on the infant’s nose. Alternatively, the mask should be snugly

fitted around the nose. The mask should not press down on the infant’s face

or come into contact with the infant’s eyes or mouth. Refer to the instruction

insert found with the bonnet or generator packaging for a diagram of final

fixation position.

18 Small adjustments to the nasal CPAP flow rate may be required until the

display reads the prescribed CPAP level. The relationship between the flow

setting and CPAP pressure should be compared with Figure 1 as a reference.

If outside the suggested range, check with the troubleshooting section of the

manual.

19 If Apnea monitoring or trPA is required, attach the abdominal respiratory

sensor to the patient and to the Transducer Interface, and the Transducer

Interface to the Infant Flow Advance Driver. Refer to Appendix C for

placement instructions. At this point a ; will appear on the screen to identify

the Transducer Interface is connected and remain on the screen until the

Transducer Interface is disconnected.

WARNING

The abdominal respiratory sensor is used only to enable features associated

with the Pressure Assist (PA) and Triggered PA (trPA) modes on the Advance

driver. When using the abdominal respiratory sensor, always use an

additional, external device for monitoring of the respiratory rate and detection

of apneic episodes as well as an appropriate monitor for continuous SaO2

monitoring.

CAUTION

The 5 mark indicates the connection between the Transducer Interface and the

Driver only. It does not indicate correct positioning of the abdominal respiratory

sensor.

777077-101 Revision B June 2004

Page 26

26 Infant Flow Advance™ System

NOTE

The LED on the Transducer Interface and the Infant Flow Advance™ will flash

simultaneously when a patient breath is detected. If either LED does not illuminate

fit an alternative Transducer Interface, or contact your local VIASYS Healthcare

representative.

20 Using the Treatment Set-up screens;

• Set the duration of the Pressure Assist by adjusting Ti and Ti. The

default setting is 0.3 seconds.

• Set the rate in Pressure Assist mode by adjusting R and R. The default

is 30 per minute.

• In Triggered Pressure Assist, the rate is the back-up rate should the patient

become apneic. In this mode the default setting is 10 per minute.

• Set the Apnea alarm period by pressing the Alarm bell button. The alarm

period can be set at 10, 15, 20, 25 and 30 seconds. The default setting is 20

seconds.

NOTE

During set-up of any mode the user can return to the Treatment Selection screen by

selecting ‘

21 Set the pressure and FiO2 alarms by pressing and holding the Alarm Silence

’ key.

button for three seconds.

NOTE

The over and under pressure alarms are set and detect pressure over a period of

time. In the Pressure Assist modes, the mean pressure over the timed period will be

higher than just CPAP. The alarms should therefore be set around this average.

22 Ensure that the nasal CPAP pressure is that which is prescribed. The "Target

Range" section of the bar graph indicates the most commonly used pressures

with the Infant Flow Generator. However, the actual pressures used for the

treatment of individual patients must be prescribed by the clinician.

Minor variations between devices occur but the pressure delivered should

always be within ± 10% of those shown on the Nomogram (Figure 1). If they

are out of specification check that there are no leaks in the patient circuit.

23 The electronic alarms for FiO

minute stabilization period. Should you wish to set them earlier, simply hold

the Arm/Mute button in for three seconds. The alarm will bleep to indicate that

and pressure will automatically set after a 2

2

777077-101 Revision B June 2004

Page 27

Operator’s Manual 27

your command has been accepted and the Alarms Armed indicator will

illuminate.

24 Should you change the nasal CPAP treatment pressure or the Oxygen

concentration, it is necessary to reset the alarm levels by holding the Arm/Mute

button in for three seconds.

25 In order to change treatments at anytime, first unlock the screen by pressing

the ‘key strike-thru’

to end the current treatment and return to the treatment selection screen.

CPAP will always be applied.

26 A single Pressure Assist may be delivered at any time. This can be applied to

the patient by first unlocking the screen by pressing the ‘key strike-thru’

button, and then pressing the

button. Then, press the ‘treatment strike-thru’ button

button.

NOTE

The duration of the single Pressure Assist will be the default value of Ti unless

changed through the PA Set-Up screen.

NOTE

The ball in the Flow meter will ‘bounce’ during operation in the PA and trPA modes.

This is a normal occurrence during these modes. For pressure reading see the LED

display.

27 Should Apnea monitoring be required, the Transducer Interface must first be

attached to the Infant Flow Advance Driver, then an Abdominal Respiratory

Sensor should be attached to the patient and the Transducer Interface. The

apnea monitoring period may be adjusted between 10 and 30 seconds in 5

second interval by pressing the button beneath the bell symbol.

