Vetter Pipe and Test Sealing Bags User Manual

Industrial Pneumatics.

Operating Instructions

VETTER Pipe and Test Sealing Bags

Art.-Nr. 9987044604 | © Vetter GmbH I 08/14 I Changes and errors excepted.

Vetter Pipe and Test Sealing Bags

Contents

1. Introduction ......................................................4

1.1 Symbols used ...............................................4

1.2 Correct handling and usage .................................4

2. Safety instructions ................................................5

2.1 General information ........................................5

2.2 Information about the dangers ..............................6

2.3 Warnings ...................................................6

3. Operation of Pipe and Test Sealing Bags ...........................7

3.1 Operation with controller, ination hose and compressed

air bottle ...................................................7

3.2 Operation with controller, ination hose and other

compressed air sources .....................................8

3.3 Operation with a foot pump having a safety valve ...........9

4. Operation of Pipe and Test Sealing Bags ...........................9

4.1 Preparations for operation ..................................9

4.2 Support structure ......................................... 10

4.3 Blocking a pipeline .......................................11

4.4 Emptying the pipeline ....................................12

4.5 Water test and compressed air test ........................12

4.6 Water pressure test (open channel) ........................ 12

4.7 Compressed air test ....................................... 13

4.8 Construction of a temporary bypass ....................... 14

5. Maintenance and care ..........................................14

5.1 Maintenance intervals ....................................14

6. VETTER Round Proles ..........................................16

Page 2/33

6.1 Vetter Mini Pipe Sealing Bags 2.5 bar ......................16

6.2 VETTER Mini

6.3 Vetter Pipe Sealing Bags 0.5, 1.5 and 2.5 bar ...............18

6.4 Vetter Test Sealing Bags 0.5, 1.5 and 2.5 bar ................20

6.5 Vetter Bypass Bags 1.5 bar. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

6.6 Vetter House connection Testing system 2.5 bar ...........23

6.7 Vetter Test Sealing Bags for Gullies 1,0 bar ................. 24

6.8 Vetter Pipe Sealing Bags CR ............................... 25

Test Sealing Bags 2.5 bar. . . . . . . . . . . . . . . . . . . . . . . 17

6.9 Vetter Pipe Sealing Bags NBR .............................. 26

6.10 Vetter High Pressure Pipe Sealing Bags 6 bar ............... 27

7. VETTER Egg Proles ............................................. 28

7.1 Vetter Egg Prole Bags 1 & 1.5 bar .........................28

7.2 Vetter Egg Prole Testing and Bypass bags 1 & 1.5 bar ...... 29

8. Material and resistance charts ...................................31

8.1 Material list ............................................... 31

8.2 Temperature resistance ...................................31

8.3 Resistance chart ..........................................32

Important information

Owing to an increase in demand, all pipe and test sealing

bags will be tted with brass couplings as a standard from

01.01.2012 onwards.

If you still wish to have the safety couplings (blue at

1.5 bar, black at 2.5 bar), we kindly ask you to state

this explicitly when placing an order.

Page 3/33

Vetter Pipe and Test Sealing Bags

1. Introduction

The precondition for the safe use and the defect-free operation of

Vetter pipe and test sealing bags is the knowledge and the observance of this operating manual as well as the safety instructions.

DIN 7716 is to be adhered to in cases of long-term

storage.

In addition to this, the pertinent work protection regulations, work

safety regulations and accident prevention regulations are to be

observed the same as the generally recognized technology laws.

The operating instructions given here are to be regarded as part

of the product and are to be kept for the complete life duration of

the product. In case the product should be passed on to a successive user then the operating instructions must also be included.

1.1 Symbols used

The following symbols are used in the text for dangers and warnings:

This symbol means that there is imminent danger. If it is not avoided then

death or serious injury will result.

This symbol means that there is a possible dangerous situation. If it is not

avoided then death or serious injury

could result.

This symbol means that there is possibly a dangerous situation. If it is not avoided then light injuries or slight injuries

could result.

This symbol means that there is the

possibility of damage being caused. If

it is not avoided then the product or

something else in its vicinity could be

damaged.

