Vetter SP 16 User Manual

Emergency Pneumatics.

Operating Instructions

VETTER Safety cushion SP 16

|

|

|

|

|

|

Manufacturing No. |

|

Year of manufacture: |

|

|

|

|

|

|

|||

|

|

|

|

|

|

Article No. 9987003503 | © Vetter GmbH I 02/12 I Changes and errors excepted.

VETTER Safety cushion SP 16

Contents

1. |

Preliminary remarks. . . . . . . . . . |

. |

. |

. |

. . |

. |

. |

. |

|

|

2 |

|

2. |

Completeness check. . . . . . . . . . |

. |

. |

. |

. . |

. |

. |

. |

|

|

3 |

|

3. |

Description. . . . . . . . . . . . . . |

. |

. |

. |

. |

|

|

|

|

|

4 |

|

|

3.1 |

Technical description. . . . . . |

. |

. |

. |

. . |

. |

. |

. |

. |

. |

. . 4 |

|

3.2 |

Technical data. . . . . . . . . . |

. |

. |

. |

. . |

. |

. |

. |

|

|

5 |

4. |

Using the Vetter safety cushion. . . . . |

. |

. |

. |

. . |

. |

. |

. |

. |

. |

. . . 5 |

|

|

4.1 |

Selecting the site. . . . . . . . |

. |

. |

. |

. . |

. |

. |

. |

. |

. |

5 |

4.2Preparing the safety cushion for use. . . . . . . . . . . . . 6

4.3 After the use. . . . . . . . . . . . . . . . . . 6

4.4Inspection and cleaning after use . . . . . . . . . . . . . . 7

4.5 Storage and maintenance. . . . . . . . . . . . . . . . . . 7

5. |

Tests and inspections . . . . . . . . . . . . |

. |

. |

. |

. |

. |

. |

8 |

|

|

5.1 |

Test periods . . . . . . . . . . . . . |

. |

. |

. |

. |

. |

|

8 |

|

5.2 |

Test instructions and certificates . . . |

. |

. |

. |

. |

. |

. . . . . |

. .9 |

6. |

Packing instructions . . . . . . . . . . . . |

. |

. |

. |

. |

. |

. |

9 |

|

Test regulation for annual inspection. . . . . . |

. |

. |

. |

. |

. |

. . . . . |

11 |

||

Test regulation for main safety check . . . . . . |

. |

. |

. |

. |

. |

. . . . . |

13 |

||

Test regulation for general safety check. . . . . |

. |

. |

. |

. |

. |

. . . . . |

13 |

||

Test certificate for safety cushions. . . . . . . |

. |

. |

. |

. |

. |

. . . . . |

. 14 |

||

Page 1/15

VETTER safety cushions must only be used for the rescue of jumping or falling persons.

The falling height must not exceed 16 m

No jumps for exercising or demonstration purposes.

Important note!

The Safety Cushion must not be inflated with a pressure container having a valve fitted with an integrated excess flow valve (EFV).

1.Preliminary remarks

A prerequisite for the safe use of the VETTER safety cushions is that these operating instructions and the safety instructions are strictly observed after they have been carefully read.

Only duly authorized and trained personnel of the fire department must be commissioned with the use of the safety cushion.

The safety cushion must only be used in case of an emergency for the rescue of jumping or falling persons.

Jumps for training or demonstration purposes are strictly forbidden!

Only specifically designed falling objects, such as sand bags or dummies, must be used for training or test purposes.

Any non-compliance with this instruction is a violation of the preventive measures of the fire departments and will result in the exclusion of any liability. Please note that any non-compliance may have legal consequences.

The improper application of or any unauthorized modification to the safety cushion will exclude the liability of the manufacturer for any resultant damage.

Only perfect and tested safety cushions must be used.

Please make sure that only the original Vetter fittings and valves are used for filling the safety cushion.

Page 2/15

VETTER Safety cushion SP 16

2.Completeness check

The completeness and integrity of the components must be checked before and after every use.

Safety cushion completely erected

Filling adapter

Compressed-air cylinder 6 l/300 bar

Quick-action ventilating valve, item 1

with air vent key, item 2

1

2

Safety valve

Page 3/15

3.Description

The VETTER safety cushion consists of a self-erecting hose-equip- ped load-bearing frame. The supporting structure consists of an extremely tear-proof and neoprene-coated fabric. The material used for the external tarpaulins is hardly flammable and does not disintegrate.

