Page 1

Emergency Pneumatics.

Operating Instructions

VETTER Ultra Flat Bags 8.0 bar

Article No. 9987023501 | © Vetter GmbH I 07/14 I Changes and errors excepted.

Page 2

Vetter Ultra Flat Bags 8.0 bar

Contents

1. Important preliminary remarks ....................................2

2. Description of the product ........................................2

2.1 Description of the set .......................................2

2.2 Additional accessories ......................................4

2.3 The Vetter safety coupling system ...........................5

2.4 Description of the product ..................................6

2.5 Correct handling and usage .................................7

2.6 Safety instructions ..........................................7

3. Preparing the product for use .....................................9

3.1 Preparations for operation ..................................9

3.2 Application instructions .....................................9

4. Operating Instructions ............................................9

4.1 Operation with compressed air bottles ......................9

4.2 Operation with other compressed air supplies. . . . . . . . . . . . . 10

4.3 Dismantling of the lifting bag system after use .............11

4.4 Limit for the period of use ................................. 11

4.5 Care, maintenance and storage. . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

5. Trouble-shooting for faults ......................................12

6. Repetitive tests .................................................12

7. Technical Data ..................................................13

8. List of possible dangers according to EN 12100-1 and EN 12100-2 14

EC Conformity Declaration (available on request) ...................15

Page 1/16

Page 3

1. Important preliminary remarks

Only knowledge and the exact observance of this operating manual guarantee correct and reliable operation, achieve the best

possible usage and ensure any claims made within the framework

of the Vetter guarantee.

Only sta are to use Vetter Ultra Flat Bags who have been instructed in their use by the manufacturer‘s operating manual and

operating instructions.

The disposal of discarded lifting bags is to be carried out according to disposal regulations valid for the region.

The operating instructions given here are to be regarded as part

of the product and are to be kept for the complete life duration of

the product. In case the product should be passed on to a successive user then the operating instructions must also be included.

