Vetter S.Tec Lifting bags 10 bar User Manual

Emergency Pneumatics.

Operating Instructions

VETTER S.Tec Bags 10 bar

Article No. 9987026702 | © Vetter GmbH I 07/14 I Changes and errors excepted.

Vetter S.Tec Bags 10 bar

Contents

1. Important preliminary remarks ....................................2

2. Product description ...............................................2

2.1 Description of the set .......................................2

2.2 Other accessories ...........................................4

2.3 Vetter safety coupling system ...............................5

2.4 Product description .........................................5

2.5 Correct usage ...............................................7

2.6 Safety instructions ..........................................7

3. Preparing the product for use .....................................9

3.1 Preparations for operation ..................................9

3.2 Application instructions .....................................9

4. Operating instructions ............................................9

4.1 Operation with compressed bottles .........................9

4.2 Operation with other sources of compressed air ........... 10

4.3 Dismantling of the lifting bag system after use .............11

4.4 Limit for the period of use ................................. 11

4.5 Care, maintenance and storage. . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

5. Elimination of defects ........................................... 12

6. Repetitive tests .................................................12

7. Technical data ..................................................13

8. Diagram: Force vs. Stroke V 1 - V 85 S.Tec ......................... 15

9. Safety of machines - DIN EN ISO 12100-1 and 12100-2 ............16

EC Conformity Declaration (available on request) ...................17

Page 1/18

1. Important preliminary remarks

Only the knowledge and exact observance of these operating instructions guarantees correct and professional operation, produces the greatest possible use and ensures any claims made within

the scope of the Vetter guarantee.

The handling of the Vetter S.Tec Bag is only to be made by trained

persons using the operating instructions of the manufacturer and

the information from the user. The disposal of discarded lifting

bags is to be carried out according to disposal regulations valid

for the region.

The operating instructions given here are to be regarded as part

of the product and are to be kept for the complete life duration of

the product. In case the product should be passed on to a successive user then the operating instructions must also be included.

2. Product description

2.1 Description of the set

a. S.Tec Bag 10 bar

The selection of bag size must correspond to operation requirements. There are 15 sizes available from 1.1 t to 84.6 t.

b. Ination hoses

In order to inate S.Tec Bags from a safe position for the operator,

there are ination hoses available with lengths of 5 m and 10 m.

The hose colours in RED and YELLOW are used exclusively to assist

the operator in recognizing the correct side when controlling the

S.Tec Bag.

c. Air CU (Control Unit) 10 bar deadman

Connect the ination hoses on the output couplings on the rear

side of the controller. Connect the air suppply to the input coupling on the side. Move the switching lever to the front in order

to inate the S.Tec Bag. In doing this, observe the corresponding

manometer and the load.

When the required operating pressure for the lifting power or lift

height is reached, terminate the ination sequence by releasing

the lever. The switching lever automatically returns back to the

zero position (dead-man switching). The integrated safety valve

activates automatically as soon as the maximum operating pressure of 10 bar is exceeded when inating or when there is a sudden increase in bag pressure caused by an unintended loading of

the bag.

The activation tolerance for opening and closing of the

safety valve must only be a maximum of +/- 10%.

Press the switching lever in the opposite direction in order to deate the bag or to lower the load.

