Page 1

Emergency Pneumatics.

Operating Instructions

VETTER Safety Cushion SP 60

Type Safety Cushion SP 60

based on DIN 14151, Part 3

Serial No.: Year of manufacture:

Art. No. 9987038801 | © Vetter GmbH I 07/14 I Changes and errors excepted.

Page 2

Vetter Safety Cushion SP 60

Contents

1. EC Conformity declaration ........................................2

2. Description of product ............................................5

2.1 Correct use according to instructions ........................5

2.2 Technical data for safety cushion ............................5

2.3 Technical data for blowers ..................................6

2.4 Ambient conditions and limits ..............................7

2.5 Safety instructions ..........................................7

3. Preparing the product for use .....................................8

3.1 Transport + Storage .........................................8

3.2 Inspection for completeness ................................8

3.3 Packing plan ................................................9

3.4 Safety measures before use ............................... 10

3.5 Preparations for operation ................................ 11

4. Operating instructions .......................................... 12

4.1 Safe operation ............................................ 12

4.2 Normal functions ......................................... 13

4.3 Exceptional situations .....................................14

4.4 After operation ........................................... 14

4.5 Maintenance, repair and cleaning after every .................

operation period .........................................14

5. Possible defects: safety cushion .................................16

6. Repetitive inspections ..........................................16

6.1 Inspection deadlines ...................................... 17

6.2 Inspection regulations and certication ...................17

Page 1/30

Regulations Annual inspection ..................................... 18

Regulations Main safety inspection ................................. 20

Regulations General safety inspection .............................. 20

Inspection report for the Vetter Safety Cushion .....................21

7. Spare parts list .................................................. 22

8. Withdrawal from use ............................................23

9. Operating instructions for blowers ..............................24

Page 3

1. EC Conformity declaration

EC Conformity declaration for Ramfan blowers

Page 2/30

Page 4

Vetter Safety Cushion SP 60

EC conformity declaration for Leader blowers

Page 3/30

Page 5

EC Conformity declaration for safety cushions

(available on request)

in accordance with Directive 2006/42/EC

Manufacturer name and address

Vetter GmbH

A Unit of IDEX Corporation

Blatzheimer Str. 10 - 12

53909 Zülpich

We hereby declare, that the Vetter Safety Cushion SP 60 (Rescue

height 50 m/192 ft.)

Type: SP 60

Serial No: _____________

Model: _____________

(see appliance plate, to be entered by customer)

meets the following relevant provisions:

Directive 2006/42/EC on Machinery

Applied harmonised standards, references to which have been

published in the Ocial Journal of the European Union:

EN ISO 12100 part 1/2

Applied national standards and technical specications:

DIN 14151-part 1 & 3

Authorised representative for the compilation of technical documents:

Vetter GmbH

Blatzheimer Str. 10 - 12

53909 Zülpich

This EC Conformity Declaration was issued:

Zülpich, 22.07.2014

(Place, Date, Signature)

Page 4/30

Page 6

Vetter Safety Cushion SP 60

2. Description of product

The self-aligning VETTER safety cushion SP 60 consists of a dual

chamber system. It is also equipped with an innovative pressure

regulation system.

A minimum of 4 persons are required to assemble and disassemble it. The external covers are made of inammable resistive and rot

resistive material (according to DIN 4102 B1) and has a combination of welded and sown seams.

The VETTER Safety Cushion SP 60 is produced according to the

requirements specied in DIN 14 151, Part 3.

2.1 Correct use according to instructions

The safety cushion is inated by connecting and starting the blower.

The ventilation openings on all 4 sides prevent over-ination of

the cushion.

The safety cushion should be used when it is not possible to carry

out rescue with other means (e.g. aerial ladder trucks) or when it is

necessary to use the safety cushion owing to lack of time.

Possible injury cannot be excluded in every single case when

using the safety cushion.

The safety cushion is only permitted to be used in emergencies and only for person rescue! It is strictly forbidden to use it for exercises and shows!