WARNING

The abdominal respiratory sensor is used only to enable features associated

with the Pressure Assist (PA) and Triggered PA (trPA) modes on the Advance

driver. When using the abdominal respiratory sensor, always use an

additional, external device for monitoring of the respiratory rate and detection

of apneic episodes as well as an appropriate monitor for continuous SaO2

monitoring.

28 What to do if an alarm occurs - Always attend alarm conditions immediately as

the patient may not be receiving the prescribed FiO

have become apneic. Check all connections between the device and the

patient.

29 There are two distinct alarm types built in the Infant Flow Advance. The

Air/Oxygen Mixer has a mechanical bypass and alarm system which will sound

if one of the supply gases is below or above the range of pressure which can

be handled satisfactorily.

30 The second alarm system consists of an electronic system built into the

pressure and Oxygen monitoring module. This has several functions as shown

in Table 1 in this chapter. All electronic alarms with the exception of the

or nasal CPAP or may

2

777077-101 Revision B June 2004

Page 28

28 Infant Flow Advance™ System

overpressure alarm are self re-setting. In the event of an overpressure being

detected (> 11 cmH

which removes gas flow from the patient circuit.

O), the Driver activates a vent-to-ambient solenoid valve

2

WARNING

Nasal CPAP treatment in general can cause nasal irritation, septal distortion,

skin irritation and pressure necrosis. Adherence to the recommended usage

instructions for the Infant Flow Advance accessories may reduce the incidence

of these complications.

31 Nasal CPAP is not a benign procedure, all operators must be aware of the

possible hazards and complications associated with this treatment. Operators

must apply all necessary precautions to ensure safe and effective application

and treatment.

32 Do not over-tighten the generator straps. There is a risk of tissue damage.

33 Always choose the correct interface size.

34 Check the infant at least every 3-4 hours for the following:

• nasal irritation and septal distortion;

• skin irritation and pressure necrosis;

• nasal mucosal damage due to lack of humidification;

• gastric insufflation;

• abdominal distention.

777077-101 Revision B June 2004

Page 29

Operator’s Manual 29

TABLE 1 - Infant Flow Advance Driver Alarm Systems

Alarm function Device Action Operator Action

Oxygen supply failure Audible alarm. Check and restore oxygen

supply.

Air supply failure Audible alarm. Check and restore air supply.

High oxygen

concentration

Low oxygen

concentration

High pressure Audible alarm & high pressure

Low pressure Audible alarm & low pressure

Apnea timeout period Audible alarm & LED illuminated Check patient to determine

Audible alarm & high oxygen

indicator illuminated.

Audible alarm & low oxygen indicator

illuminated.

indicator illuminated.

indicator illuminated.

Check supply gases and/or

galvanic fuel cell. Press the

Arm/Mute button to silence the

audible alarm.

Check supply gases and/or the

galvanic fuel cell. Press the

Arm/Mute button to silence the

audible alarm.

Check the flow rate and check

for occluded tubes. Press the

Arm/Mute button to cancel the

alarm or restore pressure in the

circuit.

Check the flow rate and check

for occluded or disconnected

tubes or nasal interface. Press

the Arm/Mute button to silence

the audible alarm.

breathing. Check position of

abdominal respiratory sensor.

Check connections between

the sensor, the Transducer

Interface and the Driver.

Replace Transducer Interface

and sensor as appropriate.

The alarm will self cancel if the

cause is removed within the

first timeout period. If it is not

removed, then the Arm/Mute

button must be pressed to

silence the audible alarm.

777077-101 Revision B June 2004

Page 30

30 Infant Flow Advance™ System

TABLE 2 – Default Settings and Set Ranges

DEFAULT SETTINGS

Inspiration Time Ti: 0.3 seconds (+/- 1%)

Breath rate - detected Breaths Per Minute bpm +/- 1

PA Rate (During Pressure Assist) R: 30 / minute

Back Up Rate (During Triggered Pressure Assist) Rb: 10 / minute

Apnea Alarm Delay 20 seconds (+/- 1%)

SET RANGES

Inspiration Time Ti: 0.1s to 1.0s

PA Rate (During Pressure Assist) R: 1 – 120 / minute

Back Up Rate (During Triggered Pressure Assist) Rb: 1 – 30 / minute

Apnea Alarm Delay 10, 15, 20, 25, 30 seconds

Variable Additional Flow 0 – 5 L/min

777077-101 Revision B June 2004

Page 31

Operator’s Manual 31

Chapter 5: Clinical References

1 Klausner J, Lee AY, Hutchison AA. Decreased imposed work with a new nasal

continuous positive airway pressure device. Pediatr Pulmonology 22:188-194,

1996.