Page 2/18

Vetter S.Tec Bags 10 bar

1

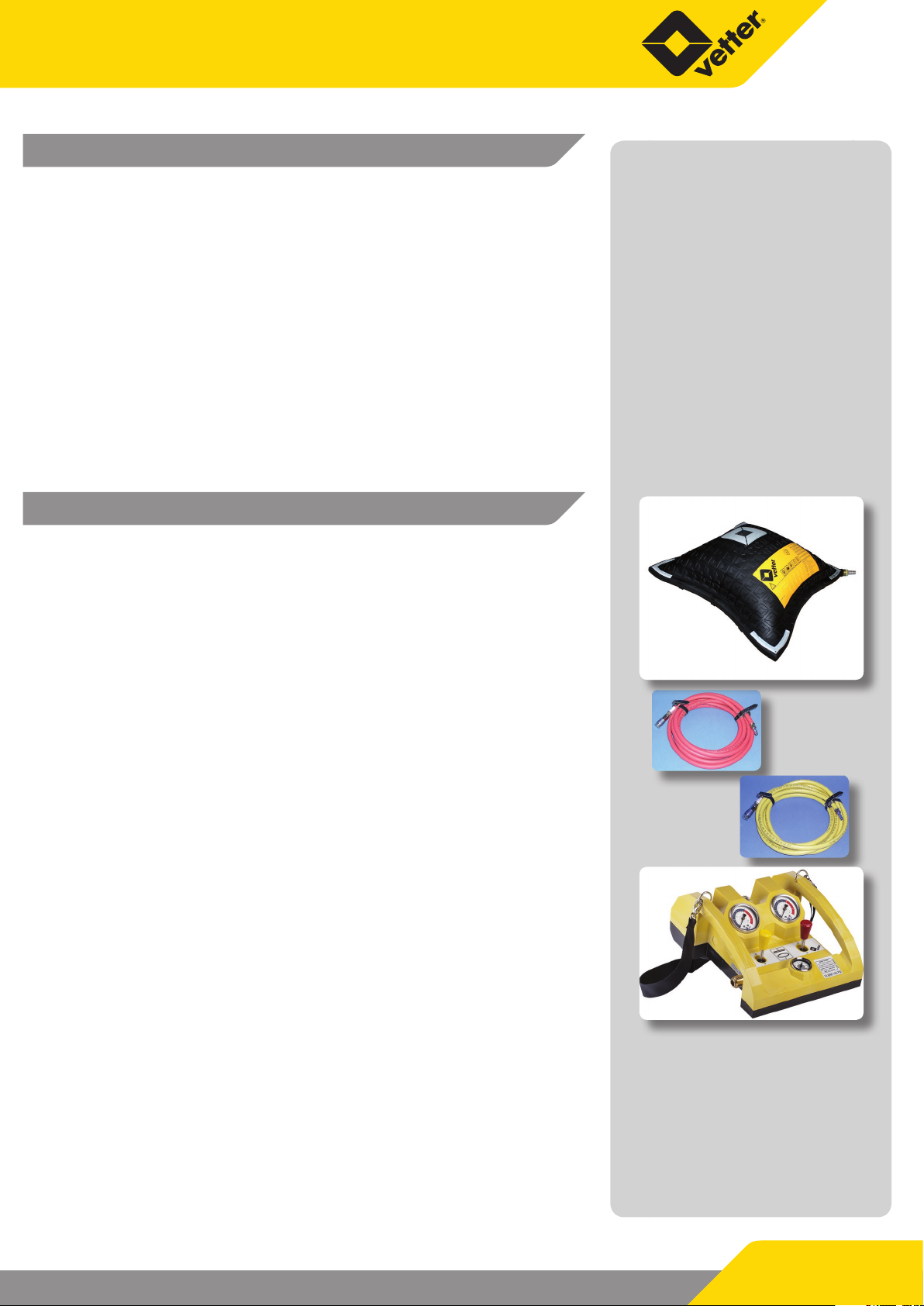

Additional information for illuminated control element

Air CU 10 bar Totmann lighting

The lighting of the control element illuminates all couplings,

switch levers and manometers. It is switched on and o with

switch (1) on the side.

The control element is supplied by a 9 V block battery. Since the

entire lifting bag system is designed for a temperature range of

-20 °C to +55 °C, only batteries with this temperature range are

allowed to be used. Based on the current state of the art, only lithium batteries meet this requirement.

To insert the battery, unscrew the battery compartment, replace

the old battery with a new one and screw the battery compartment back together.

Control elements with lighting come under the German Law on

electrical and electronic devices (ElektroG) of 24 March 2005 for

implementation of the EC Directive 2002/96/EC on electrical and

electronic waste – WEEE Directive.

Dierent couplings!

1

2

The label attached to the battery compartment cover points

out that the electronic components in this product must not be

handled as domestic waste; they have to be returned to the manufacturer (return freight paid) for recycling.

d. Dual controller 10 bar with dead-man switching,

aluminium

Press the lower button (1) in order to inate the bag. After release,

the press-button returns again to the zero position and interrupts

the ination sequence. Press the upper button (2) in order to deate.

e. Single controller 10 bar with dead-man switching,

aluminium

If only one S.Tec Bag is used for operation then this can be controlled with a single controller.

Page 3/18

Inventory check

On acceptance of the S.Tec Bag equipment a check is to be made

to see if the delivery is complete according to the delivery note.

In addition to this a visual check and function test is to be made

according to the operating instructions.