The load-bearing frame will be inflated with air with a maximum pressure of 0,3 bar when the valve at the compressed-air cylinder is opened. The safety valve integrated in the cylinder fittings will prevent over-inflation and an inadmissible pressure increase due to temperature influences.

The safety cushion will be inflated within 30 sec and erect itself automatically.

It can only be used after it is fully inflated and erected.

When a load hits the safety cushion, the internal supports will collapse.

After the load has been removed, the load-bearing frame will automatically re-erect itself and restore its original shape.

It may be possible after several load changes that minute quantities of air can leak through the safety valve. This can be easily compensated by briefly opening the air valve of the compressedair cylinder.

Attention!The position of the safety cushion may change as a result of the previous jump. It will then have to be re- aligned/re-arranged.

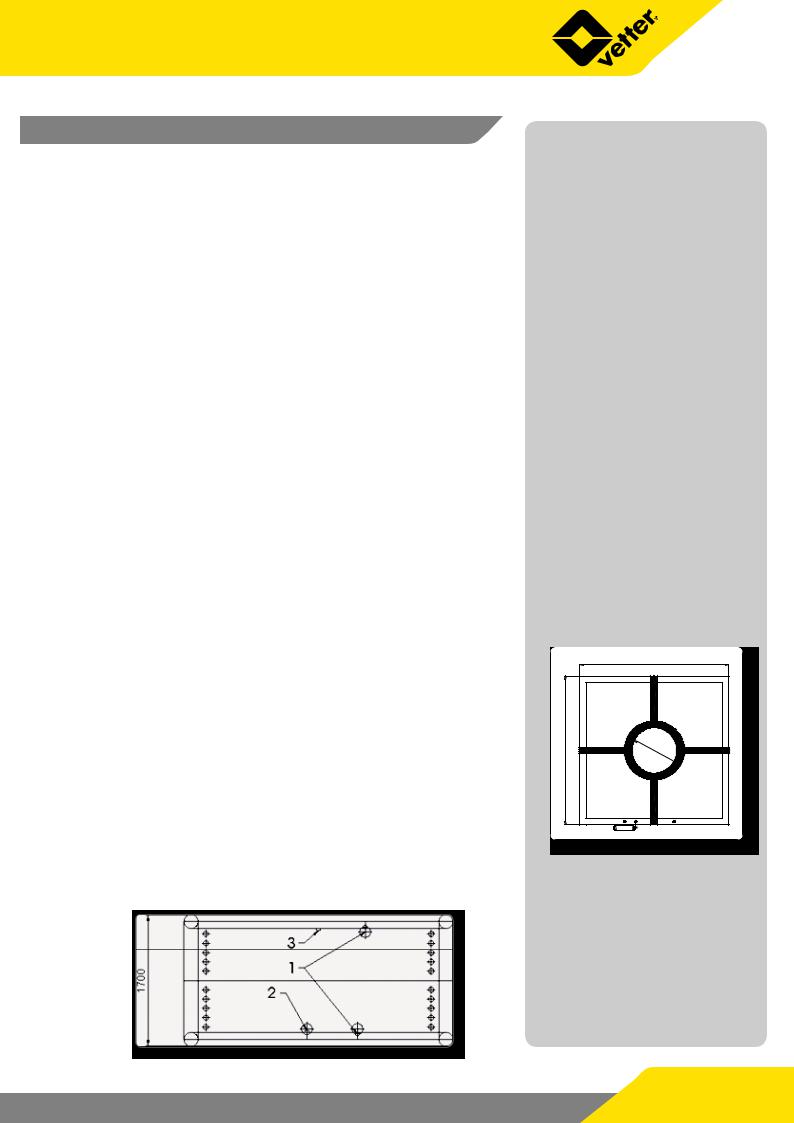

3.1 Technical description

Top view at the entire appliance

External dimensions, approx. |

mm |

3,500 x 3,500 |

Height, approx. |

mm |

1,700 |

Side view of the entire appliance

1Vent valves

2Filling adapter

3Safety valve

|

3500 |

|

|

3500 |

Ø1 |

|

|

30 |

|

||

|

0 |

||

|

|

|

mm |

Page 4/15

Loading...

Loading...