2 Moa G, Nilsson K, Zetterstrom H, Jonsson LO. A new device for administration

of nasal continuous positive airway pressure in the newborn: an experimental

study. Crit Care Med 16:1238-1242, 1988.

3 Rasanen J, Leijala M. Breathing circuit respiratory work in infants recovering

from respiratory failure. Crit Care Med 19:31-35, 1991.

4 Guilleminault C, et al. Upper airway resistance in infants at risk for sudden

infant death syndrome. J Pediatr, Volume 122, Number 6, June 1993.

5 Moa G, Nilsson K. Nasal continuous positive airway pressure: experience with

a new technical approach. Acta Pediatr 82: 210-11, 1993

6 Avery ME, et al. Is chronic lung disease in low birth weight infants preventable?

A survey of eight centers. Pediatrics 79:26-30 1987.

7 Higgins RD, Richter SE, Davis JM. Nasal continuous positive airway pressure

facilitates extubation of very low birth weight neonates. Pediatrics 88:9991003, 1991.

8 Locke RG, et al. Inadvertent Administration of Positive End-Distending

Pressure During Nasal Cannula Flow. Pediatrics (ISSN 0031 4005) 1993.

9 Stocks J. Effect of nasogastric tubes on nasal resistance during infancy.

Archives of Diseases in Childhood, 55:17-21, 1980.

10 Courtney, SE, et al. Lung volume changes during nasal continuous positive

airway pressure (nasal CPAP) in preterm infants: comparison of a variable vs a

continuous flow device. The American Pediatric Society and The Society for

Pediatric Research Abstract, #989, May 1998.

777077-101 Revision B June 2004

Page 32

32 Infant Flow Advance™ System

777077-101 Revision B June 2004

Page 33

Operator’s Manual 33

Chapter 6: Routine Maintenance

WARNING

Disconnect power supply before servicing.

Routine maintenance of the Infant Flow Advance is limited to regular checking of the

oxygen analyzer calibration and periodic (every 4 months) checking of the

Air/Oxygen Mixer and Electronic Pressure Manometer, status of the gas inlet filters,

integrity of the alarm system and cleaning of exterior surfaces.

An Infant Flow Advance in need of recalibration, service or repair must not be used

until the necessary procedures are performed and the equipment has been tested to

ascertain that it is functioning correctly.

Ensure pole clamp screws and clamp are securely fastened.

The Infant Flow Advance Service Manual is available to qualified technicians to

effect calibration, service and repair. If this is not feasible, contact VIASYS

Healthcare to insure full reliability and safety as special tools and equipment are

required.

Service and/or repair of this instrument is restricted to VIASYS Healthcare

authorized or VIASYS Healthcare Trained Personnel only. Parts designated in

this manual should be replaced only with parts manufactured or sold by VIASYS

Healthcare.

Gas Inlet Filters – The exterior air filter can be observed through the polycarbonate

bowl. If it is discolored or wet it should be replaced.

CAUTION

The precision gas blender incorporated in this product may become non-functional or

damaged if used without the protective water trap and filters provided.

Oxygen Analyzer Calibration

The integral oxygen analyzer is of the fuel cell type and as such requires regular

calibration. To perform this check, set up the Infant Flow Driver as for use and allow

2 minutes for stabilization of the electronic measuring circuits.

Select an oxygen concentration of 21%, wait 2 minutes and verify that the display

indicates 21. If not, remove the small white plug adjacent to the 21% mark on the

side of the device and adjust the potentiometer to give a reading of 21.

Set the mixer to 100%, wait 2 minutes and verify that the display indicates 100. If not,

remove the small white plug adjacent to the 100% mark on the side of the device and

adjust the potentiometer to give a reading of 100.

Return the mixer to the 21% position and verify that the display reads 21. There may

be some small interaction between the set point controls if a gross adjustment is

required and the process may need to be repeated two or three times. If this is the

case, it is indicative that the fuel cell is wearing out and should be replaced. Refer

777077-101 Revision B June 2004

Page 34

34 Infant Flow Advance™ System

the Infant Flow Advance Driver to a competent service department for replacement

of the fuel cell. Once calibration is completed, please replace the white plugs.

Cleaning

The exterior surfaces of the Infant Flow Advance Driver and Transducer Interface

can be cleaned with a mild soap or liquid disinfectant solution. Do not use cleaning

agents that contain abrasives. Care should be taken to ensure that cleaning

solutions do not enter the unit via any patient connection ports.