1.2 Correct handling and usage

Page 4/33

Vetter pipe and test sealing bags must, depending on the purpose of the task, only be inated with compressed air to the corresponding pressure level using original ination ttings.

Ination with ination ttings from another manufacturer is classied as contrary to the regulations for correct use.

They are exclusively used for blocking the intended pipes, for leak

sealing testing of pipelines and for construction of a bypass.

Any other application or use going beyond this is classied as

contrary to the regulations for correct use.

An application contrary to the regulations for correct use of Vetter

pipe and test sealing bags includes:

9 Incorrect use, operation or maintenance of pipe and test

sealing bags.

9 Use of the Vetter pipe and test sealing bags with defective

safety devices or incorrectly tted or non-functional ination

ttings.

9 Non-observance of the instructions given in the operating

manual concerning storage, operation and maintenance of

pipe and test sealing bags.

9 Insucient monitoring of accessory parts subject to wear.

9 Incorrectly carried out maintenance work.

Correct use according to regulations also includes

9 The observance of all instructions given in this operating ma-

nual.

9 The observance of the set periods for maintenance and care

specied in the chapter „Maintenance and Care“.

2. Safety instructions

The knowledge and observance of this operating manual are the

preconditions for the use of Vetter pipe and test sealing bags

2.1 General information

The observance of all pertinent work protection regulations and

safety regulations, accident prevention regulations (e.g. safety regulations from the technical authorities – TBG) as well as the recognized technical laws are to be carried out.

The pipeline is to be inspected for damage before using pipe and

test sealing bags. The area in the pipe for the pipe and test sealing

bag must be free of deposits, dirt and foreign bodies, such as fragments, sharp-edged objects etc.

Necessary personal protection devices must be made available:

protection clothing, cloves, helmets, facial and/or eye protection

etc.

Pipe and test sealing bags must be positioned full length in the

pipeline and with the sealing area on the inside wall of the pipe.

All pipe and test sealing bags (round and egg-shaped) must be

non-positively and positively positioned and tted.

Page 5/33

Vetter Pipe and Test Sealing Bags

2.2 Information about the dangers

Changes and modications to the sealing bags, ination ttings

and ination hoses are not permitted. Operation of Vetter pipe

bags, test bags and bypass bags are only permitted with original

Vetter ination ttings and ination hoses. Parts made by another

manufacturer can inuence safety.

Pipe and test sealing bags are made of a strong expanding material. If this material is expanded beyond its permitted maximum

range then this can cause bursting. No person is allowed to remain within the working area during the pressure test. With a

water pressure test, the pipeline being tested must not have any

direct connection to a high-pressure line (e.g. hydrant).

After positioning the pipe and/or the test sealing bag it is to be

ensured that nobody remain in the channel or in front of the pipe

during ination, as well as during the test procedure and emptying sequence. Before removing the set-up make certain that the

pipeline is not under any pressure and is completely empty.

2.3 Warnings

The pipe and test sealing bags as well as the accessories must be

checked for perfect condition before and after each operation.

Outside the pipeline, Vetter pipe and test sealing bags, 0.5 bar and

1 bar, must only be lled to maximum 0.2 bar for the visual test.

1.5 bar and 2.5 bar bags must only be lled to a maximum of 0.5

bar.

All controllers are tted with a safety valve that has a permitted

maximum operating pressure corresponding to the pipe and test

sealing bag. If the maximum operating pressure of 0.5, 1.5, 2.5 or

6 bar is exceeded then the safety valve will activate. The tolerance

for opening and closing of the safety valve is only permitted to be

a maximum of + 10 %. The set pressure must not be changed. If

the sealing on the top part of the valve is removed then its operation is no longer guaranteed and the safety valve must be exchanged. The permitted inlet pressure on the controller (marking

on the inlet coupling) must not be exceeded.

Page 6/33

3. Operation of Pipe and Test Sealing Bags

This chapter informs you about which compressed air sources you

can use with the Vetter pipe and test sealing bags.