2. Description of the product

2.1 Description of the set

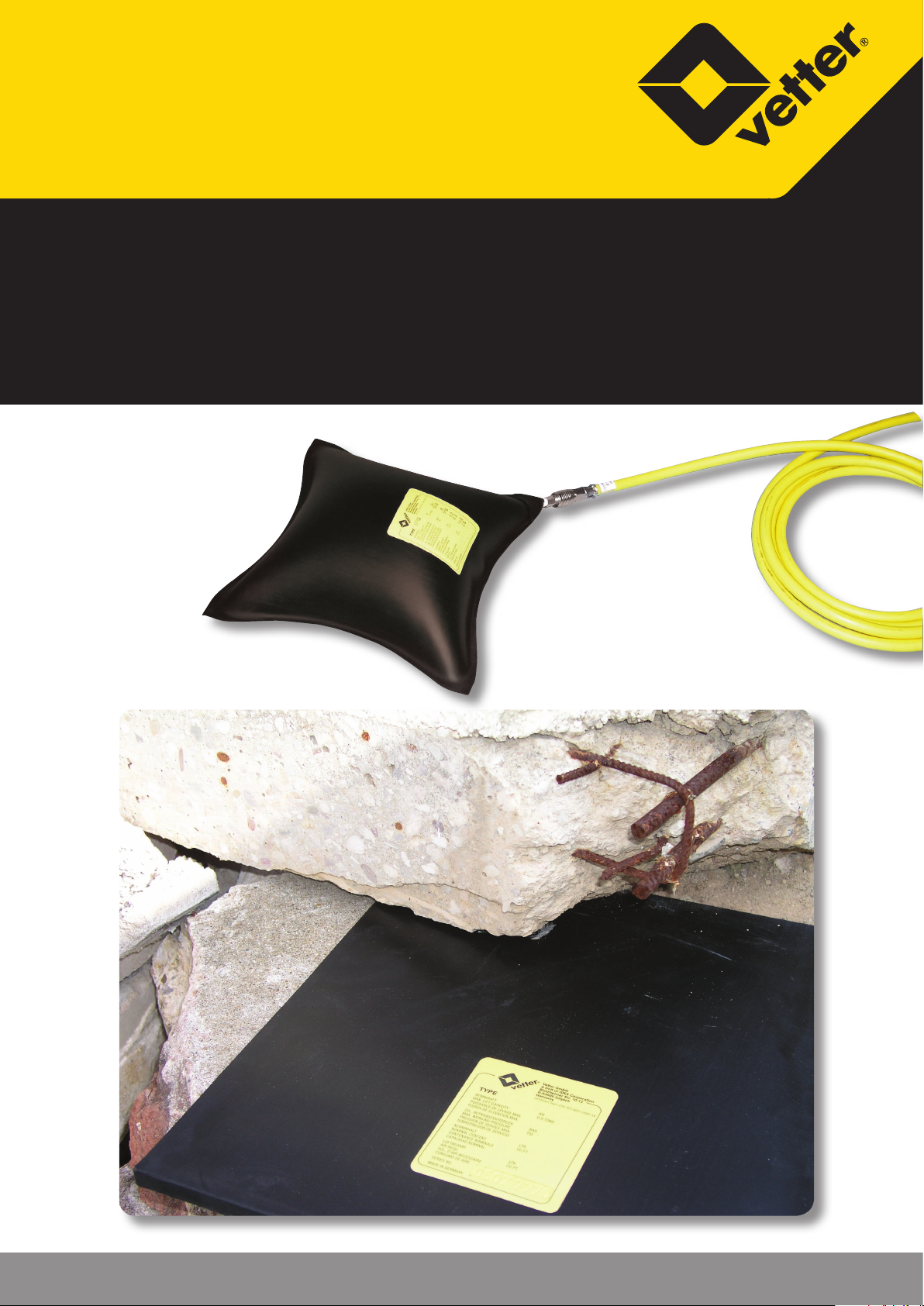

a. Ultra Flat Bags

Bag size selection is made according to the task. There are 4 dierent sizes from 1.1 t to 9.6 tons.

b. Ination hoses

There are ination hoses available (5 m and 10 m in length) which

enable the user to control the Ultra Flat Bags from a safe position.

The colours of the hoses, RED and YELLOW, avoid any confusion

during control of the dierent sides (inlets and outlets) of Ultra

Flat Bags.

c. Air CU (Control Unit) 8 bar deadman

Connect the ination hoses to the outlet coupling on the rear side

of the controller. Connect the air supply to the inlet coupling on

the side. Move the control lever to the front in order to inate the

Ultra Flat Bag. In doing this, observe the corresponding manometers and the load. Release the control lever, thus ending the ination process, when the required operating pressure for the lift

power or lift height is reached.

The control lever automatically returns to the center position

(zero) when released (deadman switched).

The built-in safety valve automatically activates when the bag is

over-inated above the maximum operating pressure of 8 bar or

when there is an unforeseen additional burden of the bag.

Page 2/16

Page 4

Vetter Ultra Flat Bags 8.0 bar

The activation tolerance for opening and closing of the

safety valve can be +/- 10 %.

Press the control lever in the opposite direction in order to deate

the bag or to reduce the load.

1

Dierent couplings!

Additional information for illuminated control element

Air CU 8 bar deadman lighting

The lighting of the control element illuminates all couplings,

switch levers and manometers. It is switched on and o with

switch (1) on the side.

The control element is supplied by a 9 V block battery. Since the

entire lifting bag system is designed for a temperature range of

-20 °C to +55 °C, only batteries with this temperature range are

allowed to be used. Based on the current state of the art, only lithium batteries meet this requirement.

To insert the battery, unscrew the battery compartment, replace

the old battery with a new one and screw the battery compartment back together.

Control elements with lighting come under the German Law on

electrical and electronic devices (ElektroG) of 24 March 2005 for

implementation of the EC Directive 2002/96/EC on electrical and

electronic waste – WEEE Directive.

The label attached to the battery compartment cover points

out that the electronic components in this product must not be

handled as domestic waste; they have to be returned to the manufacturer (return freight paid) for recycling.