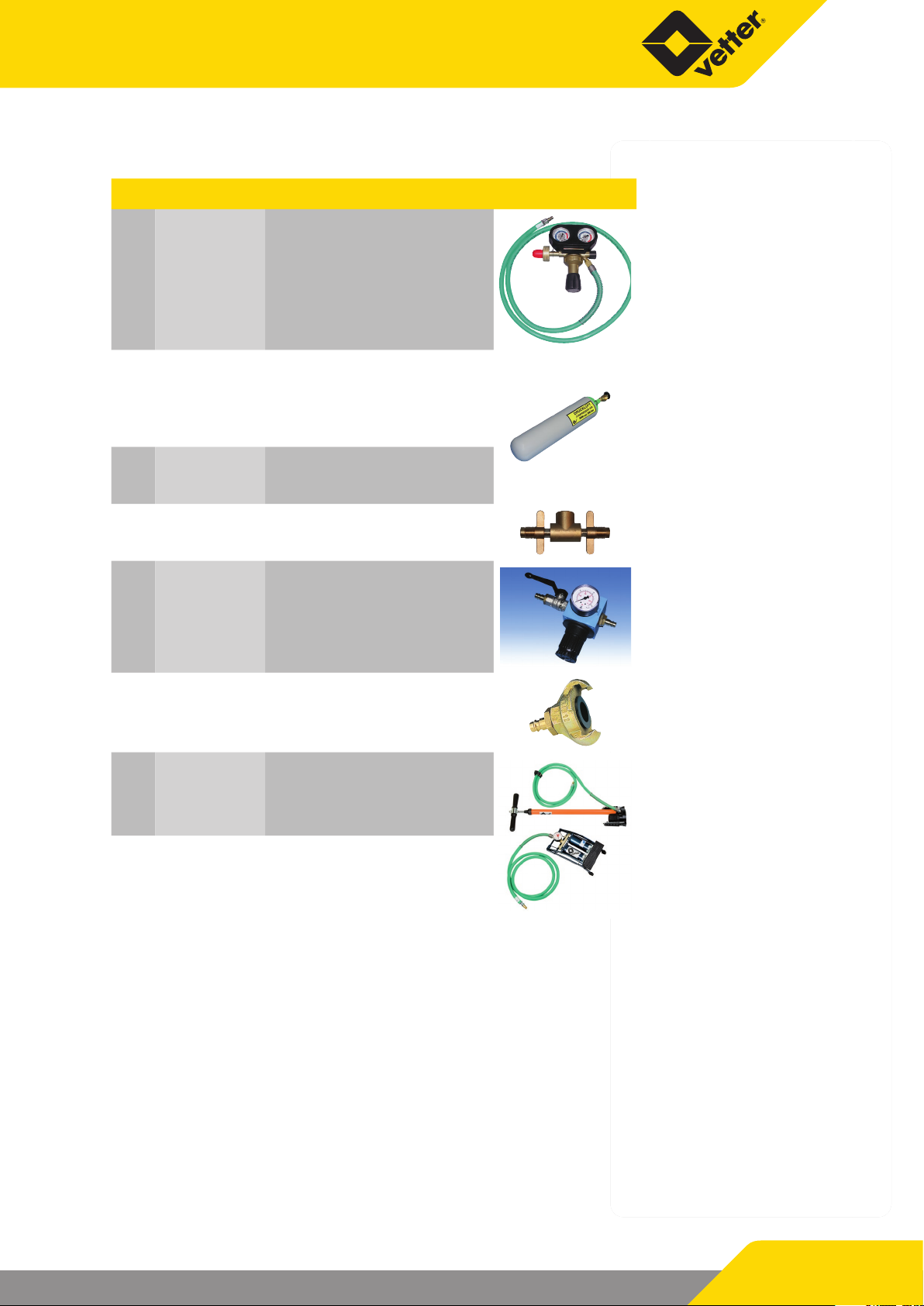

2.2 Other accessories

Pos. Article No. Description

1

or 1600 0262 00

2

3

4

5

1600 0261 00

1600 0108 00

1600 0199 00

1600 0091 00

1600 0145 00

Pressure regulator 200/300 bar

US Version 4500 psi

(not compatible with below

mentioned compressed air

bottles)

Comp. air bottle

6 l / 300 bar

Comp. air bottle 9 l / 300 bar

Dual connector

300 bar

Pressure regulator

6

7

8

1600 0120 00

1600 0087 00 Hand pump (7)

1600 0094 00 Foot pump (8)