Observe the corresponding pressure level with

operation of pipe and test sealing bags

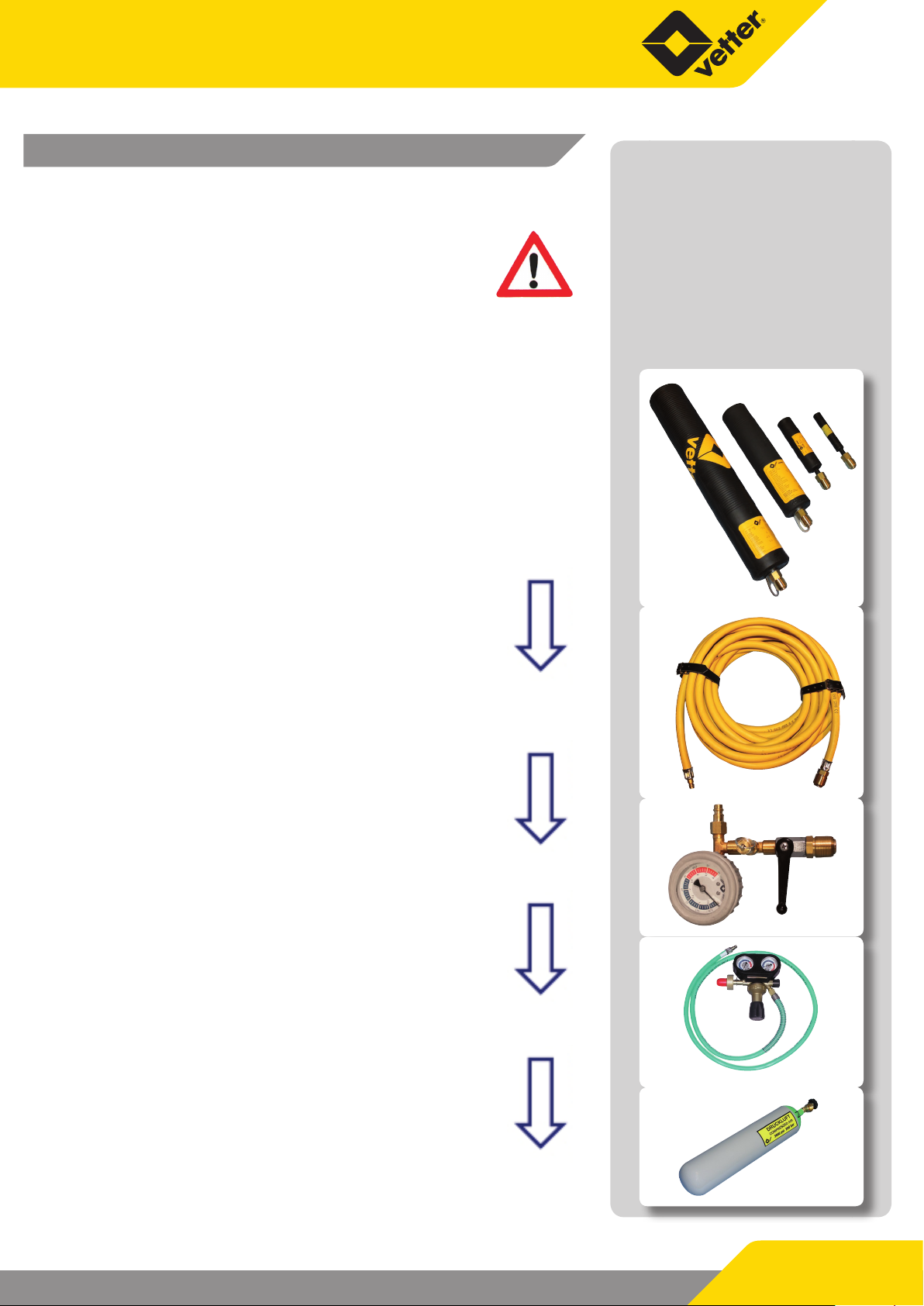

3.1 Operation with controller, ination hose

and compressed air bottle

Note! In the following presented gures the sequence of

events uses the pressure level of 2.5 bar as an example.

The corresponding bags and accessories must be used

for other pressure levels and other sources of air.