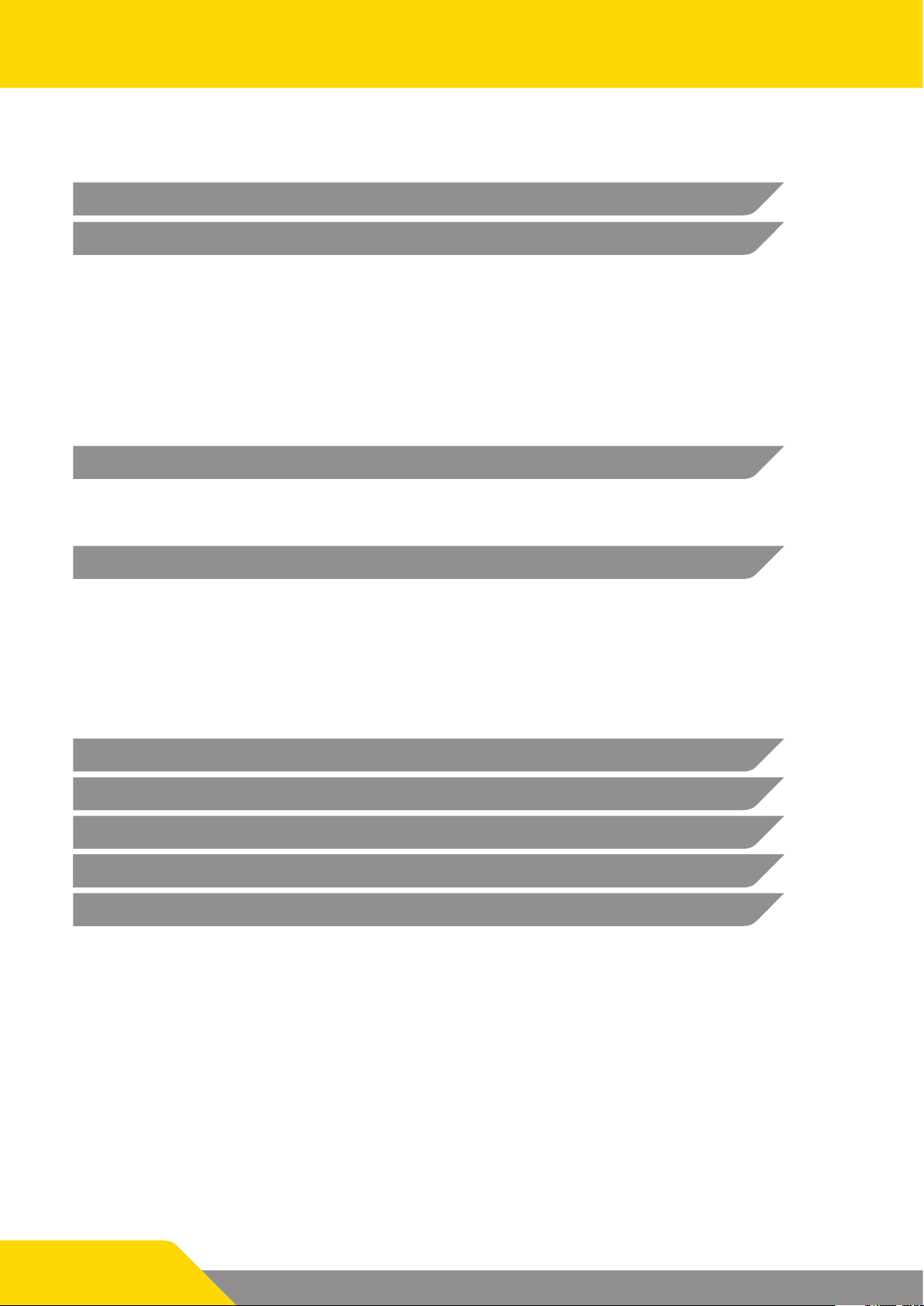

d. Dual deadman controller 8 bar, aluminium

Press down the upper button (1) in order to inate the bag. Ina-

1

2

tion is stopped when the button is released and it returns back to

the zero position. The bag is released by pressing the lower button (2).

e. Single deadman controller 8 bar, aluminium

The single deadman controller, on the left, can be used when only

one Ultra Flat Bag is to be used.

Page 3/16

Page 5

The single and dual controllers in the 8 bar tting version do

not correspond to the requirements of the Fire Service standard DIN EN 13 731.

f. Dual controller 8 bar, tting

Controller with ination regulator using a ball valve WITHOUT deadman

switching. To empty the bag, open the head of the safety valve (1) by

turning to the left. Close the safety valve by turning to the right after

deation.

g. Single controller 8 bar, tting

The same version as described in f) but used for the control of only one

Ultra Flat Bag.

Inventory of items

An inventory and check of all items in the delivery package is to be made

according to the delivery documentation when acceptance of the Ultra

Flat Bags equipment is carried out. A visual check and function check is

also to be made as specied in the operating manual.