2.2 Technical data for safety cushion

1. Blower 5. Other deventilation openings

2. Ination hose 6. Positioning loops

3. Landing area with marking 7. Packing covers

4. Deventilation system (on both

sides)

8. Type label, imprinted

Page 5/30

3

1

4

5

8

2

7

6

Page 7

The serial number on the Type Label is coded as follows:

For example: Serial number 07101234

07 10 1234

Month: July* Year: 2010* Consecutive number

* month and year of production

Safety Cushion SP 60 (Art. No. 1530016100)

External size, approx.

Height, approx.

Weight, approx.

Ination time, approx. sec. 80

Operating temp.

Folded size, approx.

cm 850 x 650 x 250

inch 331.5 x 253.5 x 97.5

cm 250

inch 97.5

kg 240

lbs 529

°C -20°C bis +50°C

cm 155 x 100 x 55

inch 60.5 x 39 x 21.5

2.3 Technical data for blowers

Ramfan EV420

Electrical blower

Art. No. 1530014800 1530019100

m³/h 16,498 33,900

Capacity

cfm 9,705 19,956

Leader

ESP 230*

Electrical blower

EV420

Noise level dB 97 84

Starting current limiter integrated integrated

1,1 kW, 2,2 kW,

Motor

240 V 50/60 Hz 230 V 50 Hz

IP protection mode IP 64 IP 55

mm 580 x 430 x 410 550 x 548 x 492

Dimensions, approx.

inch 22.6 x 16.8 x 16 21.7 x 21.4 x 19.2

kg 31 43

Weight, approx.

lbs 68 95

*Note: Only Leader blowers are to be used which have been supplied by Vetter!

ESP 230

Page 6/30

Page 8

Vetter Safety Cushion SP 60

MT 236 H

Leader

MT 236 H*

High power blower -

petrol

Art. No. 1530019300

m³/h 43,100

Capacity

cfm 25,372

Noise level dB 91

bar

Operating pressure

-

psi

6,5 PS Honda -

Motor

4 stroke

Running time (with

the tank full)

100 min.

mm 550 x 548 x 492

Dimensions, approx.

inch 21.7 x 21.4 x 19.2

kg 42

Weight, approx.

lbs 93

*Note: Only Leader blowers are to be used which have been supplied by Vetter!

2.4 Ambient conditions and limits

The assembly location is mainly dependent on the operational situation and the local conditions.

The assembly area should, as far as possible, be free of sharp objects or objects which could puncture.

The safety cushion is to be protected against heat.

2.5 Safety instructions

The main condition for reliable operation of the VETTER safety

cushion is an exact knowledge and adherence to these operating

instructions and safety information.

In addition to this, it is imperative to observe the valid regulations

and stipulations for accident prevention.

Only trained re service sta are permitted to carry out operation.

Jumping for exercises or shows is strictly forbidden!

Only special drop objects, such as sand bags or dummies, are to

be used for exercising and testing!

Page 7/30

Drop objects with a weight mass of 50 kg dropped from a height

of maximum 60 m

Page 9

Non-compliance is a contravention of re service regulations (UVV

- German Accident Prevention Regulations) and exclude any form

of liability!

It is pointed out here that this can have legal consequences.

Incorrect use or any unauthorized changes to the safety cushion

make any manufacturer liability, with respect to any resulting damage, null and void.

3. Preparing the product for use

3.1 Transport + Storage

3.2 Inspection for completeness

An inspection is to be made before and after each operational period in order to check the components for completeness and to

see if they are free of damage.

The safety cushion is complete and can be erected

without diculty.

Two permanent blowers

are available and are in

perfect condition. Turbine

blade, cover and housing

are free of damage.

Set list for SP 60

1530016100 Safety cushion SP 60 1 1 1

1530016200 Packing cover 1 1 1

1530016300 Repair and spare part set 1 1 1

1530014800 Ramfan EV420 blower 2 - 1530019100 Leader electr. blower ESP 230 - 2 1530019300 Leader blower (petrol) MT 236 H - - 2

1530016000 1530019400 1530019600

Page 8/30

Page 10

Vetter Safety Cushion SP 60

Packing cover for the safety cushion is available and

free of damage.