Pipe and test sealing bags

9 Step 1

Connect pipe and test sealing bags 2.5 bar to the

ination hose.

Ination hose

9 Step 2

Connect the ination hose to the controller.

The ination hose, the sealing bag and the controller

must have the same pressure level.

Controller

9 Step 3

Connect the connection hose of the pressure

regulator to the inlet coupling of the controller.

In doing this it is imperative that the permitted inlet

pressure of the controller is observed

Pressure regulator

9 Step 4

Screw-in the connection thread of the pressure

regulator into the inside thread of the valve on the

compressed air bottle.

Compressed air bottle

Page 7/33

Vetter Pipe and Test Sealing Bags

3.2 Operation with controller, ination hose

and other compressed air sources

Observe the maximum inlet pressure from the

compressed air source for the dierent

pressure levels (refer to the table below).

Truck compressed

air connection

Adapters in the adapter set

Applied pressure level Maximum inlet pressure

of the compressed air source

0.5 bar 2 bar

1.0 bar 2 bar

1.5 bar 2 bar

2.5 bar 4 bar

Dummy coupling

The adapter set contains adapters for the following air sources:

Truck compressed air connection and dummy coupling

Close the control line with the dummy coupling.

Local compressed air network

Connection on the output coupling of a compressed air network.

Truck tyre valve

For ination with a normal hand pump or foot pump

Truck tyre valve connection

For taping o air from a spare wheel.

Page 8/33

Hand pump and foot pump

Hand pump or foot pump with 2 m connection hose to the connection onto the inlet coupling of a controller. Hand pump and

foot pump do not belong to the delivery package of the adapter

set.