Adapter for construction site

compressor

7

8

Page 4/18

Vetter S.Tec Bags 10 bar

3

2

1

1

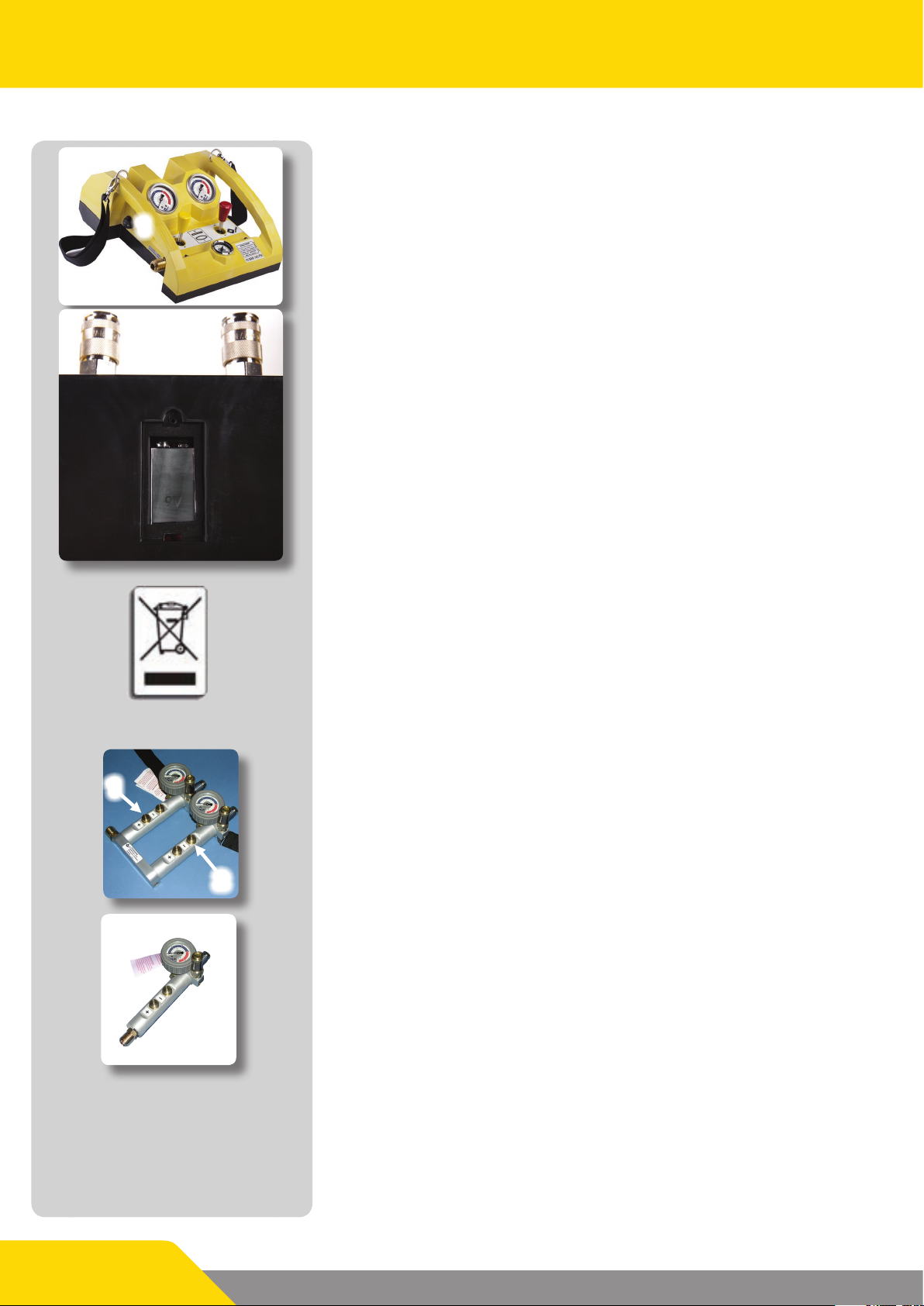

2.3 Vetter safety coupling system

a. Input coupling of the controller

Connect the air supply hose or the connection hose of the pressure regulator to the nipple of the input coupling (1) on the controller pushing the nipple solidly into the coupling until the ratchet

action can be felt. In order to ensure that it is correctly connected:

turn the brass sleeve (2) of the coupling opposite to the safety

pin (3).

b. Ination hoses

To connect the ination hoses to the corresponding controller or

to the S.Tec Bag, press the hoses or bag nipple solidly into the coupling until the ratchet action can be felt. The coupling sleeve must

be seated on the support ring without any gap (1). To release the

connection (only in the pressure-free condition) the nipple must

be solidly pressed against the spring pressure in the coupling. At

the same time the coupling sleeve must be pushed back. The coupling then releases.

c. Ination with an 8 bar ination device

The S.Tec safety coupling system cannot be used for ination with

other ination devices. However, should it be necessary, in exceptional cases, to inate with the Vetter 8 bar system then the

10 bar / 8 bar adapter must be used.

2.4 Product description

Vetter S.Tec Bags are made by hand from high quality raw materials so that after completion, a seamless bag is produced. The

semi-nished product is vulcanized under the inuence of pressure and temperature and by doing this the individual layers bond

to form an elastomer body. After production has been nalized,

each S.Tec Bag is subjected to a plant acceptance test within the

scope of quality assurance.

Material of the S.Tec Bag: CR/Aramide, hot vulcanized

Page 5/18

Loading...

Loading...