1

1

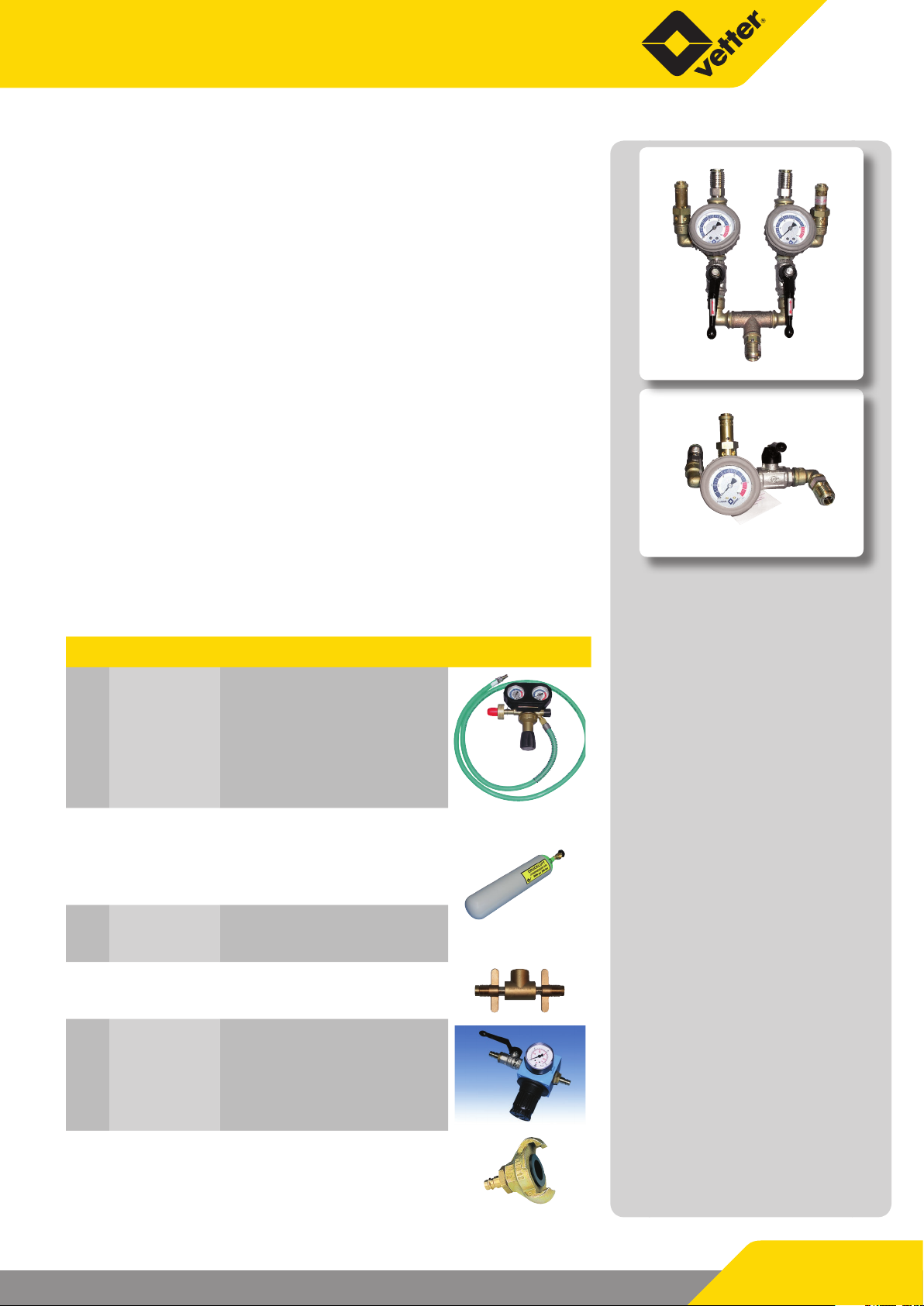

2.2 Additional accessories

Pos.

Article No. Description

Pressure regulator 200/300 bar

US Version 4500 psi

(not compatible with below

mentioned compressed air

bottles)

Comp. air bottle

Comp. air bottle 9 l / 300 bar

Dual connector

300 bar

1

or 1600 0262 00

2

3

4

1600 0261 00

1600 0108 00

1600 0199 00

1600 0091 00

6 l / 300 bar

5

6

1600 0145 00

1600 0120 00

Pressure regulator

Adapter for construction site

compressor

Page 4/16

Page 6

Vetter Ultra Flat Bags 8.0 bar

Pos.