Any other objects must not be placed on the safety cushion during transport or storage.

Only store the safety cushion in a dry room when it is clean and in

a dry condition.

The life duration of the product can be shortened by being subjected to outside inuences (e.g. heat from direct sunlight, temperature deviations etc.).

Optimum storage temperature (min to max): -20°C to +50°C

3.3 Packing plan

Before packing the VETTER safety cushion check for damage.

Safety cushions are only to be packed after inspection!

The safety cushion must only be packed when it is clean and dry.

Completely deate the safety cushion. To do this, switch o the

blower and let the air escape out of the cushion.

Only start packing when the air has completely escaped out of

the safety cushion.

Lay out the safety cushion evenly.

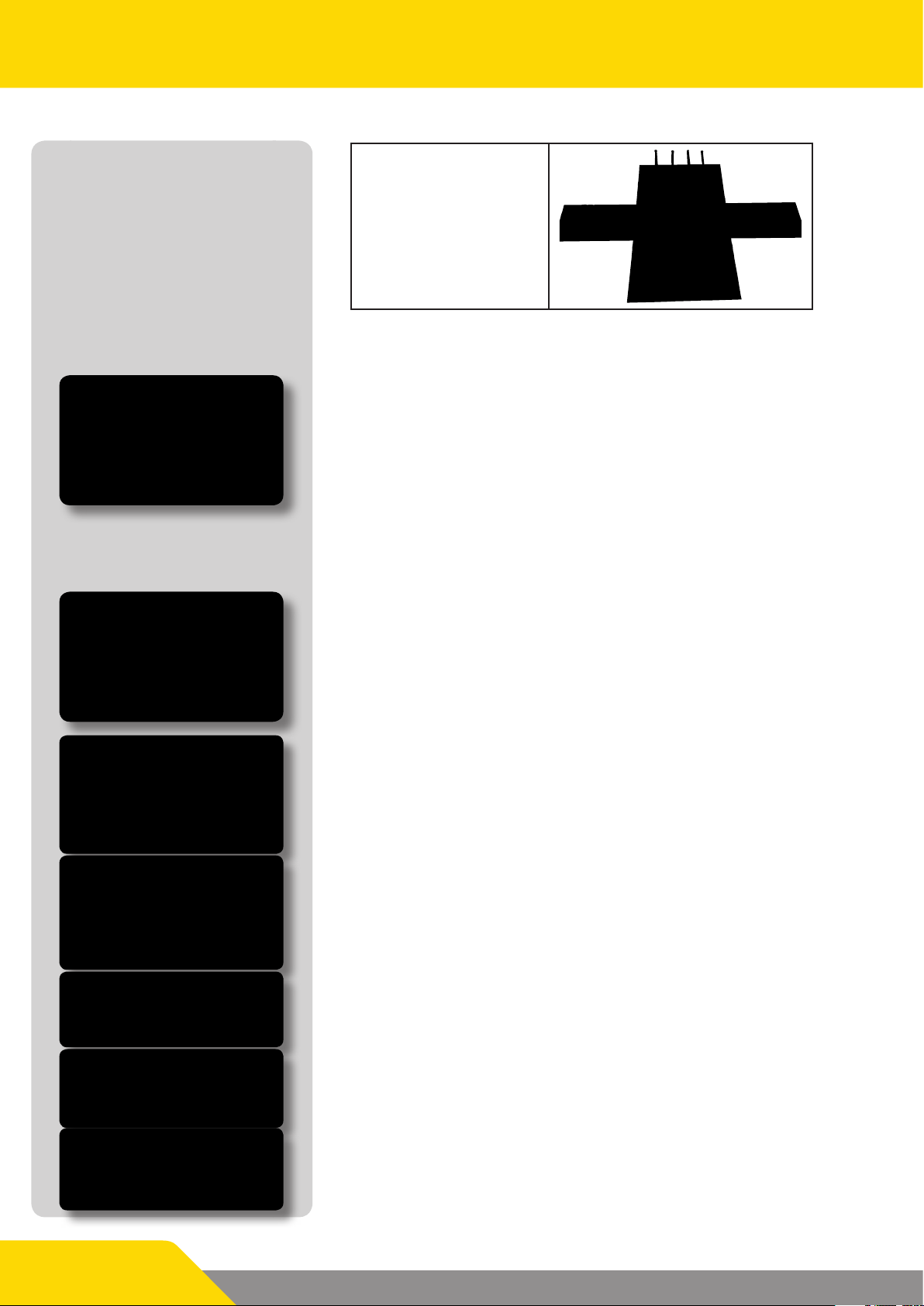

Smooth out the landing area (Fig. 2).

The initial position is the front side with the connection hoses for

the blower. Fold in the side to the left up to the ination hoses

(Fig. 3).

Turn over the right-hand side of the cushion up to the ination

hoses (Fig. 4).

Page 9/30

Once again fold both sides to the middle until the width of the

packing cover is reached (Fig. 5).

Now roll the safety cushion in the direction of the ination hoses

as tightly as possible (Fig. 6).

The width of the rolled up safety cushion must not exceed the

width of the packing cover.

Page 11

Place the packing cover behind the rolled up safety cushion. Roll

the safety cushion onto the packing cover and after this place the

hoses together on the roll.

Then fold the sides of the packing cover in the sequence shown

over the rolled up safety cushion.

Finally secure with the belts and adjust them to the corresponding tension with the tension device.

After this, the safety cushion can be stored on a vehicle.

3.4 Safety measures before use

Only extension cables or cable drums of suitable size for the corresponding current load are to be used (see „type label“). The cable

should have a minimum cross section of 3 x 2.5 mm² and be a

maximum of 100 m in length.

Page 10/30

Page 12

Vetter Safety Cushion SP 60

It must be ensured that only the original blower supplied by Vetter is used because only this one is permitted by the inspection!

Before connecting always make certain that the switch on the blower is positioned to OFF.

Only perfectly working and tested safety cushions are permitted