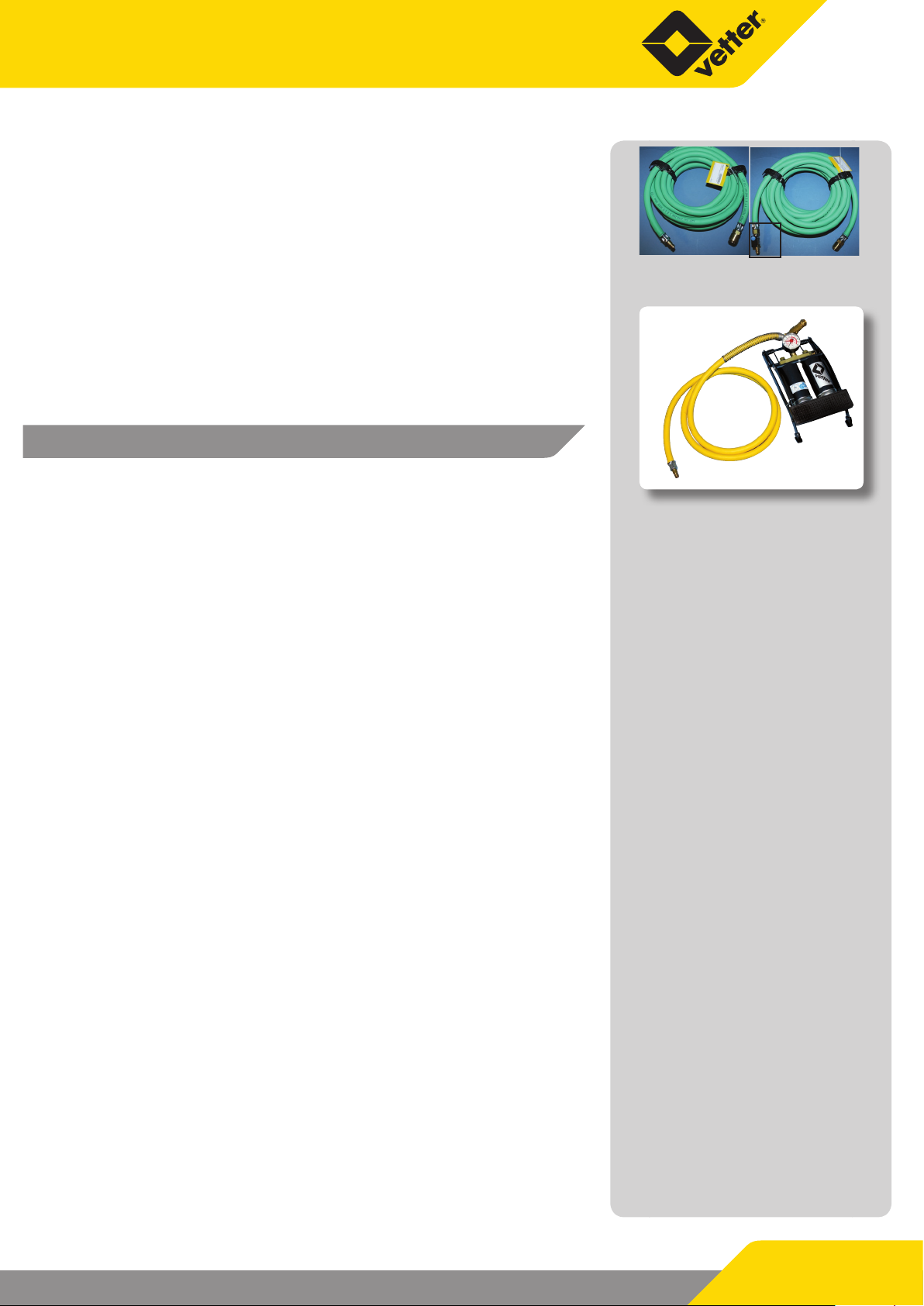

Air supply hose, 10 m, with and without blocking valve

The air supply hoses, with and without blocking valve, can be used

as an extension between the air source and the controller.

3.3 Operation with a foot pump having a

safety valve

Foot pump 2.5 bar with safety valve

Foot operated air pump 2.5 bar with safety valve and 2 m connection hose for ination of sealing bags in connection with an

ination hose.

4. Operation of Pipe and Test Sealing Bags

In this chapter you will nd out how the Vetter pipe and test

sealing bags are applied.

When using the pipe and test sealing bags, observe the

safety instructions given in chapter 2 as well as the pertinent regulations for work protection and safety protection, accident prevention regulations (e.g. the safety

regulations of the technical authorities -TGB) and the generally recognized laws of technology.

4.1 Preparations for operation

with blocking valve

Foot pump 2.5 bar with safety valve

9 Ensure that only authorized sta are in the working area and

danger area.

9 Select a suitable pipe and/or test sealing bag which corres-

ponds to the requirements.

9 Check the bag and the accessories to be used for complete-

ness and damage.

9 Damaged bags and damaged accessory parts must not be

used!

9 The bag diameter must be smaller than the inside diameter of

the pipeline.

9 Ination hose and controller must already be connected to

the sealing bag.

9 Mark the working area.

9 Position the bag (full length) into the pipe.

9 The sealing bag in the pipe is to be supported.

9 Draw the sealing bag to the support structure and inate so

that it can still be moved in the pipeline.

9 The support structure should be made so that the sealing bag

can be supported over a large area.

Page 9/33

Vetter Pipe and Test Sealing Bags

9 Leave the shaft and/or pipeline.

9 Make certain that no sta remain in the area of danger.

9 Inate the sealing bag to the permitted maximum operating

There is a danger of the bag catapulting outwards. The pressure

or water column must be completely reduced within the pipeline

before the support structure is removed. Otherwise the sealing

bag could catapult outwards.

After completion of the work, pressure reduction is to be carried

out via the ination hose (ventilation nipple) or the controller

(pressure reduction via the knurled screw of the safety valve).

Generally this must be made outside the pipeline or shaft.

9 If the water has completely owed out of the shaft / pipeline

pressure from a safe position.

then release the compressed air out of the bag.

9 Now remove the support structure and take the bag out of

the shaft/ pipeline.

4.2 Support structure

The type of support structure depends on the structural factors in

the pipe, the pipe itself and the counter-pressure to be expected.