Article No. Description

7

8

3

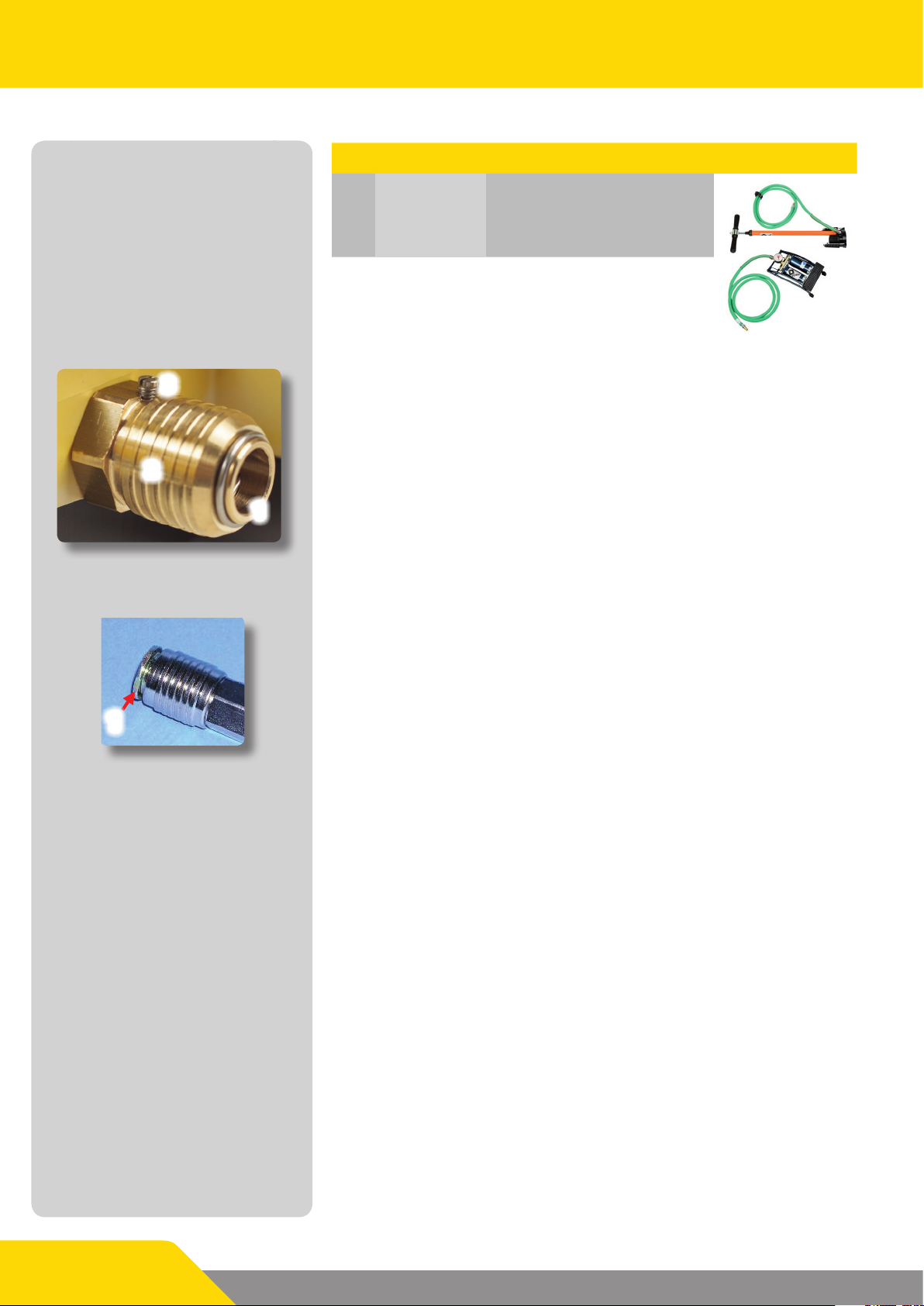

2.3 The Vetter safety coupling system

1600 0087 00 Hand pump (7)

1600 0094 00 Foot pump (8)

7

8

a. Inlet coupling controller

Connect the air supply hose, resp. connection hose of the pressure re-

2

1

ducer, to the plug nipple of the inlet coupling on the controller. In doing

this, rmly press the nipple into the coupling until it latches in. Turn the

brass sleeve of the coupling opposite to the safety pin for additional safety.

b. 8 bar ination coupling

Firmly press the hose, resp. bag nipple, into the coupling until it latches

in order to connect the ination hose with the corresponding controller,

resp. with the Ultra Flat Bag. The coupling sleeve must lay on the support

ring without any gap (1). The nipple must be rmly pressed against the

spring pressure in the coupling in order to release the connection (only

1

in pressure-free condition). At the same time, the coupling sleeve must

be pulled back. The connection is then released.

Page 5/16

Page 7

2.4 Description of the product

Vetter Ultra Flat Bags are made by hand from high quality raw materials so that after completion, a seamless bag is produced. The

semi-nished product is vulcanized under the inuence of pressure and temperature and by doing this the individual layers bond

to form an elastomer body. After production has been nalized,

each Ultra Flat Bag is subjected to a plant acceptance test within

the scope of quality assurance.

Material of the Ultra Flat Bags: CR/Aramide, hot vulcanized

Temperature resistance of Ultra Flat Bags:

Cold resistance -40 °C

Cold exible -20 °C

Heat resistance long-term +90 °C

Heat resistance short-term +115 °C

The aramide layer on the Ultra Flat Bag can

be damaged by damage made to the bag

surface, e.g. cuts, cracks, punctures or by

the eects of ozone.

Therefore with a visual check after every operation, special attention is to be made to the following types of damage:

9 Damage by separation

9 Damage by cuts

9 Damage by punctures

9 Damage by heat and chemicals

Danger of bursting! If, when carrying out the

check, this type of damage is determined

then the bag is to be immediately taken

out of service. Repair is not possible.

In order to use the maximum lifting power, the total eective area,

i.e. the total area minus the edge area, must be completely under

the load to be lifted and that the bag must be taken to the maximum permitted operating pressure.

The bag develops a spherical shape (with rectangular or square

base) as the lift height increases. This is the reason why the contact area with the load decreases until at a max. bag curvature this

will be almost zero. The largest lift height of the Ultra Flat Bag will

only be reached in the unloaded state.