to be used!

The assembly location is mainly dependent on the operational situation and local conditions.

The assembly location must, as far as possible, be free of any sharp

or pointed foreign bodies. The safety cushion is to be protected

against heat.

3.5 Preparations for operation

Remove the safety cushion from the vehicle and lay it out on a

suciently large free area.

The exact assembly location is determined by the head of operation.

Release the packing cover.

The pictogram on the cover shows the direction for rolling out the

cushion.

Open the cover and lay out the ination hoses.

Ramfan blowers

The blowers are assembled onto the ination hoses of the safety

cushion via a snap-in connection.

Lay the ination hoses with the eyes over the pins and then tension the snap-in connection using the ratchet until the ination

hoses are xed to the blower.

Finally ensure that all 4 eyes lay on one pin thus ensuring stability.

Page 11/30

Make certain that the hoses are solidly

connected to the blower!

Page 13

Leader blowers

In order to use the Leader brand of blower it must be ensured that

they are equipped with special adapters (contained in the delivery package of the blower). Place the adapter on the opening and

turn counter-clockwise until it locks. The ination hoses of the safety cushion are then xed via a snap-in coupling.

Lay the ination hoses with the eyes over the pins and then tension the snap-in coupling with the ratchet until the ination hoses

are solidly connected with the adapters.

Finally ensure that all 4 eyes lay on one pin thus ensuring stability.

Make certain that the hoses are solidly

connected to the blower!

4. Operating instructions

4.1 Safe operation

The safety cushion is to be erected so that only vertical jumps can

be made. If possible, the person jumping should not jump into the

cushion in the upright position but in the supine position. Never

ask the person to be rescued to jump at an angle.

After each jump it may be necessary to realign the safety cushion.

The safety cushion must only be lifted and moved using the positioning loops.

For safety and life duration reasons, any dragging across rough is

to be avoided.

Page 12/30

Page 14

Vetter Safety Cushion SP 60

Note! It is possible that the person to be rescued jumps

into a safety cushion which has not been completely

erected because this is not completely recognizable

from above!