CAUTION

Do not immerse any part of this device or gas or steam sterilize it. Damage will

result.

Single Use devices should be disposed of in accordance with local regulations for

bio-hazardous materials after use.

Battery Maintenance

The Infant Flow Advance™ incorporates a sealed lead acid battery. There is no

routine maintenance to be carried out on this battery which has an expected useful

life of five years. The Infant Flow Advance™ has a built in charger which will safely

charge the battery and keep it in the best possible condition. It is recommended that

the driver is connected to an external power source via the approved AC adaptor

whenever possible to ensure that the battery is fully charged should it be required for

transport or in the event of a power failure.

NOTE

Due to local regulations these options are not available in all markets.

WARNING

The Infant Flow Advance™ must only be operated with the supplied approved

AC adaptor (refer to appendix B for a list of approved accessories).

777077-101 Revision B June 2004

Page 35

Operator’s Manual 35

NOTE

All of the functional accessories supplied by VIASYS Healthcare for use with the

Infant Flow™ driver are for single patient use only. These accessories include the

Infant Flow™ generator, delivery breathing circuits, humidification chambers,

silencer/bacteria filters and fixation bonnets. Under no circumstances should

sterilization or re-use of these products be attempted.

Exhausted batteries and oxygen fuel cells both contain lead and must be disposed of

according to local regulations.

777077-101 Revision B June 2004

Page 36

36 Infant Flow Advance™ System

777077-101 Revision B June 2004

Page 37

Operator’s Manual 37

Chapter 7: Summary of Symbols

The following international standard symbols may appear on the Infant Flow

Advance and in this manual. It is essential that all users of the equipment have a firm

understanding of the symbols.

EN60601 Type B Patient

Applied Part.

AC Alternating Current

DC Direct Current

Internal Battery Fully Charged

Internal Battery Low

Year of Manufacture

Fuse

Activate / Reset Alarm

Silence Alarm

Patient Circuit Connections

Respiratory Sensor

Connections

High Alarm

Read the Accompanying

Documents

Electric Shock Hazard

Unique Batch Number

Identifier

Use Before Expiry Date

Shown

Year-Month

Single Use Only

Do NOT Re-use

External Power Source

Connected

777077-101 Revision B June 2004

Page 38

38 Infant Flow Advance™ System

Low Alarm

Keep Away From Heat

Power on

Power Off

Application of a single

Pressure Assist cycle.

EN60601 Type BF Patient

Applied Part.

Keep Dry

CE Mark and Notified Body

Number.

Please read the Operator’s

Manual.

ETL mark and registration

number.

777077-101 Revision B June 2004

Page 39

Operator’s Manual 39

Appendix A: Screen Flow Diagrams

Figure 3 – Setup Scenario I

In this scenario, the Transducer Interface is not present and therefore not all modes

are available.

777077-101 Revision B June 2004

Page 40

40 Infant Flow Advance™ System

Figure 4 - Setup Scenario II

Patient Abdominal Respiratory Sensor is present and the Transducer Interface is

connected; all modes are available. If the Transducer Interface is disconnected, the

device reverts to the treatment selection screen (see Figure 3) unless non-triggered

PA therapy is being delivered (in which case it switches to un-monitored PA).

777077-101 Revision B June 2004

Page 41

Operator’s Manual 41

Appendix B: Approved Accessories

VIASYS P/N EME P/N Ref. Description

Infant Flow Advance Generators

777085-102 D350T Infant Flow nasal CPAP Generator (Box of 20)

777085-101 D350T/10 Infant Flow nasal CPAP Generator (Box of 10)

Infant Flow Advance Bonnets

777084-101 DBWH000 Infant Flow Bonnet – Size 000 (White)

777084-102 DBGY00 Infant Flow Bonnet – Size 00 (Grey)

777084-103 DBPK0 Infant Flow Bonnet – Size 0 (Pink)

777084-104 DBBR1 Infant Flow Bonnet – Size 1 (Light Brown)

777084-105 DBYE2 Infant Flow Bonnet – Size 2 (Yellow)

777084-106 DBBL3 Infant Flow Bonnet – Size 3 (Light Blue)

777084-107 DBGO4 Infant Flow Bonnet – Size 4 (Gold)

777084-108 DBGR5 Infant Flow Bonnet – Size 5 (Green)

777084-109 DBBU6 Infant Flow Bonnet – Size 6 (Light Burgundy)

777084-110 DBOR7 Infant Flow Bonnet – Size 7 (Orange)