Page 6/16

Page 8

Vetter Ultra Flat Bags 8.0 bar

In case the lifting power produced by the Ultra Flat Bag is not sufcient, depending on the lift height, then a number of Ultra Flat

Bags can be placed next to each other.

In case the lifting height of an Ultra Flat Bag is not sucient then a

maximum of 2 bags can be placed over each other. In this mode,

the lifting height is additive for both Ultra Flat Bags.

However the lifting power only corresponds to that of the smaller

bag. Basically, the lower bag should always be inated rst.

Sequence: large bag below,

small bag on top!

Never place 3 or more bags over each other!

An Ultra Flat Bag under load can be compared to a spring under

tension with respect to its behavour. As soon as the Ultra Flat Bag

is suddenly released, e.g. by slipping, load break or anything similar then there will be spontaneous catapulting outwards of the

Ultra Flat Bag.

Never stand in front of the Ultra Flat Bag!

This is an area of danger!

2.5 Correct handling and usage

The Ultra Flat Bag is primarily a pneumatic rescue device used by

the rescue services (e.g. re services) with which trapped people

can be freed, access gained for rescue and many other tasks. The

Ultra Flat Bag can also be used as a working device in order to lift

or move loads.

Ultra Flat Bags are subject to national requirements of the re

service sector. Further instruction information can be obtained

from the operating instructions of the user. The complete Ultra

Flat Bags system is cold-resistant to -20 °C and heat-resistant up

to +55 °C.

Page 7/16

2.6 Safety instructions

Pre-specied personal protective clothing is to be worn during

operation! For example: protective clothing, helmet, protective

gloves, protection for eyes and face, noise protection etc.

The national regulations in connection with lifting bag systems

and their use are to be observed. For example: DIN EN 13731,

national regulations. The Ultra Flat Bags are only to be used with

compressed air, under no circumstances are they to be used with

inammable gases or aggressively acting gases.

Page 9

Vetter Ultra Flat Bags are only to be inated with original Vetter

ination ttings because these were subjected to an acceptance

test by the manufacturer. The lifting bag system is to be tested

for perfect condition before and after use (specications from the

manufacturer, national regulations).

The lifted load is to be continually supported during the progessive lifting sequence. The stable condition of foundation support

material must always be observed during construction of the

foundation support.

Never position 3 or more bags on top of each

other!

Ensure load against slippage.

In order to fully use the strengths of the Ultra Flat Bag, the distance between load and bag should be at a minimum.

The foundation support must brace at

least the complete area of the bag and the

smallest edge length of the foundation

support must be larger than the height of

the foundation support. Metal must

never be place on metal!

Attention: danger of slipping!

With slippery ground (ice, snow, mud etc.) place anti-slip materials

under the bag in order to increase adhesion. Point-shaped loads

are to be avoided, e.g. construction claws or screws. Never place

the bags on sharp edges, hot or red hot components. Use suitable

temporary storages and cover the complete contact area of the

bag. Protect the bag against ying sparks during welding or separation work. Do not additionally load bags with such things as

hydraulic lifting devices, winches or falling loads.

Never remain beneath a lifted load, never hold

the load from below!

Remain at a distance!

Avoid shearing eects by squeezing of the bag when lowering the

load!

During operation never stand in front of

the bag but always to one side, because the

bag could catapult outwards under

unfavourable conditions!

The lifting sequence is to be stopped

immediately if there is a function failure!

A Ultra Flat Bag can burst under adverse conditions with incorrect

operation, incorrect handling or by manipulation on the controller and/or ination hose (problems concerning pressure waves

and sound waves, uncontrolled movement)!

Page 8/16

Page 10

Vetter Ultra Flat Bags 8.0 bar

Vetter Ultra Flat Bags are not suited for use

in explosion endangered zones!

Special versions are possible on request!

3. Preparing the product for use

3.1 Preparations for operation

Remove Ultra Flat Bags from the vehicle. Prepare the ination device. Ensure sucient air supply.

Only perfectly operating and inspected

Ultra Flat Bags are to be used.

The method and type of application is to be decided from case to

case by the operation leader with his own area of responsibility as

well as the operating instructions of the user.

3.2 Application instructions

Move the lifting bag to a suitable position so that at least 75% of

the supporting bag area is under the load. Continually built up the

under-support for maintaining contact when the load is lifted during the lifting procedure. Never stand in front of the bag during

operation but to the side of the Ultra Flat Bag because it could be

catapulted outwards under unfavourable conditions.

4. Operating Instructions

4.1 Operation with compressed air bottles

4

3

1

6

2

5

Connect the pressure reducer to the compressed air bottle

200 bar or 300 bar using the tommy screw (1). Close the hand

wheel of the pressure reducer (2). Open the valve on the

bottle (3). The pre-pressure manometer (4) indicates the pressure

in the bottle.