The head of operations must decide, before erecting,

whether the safety cushion should be erected at the

operational location or whether it should be erected at

a safe location and then transported to the operation location.

4.2 Normal functions

Adjust the blower, connected to the safety cushion, to maximum

power and then switch on.

Note! The blower must always be driven at maximum power so that the safety cushion can be quickly reset and is

always lled permanently with sucient air.

Insucient air supply can negatively inuence operation. The rotary control is set to maximum power for this

purpose.

The safety cushion unfolds assisted by the operator and only has

to be positioned. Using the positioning loops, the safety cushion

is lifted for setting up purposes. The blowers should be simultaneously aligned by two persons depending on the cushion.

The safety cushion is set up within a maximum time of 80 seconds.

In doing this a check should be made to see if the vent openings,

including rubber rings, are in perfect condition.

Should parts get caught up during safety cushion set up then

switch o the blower immediately and eliminate the defect. After

this has been done continue lling.

Page 13/30

The safety cushion is fully operational only when it has been fully

set up.

The maximum jump height is 60 m!

After the person has jumped and has climbed out of the cushion,

the cushion automatically realigns itself within a maximum of 20

seconds to its original shape.

Page 15

The safety cushion is available for further jumps only after the person who jumped has left the cushion and also after it completely

realigns again.

4.3 Exceptional situations

If the position of the safety cushion shifts due to the previous jump

then the safety cushion as well as the blower are to be realigned.

Switch the blower o immediately if you hear abnormal noises in

addition to the noises that are similar to those of a turbine. In this

case please inform the manufacturer immediately.

4.4 After operation

Remove the safety cushion out of the danger zone and deate it

in a freely open space.

Switch o the blower in order to do this. The safety cushion automatically deates on its own and lays at on the ground.

Fold up the safety cushion according to the packing plan.

Let the blower cool o before storing it.

4.5 Maintenance, repair and cleaning after every

operation period

Safety cushions:

Cleaning

The safety cushion can be cleaned with warm water or soap suds.

Do not use aggressively acting cleaning agents or solvents!

Completely rinse o soap subs with clear water. Dry the safety

cushion at normal room temperature.

Storage

The safety cushion must only be stored in a dry room after cleaning

and drying. The safety cushion is to be stored in the packing cover after it has been folded together according to regulations. No

other objects are to be stored on top of the safety cushion.

The material of the safety cushion is of course subject to natural

aging.

The life duration of the product is greatly inuenced by such factors as external eects, storage conditions, how often it is used

and the type of use.

Optimum storage temperature (min. to max.): -20 °C to +50 °C

Page 14/30

Page 16

Vetter Safety Cushion SP 60

Maintenance

Maintenance on the safety cushion must be carried out

by the manufacturer.

After use without loading by a falling load:

9 Cleaning

9 Visual inspection by the user

After use with loading by a falling load or a person to be

rescued:

9 Cleaning

9 Visual and function inspections by specialists having additio-

nal training by the manufacturer

Blowers

Cleaning

Ramfan blower

Before cleaning, disconnect the blower from mains power. The

blower must be regularly cleaned with a biodegradable cleaning

solution in order to get rid of dust and dirt.

Never immerse the blower motor in liquid or directly spray it.

Do not use any solvents (e.g. MEK, Acetone) which contain chlorinated hydrocarbons. (refer to the separate instructions for the

blower - Section 9).

Maintenance

Ramfan blower

Check to see if the blower is perfectly operational. Opening the

blower for maintenance reasons is only permitted to be done by

specialists.

Page 15/30

Leader blower

Normal maintenance of the petrol motor, with respect to oil

change and oil inspection is sucient.

After operation it is recommended that a visual inspection be

made of the ventilator ns for hairline cracks or any other forms

of damage. If any damage to the n is detected then this must be

repaired by the manufacturer due to the fact that the ventilator

wheel has to be balanced after exchanging the damaged part.

Important! Inspect safety cushions and blowers for damage according to inspection instructions.

Page 17

The safety cushion is operationally available after inspection and maintenance work has been carried out.