777084-111 DBDG8 Infant Flow Bonnet – Size 8 (Dark Green)

777084-112 DBNA9 Infant Flow Bonnet – Size 9 (Navy)

Infant Flow Advance Mask/Prong Patient Interfaces

777086-101 D360XS Nasal Mask Extra Small

777086-102 D360XL Nasal Mask Extra Large

777086-103 N/A Nasal Mask Extra-Extra Large

777087-101 D360S Nasal Prong Small

777087-102 D360M Nasal Prong Medium

777087-103 D360L Nasal Prong Large

Infant Flow Advance Standard Circuits

773386 C8112E Patient Circuit IF, F&P 730 (Box 20)

773387 N/A Patient Circuit IF, F&P 850 (Box 20)

773388 N/A Patient Circuit IF, RCI 380-90 16V (Box 20)

773389 N/A Patient Circuit IF, RCI 380-88/Concha IV 21V (Box

20)

Infant Flow Advance Miscellaneous Parts and Accessories

D1420/100 Same Infant Flow Silencer/Bacteria Filter (Box 20)

M674-920 Same Infant Flow Advance Service Manual (English)

673-055-A M673055A Infant Flow Pole and Stand complete with IV

extension pole

772-235-A M772235A Infant Flow Pole and Stand without IV extension pole

772236 M772236 Infant Flow extension pole alone

674-037 MW160MA

777223 N/A AC Adapter Australia and New Zealand, M674A only

M674ARC same Abdominal Respiratory Sensor (Box 25)

M677-1 same Infant Flow Advance Transducer Interface

AC Adaptor (MW160)

Note

A complete list of service parts can be found in the Service Manual.

777077-101 Revision B June 2004

Page 42

42 Infant Flow Advance™ System

777077-101 Revision B June 2004

Page 43

Operator’s Manual 43

Appendix C: Abdominal Respiratory

Sensor Placement

1. Connect the Abdominal Respiratory Sensor (A.R.S.) to the Infant Flow

Advance

2. Switch on the Infant Flow Advance (refer to Chapter 4, Operating Instructions).

Light compression of the respiratory sensor causes the LED on the transducer

interface to illuminate, indicating that the sensor and transducer interface are

functioning.

3. Site the A.R.S., taking the following into account:

• Ensure that the abdomen exhibits consistent outward movement during each

spontaneous inspiratory effort.

• Place the sensor in a position where no retractions are present. Avoid areas

just below the rib margin and in proximity to an active pericardium.

• Ensure that the patient does not lie on the A.R.S. Considering periodic body

position changes, a lateral abdominal site may be preferred for this reason.

4. Select a fixation tape that is suitable for the patient.

5. Place the A.R.S. in the center of the tape with the pressure line perpendicular

to the tape.

6. Place the A.R.S. between the umbilicus and the xiphisternum (refer to

Figure 5).

TM

transducer interface.

Figure 5 - A.R.S. Placement

7. Stretch the tape as you apply the A.R.S. to the patient, providing a taught

profile.

8. Verify correct A.R.S. placement by observing spontaneous breathing. The

onset of inspiration for each spontaneous breath (abdomen moving outward)

must be accompanied by the LED flashing.

777077-101 Revision B June 2004

Page 44

44 Infant Flow Advance™ System

777077-101 Revision B June 2004

Page 45

Operator’s Manual 45

Glossary of Terms

CPAP Continuous Positive Airway Pressure

Nasal CPAP Nasal Continuous Positive Airway Pressure.

PA Pressure Assist – extra flow is delivered causing an increase in pressure

through the generator. This is in addition to current CPAP

trPA Triggered Pressure Assist gives the same effect as PA but only when the

baby’s inspiratory effort is detected

CDP Continuous Distending Pressure

FRC Functional Residual Capacity

L/min Liters per minute

cmH2O Centimeters water pressure

PSI Pounds per Square Inch

Bar A pressure of one atmosphere

Ti Period of time that the additional pressure is available to the patient during

Pressure Assist modes

R Rate - number of times the additional pressure will be applied during the PA

Rb Back-Up Rate - number of times the additional pressure will be applied

during detected periods of apnea in trPA

bpm Breaths Per Minute – as detected by the Abdominal Respiratory Sensor

I:E The ratio between the length of time that the additional pressure is available

to the patient (Ti) and the length of time that the CPAP pressure is available

to the patient

777077-101 Revision B June 2004

Page 46

46 Infant Flow Advance™ System

777077-101 Revision B June 2004

Loading...

Loading...