Adjust the back pressure to approximately 10 bar with the regulation bar (5) (indication of the reduced pressure on the back pressure manometer (6)).

Page 9/16

9

8

7

Connect the air hose of the pressure reducer via the nipple to the

input coupling (7) of the controller. In doing this, press the nipple

into the coupling until you feel it lock in. For additional safety: turn

the brass sleeve (8) so that it is opposite the safety pin (9).

Open the hand wheel (2) of the pressure reducer.

The lifting bag system is ready for operation.

Page 11

4.2 Operation with other compressed air

supplies

Basically, any air supply which is available can be used for operation of Ultra Flat Bags as long as the pressure does not exceed 10

bar and the air is free of oil. Amongst others, the set of transition pieces (Art. No.: 1600 0125 01) with the following adapters are

available for operation with other air sources:

8 9

3

456

2 1

1. Truck compressed air connection, dual brake system.

For tapping air out of the trailer coupling head.

2. Dummy coupling

Seals o the control line of the brake system

7

10

Remember! Ensure that the truck does not roll, use brake

blocks!

3. Truck tyre ination device adapter

For tapping o air from the so-called tyre ination bottle near

the brake.

Remember! The tyre ination connection must be ensured by a safety valve as a standard (blow-o pressure approximately 7.5 bar)!

4. Truck tyre valve

Ination with a normal hand or foot pump as well as other air

supplies for tyre ination.

5. Truck tyre valve connection, can be clamped

For extracting air for the spare tyre.

6. Adapter for the local air pressure network.

7. Adapter Construction-site compressor

8. Air supply hose, 10 m, green.

9. Air supply hose, 10 m, green, with blocking valve.

10. Case, red

Page 10/16

Page 12

Vetter Ultra Flat Bags 8.0 bar

4.3 Dismantling of the lifting bag system

after use

Dismantling of the lifting bag system is carried out after ensuring

the lifted load and complete deation of the lifting bag system,

including dismantling of all accessory parts in the reverse order.

4.4 Limit for the period of use

Ultra Flat Bags are subject, the same as other rubber products, to

natural aging. The rst sign of material aging is the loss of exibility, this is especially seen in the formation of „age cracks“. If these cracks propagate so far along the upper layer so that the supporting cord layer (ARAMIDE) is no longer fully insulated then this

can quickly limit the tear resistance of the bag wall. This can cause

wall tearing and thus lead of bursting. The experiences over the

past decade have clearly shown that the failure rate in general for

rubber products considerably increases with application periods

exceeding 15 years. Therefore Ultra Flat Bags should be replaced

after 15 to 18 years of use at the latest. The danger for operational

services using over-aged Ultra Flat Bags must never be under-estimated, alone due to the consideration aspect. Although at present there is no regulation about the time limit for the maximum

period of use, the responsibility for this lies wholy and soly with

the user, resp. the person who has been commissioned by him to

carry out testing.

4.5 Care, maintenance and storage

The lifting bag equipment is to be cleaned after each operation.

Cleaning is normally carried out with warm water and a detergent.

Cleaning must never be carried out with

a chemical cleaning agent and never

with high-pressure hot water devices.

Drying is made at normal room temperature. A bag is to be immediately discarded if, during inspection, any sign of damage is established (refer to Page 6). Repair is not possible. If needed, components such as manometers, safety valves and piston valves can be

exchanged. Hose couplings and nipples can also be exchanged.

After necessary repair, the equipment is to be checked according

to the repetitive tests. This special test is also to be documented.

DIN 7716 is to be observed for long-term storage.

The VETTER guarantee is 36 months for Mini-Lifting Bags.

Page 11/16

Page 13

5. Trouble-shooting for faults

If the safety valve blows too early because of foreign body penetration caught up inside then the blow-o valve is to be fully

opened on the head of safety valve by turning counter-clockwise

so that the compressed air can escape. If, due to this, the foreign

body is not removed then the upper part of the safety valve is to

be unscrewed when the safety valve is disassembled. To do this,

position the pipe wrench in the centre and unscrew by turning to

the left.

Carefully take out the valve ball and remove foreign body. Firmly

screw on the upper part of the valve again, assemble the safety

valve and check operation. The set pressure must not be changed.

Should the sealing or sealing plate on

the upper part of the valve be removed

then correct operation can no longer

be guaranteed.

The safety valve is to be exchanged.

6. Repetitive tests

Lifting bag systems are to be subjected to repetitive tests according to DIN EN 13731 and national regulations (e.g. GUV-G 9102).

9 Testing on acceptance

Testing for completeness by the person/people delegated by

the user.

Visual check and operation test by a trained person according to the operation manual.

9 Visual check and operation test after each application/use by

the user.

This test is to be documented.

9 At least once every year the lifting bag system is to be given a

visual check and operation test by a trained person according

DIN EN 13731 and national regulations.

This test is to be documented.