5. Possible defects: safety cushion

Problem/Defect Solution

The safety cushion does not align

itself correctly.

The hoses are bent. Switch o the blower and realign

Check to see if parts of the safety

cushion have been caught up. In

this case, switch o the blower

and eliminate the defect immediately. Ination can continue after

this has been done.

Check to see if the ventilation

openings are in perfect condition, including rubber rings. If

necessary align the rubber rings

so that the ventilation openings

remain closed.

Check to see if the blower is set

to maximum power, correct this if

necessary.

blower and hoses.

Possible defect: blower

Ramfan: Refer to the operating instructions for the blower from Page 27

onwards

Leader: Refer to the operating instructions for the blower from Page 29

onwards

6. Repetitive inspections

Safety cushions are only permitted to be repaired by the manufacturer.

Maintenance work is only permitted to be carried out by persons who

have undergone special training by the manufacturer in maintenance

and repair work and are authorized to do this by the manufacturer. In

addition to this, they must work in a maintenance shop authorized by

the manufacturer and have a knowledge of the safety and accident prevention regulations.

The following come solely into consideration for safety cushion inspection:

for Annual Inspection

The specialist according to the preliminary remarks in GUV-G 9102.

for the Main Safety Inspection

The specialist according to the preliminary

remarks in GUV-G 9102 in addition to extra

training by the manufacturer or a trainer

authorized by the manufacturer.

Page 16/30

Page 18

Vetter Safety Cushion SP 60

1st Year Annual Inspection 9th Year Annual Inspection

2nd Year Annual Inspection 10th Year General safety inspection

Authorization must be made in writing.

This authorization is valid for a maximum period of 60 months

and can, after registration and training, be extended.

The specialist or the inspection institute in which he is employed,

must have the necessary testing devices for the scope of the inspection.

for the Main Safety Inspection

The General Safety Inspection is to be exclusively carried out by

the manufacturer

6.1 Inspection deadlines

3rd Year Annual Inspection 11th Year Annual Inspection

4th Year Annual Inspection 12th Year Annual Inspection

5th Year Main safety inspection 13th Year Main safety inspection

6th Year Annual Inspection 14th Year Annual Inspection

7th Year Annual Inspection 15th Year Disposal

8th Year Main safety inspection

Should there be any doubt about safety or reliability then a General Safety Inspection must be arranged with the manufacturer.

The life period of the safety cushion is limited to 15 years due to

product reliability and safety.

After this life period, the safety cushion must not be used

for exercises or any other purposes.

6.2 Inspection regulations and certication

The individual inspections, such as the annual visual and function

inspection, are to be carried out according to the inspection instructions in the operating manual.

Page 17/30

A test report is to be made about the inspection carried out (copy

the corresponding page if required).

The inspections carried out are to be entered into an inspection

log book (contained in the standard delivery package) as well as

on the safety cushion itself.

Page 19

Regulations Annual inspection

123

4

6

7

91112

14

15

and after each period of use

Serial number:

Year of construction:

Inspection due 1st Year

2nd Year

3rd Year

4th Year

6th Year

7th Year

9th Year

11th Year

12th Year

14th Year

Disposal after 15 years

In order to carry out this inspection, the inspector must have the

corresponding qualications according to GUV-G 9102.

The execution and results of the inspection are to be recorded in

writing. This is made by:

9 Filling out an inspection report (see attachment)

9 Entry into the inspection log book

9 Direct entry on the safety cushion itself (only once annually)

Testing instructions for the inspection after each period

of use without loading by a falling object

1. Visual inspection of the cleaned safety cushion for externally

recognizable damage in the inated condition.