The following support possibilities are only drawing diagrams and

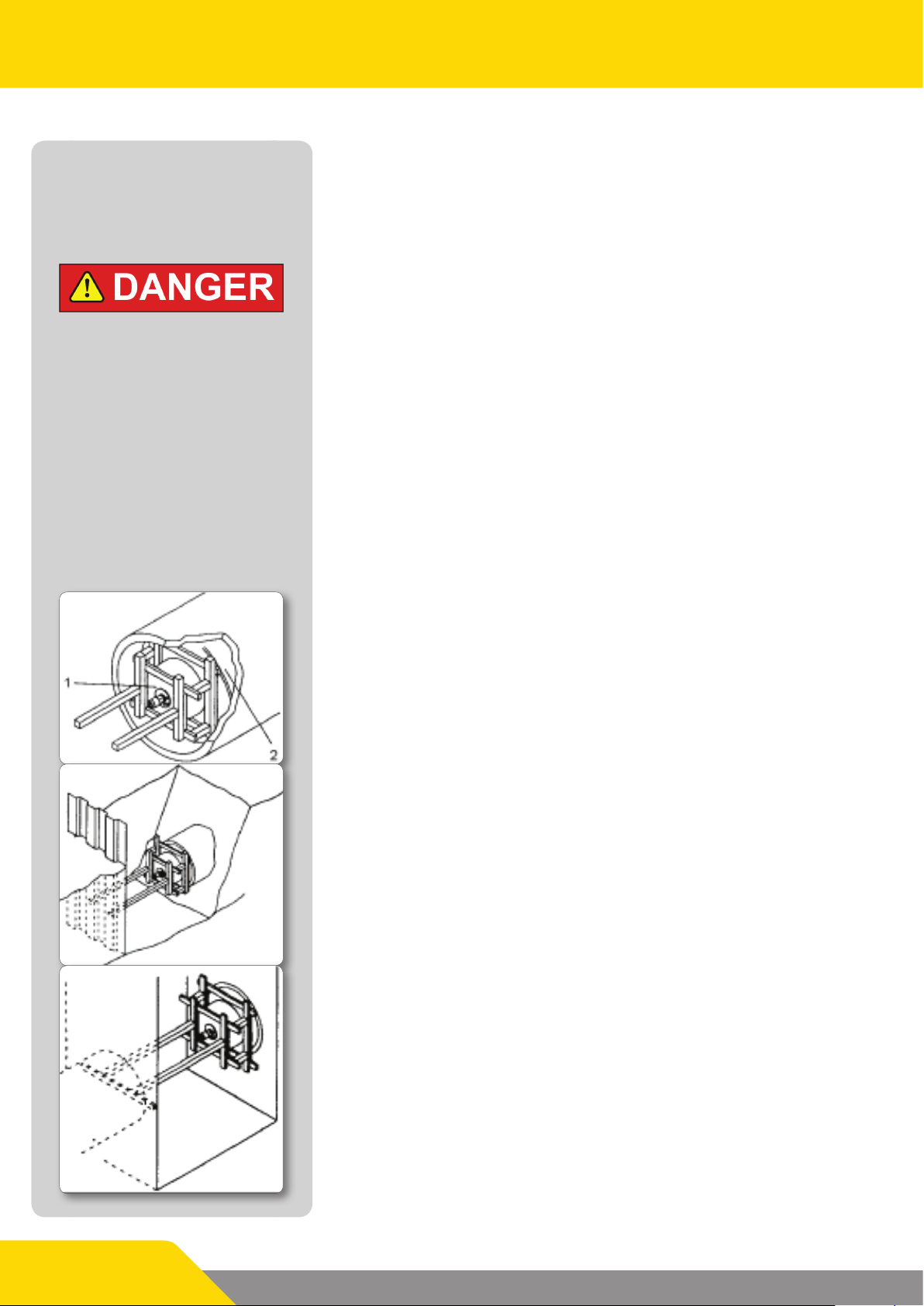

are given as examples.

General details of support (presented as a diagram)

1 Bag centre

2 Inatable bag sleeve

Support suggestion for a ditch

(presented as a diagram)

Page 10/33

Support suggestion for a street inlet shaft

(presented as a diagram)

Loading...

Loading...