9 At least every 5 years or if there is any doubt about the safety

or reliability, the lifting bag system is to be given a pressure

test by the manufacturer or a trained person with further training of the manufacturer, according to DIN EN 13731 and national regulations.

The user is responsible for the correct and professional execution

of the repetitive tests!

Page 12/16

Page 14

Vetter Ultra Flat Bags 8.0 bar

7. Technical Data

Ultra Flat Bags with ARAMIDE reinforcement

Type UF 1 UF 3 UF 6 UF 10

Item No. 1314018800 1314018700 1314018600 1314020700

Lift power,max to 1.0 3.29 6.36 9.60

Lift height, max cm 7,5 12.0 16.5 20.3

Size cm 14 x 13 25.5 x 20.0 29.5 x 29.5 36 x 36

Insertion height cm 1.2 1.2 1.2 1.2

Nom. content l 0.30 1.8 4.2 8.3

Air capacity l 2.8 15.9 37.8 74.2

Operating

pressure max.

Test pressure bar 12 12 12 12

bar 8 8 8 8

Weight kg 0.26 0.74 1.3 1.7

All rights reserved for technical changes within the scope of product improvement.

Ultra Flat Bag UF 1 Ultra Flat Bag UF 6

Page 13/16

Ultra Flat Bag UF 3 Ultra Flat Bag UF 10

Page 15

8. List of possible dangers according to

EN 12100-1 and EN 12100-2

Danger see Page

A.1 Mechanical dangers

1.1 Danger by squeezing 3 / 4 / 8 / 9

1.7 Danger by puncturing 4 / 6

1.9 Danger by catapulting out 3 / 4 / 8 / 9

A.2 Danger due to noise

2.1 Injury to hearing 3

2.2 Impairment of speech 3

A.3 Material danger

3.1 Explosion 3

A.4 Danger due to negligence of ergonomic principles

4.1 Positions which impair health 4

4.2 Negligent use of personal protection devices 3

4.3 Mental over and under demands, stress etc. 3

4.4 Human error 3

4.5 Unfavourable arrangement of visual indications 5

A.5 Unintended movements

5.1 Faults/erroneous functions of the control elements 9

A.6 Mechanical failure

6.1 Failure of energy supplies 9 / 12

6.2 Failure of the control device 9 / 12

6.3 Loss of stability 3 / 8

A.7 Additional dangers

7.3 due to the control device 8 / 9

7.5 Movements 8 / 9

7.8 Negligent use 8 / 9

7.9 Movement of parts from the stationary position 8 / 9

7.10 Missing or insucient visual or acoustic warning devices 11 / 12

7.11 Insucient instructions for the user 3

7.12 Falling loads 11

7.13 Missing stability 8 / 9

7.14 Uncontrolled sudden movements 8 / 9

7.15 Uncontrolled/unintended load movement 8 / 9

7.16 Insucient holding devices 3 / 8

7.17 Insucient solidity of parts 3 / 7

7.18 Exceptional conditions during assembly, testing, use, maintenance

7.19 The eects of loads on persons 3

7.20 Dangers due to negligence of ergonomic principles (load

bumping)

7.21 Fire and explosion 3

7.22 Control failure 3

3 / 9

11

Page 14/16

Page 16

Vetter Ultra Flat Bags 8.0 bar

EC Conformity Declaration (available on request)

in accordance with Directive 2006/42/EC

Manufacturer name and address

Vetter GmbH

A Unit of IDEX Corporation

Blatzheimer Str. 10 - 12

53909 Zülpich

We hereby declare that the Ultra Flat Bags for lifting and lowering loads

Type: ______________

Serial-No.: ______________

Model: ______________

(refer to equipment label, to be entered by the customer)

meets the following relevant provisions:

Directive 2006/42/EC on Machinery

Applied harmonised standards, references to which have been published in the

Ocial Journal of the European Union:

DIN EN ISO 12100

EN 13731

Applied national standards and technical specications:

Authorised representative for the compilation of technical documents:

Vetter GmbH

A Unit of IDEX Corporation

Blatzheimer Str. 10 - 12

53909 Zülpich

This EC Conformity Declaration was issued:

Zülpich, 23.07.2014

(Place, Date, Signature)

Page 15/16

Page 17

Place your trust in emergency pneumatics!

We are the company who can help you, nd a solution to your problem!

Vetter GmbH

A Unit of IDEX Corporation

Sales Germany

Blatzheimer Str. 10 - 12

D-53909 Zülpich

Germany

www.vetter.de

Tel.: +49 (0) 22 52 / 30 08-0

Fax: +49 (0) 22 52 / 30 08-590

Mail: vetter.rescue@idexcorp.com

Article No. 9987023501 | © Vetter GmbH I 07/14 I Changes and errors excepted. I Made in Germany

Loading...

Loading...