Testing instructions for the inspection after each period

of use with loading by a falling object or under operation conditions by a person being rescued

1. Visual inspection of the cleaned safety cushion for externally

recognizable damage in the deated condition (upper and lower cover)

2. Inate the safety cushion

Page 18/30

Page 20

Vetter Safety Cushion SP 60

3. Inspect the following parts and visually check for recognizable damage in the assembled condition

9 Landing area with marking

9 Packing cover

9 Side covers

9 Quick snap-in connection on the blower

9 Floor covers

9 Ination hoses

9 Horizontal separation covers

9 Ventilation openings

9 Internal connection covers

9 Rubber bands on the ventilation openings (exchange if ne-

cessary)

9 Seams

9 Positioning loops

9 Blower (according to manufacturers instructions)

4. Inspection of the inside area for foreign bodies (clean if necessary)

5. Documentation (test report lled out, type label marked, inspection entered into the inspection log book)

Maintenance and repair work must only be carried out by the manufacturer.

Contact the manufacturer if there are any doubts about safety or

reliability of the Vetter safety cushion!

Page 19/30

Page 21

Regulations Main safety inspection

5

81310

15

15

Serial number:

Year of construction:

Inspection due on: 5th Year

8th Year

13th Year

Disposal after 15 years

In order to carry out this inspection, the specialist must meet the

conditions stipulated in the preliminary remarks contained in

GUV-G 9102 including additional training by the manufacturer or

an authorized trainer.

For information concerning training courses at our company please contact: vetter.rescue@idexcorp.com or call us at:

+49 (0) 2252/3008-0

Further information about the Vetter Academy can be found on

our website: www.vetter.de!

Regulations General safety inspection

Serial number:

Year of construction:

Inspection due on: 10th Year

Disposal after 15 years

This inspection is to be exclusively carried out by the manufacturer!

Arrange an inspection date with the manufacturer in good time.

Page 20/30

Page 22

Vetter Safety Cushion SP 60

Inspection report for the Vetter Safety Cushion

Certication for the execution of the

Annual inspection

Main safety inspection

General safety inspection

according to GUV G 9102 and DIN 14 151-1

User: Name 1

Name 2

Street

Code/Town

Country

The Vetter safety cushion Type SP 60

Serial number:

Year of constr.

was tested on by inspector

____________________________________________________

The inspection produced the following results:

No defects Defects were as follows

Page 21/30

Next inspection:

The inspection was permanently noted down on the type label

and in the inspection log book.

____________________ ____________________

Location / Date Inspector responsible

Page 23

7. Spare parts list

Pos. Description Art. No. Picture

1 Rubber band 1530017700

2 Wooden clamp 1530017800

3 Ramfan EV420 blower 1530014800

4 Leader blower Electr.: 1530019100

Petrol: 1530019300

Page 22/30

Page 24

Vetter Safety Cushion SP 60

8. Withdrawal from use

Safety cushion

The life duration of the safety cushion is limited to 15 years

due to product safety and reliability.

The safety cushion is not permitted to be used for exercises or any other purposes after this period.

Blowers:

Disposal of used electrical and electronic equipment (to be

used in the countries belonging to the European Union and

other European countries with a separate equipment collection system) is to be made according to the law governing

electrical and electronic equipment (Electrical and Electronic

Equipment Act / ElektroG) dated 24th March 2005 for the implementation of EU Guidelines 2002/96/EG concerning electrical / electronic equipment (WEEE Guidelines).

This symbol on the product or its packaging indicates that the

electronic component of this product must not be treated as

normal household waste but must be returned to the manufacturer for recycling (freight-free return).

Page 23/30

Page 25

9. Operating instructions for blowers

Page 24/30

Page 26

Vetter Safety Cushion SP 60

Page 25/30

Page 27

Page 26/30

Page 28

Vetter Safety Cushion SP 60

Page 27/30

Page 29

Page 28/30

Page 30

Vetter Safety Cushion SP 60

Page 29/30

Page 31

Place your trust in emergency pneumatics!

We are the company who can help you, nd a solution to your problem!

Vetter GmbH

A Unit of IDEX Corporation

Sales

Blatzheimer Str. 10 - 12

D-53909 Zülpich

Germany

www.vetter.de

Tel.: +49 (0) 22 52 / 30 08-0

Fax: +49 (0) 22 52 / 30 08-590

Mail: vetter.rescue@idexcorp.com

Article No. 9987038801 | © Vetter GmbH I 07/14 I Changes and errors excepted. | Made in Germany

Loading...

Loading...